ADEMCO 4192 Installation Instructions Manual

s:

MARGIN LINES INDICATE PRINCIPAL CHANGES IN THIS l/88 ISSUE *

GENERAL INFORMATION:

WIRING THE No. 4192

The ADEMCO No. 4192 PLUG-IN SMOKE DETECTOR BASE is a

VECTOR POINT PROTECTION SECURITY SYSTEM component. It IS

intended for use with interchangeable UL Ltsted detector heads, Model

BK-2851 B (PHOTOELECTRIC); Model BK-2851 BTH (PHOTOELECTRIC

WITH BUILT-IN THERMOSTAT) and Model BK-1851 B (IONIZATION). The

base can be installed on a standard ceiling mount electrical box and both

the base and the detector are powered through the polling loop.

IMPORTANT! The instructions which accompany the aforementtoned

detector heads only parttally pertatn to the No. 4192 SMOKE DETECTOR

BASE/TRANSPONDER. The relevant sections are: Preface; Specifica-

tions; SENSITIVITY TESTING AND MAINTENANCE, TAMPER-

PROOF FEATURE, and LIMITATIONS OF SMOKE DETECTORS.

All wrring must be installed in compliance wrth the National Electrical Code

and with all local codes. For complete lnformatton regardrng the polltng

loop, refer to the instructions which accompany the control panel.

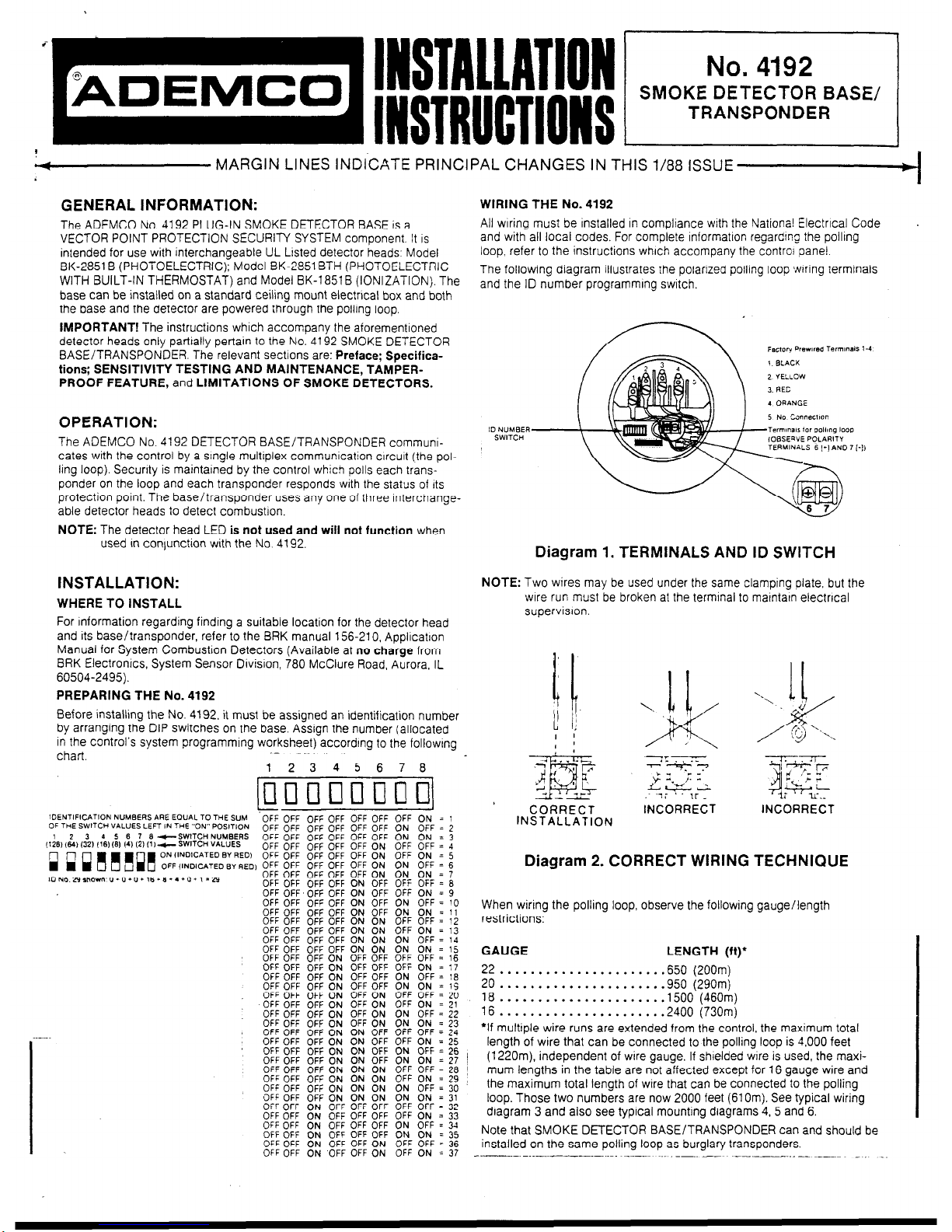

The followmg diagram illustrates the polarzed polling loop jwrrrng terminals

and the ID number programming switch.

OPERATION:

The ADEMCO No. 4192 DETECTOR BASE/TRANSPONDER communicates with the control by a stngle multiplex communrcation crrcutt (the pol-

ling loop). Security is maintained by the control which polls each transponder on the loop and each transponder responds wtth the status of Its

protection point. The base/transponder uses any one of three rnterchangeable detector heads to detect combustton.

NOTE: The detector head LED is not used and will not function when

used In contunction with the No. 4192.

INSTALLATION:

WHERE TO INSTALL

For information regarding findtng a suitable location for the detector head

and its base/transponder, refer to the BRK manual 156-210, Appltcatron

Manual for System Combustton Detectors (Available at no charge from

BRK Electrontcs, System Sensor Dtvisron, 780 McClure Road, Aurora, IL

60504-2495).

PREPARING THE No. 4192

Before installing the No. 4192. it must be assigned an identification number

by arranging the DIP switches on the base. Assign the number (allocated

in the control’s system programming worksheet) accordtng to the followtng

chart

.-

1 2345678

pm

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

1) OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF. OFF OFF

OFF OFF OF: OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF ON

OFF OFF OFF ON

OFF OFF

II

FF

OFF

OFF

OFF

OFF

OFF

“0:

:I

%

%

OFF

OFF

OFF

ON

ON

OFF

OFF

i%

i%

OFF

OFF

ml

OFF ON = 1

ON OFF = 2

ON ON = 3

OFF OFF = 4

OFF ON = 5

g; :‘N’:;

OFF OFF = 6

OFF ON = 9

ON OFF = 10

ON ON = 11

OFF OFF = 12

OFF ON = 13

ON OFF=14

ON ON = 15

OFF OFF = 16

OFF ON = 17

OFF = 16

ON = 1S

g’N’ : ;y

OFF = 22

:F”F : ;;

ON = 25

OFF OFF OFF ON ON OFF ON OFF = 26

OFF OFF OFF ON ON OFF ON ON = 27

OFF OFF OFF ON ON ON OFF OFF = 26

OFF OFF OFF ON ON ON OFF ON = 29

OFF OFF OFF ON ON ON ON OFF = 30

OFF OFF OFF ON ON ON ON ON = 31

OFF OFF ON OFF OFF OFF OFF OFF = 32

OFF OFF ON OFF OFF OFF OFF ON = 33

OFF OFF ON OFF OFF OFF ON OFF = 34

OFF OFF ON OFF OFF OFF ON ON = 35

OFF OFF ON OFF OFF ON OFF OFF = 36

OFF OFF ON OFF OFF ON OFF ON = 37

Diagram 1. TERMINALS AND ID SWITCH

NOTE: Two wires may be used under the same clamping plate. but the

wire run must be broken at the termtnal to matntarn electrical

supervision.

CORRECT

INCORRECT INCORRECT

INSTALLATION

Diagram 2. CORRECT WIRING TECHNIQUE

When wiring the polling loop, observe the following gauge/length

restrictions:

GAUGE LENGTH (ft)’

;i

. . . . . . . . . . . . . . . . . . . . . . 650 (200m)

. . . . . . . . . . . . . . . . . . . .950 (290m)

18 ::. . . . . . . . . . . . . . . . . . . .1500 (460m)

16 . . . . . . . . . . . . . . . . . . . . . .2400 (730m)

‘If multiple wire runs are extended from the control, the maximum total

length of wire that can be connected to the polling loop is 4,000 feet

(1220m). independent of wire gauge. If shrelded wtre is used, the maximum lengths in the table are not affected except for 16 gauge wire and

the maximum total length of wtre that can be connected to the polling

loop. Those two numbers are now 2000 feet (61 Om). See typical wiring

diagram 3 and also see typical mounting diagrams 4. 5 and 6.

Note that SMOKE DETECTOR BASE/TRANSPONDER can and should be

installed on the same polling loop as burglary transponders.

---.- ..___ -.-..-. ~_._.~

~..

-

.

VECTOR

CONTROL

--

4190 4196

0

c

,

Diagram 3. TYPICAL WIRING TO VECTOR SERIES C-COM

MOUNTING THE No. 4192

The ADEMCO No. 4192 SMOKE DETECTOR BASE!TRANSPONDER

mounts directly to 3-inch or 4-tnch octagon lunctron boxes, or with the

addition of a plaster ring or an ADEMCO specrally designed adapter plate,

to a 4-inch square lundron box

OCTAGON

BOX

Diagram 4:

TYPICAL MOUNTING DETAIL

_ --_

,.,‘..

.;------;

‘,\\

LEFToR

t’

i

DEECTOA

/

BASE

Diagram 5: DETAIL FOR MOUNT-

Diagram 6: DETAIL FOR MOUNTING DETECTOR BASE ON 4-INCH ING DETECTOR BASE ON A 4SQUARE JUNCTION BOX USING

PLASTER RING

INCH SQUARE JUNCTION BOX,

OR DIRECTLY TO CEILING,

USING ADEMCO ADAPTER

NOTE: Only two mounting screws are provided with each detector base.

The additional screws shown in Figure 5 and 6 for mounting the

plaster ring or the adapter bracket on the square junction box may

be supplied or purchased with the junction box.

TESTING THE lh%TALLATlON

Once all the detector bases have been wired and mounted, and the

wiring has been checked, the detector heads may be installed in the

loop

bases. To install the detector heads, line up the terminals in the base with

the holes in the bottom of the detector heads, insert the detector head, and

turn it about 10 degrees clockwise until the detent clicks into place.

NOTE: If a detector goes into alarm, it will reset only if all products of

combustion are cleared from the senstng chamber. If not. remove

the detector head from the base to cut off its power. Then reinstall

the detector head in the base.

TAMPER-PROOF FEATURE

These detector bases also include an optional tamper-proof tab that pre-

vents removal of the detector without the use of a tool. The tab is slipped

into a slot in the rim of the detector cover before the detector head is

installed in the detector base. Then the locking tab is pushed into the base

(See Frgures 7A and 78 on the next page). This prevents the detector head

from being turned counterclockwise and removed, unless the locking tab is

first released. To remove the detector head, insert a small-bladed screw

driver into release slot of tab and slide it out of the base. Then turn the

detector head counterclockwise about 10 degrees.

-__^--.. -..- -_.

CAUTION: TO AVOID POSSIBLE DAMAGE To clRculT, DISCON- NECT BOTH POLLING LOOP WIRES AT CONTROL PANEL PRIOR

TO INSTALLATION OR SERVICING THIS UNIT.

ALSO ONCE DETECTOR HEAD IS INSTALLED IN THE BASE, THE

OPTIONAL TAMPER-PROOF TAB MUST BE PUSHED INTO THE

BASE SO THAT WITHOUT TOOL, DETECTOR HEAD CANNOT BE

REMOVED FROM THE BASE. (SEE FIGURES 7A AND 78).

. -. _

Loading...

Loading...