Page 1

BCR

BARCODE / CONTACTLESS

READER

___________________

USER MANUAL

PRODUCED BY

ADEL S.r.l.

Legal address: Via Saffi

Operative address Via Nonantolana N. 970/1

41100 MODENA

Tel 059-2550137 Fax 059-2551207

e-mail adel@adel2000.it

Rif. BCR TECHM 1_3.ENG.PDF TECHNICAL DATA ARE SUBJECT TO CHANGE WITHOUT ADVISE

N. 58

Page 2

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

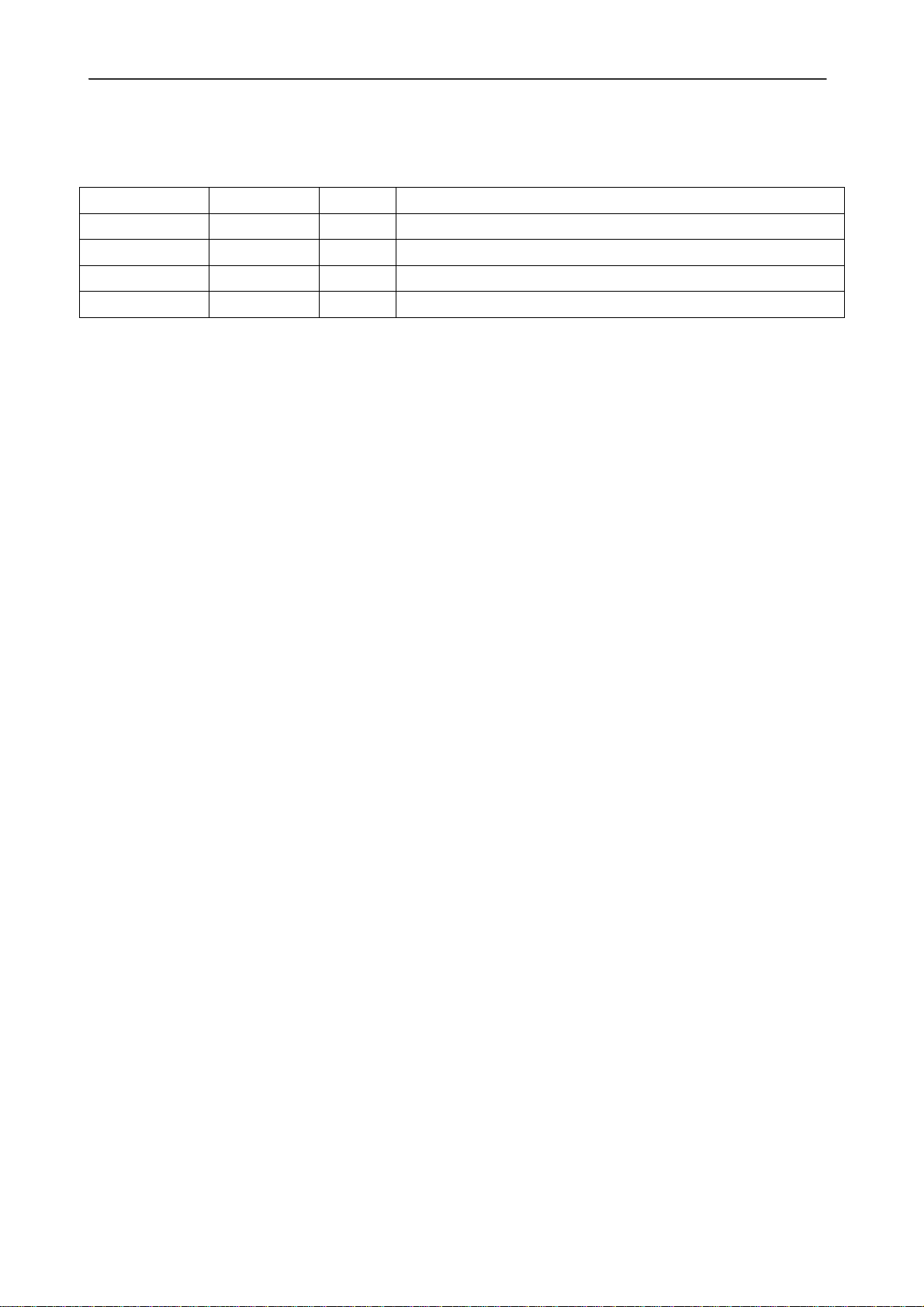

REVISIONS

DATE AUTHOR VER. CHANGES

12/03/2005 FC 1.0 First edition

27/11/2006 SM 1.1 Modified paragraph 3.1.4

01/07/2008 GB 1.2 Modified paragraphs 5.2 and 5.3

18/09/2008 AC 1.3 Modified paragraphs 3.1.4 and 3.1.5

pag. 2

Page 3

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

INDICE

1. GENERALITIES.....................................................................................................................................................4

2. ELECTRIC AND MECHANICAL SPECIFICATIONS.....................................................................................4

2.1 DIMENSIONS AND WEIGHT; BASE AND COMBO VERSIONS .........................................................4

2.2 ELECTRIC POWER SUPPLY ......................................................................................................................4

2.3 INTERFACE ...................................................................................................................................................4

2.4 AVERAGE LIFE .............................................................................................................................................4

2.5 ENVIRONMENT CONDITIONS..................................................................................................................4

3. MODULE DESCRIPTION..................................................................................................................................... 4

3.1 MECHANICAL STRUCTURE......................................................................................................................4

3.1.1 FLANKS FOR TITLE TRANSPORT.............................................................................................................5

3.1.2 TICKET AND CARD TRANSPORT.............................................................................................................. 5

3.1.3 LASER SCANNER ........................................................................................................................................5

3.1.4 CCD IMAGER SCANNER............................................................................................................................5

3.1.5 LONGITUDINAL SCANNER .......................................................................................................................5

3.1.6 R/W CONTACTLESS UNIT..........................................................................................................................5

4. ELECTRONIC CONTROL ...................................................................................................................................5

4.1 CPU BOARD ..................................................................................................................................................5

4.2 MANAGING FIRMWARE .............................................................................................................................6

5. ELECTRIC CONNECTIONS AND PREARRANGEMENTS...........................................................................6

5.1 ELECTRIC CONNECTIONS .......................................................................................................................6

5.1.1 POWER SUPPLY CONNECTOR.................................................................................................................6

5.1.2 SERIAL INT. RS232 CONNECTOR ............................................................................................................6

5.1.3 I/O SIGNAL CONNECTORS........................................................................................................................6

5.1.4 I/O SIGNAL CONNECTOR..........................................................................................................................7

5.1.5 OPTO #3 CONNECTOR ..............................................................................................................................7

5.1.6 STEPPING MOTOR CONNECTOR............................................................................................................. 7

5.1.7 SCANNER CONNECTOR.............................................................................................................................7

5.1.8 CONTACLESS MODULE CONNECTOR....................................................................................................7

5.1.9 PROGRAMMING CONNECTOR.................................................................................................................8

5.2 BUTTONS.......................................................................................................................................................8

5.3 DIP SWITCH...................................................................................................................................................8

5.4 SIGNALLING LED..........................................................................................................................................8

6. PROGRAMMING PROCEDURE.........................................................................................................................9

7. BCR CPU LAYOUT..............................................................................................................................................10

8. ADJUSTMENTS AND SETTINGS.....................................................................................................................10

8.1 BARCODE AND CONTACTLESS READER SETTING........................................................................10

8.2 BARCODE READING POSITION SETUP .............................................................................................. 10

9. DIMENSIONS........................................................................................................................................................11

10. CONNTACTLESS TICKET AND CARD FORMAT...................................................................................14

pag. 3

Page 4

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

1. GENERALITIES

The BCR module is a motorized device for barcode reading of ISO format tickets.

Barcode reading occurs by a laser scanner for transversal printed codes or with a CCD scanner for codes

printed longitudinally.

Optionally and in alternative the version with contactless card and ticket reader is available.

The BCR COMBO version, ideal for automatic cashers and payment operations allows to install both the

barcode reader and the contactless card reader.

In this way you can realize parking systems with barcode tickets for occasional parkers and contactless card

for season parkers or pre-paid cards for habitual users.

2. ELECTRIC AND MECHANICAL SPECIFICATIONS

2.1 DIMENSIONS AND WEIGHT; BASE AND COMBO VERSIONS

BASE VERSION COMBO VERSION

Length: 144.5 mm. 224.5 mm

Width: 104.2 mm. 104.2 mm. .

Height: 115 mm. 115 mm.

Weight: 1.2 Kg. 1.4 Kg.

2.2 ELECTRIC POWER SUPPLY

Tension: 24 Vcc +/- 10% Current: at rest < 100 mA in activity 2.5 A max.

2.3 INTERFACE

Standard: RS232

2.4 AVERAGE LIFE

Mechanical parts subject to wear: > 1.000 000 cycles

2.5 ENVIRONMENT CONDITIONS

Working temperature: from + 10 °C to + 50 °C.

Stocking temperature: from - 10 °C to + 60 °C.

Relative humidity: from 10 % a 85 %. RH not condensing

3. MODULE DESCRIPTION

3.1 MECHANICAL STRUCTURE

The module is composed by the following mechanical groups:

• Flanks for title transport

• Card and ticket transport

• Laser scanner

• CCD scanner

• R/W contactless unit

pag. 4

Page 5

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

3.1.1 FLANKS FOR TITLE TRANSPORT

The flanks are realized in inox steel and they host the symmetrical transport guides trough which title to be

read passes; the right flak hosts the stepping motor and the paper transport devices.

The control electronic board is fixed to the left flank.

3.1.2 TICKET AND CARD TRANSPORT

The transport is guarantied by rubber roller that adapt automatically to card and ticket width between 0.18

and 0.76 mm.

Title movement during insertion, returning to user or swallowing is managed by a stepping motor.

3.1.3 LASER SCANNER

Transversal barcode reader: reading is activated automatically by the BCR module after ticket positioning.

After reading, the code read is available and it can be required by apposite command (rif. Communication

protocol of the BCR) sent by the host on the serial communication line.

This scanner can read all kinds of barcodes.

3.1.4 CCD IMAGER SCANNER

Also this device, in alternative to the laser scanner, allows the reading of barcodes.

The IMAGER scanner is more performing than the laser scanner because it can read also bad resolution

barcodes.

The reading resolution is higher and there is a high tolerance in the reading position.

The reading is activated automatically from the BCR module sliding the ticket under the reader. After

reading the code is available and it can be required by apposite command (rif. Communication protocol of

the BCR) sent by the host on the serial communication line.

This scanner can read all kind of barcodes and two-dimensional barcodes (pdf).

3.1.5 LONGITUDINAL SCANNER

Optionally the CCD IMAGER scanner can be mounted longitudinally in order to read longitudinally printed

barcodes.

3.1.6 R/W CONTACTLESS UNIT

For reading and writing of MIFARE contactless cards in the BCR reader a module in accordance with

following standards is employed: ISO 14443-A and ISO 15693. On request the ISO 14443-B standard is

available. This module is installed between the two flanks at a distance that allows communication with the

card.

The device is connected to the CPU board by the means of the C_LESS connector and it is managed by the

CPU board FW trough special protocol encapsulated in the BCR module protocol.

NOTE: during assembling the module is set and tested for optimal functioning; the set changing can

compromise the correct functioning of the device.

4. ELECTRONIC CONTROL

4.1 CPU BOARD

pag. 5

Page 6

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

All elaboration and management tasks are entrusted to this control board.

The base circuit modules are:

• Microprocessor Fujitsu 16 bit

• Laser Scanner and IMAGER driver interface

• Set of optical sensor for title position survey within the module

• Stepping motor driving circuit

• RS232 serial interface

4.2 MANAGING FIRMWARE

The managing FW controls all functions performed by the module, such as:

• Host communication management trough RS232 serial communication port

• Title movement control within the module

• Laser scanner, IMAGER and R/W contactless module communication management.

5. ELECTRIC CONNECTIONS AND PREARRANGEMENTS

5.1 ELECTRIC CONNECTIONS

5.1.1 POWER SUPPLY CONNECTOR

Power supply is given by the connector SUPPLY (JST PH 4x1 PM 90°) with the following pinout:

Pin 1 +24V

Pin 2 +24V

Pin 3 GND

Pin 4 GND

5.1.2 SERIAL INT. RS232 CONNECTOR

The serial interface used for communication with the BCR module is available in the connector RS232 (JST

PHD 2x5 PM 90°), with the following pinout:

Pin 1 NC Pin 2 NC

Pin 3 Tx RS232 Pin 4 NC

Pin 5 Rx RS232 Pin 6 GND

Pin 7 NC Pin 8 NC

Pin 9 GND Pin 10 NC

5.1.3 I/O SIGNAL CONNECTORS

It is possible to connect to the BCR module three input digital signals and three output signals open collector

type. The I/O connector 1 (JST PHD 6x2 PM 90°) pinout is the following:

Pin 1 OUT 0B Pin 2 GND

Pin 3 OUT 1B Pin 4 GND

Pin 5 OUT 2B Pin 6 GND

Pin 7 IN 0B Pin 8 GND

Pin 9 IN 1B Pin 10 GND

Pin 11 IN 2B Pin 12 GND

pag. 6

Page 7

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

5.1.4 I/O SIGNAL CONNECTOR

Besides the I/O signals present on the I/O 1 connector, on the I/O 2 connector an input digital signal and a

power output signal are available and ideal to drive a ralay.

The I/O 2 (JST PH 4x1 PM 90°) connector pinout is the following:

Pin 1 OUT 3B

Pin 2 GNDPP

Pin 3 IN 3B

Pin 4 GND

5.1.5 OPTO #3 CONNECTOR

On the OPTO #3 connector the connection for a optional external optical sensor is available.

The OPTO #3 (JST PH 4x1 PM 90°) connector pinout is the following:

Pin 1 VCC

Pin 2 OSC

Pin 3 VCC

Pin 4 OPTO

5.1.6 STEPPING MOTOR CONNECTOR

The connection of the stepping motor occurs by the means of the connector MOTOR (AMP MODII 4 PM

90°) with the following pinout

Pin 1 OUT 1

Pin 2 OUT 2

Pin 3 OUT 3

Pin 4 OUT 4

5.1.7 SCANNER CONNECTOR

The laser scanner is connected to the CPU board by the means of the connector BCR (JST PH 4x1 PM 90°)

with the following pinout:

Pin 1 VCC

Pin 2 GND

Pin 3 LASER_TRIGGER

Pin 4 TX

5.1.8 CONTACLESS MODULE CONNECTOR

The contactless module is connected to the CPU board by the means of the connector C_LESS (JST PHD

2x5 PM 90°) with the following pinout:

Pin 1 VCC Pin 2 Rx1

Pin 3 Rx1_RS232 Pin 4 Tx1

Pin 5 Tx1_RS232 Pin 6 I/O AUX1B

Pin 7 C_GND Pin 8 C_GND

Pin 9 I/O AUX0B Pin 10 I/O AUX2B

Following drawing and form show the pinout of the connector that must be inserted in the contactless

module.

pag. 7

Page 8

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

Pin N°

3 TxD RS232 TTL –Transmit data

4 GND GND

5 RxD RS232 TTL –Receive Data

8 VCC +5V DC

9 GND GND

Function

Description X1

ID CPR.M02 –B/-BA

5.1.9 PROGRAMMING CONNECTOR

The firmware download occurs by the means of the connector FLASHPRG (JST PH 4x1 PM 90°)

Pin 1 GND

Pin 2 TX

Pin 3 GND

Pin 4 RX

5.2 BUTTONS

The RESET button allows to reset the board without disconnecting power supply.

The SWP1 button activates the ticket issue function.

The SWP2 button activates the barcode scanner.

5.3 DIP SWITCH

The dip switch SW1 allows the execution of special statements and to activate the firmware download.

The dip switch function is the following:

Dip 1 On = Contactless reader Off = Barcode reader

Dip 2 On = Activates the reverse ticket reading function Off = Disabled function

Dip 3 On = Activates the barcode slow reading function Off = Disabled function

Dip 4 On = Disabled function Off = Activates an Output switch off timer

Dip 5 RESERVED

Dip 6 On = firmware Download

See paragraph 6 for programming procedure

5.4 SIGNALLING LED

DL1 Photo sensor status display OP1

DL2 Photo sensor status display OP2

DL3 Photo sensor status display OP3

DL4 On in programming

DL5 Display trough flash sequences machine status and possible alarms

FIXED ON Regular functioning

pag. 8

Page 9

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

1 FLASH Command in execution

2 FLASHES Command not executed for title not present in the module

3 FLASHES Command not executed for title already present in the module

4 FLASHES Command not executed for reading already enabled

5 FLASHES Position error

7 FLASHES Title jammed

8 FLASHES Configuration not valid

6. PROGRAMMING PROCEDURE

For FW download, after setting dip 4-5-6 follow these instructions:

a. Connect serial cable to connector FLASHPRG (JST 4 P.M. a 90°).

b. Keep RESET button pressed and, at the same time, move the dipswitch 6 to On position; verify that

the DL4 led is on and release RESET button.

c. Execute the FUJITSU FLASH MCU Programmer program.

• Select in the Target Microcontroller field the MB90F497/G model.

• Select in the Cristal Fquency field the value of 4MHz.

• Open the file with MHX extension.

• Select the COM port to which the serial cable is connected.

• The screen appears as the one on the button if the COM1 port is used.

• Press the “Full Operation(D+E+B+P)” button.

• When the Flash window appears press “OK”.

• Wait for procedure to finish.

d. At the end of the procedure press OK and close the program.

e. Select in the Target Microcontroller field the MB90F497/G model.

f. Press reset button and at the same time move the dipswitch 6 in Off position and verify that the LED

DL4 switches off. Release the reset button.

pag. 9

Page 10

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

7. BCR CPU LAYOUT

8. ADJUSTMENTS AND SETTINGS

8.1 BARCODE AND CONTACTLESS READER SETTING

The barcode reader is regulated in the position that guaranties best reading performances of barcodes.

The change of this position can reduce or compromise reading realibility.

8.2 BARCODE READING POSITION SETUP

The communication protocol provides a special command to define the ticket position under the

scanner.

It is recommended to position barcode printing near the front edge f the ticket.

pag. 10

Page 11

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

9. DIMENSIONS

CONTACTLESS VERSION

pag. 11

Page 12

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

BARCODE VERSION

pag. 12

Page 13

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

COMBO VERSION

pag. 13

Page 14

ADEL S.r.l. – BCR Barcode / Contactless reader - User Manual Rev. 1.3

10. CONNTACTLESS TICKET AND CARD FORMAT

The contactless card in paper or in plastic format is ISO.

The paper ticket with barcode can be in fan fold or cut directly from roll and with following dimensions:

54x85,6 mm.

Here following is the recommended barcode ticket printing layout.

TRANSVERSAL BARCODE

LONGITUDINALE BARCODE

pag. 14

Loading...

Loading...