Additel 916-N Instruction Manual

Warnings and cautions

Avoid possible damage when suddenly apply pressure to low pressure

and small chamber gauges.

Do not exceed the safety pressure limit(1000 psi ).

Compressed air may cause problem in explosive or corruptive

environment.

Do not shift between pressure and vacuum mode under pressure.

Do not over tighten connectors to avoid any damage.

Store the pump in the dry and non-corruptive environment.

Any security problems or damages caused by incorrect operation,

is beyond Additel's responsibility.

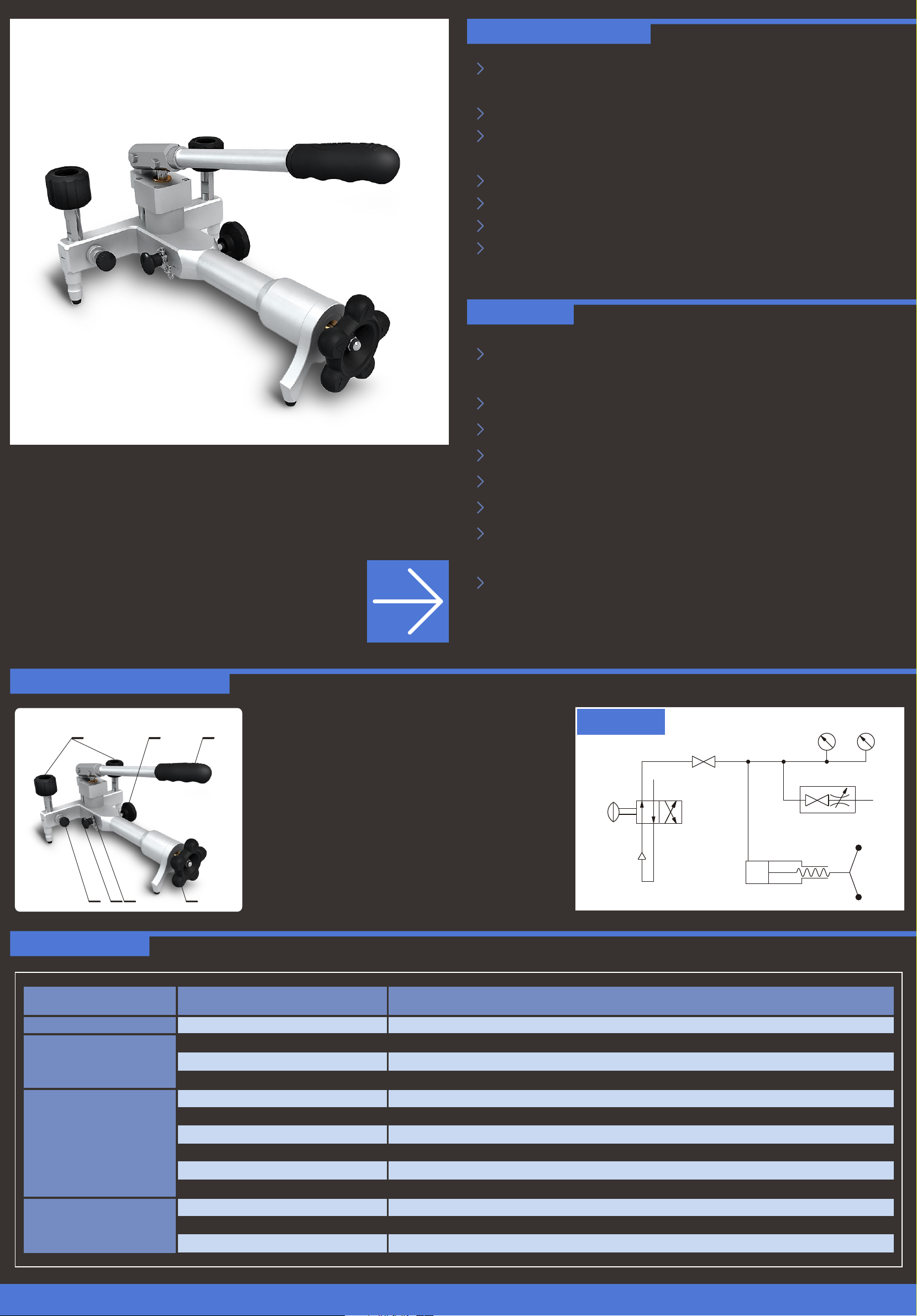

Specification

ADT916

Pneumatic Pressure Test Pump User's Manual

[Version number:1103V10]

Pressure range: 14 psi ( 0.95 bar ) vacuum to

600 psi ( 40 bar ) positive pressure

Temperature: (0~50)℃

Humidity: < 85%RH

Adjusting fineness: 10 Pa ( 0.1 mbar )

Safety pressure: < 1000 psi ( 70 bar )

Pressure media: Air

Size: Height: 5.5'' ( 140 mm );

Base: 12.4'' ( 315 mm ) x 7.8'' ( 198 mm )

Weight: 6.0 lb ( 2.7 kg )

Remark:If local atmosphere pressure is 1 bar, the vacuum can reach to -0.95 bar;

If local atmosphere pressure is P, the vacuum can reach to - 0.95P bar.

Configuration & Air routine

1 2 3

7

56

4

Troubleshooting

Problems

1 - 1/4 NPT connector

2 - Isolating valve

(isolate the calibration from pressurizing system)

3 -Pressure lever

4 - Fine adjust handles

(clockwise to increase pressure)

5 -Security bolt pin

(use it to ensure safety)

6 -Pressure/vacuum selector

(Pressure: pull it out; Vacuum: push it in)

7 -Release valve

(clockwise to close/ anticlockwise to open)

Causes

Air routine

2

6

7

3

4

Solutions

Hard to use pressure lever

Hard to pressurize

Hard to use vernier

Not easy to turn the fittings

The isolating valve is not open.

A. Release valve is not closed.

B. The sealing ring is broken or loosen.

C. P/V selector is in wrong position.

A. The isolating valve is not closed.

B. The gauges is not tightened.

C. The sealing ring is aged or frayed.

D. The thread surface is not smooth.

E. The connector type is unmatched.

F. The impurity blocks the air routine.

A. Too tightly turned last time!

B. The new pump is not smooth.

C. The threads have no lubrication.

Open the isolating valve.

Close the release valve.

Replace sealing ring.

Pressure: pull it out; Vacuum: push it in.

Close the isolating valve.

Tighten the reference gauge or the gauge under test.

Replace sealing ring.

Put in a Teflon seals and turn it tightly.

Use the right and suitable adapter.

Repeat pressurizing several times and then release it suddenly, make airflow to bring the impurity out.

Do not apply much force to close the fittings and valves.

The new pump needs time to abrade.

Lubricate the thread.

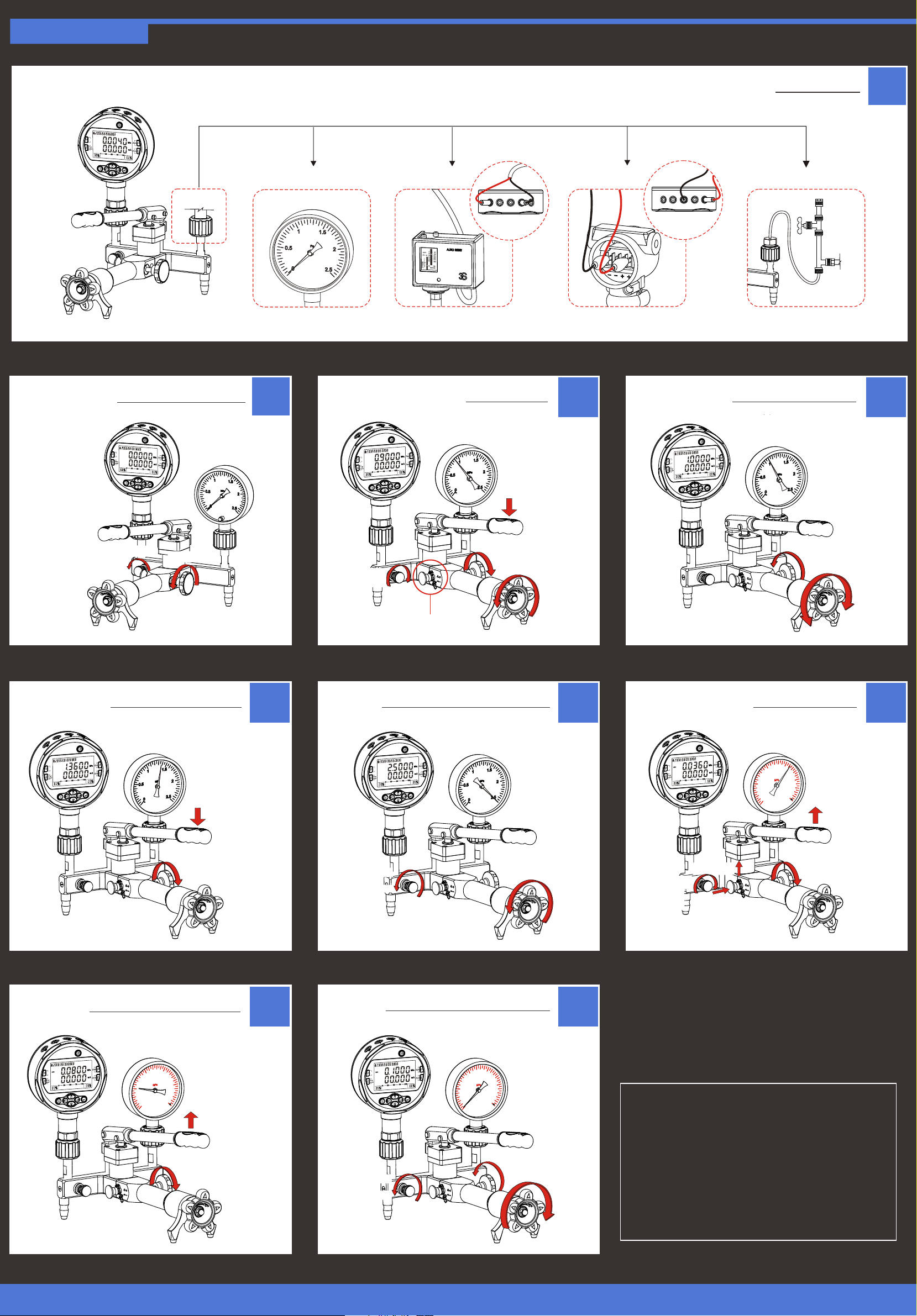

Basic Operation

DIG

ITAL PESSU

RE

CAL

IB

R

AT

O

R R

Un

i

ts

Open to atmosphere

B

Pressure GaugePressure Gauge

kk

dial gauge

SW V mA COM 24VSW V mA COM 24V

SW V mA COM 24VSW V mA COM 24V

pressure switch pressure transmitter

Pre-pressure

C

Connection

flexible hose

Fine adjust process

A

D

Zeroing should

be operated

under this

condition only.

R

O

T

A

I

CALBR

RE

SU

ES

R

TAL

GI P

DI

s

i

ntU

DIGIT

A

L

A

PR

ESSU

RE

CAL

IB

R

TO

R

Units

P

P

r

r

e

e

s

s

s

s

ur

ur

e

e

G

G

a

a

u

u

ge

ge

open

open

Pressurizing process

e

e

g

g

Gau

Gau

r

r

su e

su e

s

s

e

e

r

r

P

P

operate it to

②

get the desired

value

E

close,do not

④

use too much

force

R

O

T

A

BR

I

CAL

RE

ES

R SU

TAL

GI P

DI

s

i

ntU

ePr

e

g

g

au

au

G

G

e

e

r

r

u

u

ss

ss

e

e

Pr

③

①

push the security bolt pin in

Decrease pressure process

OR

T

AGT

I

CALBR

RE

ES

PR SU

AL

DI I

nU its

e

r r a

r r a

P

P

uge

uge

G

G

u e

u e

ss

ss

e

operate it to get

⑤

the desired value

open

set it to the

②

mid position

of its travel

F

Un

s

i

Unt

DI

s

t

i

PR

AL

GIT

I A

D

ESS RE

A PR

GI

OR

A

REC LIBRT

SU

ES

ge

ge

G

G

u auP

u auP

ss re

ss re

e

e

r

r

close,do not use

①

too much force

fine adjust

②

Vacuum process

ORT L

T

BRA

CALI

U

04

0.040.

. 6

. 6

0 0

0 0

ge

ge

u

u

a

a

Va

mG

mG

u

u

c u

c u

Va

02

02

.

.

0

0

80.0

8

0.0

00

0 1- .0 1- .

operate it to

⑤

get the desired

G

value

Uni

GITAL

I E

D

ts

Repeat Vacuum process

OR

R T

ALB A

SUR C I

ES

PR

4

4

0

0

.

.

0

0

6

00.600.

ea

e

g

g

u

u

a

m G

m G

u

u

u

u

c

c

Va

Va

02

02

.

.

0

0

8

.

0 08.0 0

00

0 1- .0 1- .

①

①

Open

②

open

H

operate it to

get the desired

value

open it slowly

①

to get the

desiredvalue,

and close!

open it slowly

②

to get the

desired value,

and close!

Decrease vacuum process

OR

T

ALBRA

C I

E

UR

SS

PR

GITAL

I E

D

ts

Uni

0.080.08

40

4

0

0

.

.

0

06

0.060.

ea

e

g

g

auV u mG

auV u mG

c u

c u

a

020.

02

0.

0

0

0.1- 0.1-

①

close

fine adjust

②

fine adjust

③

open

①

close(

but it

must be open

when select

the pressure /

vacuum

)

④

pull out

③

push in,select

the vacuum

position

②

I

Remark:

A: Additel has made a concerted effort to provide

complete and current information for the proper

use of the equipment. The product specifications

and other information contained this manual are

subject to change without notice.

B: Above pictures are just for reference.

Loading...

Loading...