Adcon Telemetry A733 Revised technical manual and photos with schematics and bill of materials removed

Page 1

ADCON

TELEMETRY

A733 RTU

Technical Reference (Type Approval)

SMART WIRELESS SOLUTIONS

Page 2

ADCON

TELEMETRY

ADCON TELEMETRY AG

INKUSTRASSE 24

A-3400 KLOSTERNEUBURG

AUSTRIA

TEL: +43 (2243) 38 280-0

FAX: +43 (2243) 38 280-6

http://www.adcon.at

ADCON TELEMETRY INC

1001 YAMATO ROAD

SUITE #305, BOCA RATON

FL 33431 USA

TEL: +1 (561) 989-5309

FAX: +1 (561) 989-5310

http://www.adcon.com

ADCON TELEMETRY SRL

BD. ION IONESCU DELABRAD 8

R-71592 BUCHAREST

ROMANIA

TEL: +40 (1) 490-6083

FAX: +40 (1) 490-6086

http://www.adcon.ro

Proprietary Notice:

The Adcon logo, the A730 series, A720 series and addIT™, A733 series and

addWAVE, addVANTAGE and AgroExpert™ are trademarks or registered

trademarks of Adcon Telemetry AG. All other registered names used throughout this publication are trademarks of their respective owners.

This publication contains confidential information, property of Adcon Telemetry AG. Disclosure to third parties of the information contained herein is prohibited. Neither the whole nor any part of the information contained in this

publication may be reproduced in any material form except with the prior written permission of Adcon Telemetry AG.

Release 1.0, December 14, 1999

Copyright ©1999 by Adcon Telemetry AG.

All rights reserved.

Page 3

Table of Contents

Introduction ____________________________________________________7

About the A733 ______________________________________________________________ 7

Hardware _______________________________________________________9

Overview_____________________________________________________________________ 9

The Modem Interface _________________________________________________________________ 10

The Microcontroller and the Power Management Sections _________________________________ 10

The Analog + Digital I/O Interface Board ________________________________________________ 13

The Power Supply and the Serial Interface _______________________________________________ 13

External Power Supply_________________________________________________________________ 14

Specifications________________________________________________________________15

PCB Parts Placement (A733) __________________________________________________16

Bills of Materials _____________________________________________________________17

A733MB _____________________________________________________________________________ 17

A733CA _____________________________________________________________________________ 19

A733 Device’s Photographs___________________________________________________ 20

The A431 Radio Module _______________________________________ 25

About the A431 Radio Module________________________________________________25

Functional description________________________________________________________25

Receiver Section ______________________________________________________________________ 25

Transmitter Section____________________________________________________________________ 26

3

Page 4

Manufacturing Issues ________________________________________________________ 28

Marking and labeling issues ____________________________________________________________ 28

Alignment Range and Switching Range __________________________________________________ 28

Tuning Procedure _____________________________________________________________________ 29

Setting Up the Default Parameters ______________________________________________________ 29

Commands valid for all bands ____________________________________________________ 30

Commands required for band 1 __________________________________________________ 30

Commands required for band 2 __________________________________________________ 30

Commands required for band 3 __________________________________________________ 30

Commands required for band 4 __________________________________________________ 30

Definitions ___________________________________________________________________________ 31

Test Equipment Settings _______________________________________________________________ 32

Network Analyzer (HP 8712 or equivalent)_____________________________________________ 32

Service Monitor (Rohde & Schwarz CMS50 or equivalent) _______________________________ 32

Trimming Elements____________________________________________________________________ 33

Adjusting the Receiver Front End _______________________________________________________ 33

Adjusting the VCOs ___________________________________________________________________ 34

Adjusting the Crystal Reference _________________________________________________________ 35

Checking the Receiver Parameters ______________________________________________________ 35

Checking the Transmitter Parameters ____________________________________________________ 35

Data Transfer Check ___________________________________________________________________ 36

PCB Parts Placement_________________________________________________________ 37

Bill of Materials (A431) _______________________________________________________ 38

Frequency Reference Specifications ___________________________________________ 42

A431 Module’s Photographs _________________________________________________ 43

Software ______________________________________________________45

Short Description____________________________________________________________ 45

Tasks _______________________________________________________________________ 45

Controlling the Unit__________________________________________________________ 47

Serial Communication Protocol _________________________________________________________ 47

General Format of a Command _________________________________________________________ 47

General Format of an Answer___________________________________________________________ 48

Commands___________________________________________________________________________ 48

CMDS _____________________________________________________ 48

TIME _____________________________________________________ 49

BL ____________________________________________________________________________ 49

FREQ _________________________________________________________________________ 49

DATA _________________________________________________________________________ 50

IMME _________________________________________________________________________ 52

4

Page 5

INFO _________________________________________________________________________ 52

RX ___________________________________________________________________________ 53

TX ___________________________________________________________________________ 54

B ____________________________________________________________________________ 54

Returned errors list____________________________________________________________________ 54

Command line interpreter _______________________________________________________ 54

Device descriptors and storage handler ___________________________________________ 55

Real time clock ________________________________________________________________ 55

Radio interface ________________________________________________________________ 55

Notifications __________________________________________________________________ 55

Adcon Packet Radio Protocol _________________________________________________56

Digital Squelch _______________________________________________________________________ 56

Modulation Technique Used____________________________________________________________ 57

Generic Format of a Radio Frame _______________________________________________________ 57

Data Frames _________________________________________________________________________ 59

Frame Types _________________________________________________________________________ 59

Request ______________________________________________________________________ 59

Broadcast Answer ______________________________________________________________ 60

Broadcast Request _____________________________________________________________ 60

Ping __________________________________________________________________________ 61

Pong _________________________________________________________________________ 61

Fdev _________________________________________________________________________ 62

Data12 _______________________________________________________________________ 62

Set ID ________________________________________________________________________ 63

Set Slot Time and Sample Rate __________________________________________________ 64

Set Frequency _________________________________________________________________ 64

Set Battery Charge Levels _______________________________________________________ 65

General Acknowledge __________________________________________________________ 65

5

Page 6

6

Page 7

1. Introduction

1.1. About the A733

The A733 Remote Telemetry Unit (RTU) is a portable low-power, medium-range telemetry device capable of sampling up to 12 analog and 8 digital inputs (of which 4

are counter types); in addition, it can control up to 4 outputs. A 3-volt CMOS serial

interface is also built-in, allowing for configuration, data download, or expansion

(e.g. various bus implementations). The unit is based on a powerful 8-bit Flash RISC

microcontroller, which can also be programmed in the field (for software upgrades).

The units incorporates an A431 radio module operating in the 430 to 470 MHz

range, making it adaptable to most radio communication regulations in the world.

The output power is 0.5 W, while the modulation is narrow band FM (12.5, 20 or 25

kHz channel spacing).

Due to its construction, as well as to the software controlling it, the power consumption is extremely low (average 1 mA—without sensors). The unit operates from a

built-in NiCd 6.2 Volt rechargeable battery, which is charged using either a solar

panel or an external power supply adapter. A special configuration may be implemented where no internal battery is used, rather the power is obtained exclusively

over an external connector.

The A733 is a ruggedized unit, complying with the IP65 environmental protection

class (NEMA 4). It can be easily installed and it integrates perfectly with an Adcon

A730 network.

This manual describes the technical details of the A733, both hardware and software. It is organized in several parts, as follows:

7

Page 8

Introduction

• Hardware: includes the schematics as well as a description of the main board

and interface boards of the A733

• The A431 radio module: includes the schematics and description of the radio

module

• Software: a short description of the software with the most important commands that can be used to control the unit over the serial interface

This manual is intended for the radio approval authorities and laboratories.

8

Page 9

2. Hardware

2.1. Overview

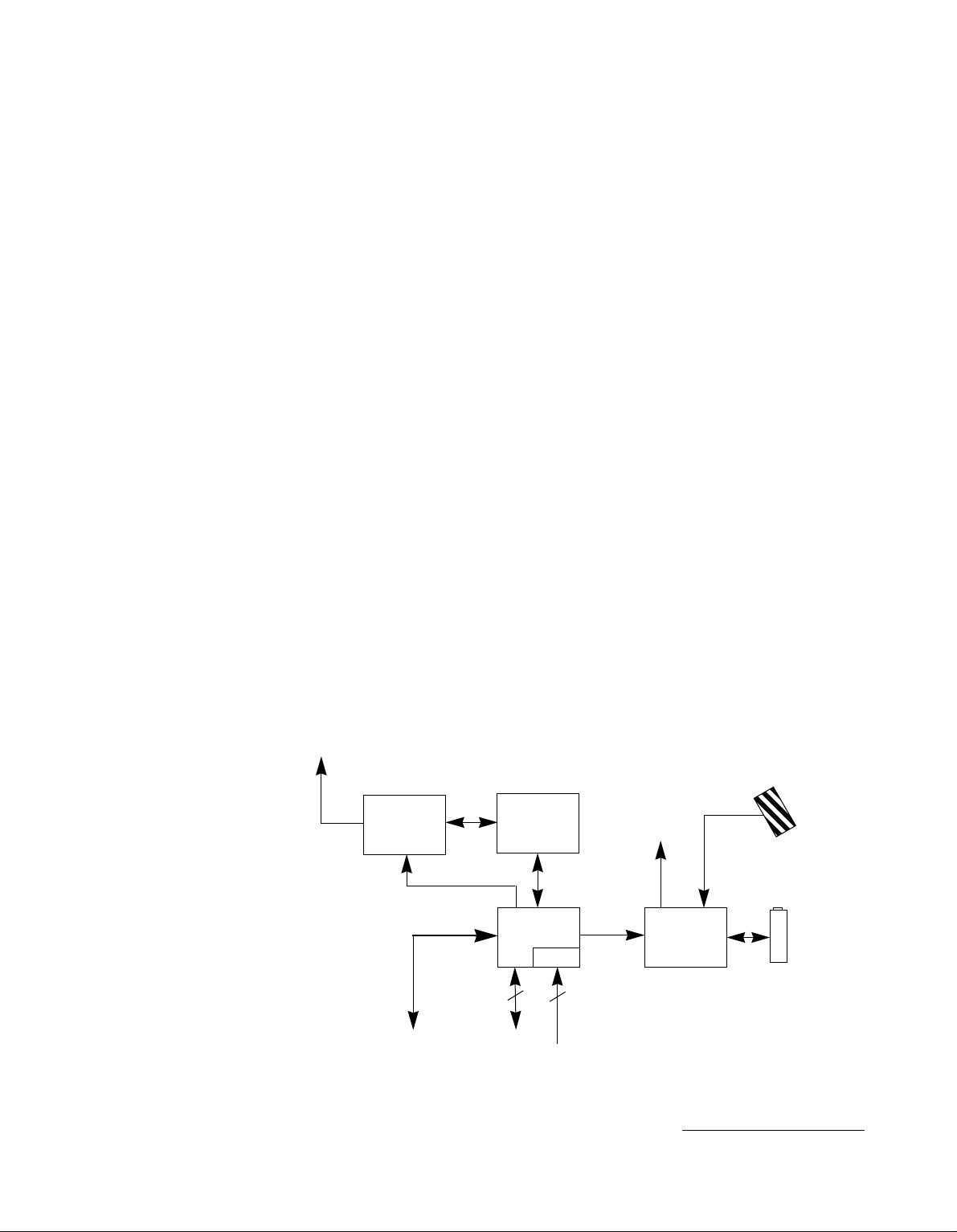

Most of the electronics (including the A431 radio module) are situated on the main

board (for the A431 description, see “The A431 Radio Module” on page 25). The

main board (Figure 1) contains the radio unit, a low-speed modem interface, a microcontroller and a power management subsystem. For the analog inputs and the

digital inputs/outputs, two identical interface boards (A733CA) holding the 7-pin

Binder connectors are used. The serial line and the power are provided on a 5-pin

Binder connector, while the antenna is fed through a 50 Ω BNC connector.

Antenna

Figure 1.

A431 Radio

Module

3 V CMOS

Serial

Interface

A733 Block Diagram.

Digital I/O

Modem

Interface

µController

ADC

8

System Supply

12

Analog Inputs

External Power

Power

Management

Battery

9

Page 10

Hardware

For further details, consult the schematic diagram in Figure 2.

2.1.1. The Modem Interface

The modem operates with two tones: 1 kHz (representing the “1” bits) and 2 kHz

(representing the “0” bits). A bit cell is represented by a complete time period (

thus the raw throughput varies between 1 and 2 kbps (average 1.5 kbps). The modem functions are essentially implemented in software. However, a signal conditioning is performed on both receive and transmit paths.

On receive, the buffered analog data signal from the radio unit is applied to a 3 kHz

low pass filter (U6). The filter output is further fed both to a Schmidt trigger (U5:A)

and a 100 Hz low-pass filter (U5:B), the output of the latter being used as a reference

for the slicer (the Schmidt trigger). The TTL data,

of the slicer (i.e. on TP1). The microcontroller overtakes the decoding operation (see

also “Modulation Technique Used” on page 57).

On transmit, a two-poles low-pass filter (U11) is used: its role is to “smooth” the

square signal

microprocessor-controlled, variable-gain amplifier built with U12/U13 is used to set

the modulation level for different bandwidths (12.5, 20 or 25 kHz). The selected value is stored in the microcontroller’s EEPROM during the aligning procedure.

TXDI

generated by the microcontroller. Before entering the filter, a

RXDO

, is obtained at the output

1/f

),

2.1.2. The Microcontroller and the Power Management Sections

The operation of the whole unit is under the control of U9, an Atmel ATMega 103

microcontroller. It is a powerful chip exhibiting a very low power consumption. Its

main functions are:

• Controls the radio unit

• Implements the modem functionality

• Assembles the radio frames and waits for requests from a remote

• Performs the sampling of the sensor inputs and the A/D conversion

• Stores the values in a local FIFO; manages the FIFO

• Implements the pulse counter function

• Manages the real-time clock

• Assures the power management

• Implements a serial Command Line Interface (CLI)

The chip operates at its maximum speed, in this case 4 MHz (the “L” version), and

uses a crystal (X2) for the on-board clock generator. The real time clock is implemented by means of a 32.768 kHz crystal (X1) connected on the internal Timer/

Counter0.

10

Page 11

The Microcontroller and the Power Management Sections

The radio unit is controlled via the SPI bus (to set the PLL chip parameters) and via

several ports of the microcontroller for such operations as transmit and receive. In

addition, the high current 5 volt LDO voltage source (U4) is switched on before the

radio module’s PA must be activated.The modem’s output (implemented in software) is available on PB5 (

TXDI

), while the receiver output is fed to PD4 (

RXDO

).

The A/D subsystem is used to sample the inputs (ADC0 to ADC5); the 6th and 7th

analog input are used for on-board measurements as local battery, internal temperature and

RSSI/PO

signal; the battery and temperature voltages are switched by

means of the analog switch U19. A stable 2.5 Volt reference supplied by U8 is applied to the A

pin. The reference is powered by the microcontroller only when

ref

sampling the A/D inputs. The external sensors are powered through U17. In order

to enlarge the maximum number of sensors sampled, several analog multiplexers

are used (U3/U7/U10). After sampling the A/D once, the software switches the multiplexers (using the signal

MUX

, pin PD2) and samples the inputs once again, thus

doubling to 12 the maximum number of analog inputs.

The sampled input values are stored in a FIFO memory based on a serial EEPROM

chip, U18. These values may be retrieved when a request is received over radio, or

over the serial line. The configuration parameters (e.g. the serial number of the device, the operating frequency, etc.) are stored in the microcontroller’s on-chip EEPROM.

The pulse counter functionality is implemented by means of the four interrupt inputs

INT4 to INT7 of the ATMega 103 microcontroller.

The power management supervises the charge/discharge of the battery (via Q1 and

half of U15), senses when it reaches the “misery” state and switches off the unit in

order to protect the battery (second half of U15). In addition, the software senses the

unit’s idle state (e.g. the unit is in a warehouse in storage condition), where no activities must be performed thus driving the unit into hibernation. If the unit is switched

off due to an extremely low battery level, Q2 would start it up again only if external

power is applied to the power connector (e.g. from a solar panel).

The terminal mode is implemented by means of the built-in UART. No on-board level drivers are present in order to minimize power consumption; a special adapter cable that performs the CMOS to RS232 level shift is available. By means of this cable

and using the implemented commands, various parameters can be changed/configured.

A brown-out supervisor chip (U14) is used to assure a smooth start-up of the microcontroller and avoid possible erratic behavior when the battery level descends below the minimum operating value (2.7 volts). The same chip activates the writeprotect signal of the serial EEPROM during reset, in order to protect the data in the

EEPROM.

11

Page 12

The Analog + Digital I/O Interface Board

2.1.3. The Analog + Digital I/O Interface Board

The two identical interface boards ensure the connection between the main board

and the outside world (see Figure 3). The interface boards contain two connectors

each (

I/O A

and

I/O B

or

I/O C

and

I/O D

respectively) and some active/passive

components protecting the inputs. Each of the

I/O

connectors can accept:

• Three analog inputs

• One digital Input or Output (its function can be switched under program control, also remotely)

• One pulse counter input

Depending on the way R3 and R4 are populated, the power supply to the I/O devices can be either switched or permanent. This option is factory programmable

only. If R3 is populated, the power will be permanently applied to the sensors while

if R4 is populated, the power will be applied for a defined time (typically 2 seconds)

only shortly before the microcontroller samples the inputs.

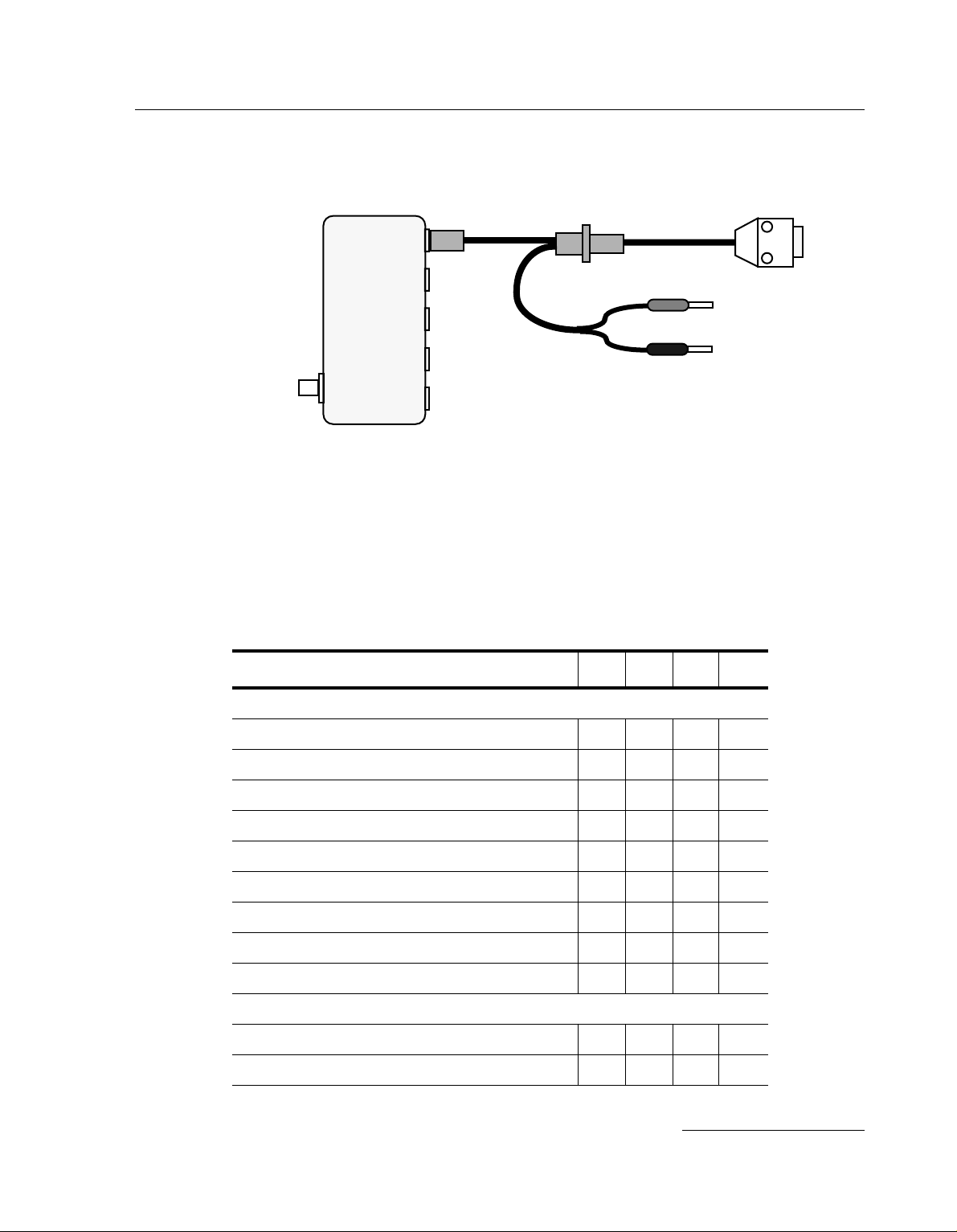

2.1.4. The Power Supply and the Serial Interface

The

POWER

• External supply (battery or any DC source from

• External charge supply (either a solar panel or

• Communication over serial lines, at 19200 baud

connector allows for:

5.6 to 10 volts)

an AC adapter) if an internal rechargeable battery is used

Battery

Ext Power

5

4

3

Ground

RxD

1

2

TxD

Note: The serial line is 3 volt CMOS compatible, therefore a special adapter cable

must be used to reach the RS-232 levels. Also, if an external battery is used,

the internal battery must be disconnected.

13

Page 13

External Power Supply

when the battery voltage drops below 5.6 Volts, and under 5.9 Volts the RF operation may stop.

POWER

I/O D

I/O C

I/O B

ANT

Figure 4.

I/O A

Connection of an external power supply.

2.2. Specifications

The A733 fulfills the specifications of the EN 300 220-1, Class 12, ETS 300 086 and

ETS 300 113, as well as the FCC Part 90.214 (Subpart J) of the CFR 47.

Note: The parameters below were measured with the A733 + A431 combination.

Parameter Min Typ Max Unit

Power Cable Serial Adapter Cable

Red

+

Black

-

+

RS232

+

5 to 10 Volt

Common

Supply 5.6 6.2 10.0 V

Operating Temperature -30 +70 °C

Relative Humidity 99 %

Class Protection IP65

Data Rate (Using the On-board Software Modem) 1000 1500

Operating Frequency (-44 version)

Operating Frequency (-46 version)

b

b

430 450 MHz

450 470 MHz

a

Frequency Stability (-20 to +50°C) ±1.5 kHz

Frequency Stability (-30 to +60°C) ±2.5 kHz

Receiver

Sensitivity (12 db S/S+N) -118 dBm

Image Frequency Attenuation (1st IF = 45 MHz) -70 dB

2000 bps

15

Page 14

Hardware

Parameter Min Typ Max Unit

Local Oscillator Leakage 2 nW

Adjacent Channel Attenuation -70 dB

RSSI dynamic 90 dB

Operating Current (incl. On-board Microcontroller) 25 mA

Transmitter (all measurements made on a 50 Ω resistive load)

Output Power 27 dBm

Spurious Radiation 200 nW

Adjacent Channel Power (12.5 kHz version) -34 dBm

Adjacent Channel Power (25 kHz version) -44 dBm

Occupied Bandwidth (12.5 kHz version) 7.0 kHz

Occupied Bandwidth (25 kHz version) 12 kHz

Operating Current (incl. On-board Microcontroller) 600 mA

a. Data rate is content dependent.

b. This parameter represents the alignment range; the switching range can

be limited in the software to a narrower space (even to the extent of a

single channel).

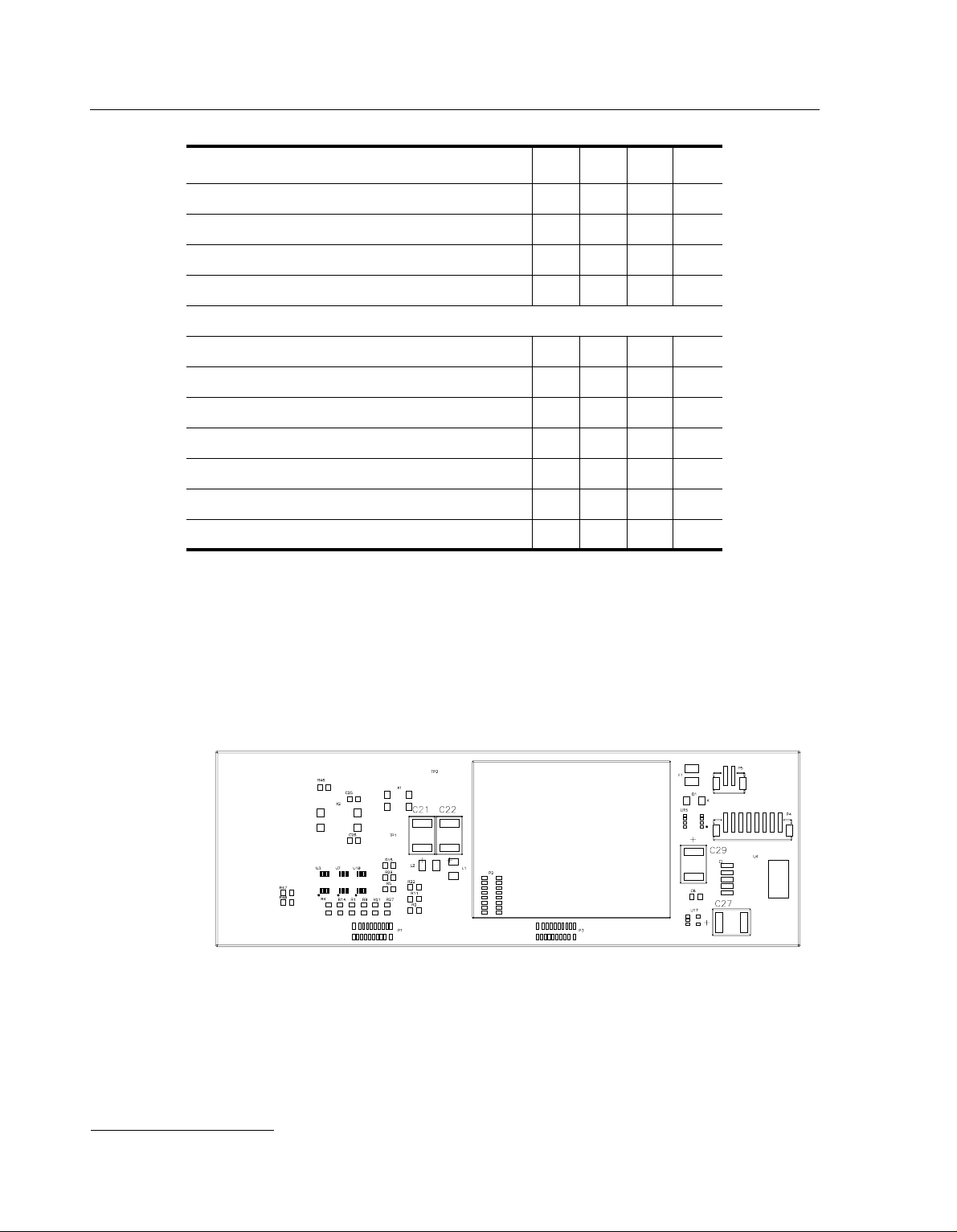

2.3. PCB Parts Placement (A733)

Figure 5.

A733MB Parts placement (top).

16

Page 15

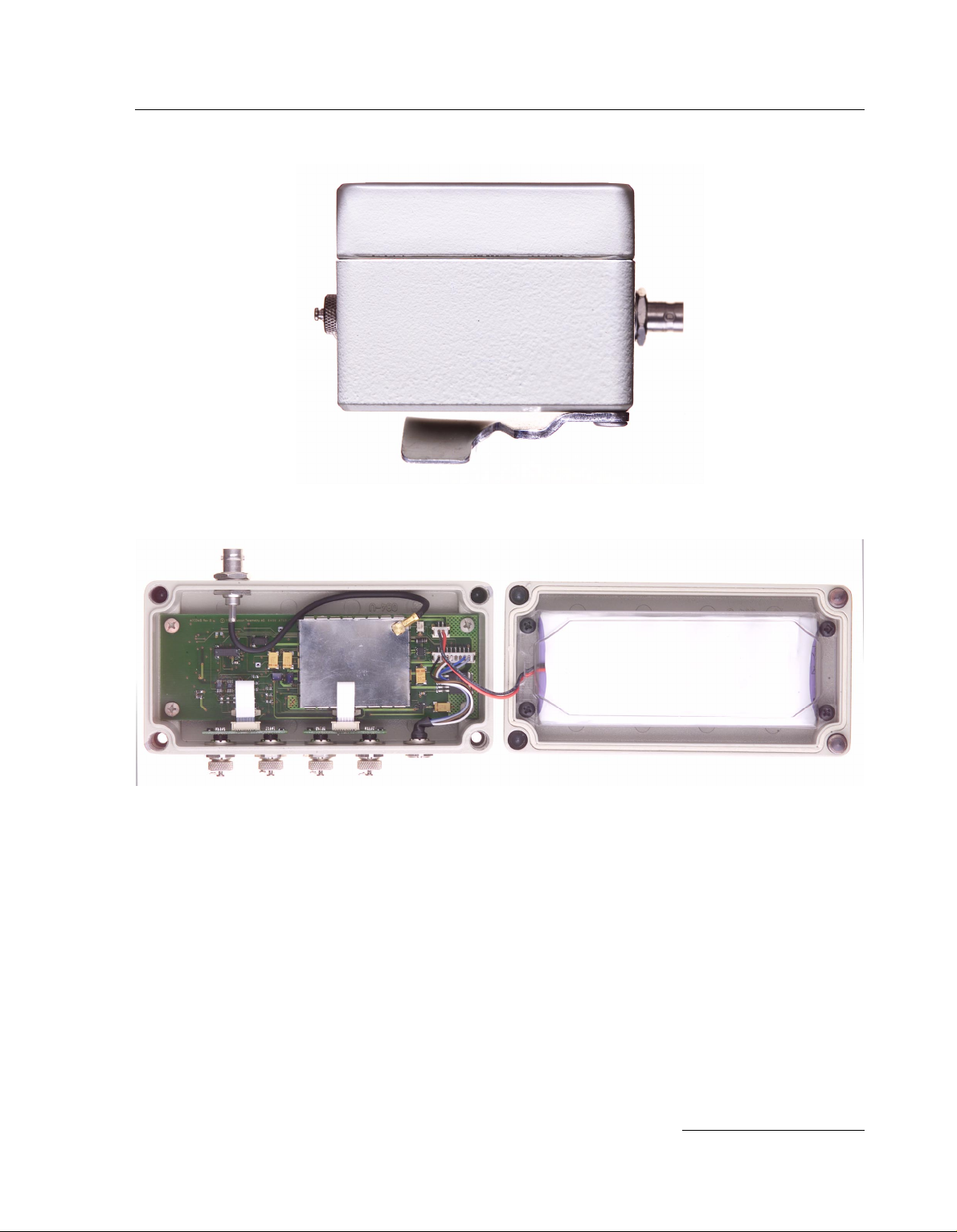

A733CA

Figure 9.

Figure 10.

A733, Back view.

A733, Top view.

21

Page 16

Hardware

Figure 11.

Figure 12.

A733, Bottom view.

A733, Left view.

22

Page 17

A733CA

Figure 13.

Figure 14.

A733, Right view.

A733, Case opened.

23

Page 18

Hardware

Figure 15.

Figure 16.

A733 Motherboard, top view.

A733 Motherboard, bottom view.

24

Page 19

3. The A431 Radio Module

3.1. About the A431 Radio Module

The A431 was specially designed for narrow-band FM data communication. It exhibits a relatively flat response in the audio band from 10 Hz to 2.5 kHz, both on send

as well as on receive paths. Additionally, the receiver’s group delay is very low.

The module operates in the 430 to 470 MHz range, making it compatible with most

radio communication regulations in the world. The output power is 0.5 W, while the

modulation is narrow-band FM (12.5, 20 or 25 kHz channel spacing). The power consumption in receive mode is remarkably low (under 25 mA), in spite of the excellent

IP3 characteristics and high sensitivity. The switching from receive to transmit is fast,

under 20 mS.

3.2. Functional description

The following functional description refers to the schematic diagram in Figure 17.

3.2.1. Receiver Section

The antenna signal is fed through the common low-pass filter for both receive and

transmit and applied to the U3 antenna switch. From the J3 port of the switch, it is

then fed to the FL1 helical filter and amplified by the LNA built with Q2 that assures

a high amplification factor (over 20 dB). Another helical filter follows (FL2), giving a

total of more than 70 dB attenuation of the first image frequency.

25

Page 20

The A431 Radio Module

The incoming signal is then applied to the first mixer, U7, through an LC impedance

matching network (L12/C48). The local oscillator signal is obtained by means of the

VCO built around U10 and applied to the mixer. The VCO is locked to the OSC1 reference by means of the U9 dual-PLL chip.

The mixer’s output on 45 MHz is filtered by means of XF1, which is needed to ensure

a sufficient attenuation (over 70dB) of the second image frequency (at 44.090 MHz).

The signal is pre-amplified with Q6 before entering the U8 mixer/IF chip. The second local oscillator is built around the IF chip, but it is locked by means of the second

PLL of U9. In this way, all signals are generated from a common reference oscillator

(OSC1, see also “Frequency Reference Specifications” on page 42).

The IF chain chip amplifies the signal to a proper level for FM detection. A particularity of this chip is that the FM detector is PLL-based, thus no coils or ceramic discriminators are needed. Two ceramic filters, CF1 and CF2, ensure the required

adjacent channel separation. The audio output is delivered on pin 17 and is slightly

amplified through U11 in order to bring it to 1Vpp, and centered on half the supply

voltage (which is 3.3 volt approximately). The signal is inverted in order to compensate the inversion caused by the first mixer (the LO is higher than the received RF

signal). The audio signal is fed out of the module on the pin RXDO of the interface

connector. In addition, an RSSI level signal is obtained on pin 18 of U8 and is fed to

switch U6. As long as the module is in receive mode, the RSSI signal will be present

on the RSSI/PO pin of the interface connector.

3.2.2. Transmitter Section

The carrier is generated directly on the operating frequency by means of the VCO

built around U2. The signal is locked on the reference OSC1 with the aid of the dual

PLL chip based on U9. The chip, a National Semiconductor LMX2332L, was chosen

for its fast locking scheme, low power consumption, and good RF characteristics.

The modulation is applied on both the VCO and the reference, in order to attain a

flat characteristic in the whole band (10 Hz to 2.5 kHz). Due to the phase differences

between the two modulation points, the signal applied on the reference is inverted

by means of U4. Meanwhile, U4 is used to center the reference on the channel (using

the trimpot R75). The PLL low-pass filter (third-order) composed of C66/C67/R69/

R59/C64 is calculated around 800 Hz. R64 is used for the FastLock® mechanism.

(For further details on the FastLock mechanism, please consult the National Semiconductor documentation.)

The signal is pre-amplified to approximately 0 dBm by Q1 and then it is applied to

the PA built with U1. The output signal is pre-filtered and impedance-matched by

means of theC21/L10/C22 low-pass filter and then fed to the antenna switch. Before

reaching the antenna output, a three-cell, low-pass filter (used also on the receive

path) is used to attenuate the unwanted harmonics and keep them below the required limits.

26

Page 21

The A431 Radio Module

An Automatic Level Control (ALC) system is responsible for keeping the output power constant, regardless of the external influences (temperature, VCO excitation and/

or supply). A small part of the RF energy is rectified by D2 and applied to the U5:A

amplifier. By means of U5:B, the power is controlled according to the pre-set power

level (ALC input). U5:A is basically an analog comparator between the actual and the

programmed power output. Depending on the error signal obtained, a variable voltage is applied on the PD input of the PA chip, thus effectively controlling its output

power. In addition, the actual power output level is fed to the U6 analog switch and

presented to the RSSI/PO output while the unit is switched in transmit mode.

The modulation is applied on two-points: the VCO and the reference oscillator—this

is needed to obtain a flat response in the audio range from 10Hz to 2.5 kHz and compensate for the counter-effect opposed by the synthesizer loop. The input signal

(must be 1 Vpp) is fed through a resistive divider (R14/R13) to the “cold” end of the

varactor diode controlling the VCO (D1). At the same time, the same modulation

signal is applied to the inverting op-amp U4 and then to the OSC1 reference oscillator (a VCTCXO). The modulation signal is inverted in order to bring it in phase with

the VCO modulation point.

3.3. Manufacturing Issues

3.3.1. Marking and labeling issues

The A431 Module is manufactured in two versions:

• Low band—able to operate between 430 and 450 MHz

• High band—able to operate between 450 and 470 MHz

From a manufacturing perspective, the difference between the high and low band

are the two helical filters FL1 and FL2 used on the receiving chain. The low band version is marked as A733-44 while the high band is marked as A733-46.

3.3.2. Alignment Range and Switching Range

The A431 radio module’s alignment range is 20 MHz, while the switching range is

10 MHz. According to the definitions formulated in the ETS 300086 and ETS 300013

specifications, the A431 radio module belongs to the AR1 category. Therefore, for

the European testing, two units should be presented for test purposes, as follows:

• One A733 unit containing an A431-44 radio module, alignment range 430450 MHz, switching range 435-455 MHz

• One A733 unit containing an A431-46 radio module, alignment range 450470 MHz, switching range 455-465 MHz.

Consequently, two test reports will be provided to Adcon Telemetry AG.

28

Page 22

For North America (FCC), only the portion 460 to 470 MHz will be used; therefore,

a single device model A733-46 having the switching range between 460 and 470

MHz will be submitted for testing.

3.3.3. Tuning Procedure

The A431 modules are to be tuned by mounting them on a test fixture consisting of

a specially modified A733 motherboard. The modification refers to certain mechanical aspects, in order to provide an easy plug in and out of the control connector (P2)

as well as to the TP1 and TP2 test points.

The alignment operation must differentiate between following classes of units:

• Band 1: from 430 to 440 MHz

• Band 2: from 440 to 450 MHz

• Band 3: from 450 to 460 MHz

• Band 4: from 460 to 470 MHz

Note: The boards differ only through the FL1 and FL2, in that Band 1 and 2 use

models TOKO 493S-1071A and 492S-1056A while Band 3 and 4 use models

TOKO 493S-1075A and 492S-1060A, respectively. In addition, the tuning procedure and some software parameters differ. The differences are clearly stated in the following paragraphs, where applicable.

Tuning Procedure

3.3.4. Setting Up the Default Parameters

The tuning procedure is not possible without first configuring some default parameters for the A733 motherboard used in the testing fixture. This is done via the serial

interface of the motherboard by using a communication terminal program (e.g. Hyperterminal, in Microsoft® Windows™ 95). The terminal program must be configured as follows:

• 19200 Baud

• 1 Stop bit

• No parity

• No protocol (neither hardware, nor software)

To check if the communication is operational, press the

ENTER key. An

nnnn 0

#

prompt should appear on the terminal screen (

is printed on its label). The following default parameters must be pre-loaded (for

more information about the meaning of the commands, consult the section “Commands” on page 48):

Battery

Ext Power

nnnn

is the actual ID of the unit that

5

4

3

Ground

RxD

1

2

TxD

29

Page 23

The A431 Radio Module

Commands valid for all bands

ID 1

PMP 65 72

SLOT 900 15

RSSI 58

Commands required for band 1

TF 430000000

BL 430000000 440000000

FREQ 430000000 12500

Commands required for band 2

TF 440000000

BL 440000000 450000000

FREQ 440000000 12500

Commands required for band 3

TF 450000000

BL 450000000 460000000

FREQ 450000000 12500

Commands required for band 4

TF 460000000

BL 460000000 470000000

FREQ 460000000 12500

Note: The TF command sets the start tuning frequency, the BL command sets the

band limits, and the FREQ command sets the actual operating frequency;

before shipping and depending on the target country, the last two parameters may be changed. The BL command must always be issued before the

FREQ command.

30

Page 24

3.3.5. Definitions

The diagram of the setup environment is depicted in Figure 18.

Definitions

Scope Service Monitor Network Analyzer

Voltmeter

0.765 V

Optional

Testing

Fixture

Out

Scope

Power/

Sens

Wobble

Ant I/O Out

Voltmeter

Out

Network

Analyzer

A733MB

Connector

RS232 To/From PC

+

6.5 V

–

Figure 18. Trimming Setup.

The testing fixture is used to fasten the A431 Module under test both mechanically

and electrically in such a way as to allow its rapid and comfortable alignment. It consists of a mechanical board with two screws that are used to fasten the board; two

elastic pins are used to transport the relevant signals from the module to their corresponding test cables. The external coaxial switch or relay (Power/Sens. <–> Wob-

ble) allows switching of the antenna input/output to the network analyzer or to the

service monitor. The schematic diagram of the testing fixture is depicted in

Figure 19.

Antenna

Out Network

Analyzer

Scope

Ant

TP1

A431

Module

TP2

Gnd

Figure 19. Schematic Diagram of the Testing Fixture.

TP2

A733MB

470KΩ

Voltmeter

31

Page 25

The A431 Radio Module

3.3.6. Test Equipment Settings

Before proceeding, certain controls on the test equipment must be set; some of the

settings depend of the operating band (high or low) of the device under test (DUT).

In addition, it is highly recommended that the ambient temperature during alignment is kept to 24° C (±2°C).

3.3.6.1. Network Analyzer (HP 8712 or equivalent)

The settings for the Network Analyzer are as follows:

• Center frequency: 450 MHz

• Span: 100 MHz

• Display: 10.0 dB/div

• Power: -20 dBm

• Markers:

— band 1: Mkr1 – 435 MHz, Mkr2 – 430 MHz, Mkr3 – 440 MHz

— band 2: Mkr1 – 445 MHz, Mkr2 – 440 MHz, Mkr3 – 450 MHz

— band 3: Mkr1 – 455 MHz, Mkr2 – 450 MHz, Mkr3 – 460 MHz

— band 4: Mkr1 – 465 MHz, Mkr2 – 460 MHz, Mkr3 – 470 MHz

Note: It is a good idea to store the instrument state for the four settings for a rapid

recall when needed.

3.3.6.2. Service Monitor (Rohde & Schwarz CMS50 or equivalent)

The setting for the receiver section check are as follows (RX-TEST):

• SET RF: 430000000 Hz (Band 1) / 440000000 Hz (Band 2) / 450000000 Hz

(Band 3) / 460000000 Hz (Band 4)

• RF LEV: 1 µV

• SINAD

• AF1: 1kHz

• MOD1: 2.5 kHz

• SCOPE MODE

• BEST RANGE

The settings for the transmitter section check (TX-TEST):

• COUNT: (should show the transmitter carrier frequency)

• POWER: (should show the transmitter carrier power)

32

Page 26

3.3.7. Trimming Elements

The location of the trimming elements on the A431 Module is shown in Figure 20.

L15 (RX VCO)

L7 (TX VCO)

Figure 20. Location of the trimming elements.

Trimming Elements

FL1FL2

R75 (Crystal Reference)

3.3.8. Adjusting the Receiver Front End

1. Mount the DUT (Device Under Test) on the testing fixture and connect it to the

host via the serial cable.

2. Select the appropriate instrument profile depending on the device’s band.

3. Turn the DUT in permanent receive mode by entering the RX command at the

terminal.

4. Check that the switch on the Testing Fixture is in the Wobble position.

5. Adjust the FL1 and FL2 filters (see Figure 20) until you obtain a curve similar to

the one shown in Figure 21 (depending on the band, the markers may be

different); this is done by successively adjusting the five trimming screws

located on the filters.

33

Page 27

The A431 Radio Module

If the adjustments do not achieve the appropriate curve, check the power supply,

the cable connections to/from the test equipment, etc. Verify also that all the pins of

the FL1 and FL2 filters are properly soldered.

Figure 21. Helical Filter + LNA’s selectivity diagram.

3.3.9. Adjusting the VCOs

1. Flip the switch on the Testing Fixture to the Power/Sens. position.

2. Verify that the DUT is in receive mode (enter the RX command at the terminal

program).

3. Adjust the L15 coil (see Figure 20) until the voltage shown on the digital

voltmeter is 900 mV, ±50 mV (see also the note below).

4. Switch the unit to transmit mode by entering TX at the terminal.

5. Adjust the L7 coil (see Figure 20) until the voltage shown on the voltmeter is

again 900 mV, ±50 mV.

6. Press the enter key at the terminal to switch the unit off.

Note: A calibration may be needed due to the internal resistance of the voltmeter

and the serial resistor mounted on the Testing Fixture. The calibration is performed by measuring the VCO voltage directly on the TP2 and by comparing

the value with that measured through the Testing Fixture. The values given

above are the real ones, measured directly.

If the above limits cannot be obtained, or the readout is unstable, verify the following:

• The programmed operating frequencies are indeed 430 (Band 1), 440

(Band 2), 450 (Band 3) and 460 MHz (Band 4). To check this, type the command FREQ at the terminal prompt; the device will answer by returning the

current frequency.

• The respective commands (RX and TX) were issued.

34

Page 28

• No parts are missing, or have the incorrect value, or are badly soldered (check

the parts around U2 and U10).

3.3.10. Adjusting the Crystal Reference

1. Flip the switch on the Testing Fixture to the Power/Sens. position.

2. Switch the unit to transmit mode by entering TX at the terminal.

3. Observe the indication shown by the Service Monitor: adjust R75 (see

Figure 20) until the carrier frequency indicates 430000000 (Band 1), 440000000

(Band 2), 450000000 (Band 3), or 460000000 MHz (Band 4) ± 200 Hz,

respectively.

3.3.11. Checking the Receiver Parameters

1. Verify that the switch on the Testing Fixture is flipped to the Power/Sens.

position.

2. Switch the DUT to receive mode by entering RX at the terminal.

3. Switch the Service Monitor to RX TEST mode, on the appropriate frequency

(430 / 440 / 450 or 460 MHz respectively); the level should be 1 µV (see also

“Test Equipment Settings” on page 32).

4. Verify that the S/N ratio is at least 12 dB; in addition, if a scope is also

connected, a clear 1 kHz sine wave should be visible, with a relatively low

amount of noise superimposed.

5. Switch the DUT to pulsed mode by pressing the Enter key. After several

seconds, you will see the image on the scope pulsing at about one-second

intervals.

6. Switch the RF generator output off.

7. Verify that the RSSI threshold is correct by typing the command RSSI; the actual

value must be lower than the threshold set. If this is not the case, repeat the

RSSI command several times—perhaps the frequency is in use (a radio receiver

set on the operating frequency would help detect foreign transmissions). If the

threshold difference is marginal, it must be increased by using the RSSI

<value> command (it must be 20 to 30% higher than the actual value).

Adjusting the Crystal Reference

If any of the above targets are not reachable, visually verify first that the U8 chip is

correctly soldered and that there are no shorts between its pins (most problems usually appear around this chip).

3.3.12. Checking the Transmitter Parameters

1. Verify that the switch on the Testing Fixture is flipped to the Power/Sens.

position.

2. Switch the DUT to transmit mode by typing the command TX 0 at the terminal.

35

Page 29

The A431 Radio Module

3. Switch the Service Monitor to TX TEST mode, on the appropriate frequency

(430 / 440 / 450 or 460 MHz respectively). You should see the following

parameters on the Service Monitor readout:

a. Carrier: 430000000 ± 200 Hz (or 440000000 / 450000000 / 460000000

respectively)

b. Output Power: 26.5 dBm (+ 0.5 dBm / - 1 dBm)

c. Frequency Deviation: ±2.0 kHz (±0.2 kHz)

4. Switch the unit to stand-by by pressing the Enter key.

For item 3.a above, adjust R75 (see Figure 20). For item 3.b, issue the command

PWR at the terminal and use the D (down) and U (up) keys until the required value

is reached. Finally, for item 3.c, issue the command BW at the terminal and again

use the D and U keys to reach the required value.

3.3.13. Data Transfer Check

The last check is a radio data transfer. In order to perform it, at least a base station

(model A730SD) or another remote station (model A733) must be installed and operated on the same test frequency, in the near vicinity (no more than 30 m).

Note: The base or remote station used for this test must be operated with a fictive

antenna (a 50Ω resistor).

To perform the test, enter the command B at the terminal prompt: the base and/or

remote station must answer with the RF in and out values. If an answer is not received after several seconds, retry the command. If an answer is still not received,

then use a scope on TP1 on the A733MB board (the Text Fixture) to verify that the

digital data is present (on receive). In addition, a radio receiver tuned on the operating frequency can also supply a rough indication of whether the receiver or the

transmitter is defective.

36

Page 30

3.4. PCB Parts Placement

Data Transfer Check

Figure 22. A431 Parts placement (top).

37

Page 31

The A431 Radio Module

3.6. Frequency Reference Specifications

42

Page 32

3.7. A431 Module’s Photographs

Figure 24. A431 Module, General view.

Data Transfer Check

Figure 25. A431 Module, Top view.

43

Page 33

The A431 Radio Module

Figure 26. A431 Module, Bottom view.

44

Page 34

4. Software

4.1. Short Description

The software is written entirely in C. It consists of a collection of standard C library

functions, a pre-emptive multitasking operating system (CMX) offering basic configuration and administration functions (including a command line terminal on a serial

port), and the application software itself, which assures the desired functionality of

the device.

4.2. Tasks

Following tasks are currently implemented:

The system usually remains in sleep mode. Each 0.5 seconds, an interrupt is generated by the local 32.76 Khz crystal oscillator. This wakes up the processor and activates the CMX RTOS, which allows all active tasks to perform their functions. After

all the tasks have finished their jobs, CMX brings the system back to sleep. The 0.5

seconds interrupt routine is also used as time reference for the RTC task.

In parallel to the normal, regular operation of the CMX, the system responds to the

pulse counter interrupts (they are generated by four inputs on the microcontroller

• Command Line Interpreter Task

• Radio Task

• Memory Management Task

• Real Time Clock (RTC) Task

45

Page 35

Software

and are used for event counting, e.g. rain gauges). These interrupts are handled by

a separate driver.

One of the main concerns of the software design is the power consumption of the

device. The software must ensure that all the peripherals are left in the correct state

in order to reduce their consumption to a minimum; all operations are executed in

the shortest possible time.

0.5 sec Interrupt

No

Increment

the RTC?

Advance the

RTC one second

Return

Counter Interrupt

Debounce input

Increment

affected Counter

Yes

No

A/D Sample

and Process

Battery

Low?

Yes

Battery

Distress?

Yes

Switch off

Everything

Stop

No

No

Yes

Reset

Initialization

Sleep

0.5 sec

interrupt?

Yes

Time to A/D

Sample?

No

Storage

Mode?

No

Terminal

Mode?

No

Connectivity

Check?

No

Yes

Yes

Yes

Enable Terminal

Mode

Do Connectivity

Check

46

RF Channel

Return

Activity?

Figure 27. General flow chart of the A733 software.

No

Yes

Handle Incoming

Message

Page 36

4.3. Controlling the Unit

The unit under test can be controlled by means of the special serial cable supplied

by Adcon Telemetry that is connected to a PC (e.g. a laptop) on one side and to the

POWER connector on the other side. In order to switch the unit to various modes of

operations, a simple communications terminal program will suffice (e.g. Terminal or

Hyperterminal in Windows, or Kermit under other platforms). The terminal program

must be configured as follows:

• 19200 Baud

• 8 Data Bits

• No Parity

• 1 Stop Bit

• Force LF after CR

Note: The interface is TTL, not RS-232. The adapter cable provided by Adcon must

be used.

4.3.1. Serial Communication Protocol

Serial Communication Protocol

This protocol is based on a master sending commands and a node answering; the

whole communication is conducted in plain ASCII, as strings. When exchanging

numbers, they are represented in decimal format. All commands are terminated with

a CR/LF combination. All responses (answers) are terminated with the # character.

4.3.2. General Format of a Command

The commands have the following format:

ID Command Param1 Param2 ... ParamN

• ID is the destination device. If you include an ID as part of a command, the

node checks whether ID=ownID. If it does, the node executes the command

on itself. If the ID is not the node’s ID, the node executes the command on a

remote device, if such an ID exists. If the ID is missing, this implies that the

command is addressed locally.

Note: Not all the commands can be relayed remotely.

• Command is the command proper, which can be composed of a variable string

of characters (for example, SLOT). Each node can implement a set of commands depending on the functionality of the node itself. However, as a minimum requirement, a node recognizes the CMDS command, which returns a list

with the commands recognized by the node.

• Param1 Param2 ... ParamN represent the parameters, which are com-

mand dependent. If you type no parameters when you issue a command, it is

the equivalent of querying for information (the GET version of a command). If

47

Page 37

Software

you type parameters, you are issuing the SET version of a command and are

setting the command to the parameters you typed.

4.3.3. General Format of an Answer

The answers have the following format:

ID Command Result1 Result2 ... ResultN ErrResult

• ID is the answering device. If a command was further routed, it is the ID of

the end device. The answer must always contain the ID on return.

• Command is the string representing the original command. It is supplied so

that a master can distinguish between the answers it is waiting for, and outof-band notifications (which may come, for example, over the radio port of a

node). As with the ID, the command name must be always supplied.

• Result1 Result2 ... ResultN are the result values returned by the remote node. If the ErrResult is not zero, all other possible characters and/

or strings until the end of the line may be ignored.

• ErrResult shows whether the command was successfully executed. If this

value is 0, the command was successfully executed. If this value is other than

0, the command failed. The number may further indicate the error type. (See

also “Returned errors list” on page 54.)

The answer string may contain any number of spaces or CR/LF characters between

its components; however, after the terminator (#) no other characters are allowed.

4.3.4. Commands

Both uppercase and lowercase characters can be typed because the commands are

not case sensitive. The commands list is not exhaustive, only those commands

deemed necessary for type approval testing were included.

#

CMDS

DESCRIPTION Returns a list of supported commands.

PARAMETERS None.

REMARKS GET only.

RETURNS A list of strings separated by spaces.

REMOTE No.

EXAMPLE CMDS

193 CMDS CMDS ID PMP RSSI TIME FREQ DEV DEL REPL SLOT DATA INFO RX TX ERA 0

#

48

Page 38

TIME

DESCRIPTION Sets/returns the real time clock.

PARAMETERS The actual time, or none in the GET version.

RETURNS The actual time as dd/mm/yyyy hh:mm:ss.

REMARKS GET/SET.

REMOTE No.

EXAMPLES TIME 12/12/1999 22:10:10

193 TIME 0

#

TIME

193 TIME 12/12/1998 22:10:10 0

#

BL

DESCRIPTION Sets/returns the band limits.

PARAMETERS The frequency band limits (Hz), or none in the GET version.

Commands

RETURNS The actual frequency band limits, in Hz.

REMARKS GET/SET. This is a hidden command (i.e. not available for the normal user in the

CMDS list).

REMOTE No.

EXAMPLE BL 432000000 450000000

193 BL 0

#

BL

193 BL 432000000 450000000 0

#

FREQ

DESCRIPTION Sets/returns the operating frequency.

PARAMETERS The operating frequency and step (Hz), or none in the GET version.

RETURNS The actual frequency and step, in Hz.

REMARKS GET/SET.

REMOTE Yes, SET only.

EXAMPLE FREQ 433925000 25000

193 FREQ 0

#

49

Page 39

Software

FREQ

193 FREQ 433925000 25000 0

#

DATA

DESCRIPTION Returns data stored for a certain device.

PARAMETER The ID of the device for which the data is requested and the date/time (in the stan-

dard format) the data was stored. If missing, it refers to the data of the local device.

RETURNS A data block.

REMARKS GET only. If the date/time parameter is not included, the latest data is returned. If

the date/time parameter is included, the date and time closest to, but later than, the

given date/time is returned.

REMOTE Yes, for a GET, but only one frame at a time. The A733 can issue the command only

for itself, locally.

EXAMPLE DATA 193 12/12/1998 12:12:12

193 DATA b1 b2 b3 ... bn 0

#

The data block returned will typically contain a number of data frames (telegrams).

The structure of a block is as follows:

dd mm yyyy hh mm ss si ft d1 d2 ... dn dd mm yyyy ... dn cs

where:

• dd mm yyyy is the date

• hh mm ss is the time

• si is the size of the frame (21 for frame type 37)

• ft is the frame type (37 for the A733)

• d1 d2 ... dn are the data values (the frame content)

• cs is a 16-bit checksum obtained by summing the bytes and discarding the

carries over 0xFFFF

50

Page 40

Commands

The A733 devices always respond with a type 37 data frame (see also “Data12” on

page 62). The composition of the data block of such a frame (the values marked as

d1, d2... dn) is depicted in Figure 28, while the digibyte is depicted in Figure 29.

RF incoming

RF outgoing

Digibyte

I/O A Pulse Counter

I/O B Pulse Counter

I/O C Pulse Counter

I/O D Pulse Counter

Battery

I/O A Cabling 1

I/O A Cabling 2

I/O A Cabling 3

I/O B Cabling 1

I/O B Cabling 2

I/O B Cabling 3

I/O C Cabling 1

I/O C Cabling 2

I/O C Cabling 3

I/O D Cabling 1

I/O D Cabling 2

I/O D Cabling 3

Figure 28. Frame 37 description

b7 b0

SC Dig 6 Dig 5 Dig 4 Dig 3 Dig 2 Dig 1 Dig 0

SC — Battery charge (0–off, 1–on)

Dig n — Digital I/O n

Figure 29. The Digibyte

The remote version is limited to a single frame. An example of such a command is

given below:

9999 DATA 9999 30/9/1999 14:50:00

9999 DATA

30 9 1999 14 54 55 21 37 255 255 77 0 0 0 0 89 156 126 20 0 0 0 0 0 0 0 0 0 3197 0

#

Notice that if you need to get data that is not the last (newest) slot remotely from a

device, the ID must be supplied twice. If you need to get the last slot stored, you

can ignore the ID and the date/time parameters:

9999 DATA

9999 DATA

13 9 1999 19 26 36 21 37 255 255 79 0 0 0 0 87 148 149 15 0 0 0 0 0 0 0 0 0 3148 0

51

Page 41

Software

#

IMME

DESCRIPTION Samples all inputs and immediately returns the sampled data.

PARAMETER The ID of the requested subsystem, default is the standard A/D subsystem of the

A733 (ID=0).

Note: Currently only the default subsystem is implemented on the A733.

RETURNS A data block.

REMARKS GET only. The command needs a certain delay to execute, e.g. for the standard sub-

system this delay amounts to two seconds. The delay is necessary to allow for the

sensors to settle after applying power to them.

REMOTE No.

EXAMPLE IMME

9999 IMME

13 9 1999 19 26 36 21 37 255 255 79 0 0 0 0 87 148 149 15 0 0 0 0 0 0 0 0 0 3148 0

#

INFO

DESCRIPTION Returns various status information.

PARAMETERS None.

RETURNS A list of a device’s internal variables:

ID INFO rf_in rf_out date time ver clk stack cop batt temp days_uptime

hr:min_uptime rssi pmp_low pmp_high type slot samples err_level

#

The formats for the above parameters are as follows:

• rf_in and rf_out as a decimal (unsigned char)

• date as dd/mm/yyyy

• time as hh:mm:ss

• ver as x.x

• clk, stack, and cop as decimal (unsigned char); they represent internal

housekeeping parameters: the A733 uses cop to number watchdog occurrences, but clk and stack are currently undefined

• batt as battery level using the standard voltage conversion equation (0 is 0

volts, 255 is 20 volts)

• temp as internal temperature in the A733 housing, which is device dependent. The precision of the sensing element is low (±2°C), but it is sufficient for

52

Page 42

Commands

battery power management (charge/discharge). To compute the actual value

(in °C), the following equation must be used:

• days_uptime in days; together with hr:min_uptime, it represents the

amount of time the device is up without a reset or watchdog

• hr:min_uptime in hours:minutes format

• rssi as decimal (unsigned chars); it is the programmed value with the RSSI

command

• pmp_low and pmp_high are the programmed values with the PMP com-

mand

• type is used to represent the device type; following types are assigned cur-

rently:

— 0 for A730MD

— 1 for A720

— 2 for A730SD

— 3 for A720B

— 4 for A733

• slot and samples are the actual values programmed by means of the SLOT

command

• err_level is the error value; 0 means no error

REMARKS GET only.

Temp

°C[]

internalTemp 400⋅

------------------------------------------------- 68–=

255

REMOTE Yes, GET only. The A733 can issue the command both remotely and locally.

EXAMPLE INFO

193 INFO 255 0 18/4/1999 21:5:11 1.3 0 0 0 91 72 40 1:46 58 65 72 3 900 15 0

#

RX

DESCRIPTION Switches the unit to permanent receive mode (for tuning purposes).

PARAMETERS None.

RETURNS Nothing.

REMARKS The system stops, and exits the command only when a key is pressed. This com-

mand returns no message.

REMOTE No.

EXAMPLE RX

193 RX 0

#

53

Page 43

Software

TX

DESCRIPTION Switches the unit to transmit mode (for tuning purposes).

PARAMETERS None (sends an unmodulated carrier), 1 (sends a 1 kHz modulated carrier), 0 (sends

a 2 kHz modulated carrier) or 5 (sends a mixed 1 + 2 kHz modulated carrier).

RETURNS Nothing.

REMARKS The system stops, and exits the command only when a key is pressed. This com-

mand returns no message.

REMOTE No.

EXAMPLE TX

193 TX 0

#

TX 1

193 TX 0

#

TX 5

193 TX 0

#

B

DESCRIPTION Sends a broadcast frame.

PARAMETERS None.

RETURNS A data block.

REMARKS After the device sends the broadcast frame, it will listen for answers. All valid an-

swers will be listed with their IDs.

REMOTE No.

EXAMPLE B

193 B 0

#234 BA 0

#7851 BA 0

4.3.5. Returned errors list

Following are error messages you might get.

Command line interpreter

• 1 — nonexistent command

• 2 — command line buffer overflow (input line too long)

• 3 — internal error

54

Page 44

• 4 — reserved

• 5 — missing or false parameters in command

• 6 — operation not implemented

Device descriptors and storage handler

• 10 — device not found (attempt to perform a command on a nonexistent device)

• 11 — device already exists

• 12 — reserved

• 13 — no more space for descriptors (too many devices)

• 14 — no more records for the specified device

• 15 — temporary communication break, no more data (the last request was not

successful)

• 16 — time-out (the handler blocked or is busy)

• 17 — internal error

• 18 — attempt to insert a reserved device ID number (0 or 65535)

Returned errors list

Real time clock

• 20 — incorrect time supplied (no conversion to time_t was possible)

Radio interface

• 30 — error at receive (CRC, etc.)

• 31 — unexpected frame received

• 32 — wrong length

• 33 — reserved

• 34 — reserved

• 35 — time-out (remote device not responding)

• 36 — receiver busy (for example, just making the request round)

Notifications

• 40 — request to read a notification when no notification is pending

55

Page 45

Software

4.4. Adcon Packet Radio Protocol

The A733 is basically intended as an end device in a radio network. Most frames defined by the Adcon Packet Radio Protocol are recognized and answered by an A733;

a complete list is provided (see “Frame Types” on page 59). In addition, full source

routing of frames for other destinations is implemented.

Timeout Expired

0.5 sec

Idle

Not for us

Check

Destination

Figure 30. State Transition Diagram of the radio communication task.

4.4.1. Digital Squelch

Interrupt

No Signal

Measure RF

Header Detected

We are called

New Frame Possible

Must route

Get Frame

Update

Header

and Send

Payload is for us

Ack

Wait

Nhops + 1 s

and

Hunt Syncs

No Ack

Ack

Answer

Appropriately

Frame Sent Twice

Resend

Frame with

Long

Header

No Ack

56

In order to reduce the power consumption during receive mode, the unit uses a protocol developed by Adcon Telemetry for the A730 family, but with some additional

refinements to further reduce the power consumption. The receiver is pulsed at a

0.5 seconds interval. At wake-up, the receiver samples first the RF channel for a carrier, by measuring the RSSI. The RSSI output is extremely stable due to the wide dynamic range that the IF chip exhibits (over 100 dB, temperature compensated). If the

sampled RSSI is under a preset threshold, the unit will immediately go back to sleep.

This procedure takes under 20 mS, typically (from wake-up to result).

If, however, an RF level superior to the preset threshold is detected, the microprocessor will try to detect a valid header, which is composed of a 2 kHz tone of at least

0.5 seconds long. The tone detection is performed by the microcontroller in soft-

Page 46

ware, and takes at most 6 additional milliseconds. If no valid tone is detected, the

unit goes back to sleep, otherwise it tries to decode the frame.

Based on the destination ID, the frame will be identified. If it is not for that particular

unit (own ID), then the microcontroller will cease decoding it and will go immediately

to sleep. The destination ID is positioned very early in the frame header (see also

“Generic Format of a Radio Frame” on page 57).

From the above it becomes clear that in order to initiate a communication, a requester must send first a header which is at least 0.5 seconds long: these are called

long header frames

. Of course, after the communication is established the headers

are short, of only 16 bytes (i.e. 8 msec. – called

occurs, the system will restart by sending long header frames.

4.4.2. Modulation Technique Used

The communication via radio is made by using a special MSK (Minimum Shift Keying)

scheme; both the encoding and the decoding of the MSK frames is made in software—there is virtually no hardware modem. A

of 250 µs one level followed by a 250 µs zero level, while a

a 500 µs one level followed by a 500 µs zero level. A complete sequence of one and

zero level forms a

bit cell

.

Modulation Technique Used

short header frames

zero

bit is transmitted as a sequence

one

). If a timeout

bit is transmitted as

00

1

This modulation scheme is self-clocked. The transmission speed is content-dependent, varying from 1 kbps (when sending only ones) to 2 kbps (when sending only

zeros). On the average, an 1500 bps transmission speed is reached.

The data interchange between stations is made by means of

have a header, a 16 bit-sync character, a data block, and a 16-bit CRC number. The

bytes forming the frame are send synchronously, with no start and/or stop bits. The

data block is assembled after the sync character was detected. The LSB of a byte is

sent first and the MSB is sent last.

4.4.3. Generic Format of a Radio Frame

The standard frame format used by the A730 family is as follows:

00 00

.......

00 0xAA DST-H DST-L SRC-H SRC-L DLEN

1

0

frames

DATA1 D ATA2 D ATAn CRC-H CRC-L

.......

Data Frame

1

. The frames

57

Page 47

Software

• The frame starts with a header of zeros and there are two header types: long

and short. The long headers are used to wake up a remote station and must

be 140 bytes long, while the short headers are only 16 bytes long.

• After the header, a synchronization character is used; this is a hex 0xAA byte.

The implementation must ensure that a 16-bit sync character is checked, i.e.

0x00AA, and not only an 8-bit 0xAA character.

• Following the synchronization pattern, the bytes are assembled by shifting

the bits one by one: each 8 contiguous bits will be “cut” into a byte. First information assembled is the destination (DST) address: this is in order for all

the receiving stations to know if they must assemble the whole frame, or they

can go back to sleep. Only the addressed station will remain active after this

information was decoded.

Note: The byte ordering convention used on the network is “big endian,” i.e. the

MSB is sent first and the LSB last.

• Next are the source (SRC) address and the length of the data field. The data

field follows, and the frame is ended by a 16-bit CRC field. The CRC is computed starting with the first byte after the SYNC character until (but not including) the CRC bytes.

The data field can transport various type of data frames. After being successfully decoded and checked, these data frames are passed to the upper layer of the software. The data frames recognized by the A733 and their answers are detailed in

“Data Frames” on page 59.

A device will answer to the requesting device with the answer frame. The answering

device will poll the radio channel for an acknowledge; the acknowledge may be either the same frame send further up the network (if the communication has hops, i.e.

routing stations in between the master and remote device), or an acknowledge send

by the master – the master sends only a short radio frame containing the SRC and

DST, both being its own ID. If the answering device does not receive the acknowledge, it will repeat the frame after a one second delay (only once).

Another notable feature of the system is the way it handles the long and short header frames. When a frame is sent by the master for the first time, it will be one with a

long header; all the stations on the path of the frame participating in a certain transaction will relay the frame with a long header. After relaying the frame, the stations

will remain active for a time calculated as (in seconds):

Delay Hops 1+=

The above scheme assures that as long as another frame will follow during this time

interval (addressed to a station that is known to be also active), the header sent to

that station will be a short one.

58

Page 48

4.4.4. Data Frames

The data frames (payload) are the blocks of data extracted from the radio frames,

after the CRC and other information (source address) was checked. The data frame

and its length are passed to the upper layers of the software.

Data Frames

TYPE HLEN SRC-H

SRC-L

HOP1-H HOP1-L HOPn-H HOPn-L DEST-LDEST-H DATA1 DATA2 DATAn

Header (Frame Type + Routing Information)

.......

.......

Data

Figure 31. Generic Data Frame structure.

A data frame is composed of two main parts: a header, containing the frame type as

well as the routing information, and a data block. The length of the data block can

be easily computed by subtracting the header length (HLEN + 1 byte for the TYPE)

from the original data frame length received from the lower layer of the software (the

radio frame length). Additional explanations on the notation used in the diagram:

• TYPE is the type of frame; the types recognized and/or used by the A733 will

be detailed individually later in this chapter (see “Frame Types.”)

• HLEN is the header length: it represents the number of bytes used to describe the route the frame will go (or went). The maximum number of hops is

8, that is, 8 intermediate stations plus source and destination. Each station is

described by its unique 16-bit address.

• SRC, HOP and DEST, are the source, the hops and the destination addresses.

While the hops may be missing (no routing stations between source and destination), the source and destination are mandatory.

• DATA is the data proper field. It is limited in length, its maximum size being

dependent also on the particular route: if the route is longer (8 hops) then the

data block is limited to 48 bytes. Depending on the frame type, the data block

may be nonexistent (zero length).

4.4.5. Frame Types

Although the original Adcon Packet Radio Protocol contains many frame types, only

those relevant to the A733 are presented here.

Request

ID 1

FORMAT struct {

time_t init_time;

time_t req_time;

} request;

DESCRIPTION

The Request frame is used by a master to request data frames from a remote station.

A remote will answer with a data frame. There are currently three types of data

59

Page 49

Software

frames: normal (type 8), extended (type 37), and reduced (type 38); the A733 answers with the extended type (see also “Data12” on page 62).

• init_time represents the actual time to be used by the remote to re-initialize

its local RTC; if its value is time_t NULL (default), then no re-initialization will

be performed.

• req_time is the time for requested data. An A733 will search its internal data

buffer for data that has a time stamp that is strictly newer than req_time.

Therefore, if a master requests data with exactly the time stamp previously

supplied by the remote, the remote must deliver a newer data slot. If the requested data is too old, the remote will send its oldest data, while if the requested data is too new, the remote will answer with the newest data it has.

If the device is not yet initialized and has no data (i.e. its internal time is 1/1/

1970), then it will send a Data12 frame with no relevant data, but with the time

stamp of 1/1/1970. This mechanism will inform a master that the device needs

initialization.

On the A733 this command can be initiated by means of the DATA command (see

also “DATA” on page 50).

SEE ALSO Data12 frame.

Broadcast Answer

ID 2

FORMAT struct {

unsigned char RF_levelOut;

} broadcast_answer;

DESCRIPTION

This is the answer to a broadcast request frame; the RF_levelOut is the level record-

ed by the device when receiving the broadcast request frame. The A733 will receive

and interpret such frames depending on the mode it was in when it issued the

broadcast request (see also “Broadcast Request” on page 60). In terminal mode, all

the broadcast answers will be displayed with their RF levels, while in connectivity

check mode, the LED tool will be activated. The device will pulse the LED tool for

the number of answers it identified.

If the A733 receives a Broadcast request, it must answer to it, but in a random manner. An 8 seconds time interval starting with the end of the Broadcast request frame

is divided in 16 slots, each 0.5 seconds long. The A733 must select randomly one of

these 16 slots for sending its answer. This frame, as well as the Broadcast request

frame, is not routable.

SEE ALSO Broadcast Request frame.

Broadcast Request

ID 6

FORMAT The data frame body is empty.

60

Page 50

Frame Types

DESCRIPTION This frame is sent by the device when the LED tool is inserted in the POWER con-

nector, or if the command B is issued in terminal mode. This frame is special in that

the destination address (DST) in the header is 0. This type of frame is not routable.

All devices having received this frame must reply in a random fashion with a Broadcast answer frame.

SEE ALSO Broadcast Answer frame.

Ping

ID 9

FORMAT The data frame body is empty.

DESCRIPTION This frame is used to request an answer from a device; it is used to check if the de-

vice is available and reports on various conditions of the remote. The addressed device must answer with a Pong frame. On an A733, this command can be initiated

from the terminal by means of the INFO command (see also “INFO” on page 52).

SEE ALSO Pong frame.

Pong

ID 10

FORMAT struct {

} pong;

DESCRIPTION

The Pong frame is an answer to the Ping frame. In addition to informing a caller that

a remote is active, it carries some useful information about the device’s status:

• RF_levelIn is the left zero (it is a placeholder and will be filled by the first de-

vice receiving the frame).

• RF_levelOut is the RF level measured by the device when receiving the Ping

frame.

• RTC is the actual value of the remote’s Real Time Clock.

unsigned char RF_levelIn;

unsigned char RF_levelOut;

time_t RTC;

unsigned char version;

unsigned char clkfail;

unsigned char stackfail;

unsigned char WDT;

unsigned char batt;

unsigned char internalTemp;

time_t uptime;

unsigned char rssi;

unsigned char pmp_low;

unsigned char pmp_high;

unsigned char type;

unsigned int slot;

unsigned char samples;

61

Page 51

Software

• version is the software/hardware version of the device.

• clkfail and stackfail are meaningless for an A733; they are kept for historical reasons.

• WDT is a counter incremented each time the device was reset due to a Watchdog timeout; its value is cleared at power-on reset.

• batt is the battery voltage (this value will be also found in the Data frame).

• internalTemp is the temperature in the A733 housing; the precision of the

sensing element is vry low (±2C°), but it is sufficient for battery power management (charge/discharge). To compute the actual value (in C°), the following equation must be used:

°C[]

internalTemp 400⋅

------------------------------------------------- 68–=

Temp

• uptime is the time elapsed since the last reset (including a Watchdog reset).

• rssi is the programmed RSSI threshold value.

• pmp_low and pmp_high are the programmed power management parameters.

•

type

is the type of the device (will return always 4 – for A733).

Note: Some of the values described above are specific to the A733. The implemen-

tation of the Pong frame, as well as its length (number of bytes), may vary

from one device type to another.

SEE ALSO Ping frame.

Fdev

ID 32

FORMAT The data frame body is empty.

DESCRIPTION

This frame requests that a remote clear its data memory (format). The remote will

answer with a General acknowledge frame. An A733 will never issue this frame type,

but it will execute and answer it.

SEE ALSO General Acknowledge frame.

255

Data12

ID 37

FORMAT struct {

62

unsigned char RF_levelIn;

unsigned char RF_levelOut;

time_t slot_timeStamp;

unsigned char digibyte;

unsigned int counter0; /* Pulse Counter I/O A input */

unsigned int counter1; /* Pulse Counter I/O B input */

unsigned int counter2; /* Pulse Counter I/O C input */

Page 52

unsigned int counter3; /* Pulse Counter I/O D input */

unsigned char battery;

unsigned int analog_data[9];

} data_frame;

Frame Types

DESCRIPTION

This frame will be sent back by the device as an answer to the Request frame.

• RF_levelIn is the left zero (it is a placeholder and will be filled by the first de-

vice receiving the frame).

• RF_levelOut is the RF level measured by the device on the Request frame.

• slot_timeStamp is the actual time stamp on the data sent.

• digibyte represents the result of OR-ing the following bits:

b7

Dig6 Dig5 Dig4 Dig3 Dig2 Dig1 Dig0

SC

b0

— SC represents the battery charge switch’ status.

— DIG0 to DIG7 are the I/O pins on the I/O connectors. Note that only the

first 4 DIGs are usable (there are only four I/O connectors on the A733).

Note: For additional info on the bits in the digibyte, check the hardware section of

this manual.

• counter0 to counter3 are the values of the pulse counters.

• battery is the value of the main power supply; its actual value can be com-

puted using the equation:

battery 20×

V[]

-------------------------------=

255

Batt

• analog_data[9] is an array of 8 unisgned integers that represents the result of

packing the 12 12-bit values. These are the values returned by the internal

A/D converter from the respective I/O connectors (see the hardware section

for more details). The packing mechanism is depicted below:

Integer 0 Integer 1

12 bits 12 bits 12 bits 12 bits

Byte 0 Byte 1 Byte 2 Byte 3 Byte 6Byte 5Byte 4 Byte 16 Byte 17

SEE ALSO Request frame.

Set ID

ID 40

16 bit values

Integer 2

8 bit packed values

Integer 3

63

Page 53

Software

FORMAT struct {

} setId;

unsigned int ID;

DESCRIPTION

This frame requests a remote to change its own ID number. The remote will answer

with a General acknowledge frame

this frame type, but it will answer to it.

SEE ALSO General Acknowledge frame.

Set Slot Time and Sample Rate

ID 41

FORMAT struct {

unsigned int slot;

unsigned char rate;

} setSlot;

DESCRIPTION

This frame requests that a remote change the size of its slot (default 900 seconds,

i.e. 15 minutes) and the sampling rate (default 15).

• slot is the number of seconds a new slot of sampled and averaged data will

be stored in the internal FIFO memory of the device.

• rate is the number of samples per slot taken; these samples will be averaged

before being stored.

The remote will answer with a General acknowledge frame. An A733 will never issue

this frame type, but it will answer to it.

before