Page 1

A720 – addIT™

Technical Documentation

Adcon Telemetry GmbH

Inkustr. 24, A-3400 Klosterneuburg

Austria

Tel: +43-2243-38280

Fax: +43-2243-38280-6

http://www.adcon.at

Adcon Telemetry, Inc.

1001 Yamato Road, Suite #305, Boca Raton, FL 33431

USA

Tel: +1-561-989-5309

Fax: +1-561-989-5310

http://www.adcon.com

Adcon Telemetry srl.

Bd. Ana Ipãtescu nr. 27 ap. 11 R-71111 Bucharest

Romania

Tel: +40-1-312-6886

Fax: +40-1-312-6668

http://www.adcon.ro

Page 2

Proprietary Notice:

The Adcon logo, the A730 series, addIT™, addVANTAGE and

AgroExpert™ are trademarks or registered trademarks of Adcon Telemetry

GmbH. All other registered names used throughout this publication are

trademarks of their respective owners.

This publication contains confidential information property of Adcon

Telemetry GmbH. Disclosure to third parties of the information contained

herein is prohibited. Neither the whole nor any part of the information

contained in this publication may be reproduced in any material form

except with the prior written permission of Adcon Telemetry GmbH.

Release 1.0, October 1998

Copyright ©1998 by Adcon Telemetry GmbH.

All rights reserved.

Page 3

Table of Contents

1. About the A720 5

2. Hardware 6

2.1. The Radio Unit 6

2.1.1. Receiver Section 6

2.1.2. Synthesizer Section 8

2.1.3. Transmitter Section 9

2.2. The Modem Interface 9

2.3. The Microcontroller and the Power Management Sections 10

2.4. The Interface Board 11

3. Tuning Procedure 12

3.1. Programming the Boards 13

3.2. Setting-up the Default Parameters 13

3.3. Tuning 13

3.3.1. Definitions 14

3.3.2. Test Equipment Settings 15

3.3.2.1. Network Analyzer (HP 8711) 15

3.3.2.2. Service Monitor (Rohde & Schwarz CMS50) 15

3.3.3. Adjusting the Receiver Front End 16

3.3.4. Adjusting the VCOs 17

3.3.5. Checking the Receiver Parameters 17

3.3.6. Checking the Transmitter Parameters 18

3.3.7. Data Transfer Check 18

3.4. Additional Issues Related to Type Approval Testing 19

3

Page 4

3.4.1. Controlling the Unit 19

3.4.2. External Power Supply 19

3.4.3. Specifications 20

3.4.4. Bill of Materials 24

3.4.5. Device Photographs 29

4. Software 34

4.1. AMOS 34

4.1.1. Initialization 35

4.1.2. 1/2 Second Interrupt 36

4.1.3. Pulse Counters Interrupt 36

4.2. Mode Check 36

4.3. A/D Task 38

4.4. The Terminal Task 39

4.4.1. Supported Commands 39

4.4.1.1. The SET Series of Commands 39

4.4.1.2. Querying the Actual Configuration Parameters 41

4.5. The Radio Interface Task 41

4.5.1. Digital Squelch 42

4.5.2. Modulation Technique Used 43

4.5.3. Generic Format of a Radio Frame 44

4.5.4. Data Frames 45

4.5.5. Frame Types 45

4.5.5.1. Request 45

4.5.5.2. Broadcast Answer 46

4.5.5.3. Set I/O Request 46

4.5.5.4. Read I/O Answer 47

4.5.5.5. Broadcast Request 47

4.5.5.6. Ping 47

4.5.5.7. Pong 47

4.5.5.8. Memory Dump Request 48

4.5.5.9. Memory Dump Answer 49

4.5.5.10. Data 49

4.5.5.11. Set ID 50

4.5.5.12. Set Slot Time and Sample Rate 50

4.5.5.13. Set Frequency 50

4.5.5.14. Set Battery Charge Levels 51

4.5.5.15. Set Pulse Counters Parameters 51

4.5.5.16. General Acknowledge 51

4

Page 5

Wireless Sensor Interface A720 (addIT™)

1. About the A720

The A720 Wireless Sensor Interface (also known as

range telemetry device, capable of sampling up to 6 analog sensors and 4 digital inputs (of which 2 counter types); in addition, it can control two relays.

The frequency of operation is in the 432 to 470 MHz range, making it adaptable to

most radio communication regulations in the world. The output power is under 10

mW, while the modulation is narrow band FM (12.5 or 25 kHz channel spacing).

Due to its construction, as well as to the software controlling it, the power consumption is extremely low (average 6 mW). The unit operates from a built in NiCd 6.2 Volt

rechargeable battery, which is charged either using an 600mW solar panel or an external power supply adapter. A special configuration may be implemented where no

internal battery is used, rather the power is obtained exclusively over an external

connector.

The A720 is a ruggedized unit, complying with the IP65 environmental protection

class (NEMA 4). It can be easily installed and it integrates perfectly in an Adcon A730

system. Depending on the terrain, it assures a reliable wireless connection to an

A730MD or A730SD device to distances up to 800 meters, under favorable conditions

even more.

addIT™

) is a low power, short

5

Page 6

Wireless Sensor Interface A720 (addIT™)

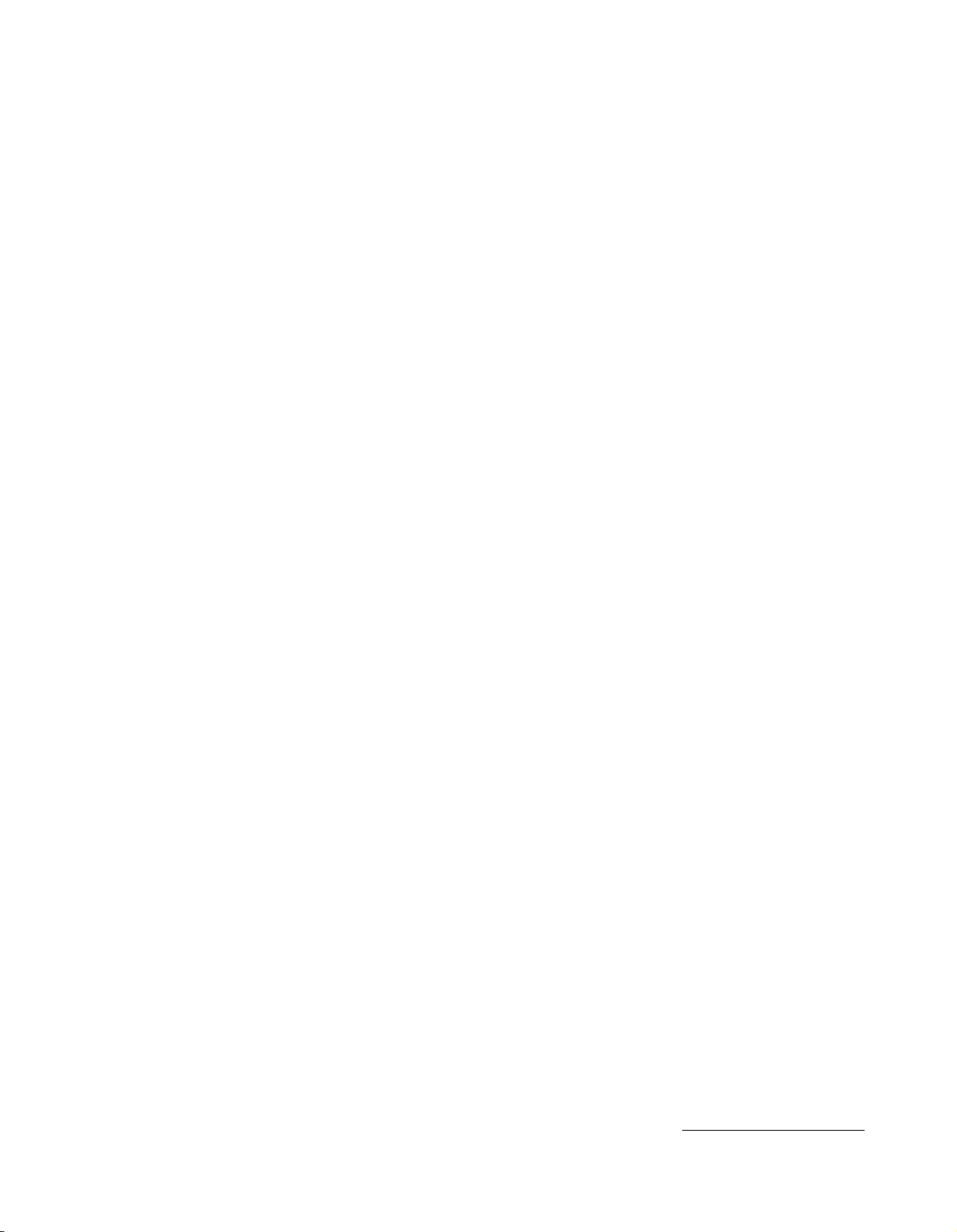

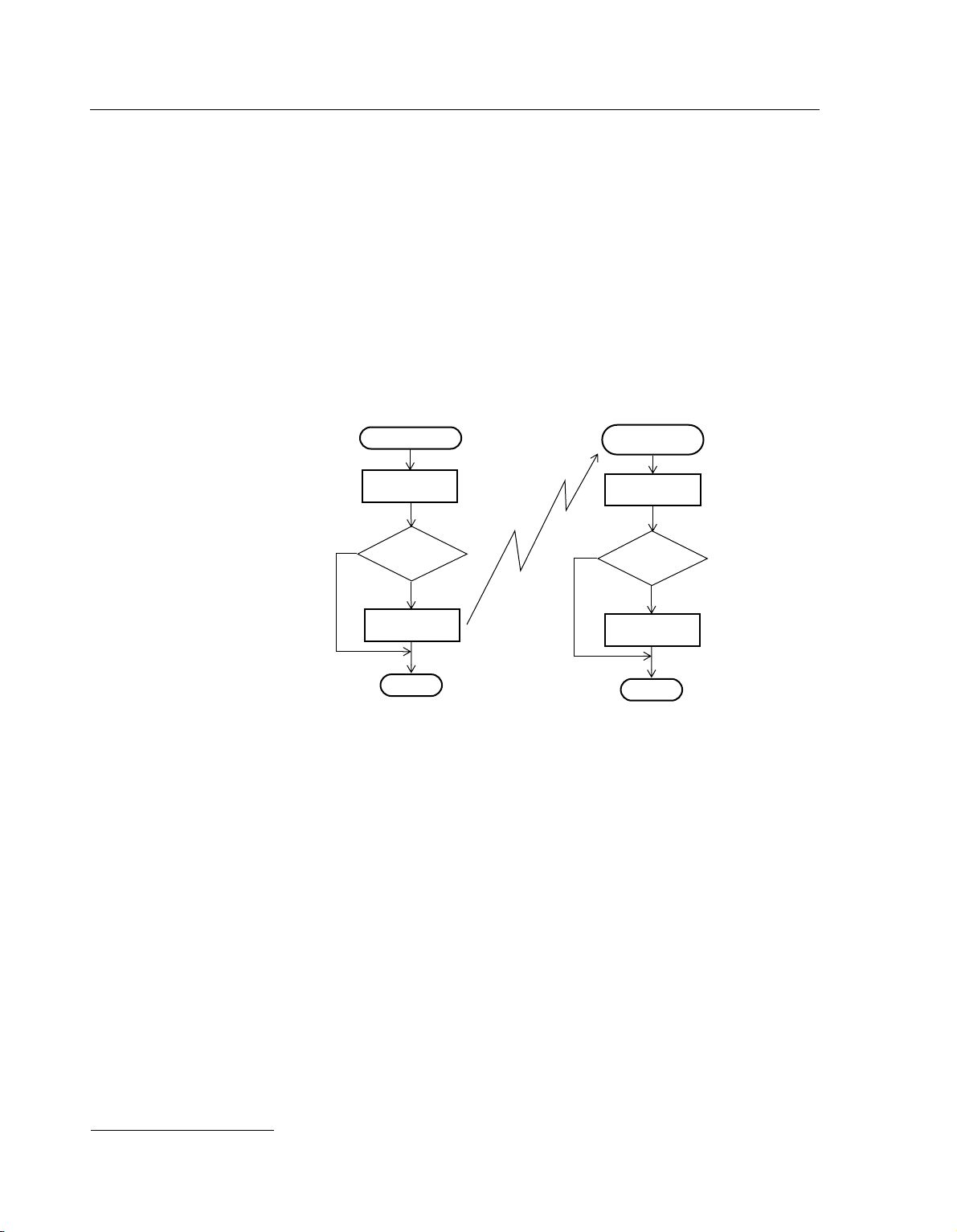

2. Hardware

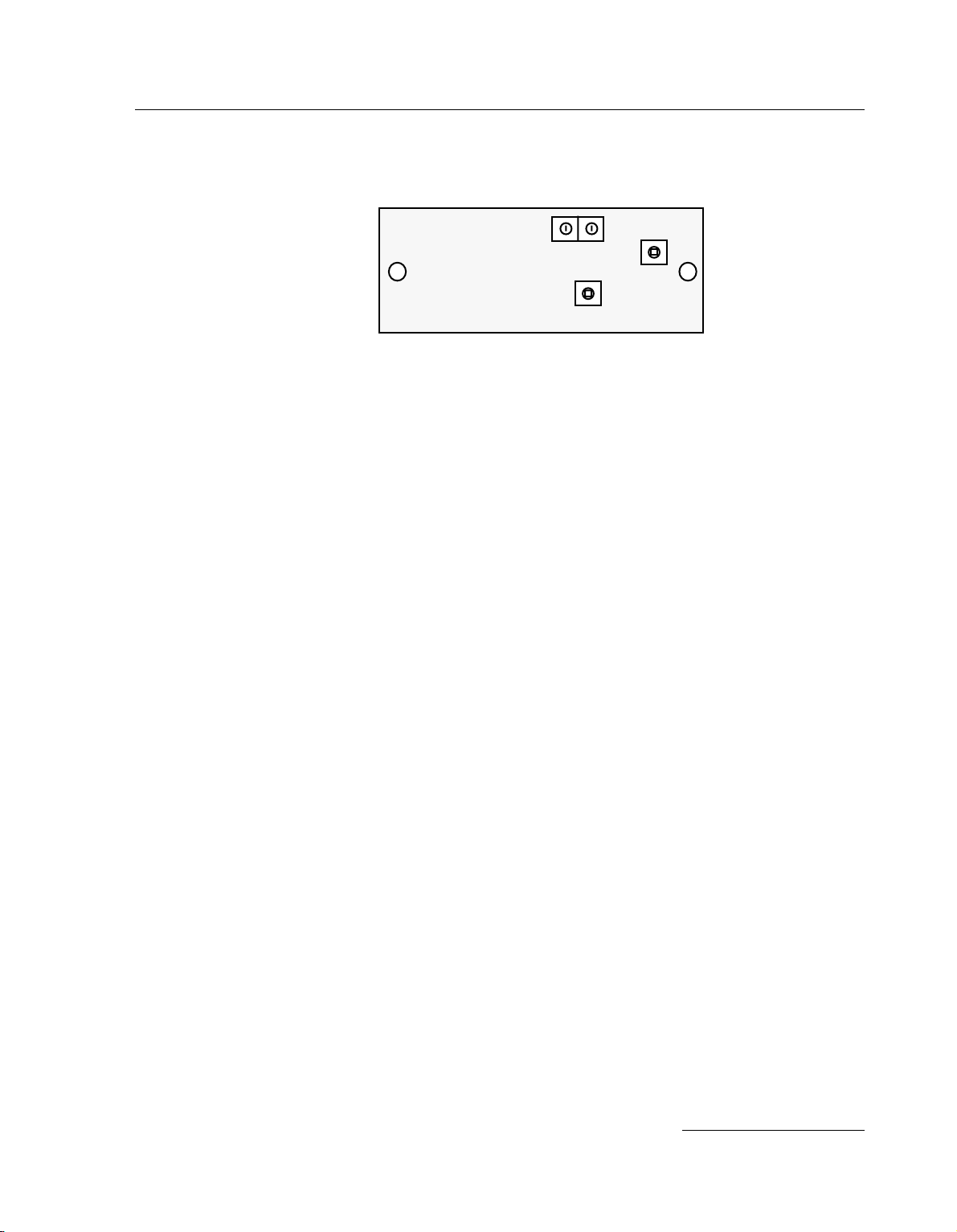

Most of the electronics are situated on the main board, while an interface board is

used to connect the unit to the outside world. The main board contains a radio unit,

a low speed modem interface, a microcontroller and a power management subsystem.

Antenna

Radio Unit

Modem

Interface

External Power

System Supply

Battery

For further details you may want to consult the schematic diagram located on page 7.

2.1. The Radio Unit

It consists of a RF transceiver, that conforms or surpasses the ETSI 300 220 specifications. The receiver is a double superheterodyne type, first oscillator being synthesized. The transmitter is also synthesized, only the PLL chip and the frequency

reference being common (there are two separate VCOs, one for the receiver’s local

oscillator and another for the transmitter).

2.1.1. Receiver Section

The antenna signal is fed through a low pass filter and the antenna switch (D1/D2)

to a helical band-pass filter (it has a 20 MHz passband at 3dB), which attenuates the

first image and the oscillator fed-through signal. A cascode chip (U3) is used for RF

signal preamplification and first mixer, the LO being fed via the second emitter of the

cascode. The resulting IF on 45 MHz is filtered through XF1 which in this case provides the image attenuation for the second mixer.

Digital I/O

µController

ADC

4

6

Analog Inputs

Power

Management

After a pre-amplification by means of the transistor Q11, the 45 MHz IF signal is applied to U10, which provides the second frequency change to 455 kHz, pre-amplification, limiting and FM demodulation. The second oscillator is also built into this

6

Page 7

Wireless Sensor Interface A720 (addIT™)

chip, a third-overtone quartz oscillator oscillating on 44.545 MHz. The 12.5/25 kHz

selectivity is obtained through the use of the two ceramic filters CF1 and CF2 (version GX for 12.5 kHz or EX for 25 kHz channel spacing), exhibiting a low group delay

time. An interesting feature of U10 is its coilless demodulator, which is PLL based.

By adjusting R67 and R60 one can change the bandwidth and the central frequency

of the IF demodulator.

The data signal is obtained on pin 17 of U10 and is buffered by means of U8:D. In

addition to the data signal, an RSSI signal is obtained on the pin 18 of the same U10.

The signal is multiplexed with other DC signals (battery level and on-board temperature) by means of U6 and U7 and then is presented to one of the A/D inputs of the

microcontroller.

The entire receiver section is enabled by the microcontroller through Q8.

2.1.2. Synthesizer Section

The synthesizer is based on a very low power PLL chip, U2. An important feature of

the chip is its FastLock™ mechanism, which improves the locking speed of the loop

without compromising on the VCO noise. The operation of the PLL chip is directed

by the microcontroller (operating frequency and channel step) and are therefore fully

under software control. The frequency reference is obtained from the highly stable

temperature compensated crystal oscillator OSC1.

There are two separated VCOs: one for the receiver section and a second for the

transmitter section. The receiver oscillator is 45 MHz higher than the transmitter oscillator, the latter being on the programmed operating frequency. This solution optimizes the operating range of the individual VCOs, and keeps the noise level down.

The receiver VCO is realized with Q6 as oscillator and Q4 as buffer/amplifier, while

the transmitter VCO with the pair Q2/Q1. The configuration of the two VCOs is very

similar: in order to minimize the power consumption, the transistors are connected

in series from a DC perspective, the buffer being the load of the oscillator.

A small amount of RF from each VCO is fed to the PLL chip input (to the internal

prescaler) by means of the group C47/R27, and C16/R7 respectively. The output of

the PLL from the phase comparator/charge pump is filtered by means of the low

pass filter formed by C35/R29/C36/R22/C55 and applied to the two varicap diodes

D4 and D3. In addition, the FastLock mechanism occasionally activates R21 to increase the current of the charge pump (you may want to consult National Semiconductor’s Application Note AN-1000 “A Fast Locking Scheme for PLL Frequency

Synthesizers”, by D. Byrd, C. Davis, W.O. Keese, July 1995 for additional details on

the FastLock mechanism).

8

Page 8

2.1.3. Transmitter Section

The transmitter section uses the VCO composed by Q2/Q1. This VCO is modulated

on the anode of its varicap diode (D3) by means of a small amount of the data signal.

Before modulation, the data signal is filtered by a four-pole low-pass filter built

around U1. The filter effectively removes the harmonics on the data signal in order

to keep the adjacent channel power under the required level.

The output of the VCO/buffer amplifier is applied to the power amplifier, operating

in class A thus minimizing the harmonics (Q3). The output of the amplifier is directed to the antenna through the antenna switch and the low pas filter. The antenna is

switched on transmit mode when a positive current is applied on the anode of D1 via

R12. The DC component is obtained from the collector of the power amplifier (Q3).

C11 is used to pass along the RF component.

The transmitter is activated by the microcontroller in two steps:

• The PLL is switched on (by means of Q5);

• After a delay of about 5 mS when the PLL has settled, the power amplifier is

switched on (by means of Q7).

The above mechanism assures a clean transmission start, avoiding that the transmitter “spills-out” its carrier on several channels before stabilizing. The switch off follows the same principles, but in a reverse order.

The Modem Interface

2.2. The Modem Interface

The modem operates with two tones: 1 kHz (representing the 1 bits) and 2 kHz (representing the 0 bits). A bit cell is represented by a complete time period (

raw throughput varies between 1 and 2 kbps (average 1.5 kbps). The modem functionality is essentially implemented in software. However, a signal conditioning is

performed on both receive and transmit paths.

On receive, the buffered analog data signal from U8:D is applied to a 3 kHz low pass

filter (U8:A). The filter output is further fed both to a Schmidt trigger (U8:C) and a 50

Hz low pass filter (U8:B), the output of the latter being used as a reference for the slicer (the Schmidt trigger). The TTL data,

(i.e. on TP2). The microcontroller overtakes the decoding operation (see also “Modulation Technique Used” on page 43).

On transmit, only the low pass filter built around U1 is used: its role is to “smooth”

the square signal

TXDI

generated by the microcontroller.

RXDO

, is obtained at the output of the slicer

1/f

), thus the

9

Page 9

Wireless Sensor Interface A720 (addIT™)

2.3. The Microcontroller and the Power Management Sections

The operation of the whole unit is under the control of U9, a PIC16C77L microcontroller. It is a powerful chip exhibiting an extreme low power consumption. Its main

jobs are:

• Controls the radio unit;

• Implements the modem functionality;

• Assembles the radio frames and waits for requests from a remote;

• Performs the sampling of the sensor inputs and the A/D conversion;

• Stores the values in a local FIFO; manages the FIFO;

• Implements the pulse counter function;

• Increments the Real-time clock;

• Assures the power management;

• Implements a serial Command Line Interface (CLI).

Note: For more details on some of these functions, see also the chapter “Software” on page 34.

The chip operates at its maximum speed, in this case 4 MHz (the “L” version) and

uses a crystal (X1). The real time clock is implemented by means of a 32.768 kHz crystal (X3) connected on the internal TIMER1.

The radio unit is controlled via the SPI bus on one hand (to set the PLL chip parameters) and via the switches Q8 (for receive) and Q5/Q7 (transmit). As already mentioned, the modem is implemented in software: the output signal is available on RB1

TXDI

(

), while the receiver output is fed on the RB0/INT pin (

The A/D subsystem is used to sample the inputs (AN0 to AN5); the 7th analog input

is used for on-board measurements (local battery, internal temperature and RSSI signal, switched by means of the analog switches U6 and U7); a stable 2.5 Volt reference

supplied by U4 is applied to the RA3/AN3/Vref pin. The reference is powered by

the microcontroller only when sampling the A/D inputs. The external sensors are

powered through U13.

The sampled input values are stored in a FIFO built with a serial EEPROM chip, U5.

These values may be retrieved when a pertinent request is received over radio, or

over the serial line. Additional configuration parameters are stored in the EEPROM,

e.g. the serial number of the device, the operating frequency, etc.

The pulse counter functionality is implemented by means of the two inputs RB6 and

RB7, based on the

microcontrollers.

The power management controls the charge/discharge of the battery (via Q9 and

U11), senses the misery levels and switches off the unit in order to protect the battery

(again U11). In addition, the software senses a storage condition, where no activities

interrupt on change

feature implemented in the PIC16C7x series of

RXDO

).

10

Page 10

must be performed thus driving the unit in the hibernation mode. If the unit was

completely switched off due to an extremely low battery level, Q10 would start it up

again only if external power is applied to the power connector (e.g. from a solar panel).

The terminal mode is implemented by means of the built-in UART. No on-board level drivers are present in order to minimize power consumption; a special adapter cable that performs the TTL to RS232 level shift and vice-versa is available. By means

of this cable and using the implemented commands, various parameters can be

changed/configured (see also the chapter “Software” on page 34).

2.4. The Interface Board

The interface board assures the connection between the main board described above

and the outside world. It contains the three connectors (

some passive components protecting the pulse inputs. Each of the

accept:

• Three analog inputs;

• One digital Input or Output (its functionality can be switched remotely);

The Interface Board

I/O A, I/O B

and

POWER

connectors can

I/O

) and

• One pulse counter input.

POWER

The

connectors allows for:

• External supply (battery or any DC source from 5 to 10 volts);

• External charge supply (either a solar panel or an AC adaptor) if an internal

rechargeable battery is used;

• Communication over serial lines, at 19200 baud.

Note: The serial line is TTL compatible, a special adaptor cable must be used to reach the RS-232

levels. If an external battery is used, then the internal battery must be disconnected.

11

Page 11

3.1. Programming the Boards

This section will be completed later.

3.2. Setting-up the Default Parameters

The tuning procedure is not possible without first configuring some default parameters on each unit. This is done using a special serial cable connected between the

A720MB with an A720CA interface to a PC; in addition, a communication terminal

program (e.g. Hyperterminal, in Microsoft® Windows™ 95) is needed to send the

commands. The terminal program must be configured as follows:

Programming the Boards

• 19200 Baud

• 1 Stop bit

• No parity

• No protocol (neither hardware, nor software)

To check that the communication is operational, press the

appear on the terminal screen. Using the

SET

command, following default parame-

Battery

Ext Power

ENTER

4

Ground

key: an OK should

5

3

RxD

1

2

TxD

ters must be pre-loaded (for more details on the meaning of the commands, consult

the section “The Terminal Task” on page 39):

SET OWNID 1

SET PMP 65 72

SET SLOT 900 3

SET RSSI 58

SET BL 432000000 450000000

SET FREQ 432000000 25000

The last two

SET

commands are valid for the units that will be trimmed for the low

band; for the high band, they must be replaced by:

SET BL 450000000 470000000

SET FREQ 450000000 25000

Note: The SET BL command sets the band limits, while SET FREQ sets the operating frequency;

before shipping and depending on the target country these two parameters may be changed.

The SET BL command must be issued always before the SET FREQ command.

3.3. Tuning

The tuning can be performed only after the units are programmed and the default

parameters are set, as described previously.

13

Page 12

Wireless Sensor Interface A720 (addIT™)

3.3.1. Definitions

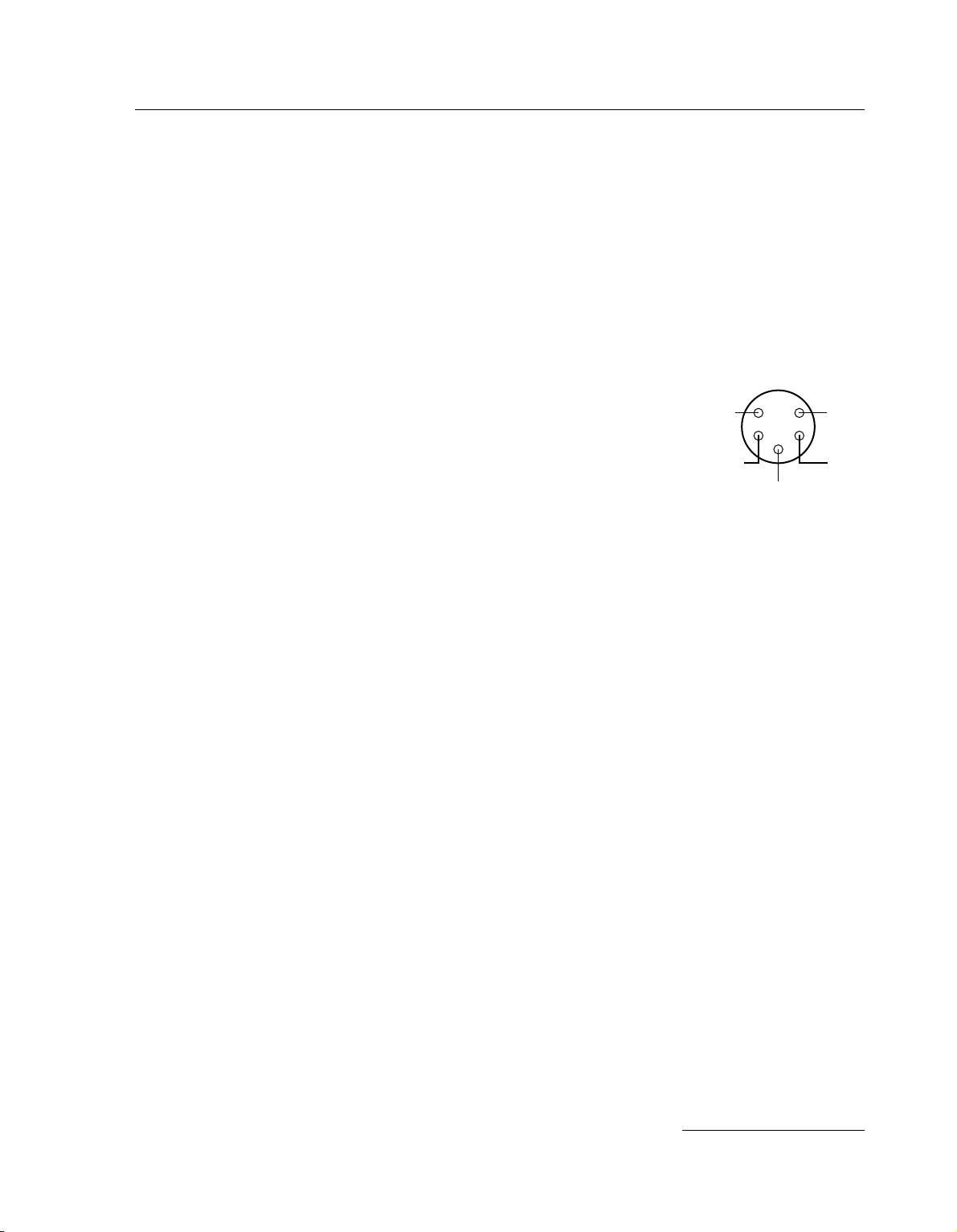

The diagram of the setup environment is depicted in

Scope Service Monitor Network Analyzer

Figure 3.

Voltmeter

0.765 V

Optional

Figure 2.

Testing

Fixture

Trimming Setup.

Out

Scope

In/Out

Service

Monitor

Power/

Sens

In

Network

Analyzer

Out

Voltmeter

Wobble

Out

Network

Analyzer

A720MB

Connector

RS232 To/From PC

+

6.5 V

–

The testing fixture is used to fasten the PCB under test both mechanically and electrically in such a way to allow its rapid and comfortable trimming. It consists of a mechanical breadboard with two screws that are used to fasten the board; 5 elastic pins

are used to transport the relevant signals from the PCB to their corresponding apparatus test cables. In addition, a switch (

Power/Sens. <–> Wobble

) allows switching of

the antenna input/output to the network analyzer or to the service monitor. The

schematic diagram of the testing fixture is depicted in

Figure 3.

14

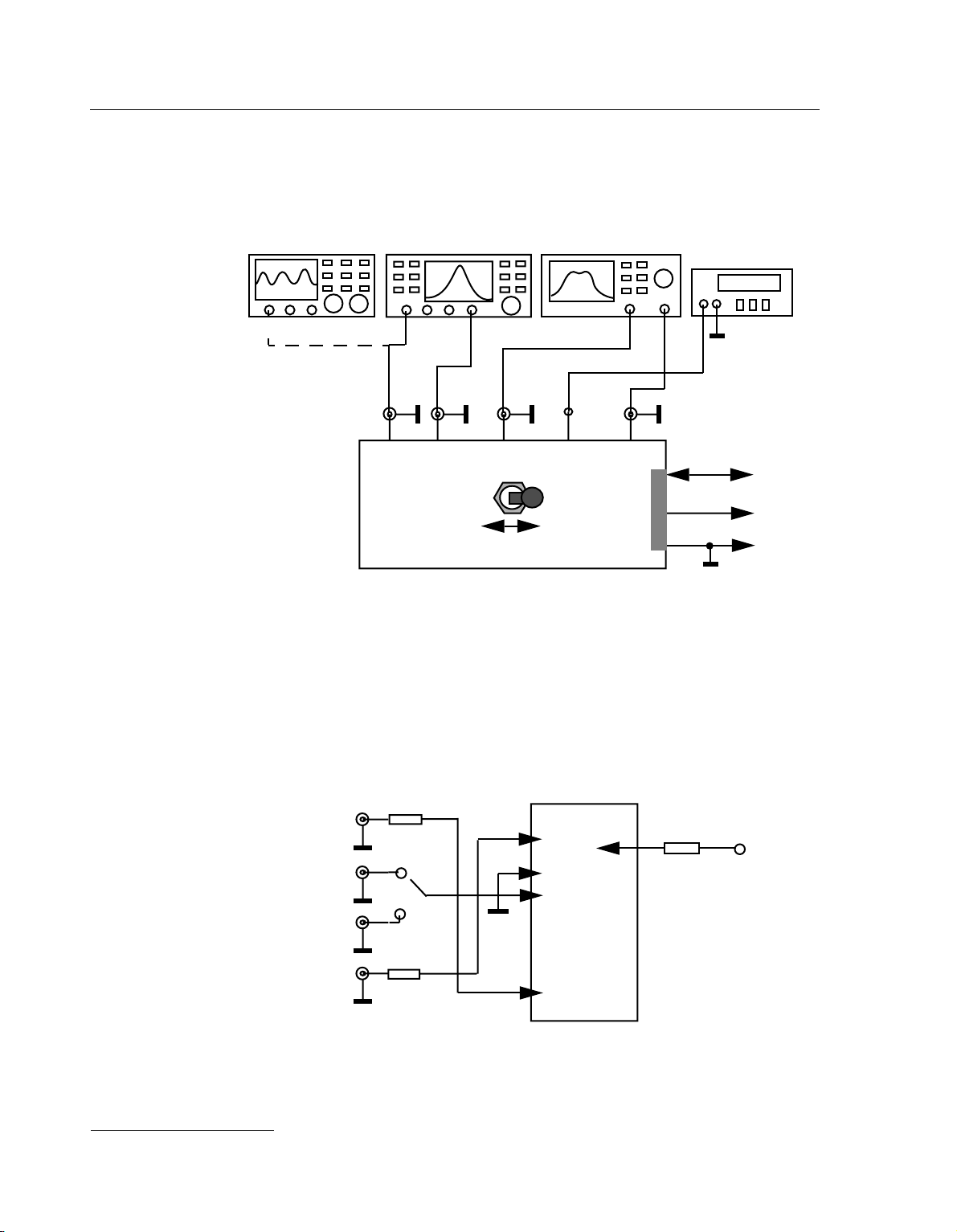

Figure 3.

Scope

Service

Monitor

In Network

Analyzer

Out Network

Analyzer

12 KW

Power/Sens.

Wobble

680 W

Schematic Diagram of the Testing Fixture.

TP4

Gnd

Ant

TP2

TP1

A720MB

1 MW

Voltmeter

Page 13

There are only three tuning elements to be acted upon: FL3, L6 and L10. Their location on the PCB (all upper side) is depicted in the schematic below:

3.3.2. Test Equipment Settings

Before proceeding, certain controls on the test equipment must be set; some of the

settings depend of the operating band (high or low) of the device under test (DUT).

In addition, it is highly recommended that the ambient temperature during trimming is 24° C (±2°C).

3.3.2.1. Network Analyzer (HP 8711)

Tuning

FL3

L10

L6

The settings for the Network Analyzer are as follows:

• Center frequency: 450 MHz

• Span: 100 MHz

• Display: 5.0 dB/div

• Power: -20 dBm

• Markers:

— low band Mkr1 – 440 MHz, Mkr2 – 430 MHz, Mkr3 – 450 MHz;

— high band Mkr1 – 460 MHz, Mkr2 – 450 MHz, Mkr3 – 470 MHz.

Note: A good idea is to store the instrument state for the two settings, low band and high band.

3.3.2.2. Service Monitor (Rohde & Schwarz CMS50)

The setting for the receiver section check are as follows (RX-TEST):

• SET RF: 432000000 Hz (Low band) / 450000000 Hz (High Band);

• RF LEV: 5 µV (see also note below);

• SINAD;

• AF1: 2kHz;

• MOD1: 3.5 kHz;

• SCOPE MODE;

• BEST RANGE.

15

Page 14

Wireless Sensor Interface A720 (addIT™)

The settings for the transmitter section check (TX-TEST):

• COUNT: (should show the transmitter carrier frequency);

• POWER: (should show the transmitter carrier power).

Note: If using the Testing Fixture, a calibration should be performed to check the losses in the an-

tenna switch, cables, etc. Depending on these losses (which at 450 MHz can amount up to 6

dB), it may be needed to adjust the RF LEV value accordingly (up to 10 µV). Similarly, the

measured output power must be correspondingly downgraded (see also “Checking the Transmitter Parameters” on page 18).

3.3.3. Adjusting the Receiver Front End

• Mount the DUT on the testing fixture and connect it to the PC via the serial

cable;

• Select the appropriate instrument profile depending on the device’s band

(High or Low);

• Turn on the receive subsystem of the DUT by entering the RX command at the

terminal;

• Check that the switch on the Testing Fixture is in the

Wobble

position;

• Adjust the filter FL3 until you obtain a curve similar with one of those shown

in

Figure 4.

(depending on the band); this is done by successively adjusting the

two trimming screws located on the filter.

If this is not possible, check the power supply, the cable connections to/from the test

equipment, etc. In addition, verify if you have approx. 1.1 volts on the test point TP4.

Finally, check if all 8 pins of the filter FL3 are properly soldered.

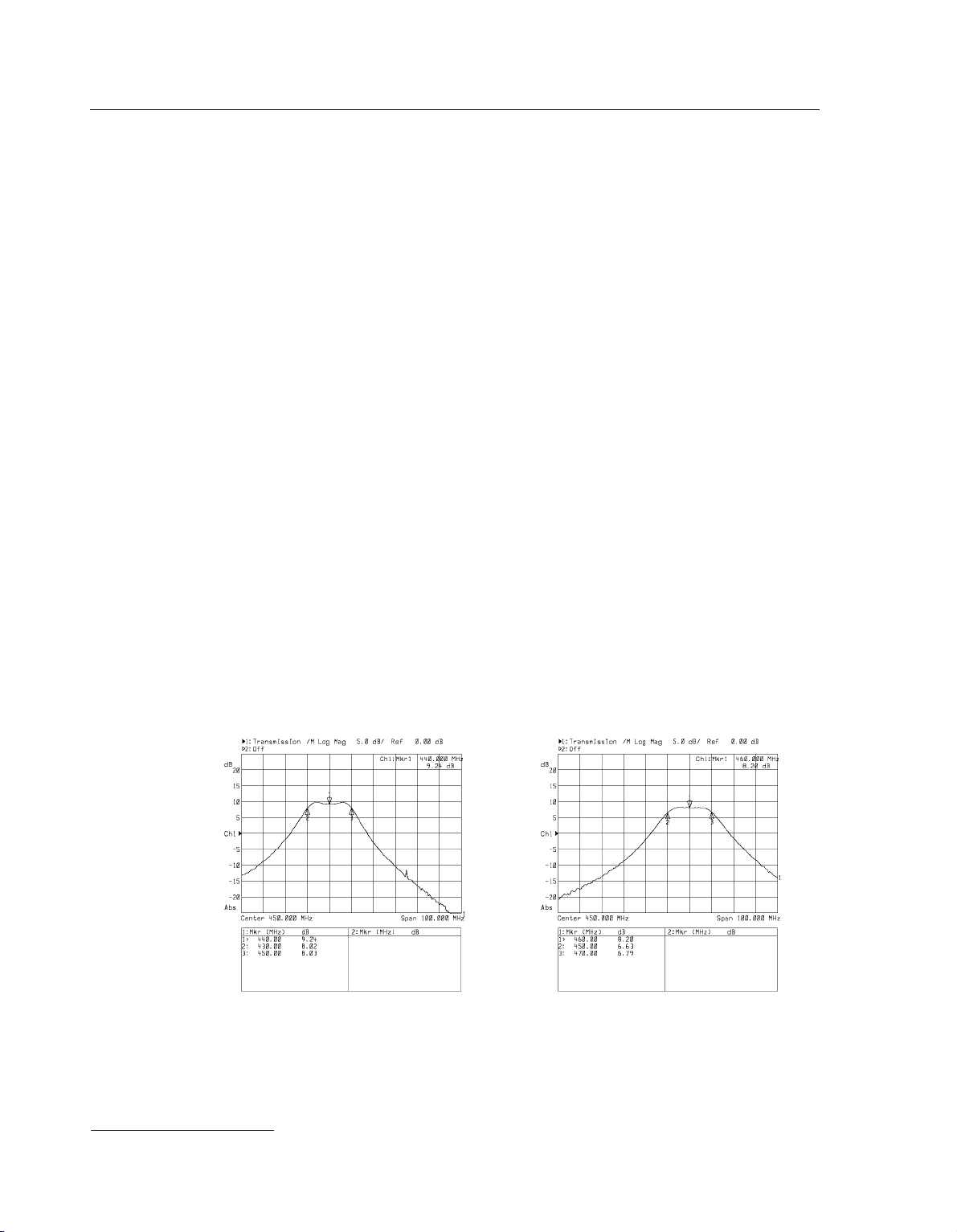

Low Band High Band

16

Figure 4.

Helical filter’s diagrams for Low Band and High Band devices.

Page 15

3.3.4. Adjusting the VCOs

Tuning

• Flip the switch on the Testing Fixture to the

Power/Sens.

position;

• Be sure that the DUT is in receive mode (enter the RX command at the terminal

program);

• Adjust the coil L10 until the voltage shown on the digital voltmeter is 700 mV,

±50 mV (see also the note below);

• Switch the unit in transmit mode, by entering

at the terminal;

XMIT

• Adjust now the coil L6 until the voltage shown on the voltmeter is again

700 mV, ±50 mV;

• Press the enter key at the terminal to switch the unit off.

Note: If using the Testing Fixture, a calibration may be needed, due to internal resistance of the

Voltmeter and the serial resistor mounted on the Testing Fixture. The calibration is performed

by measuring the VCO voltage directly on the TP1 and by comparing the value with that

measured through the Testing Fixture. The values given above are the real ones, measured directly.

If the above limits cannot be attained, or the readout is very unstable, check the following:

• If the programmed operating frequency is 432 (Low Band) and 450 MHz

(High band) respectively. To check this, type at the terminal prompt the com-

FREQ

mand

• If the respective commands (RX and

, the device will answer returning this parameter;

XMIT

) were issued;

• If some parts are not missing, have the incorrect value, or badly soldered

(check the parts around Q2 and Q6).

3.3.5. Checking the Receiver Parameters

• Check that the switch on the Testing Fixture is flipped to the

sition;

• Switch the DUT to receive mode by typing at the terminal the command RX;

• Switch the Service Monitor to RX TEST mode, on the appropriate frequency

(432 MHz for low band and 450 MHz for high band); the level should be 5 µV

(see also “Test Equipment Settings” on page 15);

• The S/N ratio should be at least 10 dB; in addition, if a ‘scope is also connected

a clear 2 kHz sine wave should be visible, with a relatively low amount of

noise superimposed;

• Switch the DUT in pulsed mode (press the enter key);

• After several seconds, you will see the image on the ‘scope pulsing at about

one second intervals;

• Switch the RF generator output off;

Power/Sens.

po-

17

Page 16

Wireless Sensor Interface A720 (addIT™)

• Check if the RSSI threshold is correct: type the command

ue must be lower than the threshold set. If this is not the case, repeat several

time the

command, maybe a transmission just happens (a radio scanner

RSSI

set on the operating frequency would help detect foreign transmissions). If the

threshold difference is marginal, then you must increase it by using the

command (it must be 20 to 30% higher than the actual value).

RSSI

If the any of the above targets is not reachable, check first visually if the chip U10 is

correctly soldered and that no shorts exist between its pins (most problems usually

appear around this chip). If the S/N ratio test is positive but the last check is not, then

check U8 and the components around it.

3.3.6. Checking the Transmitter Parameters

• Check that the switch on the Testing Fixture is flipped to the

sition;

• Switch the DUT to transmit mode by typing at the terminal the command

;

XMIT 0

• Switch the Service Monitor to TX TEST mode, on the appropriate frequency

(432 MHz for low band and 450 MHz for high band);

• You should see the following parameters on the Service Monitor readout:

1. Carrier: 432000000, respectively 450000000 Hz (± 500 Hz);

2. Output Power: 9 dBm (+1dBm, -2dBm);

3. Frequency Deviation: ±2.3 kHz (±0.2 kHz) for 12.5 kHz units and ±4.0 kHz

(±0.5 kHz) for 25 kHz units;

– the actual val-

RSSI

Power/Sens.

SET

po-

• Switch the unit in stand-by (press the enter key).

If item 1 above cannot be achieved, replace R36 with a 12 KW resistor to shift the frequency up, or R35 with a 10 kW resistor to shift the frequency down. If item 2 cannot

be achieved, check the solder and components around Q1 and Q3; in addition, check

if D1 and D2 are the right components (sometimes they are replaced by other visually similar parts). Finally, if item 3 cannot be achieved, replace R17 with a lower resistor to reduce the deviation, or a higher one to increase it. Note that depending on

the device type, R17 can be either 470 W (12.5 kHz) or 1 kW (25 kHz). If no modulation

is present at all, then check U1 and the parts around it.

3.3.7. Data Transfer Check

The last check is a radio data transfer. In order to perform it, at least a base station

(model A730SD) or a normal remote station (model A730MD) should be installed

and operated on the same test frequency (either 432 or 450 MHz), in the near vicinity

(no more than 30 m).

Note: The base or remote station used for this test must be operated with a fictive antenna (a 50W

resistor).

18

Page 17

Additional Issues Related to Type Approval Testing

The test is performed by entering at the terminal prompt the command B: the base

and/or remote station must answer with the RF in and out values. If no answer is

received after several seconds, then retry the command. If still no answer is received,

then check with a scope on TP2 if the digital data is present (on receive); if not available, check U8:C and the parts around it. In addition, a radio receiver tuned on the

operating frequency can also supply a rough indication whether the receiver or the

transmitter are defective.

3.4. Additional Issues Related to Type Approval Testing

This chapter is intended for the bodies (laboratories) performing the tests required

to obtain a Test Report.

3.4.1. Controlling the Unit

The unit under test can be controlled by means of the special serial cable supplied by

Adcon Telemetry connected to a PC (e.g. a laptop) on one side and the

nector of the unit on the other side. In order to switch the unit in various modes of

operations, a simple communications terminal program will suffice (e.g. Terminal or

Hyperterminal in Windows, or Kermit under other platforms). The most important

commands used are

the parameters they expect, see also “Supported Commands” on page 39. For additional details on how to configure your terminal program, see “Setting-up the Default Parameters” on page 13.

XMIT, RX

and

SET FREQ

. For a list of all supported commands and

POWER

con-

3.4.2. External Power Supply

In order to test the unit over the specified supply range, a special power cable is supplied by Adcon Telemetry. This cable must be connected to the

the unit before the serial cable. The two wires with banana plugs can then be connected to an external variable power supply: the red plug to plus and the black one to

minus. However, before doing this, the internal battery must be disconnected. Here

is how:

• Open the lid by unscrewing the four screws in the corners of the addIT box;

• Gently remove the lid (the battery is fixed on the lid and is connected to the

electronics board by means of two wires);

• Remove the battery’s plug from the PCB connector;

• Mount the lid back, taking care that the rubber gasket sealing the box is not

out of its place;

• Screw the four screws back, applying a moderate force.

Note: If the rubber gasket is not properly mounted, the unit loses its IP65 environmental protection.

In addition, certain radiated limits cannot be guaranteed.

POWER

connector of

19

Page 18

Wireless Sensor Interface A720 (addIT™)

WARNING! Do not apply more than 10 Volts to the unit: permanent damage of the de-

vice may result. Note also, that the internal microcontroller will switch off the unit

when the battery voltage drops below 5.5 Volts, and under 5.9 Volts the RF operations may be stopped.

Figure 5. Connection of an external power supply.

3.4.3. Specifications

The A720 was intended to fulfill the specification of the ETSI 300 220, Class I, Subclasses a and b, but other national norms are similar to this (e.g. the CFR 47, Part 90,

Subpart J). Following are the main operational parameters of the A720:

Common

POWER

I/O B

I/O A

Power Cable Serial Adapter Cable

Red

Black

+

RS232

+

+

5 to 10 Volt

-

Parameter Min Typ Max Unit

Supply 5.0 6.2 10.0 V

Operating Temperature -30 +70 °C

20

Relative Humidity 10 99 %

Class Protection IP65

Data Rate (Using the On-board Software Modem) 1000

Operating Frequency (Low Band version)

Operating Frequency (High Band version)

b

b

432 450 MHz

450 470 MHz

150

a

Frequency Stability (-20 to + 60 °C) ±1.5 kHz

Frequency Stability (-30 to + 70 °C) ±2.5 kHz

Receiver

Sensitivity (10 db S/N) -93 dBm

Image Frequency Attenuation (1st IF = 45 MHz) 70 dB

2000 bps

Page 19

Additional Issues Related to Type Approval Testing

Parameter Min Typ Max Unit

Local Oscillator Leakage 2 nW

Adjacent Channel Attenuation (both versions) 70 dB

RSSI dynamic 90 dB

Operating Current (incl. On-board Microcontroller) 15 mA

Transmitter (all measurements made on a 50 W resistive load)

Output Power 7 9 10 dBm

Spurious Radiation (0 to 862 MHz) 2 nW

Spurious Radiation (862 MHz to 3.5 GHz) 200 nW

Adjacent Channel Power (12.5 kHz version) -32 dBm

Adjacent Channel Power (25 kHz version) -44 dBm

Occupied Bandwidth (12.5 kHz version) 8.5 kHz

Occupied Bandwidth (25 kHz version) 15 kHz

Operating Current (incl. On-board Microcontroller) 50 mA

a. Data rate is content dependent.

b. This parameter represents the tunning range; the switching range can be

software limited to a narrower space (even to the extent of a single channel).

21

Page 20

Wireless Sensor Interface A720 (addIT™)

Several graphs obtained by means of a Rohde & Schwarz Spectrum Analyzer (model

FSEA) are attached, reflecting some of the measured parameters.

Figure 6. Spurious radiations (Marker 2); except the second harmonic, no other overtones

are visible.

Figure 7. Adjacent Channel Power, 460 MHz, 12.5 kHz version, modulated with a 0x55

tone (1500 bps).

22

Page 21

Additional Issues Related to Type Approval Testing

Figure 8. Spectral purity: an unmodulated carrier at 460 MHz is shown.

Figure 9. The TOP side of the printed circuit board.

Figure 10. The BOTTOM side of the printed circuit board.

23

Page 22

Wireless Sensor Interface A720 (addIT™)

28

Figure 11. The VCTCXO Specification. This part is used as frequency reference for the PLL

synthesizer.

Page 23

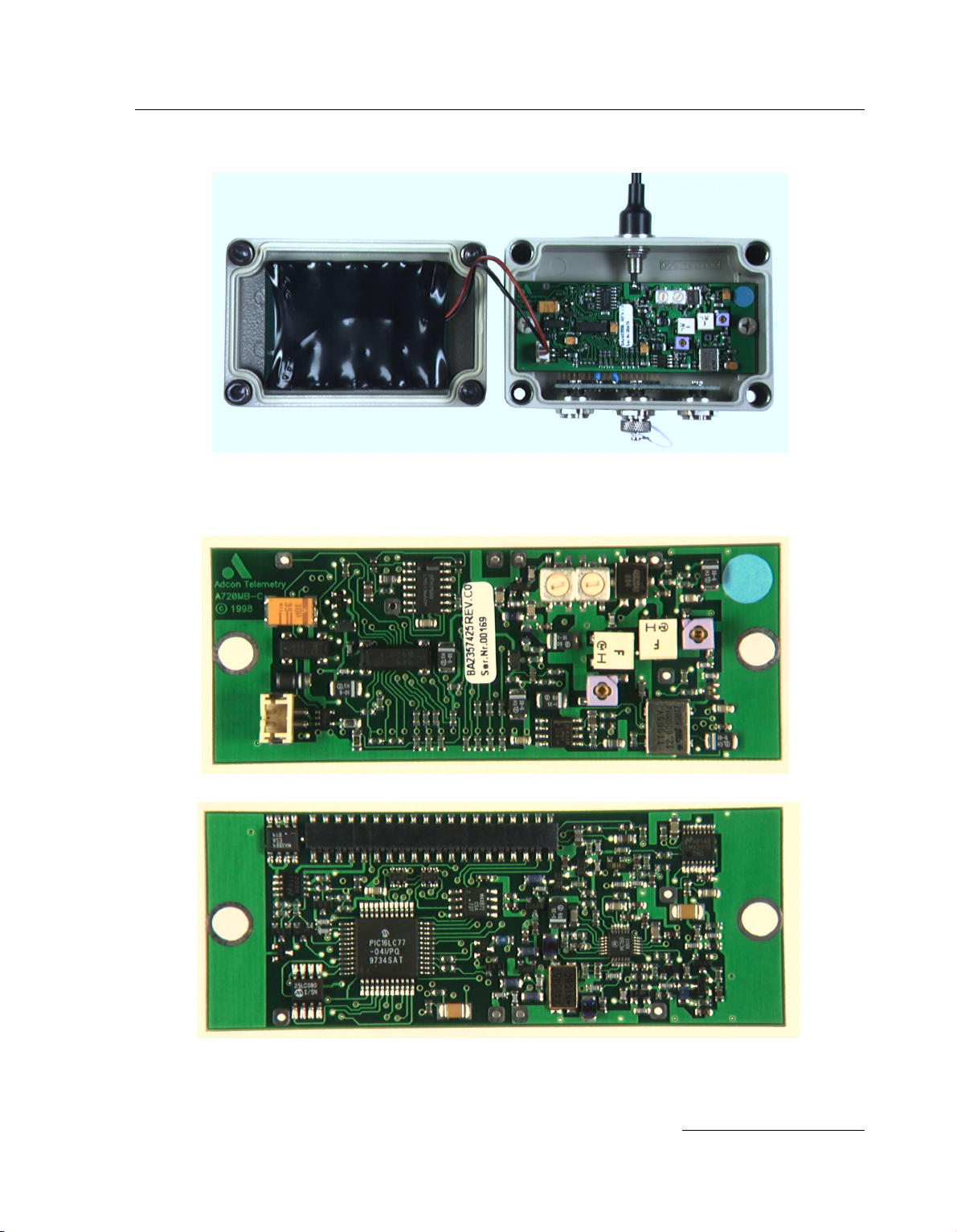

3.4.5. Device Photographs

Additional Issues Related to Type Approval Testing

Figure 12. General view.

29

Page 24

Wireless Sensor Interface A720 (addIT™)

Figure 13. Front view.

Figure 14. Bottom view.

30

Page 25

Additional Issues Related to Type Approval Testing

Figure 15. Back view.

Figure 16. Top view.

31

Page 26

Wireless Sensor Interface A720 (addIT™)

Figure 17. Left view.

32

Figure 18. Right view.

Page 27

Figure 19. The A720 Opened.

Additional Issues Related to Type Approval Testing

Figure 20. The PCB.

TOP

BOTTOM

33

Page 28

Wireless Sensor Interface A720 (addIT™)

4. Software

The software is written entirely in C. It consists of a collection of standard C library

functions, a minimalistic operating system (AMOS – Adcon Minimal Operating System) offering basic configuration and administration functions (including a command line terminal on a serial port), and the application software itself which assures

the desired functionality of the device.

Figure 21. General structure of the A720 software.

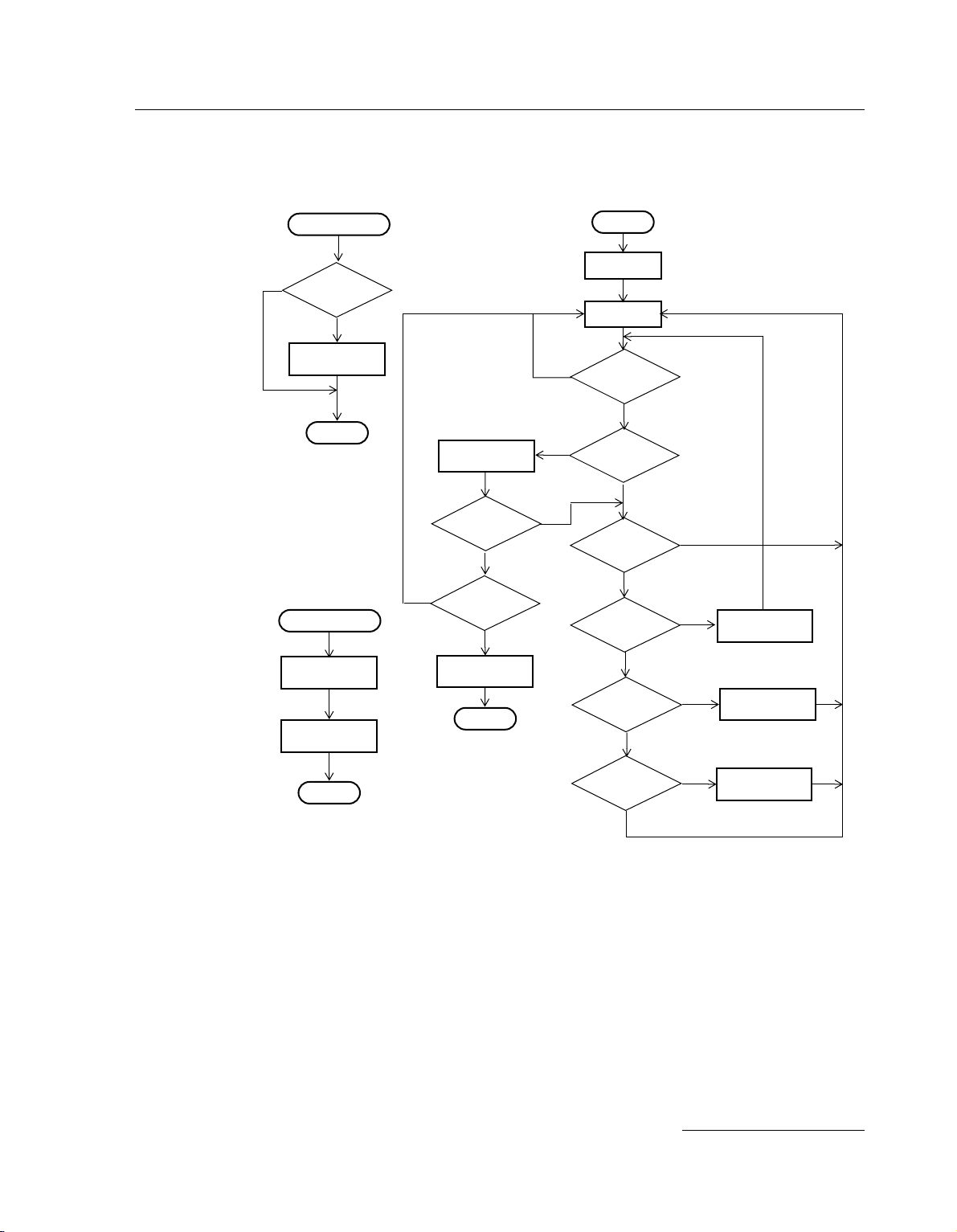

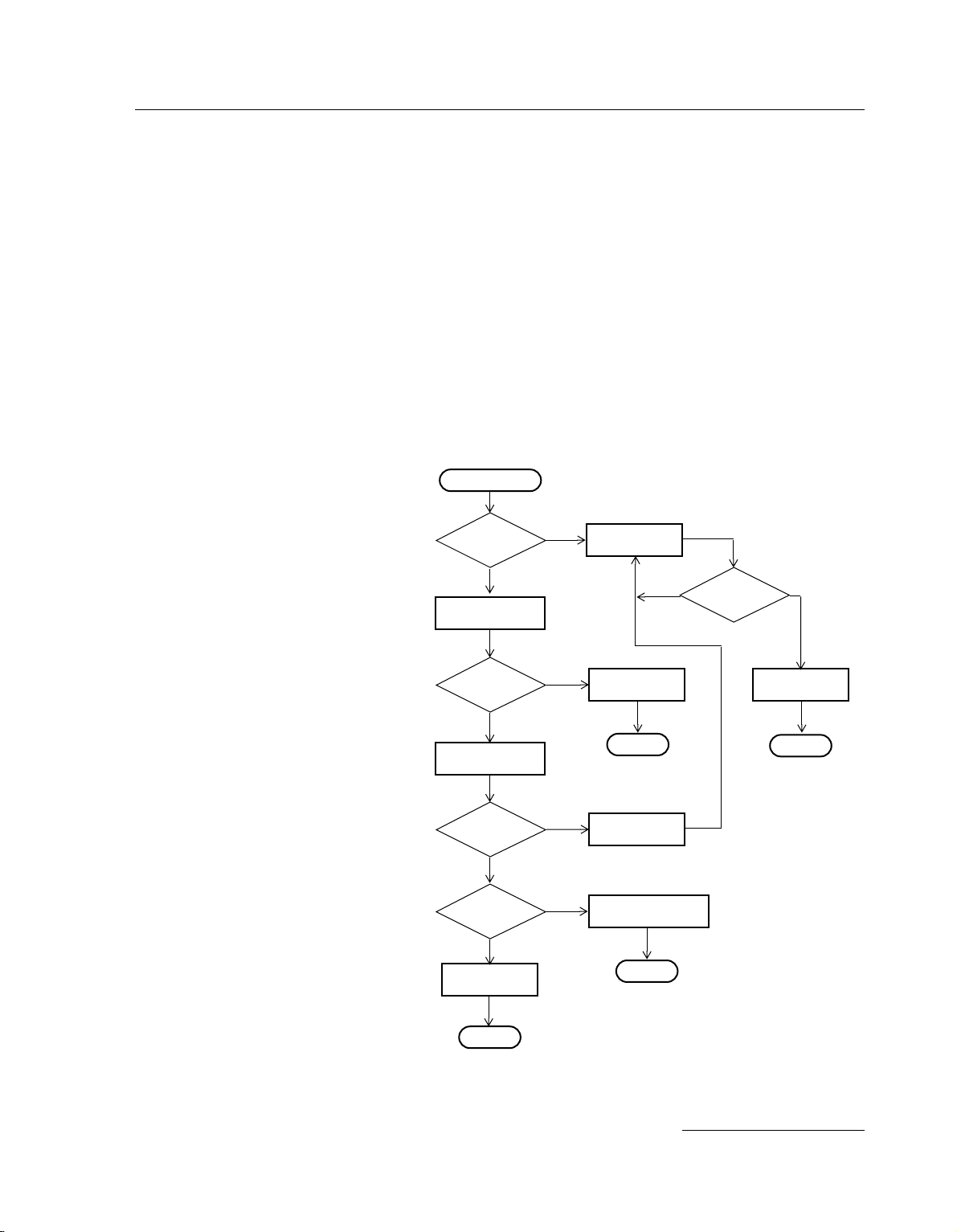

4.1. AMOS

Most of its time, the system is in sleep mode. Each 0.5 seconds, an interrupt is generated by the local 32.76 Khz crystal based real time clock (RTC). AMOS will check

what tasks need attention (i.e. must be executed) and pass them the control accordingly. After all the tasks have finished their jobs, AMOS brings the system back to

sleep. The 0.5 seconds interrupt routine is used to increment the RTC.

In parallel to the normal, regular operation of the AMOS, the system responds to the

pulse counter interrupts (they are generated by two inputs on the microcontroller

and are used for event counting, e.g. rain gauges). These interrupts are handled by a

separate routine.

Task 1

Task 2

Standard

C Library

Device

Drivers

Hardware

AMOS

Task 3

Device

Drivers

Task 4

34

One of the main concerns of the software design is the power consumption of the device. The software must assure that all the peripherals are left in the correct state in

Page 29

AMOS

order to reduce their consumption to a minimum; all operations are executed in the

shortest possible time.

0.5 sec Interrupt

No

Increment

the RTC?

Advance the

RTC one second

Return

Counter Interrupt

Debounce input

Increment

affected Counter

Yes

No

A/D Sample

and Process

Battery

Low?

Yes

Battery

Distress?

Yes

Switch off

Everything

Stop

No

No

Yes

Reset

Initialization

Sleep

0.5 sec

interrupt?

Yes

Time to A/D

Sample?

No

Storage

Mode?

No

Terminal

Mode?

No

Connectivity

Check?

No

Yes

Yes

Yes

Enable Terminal

Mode

Do Connectivity

Check

Return

Figure 22. General flow chart of the AMOS.

4.1.1. Initialization

This section initializes the peripherals needing an one time configuration, like:

• Microcontroller option registers;

• The RTC timer (Timer 1), in order to generate the 0.5 sec RTC interrupts;

• Various peripherals (SCI, Timers, A/D Converter, parallel ports).

RF Channel

Activity?

No

Yes

Handle Incoming

Message

35

Page 30

Wireless Sensor Interface A720 (addIT™)

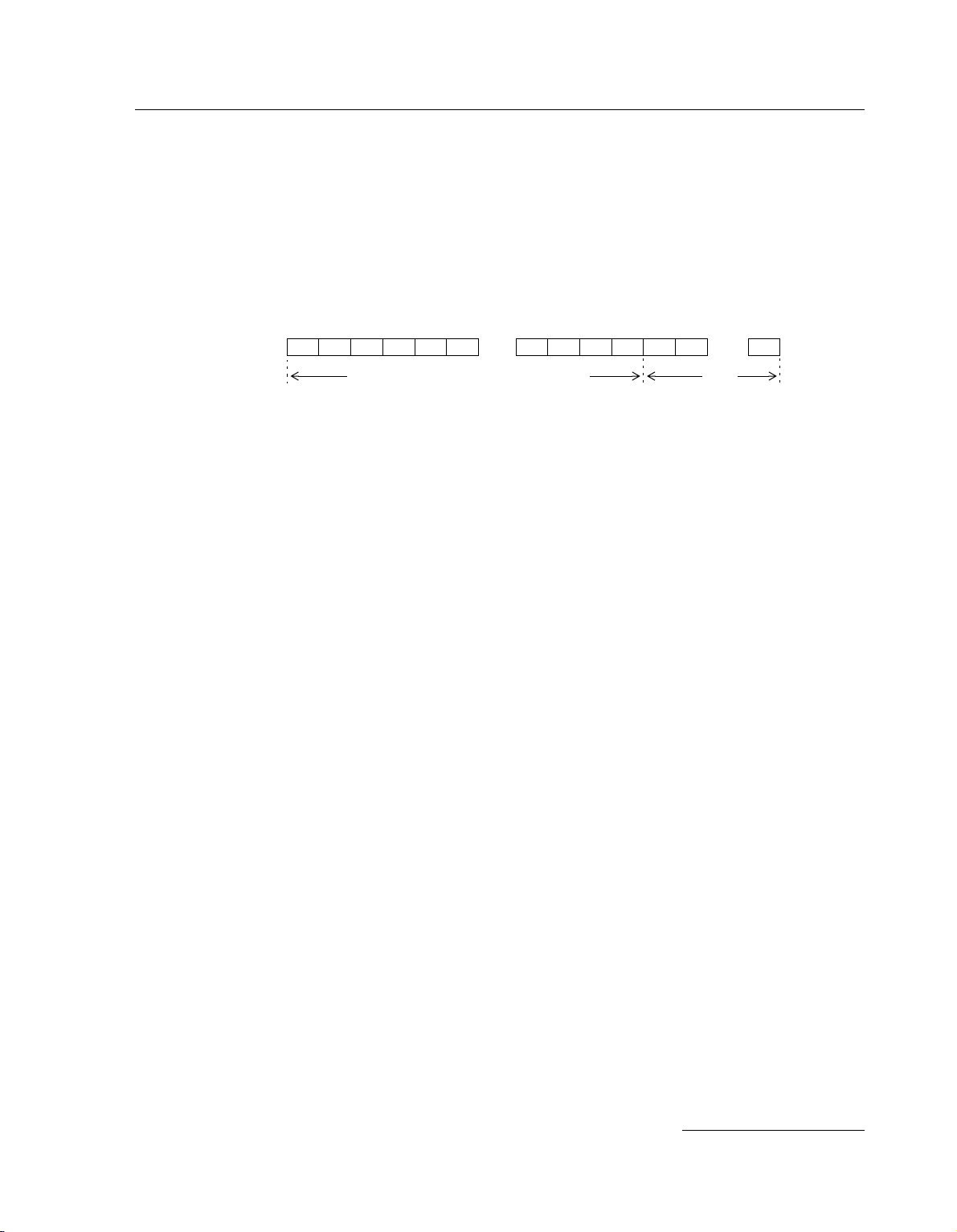

4.1.2. 1/2 Second Interrupt

The interrupt handler will only increment the RTC, when needed (every other interrupt); no other tasks are performed on this interrupt level. The interrupt is generated

by TIMER1 of the microcontroller.

4.1.3. Pulse Counters Interrupt

Interrupts are generated by two pins on the PORTB, having the Interrupt on Change

feature. The interrupt handler must store the previous state of the port, to act only on

a certain level (user programmable, by default is zero). Additionally, a debouncing

mechanism is implemented, allowing for different types of pulses to be counted. By

default, the filter is set at 1 ms (user configurable).

Counter Interrupt

Read

Port Input

No

Figure 23. Flow chart of the Pulse Counters Interrupt handlers.

Right

Level?

Yes

Arm

Debounce Timer

Return

Debounce Timer

No

Interrupt

Read

Port Input

Right

Level?

Yes

Increment

Counter

Return

Note: The commands to configure the level and filter values must be documented; they are not yet

implemented in the current version.

4.2. Mode Check

The system has the ability to check two input ports to switch itself in one of four operating modes:

36

• Storage mode: in this mode, the unit is in a stand-by state, possibly stored in a

warehouse. The power supply is reduced to a minimum, by switching off almost all the functions of the device: the radio interface, the A/D sampling and

storage (only the battery will be monitored), and the pulse counter interrupts

will be disabled. To further reduce the power consumption, the 0.5 second interrupt is switched to 2 second. However, the software accounts for this

change and the internal RTC will be correctly maintained.

Page 31

Mode Check

• Terminal mode: the device notices that a serial cable is connected to its POWER

connector, and is ready to accept commands. In this mode, all the subsystems

are enabled (A/D, pulse counters, radio interface, etc.), and the complete

functionality of the device is available.

• Connectivity check mode: in this mode, a special tool is plugged in the POWER

connector, in order for a user to check if the device is able to contact other devices (normally an A730MD or an A730SD). The tool has a LED that will be

pulsed in several modes, depending on the results of the connectivity check

operation. After the operation is finished, the device will enter automatically

the normal operating mode (see next paragraph).

• Normal operating mode: this is the mode where the device polls every 0.5 seconds the RF channel and waits for requests from a master (an A730MD or an

A730SD). In addition, it samples the analog and digital inputs every 5 minutes

and stores the averaged values in the EEPROM FIFO every 15 minutes. The

pulse counters are operated normally.

0.5 Sec Interrupt

SCI

mode?

No

PD6 = Out; PD6 = 1

PD7 = In

PD7 = 1?

Yes

PD6 = 0

PD7 = 1?

No

STORAGE Set?

No

Normal mode

Yes

Terminal mode

No

Storage mode;

Set STORAGE

Yes

Yes

Enable SCI

Do connectivity test;

Reset STORAGE

Return

Return

No

Framing error?

Yes

Disable SCI

Return

Return

Figure 24. Flow chart of the Mode Check procedure.

37

Page 32

Wireless Sensor Interface A720 (addIT™)

More details on the functionality of each mode will be described when dealing with

the individual tasks.

4.3. A/D Task

This task is responsible for the actual sampling of the A/D inputs (where the sensors

are connected). In addition, the task is responsible for the power management of the

system: it checks the battery level and performs the following actions:

• Switches on and off the solar panel (that charges the battery), depending on

the battery state and internal temperature of the device;

• Brings the system in a low consumption mode if the battery is low;

• Switches the system off if the battery is in a misery state, in order to protect it.

Measure Battery

and Temperature

Yes

Batt

> 7.6 V?

No

Note: The thresholds shown are

for reference only; actually

they are computed based

on the SET PMP command.

Yes

Yes

Temp

> 20°C?

No

Temp

< -10°C?

No

Batt

> 7.3 V?

Yes Batt

No

> 7.0 V?

< 6.5 V?

< 5.5 V?

< 5.0 V?

Switch

Device Off

Batt

Batt

Batt

No

Yes

Yes

Yes

No

No

Yes

No

Switch Off

Exit

Switch On

Enter

Misery Mode

38

Figure 25. Power Management flow chart.

Page 33

The A/D task is not executed at each 0.5 seconds interval, but rather every 5 minutes

(default). This parameter can be user configured (it is stored in the EEPROM section).

After the sensors inputs are sampled their values are averaged and stored as a slot in

the EEPROM FIFO buffer, time stamped. The number of samples is by default 3, but

is user configurable (this parameter is stored in the EEPROM section). These parameters are defined and can be changed by the SET SLOT command (see also “Supported

Commands” on page 39).

A special method of averaging is used in order to deal with various sorts of sampled

values (e.g. wind direction). In addition, the pulse counters are stored in the EEPROM with the slot and cleared afterwards.

4.4. The Terminal Task

The terminal offers a minimum of commands needed to configure and administer

the device, like setting and reading parameters (time, frequency, sampling rate, etc.),

checking the radio subsystem (switch it in various modes – receive, transmit, etc.).

The device enters in terminal mode whenever the mode checking routine senses that

a serial cable is inserted in the

dition, in order to automatically exit this mode (see also “Mode Check” on page 36).

In the inset are depicted the connection pins on the POWER connector, where the serial cable is plugged.

The Terminal Task

POWER connector. Periodically, it checks for that con-

Note: The interface is TTL, not RS-232! An adapter cable provided by Adcon must be used.

4.4.1. Supported Commands

Following is a list of available commands and an explanation of their use (the commands are listed in upper case, but you can use lower case too, the device is not case

sensitive).

4.4.1.1. The SET Series of Commands

• SET OWNID nnnn – where nnnn is the Id number of the unit. The Id number

must be identical to the one written on the unit’s label.

• SET PMP bl bh – set the power management parameters. bl is the lower battery

level (the threshold where the charging of the battery will be switched on) and

bh is the higher battery level (the charging will be switched off). Both bl and bh

are expressed in volts x 10 (e.g. 72 means actually 7.2 V). Default values (factory programmed) are 65 and 72, meaning 6.5 and 7.2 volts respectively. Example:

— if you want to change the switch on threshold to 6.3 and the switch off

threshold to 7.0 volts, issue the command SET PMP 63 70.

• SET SLOT storage samples – configures the input sampling and storing intervals: storage represents the time (in seconds) elapsed between two slots stored

in the internal memory, while samples represents the numbers of samples used

39

Page 34

Wireless Sensor Interface A720 (addIT™)

to build the average that will be stored. The default storage is 900 (15 minutes)

and samples is 3 (3 samples per quarter of an hour). Example:

— if you want to sample the inputs (sensors) every minute and build an hourly average, issue the command SET SLOT 3600 60.

— if you want to sample the inputs once per hour and store the values as they

are, then the command SET SLOT 3600 1 will do the job.

In order to better understand the importance the samples parameter has, a table is

provided showing addIT’s expected operation time on a fully charged battery and a

50 mA total consumption for the sensors:

Radio activity

No No sensors 450 92

Yes No sensors 540 77

Yes 1 750 55

Yes 3 (default) 1080 38

Yes 5 1450 28

Yes 15 3100 13

Sensor sampling

(samples/15 min)

Average

consumption (µA)

Estimated

operation (days)

Note: Radio activity refers to the fact that one base station and between one and three A730MD sta-

tions/addITs are active on the same operating frequency as the addIT under test.

• SET BL ll ul – sets band limits; ll is the minimum allowable frequency, while ul

is the maximum allowable frequency. This command effectively limits the user’s possibility to change the device’s operating frequency and it can be used

to fulfill specific requirements existing in certain countries. Example:

— if the law in a country limits the operation of the device between 433.150

and 434.750 MHz, then the command is

SET BL 433150000 434750000.

— if the users are not allowed to change the frequency at all, then use the same

frequency for both ll and ul: SET BL 433925000 433925000.

Note: The SET BL command is not documented in the user manual.

• SET FREQ freq step – sets the unit’s operating frequency; freq is the frequency

and step is the channel spacing (both expressed in Herz). Example:

— suppose you want to change the frequency of an addIT to 467.1125 MHz

with a channel spacing of 12.5 kHz. After converting all the values to Hz, the

command to be used is SET FREQ 467112500 12500.

Note: The SET FREQ command may return an error if trying to program a frequency outside the

band limits; see SET BL command.

• SET RSSI value – set the Relative Signal Strength Indicator threshold. The factory default is set to 58 units. The RSSI threshold is used to detect if there is any

radio activity on the channel. The value set must be approximately 30% higher

than the actual measured value when no signal is present on the channel. To

measure the actual value use the command RSSI (explained later in this chapter). Example:

— to set the RSSI threshold to 55, use the command SET RSSI 55.

40

Page 35

The Radio Interface Task

Note: The values of RSSI have no units, they are arbitrary; however, a value of 85 corresponds more

or less to the maximum value in addVANTAGE, i.e. 8 µV.

4.4.1.2. Querying the Actual Configuration Parameters

You can query an addIT to find out its actual configuration parameters. Typing OWN-

ID, for instance will return the actual ID an addIT answers to (it should be the same

as the one on its label). In addition to OWNID, PMP, SLOT, BL, FREQ and RSSI, the command VER will return the current software version of the device.

The RSSI commands returns two values: the actual measured value of the RSSI and

the value set as threshold. As noted elsewhere, the threshold must be approximately

30% higher than the actual measured value. The actual RSSI is unstable due to the

channel’s random noise, receiver’s internal noise, and/or to transmissions just taking place. If the actual RSSI value is consistently higher than the programmed value,

something must be wrong, or the channel is very noisy (however, before re-adjusting

the RSSI threshold, check this with a handheld radio receiver or a scanner).

Other commands available in terminal mode are:

• DUMP addr – displays 256 bytes of the internal EEPROM memory, starting

with the address addr (specified as hex values). Valid addresses for the model

A720 are B600 to B9FF. The last 16 slots of data (for 15 minutes slots, that

makes 4 hours of data) are stored at B900 to B9FF. The remainder are used for

internal configuration parameters or reserved for future use.

• RX – switches the device to receive mode until a key is pressed. This command

is used for trimming or checking purposes.

• XMIT param – switches the device to transmit mode until a key is pressed;

param may be 0 – a 2 kHz tone will be modulated on the transmitted carrier, 1

– a 1 kHz tone will be modulated on the transmitted carrier, T – a mixture of

1 and 2 kHz test tones, or missing – an unmodulated carrier will be transmitted. This command is used for trimming or checking purposes.

• B – sends a broadcast frame and displays all the answers, with the RF levels

recorded for each received station.

4.5. The Radio Interface Task

The A720 is intended only as an end device in a radio network. Following frames are

recognized and serviced by an A720:

• PING – used to check if a device is alive; returns a PONG frame;

• REQUEST – returns a reduced data frame (DATA);

• RSETIO – switches the digital outputs and returns the digital inputs value;

• RDUMP – returns a dump of a block of memory;

41

Page 36

Wireless Sensor Interface A720 (addIT™)

• RSET – sets remotely certain parameters (id, frequency, slot, power management parameters).

Note: RSETIO frame is provided only for backwards compatibility with the A730MD. Better ways

to control the ports will be implemented at a later date.

The device will not recognize a broadcast frame and will not answer to such frames.

It will however send a broadcast and wait for answers in the Connectivity Check Mode,

or if a Broadcast command is issued at the terminal. Even if the device is not intended

to be used as a router, the current software version implements routing; due to power

consumption reasons, this mode of operation is not recommended.

Timeout Expired

Nhops + 1 s

Measure RF

Ack

Wait

and

Ack

No Ack

0.5 sec

Idle

Not for us

Check

Destination

Interrupt

No Signal

Measure RF

Header Detected

We are called

New Frame Possible

Request

Get Frame

Send

Answer

and Wait

for Ack

Ping

Etc.

Ack

Send

Pong

Answer

Appropriately

Figure 26. State Transition Diagram of the radio communication task.

No Ack

No Ack

Frame Sent Twice

Resend

Frame with

Long

Header

4.5.1. Digital Squelch

In order to reduce the power consumption during receive mode, the unit uses a protocol developed by Adcon Telemetry for the A730 family, but with some additional

refinements to further reduce the power consumption. The receiver is pulsed at a 0.5

seconds interval. At wake-up, the receiver samples first the RF channel for a carrier,

by measuring the RSSI. The RSSI output is extremely stable due to the wide dynamic

range that the IF chip exhibits (over 100 dB, temperature compensated). If the sam-

42

Page 37

pled RSSI is under a preset threshold, the unit will immediately go back to sleep. This

procedure needs under 20 mS, typically (from wake-up to the result).

If however, a RF level superior to the preset threshold is detected, the microprocessor

will try to detect a valid header, which is composed of a 2 kHz tone of at least 0.5 seconds long. The tone detection is performed by the microcontroller in software, and

takes at most 6 additional milliseconds. If no valid tone is detected, the unit goes

back to sleep, otherwise it tries to decode the frame.

Based on the destination ID, the frame will be identified. If it is not for that particular

unit (OWN ID), then the microcontroller will cease decoding it and will go immediately to sleep. The destination ID is situated very early in the frame header (see also

“Generic Format of a Radio Frame” on page 44).

From the above it becomes clear that in order to initiate a communication, a requester

must send first a header which is at least 0.5 seconds long: these are called long header

frames. Of course, after the communication is established the headers are short, of

only 16 bytes (i.e. 8 msec. – called short header frames). If a timeout occurs, the system

will restart by sending long header frames.

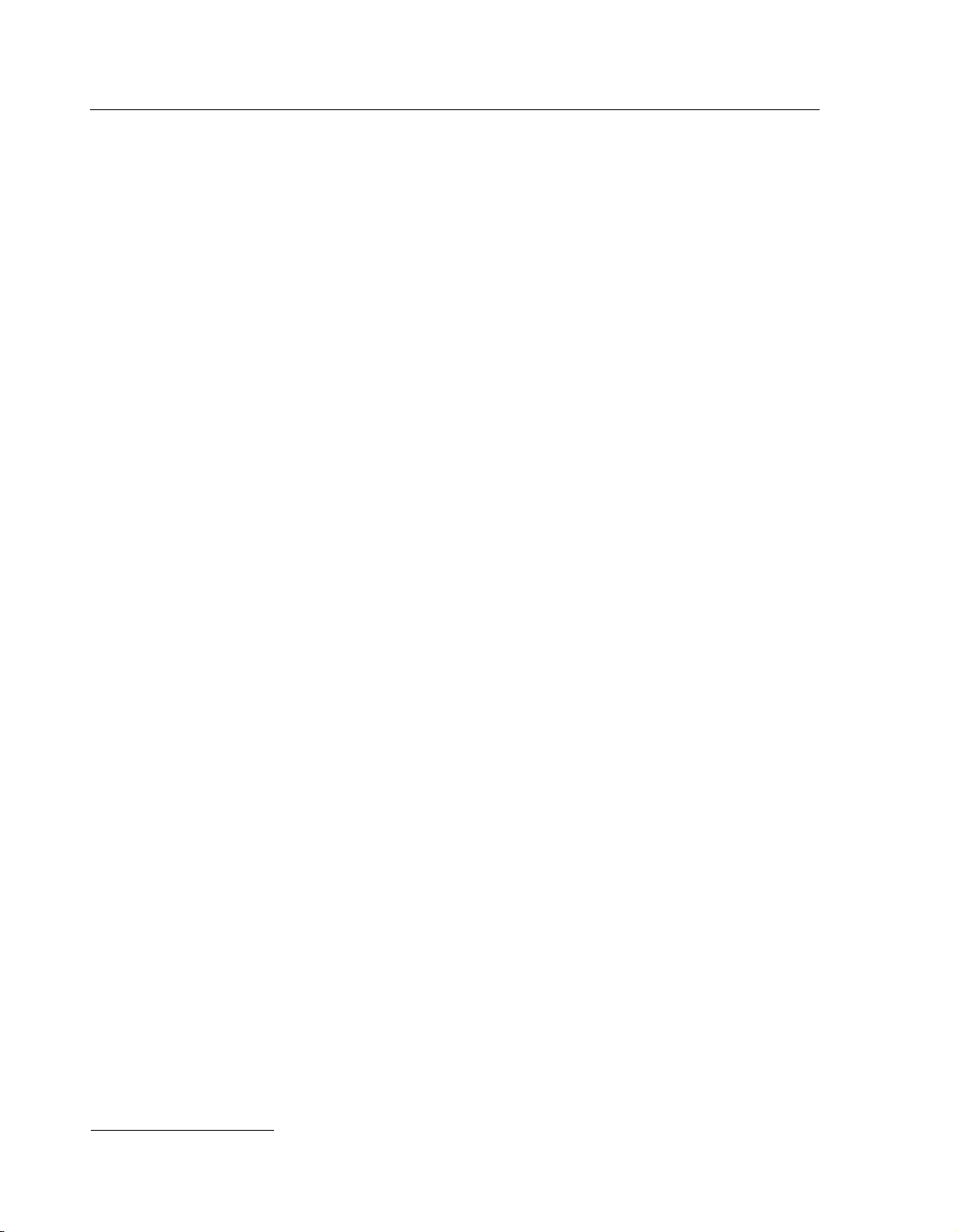

4.5.2. Modulation Technique Used

The Radio Interface Task

The communication via radio is made by using a special MSK (Minimum Shift Keying) scheme; both the encoding and the decoding of the MSK frames is made in software – there is virtually no hardware modem. A zero byte is transmitted as a

sequence of 250 µS one level followed by a 250 µs zero level, while a one byte is transmitted as a 500 µS one level followed by a 500 µS zero level. A complete sequence of

one and zero level forms a bit cell.

00

1

1

0

1

The modulation scheme is self-clocked. The transmission speed is content-dependent, varying from 1 kbps (when sending only ones) to 2 kbps (when sending only

zeroes). On the average, an 1500 bps transmission speed is reached.

The data interchange between stations is made by means of frames. The frames have

a header, a 16 bit-sync character a data block and a 16-bit CRC number. The bytes

forming the frame are send synchronously, with no start and/or stop bits. The data

block is assembled after the sync character was detected.

43

Page 38

Wireless Sensor Interface A720 (addIT™)

4.5.3. Generic Format of a Radio Frame

The standard frame format used by the A730 family (and therefore by the A720) is as

follows:

00 00

.......

00 0xAA DST-H DST-L SRC-H SRC-L DLEN

DATA1 D ATA2 DATAn CRC-H CRC-L

.......

Data Frame

• The frame starts with a header of zeroes; there are two header types: long and

short. The long headers are used to wake-up a remote station and must be 140

bytes long, while the short headers are only 16 bytes long.

• After the header, a synchronization character is used; this is a hex 0xAA byte.

The implementation must assure that a 16-bit sync character is checked, i.e.

0x00AA, and not only an 8-bit 0xAA character.

• Following the synchronization pattern, the bytes are assembled by shifting the

bits one by one: each 8 contiguous bits will be “cut” into a byte. First information assembled is the destination (DST) address: this is in order for all the receiving stations to know if they must assemble the whole frame, or they can

go back to sleep. Only the addressed station will remain active after this information was decoded.

Note: The byte ordering convention used on the network is “big endian”, i.e. the MSB is sent first

and the LSB last.

• Next are the source (SRC) address and the length of the data field. The data

field follows, and the frame is ended by a 16-bit CRC field. The CRC is computed starting with the first byte after the SYNC character until (but not including) the CRC bytes.

44

The data field can transport various type of data frames. After being successfully decoded and checked, these data frames are passed to the upper layer of the software.

The data frames recognized by the A720 and their answers are detailed in the next

chapter.

A device will answer to the requesting device with the answer frame. The answering

device will poll the radio channel for an acknowledge; the acknowledge may be either the same frame send further up the network (if the communication has hops, i.e.

routing stations in between the master and remote device), or an acknowledge send

by the master – the master sends only a short radio frame containing the SRC and DST,

both being its own Id. If the answering device does not receive the acknowledge, it

will repeat the frame after a one second delay (only once).

Another notable feature of the system is the way it handles the long and short header

frames. When a frame is send by the master for the first time, it will be a long header

one; all the stations on the path of the frame, participating in a certain transaction,

will relay the frame with a long header. After relaying the frame, the stations will remain active for a time calculated as (in seconds):

Delay Hops 1+=

Page 39

As long as another frame will follow in this time interval addressed to a station that

is known to be also active, the header sent to that station will be a short one.

4.5.4. Data Frames

The data frames are the blocks of data extracted from the radio frames, after the CRC

and other information (source address) was checked. The data frame as well as its

length are passed to the upper layers of the software.

The Radio Interface Task

TYPE HLEN SRC-H

Figure 27. Generic Data Frame structure.

SRC-L

HOP1-H HOP1-L HOPn-H HOPn-L DEST-LDEST-H DATA1 DATA2 DATAn

Header (Frame Type + Routing Information) Data

.......

.......

A data frame is composed of two main parts: a header, containing the frame type as

well as the routing information, and a data block. The length of the data block can be

easily computed by subtracting the header length (HLEN + 1 for the TYPE) from the

original data frame length received from the lower layer of software (the radio frame

length). Additional explanations on the notation used in the diagram:

• TYPE is the type of frame; the types recognized and/or used by the A720 will

be detailed individually later in this chapter.

• HLEN is the header length: it represents the number of bytes used to describe

the route the frame will go (or went). The maximum number of hops is 8, that

is, 8 intermediate stations plus source and destination. Each station is described by its unique 16-bit address.

• SRC, HOP and DEST, are the source, the hops and the destination addresses.

While the hops may be missing (no routing stations between source and destination), the source and destination are mandatory.

• DATA is the data proper field. It is limited in length, its maximum size being

dependent also on the particular route: if the route is longer (8 hops) then the

data block is limited to 48 bytes. Depending on the frame type, the data block

may be inexistent (zero length).

4.5.5. Frame Types

Although the original Adcon Radio Protocol contains many frame types, only those

relevant (recognized and /or used) to the A720 will be presented here.

4.5.5.1. Request

ID 1

FORMAT struct {

time_t init_time;

time_t req_time;

45

Page 40

Wireless Sensor Interface A720 (addIT™)

} request;

DESCRIPTION

The Request frame is used by a master to request data frames from a remote station.

A remote will answer with a data frame (there are currently two types of data frames:

normal and reduced – the A720 answers with the reduced type – see also “Data” on

page 49).

• init_time represents the actual type to be used by the remote to re-initialize

its local RTC; if its value is time_t NULL (default), then no re-initalization will

be performed;

• req_time is the time for requested data. A remote will search its internal data

buffer for data which has a time stamp that is strictly newer than req_time.

Therefore, if a master will request data with exactly the time stamp previously

supplied by the remote, the later must deliver a newer data slot. If the requested data is too old, the remote will send its oldest data, while if the requested

data is too new, the remote will answer with the newest data it has.

4.5.5.2. Broadcast Answer

ID 2

FORMAT struct {

unsigned char RF_levelOut;

} broadcast_answer;

DESCRIPTION

This is the answer to a broadcast request frame; the RF_levelOut is the level recorded

by the device when receiving the broadcast request frame. An A720 will never send

such frames, but will receive and interpret them depending on the mode it was when

it issued the broadcast request frame (see also “Broadcast Request” on page 47). In

terminal mode, all the broadcast answers will be displayed with their RF levels,

while in connectivity check mode, the LED tool will be activated. This frame is not

routable.

4.5.5.3. Set I/O Request

ID 3

FORMAT struct {

} setio_request;

DESCRIPTION

This frame is issued by a master and instructs a remote device to switch its ports to

a certain state, as follows:

• DDR specifies if a port will be set as input or as output; if the corresponding bit

is a one, that port will be set as output;

• PORT is evaluated only for the bits set as outputs; it will set or reset the respective port according to its value in PORT.

The device will answer with the Read I/O frame.

46

unsigned char DDR;

unsigned char PORT;

Page 41

4.5.5.4. Read I/O Answer

ID 4

FORMAT struct {

unsigned char RF_levelIn;

unsigned char RF_levelOut;

unsigned char DDR;

unsigned char PORT;

} readio_answer;

The Radio Interface Task

DESCRIPTION

This is the answer to a Set I/O request frame. It returns the actual state of the port

and its data direction register.

4.5.5.5. Broadcast Request

ID 6

FORMAT The data frame body is empty.

DESCRIPTION This frame is send by the device when the LED tool is inserted in the POWER connec-

tor, or if the command “B” is issued in terminal mode. This frame is special in that

the destination address (DST) in the header is 0. In addition, this type of frame is not

routable. All the devices having received this frame must reply in a random fashion

with a Broadcast answer frame.

4.5.5.6. Ping

ID 9

FORMAT The data frame body is empty.

DESCRIPTION This frame is used to request an answer from a device; it is used to check if the device

is available. The addressed device must answer with a Pong frame. The A720 does

not send such frames, but must answer to them.

4.5.5.7. Pong

ID 10

FORMAT struct {

} pong;

unsigned char RF_levelIn;

unsigned char RF_levelOut;

time_t RTC;

unsigned char version;

unsigned char clkfail;

unsigned char stackfail;

unsigned char WDT;

unsigned char batt;

unsigned char internalTemp;

time_t uptime;

unsigned char reserved[4];

47

Page 42

Wireless Sensor Interface A720 (addIT™)

DESCRIPTION The Pong frame is an answer to the Ping frame. In addition to inform a caller that a

remote is active, it carries some useful information about the device’s status:

• RF_levelIn is the left zero (it is a placeholder and will be filled by the first device receiving the frame);

• RF_levelOut is the RF level measured by the device when receiving the Ping

frame;

• RTC is the actual value of the remote’s Real Time Clock;

• version is the software/hardware version of the device;

• clkfail and stackfail are meaningless for an A720 – they are kept due to historical reasons;

• WDT is a counter incremented each time the device was reset due to a Watchdog

timeout;

• batt is the battery voltage (this value will be also found in the Data frame);

• internalTemp is the temperature in the A720 housing; the precision of the

sensing element is very low (±4C°), but it is sufficient for battery power management (charge/discharge). To compute the actual value (in C°), the following equation must be used:

1087

----------- -

Temp internalTemp

· 275–=

255

• uptime is the time elapsed since the last reset (including a Watchdog reset);

• reserved – these bytes are reserved for future use.

Note: Some of the values send in the Pong frame are specific to the A720 only.

4.5.5.8. Memory Dump Request

ID 20

FORMAT struct {

unsigned int startAddress;

unsigned char length;

} memoryDump_request;

DESCRIPTION

This frame requests a remote to return a number of length bytes, starting from its internal address startAddress. In general, the useful addresses are located at address

0xB600. An A720 will not issue such frames, but answers to them using the Memory

dump answer frame. The length parameter is limited to the amount of memory

available, therefore if more bytes are requested than a device can cope with, the maximum possible will be sent (depending on the memory availability). However, an

A720 will send always a fixed amount of bytes, that is 32.

48

Page 43

4.5.5.9. Memory Dump Answer

ID 21

FORMAT struct {

unsigned int startAddress;

unsigned char 32;

unsigned char data[32];

} memoryDump_answer;

The Radio Interface Task

DESCRIPTION

This is the answer to a Memory dump request frame; although the frame has a flexible format, an A720 will always return 32 bytes of data.

4.5.5.10. Data

ID 38

FORMAT struct {

} data_frame;

DESCRIPTION

This frame will be sent back by the device as an answer to the Request frame.

• RF_levelIn is the left zero (it is a placeholder and will be filled by the first device receiving the frame);

unsigned char RF_levelIn;

unsigned char RF_levelOut;

time_t slot_timeStamp;

unsigned char digibyte;

unsigned char counter1; /* Pulse Counter I/O B input */

unsigned char counter2; /* Pulse Counter I/O A input */

unsigned char battery;

unsigned char analog0; /* I/O B input, pin x */

unsigned char analog1; /* I/O B input, pin x */

unsigned char analog2; /* I/O B input, pin x */

unsigned char analog4; /* I/O A input, pin x */

unsigned char analog5; /* I/O A input, pin x */

unsigned char analog6; /* I/O A input, pin x */

unsigned char internalTemp; /* Internal Temperature */

• RF_levelOut is the RF level measured by the device on the Request frame;

• slot_timeStamp is the actual time stamp on the data sent;

• digibyte represents the result of OR-ing the following bits:

b7

RB7 u u RB6 RD2 RD1 RD0

RD7

b0

— RD7 represents the battery charge switch’ status;

— u means undefined;

— RD2, RD1 and RD0 are the DIG2, DIG1 and DIG0 pins respectively.

Note: For additional info on the bits in the digibyte, check also the hardware section of this manual.

• counter1 and counter2 are the values of the pulse counters;

49

Page 44

Wireless Sensor Interface A720 (addIT™)

• analog0 to analog2 and analog4 to analog6 are the values returned by the internal A/D converter from the respective connectors (see the hardware section for more details).

• internalTemp is the temperature in the A720 housing (it’s the same value

transmitted with a Pong frame – see “Pong” on page 47 for more details).

4.5.5.11. Set ID

ID 40

FORMAT struct {

unsigned int ID;

} setId;

DESCRIPTION

This frame requests a remote to change its own Id number. The remote will answer

with a General acknowledge frame before changing its Id. An A720 will never issue

this frame type, but it will answer to it.

4.5.5.12. Set Slot Time and Sample Rate

ID 41

FORMAT struct {

unsigned int slot;

unsigned char rate;

} setSlot;

DESCRIPTION

This frame requests a remote to change the size of its slot (default 900 seconds, i.e. 15

minutes) and the sampling rate (default 3).

• slot is the number of seconds a new slot of sampled and averaged data will

be stored in the internal memory FIFO of the device;

• rate is the number of samples per slot taken; these samples will be averaged

before being stored.

The remote will answer with a General acknowledge frame. An A720 will never issue

this frame type, but it will answer to it.

4.5.5.13. Set Frequency

ID 42

FORMAT struct {

} setFreq;

DESCRIPTION

This frame requests a remote to change its frequency. The remote will answer with a

General acknowledge frame before changing its operating frequency. To further secure the transaction, the frequency change will be performed only after the remote

receives the acknowledge frame from its next neighbor (for more details, see also

50

unsigned long frequency;

unsigned int step;

Page 45

“Generic Format of a Radio Frame” on page 44). An A720 will never issue this frame

type, but it will answer to it.

4.5.5.14. Set Battery Charge Levels

ID 43

FORMAT struct {

unsigned char chargeStart;

unsigned char chargeStop;

} setBattCharge;

The Radio Interface Task

DESCRIPTION

This frame requests a remote to change the battery charge management parameters.

The device will answer with a General acknowledge frame. An A720 will not issue

such a frame, but it will answer to it.

• chargeStart is the value where the external power (normally a solar panel)

will be enabled to charge the battery;

• chargeStop is the value where the external power will be switched off.

From the above two values, the system will compute all other limits (e.g. misery, battery low, etc.).

4.5.5.15. Set Pulse Counters Parameters

ID 44

FORMAT

DESCRIPTION

This frame will set the trigger level and the delay of the pulse counters of a remote.

The device will answer with a General acknowledge frame. An A720 will not issue

such a frame, but will answer to it.

Note: The format and description of this frame must be detailed later; it is not yet implemented.

4.5.5.16. General Acknowledge

ID 127

FORMAT struct {

} generalAck;

DESCRIPTION

This frame is sent as an acknowledge to various Set type of frames. The result field

is NULL if the request was successfully performed; in case of failure, this field may

contain information on the cause of the failure. Its value will depend from the type

of request requested.

int result;

51

Loading...

Loading...