Page 1

HiGain® Managed Shelf

19-inch, 3190 Mechanic, 22-Slot Managed

CO Shelf (HMS-318 List 3)

User Manual

CLEI:

Product Catalog:

Document Number:

T1MF2S04RA

HMS-318 List 3

LTPH-UM-1261-01

Page 2

REVISION HISTORY

The Revision History provides a summary of any changes in this manual. Please make sure you are using the

latest revision of this manual.

December 20, 2004

Revision Release Date Revisions Made

01 December 20, 2004 Initial Release

This manual is available online at ADC’s website (www.adc.com/documentationlibrary/) or you can order copies

of the manual by contacting your sales representative. Please ask for document LTPH-UM-1261-01.

Copyright

©2004 ADC Telecommunications, Inc. All rights reserved.

Trademark Information

ADC is a registered trademark of ADC T e lecommunications, Inc. LoopS t ar is a trademark of ADC Telecommunications, Inc.

No right, license, or interest to such trademarks is granted hereunder, and you agree that no such right, license, or interest

shall be asserted by you with respect to such trademark.

Other product names mentioned in this practice are used for identification purposes only and may be trademarks or registered trademarks of their respective companies.

Disclaimer of Liability

Information contained in this document is company private to ADC Telecommunications, Inc., and shall not be modified,

used, copied, reproduced or disclosed in whole or in part without the written consent of ADC.

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice.

In no event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits, and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar dama ges. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

Page 3

Table of Contents

About This Manual ..........................................................................................................ix

Introduction ...............................................................................................................................ix

Audience ...................................................................................................................................ix

Related Publications .................................................................................................................ix

Organization ..............................................................................................................................ix

Conventions ...............................................................................................................................x

EU Compliance .........................................................................................................................xi

Safety Guidelines ......................................................................................................................xi

Inspecting Your Shipment ........................................................................................................xii

Chapter 1: Product Description .................................................................................... 1-1

Typical HMS-318 List 3 Shelf Applications .............................................................................. 1-2

Power and Alarm Connections ................................................................................................. 1-5

Connecting to HDSL, HDSL2, and HDSL4 Circuits ................................................................. 1-8

Connecting Sp a n Po wered xDSL Circuits to the HMS-318 List 3 Shelf ................................1-10

RS-232/X.25 Remote Management Ports ............................................................................. 1-12

Ethernet Remote Management Ports .................................................................................... 1-13

Heat Dissipation Factors ........................................................................................................ 1-13

Air Flow Guidelines ................................................................................................................ 1-15

Chapter 2: Installation .................................................................................................... 2-1

Before You begin ...................................................................................................................... 2-1

Safety Guidelines .....................................................................................................................2-4

Mounting the HMS-318 List 3 Shelf ......................................................................................... 2-4

DSX-1 and HDSLx Connections ..............................................................................................2-7

Sp a n Po wered xDSL Conne ctions ........................................................................................... 2-8

Bonding (Safety) Ground, Power and Frame Ground, Alarm, and Optional Fan Inputs ......... 2-9

Installing the HMU-319 with HLU-319, H2TU-C-319, H4TU-C-319 .......................................2-13

Installing LPS-300C Power Module ....................................................................................... 2-13

Appendix A: Signal and Pin Assignments .................................................................A-1

Appendix B: Standard PIC Color Code ......................................................................B-1

Appendix C: Circuit Card Preventive Measures ........................................................C-1

Handling Circuit Cards .............................................................................................................C-1

Storing Circuit Cards ................................................................................................................C-1

Installation/Replacement ..........................................................................................................C-1

Appendix D: Specifications .........................................................................................D-1

Appendix E: Product Support .....................................................................................E-1

Glossary ......................................................................................................................GL-1

LTPH-UM-1261-01 iii

Page 4

Table of Contents December 20, 2004

iv LTPH-UM-1261-01

Page 5

List of Figures

Figure 1-1. HMS-318 List 3 Shelf - Front View ......................................................... ..........1-2

Figure 1-2. HMS-318 List 3 Shelf - Rear View ....................................................................1-3

Figure 1-3. Input Power Terminal Block (TB1) ....................................................................1-5

Figure 1-4. Alarms Wire-Wrap Field (TB2) ............................................................... ..........1-6

Figure 1-5. HLU Slot Wire-wrap Pinouts for HDSL Circuits ................................................ 1-9

Figure 1-6. HLU Slot Wire-wrap Pinouts for HDSL2 Circuits .............................................. 1-9

Figure 1-7. HLU Slot Wire-wrap Pinouts for HDSL4 Circuits ............................................1-10

Figure 1-8. HLU Slot Wire-wrap Pinouts for Span Powered xDSL ................................... 1-11

Figure 1-9. HMS-318 List 3 Shelf RS-232/X.25 Remote Management Ports ..................1-12

Figure 1-10.Multishelf Network Ports ........................................................... .............. ........1-13

Figure 1-11.Central Office Equipment Rack Configuration ................................................1-14

Figure 2-1. Grounding Lug ................................................................................................2-10

Figure 2-2. Input Power Terminal Block (TB1) .................................................................. 2-11

Figure 2-3. Alarms Wire-wrap Field (TB2) ........................................................................2-12

LTPH-UM-1261-01 v

Page 6

List of Figures December 20, 2004

vi LTPH-UM-1261-01

Page 7

List of Tables

Table 1-1.HMS-318 List 3 Shelf Rear-Panel Connections (LPS-300C) ..............................1-4

Table 1-2.Alarms Wire-wrap Field Functional Description ..................................................1-7

Table 1-3.J26 – RS-232/X.25 Management Port (DTE) ...................................................1-12

Table 1-4.J27 – AUX RS-232 Management Port (DTE) ...................................................1-13

Table 2-1.HMS-318 List 3 Shelf Parts List ..........................................................................2-2

Table A-1.P1-DSX-1 Receive or Span Powered xDSL B IN, Tip and Ring .........................A-1

Table A-2.P2-DSX-1 Transmit or Span Powered xDSL A IN, Tip and Ring ............ ............A-2

Table A-3.P3-HDSL Span 1 or Span Powered xDSL A OUT, Tip and Ring ........................A-4

Table A-4.P3-HDSL Span 1 or Span Powered xDSL A OUT, Tip and Ring ........................A-5

Table B-1.Standard PIC Color Code ....................................................................................B-1

LTPH-UM-1261-01 vii

Page 8

List of Tables December 20, 2004

viii LTPH-UM-1261-01

Page 9

ABOUT THIS MANUAL

INTRODUCTION

This manual provides essential information about the HiGain® Management Shelf (HMS-318 List 3) along with stepby-step instructions on how to install the shelf into a Central Office (CO) or telco-style equipment rack.

AUDIENCE

This manual is written for people who install and plan the installation of ADC products in a Central Of fice

environment. If you are an installer, technician, or a local craft person, this manual contains in formation you ca n use

to install the HMS-318 List 3 shelf. It also provides information that can help you plan and make decisions about

your installation.

This manual is also appropriate for managers and planners who are thinking about inst alling HMS-318 List 3 shelves

into a CO or telco-style equipment rack, as well as people who are interested in the HMS-318 List 3 shelf in general .

This manual is written with the assumption that you are familiar with ADC equipment shelves or equivalent hardware

and cabling, electronic circuitry, and wiring practices.

RELATED PUBLICATIONS

Listed below are related ADC publications and their document catalog numbers. These document s pr ovide

supplementary information for the HMS-318 List 3 Shelf User Manu al. Copies of these manuals are available online

at ADC’s web site at www .adc.com/documentationlibrary/

your sales representative.

or you can order copies of these documents by contacting

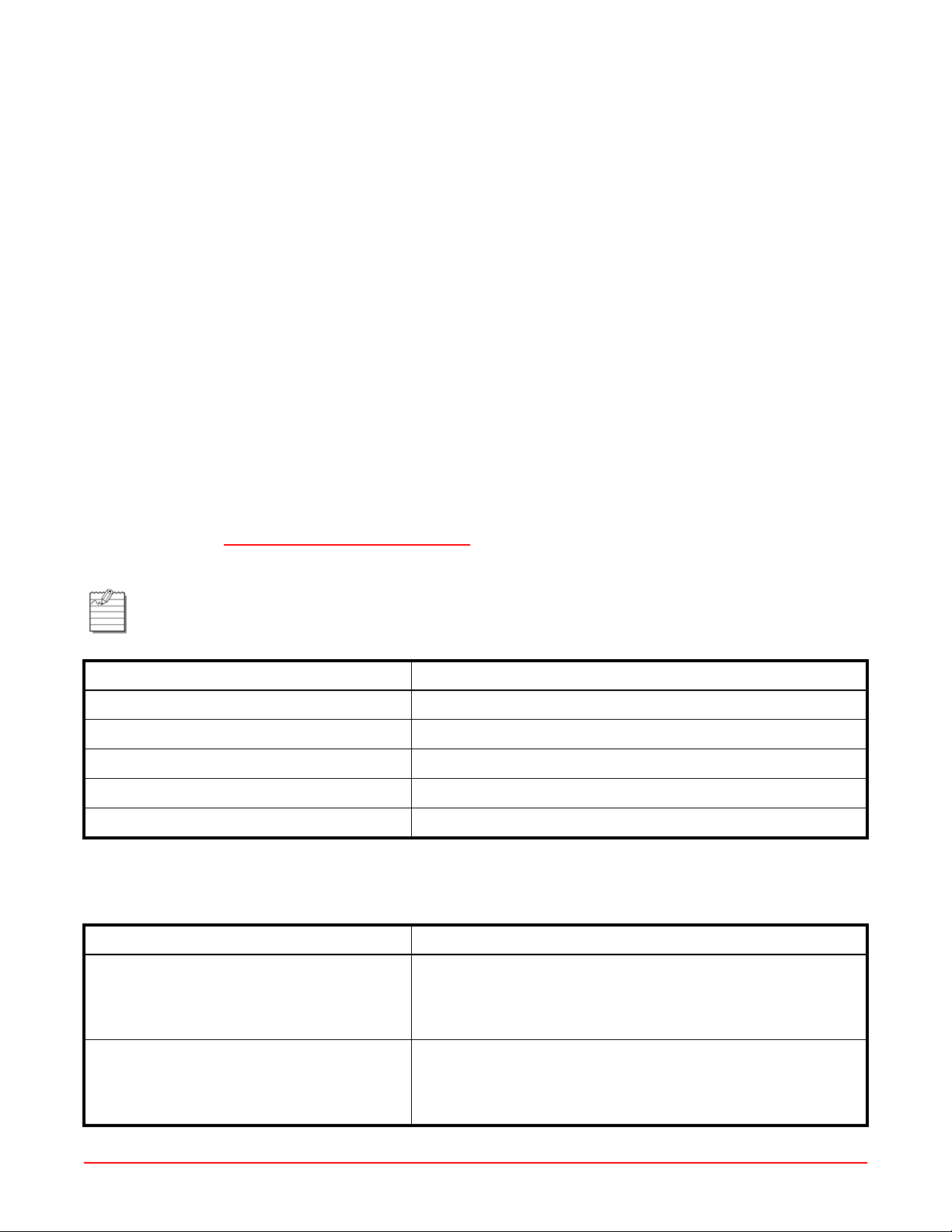

Note: The list of related publications is not all-inclusive. It is only a representative sampling of the instruction

manuals that are available. Depending on your particular product model and List number, refer to that

instruction manual for proper installation and provisioning information.

Catalog Number Title

350-319-105 HLU-319 List 5 Quick Installation Guide

LTPH-UM-1182 H2TU-C-319 List 7 User Manual

LTPH-QI-1032 H4TU-C-319 List 1 Quick Installation Guide

LTPH-UM-1142 HMU-319 L7AV32 and L9V32 User Manual

SCP-LPS300-010 LoopStar LPS-300C L1 Power Module Technical Practice

ORGANIZATION

This manual includes the following chapters:

Chapter Description

Chapter 1: Product Description Summarizes the HMS-318 List 3 configuration, including details

on power and alarm connections, connecting to HDSL, HDSL2,

HDSL4 and xDSL circuits, and remote management via RS-232

and Ethernet interfaces.

Chapter 2: Installation Provides installation instructions for mounting the shelf,

connecting DSX/HDSL/xDSL connections, grounding the shelf ,

and installing the HMU-319, HLU-319, H2TU-C-319,

H4TU-C-319, and LPS-300C power module, as necessary.

LTPH-UM-1261-01 ix

Page 10

About This Manual December 20, 2004

Chapter Description

Appendix A: Signal and Pin Assignments Lists Tip and Ring signal and pin assignments to the HMS-318

List 3 shelf, including:

• P1-DSX-1 Receive or xDSL B IN, Tip and Ring

• P2-DSX-1 Transmit or xDSL A IN, Tip and Ring

• P3-HDSL Span 1 or xDSL A OUT, Tip and Ring

• P4-HDSL Span 2 or xDSL B OUT, Tip and Ring

Appendix B: Standard PIC Color Code Lists the standard PIC color codes with the Pair Number cross-

referenced with the colors of the Tip and Ring wires used by the

installer.

Appendix C: Circuit Card Preventive

Measures

Appendix D: Specifications Provides power requirements, physical dimensions,

Appendix E: Product Support Provides information on how to contact the ADC Technical

Glossary Defines abbreviations and acronyms used in this document and

Describes the preventive measures that should be observed

when using the shelf, including:

• Handling and storing of circuit cards

• Installing/replacing circuit cards sensitive to static electricity

recommended operational and storage environments, and

accessories for the HMS-318 List 3 shelf.

Support group.

that relate to the HMS-318 List 3 shelf.

CONVENTIONS

The following style conventions and terminology are used throughout this guide.

Element Meaning

Bold font Text that you must input exactly as shown (e.g., type 1 for card 1), menu buttons

(e.g., ACCEPT SHELF OPTIONS) or menu screen options (e.g., ALARMS screen) that

you must select

Italic font Variables that you must determine before inputting the correct value (e.g., Password )

Monospace font References to screen prompts (e.g., Invalid Password...Try Again:.)

Reader Alert Meaning

Alerts you to supplementary information

IMPORTANT

Alerts you to supplementary information that is essential to the completion of a task

!

Alerts you to possible equipment damage from electrostatic discharge

ATTENTION

x LTPH-UM-1261-01

Page 11

December 20, 2004 About This Manual

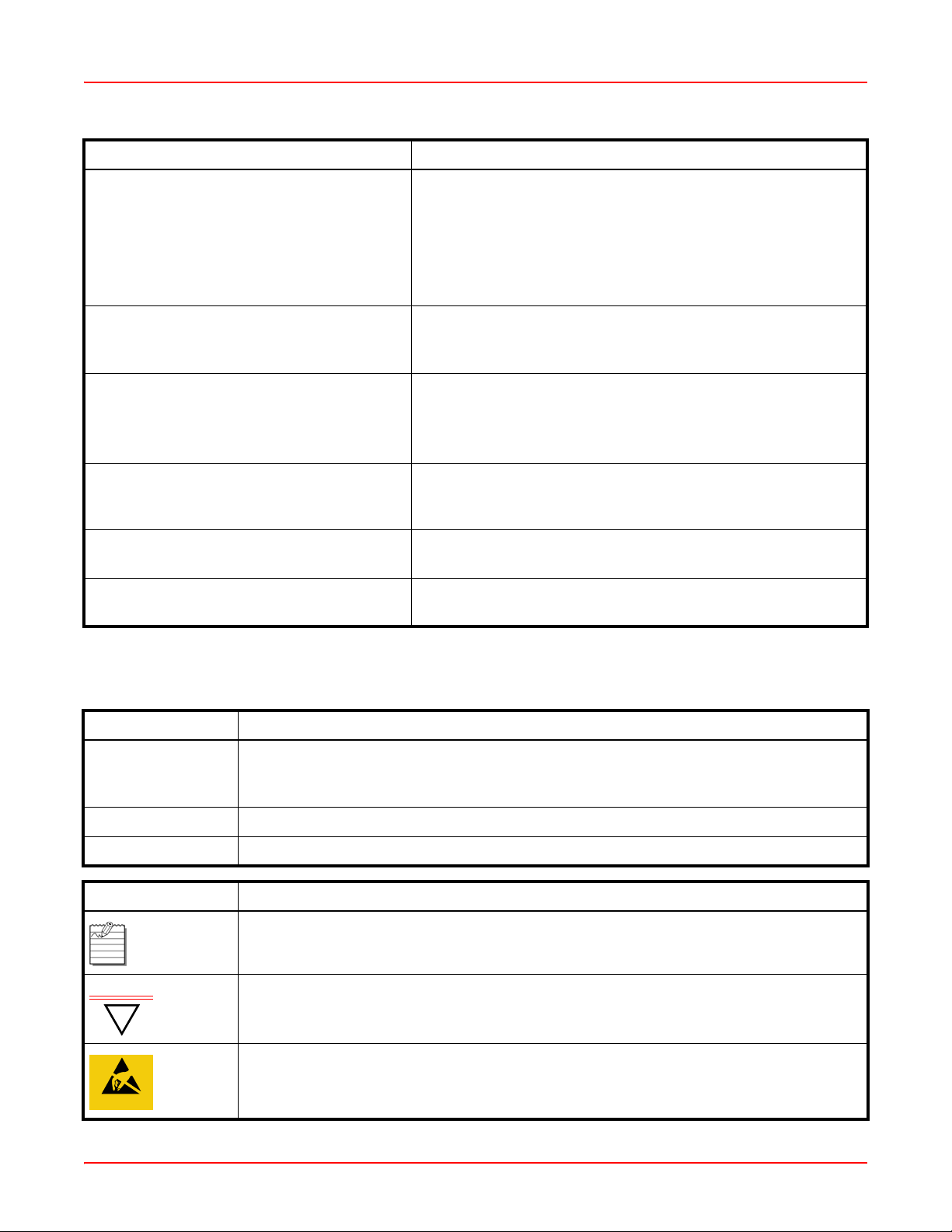

Reader Alert Meaning

CAUTION

Alerts you to possible data loss, service-affecting procedures, or other similar type

problems

WARNING

DANGER

Alerts you that failure to take or avoid a specific action might result in hardware damage or

loss of service

Alerts you that failure to take or avoid a specific action might result in personal harm

EU COMPLIANCE

The product complies with the requirements of the Low Voltage Directive 73/23/EEC, EMC Directive 89/336/EEC,

and the R&TTE Directive 1999/5/EC Articles 3.1a and 3.1b.

SAFETY GUIDELINES

The following safety guidelines are presented to help you avoid injury to yourself and avoid damage to the

equipment. These guidelines are recommended when working with any equipment that connect s to electrical power

or telco wiring.

• Locate the emergency power-off switch for the area in which you are working before beginning any procedures requiring access to the telco-style equipment rack. Then, if an electrical accident occurs, you can

quickly shut off the power.

• Disconnect all power before doing the following:

– Installing or removing the shelf

– Working near power supplies

• Never work alone if potentially hazardous conditions exist.

• Never assume that power has been disconnected from a circuit; always check.

• Never perform any action that creates a potential hazard to people or makes the equipment unsafe.

• Carefully examine your work area for possible hazards, such as moist floors, ungrounded power extension

cables, and missing safety grounds.

• Keep the work area free of obstructions before, during , and after shelf installation.

• If an electrical accident occurs, proceed as follows:

– Use caution; do not become a victim yourself.

– Turn power off to the telco-style rack that the shelf is located in.

– If possible, send another person to get medical aid. Otherwise, determine the condition of the victim and

then call for help.

– Determine if the victim needs rescue breathing or external cardiac compressions; then take appropriate

action.

• Circuit Overloading - Consideration should be given to the connection of the equipment to the supply circuit

and the effect that overloading of the circuits might have on overcurrent protection and supply wiring. Appropriate consideration of equipment nameplate ratings should be used when addressing this concern.

• Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained. Particular attention

should be given to supply connections other than direct connections to the branch circuit (e.g., use of power

strips).

• The following precautions may appear in this manual in procedures that, if performed incorrectly, may harm

you or your equipment.

LTPH-UM-1261-01 xi

Page 12

About This Manual December 20, 2004

DANGER

To prevent electrical shock, be careful whe n working near HDSL loops and telecommunications

circuits. Coming in contact with high electrical potential will result in death or severe personal

injury.

IMPORTANT

!

DANGER

The shelf chassis must be properly grounded to ensure personal and equipment safety.

To prevent electrical shock, never install telco equipment in a wet location or during a lightning

storm. When installing or modifying telco lines, disconnect lines on the network side before

working with uninsulated lines or terminals.

DANGER

To prevent electrical shock, be careful when wor king near power supplies. Telco equipment uses

-48 Vdc office power.

Electronic components can be damaged by electrostatic discharge (ESD). Before handling circuit

cards, wear an antistatic discharge wrist strap to prevent damage to electronic components.

ATTENTION

Place components in static-shielding protective bags when transporting or storing. When

working on components, always place them on an approved antistatic mat that is electrically

grounded.

INSPECTING YOUR SHIPMENT

Upon receipt of the equipment:

• Unpack each container and visually inspect the contents for signs of damage. If the equipment has been damaged in transit, immediately report the extent of damage to the transportation company and to ADC. Order

replacement equipment, if necessary.

• Check the packing list to ensure complete and accurate shipment of each listed item. If the shipment is short

or irregular, contact ADC as described in Appendix E: Product Support on page E-1. If you must store the

equipment for a prolonged period, store the equipment in its original co ntainer.

xii LTPH-UM-1261-01

Page 13

Chapter

1

PRODUCT DESCRIPTION

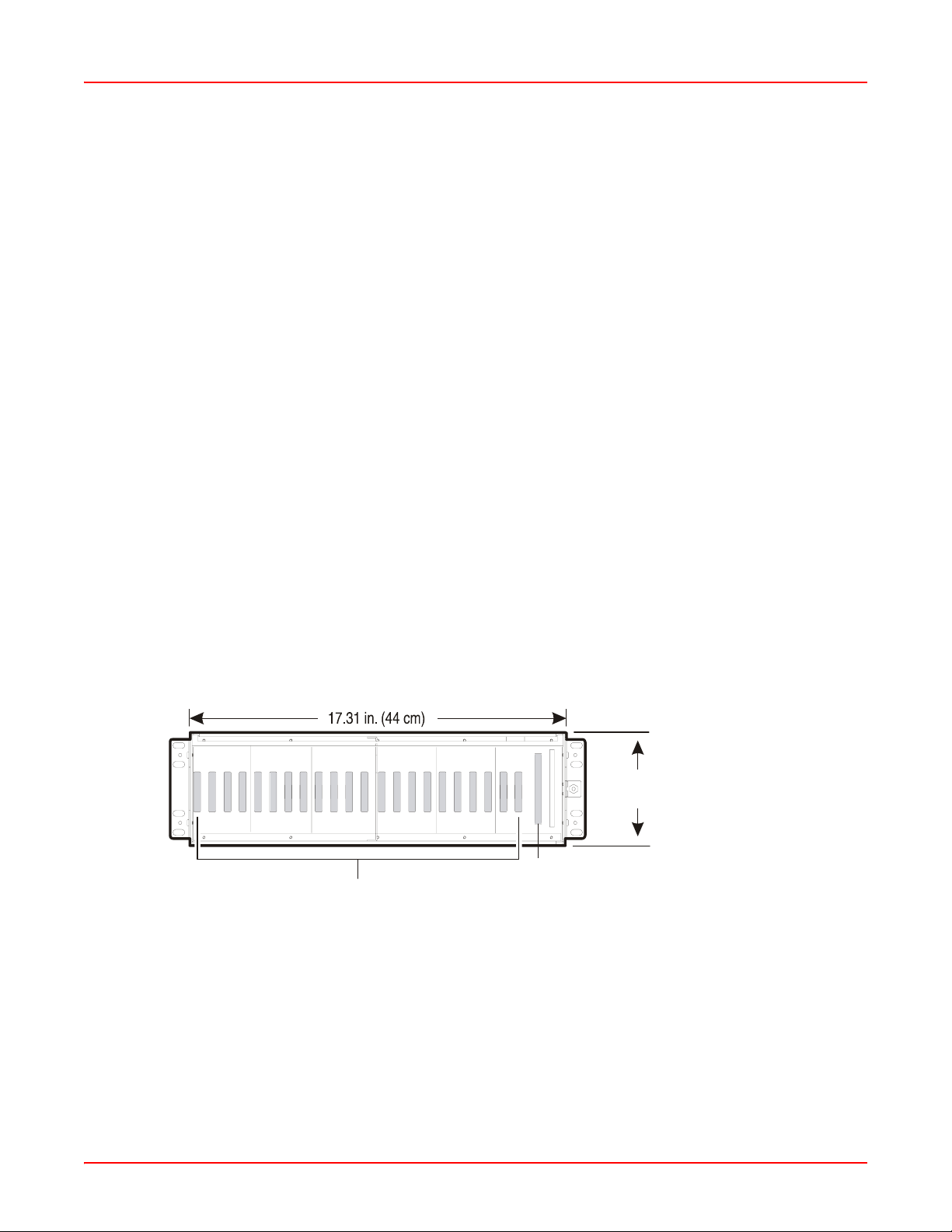

The HMS-318 L3 is a 22-slot, 3190 mechanics shelf that is capable of being managed locally or remotely. It can be

mounted in a 19-inch rack and is fully NEBS 3 and UL-60950 complaint.

®

The ADC HiGain

in. wide x 5.22 in. high x 12 in. deep (43.9 cm x 13.3 cm x 30.5 cm). These dimensions do not include the mounting

brackets that are factory-installed to the shelf.

The HMS-318 List 3 shelf can be mounted in three different types of rack mount configurations:

• A standard (EIA or WECO) 19-inch (48.3-cm) Central Office (CO) or telco-style equipment rack (using the

mounting rack adapter brackets provided). These brackets can be positioned for either 2- or 5-inch recess.

• A standard (EIA or WECO) 23-inch (58.4-cm) Central Office (CO) or telco-style equipment rack (using the

optional Extender Bracket: EB-52). These brackets can be positioned for either 2- or 5-inch recess.

• A European Telecommunications Standards Institute (ETSI) telco-style rack mounting (using ETSI mounting

adapter brackets and hardware provided).

The HMS-318 List 3 shelf supports:

• 1.544 Mbps (T1) full-duplex transmission over two uncondition ed, non-load ed copper loops

• DSX-1 interfaces at the CO and the remote end, with remote provisioning and performance monitoring

• CO power modules (LPS-300C) which provide xDSL span powering to ADC’s LoopStar

(AP) solution.

The HMS-318 List 3 shelf is shipped with:

• Adjustable mounting brackets ( as described above) that allow the shelf to be positio ned in the equipment r ack to

match the recess of the existing equipment (either 2- or 5-inch mounting).

• HMS-318 List 3 Shelf Rack Mounting Kit:

– 3 x 5 inch label holder (1)

– Label, HMS-318 (1)

– BNC-T female connector (1) – used with 10 BASE-2 managed systems

– 50-ohm BNC terminator (1) – used with 10BASE-2 managed systems

– #12-24 x .5 inch mounting screws (4).

• ETSI mounting hardware:

– #6-32 x 0.250 inch mounting Phillips head screws w/lock washer (8)

– M6-1.0 x14 mm mounting panhead screws (4)

• Shelf grounding kit:

– #10-32 x .5 inch mounting Hex screw w/washer (1)

– Ring terminal stud, taped 12-10 AWG (1)

– ground jumper, 2-position (1)

– Cable ties (10)

• ETSI mounting brackets (2)

• This instruction manual, HiGain Management Shelf (HMS-318 List 3) User Manual, catalog number

LTPH-UM-1261.

The following optional accessories are available:

• Extender Bracket Kit, 5.25 inches high for mounting a shelf into a 23-inch (58.4-cm) telco-style equ ip ment rack

Management Shelf (HMS-318 List 3) weighs approximately 17 pounds (7.7 kg). It measures 17.3

™

Wi-Fi® Access Point

LTPH-UM-1261-01 1-1

Page 14

Chapter 1: Product Description December 20, 2004

y

A

R

TYPICAL HMS-318 LIST 3 SHELF APPLICATIONS

Capable of using various components in different types of applications, the HMS-318 List 3 shelf is designed as a

very adaptable shelf. It can be used in the following applications:

• Managed HDSLx configuration - HMU-319 (HiGain Manag ement Unit) with HLU-3 19, H2TU-C-319, or H4TU-C319 (HiGain Line Unit) configuration

• LoopS tar™ (LPS-300C) Power Module configuration (for Wi-Fi)

The HMU-319 with HLU-319/H2TU-C-319/H4TU-C-319 use 23 slots in the HMS-318 List 3 shelf. The first 22 slots

are for the HLU-319/H2TU-C-319/H4TU-C-319 and the 23rd slot is for the HMU-3 19 (for in for matio n about

installation and provisioning, see “Installing the HMU-319 with HLU-319, H2TU-C-319, H4TU-C-319” on page 2-13

and refer to “Related Publications” on pageix).

The LPS-300C Power Module configuration is a double-wid th module th at su ppor ts two Span Powered xDSL or

ADSL pairs per module and is used as an integral part of the LoopStar Wi-Fi span powered Access Point (AP)

solution. A total of 11 LPS-300C modules can be installed in the UL-60950 compliant HMS-318 List 3 po wer shelf for

a total of 22 span powered pairs (for infor mation about inst allation and provisioning, see “Installing LPS-300 C Power

Module” on page 2-13 and refer to “Related Publications” on page ix).

The following front and rear views show the HMS-318 List 3 shelf using the HMU-319 and HLU-319 configuration

and the LPS-300C.

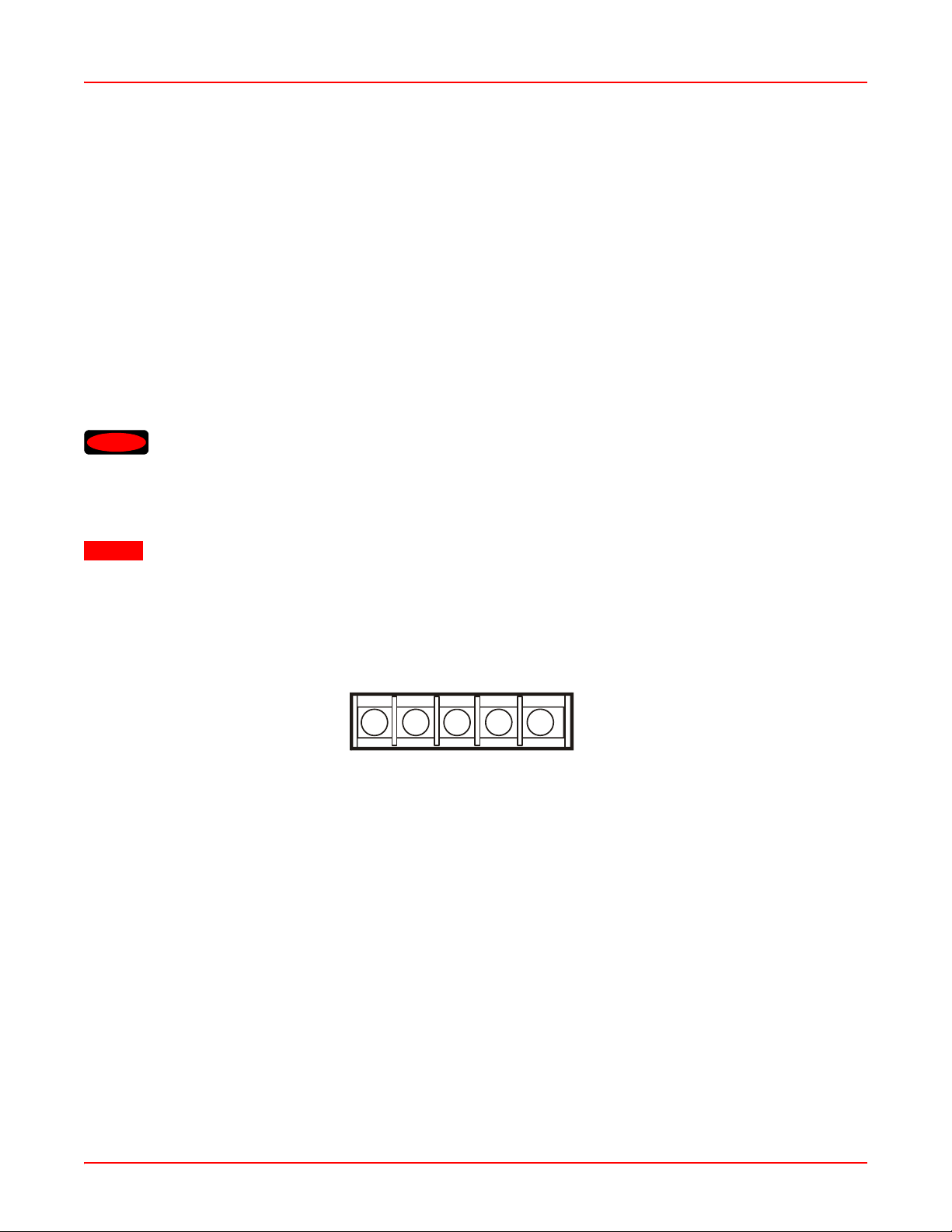

HMS-318 List 3 Front View

On the front panel, viewing from left to right, the HMS-318 List 3 shelf (see Figure 1-1) shows the orientation of the

following components:

• HiGain Line Unit (HLU): first 22 (HLU1-HLU22) slots

• HiGain Management Unit (HMU): last or 23rd slot.

Communications between the HMU slot and the HLU card slots is routed through the rear panel.

• LPS-300C: the first 22 [odd numbered slots (1, 3, 5, 7, ... 21 connections)] slot

1

-1261

01

5.22 in.

(13.26 cm)

HMU

HLU 1-22 single-wide cards

LPS-300C 1-11 double-wide cards (fits in odd-numbered slots onl

)

Figure 1-1. HMS-318 List 3 Shelf - Front View

1-2 LTPH-UM-1261-01

Page 15

December 20, 2004 Chapter 1: Product Description

J

HMS-318 List 3 Rear View

The HMS-318 List 3 shelf input power, 5-position terminal block (labeled TB1) and the alarms (labeled Alarms) wirewrap connections are located on the rear panel (see Figur e 1-2). The Bonding (Safety ground) is located on the

upper right corner extension of the right p anel. The la bel (BONDING WIRE MIN #10 AWG) is located on the right

corner of the rear panel (see Grounding Lug and Hexhead Screw, Figure 1-2).

Managed HDSLx configuration

Also located on the rear panel, connectors P1 and P2 (labeled CO PAIR 1 and 2) are DSX-1 receive and transmit

connections. Connectors P3 and P4 (labeled SPAN PA IR 1 and 2) are HDSL Spans (Loops 1 and 2) receive and

transmit connections (see Figure 1-2). All of these plug-in connectors (P1, P2, P3, and P4) are 50-pin Amphenoltype male connectors and provide Tip and Ring for all the cards in the shelf. For information on the signal and pin

assignments, see Appendix A: ”Signal and Pin Assignments” on page A-1.

LoopSt ar™ (L PS-3 00C) Power Module configuration (for Wi-Fi)

Also located on the rear panel (for Visual & Audible Alarm Contact operation, install an HMU-319), connectors P1

and P2 (labeled CO P AIR 1 and 2) are xDSL B and A IN transmit and receive connections, r espectively. Connectors

P3 and P4 (labeled SPAN PAIR 1 and 2) are xDSL A and B OUT transmit and receive connections, respectively

(see Figure 1-2). All of these plug-in connectors (P1, P2, P3, and P4) are 50-pin Amphenol-type male con nector s

and provide Tip and Ring for all the cards in the shelf. For information on the signal and pin assignments, see

Appendix A: ”Signal and Pin Assignments” on page A-1.

Table 1-1 on page 1-4 provides a description of each rear-panel component.

Alarms wire-wrap

field (TB2)

J22

24J25J27

10 BASE-2

10 BASE-T

02A-1261R1

OS RS232 PORT

J23

J26

Connector (P3)

Connector (P1)

AUX RS232 DTE PORT

SPAN PAIR 1

CO PAIR 1

1234

-48VA-48VBBATRTNFGND

Input Power

Terminal Block

(T 1)B

Figure 1-2. HMS-318 List 3 Shelf - Rear View

Connector (P2)

CO PAIR 2

Grounding Lug

and Hexhead Screw

5

SPAN PAIR 2

J1

Connector (P4)

LTPH-UM-1261-01 1-3

Page 16

Chapter 1: Product Description December 20, 2004

T able 1-1. HMS-318 List 3 Shelf Rear-Pane l Connections (LPS- 300C)

Connector/Terminal

Block Connector T ype Connectory Label Description

J24 BNC-T (Female) 10 BASE-2 10BASE-2 Management

Port

J25 RJ-45 10 BASE-T 10BASE-T Management

Port

J26 RS-232 DB-25 (Female) OS RS232 DTE PORT RS-232/X.25 Management

Port

J27 RS-232 DB-25 (Female) AUX RS232 DTE PORT Auxiliary RS-232

Management Port

P1 Amphenol 50-pin (Male) CO PAIR 1 DS1/xDSL B IN Tip and

Ring (non-powered xDSL

signal to and from the

DSLAM)

P2 Amphenol 50-pin (Male) CO PAIR 2 DS1/xDSL A IN Tip and

Ring (non-powered xDSL

signal to and from the

DSLAM)

P3 Amphenol 50-pin (Male) SPAN PAIR 1 HDSL/xDSL A OUT Tip

and Ring (bi-directional

span powered xDSL signal

to and from the Customer

Premises)

P4 Amphenol 50-pin (Male) SPAN PAIR 2 HDSL/xDSL B OUT Tip

and Ring (bi-directional

span powered xDSL signal

to and from the Customer

Premises)

J1 - J22 20-pin wire-wrap J1 - J22 HLU connectors

J1 - J22 20-pin wire-wrap J1 - J22 (odd-numbered

LPS-300C connectors

slots only)

J23 DIN 96-pin (Female) J23

HMU connector

a

TB1 5-position terminal block TB1 Input Power connector

TB2 26-pin wire-wrap field Alarms Alarm connector

a.Not used in LPS-300C Power Module configuration.

1-4 LTPH-UM-1261-01

Page 17

December 20, 2004 Chapter 1: Product Description

5

POWER AND ALARM CONNECTIONS

The HMS-318 List 3 shelf has a separate split input power (TB1) and an Alarms wire-wrap field (TB2). The following

paragraphs provide information about TB1 and TB2.

Safety Precautions

Observe the following general precautions and recommendations in planning the source power r equirements for th e

HMS-318 List 3 shelf (for additional safety infor mation, please r efer to the section describ ing the “Safety Guidelines”

on page xi):

• Check the power at your site before shelf installation (an d periodically af ter inst allation) to ensure clean power is

being received.

• Always disconnect the power source and unplug all the power cables before working on the shelf.

• Install proper grounding for the site to avoid damage from lightning and power su rges.

DANGER

To avoid electrical shock, be careful when working near power supplies. Telco equipment uses 48 Vdc office power.

Input Power Terminal Block

CAUTION

Before making any power connections (CO primary power feeds A and B) to the HMS-318 List 3

shelf, ensure that the Main CO power breaker is off. Otherwise, severe injury to the installer or

damage to the unit may result.

The 5-position input power terminal block (TB1, see Figure 1-3) provides a central connection point for the CO

primary power feeds (A and B).

1234

TB1

-48VA

-48VB

FUSE

FUSE

15A MAX 15A MAX

BAT RTN

US E

SUPPLIED BRIDGE

FGND

Figure 1-3. Input Power Terminal Block (TB1)

HMS-318 List 3 Shelf Input Power Connections

The input power terminal block supports split -48V battery power bussing. Slot s 1 through 11 on the HMS-318 List 3

shelf are powered by the -48 Vdc A bus (labeled -48VA). Slots 12 through 22 are powered by the -48 Vdc B bus

(labeled -48VB). The two GND terminals are tied together. In the HMU/HLU configuration, the HMU-319 is diodeOR’ed to both power busses, to guard against power failure in the event that one power supply is lost. This feature

requires the two ground terminals to be tied together on the HMU card (for proper power and grounding of the HLU319 and HMU-319, see “Related Publications” on page 1-ix and choose the most appropriate instruction manual for

your product).

LTPH-UM-1261-01 1-5

Page 18

Chapter 1: Product Description December 20, 2004

Alarms Wire-Wrap Field

IMPORTANT

!

Before making power connections (CO primary power feeds A and B) to the HMS-318 List 3 shelf,

ensure that the Main CO power breaker is off. Otherwise, sev ere injury to the installer or damage

to the unit may result.

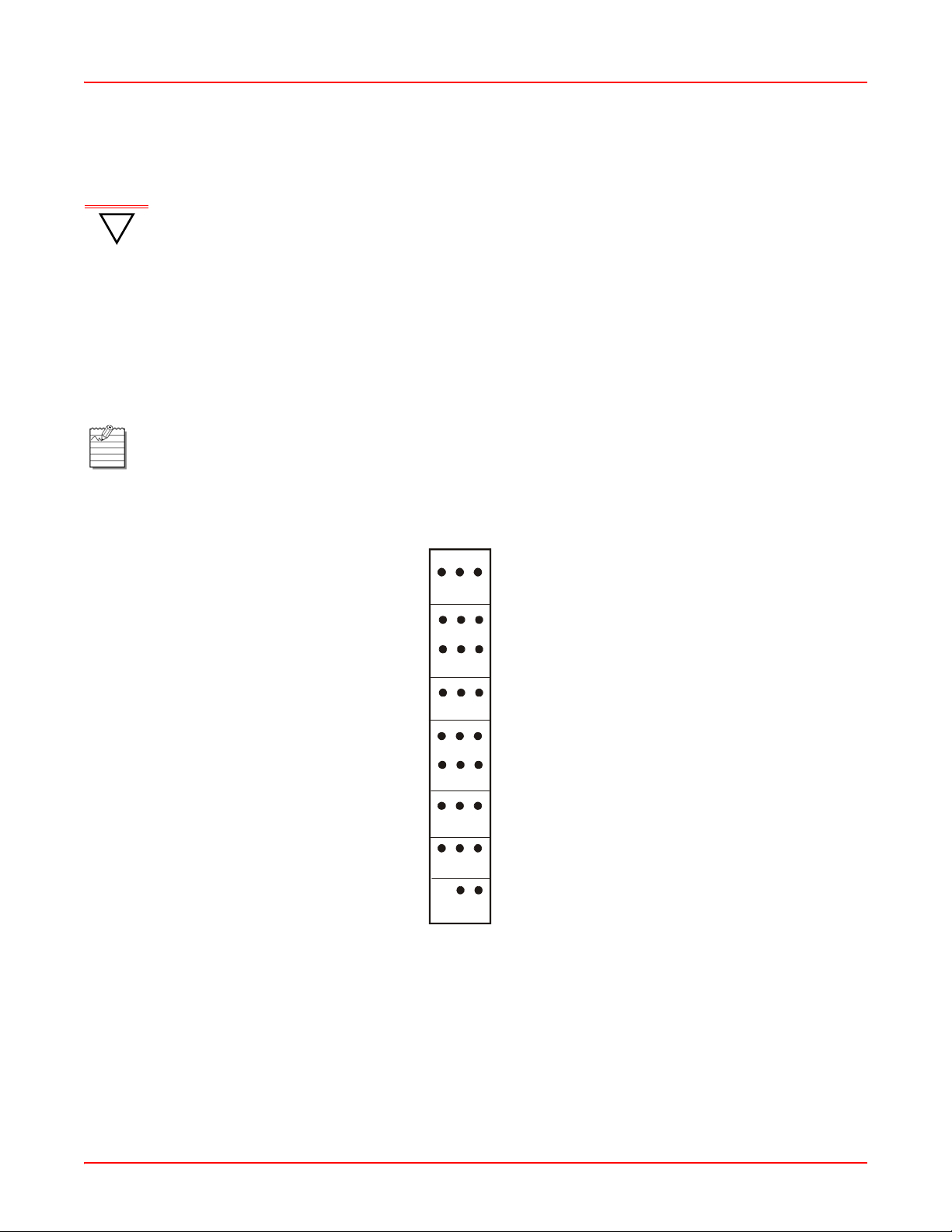

Terminate the alarm leads from the CO alarm system to the HMS-318 List 3 shelf. The Alarms wire-wrap field (TB2,

see Figure 1-2) is a 26-pin wire-wrap connector and provides a central connection point to the Normally Closed

(NC), Common (COM), and Normally Open (NO) relay contacts for installing optional alarm input connections (see

Table 1-1 on page 1-4 for Alarm descriptions). When an alarm is not active, there is continuity between the NC and

COM connections; when an alarm is active, there is continuity between the NO and COM connections.

Note: The NO and COM alarm relay connections can be daisy-chained between HMS-318 List 3 shelves

for multi-shelf applications in the same equipment rack.

ALARMS

NC C NO

123

CRIT AUD

5

4

7

89

10 11 12

6

CRIT VIS

MAJ AUD

MAJ VIS

13 14 15

MIN AUD

MIN VIS

SYS ID

ACO

1

R

1

6

2

NO COM

1

6

FAN

0

GND

EXT

TEMP

16 17 18

19 20 21

23 24

22

25 26

Figure 1-4. Alarms Wire-Wrap Field (TB2)

Alarm Cutoff (ACO)

The Alarm Cutoff (ACO) function silences active audible alarms. Alarm cutoff can be achieved by pre ssing the ACO

button on the front panel of the Management Unit (for example, HMU-319) or by connecting the ACO pin 22 on the

HMS-318 List 3 shelf Alarms wire-wrap field (see Figure 1-4 on this page and Table 1-2) to ground through an

external NO push button switch. The ACO lead can be daisy-chained to other shelves for multi-shelf applications in

the same equipment rack.

1-6 LTPH-UM-1261-01

Page 19

December 20, 2004 Chapter 1: Product Description

In the HMU/HLU configuration, for example, for detailed information about the different types of alarms, refer to the

“Managing Alarms” section in the HMU-319, H2TU-C-319, or H4TU-C-319 User Manuals. Specifically, the manual

describes the types of alarms the HMU-319 reports, when the alarm occurs, and how to respond to the alarm usin g

the ACO.

Table 1-2. Alarms Wire-wrap Field Functional Description

Alarm Alarm Description Function

CRIT AUD Critical Audible There is a critical alarm active on the HMS-318

List 3 shelf. Connect this relay to the critical

alarm audible indicator of the CO alarm

system.

CRIT VIS Critical Visible There is a critical alarm active on the HMS-318

List 3 shelf. Connect this relay to the critical

alarm visual indicator of the CO alarm system.

MAJ AUD Major Audible There is a major alarm active on the HMS-318

List 3 shelf. Connect this relay to the major

alarm audible indicator of the CO alarm

system.

MAJ VIS Major Visible There is a major alarm active on the HMS-318

List 3 shelf. Connect this relay to the major

alarm visual indicator of the CO alarm system.

MIN AUD Minor Audible There is a minor alarm active on the HMS-318

List 3 shelf. Connect this relay to the minor

alarm audible indicator of the CO alarm

system.

MIN VIS Minor Visible There is a minor alarm active on the HMS-318

List 3 shelf. Connect this relay to the minor

alarm visual indicator of the CO alarm system.

SYS ID System ID There is a critical, major, or minor alarm active

on the HMS-318 List 3 shelf. Connect this relay

to the equipment rack alarm indicator.

ACO Alarm Cutoff External Alarm Cutoff (ACO) function silences

active audible alarms (see “Alarm Cutoff

(ACO)” on page 1-6).

GND Ground External ground

EXT TEMP External Temperature

Thermostat

NO COM FAN Fan Control The Fan Control manually disables a Fan

Thermal control (digital temperature sensor).

Connect this pin to an external snap-action

thermostat to activate the fan relay. This

thermostat provides a switch closure to ground

that is sensed by the HMU-319.

Assembly using the NO and COM fan control

contacts.

LTPH-UM-1261-01 1-7

Page 20

Chapter 1: Product Description December 20, 2004

CONNECTING TO HDSL, HDSL2, AND HDSL4 CIRCUITS

The following paragraphs provide information on making DSX-1 and HDSL, HDSL2, and HDSL4 connections to the

HMS-318 List 3 shelf.

Plug-in Connections DSX-1 and HDSL, HDSL 2, or HDSL4

DSX-1 connections to the HMS-318 List 3 shelf can be made through the HMS-318 List 3 shelf’s rear-panel 50-pin

Amphenol-type male connectors P1, RCV to DSX (labeled CO PAIR 1) and P2, XMT from DSX (labeled CO PAIR

2). HDSL, HDSL2, or HDSL4 connections to the shelf can be made through rear-panel 50-pin Amphenol-type male

connectors P3, HDSL Loop 1 (labeled SPAN PAIR 1) and P4, HDSL Loop 2 (labeled SPAN PAIR 2). All of these

connectors (P1, P2, P3 and P4) are described in the section titled “HMS-318 List 3 Rear View” on page 1-3.

Wire-Wrap Connections DSX-1 and HDSL, HDSL2, or HDSL4

DSX-1 and HDSL, HDSL2, or HDSL4 connections can be made to the individual card connectors through the HMS318 List 3 shelf’s rear-panel wire-wrap pins (0.045-inch square/1.14 mm). Straps for cable dressings and a

protective Lexan rear cover are provided with each shelf. Figure 1-5, Figure 1-6, and Figure 1-7 show the HLU card

slot pinouts for HDSL, HDSL2, and HDSL4, respectively on the HMS-318 List 3 shelf rear panel.

Each circuit card is identified by name and list ID (for example, HLU-319 HiGain G.703 L1). The name and list ID are

labeled on the upper portion of the front panel. All circuit cards are inserted straight into the slot, using guide pins to

align each circuit card.

ATTENTION

To ensure against da mage to electronic components, ESD protection must be employed in the

handling of all circuit cards. Therefore, antistatic discharge wrist-straps should be used

whenever circuit cards are being removed or replaced. The antistatic discharge straps should be

connected to frame ground. At all other times (shipping, storage, and so forth), these circuit cards

should remain in static-shielding protective bags (for a description of card preventive measures,

see Appendix C: ”Circuit Card Preventive Measures” on page C-1).

1-8 LTPH-UM-1261-01

Page 21

December 20, 2004 Chapter 1: Product Description

(

DSX-1 Tip (IN)

DSX-1 Tip 1 (OUT) DSX-1 Ring (OUT)

A

B

C

D

Error Alarm Bus Ground (GND)

HDSL Loop 1 - Tip

System Alarm*

Frame Ground -48 Vdc Battery

HDSL Loop 2 - Tip HDSL Loop 2 - Ring

FL (not used) Fuse Alarm **

Notes:

*

Minor alarm output is normally floating (0 to -60V maximum) and a

ground (10 ma maximum, +5 Vdc for HLU-319 List 2D) when activated

**

Fuse alarm is normally floating (0 to -80V maximum) and at -48V

10 ma maximum) when activated

E

F

H

J

K

L

1

2

3

4

5

6

7

8

9

10

Management Bus*

Figure 1-5. HLU Slot Wire-wrap Pinouts for HDSL Circuits

DSX-1 Tip (IN)

DSX-1 Tip 1 (OUT) DSX-1 Ring (OUT)

A

B

C

D

Error Alarm Bus Ground (GND)

HDSL Loop 1 Span Tip

System Alarm*

Frame Ground -48 Vdc Battery

HDSL2 Loop 2 - Tip*** HDSL2 Loop 2 - Ring***

Factory Use Only Fuse Alarm **

Notes:

*

Minor alarm output is normally floating (0 to -60V maximum) and a

ground (10 ma maximum, +5 Vdc for HLU-319 List 2D) when activated

**

Fuse alarm is normally floating (0 to -80V maximum) and at -48V

(10 ma maximum) when activated

***

Loop2 is used on H2TU-C-319-L7FX line of cards

E

F

H

J

K

L

1

2

3

4

5

6

7

8

9

10

Management Bus*

Figure 1-6. HLU Slot Wire-wrap Pinouts for HDSL2 Circuits

LTPH-UM-1261-01 1-9

Page 22

Chapter 1: Product Description December 20, 2004

DSX-1 (IN)Tip

DSX-1 Tip 1 (OUT)

A

B

C

D

E

HDSL4 Loop 1 Tip

System Alarm *

Frame Ground -48 Vdc Battery

HDSL4 Loop 2 Tip

Factory use only

Notes:

* System alarm and management bus reserved.

** Fuse alarm normally floating (0 to -80 Vdc maximum)

and at -48Vdc (10 ma maximum) when activated.

F

H

J

K

L

1

2

3

4

5

6

7

8

9

10

DSX-1 (IN)Ring

DSX-1 Ring 1 (OUT)

Ground (GND)

HDSL4 Loop 1 Ring

Management Bus *

HDSL4 Loop 2 Ring

Fuse Alarm **

Figure 1-7. HLU Slot Wire-wrap Pinouts for HDSL4 Circuits

CONNECTING SPAN POWERED XDSL CIRCUITS TO THE HMS-318 L IST 3 SHELF

The following paragraphs provide information on making Span Powered xDSL connections to the HMS-318

List 3 shelf.

Span Powered xDSL Plug-in Connections

Span Powered xDSL (labeled xDSL B and A IN) connections to the HMS-318 List 3 shelf can be made through

HMS-318 List 3 shelf’s rear-panel 50-pin Amphenol-type male connectors P1 (labe led CO PAIR 1) and P2 (labeled

CO PAIR 2), respectively. Span Powered xDSL (labeled xDSL A and B OUT) connections to the shelf can be made

through rear-panel 50-pin Amphenol-type male connectors P3 (labeled SPAN PAIR 1) and P4 (labeled SPAN PAIR

2). All of these connectors (P1, P2, P3 and P4) are described in the section titled “HMS-318 List 3 Rear View” on

page 1-3 (refer to the LoopStar LPS-300C L1 Power Module Technical Practice, cat alog number SCP-LPS300-010

for installation, initialize and power up information).

To ensure against da mage to electronic components, ESD protection must be employed in the

handling of all circuit cards. Therefore, antistatic discharge wrist-straps should be used

ATTENTION

whenever circuit cards are being removed or replaced. The antistatic discharge straps should be

connected to frame ground. At all other times (shipping, storage, and so forth), these circuit cards

should remain in static-shielding protective bags (for a description of card preventive measures,

see Appendix C: ”Circuit Card Preventive Measures” on page C-1).

1-10 LTPH-UM-1261-01

Page 23

December 20, 2004 Chapter 1: Product Description

Wire Wrap Connections – Span Powered xDSL

Figure 1-8 shows the LPS-300C slot pinouts on the HMS-318 List 3 shelf rear panel for xDSL circuits.

xDSL A IN

xDSL B IN

A

B

C

D

E

xDSL A OUT

F

H

Frame Ground -48 Vdc Battery

xDSL B OUT

J

K

L

Notes:

*

System alarm and managem ent bus reserved.

**

Fuse alarm nor mally floating (0 to -80 Vdc m aximum)

and at -48Vdc (10 ma maxim um) when activated .

1

2

3

4

5

6

7

8

9

10

xDSL A IN

xDSL B IN

Ground (GND)

Management Bus *

Fuse Alarm **

Figure 1-8. HLU Slot Wire-wrap Pinouts for Span Powered xDSL

LTPH-UM-1261-01 1-11

Page 24

Chapter 1: Product Description December 20, 2004

RS-232/X.25 REMOTE MANAGEMENT PORTS

Two EIA RS-232 communications por t s , J26 (labeled OS RS232 PORT) and J27 (labeled AUX RS232 PORT),

located on the HMS-318 List 3 shelf rear panel (see Figure 1-9 on p age 12), provide optional OS and AUX

management interfaces for connection to a HiGain system. Table 1-3 on page 1-12 lists the pin connections for the

OS communications port connector, and Table 1-4 on page 1-13 lists the pin connections fo r the AUX

communications port connector .

J27

2650

10 BA SE-2

13-1261R1

10 BASE-T

OS RS232 PORT

AUX RS 232 D TE PO RT

50

25 1

SPAN PAIR 1

25

CO PAIR 1

26

1

12345

-48VA -4 8V B BAT RTN

FUSE FUSE

15A MAX 15 A MAX

P INS 3 & 4

MUST BE BRIDGED

FGND

1

26 50

CO PAIR 2

1

26

SPAN PAIR 2

25

25

50

J26

Figure 1-9. HMS-318 List 3 Shelf RS-232/X.25 Remote Management Ports

Note: The HMU-319 requires that Data Set Ready (DSR) be asserted by the connected Data

Communications Equipment (DCE) in order to establish communications on this port. In the HMU/HLU

configuration, the HMU-319 always asserts Data Terminal Ready (DTR) on this port.

T a ble 1-3 . J26 – RS-23 2/X.25 Management Port (DTE)

Pin No. Signal Direction

1Shield —

2 Transmit Data (TD) Out

3 Receive Data (RD) In

4 Request to Send (RTS) Out

5 Clear to Send (CTS) In

6 Data Set Ready (DSR) In

7 Ground (GND) —

15 TCLK In

17 RCLK In

20 Data Terminal Ready (DTR) Out

24 TCLK In

1-12 LTPH-UM-1261-01

Page 25

December 20, 2004 Chapter 1: Product Description

T a ble 1-4 . J27 – AUX RS- 232 Manage men t Port (DTE)

Pin No. Signal Direction

1Shield —

2 Transmit Data (TD) Out

3 Receive Data (RD) In

6 Data Set Ready (DSR) In

7 Ground (GND) —

20 Data Terminal Ready (DTR) Out

ETHERNET REMOTE MANAGEMENT PORTS

The BNC connector J24 (labeled 10 BASE-2), see Figure 1-10, can be used to connect the management ports o f up

to 32 shelves into an integrated network through a 10 BASE-2 (Thinnet) Ethernet LAN (IEEE.802.3). The r ear-panel

RJ-45 connector J25 (labeled 10 BASE-T), see Figure 1-10, provides a 10 BASE-2 or a 10 BASE-T (Twisted-Pair)

Ethernet LAN (both IEEE.802.3 compatible).

J24 J25

50

10 BA SE-2

14-1261R1

10 BA SE- T

OS RS232 PORT

AUX RS 232 D TE PO RT

50

25 1

SPA N PAIR 1

25

CO PAIR 1

26

26

1

12345

-48VA -48VB BAT RTN

FUSE FUSE

15A MAX 15 A MAX

PINS 3 & 4

MUST BE BRIDGED

FGND

1

26

CO PA IR 2

1

26

SPAN PAIR 2

Figure 1-10. Multishelf Network Ports

Daisy-Chaining 10BASE-2 Connections

10BASE-2 management ports of up to x number of shelves can be hubbed together by daisy-chaining together

using the included BNC-T connector. The last 10BASE-2 connection must be terminated with the included 50 ohm

BNC terminator.

HEAT DISSIPATION FACTORS

The HMS-318 List 3 shelf is a 12-inch (30.48 cm) deep individual CO equipment shelf with open-fa ced mountings for

natural convection cooling. The maximum heat dissipation for open-faced, natural convection-cooled mountings is

limited to 134.7 Watts per square foot as defined in Section 4.1.4 of the NEBS standard for Physical Protection

(GR-63-CORE) for all equipment placed in a CO environment.

The heat dissipation footprint of an HMS-318 List 3 shelf is approximately 5.9 square fee t. Therefo re, the maxim um

permissible heat dissipation per rack is 5.9 square feet x 134.7 Watts per squar e foot equals 790 Watts.

The maximum allowable heat dissipation for each telco-style equipment rack is:

• 790 watts for a 19-inch (48.3-cm) wide rack

25

50

25

50

LTPH-UM-1261-01 1-13

Page 26

Chapter 1: Product Description December 20, 2004

Note: Refer to the respective ADC card user manuals to determine the maximum number of cards that can

be installed in a shelf before exceeding the maximum heat dissip ation density of the telc o-style eq uipment

rack configuration.

Figure 1-11 shows a typical example of a CO equipment rack layout using HMS-318 List 3 shelves. The figure

shows a rack with a fuse panel, eight HMS-318 List 3 shelves, each separated by a two rack space baffle with the

remaining shelf space open. As the figure illustrates, baffles should be placed between each shelf to reduce the

chimney heating effect (see “Air Flow Guidelines” on page 1-15 for further information about cooling the HMS-318

List 3 shelf).

Outdoor cabinet applications require forced air to ensure proper cooling.

Fuse Panel

Shelf

Baffle

Shelf

Baffle

Shelf

Baffle

Shelf

Baffle

Shelf

Baffle

Shelf

Baffle

Shelf

Baffle

Shelf

Baffle

16A-1261R1

Figure 1-11. Central Office Equipment Rack Configuration

1-14 LTPH-UM-1261-01

Page 27

December 20, 2004 Chapter 1: Product Description

AIR FLOW GUIDELINES

To ensure adequate air flow through the telco-style equipment rack, it is recommended that you maintain a

clearance of at least 6 inches (15.2 cm) in the front and the back of the rack at all times.

If airflow through the telco-style equipment rack and the shelves that occupy it is blocked or restricted, or if the

ambient air being drawn into the rack is too warm, an over temperature condition within the rack and the shelves that

occupy it can occur.

The site should also be as dust-free as possible. Dust tends to clog the shelves, reducing the flow of cooling air

through the telco-style equipment rack and the shelves that occupy it and increasing the risk of a n over temperature

condition.

Additional rack-mounting guidelines are:

• Install the shelf in an enclosed rack only if the rack has adequate air flow (see Chapter 2: “Installation” on

page 2-1); install the shelf in an open rack whenever possible.

• The proper use of heat (air) baffles inside an enclosed rack can help ensure adequate shelf cooling.

LTPH-UM-1261-01 1-15

Page 28

Chapter 1: Product Description December 20, 2004

1-16 LTPH-UM-1261-01

Page 29

Chapter

2

INSTALLATION

This section provides specific information about preparing your site for insta llation. Included are specific prep aratory

information, safety guidelines, specific rack-mounting guidelines, adapter bracket mounting, rack mounting, DSX

and HDSL or S pan Powered xDSL connections, and power and alarm connections. Once you have completed the

basic installation and verified that your shelf is functioning properly, you can refer to the instruction manuals for the

individual modules (HLU, HMU, or LPS-300C). These instruction manuals provide comprehensive config uration and

technical information that will help you further define the parameters to meet your particular requirements (see

“Related Publications” on page ix).

BEFORE YOU BEGIN

Before installing the HMS-318 List 3 shelf, it is important to prepare for installation by:

• Preparing the site (site preparations) or reviewing the installation plans by establishing a Method of

Procedure (MOP)

• Unpacking and inspecting the shelf shipment

• Gathering the tools and test equipment required to properly install the shelf.

Site Preparations

Typically, you should have prepared the installation site beforehand. As part of your pre p ar atio n, obtain a floor plan

of the site and the Central Office (CO) or telco-style equipment rack (either EIA with 1.75 in. mounting spaces or

WECO with 2 in. mounting spaces) where the HMS-318 List 3 shelf will be housed. Determine the location of any

existing shelves and their interconnections, including communications and power. The -48VA and -48VB busses

provide the -48V shelf battery feed. Each bus should be fused at 15 Amperes. All personnel involved in the

installation of the shelf, including installers, engineers, and supervisors, should participate in the preparation of a

MoP for approval by the customer.

Method of Procedure

An example of a Method of Procedure (pre-installation checklist of tasks and considerations that needs to be

addressed and agreed upon before proceeding with the installation) is given below:

• Assign personnel.

• Determine protection requirements for personnel, equipment, and too l s.

• Evaluate potential hazards that may affect service.

• Schedule time for installation.

• Determine any space requirements.

• Determine any power requirements.

• Identify any required procedures or tests.

• On an equipment plan, make a preliminary decision that locates each of the HMS-318 List 3 shelves that you

plan to install.

• Read this manual.

• Modify the preliminary plan, if necessary.

• Verify the list of replaceable parts for the installation (screws, bolts, washers, and so on) so that the parts are

identified (see Table 2-1 on page 2-2).

• Check the required tools list to make sure the necessary tools and test equipment are available (see Chapter 2:

“Required Tools” on page 2-3).

• Purchase necessary parts.

• Perform the installation (see Chapter 2: “Safety Guidelines” on page 2-4).

LTPH-UM-1261-01 2-1

Page 30

Chapter 2: Installation December 20, 2004

Unpacking and Checking the Contents of your Shipment

The shipping package for the HMS-318 List 3 is designed to reduce the possibility of product damage associated

with routine material handling experienced during shipment. To reduce the potential damage to the product,

transport the shelf in its ADC-specified packaging. Failure to do so may result in damage to the shelf. Also do not

remove the shelf from its shipping container until you are ready to install it. Refer to “Inspecting Your Shipment” on

page xii for unpacking instructions.

Note: Do not discard the packaging materials used in shipping your HMS-318 List 3 shelf. Y ou will need the

packaging materials in the future if you move or ship your HMS-318 List 3 shelf.

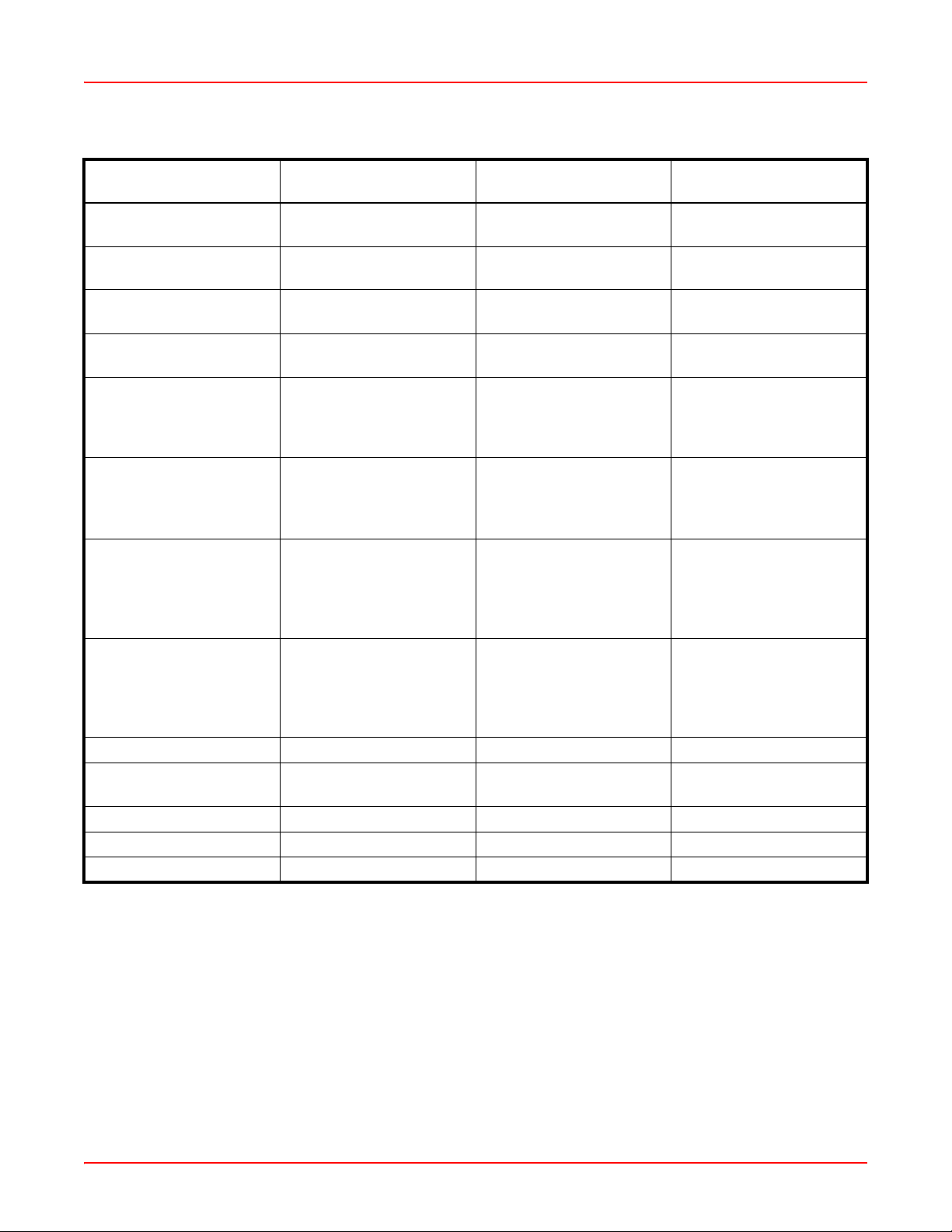

Table 2-1 lists the items included in the HMS-318 List 3 shipment. After inspecting each item, check and initial that it

has been received. A “Notes” section has bee n provid ed on the next page to record damaged or missing parts.

Table 2-1. HMS-318 List 3 Shelf Parts List

Check

9 Item Quantity Catalog/Part No.

HiGain Management Shelf (HMS-318

List 3)

Adjustable Mounting Brackets, two

(either 2-inch recess or 5-inch recess)

installed at factory

HMS-318 List 3 Shelf Installation Kit

includes mounting hardware (four #1224 x 0.5 inch panhead screws), label

holder, label, 50-ohm BNC terminator,

and BNC-T female connector

ETSI Mounting parts kit includes

mounting hardware (eight #6-32 x .250

inch Phillips head screws w/lock

washer, four M6-1.0 x 14 mm panhead

screws), and two ETSI Mounting

Brackets, one

Shelf Grounding kit includes one

cabletie, one #12-24 x 0.5 inch Hexhead

screw w/washer, one #12 Ring

Terminal, 12-10 AWG (used to connect

the grounding cables to the grounding

stud), and one ground jumper

HiGain Management Shelf (HMS-318

List 3) User Manual

(Optional) Extender Bracket for

mounting into 23-inch (58.4 cm) rack

includes two brackets and all the

appropriate mounting hardware.

1 HMS-318 List 3

1 set N/A

1 bag 130-1028-01

1 bag N/A

1 bag N/A

1 LTPS-UM-1261

1EB-52

Installer Initial

"

2-2 LTPH-UM-1261-01

Page 31

December 20, 2004 Chapter 2: Installation

Notes:

Required Tools

The following tools are required to install the shelf:

• Grounding or ESD-preventive wrist strap

• #2 Phillips-head screwdriver

• #1 Phillips-head screwdriver

• Straight-slot-head screwdriver

• Cable preparation tools

5

•A

/16-inch open-end wrench

• Tape measure

• Wire strippers

• An Amphenol crimping tool for making up connectors (if necessary).

Note: All other tools are normally carried in a craftsman’s tool set.

LTPH-UM-1261-01 2-3

Page 32

Chapter 2: Installation December 20, 2004

SAFETY GUIDELINES

The safety guidelines (see Chapter 1: “Safety Guidelines” on page 1-iv) are provided to help ensure your safety and

to protect your equipment. The list on page iv may not identify all potentially hazardous situations in your working

environment, so be alert and exercise good judgment at all times.

MOUNTING THE HMS-318 LIST 3 SHELF

Each HMS-318 List 3 shelf has a hardware kit. The rack adapter brackets are attached to the HMS-318 List 3 shelf

at the factory. They are supplied with the shelf to allow mounting on 19-inch (48.3-cm) telco-style EIA or WECO

equipment racks. Select the appropriate position for the brackets (2 or 5 inches) and mount the shelf to the bracket

as described in the Chapter 2: “Adapter Bracket Mounting Procedure (19-inch Telco-style Equipment Rack)” on

page 2-5 and the Chapter 2: “Adapter Bracket Mounting Procedure (23-inch Telco-style Equipment Rack)” on

page 2-5. When installed in an EIA rack, a total of three 1.75-inch (4.4-cm) mounting spaces [5.25 inches (13.3 cm)

of vertical rack space] are required for mounting an HMS-318 List 3 shelf. When installed in a WECO rack, a tot al of

three 2.0-inch (5.08-cm) mounting spaces [6 inches (15.2 cm) of vertical rack space] are required for mounting.

ETSI adapter brackets are included for inst allation of the HMS-318 List 3 sh elf in an ETSI-style equipment rack (see

Chapter 2: “Adapter Bracket Mounting Procedure (ETSI-style Equipment Rack)” on p ag e 2-6).

IMPORTANT

!

Special Rack-Mounting Precautions

Special rack-mounting precautions must be followed to ensure safety. They are:

• Never wear loose clothing, jewelry (such as rings, bracelets, or chains), or other items that could get caught in

the shelf housing during handling and use.

• When mounting the shelf to a telco-style rack, ensure that the rack is bolted to the floor.

• Since you will probably be installing more than one shelf into the rack, ensure that the weight of all the shelves

installed does not make the rack unstable.

IMPORTANT

!

• As mentioned in “Air Flow Guidelines” on page 1-15, maintain a clearance of 6 inches (15.2 cm) at the front and

back of the shelf to ensure adequate air int ake and exha ust.

• Avoid installing the shelves in an overly congested rack (see “Heat Dissipation Factors” on page 1-13). Air flowing to or from other shelves in the rack might interfere with the normal flow of cooling air through the shelves,

increasing the potential for over temperature condition s wi thin the shelves.

• Allow at least 19 inches (48.7 cm) of clearance at the front and back of the rack for shelf mainten ance.

• Follow your local practices for cable management. Ensure that cables to and from the shelves do not impair

access to perform equipment maintenance or upgrades.

Clearance above and below the shelf must be allowed for cooling air to be drawn in the front and

circulated through the shelf and out. A heat (air) baffle must be used between shelves to ens ure

that heated air is dissipated appropriately (see “Air Flow Guidelines” on page 21 for detailed

information about air flow guidelines).

Some telco-style racks are also secured to ceiling brackets, if necessary, due to the weight of the

equipment in the rack. Make sure that the rack you are using to install the shelves is secured to

the building structure.

2-4 LTPH-UM-1261-01

Page 33

December 20, 2004 Chapter 2: Installation

Adapter Bracket Mounting Procedure (19-inch Telco-style Equipment Rack)

Adapter bracket placement depends on the type of telco-style rack you plan to use to install the HMS-318 List 3

shelf. First, check the mounting adapter brackets on the shelf to determine whether the factory-installed

configuration is correct for the planned telco-style equipment rack installation. The following procedure describes

how to install the adapter brackets. Threaded holes on the HMS-318 Li st 3 shelf are str ategically located to p osition

and mount the adapter brackets.

Note: As mentioned in Chapter 1: “Product Description” on page1-1 and “Mounting the HMS-318 List 3

Shelf” on page 2-4, the adapter brackets are normally attached to the HMS-318 List 3 shelf at the factory

for a 19-inch telco-style equipment rack. When changing the position of the brackets from a 2- or 5-inch

recess mounting or vice versa, ensure that you place the appropriate hardware (screws, washers, and so

on) you remove in a convenient location for re-assembly.

Perform the following procedure to mount the HMS-318 List 3 shelf to the adapter brackets for a 19-inch telco-style

equipment rack.

Note: When mounting a 19-inch HMS-318 List 3 shelf into a 23-inch telco-style equipment rack (see

Adapter Bracket Mounting Procedure (23-inch Telco-style Equipment Rack)on this page, use extender

brackets (including mounting hardware: EB-52).

Step Action

1 Locate the mounting holes of the HMS-318 List 3 shelf for the desired rack width 19 inches (48.3 cm) and

position (2- or 5-inch recess mounting).

2 Align each adapter bracket with the HMS-318 List 3 shelf and attach to the desired rack width 19 inches

(48.3 cm) and position (2- or 5-inch recess mounting) with the #6-32 x .25 inch screws (provided).

3 Insert the screws (4 places) and tighten using a #2 Phillips screwdriver.

4 Repeat for the other adapter bracket.

5 You are now ready to install the HMS-318 List 3 shelf into the telco-style rack (see “Rack Mounting

Procedure” on page 2-7).

Adapter Bracket Mounting Procedure (23-inch Telco-style Equipment Rack)

To mount the adapter brackets for a 23-inch Telco-style Equipment Rack, select the appropriate position

(2- or 5-inch recess) and mount the HMS-318 List 3 shelf to the adapter brackets as described in this procedure.

Note: As mentioned in Chapter 1: “Product Description” on page1-1 and “Mounting the HMS-318 List 3

Shelf” on page 2-4, the adapter brackets are attached to the HMS-318 List 3 shelf at the factory for a 19-

inch telco-style equipment rack. When changing the position of the brackets from a 2- or 5-inch recess

mounting or vice versa, ensure that you place the appropriate hardware (screws, washers, and so on) you

remove in a convenient location for re-assembly.

Perform the following procedure to mount the HMS-318 List 3 shelf to the adapter brackets for a 23-inch telco-style

equipment rack.

Note: When mounting a 19-inch HMS-318 List 3 shelf into a 23-inch equipment rack, use e xtender brackets

(including mounting hardware: EB-52).

LTPH-UM-1261-01 2-5

Page 34

Chapter 2: Installation December 20, 2004

Step Action

1 Locate the mounting holes of the HMS-318 List 3 shelf for the desired rack width 23 inches (58.4 cm) and

position (2- or 5-inch recess mounting).

2 Align each adapter bracket with the HMS-318 List 3 shelf and attach to the desired rack width 23 inches

(58.4 cm) and position (2- or 5-inch recess mounting) with the #6-32 x .25 inch screws (provided).

3 Insert the screws (4 places) and tighten using a #2 Phillips screwdriver.

4 Repeat for the other adapter bracket.

5 You are now ready to install the HMS-318 List 3 shelf into the telco-style rack (see “Rack Mounting

Procedure” on page 2-7).

Adapter Bracket Mounting Procedure (ETSI-style Equipment Rack)

To mount the adapter brackets for a 600-mm ETSI-style Equipment Rack, mount the HMS-318 List 3 shelf to the

adapter brackets as described in this procedure.

Note: As mentioned in Chapter 1: “Product Description” on page1-1 and “Mounting the HMS-318 List 3

Shelf” on page 2-4, the adapter brackets are attached to the HMS-318 List 3 shelf at the factory for a 19-

inch telco-style equipment rack. When disassembling the brackets from the shelf, ensure that you place the

appropriate hardware (screws, washers, and so on) you remove in a convenient se aled package for

possible re-assembly later.

Perform the following procedure to mount the HMS-318 List 3 shelf to the adapter brackets for a 600-mm ETSI-style

equipment rack.

Note: When mounting a 19-inch (48.3-cm) HMS-318 List 3 shelf into a 600-mm ETSI-style equipment rack,

use the adapter brackets provided (see “Product Description” on page 1-1 and Table 2-1 on page 2-2).

Step Action

1 Locate the mounting holes of the HMS-318 List 3 shelf for the desired rack width 23 inches (58.4 cm) and

position (2- or 5-inch recess mounting).

2 Align each adapter bracket with the HMS-318 List 3 shelf and attach to the desired rack width 23 inches

(58.4 cm) and position (2- or 5-inch recess mounting) with the #6-32 x .25 inch screws (provided).

3 Insert the screws (4 places) and tighten using a #2 Phillips screwdriver.

4 Repeat for the other adapter bracket.

5 You are now ready to install the HMS-318 List 3 shelf into the ETSI-style rack (see “Rack Mounting

Procedure” on page 2-7).

2-6 LTPH-UM-1261-01

Page 35

December 20, 2004 Chapter 2: Installation

Rack Mounting Procedure

To secure the HMS-318 List 3 shelf to the telco-style rack, you must use the mounting screws provided or follow

your local practices for installing the shelves in to your te lco- st yle equipme nt rack. Ensur e that the adapter brackets

have been securely fastened [see “Adapter Bracket Mounting Procedure (19-inch Telco-style Equipment Rack)” on

page 2-5, “Adapter Bracket Mounting Procedure (23-inch Telco-style Equipment Rack)” on page 2-5, or “Adapter

Bracket Mounting Procedure (ETSI-style Equipment Rack)” on page 2-6 for more information].

Perform the following procedure to mount the HMS-318 List 3 shelf into a telco-style equipment rack.

IMPORTANT

!

To prevent injury, review the “Safety Guidelines” on page xi and the “Special Rack-Mounting

Precautions” on page 2-4 before installing the HMS-318 List 3 shelf in the telco-style equipment

rack.

Step Action

1 Locate the telco-style equipment rack position you plan to install the HMS-318 List 3 shelf into.

2 Verify that there are no obstructions and ensure that the telco-style equipment rack is stabilized.

3 Position the shelf in the telco-style equipment rack lining up the bracket holes on the shelf with the holes

on the rack and secure with the four #12-24 x .375 inch mounting screws (see Tabl e 2-1 on page 2-2).

Note: The vertical spacing for EIA racks is 1.75 inches (4.44 cm), with mounting holes

spaced 1.5 inches (3.81 cm) apart. V e rtical spacing for WECO racks is 2.0 inches (5.08 cm),

with mounting holes spaced 1.0 inch (2.54) apart.

4 Tighten the screws using a 1/4-in ch flat -b lad e scr ew dr ive r.

5 You are now ready to begin interconnecting the communications cables that apply to your application

(see “DSX-1 and HDSLx Connections” on page 2-7 or “Span Powered xDSL Connections” on page 2-8).

DSX-1 AND HDSLX CONNECTIONS

Perform the following procedure to connect the DSX-1 and HDSLx interface cables to connectors P1, P2, P3 and P4

(see Figure 1-2 on page 1-3 for connector location and “Connecting to HDSL, HDSL2, and HDSL4 Circuits” on

page 1-8, for connector descriptions).

DANGER

LTPH-UM-1261-01 2-7

Before making both DSX-1 and HDSLx connections to the HMS-318 List 3 shelf, ensure that the

Main CO power breaker is off. Otherwise, severe injury to the installer or damag e to the unit may

result.

Page 36

Chapter 2: Installation December 20, 2004

DSX and HDSL Connector Procedure

Step Action

1 Complete one of the following steps to make the DSX-1 and HDSLx connections to the shelf using one of

the following methods: Plug the DSX-1 interface cables into P1 and P2 and the HDSLx interface cables

into P3 and P4. Wire-wrap the DSX-1 and HDSLx inputs to the appropriate individual card slots. Pin

assignments are listed in Appendix A: “Signal and Pin Assignments” on page A-1.

Note: See Figure 1-2 on page 1-3 for the location of the HDSLx Sp an connectors. HDSLx S pan

pin assignments are listed in Appendix A: “Signal and Pin Assignments” on page A-1. Standard

PIC cable color codes are listed in Appendix B: “Standard PIC Color Code” on page B-1.

2 Continue to “Bonding (Safety) Ground, Power and Frame Ground, Alarm, and Optional Fan Inputs” on

page 2-9.

SPAN POWERED XDSL CONNECTIONS

Perform the following procedure to connect the Span Powered xDSL interface cables to connectors P1, P2, P3 and

P4 (see Figure 1-2 on page 1-3 for connector location and “Connecting Span Powered xDSL Circuits to the HMS-

318 List 3 Shelf” on page 1-10 for connector descriptions).

DANGER

Span Powered xDSL Connector Procedure

Before making any Span Powered xDSL connections to the HMS-318 List 3 shelf, ensure that the

Main CO power breaker is off. Otherwise, severe injury to the installer or damag e to the unit may

result.

Step Action

1 Complete one of the following steps to make the Span Powered xDSL connections to the shelf using one

of the following methods:

• Plug the Span Powered xDSL interface cables into P1, P2, P3 and P4.

• Wire-wrap the Span Powered xDSL inputs to the appropriate individual car d slots. Pin assignments

are listed in Appendix A: “Signal and Pin Assignments” on page A-1.

Note: See Figure 1-2 on page 1-3 for th e location of the HDSL S pan connectors. HDSL S pan

pin assignments are listed in Appendix A: “Signal and Pin Assignments” on page A-1.

Standa rd PIC cable color codes are listed in Appendix B: “Standard PIC Color Code” on

page B-1.

2 Continue to “Bonding (Safety) Ground, Power and Frame Ground, Alarm, and Optional Fan Inputs” on

page 2-9.

2-8 LTPH-UM-1261-01

Page 37

December 20, 2004 Chapter 2: Installation

BONDING (SAFETY) GROUND, POWER AND FRAME GROUND, ALARM, AND OPTIONAL

AN INPUTS

F

IMPORTANT

!

Bonding (safety) ground, power and frame ground, and alarm connections and cabling are marked for ease of

installation [see ground lug location (lab eled BONDING WIRE M IN #10 AWG)], TB1, and TB2 on the rear panel of

the HMS-318 List 3 Shelf, and the following procedures for proper safety ground, power, alarm, and optional fan

(alarms) connections (see Figure 1-2 on page 1-3).

Bonding (Safety) Ground Procedure

To connect the Bonding (Safety) ground to the HMS-318 List 3 Shelf, complete the following steps:

Before making connections to the HMS-318 List 3 shelf, ensure that the Main CO power breaker

is off. Otherwise, severe injury to the installer or damage to the unit may result.

Note: The ground wire exiting the HMS-318 List 3 Shelf is terminated with a ground lug. The lug can be

either a one-hole or two-hole lug. The surface of the lug that connects to the HMS-318 List 3 Sh elf sh ould

be cleaned with an antioxidant. The same should also be applied to the surface of the telco-style rack where

the connection is to be made. The #12 Hexhead screw (supplied) is used to connect the grounding lug to

the HMS-318 List 3 Shelf.

LTPH-UM-1261-01 2-9

Page 38

Chapter 2: Installation December 20, 2004

Step Action

1 Looking at the HMS-318 List 3 rear panel, find the ground lug location (labeled BONDING WIRE MIN #10

AWG) on the upper right corner extension of the right panel (see Figure 2-1).

2 Measure between the telco-style rack and the HMS-318 List 3 Shelf the correct length of a #10 AWG

(minimum) ground wire so that it reaches the ground lug location on the HMS-318 List 3 Shelf, and cut.

Leave enough excess to allow for tying to the rack.

3 Using wire strippers, strip about 5/8 inches of insulation from the ground wire that you will fasten to the

ground lug.

4 Next, using a crimping tool, insert the stripped end of the ground wire into the ground lug, and crimp.

5 Attach the ground lug to the HMS-318 List 3 Shelf by placing the ground lug against the ground lug

location, aligning the hole. Insert the ground-lug screw (#12 Hexhead) through the locking washer and

then through the hole in the ground lug and the ground lug location on the HMS-318 List 3 Shelf. Ensure

that the ground lug and attached ground wire does not interfere with the HMS-31 8 List Shelf or the telco-

style rack.

6 Tighten the screws to secure the locking washer and the ground lug to the ground lug location on the

HMS-318 List 3 Shelf.

7 Using wire strippers, strip about 5/8 inches of insulation from the other end of the ground wire. Using

locally approved practices and fasten the stripped end of the ground wire to the telco-style rack.

8 Use the tie-wraps (supplied) and secure the ground wire to the rack to prevent rotation.

P2 CONNECTOR

25

BONDING WIRE

MIN #10 AWG

P2

SHIELD

GND

4

A

1

B

2

C

3

D

4

E

5

F

6

H

7

J

8

K

9

L

10

P4

3

A

1

A

B

2

C

3

D

4

E

5

F

6

H

7

J

8

K

9

L

10

25

SHIELD

GND

1

B

2

C

3

D

4

E

5

F

6

H

7

J

8

K

9

L

10

P4

12

A

1

B

2

C

3

D

4

E

5

F

6

H

7

J

8

K

9

L

10

WIREWRAP

PINS

GROUND LUG

HEXHEAD SCREW

17-1261R1

P4 CONNECTOR

Figure 2-1. Grounding Lug

2-10 LTPH-UM-1261-01

Page 39

December 20, 2004 Chapter 2: Installation

1234

5

/

Power and Frame Ground Procedure

IMPORTANT

!

To avoid voltage differences from building up between the shelf ground (GND) bus and the

ground pins of the management terminal that connects to the RS-232 ports, connect the shelf

ground pins and the terminal ground bus to the TB1 FGND (frame ground) pin.

Step Action

1 Use locally approved practices to connect #12 AWG (minimum) power wiring from -48Vdc Office Battery

to -48VA and -48VB terminals on TB1-1 and TB1-2 (see <Cross-Ref>Figure 2).

2 Connect #12 AWG (minimum) power wiring from the Battery Returns to BAT RTN terminals on TB1-3

and TB1-4 (see <Cross-Ref>Figure 2).

Note: Slots 1 through 11 on the HMS-318 List 3 shelf are powered by the -48VA bus. Slots 12 through 22

are powered by the -48VB bus.

In the HMU/HLU configuration, the HMU-319 is diode-OR’ed to both power busses to guard against power

failure in the event that one power supply is lost. This feature requires the two ground (GND) terminals to

be connected on the HMU card.

16-1261R1

3

-48VA

FUSE

15A MAX 15A MAX

-48VB

FUSE

TB1

BAT RTN

FGND

Figure 2-2. Input Power Terminal Block (TB1)

Alarms Procedure

Note: As described in “Power and Alarm Connections” on page 7, the HMS-318 List 3 shelf provides alarm

outputs in the form of an Alarms wire-wrap field. This field consist s of a three-pin wire-wrap header for alarm

management. Before connecting the alarm inputs, you must first determine whether the external alarm

equipment requires either an NO or an NC circuit to pass an alarm.

Step Action

1 Use locally approved practices to connect the alarm inputs to the Alarms wire-wrap field (see Figure 2-3

on page 2-12).

Note: The HMU-319 is required for NO and NC alarm operation.

LTPH-UM-1261-01 2-11

Page 40

Chapter 2: Installation December 20, 2004

Optional Fan Alarm Procedure

Note: The FAN terminals wire-wrap field provide s access to the Normally Open (NO), Form A fan relay

contact located on the HMU-319 management u nit. A temperature monitor activates this fan relay when the

shelf temperature exceeds 45°C (±1°C) and deactivates the relay when the temperature drops below 35°C

(±1°C). If the temperature exceeds 77°C (±1°C) a critical alarm is also generated. The critical alarm reset s

when the temperature drops below 40°C (±1°C).

Step Action

1 Connect the optional fan inputs to the Alarms wire-wrap field pins 25 and 26 (see Figure 2-3).

ALARMS

NC C NO

123

CRIT AUD

5

4

7

89

10 11 12

13 14 15

16 17 18

19 20 21

22

23 24

25 26

6

CRIT VIS

MAJ AUD

MAJ VIS

MIN AUD

MIN VIS

SYS ID

ACO

GND

1

R

1

6

2

NO COM

1

-

FAN

6

0

TEMP

EXT

Figure 2-3. Alarms Wire-wrap Field (TB2)

2-12 LTPH-UM-1261-01

Page 41

December 20, 2004 Chapter 2: Installation

INSTALLI NG THE HMU-319 WITH HLU-319, H2TU-C-319, H4TU-C-319

Install the line units (HLUs) into slots 1 through 22 and the HMU-319 management unit into slot 23 of the HMS-318

List 3 shelf (see “HMS-318 List 3 Shelf - Front View” on page 1-2 for slot location).

Install HMU and HLU Procedure

Use anti-static wrist-straps connected to the ESD Jack (located on the right adapter bracket, see

ATTENTION

Step Action

1 Hold the HLU and HMU vertically with the front of the circuit card toward you. Align the top and bottom

2 Slide the HLU and HMU into their respective slots.

3 Press the HLU and HMU firmly into the connector until it is seated into the edge-connector on the shelf

Figure 1 on page 3) when inserting a circuit card. Avoid touching components on the circuit card.

edges of the HLU and HMU with the HMS-318 List 3 shelf slot guides.

backplane.

Note: The HLU and HMU will power up with various status LEDs and displays indicating power up status