Page 1

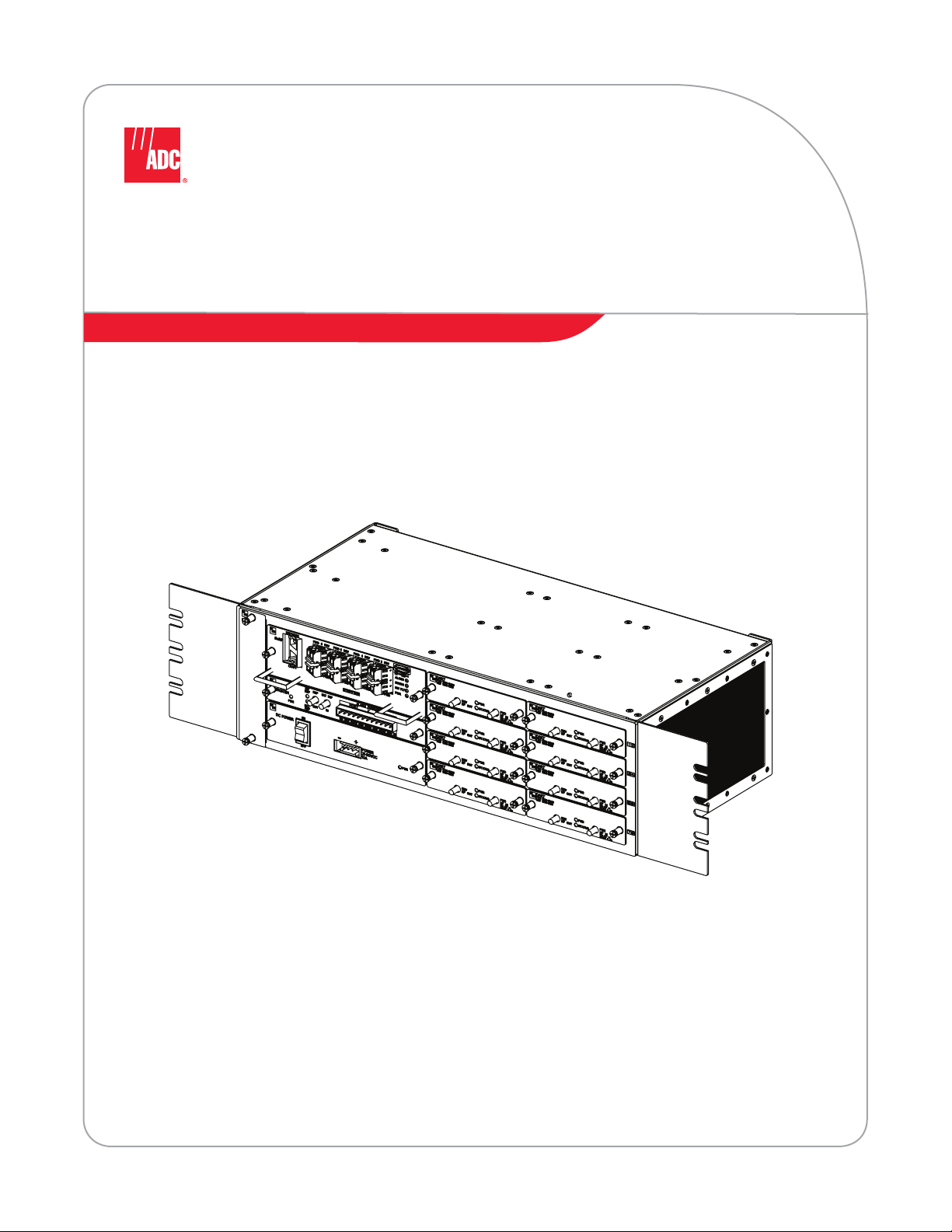

ADC FlexWave™ Universal

Radio Head (URH) Host Unit

Installation Instructions

ADCP-75-348 • Issue 1 • 04/2008ADCP-75-348 • Issue 1 • 04/2008

1427955 Rev A

22408-A

Page 2

ADCP-75-348 • Issue 1 • 04/2008 • Preface

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 917-1717

COPYRIGHT

© 2008, ADC Telecommunications, Inc.

All Rights Reserved

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

1 04/2008 Original

TRADEMARK INFORMATION

ADC is a registered trademark of ADC Telecommunications, Inc., FlexWave is a trademark of ADC Telecommunications, Inc.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting ADC’s Technical Assistance Center at 1-800-366-3891, extension 73475

(in U.S.A. or Canada) or 952-917-3475 (outside U.S.A. and Canada), or by e-mail to connectivity_tac@adc.com.

Page ii

Page 3

TABLE OF CONTENTS

Content Page

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Admonishments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

STANDARDS CERTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

List of Acronyms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 HOST UNIT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2 SeRF Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.3 DART Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.4 System Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.5 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.6 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 HOST UNIT ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Wavelength Division Multiplexer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1 Before Starting Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.2 Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.3 OSP Fiber Cable Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.4 WDM Host Module Mounting Shelf and WDM Host Module Installation Procedure . . . . . . . . . . . . . . . . . . . . 12

6.5 HU Mounting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.6 Chassis Ground Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.7 Coaxial Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.8 Optical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.9 EXT REF Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.10 Computer Connection (CRAFT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.11 Network Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.12 System Alarm System Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.13 Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.14 Installation Complete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

ADCP-75-348 • Issue 1 • 04/2008 • Preface

3.2.1 Network Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2.2 Craft Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2.3 Optical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3.1 RF Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.1.1 Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.8.1 Optical Connections Without WDM System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.8.2 Optical Connections For Systems With a WDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.13.1 DC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

© 2008, ADC Telecommunications, Inc.

Page iii

Page 4

ADCP-75-348 • Issue 1 • 04/2008 • Preface

TABLE OF CONTENTS

Content Page

7 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1 Host Unit Fan Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.2 Power Supply Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.3 System Card Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.4 SeRF Card Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.5 DART Card Replacement/Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.5.1 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.5.2 Install New DART Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8 CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Page iv

© 2008, ADC Telecommunications, Inc.

Page 5

ABOUT THIS MANUAL

This manual describes how to install and cable a URH Host chassis within a non-condensing

indoor environment such as inside a wiring closet or an outdoor controlled environment cabinet.

RELATED PUBLICATIONS

Listed below are related manuals, their content, and their publication numbers. Copies of these

publications can be ordered by contacting the Technical Assistance Center at 1-800-366-3891,

extension 73476 (in U.S.A. or Canada) or 952-917-3476 (outside U.S.A. and Canada). All ADC

technical publications are available for downloading from the ADC web site at www.adc.com.

Title/Description ADCP Number

ADC FlexWave™ Universal Radio Head (URH) Remote Installation Instructions 78-347

ADC FlexWave™ Universal Radio Head (URH) System User Manual 75-349

ADC FlexWave™ Universal Radio Head (URH) System EMS User Manual 75-350

ADC FlexWave™ URH Remote Unit Mounting Kit Installation Instructions 75-351

ADCP-75-348 • Issue 1 • 04/2008 • Preface

ADMONISHMENTS

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times.

These warnings are flagged by use of the triangular alert icon (seen below), and are listed in

descending order of severity of injury or damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

GENERAL SAFETY PRECAUTIONS

-

Warning: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrically-powered equipment. To prevent electrical shock, never install or

use electrical equipment in a wet location or during a lightning storm.

© 2008, ADC Telecommunications, Inc.

Page v

Page 6

ADCP-75-348 • Issue 1 • 04/2008 • Preface

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the eye. Do not look into the ends of any optical fiber. Do not

look directly into the optical transceiver of any digital unit or exposure to laser radiation may

result. An optical power meter should be used to verify active fibers. A protective cap or hood

MUST be immediately placed over any radiating transceiver or optical fiber connector to avoid

the potential of dangerous amounts of radiation exposure. This practice also prevents dirt

particles from entering the adapter or connector.

Caution: This system is a RF Transmitter and continuously emits RF energy. Maintain 3 foot

(91.4 cm) minimum clearance from the antenna while the system is operating. Wherever

possible, shut down the RAN before servicing the antenna.

Caution: Always allow sufficient fiber length to permit routing of patch cords and pigtails

without severe bends. Fiber optic patch cords or pigtails may be permanently damaged if bent

or curved to a radius of less than 2 inches (5.1 cm).

Caution: Exterior surfaces of the RU may be hot. Use caution during servicing.

STANDARDS CERTIFICATION

FCC: This equipment complies with the applicable sections of Title 47 CFR Part 15 (Host unit), Part 22 (800 MHz Cellular), Part 24 (1900 MHz - PCS), and Part 90 (800/900 - SMR).

IC:

This equipment complies with the applicable sections of RSS-131. The term “IC:” before the

radio certification number only signifies that Industry Canada Technical Specifications were met.

The Manufacturer's rated output power of this equipment is for single carrier operation. For

situations when multiple carrier signals are present, the rating would have to be reduced by 3.5

dB, especially where the output signal is re-radiated and can cause interference to adjacent band

users. This power reduction is to be by means of input power or gain reduction and not by an

attenuator at the output of the device.

Caution: Modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.

Note: To comply with Maximum Permissible Exposure (MPE) requirements, the maximum

composite output form the antenna cannot exceed 1000 Watts ERP (Cellular and SMR), the

antenna cannot exceed 1640 Watts EIRP (PCS), and the antenna must be permanently installed

in a fixed location that provides at least 6 meters (20 feet) of separation from all persons.

UL/CUL:

NEMA Type 6, per UL and CUL 50, Standard for Enclosures for Electrical Equipment. This

equipment provides the degree of protection specified by IP67 as defined in IEC Publication 529.

This will be installed in a restricted access location. This equipment complies with

Conforms to ANSI/UL Std. 60950. Certified to CAN/CSA STD C22.2 No 60950

UL/CUL: This Host equipment complies with UL and CUL 60950 Standard for Safety for Information Technology Equipment, including Electrical Business Equipment.

FDA/CDRH: This equipment uses a Class 1 LASER according to FDA/CDRH Rules. This product conforms to all applicable standards of 21 CFR Part 1040.

Page vi

© 2008, ADC Telecommunications, Inc.

Page 7

LIST OF ACRONYMS AND ABBREVIATIONS

The acronyms and abbreviations used in this manual are detailed in the following list:

AC Alternating Current

BTS Base Transceiver Station

C Centigrade

CM Centimeter

CPU Central Processing Unit

DART Digital/Analog Radio Transceiver (DART board)

DAS Distributed Antenna System

dB decibel

dBc The ratio (in dB) of the sideband power of a “signal” measured in a given band-

width at a given frequency offset from the center frequency of the same signal,

to the total inband power of the signal.

dB(FS) decibals (Full Scale – digital reading)

dBm deciBels relative to 1mW

DC Direct Current

Div Diversity

EMS Element Management System

ESD Electrostatic Discharge

F Fahrenheit

FCC Federal Communications Commission

GPS Global Positioning System

GUI Graphical User Interface

HU Host Unit

IC Industry Canada

IF Intermediate Frequency

IP Internet Protocol

LED Light Emitting Diode

LNA Low Noise Amplifier

LPA Linear Power Amplifier

LSE Location Services Equipment

LVD Low Voltage Disconnect

MUX Multiplexer

OSP Outside Plant

PA Power Amplifier

PC Personal Computer

PCI Peripheral Component Interconnect bus

QMA Quick disconnect version of Sub Miniature version A

RAN Radio Access Node

RDI Remote DART Interface (RDI board)

RF Radio Frequency

ADCP-75-348 • Issue 1 • 04/2008 • Preface

© 2008, ADC Telecommunications, Inc.

Page vii

Page 8

ADCP-75-348 • Issue 1 • 04/2008 • Preface

RU Remote Unit

SeRF Serialized RF (SeRF board)

SFP Small Form-Factor Pluggable Optical Transceiver

SMA Subminiature version A; Small form factor coaxial connector

UL Underwriters Laboratories

VA C Volts Alternating Current

VDC Volts Direct Current

VSWR Voltage Standing Wave Ratio

WDM Wave Division Multiplex

WSP Wireless Service Provider

Page viii

© 2008, ADC Telecommunications, Inc.

Page 9

1 GENERAL

Flexwave

URH

HOST

FWD RF IN

REV RF OUT

BTS 1

Flexwave

URH

REMOTE

ANTENNA

INTERFACE

BTS 1

BTS 2

BTS 3

ANTENNA

INTERFACE

BTS 2

ANTENNA

INTERFACE

BTS 3

NON-DIVERSITY

Flexwave

URH

HOST

FWD RF IN

REV RF OUT

BTS 1

Flexwave

URH

REMOTE

ANTENNA

INTERFACE

BTS 1

BTS 2

BTS 3

ANTENNA

INTERFACE

BTS 2

ANTENNA

INTERFACE

BTS 3

DIVERSITY

REV DIV RF OUT

FWD RF OUT

REV RF IN

REV DIV RF IN

FWD RF OUT

REV RF IN

REV DIV RF IN

FWD RF OUT

REV RF IN

REV DIV RF IN

FWD RF IN

REV RF OUT

REV DIV RF OUT

FWD RF IN

REV RF OUT

REV DIV RF OUT

FWD RF IN

REV RF OUT

FWD RF IN

REV RF OUT

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

22380-A

ADCP-75-348 • Issue 1 • 04/2008

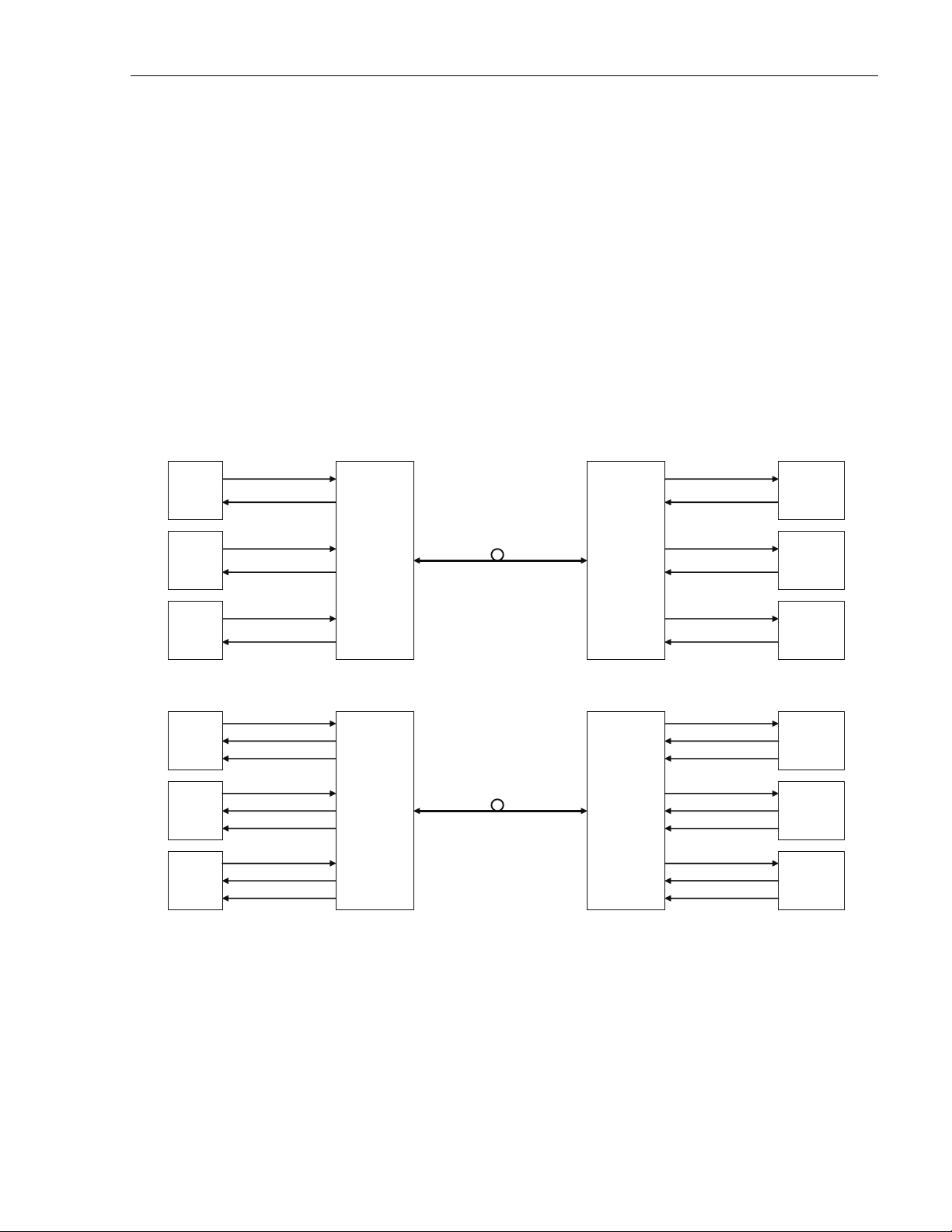

The FlexWave URH product family of products is intended as a “next generation” distributed

antenna system (DAS). DAS products provide bidirectional transport of digitized RF spectrum.

Each link consists of a host unit (providing the interface between the base station RF ports and the

optical fiber) and at least one remote unit (providing the interface between the optical fiber and the

remote antenna). The difference in this product is the high-speed digitalization of a wideband

portion of spectrum, that allows for transport of RF signals over extended distances, without the

RF degradation that normally results when analog systems are impacted by optical effects.

The basic function of the FlexWave URH platform is to transport via fiber optic cable RF

signals form a Base Transceiver Station (BTS) to an antenna interface allowing communication

to a mobile device. Multiple BTS communication paths are allowed over a single URH system.

Diversity receive is supported. A block diagram of the system is shown in

Figure 1.

Figure 1. FlexWave URH Block Diagram

The basic function of the FlexWave URH simulcast (point-to-point) platform is to transport, via

fiber optic cable, RF signals form a Base Transceiver Station (BTS) to multiple antenna interfaces

allowing communication to a mobile device. Up to 8 simulcast remotes are supported.

© 2008, ADC Telecommunications, Inc.

Page 1

Page 10

ADCP-75-348 • Issue 1 • 04/2008

2 INTRODUCTION

The front access URH Host Unit interfaces with the BTS and performs the analog to digital and

electrical to optical conversions for transport to the URH Remote Units. A typical URH system

consists of a Host Unit (HU) and a Remote Unit (RU).

The HU is designed for maximum RF flexibility to address Carriers changing and evolving

spectrum needs, making the most use of cost efficient resources for serving multiple remotes

such as simulcast architecture and sharing of common functions such as power, control and

management over multiple host units. These features are designed into a compact package that

reduces the amount of overall rack space required within a BTS Hotel. Each host chassis can

support up to eight RUs.

The HU is a three rack-unit high single-unit assembly that mounts in a standard equipment rack.

The RU consists of an outdoor enclosure that houses various electronic components. The RU is

a modular self-contained enclosure. Together the HU and the RU together comprise an URH

system. Various accessory items are also available for use with each system. All items

referenced as “accessory items” are not furnished and must be purchased separately.

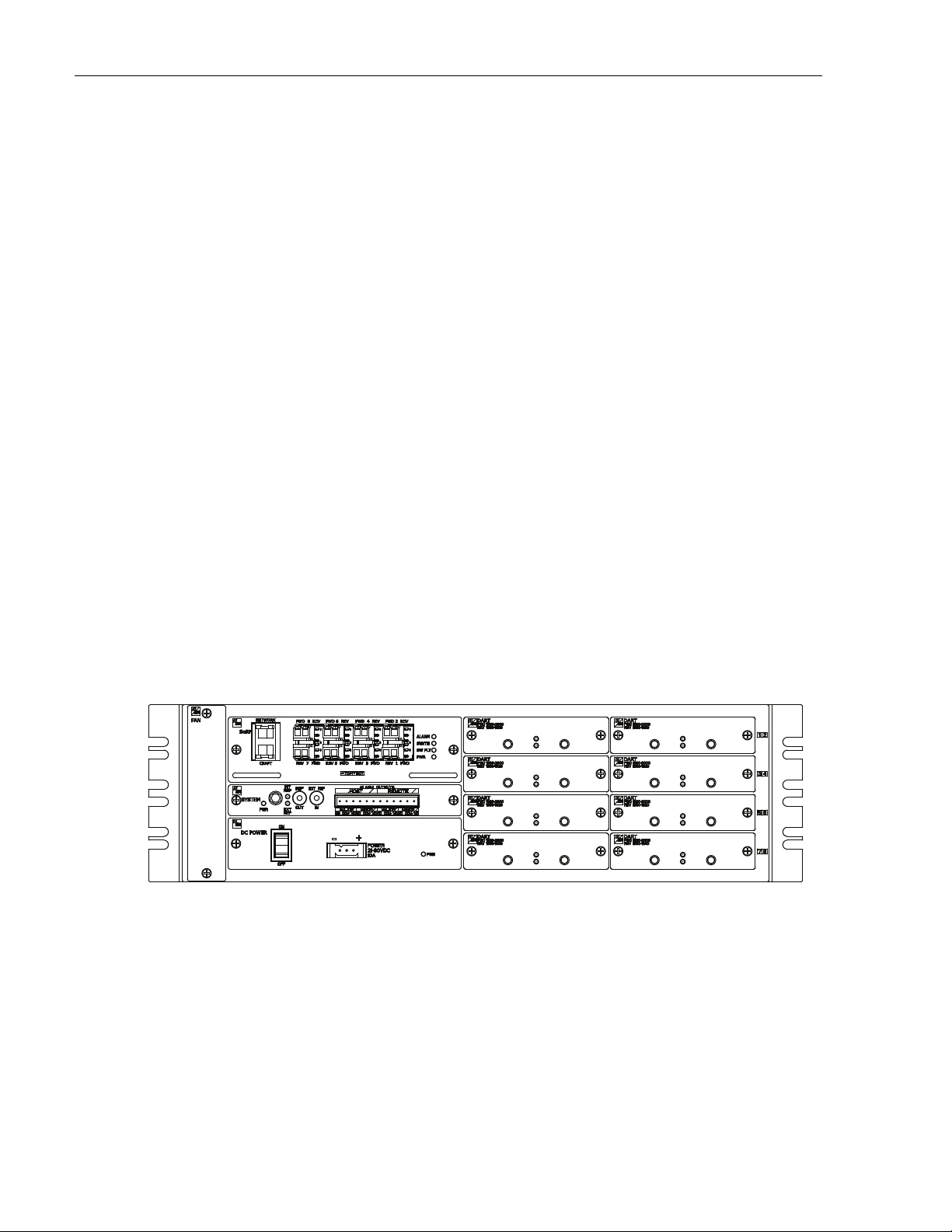

3 HOST UNIT DESCRIPTION

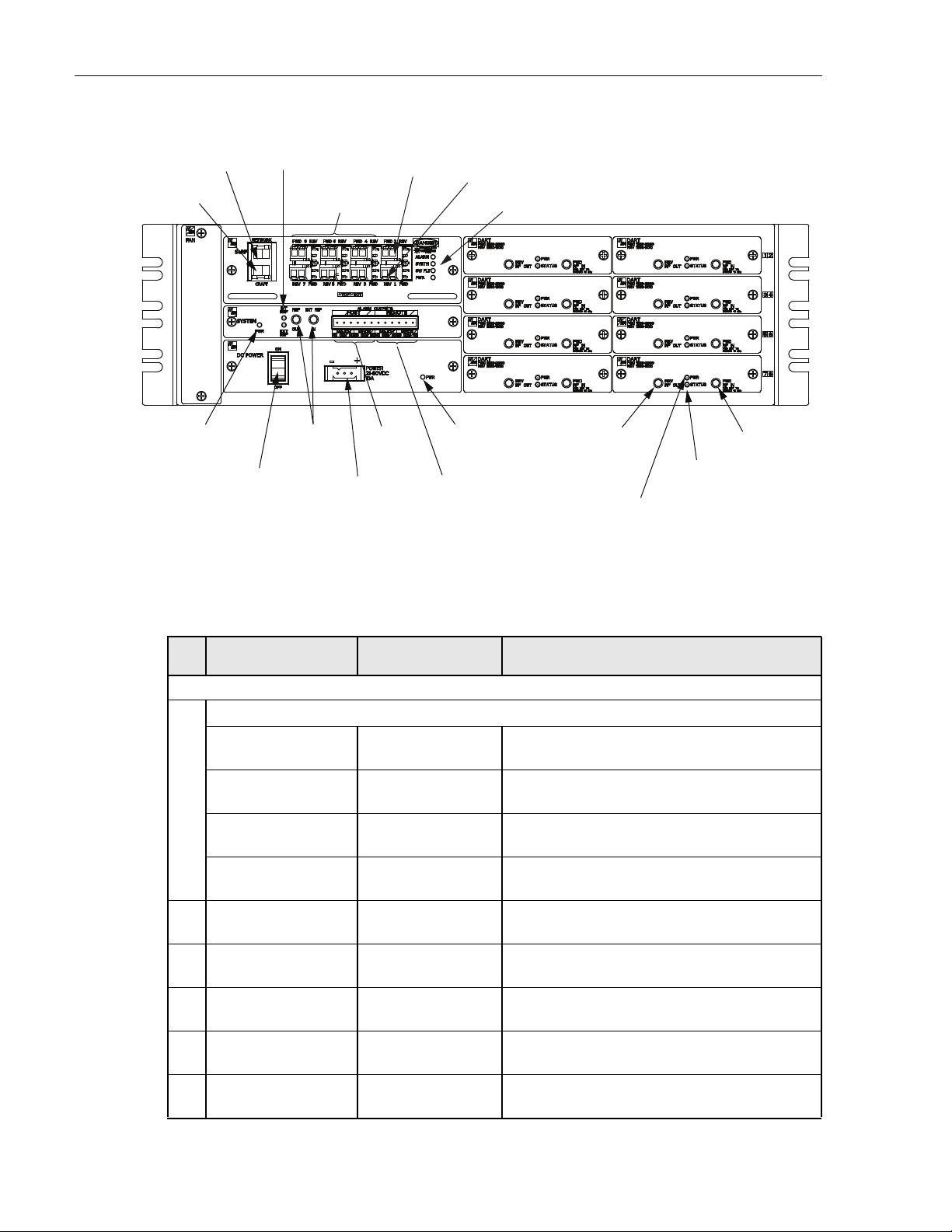

A front view of the HU, shown in

fan assembly that are mounted within a powder-paint coated sheet metal enclosure. The enclosure

provides a mounting point for the circuit board and fan assembly and controls RF emissions. Fan

assembly can be replaced in the field. Host Unit may be upgraded once it is installed to support

additional URH Remote Units. This can be performed without disrupting service.

The HU is designed for use within a non-condensing indoor environment such as inside a wiring

closet or controlled environment cabinet. All controls, connectors, and indicators (except the

grounding point) are mounted on the HU front panel. Current versions of the HU allow vertical

cable guides to be installed over the mounting brackets on either side of the HU.

Figure 2

, consists of an electronic circuit board assembly and a

STATUS

REV

RF OUT

REV

RF OUT

REV

RF OUT

REV

RF OUT

PWR

STATUS

PWR

STATUS

PWR

STATUS

PWR

REV

RF IN

REV

RF IN

REV

RF IN

REV

RF IN

Figure 2. Front View Host Unit

REV

RF OUT

REV

RF OUT

REV

RF OUT

REV

RF OUT

STATUS

PWR

STATUS

PWR

STATUS

PWR

STATUS

PWR

REV

RF IN

REV

RF IN

REV

RF IN

REV

RF IN

22381-A

Page 2

© 2008, ADC Telecommunications, Inc.

Page 11

3.1 Mounting

The HU is intended for rack-mount applications. A pair of reversible mounting brackets is

provided that allow the HU to be mounted in either a 19-inch or 23-inch EIA or WECO

equipment rack. When installed, the front panel of the HU is flush with the front of the rack.

Screws are provided for securing the HU to the equipment rack.

3.2 SeRF Card

3.2.1 Network Interface Connection

SeRF front panel has an Ethernet port allowing interface communication with the internal

processor and transfer of data to the optical protocol allowing IP transport between the HU and

the remote(s). The network interface allows the HU to be controlled through a network.

Network interface connection between the HU and the network is supported by a RJ-45 jack 10/

100Base-T (IEEE802.3 compliant) with integrated green ACTIVITY and LINK LEDs. The

Ethernet port supports a maximum cable length of 100 meters (328 feet) to a hub or back-toback nodes. CAT5 or better cable should be used when making this connection. The Ethernet

connection should not be connected to an Ethernet circuit used outside the building.

ADCP-75-348 • Issue 1 • 04/2008

1. The IEEE Specification for Ethernet 100BaseT requires that two twisted pairs be used and that one pair is connected to pins 1 and 2, and that the second pair is connected to pins 3 and 6.

2. Pinout information is shown in Tab le 1. See Figure 3 for RJ45 connector wiring information.

Table 1. 100BaseT Ethernet RJ45 Connector

PIN # DESCRIPTION

1 TRD0+

2 TRD0–

3 TRD1+

4 TRD2+

5 TRD2–

6 TRD1–

7 TRD3–

8 TRD3+

© 2008, ADC Telecommunications, Inc.

Page 3

Page 12

ADCP-75-348 • Issue 1 • 04/2008

RJ-JACK

PIN 1

PIN 8

11899-A

3.2.2 Craft Interface Connection

SeRF front panel provides a craft port that can be used to provision remote units through the

optical protocol supported by a single RJ-45 connector. The Craft connector provides an

Ethernet interface.

Craft interface connection between the HU and the network is supported by a RJ-45 jack 10/

100Base-T (IEEE802.3 compliant) with integrated green ACTIVITY and LINK LEDs. The

Ethernet port supports a maximum cable length of 100 meters (328 feet) to a hub or back-toback nodes. CAT5 or better cable should be used when making this connection.

Figure 3. RJ45 Connector Wiring

1. The IEEE Specification for Ethernet 100BaseT requires that two twisted pairs be used and that

2. Pinout information is shown in Table 1. See Figure 3 for RJ45 connector wiring

3.2.3 Optical Interface

Optical connections between the HU SeRF card and the RU are supported through Small Formfactor Pluggable (SFP) transceivers. The optical interfaces are standard single-mode duplex LC

(flat polished UPC). There are 8 duplex optical interfaces, one for each simulcast remote.

3.3 DART Card

The host DART provides the interface between base station equipment and the SeRF. It is a band specific assembly and exists in the following versions:

• Cellular

•SMR 800

•SMR 900

•PCS

one pair is connected to pins 1 and 2, and that the second pair is connected to pins 3 and 6.

information.

The following features and capabilities are available on the DART Card:

• Amplifies, down-converts, filters and digitizes from a 1.5MHz to 35MHz band of the

incoming RF signal

Page 4

© 2008, ADC Telecommunications, Inc.

Page 13

• Converts incoming digital signal to analog, filters, amplifies and up-converts

• Provides bi-directional interface between parallel digital RF (to D/A and from A/D) and

Serial RF (SeRF) to/from SeRF board

• Performs digital up/down conversion and adjustable delay processing

• Non-contiguous bands and receive diversity is implemented with multiple DART Cards

3.3.1 RF Signal Connections

The RF signal connections between the HU DART cards and the BTS are supported through

two (FWD RF IN and REV RF OUT) QMA-Type female connectors. One connector is used for

the forward path RF signal. The other connector is used for the reverse path RF signal. In some

installations, it may be necessary to install a Conditioning Panel and/or Duplexing Panel

(accessory items) to support the interface between the HU and the BTS. The HU should be as

close as possible to the BTS to minimize cable losses.

3.4 System Card

ADCP-75-348 • Issue 1 • 04/2008

The System Interface Card gives additional front panel space for the SeRF card. The System

Card front panel also provides connections for alarm outputs, 10 MHz output, and status LEDs.

This card may be used to provide a 10 MHz clock reference to which the SeRF's Master clock is

frequency locked from the internal crystal oscillator. When the internal clock is not used the

clock can be obtained from an external 10 MHz input.

3.5 Power Supply

HU is powered by a modular DC to DC power supply located on the lower left side of the

chassis. An On/Off switch is provided on the HU power supply module front panel.

HU is powered by ± 20 to ± 60 VDC power (nominal ± 24 or ± 48 VDC), power is fed to the HU

through a connector located on the front of the module. Power to the HU must be supplied

through a fuse panel (available separately). Each HU must be protected with a fuse.

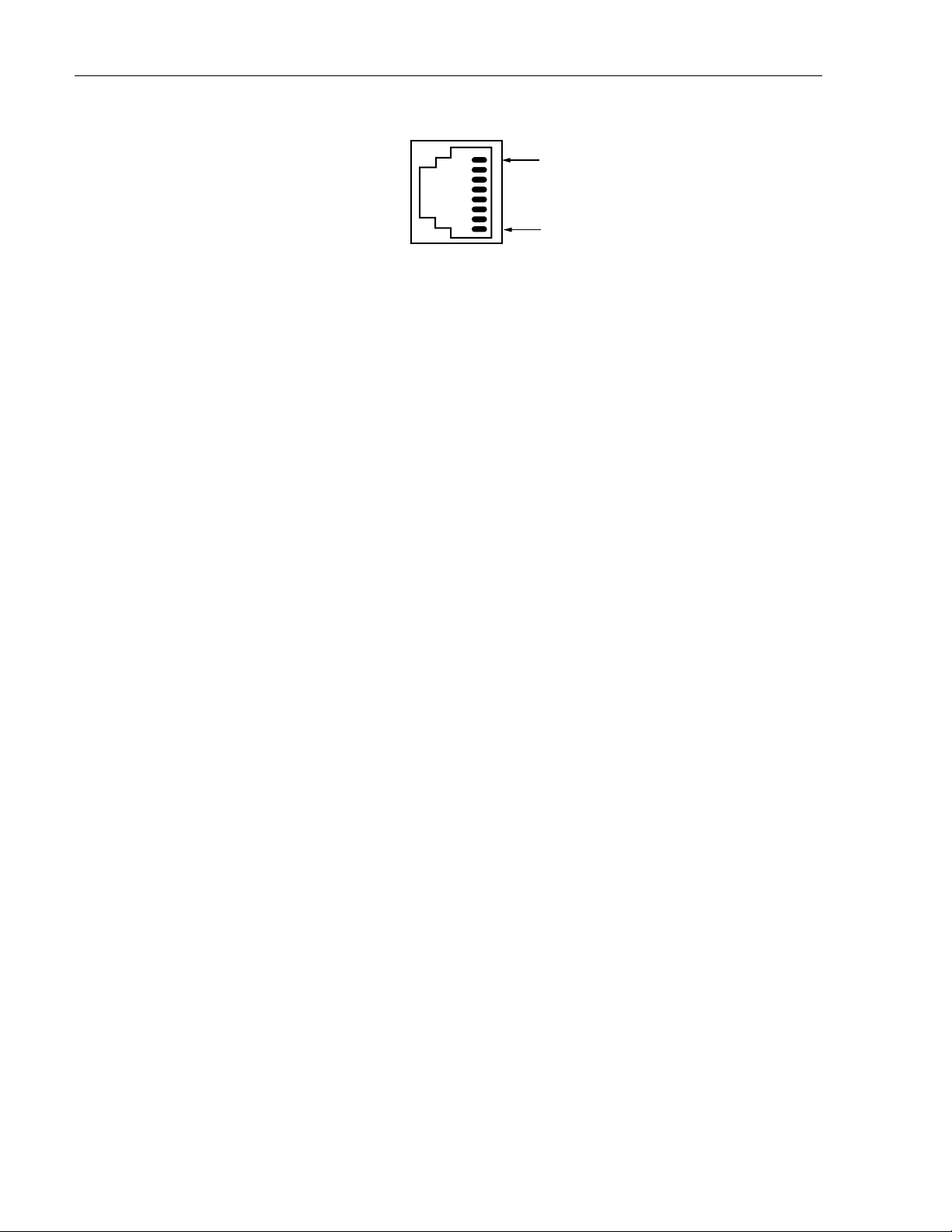

3.6 User Interface

The HU user interface consists of the various connectors, switches, terminals, and LEDs that are

provided on the HU front panel. The HU user interface points are indicated in

described in Tabl e 2.

Figure 4 and

© 2008, ADC Telecommunications, Inc.

Page 5

Page 14

ADCP-75-348 • Issue 1 • 04/2008

(5) NETWORK

INTERFACE

(6) CRAFT

INTERFACE

(10) SYSTEM CARD

POWER LED

INDICATOR

(8) DC POWER

ON/OFF SWITCH

(13) REF LED

INDICATORS

(4) OPTICAL PORT

CONNECTORS 3 - 8

(14 & 15)

REF OUT

AND IN JACKS

CONNECTOR

(11) HOST

ALARM

OUTPUTS

(9) POWER

(3) PORT 2

REV

CONNECTOR

(12) REMOTE

OUTPUTS

(2) PORT 1

FWD

CONNECTOR

(1) SeRF CARD

ALARM LEDS

(7) POWER

LED INDICATOR

ALARM

Figure 4. Host Unit User Interface

(18) REV RF

OUT JACK

(16) DART POWER

LED INDICATOR

22382-B

(19) FWD RF

IN JACK

(17) DART STATUS

LED INDICATOR

Table 2. Host Unit User Interface

REF NOUSER INTERFACE

DESIGNATION

DEVICE

FUNCTIONAL DESCRIPTION

SeRF CARD

1 SeRF Card LEDs

ALARM GREEN

RED

SYNTH GREEN

RED

SW FLT GREEN

RED

PWR GREEN

OFF

2 PORT 1 or FWD LC connector

(single-mode)

3 PORT 2 or REV LC connector

(single-mode)

4 PORT 3 –8 LC connector

(single-mode)

No alarms

Alarms present

Locked

Unlocked

Software operating OK

Software fault present

Power OK and operating properly

No power present

Output connection point for the forward path

optical fiber.

Input connection point for the reverse path primary optical fiber.

Input/output connection points for the remaining

optical fibers.

5 NETWORK RJ-45 jack (female) Connection point for the NETWORK interface

input cable.

6 CRAFT RJ-45 jack (female) Connection point for the CRAFT interface input

Page 6

© 2008, ADC Telecommunications, Inc.

cable.

Page 15

Table 2. Host Unit User Interface, continued

ADCP-75-348 • Issue 1 • 04/2008

REF NOUSER INTERFACE

DESIGNATION

7 PWR (LED) GREEN

RED

DEVICE

POWER SUPPLY

FUNCTIONAL DESCRIPTION

DC Power Supply OK

DC Power Supply Fault

8 ON/OFF On/Off rocker switch Provides HU power on/off control.

9 POWER 20–60 VDC Three position

Connection point for the DC power wiring.

connector

SYSTEM CARD

10 PWR (LED) GREEN

RED

11 ALARM OUTPUTS

HOST

12 ALARM OUTPUTS

REMOTE

13 INT REF (LED)

EXT REF (LED)

Twelve position terminal block. Screwtype terminal

connector (14–26

AWG)

GREEN

OFF

GREEN

OFF

System Card Power Supply OK

System Card Power Supply Fault

Connection points for an major and minor dry

alarm contacts. Includes normally open (NO),

normally closed (NC), and common (COM) wir

ing connections.

Internal 10 MHz reference selected as the as Reference Clock.

Internal 10 MHz reference not selected.

External 10 MHz reference selected as the as

Reference Clock.

External 10 MHz reference not selected

-

14 REF OUT QMA-Type female

15 EXT REF IN QMA-Type female

16 PWR (LED) GREEN

17 STATUS (LED) GREEN

18 REV RF OUT QMA-Type female

19 FWD RF IN QMA-Type female

4 HOST UNIT ACCESSORIES

This section provides a brief description of various accessory items that are available separately.

The accessory items may or may not be required depending on the application.

RF coaxial connector

RF coaxial connector

DART CARD

OFF

RED

YELLOW

RF coaxial connector

RF coaxial connector

Ref Clock

Ref Clock

Card is powered.

No power present at card.

OK

Fault

Unlocked

Output connection point for the primary reverse

path RF coaxial cable.

Input connection point for the forward path RF

coaxial cable.

© 2008, ADC Telecommunications, Inc.

Page 7

Page 16

ADCP-75-348 • Issue 1 • 04/2008

22390-A

4.1 Wavelength Division Multiplexer System

The Wavelength Division Multiplexer (WDM) system is an accessory product that is used when

it is desirable or necessary to combine the forward and reverse path optical signals from one

URH system onto a single optical fiber. Each WDM system consists of a host module and a

remote module.

Both the host unit WDM module and the RU WDM module consist of a bi-directional wavelength

division multiplexer. The host unit WDM module is mounted within a powder-paint coated sheet

metal enclosure. A straight LC-type optical connector port is provided for connecting the forward/

reverse path optical fiber to the WDM module. A pair of pigtail leads with LC-type connectors are

provided for connecting the WDM module to the forward and reverse path optical ports on the HU

SeRF card.

The WDM host module mounting shelf and host module are shown in Figure 5. The WDM

module is shown in Figure 6.

Page 8

© 2008, ADC Telecommunications, Inc.

Figure 5. WDM Host Module and Host Module Mounting Shelf

22391-A

Figure 6. Host Unit WDM Module

Page 17

5 SPECIFICATIONS

The specifications for the host unit are provided in Tabl e 3.

PARAMETER SPECIFICATION REMARKS

Dimensions (H×W×D) 5.17 × 17.26 × 9.5 inches

Mounting 19- or 23-inch rack EIA or WECO

Weig ht 20 lbs. (9.1 kg)

Weather resistance Indoor installation only Environmentally controlled out-

Operating temperature 0º to 55º C (32º to 131º F)

Storage temperature –40º to 70º C (–40º to 158ºF)

Humidity 10% to 90% No condensation

Optical ports SFP pluggable transceivers LC (UPC)

Transceivers Fujitsu FIM32151 or FIM32141 Available from ADC

Table 3. Host Unit Nominal Specifications

Dimension for width does not

(131.3 × 438.4 × 241.3 mm)

include the mounting brackets

which can be installed for either

19- or 23-inch racks.

door cabinet.

ADCP-75-348 • Issue 1 • 04/2008

External alarm connector Screw-type terminals NO, COM, and NC relay contacts

Voltage input

DC Power ±20 – ±60 VDC

Power consumption 320 Watts (Maximum) 202 Watts nominal

Current rating 4.2 Amps

RF coaxial cable connectors 50 ohm QMA – type (female) 50 ohms input/output impedance

Network and Craft connectors RJ–45 jack

Reliability at 25ºC MTBF 100,000 hours Including fans

6 INSTALLATION

This section provides the installation procedures for the HU and the WDM host module (accessory item). Installation of the RU components may proceed separately from installation of the HU.

6.1 Before Starting Installation

Before beginning the installation, review the system design plan with the system engineer.

Make sure each equipment installation site is identified and located and all cable runs are

mapped out. Also identify all tools and materials that are required to complete the installation.

7.2 Amps

At –48VDC

At +28VDC

© 2008, ADC Telecommunications, Inc.

Page 9

Page 18

ADCP-75-348 • Issue 1 • 04/2008

6.1.1 Tools and Materials

The following tools are required to complete the procedures in this section:

• Box cutter

• Pencil or scribe

• Medium size flat-bladed screwdriver

• Phillips screwdriver (#2)

•Pliers

• Wire cutters

• Wire stripper

• Tool kit for attaching QMA-Type male connectors to coaxial cable

• Multimeter

•Optical power meter

The following materials are required to complete the procedures in this section:

• #18 AWG (1.0 mm) insulated stranded copper wire (for chassis grounding wire)

• #18 AWG (1.0 mm) red and black insulated copper wire (for DC power wires)

• Category 3 or 5 cable (for external alarm system wires)

• Category 5 cable with RJ45 connectors for the Network and Craft port

• #6 ring terminal (1) for #18 wire (for chassis ground wire connection)

• #6 fork terminals (2) for #18 wire (for DC power wiring connection)

• Single-mode patch cord(s) with LC connectors (1 – 8 depending on the application)

• High performance, flexible, low-loss 50-ohm coaxial cable

• QMA-type male connectors

• Wire ties

6.2 Unpacking and Inspection

This section provides instructions for opening the shipping boxes, verifying that all parts have been received, and verifying that no shipping damage has occurred. Use the following procedure to unpack and inspect the HU and any accessories:

Unpack and inspect the various components as follows:

1. Inspect the exterior of the shipping container(s) for evidence of rough handling that may have damaged the components in the container.

2. Unpack each container while carefully checking the contents for damage and verify with the packing slip.

3. If damage is found or parts are missing, file a claim with the commercial carrier and notify ADC Customer Service. Save the damaged cartons for inspection by the carrier.

4. Refer to Section 8 if you need to contact ADC.

5. Save all shipping containers for use if the equipment requires shipment at a future date.

Page 10

© 2008, ADC Telecommunications, Inc.

Page 19

6.3 OSP Fiber Cable Installation Guidelines

The outside plant (OSP) fiber optic cables should be routed between the HU distribution panel

and RU outside plant cabinet and terminated before the equipment is installed. A diagram of a

typical OSP cable routing is shown in

at a fiber distribution panel and spliced to pigtails. Jumper patch cords may then be used to link

the HU optical ports to the OSP cable terminations. Whenever possible, a guideway such as the

FiberGuide system should be provided to protect the fiber optic patch cords from damage and to

prevent excessive bending. The procedures for connecting the OSP cable optical fibers to the

HU is provided in

X

Section 6.8.

SPLICE

TERMINATION

ADCP-75-348 • Issue 1 • 04/2008

Figure 7. At the HU, the OSP cable should be terminated

HOST UNIT

PATCH

CORDS

INDOOR

REMOTE SITE

FIBER DISTRIBUTION

URH

REMOTE

UNIT

PANEL

X

OUTDOOR

REMOTE SITE

HOST SITE

OUTSIDE PLANT

CABLE

URH

REMOTE

UNIT

INDOOR/OUTDOOR

QUAD CABLE WITH

PRE-TERMINATED

CONNECTOR

X

OUTSIDE PLANT

CABINET

Figure 7. Typical Fiber Optic Cable Routing

22383-A

Page 11

© 2008, ADC Telecommunications, Inc.

Page 20

ADCP-75-348 • Issue 1 • 04/2008

6.4 WDM Host Module Mounting Shelf and WDM Host Module Installation Procedure

A bi-directional wavelength division multiplexer (WDM) system is available as an accessory

item for the URH system. If the application does not require the use of a WDM system, skip this

section and proceed to

The WDM host module mounting shelf installs in the equipment rack with the HU. Each host

module mounting shelf can hold multiple modules and each host module can support two HU’s.

When multiple HU’s require connection to a WDM system, the host module mounting shelf and

the HU’s should be mounted in the equipment rack as shown in

allows the pigtail leads from the two host modules to be connected directly to the optical ports

on any one of the four HU’s.

POWERWORX

FUSE PANEL

WDM MOUNTING

SHELF

(WITHOUT MODULES)

Section 6.5.

Figure 8. This configuration

HOST SLACK FIBER STORAGE

HOST UNITS

The WDM host module mounting shelf may be mounted in either a 19-inch or 23-inch EIA or

WECO equipment rack. Four #12-24 screws are provided for securing the mounting shelf to the

rack. Use the following procedure to install the WDM host module mounting shelf in the

equipment rack and to mount the WDM modules in the WDM host module mounting shelf:

Page 12

© 2008, ADC Telecommunications, Inc.

22392-A

Figure 8. Typical WDM and HU Configuration

Page 21

ADCP-75-348 • Issue 1 • 04/2008

22393-A

1. The WDM host module mounting shelf is shipped with the mounting brackets installed for

23-inch rack installations. If installing the mounting shelf in a 23-inch rack, proceed to

Step 4. If installing the mounting shelf in a 19-inch rack proceed to Step 2.

2. Remove both mounting brackets from the mounting shelf (requires Phillips screwdriver) and save screws for reuse.

3. Reinstall both mounting brackets so the short side of the bracket is flush with the front

panel as shown in as shown in

Figure 9. Use the screws removed in Step 2 to attach the

new brackets to the mounting shelf.

4. Position the mounting shelf in the designated mounting space in the rack (per system design plan) and then secure the mounting brackets to the rack using the four #12-24 machine screws provided.

5. Install each WDM host module in the mounting shelf. A rail on the side of the module fits into a guide within the mounting.

6. Secure each host module to the mounting shelf by twisting the handle on each quarter-turn fastener 90º.

7. Carefully store the pigtail leads from each host module. The routing and connection

procedures for the pigtails are provided in

6.5 HU Mounting Procedure

The HU may be mounted in either a 19-inch or 23-inch EIA or WECO equipment rack. Both

US standard and metric machine screws are included for rack mounting the HU. When loading

the HU in a rack, make sure the mechanical loading of the rack is even to avoid a hazardous

condition such as a severely unbalanced rack. The rack should safely support the combined

weight of all the equipment it holds. In addition, maximum recommended ambient temperature

for the HU is 55º C (131º F). Allow sufficient air circulation or space between units when the

HU is installed in a multi-rack assembly because the operating ambient temperature of the rack

environment might be greater than room ambient.

Figure 9. Installing the Replacement Mounting Brackets

Section 6.8.

© 2008, ADC Telecommunications, Inc.

Page 13

Page 22

ADCP-75-348 • Issue 1 • 04/2008

Warning: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrically powered equipment. To prevent electrical shock, never install or

use electrical equipment in a wet location or during a lightning storm.

Note: To insure that all optical connectors remain dust-free during installation, leave all dust

caps and dust protectors in place until directed to remove them for connection.

Use the following procedure to install the HU in the equipment rack:

1. The HU is shipped with the mounting brackets installed for 19-inch rack installations. If

mounting the HU in a 19-inch rack, proceed to

rack, proceed to Step 2.

2. Remove both mounting brackets from the HU (requires TORX screwdriver with T20 bit) and save screws (six-screws on each side) for reuse.

3. Reinstall both mounting brackets so the short side of the bracket is flush with the HU front

panel as shown in

the HU chassis.

Step 4. If mounting the HU in a 23-inch

Figure 10. Use the screws removed in Step 2 to re-attach the brackets to

INSTALL MOUNTING

BRACKETS AS SHOWN FOR

INSTALLATION IN 23-INCH RACKS

22394-A

Figure 10. Installing the Mounting Brackets for 23-Inch Rack Installations

4. Position the HU in the designated mounting space in the rack (per system design plan) and then secure (but do not tighten) the HU to the rack using the four machine screws provided (use #12-24 or M6 x 10 screws, whichever is appropriate).

Note: Provide a minimum of 3 inches (76 mm) of clearance space on both the left and

right sides of the HU for air intake and exhaust.

5. Locate two vertical cable guides, not provided with the HU.

Note: A vertical cable guide kit is available separately as an accessory.

Page 14

© 2008, ADC Telecommunications, Inc.

Page 23

6. Back out the HU mounting screws just enough to provide clearance for installation of the

22395-A

REAR OF

CHASSIS

STAR

WASHER

HEX

NUT

GROUND

WIRE

cable guides.

7. Slide each cable guide into position for installation and then securely tighten the corresponding mounting screws.

6.6 Chassis Ground Connection

A stud is provided on the rear side of the chassis for connecting a grounding wire to the chassis.

Use the following procedure to connect the grounding wire to the chassis and to route the

grounding wire to an approved earth ground source.

1. Obtain a length of #18 AWG (1.00 mm) insulated stranded copper wire for use as a chassis grounding wire.

2. Terminate one end of the wire with a ring terminal.

3. Locate the chassis ground stud at the rear of the HU as shown in Figure 11.

4. Attach the ring end of the wire to the chassis ground stud (see Figure 11).

ADCP-75-348 • Issue 1 • 04/2008

Figure 11. Chassis Ground Stud

5. Route the free end of the chassis grounding wire to an approved (per local code or practice) earth ground source.

6. Cut the chassis grounding wire to length and connect it to the approved ground source as required by local code or practice.

Note: Be sure to maintain reliable grounding. Pay particular attention to ground source

connections.

© 2008, ADC Telecommunications, Inc.

Page 15

Page 24

ADCP-75-348 • Issue 1 • 04/2008

6.7 Coaxial Cable Connections

The RF interface between the HU DART card and the EBTS/BTS is supported through two type

QMA female connectors mounted on each DART front panel. One connector provides the

coaxial cable connection for the forward path (downlink) signal and the other connector

provides the coaxial cable connection for the reverse path (uplink) signal.

In most installations, it is usually necessary to insert an

external attenuator

into the forward path

link between the HU and the BTS. A signal level that is greater than –9 dBm will overdrive and

possibly damage the HU receiver. Before completing the forward path connection at the BTS,

verify that the composite forward path RF signal level at the HU is between

–25 and +5 dBm

.

The HU should be mounted as close as possible to the EBTS/BTS to minimize cable losses. Use the following procedure to route and connect the forward and reverse path coaxial cables to the HU DART cards:

1. Obtain the required lengths of high performance, flexible, low loss 50-ohm coaxial communications cable (RG-400 or equivalent) for all coaxial connections.

2. Route the forward and reverse path coaxial cables between the HU and the BTS interface

(per system design plan) and cut to the required length. Allow sufficient slack for dressing

and organizing cables at the HU and for installing an external attenuator in the forward

path link.

3. Terminate each cable with an QMA-Type male connector following the connector supplier’s recommendations.

4. If required, install an external attenuator in the forward path.

Note: The composite forward path RF signal level at the HU must be between –25 and

+5 dBm. Do not connect the forward path cable until the composite forward path RF

signal level is measured and the amount of external attenuation required is determined.

5. Connect the forward path cable to the FWD RF IN connector on the HU DART front

panel as shown in

6. Connect the reverse path cable to the REV RF OUT connector on the HU DART front

panel (see

7. Repeat this procedure for the remaining DART cards in the HU.

8. Dress and secure cables at the right side of the HU.

9. Complete all remaining coaxial connections as specified in the system design plan.

Page 16

© 2008, ADC Telecommunications, Inc.

Figure 12.

Figure 12).

Page 25

ADCP-75-348 • Issue 1 • 04/2008

6.8 Optical Connections

The optical interface between the HU and the RU is supported by optical ports. Each optical

port consists of an SFP with LC optical transceivers mounted on the SeRF card front panel.

Each FWD port provides an optical connection for the forward path (downlink) signal. Each

REV port provide an optical connection for the reverse path (uplink) signal. Each REV port can

also provide the optical connection for the diversity reverse path (uplink) signal.

The optical connections are dependent on whether or not a WDM host module (accessory) is installed:

• If the installation does not include a WDM module, proceed to Section 6.8.1 for the

optical connections procedure.

• If the installation includes a WDM module, proceed to Section 6.8.2 for the optical

connections procedure.

22411-A

Figure 12. Forward and Reverse Path Coaxial Cable Connections

© 2008, ADC Telecommunications, Inc.

Page 17

Page 26

ADCP-75-348 • Issue 1 • 04/2008

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the eye. Do not look into the ends of any optical fiber. Do not

look directly into the optical transmitter of any unit or exposure to laser radiation may result.

An optical power meter should be used to verify active fibers. A protective cap or hood MUST

be immediately placed over any radiating transmitter or optical fiber connector to avoid the

potential of dangerous amounts of radiation exposure. This practice also prevents dirt particles

from entering the connector.

6.8.1 Optical Connections Without WDM System

Use the following procedure to connect the optical fibers when there is no WDM installed with the HU:

1. Obtain two patch cords that are of sufficient length to reach from the HU to the fiber distribution panel.

2. Designate one of the patch cords as the forward path link and the other as the reverse path link and attach an identification label or tag next to the connector.

3. Remove the dust caps from the HU SeRF SFP optical ports and from the patch cord connectors that will be connected to the SeRF SFP optical ports.

4. Clean each patch cord connector following the patch cord supplier’s recommendations.

Note: To protect the optical receivers, insert a 15 dB attenuator in each optical path. When

the system is turned-up and tested, the attenuator may be resized or removed.

5. Insert each patch cord connector into the appropriate optical port as shown in Figure 13 and as specified by the following:

PORT 1 FWD - Forward path patch cord

PORT 1 REV - Reverse path patch cord

Caution:

Improper handling can damage fiber optic cables. Do not bend fiber optic cable more

sharply than the minimum recommended bend radius specified by the cable manufacturer. Do not

apply more pulling force to the cable than specified.

6. Route the patch cords from the HU to the fiber distribution panel.

Note: The HU optical adapters are angled to the left. Therefore, always route patch cords

to the HU from the left side of the rack. Routing patch cords to the HU from the right may

exceed the bend radius limitations for the optical fiber.

7. At the fiber distribution panel, identify the OSP cable optical fiber terminations that correspond to the forward and reverse paths.

8. Remove the dust caps from the OSP cable optical fiber adapters and from the patch cord connectors.

9. Clean each patch cord connector (follow patch cord supplier’s recommendations) and then mate the connector with the appropriate OSP cable adapter.

Page 18

© 2008, ADC Telecommunications, Inc.

Page 27

PORT 8 FWD

(FORWARD PATH)

PORT 8 REV

(REVERSE PATH)

ADCP-75-348 • Issue 1 • 04/2008

22410 -A

Figure 13. Fiber Optic Cable Connections To Host Unit

10. Repeat this procedure for the remaining SeRF SFPs in the HU.

11. Store any excess patch cord slack at the fiber distribution panel or storage panel.

6.8.2 Optical Connections For Systems With a WDM

Use the following procedure to connect the optical fibers when a WDM module is installed with the HU:

1. Obtain a patch cord that is of sufficient length to reach from the WDM module to the fiber distribution panel.

2. Remove the dust cap from WDM Port or Port 4 on the WDM module and from the patch cord connector that will be connected to the WDM module.

Note: WDM module ports are labeled FWD, REV, TEST, and WDM.

© 2008, ADC Telecommunications, Inc.

Page 19

Page 28

ADCP-75-348 • Issue 1 • 04/2008

FIBER DISTRIBUTION

PANEL (FDP)

X

X

HOST UNIT 1

PORT 8

FWD

PORT 8

REV

REVERSE

PATH

FORWARD

PATH

WAVELENGTH

DIVISION

MULTIPLEXERS

1234

PORT 1

FWD

PORT 1

REV

HOST UNIT 2

REVERSE

PATH

FORWARD

PATH

22416-A

TO/FROM

REMOTE UNIT 1

TO/FROM

REMOTE UNIT 1

HOST UNIT 1

(BI-DIRECTIONAL FIBER

LINK WITH REMOTE UNIT)

HOST UNIT 1

(BI-DIRECTIONAL FIBER

LINK WITH REMOTE UNIT)

PORT 1

FWD

PORT 1

REV

REVERSE

PATH

FORWARD

PATH

1234

TESTTEST

1234

TEST

FIBER DISTRIBUTION

PANEL (FDP)

X

TO/FROM

REMOTE UNIT 2

HOST UNIT 2

(BI-DIRECTIONAL FIBER

LINK WITH REMOTE UNIT)

Figure 14. Fiber Optic Connections To WDM Module

3. Clean the patch cord connector (follow patch cord supplier’s recommendations).

4. Insert the connector into the WDM module optical WDM port (port 4).

5. Route the patch cord from the WDM to the fiber distribution panel or storage panel.

6. Identify the OSP cable optical fiber termination that corresponds to the RU.

7. Remove the dust cap from the OSP cable optical adapter and from the patch cord connector.

8. Clean the patch cord connector (follow patch cord supplier’s recommendations) and then mate the connector with the appropriate OSP cable adapter.

9. Store any excess patch cord slack at the fiber distribution panel.

10. Obtain two patch cords that are of sufficient length to reach from the WDM module to the HU.

11. Designate one of the patch cords as the forward path link and the other as the reverse path link and attach an identification label or tag next to the connector.

12. Remove the dust caps from the HU SeRF SFP optical ports and from the patch cord connectors that will be connected to the SeRF SFP optical ports.

13. Clean each pigtail connector (follow the procedures provided with the WDM module) and

then insert the connector into the appropriate optical port on the HU as shown in

and as diagramed in Figure 14.

Note: To protect the optical receivers, insert a 15 dB attenuator in each optical path. When

the system is turned-up and tested, the attenuator may be resized or removed.

Figure 13

Page 20

© 2008, ADC Telecommunications, Inc.

Page 29

Note: The HU SeRF SFP optical adapters are angled to the left. Therefore, pigtails should

22407-A

always be routed to the HU from the left side of the rack. Routing pigtails to the HU from

the right side of the rack may exceed the bend radius limitations for the optical fiber.

6.9 EXT REF Connections

Note: When using the 10 MHz external reference clock the signal must be connected to

the HU before enabling the clock source in the software.

EXT REF connections between multiple HU’s is supported through two QMA type female

connectors mounted on the System card. One of the jacks is designated as the IN port and the

other jack is designated as the OUT port. The EXT REF interface allows HU’s to be connected

together (in daisy-chain fashion) and clocked through a single source. Use the following

procedure to connect EXT REF interface cables between multiple HU’s:

1. Connect one end of the EXT REF interface cable (accessory) to either the IN or OUT port

on HU #1 as shown in

ADCP-75-348 • Issue 1 • 04/2008

Figure 15.

Figure 15. EXT REF Connections

2. Route the EXT REF interface cable to HU #2 and connect the cable’s free end to the port that is the logical opposite of the EXT REF interface connection at HU #1.

© 2008, ADC Telecommunications, Inc.

Page 21

Page 30

ADCP-75-348 • Issue 1 • 04/2008

HOST UNIT 3 HOST UNIT 2 HOST UNIT 1

OUT EXT IN

NET IN NET OUT

NET IN NET OUT

22414-A

COAXIAL

INTERFACE CABLES

TO NEXT HOST UNIT

(NOTE: LAST HOST HAS NO

CONNECTION AT EXT OUT)

OUT EXT IN OUT EXT IN

REF CLOCK

INPUT

Note: Connect OUT to IN and IN to OUT. If connected to a EXT REF OUT port at HU

#1, connect to the EXT REF IN port at HU #2. If connected to a EXT REF IN port at HU

#1, connect to a EXT REF OUT port at HU #2.

3. If a third HU will be connected to the network, connect a second EXT REF interface cable to the remaining network port on HU #2.

4. Route the second EXT REF interface cable to HU #3 and connect the cable’s free end to the port that is the logical opposite of the EXT REF interface connection at HU #2.

5. Repeat steps 3 and 4 for each additional HU that is added to the network. A diagram of

typical EXT REF interface connections is shown in

Figure 16.

Figure 16. Configuring EXT REF Connections with Multiple Host Units

6.10 Computer Connection (CRAFT)

The service interface connection between the HU and the computer is supported by a single RJ45 connector. Use the following procedure to install the service interface cable:

1. Connect one end of the service interface cable (accessory) to the CRAFT port as shown in

Figure 17.

2. Route the service interface cable to the computer and connect the free end of the cable to the computer’s port. Refer to the user manual provided with the computer to locate and configure the specified port.

Page 22

© 2008, ADC Telecommunications, Inc.

Page 31

ADCP-75-348 • Issue 1 • 04/2008

22403-A

RJ-45

CONNECTOR

DETAIL

Figure 17. Craft Interface and Network Interface Connections

6.11 Network Connection

A network connection between the HU and the network is used to monitor and configure the

FlexWave URH system through a single IP connection. Use the following procedure to install

the network interface cable:

1. Connect one end of the cable (accessory) to the NETWORK port as shown in Figure 17.

2. Route the cable to the computer and connect the free end of the cable to the computer’s port. Refer to the user manual provided with the computer to locate and configure the specified port.

Page 23

© 2008, ADC Telecommunications, Inc.

Page 32

ADCP-75-348 • Issue 1 • 04/2008

6.12 System Alarm System Connections

The alarm interface between the HU and an alarm system is supported by twelve-terminal plug

(with screw-type terminals) that connects to a receptacle mounted on the HU System card front

panel. The terminal plug provides connections to normally open (NO) and normally closed

(NC) dry type alarm contacts for both major and minor alarms. A category 3 or 5 cable is

typically used to connect the HU System card to the alarm system. Use the following procedure

to install the alarm wiring and connect it to the HU:

1. Obtain the required length of category 3 or 5 cable.

2. Route the cable between the HU System card and the alarm system (if not already routed) and then cut to the required length. Allow sufficient slack for dressing and organizing the cable at the HU.

3. Strip back the outer cable sheath and insulation to expose the wires at both ends of the cable and strip back 0.2 inches (5 mm) of insulation from each wire.

4. Connect the Major alarm wire pair to the MAJOR COM/NC or MAJOR COM/NO

terminals (whichever is required by the alarm system) on the HU System card alarm

terminal connector (supplied with HU System card) as shown in

Figure 18.

5. Connect the Minor alarm wire pair to the MINOR COM/NC or MINOR COM/NO

terminals (whichever is required by the alarm system) on the HU System card alarm

terminal connector (see

Figure 18 and Table 4).

6. Connect the Major and Minor alarm wire pairs to the appropriate terminals on the external alarm system.

7. Dress and secure cable per standard industry practice.

Table 4. System Card Alarm Pin Designations

PIN DESCRIPTION

1 Host Minor Normally Closed

2 Host Minor Common

3 Host Minor Normally Open

4 Host Major Normally Closed

5 Host Major Common

6 Host Major Normally Open

7 Remote Minor Normally Closed

8 Remote Minor Common

9 Remote Minor Normally Open

10 Remote Major Normally Closed

11 Remote Major Common

Page 24

© 2008, ADC Telecommunications, Inc.

12 Remote Major Normally Open

Page 33

PIN 1

ADCP-75-348 • Issue 1 • 04/2008

PIN 12

6.13 Power Connections

HU is powered by a modular power supply located on the lower left side of the chassis. An On/

Off switch is provided on the HU power supply module front panel.

6.13.1 DC Power Connections

The HU is powered by ± 20 to 60 VDC power (nominal ± 24 or ± 48 VDC), install DC Power

Supply in the lower left side of the HU chassis. Secure in place by turning screws clock-wise

until tight.

22406-A

Figure 18. Alarm System Connections

© 2008, ADC Telecommunications, Inc.

Page 25

Page 34

ADCP-75-348 • Issue 1 • 04/2008

A three position terminal block is provided for connecting the power wires. The power is fed to

the HU Power Supply module through a connector located on the front of the unit. Power to the

HU must be supplied through a fuse panel such as the 20 position PowerWorx GMT Fuse Panel

(available separately) and the power must be protected with a 15 Amp GMT fuse.

Use the following procedure to install the power wiring:

1. Obtain the items listed below:

• Wire stripper and screwdriver

•Wire,

for the power leads, when fused in the same bay.

2.

Turn power switch on power supply OFF.

3. Connect the wires to the designated terminals on the fuse panel.

4. Dress and secure the wires to the rack following local practice. Route wiring away from sharp edges and secure in place to prevent chaffing and provide strain relief.

Note: All DC input wiring should be routed away from any sharp edges and properly

secured in place to prevent chafing and to provide strain relief. This may be achieved by

tie-wrapping wires to the rack frame or by a similar means.

#18 AWG (1.00 mm) red and black insulated copper wire

. Recommended wire size

5. Route the wires to the terminal block (Figure 19) on the HU Power Supply and cut them to length, allowing sufficient length for termination.

6. Loop both power wires around and through the Ferrite as shown in Figure 19.

7. Strip 1.27 cm (0.5 inch) of insulation from the end of each wire.

8. Insert one end of each wire into the terminal block, one into + and the other into the – position.

9. The terminal block must plug into the three-pin receptacle on the front of the HU Power Supply.

10. Install fuses in the fuse panel. Update office records as required.

Note: When connecting the equipment to the supply circuit, be sure to check equipment

nameplate ratings to avoid overloading circuits which may cause damage to over-current

protection devices and supply wiring.

11.

Turn power switch on power supply ON.

12. The procedure for checking the voltage level and verifying that the HU is ready to power up is provided in the applicable System Operation and Maintenance Manual (see Related Publications section).

Page 26

© 2008, ADC Telecommunications, Inc.

Page 35

ADCP-75-348 • Issue 1 • 04/2008

22405-A

FERRITE

6.14 Installation Complete

When the installation is complete, refer to the applicable System User Manual (see Related

Publications section) for the system turn-up and test procedures.

7 MAINTENANCE

This section provides the HU maintenance procedures. Refer to this section when scheduled

maintenance is required. The fault isolation and troubleshooting procedures are provided in the

applicable System Operation and Maintenance Manual (see Related Publications section). Host

Unit card locations are shown in

Figure 19. DC Power Connections

Figure 20.

Page 27

© 2008, ADC Telecommunications, Inc.

Page 36

ADCP-75-348 • Issue 1 • 04/2008

SeRF CARD

SYSTEM CARD

POWER SUPPLY

DART CARD

DART CARD

DART CARD

DART CARD

DART CARD

DART CARD

DART CARD

DART CARD

FAN ASSEMBLY

22402-A

Figure 20. Host Unit Card Locations

7.1 Host Unit Fan Replacement Procedure

The HU is equipped with a fan assembly consisting of two cooling fans which is located on the

left side of the HU enclosure. The cooling fans blow cool air into the enclosure. Heated air is

exhausted through the vent openings on the right side of the enclosure. Replacement of fan

assembly does not require that the HU be turned off. The recommended replacement interval is

60 months. Use the following procedure to remove and replace the HU cooling fans:

1. Before working on the HU or handling a fan, slip on an Electro-Static Discharge (ESD) wrist strap and connect the ground wire to an earth ground source. Wear the ESD wrist strap while completing each section of the fan installation procedure.

Warning: Electronic components can be damaged by static electrical discharge. To prevent

ESD damage, always wear an ESD wrist strap when working on the HU and when handling

electronic components.

2. Notify the NOC or alarm monitoring system operator that the fan is being replaced.

3. Loosen the two thumb screws that secure the fan/grill assembly to the front of the HU

enclosure as shown in

Figure 21.

4. Carefully withdraw the fan/grill assembly from the enclosure.

5. Slide the new fan assembly into the HU chassis until it is firmly seated.

6. Secure the fan/grill assembly to the front of the enclosure (see Figure 21) using the two screws loosened in Step 3.

7. Verify that the fans run properly following power-up.

8. Notify the NOC or alarm monitoring system operator that the fans are back in operation.

Page 28

© 2008, ADC Telecommunications, Inc.

Page 37

ADCP-75-348 • Issue 1 • 04/2008

THUMB

SCREWS

Figure 21. Host Unit Fan Assembly Removal

7.2 Power Supply Replacement Procedure

Removing the power supply will disable the Host Unit and interrupt service. Notify the NOC or

alarm monitoring system operator that the system will be out of service for a period of time.

1. Before working on the HU or handling a power supply, slip on an Electro-Static Discharge

(ESD) wrist strap and connect the ground wire to an earth ground source. Wear the ESD

wrist strap while completing each section of the fan installation procedure.

Warning: Electronic components can be damaged by static electrical discharge. To prevent

ESD damage, always wear an ESD wrist strap when working on the HU and when handling

electronic components.

2. Turn power switch to the OFF position.

22396-A

FAN

ASSEMBLY

3. Unplug power plug by applying pressure to the left and right side of the connector and pulling it straight out.

4. Loosen the two thumb screws that secure the Power Supply to the front of the HU

enclosure. See

Figure 22.

5. Carefully withdraw the Power Supply from the enclosure.

6. Slide replacement Power Supply into the HU chassis until it is firmly seated.

7. Secure the Power Supply to the front of the enclosure using the two thumb screws

loosened in

Step 4.

8. Plug power plug into the power connector on the front of the Power Supply. Make certain that it is fully seated.

© 2008, ADC Telecommunications, Inc.

Page 29

Page 38

ADCP-75-348 • Issue 1 • 04/2008

22400-A

Figure 22. Power Supply Replacement

9. Turn power switch to the ON position.

10. Notify the NOC or alarm monitoring system operator that the system is back in operation.

7.3 System Card Replacement Procedure

System Card can be replaced without disrupting service. If the EXT REF is being used

communications to other HU’s will be disrupted.

1. Before working on the HU or handling a System Card, slip on an Electro-Static Discharge

(ESD) wrist strap and connect the ground wire to an earth ground source. Wear the ESD

wrist strap while completing each section of the fan installation procedure.

Warning: Electronic components can be damaged by static electrical discharge. To prevent

ESD damage, always wear an ESD wrist strap when working on the HU and when handling

electronic components.

2. Notify the NOC or alarm monitoring system operator that the System Card is being replaced.

3. If used, disconnect EXT REF cables from the front of the System Card.

4. Remove alarm plug from the front of the System Card by pressing on the lock tabs.

5. Loosen the two thumb screws that secure the System Card to the front of the HU

enclosure. See

Page 30

© 2008, ADC Telecommunications, Inc.

Figure 23.

Page 39

ADCP-75-348 • Issue 1 • 04/2008

6. Carefully withdraw the System Card from the enclosure.

7. Slide replacement System Card into the HU chassis until it is firmly seated.

8. Secure the System Card to the front of the enclosure using the two thumb screws loosened

Step 5.

in

9. If used, connect EXT REF cables to the front of the System Card.

10. Plug alarm plug into the connector on the System Card.

11. On the Power Supply turn the power switch OFF and then back ON to reset the System Card.

12. Notify the NOC or alarm monitoring system operator that the system is back in operation.

Figure 23. System Card Replacement

7.4 SeRF Card Replacement Procedure

Removing the SeRF Card will disable the Host Unit and interrupt service. Notify the NOC or

alarm monitoring system operator that the system will be out of service for a period of time.

1. Before working on the HU or handling a SeRF Card, slip on an Electro-Static Discharge

(ESD) wrist strap and connect the ground wire to an earth ground source. Wear the ESD

wrist strap while completing each section of the fan installation procedure.

Warning: Electronic components can be damaged by static electrical discharge. To prevent

ESD damage, always wear an ESD wrist strap when working on the HU and when handling

electronic components.

22398-A

Page 31

© 2008, ADC Telecommunications, Inc.

Page 40

ADCP-75-348 • Issue 1 • 04/2008

22397-A

HANDLES

2. Remove Network and Craft RJ-45 plugs from the front of the SeRF Card.

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the eye. Do not look into the ends of any optical fiber. Do not

look directly into the optical transmitter of any unit or exposure to laser radiation may result.

An optical power meter should be used to verify active fibers. A protective cap or hood MUST

be immediately placed over any radiating transmitter or optical fiber connector to avoid the

potential of dangerous amounts of radiation exposure. This practice also prevents dirt particles

from entering the connector.

3. Remove fiber pigtails from the SFP’s. Note the location of the pigtails.

Caution:

Improper handling can damage fiber optic cables. Do not bend fiber optic cable more

sharply than the minimum recommended bend radius specified by the cable manufacturer. Do not

apply more pulling force to the cable than specified.

4. Loosen the two thumb screws that secure the System Card to the front of the HU

enclosure. See

Figure 24.

Figure 24. SeRF Card Replacement

5. Use the two handles to carefully withdraw the SeRF Card from the enclosure.

6. Slide replacement SeRF Card into the HU chassis until it is firmly seated.

7. Secure the SeRF Card to the front of the enclosure using the two thumb screws loosened in

Step 4.

8. If necessary install new SFP’s or remove them from the SeRF card removed in Step 5 and install them in the new SeRF Card.

9. Plug fiber pigtails back into the SFP’s.

Page 32

© 2008, ADC Telecommunications, Inc.

Page 41

10. Plug Network and Craft RJ-45 plugs into the connector on the SeRF Card. Make certain the pigtails are inserted in the correct SFP.

11. Notify the NOC or alarm monitoring system operator that the system is back in operation.

7.5 DART Card Replacement/Installation Procedure

Each DART Card provides an interface between the SeRF and the Power Amplifier they are

spectrum specific. When additional service is needed another DART Card can be added to the

HU and the corresponding cover added to a Remote Unit. Individual DART Cards may be

replaced without disrupting service to the entire remote system. Only the RF spectrum of the

DART Card being removed is affected. Refer to

7.5.1 Replacement

1. Before working on the HU or handling a DART Card, slip on an Electro-Static Discharge

(ESD) wrist strap and connect the ground wire to an earth ground source. Wear the ESD

wrist strap while completing each section of the fan installation procedure.

ADCP-75-348 • Issue 1 • 04/2008

Figure 25.

Warning: Electronic components can be damaged by static electrical discharge. To prevent

ESD damage, always wear an ESD wrist strap when working on the HU and when handling

electronic components.

2. Notify the NOC or alarm monitoring system operator that the DART Card is being replaced.

3. Disconnect REF IN and OUT cables from the front of the DART Card.

4. Loosen the two thumb screws that secure the DART Card to the front of the HU enclosure.

5. Carefully withdraw the DART Card from the enclosure.

6. Slide replacement DART Card into the HU chassis until it is firmly seated.

7. Secure the DART Card to the front of the enclosure using the two thumb screws loosened

in

Step 4.

8. Connect REF IN and OUT cables to the front of the DART Card.

9. Notify the NOC or alarm monitoring system operator that the system is back in operation.

© 2008, ADC Telecommunications, Inc.

Page 33

Page 42

ADCP-75-348 • Issue 1 • 04/2008

22401-A

Figure 25. DART Card Replacement/Installation

7.5.2 Install New DART Card

1. Before working on the HU or handling a DART Card, slip on an Electro-Static Discharge

(ESD) wrist strap and connect the ground wire to an earth ground source. Wear the ESD

wrist strap while completing each section of the fan installation procedure.

Warning: Electronic components can be damaged by static electrical discharge. To prevent

ESD damage, always wear an ESD wrist strap when working on the HU and when handling

electronic components.

2. Notify the NOC or alarm monitoring system operator that another DART Card is being added the HU.

3. Determine slot location of the new DART Card. Remove blank panel from the front of the HU.

4. Slide DART Card into the HU chassis until it is firmly seated.

5. Secure the DART Card to the front of the enclosure using the two thumb screws.

6. Obtain the required lengths of high performance, flexible, low loss 50-ohm coaxial communications cable (RG-400 or equivalent) for all coaxial connections.

7. Route the forward and reverse path coaxial cables between the HU and the BTS interface

(per system design plan) and cut to the required length. Allow sufficient slack for dressing

and organizing cables at the HU and for installing an external attenuator in the forward

path link.

8. Terminate each cable with an QMA-type male connector following the connector supplier’s recommendations.

9. If required, install an external attenuator in the forward path.

Page 34

© 2008, ADC Telecommunications, Inc.

Page 43

ADCP-75-348 • Issue 1 • 04/2008