Page 1

ADCP-61-743 • Issue 3 • September 2004

Content Page

1 DESCRIPTION ........................................................................................................................................4

2 INSTALLATION ......................................................................................................................................6

3 LED CHECK ......................................................................................................................................... 10

4 FRONT PANEL OPERATION ...................................................................................................................... 11

5 CONFIGURATION .................................................................................................................................. 12

6 TL1 COMMANDS................................................................................................................................... 28

7 SPECIFICATIONS .................................................................................................................................. 29

8 CUSTOMER INFORMATION AND ASSISTANCE ............................................................................................... 30

INTRODUCTION

Soneplex

®

Remote Test Access Unit (RTAU)

User Manual)

1.1 DS3 MUX Compatibility .....................................................................................................................6

2.1 Initial Installation ............................................................................................................................7

2.1.1 Damaged Pins......................................................................................................................... 8

2.2 Maintenance Installation (Existing System) .............................................................................................9

This manual describes and provides installation procedures for the Remote Test Access Unit

(RTAU) module used in the Soneplex Broadband System (MPU V5.3 and SCU V3.0 or later).

Revision History

ISSUE DATE REASON FOR CHANGE

Issue 1 06/1999 Original

Issue 2 04/2000 Add DS3 MUX compatibility and SCU 3.0 or later support.

Issue 3 09/2004 Technically updated 2. Installation, 3. LED Check, and 8. Customer Information and Assistance

Trademark Information

ADC and ADC Telecommunications are registered trademarks of ADC Telecommunications, Inc.

Soneplex is a registered trademark of ADC Telecommunications, Inc.

sections.

1304058 Page 1

2004, ADC Telecommunications, Inc.

Page 2

ADCP-61-743 • Issue 3 • September 2004

Related Publications

Listed below are related manuals and their publication numbers. Copies of these publications

can be ordered by contacting the ADC Technical Assistance Center at 1-800-366-3891.

Title ADCP Number

Soneplex Broadband System Description, Design, and Application Manual (V5) ADCP-61-472

Soneplex Broadband System Operation and Maintenance Manual (V5) ADCP-61-471

Soneplex DS3 MUX Module Installation Instructions ADCP-61-742

Soneplex System Installation Manual LTPS-UM-8010

Soneplex Shelf Controller Unit (V4.1) User Manual LTPS-UM-8031

Admonishments

Important safety admonishments are used throughout this manual to warn of possible hazards

to persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below), and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

General Safety Precautions

Caution: Electronic modules can be damaged by electrostatic discharge (ESD). Before

handling modules, wear an anti-static discharge wrist strap to prevent damage to electronic

components. Place modules in anti-static packing material when transporting or storing. When

working on modules, always place them on an approved anti-static mat that is electrically

grounded.

Page 2

2004, ADC Telecommunications, Inc.

Page 3

FCC Compliance Statement

The Remote Test Access Unit has been certified to comply with the requirements for Class A

computing devices per part 15 of the FCC regulations.

ADCP-61-743 • Issue 3 • September 2004

Warning: This equipment generates, uses, and can radiate radio frequency energy and if not

installed and used in accordance with the instruction manual, may cause interference to radio

communications. It has been tested and found to comply with limits for a Class A digital device

pursuant to Subpart A of Part 15 of FCC Rules, which are designed to provide reasonable

protection against such interference when operated in a commercial environment. Operation

of this equipment in a residential area is likely to cause interference to TV and radio reception

in which case the user, at their own expense, will be required to take whatever measures may

be required to correct the interference.

This equipment does not exceed Class A limits for radio emission for digital apparatus, set out in

the radio interference regulation of the authorization methods of Industry Canada. Operation in

a residential area may cause unacceptable interference to TV and radio reception requiring the

owner or operator to take whatever steps are necessary to correct the interference.

Certification

The Soneplex Broadband system is compliant with UL 1459.

Standards

ANSI T1.403-1997 Carrier to Customer Installation: DS1 Metallic Interface, 1997

TR-NPL-000054 High-Capacity Digital Service (1.544 Mbps) Interface General

Requirements for End Users, Issue 1, April 1989

© 2004, ADC Telecommunications, Inc.

Page 3

Page 4

ADCP-61-743 • Issue 3 • September 2004

1 DESCRIPTION

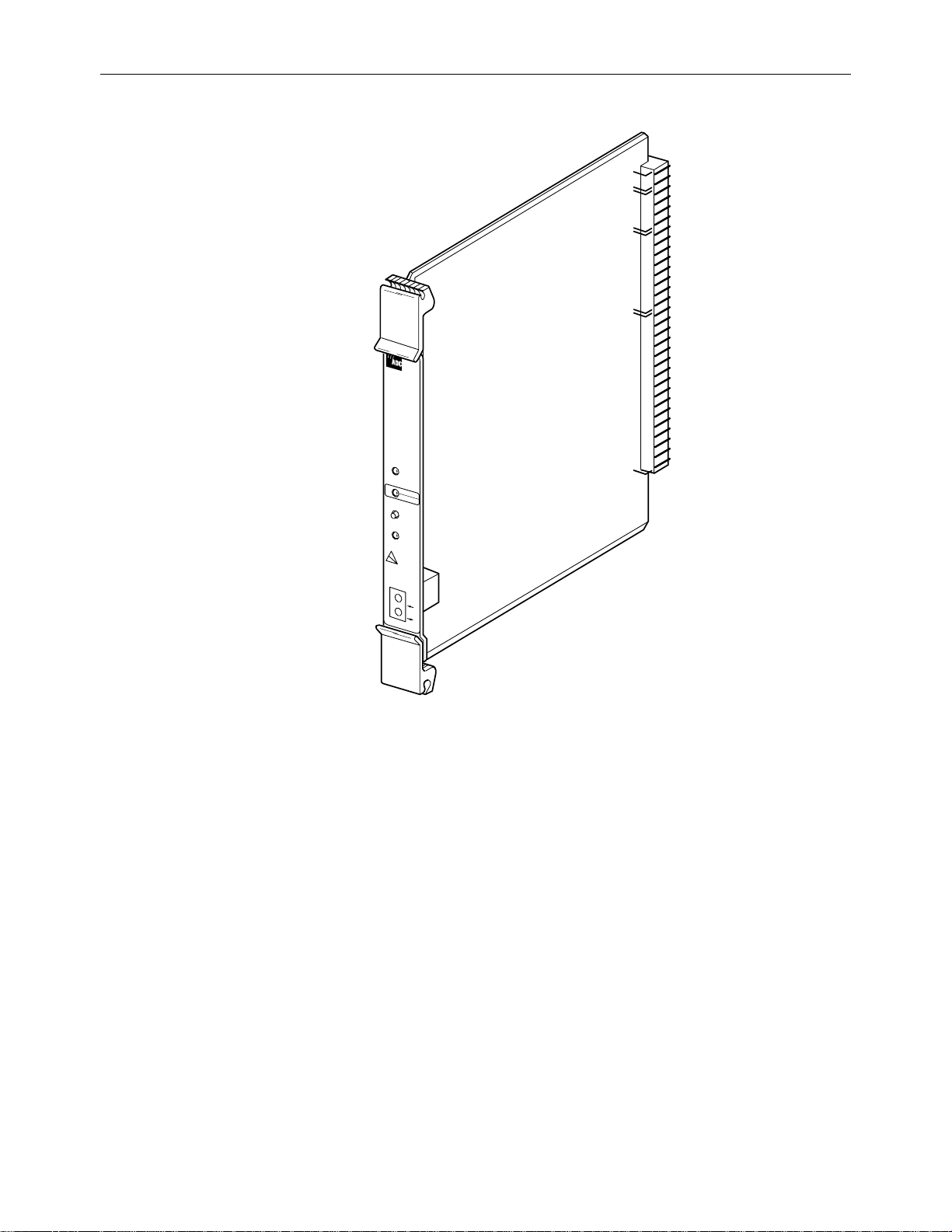

The Remote Test Access Unit (RTAU) (Figure 1) provides maintenance functionality for

monitoring and intrusive test access to the DS1 channels in the chassis between the DS3 MUX

and the low speed distribution modules (DLX, HLXC, ODS2, and RLX). The RTAU requires

no periodic maintenance. It requires the Version D1 or later DS3 MUX module and MPU

Version 5.3 or SCU Version 3.0 or later system software to be functional in the Soneplex

Broadband System for DS3 applications. If an earlier version of MPU software is used, the

RTAU will appear as a blank slot on the Craft Interface’s Inventory Status screen. Earlier

versions of the SCU software will not display the TAU slot.

The RTAU has the following features:

• Access supervision for intrusive testing (i.e., monitor access, split access for both A and

B transmission paths, and loop access for both A and B transmission paths).

• Stress testing of any circuit within the system via the Internal Test Signal Generation

feature. Many DS1 networks are tested by passing repeating sequences (patterns) of

logical ones and zeros through the network, also known as stress test patterns. As the test

patterns are applied to the circuit, they are compared with the original pattern to

determine if any errors are introduced. QRS (Quasi Random Signal) is one of the test

patterns supported. (QRS conforms to TR-NPL-000054.)

• Capable of inserting bit errors at a specified rate or as single errors or burst errors to the

DS1 circuit being tested.

• Ability to monitor (intrusively or non-intrusively) the DS1 circuit being tested.

• User control through the Craft Interface or via the TL1 interface.

• Access to the DS1 through front panel bantam jacks or through the internal test signal

generator. This control is configurable through the Craft Interface.

• Supports the Building Integrated Timing Supply (BITS) primary interface through the

wire wrap pins on the back of the Soneplex Broadband chassis. If a valid BITS signal is

applied to the Broadband chassis, the RTAU will automatically switch over to the BITS

primary interface and use the recovered clock for timing.

Note: The BITS secondary interface on the Soneplex Broadband chassis is not supported

by the RTAU.

Page 4

2004, ADC Telecommunications, Inc.

Page 5

RTAU

STATUS

B8ZS

AMI

LINE CODE

INTRUSIVE

TEST

ADCP-61-743 • Issue 3 • September 2004

BIPOLAR

ACCESS

D

S

RX

1

TX

11897-A

Figure 1. Remote Test Access Unit (RTAU) Module

© 2004, ADC Telecommunications, Inc.

Page 5

Page 6

ADCP-61-743 • Issue 3 • September 2004

1.1 DS3 MUX Compatibility

Refer to Table 1 for compatibility information for DS3 MUXs, test access units, and MPU/SCU

software versions.

Table 1. DS3 MUX, TAU/RTAU, and MPU/SCU Software Compatibility

DS3 MUX TYPE

C1 TAU 5.1.1 or later 2.5 or later TAU

C1 RTAU 5.1.1 or later 2.0 or later NO TEST ACCESS

D1 TAU 5.1.1 or later 2.5 or later TAU

D1 RTAU 5.2 or earlier 2.5 or earlier NO TEST ACCESS

D1 RTAU 5.3 3.0 or later RTAU

G1 TAU 5.1.1 or later 2.5 or later TAU

G1 RTAU 5.2 or earlier 2.5 or earlier NO TEST ACCESS

G1 RTAU 5.3 3.0 or later RTAU

Refer to the Soneplex System Operation and Maintenance Manual listed under Related

Publications at the beginning of this manual for more information.

2 INSTALLATION

There are two installation procedures:

• Initial Installation - This installation procedure applies to the first time an IBBC shelf

will be populated with a RTAU module.

TEST ACCESS

UNIT TYPE

MPU SOFTWARE

VERSION

SCU SOFTWARE

VERSION

FUNCTIONALITY

• Maintenance Installation (Existing System) - This installation procedure applies to an

IBBC shelf that has already been populated with a RTAU module.

Please follow the appropriate procedure per your system configuration.

Page 6

2004, ADC Telecommunications, Inc.

Page 7

2.1 Initial Installation

This installation procedure applies to the first time an IBBC shelf will be populated with

a RTAU module. If the IBBC shelf has already been populated with a RTAU module, go

to 2.2. Maintenance Installation (Existing System).

Installation consists of unpacking and installing the RTAU module, and verifying that it is

functioning properly. Use the following procedure to install a RTAU module:

ADCP-61-743 • Issue 3 • September 2004

Caution: Electronic modules can be damaged by static electrical discharge. Before handling

modules, wear an anti-static discharge wrist strap to prevent damage to electronic

components. Place modules in anti-static packing material when transporting or storing. When

working on modules, always place them on an approved anti-static mat that is electrically

grounded.

Warning: If the RTAU module is improperly installed, damage can be caused to the system.

Be careful when inserting the RTAU module into a new chassis.

Caution must be used to prevent bending pins when inserting modules into a new IBBC shelf.

Once a module has been successfully seated in the connector, it “trains” the pins and aligns

them to the modules connector greatly reducing the chances of bending pins on subsequent

insertions. The following procedure outlines a method to mitigate the risk on a new shelf

installation.

1. Open the front cover of the Soneplex Broadband system.

2. Open the shipping carton and carefully unpack the RTAU module from its protective

packing material.

3. Once the Soneplex shelf has been installed and powered up:

a. Remove both-48V A and B side fuses (and “pilot” fuses if used).

b. Inspect the RTAU slots for bent or misaligned pins.

c. If pins are not bent, continue to the next step. If pins are bent, refer to 2.1.1 Damaged

Pins section.

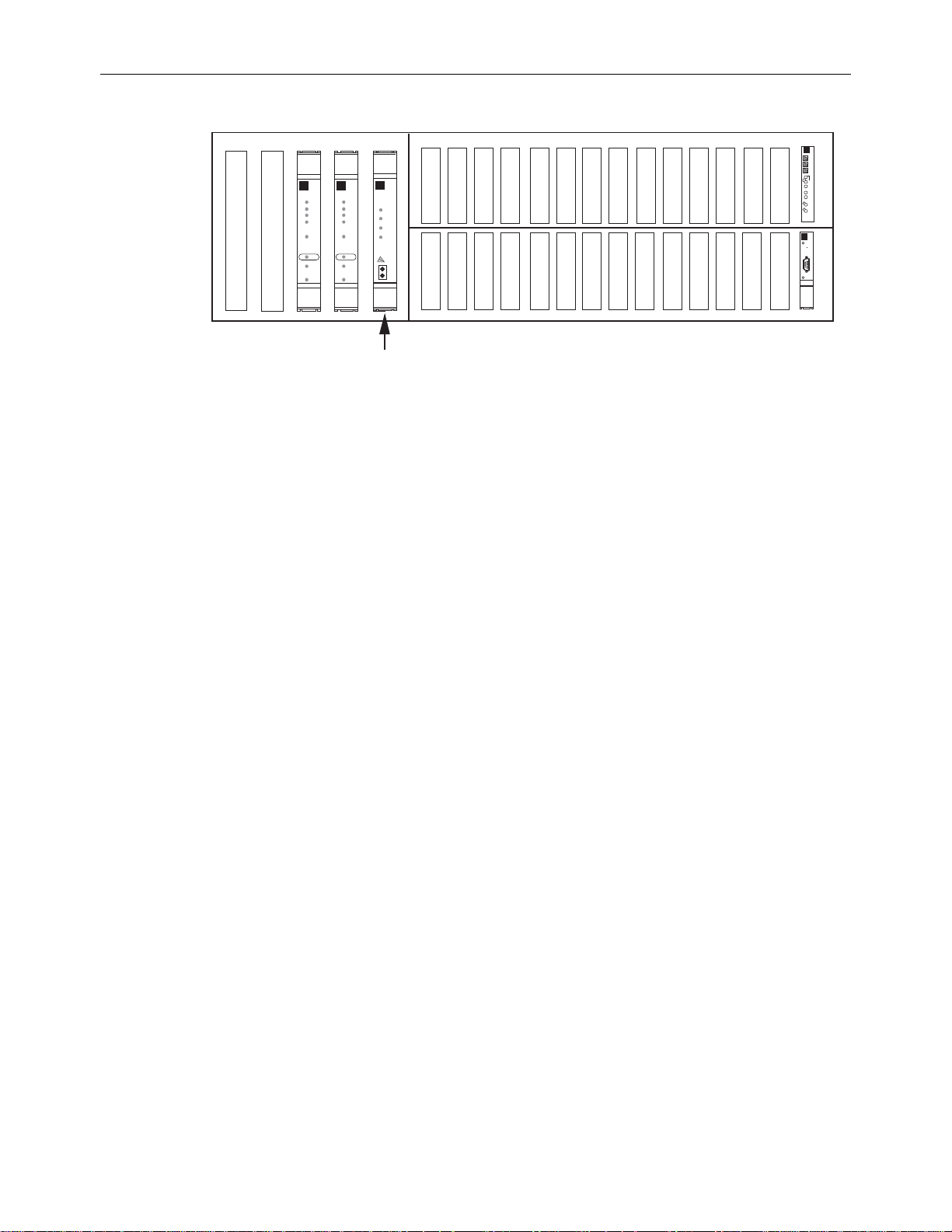

4. With shelf unpowered, refer to the chassis marking above the module slot (Figure 2) to

install the RTAU module in the full-height slot labeled TAU.

© 2004, ADC Telecommunications, Inc.

Page 7

Page 8

ADCP-61-743 • Issue 3 • September 2004

HSW

HSP

MXPMXW

TAU

RTAU

STATUS

STATUS

LPBK

LPBK

ENABLE

ONLINE

DS3 FAIL

LOCKOUT

APS

APS

FORCE

LMPTST/

APS

RESET

STATUS

ENABLE

B8ZS

AMI

ONLINE

LINE CODE

INTRUSIVE

DS3 FAIL

TEST

LOCKOUT

FORCE

LMPTST/

APS

RX

D

S

1

TX

RESET

1-31-1 2-1 2-3 3-1 3-3 4-1 4-3 5-1 5-3 6-1 6-3 7-1 7-3

1-41-2 2-2 2-4 3-2 3-4 4-2 4-4 5-2 5-4 6-2 6-4 7-2 7-4

APU

DISP RMT

LMPTST

APU

STATUS

C

R

A

F

T

RESET

SCU

CR

MJ

MN

ACO

PWR

HSKP

RMT

ALM

14185-A

RTAU MODULE

Figure 2. RTAU Mounting Position in the Soneplex Broadband

5. Align the module edges of the RTAU with the mounting slot module guides. Use the

injectors to seat the module in the chassis.

6. Remove the RTAU module.

7. Inspect the backplane connector for bent pins.

8. If pins are not bent, continue to the next step. If pins are bent, refer to 2.1.1 Damaged

Pins section.

9. Re-install the RTAU module.

10. With the RTAU module installed, power up the shelf one fuse at a time.

a. Install the -48V A fuse.

b. Install the -48V B fuse.

Refer to 8. Customer Information and Assistance, if needed.

2.1.1 Damaged Pins

The pins used in the back plane connector should not be straightened after they have been

deflected more than 10 degrees from vertical as they will “work harden” and break at the

bend. Bent pins must be removed and replaced using special tools and is not

recommended as a field repair. Remove shelf with damaged pins and contact ADC for

replacement. Refer to 8. Customer Information and Assistance.

Page 8

2004, ADC Telecommunications, Inc.

Page 9

2.2 Maintenance Installation (Existing System)

Replacement of the RTAU module in existing IBBC shelves should follow normal

maintenance procedures. Since a module has already been in service in the affected slot, the

backplane pins will have been trained into alignment with subsequent replacement modules. If

excessive resistance is encountered upon insertion, remove the module and inspect for

misalignment or obstructions.

This procedure assumes that the IBBC shelf has already been populated with a RTAU

module. If this is the first time that the IBBC shelf has been populated with a RTAU

module, go to 2.1 Initial Installation.

Installation consists of unpacking and installing the RTAU module, and verifying that it is

functioning properly. Use this procedure to install a RTAU module.

ADCP-61-743 • Issue 3 • September 2004

Warning: To prevent electrical shock, never install equipment in a wet location or during a

lightning storm. When installing or modifying telephone lines, disconnect lines at the network

interface before working with uninsulated lines or terminals.

Caution: Electronic modules can be damaged by electrostatic discharge (ESD). Before

handling modules, wear an anti-static discharge wrist strap to prevent damage to electronic

components. Place modules in anti-static packing material when transporting or storing. When

working on modules, always place them on an approved anti-static mat that is electrically

grounded.

1. Open the front cover of the Soneplex Broadband (V5) chassis.

2. Open the shipping carton and carefully unpack the RTAU module from its protective

packing material. Inspect the module for damage

3. Refer to chassis markings above the module slot (Figure 2) to install the RTAU module

in the full-height slot marked TAU.

4. Align the module edges of the RTAU with the mounting slot module guides. Use the

injectors to seat the module in the chassis. If there is excessive resistance, remove the

module and check for obstructions or improper alignment.

© 2004, ADC Telecommunications, Inc.

Page 9

Page 10

ADCP-61-743 • Issue 3 • September 2004

3 LED CHECK

1. When the RTAU module (Figure 3) is seated, the STATUS LED will be lit red for

approximately 5 seconds. All LEDs will then flash yellow, and then the STATUS LED

will be lit green. If the STATUS LED is not lit green after 10 seconds, replace the

module. Refer to 2.2 Maintenance Installation (Existing System).

RTAU

STATUS

B8ZS

AMI

LINE CODE

INTRUSIVE

TEST

BIPOLAR

ACCESS

RX

D

S

TX

1

12693-B

Figure 3. RTAU Front Panel

Page 10

2004, ADC Telecommunications, Inc.

Page 11

4 FRONT PANEL OPERATION

All controls and indicators of the RTAU including the jack accesses for a selected DS1 signal

are located on the front panel (Figure 3). The controls and indicators are described in Table 2.

INDICATOR COLOR DESCRIPTION

STATUS Red Module failure.

Yellow LED test.

Green Module operating normally.

B8ZS / AMI Green Indicates that the user has selected B8ZS line code for the bipolar

Yellow Indicates that the user has selected AMI line code for the bipolar

Off Indicates that the user has selected the internal signal monitor

Intrusive Test Yellow LED test.

Green Indicates that the selected test mode of the RTAU is intrusive.

Off No intrusive testing in progress.

SWITCH DESCRIPTION

LINE CODE This is a pushbutton switch that toggles the DS1 interface between B8ZS, AMI, or

the internal signal monitor generator at the RTAU. When B8ZS has been selected,

the B8ZS/AMI LED will turn green; when AMI has been selected, the B8ZS/AMI

LED will turn yellow; when the internal signal monitor generator at the RTAU is

selected, the B8ZS/AMI LED will turn off. Using this switch overrides the Craft

Interface RTAU Line Code field setting.

BIPOLAR

ACCESS JACKS DESCRIPTION

ADCP-61-743 • Issue 3 • September 2004

Table 2. RTAU Front Panel Description

interface.

interface.

generator at the RTAU.

DS1 RX Bantam jack connection from DS1 receive to test equipment. Bipolar DS1 signals

from external test equipment can be applied to the RX jack for testing.

DS1 TX Bantam jack connection from DS1 transmit to test equipment. Bipolar DS1 signals

from external test equipment can be applied to the TX jack for testing.

Note: The DS1 RX and DS1 TX jacks may be used with 22 AWG Plastic Insulated

Cable (PIC) up to 655 feet in length. Access for drop or insert of DS1 signals

towards the network (DS3 interface) or toward the customer (DS1 distribution

modules) for monitoring and intrusive testing is configured through the Craft

Interface or the TL1 interface.

© 2004, ADC Telecommunications, Inc.

Page 11

Page 12

ADCP-61-743 • Issue 3 • September 2004

5 CONFIGURATION

Use this menu to view or edit the configuration for the RTAU module after it is installed in the

chassis. This menu can also be used to equip, provision, assign thresholds, and assign service

state.

Note: A “toggle” field type means the user can press the space bar to view and select the

next option that is described; or the user can press the “R” key to view and select the previous

option. An “input” field type means the user must type an entry in the field according to the

parameters described. A “fixed” field is locked and cannot be changed by the user.

Note: Edits can be made in the configuration database in one of two ways: 1) If the

complete field is highlighted, use the space bar to toggle forward or the “R” key to

reverse toggle through the options for that field. 2) If only the first space or the field is

highlighted, type in the data that applies to that field.

Note: Edits can be saved into the configuration database after each change is made in

one of two ways: 1) Press an arrow key and then Enter or Return once; or 2) Press Enter

or Return twice after all selections and entries are made in the screen but before leaving

the screen. If the entries have been accepted, a message “Configuration Successful…

Press Any Key To Continue” will appear on the screen.

Note: Press CONTROL-A for help information on moving around and editing fields.

Note: The RTAU’s status can also be displayed using the Shelf Status screen, where the

letter “R” in the TAU slot column means an RTAU is present. Refer to the Soneplex

System Operation and Maintenance Manual listed under Related Publications at the

beginning of this manual for more information on the Shelf Status screen.

Note: Be sure to configure the line card to be tested before setting up test access.

1. Refer to Figure 3 (shown previously). Check that the STATUS LED on the front panel of

the RTAU module is green, indicating that the module is operating normally.

2. Log on to the Craft Interface. If you are unfamiliar with the log on procedure, refer to the

Soneplex System Operation and Maintenance Manual listed under Related Publications at

the beginning of this manual for more information.

3. Use the arrow or number keys to select System Maintenance from the Main Menu. Press

Enter or Return. The System Maintenance menu will appear as shown in Figure 4.

4. Use the arrow or keyboard keys to select Test Access Unit Commands from the System

Maintenance menu. Press Enter or Return. The RTAU Configuration menu will appear as

shown in Figure 5.

Note: The User Pattern Definition screen is not available for the MPU 5.3 or SCU V3.0

releases.

Page 12

2004, ADC Telecommunications, Inc.

Page 13

ADCP-61-743 • Issue 3 • September 2004

5. Use the arrow or number keys to select RTAU Setup and Control from the RTAU

Configuration menu. Press Enter or Return. The RTAU Setup and Control screen will

appear as shown in Figure 6.

Note: If the RTAU is not plugged into the chassis and the Test Access Unit Commands

selection is made from the System Maintenance menu, the Test Access Unit

Status/Commands screen will appear as shown in Figure 7. This screen cannot be

configured. However, if the TAU is plugged into the chassis and the Test Access Unit

Commands selection is made from the System Maintenance menu, the Test Access Unit

Status/Commands screen will appear and can be configured.

© 2004, ADC Telecommunications, Inc.

Page 13

Page 14

ADCP-61-743 • Issue 3 • September 2004

1. Force/APS Commands

2. Reset/LED Test Commands

3. Execute ACO (Alarm Cutoff)

4. Loopback Status/Commands

5. Display Inventory

6. Display Circuit IDs

7. SCU-860 Data Transfer Commands

8. Trouble Isolation

9. Metallic Testing Screen (for IBBCMLQ only)

A. Test Access Unit Commands

SYSTEM MAINTENANCE

Press CONTROL-A For Assistance

Figure 4. System Maintenance Menu

RTAU CONFIGURATION

1. RTAU Setup and Control

2. User Pattern Definition

Press CONTROL-A For Assistance

6. Starting at the top of Table 3 and working your way to the bottom, configure RTAU

fields. Use the arrow keys to move from field to field.

Page 14

2004, ADC Telecommunications, Inc.

Figure 5. RTAU Configuration Menu

Page 15

ADCP-61-743 • Issue 3 • September 2004

7. Assign the selections by pressing Enter or Return.

RTAU SETUP AND CONTROL

EQUIPMENT SETUP

===============

Current User : NONE Test Circuit: 1-1

Line Code : INTERNAL Mode : DISABLE

SIGNAL GENERATOR SETUP

======================

Pattern Type : QRS #: ------------------------------- Frame Format : UNFRAMED

Loop Code : NONE #: ----------------

BIT ERROR SETUP Error Counts Status Elapsed Time

=============== ============ ====== ============

Error Count : 0 Data : F Sync: ES :

Error Rate : OFF BPV : P Sync: EFS:

Error Locn : NONE Frame: RAI :

CRC :

COFA :

Test Timeout : 60 Measurement : STOP

In Minutes

Press CONTROL-A For Assistance

Figure 6. RTAU Setup and Control Screen

(Showing Defaults for Screen With Line Code Field Set to INTERNAL)

TEST ACCESS UNIT STATUS/COMMANDS

Group: 1 DS1#: 1

Drop Direction Insert Direction

============== ================

Status :

Command :

TAU Present Status: NO

Press Control-A For Assistance

Figure 7. Test Access Unit Status/Commands Screen

(If there is a TAU in the chassis, the TAU Present Status: displays YES)

© 2004, ADC Telecommunications, Inc.

Page 15

Page 16

ADCP-61-743 • Issue 3 • September 2004

FIELD TYPE OPTIONS DESCRIPTION DEFAULT

EQUIPMENT SETUP FIELDS

Current User Toggle OVER VI E W : T h e Cu r r e n t U s e r f ie l d c a n o n l y b e

NONE The RTAU is not being used.

CRAFT The RTAU is being controlled via the Craft.

TL1 The RTAU is being controlled via the TL1

EM The RTAU is being controlled via the Element

Line Code Toggle O VE R V I EW : I f ex t e r n a l t e st e q u i p m e n t i s b e in g

INTERNAL Disables RTAU front panel bantam jacks for

B8ZS Enables Bipolar Eight-Zero Substitution line

AMI Enables Alternate Mark Inversion line code

Test Circuit Input 1-1, 1-2, 1-3, 1-4,

Table 3. RTAU Configuration Fields

2-1, 2-2, 2-3, 2-4,

3-1, 3-2, 3-3, 3-4,

4-1, 4-2, 4-3, 4-4,

5-1, 5-2, 5-3, 5-4,

6-1, 6-2, 6-3, 6-4,

7-1, 7-2, 7-3, 7-4

set to NONE or CRAFT from the Craft menu. If

the Current User field is set to NONE, the Mode

field is automatically set to DISABLE. However,

to change this field to CRAFT, the Mode field

must first be set to an option other than DISABLE.

At that point, the Current User field is

automatically set to CRAFT.

interface. This option cannot be enabled from

the Craft menu. When a “Connect Test Access

T1” command is issued, the Current User field

is automatically set to TL1.

Manager.

used, set the Line Code field to either AMI or

B8ZS. (External test equipment required: T-Berd

211 DS1 test set or equivalent that can generate a

T1 signal.) If the internal signal monitor and

signal generator of the RTAU is being used, set

the line code to INTERNAL. In addition, when

an intrusive test mode is selected and the line

code is set to INTERNAL, the signal generator

“Pattern Type” field defaults to QRS to transmit

an unframed QRSS signal.

test access. Selects internal TSG and SPD.

code through the Craft Interface.

through the Craft Interface.

Group and slot number to be dropped by the

DS3 MUX. The Test Circuit option can only be

changed if the value set in the Mode field is

DISABLE.

NONE

INTERNAL

1-1

Page 16

2004, ADC Telecommunications, Inc.

(continued)

Page 17

ADCP-61-743 • Issue 3 • September 2004

Table 3. RTAU Configuration Fields, continued

FIELD TYPE OPTIONS DESCRIPTION DEFAULT

EQUIPMENT SETUP FIELDS, continued

Mode Toggle OVERV I E W : V al i d access modes and the resulting

configurations are shown in Figure 8 (RTAU Test

Configuration Block Diagram), Figure 9 (MONF and

MONE), Figure 10 (SPLTB and SLPTA), Figure 11

(Typical Round-Robin Test Configuration), Figure 12

(Typical End Test Configuration), Figure 13 (SPLTF

and SLPTE), Figure 14 (Typical Point-to-Point Test

Configuration), Figure 15 (SPLTFL and SPLTEL),

and Figure 16 (LOOPF and LOOPE). In addition,

when the Mode field change is saved by pressing the

Enter or Return key, the MPU or SCU will instruct

the DS3 MUX to drop and insert the selected circuit.

DISABLE When DISABLE is selected, no monitor or split

access can take place. Setting the Mode field to

DISABLE also stops any measurement in

progress, as if the Measurement field (described

below) had been set to STOP. The tested circuit

will also be restored to normal operation.

MONE Non-intrusive monitor access to the A pair.

MONF Non-intrusive monitor access to the B pair.

SPLTA SPLTA mode indicates a split in the A

transmission path with a Test Signal Generator

(TSG) connected in the F direction, and a Signal

Presence Detector (SPD) connected to the signal

from the E direction.

SPLTB SPLTB mode indicates a split in the B

transmission path with a TSG connected in the E

direction and an SPD connected to the signal from

the F direction.

SPLTE SPLTE mode indicates a split in both the A and B

transmission paths. An SPD is connected to the line

incoming from the E direction and a TSG is

connected to the line outgoing to the E direction. The

line outgoing in the F direction is connected to a

QRSS source and the line incoming from the E

direction is terminated by the nominal characteristic

impedance of the line.

SPLTF SPLTF indicates a split in both the A and B

transmission paths with a TSG connected to the line

outgoing to the F direction and an SPD connected to

the line incoming from the F direction. The line

outgoing in the E direction is connected to a QRSS

source and the line incoming from the E direction is

terminated by the nominal characteristic impedance

of the line.

DISABLE

(continued)

© 2004, ADC Telecommunications, Inc.

Page 17

Page 18

ADCP-61-743 • Issue 3 • September 2004

FIELD TYPE OPTIONS DESCRIPTION DEFAULT

EQUIPMENT SETUP FIELDS, continued

Mode, continued SPLTEL SPLTEL indicates a split in both the A and B paths

Toggle SPLTFL SPLTFL indicates a split in both the A and B paths

LOOPE The LOOPE mode is a full split of both A and B

LOOPF The LOOPF mode is a full split of both A and B

SIGNAL GENERATOR SETUP FIELDS

Pattern Type Toggle OV E R V I E W: I f t h e d e s i r e d p a tt e r n t y p e i s n o t

QRS Quasi-Random Signal. QRS (220-1) is a 1,048,575-

Table 3. RTAU Configuration Fields, continued

and connects an SPD to the line incoming from the

E direction and a TSG to the line outgoing in the E

direction similar to SPLTE mode. The signal in the

F direction is looped back.

and connects an SPD to the line incoming from the

F direction and a TSG to the line outgoing in the F

direction similar to SPLTF mode. The signal in the

E direction is looped back.

transmissions paths. The incoming line in the E

direction is connected to the SPD and this line is

connected to the outgoing line in the E direction.

The circuit will be looped in one direction. The

outgoing line in the F direction (non-test direction)

will be connected to a QRSS source and the line

incoming from the F direction is terminated by the

nominal characteristic impedance of the line.

transmissions paths. The incoming line in the F

direction is connected to the SPD and this line is

connected to the outgoing line in the F direction. The

circuit will be looped in one direction. The outgoing

line in the E direction (non-test direction) will be

connected to a QRSS source and the line incoming

from the E direction is terminated by the nominal

characteristic impedance of the line.

QRS

available, select the User Code option to enter a

pattern 32 bits or less.

bit sequence generated by a 20-stage shift register

with feedback taken from the 17th and 20th stages.

The non-inverted output is taken from the 20th

stage, and an output bit is forced to be a ‘1’

whenever the next 14 bits are all 0’s. QRS is

typically used to verify continuity and to check

circuit performance in the presence of traffic-like

signals. Quasi-random Signal (QRS) is a signal

repeated every 1 to 24 bits as specified by the

Operation System (OS) application. QRS must

conform to the description in Bellcore TR-NPL-

000054.

Page 18

2004, ADC Telecommunications, Inc.

(continued)

Page 19

ADCP-61-743 • Issue 3 • September 2004

Table 3. RTAU Configuration Fields, continued

FIELD TYPE OPTIONS DESCRIPTION DEFAULT

SIGNAL GENERATOR SETUP FIELDS, CONTINUED

Pattern Type, continued Toggle 2^15-1 215-1 is a 32,767-bit, pseudo-random pattern

that generates a maximum of 14 sequential 0’s

and 15 sequential 1’s. The pattern provides a

maximum number of 0’s allowed for framed,

non-B8ZS testing. The pattern does not meet

the minimum 1’s density requirement.

2^23-1 223-1 is a 8,388,607-bit, pseudo-random

pattern that generates a maximum of 22

sequential 0’s and 23 sequential 1’s. The

pattern exceeds excess 0’s and does not meet

the minimum 1’s density requirements for T1

applications.

All Ones Test of T1 span line. The all-1’s pattern causes

the span line repeater to consume the maximum

amount of power. If the current powering the

span line is low, transmission errors may occur

due to the inter-symbol interference resulting

from the inability of a weak repeater power

supply to develop the energy necessary to

support the transmission of a long sequence of

1’s.

(Framed) All Zeros Used as a final confirmation that all network

elements in a circuit are properly optioned with

B8ZS for clear channel operation. The framed

all 0’s pattern consisting of a frame bit

followed by an all 0’s payload will only be

applied to circuit optioned with B8ZS for clear

channel operation.

3 in 24 Used to determine the ability of network

equipment to function properly when transporting

signal sequences containing both a maximum of

15 consecutive 0’s during periods of minimum

overall pulse density.

• Unframed = 1000 1000 1000 0000

0000 0000 1000 1000

• Framed = 0100 0100 0000 0000

0000 0100 0100 1000

2 in 8 Used in conjunction with the 1-in-8 pattern.

Useful when performing test to reveal the

presence of incorrectly-optioned AMI or B8ZS

equipment. Use of the 2-in-8 pattern will

confirm the circuits ability to support error-free

transmission.

• Unframed = 0100 0010 0100 0010

• Framed = 0100 0010 0100 0010

(continued)

© 2004, ADC Telecommunications, Inc.

Page 19

Page 20

ADCP-61-743 • Issue 3 • September 2004

FIELD TYPE OPTIONS DESCRIPTION DEFAULT

SIGNAL GENERATOR SETUP FIELDS, continued

Pattern Type, continued Toggle 1 in 8 Containing strings of 7 sequential 0’s. It is used

Daly Daly Pattern (Modified 55 Octet). This is useful

User Code For user-defined patterns of 32 bits or less, set the

Pattern Bits Display

Frame Format Toggle UNFRAMED Unframed data pattern. UNFRA MED

Ft ONLY Used for SLC framing.

SF Super Frame

ESF Extended Super Frame

only

Table 3. RTAU Configuration Fields, continued

to determine the ability of a circuit to handle

payload signals having minimum 1’s density.

Use of this pattern often reveals the existence

of timing recovery problem under conditions of

low signal density.

• Unframed = 1000 0000 1000 0000

• Framed = 0100 0000 0100 0000

for stressing the timing recovery circuits of line

cards and the preamplifier/ equalizer circuits of

repeaters. The pattern stresses a circuit by

introducing rapid transitions from long sequences

of low density octets to high density octets, high

density octets to low density octets, and rapid

transitions. The pattern may be transmitted framed

or unframed. When framed, the frame bit shall be

inserted at the octet boundaries and will not

overwrite the bits.

Pattern Type field to User Code. The bits can be

entered by typing a string of 0’s or 1’s in the bit

field located to the right of the designated entry.

None If the Pattern Type field is configured for User

Code, pattern bits will be displayed to the right

of the Pattern type field parameter. This field’s

name is not shown on the screen. If no User

Code is entered in the Pattern Type field, this

field displays 32 dashes.

None

Page 20

2004, ADC Telecommunications, Inc.

(continued)

Page 21

ADCP-61-743 • Issue 3 • September 2004

Table 3. RTAU Configuration Fields, continued

FIELD TYPE OPTIONS DESCRIPTION DEFAULT

SIGNAL GENERATOR SETUP FIELDS, continued

Loop Code Toggle OVERV I E W : T h e M o d e f i el d m u s t b e se t t o a

SPLT option before the Loop Code field can be

configured. Loop codes will be transmitted until

the RTAU detects a change in the signal being

received. At that time, the pattern selected before

the loop code was set will be transmitted. For

example, when sending a Loop Up code, the

RTAU will restore the original pattern after it

receives the loop code it is transmitting, indicating

that the circuit is looped up. Note that the Loop

Code bits are displayed in the Loop Code bit field

as each code is selected. This is provided as a

convenience to the operator who may not know

the name chosen for the loop code but does know

the pattern.

NONE Disables any active loop code selected for this

field. When NONE is selected, the Loop Code

field displays 16 dashes.

Line Loop Up 10000

Line Loop Down 100

4-Bit Loop Up 1100

4-Bit Loop Down 1110

5-Bit Loop Up 11000

5-Bit Loop Down 11100

ESF CSU Loop Up 0EFF (0000 1110 1111 1111)

ESF CSU Loop

Down

ESF NI* Loop Up 12FF (0001 0010 1111 1111)

ESF NI* Loop Down 24FF (0010 0100 1111 1111)

ESF CSU Payload

Loop Up

ESF CSU Payload

Loop Down

User Loop Up

(toggle and input)

User Loop Down Enter a 16-value expression using only 1’s, 0’s,

*Note: “NI” means Network Interface device.

38FF (0011 1000 1111 1111)

14FF (0001 0100 1111 1111)

32FF (0011 0010 1111 1111)

Enter a 16-value expression using only 1’s, 0’s,

or “-”. The bits can be entered by typing a

string of 0’s or 1’s in the bit field located to the

right of the designated entry.

or “-”. The bits can be entered by typing a

string of 0’s or 1’s in the bit field located to the

right of the designated entry.

NONE

(continued)

© 2004, ADC Telecommunications, Inc.

Page 21

Page 22

ADCP-61-743 • Issue 3 • September 2004

FIELD TYPE OPTIONS DESCRIPTION DEFAULT

BIT ERROR SETUP FIELDS

OVERVIEW: Bit errors can be injected by the RTAU using the Bit Error Set Up fields. These sections are display-only fields that are

only displayed when the line code setting is INTERNAL. The Status field always shows the current status if the line code is

INTERNAL, but the Error Counts and Elapsed Time fields only show a value when a measurement is being made.

Error Count Input Range of 0 to 1544 Select either Error Count or Error Rate for bit

Error Rate Toggle OFF, 1E-3, 1E-4,

Error Locn Toggle OVERVIEW: The Error Location field must be

NONE Indicates count is 0 and rate is off.

PAYLOAD Bit errors are injected.

FBE Frame Bit Error. Frame errors are injected.

Error Counts Data Display

Error Counts BPV Display

Error Counts Frame Display

Error Counts CRC Display

Error Counts COFA Display

Status F Sync Display

Status P Sync Display

Status RAI Display

only

only

only

only

only

only

only

only

Table 3. RTAU Configuration Fields, continued

0

error setup. Both cannot be set at the same time.

If single errors or a burst of errors is desired, set

the Error Count field to the number of errors to

insert. If the Error Count field is set, the

number of errors will be transmitted each time

the Enter key is pressed.

Select either Error Count or Error Rate for bit

1E-5, 1E-6, 1E-7

None Eight-digit counter or blank. Blank

None Eight-digit counter or blank. Blank

None Eight-digit counter or blank. Blank

None Eight-digit counter or blank. Blank

None Eight-digit counter or blank. Blank

None * or blank Blank

None * or blank Blank

None * or blank Blank

error setup. Both cannot be set at the same time.

If a steady error rate is desired, set the Error

Rate field which indicates the rate bit or frame

errors are injected.

set to either PAYLOAD or FBE if the count or

rate field is set. Pressing the Enter or Return

key will cause the RTAU to send the errors.

OFF

NONE

Page 22

2004, ADC Telecommunications, Inc.

(continued)

Page 23

ADCP-61-743 • Issue 3 • September 2004

Table 3. RTAU Configuration Fields, continued

FIELD TYPE OPTIONS DESCRIPTION DEFAULT

Elapsed Time ES Display

only

Elapsed Time EFS Display

only

Test Timeout in Minutes Input 0 to 1440 Timeout counter for test access. If the counter

Measurement Toggle

Display

START Initiate measurement.

STOP Terminate measurement. Note: Setting the

RUNNING (display) Measurement active.

Waiting on Sync Display

only

Mode Toggle DISABLE To end t h e t e st s e s s io n , r e s t o r e the te st e d c i r c u i t t o

None Six-digit counter or blank. Blank

None Six-digit counter or blank. Blank

is set to a number higher than “0” and then

reaches “0” during test, the Mode field will be

set to DISABLE automatically. If the counter is

set to “0”, the test timeout will be turned off,

and the test will have unlimited time.

OVERVIEW: Start a measurement by selecting

and

None This parameter is displayed to the right of the

START at the Measurement field. The RTAU will

wait for pattern sync and frame sync for framed

patterns before starting the measurement. After

synchronizing, the measurement display will

change to RUNNING. Stop any measurement by

selecting STOP. Refer to Figure 17 for a RTAU

configuration screen showing a test that is starting.

Note: If the Mode is set to MONE, MONF,

LOOPE, or LOOPF, only frame sync is required

before starting the measurement. If the pattern is

not in sync, then the Data Error Counts will read

“N/A” until pattern sync is established.

Mode field to DISABLE also stops any

measurement in progress as if the Measurement

field had been set to STOP.

Measurement field when the Measurement field

is set to START. The WAITING ON SYNC

message is display-only; it only shows up when

the RTAU is waiting for either frame or pattern

sync. Examine the status section to determine

what sync is needed.

normal operation by selecting DISABLE.

60

STOP

Blank

DISABLE

© 2004, ADC Telecommunications, Inc.

Page 23

Page 24

ADCP-61-743 • Issue 3 • September 2004

DS3

EQUIPMENT

DS3 MUX RTAU

PATTERN GEN

DETECTOR

CONTROLLER

A

B

MPU

or

SCU

LINE

CARD

BIPOLAR

ACCESS

RTAU

FRONT

PANEL

DS1 TEST

SET

RX

TX

EQUIPMENT (E)

[NETWORK]

A

DS1

MONITOR

SPLIT

Figure 8. RTAU Test Configuration Block Diagram

DS3 MUX

RTA U

B

B

FACILITY (F)

[CUSTOMER]

CIRCUIT

UNDER TEST

MONF

SIGNAL

PRESENCE

DETECTOR

EQUIPMENT (E)

[NETWORK]

CIRCUIT

UNDER TEST

MONE

SIGNAL

PRESENCE

DETECTOR

A

A

DS3 MUX

RTA U

FACILITY

B

11864-C

FACILITY (F)

[CUSTOMER]

11865-C

Page 24

2004, ADC Telecommunications, Inc.

Figure 9. MONF and MONE

Page 25

ADCP-61-743 • Issue 3 • September 2004

EQUIPMENT (E)

[NETWORK]

A END

FACILITY (F)

DS3 MUX

[CUSTOMER]

CIRCUIT

UNDER TEST

SPLTB

SIGNAL

AB

PRESENCE

DETECTOR

RTA U

TEST SIGNAL

GENERATOR

Figure 10. SPLTB and SLPTA

OFFICE A OFFICE Z

RTAU

FE

AA

INTEROFFICE

FACILITY

EQUIPMENT (E)

[NETWORK]

CIRCUIT

UNDER TEST

SPLTA

SIGNAL

PRESENCE

DETECTOR

TEST SIGNAL

GENERATOR

FACILITY (F)

DS3 MUX

[CUSTOMER]

AB

RTA U

RTAU

Z END

FE

11866-B

LOOPBACK

INSERT:

NETWORK

CPE

BB

SPLTB

A = "A" TRANSMISSION PATH

B = "B" TRANSMISSION PATH

E = EQUIPMENT (NETWORK)

F = FACILITY (CUSTOMER)

= SIGNAL PRESENCE DETECTOR

= TEST SIGNAL GENERATOR

OR UNFRAMED (QRS)

Figure 11. Typical Round-Robin Test Configuration

DROP:

CUSTOMER

LOOPBACK

CPE

11867-B

Page 25

© 2004, ADC Telecommunications, Inc.

Page 26

ADCP-61-743 • Issue 3 • September 2004

LOOPBACK

A END

CPE

INSERT:

NETWORK

DROP:

NETWORK

OFFICE A OFFICE Z

FE

BB

SPLTE

A = "A" TRANSMISSION PATH

B = "B" TRANSMISSION PATH

E = EQUIPMENT (NETWORK)

F = FACILITY (CUSTOMER)

= SIGNAL PRESENCE DETECTOR

= TEST SIGNAL GENERATOR

OR UNFRAMED (QRS)

= TERMINATED SIGNAL

Figure 12. Typical End Test Configuration

INTEROFFICE

RTAU

AA

QRS

FACILITY

EF

Z END

CPE

11868-B

EQUIPMENT (E)

[NETWORK]

QRS

DS3 MUX

RTA U

FACILITY (F)

[CUSTOMER]

A

B

CIRCUIT

UNDER TEST

SPLTF

SIGNAL

PRESENCE

DETECTOR

TEST SIGNAL

GENERATOR

Figure 13. SPLTF and SLPTE

EQUIPMENT (E)

[NETWORK]

A

B

CIRCUIT

UNDER TEST

SPLTE

TEST SIGNAL

GENERATOR

SIGNAL

PRESENCE

DETECTOR

DS3 MUX

RTA U

FACILITY (F)

[CUSTOMER]

QRS

11869-B

Page 26

2004, ADC Telecommunications, Inc.

Page 27

ADCP-61-743 • Issue 3 • September 2004

A END

FE

INSERT:

NETWORK

CPE

A = "A" TRANSMISSION PATH

B = "B" TRANSMISSION PATH

E = EQUIPMENT (NETWORK)

F = FACILITY (CUSTOMER)

= SIGNAL PRESENCE DETECTOR

= TEST SIGNAL GENERATOR

OR UNFRAMED (QRS)

= TERMINATED SIGNAL

B

QRS

OFFICE A OFFICE Z

RTA U

DROP:

CUSTOMER

INSERT:

CUSTOMER

SPLTF

INTEROFFICE

FACILITY

DROP:

NETWORK

INSERT:

NETWORK

RTA U

AA

B

SPLTE

Figure 14. Typical Point-to-Point Test Configuration

FE

INSERT:

CUSTOMER

QRS

Z END

CPE

11870-B

EQUIPMENT (E)

[NETWORK]

DS3 MUX

RTA U

FACILITY (F)

[CUSTOMER]

A

B

CIRCUIT

UNDER TEST

SPLTFL

SIGNAL

PRESENCE

DETECTOR

TEST SIGNAL

GENERATOR

EQUIPMENT (E)

[NETWORK]

A

B

CIRCUIT

UNDER TEST

SPLTEL

TEST SIGNAL

GENERATOR

SIGNAL

PRESENCE

DETECTOR

Figure 15. SPLTFL and SPLTEL

DS3 MUX

RTA U

FACILITY (F)

[CUSTOMER]

11871-B

© 2004, ADC Telecommunications, Inc.

Page 27

Page 28

ADCP-61-743 • Issue 3 • September 2004

EQUIPMENT (E)

[NETWORK]

QRS

DS3 MUX

RTA U

FACILITY (F)

[CUSTOMER]

A

B

CIRCUIT

UNDER TEST

LOOPF

SIGNAL

PRESENCE

DETECTOR

EQUIPMENT (E)

[NETWORK]

A

B

CIRCUIT

UNDER TEST

LOOPE

SIGNAL

PRESENCE

DETECTOR

DS3 MUX

RTA U

Figure 16. LOOPF and LOOPE

RTAU SETUP AND CONTROL

EQUIPMENT SETUP

===============

Current User : CRAFT Test Circuit: 1-2

Line Code : INTERNAL Mode : SPLTE

SIGNAL GENERATOR SETUP

======================

Pattern Type : QRS #: ------------------------------- Frame Format : ESF

Loop Code : NONE #: ----------------

BIT ERROR SETUP Error Counts Status Elapsed Time

=============== ============ ====== ============

Error Count : 0 Data : F Sync: * ES :

Error Rate : OFF BPV : P Sync: * EFS:

Error Locn : N/A Frame: RAI :

CRC:

COFA

Test Timeout : 60 Measurement : START WAITING ON SYNC

In Minutes

Press CONTROL-A For Assistance

FACILITY (F)

[CUSTOMER]

QRS

11872-B

6 TL1 COMMANDS

The TL1 commands shown in Table 4 that are used for the RTAU are defined in Bellcore

requirement GR-000834-CORE. For more information about TL1 commands, refer to the

Soneplex System Operation and Maintenance Manual listed under Related Publications at the

beginning of this manual.

Page 28

2004, ADC Telecommunications, Inc.

Figure 17. RTAU Setup and Control Screen (Starting a Measurement)

Page 29

COMMAND DESCRIPTION

CHG-ACCMD-T1 Change Access Mode T1

CHG-LPBK-T1 Change Loopback T1

CHG-TSTSIG-T1 Change Test Signal T1

CONN-TACC-T1 Connect Test Access T1

DISC-MEAS Disconnect Measurement

DISC-TACC Disconnect Test Access Metallic/Digital

DISC-TSTSIG Disconnect Test Signal

MEAS-SIG-T1 Measure Signal T1

REPT-RSLT Report Result

TST-INSERRBITS Test Insert Error Bits

7 SPECIFICATIONS

The technical specifications for the RTAU modules are given in Table 5.

ADCP-61-743 • Issue 3 • September 2004

Table 4. TL1 Commands Used for the RTAU

Table 5. RTAU Specifications

PARAMETER SPECIFICATION REMARKS

Input Power

Input Current (Max.) 175 mA at –48 Volts

Input Current (Nominal) 100 mA at –48 Volts

Input Voltage (Nominal) –48 Vdc

Input Voltage Range –42 to –60 Vdc

Power Consumption /

8.2 watts

Dissipation (Max.)

DS1 Jack Access

Electrical Interface Bipolar

Termination 100 ohms nominal ± 5%

Jack Type Bantam

Line Code AMI or B8ZS Controlled by front panel switch

Line Rate 1.544 Mbps ± 130 ppm max.

Dimensions

Height × Width × Depth 9.5 × 9.9 × 1.0 inches

(24.1 × 25.1 × 2.5 cm)

Weight 12 oz. (.34 kg)

Environment

Operating Temperature –40° to 149° F (–40° to 65° C)

Storage Temperature –40° to 158° F (–40° to 70° C)

Relative Humidity (Operating) 5% to 95% No condensation

Altitude (Operating

or Non-operating)

–1,312 to + 14,764 ft.

(–400 to +4,500 m)

© 2004, ADC Telecommunications, Inc.

Page 29

Page 30

ADCP-61-743 • Issue 3 • September 2004

8 CUSTOMER INFORMATION AND ASSISTANCE

ADC Technical support is available 24 hours a day, 7 days a week by contacting the ADC

Technical Assistance Center.

Sales Assistance

800.366.3891

• Quotation Proposals

• Ordering and Delivery

• General Product Information

Systems Integration

800.366.3891

• Complete Solutions (from Concept to Installation)

• Network Design and Integration Testing

• System Turn-Up and Testing

• Network Monitoring (Upstream or Downstream)

• Power Monitoring and Remote Surveillance

• Service/Maintenance Agreements

• Systems Operation

ADC Technical Assistance Center

800.366.3891

Email: wsd.support@adc.com

• Technical Information

• System/Network Configuration

• Product Specification and Application

• Training (Product-Specific)

• Installation and Operation Assistance

• Troubleshooting and Repair/Field Assistance

Online Technical Support • www.adc.com/Knowledge_Base/index.jsp

Online Technical Publications • www.adc.com/documentationlibrary/technicalpublications/

Product Return Department

800.366.3891

• ADC Return Authorization number and instructions must

be obtained before returning products.

E-Mail: repair.return@adc.com

Product information may also be obtained using the ADC web site at www.adc.com or by writing ADC Telecommunications, Inc.,

P.O. Box 1101, Minneapolis, MN 55440-1101, U.S.A.

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting ADC’s Technical Assistance Center at 1-800-366-3891 or by writing to

ADC Telecommunications, Inc., Attn: Technical Assistance Center, P.O. Box 1101, Minneapolis, MN 55440-1101, U.S.A.

Product Catalog: SPX-RTAU0A11

Part Number: 1169023

CLEI: SNPQCN2D~~

Document: ADCP-61-743, Issue 3

1304058

´-$%¶8K¨

September 17, 2004

© 2004, ADC Telecommunications, Inc.

All Rights Reserved

Printed in U.S.A.

Page 30

Loading...

Loading...