Page 1

Cellworx STN

Release 3.1 GUI Users Manual

Issue 1

February 2001

1152700 Rev A

Page 2

Page 3

Release 3.1 GUI Users Manual

Issue 1

February 2001

1152700 Rev A

Page 4

1152700• Issue 1 • February 2001 • Preface

COPYRIGHT

2000, ADC Telecommunications, Inc.

All Rights Reserved

Printed in the U.S.A.

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

Issue 1 02/2001 Phase 3.1 release features added, (622 CRS)

TRADEMARK INFORMATION

ADC and ADC Telecommunications are registered trademarks of ADC Telecommunications, Inc.

Cellworx is a trademark of ADC Telecommunications, Inc.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior

notice. In no event shal l ADC be l ia ble for any dam ag es r esul ting fro m lo ss o f data , lo ss of use, o r l oss o f pr ofi ts

and ADC further disclaim s any and al l liability for indirect, incidental, special, consequential or other similar

damages. This disclaimer of liability applies to all products, publications and services during and after the

warranty period.

This publication may be verified at any time by contacting ADC’s Technical Assistance Center at 1-800-366-3891,

extension 54878 (in U.S.A. or Canada) or 1-972-680-4878 (outside U.S.A. and Canada), or by writing to ADC

Telecommunications, Inc., Attn: Technical Assistance Center, Mail Station #77, P.O. Box 1101, Minneapolis, MN

55440-1101, U.S.A.

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 946-3292

Page ii

© 2000, ADC Telecommunications, Inc.

Page 5

TABLE OF CONTENTS

Content Page

ABOUT THIS MANUAL................................................................................................................................VII

REVISION HISTORY LIST............................................................................................................................VII

LIST OF CHANGES ....................................................................................................................................VII

TRADEMARK INFORM ATION........................................................................................................................VII

RELATED PUBLICATIONS............................................................................................................................VII

ADMONISHMENTS....................................................................................................................................VII

GENERAL SAFETY PRECAUTIONS.................................................................................................................VIII

FCC COMPLIANCE STATEMENT .....................................................................................................................IX

DOC COMPLIANCE.....................................................................................................................................IX

FDA COMPLIANCE .....................................................................................................................................IX

COMPLIANCE ................................................................................................................................IX

SAFETY

NEBS COMPLIANCE ...................................................................................................................................IX

ISO 9000 COMPLIANCE...............................................................................................................................IX

REFERENCES............................................................................................................................................X

LIST OF ACRONYMS AND ABBREVIATI ONS ......................................................................................................XII

1152700 • Issue 1 • February 2001 • Preface

PREFACE

SECTION 1

INTRODUCTION

Content Page

1. GENERAL........................................................................................................................................... 1-1

2. USER INTERFACES............................................................................................................................... 1-2

A. NMIC RS232 Interface........................................................................................................... 1-3

B. NMIC EIM RJ45 E thernet Interf ace............................................................................................ 1-3

C. NMIC Serial Equipment Port ................................................................................................... 1-4

3. CELLWORX STN SYSTEM SOFTWARE........................................................................................................ 1-4

A. NMIC Graphical User Interface (GUI)......................................................................................... 1-4

GUI Screen Icon Definitions ....................................................................................... 1-5

GUI Menu Structure and Utilization .............................................................................. 1-8

X-Terminal Keyboard Functions..................................................................................1-11

Manipulating the GUI Net work Layout on an X-Terminal Screen ..........................................1-12

4. REMOTE MANAGEMENT CAPABILITIES......................................................................................................1-12

A. Real Time Alarm and trap Screens.....................................................................................................1-13

© 2000, ADC Telecommunications, Inc.

Page iii

Page 6

1152700• Issue 1 • February 2001 • Preface

Content Page

1. GENERAL........................................................................................................................................... 2-1

2. USING A TOP DOCUMENT....................................................................................................................... 2-1

ALPHABETICAL TASK I NDEX LIST ................................................................................................................ 2-3

INDEXED TASK LI ST ...........................................................................................................................IXL-001

TURN UP A NEW CELLWORX STN RING NETWORK .....................................................................................NTP-002

ADD A CELLWORX STN NODE TO AN IN SERVICE RING NETWORK...................................................................NTP-003

ADD A SECOND NETWORK ELEMENT TO AN IN SERVICE STAND-ALONE TERMINAL

TO CREATE A RING NETWORK .....................................................................................................NTP-004

TURN UP (PROVISION) CELLWORX STN EXPANSION SHELVES.......................................................................N TP-005

PROVISION NODE PARAMETERS ...........................................................................................................NTP-006

DISPLAYING STATUS AN D ALARMS........................................................................................................NTP-007

RETRIEVE PER FORMANCE MONITORING STATISTICS..................................................................................NTP-008

ADDING SERVICES TO A CELLWORX STN NODE.........................................................................................NTP-009

DELETE A CELLWORX STN NODE...........................................................................................................NTP-010

CONDUCT ACCEPTANCE TESTS ON CELLWORX STN NODE ............................................................................NTP-011

PERFORM ROUTINE AND NON-ROUTINE MAINTENANCE...............................................................................NTP-012

PROVISION ATM VP AND VC CONNECTIONS..............................................................................................NTP-013

MONITORING TH E NETWORK................................................................................................................NTP-014

ADMINISTRATIVRE TASKS...................................................................................................................NTP-015

CELLWORX UPGRADE PROCEDURES......................................................................................................NTP-016

POWER UP A CELLWORX STN NODE.......................................................................................................DLP-700

CONNECT FIBERS TO OPT ICAL CARDS ....................................................................................................DLP-701

CONNECT VT1OO TO NMIC RS-232 PORT AND MODIFY NMIC IP ADDRESS........................................................DLP-702

LOGON TO REMOTE NODE CRAFT SESSION VIA TELNET FROM GUI ................................................................DLP-703

CONNECT NMS OR X-TERMINAL TO THE NMIC EIM SNMP/GUI PORT ...............................................................DL P-704

LAUNCH THE GRAPHI CAL USER INTERFACE (GUI ) ......................................................................................DLP-705

PERFORM DISCOVERY ON A NEW CELLWORX STN RING NETWORK ...............................................................DLP-706

TIME AND DATE................................................................................................................................DLP-707

CREATE A N ATM OR CES CONNECTION...................................................................................................DLP-708

CONFIGURE OR DELETE A TRAFFIC CONTRACT..........................................................................................DLP-709

VIEW CONNECTIONS ..........................................................................................................................DLP-710

LOG OFF OF CELLWORX STN GRAPHICAL USER INTERFACE..........................................................................DLP-711

ADD EXPANSION NODES (STN-EPS)........................................................................................................DLP-712

DISPLAY NETWORK ALARM SUMMARY...................................................................................................DLP-713

CONFIGURE SERVICE PROVIDER PROFILE................................................................................................DLP-714

VIEW RING RESOURCE USAGE..............................................................................................................DLP-715

VIEW FIBER BANDWIDTH USAGE...........................................................................................................DLP-716

CONFIGURE NE ALARM THRESHOLD ......................................................................................................DLP-717

REFRESH TOPOLOGY .........................................................................................................................DLP-718

FORCE NETWOR K DISCOVERY..............................................................................................................DLP-719

SOFTWARE SELECTION.......................................................................................................................DLP-720

SECTION 2

OPERATION AND MAINTENANCE

(continued)

Page iv

© 2000, ADC Telecommunications, Inc.

Page 7

1152700 • Issue 1 • February 2001 • Preface

SECTION 2

OPERATION AND MAINTENANCE, CONTINUED

Find Your Job in the List Below Then Go To

ABOUT NE.......................................................................................................................................DLP-721

NMIC SYSTEM FILE REPLICATION..........................................................................................................DLP-722

CHANGE CONFIGURATION/TEST ON AN EXISTING CONNECTION ....................................................................DLP-723

NMIC PROTECTIO N ............................................................................................................................DLP-724

NMIC PROTECTIO N R ESTORATION.........................................................................................................DLP-725

SET / RETRIEVE OPTICAL PORT PERFOR MANCE MONITORING STATISTICS .......................................................DLP-726

SET / RETRIEVE T3 TMUX PERFORMANCE MONITORING STATISTICS...............................................................DLP-727

SET / RETRIEVE T3 CRS PORT PERFORMANCE MONITORING STATISTICS.........................................................DLP-728

SET / RETRIEVE T1/E1 MULTI 1 CRS PERFORMANCE MONITORI N G STATISTICS ................................................DLP-729

RETRIEVE NETWORK DATA COLLECTION (NDC) STATISTICS..........................................................................DLP-730

RING UPGRADE PROCEDURE................................................................................................................DLP-731

SET / RETRIEVE FT1 FRS PERFORMANCE MONITORING STATISTICS ...............................................................DLP-732

SET / RETRIEVE FE1 FRS PERFORMANCE MONITORING STATISTICS ...............................................................DLP-733

SOFTWARE FALLBACK........................................................................................................................DLP-734

HELP ...........................................................................................................................................DLP-735

REVERT TO SAVED ICON LAYOUT ..........................................................................................................DLP-736

ADD A RING NETWORK ELEMENT ..........................................................................................................DLP-737

ADD A SECOND NETWORK ELEMENT ......................................................................................................DLP-738

DELETE CONNECTIONS.......................................................................................................................DLP-739

DELETE A CELLWORX STN SHELF..........................................................................................................DLP-740

RETRIEVE LOGS FROM THE NMIC VIA FTP ...............................................................................................DLP-741

RETRIEVE COMPRESSED LOGS FROM THE NMIC VIA FTP.............................................................................DLP-742

REFLASH BOOT IM AG E .......................................................................................................................DLP-744

SYSTEM DATABASE ACCESS ................................................................................................................DLP-745

DELETE A CELLWORX STN EXPANSION SHELF (EPS)...................................................................................DLP-746

SET E1 MULTI 1 CARD CONFIGURATION..................................................................................................DLP-747

SET SC CARD CONFIGURATION (IP ADDRESS, CRAFT INTERFACE)..................................................................DLP-748

SET SHELF TIMING RESOURCE .............................................................................................................DLP-749

SET SHELF HOUSEKEEPING ALARM CONFIGURATION..................................................................................DLP-750

SET 622 RING CARD CONFIGURATION.....................................................................................................DLP-751

SET 155 SM/MM CRS CARD CONFIGURATION ...........................................................................................DLP-752

SET T3 CRS CARD CONFIGURATION .......................................................................................................DLP-753

SET T3 TMUX MULTI 1 AND TMUX EXP CONFIGURATION..............................................................................DLP-754

SET T1 MULTI 1 CARD CONFIGURATION .................................................................................................DLP-755

SET 155 RING INTERFACE CARD CONFIGURATION......................................................................................DLP-758

SET 2488 RING INTERFACE CARD CONFIGURATION....................................................................................DLP-756

RETRIEVE SC CARD STATUS.................................................................................................................DLP-757

RETRIEVE 622 RIC STATUS..................................................................................................................DLP-759

RETRIEVE 155 CRS STATUS.................................................................................................................DLP-760

RETRIEVE T3 CRS CARD STATUS...........................................................................................................DLP-761

RETRIEVE T3 TMUX MULTI 1 CARD STATU S .............................................................................................DLP-762

© 2000, ADC Telecommunications, Inc.

Page v

Page 8

1152700• Issue 1 • February 2001 • Preface

SECTION 2

OPERATION AND MAINTENANCE, CONTINUED

Find Your Job in the List Below Then Go To

RETRIEVE 155 RING INTERFACE CARD STATUS.........................................................................................DLP-763

RETRIEVE T1 MULTI 1 CARD STATUS......................................................................................................DLP-764

CONFIGURE CARD PROTECTION GROUPS ................................................................................................DLP-765

PERFORM DIAGNOSTICS ON OPTICAL CARDS ...........................................................................................DLP-766

SET SYSTEM IDEN TIFIER ....................................................................................................................DLP-767

SET CRAFT USER CONFI GURATION .......................................................................................................DLP-768

SET CRAFT MENU CONFIGURATION........................................................................................................DLP-769

HARDWARE INVENTORY .....................................................................................................................DLP-770

INITIATE A PRO TECTION SWITCH...........................................................................................................DLP-771

LOOPBACK TEST ...............................................................................................................................DLP-772

CARD AND SHELF RESET.....................................................................................................................DLP-773

VIEWING AND EDITING THE NMIC IP ADDRESS..........................................................................................DLP-774

ADD OR EDIT AN SNMP T R AP HOST ON THE NMIC...................................................................................... DLP-775

ALARM CUT-OFF (ACO) ......................................................................................................................DLP-776

REMOVE AND/OR REPLACE CELLWORX CARDS.........................................................................................DLP-777

ENDING A GUI SESSION FOLLO WING AN ABNORMAL SESSION ENDING............................................................DLP-778

RETRIEVE 2488 RING INTERFACE CARD STATUS........................................................................................DLP-779

PHASE 2.0 TO 3.0 SOFTWARE UPGRADE PROCEDURE .................................................................................DLP-780

REMOVING A NMIC CARD F ROM THE SHELF.............................................................................................DLP-781

FTP DATABASE FILES OFF OF NMIC .......................................................................................................DLP-782

ADD/DELETE GUI USERS OR CHANGE GUI USER LEVEL SECURITY..................................................................DLP-783

SET FE1 FRS CARD CONFIGURATION......................................................................................................DLP-784

SET FT1 FRS CARD CONFIGURATION......................................................................................................DLP-785

CREATE A FRAME RELAY CONNECTION ...................................................................................................DLP-786

CREATE AN ATM MULTICAST CONNECTION ..............................................................................................DLP-787

RETRIEVE FT1 FRS CARD STATUS .........................................................................................................DLP-788

RETRIEVE FE1 FRS CARD STATUS .........................................................................................................DLP-789

CREATING AN ATM BUNDLED VC MULTICAST CONNECTION. .........................................................................DLP-790

ADD A LEAF ENDPOINT TO AN IN-SERVICE CONNECTION..............................................................................DLP-791

SET T3 CES CARD CONFIGURATION........................................................................................................DLP-792

RETRIEVE T3 CES CARD STATUS. ..........................................................................................................DLP-793

SET / RETRIEVE T3 CES PORT PERFORMAN CE MONITORING STATISTICS. ........................................................DL P-794

PHASE 3.0 TO 3.1 SOFTWARE UPGRADE PROCEDURE .................................................................................DLP-795

RETRIEVE 622 CRS STATUS.................................................................................................................DLP-796

SET 622 SM CRS CARD CONFIGURATION.................................................................................................DLP-797

SOFTWARE FALLBACK FROM RELEASE 3.1 TO RELEASE 3.0.........................................................................DL P-798

TROUBLE ANALYSIS PROCEDURE ..........................................................................................................TAP-100

Page vi

© 2000, ADC Telecommunications, Inc.

Page 9

1152700 • Issue 1 • February 2001 • Preface

SECTION 3

GENERAL INFORMATION

Content Page

1. WARRANTY/SOFTWARE................................................................................................................... 3-1

2. REPAIR/EXCHANGE POLICY............................................................................................................... 3-1

3. REPAIR CH AR GES .......................................................................................................................... 3-2

4. REPLACEMENT/SPARE PRODUCTS...................................................................................................... 3-2

5. RETURNED MATERIAL..................................................................................................................... 3-2

6. SYSTEM INTEGRATION SERVICES....................................................................................................... 3-3

7. CUSTOMER SUPPORT SERVICES ........................................................................................................ 3-3

© 2000, ADC Telecommunications, Inc.

Page vii

Page 10

1152700• Issue 1 • February 2001 • Preface

ABOUT THIS MANUAL

This manual provides the system administrator with information necessary to turn up and test the

Cellworx Service Transport Node (STN), and/or services, as well as configure connections and monitor

the network using the CellworxVision Graphical User interface (GUI). Information provided within this

document deals primarily with the Phase 3.1 design features of the Cellworx STN system.

Trademark Information

The following trademarks are documented in this manual:

ADC and ADC Telecommunications are registered trademarks of ADC Telecommunications Inc.

Cellworx is a registered trademark of ADC Telecommunications Inc.

Open View is a registered trademark of Hewlett-Packard.

SRTS – Synchronous Residual Time Stamp is a patent of Bell Communications Research, N ov 9, 1993

Related Publications

Listed below are all of the related manuals and their publication numbers. Copies of these publications can

be ordered by contacting the ADC Technical Assistance Center at 1-800-366-3891 extension 63434 (in

U.S.A. or Canada) or 612-946-3434 (outside U.S.A. and Canada).

Title/Description Part Number

Application and Engineering Guide 3.1 1152699

Contains an introduction to the ADC Cellworx STN system, hardware and software

descriptions, applications, and engineering information required for system deployment.

Craft User’s Manual 3.1 1152703

Contains information required for provisioning, operation, and administration of the

Cellworx STN system through the craft access. Information includes detecting and isolating

alarms, and turn up of features over the entire network.

System Description Manual 3.1 1152712

Combines information from the Users Manual, Installation Manual, and Applications

Engineering Manual to provide introductory information and a general overview of the

Cellworx STN system.

Cellworx CLEI Code Guide 1112344

Lists all CLEI codes used to order Cellworx equipment.

Page viii

© 2000, ADC Telecommunications, Inc.

Page 11

Admonishments

Important safety admonishments are used throughout this manual to warn of possible hazards

to persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below), and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

1152700 • Issue 1 • February 2001 • Preface

General Safety Precautions

Danger: Do not look into the ends of optical fibers. Exposure to invisible LASER radiation may

cause serious retinal damage or even blindness. Verify the optical source is disabled through

the use of an optical power meter before handling optical fibers.

Caution: Use caution when routing wires and cables. Avoid severe bending and routing over

sharp edges. Use grommet material when possible to avoid wear on cable insulation.

Caution: Allow sufficient fiber length to permit routing without severe bends. Fibers may be

permanently damaged, or signal degradation may be experienced if fibers are bent or curved to

a radius of less than 1.5 inches (3.81 cm).

Caution: Modules can be damaged by electrostatic discharge. Before handling any modules

connect your wrist to an equipment ground using an approved anti-static wrist strap. Ensure

that all uninstalled modules are stored in anti-static packing material. When working with

modules, always place the module on an electrically grounded approved anti-static mat.

Caution: Using excessive force when seating cards and modules into the backplane may result

in physical or severe electrical damage to the backplane pins or module connectors, and if

power is applied, may result in serious electrical damage to both the modules or the backplane

© 2000, ADC Telecommunications, Inc.

Page ix

Page 12

1152700• Issue 1 • February 2001 • Preface

FCC COMPLIANCE STATEMENT

Class A

The Cellworx STN System complies with the requirements for class A digital device per Part

15 of the FCC Rules.

Warning: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

DOC Compliance

This equipment does not exceed Class A limits for radio emission for digital apparatus, set out

in the radio interference regulation of the authorization methods of Industry Canada.

Operation in a residential area may cause unacceptable interference to TV and radio reception

requiring the owner or operator to take whatever steps are necessary to correct the

interference.

FDA Compliance

This product uses a Class 1 LASER according to FDA Rules. This product conforms to all

applicable standards of 21 CFR 1040.

Safety Compliance

UL listed for use in the U.S. and Canada.

IEC 950 (1991) Second Edition with Amdts. No. 1 (1992), 2 (1993), 3 (1995), and 4 (1996)

EN60950 (1992) with Amdts. No. 1 (1993), 2 (1993), 3 (1995, 4 (1997), and No.11 (1997); and

with National Differences as specified in the CB Test Report 99RT07840-121698.

The Cellworx STN system complies with EN 55022:1995, IEC 801-2:1991, IEC 801-3:1984

and draft IEC 801-3-1990, and IEC 801-4:1988.

The Cellworx STN system complies to all the applicable EC directives of the European Union

and is CE marked.

NEBS Compliance

The Cellworx STN system is fully NEBS compliant.

Page x

© 2000, ADC Telecommunications, Inc.

Page 13

ISO9000 Compliance

ADC Telecommunications Inc. is ISO 9001 certified.

STANDARDS

The following listing is a bibliography of applicable documents:

ANSI/IEEE Std 802.1D,1993 Edition.

ANSI T1.403-1989, Carrier to Customer Installation: T1 Metallic Interface, February 22, 1989

ATM UNI specification 3.1, ATM Forum

Bellcore GR-253-CORE, Synchronous Optical Network (SONET) Transport Systems:

Bellcore GR-1110-CORE, Broadband Switching System Generic Requirements,

Bellcore GR-1113-CORE, Asynchronous Transfer Mode (ATM) and ATM Adaptation

1152700 • Issue 1 • February 2001 • Preface

Common Generic Criteria, Issue 2, 12/95

Issue 1, 9/94, Revision 3, 4/96

Layer (AAL) Protocols, Bellcore.

Bellcore GR-1117-CORE, Generic Requirements for Exchange PVC CRS Customer

Network Management Service, Bellcore.

Bellcore GR-1244-CORE, Clocks for the Synchronized Network: Common Generic

Criteria, Bellcore.

Bellcore GR-1248-CORE, “Generic Requirements for Operations of ATM Network

Elements (NEs),” Issue 3, 8/96

Bellcore GR-1400-CORE, SONET Dual-fed Unidirectional Path Switched Ring (UPSR)

Equipment Generic Criteria, Bellcore.

Bellcore GR-20-CORE, Generic Requirements for Optical Fiber and Optical Fiber Cable,

Bellcore.

Bellcore GR-253-CORE, SONET Transport Systems: Common Criteria, Bellcore.

Bellcore GR-2837-CORE, “ATM Virtual Path Functionality in SONET Rings—Generic

Criteria,” Issue 2, 12/95

Bellcore GR-2842-CORE, “ATM Service Access Multiplexer (SAM) Generic

Requirements,” Issue 1, 11/94

Bellcore GR-2848-CORE, Broadband Multi-service UNI Generic Requirements, Bellcore.

Bellcore GR-436-CORE, Digital Network Synchronization Plan, Bellcore.

Bellcore TR-TSY-000496, Issue 2, September 1989, Supplement 1, September 1991

© 2000, ADC Telecommunications, Inc.

Page xi

Page 14

1152700• Issue 1 • February 2001 • Preface

The ATM Forum ATM User-Network Interface (UNI), Specification, Version 3.1

NFOEC, Volume 2 1995, pg 445. “A Comparative Analysis of 2 Fiber and

NFOEC, Volume 3 1995, pg 885. “SONET Operations Networking; The

RFC-1406, Definitions for Managed Objects for the T1 and E1 Interface

RFC-1407, Definitions for Managed Objects for the T3 and E3 Interface

ITU I.350

ITU I.371

ITU I.610

Bellcore TA-1230

ITU M.3010

ITU M.3020

ITU M.3100

ITU M.3180

4 Fiber Bi Directional Line Switched Rings.”

Key to the Future.”

Types, IETF.

Types, IETF.

TA-NWT-000487, Generic Requirements for Electronic Equipment Cabinets,

Bellcore.

TA-TSV-1408, Generic Requirements for Exchange PVC Cell Relay Service,

Bellcore.

TA-TSV-1409, Generic Requirements for Exchange Access PVC Cell Relay

Service, Bellcore.

TR-NWT-000063, Network Equipment Building System (NEBS) Generic

Equipment Requirements, Bellcore.

TR-NWT-000078, Generic Physical Design Requirements for Telecommunications

Products and Equipment, Bellcore.

TR-NWT-000468, Reliability Assurance Practices for Optoelectronic Devices in

Central Office Applications, Bellcore.

TR-NWT-000496, SONET ADM Equipment Generic Criteria, Bellcore.

TR-NWT-000499, Transport Systems Generic Requirements (TSGR): Common

Requirements, Bellcore.

TR-NWT-000815, OTGR Section 2.3: Network Element and Network System

Security, Bellcore.

TR-NWT-000930, Generic Requirements for Hybrid Microelectronics Used in

Telecommunications Equipment, Bellcore.

TA-NWT-000983, Reliability Assurance Practices for Optoelectronic Devices in

TR-NWT-001112, Broadband-ISDN User to Network and Network Node Interface

Page xii

© 2000, ADC Telecommunications, Inc.

Loop Applications, Bellcore.

Physical Layer Generic Criteria, Bellcore.

Page 15

1152700 • Issue 1 • February 2001 • Preface

TR-TSV-000772, Generic System Requirements in Support of Switched Multi-

Megabit Data Service, Bellcore.

TR-TSV-001369, Generic Requirements for Frame Relay PVC Exchange Service,

Bellcore.

TR-TSV-001370, Generic Requirements for Exchange Access Frame Relay PVC

Service, Bellcore.

TR-TSY-000454, Supplier Documentation for Network Elements, Bellcore.

List of Acronyms and Abbreviations

The acronyms and abbreviations used in this manual are detailed in the following list:

155 CRS Dual port Optical Carrier card providing Cell Relay Service in a

concatenated payload at a data rate of 155Mbps

155 RIC Optical Carrier Ring Interface Card providing cell relay service in a

concatenated payload at a data rate of 155Mbps

622 RIC Optical Carrier Ring Interface Card providing cell relay service in a

concatenated payload at a data rate of 622Mbps

2488 RIC Optical Carrier Ring Interface Card providing cell relay service in a

concatenated payload at a data rate of 2488Mbps

ABR Available Bit Rate

ADM Add / Drop Multiplexer

AIC Access Interface Card

AIS Alarm Indication Signal

APS Automatic Protection Switching

ATM Asynchronous Transfer Mode

B-ICI Broadband Inter-Exchange Carrier Interface

BPS Bits Per Second

CAC Connection Admission Control

CBR Constant Bit Rate

CDV Cell Delay Variation

CDVT Cell Delay Variation Tolerance

CES Circuit Emulation Service

CIR Committed Information Rate

CO Central Office

CPE Customer Premise Equipment

CRS Cell Relay Service

CTD Cell Transfer Delay

DCC Data Communications Channel

E1 TMUX Multi 1 A 16 E1 port card that converts digital signals into ATM streams

EIM Electrical Interface Module

EPS Expansion Shelf

ESF Extended Superframe

FRS Frame Relay Service

FTP File Transfer Protocol

GNE Gateway Network Element

GUI Graphical User Interface

IP Internet Protocol

© 2000, ADC Telecommunications, Inc.

Page xiii

Page 16

1152700• Issue 1 • February 2001 • Preface

LAN Local Area Network

LEC Local Exchange Carrier

LTE Line Terminating Equipment

msec millisecond

NDC Network Data Collection

NE Network Element

NIC Network Interface Card

NMIC Network Management Interface Card

NMS Network Management System

NNI Network to Network Interface

NPC Network Parameter Control

OAM&P Operations, Administration, Maintenance, and Provisioning

OS Operations System

PCR Peak Cell Rate

PEIM Protection EIM

PTE Path Terminating Equipment

PVC Permanent Virtual Circuit

QoS Quality of Service

RIC Ring Interface Card

SAM Service Access Multiplexer

SC Shelf Controller card

SCR Sustained Cell Rate

SDH Synchronous Digital Hierarchy

SEPIC Shelf ExPansion Interface Card

SNMP Simple Network Management Protocol

SONET Synchronous Optical NETwork

SPE Synchronous Payload Envelope

SRTS Synchronous Residual Time Stamp (patent 5260978 Bell Comm. Research)

STM Synchronous Transport Mode

STN Service Transport Node

STS Synchronous Transport Signal

STS-3c Concatenated STS-3 signal (one payload)

SVC Switched Virtual Circuit

T1 Digital Signal Level 1

T1 TMUX Multi 1 A 16 DS1 port card that converts digital signals into ATM streams

T3 Digital Signal Level 3

T3 CES Three port Digital Subscriber line card providing Circuit Emulation

T3 CRS Three port Digital Subscriber line card providing Cell Relay Service at a

T3 TMUX Multi 1 A single DS3 port line card providing individual DS1 channel multiplexing

TC Transmission Convergence

TCA Threshold Crossing Alert

TDM Time Division Multiplexer

TEIM Terminating Electrical Interface Module

TFTP Trivial File Transfer Protocol

TID Target Identifier

TMN Telecommunication Management Network

Service at a data rate of 45Mbps

data rate of 45Mbps

Page xiv

© 2000, ADC Telecommunications, Inc.

Page 17

UBR Unspecified Bit Rate

UNI User Network Interface

UPC Usage Parameter Control

UPSR Unidirectional Path Switch Ring

UVPSR Unidirectional Virtual Path Switch Ring

VC Virtual Channel

VCC Virtual Channel Connection

VP Virtual Path

VPC Virtual Path Connection

VT Virtual Tributary

W/P Working/Protect

1152700 • Issue 1 • February 2001 • Preface

© 2000, ADC Telecommunications, Inc.

Page xv

Page 18

SECTION 1

INTRODUCTION

CONTENT..........................................................................................................................PAGE

1. GENERAL ...........................................................................................................................1

2.USER INTERFACES.................................................................................................................2

A.NMIC RS232 Interface........................................................................................................3

B.NMIC EIM RJ45 Ethernet Interface.........................................................................................3

C.NMIC Serial Equipment Port ................................................................................................4

3.CELLWORX STN SYSTEM SOFTWARE..........................................................................................4

A.NMIC Graphical User Interface (GUI) ......................................................................................4

4. REMOTE MANAGEMENT CAPABILITIES ..................................................................................... 13

A.Real Time Alarm and trap Screens ...................................................................................... 14

1152700• Issue 1 • February 2001 • Section 1 Introduction

GUI Screen Icon Definitions......................................................................................5

GUI Menu Structure and Utilization.............................................................................8

X-Terminal Keyboard Functions............................................................................... 12

Manipulating the GUI Net work Layout on an X-Terminal Screen........................................ 12

1. GENERAL

This section provides information on the Cellworx Service Transport Node’s (STN)

Graphical User interface (GUI) and alarm monitoring capabilities. Information in

this document relates to the Release 3.1 design features of the Cellworx STN

system. Future revisions of this document will cover added features and

enhancements to the system and/or software.

The Cellworx STN system has been designed to accelerate the migration of

networks to support broadband services. It is an Add/Drop Multiplexer (ADM)

utilizing Asynchronous Transfer Mode (ATM) technologies to support access and

delivery of emerging and legacy services. Through the use of simple transport

provisioning, the Cellworx STN enables broadband services on an ATM backbone

to coexist within the TDM infrastructure. A single platform is used to both deploy

new services to thousands of customers, and provide significant bandwidth savings

in existing networks. At the same time, it provides the utility and survivability that

service providers have come to expect from true Telecom-oriented SONET

products.

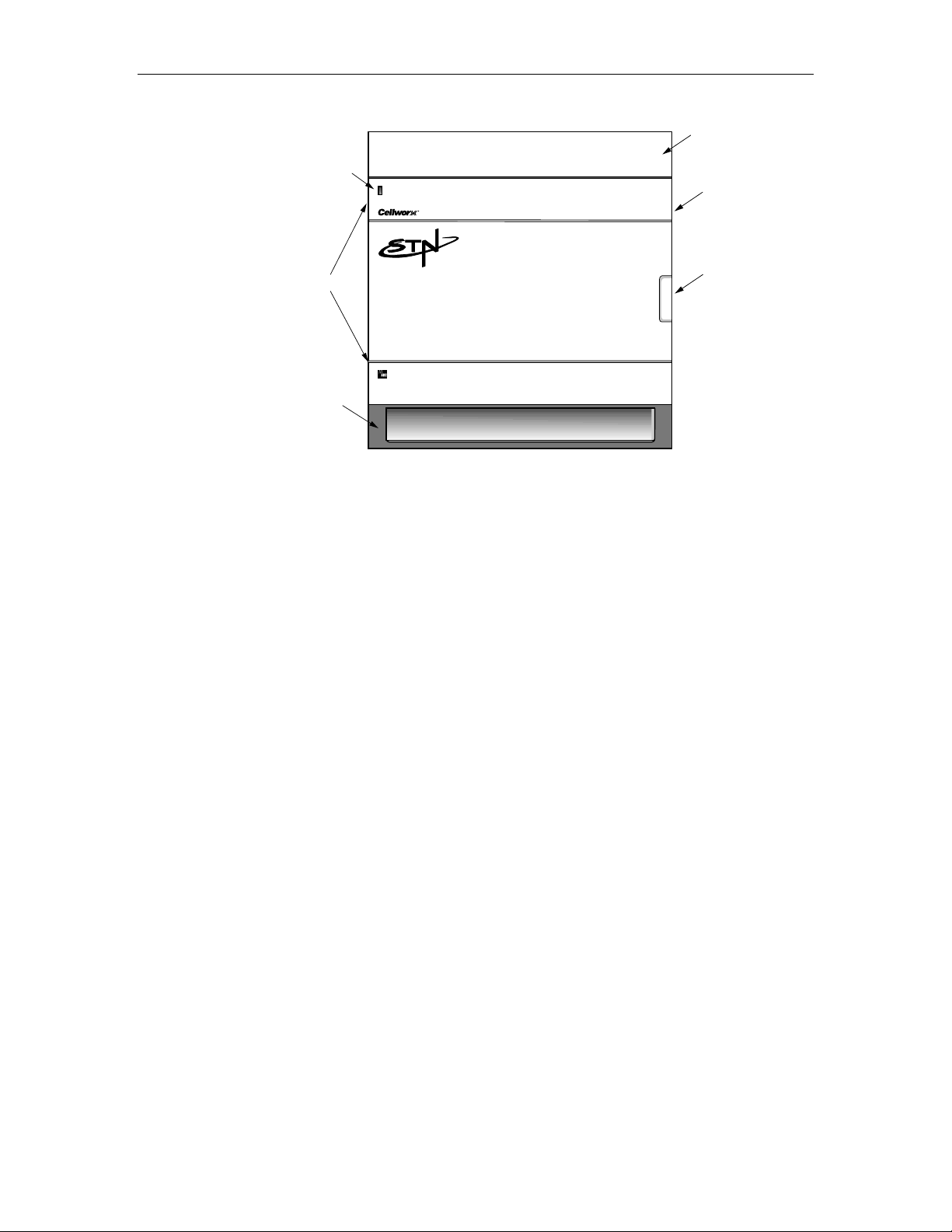

The Cellworx STN shelf is shown in Figure 1-1. It is available in a 19-inch or a 23inch rack mount shelf that has specific card slot assignments for the Ring Interface

Cards (RICs), Network Management Interface Cards (NMICs), and Shelf

Controller cards (SCs). The intent of specific slot locations is to maximize bus

performance and the number of working and protect pairs. The Cellworx STN can

be used as a collocated or remote Expansion node utilizing 622, 155 or T3 CRS

cards as links to a ring node to provide subscriber fan out or remote access

capabilities to a ring. Certain card slots are keyed to prevent the installation of

wrong card types into those slots. The remainder of the slots can accept any Access

Interface Card (AIC) provided the proper Electrical Interface Module (EIM) is

installed at the rear of the shelf for that AIC service type.

© 2000 ADC Telecommunications, Inc.

Page 1-1

Page 19

1152700• Issue 1 • February 2001 • Section 1 Introduction

SHELF

ALARM

INDICATOR

DOOR

HINGES

LOWER AIR INTAKE/

CABLE ROUTING TRAY

Figure 1-1. Cellworx STN Shelf

UPPER HEAT BAFFLE/

FIBER MANAGEMENT TRAY

ESD GROUND JACK

DOOR

LATCH

10479-C

2. USER INTERFACES

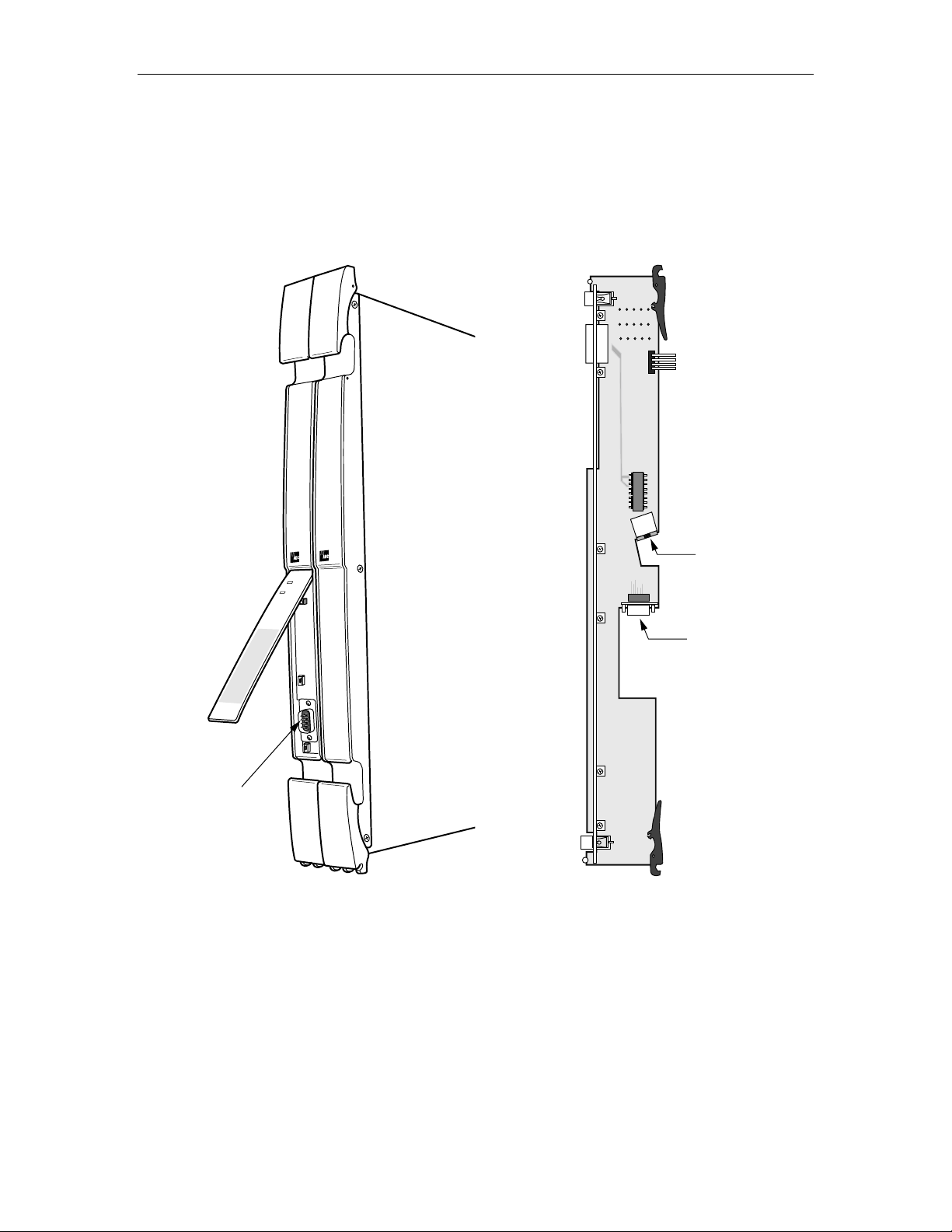

The Network Management Interface Controller (NMIC) shown in Figure 1-2

provides a common ring and element management system platform where all

aspects of network management are performed. The NMIC houses the operating

system and application software for each node and card to provide Fault,

Configuration, Performance, and Security management functions based on TMN

principles at the Element Management Layer.

Page 1-2

© 2000, ADC Telecommunications, Inc.

Page 20

A. NMIC RS232 Interface

3

The NMIC provides an asynchronous RS-232 port for character based access

provided through a DB9 connector located under the front hinged faceplate. This

port is used to load the operating system information and IP addresses at initial

network turn up.

ADCP-70-220 • Issue 1 • September 2000 • Section 1 Introduction

IC

M

N

S

ta

tu

s

Active

C

ra

ft

A

c

c

e

s

s

E

n

ab

le

G

M

S

C

ra

ft

R

e

s

e

t

JA7

P5

P1

A

GND

E11

B

GND

U2

J6

RJ45 ETHERNET

CONNECTION

J2

9 PIN D-SUB EXTERNAL

EQUIPMENT PORT

RS232 PORT

117

J1

Figure 1-2. NMIC Craft Port Identification Figure 1-3. NMIC EIM Port Identifications

B. NMIC EIM RJ45 Ethernet Interface

An external Network Management System (NMS) and/or X-Terminal connection is

provided through an RJ45 10 Base-T Ethernet connection on either NMIC

Electrical Interface Module (NMIC EIM) in slot 2 or 4 at the rear of the shelf.

Refer to Figure 1-3. This connection is available only in the Gateway Network

Element (GNE) located at a Central Office or controlled environment (0-50° C)

location. It provides access to the GUI software screens for all management

© 2000, ADC Telecommunications, Inc.

10490-A

Page 1-3

Page 21

1152700• Issue 1 • February 2001 • Section 1 Introduction

functions, or SNMP access for Sets, Gets, Traps etc. Up to five GUI sessions may

be launched at a time. An X-Terminal may remain active while the GUI is launched

on another terminal. A user establishes a Telnet session to the NMIC to launch the

GUI. The NMIC can maintain the Telnet session after the GUI is exited, or

maintain the GUI functionality after the user terminates the Telnet session, but

once both the Telnet session is terminated and the GUI is exited, the Telnet session

must be re-established.

NMICs support 1:1 protection and provide independent Ethernet connections. Each

NMIC has a unique IP address and a shared IP address, requiring the administrator

to provision each of them on the X-Terminal. If the administrator cannot connect

using the shared IP address (NMICs are unobtainable or a no response message is

generated from a remote Telnet session connection attempt), the administrator can

reattempt the Telnet session utilizing either the working or the protection NMIC IP

addresses.

C. NMIC Serial Equipment Port

A serial port is provided on the NMIC EIM that can be used for modem access or

other types of serial equipment. This port will provide the same system access as

the Ethernet port. It has jumpers that enable the user to strap the port for DTE or

DCE depending on the serial device connected to it.

3. CELLWORX STN SYSTEM SOFTWARE

A. NMIC Graphical User Interface (GUI)

The Cellworx NMIC GUI interface provides a simple, consistent means of

interaction through menu, mouse, and keyboard driven software configuration

options. It is an executable program residing on the NMIC that a user gains access

to through an X-Terminal window from the shell command prompt. The GUI

retrieves data for the user initiated events via SNMP to the Application Core or by

accessing the information stored on its hard disk.

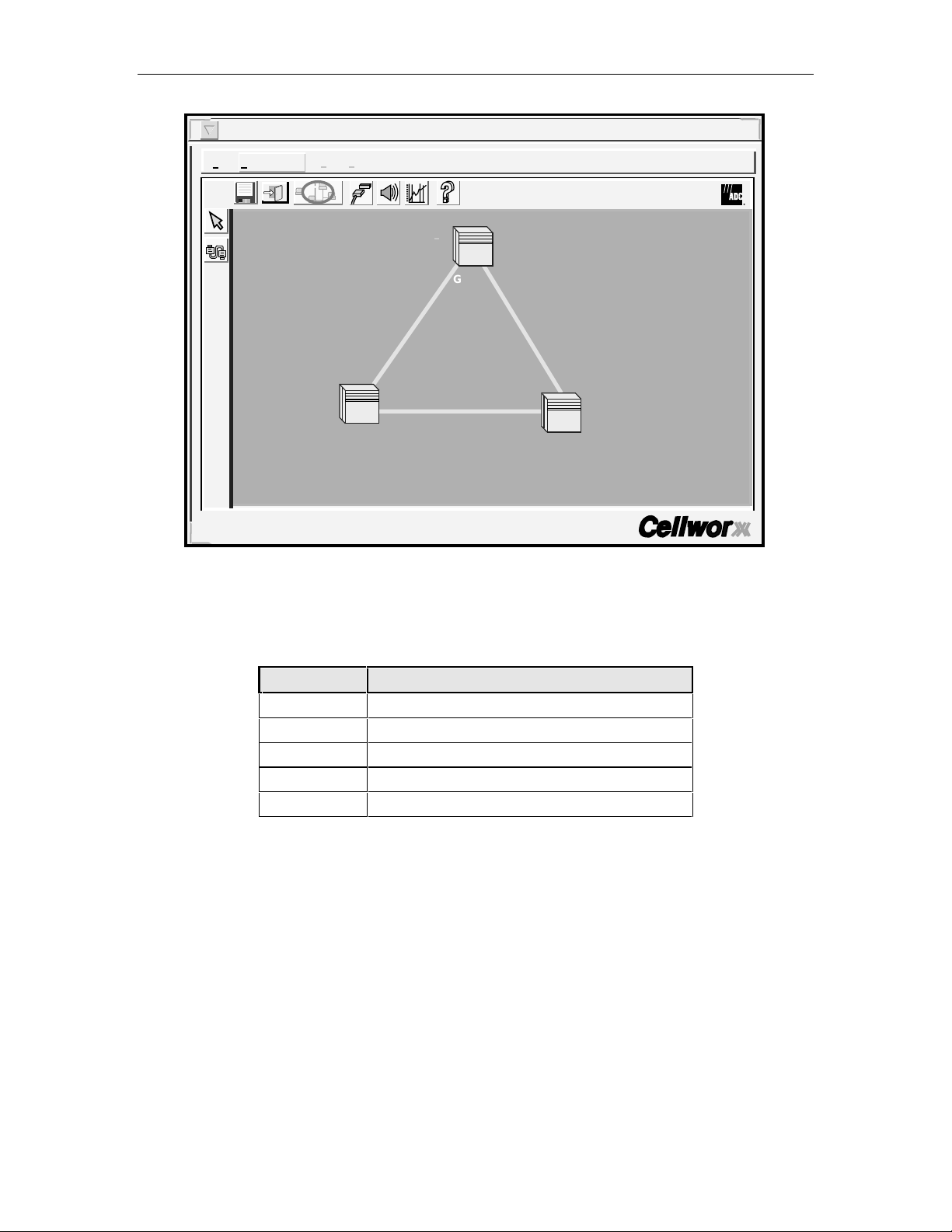

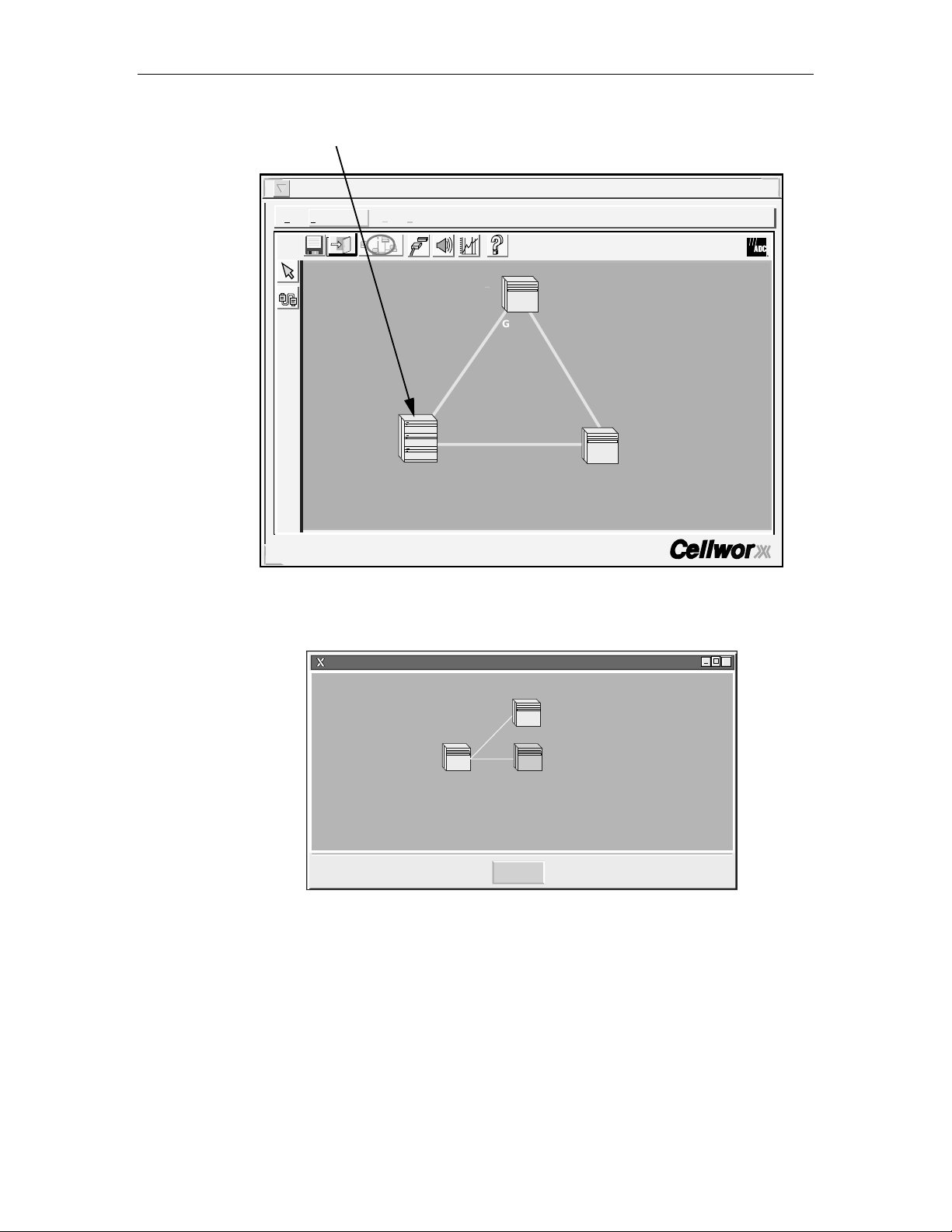

Once connected to the NMIC and logged on to the network, a full network view

encompassing each node in the network is displayed on the screen. An example is

shown in Figure 1-4. An arrangement of icons representing Cellworx STN nodes

reflect the network configuration (if configured) and are color-coded indicating the

current alarm state of each node. Table 1-1 describes the color codes of the icons.

The NE containing the NMICs is referred to as the Gateway Network Element

(GNE) and can be determined at a glance from the yellow text underneath it. All

other nodes will have white text.

The fiber connections shown between the nodes will appear green if there are no

fiber fragment failures. They will turn orange in the event of a fiber fragment

failure indicating a major alarm condition on the link between nodes.

Page 1-4

© 2000, ADC Telecommunications, Inc.

Page 22

ADCP-70-220 • Issue 1 • September 2000 • Section 1 Introduction

Cellworx Vision: Subnetwork Management System

File Configuration Fault Performance Help

i

GNE-1

NE-2

Cellworx User: root

Local Time: 21:35 GMT Time: 21:35

NE-3

10924-D

Figure 1-4. Network Manager Main Screen

Table 1-1. GUI Cellworx STN Node Icon Color Codes

COLOR INDICATION

Green No existing alarms, normal operation.

Yellow Minor alarms exist at this site.

Orange Major alarms exist at this site.

Red Critical alarms exist at this site.

Blue Cannot communicate with the site.

GUI Screen Icon Definitions

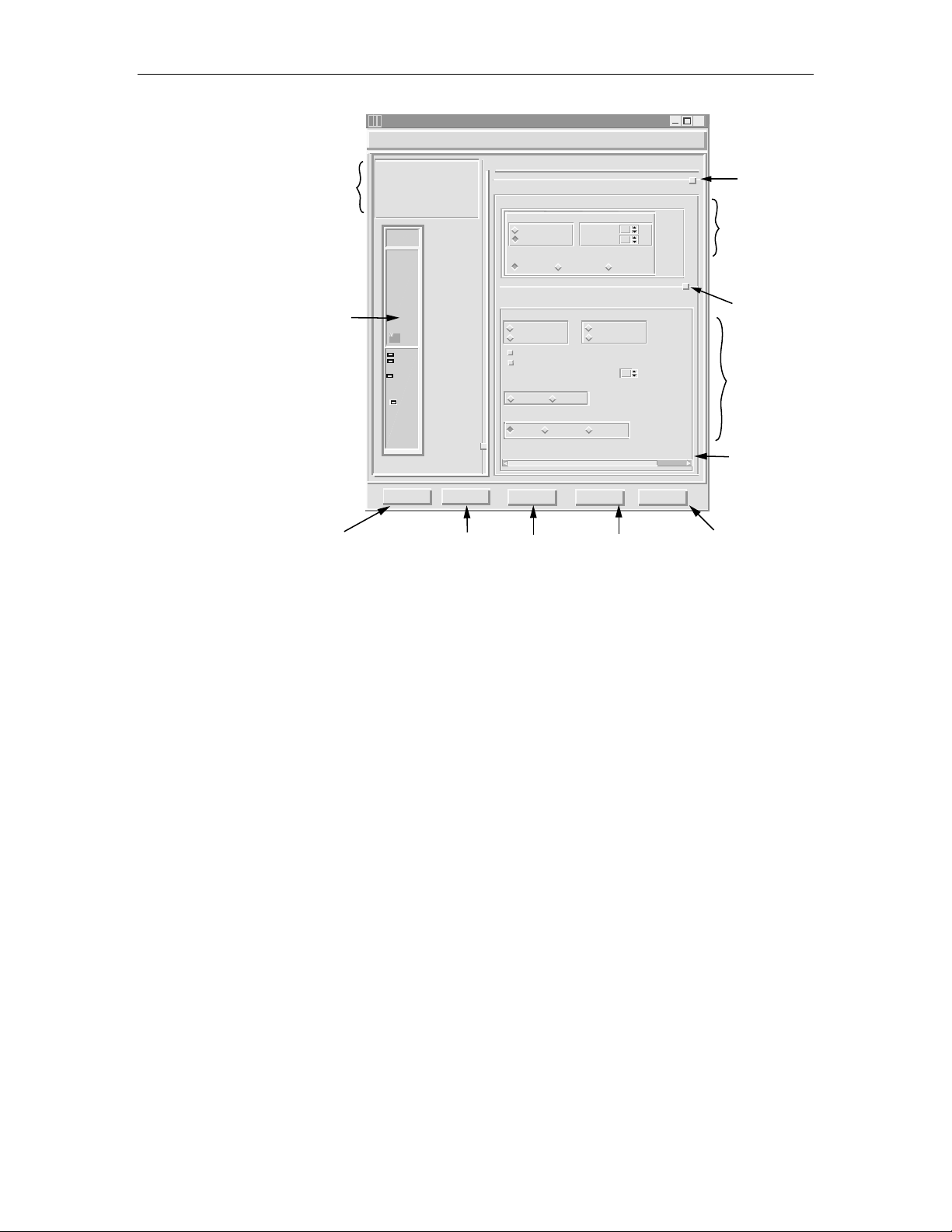

Larger icons are used to represent the Cellworx STN shelves that have Secondary

nodes (expansion shelves called STN-EPS) connected to them. These icons are

referred to as Primary nodes and will look the same whether there are 2 or 10 STNEPS nodes connected to them. Refer to Figure 1-5. The Secondary nodes may be

collocated or reside at remote sites. When a user selects a node, it is highlighted by

a white square that surrounds it. By double clicking on one of these nodes with the

left mouse button, a new window is displayed reflecting the interconnecting

relationship between the Primary and Secondary nodes. It is at this point that the

user can determine the number of nodes involved. Refer to Figure 1-6. The Primary

node now appears as a normal size ICON and the ring network interconnections are

not displayed. To return to the ring network view, the operator clicks on the Cancel

button at the bottom of the window.

© 2000, ADC Telecommunications, Inc.

Page 1-5

Page 23

1152700• Issue 1 • February 2001 • Section 1 Introduction

ICON FOR NE-2 INDICATES

THE PRESENCE OF STN-EPS

SHELVES

Cellworx Vision: Subnetwork Management System

File Configuration Fault Performance Help

i

STN

STN

STN

NE-2

GNE-1

NE-3

Cellworx User: root

Local Time: 21:37 GMT Time: 21:37

10926-D

Figure 1-5. Example of Primary Node with Secondary Expans i ons

Cellworx Vision:Physical Layouts for NE-2

EPS-2

NE-2 EPS-1

Cancel

X

10960-B

Figure 1-6. Primary Node Physical Layout to Secondary Nodes

An Auto Discovery feature allows the NMIC to search for and display all nodes

connected in the network during initial system turn-up. Main menu headings are

displayed at the top of the screen (File, Configuration, Fault, Performance) and

when selected will allow the user to perform all higher level functions such as

system administration, establish end to end VP/VC connections, request

performance reports, or display network alarm summaries.

Page 1-6

© 2000, ADC Telecommunications, Inc.

Page 24

ADCP-70-220 • Issue 1 • September 2000 • Section 1 Introduction

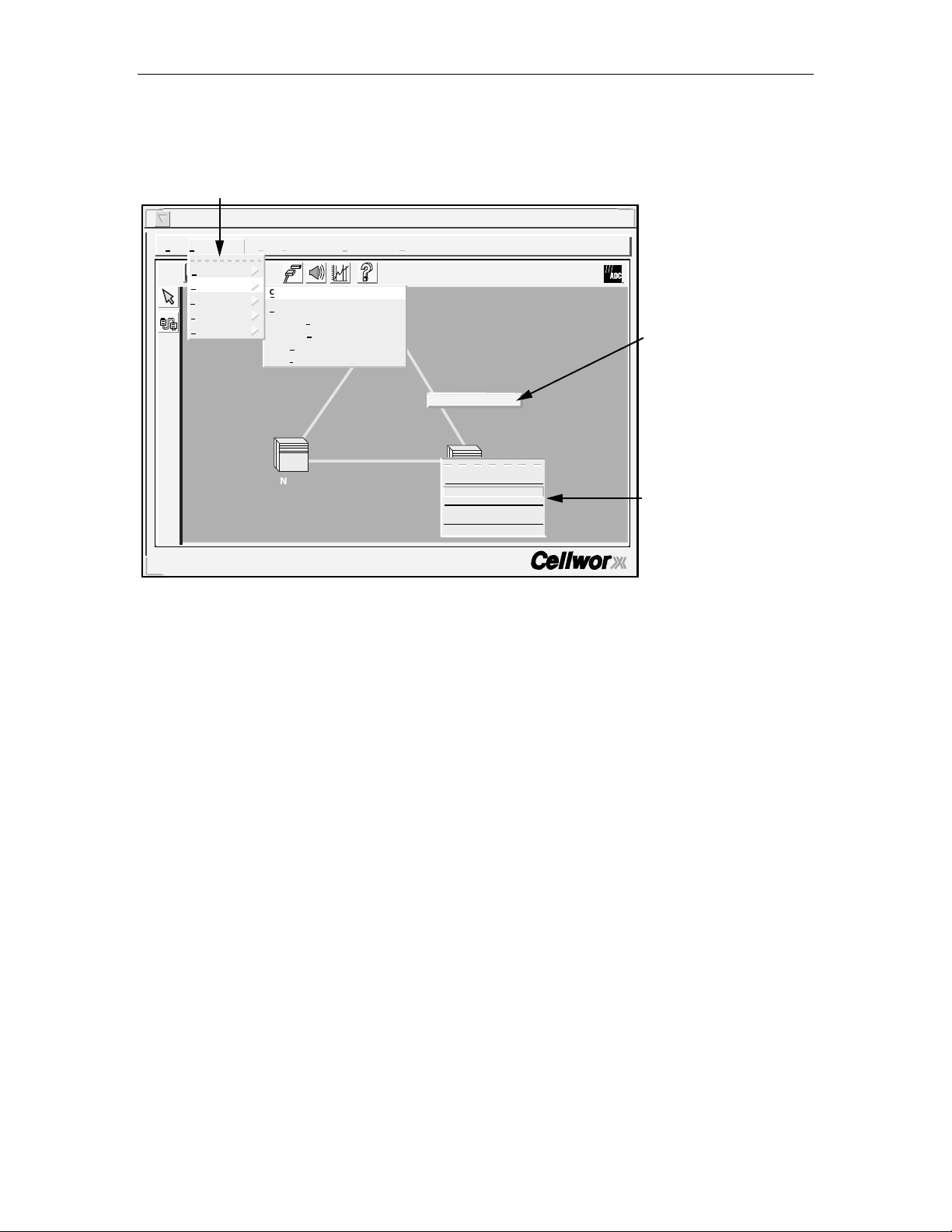

To access any node in the network, the administrator selects the direct selection

arrow tool located on the left tool bar, and then double clicks on the NE ICON to

open a shelf level GUI session. To start a craft session with the node, the user

selects the node with a single click, right click to open the pop-up menu, and select

Craft Interface. The administrator is required to enter a valid user name and

password assigned for the node to gain access to the craft menus. The shelf level

GUI is shown in Figure 1-7 below.

CHASSIS STATUS

CHASSIS

CONFIGURATION

APPLIES CHANGES

AND SENDS TO SHELF

CONTROLLER.

Cellworx Vision: Chassis View, Network Element 2

File Configuration Fault Security

SCN

M

I

C

123456789101112131415161718

Status:

Power Status: normal

Identifier:

Start Time:

Vendor:

Configuration:

2

19:30:47 8/31/1999

ADC-TSG

Cellworx2

Name:

Location:

5th Street

Apply Topology View

T

3

T

M

U

X

T

T

T

3

1

M

M

U

C

u

X

R

l

S

t

E

i

X

P

1

Memory Utilization Threshold:

RETURNS TO GUI MAIN

VIEW WITHOUT CLOSING

CHASSIS LEVEL VIEW.

E

E

T

1

1

3

M

M

u

u

C

l

l

R

t

t

S

i

i

1

1

Alarm Status:

Version:

Current Time:

Up Time:

Suppress Zero Stats

Refresh Close

REP AINTS WINDOW

TO REFLECT ANY

CHANGES.

2

4

8

8

R

i

n

g

minor

1.2.0.35

10:12:09 09/01/1999

1d 19:41:22:00

4

8

8

R

i

n

g

X

SC2

EQUIPPED CARD

REPRESENTATIONS WITH

ALARM INDICATIONS.

CLICK ON BOXES AND DRAG

UP OR DOWN TO WIDEN

STATUS, CONFIGURATION OR

CHASSIS VIEW.

USE SLIDERS TO VIEW

HIDDEN STATUSES OR

SELECTIONS.

CLOSES CHASSIS LEVEL

VIEW AND RETURNS TO

GUI MAIN VIEW.

13454-C

Figure 1-7. Cellworx Shelf Level GUI Screen

The user can now provision parameters on individual cards in the shelf. To bring up

a card level GUI display, double click on the card displayed in the shelf level view

or put the mouse pointer over the card and hit a right click to open a menu window

for the card and select Open. The Card level view will appear similar to the

example shown in Figure 1-8 below. Some functions available in this view are

described in the figure.

© 2000, ADC Telecommunications, Inc.

Page 1-7

Page 25

1152700• Issue 1 • February 2001 • Section 1 Introduction

NE AND CARD TYPE/

SLOT INFORMATION.

CARD REPRESENTATION

WITH REAL-TIME ALARM

INDICATIONS.

APPLIES CHANGES

AND SENDS TO SHELF

CONTROLLER.

Cellworx Vision: Card View - 622 Ring Interface Card

NE Name: Cellworx1

NE Id: 1

Card: 622 Ring

Slot Number: 17

Port Number: 1

622

Ring

ADC

Status

Status

Active

Active

Protect

Timing

Timing

Port

1

Apply Chassis View

RETURNS TO CHASSIS

VIEW WITHOUT CLOSING

CARD LEVEL VIEW.

Status:

Configuration:

Card Level

Administrative State: Congestion Thresholds:

Ring Selection :

Port Level

Administrative State: Transmit Timing Source:

Locked

Unlocked

Do not use for synchronization

Enable signal degrade

Signal Degrade BER Threshold: 10EMedium Type:

SONET

Loopback towards:

None Terminal

Line Coding:

Line Type:

Diagnostics

PERFORMS TEST

OVER FIBER

LINK.

Locked

Unlocked

Auto Ring 16 Ring 17

SDH

80

Ingress:

Egress:

80

System

Recieved

5

Facility

sonetMediumNRZ

sonetLongSingleMode

Refresh

REPAINTS WINDO W

TO REFLECT ANY

CHANGES.

X

CLICK ON BOX AND DRAG

UP OR DOWN TO WIDEN

STATUS OR CONFIGURATION

VIEWS.

%

%

Close

CARD LEVEL

CONFIGURATION OPTIONS.

CLICK ON BOX AND DRAG UP

OR DOWN TO WIDEN PORT

LEVEL VIEW.

622 MBPS PORT LEVEL

CONFIGURATION OPTIONS.

USE SLIDERS TO VIEW

HIDDEN SELECTIONS.

CLOSES CARD LEVEL

VIEW AND RETURNS TO

SHELF LEVEL VIEW.

13443-B

Figure 1-8. Cellworx Vision Card Level View (622 Ring Interface Car d example)

GUI Menu Structure and Utilization

There are three possible methods for performing configuration tasks using the GUI;

1) utilizing the pull down menu trees, 2) mouse controlled popup menus, 3)

keyboard operations. Refer to Figure 1-9 for examples.

• Using the mouse, click the right button over the work area to display the

popup menu and select desired task using the left mouse button. This may

bring up another pop up menu, depending on the task.

• Using the mouse, select a topic on the menu bar above the work area using the

left mouse button. Select a task shown on the pull down menu using the left

mouse button. This may bring up a pop up menu, depending on the task.

• Using the keyboard, select “Alt” plus the underlined letter of a topic shown on

the menu bar above the work area. This opens the pull down menu from the

menu bar. Using the arrow keys on the keyboard, step up or down to the

desired task and hit enter, or return, or right arrow. Other pop up menus may

be generated depending on the task.

Page 1-8

© 2000, ADC Telecommunications, Inc.

Page 26

ADCP-70-220 • Issue 1 • September 2000 • Section 1 Introduction

SELECTING THE TOPIC USING THE LEFT MOUSE BUTTON,

OR ALT PLUS THE UNDERLINED LETTER, OPENS THE PULL

DOWN MENU LIST. SELECT OPTION USING LEFT MOUSE

BUTTON OR DOWN ARROW FOLLOWED BY A RIGHT ARROW.

Cellworx Vision Subnetwork Management System

File Configuration Fault Performance Accounting Security Help

Time and Date

Connection

Topology

Software

NMIC Platform

Cellworx User: root

Local Time: 23:30 GMT Time: 23:30

i

Create...

View ...

Configure Traffic Contract ...

Configure Service Provider Profile ...

View Ring Resource Usage ...

View Fiber Bandwidth Usage ...

NE-2

GNE-1

Fiber Bandwidth Usage...

About...

Craft Interface...

NE-3

Create Connection...

View Connection...

Configure Alarm Threshold...

Configure Software...

Reflash Boot Image

Figure 1-9. Cellworx STN GUI Di splay (sample)

CLICK THE RIGHT MOUSE

OVER THE FIBER TO

OPEN POP UP WINDOW.

SELECTING A NODE WITH LEFT

MOUSE BUTTON AND THEN

HITTING RIGHT MOUSE BUTTON

OPENS THE NE POP UP MENU.

10921-F

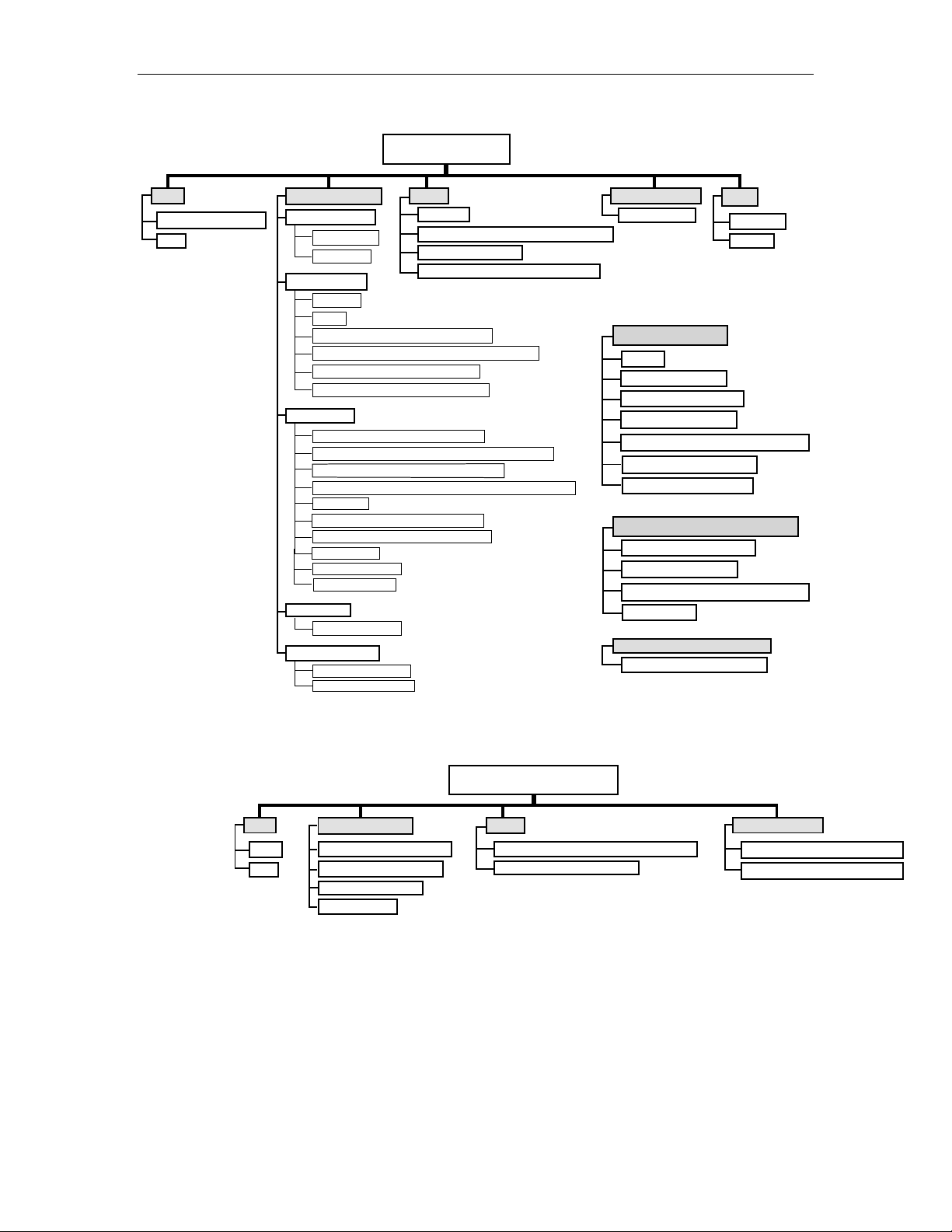

The pull down menus and pop-up window menu structures for the main GUI screen

are shown in the menu tree in Figure 1-10. The pull down menus for the Shelf level

GUI is shown in Figure 1-11.

© 2000, ADC Telecommunications, Inc.

Page 1-9

Page 27

1152700• Issue 1 • February 2001 • Section 1 Introduction

GUI MAIN SCREEN

FILE

SAVE ICON LAYOUT

EXIT

CONFIGURATION

TIME AND DATE

ABSOLUTE

RELATIVE

CONNECTION

CREATE

VIEW

CONFIGURE TRAFFIC CONTRACT

CONFIGURE SERVICE PROVIDER PROFILE

VIEW RING RESOURCE USAGE

VIEW FIBER BANDWIDTH USAGE

TOPOLOGY

ADD RING NETWORK ELEMENT

ADD EXPANSION SHELF NETWORK ELEMENT

REMOVE RING NETWORK ELEMENT

REMOVE EXPANSION SHELF NETWORK ELEMENT

REFRESH

FORCE NETWORK DISCOVERY

REVERT TO SAVED ICON LAYOUT

RING AUDIT

RING UPGRADE

TURN-UP RING

SOFTWARE

CONFIGURE NE

NMIC PLATFORM

ADMINISTRATION

FILE REPLICATION

FAULT

ALARMS

CONFIGURE NE ALARM THRESHOLD

NMIC PROTECTION

NMIC PROTECTION RESTORATION

PERFORMANCE

MONITORING

NE POP-UP WINDOW

ABOUT

CRAFT INTERFACE

CREATE CONNECTION

VIEW CONNECTIONS

CONFIGURE ALARM THRESHOLDS

CONFIGURE SOFTWARE

REFLASH BOOT IMAGE

PRIMARY NODE POP-UP WINDOW

CREATE A CONNECTION

VIEW CONNECTIONS

CONFIGURE ALARM THRESHOLDS

REFRESH NE

FIBER LINK POP-UP WINDOW

FIBER BANDWIDTH USAGE

HELP

CONTACT

ABOUT

10922-F

Figure 1-10. Cellworx Vision Pull Down Menus and Pop-up Window Trees

FILE

SAVE

EXIT

CONFIGURATION

HARDWARE INVENTORY

PROTECTION GROUPS

TIMING RESOURCE

RESET SLOTS

Figure 1-11. Cellworx Shelf Level GUI Pull Down Menu Structure

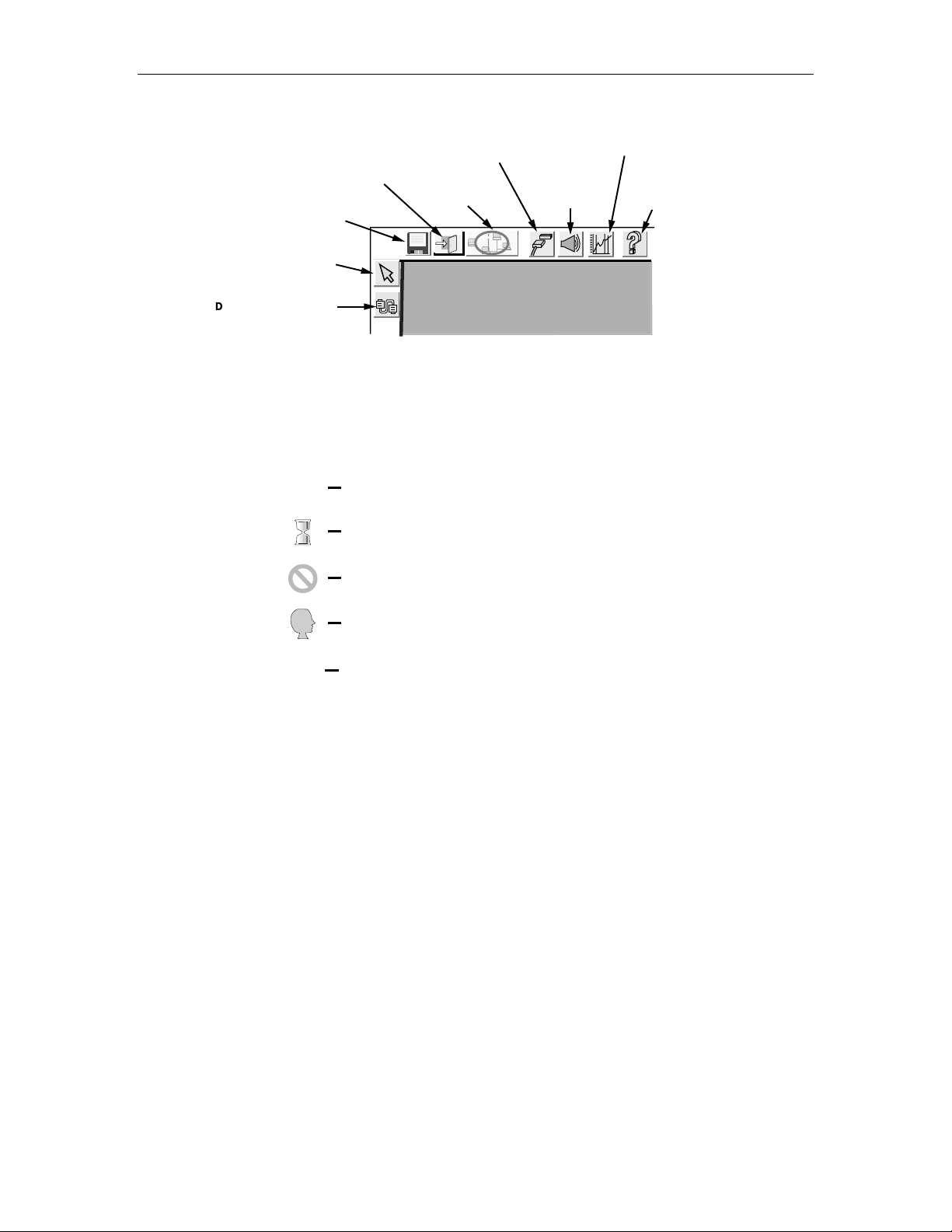

Just outside the workspace the tool bar displays icons placed horizontally and

vertically. These Icons provide shortcuts to common tasks for the advanced user.

The functions of these icons are described in Figure 1-12.

Page 1-10

© 2000, ADC Telecommunications, Inc.

SHELF LEVEL GUI MENU

FAULT

CONFIGURE HOUSEKEEPING ALARMS

EXECUTE ALARM CUT-OFF

SECURITY

CRAFT USER CONGIURATION

CRAFT MENU CONGIURATION

13571-A

Page 28

ADCP-70-220 • Issue 1 • September 2000 • Section 1 Introduction

PERFORMANCE

ALARM

HISTORY

DATA

MANAGEMENT

DATA

CELLW ORX VISION

HELP SCREEN

SAVE NE ICON LAYOUT

VIEW ALL SUBNETWORK

CONNECTIONS...

EXIT

REFRESH

TOPOLOGY

i

SELECT MODE TOOL

DRAG AND DROP TO

CREATE A CONNECTION

Figure 1-12. GUI Tool Bar Icon Definitions

While performing tasks, a user may encounter message windows, confirmation

windows, and informational windows. Each window can be distinguished by the

icon to the left as shown in Figure 1-13.

INFORMATIONAL WINDOW INDICATING A TASK HAS BEEN COMPLETED,

i

i

OR INSTRUCTING THE USER TO ENTER INFORMATION. GENERALLY

REQUIRES THE USER TO SELECT "OK".

10940-B

HOURGLASS INDICATES A TASK IS IN PROGRESS AFTER CHANGES

TO THE SYSTEM HAVE BEEN SENT BY THE USER.

ERROR MESSAGE INDICATES THAT THE TASK COULD NOT BE COMPLETED

DUE TO LACK OF INFORMATION, HARDWARE, COMMUNICATION, ETC.

QUESTION ICON INDICATES THAT THE USER MUST THINK AND MAKE

?

!

A SELECTION BEFORE CONTINUING.

WARNING MESSAGE INDICATING A POTENTIAL PROBLEM, GENERALLY

REQUIRES THE USER TO SELECT "OK".

!

10939-C

Figure 1-13. Cellworx Vision Window Icon Definitions

© 2000, ADC Telecommunications, Inc.

Page 1-11

Page 29

1152700• Issue 1 • February 2001 • Section 1 Introduction

X-Terminal Keyboard Functions

All of the functions that can be performed through pop up menus using the mouse

can also be performed via the menu bar at the top of the screen. The menu bar

provides pull down menus under these options: File, Configuration, Fault, and

Performance.

The keyboard is used to select the menu bar items, navigate and select sub menu

items, bring up the configuration or query screens, and when necessary, to enter

alphanumeric information into the system. Keyboard operations for the GUI also

make use of the arrow keys, enter or return key, tab key, space bar, and control key.

The user must hit the Alt key along with the underlined letter of the menu item

desired (ex. Alt + F selects the File menu tree).

By entering the tab key, the operator moves the highlighted or underlined selection

to the next menu item (ex. File to Configuration.) Hitting the enter or return key

opens the menu item. The operator may now use the arrow keys to step down or up

to the desired item selection. The right arrow will bring up a sub menu if one exists,

indicated by the arrow pointing to the right beside the text in the menu list.

Manipulating the GUI Network Layout on an X-Terminal Screen

The user may redraw the layout of the network that is displayed by the GUI. This

may be performed to set a group of nodes that are co-located apart from others, to

place the nodes in a city or state map layout, or just to make use of more room on

the screen itself. By selecting a node using the select mode tool and a single click

and hold of the left mouse button, the operator can drag it to any area of the screen

and then release the mouse button. The node is now planted in its new location on

the screen and all of the connections stay intact (the operator cannot change the

physical location or inter-connections between the nodes by moving an icon into

another area of the software screen).

Once the user has redrawn the GUI screen layout, the new screen configuration

should be saved. This can be done through the menu bar under File: Save Icon

Layout, or by single clicking on the floppy disk icon on the tool bar above the work

area.

Page 1-12

© 2000, ADC Telecommunications, Inc.

Page 30

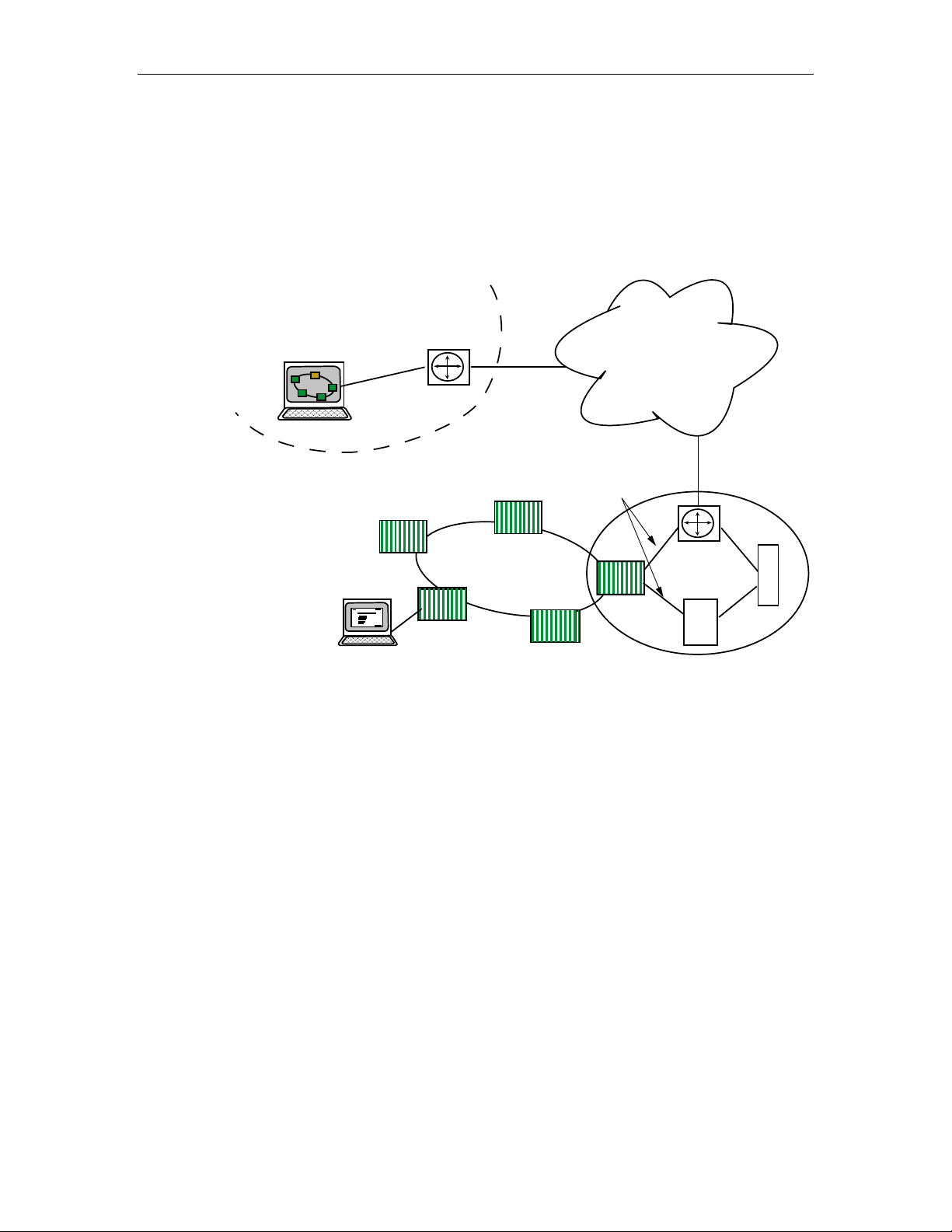

4. REMOTE MANAGEMENT CAPABILITIES

The X-Terminal used for operations and maintenance of the Cellworx STN

network can be linked through existing customer Ethernet networks using TCP/IP

over any transport layer (e.g. Frame Relay, ATM, Private Line, etc.) Refer to

Figure 1-14 for an example.

NETWORK SURVEILLANCE CENTER

X TERMINAL

ROUTER

ADCP-70-220 • Issue 1 • September 2000 • Section 1 Introduction

EXISTING DEDICATED

NETWORK FOR

MANAGEMENT TRAFFIC

TCP/IP

10 BASE T

ETHERNET

ROUTER

FR

CENTRAL OFFICE

B

S

S

10504-B

LOCAL CRAFT USER

CELLWORX

OC12C RING

GNE

Figure 1-14. Remote X- Terminal Operations

The network operator can use any workstation with a standard X-Windows

platform or a PC with X-Terminal emulation to remotely access the network,

launch the GUI, and monitor or troubleshoot the Cellworx STN ring network. The

operator can remotely connect to a node via Telnet session through the NMIC, and

use craft menus to retrieve alarm and performance information. These functions are

performed utilizing IP addresses set up for each node at turn up.

Messaging between remote nodes and the GNE NMIC is performed by targeting

the NE’s IP address. Many existing network components (BSS, ATM Switches,

frame relay switches, and routers) can also be pulled up on the same X-Terminal

for maintenance and troubleshooting capabilities.

© 2000, ADC Telecommunications, Inc.

Page 1-13

Page 31

1152700• Issue 1 • February 2001 • Section 1 Introduction

A. Real-time Alarm and Trap Screens

The Cellworx NMIC provides real time alarm monitoring capabilities to an

External Management System (EMS) via SNMP traps through an Ethernet port on

the NMIC EIM. This scheme supports remote retrieval of NMIC collected data for

user manipulation and report creation via ftp using four simple file types. These

files are comma, space, or tab delimited and cover the following categories of

collected data: Alarm history, Accounting, PM data, and Network Data Collection.

The NMIC serves as an ATM domain operations interface provided on a Cellworx

STN shelf configured as a Gateway Network Element (GNE), generally located in

the CO or manned site. The NMIC can process 1.6K TFTP (Trivial FTP)/FTP

packets as well as 0.8Mbytes of data per second, serving as an FTP server for each

of the NE Shelf Controllers (SCs). The alarm history from each of the NE SC traps

is stored up to 24 hours for future queries. The NMIC sends an SNMP request to

the destined NE based on legitimate SNMP requests received from the EMS, and

discards all IP packets that are different from its IP address.

The SNMP MIB for ring management is ATM Forum network view M4 based. The

NE processes up to ten SNMP traps per second also.

GR-1248, [213] is supported. The NMIC supports the user identification,

authentication, system access control, resource access control, security log, and

security administration requirements as stated in GR-1248 [213]. The administrator

can configure the option of allowing the user to only perform SNMP get requests

and receive SNMP traps.

Page 1-14

© 2000, ADC Telecommunications, Inc.

Page 32

1152700• Issue 1 • February 2001 • Section 2 Operation and Maintenance

SECTION 2

OPERATION AND MAINTENANCE TOP

Content Page

1. GENERAL ................................................................................................................................................. 2-1

2. USING A TOP DOCUMENT................................................................................................................................ 2-1

ALPHABETICAL TASK I NDEX LIST ......................................................................................................................... 2-3

INSTALLATION TASK INDEX LIST.....................................................................................................................IXL-001

1 GENERAL

This section provides operation and maintenance procedures for the Cellworx Service Transport Node

(STN) for the system administrator/operator.

Operation and maintenance includes but is not limited to the following tasks:

• Performing end to end signal tests to verify system operation.

• Adding modules to an in-service chassis.

• Configuring the modules for operation (S/W configuration and download).

• Configuring the VP/VC traffic connections for operation.

• Troubleshooting alarm conditions.

• Using the GUI interface to check network and node statuses.

• Performing card/traffic level switching for maintenance, troubleshooting, or testing

purposes.

2 USING A TOP DOCUMENT

The procedures in this section are written in the Task Oriented Process (TOP) format. The TOP method of

presenting information provides step by step instructions for the successful completion of the indicated

task. To find the instructions for performing enclosure installation, module installation and initial turn up,

and installation troubleshooting tasks, refer to Figure 2-1 for the flow chart of a TOPS document or

proceed as follows:

1. Find the task to be performed in the Indexed Task List (IXL-001), or the Alphabetical

Task Index List.

2. Locate the specified director level, detail level, or trouble clearing procedure. All

procedures are in numerical order, regardless of type. The TOP procedures in this

manual are of the following four types:

a) Non-Trouble Clearing Procedure (NTP) − A director level procedure that lists

normal work items to be performed that are not trouble clearing procedures.

b) Trouble Analysis Procedure (TAP) − A director level procedure that provides step

by step instructions to locate and fix problems.

c) Detailed Level Procedure (DLP) − Detailed step by step instructions or procedures.

© 2000 ADC Telecommunications, Inc.

Page 2-1

Page 33

1152700• Issue 1 • February 2001 Section 2 Operation and Maintenance

d) Trouble Analysis Data (TAD) − A trouble clearing aid containing non-procedural

data.

3. Perform all the items in the director level procedure (NTP ‘or TAP) in the order listed

unless sent to another director level procedure. When a director level procedure is

finished, the task is completed. When more detailed information is required, the reader

will be sent to a DLP. A DLP may also direct the reader to another DLP.

Note: When a DLP is complete, return to the procedure that preceded the DLP.

Note: When sent from one DLP to another DLP, in most instances it will not be necessary to go

back to the first DLP after competing the second.

4. In some procedures, it will be necessary to verify that certain responses have occurred. If the

expected response is not observed, refer to the TAP. If additional data is required such as a

schematic diagram, line drawing, tabulated data, maintenance philosophy, or trouble clearing

strategy, the reader will be sent to a TAD.

Find the task to be performed in either the Indexed T ask List,

or the Alphabetical Task List. These will refer to NTP, DLP,

or T AP procedures.

NTP?

Perform each task

listed in order in

an NTP until

completed.

DONE?

Perform each task

listed in order in

an NTP until

completed. In most

cases, will not

return to previous

NTP.

Locate the NTP, DLP, or TAP referred to in the Task Lists.

DLP?

REFERS

TO DLP

REFERS TO

ANOTHER

NTP?

REFERS

TO DLP

DONE? DONE?

Perform detailed

steps listed in a DLP

until completed.

Return to NTP if

applicable.

DONE?

Perform detailed

steps listed in

a DLP until completed.

Return to NTP if

applicable.

REFERS

TO T AP?

REFERS

TO T AP?

REFERS TO

ANOTHER

DLP?

REFERS TO

ANOTHER

DLP?

TAP?

Perform detailed

steps listed in a DLP

until completed,

then return to previous

procedure.

REFERS

TO T AP?

REFERS

TO T AP?

Perform detailed

steps listed in a DLP

until completed,

then return to previous

procedure.

RETURN

TO DLP

Trouble Analysis Procedure,

located at the back of the section,

referenced to by DLPs when

expected responses are not

observed. Perform each step in

order to locate and fix troubles,

then return to DLP if applicable.

Page 2-2

© 2000 ADC Telecommunications, Inc.

Task Completed

Figure 2-1. TOPS Docum ent Flow Chart

10556-C

Page 34

1152700• Issue 1 • February 2001 • Section 2 Operation and Maintenance

Page 1 of 3

ALPHABETICAL TASK INDEX LIST

Find Your Job in the List Below Then Go To

ABOUT NE ............................................................................DLP-721

ADD A CELLWORX STN NODE TO AN IN-SERVICE RING NETWORK .........................................NTP-003

ADD A SECOND NETWORK ELEMENT TO AN IN SERVICE STAND-ALONE TERMINAL NODE

TO CREATE A RING NETWORK .......................................................NTP-004

ADD/DELETE A LEAF ENDPOINT TO/FROM AN EXISTING MULTICAST CONNECTION .............................DLP-791

ADD/DELETE GUI USERS OR CHANGE GUI USER LEVEL SECURITY .........................................DLP-783

ADD EXPANSION SHELF (STN-EPS) ..............................................................DLP-712

ADD A RING NETWORK ELEMENT ...............................................................DLP-737

ADD A SECOND NETWORK ELEMENT .............................................................DLP-738

ADD OR CHANGE AN SNMP TRAP HOST ON THE NMIC .................................................DLP-775

ADDING SERVICES TO A CELLWORX STN NODE......................................................NTP-009

ADMINISTRATIVE TASKS .....................................................................NTP-015

ALARM CUT-OFF ..........................................................................DLP-776

CARD RESET ............................................................................DLP-773

CHANGE CONFIGURATION/TEST AN EXISTING CONNECTION .............................................DLP-723

CONDUCT ACCEPTANCE TESTS ON CELLWORX STN NODE ..............................................NTP-011

CONFIGURE CARD PROTECTION GROUPS..........................................................DLP-765

CONFIGURE NE ALARM THRESHOLD .............................................................DLP-717

CONFIGURE OR DELETE A TRAFFIC CONTRACT......................................................DLP-709

CONFIGURE SERVICE PROVIDER PROFILE .........................................................DLP-714

CONNECT FIBERS TO OPTICAL CARDS ...........................................................DLP-701

CONNECT NMS OR X-TERMINAL TO THE NMIC EIM SNMP/GUI PORT .......................................DLP-704

CONNECT VT100 TO NMIC RS-232 PORT AND VERIFY NMIC IP ADDRESS ....................................DLP-702

CREATE AN ATM OR CES CONNECTION ...........................................................DLP-708

CREATE A FRAME RELAY CONNECTION ...........................................................DLP-786

CREATE AN ATM BUNDLED VC MULTICASTING CONNECTION. ............................................DLP-790

CREATE AN ATM MULTICAST CONNECTION.........................................................DLP-787