Page 1

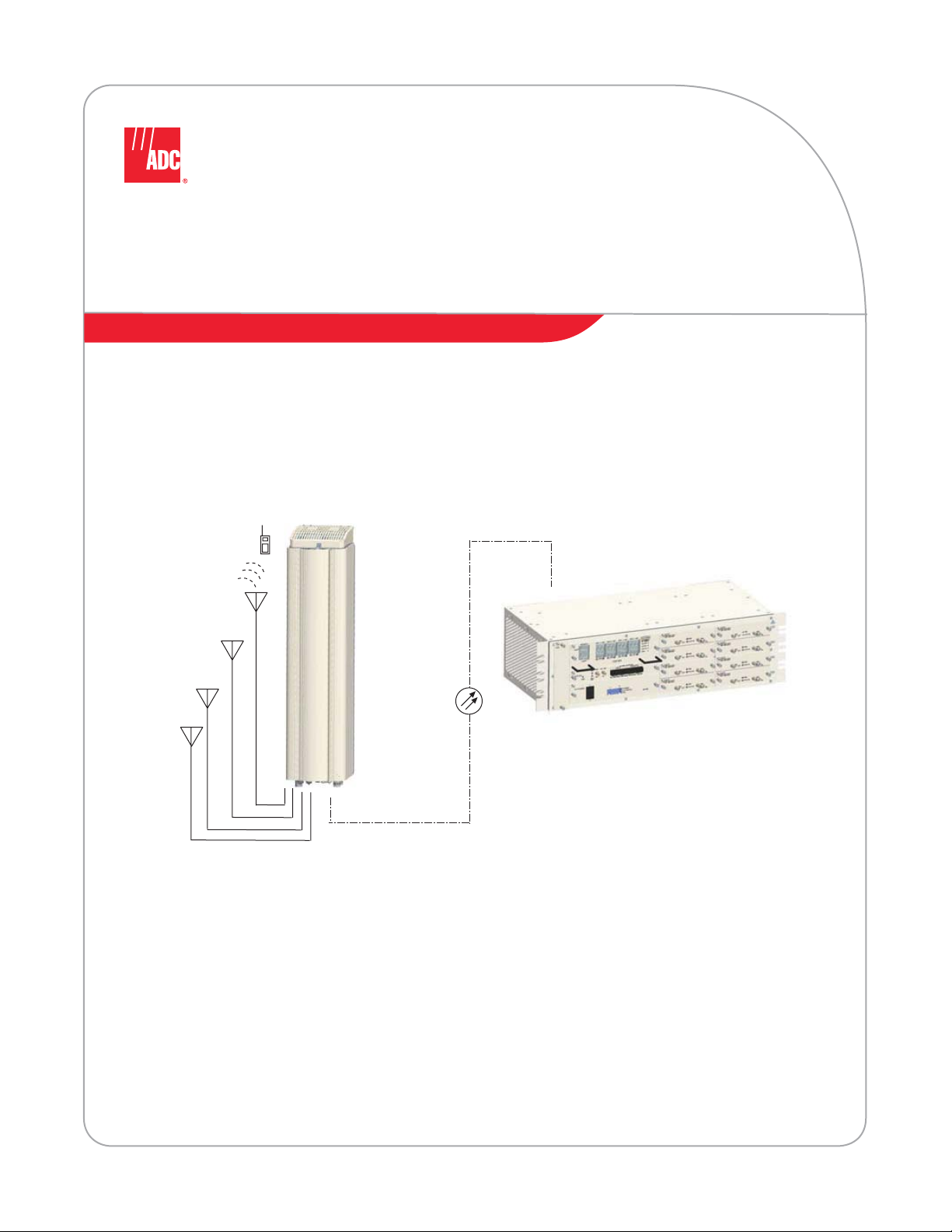

ADC FlexWave™ Prism

Antenna

Antenna

Antenna

Quad Band

Remote Unit

Host Unit

Antenna

77073-001

Host, Remote and EMS 5.1

System Reference

ADCP-77-073 x Issue 2 x 11/2009

D-620098-0-20 Rev B

Page 2

Copyright

© 2009 ADC Telecommunications, Inc. All Rights Reserved.

Information contained in this document is company private to ADC Telecommunications, Inc. and

shall not be modified, used, copied, reproduced or disclosed in whole or in part without the written

consent of ADC.

Trademark Information

ADC is a registered trademark and FlexWave is a trademark of ADC Telecommunications, Inc. No

right, license, or interest to such trademarks is granted hereunder, and you agree that no such right,

license, or interest shall be asserted by you with respect to such trademark.

Other product names mentioned in this practice are used for identification purposes only and may

be trademarks or registered trademarks of their respective companies.

Disclaimer of Liability

Contents herein are current as of the date of publication. ADC reserves the right to change the

contents without prior notice. Should the content of printed user documentation shipped with

product differ from documentation provided on a product CD (inclusive of the associated Help

modules), the printed user documentation supersedes the documentation on the product CD. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits,

and ADC further disclaims any and all liability for indirect, incidental, special, consequential or other

similar damages. This disclaimer of liability applies to all products, publications and services during

and after the warranty period.

Specific Disclaimer for High-Risk Activities

This Software Product is not specifically designed, manufactured, tested or intended for use in highrisk activities including, without restricting the generality of the foregoing, on-line control of aircraft,

air traffic, aircraft navigation or aircraft communications; or in the design, construction, operation

or maintenance of any nuclear facility. ADC (including its affiliates) and its suppliers specifically

disclaim any express or implied warranty of fitness for such purposes or any other purposes.

Screenshots in User Documentation

Due to concurrent development of this documentation, artwork, and the FlexWave URH EMS

product, there may be some minor discrepancies between screenshots contained in this

documentation and those actually displayed in the FlexWave URH EMS. These discrepancies will

generally be few and minor and should not affect your understanding of FlexWave URH EMS.

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 917-1717

Page 3

TABLE OF CONTENTS

Preface _______________________________________________ix

FlexWave Prism User Documentation........................................................................... x

Following the EMS Procedures in This Document ...........................................................xi

General Safety Precautions .......................................................................................xii

Standards Certification ............................................................................................ xiii

Part I: FlexWave Prism System Overview ____________1

Chapter 1: FlexWave Prism System _________________________ 3

1.1 Prism System Overview ....................................................................................... 4

1.1.1 Product Features ......................................................................................... 4

1.1.2 Applications ................................................................................................ 5

1.2 Basic System Components.................................................................................... 6

1.3 Multi-Host Systems ........................................................................................... 10

1.4 DART Cards...................................................................................................... 12

1.4.1 DARTs and Host Units ................................................................................ 13

1.4.2 DARTs and Remote Units ............................................................................ 15

1.5 E911 Support ................................................................................................... 16

1.6 Fiber Optic Transport ......................................................................................... 17

1.7 Timeslots Versus Bandwidth ............................................................................... 19

1.8 Bandwidths ...................................................................................................... 20

1.9 AWS and PCS Band Options................................................................................ 24

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page iii

ADCP-77-073 • Issue 2 • 11/2009 ©2009 ADC Telecommunications, Inc.

Page 4

Chapter 2: Prism System Components ______________________ 27

2.1 FlexWave Prism Family Overview ........................................................................ 28

2.2 FlexWave Prism Host Units ................................................................................. 30

2.2.1 Host Front Panel........................................................................................ 30

2.2.2 Host Network Connection ........................................................................... 33

2.2.3 Host RF Signal Connections......................................................................... 33

2.2.4 Host System Card...................................................................................... 34

2.3 Prism Remote Units ........................................................................................... 35

2.3.1 Handset Interface...................................................................................... 36

2.3.2 Remote Components.................................................................................. 36

2.3.2.1 Remote RF Modules............................................................................ 38

2.3.2.1.1 Remote Duplexer and Low Noise Amplifier ..................................... 40

2.3.2.1.2 Linear Power Amplifiers............................................................... 41

2.3.2.2 Remote SeRF Modules ........................................................................ 43

2.3.2.3 Remote Power Supply and Cable Assembly............................................ 44

2.3.2.4 Solar Shield ...................................................................................... 45

2.3.2.5 Mounting Bracket (Remotes) ............................................................... 46

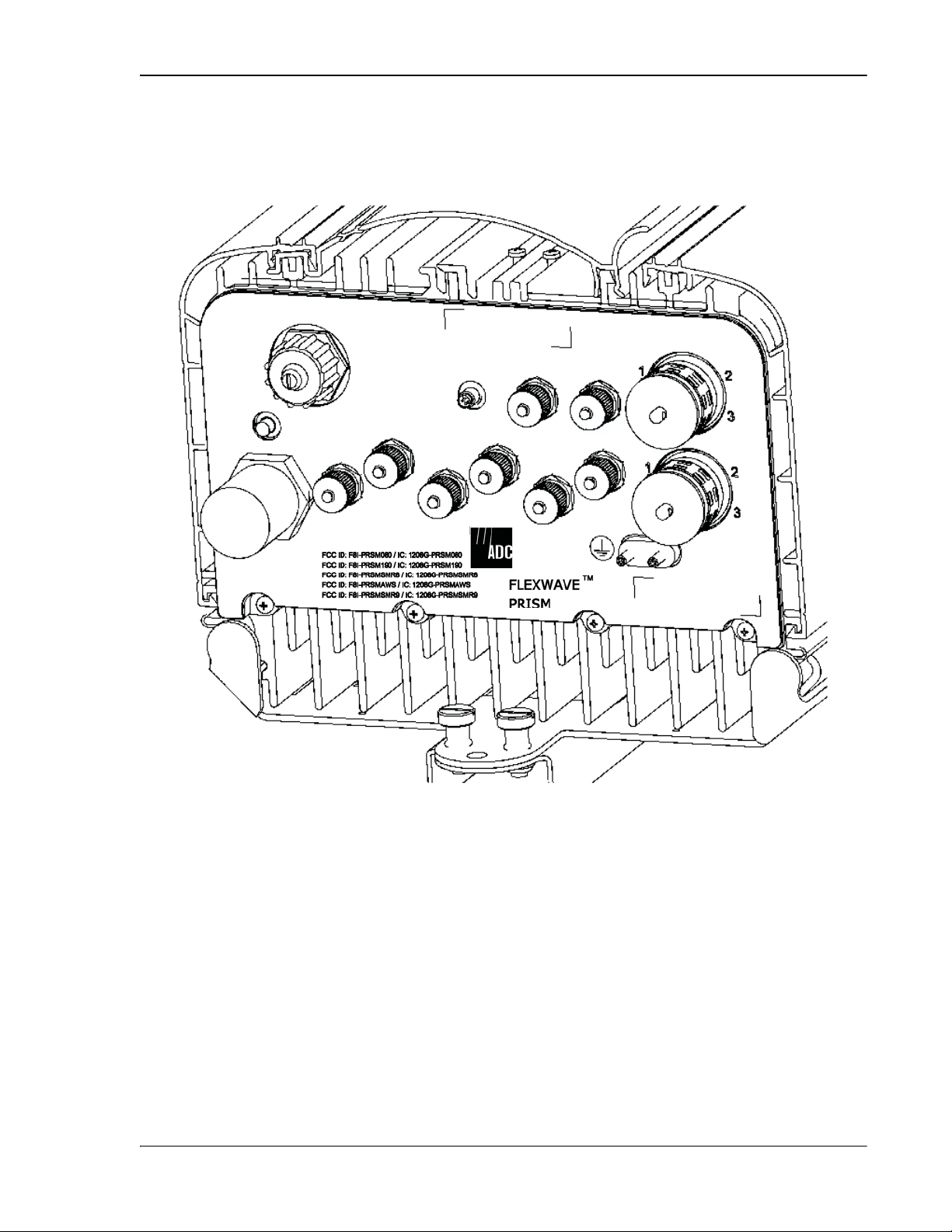

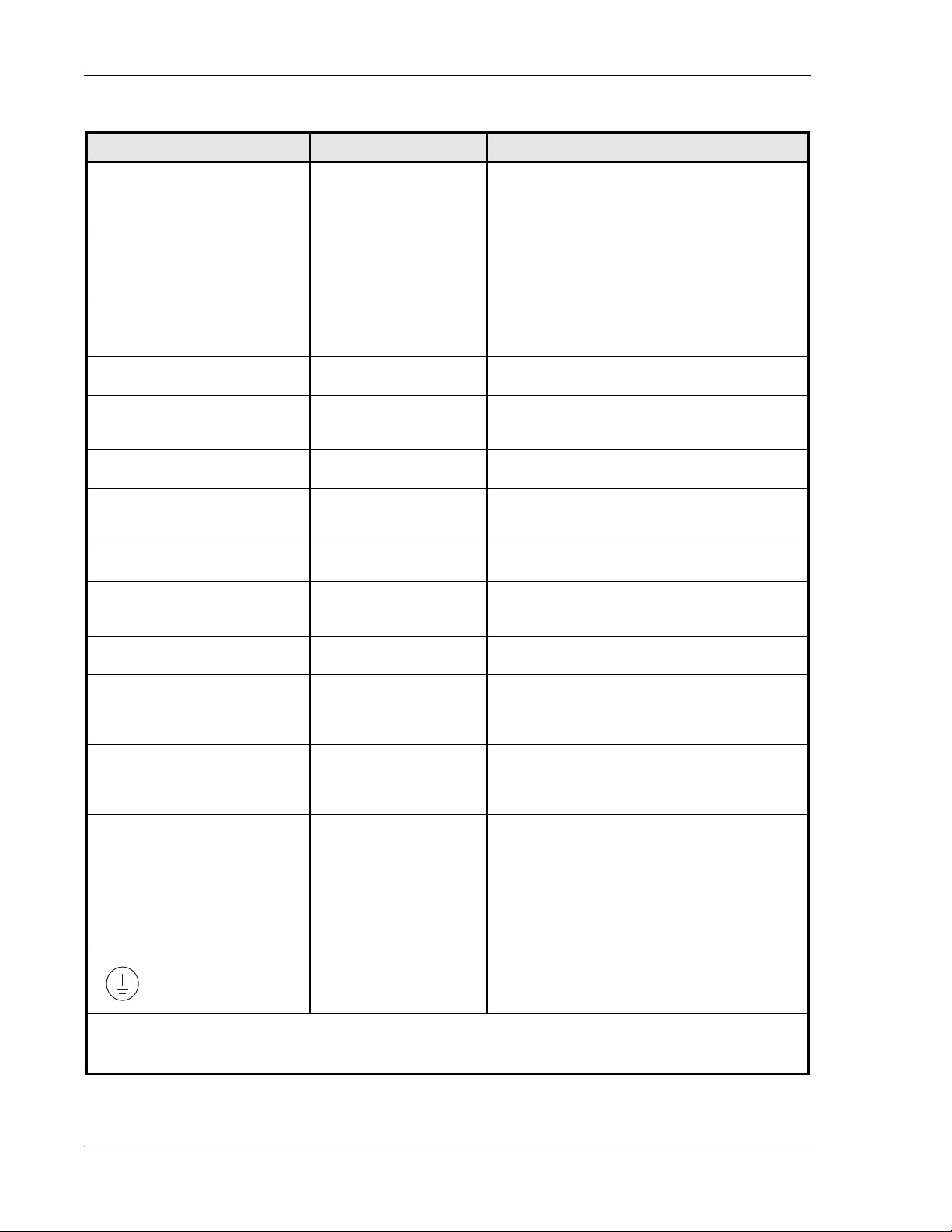

2.3.2.6 Remote Connectors............................................................................ 47

2.3.2.7 Remote Fiber Connector Cable Assembly............................................... 49

2.3.2.8 Remote Antenna Cable Connections ..................................................... 49

2.3.2.9 Remote Grounding ............................................................................. 49

2.3.2.10 Remote Cooling ............................................................................... 49

2.4 Prism System Accessories .................................................................................. 50

2.4.1 Lightning Surge Suppressor (Remote Accessory) ........................................... 50

2.4.2 Uninterruptible Power Supply (Accessory)..................................................... 50

2.4.3 Wavelength Division Multiplexer System (Accessory)...................................... 50

2.4.4 Course Wavelength Division Multiplexer System (Accessory) ........................... 51

2.4.5 Millimeter Wave Systems (Accessory) .......................................................... 55

2.5 Prism System Specifications ............................................................................... 56

2.5.1 Host Unit Specifications.............................................................................. 56

2.5.2 Remote Unit Specifications ......................................................................... 57

2.5.3 System Nominal Optical Specifications.......................................................... 58

Part II: Host and Remote Installation ______________ 61

Chapter 3: Installing the Host Unit ________________________ 63

3.1 Before Starting Installation................................................................................. 64

3.2 Tools and Materials............................................................................................ 65

3.3 Install the Host ................................................................................................. 66

3.3.1 Unpacking and Inspection........................................................................... 66

3.3.2 Install Host in Equipment Rack .................................................................... 66

3.3.3 OSP Fiber Cable Installation Guidelines......................................................... 68

3.3.4 Chassis Ground Connection......................................................................... 69

3.3.5 Coaxial Cable Connections .......................................................................... 70

3.3.6 Optical Connections ................................................................................... 72

3.3.7 LC Attenuator ........................................................................................... 73

3.3.7.1 Optical Connections Without WDM System ............................................ 74

3.3.7.2 Optical Connections For Systems With a WDM ....................................... 76

3.3.8 EXT REF Connections ................................................................................. 78

3.3.9 Computer Connection (Craft) ...................................................................... 80

3.3.10 System Alarm Connections........................................................................ 81

3.3.11 Power Connections................................................................................... 83

Page iv FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 5

3.4 Installing the WDM Host Module Mounting Shelf and WDM Host Module .................... 87

3.4.1 Wavelength Division Multiplexer System Overview ......................................... 87

3.4.2 Install WDM Host Components .................................................................... 90

Chapter 4: Installing the Remote Unit ______________________ 93

4.1 Remote Installation Overview ............................................................................. 94

4.1.1 Installation Hardware Provided with Remote.................................................. 94

4.1.2 Required Tools and Materials....................................................................... 95

4.2 Remote Mounting Plans...................................................................................... 96

4.3 Install the Remote............................................................................................. 97

4.3.1 Unpack and Inspect the Remote and Components .......................................... 97

4.3.2 Install the Remote RF Module(s).................................................................. 98

4.4 Install any 40W RF Module(s) ............................................................................107

4.4.1 Prepare the Remote and RF Module.............................................................108

4.4.2 Remove Module Shelf(s)............................................................................108

4.4.3 Install the 40W RF Module .........................................................................110

4.4.4 Ground Wire Installation............................................................................118

4.4.5 Network Cable Installation .........................................................................119

4.4.6 Quad Fiber Cable Installation .....................................................................121

4.4.7 Antenna Cable Installation .........................................................................123

4.4.8 AC Power Wiring Installation ......................................................................125

4.4.9 Determine the Circuit Breaker or Fuse for Remote.........................................129

4.4.9.1 Power Consumption ..........................................................................129

4.4.9.2 Power Consumption Tables.................................................................131

4.4.10 Mount the Remote and Power Up ..............................................................132

Part III: System Setup and Management __________133

Chapter 5: FlexWave Element Management System __________ 135

5.1 FlexWave EMS Overview ...................................................................................136

5.2 EMS Graphical User Interface.............................................................................138

5.3 Product Identity ...............................................................................................139

5.4 EMS Menu Bar .................................................................................................140

5.5 EMS Alarm Indications ......................................................................................141

5.6 EMS System Requirements ................................................................................142

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page v

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 6

Chapter 6: Initial Prism System Setup _____________________ 143

6.1 Access the EMS................................................................................................144

6.2 Discover IP Addresses.......................................................................................146

6.3 Enter a Host Name, Clock Source, and Linking Mode .............................................147

6.4 Set the Clock Priority Level................................................................................150

6.5 Provision the Host SeRF Optical Ports..................................................................151

6.6 Configure the Host DARTs .................................................................................152

6.7 Enter a Remote Name.......................................................................................156

6.8 Configure the Remote SeRF Optical Ports ............................................................158

6.9 Link the Host and Remote DARTs. ......................................................................159

6.9.1 Use of Multi Fibers ....................................................................................159

6.9.2 RF Groups in the Remote and the EMS GUI ..................................................160

6.9.3 Link a Remote DART to a Host DART ...........................................................162

6.10 Conclude Initial System Setup..........................................................................167

6.11 (Optional) Configuring Multi-Host Systems for Manual Mode .................................168

6.11.1 Set the Multi-Host System to Manual Mode ................................................168

6.11.2 Configure the Host DARTs........................................................................168

6.11.3 Configure the Remote DARTs ...................................................................173

Chapter 7: Using the EMS to Manage a Prism System _________ 177

7.1 Displaying the System View...............................................................................178

7.2 Setting Auto Refresh.........................................................................................179

7.3 Working with the System Inventory....................................................................180

7.3.1 System Inventory View Components ...........................................................180

7.3.1.1 System Inventory and Host Inventory Tables........................................ 181

7.3.1.2 Remote Inventory Tables ...................................................................182

7.4 Working with Prism System Network Interfaces....................................................184

7.4.1 Changing to Built-In Network Mode............................................................. 186

7.4.2 EMS Access Methods.................................................................................188

7.4.2.1 Accessing the EMS Through the Remote Network Port............................189

7.4.2.2 Accessing the EMS Through the Remote Craft Port ................................192

Chapter 8: Managing User Accounts_______________________ 195

8.1 FlexWave EMS User Accounts ............................................................................196

8.2 Viewing User Accounts......................................................................................197

8.3 Adding a User Account......................................................................................198

8.4 Changing a User Access Level ............................................................................202

8.5 Changing the Password of Another User ..............................................................206

8.6 Changing Your Own Password ............................................................................208

8.7 Deleting a User Account ....................................................................................210

Chapter 9: Managing Host Units__________________________ 213

9.1 Viewing the Host Summary ............................................................................... 214

9.2 Resetting the Host Unit .....................................................................................215

9.3 Viewing Host SeRF Ethernet Ports.......................................................................217

9.4 Decommissioning a DART in a Host.....................................................................220

9.5 Viewing the Host SeRF Summary .......................................................................222

9.6 Viewing Host SeRF Optical Ports.........................................................................224

9.7 Viewing Host DART Alarms ................................................................................226

Page vi FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 7

Chapter 10: Managing Remote Units ______________________ 229

10.1 Viewing Remote SeRF Ethernet Ports.................................................................230

10.2 Decommissioning an RF Module in a Remote ......................................................232

10.3 Configuring Dual-Slot LPAs ..............................................................................235

10.4 Restarting an LPA ...........................................................................................236

10.4.1 Identify the LPA Fault ..............................................................................236

10.4.2 Reset the LPA.........................................................................................238

10.5 Monitoring a Remote Unit ................................................................................240

10.6 Decommissioning a Remote Unit.......................................................................244

10.7 Resetting a Remote Unit..................................................................................246

10.8 Viewing Remote SeRF Alarms...........................................................................248

10.9 Viewing Remote SeRF Optical Ports...................................................................248

10.10 Viewing an Alarm Summary of the Remote RF Groups .......................................250

10.11 Viewing RF Band Alarm Details .......................................................................252

10.12 Viewing Remote GPS Alarms and Location Parameters .......................................255

Chapter 11: Managing Alarms ___________________________ 257

11.1 Viewing Active Alarms .....................................................................................258

11.2 Viewing an Alarm History Log...........................................................................259

11.3 Masking an Alarm Type ...................................................................................260

11.4 Unmasking an Alarm Type ...............................................................................262

11.5 Troubleshooting Alarms...................................................................................264

Chapter 12: SNMP Interface ____________________________ 275

12.1 EMS SNMP Interface .......................................................................................276

12.2 SNMP Overview..............................................................................................277

12.2.1 Background Information on SNMP .............................................................278

12.2.2 MIB Used by FlexWave System .................................................................280

12.3 SNMP Procedures ...........................................................................................281

12.4 Accessing the FlexWave-Prism Agent MIB ..........................................................282

12.5 Configuring the Trap Viewer.............................................................................283

12.5.1 Registering the Manager for Receiving Traps

(static—non AdventNet MIB Browser) .............................................................283

12.5.2 Registering the Manager for Receiving Traps

(dynamic—AdventNet MIB Browser) ...............................................................284

12.5.3 Viewing Traps.........................................................................................287

12.5.3.1 Date and Time Stamps ....................................................................287

12.5.3.2 Variable Bindings ............................................................................288

12.5.3.3 View the Traps................................................................................290

12.6 FlexWave-URH Agent MIB................................................................................292

12.7 Traps ............................................................................................................308

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page vii

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 8

Part IV: Appendices __________________________ 311

Appendix A: Host Unit Module Replacement ________________313

A.1 Host Fan Replacement Procedure .......................................................................314

A.2 Power Supply Replacement Procedure ................................................................315

A.3 System Card Replacement Procedure..................................................................317

A.4 SeRF Card Replacement Procedure .....................................................................319

A.4.1 Preserve System Configuration...................................................................319

A.4.2 Remove the SeRF Card .............................................................................322

A.4.3 Swap Compact Flash From Old SeRF Card to New SeRF Card.......................... 323

A.4.4 Install New SeRF Card............................................................................... 324

A.5 DART Card Replacement/Installation Procedure....................................................325

A.5.1 Replacing a DART Card in the Host Chassis ..................................................325

A.5.2 Installing a New DART Card in the Host Chassis............................................325

Appendix B: General Information_________________________ 329

B.1 Warranty/Software...........................................................................................329

B.2 Software Service Agreement..............................................................................329

B.3 Repair/Exchange Policy.....................................................................................329

B.4 Repair Charges ................................................................................................330

B.5 Replacement/Spare Products .............................................................................330

B.6 Returned Material ............................................................................................ 330

Appendix C: Glossary __________________________________ 331

Appendix D: Contacting ADC ____________________________ 335

Index ______________________________________________ 337

Page viii FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 9

PREFACE

Content Page

FlexWave Prism User Documentation........................................................................... x

Following the EMS Procedures in This Document ...........................................................xi

General Safety Precautions .......................................................................................xii

Standards Certification ............................................................................................ xiii

This document provides basic description, application, and configuration

®

information about the ADC

FlexWave™ Prism system. The information in this

document guides you through:

•• designing a Prism system

•• installing Prism Host and Remote Units

•• configuring the Prism system through the FlexWave Web-Based Element

Management System (EMS) Version 5.1. The EMS is an embedded software

application that runs on the Host and that may be accessed via an internet

connection using a Web browser. This document shows how to connect to the EMS

software using a SNMP manager to interact with the SNMP database that is used

to store system parameters. SNMP (Simple Network Management Protocol) is an

international standard for remote management of online devices.

Throughout this publication, all items referenced as “accessory items” are not

furnished with the basic product and must be purchased separately.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page ix

ADCP-77-073 • Issue 2 • 11/2009 ©2009 ADC Telecommunications, Inc.

Page 10

FLEXWAVE PRISM USER DOCUMENTATION

The FlexWave Prism user documentation is intended for system engineers,

administrators, and end users that are responsible for planning, administering,

configuring, and maintaining ADC FlexWave Prism systems. Familiarity with SNMP

and common network technologies is required.

Each FlexWave Prism document describes a different aspect of the FlexWave Prism

system. The following manuals correspond to this FlexWave Prism release:

Title ADCP Number

ADC® FlexWave Prism Host, Remote and EMS 5.1 System Reference 77-073

ADC® FlexWave Prism Host Unit Installation Guide 77-071

ADC® FlexWave Prism Remote Unit Installation Guide 77-072

ADC® FlexWave Prism Remote Mounting Kit Installation Instructions 77-077

ADC® FlexWave Prism Remote RF Module Installation Instructions 77-079

ADC® FlexWave Prism Coarse Wavelength Division Multiplexer User Manual 77-075

Icons

Three types of messages, identified by icons, appear in the text:

The Caution icon indicates operations or steps that could:

•• cause personal injury

• induce a safety pro

• destroy or corrupt information

• interrupt or stop serv ices.

The Note icon indicates text that contains information about special circumstances.

The User icon indicates text that lists which user roles are required for a procedure or

EMS access.

blem in a managed device

Page x FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 11

Fonts

This font

User Account Management,User Account

User Account Management

User Account

OK

Apply

Close

Apply

Refresh

OK

Apply

Close

Apply

Refresh

You will find the following font conventions in use throughout the document:

•

indicates a reference to a EMS dialog box, menu item, configuration

option, or other parameter.

• This font indicates text you type at a prompt.

• T

HIS FONT indicates keys that you need to press on your keyboard.

•• When a procedure requires clicking on a sequence of items, commas separate the

items. For example, “click

the Function Explorer Tree, you select the

select the

node.

” indicates that in

node, and then

Illustrations

Some illustrations have numeric callouts. These callouts indicate the related step

numbers in the accompanying text.

FOLLOWING THE EMS PROCEDURES IN THIS DOCUMENT

This document includes descriptions of how to use the FlexWave EMS to configure

and manage FlexWave Prism devices.

Starting a Procedure

All procedures in this document assume that you have already logged in to FlexWave

EMS as described in “Access the EMS” on page 144.

Finishing or Canceling a Procedure

In general, the procedures in this document end each procedure with having you click

or

clicking

to accept changes or input. However, you can also click

to abandon any changes made, or click

without

to update the data being

shown.

The following table describes the most common EMS dialog buttons.

Button Function

Applies your configuration changes and closes the dialog.

Applies your configuration changes without closing the dialog.

Discards any changes you have made in the dialog—unless you have

previously clicked

status dialog, closes the dialog.

Updates status information to reflect current conditions.

—and closes the dialog. In a performance or

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page xi

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 12

GENERAL SAFETY PRECAUTIONS

Wet conditions increase the potential for receiving an electrical shock when installing or

using elec

electrical equipment in

This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation can

seriously damage

not look directly into the

radiation may result. An optical power

protectiv e cap or hood MUST be immediately placed ove

optical fiber connector to avoid the potential of dangerous amounts of

exposure. This practice also prevents dirt particles from entering the adapter or

connecto

This system is an RF Transmitter and continuously emits RF energy. Maintain 3 foot

(91.4 cm) minimum

possible, shut down the RAN before

Always allow sufficient fiber length to permit routing of patch cords and pigtails w ithout

severe ben

or curv ed to a radius of l

Exterior surfaces of the Remote may be hot. Use caution during servicing.

trically- powered equipment. To prevent electrical shock, never install or use

a wet location or during a lightning storm.

the retina of the eye. Do not look into the ends of any optical fiber. Do

optical transceiv er of any digital unit or exposure to laser

meter should be used to v erify active fibers. A

r any radiating transceiver or

radiation

r.

clearance from the antenna while the system is operating. Wherever

servicing the antenna.

ds. Fiber optic patch cords or pigtails may be permanently damaged if bent

ess than 2 inches (5.1 cm).

Page xii FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 13

STANDARDS CERTIFICATION

FCC:: This equipment complies with the applicable sections of Title 47 CFR Part 15

(Host unit), Part 22 (800 MHz Cellular), Part 24 (1900 MHz - PCS), Part 90 (800/900 SMR), and Part 27 (2100 MHz - AWS).

IC:: This equipment complies with the applicable sections of RSS-131. The term “IC:”

before the radio certification number only signifies that Industry Canada Technical

Specifications were met.

The Manufacturer's rated output power of this equipment is for single carrier

operation. For situations when multiple carrier signals are present, the rating would

have to be reduced by 3.5 dB, especially where the output signal is re-radiated and

can cause interference to adjacent band users. This power reduction is to be by

means of input power or gain reduction and not by an attenuator at the output of the

device.

Note:: To comply with Maximum Permissible Exposure (MPE) requirements, the

maximum composite output form the antenna cannot exceed 1000 Watts ERP

(Cellular and SMR), the antenna cannot exceed 1640 Watts EIRP (PCS), and the antenna

must be permanently installed in a fixed location that provides at least 6 meters (20

feet) of separation from all persons.

UL/CUL:: This will be installed in a restricted access location. This equipment

complies with NEMA Type 4, per UL and CUL 50, Standard for Enclosures for Electrical

Equipment. This equipment provides the degree of protection specified by IP65 as

defined in IEC Publication 529.

FDA/CDRH:: This equipment uses a Class 1 LASER according to FDA/CDRH Rules.

This product conforms to all applicable standards of 21 CFR Part 1040.

Caution:: Modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

EU Harmonized Standardss: Meets essential requirements of R&TTE 1999/5/EC.

•• Article 3.1a—The protection of the health and the safety of the user and any other

person, including the objectives with respect to safety requirements contained in

Directive 2006/95/EC, but with no voltage limit applying.

•• Article 3.1b—The protection requirements with respect to electromagnetic

compatibility contained in Directive 2004/108/EC.

•• Article 3.2—In addition, radio equipment shall be so constructed that it effectively

uses the spectrum allocated to terrestrial/space radio communication and orbital

resources so as to avoid harmful interference.

EMC Standards:: EN 55022 and EN55024 (CE marked)

Safety Standards:

•• IEC 60950-1, First Edition (CE marked)

•• UL 60950-1 (File number E174166) (USA and Canada)

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page xiii

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 14

Intentionally Blank Page

Page xiv FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 15

PART 1

FLEXWAVE PRISM SYSTEM OVERVIEW

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 1

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 16

Intentionally Blank Page

Page 2 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 17

1

FLEXWAVE PRISM SYSTEM

Content Page

1.1 Prism System Overview ....................................................................................... 4

1.1.1 Product Features ......................................................................................... 4

1.1.2 Applications ................................................................................................ 5

1.2 Basic System Components.................................................................................... 6

1.3 Multi-Host Systems ........................................................................................... 10

1.4 DART Cards...................................................................................................... 12

1.4.1 DARTs and Host Units ................................................................................ 13

1.4.2 DARTs and Remote Units ............................................................................ 15

1.5 E911 Support ................................................................................................... 16

1.6 Fiber Optic Transport ......................................................................................... 17

1.7 Timeslots Versus Bandwidth ............................................................................... 19

1.8 Bandwidths ...................................................................................................... 20

1.9 AWS and PCS Band Options................................................................................ 24

This section provides a basic description and application and configuration

information about the FlexWave Prism system. Throughout this publication, all items

referenced as “accessory items” are not furnished with the basic product and must

be purchased separately.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 3

ADCP-77-073 • Issue 2 • 11/2009 ©2009 ADC Telecommunications, Inc.

Page 18

FlexWave Prism System

1.1 PRISM SYSTEM OVERVIEW

ADC’s FlexWave™ Prism is a compact radio head for macro gap coverage that

supports up to four frequency bands delivering high-performance coverage with

end-to-end management.

The FlexWave Prism enhances wireless networks in outdoor locations and large

venues in an easy and cost-effective manner. Based on patented technology and

ADC’s 15-year leadership in outdoor wireless distributed antenna system (DAS)

technology, FlexWave Prism offers mobile operators a small, light, and flexible

solution for extending macro network coverage for 2G, 3G, and 4G services.

The new FlexWave Prism system is ideal for enhancing outdoor and indoor coverage

in cities, suburbs, canyons, tunnels, campuses, stadiums, and other public areas. It is

35 percent lighter and up to 60 percent smaller than the FlexWave URH product it

replaces, and is available in four different cabinet sizes to support one, two, three or

four frequency bands. Operators can future-proof their deployments by purchasing

a larger cabinet and adding more frequency bands when needed. FlexWave Prism uses

ADC’s proven radio head technology and management system along with an IP-65

rated remote.

1.1.1 Product Features

•• Management under the same host end equipment and EMS as the FlexWave URH,

allowing operators to scale legacy URH deployments with the FlexWave Prism

•• ADC’s patented RF-over-fiber transport eliminates installation-dependent gain or

fiber length adjustments

•• Improved manageability for installation and upgrades

•• Smaller size to ease placement and zoning approvals

•• 4G readiness with Four Band remote, which is ideal for incorporating 2G and 3G

services with needs of 4G technologies such as LTE

•• The unique capability to support digital RF as well as baseband compatibility into

a single fiber pair and remote radiating point

•• Support for millimeter wave backhaul

•• With its unique use of wideband digital RF transport, FlexWave Prism delivers

reliable and consistent performance in all environments. Signals are not affected

by reflection, dispersion, or frequency attenuation over fiber. FlexWave Prism

delivers a reliable signal at every remote location.

Page 4 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 19

1.1.2 Applications

•• Dense urban environments

•• Tunnels and canyons

•• Roadside and coastal

•• Suburban areas

•• Corporate and university campuses

•• Stadium and large public venues

•• Next-generation network augmentation

Prism System Overview

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 5

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 20

FlexWave Prism System

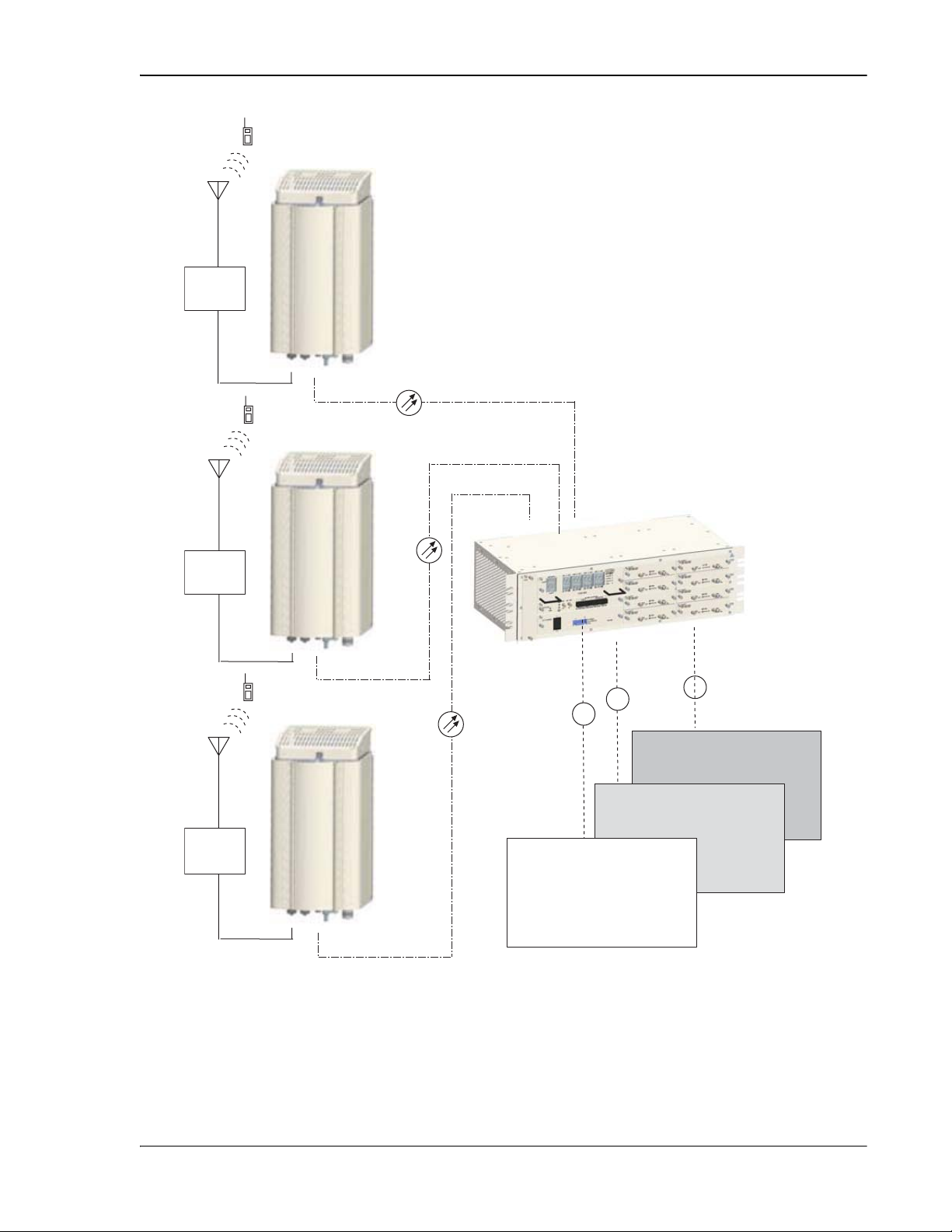

1.2 BASIC SYSTEM COMPONENTS

A very basic Prism system consists of a Host Unit (Host) and a Remote Unit (Remote):

•• The Host is a three rack unit high chassis with multiple cards that mounts in a

standard equipment rack.

•• The Remote consists of multiple electronic and optical modules mounted in an

outdoor enclosure.

On an optional basis, the Prism system supports reverse path diversity. In addition,

various accessory items including a passive Wavelength Division Multiplexer (WDM)

system, Coarse Wavelength Division Multiplexer (CWDM) system, and expansion

panels are available as accessories.

Control and monitoring functions are provided by the FlexWave Element

Management System (EMS).

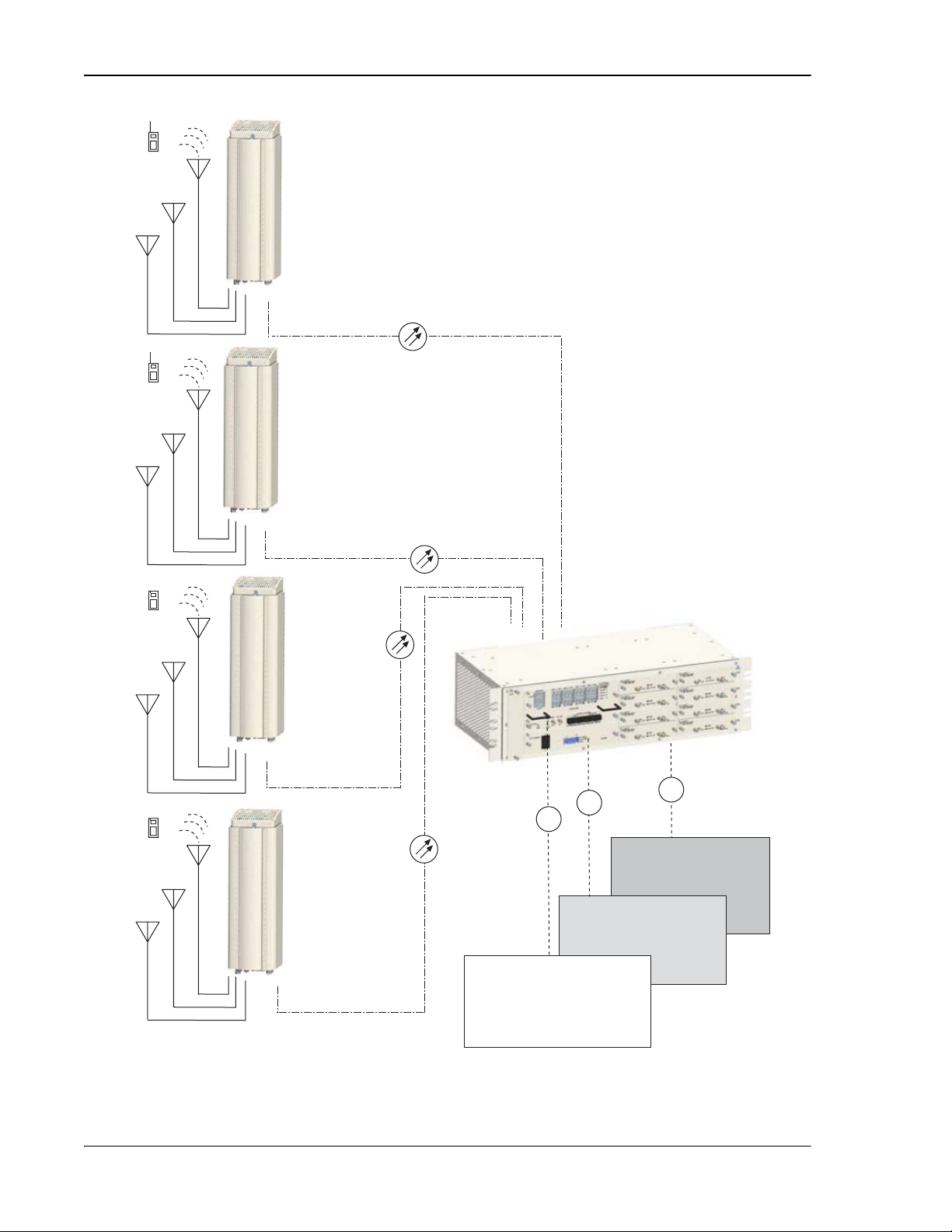

Some examples of FlexWave Prism Systems are shown in Figure 1-1, Figure 1-2,

Figure 1-3.

Page 6 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 21

Host Unit

Antenna

Band A

Sector Y

Antenna

Band A

Sector B

Antenna

Band A

Sector A

Remote Unit

Remote Unit

Remote Unit

77073-002

RF

Base

Transceiver

Stations

Band A

Sector Y

Band A

Sector B

Band A

Sector A

RF

RF

Basic System Components

Figure 1-1. Multiple Point-to-Point Configuration

(One Band per Remote, Three Nodes)

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 7

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 22

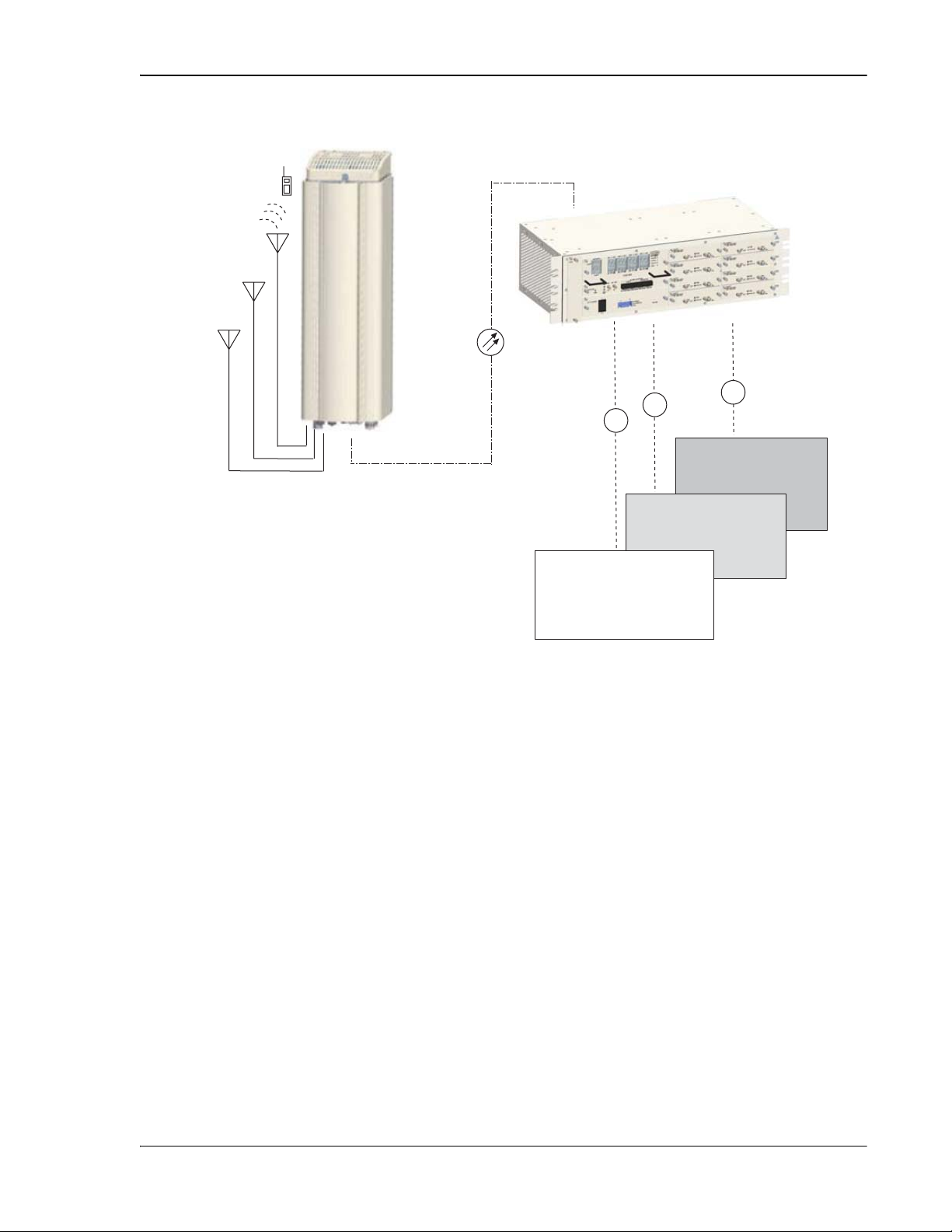

FlexWave Prism System

Antenna

Band A

Antenna

Band B

Antenna

Band C

Antenna

Band A

Antenna

Band B

Antenna

Band C

Tri-Band

Remote

Tri-Band

Remote

Antenna

Band B

Antenna

Band C

Antenna

Band B

Antenna

Band C

Antenna

Band A

Antenna

Band A

Tri-Band

Remote

Tri-Band

Remote

Host Unit

RF

RF

RF

Band A

Band B

77073-003

Band C

Base

Transceiver

Stations

Figure 1-2. Four Remote Simulcast, Three Bands

Page 8 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 23

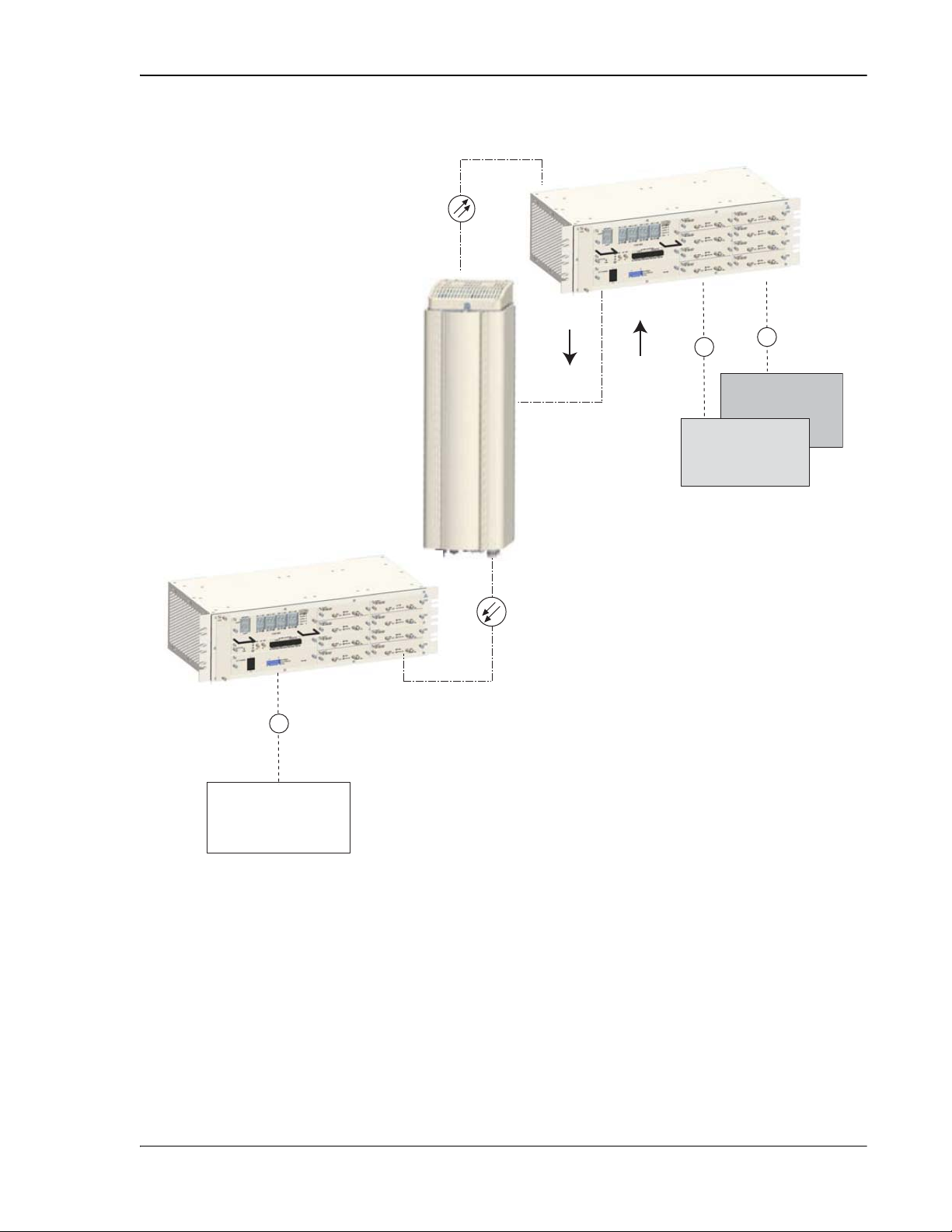

Basic System Components

Antenna

Band A

Antenna

Band B

Antenna

Band C

Host Unit

Tri-Band

Remote Unit

Base

Transceiver

Stations

Band C

Band B

Band A

RF

RF

RF

77073-004

Figure 1-3. Three Bands to One Remote

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 9

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 24

FlexWave Prism System

0-15

1

Linking Mode

Automated

Manual

Linking Mode

Linking Mode

Manual

1.3 MULTI-HOST SYSTEMS

ADC’s FlexWave Prism provides a Multi-Host feature that allows a Prism Remote to be

shared by multiple Host Units. To accomplish this:

•• One Host is designated as the IP Manager for a set of Remotes; this Host can serve

as IP manager for multiple Remotes. As the IP Manager, the managing Host

controls the exchange of management data with the Remote(s).

•• There is no Host to Host connectivity.

•• A Prism Remote can receive bands over multiple fibers that originate on different

Hosts. However, only one Host, the IP Manager, can manage the Remote. If a Host

attempts to manage a Remote already under the management of an IP Manager,

the second Host causes an IP Conflict fault (see “Viewing Host SeRF Optical Ports”

on page 224).

•• All the Hosts in a Multi-Host network can be configured to serve as clock master.

Each Host will be configured with a priority level in the range of

with the priority level of

distributes the clock in the network. If the Host

designated as clock master fails or shuts down, the Host with the next highest

priority level takes over. (For information on setting the master clock, see “Set the

Clock Priority Level” on page 150.)

. The Host

•• The FlexWave EMS provides a

or

for each Host. The

to the IP Manager. A Multi-Host system requires that the

(see “(Optional) Configuring Multi-Host Systems for Manual Mode” on

parameter that can be set to

is applicable for all Remotes connected

be set to

page 168.

•• The Host that manages the Remote must be able to provision one or more

passbands on that Remote for which the Host does not have a DART card. Remote

DARTs are linked back to one or more Hosts in a Multi-Host system.

Page 10 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 25

Tri-Band

Remote

Base

Transceiver

Stations

Band B

Band A

RF

RF

GET SET

(Host that manages the Remote)

Host 1 Location A

Host 2 Location B

77073-022

Base

Transceiver

Station

Band C

RF

Multi-Host Systems

Figure 1-4. Multi-Host System

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 11

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 26

FlexWave Prism System

1.4 DART CARDS

Digital/Analog Radio Transceiver (DART) cards provide the interface between base

station equipment and the SeRF. There are three types of FlexWave DART cards:

•• Classic

•• Single SuperDART

•• Dual SuperDART.

FlexWave DARTS are band specific assemblies available in the versions listed in

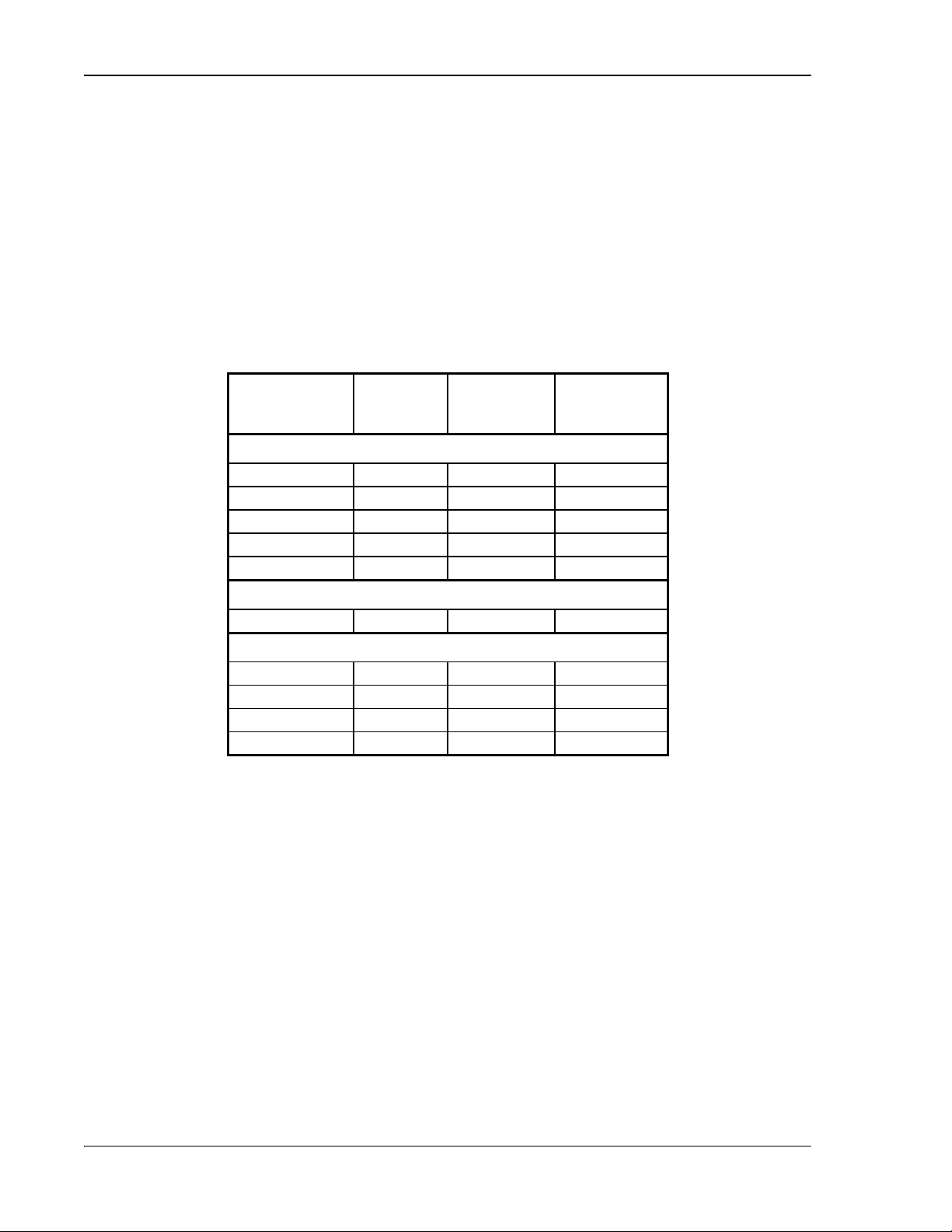

Table 1-1.

Table 1-1. FlexWave DART Card Types

Band Maximum

Bandwidth

(MHz)

Classic DART Cards

AWS 2100 35 6 Single

Cell 850 35 6 Single

PCS 1900 35 6 Single

SMR 800 35 6 Single

SMR 900 35 6 Single

Single SuperDART

GSM 900 35 6 Single

Dual SuperDART Cards

AWS 2100 45 8 Dual

GSM 1800 75 12 Dual

PCS 1900 70 12 Dual

UMTS 2100 60 12 Dual

Cards

Number of

Fiber Slots

Slot

Requirement

DART cards:

•• amplify, down-convert, filter and digitize the incoming RF signal from the BTS

•• convert incoming digital signal from the Remote to analog, filter, amplify and

up-convert the frequency from Intermediate Frequency (IF) to RF

•• provide a bi-directional interface between parallel digital RF (to D/A and from

A/D) and Serial RF (SeRF) to/from SeRF board

•• perform adjustable delay processing.

Page 12 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 27

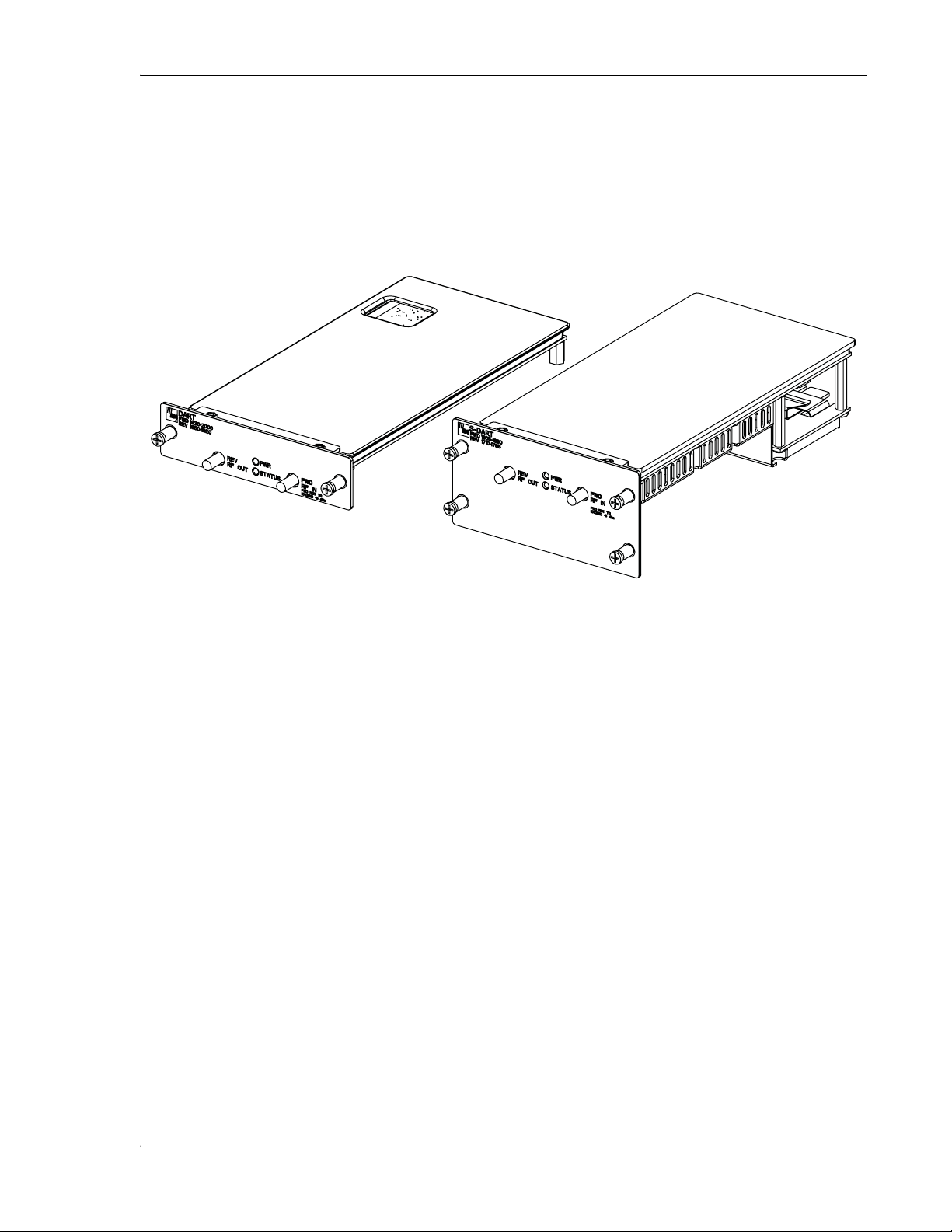

DART Cards

Generic representation of a

Classic DART or Single SuperDART

Genreic representation of a

Dual SuperDART

77073-076

1.4.1 DARTs and Host Units

The Host can support up to eight Classic DARTS and/or Single SuperDARTs or up to

four Dual SuperDARTs. Figure 1-5 provides generic representations of Classic DARTS

or Single SuperDARTs and Dual SuperDARTs.

Figure 1-5. DART Cards

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 13

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 28

FlexWave Prism System

SeRF Card

System Card

Power Supply

Fan Assembly

Dual SuperDART

in Slots 1 and 3

Dual SuperDART

in Slots 2 And 4

Dual SuperDART

in Slots 5 And 7

Dual SuperDART

in Slots 6 And 8

77073-078

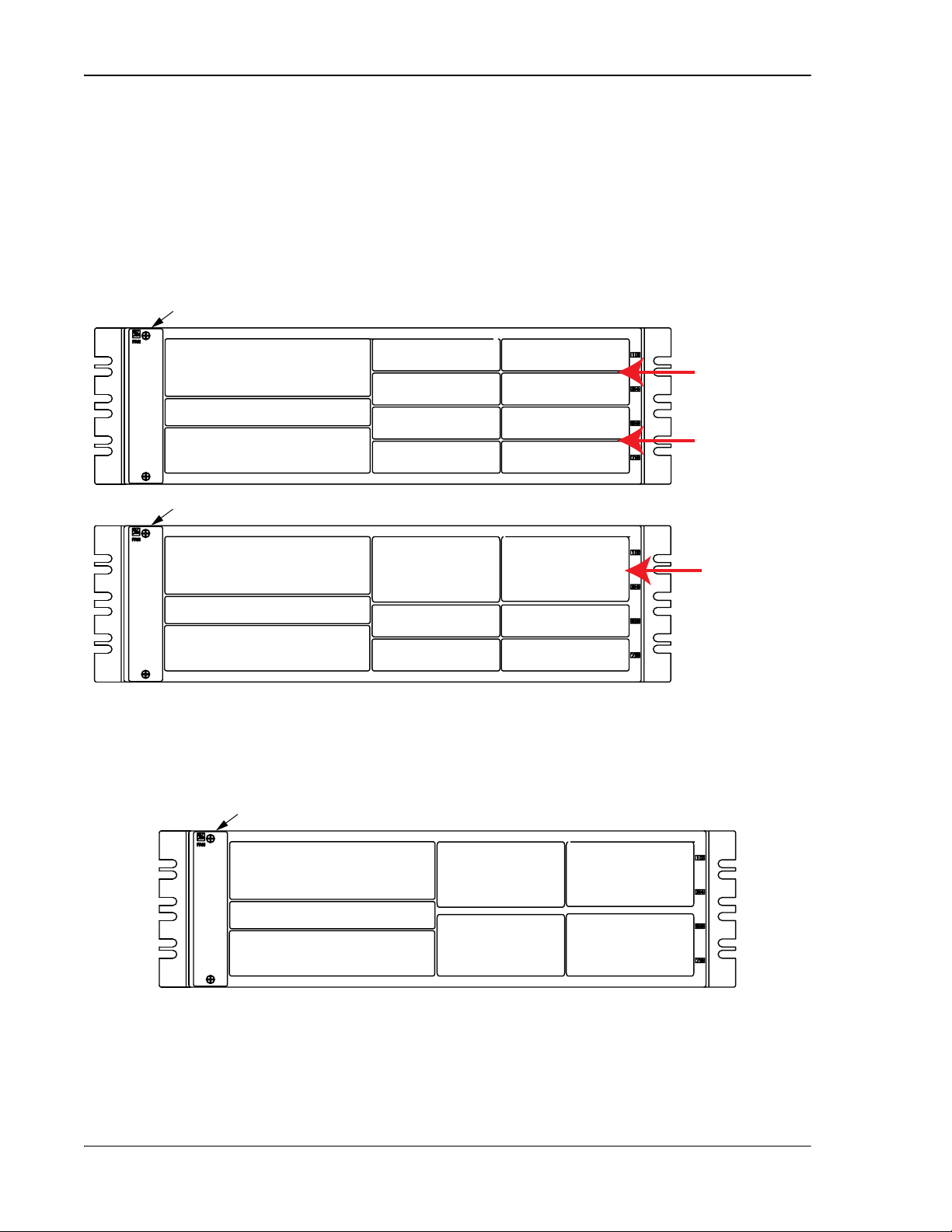

Figure 1-6 shows the possible slot assignments for Single and Dual SuperDARTs, and

where slot-divider bars are located.

•• A Classic DART or Single SuperDART can be installed in each of the eight slots in

the Host.

•• Dual SuperDARTs occupy two slots (1/3, 2/4, 5/7 or 6/8).

•• Dual SuperDARTs cannot occupy slot combinations 3/5 or 4/6.

•• Any combination of DARTs may be installed.

Fan Assembly

Single-Slot DART

in Slot 2

Single-Slot DART

in Slot 4

Single-Slot DART

in Slot 6

Single-Slot DART

in Slot 8

Dual-Slot DART

in Slots 2 and 4

Single-Slot DART

in Slot 6

Single-Slot DART

in Slot 8

77073-077

System Card

Power Supply

Fan Assembly

System Card

Power Supply

SeRF Card

SeRF Card

Single-Slot DART

in Slot 1

Single-Slot DART

in Slot 3

Single-Slot DART

in Slot 5

Single-Slot DART

in Slot 7

Dual-Slot DART

in Slots 1 and 3

Single-Slot DART

in Slot 5

Single-Slot DART

in Slot 7

Figure 1-6. DART Slot Assignments in Host Chassis

Figure 1-7 shows a Host that is fully loaded with Dual SuperDART cards.

Divider bars between

Slots 1 and 3

and Slots 2 and 4

Divider bars between

Slots 5 and 7

and Slots 6 and 8

Divider bars between

Slots 1 and 3 and

Slots 2 and 4 removed

to accommodate

Dual-Slot DARTs

Figure 1-7. Host with Dual SuperDARTs

Page 14 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 29

DART Cards

1.4.2 DARTs and Remote Units

The Remote DARTs are encased in its RF Module. Each RF Module will have up to two

Classic DARTs or Single SuperDARTs, or one Dual SuperDART, and there can be up to:

•• one RF Module in a Single-Band chassis

•• two RF Modules in a Dual-Band chassis

•• three RF Modules in a Tri-Band chassis

•• four RF Modules in a Quad-Band chassis.

The Remote DART Interface cards (RDI) and the Remote SeRF interface board (RSI)

provide Remote SeRF and DART connectivity for the Prism high speed digital

connections. The configuration of the DART cards provide the RF spectrum.

Prism Remote RF Modules are not field serviceable. To replace a DART within a P rism

Remote, you must

replace the RF Module.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 15

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 30

FlexWave Prism System

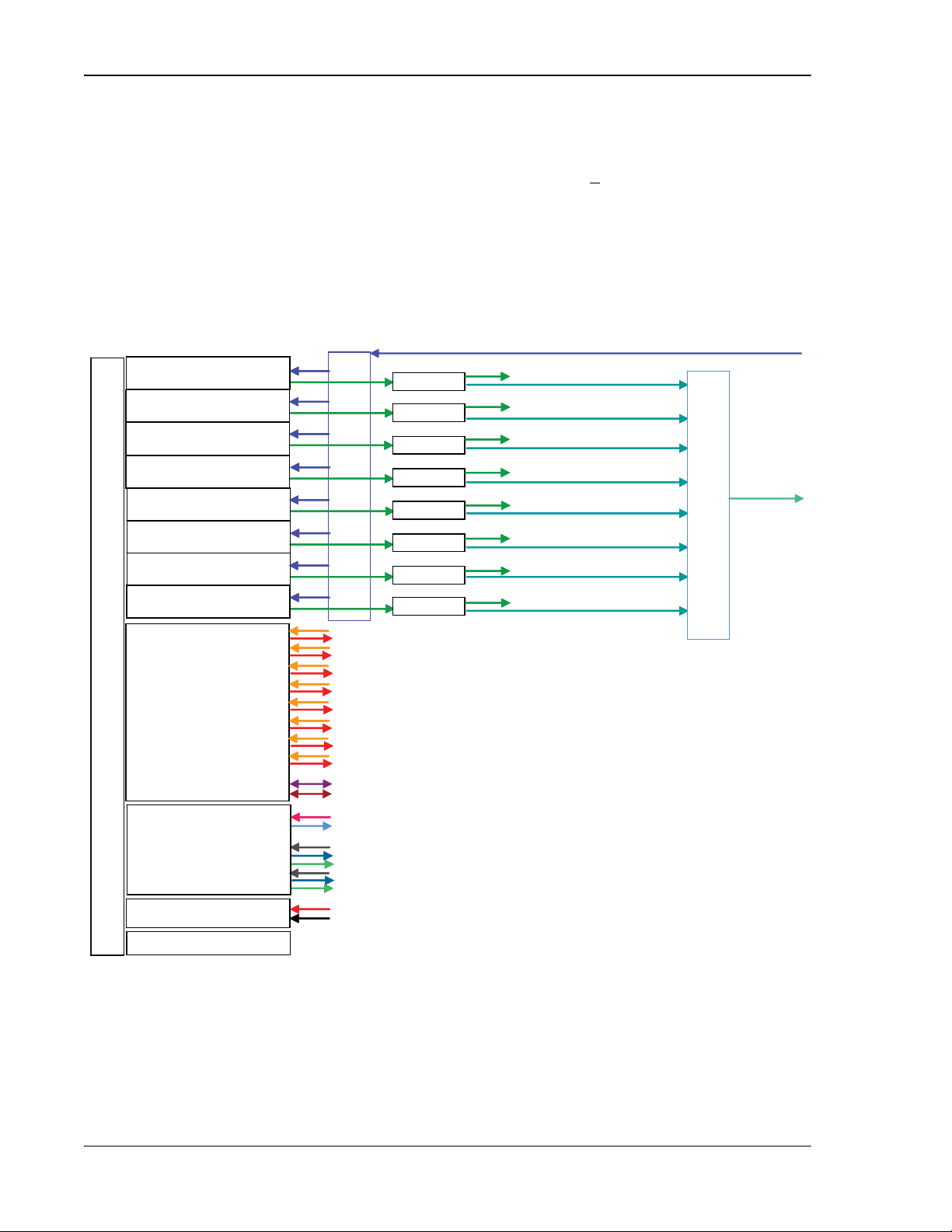

1.5 E911 SUPPORT

The DART type determines the maximum number of links, where there can be up to

8 DARTs for a 35MHz spectrum and up to 4 DARTs for a <

E911 support may be achieved by using a configuration similar to the one shown in

Figure 1-8. Remote simulcasting in this configuration requires analog splitting and

combining to and from the individual Host DARTs. External analog

splitting/combining ensures that the E911 system receives uplink signals from each

Remote location before they are combined with uplink signals from the other

Remotes in the simulcast.

75MHz spectrum.

B

A

C

K

P

L

A

N

E

B

O

A

R

D

DART BOARD (1)

DART BOARD (2)

DART BOARD (3)

DART BOARD (4)

DART BOARD (5)

DART BOARD (6)

DART BOARD (7)

DART BOARD (8)

SeRF BOARD

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

2:1 Splitter

E911

E911

E911

E911

E911

E911

E911

E911

BTS FWD

8:18:1

BTS REV

77073-031

SYSTEM BOARD

POWER BOARD

FAN CARD

Figure 1-8. 8:1 Analog Simulcast U-TDoA E911 Support Diagram

Page 16 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 31

Fiber Optic Transport

1.6 FIBER OPTIC TRANSPORT

In a typical Prism system the Host is connected to the Remote using two single-mode

optical fibers. One fiber is used to transport the forward pathh optical signal and a

second fiber is used to transport the rev erse pathh optical signal. With the diversity

option, the div ersity rev erse pathh optical signal is sent on the same reverse path

fiber. (However, the diversity signal can also be transmitted on a separate fiber pair

if more than 12 timeslots are required at a single Remote.) Because the optical signal

is digital, the input and output RF signal levels at the Host or the Remote are not

dependent on the level of the optical signal or the length of the optical fiber. A

diagram of the standard fiber optic transport system for both a non-diversity and

diversity system is shown in Figure 1-9.

The maximum length of the optical links is dependent on the loss specifications of

the optical fiber and the losses imposed by the various connectors and splices. The

system provides an optical budget of 25 dBB (typical) when used with 9/125

single-mode fiber. There must be at least 10 dB of optical loss to prevent over-driving

and possible damage to the optical receiver.

Non-Diversity Fiber Optic Link

Forward Path

Reverse Path

Remote

Unit

Host

Unit

Diversity Fiber Optic Link

Forward Path

Reverse Path

And

Diversity Reverse Path

Up To

Eight

Remote

Unit

77073-008

Figure 1-9. Standard Fiber Optic Transport Application

The SeRF (Serialized RF) digital protocol consists of digitized RF, Fast Ethernet, and

Host to Remote communication and management. The protocol provides you with

full access to the 100BASE-T (Ethernet) connection between the Host and each

Remote, and the ability to provision the RF spectrum of the DARTs. The digitized RF

portion of the SeRF protocol is divided into 12 timeslots, with each timeslot

representing roughly 5 MHz of digitized RF spectrum. Utilizing the full 12 timeslots

yields between 60 and 75 MHz of total digitized RF on each SeRF Small Form-Factor

Pluggable (SFP) laser connection.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 17

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 32

FlexWave Prism System

The available RF bandwidth per timeslot is shown in Table 1-2.

Table 1-2. Available RF Bandwidth

Number

of

Times lots

15 6

2 12.5 12

320 18

425 ---

635 39

8 --- 45

12 --- 60-75

Maximum Contiguous

RF Bandwidth (MHz)

Classic

DART s

Single and Dual

SuperDARTs

For example, a user who wishes to transport PCS A block, Cellular A, and AWS B block,

the system would require the following:

PCS A 15MHz, 3 timeslots

Cellular A 10MHz, 2 timeslots

AWS B 10MHz, 2 timeslots

Total = 35MHz, 7 timeslots

Page 18 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 33

Timeslots Versus Bandwidth

1.7 TIMESLOTS VERSUS BANDWIDTH

Ea ch fiber p air supports 12 timeslots, or up to 75 MHz of bandwidth. Table 1-2 shows

the maximum bandwidth versus the number of timeslots.

If more than 70 MHz is required per Remote, up to three additional fiber pairs can be

brought to the Remote to get up to up to 280MHz per Remote (or 300MHz if all four

are GSM-1800). This supports applications where there are two Classic DARTs or

Single SuperDARTs or one Dual SuperDART in a Remote RF Module.

The SeRF (Serialized RF) digital protocol consists of digitized RF, 100BASE-T Ethernet,

and Host to Remote communication and management. The protocol provides you

with full access to the 100BASE-T Ethernet connection between the Host and each

Remote, and the ability to provision the RF spectrum of the DARTs. The digitized RF

portion of the SeRF protocol is divided into 12 timeslots, with each timeslot

representing roughly 5 MHz of digitized RF spectrum. Utilizing the full 12 timeslots

yields between 60 and 80 MHz of total digitized RF on each SeRF SFP laser connection.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 19

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 34

FlexWave Prism System

PCS D+B+E

1.8 BANDWIDTHS

In the FlexWave Prism system, there are different Bandwidths from which to select,

ranging from 5 to 75 MHz. The different bandwidths allow you to configure the

system to use any contiguous or non-contiguous blocks within the 35 MHz of a single

Host 6-timeslot DART or 60-75 MHz using a 12-timeslot DART. DART bandwidth

options are shown in Table 1-3.

For DART cards, if you need to use non-contiguous blocks within a given 35 MHz,

then the selected bandwidth must span both of these blocks, even if the blocks in

between are not used. For example, if you want to use both PCS DD and EE blocks, select

the BB block is effectively unused.

PCS D and E are only 10 MHz of spectrum, four timeslots are required since the actual

transported spe

, which spans 25 MHz. This allows both PCS DD & EE to be transported and

ctrum is 25 MHz for the PCS D, B, E block, as shown in Table 1-3.

Table 1-3. DART Bandwidths

Dow n- Link RF Band

Band

AWS A 2110 2120 1710 1720 10 2

AWS A+B 2110 2130 1710 1730 20 3

AWS A+B+C 2110 2135 1710 1735 25 4

AWS A+B+C+D 2110 2140 1710 1740 30 6

AWS A+B+C+D+E 2110 2145 1710 1745 35 6

AWS B 2120 2130 1720 1730 10 2

AWS B+C 2120 2135 1720 1735 15 3

AWS B+C+D 2120 2140 1720 1740 20 3

AWS B+C+D+E 2120 2145 1720 1745 25 4

AWS B+C+D+E+F 2120 2155 1720 1755 35 6

AWS C 2130 2135 1730 1735 5 1

AWS C+D 2130 2140 1730 1740 10 2

AWS C+D+E 2130 2145 1730 1745 15 3

AWS C+D+E+F 2130 2155 1730 1755 25 4

AWS D 2135 2140 1735 1740 5 1

AWS D+E 2135 2145 1735 1745 10 2

AWS D+E+F 2135 2155 1735 1755 20 3

AWS E 2140 2145 1740 1745 5 1

AWS E+F 2140 2155 1740 1755 15 3

AWS F 2145 2155 1745 1755 10 2

AWS 2100 2110 2155 1710 1755 45 8

AWS H 1995 2000 1915 1920 5 1

Cellular A 870 880 825 835 10 2

(MHz)

Start Stop Start Stop

Up- Link RF Band

(MHz)

Bandw idth Slots

(MHz)

Bandw idth

in MHz

# of

Times lots

Page 20 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 35

Table 1-3. DART Bandwidths (Cont.)

Bandwidths

Band

Dow n- Link RF Band

(MHz)

Start Stop Start Stop

Up- Link RF Band

(MHz)

Bandw idth Slots

(MHz)

Bandw idth

in MHz

# of

Times lots

Cellular A' 890 891.5 845 846.5 1.5 1

Cellular A''+A 869 880 824 835 11 2

Cellular A''+A+A' 869 891.5 824 846.5 22.5 4

Cellular A''+A+B+A'+B' 869 894 824 849 25 4

Cellular B 880 890 835 845 10 2

Cellular B' 891.5 894 846.5 849 2.5 1

Cellular B+B' 880 894 835 849 14 3

GSM 1800 FullBand 1805 1880 1710 1785 75 12

GSM 900 FullBand 921 960 876 915 39 6

PCS A 1930 1950 1850 1865 20 3

PCS A+D 1930 1950 1850 1870 20 3

PCS A+D+B 1930 1965 1850 1885 35 6

PCS A+D+B1 1930 1955 1850 1875 25 4

PCS A+D+B1+B2 1930 1960 1850 1880 30 6

PCS A1 1930 1935 1850 1855 5 1

PCS A1+A2 1930 1940 1850 1860 10 2

PCS A2 1935 1940 1855 1860 5 1

PCS A2+A3 1935 1945 1855 1865 10 2

PCS A2+A3+D 1935 1950 1855 1870 15 3

PCS A2+A3+D+B 1935 1965 1855 1885 30 6

PCS A2+A3+D+B+E 1935 1970 1855 1890 35 6

PCS A2+A3+D+B1 1935 1955 1855 1875 20 3

PCS A2+A3+D+B1+B2 1935 1960 1855 1880 25 4

PCS A3 1940 1945 1860 1865 5 1

PCS A3+D 1940 1950 1860 1870 10 2

PCS A3+D+B 1940 1965 1860 1885 25 4

PCS A3+D+B+E 1940 1970 1860 1890 30 6

PCS A3+D+B+E+F 1940 1975 1860 1895 35 6

PCS A3+D+B1 1940 1955 1860 1875 15 3

PCS A3+D+B1+B2 1940 1960 1860 1880 20 3

PCS B 1950 1965 1870 1885 15 3

PCS B+E 1950 1970 1870 1890 20 3

PCS B+E+F 1950 1975 1870 1895 25 4

PCS B+E+F+C3 1950 1980 1870 1900 30 6

PCS B+E+F+C3+C4 1950 1985 1870 1905 35 6

PCS B1 1950 1955 1870 1875 5 1

PCS B1+B2 1950 1960 1870 1880 10 2

PCS B2 1955 1960 1875 1880 5 1

PCS B2+B3 1955 1965 1875 1885 10 2

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 21

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 36

FlexWave Prism System

Table 1-3. DART Bandwidths (Cont.)

Band

Dow n- Link RF Band

(MHz)

Start Stop Start Stop

Up- Link RF Band

(MHz)

Bandw idth Slots

(MHz)

Bandw idth

in MHz

# of

Times lots

PCS B2+B3+E 1955 1970 1875 1890 15 3

PCS B2+B3+E+F 1955 1975 1875 1895 20 3

PCS B2+B3+E+F+C 1955 1990 1875 1910 35 6

PCS B2+B3+E+F+C2 1955 1982.5 1875 1902.5 27.5 6

PCS B2+B3+E+F+C3 1955 1980 1875 1900 25 4

PCS B2+B3+E+F+C3+C4 1955 1985 1875 1905 30 6

PCS B3 1960 1965 1880 1885 5 1

PCS B3+E 1960 1970 1880 1890 10 2

PCS B3+E+F 1960 1975 1880 1895 15 3

PCS B3+E+F+C 1960 1990 1880 1910 30 6

PCS B3+E+F+C + SMR G 1960 1995 1880 1915 35 6

PCS B3+E+F+C2 1960 1982.5 1880 1902.5 22.5 4

PCS B3+E+F+C3 1960 1980 1880 1900 20 3

PCS B3+E+F+C3+C4 1960 1985 1880 1905 25 4

PCS C 1975 1990 1895 1910 15 3

PCS C + SMR G 1975 1995 1895 1915 20 3

PCS C + SMR G + AWS H 1975 2000 1895 1920 25 4

PCS C1 1982.5 1990 1902.5 1910 7.5 2

PCS C1 + SMR G 1982.5 1995 1902.5 1915 12.5 2

PCS C1 + SMR G + AWS H 1982.5 2000 1902.5 1920 17.5 3

PCS C2 1975 1982.5 1895 1902.5 7.5 2

PCS C3 1975 1980 1895 1900 5 1

PCS C3+C4 1975 1985 1895 1905 10 2

PCS C4 1980 1985 1900 1905 5 1

PCS C4+C5 1980 1990 1900 1910 10 2

PCS C4+C5 + SMR G 1980 1995 1900 1915 15 3

PCS C4+C5 + SMR G + AWS H 1980 2000 1900 1920 20 3

PCS C5 1985 1990 1905 1910 5 1

PCS C5 + SMR G 1985 1995 1905 1915 10 2

PCS C5 + SMR G + AWS H 1985 2000 1905 1920 15 3

PCS D 1945 1950 1865 1870 5 1

PCS D+B 1945 1965 1865 1885 20 3

PCS D+B+E 1945 1970 1865 1890 25 4

PCS D+B+E+F 1945 1975 1865 1895 30 6

PCS D+B+E+F+C3 1945 1980 1865 1900 35 6

PCS D+B1 1945 1955 1865 1875 10 2

PCS D+B1+B2 1945 1960 1865 1880 15 3

PCS E 1965 1970 1885 1890 5 1

PCS E+F 1965 1975 1885 1895 10 2

Page 22 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 37

Table 1-3. DART Bandwidths (Cont.)

Bandwidths

Band

Dow n- Link RF Band

(MHz)

Start Stop Start Stop

Up- Link RF Band

(MHz)

Bandw idth Slots

(MHz)

Bandw idth

in MHz

# of

Times lots

PCS E+F+C 1965 1990 1885 1910 25 4

PCS E+F+C + SMR G 1965 1995 1885 1915 30 6

PCS E+F+C + SMR G +AWS H 1965 2000 1885 1920 35 6

PCS E+F+C2 1965 1982.5 1885 1902.5 17.5 3

PCS E+F+C3 1965 1980 1885 1900 15 3

PCS E+F+C3+C4 1965 1985 1885 1905 20 3

PCS F 1970 1975 1890 1895 5 1

PCS F+C 1970 1990 1890 1910 20 3

PCS F+C + SMR G 1970 1995 1890 1915 25 4

PCS F+C + SMR G + AWS H 1970 2000 1890 1920 30 6

PCS F+C2 1970 1982.5 1890 1902.5 12.5 2

PCS F+C3 1970 1980 1890 1900 10 2

PCS F+C3+C4 1970 1985 1890 1905 15 3

PCS FullBand 1930 2000 1850 1920 70 12

SMR 851-869 (SMR Low Wide) 851 869 806 824 18 3

SMR 863-869 (SMR Low) 863 869 818 824 6 2

SMR 935-940 (SMR High) 935 940 896 901 5 1

SMR G 1990 1995 1910 1915 5 1

SMR G + AWS H 1990 2000 1910 1920 10 2

UMTS 2100 2110 2170 1920 1980 60 12

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 23

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 38

FlexWave Prism System

Prism Host

Prism Remote

PCS

DART

PCS

DART

TX

RX

TX

RX

PCS

DART

PCS

DART

LPA

PCS

Duplexor

Duplexer/

LNA

+

SeRF SeRF

77073-028

1.9 AWS AND PCS BAND OPTIONS

The Dual-AWS and Dual-PCS DARTs allow you to span non-contiguous bands:

•• the Dual-AWS DART comprises two 6-Timeslot AWS DARTs that span the full 45

MHz of the AWS band

•• the Dual-PCS DART provides two PCS blocks over the entire 70 MHz PCS

spectrum.

In the forward path, the two Remote DARTs are summed together before being sent

to the Linear Power Amplifier (LPA). In the reverse direction, the Low Noise Amplifier

(LNA) is split providing the full PCS or AWS spectrum to each DART. Each DART is

responsible for transporting its own spectrum, as shown in an the following example

for a PCS configuration.

Page 24 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 39

AWS and PCS Band Options

PCS Configuration Example:

If the application requires both the A and C block, in the Remote the forward path of

the PCS A band is combined with the forward path of the PCS C band and these

signals are sent to the LPA to be amplified. In the reverse direction, the Duplexer/LNA

passes/amplifies the entire PCS band. The first DART digitizes the PCS A block

reverse path and the second DART digitizes the PCS C block reverse path and then

sends them back to the Host to be reconstructed back into RF.

The installer needs to provide the separate connections at the Host location either by

splitting already combined signals to/from each DART, or by providing them

independently.

If the tw o PCS reverse path blocks are combined at the Host location, then they must be

separated by

other during the re- combin

at least 5 MHz to insure that the reverse paths do not interfere with each

ing.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 25

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 40

FlexWave Prism System

Intentionally Blank Page

Page 26 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 41

2

PRISM SYSTEM COMPONENTS

Content Page

2.1 FlexWave Prism Family Overview......................................................................... 28

2.2 FlexWave Prism Host Units ................................................................................. 30

2.2.1 Host Front Panel........................................................................................ 30

2.2.2 Host Network Connection............................................................................ 33

2.2.3 Host RF Signal Connections......................................................................... 33

2.2.4 Host System Card...................................................................................... 34

2.3 Prism Remote Units ........................................................................................... 35

2.3.1 Handset Interface...................................................................................... 36

2.3.2 Remote Components.................................................................................. 36

2.3.2.1 Remote RF Modules............................................................................ 38

2.3.2.1.1 Remote Duplexer and Low Noise Amplifier ..................................... 40

2.3.2.1.2 Linear Power Amplifiers............................................................... 41

2.3.2.2 Remote SeRF Modules ........................................................................ 43

2.3.2.3 Remote Power Supply and Cable Assembly............................................ 44

2.3.2.4 Solar Shield ...................................................................................... 45

2.3.2.5 Mounting Bracket (Remotes) ............................................................... 46

2.3.2.6 Remote Connectors............................................................................ 47

2.3.2.7 Remote Fiber Connector Cable Assembly............................................... 49

2.3.2.8 Remote Antenna Cable Connections ..................................................... 49

2.3.2.9 Remote Grounding ............................................................................. 49

2.3.2.10 Remote Cooling ............................................................................... 49

2.4 Prism System Accessories .................................................................................. 50

2.4.1 Lightning Surge Suppressor (Remote Accessory) ........................................... 50

2.4.2 Uninterruptible Power Supply (Accessory) ..................................................... 50

2.4.3 Wavelength Division Multiplexer System (Accessory)...................................... 50

2.4.4 Course Wavelength Division Multiplexer System (Accessory) ........................... 51

2.4.5 Millimeter Wave Systems (Accessory)........................................................... 55

2.5 Prism System Specifications ............................................................................... 56

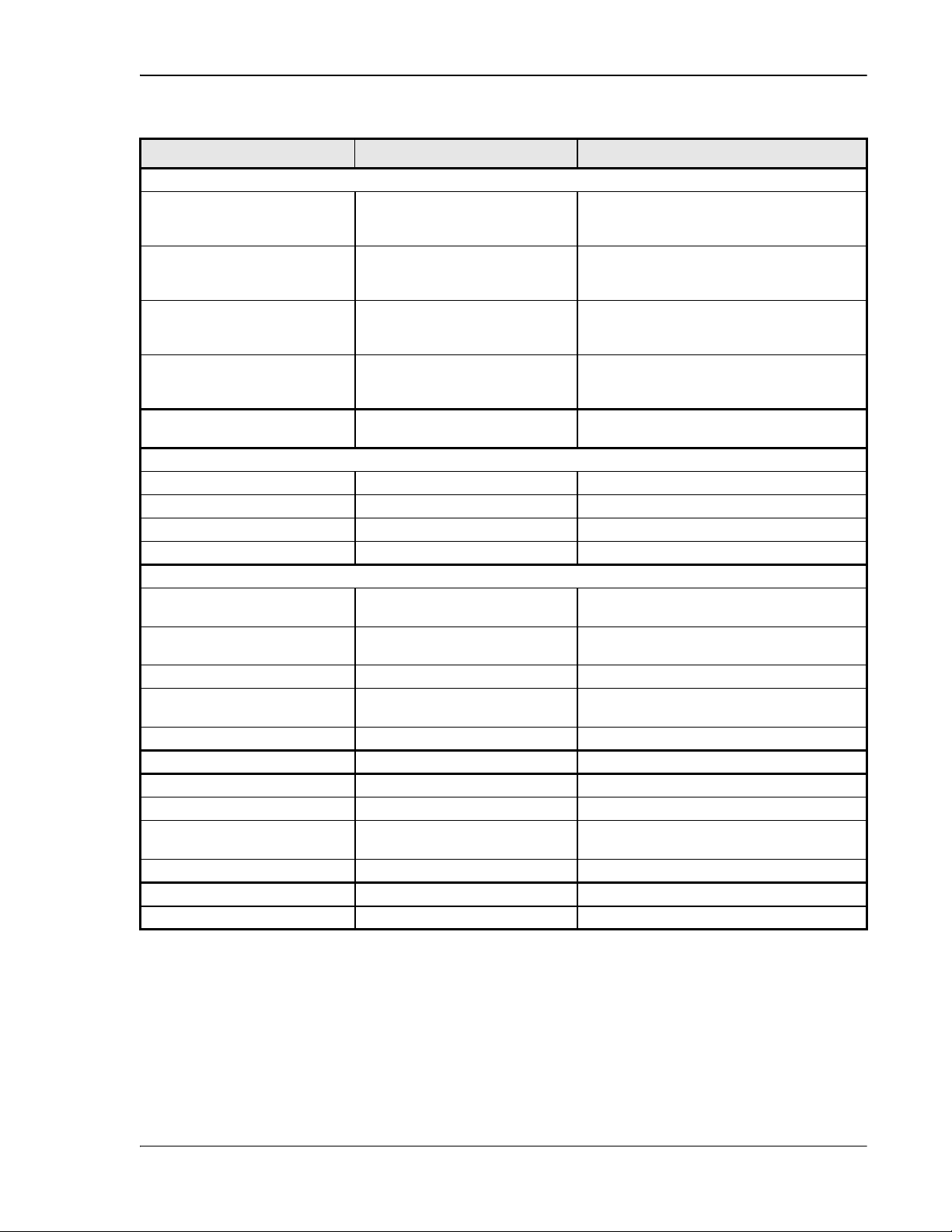

2.5.1 Host Unit Specifications .............................................................................. 56

2.5.2 Remote Unit Specifications.......................................................................... 57

2.5.3 System Nominal Optical Specifications.......................................................... 58

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 27

ADCP-77-073 • Issue 2 • 11/2009 ©2009 ADC Telecommunications, Inc.

Page 42

Prism System Components

2.1 FLEXWAVE PRISM FAMILY OVERVIEW

The ADC FlexWave Prism family of products is a Distributed Antenna System (DAS)

that provides ADC’s patented technology—bidirectional transport of digitized RF

spectrum over fiber. The high-speed digitalization of a wideband portion of spectrum

allows for transport of RF signals over extended distances, without the RF

degradation that normally results when analog systems are impacted by optical

effects. The basic function of the FlexWave Prism platform is to transport via fiber

optic cable RF signals from a Base Transceiver Station (BTS) to an antenna interface

allowing communication to a mobile device. Multiple BTS communication paths are

allowed over a single Prism system. Each link consists of a Host that provides the

interface between the base station RF ports and the optical fiber, and at least one

Remote that provides the interface between the optical fiber and the remote antenna.

A block diagram of the system is shown in Figure 2-1.

BTS 1

BTS 2

BTS 3

BTS 1

BTS 2

BTS 3

FWD RF IN

REV RF OUT

FWD RF IN

REV RF OUT

FWD RF IN

REV RF OUT

FWD RF IN

REV RF OUT

REV DIV RF OUT

FWD RF IN

REV RF OUT

REV DIV RF OUT

FWD RF IN

REV RF OUT

REV DIV RF OUT

FlexWave

Host

FlexWave

Host

NON-DIVERSITY

DIVERSITY

FlexWave

Remote

FlexWave

Remote

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

REV DIV RF IN

FWD RF OUT

REV RF IN

REV DIV RF IN

FWD RF OUT

REV RF IN

REV DIV RF IN

Antenna

Interface

BTS 1

Antenna

Interface

BTS 2

Antenna

Interface

BTS 3

Antenna

Interface

BTS 1

Antenna

Interface

BTS 2

Antenna

Interface

BTS 3

77073-005

Figure 2-1. FlexWave Tri-Band Prism Block Diagram

Page 28 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 43

FlexWave Prism Family Overview

The basic function of FlexWave Prism simulcast (point-to-multipoint) is to transport,

via fiber optic cable, RF signals from a Base Transceiver Station (BTS) to multiple

antenna interfaces allowing communication to a mobile device (see Figure 2-2). Up to

8 simulcast Remotes are supported.

BTS 1

BTS 2

BTS 3

FWD RF IN

REV RF OUT

FWD RF IN

REV RF OUT

FWD RF IN

REV RF OUT

FlexWave

Host

FlexWave

Remote 1

FlexWave

Remote 2

FlexWave

Remote 8

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

FWD RF OUT

REV RF IN

Antenna

Interface

BTS 1

Antenna

Interface

BTS 1

Antenna

Interface

BTS 1

Antenna

Interface

BTS 1

Antenna

Interface

BTS 1

Antenna

Interface

BTS 1

Antenna

Interface

BTS 1

Antenna

Interface

BTS 1

Antenna

Interface

BTS 1

77073-006

Figure 2-2. System Block Diagram for Eight-Way Simulcast

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 29

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 44

Prism System Components

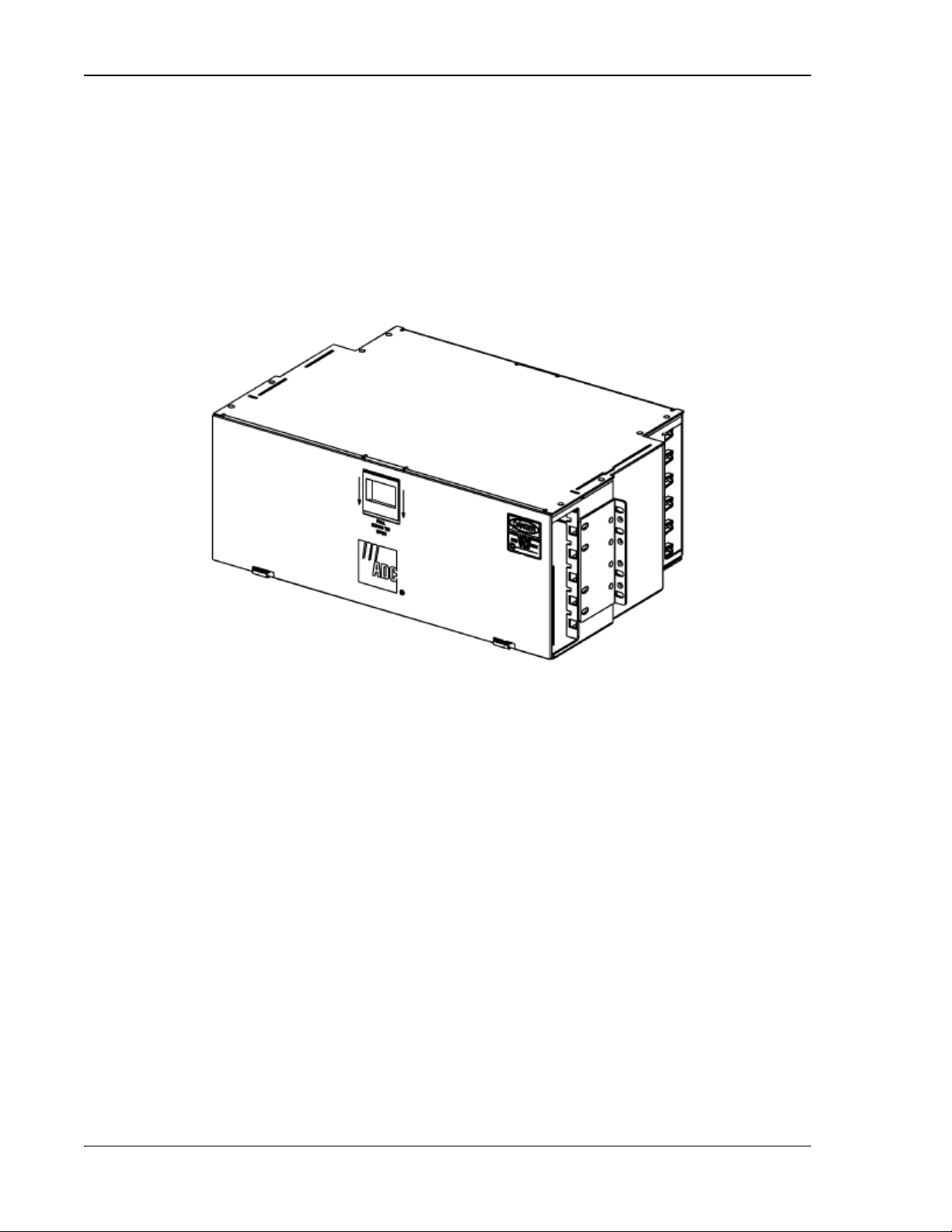

2.2 FLEXWAVE PRISM HOST UNITS

The Host is designed for maximum RF flexibility to address Carriers’ changing and

evolving spectrum needs, making the most use of cost efficient resources for serving

multiple remotes such as simulcast architecture and sharing of common functions

such as power, control and management over multiple Hosts. Each Host may be

interfaced with one or more Base Transceiver Station (BTS). Each BTS provides the RF

channel inputs and outputs for a designated sector.

The Host is designed as a compact package that reduces rack space required within

a BTS Hotel. The Host is a three rack-unit high single-unit assembly that mounts in a

standard 19- or 23-inch equipment rack. Its front access interfaces with the BTS for

transport to subtended Remotes, and performs the analog to digital and electrical to

optical conversions for transport to a Host and subtended Remotes. Each Host can

support up to eight Remotes. The Remote is a modular self-contained outdoor

enclosure that houses various electronic components.

2.2.1 Host Front Panel.

The Host is designed for use within a non-condensing indoor environment such as

inside a wiring closet or controlled environment cabinet. All controls, connectors, and