Page 1

4

INSTALLING THE REMOTE UNIT

Content Page

4.1 Remote Installation Overview ............................................................................. 94

4.1.1 Installation Hardware Provided with Remote.................................................. 94

4.1.2 Required Tools and Materials....................................................................... 95

4.2 Remote Mounting Plans...................................................................................... 96

4.3 Install the Remote............................................................................................. 97

4.3.1 Unpack and Inspect the Remote and Components .......................................... 97

4.3.2 Install the Remote RF Module(s).................................................................. 98

4.4 Install any 40W RF Module(s) ............................................................................107

4.4.1 Prepare the Remote and RF Module.............................................................108

4.4.2 Remove Module Shelf(s)............................................................................108

4.4.3 Install the 40W RF Module .........................................................................110

4.4.4 Ground Wire Installation............................................................................118

4.4.5 Network Cable Installation .........................................................................119

4.4.6 Quad Fiber Cable Installation .....................................................................121

4.4.7 Antenna Cable Installation .........................................................................123

4.4.8 AC Power Wiring Installation ......................................................................125

4.4.9 Determine the Circuit Breaker or Fuse for Remote.........................................129

4.4.9.1 Power Consumption ..........................................................................129

4.4.9.2 Power Consumption Tables.................................................................131

4.4.10 Mount the Remote and Power Up ..............................................................132

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 93

ADCP-77-073 • Issue 2 • 11/2009 ©2009 ADC Telecommunications, Inc.

Page 2

Installing the Remote Unit

4.1 REMOTE INSTALLATION OVERVIEW

Installation of the Remote consists of the following basic steps:

To insure that all connectors and ports remain dust- free during installation, leave all

dust caps and

11 Unpack and inspect your shipment.

22 Install the RF module(s).

33 Connect the ProAx Fiber Cables.

44 Connect external coaxial antenna cables must be routed from the antenna to the

Remote TX0/RX0 and RX1 connectors.

55 Install the AC power cable and connect it the Remote’s AC power port and to an

external junction box .

4.1.1 Installation Hardware Provided with Remote

dust protectors in place until directed to remove them.

The installation hardware provided with the Remote is listed in Table 4-1.

Table 4-1. Remote Unit Installation Hardware

Item Quantity

AC Power Cable (15 feet/4.6m) 1

Quad Fiber Cable Assembly 1

3/8-inch hex standoff 3

3/8-inch 10-32 phillips screw 3

#10 split washer 3

(a) If the Remote has more than 2 SFPs, two Quad

Fiber Cable Assemblies are required.

(a)

Page 94 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 3

Remote Installation Overview

4.1.2 Required Tools and Materials

The following tools are required in order to complete the procedures in this

instruction:

•• Socket Wrench and 3/8-inch Deep Socket

•• Wire cutters

•• Wire stripper

•• Compression pliers for splicing grounding cable

•• Tools for installing exterior AC circuit

•• Tool kit for attaching N-Type connectors to coaxial cable

•• Fiber cleaning kit

The following materials are required in order to complete the installation procedures:

•• #6 AWG (4 mm) copper wire and splice

•• #10 ring terminal for attaching #6 grounding wire to bottom of unit

•• Connector for attaching #6 grounding wire to approved earth ground source

•• Junction box, conduit, fasteners, connectors, and wire to install an exterior AC

circuit.

•• N-Type male connectors

•• RJ-45 connector (if making a permanent external network cable connection)

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 95

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 4

Installing the Remote Unit

4.2 REMOTE MOUNTING PLANS

The FlexWave Prism Remote Unit has a low profile design that requires minimal real

estate for installation. The basic dimensions and weights of the Remote are listed in

Table 4-2.

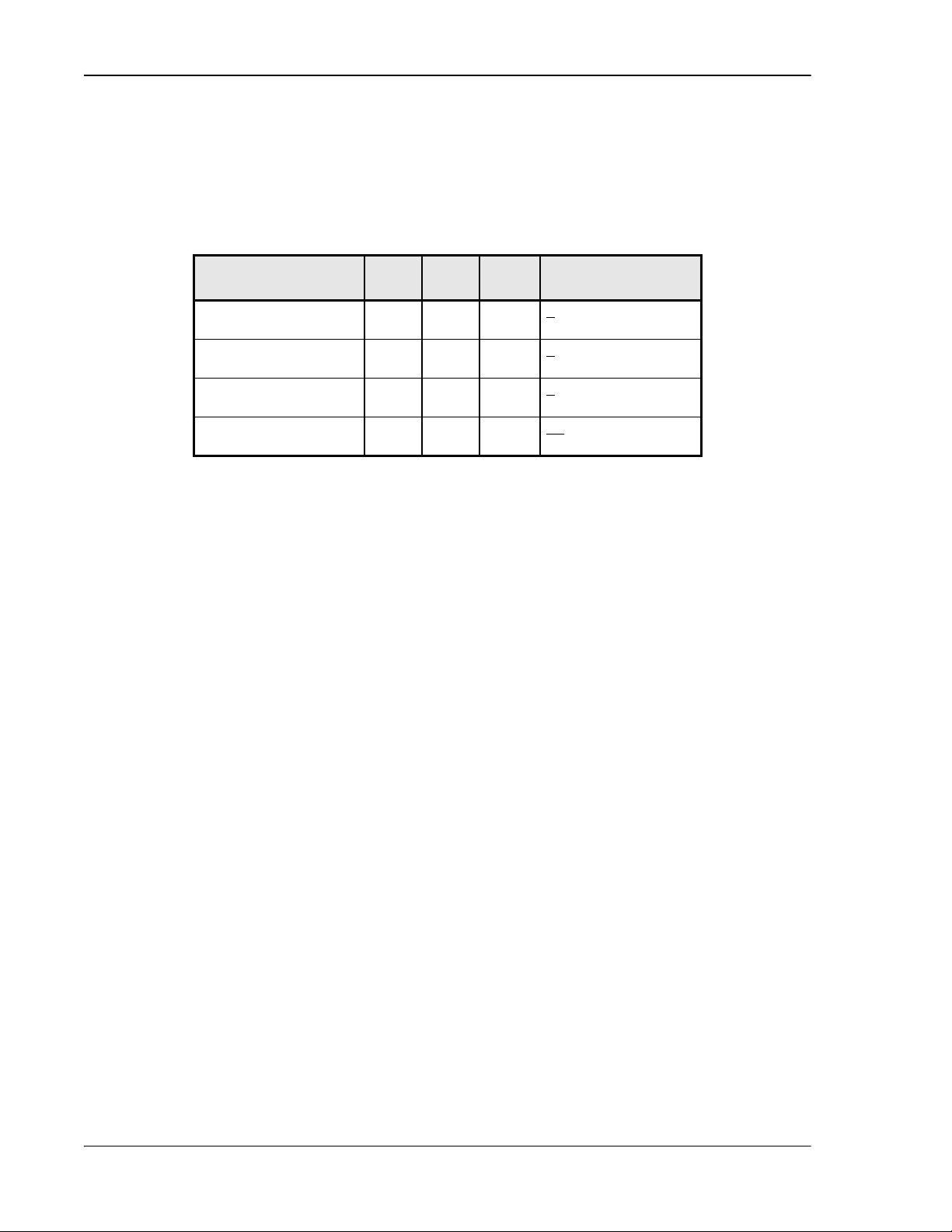

Table 4-2. Remote Dimensions

Remote Configuration Depth Width Height Weight of Fully

Populated Units

Single- Band

10.51"12.15"22.50" <

65 lbs

Double Band

Triple Band

Quad- Band

10.51"12.15"30.50" <

10.51"12.15"38.46" <

10.51"12.15"49.60" <1

96 lbs

127 lbs

65 lbs

The Prism Remote should be mounted on a utility pole, mast, or on a flat surface. A

mounting kit is available for each unit. Installation consists of securing the bracket

to the mounting surface (wood, concrete, or steel) and then hanging the unit from the

bracket. The Remote should only be mounted in a restricted access location.

Detailed instructions for mounting the FlexWave Prism Remote are in the Remote Unit

Mounting Kit Installation Instructions (ADCP-77-077).

Page 96 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 5

Install the Remote

4.3 INSTALL THE REMOTE

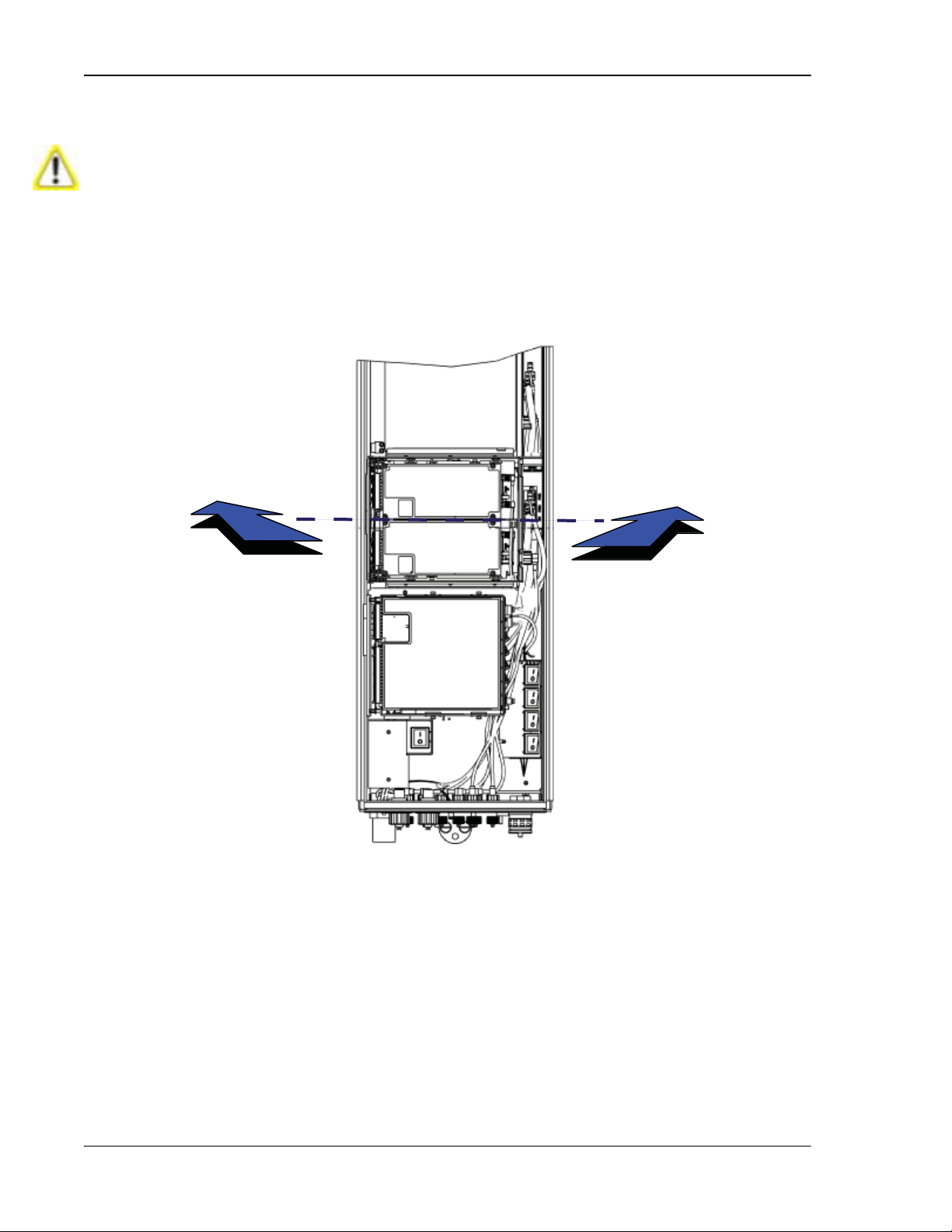

This chapter guides you through installing a Prism Remote, which requires 63 steps

that are divided into 9 sections. Follow the steps in the order in which they are

provided.

This is restricted access equipment and only service personnel should open and operate

this equipment

Wet conditions increase the potential for receiv ing an electrical shock when installing or

using elec

electrical equipment in

Installation of the Remote may proceed separately from the installation of the

corresponding Host.

4.3.1 Unpack and Inspect the Remote and Components

using appropriate tools

trically- pow ered equipment. To prev ent electrical shock, never install or use

a wet location or during a lightning storm.

This section provides instructions for opening the shipping boxes, verifying that all

parts have been received, and verifying that no shipping damage has occurred. Use

the following procedure to unpack and inspect the Host and any accessories:

Unpack and inspect the various components as follows:

11 Inspect the exterior of the shipping container(s) for evidence of rough handling

that may have damaged the components in the container.

22 Unpack each container while carefully checking the contents for damage and

verify with the packing slip.

33 If damage is found or parts are missing, file a claim with the commercial carrier

and notify ADC Customer Service (see “Contacting ADC” on page 335). Save the

damaged cartons for inspection by the carrier.

44 Save all shipping containers for use if the equipment requires shipment at a

future date.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 97

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 6

Installing the Remote Unit

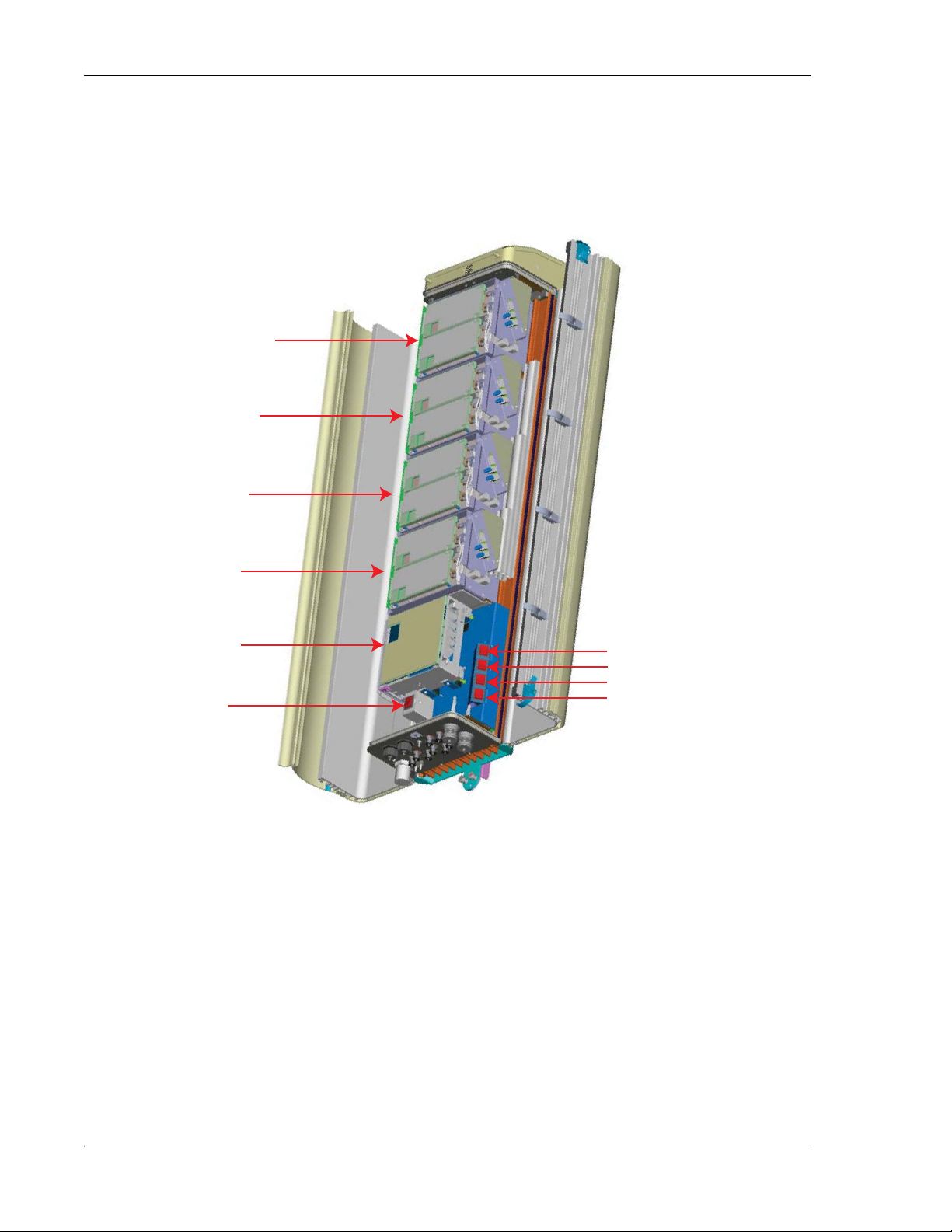

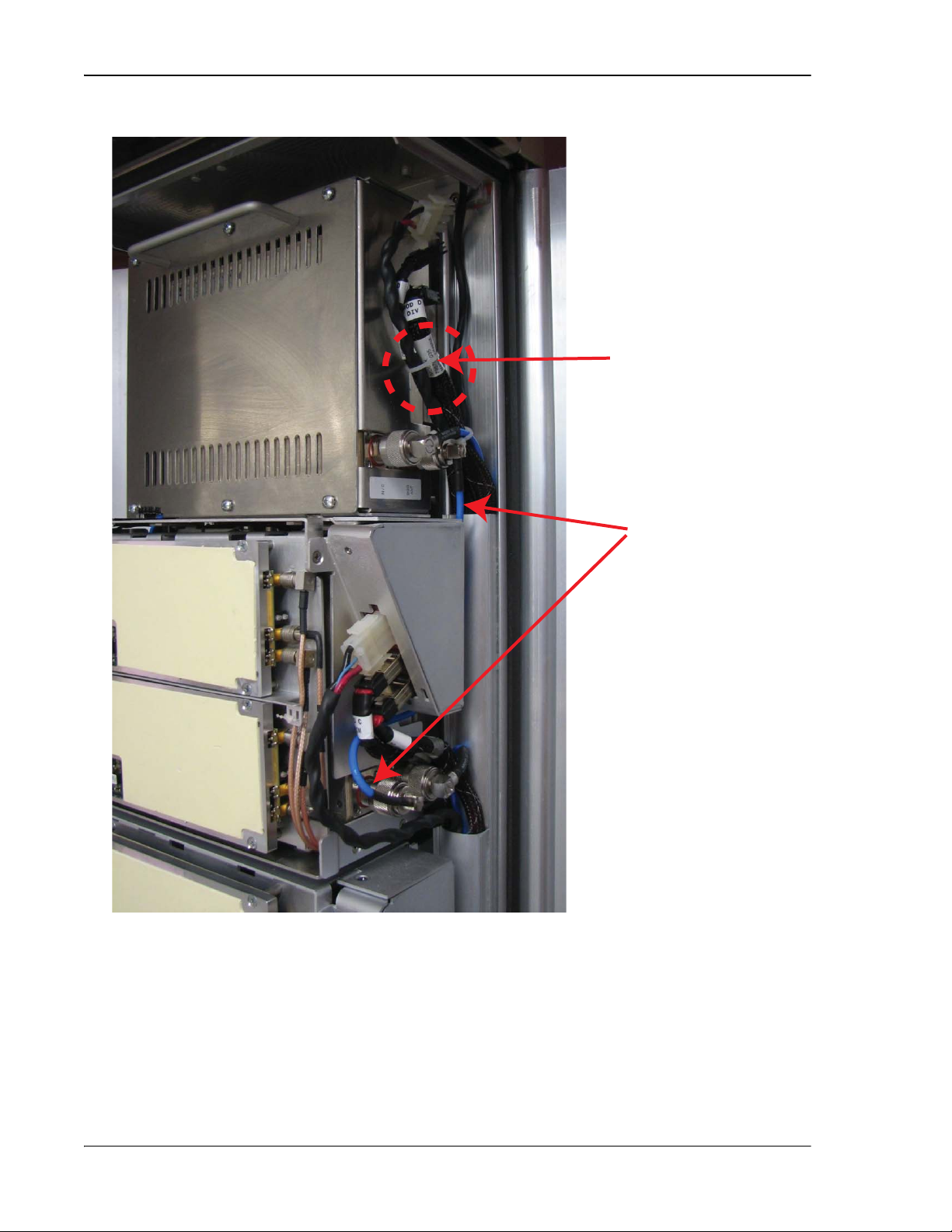

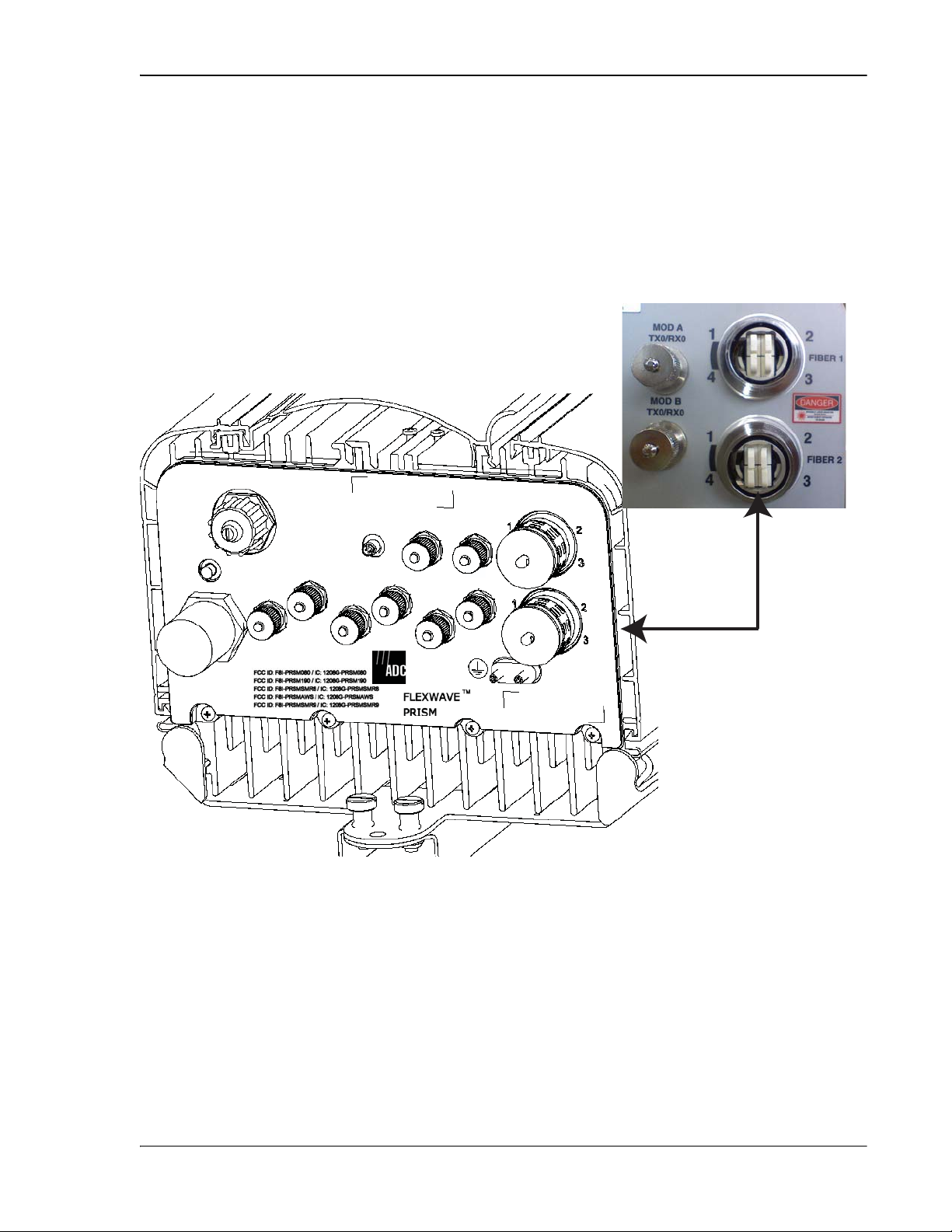

4.3.2 Install the Remote RF Module(s)

The RF Module cables that are pre installed in the Remote connect to the

corresponding connectors on the RF Module. The RF Module cables correlate to the

antenna connectors on the bottom of the Remote chassis. The cables and connectors

have corresponding labels as shown in Table 4-3. The RF cable and connector labels

also correspond to the RF Module slots in the Remote chassis, where MOD A is the

bottom shelf and MOD D is the top shelf.

Table 4-3. RF Antenna Labels

Remote RF

Module

Shelf

MOD A Mod A TX0/RX0 Transmit RF power and primary receive to/from the antenna

MOD B Mod B TX0/RX0 Transmit RF power and primary receive to/from the antenna

MOD C Mod C TX0/RX0 Transmit RF power and primary receive to/from the antenna

MOD D Mod D TX0/RX0 Transmit RF power and primary receive to/from the antenna

RF Module Cable,

RF Module

Connector, and

Remote Antenna

Connector Labels

Mod A RX1 Diversity receive for RF power from the antenna for RF

Mod B RX1 Diversity receive for RF power from the antenna for RF

Mod C RX1 Diversity receive for RF power from the antenna for RF

Mod D RX1 Diversity receive for RF power from the antenna for RF

Function

for RF Module A

Module A

for RF Module B

Module B

for RF Module C

Module C

for RF Module D

Module D

Page 98 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 7

Install the Remote

MOD N TX0/RX0

MOD N TRX1

In the following steps, the RF cables and connectors are referred to as

and as

where N equals A,B,C, or D.

55 Unpack and inspect the RF Module as described in “Unpack and Inspect the

Remote and Components” on page 97.

Handle the RF Module with care during installation. Be especially careful to not damage

the thermal- i

the LPA can ov erheat. B

material is gouged or cracked. If the TI

contact ADC for assistance (see “Contacting ADC” on page 335 for contact informat

If the thermal- interface material is damaged, the installation and use of the RF Module

may void the

nterface material (TIM), which is attached to the LPA. If the TIM is damaged,

efore installing the RF Module, check to see if the heatsink

M is damaged, do not install the R F Module and

ion).

warranty of the RF Module.

66 Open the Remote enclosure.

77 Remove release liners, if present, from the thermal pads on the RF Module prior

to installing the module into the Remote chassis.

The thermal pads are very sensitive to mishandling—do not nick, scratch, or ding them.

Thermal pads are located as follows:

•• one large pad on the back surface (LPA)

•• up to two on the front surface (DARTs)

•• two on the left side for the (RDI).

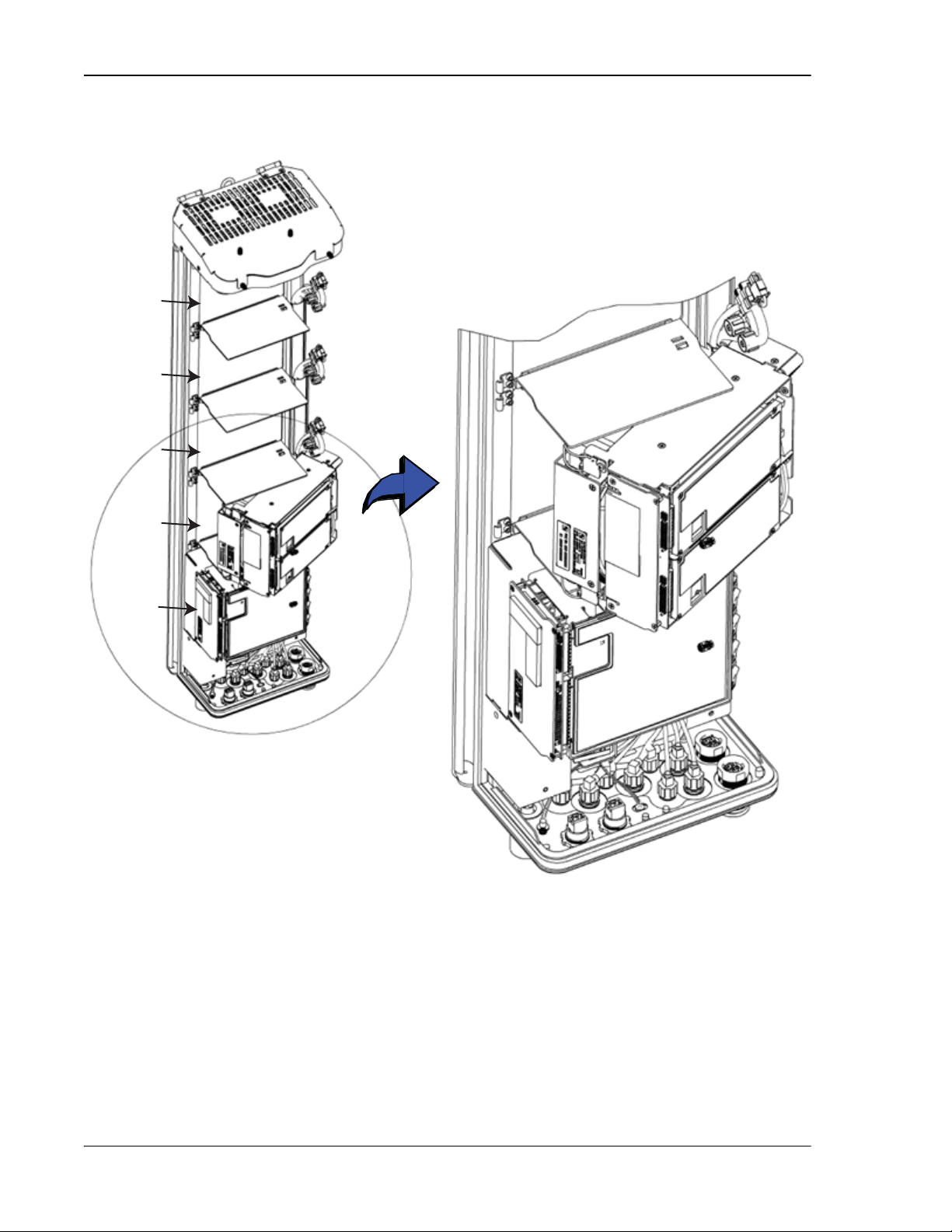

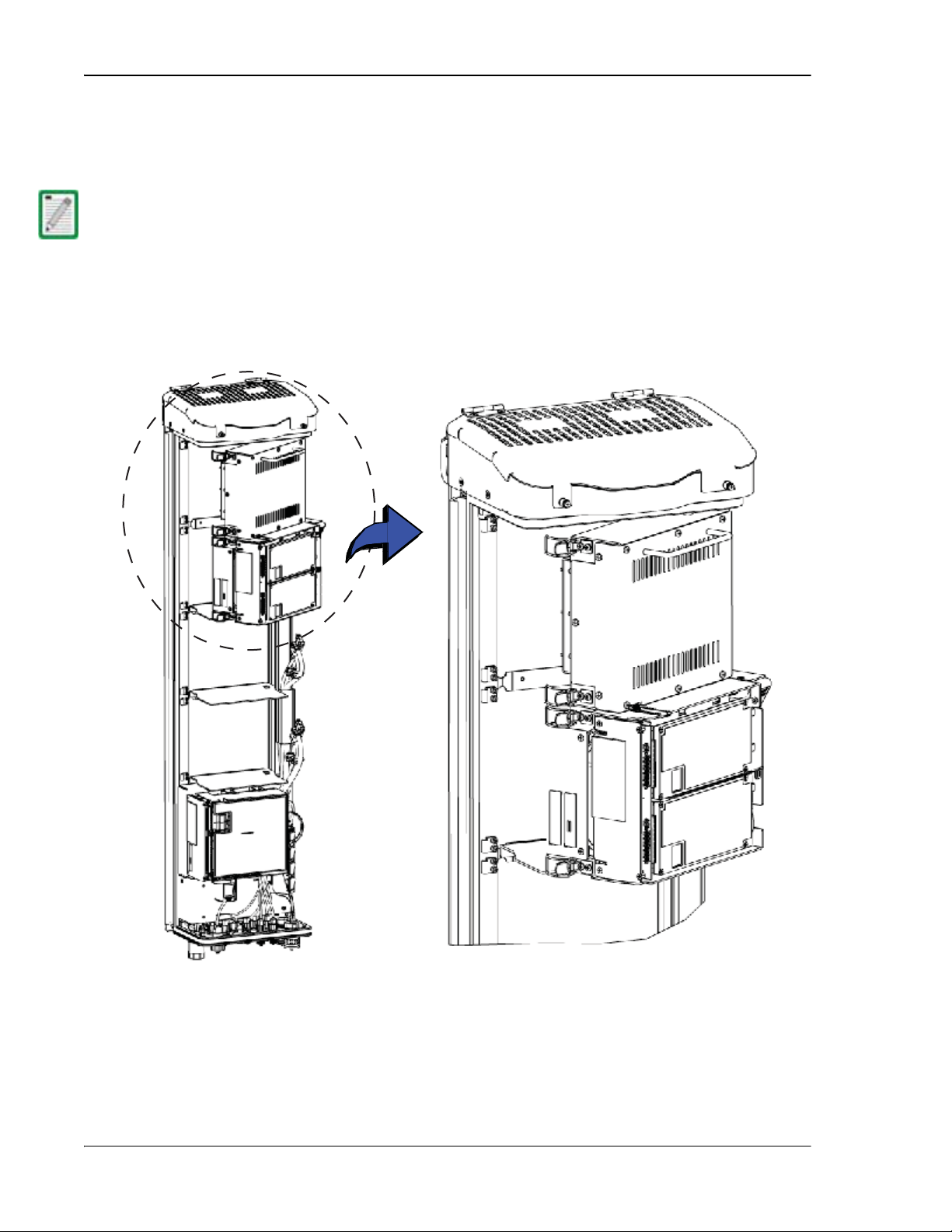

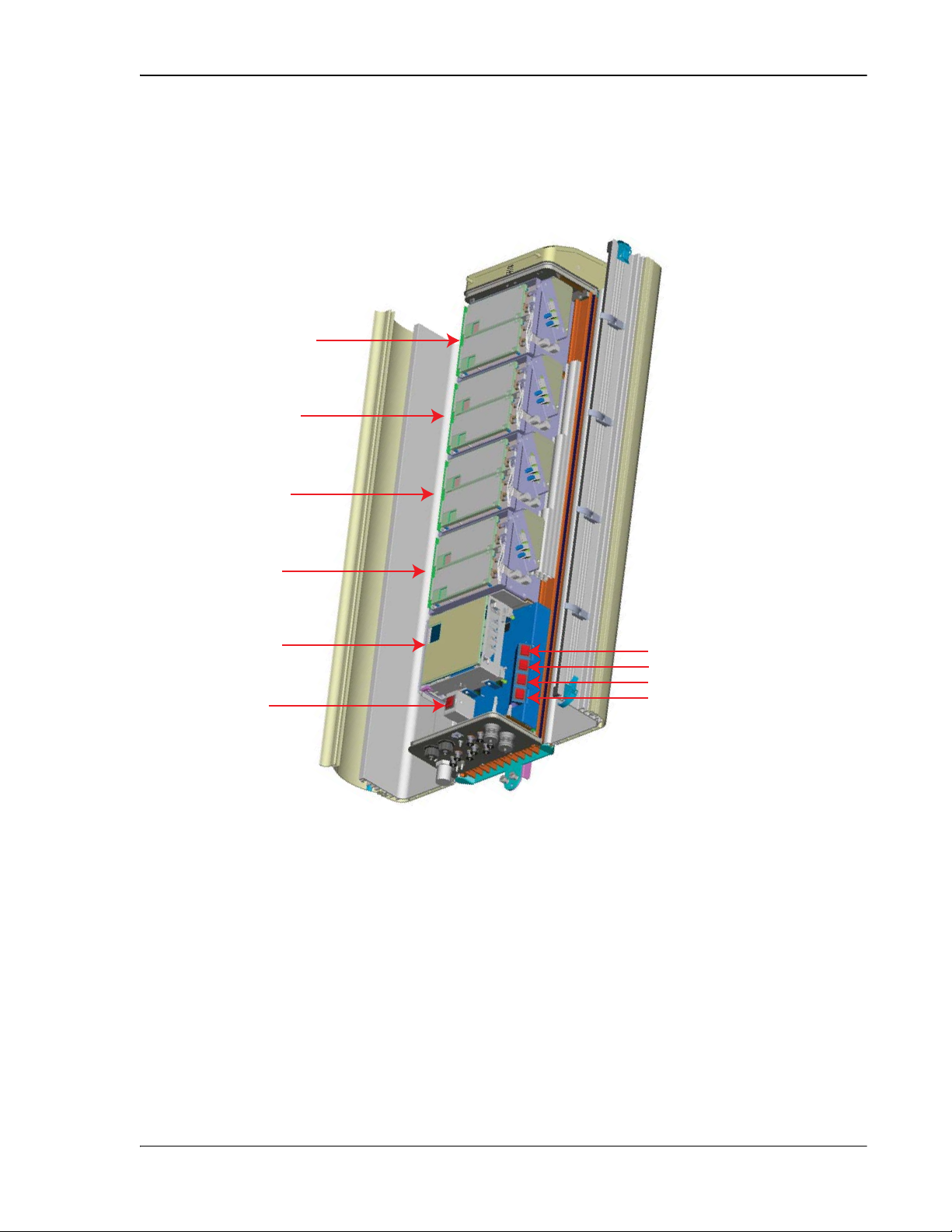

88 Hold the RF Module so that the DART card(s) face away from the Remote and the

Mounting Hook is toward the Receiving flange on the Remote chassis.

Alway s install RF Modules from the bottom up and do not skip a shelf.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 99

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 8

Installing the Remote Unit

SeRF Module

MOD A

MOD B

MOD C

MOD D

77073-040

99 Holding the RF Module at a 45° angle in respect to the rear heatsink, rest the

bottom surface of the module on the RF Module shelf.

Page 100 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 9

Install the Remote

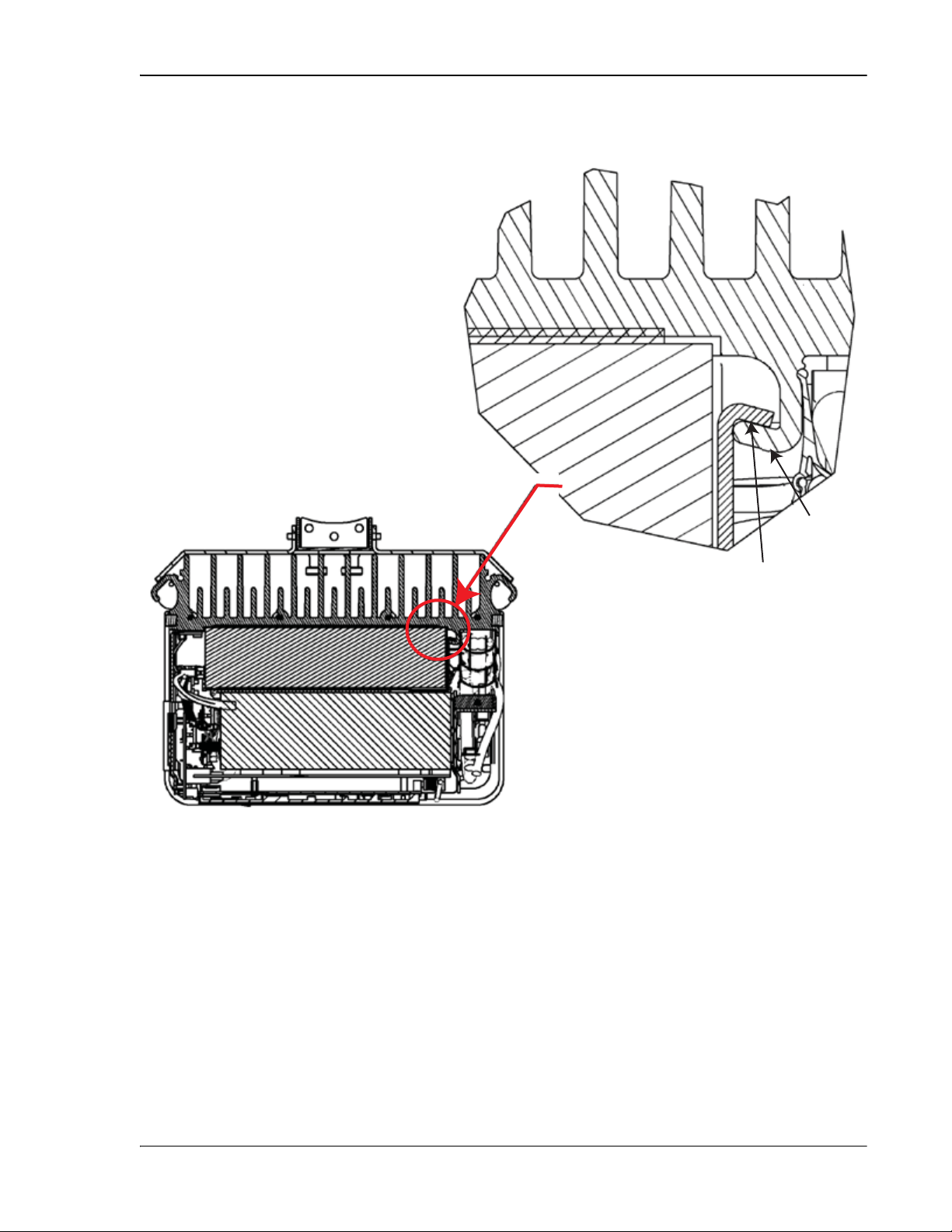

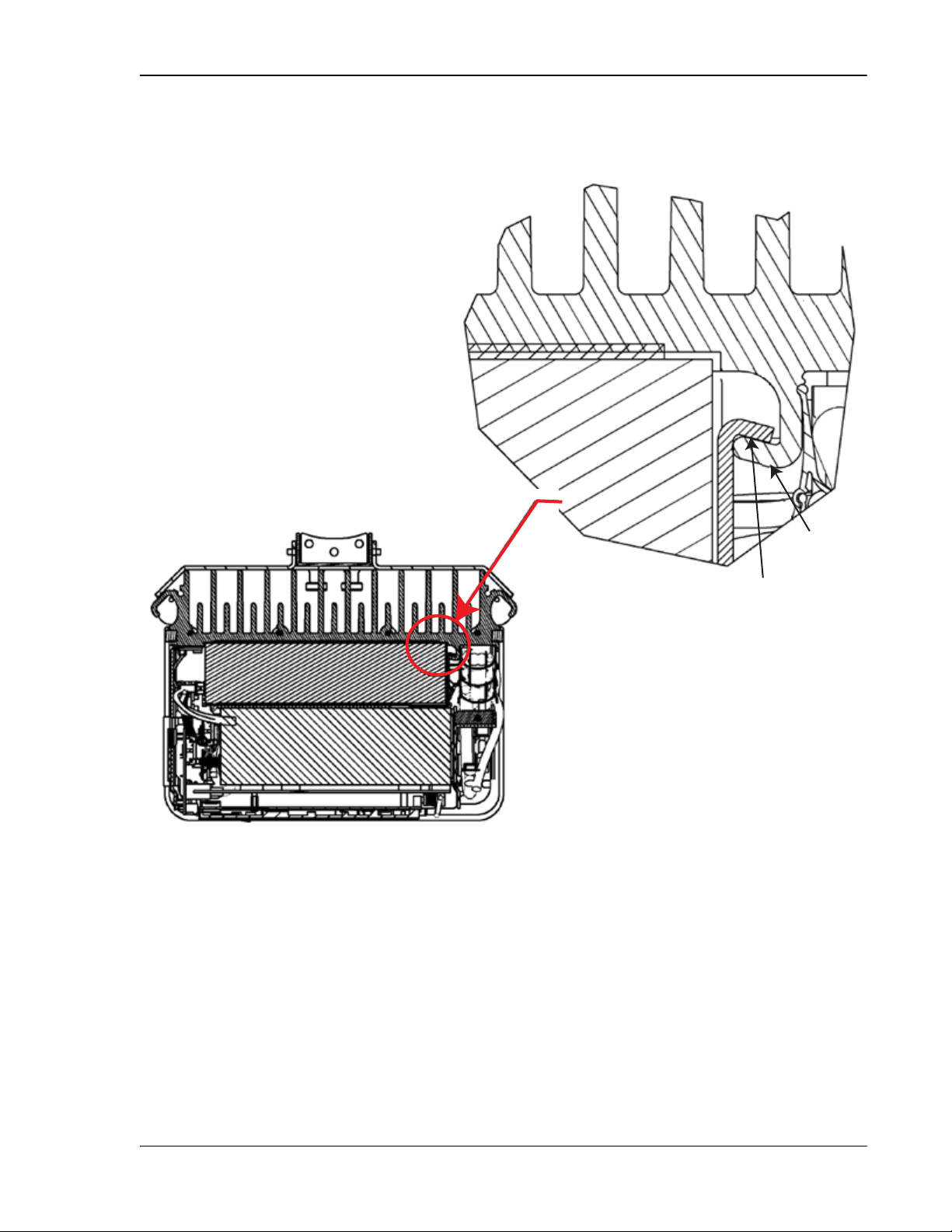

RF Module

Mounting hook

Chassis

Receiving

flange

77073-044

100 Aligning the mounting hook on the module with the receiving flange on the

Remote heat sink, and slide the RF Module in toward the flange until it can go no

further.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 101

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 10

Installing the Remote Unit

77073-045

111 Push the left edge of the RF Module back and into the Remote chassis until it can

go no further.

Make sure the RF Module is seated correctly in the Module shelf. Incorrect alignment of

the RF Module

• The front edge of the RF Module should be parallel with the shelf above it.

• The Mounting hook on the RF Module should be fully engaged with the Receiving flange

on the Remote chassis.

• If you later cannot shut the Remote door, verify that the RF Module is installed

correctly.

can cause the RF Module to fail due to ov er heating.

Page 102 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 11

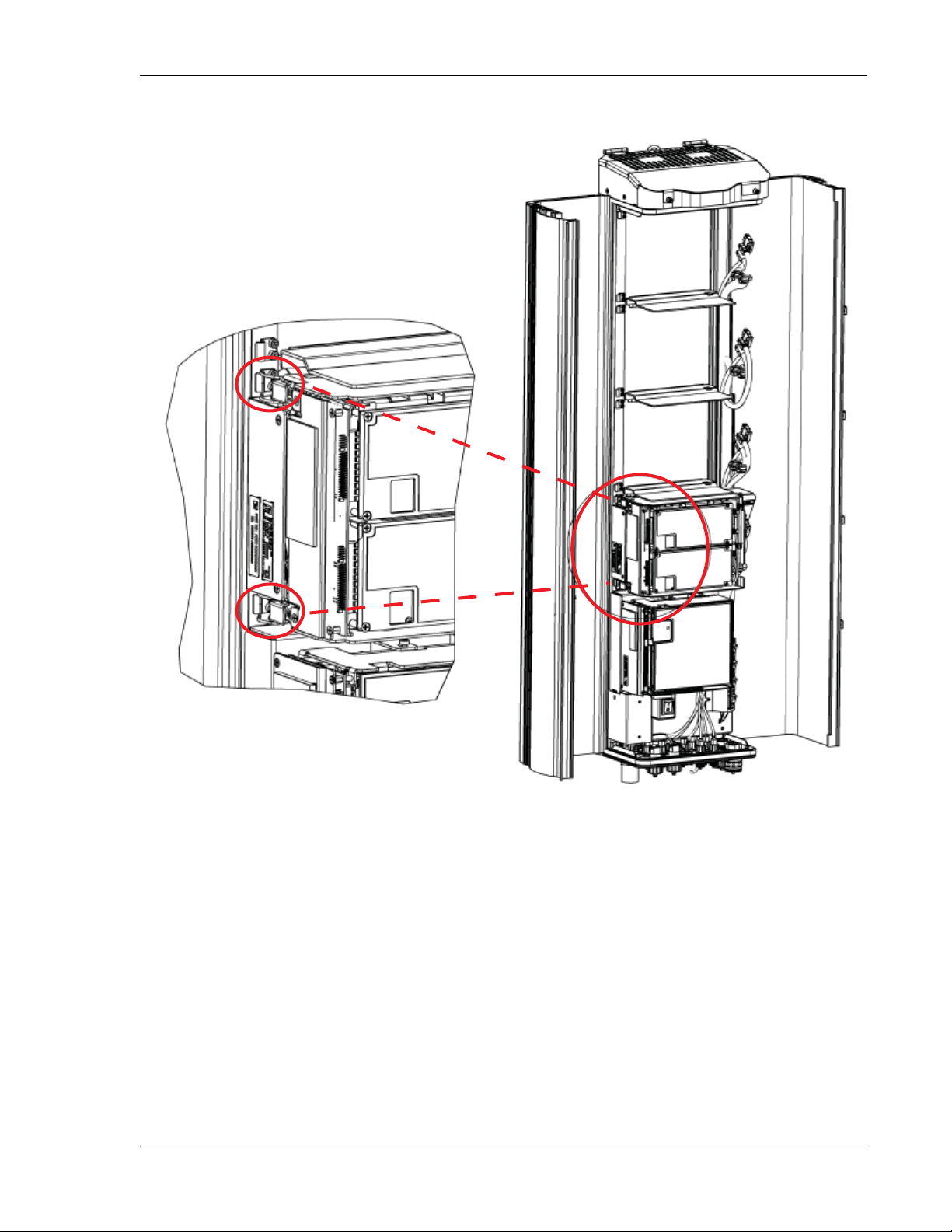

122 Secure the two module latches on the left side of the RF Module.

77073-041

Install the Remote

133 Verify that the RF Module Mounting hook is engaged correctly by pulling the

module away from the heat sink. The RF Module should not move. If the RF

Module moves during this check, repeat Step 9 on page 100 through Step 12.

144 Position the cables so that are under the right edge of the RF Module, pointing up.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 103

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 12

Installing the Remote Unit

MOD

N

TX0/RX0

DIV

MOD N TX0/RX0

MOD N RX1

PRIM

DIV

RF TX0/RX0

MOD N RX1

RX1

MOD N TX0/RX0

TX0/RX0

MOD N DIV

DIV

MOD N PRIM

PRIM

PWR

155 Follow these rules when connecting the RF Module cables:

•• At each RF Module shelf, the Power (PWR) cable and two high-speed-data

cables will always be provided.

•• If you are installing a Non-Diversity Chassis, only one RF cable labeled

•• Always connect the high-speed-data cable labeled

will be populated.

. This protects against

the cable getting caught in the chassis door.

•• If you are installing a Diversity Chassis, both RF cables labeled

and

will be populated.

•• For Diversity modules, all cables are to be connected.

•• If you order a Non-Diversity RF Module and are installing it in a Diversity

chassis, connect it as if it was being installed into a Non-Diversity chassis.

•• When you order a Dual SuperDART module, connect both high-speed data

cables (

and

) and the

cable.

•• Adhere to a minimum bend radius of 1" for all RF cables from the integrated

cable guide to the module.

•• Maintain adequate strain relief distances from connection points to the

module.

166 Working from the bottom connector up, connect the RF Module cables.

aa If this is a Diversity chassis, connect the RF Diversity cable labeled

to the

connector and turn the thumbscrew to secure the cable to the

chassis.

bb Connect the RF cable labeled

to the

connector and

turn the thumbscrew to secure the cable to the chassis.

cc Connect the

high-speed-data cable to the

connector. This

connects the Remote SeRF interface board (RSI) to the Diversity DART.

Alway s connect the Diversity high- speed- data cable, even for non- diversity modules.

This prevents the

Module.

dd Connect the

cable from getting caught betw een the chassis door and the RF

high-speed cable to the

connector. This connects

the RSI to the Primary DART.

ee Connect the Power cable to the

connector. This connects the RF Module to

the DC power connection.

Page 104 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 13

MOD D

MOD C

MOD B

Install the Remote

PWR

PRIM

DIV

TX0/RX0

RX1

MOD A

SeRF

Module

Note routing of

high-speed cables

Note bend

radii ≥ 1-inch

77073-043

Edge of Connector Interface Panel

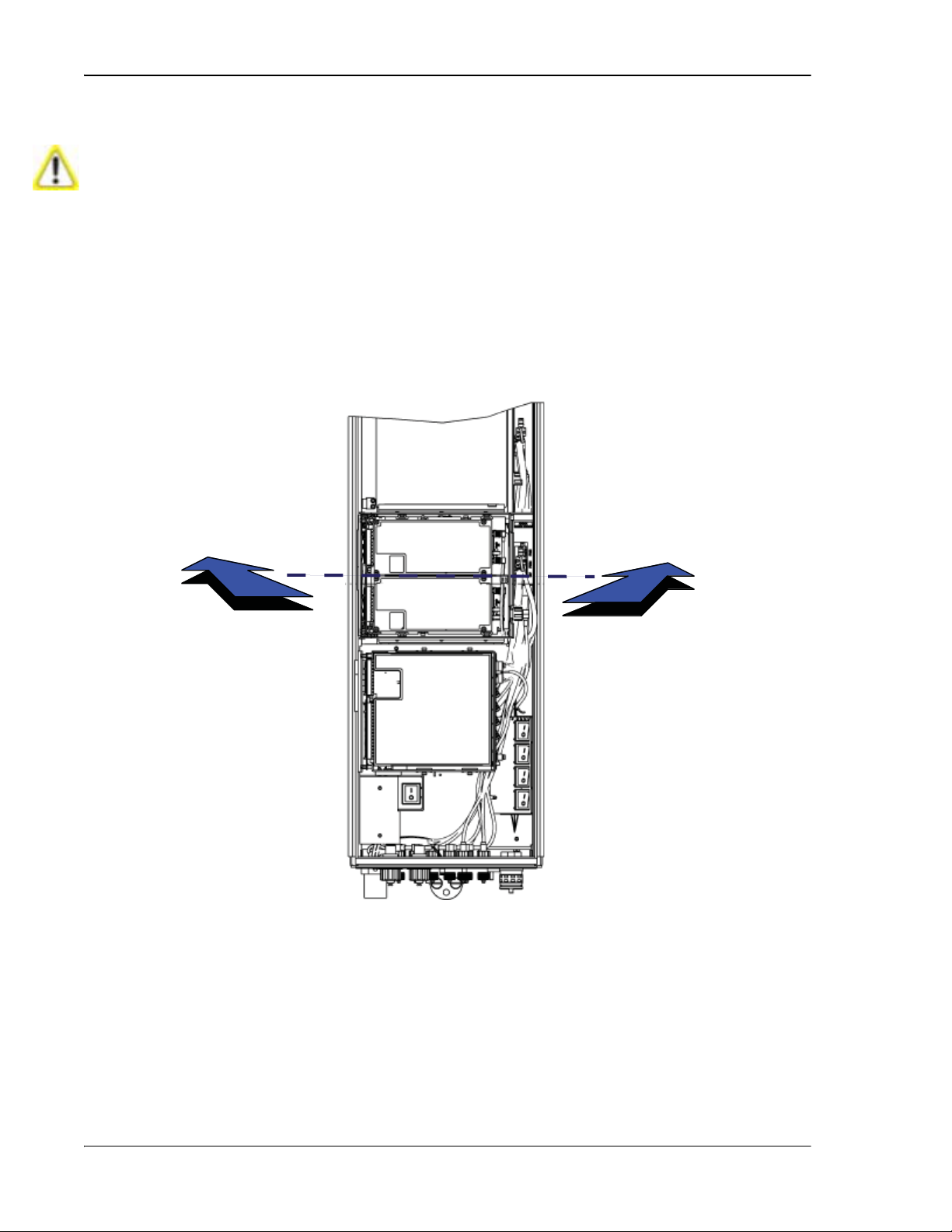

177 Ensure that all cable bends are below the top edge of the Connector Interface

Panel as indicated by the dashed line in the preceding figure. Failure to correctly

position the cables could inhibit closing the Remote door, which can result in

damage to the cables.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 105

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 14

Installing the Remote Unit

188 Toggle the Power switch that corresponds to the RF Module to its ON position.

MOD D

MOD C

MOD B

MOD A

SeRF

Module

AC Power

switch for

Remote

chassis

77073-048

DC Power switch for Mod D

DC Power switch for Mod C

DC Power switch for Mod B

DC Power switch for Mod A

199 Repeat Step 5 through Step 18 to install other RF Modules.

Page 106 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 15

Install any 40W RF Module(s)

4.4 INSTALL ANY 40W RF MODULE(S)

The 40W RF Modules can only be installed in the top most slots of the Remote:

• Slots A and B for a Dual-Band chassis.

• Slots B and C for a Tri-Band chassis

• Slots C and D for a Quad-Band chassis

The RF Module cables that are preinstalled in the Remote connect to the

corresponding connectors on the RF Module. The RF Module cables correlate to the

antenna connectors on the bottom of the Remote chassis. The cables and connectors

have corresponding labels as shown in Table 4-3. The RF cable and connector labels

also correspond to the RF Module slots in the Remote chassis, where MOD A is the

bottom shelf and MOD D is the top shelf.

Table 5. RF Antenna Labels for Dual-Slot Installations—From Top of Chassis Down

RF Module

Cable,

RF Module

Connector,

and Remote

Antenna

Connector

(a)

Labels

Mod D

TX0/RX0

Mod D RX1

Mod C

TX0/RX0

Mod C RX1

Mod B

TX0/RX0

Mod B RX1

Mod A

TX0/RX0

Mod A RX1

(a) For dual-slot installations, the RF cables and connectors are labeled as MOD N TX0/RX0 and MOD N TX1, where N refers to the bottom slot of the

double-slot installation. For example, for a dual-slot installation in a Quad-Band chassis, the RF cables and connectors are labeled as MOD C

TX0/RX0 and MOD C TX1.

Transmit RF power and primary receive

to/from the antenna for RF Module D

Diversity receive for RF power from the

antenna for RF Module D

Transmit RF power and primary receive

to/from the antenna for RF Module C

Diversity receive for RF power from the

antenna for RF Module C

Transmit RF power and primary receive

to/from the antenna for RF Module B

Diversity receive for RF power from the

antenna for RF Module B

Transmit RF power and primary receive

to/from the antenna for RF Module A

Diversity receive for RF power from the

antenna for RF Module A

Function

Single-Slot

Remote RF

Module Shelf

Designations

MOD D N/A N/A

MOD C N/A

MOD B

MOD A MOD A MOD A

Dual-Slot Remote RF Module Shelf Designations

Dual-Band Tri-Band Quad-Band

MOD C

MOD B

MOD B

MOD A

NOTE: In the following steps, the RF cables and connectors are referred to as MOD N TX0/RX0

and as MOD N TRX1 where N equals A, B, C, or D.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 107

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 16

Installing the Remote Unit

4.4.1 Prepare the Remote and RF Module

1 Unpack and inspect the RF Module as described in “Unpack and Inspect the

Remote and Components” on page 97.

Handle the RF Module with care during installation. Be especially careful to not damage the thermal-interface

material (TIM), which is attached to the LPA. If the TIM is damaged, the LPA can overheat. Before installing the

RF Module, check to see if the heatsink material is gouged or cracked. If the TIM is damaged, do not install the

RF Module and contact ADC for assistance (see “Contacting ADC” on page 335 for contact information).

If the thermal-interface material is damaged, the installation and use of the RF Module may void the warranty

of the RF Module.

2 Open the Remote enclosure.

3 Remove release liners, if present, from the thermal pads on the RF Module prior

to installing the module into the Remote chassis.

CAUTION! The thermal pads are very sensitive to mishandling—do not nick, scratch, or ding them.

Thermal pads are located as follows:

• one large pad on the back surface (LPA)

• up to two on the front surface (DARTs)

• one on the left side for the (RDI).

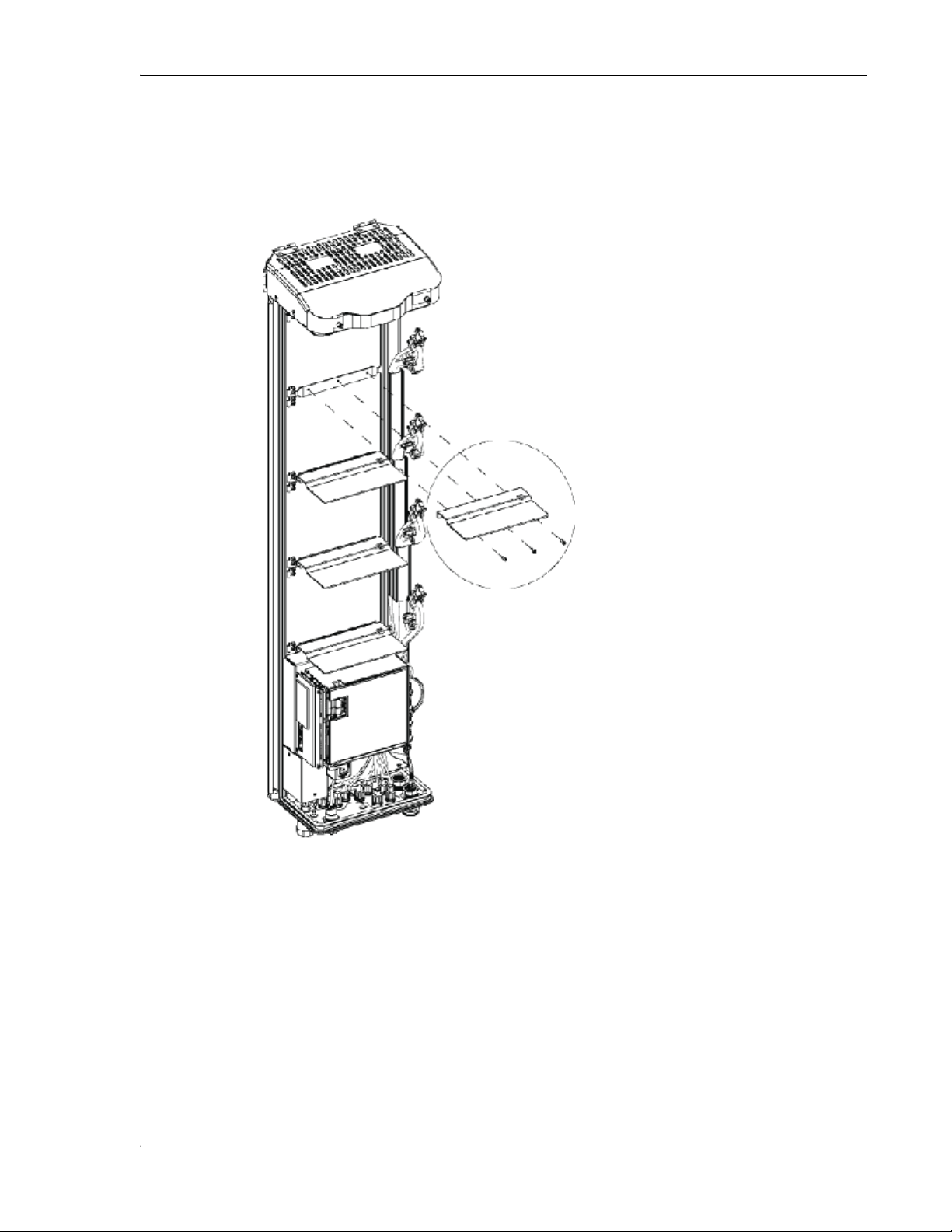

4.4.2 Remove Module Shelf(s)

The module shelf for the upper module as defined in Table 4-3 on page 98 must

be removed prior to installation of the dual-slot module:

• Module D Shelf for a Quad-Band chassis

• Module C Shelf for a Tri-Band chassis

• Module B Shelf for a Dual-Band chassis

Page 108 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 17

4 Remove the module shelf:

a Use a 9/64” Allen

™

wrench to remove the three screws that attach the

module shelf to the Remote chassis, as shown in the following graphic.

b Discard or store the module shelf and fasteners.

Install any 40W RF Module(s)

77072-003

Use 9/64” Allen wrench to

remove the three Module Shelf screws

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 109

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 18

Installing the Remote Unit

4.4.3 Install the 40W RF Module

11 Hold the RF Module so that the DART card(s) face away from the Remote and the

Mounting Hook is toward the Receiving flange on the Remote chassis.

Always install RF Modules from the bottom up and do not skip a shelf.

22 Holding the RF Module at a 45° angle in respect to the rear heatsink, rest the

bottom surface of the module on the RF Module shelf, as shown below:

Installing a dual-slot RF Module

77072-004

Page 110 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 19

Install any 40W RF Module(s)

RF Module

Mounting hook

Chassis

Receiving

flange

77073-044

3 Aligning the mounting hook on the module with the receiving flange on the

Remote heat sink, and slide the RF Module in toward the flange until it can go

no further.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 111

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 20

Installing the Remote Unit

77072-008

In Steps 9 and 10, you engaged the right side of the RF Module with the Remote chassis.

In Step 11, you set the left edge of the RF Module into the Remote chassis.

By the end of Step 11, the front edge of the RF Module should be parallel with the shelf above it.

Now in Step 12, you are pushing the RF Module back into the chassis until it can go no further.

4 Push the left edge of the RF Module back and into the Remote chassis until it

can go no further.

Make sure the RF Module is seated correctly in the Module shelf. Incorrect alignment of the RF Module can

cause the RF Module to fail due to over heating.

• The front edge of the RF Module should be parallel with the shelf above it.

• The Mounting hook on the RF Module should be fully engaged with the Receiving flange on the Remote

chassis.

• If you later cannot shut the Remote door, verify that the RF Module is installed correctly.

Page 112 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 21

Install any 40W RF Module(s)

5 Secure the four module latches on the left side of the RF Module.

6 Verify that the RF Module Mounting hook is engaged correctly by pulling the

module away from the heat sink. The RF Module should not move. If the RF

Module moves during this check, repeat Step 9 on page 100 through Step 12.

7 Position the cables so that are under the right edge of the RF Module, pointing

up.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 113

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 22

Installing the Remote Unit

8 Follow these rules when connecting the RF Module cables:

• At each RF Module shelf, the Power (PWR) cable and two high-speed-data

cables will always be provided.

• If you are installing a module into a Non-Diversity Chassis, only one RF

cable labeled MOD N TX0/RX0 will be populated.

• High-speed data cables labeled PRIM and DIV should always either be

connected or strain relieved to adjacent cables. This protects against the

cable getting caught in the chassis door.

• If you order a Non-Diversity RF Module and are installing it in a Diversity

chassis, connect it as if it was being installed into a Non-Diversity chassis.

• Connect both high-speed data cables (PRIM and DIV) and the RF TX0/RX0

cable.

• Adhere to a minimum bend radius of 1" for all RF cables from the integrated

cable guide to the module.

• Maintain adequate strain relief distances from connection points to the

module.

• When installing dual-slot RF modules:

– The upper RF Module shelf will either not be present (factory installed

module) or will be removed prior to installation (field installed module).

– For dual-slot modules, only the RF cable labeled MOD N TX0/RX0 on the

lower module slot will be connected to the module connector TX0/RX0.

–The MOD N RX1 cable should be secured to the cable bundle using the

provided cable tie.

– Ensure that the MOD N RX1 cable and connector are secured so that they

will not be pinched or prevent the Remote door from closing.

– The Power (PWR) cable and two high-speed-data cables of the upper RF

Module slot will not be used. Connect the RF cable labeled MOD N RX1 to

the connector labeled N/C on the upper half of the double-slot module.

Use one of the provided cable ties to secure the MOD N TX0/RX0 RF cable,

both high-speed data cables and the Power (PWR) cable to the RF cable

labeled MOD N RX1, ensuring that the cable bundle will not be pinched or

prevent the Remote door from closing.

Page 114 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 23

Install any 40W RF Module(s)

9 Working from the bottom connector up, connect the RF Module cables.

a Connect the RF cable labeled MOD N TX0/RX0 to the TX0/RX0 connector and turn

the thumbscrew to secure the cable to the chassis.

Always connect the Diversity high-speed-data cable, even for non-diversity modules. This prevents the cable

from getting caught between the chassis door and the RF Module.

b Connect the MOD N PRIM high-speed cable to the PRIM connector. This

connects the RSI to the Primary DART.

c Connect the Power cable to the PWR connector. This connects the RF Module

to the DC power connection.

d The Power (PWR) cable and two high-speed-data cables of the upper RF

Module shelf are not be used in a dual-slot installation. Connect the RF cable

labeled MOD N RX1 of the upper RF Module shelf to the connector labeled N/C

on the upper half of the dual-slot module. Use one of the provided cable

ties to secure the MOD N TX0/RX0 RF cable, both high-speed data cables and

the Power (PWR) cable to the RF cable labeled MOD N RX1, ensuring that the

cable bundle will not be pinched or prevent the Remote door from closing.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 115

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 24

Installing the Remote Unit

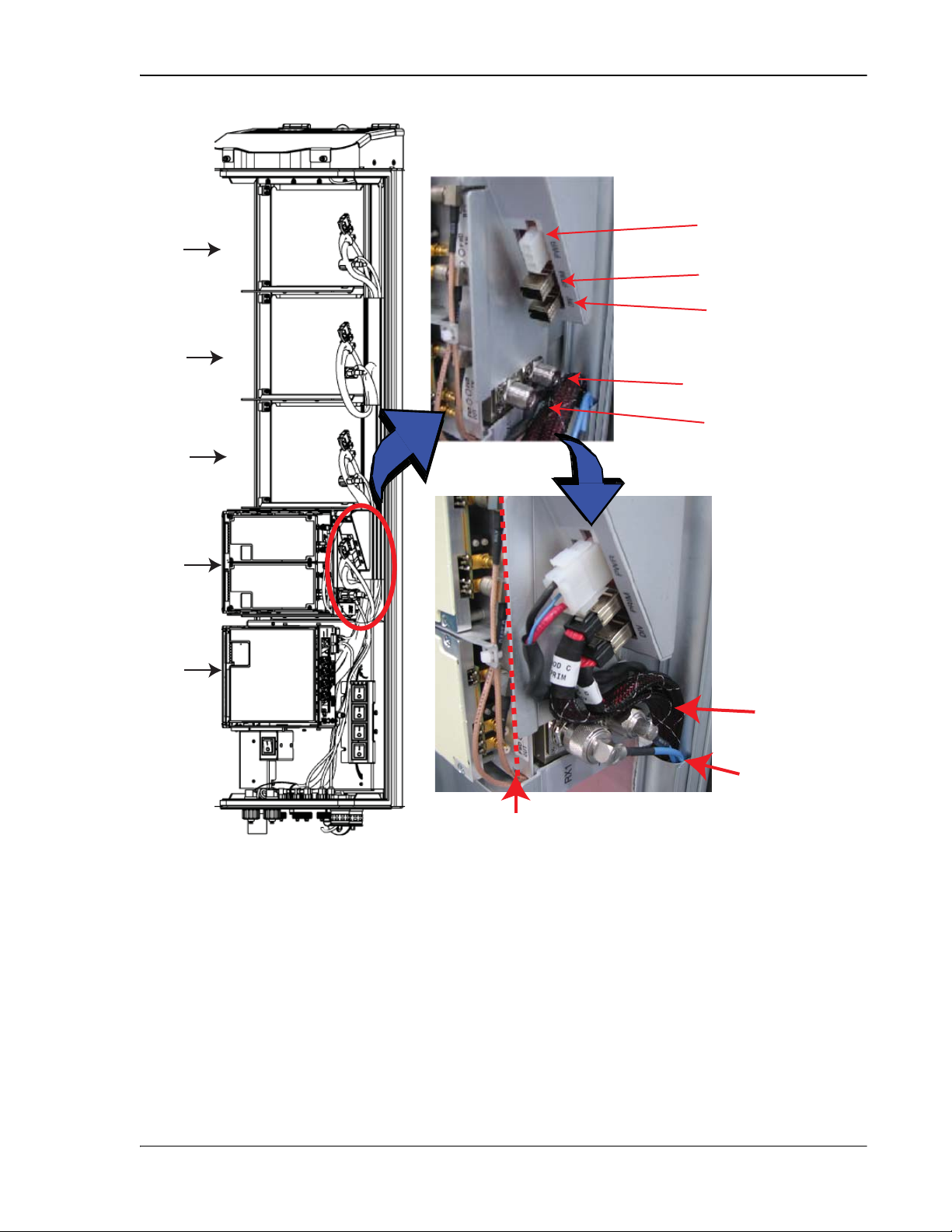

Cable connections

for a dual-slot RF Module

Tie wrap

Factory-installed

RX1 cable

77072-007

The following graphic shows cable connections for a dual-slot RF Module.

10 Ensure that all cable bends are below the top edge of the Connector Interface

Panel as indicated by the dashed line in the preceding figure. Failure to

correctly position the cables could inhibit closing the Remote door, which can

result in damage to the cables.

Page 116 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 25

Install any 40W RF Module(s)

MOD A

SeRF

Module

AC Power

switch for

Remote

chassis

DC Power switch for Mod A

DC Power switch for Mod B

DC Power switch for Mod C

DC Power switch for Mod D

MOD B

MOD C

MOD D

77079-002

For Dual-Card RF Modules, use the

Power switch for the lower module.

For example, to power up a

Dual-Card RF Module in combined

slots C+D in a Quad-Band chassis,

turn ON DC Power switch for Mod C;

leave the DC Power switch for Mod D OFF.

11 Toggle the Power switch that corresponds to the RF Module to its ON position.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 117

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 26

Installing the Remote Unit

4.4.4 Ground Wire Installation

Avoid sharp bends in the ground wire.

For proper and safe equipment operation, use a #6 copper wire terminated with the

provided ring termi

122 Locate a #6 AWG (4 mm) copper grounding wire long enough to reach an approved

earth ground.

133 Use a socket wrench with a 3/8-inch deep socket to remove the two 10-32 Keps

Nuts from the Remote’s Dual-Ground connector.

144 Secure the ring terminal end of the grounding wire to the ground studs on the unit

using the two 10-32 Keps Nuts removed in Step 13, and then torque the nuts to

18 in-lbs ± 1 in-lb.

155 Route the free end of the grounding wire to an approved earth ground source.

166 Cut the ground wire to length and connect it to the earth ground source as

specified by local code or practice.

nal to link the Remote to an earth- ground source.

Dual-Ground Connector

Ring Terminal

10-32 Keps Nut

Ground Wire

77073-014

To Earth Ground

Partial Bottom View

Page 118 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 27

Install any 40W RF Module(s)

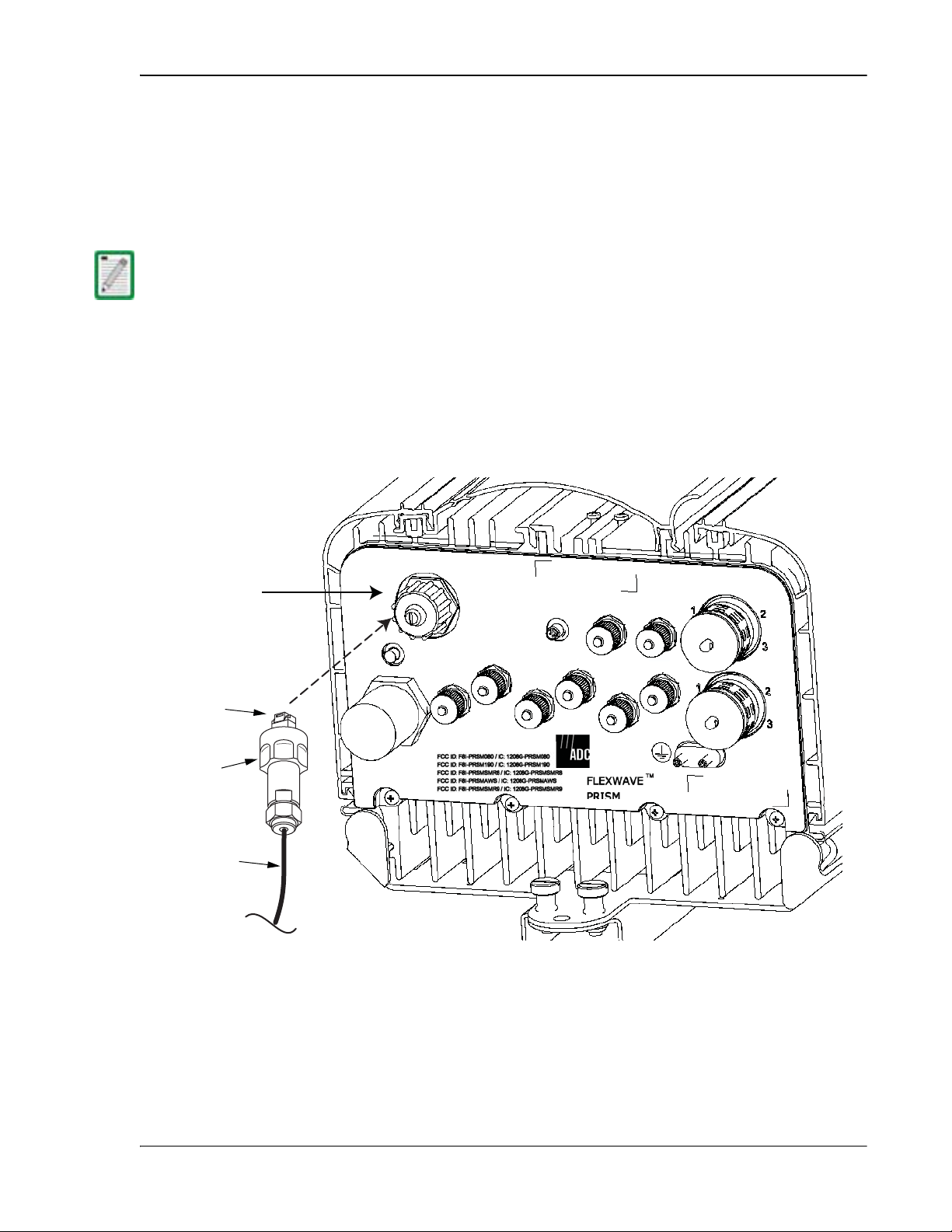

4.4.5 Network Cable Installation

The Remote provides a Network port allowing communications with the internal

processor and transfer of service data to the optical protocol allowing IP servicing

between the Host and Remote(s). That is, this provides a LAN extension to the Host

network. The Network port is 10/100/1000 BASE-T/TX (802.3ab compliant) MDI and

requires a minimum of CAT 5 cable.

Although the interface might provide GigE, only 100 Mbps is provided for bandwidth

between the Host a

The network cable must be terminated with a hardened RJ-45 male connector for

connection to the Network port. The maximum cable length is 300 feet (91.4 m).

Use the following procedure to install the Network cable:

177 Remove the dust cap from the RJ-45 connector located at the bottom of the

Remote.

nd Remote.

RJ-45 Network

Connector port

RJ-45 plug

Connector nut

Network cable

NETWORK

POWER

100-240 VAC

50-60 Hz

16 AMPS

MOD D

RX1

MOD D

TX0/RX0

MOD C

RX1

Bottom View

AUX.

MOD C

TX0/RX0

MOD A

RX1

MOD B

RX1

MOD A

TX0/RX0

MOD B

TX0/RX0

FIBER 1

FIBER 2

77073-010

188 Route the network cable from the network connection to the underside of the

Remote.

199 Align the plug end of the RJ-45 cable connector with the RJ-45 port receptacle and

then insert the cable plug into the port receptacle.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 119

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 28

Installing the Remote Unit

200 Slide the connector nut up to the port until it engages the connector locking

mechanism.

211 Tighten the connector nut in a clockwise direction (if necessary, use a wrench or

pliers to grip the connector nut) until it snaps past the indented position and

locks into place. It may be necessary to apply 30 to 50 in-lbs (3.4 to 5.6 Nm) of

torque to the connector nut in order to turn it past the indented position.

Page 120 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 29

Install any 40W RF Module(s)

NETWORK

AUX.

MOD A

RX1

MOD A

TX0/RX0

FIBER 1

FIBER 2

MOD B

TX0/RX0

MOD B

RX1

MOD C

TX0/RX0

MOD D

TX0/RX0

MOD C

RX1

MOD D

RX1

POWER

100-240 VAC

50-60 Hz

16 AMPS

77073-011

Fiber 2 is a

ProAx connector

that comprises

4 BX5 connectors.

Bottom View

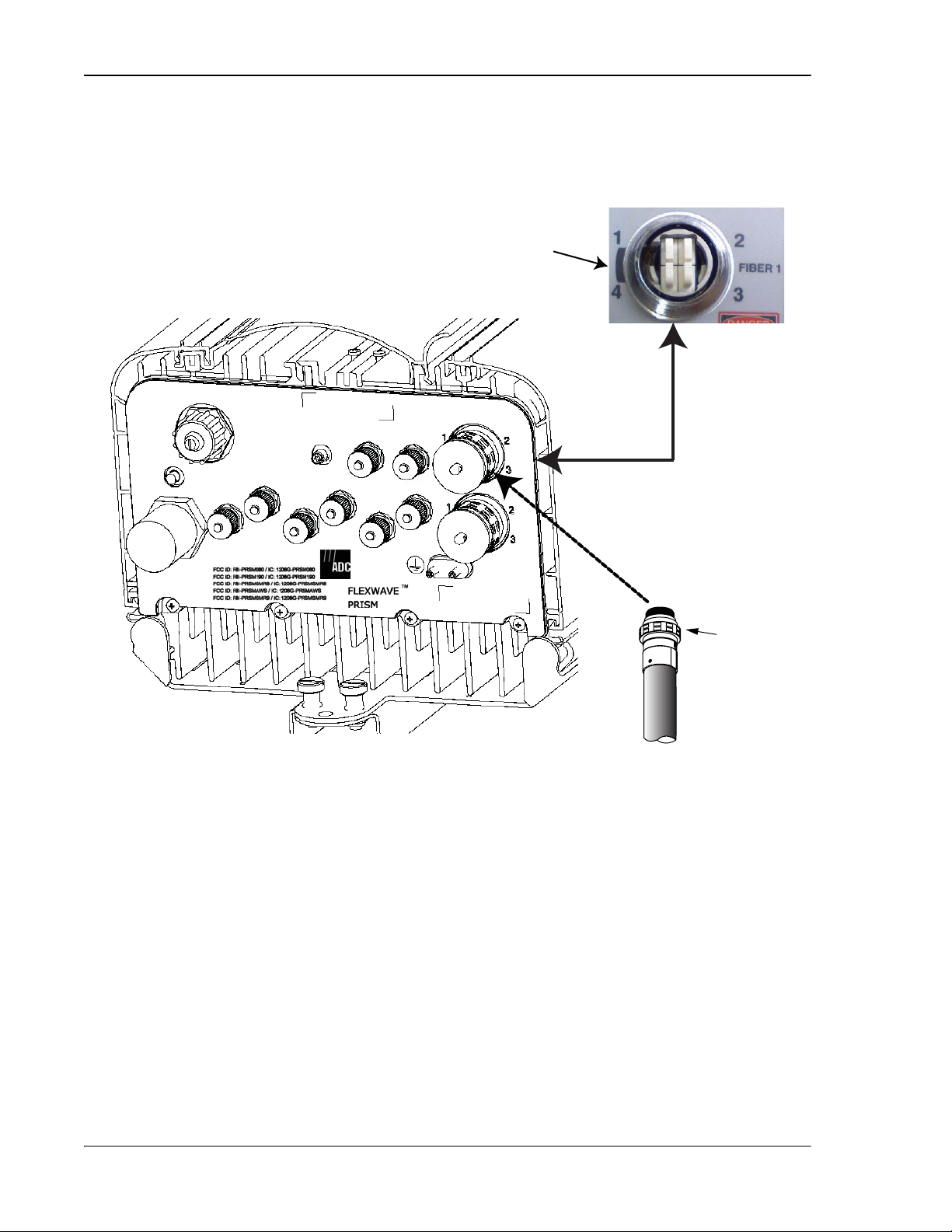

4.4.6 Quad Fiber Cable Installation

The Prism Remote ships with 10 meters of environmentally hardened cable with 1

meter of exposed, un-terminated single-mode 900μm optical fiber sufficient for

splicing in an Outside Plant (OSP) splice tray. The fiber cable connector is a BX5 4-port

fiber connector.

Use the following procedure to install the fiber cables:

222 Remove ProAx connector dust cover located at the bottom of the Remote.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 121

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 30

Installing the Remote Unit

NETWORK

AUX.

MOD A

RX1

MOD A

TX0/RX0

FIBER 1

FIBER 2

MOD B

TX0/RX0

MOD B

RX1

MOD C

TX0/RX0

MOD D

TX0/RX0

MOD C

RX1

MOD D

RX1

POWER

100-240 VAC

50-60 Hz

16 AMPS

BX5 CABLE

CONNECTOR

77073-012

Fiber 1 is a

ProAx connector

that comprises

4 BX5 connectors

Bottom View

Shaded area is the

Alignment Key for

the BX5 cable

connector

233 Remove the dust cap from the fiber cable BX5 connector (FIBER 1).

244 Align the plug end of the BX5 cable connector with the BX5 port receptacle and

then insert the cable plug into the port receptacle as shown below, and then slide

the strain relief boot over the connector.

Page 122 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 31

Install any 40W RF Module(s)

REV

Fiber 4

SFP2SFP2

77073=047

SFP3SFP3

FWD

Fiber 1

SFP1SFP1

FWD

Fiber 1

SFP1SFP1

REV

Fiber 2

SFP3SFP3

REV

Fiber 2

SFP2SFP2

FWD

Fiber 3

SFP4SFP4

FWD

Fiber 3

SFP4SFP4

REV

Fiber 4

255 Route the fiber cable from the underside of the Remote to the OSP box. Observe

the fiber numbers and their positions in the quad cable connector as shown

below. The fibers at the other end of the fiber cable are numbered with the same

numbering scheme.

266 Secure fiber cable in place following local practices.

277 If a second fiber cable assembly is required (for example, your Prism system has

three SFPs to handle up to 280 MHz of RF bandwidth), complete Step 22 through

Step 26 to add the second fiber cable assembly, only this time, connect to the

Fiber 2 ProAx connector located at the bottom of the Remote as shown in Step 22.

4.4.7 Antenna Cable Installation

Coaxial antenna cables must be routed from the antenna to the Prism Remote. The

cables must be terminated with an N-Type male connector for connection to the

Remote antenna port or the lightning surge suppressor (accessory).

To comply w ith Maximum Permissible E xposure (MPE) requirements, the maximum

composite output from the

must be permanently installed in a fixed locat

of separation from all persons.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 123

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

antenna cannot exceed 1640 Watts EIRP and the antenna

ion that provides at least 6 meters (20 feet)

Page 32

Installing the Remote Unit

Refer to Table 4-1 for the relationship between antenna numbers and Remote RF

modules.

Table 4-1. Antenna Connectors

Antenna

RF Module Function of Connection Point

Connector Label

2

Mod A TX0/RX0

RF Module A Transmit RF power and primary receive to/from the

antenna

Mod A RX1 RF Module A Diversity receive for RF power from the antenna

Mod B TX0/RX0 RF Module B Transmit RF power and primary receive to/from the

antenna

Mod B RX1 RF Module B Diversity receive for RF power from the antenna

Mod C TX0/RX0 RF Module C Transmit RF power and primary receive to/from the

antenna

Mod C RX1 RF Module C Diversity receive for RF power from the antenna

Mod D TX0/RX0 RF Module D Transmit RF power and primary receive to/from the

antenna

Mod D RX1 RF Module D Diversity receive for RF power from the antenna

2

Mod A/RF Module A is the bottommost Module in a Remote and Mod D/RF Module D is the

topmost module in a Quad-Band Remote.

Use the following procedure to install the antenna cable(s):

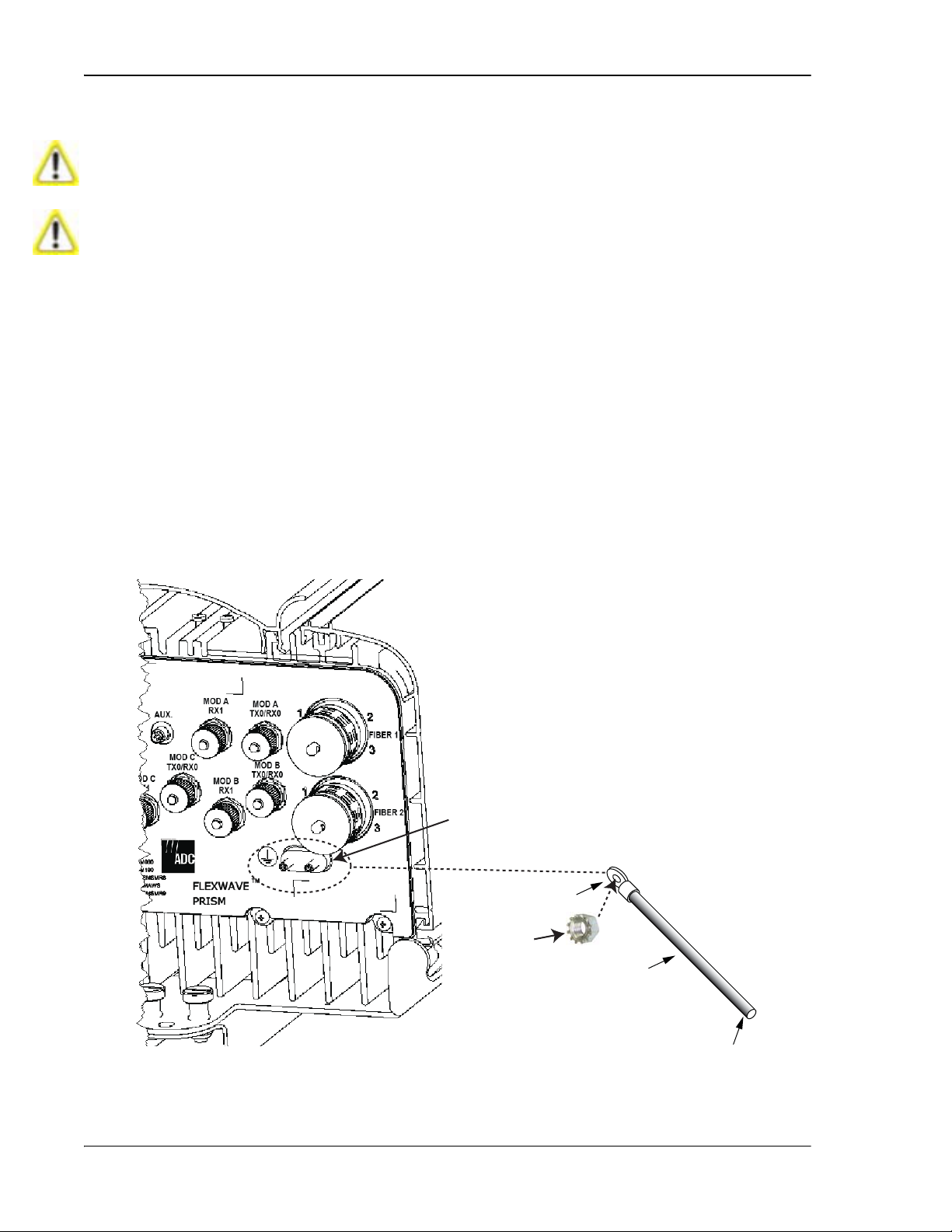

288 Remove the dust cap from the N-type female connector located on the underside

of the unit as shown below.

NETWORK

MOD D

POWER

100-240 VAC

50-60 Hz

16 AMPS

Bottom View

RX1

MOD D

TX0/RX0

MOD C

RX1

AUX.

MOD C

TX0/RX0

MOD A

RX1

MOD B

RX1

MOD A

TX0/RX0

MOD B

TX0/RX0

FIBER 1

FIBER 2

77073-013

N-type female

Antenna port

for Module A

Lightning

Surge Suppressor

(ships with RF Module)

Surge port

connector

Antenna

cable

Page 124 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 33

Install any 40W RF Module(s)

299 If specified, connect a lightning surge suppressor (accessory) to the antenna port.

300 Connect a ground wire to the lightning surge suppressor. Connect the ground wire

to an approved earth ground.

311 Route the coaxial antenna cable from the antenna to the underside of the Remote.

322 Cut the antenna cable to the required length and terminate with an N-type male

connector.

333 Connect the antenna cable to the lightning surge suppressor or to the antenna

port; apply 15 in-lbs (1.7 Nm) of torque.

The antenna cable connections must be weather proofed (sealed) for outdoor

installations.

344 Repeat the Step 28 through Step 33 for the remaining antenna cables.

4.4.8 AC Power Wiring Installation

A 15-foot, 3-wire cable with connectors is provided for the AC power connections.

The connector end of the cable connects to the AC power port located on the bottom

of the unit. The stub end of the cable must be routed to an external junction box (not

provided) for permanent connection to the AC power system wiring.

The AC power source must supply between 100 and 240 VAC, 50 or 60 Hz,

single-phase power through a circuit breaker or fuse. The AC power cable provides

three wire leads for line, neutral, and ground connections. The power cable is rated

for indoor or outdoor use and must not be placed within electrical conduit as this will

impede the cooling of the cable during usage. The electrical junction box and any

conduit, wire, and fittings required must be provided by the installer.

Use extreme caution when w orking with high voltage AC pow er. Ensure all power is

disconnected before

All electrical work must comply with local codes and requirements. A locally licensed

electrical cont

consult w ith the ADC Techn

ractor is best qualified to perform this w ork. For additional information,

working on pow er circuits.

ical Assistance Center (see “Contacting ADC” on page 335).

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 125

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 34

Installing the Remote Unit

Use the following procedure to install the AC power wiring:

355 Locate the AC power cable that is provided separately with the Remote.

366 Route the power cable between the AC power port, located on the underside of

the Remote and the nearest AC power junction box as shown below. It may be

necessary to install a new junction box if an existing junction box is not available.

Remote enclosure

AC power cable

AC power junction box

AC power wires routed

to circuit breaker panel

77073-071

377 Secure the cable between the AC power port and the AC power junction box per

local practice. Leave sufficient slack in the cable to allow it to be easily connected

and disconnected from the AC power port.

The pow er cable is rated for indoor or outdoor use and must not be placed within

electrical conduit a

run distance to the AC power sour

s this will impede the cooling of the cable during usage. The cable

ce must not exceed 100 feet.

388 Install any AC power supply wires that may be required between the AC junction

box and the AC circuit breaker box.

It is recommended that an AC outlet be installed near the Remote for powering tools

and test equipmen

An appropriate disconnect device, as well as branch circuit protection, must be provided

as part of t

he installation.

t. This outlet must include a GFCI device for protection.

Page 126 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 35

Install any 40W RF Module(s)

399 Connect the AC power cable wires to the AC power supply wires. Refer to the

following graphic to identify the color code and wire designations.

120 VAC CONNECTIONS

AC power cord

provided with Remote

Black

Green/Yellow

White

Line

Ground

Neutral

120 VAC power

wiring

240 VAC CONNECTIONS

AC power cord

provided with Remote

Connector Pin Designations

Pin 1 - Green/Yellow

Pin 2 - White

Pin 3 - Black

400 At the AC box, connect the AC power supply load wires to a circuit breaker or fuse.

For proper and safe equipment operation, an approved earth ground connection must

be provided and mai

ntained.

Black

Green/Yellow

White

Line 1

Ground

Line 2

240 VAC power

wiring

1

2

3

End view of

connector

77073-072

411 Connect the ground wire to an approved earth ground.

422 Place the circuit breaker in the ON position and then test the connector end of the

AC power cable for proper voltage levels and correct polarity.

433 When testing is complete, place the circuit breaker in the OFF position.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 127

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 36

Installing the Remote Unit

444 Remove the dust cap from the AC power port located on the bottom of the Remote

as shown below.

While trying to connect the AC power cable to the Remote AC power port, it is possible

for the line t

If the AC cable is energi

To avoid pos sible personal injury

before connecting the AC power cable to the AC po

erminal on the cable connector to contact the ground pin on the power port.

zed, this will res ult in a direct short to ground for the AC power.

and equipment damage, alw ays turn the AC pow er off

wer port.

NETWORK

MOD A

MOD C

TX0/RX0

RX1

MOD B

Green band will be

visible when coupling —

Nut is tightened

POWER

100-240 VAC

50-60 Hz

16 AMPS

MOD D

RX1

MOD D

TX0/RX0

MOD C

RX1

AUX.

Power

cable

Bottom View

455 Connect the power cable connector to the AC power port.

RX1

MOD A

TX0/RX0

MOD B

TX0/RX0

FIBER 1

FIBER 2

77073-015

466 Tighten coupling nut until the green band at the top of the connector body is

visible.

Page 128 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 37

Install any 40W RF Module(s)

Power module

AC switch

DC switches (4)

4.4.9 Determine the Circuit Breaker or Fuse for Remote

The Prism Remote supports power input from a 90 to 240 VAC power supply as

shown below.

4.4.9.1 Power Consumption

Do the following to determine the maximum power consumption, which determines

the circuit breaker or fuse to use.

477 Review the Remote order to determine the information listed below and then use

this information to find the power consumption from Table 4-2 and Table 4-3:

• RF bandwidth?

• DART type (Classic, Single SuperDART or Dual

SuperDART)

• Diversity or Non-Diversity?

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 129

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 38

Installing the Remote Unit

488 Enter the power consumption in the spaces provided below.

499 For the total RF Module power consumption, calculate the power consumption

from Table 4-3 on page 131 for each RF Module present in the Remote (RF Module

A - D), add the Watts, and then enter the total in the Total Power Consumption

field.

SeRF Module power consumption from Table 4-2 _________Watts

Additional SFPs _____ x 1.25W _________Watts

RF Module A power consumption from Table 4-3 _________Watts

RF Module B power consumption from Table 4-3 _________Watts

RF Module C power consumption from Table 4-3 _________Watts

RF Module D power consumption from Table 4-3 _________Watts

TOTAL POWER CONSUMPTION

_________Watts

500 Divide the total Watts by the input Voltage to determine the current (Amperes)

requirements.

Watts

= Amps

Volts

511 Determine the circuit breaker or fuse size based on local codes and practices.

Circuit breaker or fuse size must be 20 Amps or less.

Page 130 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 39

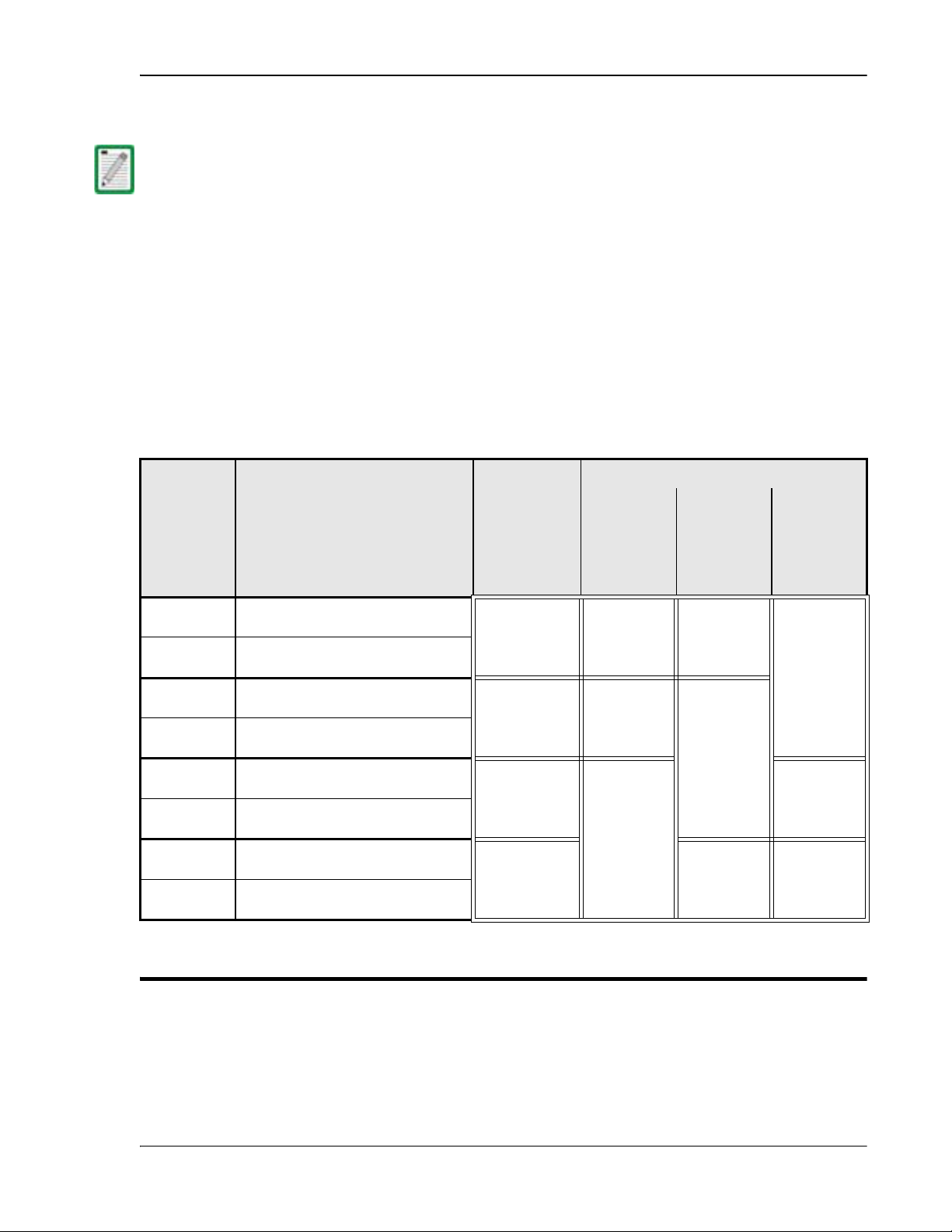

4.4.9.2 Power Consumption Tables

Table 4-2. SeRF Module Power Consumption

Install any 40W RF Module(s)

Single or Dual

SuperDART

RF Module

Classic DART

RF Module

SeRF Module

SeRF Module (1 SFP)

[add 1.25W for each SFP

added]

Power Consumption per Module

Nominal (W) @ 25C Maximum (W)

36 38

Table 4-3. RF Module Power Consumption

Power Consumption per Module

Prism RF Module Description

10W GSM900

15.8W GSM1800 Non-Diversity 299 337

15.8W UMTS Non-Diversity 285 350

20W PCS or 20W AWS Non-Diversity 299 368

20W PCS or 20W AWS

6.5W CELL or

6.5W ESMR

20W CELL

Non-Diversity 299 337

Diversity 321 359

Non-Diversity 292 358

Diversity 314 381

Non-Diversity 195 196

Diversity 218 220

Non-Diversity 271 327

Diversity 293 350

Nominal (W)@

25C

Maximum (W)

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 131

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 40

Installing the Remote Unit

SeRF

Module

AC Power

switch for

Remote

chassis

77073-049

4.4.10 Mount the Remote and Power Up

522 Refer to the detailed instructions for mounting the FlexWave Prism Remote in the

Remote Unit Mounting Kit Installation Instructions (ADCP-77-077) to mount the

Remote in the location selected in Section 4.2, Remote Mounting Plans, on page

96.

533 Power up the Remote by turning its AC power switch to On.

544 Close and tightly secure the Remote door and Solar Shield.

Page 132 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 41

PART III

SYSTEM SETUP AND MANAGEMENT

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 133

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 42

Intentionally Blank Page

Page 134 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 43

5

FLEXWAVE ELEMENT MANAGEMENT SYSTEM

Content Page

5.1 FlexWave EMS Overview ...................................................................................136

5.2 EMS Graphical User Interface.............................................................................138

5.3 Product Identity ...............................................................................................139

5.4 EMS Menu Bar .................................................................................................140

5.5 EMS Alarm Indications ......................................................................................141

5.6 EMS System Requirements ................................................................................142

This chapter introduces the ADC FlexWave Prism Element Management System (EMS).

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 135

ADCP-77-073 • Issue 2 • 11/2009 ©2009 ADC Telecommunications, Inc.

Page 44

FlexWave Element Management System

5.1 FLEXWAVE EMS OVERVIEW

The ADC FlexWave EMS is an embedded software application that is accessed through

an internet connection using a Web browser and provides a Graphical User Interface

(GUI) for control and monitoring of a Prism system.

WEB

IP

EMS

IP

Windows 2000 or Windows XP

computer running

Internet Explorer 6.0

REMOTE

UP TO 8

HOST

REMOTE

77073-020

Figure 5-1. Typica l Fl exWa ve Pris m Sy ste m

Page 136 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 45

FlexWave EMS Overview

As shown in Figure 5-2, you access the embedded EMS through the Host, where RF

signals are converted to optical signals for distribution to the local coverage area. The

EMS is thus in a position to monitor both types of signals, and to report status,

alarms, and RF signal levels through automatic, periodic updates and in response to

user requests. User requests can include commands to set RF gain and propagation

delay.

BTSs

User

Requests

Status

Alarms

RF Signal Levels

RFRF

OPTICAL

HOST

with

Embedded

Element

Management

System

WDM

(Optional)

FlexWave

REMOTE

Figure 5-2. The Function of the EMS

Antennas

77073-021

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 137

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 46

FlexWave Element Management System

5.2 EMS GRAPHICAL USER INTERFACE

Before you start using the EMS, familiarize yourself with its components.

You use a Web browser to access the EMS Graphical User Interface (GUI). A typical

display consists of the two frames shown in Figure 5-3.

•• Function Explorer Tree—appears in the left frame. Click on a node to open the

corresponding screen.

•• EMS View Frame—appears in the right frame. A typical page contains alarm

indicators, lists of parameter values, and tools such as lists and text boxes that

allow you to set parameter values.

The EMS View Frame includes the EMS Menu bar, which provides access to EMS

configuration or summary windows. For further information on the EMS Menu

bar, see “EMS Menu Bar” on page 140.

Figure 5-3. EMS Screen Example

Page 138 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 47

Product Identity

ADC FlexWave™ Prism&URH

ADC FlexWave™ Prism&URH

ADC FlexWave™ Prism&URH on Host

ADC FlexWave™ Prism Remote Unit

ADC FlexWave™ URH Remote Unit

5.3 PRODUCT IDENTITY

The FlexWave Prism system comprises a mix of URH Hosts and Prism Remotes. The

system components are therefore identified as follows in the EMS:

•• Login screens—

•• Summary views—

•• Host views—

•• Remote views refer to the Remote type:

–A

–A

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 139

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 48

FlexWave Element Management System

Configuration

Active Alarm List

Alarm

Management

System

Inventory

Help

About

Logout

5.4 EMS MENU BAR

The EMS Menu bar links (Figure 5-4) perform as described in Table 5-1.

Figure 5-4. EMS Menu Bar

Table 5-1. EMS Menu Bar Links

Link Function

Opens the General Configuration window from which you set system Auto

refresh. See “Setting Auto Refresh” on page 179.

Opens the Activ e Alarm List window, which is a means to determine alarm

type, Host unit name, Remote name, time stamp, and other information for

active alarms. See

List window provides a link to the History Log (see “Viewing an Alarm History

Log” on page 259).

Opens the Alarm Management Table, from which you can mask and unmask

alarms. See “Masking an Alarm Type” on page 260 or “Unmasking an Alarm

Type” on page 262.

Opens the System Inventory view, which identifies the main software and

hardware components of the current, working system. See “Working with the

System Inventory” on page 180.

Opens the EMS online help system that provides a description for each node

in the Function Explorer Tree. To access a specific help topic, click on the

appropriate link. (The Help: Overview topic is the default topic.)

Opens a window that provides the software-release version of the EMS, and

copyright and trademark information.

Logs you out of the EMS.

“Viewing Active Alarms” on page 258. The Active Alarm

Page 140 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 49

EMS Alarm Indications

5.5 EMS ALARM INDICATIONS

Some EMS parameter values are associated with alarms. When a parameter enters an

alarm state, an alarm status indicator is activated where the color of the indicates the

alarm severity (Figure 5-5):

•• Red status indicator—major alarm

•• Yellow status indicator—minor alarm

•• Green status indicator—normal (okay) state

•• White status indicator—a device or component is not communicating, but is in the

EMS database

•• Grey status indicator—alarm is masked.

Figure 5-5. Example of Alarm Indicators

For further information on EMS alarms, see “Managing Alarms” on page 257.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 141

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 50

FlexWave Element Management System

5.6 EMS SYSTEM REQUIREMENTS

The computer that you use to remotely access the EMS must meet the following

minimum requirements:

•• Windows 2000 or Windows XP operating system

•• Internet Explorer version 6.0. When a direct connection is made, an internet

connection is not needed, but the user interface still displays in a Web browser.

•• Network Interface Card (NIC)

•• Ethernet cable with RJ-45 connectors.

The EMS database can also be accessed remotely using an SNMP manager. In this case,

the user interface varies depending on the SNMP manager, but the underlying

parameters, parameter values, and alarms are the same as in the standard EMS

interface.

Page 142 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 51

6

INITIAL PRISM SYSTEM SETUP

Content Page

6.1 Access the EMS................................................................................................144

6.2 Discover IP Addresses.......................................................................................146

6.3 Enter a Host Name, Clock Source, and Linking Mode .............................................147

6.4 Set the Clock Priority Level................................................................................150

6.5 Provision the Host SeRF Optical Ports..................................................................151

6.6 Configure the Host DARTs .................................................................................152

6.7 Enter a Remote Name.......................................................................................156

6.8 Configure the Remote SeRF Optical Ports.............................................................158

6.9 Link the Host and Remote DARTs. ......................................................................159

6.9.1 Use of Multi Fibers ....................................................................................159

6.9.2 RF Groups in the Remote and the EMS GUI ..................................................160

6.9.3 Link a Remote DART to a Host DART ...........................................................162

6.10 Conclude Initial System Setup..........................................................................167

6.11 (Optional) Configuring Multi-Host Systems for Manual Mode .................................168

6.11.1 Set the Multi-Host System to Manual Mode.................................................168

6.11.2 Configure the Host DARTs ........................................................................168

6.11.3 Configure the Remote DARTs....................................................................173

This chapter guides you through an initial Prism system setup, which requires that

you follow the steps in the order given. There are 42 steps in this process that are

divided into 10 sections.

Only a user logged in under the admin account can complete the initial Prism setup

through the EMS.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 143

ADCP-77-073 • Issue 2 • 11/2009 ©2009 ADC Telecommunications, Inc.

Page 52

Initial Prism System Setup

6.1 ACCESS THE EMS

11 Use an Ethernet CAT 5 cable with RJ-45 connectors to connect a laptop to the Craft

port of the Host, as shown in the following figure.

RJ-45

Connector

Detail

77073-075

22 Connect your computer and start a Web browser.

33 In the Web browser URL field, enter the following IP address: 192.168.0.1

If you have configured your Prism s ystem w ith static IP addresses, enter the assigned

IP address inst

Page 144 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

ead of 192.168.0.1.

Page 53

Access the EMS

ADC FlexWave Prism&URH Embedded Web Server Welcome

Username

Password

Login

Welcome to ADC FlexWave Prism Embedded Web Server

44 When the

aa In the

Administrator. The default user name is admin.

bb In the

Administrator. The default password is adc123.

box, type the user name provided by ADC or by the Network

box, type the password provided by ADC or by the Network

window opens:

55 Click

. to open the

page.

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 145

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 54

Initial Prism System Setup

System View

Alarm Summary

Alarm Summary IP

Address

Alarm Summary

6.2 DISCOVER IP ADDRESSES

66 In the Function Explorer Tree, click on

The

columns provide the IP address for the Host and Remote. You can use this

view opens in the EMS View Frame. The

to display a system view.

IP address to log into the Host and Remote unit through a LAN or WAN

connection.

The

view will display all Remotes connected to the Host, so up to

eight Remotes can be listed. (The number of Remotes listed changes as Remotes

are added or removed from the FlexWave system.)

77 Note the Host IP address for future use: _________________________

88 Note the Remote IP address(es) for future use:

•• Remote1 _________________________

•• Remote2 _________________________

•• Remote3 _________________________

•• Remote4 _________________________

•• Remote5 _________________________

•• Remote6 _________________________

•• Remote7 _________________________

•• Remote8 _________________________

Page 146 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 55

Enter a Host Name, Clock Source, and Linking Mode

System View,Host-Unknown_HostName

Host Summary

Host Summary

Host Name

Host Name

6.3 ENTER A HOST N AME, CLOCK SOURCE, AND LINKING

MODE

99 In the Function Explorer Tree, select

the

status indicators in the

view in the EMS View Frame. (For information on the read-only

view, see “Viewing the Host Summary” on

page 214.)

100 In the

box, enter an identifying name for the Host. The

be between 5 and 40 characters, with no spaces. The only special character

allowed is an underscore, but it cannot be the first character of the name.

Numerals are allowed, but cannot be the first character of the name.

10

12

13

14

to open

must

11 and again at 15

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 147

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 56

Initial Prism System Setup

Apply

Host Name

Host

Summary

Host Name

10 MHz Reference Clock

internal

external

10 MHz Reference

Clock external

111 Click

You may need to click in the Function Explorer Tree frame and then click Refresh before

the new name

. The new

displays in the Function Explorer Tree and the

view as part of the view title and in the

appears.

box.

122 In the

list, select

(default) or

. The SeRF

board on each Host and Remote contains the master clock for that unit. At the

Remote, the reference is a clock derived from the Host clock. The

setting allows you to frequency lock the master clock to an external

10 MHz reference.

When using the 10 MHz external reference clock, the signal must be connected to the

Host before enabl

selected for operation, but is

+ /- 5ppm, communication between the Host and

ing the clock in the software. If an external 10MHz reference clock is

not present or outside of the frequency range of 10MHz

Remote over the optical fiber w ill fail.

Page 148 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 57

Enter a Host Name, Clock Source, and Linking Mode

Network Interface

Network Interface

Linking Mode

Automated.

DART Pass Band

DART Diversity Status

Manual

DART Pass Band

DART Diversity Status

Linking Mode

Automated

Apply

10 MHz Reference Clock

Linking Mode

133 Skip setting the

parameter—do not change this setting during

this procedure. Refer to “Changing to Built-In Network Mode” on page 186 for

information on setting the

144 In the

list, keep the default setting of

Linking mode, the Host passes its

connected Remotes. For a Multi-Host system, you must select

you to manually set

a Multi-Host system, leave the

and

.

and

set to

In Automated

as this allows

. If you are setting up

, complete the initial

setup, and then complete “(Optional) Configuring Multi-Host Systems for Manual

Mode” on page 168.

155 Click

to save the

and

changes.

to

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 149

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 58

Initial Prism System Setup

System View,Host-x,SERF

-

Prism on SERF of Host

Clock Priority Level

Clock Priority Level

1

14

Apply

6.4 SET THE CLOCK PRIORITY LEVEL

166 In the Function Explorer Tree, select

name) to open the

177 In the

list, set the Clock Priority Level for the Host. This is in

-n view in the EMS View Frame.

(where

x is the Host

effect a Master/Slave setting in that the Host in a multi-Host system with the

highest

(CPL) will provide the Master Clock on the fibers. All

other Hosts and Remotes will recover clocks from higher levels. The highest level

is

, the lowest level is 14.0 and 15 are “no level” settings that results in a zero

pattern being played on the fiber, which effectively shuts it down. The default is

.

In a Multi-Host system, each Host must have a unique CPL. If one or more Host is

set to the same CPL, an alarm will be generated.

188 Click

.

For information on the SeRF alarm indicators, see “Viewing the Host SeRF

Summary” on page 222.

Page 150 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 59

Provision the Host SeRF Optical Ports

System View,Host-x,SERF,Optical Ports

-

Optical Ports

Optics Name

UNKNOWN_SFPNAME

Optical Ports

Optics Name

Optics Name

Ip Enable

Ip Enable

Ip Enable

Ip Enable

Ip Enable

Apply

6.5 PROVISION THE HOST SERF OPTICAL PORTS

There can be up to eight Host SeRF optical ports that correspond to the eight physical

ports on the Host. Labeling the Host SeRF Optical Ports provides for easier off-site

management.

199 In the Function Explorer Tree, select

x is the Host name) to open the

Frame. The default

for the Optical ports is

information on the status indicators in the

SeRF Optical Ports” on page 224.)

view for the Host in the EMS View

view, see “Viewing Host

(where

. (For

200 In the

box, enter a label for the selected Optics port. The

must be between 5 and 32 characters with no spaces. The only special character

allowed is an underscore, but it cannot be the first character of the name.

Numerals are allowed, but cannot be the first character of the name.

211 Select

management traffic. By default

unselected, the SFP cannot exchange management traffic. How you set

to configure the Small Form-Factor Pluggable (SFP) for exchange of

is not selected. If

is left

is

dependent on the system configuration:

•• In a multifiber scenario, do not enable IP on both SFPs from the same Host to

the same Remote. Typically, the first SFP on the Host that goes to that Remote

is used as the IP enabled port for management communications.

•• In a Multi-Host system, multiple fibers connected to a Remote come from

different Hosts. However, a Remote can accept an IP connection from only one

Host and only one Host can “own” the Remote for the purposes of provisioning

and monitoring. When a second Host attempts to establish an IP connection,

this second connection fails and an IP Conflict alarm is triggered. You

therefore select

only for the Host that manages the Remote so that

only one of the fibers connected to the Remote will have IP.

222 Click

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 151

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

.

Page 60

Initial Prism System Setup

System View,Host-x,SERF,DARTS

-

DART’s Alarm Summary

DART’s Alarm Summary

Information

Band-Config

6.6 CONFIGURE THE HOST DARTS

Configuring a Host DART provides information required for the DART to operate in

RF transmission. Each DART is configured in hardware to operate within a specific RF

band such as PCS or Cellular; the passband is a software-defined sub-band of the

hardware-defined band. Forward and reverse path gain, diversity status, and

operating mode may also be set when a Host DART is configured. The same settings

are applied to the Remote DART when linked to the Host DART. The Host has eight

slots for DART cards.

If you are setting up a multi- host system, go to “(Optional) Configuring Multi-Host

Systems for Manual Mode” on page 168.

233 In the Function Explorer Tree, select

the Host name) to open the

The

view displays all the Host DARTS that are present,

view in the EMS View Frame.

(where

starting from slot 1 at the top of the list and working sequentially down to last

DART, which can be slots 1-8.

244 In the

column, click on the

link for the DART to be

configured.

x is

Page 152 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

Page 61

Configure the Host DARTs

Configuration and Alarm Details of DART n

DART

Attributes

DART Name

DART Pass Band (Timeslots)

DART Operating Mode

Standby

Normal

Undefined

DART Diversity Status

nonDiversity

diversity

nonDiversity

Diversity

a

b

c

d

e

f

255 In the

:

window that opens, set the

aa In the

box, enter a name for the DART between 5 and 32 characters

with no spaces. The only special character allowed is an underscore, but it

cannot be the first character of the name. Numerals are allowed, but cannot be

the first character of the name.

bb In the

list, select the DART Pass Band to be

supported by this DART. The list will include only those pass bands that are

valid selections for the DART band. For example, if the DART band is

“cellular,” only cell pass bands are listed.

cc In the

•

—forces the RF function to be muted in the Host and its linked

list, select one of the following:

Remote.

•

—allows the system to operate normally (RF function not forced to

be muted), assuming all other system components are in proper working

order. (Default setting.)

The mode

is not user selectable, and indicates that the EMS is

unaware of the current mode.

dd In the

application, one DART will be configured

FWD/REV path signal and the other DART will be configured

selection therefore determines whether the DART card being configured will

carry the primary or secondary RF path.

list, select

or

. For a diversity

for the primary

. This

FlexWave Prism Host, Remote and EMS 5.1 System Reference Page 153

ADCP-77-073 • Issue 2 • 11/2009 © 2009 ADC Telecommunications, Inc.

Page 62

Initial Prism System Setup

DART Diversity Status

nonDiversity

DART Forward Gain

-25

+5 dBm

DART Reverse Gain

5

36 dB

0

31 dB

For dual DART configurations, such as dual-pcs, smr800/smr900 and

dual-aws, both DARTs must have

The div ersity status of the Host DART w ill extend to the Remote DART connected to it.

For further inf

ormation, see “Link the Host and Remote DARTs.” on page 159.

set to

.

ee In the

list, set this value (0 to 31 dB) based upon the fully

loaded forward path signal level from the Base Station. The Host DART expects

signal levels from

to

. If the fully loaded signal is +5 dBm, then the

DART forward gain should be set to 0 dB, if the fully loaded signal is -25 dBm,

then the DART Forward Gain should be set to 30 dB. The equation is:

DART Forward Gain = 5 - fullyLoadedBasestationSignal.

If you are setting up the system when no calls are going through, you must allow

headroom for a fully

unloaded to fully loaded is typically 8

fully loaded input would be - 7 dBm and the Host For

= 12 dB.

The same rules applies for GSM carriers, except that the u

determined by the equation 10*log10(# RF Channels). So if there are 4 GSM RF Cha

then the loaded forward path is 6 dB above unloaded.

If sufficient headroom is not present, the

Of Service.

When configured correctly , the Host DART Forward input can handle peaks of 14dB

above the BTS signal

peaks up to - 11 dBm can be handl

the peaks exceed the 14 dB of headroom, then Auto

to prevent over- driving the A/D Conv erter.

loaded forw ard path. For CDMA protocols, the difference from

dB, so if the unloaded signal is - 15dBm, then the

ward Gain should be set to 5- (- 7)

nloaded to loaded is

nnels,

n the LPA can be over- powered causing a Loss

level. For example, if the fully loaded CDMA carrier is - 25dBm, then

ed (CDMA peak to average is typically 10- 12 dB). If

matic Level Control (ALC) w ill occur

ff Set the

value to achieve the required gain from the input to

the Remote to the output of the Host DART. The range is:

•

to

for Cellular, SMR800, SMR900, Narrowband PCS & Narrowband

AWS DARTs

•

to

Page 154 FlexWave Prism Host, Remote and EMS 5.1 System Reference

© 2009 ADC Telecommunications, Inc ADCP-77-073 • Issue 2 • 11/2009

for Fullband GSM1800, UMTS, Fullband AWS, and EGSM900

Page 63

Configure the Host DARTs

DART Reverse Gain

DART Reverse Gain

DART

Reverse Gain

Apply

Close

When setting the

observed:

n The

n If you want to match the URH noise floor to the BTS noise floor, then the

n Simulcast changes the actual REV gain level by 20log(n) where n = the

n Dual PCS uplink splitting causes a 3 dB degradation in the noise figure.

266 Click

setting can be used to overcome losses from the Host

value, the following rules must be

DART to the BTS. If you want unity reverse path gain and the losses to the

BTS are 20 dB, then the Reverse Gain should be set to 20 dB.

noise floors for both the URH and the BTS must be known. Use the