Page 1

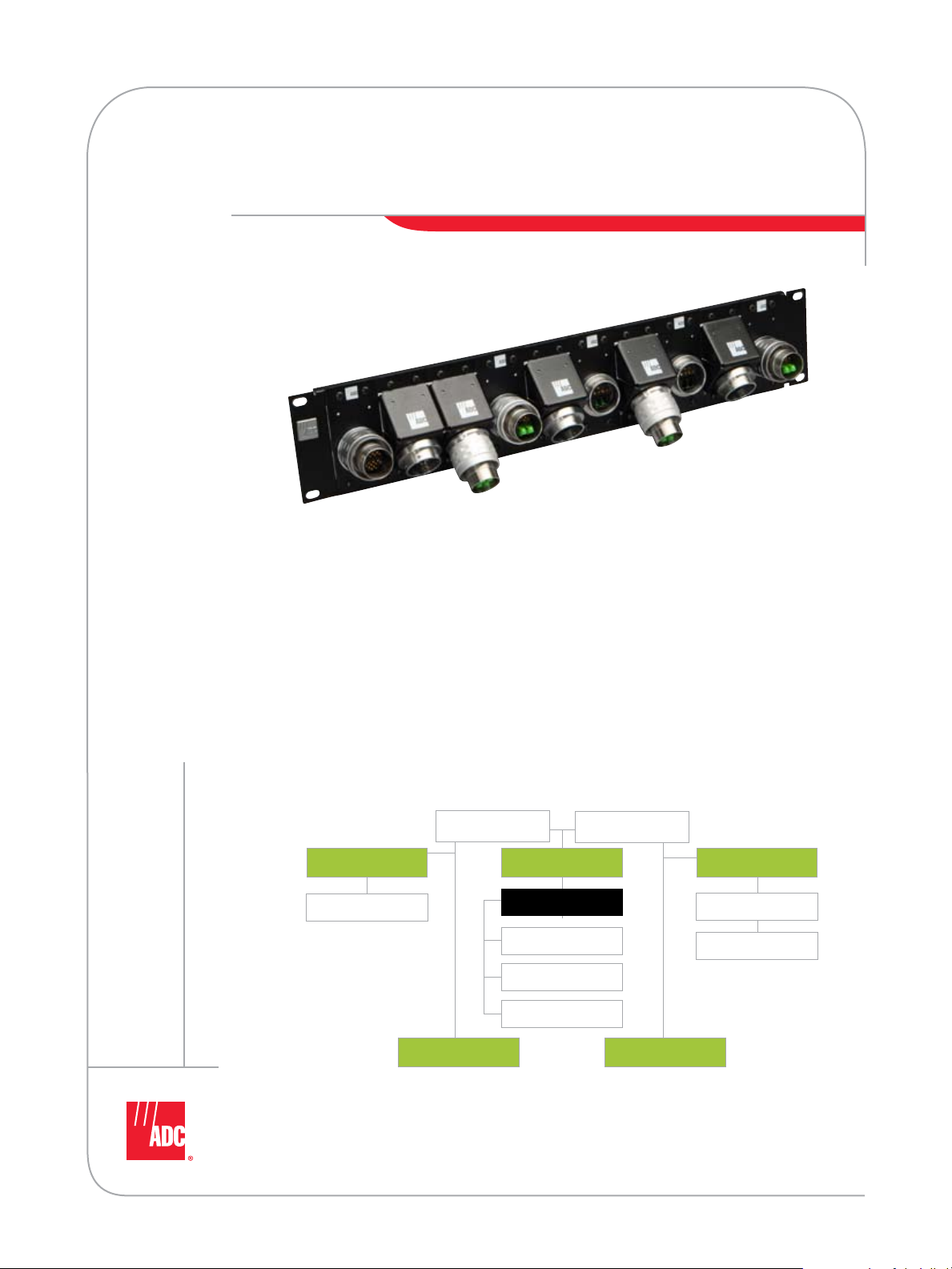

ProAx® Fiber Connector Series

ADC introduces the ProAx® Fiber Connector

Series, designed by broadcast professionals for

broadcast professionals, combining its proven

innovation, knowledge and quality in broadcast

connector design and manufacturing with its

industry-leading proficiency in fiber connectivity.

The result is a true broadcast harsh-environment

fiber optic connector series.

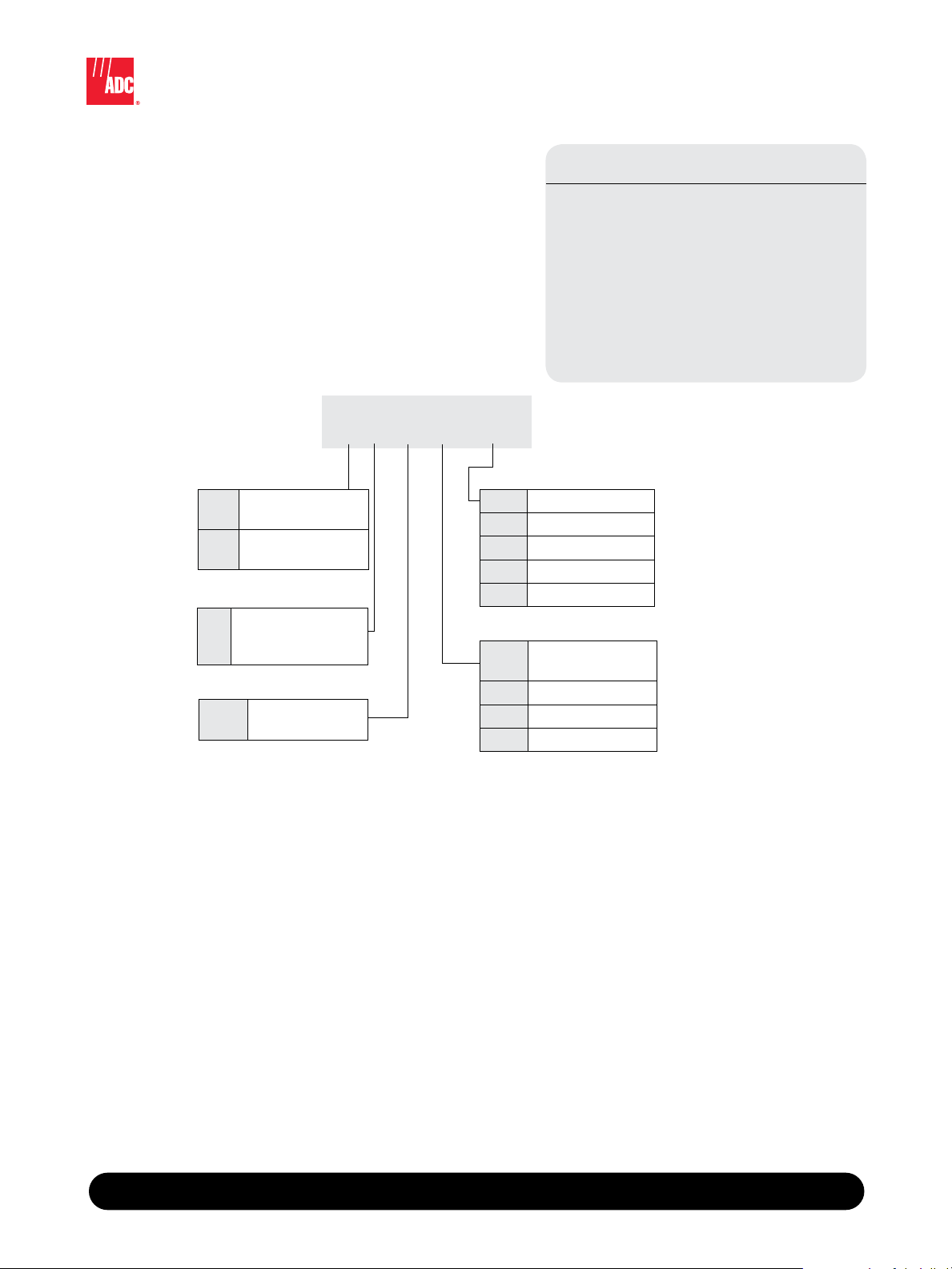

The ProAx fiber connector series is a modular

system that allows for great flexibility. ADC’s

patented gender change feature of this

connector series allows users to change genders

in less than 30 seconds, using only standard

wrenches. Hybrid fiber (HF) and quad fiber (F4)

SPEC SHEET

Gender Changer Jack

Jack Outer Shell

Repair Kit

Jack Bulkhead/Camera

Connector

Connector

Jack

Universal Backshell

(Cable Dependent)

Re-termination Kit

BX5 with V-Groove

Copper Contacts

connectors are designed to be terminated and

repaired in the field. ADC’s patented Avalanche

technology makes these field serviceable

connectors the highest performing, easiest to

install, most secure and reliable connectors on

the market.

This new fiber connector series compliments the

ProAx triax connector series providing multiple

applications for triax and fiber based camera

connectivity in one location. Both connector

series share a common mounting system

featuring the 45° mounting kit and yoke clamps

for cable mount connectors.

Plug

Connector

Gender Changer Plug

Plug Outer Shell

Repair Kit

Repair Kit

Repair Kit

Cable Clamp

Repair Kit

Plug Bulkhead/Camera

Connector

BX5 Adapter

™

www.adc.com • +1-952-938-8080 • 1-800-366-3891

Page 2

ProAx® Fiber Connector Series

ProAx® Fiber

Fiber Connector Series

®

ProAx

ProAx® HF

Hybrid Fiber

Field

Termination

Field Termination Option

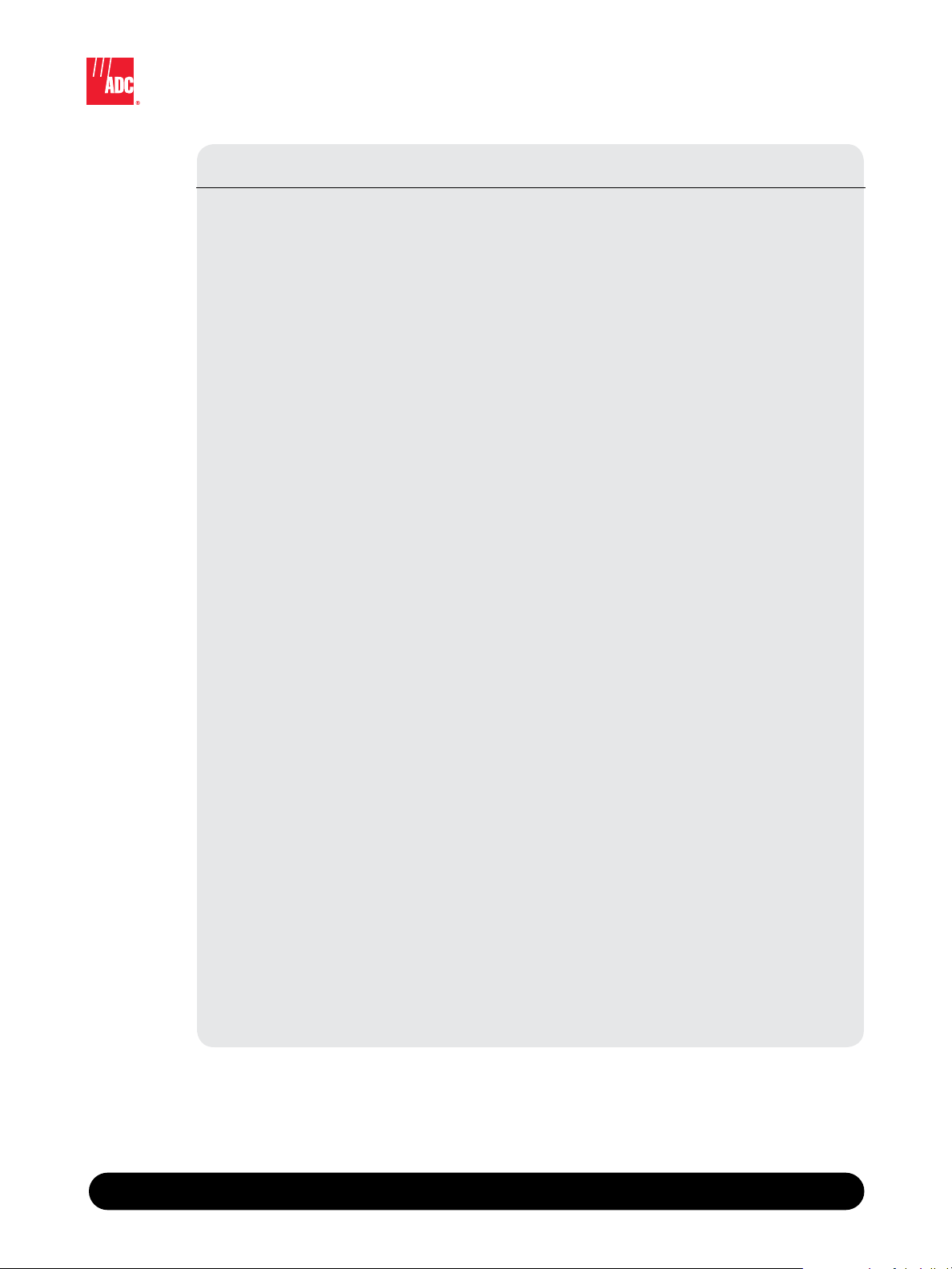

ProAx® fiber connectors are available as a true

broadcast complete field termination solution,

featuring the innovative Avalanche

splicing technology. The Avalanche optical insert

utilizes V-groove technology securing, sealing,

and protecting the spliced fiber while providing

exceptional optical performance.

Avalanche also features Lights-Out technology. By

applying a light source to the factory pre-polished

end of the BX5 connector, the installer is ensured

that the fiber ends are properly aligned for

optimal signal transfer.

Field fiber termination of the fiber components

of ProAx connectors is designed for moderately

trained installers, and uses standard industry

tooling. All copper components are crimped

and secured using standard tooling similar to

a triax connector.

™

fiber

ProAx® F4

Quad Fiber

Factory

Termination

Factory Termination Options

ADC’s ProAx fiber connector family includes

preterminated Quad Fiber (F4) connectors. The

series is designed for flexible ordering depending

on the connector and length needs. The cable

assemblies feature ADC’s superior tactical fiber

cable with reduced bend radius singlemode fiber

components and a stainless steel strength member.

ADC also offers ProAx fiber connectors for

customers that are interested in performing their

own factory terminations. The factory termination

connectors are for direct connectorization of the

BX5 connectors without Avalanche.

Field Termination

Avalanche

™

Optical Inserts

Factory Termination Cable Assembly

5/08 • 106292AE

Complete Connector Kit

www.adc.com • +1-952-938-8080 • 1-800-366-3891

2

Page 3

ProAx® Fiber Connector Series

Features Benefits

Quick and simple field termination and repair •

procedure using Avalanche

Splice Technology

Fiber connectors are standard LX.5•

small-form-factor telecom connectors compatible

Uses standard 1.25 mm ferrule• Standard ferrule size, and no single source •

™

V-Groove Thermal

®

Easy to install and exceptionally robust for use •

in the harsh outside broadcast environment.

Eliminates need for cable assembly spares and

returns to factory for service or repair.

Available from several industry sources•

components

Fiber Connector Series

®

ProAx

Uses angled polish for dramatically improved •

back reflectance

Connector rated to IP68, utilizes ball style •

locking mechanism for maximum reliability

Field assembly using standard tools in about •

20-30 minutes

No polish, no epoxy assembly, using •

Avalanche technology

Factory polished BX5 angled polish connectors •

with integral shutters

“Eye-safe” – automatic shutters on optics to •

prevent accidents and dust contamination

Robust and durable body with stainless steel •

keying feature

Common shell system for hybrid-ber •

and multi-ber only types – just internal

components change

Easily cleaned in the eld with commonly •

available products (tape & alcohol)

Increased loss budget for long links. Typical •

insertion loss .2 dB max, return loss -65 dB min

Withstands the harshest of environments from •

high moisture and submerged, to sandy and hot

environment

Simple assembly training instructions ensure •

positive installation. No need to carry spare cable

spool; signal down time is minimized

Eliminates special polishing tools or skills•

Provides dust protection to ber, accidental •

touching/damaging of the ferrule face and eye

safe for users

Provides eye protection; dust protection and •

accidental touching/damaging of the ferrule face

Visual and positive key ensures that bers are •

protected until positive mating of connectors

completed

Less cost to the customer, all components metal •

and plastic can be replaced in case of damage

without re-terminating

Ensures maximum optical transfer with every use. •

No need for specialized personal to re-terminate

Gender reversible after termination in less than •

90 seconds

Typical budget of .2 dB and return loss of -65 dB• Exceeds SMPTE requirements•

Low cost, moderate skill, repair/termination •

procedure and tools

No need to re-spool the cable to turn it around•

Eliminates the need for fusion splicer. Inexpensive •

tool kit with installer intuitive procedure.

5/08 • 106292AE

www.adc.com • +1-952-938-8080 • 1-800-366-3891

3

Page 4

ProAx® Fiber Connector Series

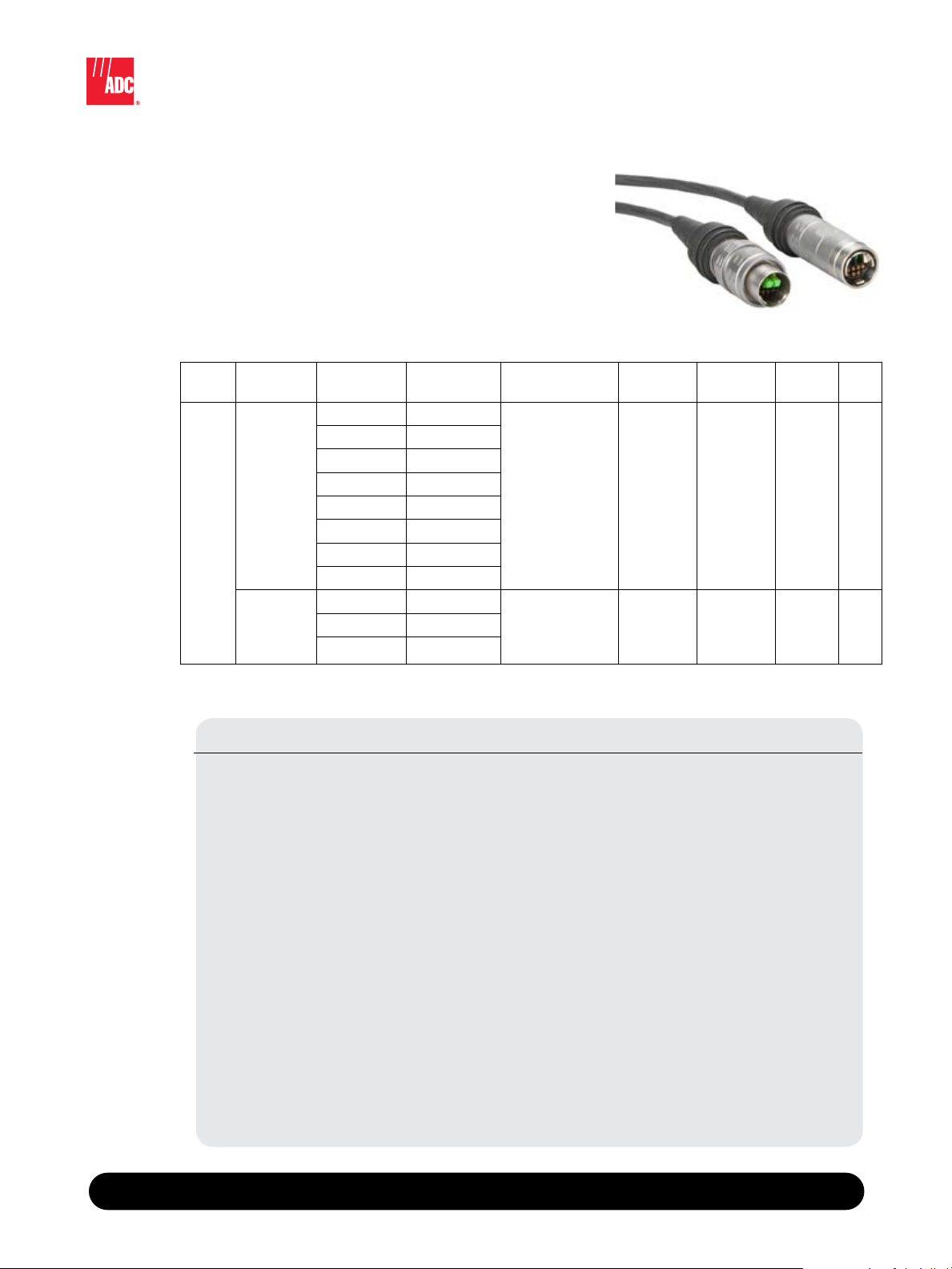

ProAx® Hybrid Fiber (HF) Connectors

Overview

The ProAx® Hybrid Fiber (HF) Connectors are the industry’s first

field repairable, gender changeable, reliable, high-performance

connector designed to be as easy to use as ProAx triax

connectors. The ProAx HF is engineered to withstand tough

mobile environments with generous use of stainless steel on

wear surfaces, shuttered optics to prevent contamination and

accidents, and exclusive o-ring protection that provides an

IP68 rating without external protection boots. Moreover, the

ProAx HF connector offers far higher optical performance than

existing formats and supports newer high-data-rate demands.

Type

Hybrid

Fiber/

Copper

Fiber Connector Series

®

ProAx

ADC

Designation Manufacturer

Argosy Image311

Belden 7804B

Draka SMPTE311M

H9A

H12A

Furukawa TV-OM-AMS

Furukawa TV-OM-CMR

Gepco HDC920

Gepco HDC920R

Mohawk M96040

Gepco HDC120P (2)

Furukawa TV-OM-HAMS

Mohawk M97938

Cable Catalog

Number

Cable reference table.

For details, please contact cable manufacturer.

Optical

Component

(2)

Singlemode

9µm Mode Field,

125µm Cladding

Singlemode

9µm Mode Field,

125µm Cladding

Features Benefits

Connector uses strength member of cable for •

improved pull strength

Copper and fiber sections of the connector are •

completely isolated to prevent the copper from

damaging the connector

With 200 lbs pull force rating, internal ber and •

copper connections are well protected

Eliminates risk of damage to ber components as •

these different materials are subjected to extreme

temperature ranges. Allows service to fiber or

copper components without affecting the other

Signal

Component

(2)

24 AWG

(2)

24 AWG

Auxiliary

Component

(4)

20 AWG

(2)

16 AWG

Strength

Member

(1)

16 AWG

(1)

16 AWG

OD

(mm)

9.2

12

Significantly higher mechanical reliability and •

durability than present format

Far higher optical reliability, durability, and •

performance than present format

Meets and exceeds all functional optical and •

5/08 • 106292AE

www.adc.com • +1-952-938-8080 • 1-800-366-3891

electrical requirements of 304M

Common design for 310M and 311M •

cable types

Power and auxiliary contacts are recessed in •

plug and jack connectors

Sturdy shell resists damage from normal handling. •

Less time worrying about “if” the connector will

work/mate.

Many more mating cycles than current standard. •

ProAx HF exceeds .25dB Insertion loss and -65dB

return loss

Can be used for applications where multiple links •

are required. Significant optical budget savings

Designed to fit existing standard cables. Flexible •

design allows for use of other cables

Safety of operator. Protects operator from electrical •

shock, and contacts from getting damaged

4

Page 5

Fiber Connector Series

®

ProAx

ProAx® Fiber Connector Series

ProAx® Hybrid Fiber (HF) Camera Connector

Specifications

OPTICAL AND ELECTRICAL PERFORMANCE

Insertion loss

1310 nm typical:

Mated pair: Less than 0.2 dB

Avalanche

1550 nm typical:

Mated pair: Less than 0.2 dB

Avalanche

Return loss typical: Greater than -65 dB

Insulation resistance: 200 MW min change

Voltage rating: 600 Vdc

Current Rating: 10 Amps

ENVIRONMENTAL

Operating temperature: -40°C to +85°C

Storage temperature: -40°C to +85°C

Installation/repair temperature: 0°C to +50°C

Humidity: 10%-90% non-condensing

Transportation shock: GR 63 CORE Section 5.3.1

Transportation vibration: GR 63 CORE Section 5.4.3

Installation shock: GR 63 CORE Section 5.3.2

Mated connector pair: Meets or exceeds IP-68

Bulkhead connector capped or mated: Meets or exceeds IP-68

Moisture resistance: MIL-STD-202 Method 106; 0% to 95%

Solvent resistance: MIL-STD-202 Method 215

Corrosion (salt spray): MIL-STD-202 Method 101, test condition B

Industrial atmosphere: STM022 Method

MECHANICAL

Mechanical durability life cycle: > 17,000 cycles

Crush force: > 1,500 lbs

Insertion/withdrawal force : < 30 lbs

Cable tension pull: > 200 lbs

Locking mechanism pull: > 275 lbs

Center contact retention: < 3.0 lbs

™

splice: Less than 0.35 dB

™

splice: Less than 0.35 dB

5/08 • 106292AE

www.adc.com • +1-952-938-8080 • 1-800-366-3891

5

Page 6

ProAx® Fiber Connector Series

ProAx® Quad Fiber (F4) Connectors

Overview

ADC’s ProAx® Quad Fiber (F4) connector is quickly becoming

the industry-standard harsh environment multi-fiber connector.

With its superb and consistent mechanical and optical

performance, the ProAx F4 connectors are the connectors

of choice for outside broadcast vehicle links, high traffic and

connect areas. The IP-68 rated four-fiber connector boasts

the same advantages, features and benefits as the ProAx

HF connector. It is available as a factory terminated cable

assembly using the ADC tactical reduced bend radius fiber

cable, a factory termination connector that can be assembled

at the customer’s factory, or as a field termination connector

featuring our Avalanche

™

technology.

Type

Quad

Fiber

Quad

Fiber

Fiber Connector Series

®

ProAx

ADC

Designation Manufacturer

F9A ADC F4CBL-F9A-BK

F12A ADC F4CBL-F12A-BK

Cable Catalog

Number

Optical

Component

(4)

Singlemode

9µm Mode Field,

125µm Cladding

(4)

Singlemode

9µm Mode Field,

125µm Cladding

Cable reference table.

Signal

Component

N/A N/A

N/A N/A

Auxiliary

Component

Strength

Member

(1)

16 AWG

Stranded

Steel

(1)

16 AWG

Stranded

Steel

OD

(mm)

9.2

12

5/08 • 106292AE

www.adc.com • +1-952-938-8080 • 1-800-366-3891

6

Page 7

ProAx® Fiber Connector Series

ProAx® Quad Fiber (F4) Connector

Specifications

OPTICAL PERFORMANCE

Insertion loss

1310 nm typical:

Mated pair: Less than 0.2 dB

Avalanche

1550 nm typical:

Mated pair: Less than 0.2 dB

Avalanche

Return loss typical: Greater than -65 dB

ENVIRONMENTAL SPECIFICATION

Operating temperature: -40°C to +85°C

Storage temperature: -40°C to +85°C

Installation/repair temperature: 0°C to +50°C

Humidity: 10%-90% non-condensing

Transportation shock: GR 63 CORE Section 5.3.1

Transportation vibration: GR 63 CORE Section 5.4.3

Installation shock: GR 63 CORE Section 5.3.2

Mated connector pair: Meets or exceeds IP-68

Bulkhead connector capped or mated: Meets or exceeds IP-68

Moisture resistance: MIL-STD-202 Method 106; 0% to 95%

Solvent resistance: MIL-STD-202 Method 215

Corrosion (salt spray): MIL-STD-202 Method 101, test condition B

Industrial atmosphere: STM022 Method

™

splice: Less than 0.35 dB

™

splice: Less than 0.35 dB

Fiber Connector Series

®

ProAx

5/08 • 106292AE

MECHANICAL SPECIFICATION

Mechanical durability life cycle: > 17,000 cycles

Crush force: > 1,500 lbs

Insertion/withdrawal force: < 30 lbs

Cable tension pull: > 200 lbs

Locking mechanism pull: > 275 lbs

www.adc.com • +1-952-938-8080 • 1-800-366-3891

7

Page 8

ProAx® Fiber Connector Series

Cable Mount Connectors

Catalog Number

__ __ C __ - _______

Cable Type and Size

Fiber Connector Series

®

ProAx

Plug

Jack

HF Hybrid Fiber

F4 Quad (4) Fiber

C Connector

P Plug

J Jack

H9A SMPTE 311M Standard Cable,

9.2 mm

H12A Hybrid Fiber/Copper Cable,

12 mm

F9A All (4) Fiber Cable, 9.2 mm

F12A All (4) Fiber Cable, 12 mm

Or

BH Bulkhead

Ordering Information

Description Catalog Number

®

ProAx

Fiber Cable Mount Connectors

Field Termination

Connectors

(with Avalanche

Factory Termination

Connectors

(no Avalanche

™

)

™

)

Hybrid Fiber/

Copper

Connector

Quad Fiber

Connector

Hybrid Fiber/

Copper

Connector

Quad Fiber

Connector

Plug 9.2 mm SMPTE 311M cable, H9A HFCP-H9A-FT

12 mm cable, H12A HFCP-H12A-FT

Jack 9.2 mm SMPTE 311M cable, H9A HFCJ-H9A-FT

12 mm cable, H12A HFCJ-H12A-FT

Plug 9.2 mm cable, F9A F4CP-F9A-FT

12 mm cable, F12A F4CP-F12A-FT

Jack 9.2 mm cable, F9A F4CJ-F9A-FT

12 mm cable, F12A F4CJ-F12A-FT

Plug 9.2 mm SMPTE 311M cable, H9A HFCP-H9A

12 mm cable, H12A HFCP-H12A

Jack 9.2 mm SMPTE 311M cable, H9A HFCJ-H9A

12 mm cable, H12A HFCJ-H12A

Plug 9.2 mm cable, F9A F4CP-F9A

12 mm cable, F12A F4CP-F12A

Jack 9.2 mm cable, F9A F4CJ-F9A

12 mm cable, F12A F4CJ-F12A

5/08 • 106292AE

Field Termination Connector

(ProAx HF Plug)

www.adc.com • +1-952-938-8080 • 1-800-366-3891

Field Termination Connector

(ProAx HF Jack)

8

Page 9

ProAx® Fiber Connector Series

Factory Terminated Connector Assemblies

Catalog Number

F4 C T - F9A - __ __ - ___

Fiber Connector Series

®

ProAx

F4 Quad (4) Fiber

C Connector

T Terminated

Cable Type and Size

F9A All (4) Fiber cable, 9.2 mm

Connector 1 Type

P Plug

J Jack

Ordering Information

Description Connector 1 Connector 2 Catalog Number

ProAx Quad Fiber (F4) Cable Assemblies;

factory terminated, 9.2 mm cable, F9A

Note: X=Cable Length.

Cable Length

2 2 meters

10 10 meters

25 25 meters

100 100 meters

Connector 2 Types

P Plug

J Jack

F Pigtail, no connector

B BX5 connectors, angled polish

SC SC connectors, angled polish

LC LC connectors, angled polish

ProAx Plug ProAx Plug F4CT-F9A-PP-X

ProAx Plug ProAx Jack F4CT-F9A-PJ-X

ProAx Jack ProAx Jack F4CT-F9A-JJ-X

ProAx Plug None F4CT-F9A-PF-X

ProAx Jack None F4CT-F9A-JF-X

ProAx Plug BX5/APC F4CT-F9A-PB-X

ProAx Jack BX5/APC F4CT-F9A-JB-X

ProAx Plug SC/APC F4CT-F9A-PSC-X

ProAx Jack SC/APC F4CT-F9A-JSC-X

ProAx Plug LC/APC F4CT-F9A-PLC-X

ProAx Jack LC/APC F4CT-F9A-JLC-X

5/08 • 106292AE

www.adc.com • +1-952-938-8080 • 1-800-366-3891

Cable Length

Connector 2Connector 1

9

Page 10

ProAx® Fiber Connector Series

Repair Kits

Gender Changer Kit

A gender changer repair kit allows you to

change a terminated cable from plug to jack

or jack to plug in less than 90 seconds. This

kit does not require user to re-terminate

connector. All kits include all necessary

components for gender change.

Gender Changer, Plug

(Quad Fiber)

Ordering Information

Description Catalog Number

Gender Changer Kit

Hybrid Fiber/Copper Plug HFRK-GCP

Jack HFRK-GCJ

Quad Fiber Plug F4RK-GCP

Jack F4RK-GCJ

Gender Changer, Plug

(Hybrid Fiber/Copper)

Fiber Connector Series

®

ProAx

5/08 • 106292AE

Outer Shell Kit

Outer shell kit is a replacement kit for damaged

connector shells. The kit includes the outer body

and stainless steel keying component.

Ordering Information

Description Catalog Number

Outer Shell Kit

Plug HFRK-POS

Jack HFRK-JOS

Plug F4RK-POS

Jack F4RK-JOS

Backshell Kit

The connector backshell is the part of the connector

that mounts on the cable. It is cable dependent, and

includes all the components necessary to terminate

it. A gender changer is then assembled onto the

connectorized cable to complete the connector.

Ordering Information

Description Catalog Number

Backshell Kit

Hybrid Fiber/Copper 9.2 mm SMPTE 311M cable, H9A HFRK-BS-H9A

12 mm cable, H12A HFRK-BS-H12A

Quad Fiber 9.2 mm Cable, F9A F4RK-BS-F9A

12 mm cable, F12A F4RK-BS-F12A

Backshell Kit

(Hybrid Fiber/Copper)

www.adc.com • +1-952-938-8080 • 1-800-366-3891

10

Page 11

ProAx® Fiber Connector Series

Repair Kits

Fiber Connector Series

®

Avalanche™ Kit

Ordering Information

Description Catalog Number

Field Re-termination Kits

Hybrid Fiber/Copper and Quad Fiber Avalanche

Hybrid Fiber/Copper Copper Contacts Kit HFRK-CU

Re-termination Kits; all components needed to re-terminate a ProAx

Hybrid Fiber/Copper HFRK-RK

Quad Fiber F4RK-RK

Cable Clamp Kits; all components needed for cable retention

Hybrid Fiber/Copper 9.2 mm SMPTE 311M cable, H9A HFRK-CC-H9A

Quad Fiber 9.2 mm Cable F4RK-CC-F9A

BX5 Adapter Kit

™

Kit

(Includes 2 simplex optical inserts)

BX5 Adapter Kit FCRK-BX5

®

connector

12 mm cable, H12A HFRK-CC-H12A

12 mm cable, F12A F4RK-CC-F12A

Copper Contacts Kit

FCRK-AK

ProAx

5/08 • 106292AE

www.adc.com • +1-952-938-8080 • 1-800-366-3891

11

Page 12

ProAx® Fiber Connector Series

Bulkhead Mount Connectors

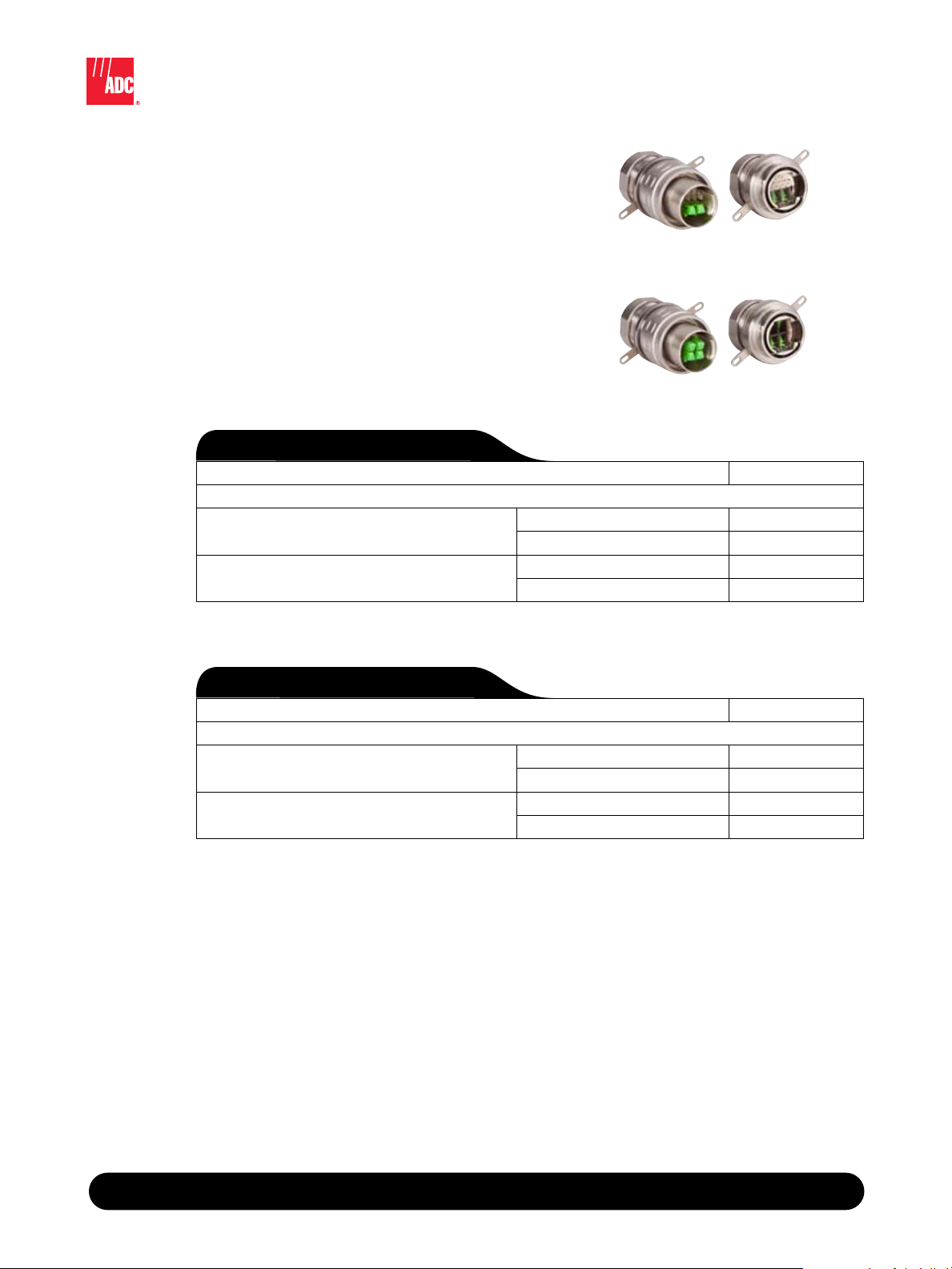

The ProAx® fiber bulkhead and camera mount

connectors are designed with flexibility, serviceability

and robustness in mind. The plug hybrid or quad

fiber connectors have direct rear access to the BX5

adapter. This allows the user to directly plug into it

with a standard BX5 or other industry-standard LX.5

compatible patch cord. The bulkhead connector

makes your breakout easy and maintenance a breeze

whether it’s at the CCU, camera, breakout box or

junction box. The BX5 adapter is easily accessible from

the rear and can be replaced by simply removing the

rear nut. With the ProAx fiber bulkhead connectors,

there is no need for expensive field polishing and

repairs. No need to send your camera anywhere for

connector repairs.

Ordering Information

Description Catalog Number

®

ProAx

Fiber Bulkhead Mount Connectors

Hybrid Fiber/Copper Plug HFCP-BH

Quad Fiber Plug F4CP-BH

®

Bulkhead Connectors

(ProAx HF)

Bulkhead Connectors

(ProAx F4)

Jack HFCJ-BH

Jack F4CJ-BH

Fiber Connector Series

®

ProAx

5/08 • 106292AE

Outer Shell Kit

Ordering Information

Description Catalog Number

Outer Shell Kit

Hybrid Fiber/Copper Plug HFRK-POS-BH

Jack HFRK-JOS-BH

Quad Fiber Plug F4RK-POS-BH

Jack F4RK-JOS-BH

www.adc.com • +1-952-938-8080 • 1-800-366-3891

12

Page 13

ProAx® Fiber Connector Series

Breakout and Test Cables

ADC offers a wide array of singlemode fiber optic

patch cords. Product configurations allow 1m

patch cord increments to fit customer specific

application needs. ADC singlemode connectors

are angled polished. Connector types may be

combined to produce ‘hybrid’ patch cords. All

patch cords are tested to ensure the highest

quality standards are met.

Catalog Number

___ 2Y - APBX ___ - P - __ M

Features

Uses reduced bend radius fiber•

Uses dual zip cable for ease of handling•

100% optically tested•

Insertion loss and return loss values •

certificated and sent with every patch cord

Factory installed connectorization•

Manufactured using advanced techniques•

Visual inspection of all features•

Fiber Connector Series

®

ProAx

Cable Option

FPC Connector on both

ends

FPT Connector on one

end (pigtail)

Cable Type

2Y 2 mm dual zip,

reduced bend radius,

yellow jacket

Connector Type, A

APBX BX5 angled polish

(LX.5 compatible)

* Additional connector types available. Contact ADC Customer Service.

Assembly Length in Meters

01 1 meter

02 2 meters

03 3 meters

10 10 meters

20 20 meters

Connector Type, B*

APBX BX5 angled polish

(LX.5 compatible)

APSC SC angled polish

APLC LC angled polish

APFC FC angled polish

5/08 • 106292AE

www.adc.com • +1-952-938-8080 • 1-800-366-3891

13

Page 14

Fiber Connector Series

®

ProAx® Fiber Connector Series

Tools and Accessories

Ordering Information

Description Catalog Number

Field Termination Tool Kit; Hybrid Fiber/Copper and Quad Fiber HFRK-FTKIT

Field Examination/Cleaning Tool Kit

Individual Tools

Termination fixture HFRK-FTF

Fiber inspection scope HFRK-FTS

Beaver cleaver HFRK-FTBC

High-end cleaver HFRK-FTHC

Melt tool HFRK-FTM

Battery, for melt tool HFRK-FTEB

Battery charger, for melt tool HFRK-FTEBC

Fiber visualizer HFRK-FTL

Crimp tool (with die) HFRK-FTCT

Crimp die HFRK-FTCD

Cable strip gauge HFRK-FTSTRIP

Fiber shard disposal container HFRK-FTDISP

Boots

Connector plug, weather protection boot HFCP-BOOT

Connector jack, weather protection boot HFCJ-BOOT

Connector, strain relief boot HFC-SRBOOT

Bulkhead Avalanche Protection and Strain Relief Kit;

(recommended when using Avalanche with bulkhead connector)

HFRK-FEKIT

HFC-SR-BH

ProAx

Field Termination Tool Kit

Fiber Inspection Scope

Beaver Cleaver

5/08 • 106292AE

Fiber Visualizer with Avalanche

www.adc.com • +1-952-938-8080 • 1-800-366-3891

™

Cable Strip Gauge

Termination Fixture

Melt Tool and Battery

Strain Relief Boot

14

Page 15

ProAx® Fiber Connector Series

Tactical Fiber Bulk Cable

ADC’s ruggedized high-density cables provide

factory standard guaranteed performance

specifications. They are 100% optically tested

and are offered with a variety of optical

performance levels.

Specifications

Simplex Cable

2.0 mm flame retardant

polyurethane subunit jacket

Flame retardant polyurethane

outer jacket

Aramid strength yarn

in subunit and jacket

Coated steel central

strength member

900 µm Hytrel Tight Buffer

Features:

245/900 polyester buffer•

Flame retardant polyurethane jacket; meets •

UL-VW-1

Extremely rugged•

Superior abrasion resistance•

Excellent performance at extreme temperature •

Compatible with all industry standard •

connectors

Available with dual reinforced jackets with •

aramid yarn served between the jackets

Fiber Connector Series

®

ProAx

Note: Drawing not to scale

245 µm Acrylate Coated Fiber

Ordering Information

Description Catalog Number

Tactical Fiber Bulk Cable;

Quad Fiber, 9.2 mm, F9A F4CBL-F9A-BK

Quad Fiber, 12 mm, F12A F4CBL-F12A-BK

Specifications

MECHANICAL

Crush Resistance: EIA-FOTP-41A 1200 N/cm

Impact Resistance: EIA-FOTP-25B 500 Impacts

Flexing: EIA-FOTP-104A 10,000 Cycles

Maximum Pulling Load: EIA-FOTP-33A 2000 N

Maximum Operating Load: 1000 N

Min Bend Radius @ Max Load: 15x Cable OD

ENVIRONMENTAL

Storage Temperature: -55°C to 85°C

Operating Temperature: -40°C to 85°C

Installation Temperature: -40°C to 85°C

Low Temp Bend Test: EIA-FOTP-37A Passed @ -40°C

5/08 • 106292AE

www.adc.com • +1-952-938-8080 • 1-800-366-3891

15

Page 16

SPEC SHEET

Website: www.adc.com

From North America, Call Toll Free: 1-800-366-3891 • Outside of North America: +1-952-938-8080

Fax: +1-952-917-3237 • For a listing of ADC’s global sales office locations, please refer to our website.

ADC Telecommunications, Inc., P.O. Box 1101, Minneapolis, Minnesota USA 55440-1101

Specifications published here are current as of the date of publication of this document. Because we are continuously

improving our products, ADC reserves the right to change specifications without prior notice. At any time, you may

verify product specifications by contacting our headquarters office in Minneapolis. ADC Telecommunications, Inc.

views its patent portfolio as an important corporate asset and vigorously enforces its patents. Products or features

contained herein may be covered by one or more U.S. or foreign patents. An Equal Opportunity Employer

106292AE 5/08 Original © 2008 ADC Telecommunications, Inc. All Rights Reserved

Loading...

Loading...