Page 1

ADCP-80-412 x Issue 1 x April 2000

DSX Bay Tracer Illuminator

User Manual

13914-B

Content Page

INTRODUCTION

1 PRODUCT DESCRIPTION

2 SPECIFICATIONS

3 INSTALLATION

4 OPERATIONAL CONSIDERATIONS

5 TROUBLESHOOTING .................................................................. 7

6 CUSTOMER INFORMATION AND ASSISTANCE

INTRODUCTION

This guide describes the ADC DSX Bay Tracer Illuminator option used in large DSX-1 or

DSX-3 environments to enable technicians to locate far end LED tracer lamps more quickly.

The Bay Tracer Illuminator option consists of a stand-alone electronic sensor device that

mounts on the top of a DSX-1 or DSX-3 bay, and an inductive pick-up coil that mounts on

one or more –48 Vdc power input conductors feeding the bay fuse panel. Power to operate the

Bay Tracer Illuminator option is obtained from a branch of the same –48 Vdc central office

source that powers the components in the DSX-1 or DSX-3 bay.

..........................................................................

Revision History

Trademark Information

Admonishments

Certification

.....................................................................

.....................................................................

........................................................................

.....................................................................

......................................................................

................................................................

...............................................................

.........................................................

.................................................

1

2

2

2

2

2

3

3

7

8

1074399 Rev A Page 1

2000, ADC Telecommunications, Inc.

Page 2

ADCP-80-412 x Issue 1 x April 2000

An LED mounted on the Bay Tracer Electronic Sensor Device provides a large, bright, easily

observable, visual indication whenever an individual jack LED is activated on a DSX bay. This

allows a technician to identify the far end bay so that a scan can be performed to identify the

specific jack LED that has been activated. The indicator flashes for a nominal period of 70–90

seconds following jack activation to allow sufficient time to scan a 6

After the 70–90 second flashing cycle, the LED on the Bay Tracer Electronic Sensor Device is

extinguished and reset in preparation for the next tracer event. The individual DSX jack LED lit

by the activation flashes for 30 seconds and stays lit in a steady on state until a switch deactivation occurs. Individual jack LEDs are not affected by Bay Tracer Illuminator operation.

Revision History

ISSUE DATE REASON FOR CHANGE

Issue 1 04/2000 Original

Trademark Information

ADC and ADC Telecommunications are registered trademarks of ADC Telecommunications, Inc.

25 bay environment.

u

Admonishments

Important safety admonishments are used throughout this manual to warn of possible hazards

to persons or equipment. An admonishment identifies a possible hazard and then explains

what may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use

of the triangular alert icon (seen below), and are listed in descending order of severity of

injury or damage and likelihood of occurrence.

Danger

injury, death, or substantial property damage if the hazard is not avoided.

Warning

personal injury, death, or substantial property damage if the hazard is not avoided.

Caution

personal injury or property damage if the hazard is not avoided.

Certification

The product described in this manual has been tested and found to comply with the requirements

of UL 1863 and CSA C22.2 No. 225.

Danger is used to indicate the presence of a hazard that

:

Warning is used to indicate the presence of a hazard that

:

Caution is used to indicate the presence of a hazard that

:

cause severe personal

will

cause severe

can

will

or

cause minor

can

Page 2

© 2000, ADC Telecommunications, Inc.

Page 3

1 PRODUCT DESCRIPTION

Electronic circuitry in the Bay Tracer sensor checks for a change in current on one or more

–48 Vdc power conductors on the DSX-1 or DSX-3 fuse panel caused by an individual jack

insertion on the far end bay and uses this change to activate an LED. The change in current is

detected by a clamp-on inductive pick-up coil encircling the –48 Vdc power conductor(s)

attached to the DSX fuse panel of the device being monitored. A two-conductor 8-foot (20.32

cm) trailing sensor cable attached to the inductive pick-up coil is used to transmit a signal to the

sensor. A customer supplied two-conductor (–48 Vdc and battery return) power cable is used to

transmit power from the fuse panel on the back of the DSX-1 or DSX-3 bay to the sensor.

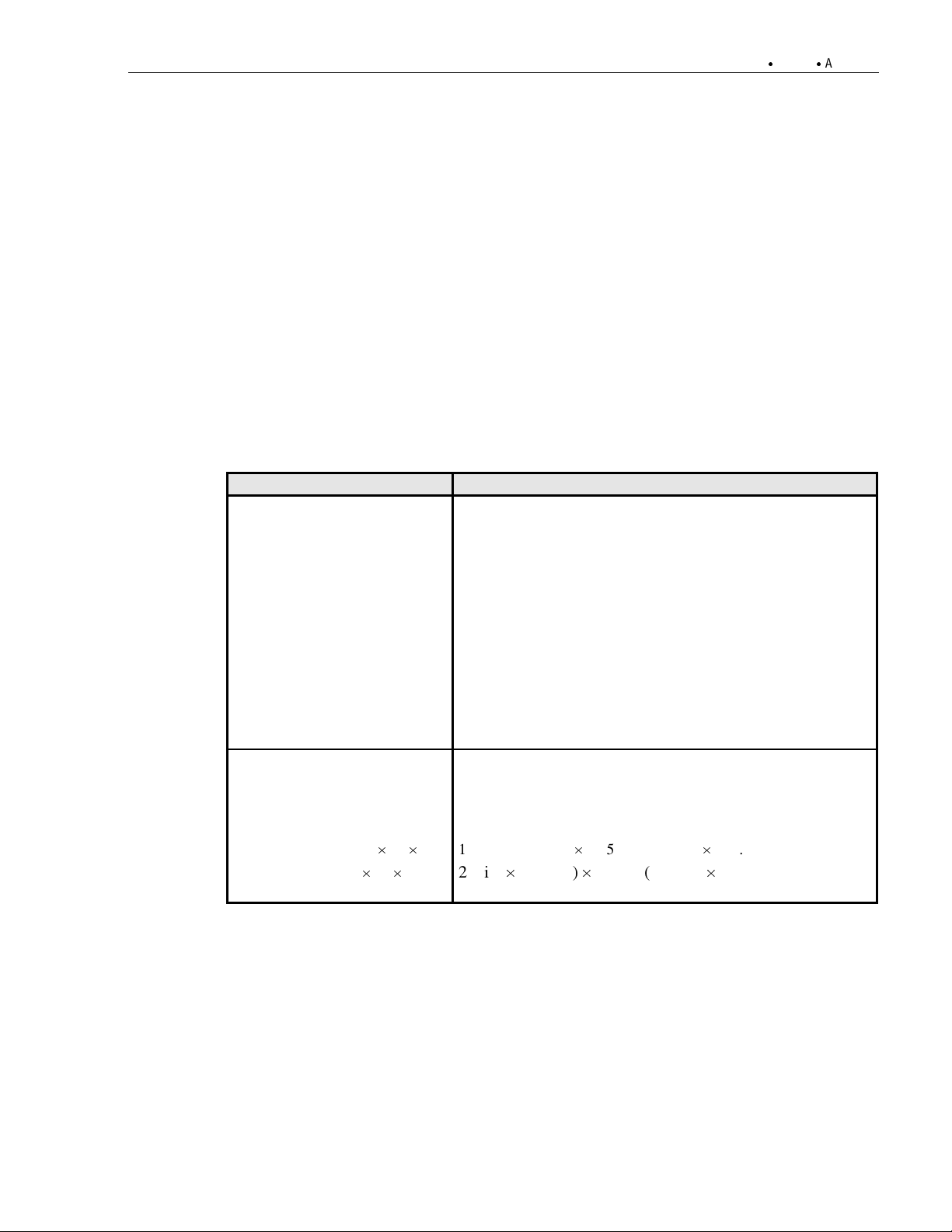

2 SPECIFICATIONS

Bay Tracer Illuminator specifications are provided in Table 1.

PARAMETER SPECIFICATION

Electrical Specification

Power

Voltage –36 Vdc to –75 Vdc

Current Consumption 40mA (maximum) @ –48Vdc

Sensor Interface Two conductor cable with screw connections, 22 AWG

Light Indicator Off: normal, On: bay current change detected

LED Flashing Rate 4 Hz

Power Interface Two conductor screw connections for –48 Vdc, and battery return,

Heat Dissipation 0.96 W (nominal)

Fusing 0.5A GMT type (customer provided at DSX fuse panel)

Mechanical Specification

Weight 1.2 lb (5.44 g)

Operating Environment

Non-Operating

Sensor Dimensions (H

Coil Dimensions (H u W u D)

ADCP-80-412 x Issue 1 x April 2000

Table 1. Bay Tracer Illuminator

18-20 AWG

23° F to 131° F (–5° to 55°C), up to 80% Relative Humidity

–40° F to 185° F (–40° C to 85° C), up to 95% Relative Humidity

u

W u D) 1.75 in. (4.45 cm) u 4.25 in. (10.8 cm) u 3 in. (7.62 cm)

2.1 in. u (5.3 cm) u 2.0 in. (5.1 cm) u 0.610 in. (1.55 cm)

3/4-in. opening

3 INSTALLATION

The ADC Bay Tracer Electronic Sensor is designed to be installed on the top cross-member or

left/right vertical support flanges of the bay. The sensor and power cabling for the device must

be routed over the top of the bay as shown in Figure 1.

© 2000, ADC Telecommunications, Inc.

Page 3

Page 4

ADCP-80-412 x Issue 1 x April 2000

FILLER

PANEL

BLANK PANEL (FRONT)

CABLE TROUGH (REAR)

FUSE PANEL

RESERVED FOR

MISCELLANEOUS

APPLICATIONS

RESERVED FOR

MISCELLANEOUS

APPLICATIONS

DSX

PANEL

DSX

PANEL

14093-A

NOTE: SENSOR AND POWER ATTACHMENT POSITION AND

APPEARANCE SHOWN EXAGGERATED FOR CLARITY.

FILLER

PANEL

Figure 1. Bay Tracer Cable Routing

1. Attach the Bay Tracer Electronic Sensor Device mounting bracket to the top cross

member or vertical support flange of the DSX-1 or DSX-3 bay using two provided 12–

24 rack mounting-screws. See Figure 2.

2. Two sensor cabling options are provided for detecting a change in current on the –48 Vdc

power conductor(s) feeding the bay. If the bay is configured with DSX-only equipment

(option A), proceed to step 2a. If the bay is configured with a mix of DSX and non-DSX

equipment (option B), proceed to step 2b.

Page 4

© 2000, ADC Telecommunications, Inc.

14001-B

Figure 2. Bay Tracer Electronic Sensor Device with Mounting Bracket

Page 5

ADCP-80-412 x Issue 1 x April 2000

a. Unsnap the top bar of the inductive pick-up coil. Insert the main DSX-1 or DSX-3

–48 Vdc power conductor into the inductive pick-up coil as shown in Figure 3, making

sure that the label side of the coil faces toward the power source. Snap the top bar back

into place after inserting the power feed wire. Anchor the power conductor to the

inductive pick-up coil with a tie wrap or lacing cord in accordance with local practice.

b. Unsnap the top bar of the inductive pick-up coil. Insert the –48 Vdc conductors for the

DSX-only equipment into the inductive pick-up coil as shown in Figure 4, making sure

that the label side of the coil faces toward the power source. Snap the top bar back into

place after inserting the power feed wire(s). Anchor the power conductor(s) to the

inductive pick-up coil with a tie wrap or lacing cord in accordance with local practice.

: The battery return main conductor, or battery return distribution conductors are not

Note

inserted into the coil and should be routed directly to the DSX-1 or DSX-3 fuse panel.

SENSOR

ATTACHMENT

FILLER

PANEL

INDUCTION

COIL

—48V

BATTERY

RETURN

FILLER

PANEL

BAYTRACER

POWER

ATTACHMENT

UPPER CABLE TROUGH

FUSE PANEL

BATTERY RETURN

—48V

BATTERY RETURN

—48V

DSX

PANEL

DSX

PANEL

REAR VIEW

—48V

BATTERY

RETURN

NOTE: SENSOR AND POWER ATTACHMENT POSITION AND

APPEARANCE SHOWN EXAGGERATED FOR CLARITY.

Figure 3. Sensor Cabling Option A

14088-A

© 2000, ADC Telecommunications, Inc.

Page 5

Page 6

ADCP-80-412 x Issue 1 x April 2000

FILLER

PANEL

SENSOR

ATTACHMENT

KEEP NON-DSX

EQUIPMENT

OUT OF COIL

INDUCTION

COIL

BAYTRACER

UPPER CABLE TROUGH

BATTERY RETURN

—48V

BATTERY RETURN

—48V

POWER

ATTACHMENT

FUSE PANEL

DSX

PANEL

DSX

PANEL

REAR VIEW

—48V

BATTERY

RETURN

NOTE: SENSOR AND POWER ATTACHMENT POSITION AND

APPEARANCE SHOWN EXAGGERATED FOR CLARITY.

Figure 4. Sensor Cabling Option B

14059-A

FILLER

PANEL

—48V

BATTERY

RETURN

4. Attach the trailing wires from the inductive pickup coil to the ADC-provided sensor

connector making sure that the white conductor is routed to the negative (–) pin on the

SENSOR receptacle and the black conductor is routed to the positive (+) pin on the

receptacle. See Figure 5.

:

Caution

The sensor and power connectors are keyed identically and can be inserted into the

wrong receptacles on the Bay Tracer Electronic Sensor Device. Use care to avoid possible

damage to the sensor.

Page 6

© 2000, ADC Telecommunications, Inc.

Page 7

ADCP-80-412 x Issue 1 x April 2000

POWER

CONNECTOR

TOP VIEW

FRONT VIEWLEFT SIDE VIEW RIGHT SIDE VIEW

RED

FLASHING

LED

SENSOR

CONNECTOR

13928-B

Figure 5. Bay Tracer Electronic Sensor Device Connectors

5. Attach the customer-supplied power feed wires for the electronic sensor device to an

unused –48 Vdc branch circuit on the DSX-1 or DSX-3 fuse panel as shown in Figures 3

and 4. Attach the opposite ends of these wires to the ADC-provided power connector on

the electronic sensor device making sure that the wire supplying –48 Vdc is routed to the

–48V pin on the POWER receptacle and the battery return wire is routed to the RET pin

on the receptacle. See Figure 5. A reverse blocking diode is incorporated into the electronic

sensor device to prevent damage from a power lead reversal.

: The fuse panel branch circuit should be fused at 0.5 A.

Note

© 2000, ADC Telecommunications, Inc.

Page 7

Page 8

ADCP-80-412 x Issue 1 x April 2000

4 OPERATIONAL CONSIDERATIONS

The electronic sensor device LED may be falsely activated by external EMI emitted by power

drills, wire wrap guns, or other AC powered devices located within 12 inches of the inductive

pick-up coil. If such a condition occurs, the electronic sensor device automatically resets after

the change in current state and returns to a constant dc state.

5 TROUBLESHOOTING

The LED on the bay tracer electronic sensor device is designed to light whenever an individual

jack LED is activated on a DSX bay configured with the device. Table 2 provides a description

of common error conditions that may occur due to improper installation.

CONDITION DESCRIPTION

Battery return conductor inserted into coil LED activates when jack is removed

Labeled side of coil is facing away from the power

source

Both –48 Vdc and battery return conductors are

inserted into the coil

–48 Vdc and battery return conductors are mis-wired

on POWER connector

Table 2. Bay Tracer Troubleshooting

LED activates when jack is removed

Bay Tracer Illuminator does not function

Bay Tracer Illuminator does not function

Page 8

© 2000, ADC Telecommunications, Inc.

Page 9

6 CUSTOMER INFORMATION AND ASSISTANCE

For customers wanting information on ADC products or help in using them, ADC offers the

services listed below. To obtain any of these services by telephone, first dial the central ADC

telephone number, then dial the extension provided below.

ADCP-80-412 x Issue 1 x April 2000

The central number for calls originating in the U.S.A. or Canada is

1-800-366-3891

originating outside the U.S.A. or Canada, dial country code “1” then dial

Sales Assistance

Extension 3000

• Quotation Proposals

• Ordering and Delivery

952-946-3000

. For calls

.

• General Product Information

Systems Integration

Extension 3000

• Complete Solutions (from Concept to Installation)

• Network Design and Integration Testing

• System Turn-Up and Testing

• Network Monitoring (Upstream or Downstream)

• Power Monitoring and Remote Surveillance

• Service/Maintenance Agreements

• Systems Operation

BCG Technical Assistance Center

Extension 3475

E-Mail: technical@adc.com

• Technical Information

• System/Network Configuration

• Product Specification and Application

• Training (Product-Specific)

• Installation and Operation Assistance

• Troubleshooting and Repair

Product Return Department

Extension 3748

• ADC Return Authorization number and instructions must

be obtained before returning products.

E-Mail: repair&return@adc.com

Product information may also be obtained using the ADC web site at

www.adc.com

or by

writing ADC Telecommunications, Inc., P.O. Box 1101, Minneapolis, MN 55440-1101, U.S.A.

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice.

no event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting ADC’s Technical Assistance Center at 1-800-366-3891, extension

3475 (in U.S.A. or Canada) or 952-946-3000 (outside U.S.A. and Canada), or by writing to ADC Telecommunications, Inc.,

Attn: Technical Assistance Center, Mail Station #71, P.O. Box 1101, Minneapolis, MN 55440-1101, U.S.A.

© 2000, ADC Telecommunications, Inc.

All Rights Reserved

Printed in U.S.A.

Page 9

In

Page 10

Loading...

Loading...