Page 1

OmniReach™ FTTX Solutions

Outdoor Fiber Distribution Terminal 24 (OFDT-24)

The Outdoor Fiber Distribution Terminal 24 (OFDT-24) is designed to terminate, splice and

interconnect fiber optic cables in an outdoor environment. This terminal may be adapted to Fiberto-The-Premise (FTTP) Multiple Dwelling Unit (MDU) applications and is particularly suited for

garden style MDU buildings. The enclosure is mounted to the exterior surface of a dwelling and

connects the distribution cable and drops routed to individual living units. The cables meet at a

central connector field that includes termination for the distribution cable and parking for the drop

cables. The cabinet may be configured with splice trays for splicing the cable to connector pigtails.

The OFDT-24 may be pre-terminated on the distribution side with outside plant cable stubs so that

the unit is quickly connected to the plant. The OFDT-24 may also be pre-wired with pigtails on the

drop side so that individual drops routed into the unit can be spliced to the connectorized pigtails.

Spec Sheet

The OFDT-24 features a unique “swing frame” type design that separates the splicing in the rear

from the patch access in the front of the swing frame. It allows for easy connector access to the

rear connectors for maintenance and cleaning. This approach allows for a single door sealing

method, ensuring reliability to withstand long-term outdoor conditions.

The unit accommodates a variety of OSP cable types via sealed grommet entry. Cables are secured

with standard grip clamps to provide required pull out strength. The enclosure provides grounding

for metallic members and for the cabinet.

The OFDT-24 product accommodates 6, 12, or 24 living units. Distribution cable fibers are

terminated on standard SC/APC adapters that are easily accessible for service connection and

maintenance. Drop pigtails are initially terminated on parking adapters adjacent to the distribution

termination adapters and staged at the parking positions until the living units request service.

Moving the drop pigtails from the parking position to the assigned distribution fiber allows for easy

service connections.

w w w . a d c . c o m • + 1 - 9 5 2 - 9 3 8 - 8 0 8 0 • 1 - 8 0 0 - 3 6 6 - 3 8 9 1

Page 2

OmniReach™ FTTX Solutions

Outdoor Fiber Distribution Terminal 24 (OFDT-24)

Features and Benefits

• Accommodates smaller fiber counts; 6-, 12- and

24-fiber

• Eliminates need for transitional NEMA box that

provides for mini-ducts

• Liquid tight fittings offer cost savings

• Aesthetic benefits to MDU building owners

• Supplied with parking, pigtails and splice tray

• Wall-mount; efficient use of wall space

• Cable termination and splicing

• Complete connector access

• Lockable 216 tool/padlock offers flexible

security options

• Environmental enclosure provides heavy-duty

protection from wind, dust, rain, and other

contaminants

• Aluminum welded construction provides

strength and resists corrosion

• Lightweight structure provides for easy

installation

• Cable entrance ports seal cable at entry

• Cable management and routing limits radius and

adds strain relief

• Standard stub lengths of 100, 300, 500, and

1000 feet

™

FTTX Solutions

OmniReach

Advantages and Cost Benefits of New OFDT-24

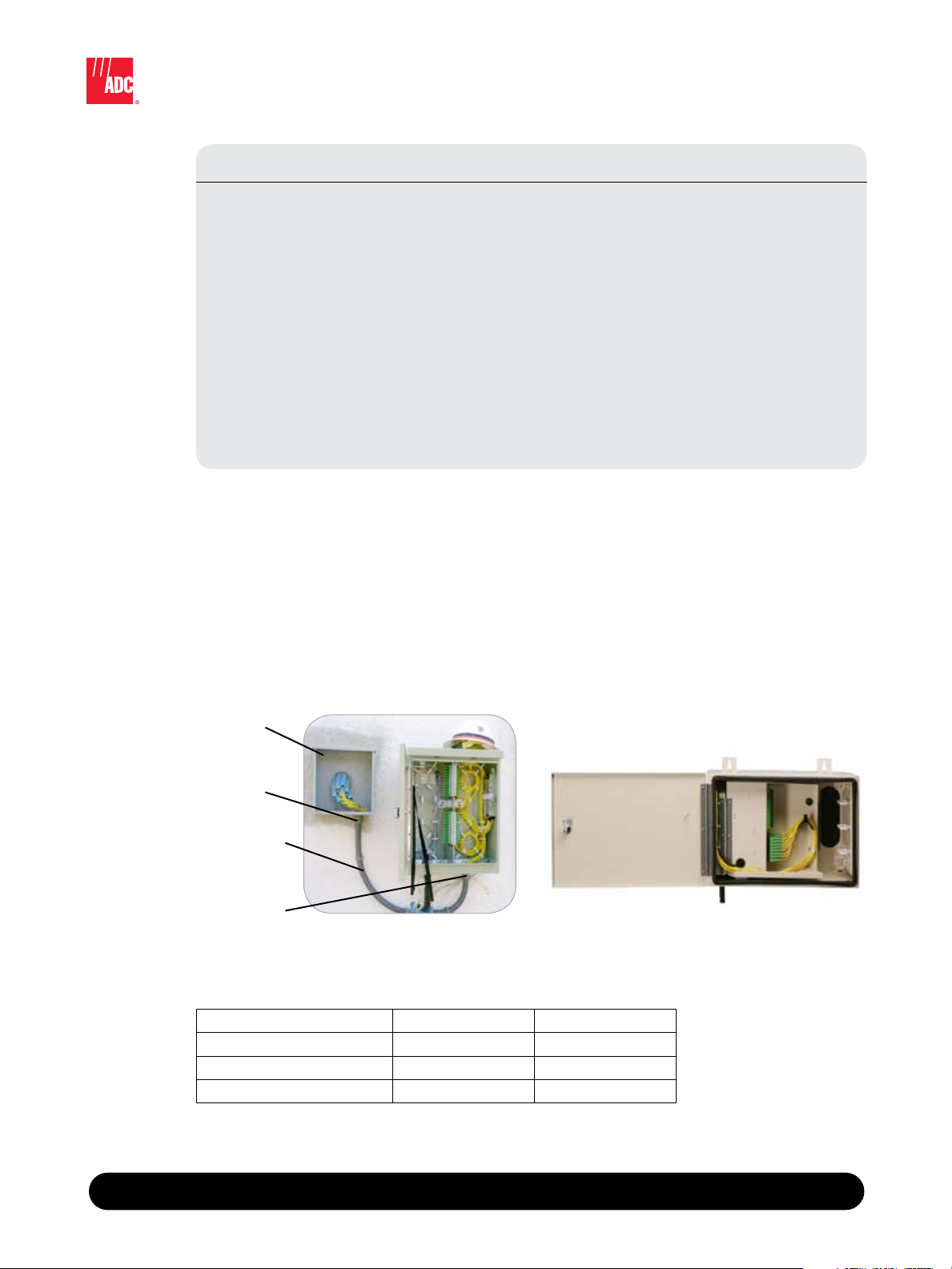

The new OFDT-24 design allows for micro-ducts to enter into the back of the OFDT box. The 8" x 3"

oval cut-out on the right side of the back wall allows the installer to locate the OFDT right over the

micro-ducts exiting the building. This feature eliminates the need for the transitional NEMA box used

to transition from the micro-duct exit location into the OFDT. This new feature offers cost, labor, and

aesthetic benefits to the MDU building owners over the current installation method. When not used,

the oval cut-out can be covered with the provided gasketed plate. There is also a knock-out hole in the

bottom of the cabinet to accommodate every type of installation application.

NEMA 3R

Enclosure

Liquid

Tight Fitting

1.25” Liquid

Tight Conduit

Liquid Tight

Fitting

Current

Outdoor FDT Installation Method

Outdoor FDT Installation Method

New

7 / 0 7 • 1 0 3 3 3 5 A E

w w w . a d c . c o m • + 1 - 9 5 2 - 9 3 8 - 8 0 8 0 • 1 - 8 0 0 - 3 6 6 - 3 8 9 1

Equipment Requirements Current Method New Method

NEMA 3R Enclosure Required Not Required

Liquid Tight Fitting Required Not Required

1.25" Liquid Tight Conduit Required Not Required

2

Page 3

OmniReach™ FTTX Solutions

Outdoor Fiber Distribution Terminal 24 (OFDT-24)

™

FTTX Solutions

OmniReach

Specifications

Height:

Width:

Depth

Weight (Empty):

Fiber Terminations:

Parking Adapters:

Splice Trays:

Cable Ports:

Color:

13.5" (35.0 cm)

19.0" (49.0 cm)

8.0" (20.0 cm)

14 lbs (31 kg)

6, 12, 24

6, 12, 24

3

2 in bottom; 1 in rear

Beige

Ordering Information

FDT- __ __ __ __ __ __ __ __ __ __ __

Enclosure

G OFDT-24

Connector Type

J SC/APC

Splice Tray

0 No Tray

2 Heat Shrink Fusion

3 Mechanical/Ribbon

Fiber Count

06 6 Fiber

12 12 Fibers

24 24 Fibers

Catalog Number

Stub Length

000 0 Feet

025 25 Feet

100 100 Feet

200 200 Feet

300 300 Feet

500 500 Feet

Cable Type

Pigtails

A Bare Ribbon Pigtail

Assembly

C Pigtails (Colored)

Stubs

S Ribbon OSP w/Conn

R Ribbon IFC w/Conn

T Loose Tube OSP w/Conn

V Loose Tube IFC w/Conn

7 / 0 7 • 1 0 3 3 3 5 A E

w w w . a d c . c o m • + 1 - 9 5 2 - 9 3 8 - 8 0 8 0 • 1 - 8 0 0 - 3 6 6 - 3 8 9 1

Parking

P Parking

N No Parking

Pigtails

P Pigtails (2mm)

X No Pigtails

3

Page 4

Spec Sheet

We bsite: www.ad c. com

From North America, Call Toll Free: 1-800-366-3891 • Outside of North America: +1-952-938-8080

Fax: +1-952-917-3237 • For a listing of ADC’s global sales office locations, please refer to our website.

ADC Telecommunications, Inc., P.O. Box 1101, Minneapolis, Minnesota USA 55440-1101

Specifications published here are current as of the date of publication of this document. Because we are continuously

improving our products, ADC reserves the right to change specifications without prior notice. At any time, you may

verify product specifications by contacting our headquarters office in Minneapolis. ADC Telecommunications, Inc.

views its patent portfolio as an important corporate asset and vigorously enforces its patents. Products orfeatures

contained herein may be covered by one or more U.S. or foreign patents. An Equal Opportunity Employer

103335AE 7/07 Revision © 2005, 2007 ADC Telecommunications, Inc. All Rights Reserved

Loading...

Loading...