Page 1

ADCP-90-297

July 2006

NG3™ High-Density Fiber Distribution

Frame System Termination, Termination/

Splice, and VAM Panels User Manual

Issue 7

1376806 Rev A

Page 2

ADCP-90-297

July 2006

NG3™ High-Density Fiber Distribution

Frame System Termination, Termination/

Splice, and VAM Panels User Manual

Issue 7

1376806 Rev A

Page 3

ADCP-90-297 • Issue 7 • July 2006 • Preface

COPYRIGHT

© 2006, ADC Telecommunications, Inc.

All Rights Reserved

Printed in the U.S.A.

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

1 1/2003 Original.

2 1/2003 Change format to reduce file size for electronic distribution.

3 7/2003 Add cautionary statements and notes.

4 12/2003 Update for new shorter top cover and related clearance dimensions.

5 6/2004 Update cable breakout diagrams on page 11 and page 12.

6 1/2005 Add information and specifications for 72-position termination and splice panel and VAM panel. Add

7 7/2006 Add Subsection 3.5 (breakout cable installation). Change patch cord length to 65 inches (165.10 cm) in

current Customer Information and Assistance drawing and edit for clarity.

Subsections 4.2.1 and 4.4.1.

TRADEMARK INFORMATION

ADC is a registered trademark of ADC Telecommunications, Inc.

NG3 and TracerLight are trademarks of ADC Telecommunications, Inc.

Kimwipes is a registered trademark of Kimberly-Clark Worldwide, Inc.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting ADC’s Technical Assistance Center at 1-800-366-3891, extension 73475

(in U.S.A. or Canada) or 952-917-3475 (outside U.S.A. and Canada), or by e-mail to connectivity_tac@adc.com (in U.S.A. or

Canada), euro_tac@adc.com (in Europe), or asiapacific_tac@adc.com (in the Asian Pacific region).

Page ii

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 917-1717

Page 4

TABLE OF CONTENTS

TABLE OF CONTENTS

Content Page

ABOUT THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

RELATED PUBLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

ADMONISHMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

GENERAL SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

LIST OF ACRONYMS AND ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

RECOMMENDED TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

TRAINING AND SUPPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 NG3 High-Density Fiber Distribution Frame System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 NG3 72-Position Standard Termination Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 NG3 72-Position Termination and Splice Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 NG3 12-Position Value Added Module Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Specifications and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 NG3 PANEL INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Mounting the NG3 Panel on the Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Opening the NG3 Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Installing Micro Value Added Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 IFC CABLE ROUTING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 General IFC Cable Routing Guidelines–All Panel Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Standard Termination Panel IFC Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Termination and Splice Panel IFC Cable Installation and Splicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4 VAM Panel IFC Cable Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5 Standard Termination Panel Breakout Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 FOT EQUIPMENT PATCH CORD ROUTING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 General FOT Equipment Patch Cord Routing - All Panel Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2 Standard Termination Panel FOT Patch Cord Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.3 Termination/Splice Panel FOT Patch Cord Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.4 VAM Panel FOT Patch Cord Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.1 Adapter Pack Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.2 VAM Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.3 Cleaning Connectors and Adapters – Standard and Termination/Splice Panels . . . . . . . . . . . . . . . . . . . . . . . 51

5.4 Cross-Connect Jumper Patch Cord Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

ADCP-90-297 • Issue 7 • July 2006 • Preface

1.2.1 NG3 Standard Termination Panel Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.2 NG3 Standard Termination Panel Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4.2.1 Cross-Connect Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.2.2 Interconnect Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4.1 Rear Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.4.2 Front Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.4.1 Standard Termination Panel and Termination/Splice Panel Cross-Connect Routing . . . . . . . . . . . . 53

© 2006, ADC Telecommunications, Inc.

Page i

Page 5

ADCP-90-297 • Issue 7 • July 2006 • Preface

TABLE OF CONTENTS

TABLE OF CONTENTS

Content Page

5.4.2 VAM Panel Cross-Connect Patch Cord Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.5 Closing the Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.1 Cable Replacement – Standard Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.2 Removing a Patch Cord – All Panel Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.3 Replacing an Adapter – Standard Panel and Termination/Splice Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.4 Replacing an Adapter Pack – Standard Panel and Termination/Splice Panel . . . . . . . . . . . . . . . . . . . . . . . . 62

6.5 Replacing a VAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7 CUSTOMER INFORMATION AND ASSISTANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

_________________________________________________________________________________________________________

Page ii

© 2006, ADC Telecommunications, Inc.

Page 6

ABOUT THIS MANUAL

This manual describes the 72-Position Standard Termination Panel, the 72-Position Termination

and Splice Panel, and the 12-Position VAM Panel. It also provides the information and

procedures required to install and use each of the three types of NG3 panels. The NG3 panels

are part of the NG3 High-Density Fiber Distribution Frame System.

RELATED PUBLICATIONS

Listed below are related manuals and their publication numbers. Copies of these publications can

be ordered by contacting the ADC Technical Assistance Center at 1-800-366-3891 (in U.S.A. or

Canada) or 952-917-3000, extension 73475 (outside U.S.A. and Canada). All ADC technical

publications are also available on the ADC web site at www.adc.com.

Title/Description ADCP Number

NG3 High-Density Fiber Distribution Frame System

Rack Installation Manual: Raised Floor 90-295

Provides step by step pictorial instructions for installing an NG3 rack on a

raised floor.

ADCP-90-297 • Issue 7 • July 2006 • Preface

NG3 High-Density Fiber Distribution Frame System Patch Cord Routing Guide 90-296

Provides pictorial guidelines for routing patch cords on a lineup consisting of

one or more NG3 frames. This manual consists of laminated cards that hang on

the lineup.

NG3 High-Density Fiber Distribution Frame System User Manual 90-298

Contains an NG3 system overview and information for planning and operating

the system.

NG3 High-Density Fiber Distribution Frame System

Rack Installation Manual: Concrete Floor 90-299

Provides step by step pictorial instructions for installing an NG3 rack on a concrete floor.

ADMONISHMENTS

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below), and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

© 2006, ADC Telecommunications, Inc.

Page iii

Page 7

ADCP-90-297 • Issue 7 • July 2006 • Preface

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warn ing: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

GENERAL SAFETY PRECAUTIONS

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber. Do not look directly into the optical adapters of the

adapter packs. Exposure to invisible laser radiation may result. An optical power meter should

be used to verify active fibers. A protective cap or hood MUST be immediately placed over any

radiating adapter or optical fiber connector to avoid the potential of dangerous amounts of

radiation exposure. This practice also prevents dirt particles from entering the adapter or

connector.

LIST OF ACRONYMS AND ABBREVIATIONS

The following acronyms are used in this manual:

FOT Fiber Optic Terminal

IFC Intra Facility Cable

NG3 New Generation High-Density Fiber Distribution Frame

OSP Outside Plant

SAP Sliding Adapter Pack

VA M Value Added Module

WDM Wavelength Division Multiplexer

RECOMMENDED TOOLS

#3 Phillips screwdriver with at least an 8-inch shaft.

TRAINING AND SUPPORT

Additional product and installation training and support are available from ADC. Please contact

your ADC representative for more information.

Page iv

© 2006, ADC Telecommunications, Inc.

Page 8

1 DESCRIPTION

This section describes the 72-Position Standard Termination Panel, the 72-Position Termination

and Splice Panel, and the 12-Position Value Added Module (VAM) Panel. This section also

explains the basic functions and features of each panel type and provides product specifications.

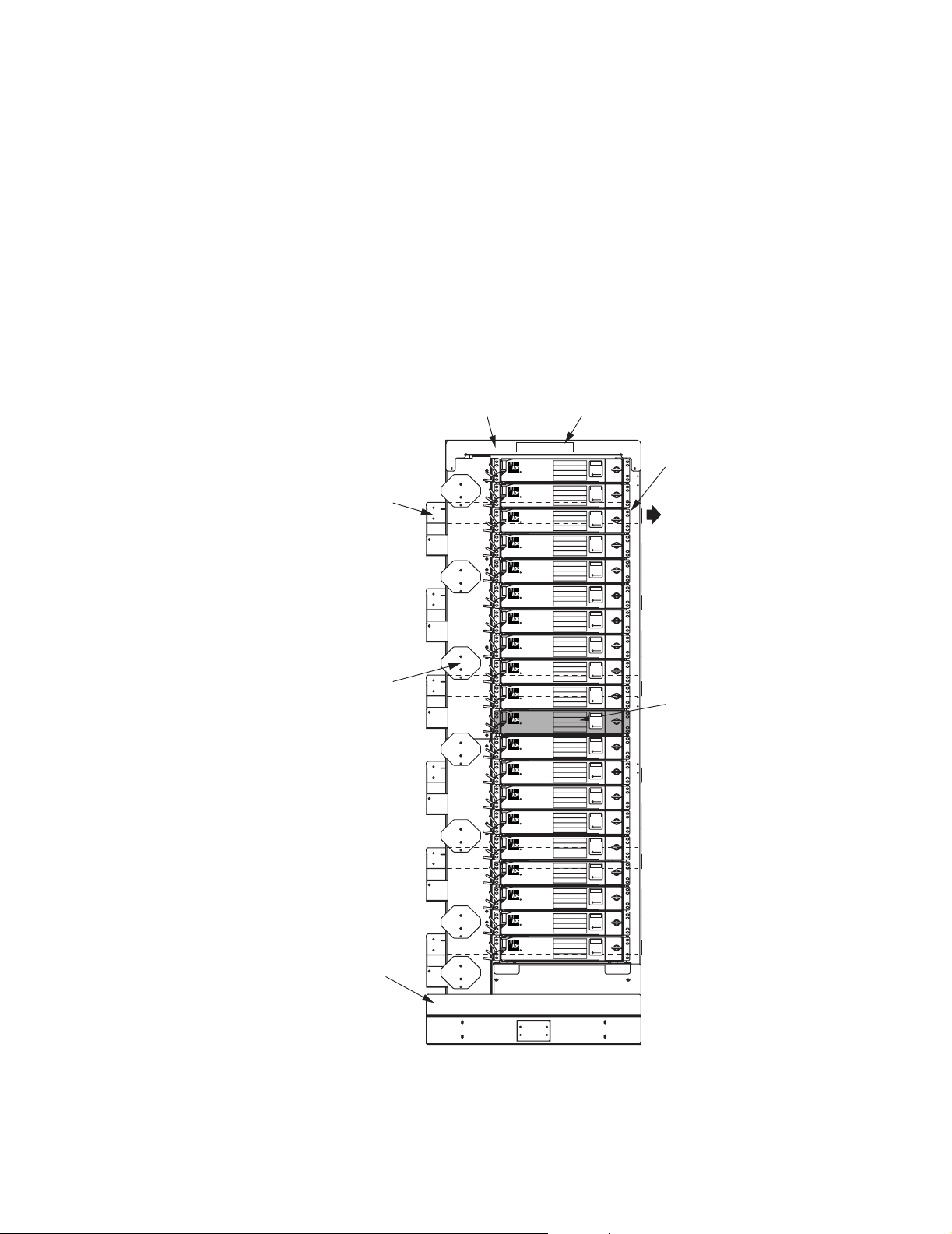

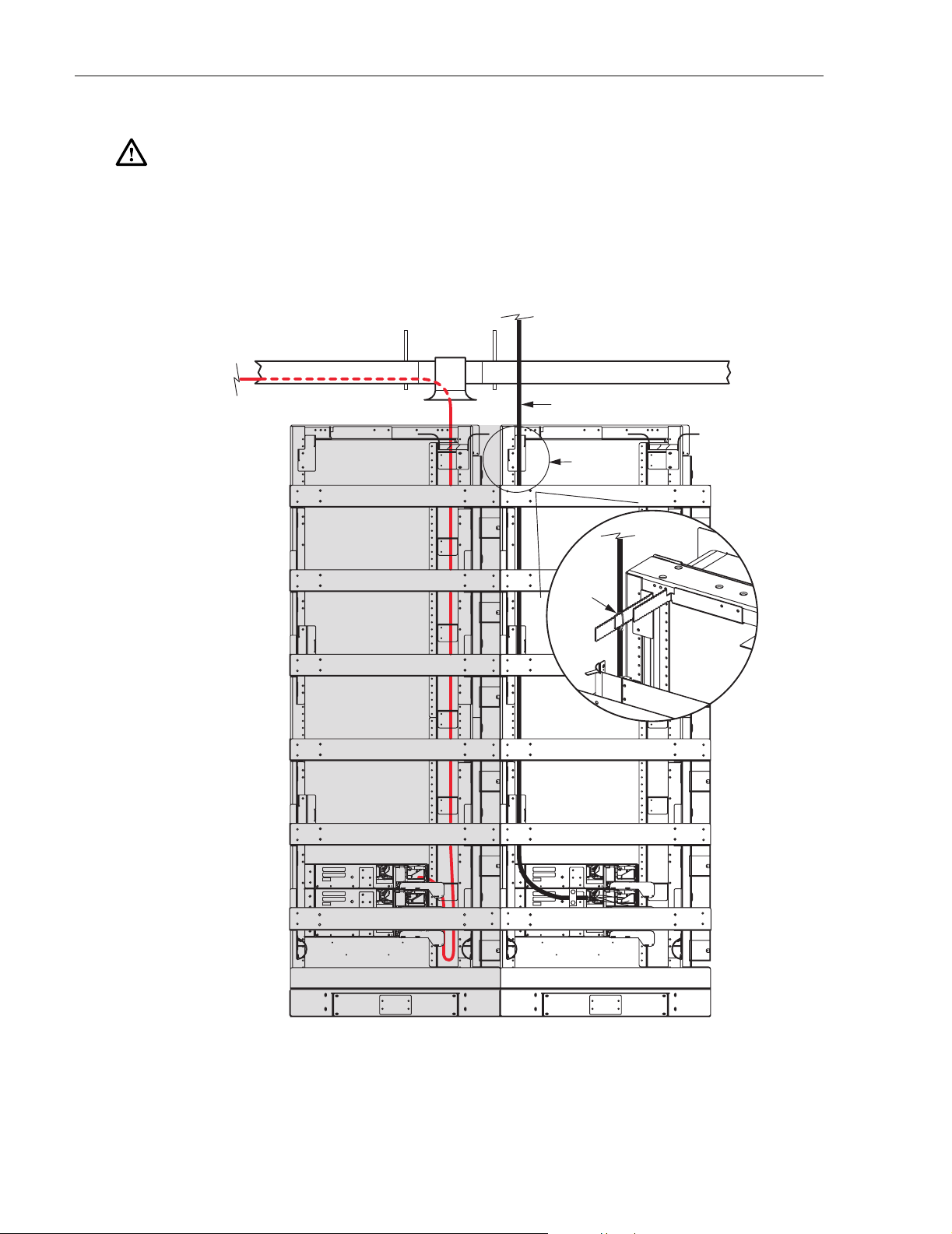

1.1 NG3 High-Density Fiber Distribution Frame System Overview

The 72-Position Standard Termination Panel, the 72-Position Termination and Splice Panel, and

the 12-position VAM Panel are components of the NG3 High-Density Fiber Distribution Frame

System. An example of a typical NG3 frame is shown in Figure 1.

ADCP-90-297 • Issue 7 • July 2006

FRONT-TO-REAR

TRANSITION

TROUGH

(6 PLACES)

SLACK

STORAGE

SPOOLS

(7 PLACES)

LOWER

TROUGH

UPPER

TROUGH

FRAME NUMBER

LABEL

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

REAR TROUGH

(NOT VISIBLE)

TO ADJACENT

REAR TROUGH

(6 PLACES)

NG3 TERMINATION

PANEL (TYPICAL)

NOTE: PANELS MAY BE

NUMBERED FROM 1 TO 20

STARTING WITH THE TOP

OR BOTTOM PANEL

18285-B

Figure 1. NG3 Panel on NG3 Frame

© 2006, ADC Telecommunications, Inc.

Page 1

Page 9

ADCP-90-297 • Issue 7 • July 2006

The NG3 frame and the optical panels mounted in the frame function as a distribution point for

fiber optic cables in a high density application. Each frame provides 20 mounting spaces for

NG3 panels with each panel providing up to 72 fiber ports. An NG3 frame also contains cable

management features including slack storage spools and cable troughs. A fully loaded frame

can support 1440 terminations using 2 mm patch cords.

1.2 NG3 72-Position Standard Termination Panel

The NG3 72-Position Standard Termination Panel is a rack-mount panel designed for mounting

on the NG3 frame. The panel has a hinged drawer that swings out to provide access to the

adapter packs within. The design of the panel allows for flexible deployment of all circuits

without a required termination plan or scheme.

The standard panel provides 72 adapter mounting positions (12 adapter packs, each with six

adapters). The adapters may be any of the standard single mode and multimode types including

SC, FC, and ST. For a complete list of adapter options, contact your ADC representative. The

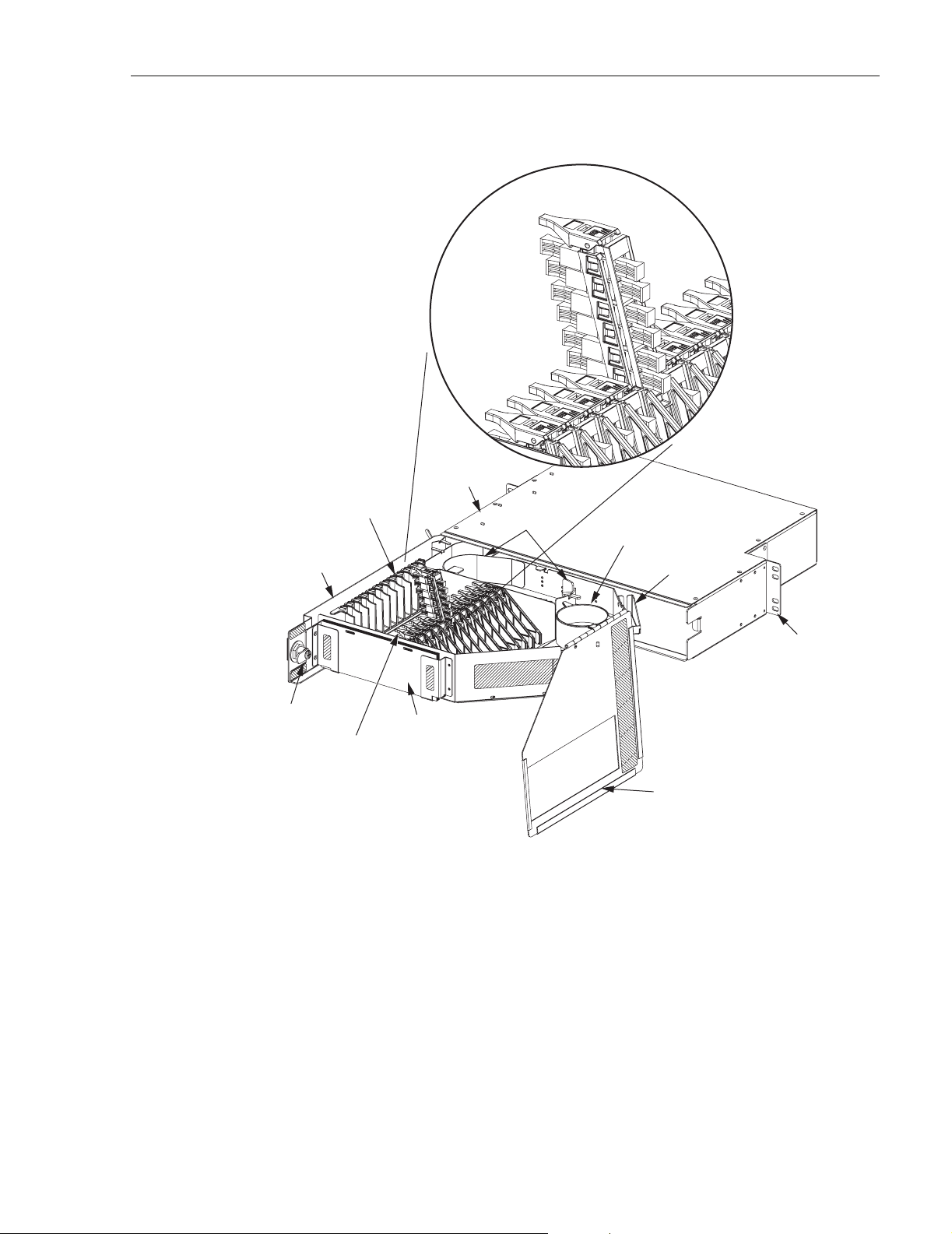

primary components of the NG3 panel are shown in Figure 2 and consist of the following:

• Panel Chassis—The foundation structure of the panel. It is 17.18 inches (43.6 cm) wide

and 3.44 inches (8.7 cm) high. Each frame holds up to 20 panels of this size.

• Radius Limiters—Hold cables to a 1.5 inch minimum bend radius within the drawer to

protect the cable from being damaged by too severe a bend.

• Cable Spool—Holds cables to a 1.5 inch minimum bend radius within the drawer and

keeps cables in position when the drawer is opened.

• Mounting Tabs—Used to fasten the panel on the NG3 rack.

• Drawer Cover—Protects cables when closed and provides access to adapters when open.

The cover is cut out above the adapter packs so as not to press on them when closed. The

cover, when open, acts as a stop to prevent the drawer from being accidentally closed.

• Designation Cards—Provide two square inches each of port designation space for all 72

ports, front and rear.

• Adapter Packs—Separately mountable assemblies, each consisting of a housing and six

adapters. The adapter packs swing up individually from their home position, providing full

access to front and rear terminations.

• Door Latch—Holds the door in a closed position, can be replaced with a key lock for

locations where security is a concern.

• Hinged Drawer—Swings out from within the panel to the position shown.

• Radius Limiters—Guide patch cords routed out of panel to front of frame.

The adapter pack ports are numbered in ascending numeric order from top to bottom in each

individual pack and from rear to front among the adapter packs. Port number 1 is at the top of

the adapter pack furthest to the rear of the drawer and port number 72 is at the bottom of the

adapter pack furthest to the front. Each of the four designation cards at the front of the drawer

have room for 18 port designations.

Page 2

© 2006, ADC Telecommunications, Inc.

Page 10

HINGED

DRAWER

RADIUS

LIMITERS

ADAPTER

POSITION

PANEL

CHASSIS

PAC K

IN OPEN

LIMITERS

ADCP-90-297 • Issue 7 • July 2006

RADIUS

CABLE

SPOOL

FIBER

TRANSPORT

18543-B

MOUNTING

TABS

(1 EACH SIDE)

DOOR LATCH

(OR KEY LOCK)

ADAPTER

PACKS

DESIGNATION

CARDS

DRAWER

COVER

Figure 2. NG3 72-Position Standard Termination Panel

1.2.1 NG3 Standard Termination Panel Options

The NG3 standard termination panel may be ordered in either of two configurations:

• Unterminated—Panel is equipped with adapter packs only.

• Preterminated—Panel is equipped with adapter packs and an IFC cable that is pre-

installed in the panel. The stub end of the cable is coiled up or placed on a spool.

© 2006, ADC Telecommunications, Inc.

Page 3

Page 11

ADCP-90-297 • Issue 7 • July 2006

1.2.2 NG3 Standard Termination Panel Accessories

The following accessories are available for use with the NG3 standard termination panel:

• Cable Clamp Kit—provides a clamp and other hardware required for securing an IFC or

OSP cable to the rear side of the NG3 panel.

• IFC Cable Assemblies—are available with single mode or multimode fiber in specified

lengths and with specified connectors.

• Patch Cords—are available with specified connectors in standard lengths of 3.0, 5.0, 6.0,

7.0, 8.0, 9.0, 10.0, and 12.0 meters.

• Adapter Packs—are available separately with specified adapters, and can be used either

as replacements for existing adapter packs. The adapters may be any of the standard single

mode and multimode types, including SC, FC, and ST. For a current list of adapter

options, contact your ADC representative.

• Inline Attenuators—are installed between a connector and an adapter to protect

equipment by attenuating optical signals to acceptable levels. ADC inline attenuators are

fused attenuators providing exceptional optical performance.

• TracerLight Connector Identification System—offers a quick and accurate method of

identifying the termination point of optical patch cords. Each end of a TracerLight patch

cord features a flashing light source allowing technicians to visually trace individual patch

cords from one end to the other without pulling or affecting the patch cord. Use of a

TracerLight system minimizes the risk of taking the incorrect fiber out of service,

improving system turn-up speed and accuracy. TracerLight patch cords meet all

performance criteria of standard ADC patch cords.

1.3 NG3 72-Position Termination and Splice Panel

The NG3 72-Position Termination and Splice Panel is similar to the standard termination panel

described in Section 1.2 but includes additional features that allow a ribbon-type 72-fiber IFC

cable to be routed to the panel and spliced to a pre-installed connectorized cable assembly

within the panel. The termination and splice panel mounts in the NG3 rack and has a hinged

drawer that swings out to provide access to the adapter packs and splice tray. The termination

and splice panel is primarily used in “tie panel” applications.

The termination and splice panel provides 72 adapter mounting positions (12 adapter packs,

each with six adapters) and one splice tray for ribbon-type fusion splices. The same adapter

types offered with the standard termination panel are available. The termination and splice panel

is equipped with a ribbon-type connectorized cable assembly which is pre-installed in the panel

drawer and ready for splicing. The additional features and equipment provided with the

termination and splice panel are shown in Figure 3 and described as follows:

• Cable Clamp–Used to secure the ribbon-type IFC cable to the rear side of the panel.

Includes cable clamps, grommet, cover plate, and screws.

• Ribbon Cable Blocking Kit–Separates and protects the fiber ribbons at the cable break-

out point. Includes a protective oval tube assembly for the six 12-fiber ribbons, a fanout

base with cover, cover screws, cable ties, and tape. Instructions for kit assembly are

included.

Page 4

© 2006, ADC Telecommunications, Inc.

Page 12

REAR VIEW

IFC CABLE

ROUTED TO PANEL

CABLE

CLAMP KIT

ADCP-90-297 • Issue 7 • July 2006

RIBBON

BLOCKING

KIT

SPLICE TRAY

FRONT VIEW

RIBBON-TYPE

CONNECTORIZED

CABLE ASSEMBLY

19993-A

Figure 3. NG3 72-Position Termination and Splice Panel

• Splice Tray–An all metal tray that protects and stores the completed splices and bare fiber

ribbons. Includes a protective cover and two 6-position fusion-type ribbon splice chips for

holding the splices.

• Ribbon-Type Connectorized Cable Assembly–A ribbon-type 72-fiber IFC cable

assembly terminated with customer-specified connectors. The cable assembly is preinstalled in the drawer and the connectors are mated with the adapter packs. At the cable

fanout point, the cable assembly is broken-out into six 12-fiber ribbons which are placed

in protective tubing and routed to the splice tray.

© 2006, ADC Telecommunications, Inc.

Page 5

Page 13

ADCP-90-297 • Issue 7 • July 2006

1.4 NG3 12-Position Value Added Module Panel

The NG3 12-Position Value Added Module (VAM) Panel is a rack-mount panel designed for

mounting on the NG3 rack. The panel has a hinged drawer that swings out to provide access to

the VAM’s within. The VAM panel, shown in Figure 4, allows optical splitter or Wavelength

Division Multiplexing (WDM) functionality to be incorporated into specified optical circuits at

the NG3 frame. Optical splitters are used to divide the optical signal for distribution to multiple

ports in order to provide test, access, and monitoring capability. WDM’s are used to increase

transmission capacity, combine separate services on an existing network, and to provide nonintrusive testing.

The following basic VAM types are available:

• Splitter–Distributes the optical signal to multiple circuits

• Monitor–Provides a test or access point in an optical circuit

• Wavelength Division Multiplexer–Allows transmission of two optical wavelengths in the

same direction on the same fiber (unidirectional) or transmission of two optical

wavelengths in the opposite direction on the same fiber (bidirectional)

PATCH CORD

STORAGE

VALUE ADDED MODULE

ASSEMBLIES (12)

Figure 4. NG3 Value Added Module Panel

19987-B

The VAM panel provides twelve micro VAM assembly mounting positions. The VAM

assemblies must be ordered separately and installed in the panel on an as needed basis. Each

VAM assembly, shown in Figure 5, provides a maximum of six front access input/output

adapter ports. The same adapter types offered with the termination panel and termination/splice

panel are also available with the VAM assembly.

Page 6

© 2006, ADC Telecommunications, Inc.

Page 14

FRONT

ACCESS

ADAPTERS

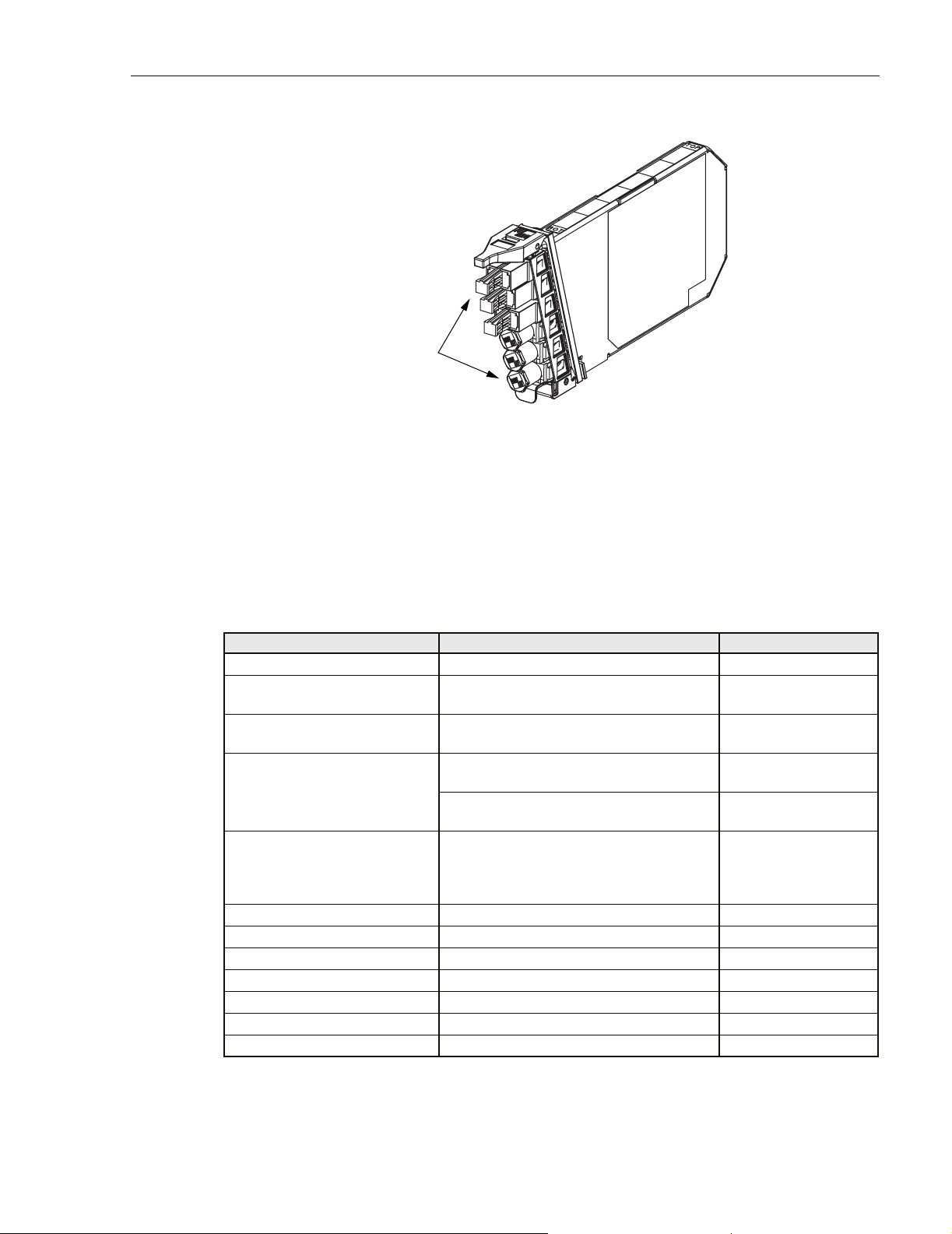

1.5 Specifications and Dimensions

ADCP-90-297 • Issue 7 • July 2006

19986-B

Figure 5. Typical Micro Value Added Module

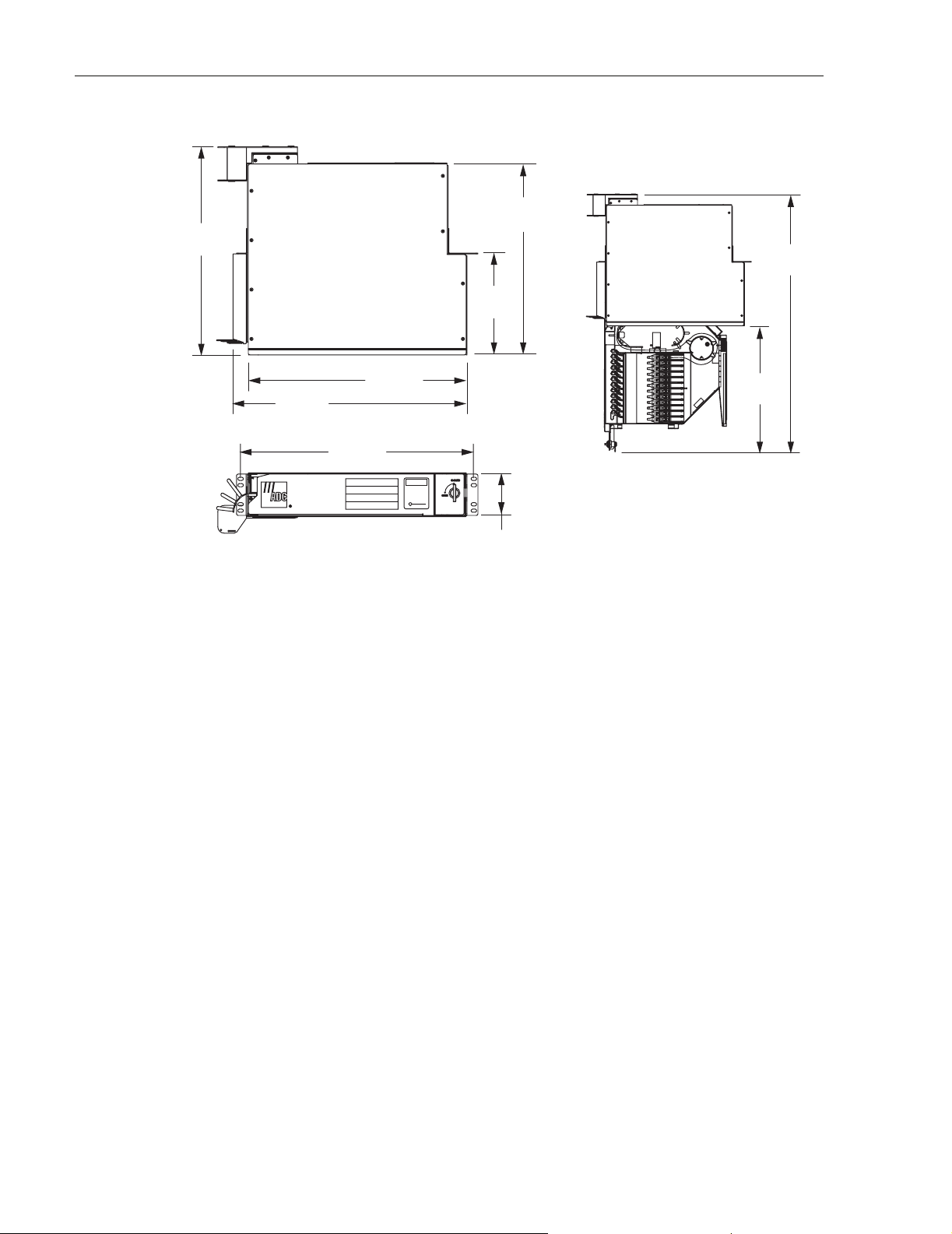

Tab le 1 provides specifications for the various NG3 Frame System panels. The dimensions of a

typical panel (with the drawer open and closed) are shown in Figure 6.

Table 1. NG3 Frame System Panel Specifications

PARAMETER SPECIFICATION REMARKS

Physical

Number of terminations or

VAM ports (maximum)

Number of adapter packs or

VA M ’s ( m a x i m um )

Dimensions (H x W x D) 3.44 x 18.31 x 16.38 in.

Connector and adapter types

available

Environment

Temperature

Operating –40° C to 65° C (–40° F to 149° F)

Storage –40° C to 85° C (–40° F to 185° F)

Relative humidity

Operating Up to 80% No condensation

Storage Up to 95% No condensation

72

12

(8.7 x 46.6 x 41.6 cm)

3.44 x 18.31 x 30.57 in.

(8.7 x 46.6 x 77.6 cm)

Available in most standard types including

singlemode PCST, PCFC, 8° SC/APC, 8°

FC/APC, 8° E-2000/APC, and duplex 8°

SC/APC, and multimode SC, FC, and ST

With hinged drawer

closed

With hinged drawer

open

Contact ADC for connector recommendations and performance

information.

© 2006, ADC Telecommunications, Inc.

Page 7

Page 15

ADCP-90-297 • Issue 7 • July 2006

16.34 IN.

(41.5 CM)

TOP VIEW

15.06 IN.

(38.3 CM)

32.01 IN.

(81.3 CM)

8.00 IN.

(20.3 CM)

18.37 IN.

(46.6 CM)

2 NG3 PANEL INSTALLATION

NG3 panel installation includes unpacking and inspecting the panel and any accessories,

mounting the panel on the frame, installing the panel label, and installing VAM’s. Installation of

an NG3 panel into the frame should take less than ten minutes.

ADC does not recommend mounting NG3 panels in any frame except the NG3 High Density

Fiber Distribution Frame. When splicing or using test equipment, work on a secure surface at a

convenient work level. Do not use the NG3 panel to support splice or test equipment.

17.25 IN.

(43.8 CM)

18.32 IN.

(46.5 CM)

FRONT VIEW

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

XXXXXXXXXXX

XXXXXXXXXXX

3.44 IN.

(8.7 CM)

TOP VIEW WITH

SWING-OUT DRAWER

OPEN 90 DEGREES

Figure 6. Typical NG3 Frame System Panel Dimensions

15.67 IN.

(39.8 CM)

20260-A

2.1 Unpacking and Inspection

Use the following procedure to unpack and inspect the NG3 panel:

1. Inspect the shipping carton for signs of damage and note any evidence of rough handling.

2. Open the carton and carefully unpack each item from the protective packing material.

3. If damage is detected or if parts are missing, file a claim with the commercial carrier. Save

the damaged carton for inspection by the carrier.

4. Contact ADC (see Section 7 at the end of this manual) for an RMA (Return Material

Authorization) and to reorder if replacement is required.

Page 8

© 2006, ADC Telecommunications, Inc.

Page 16

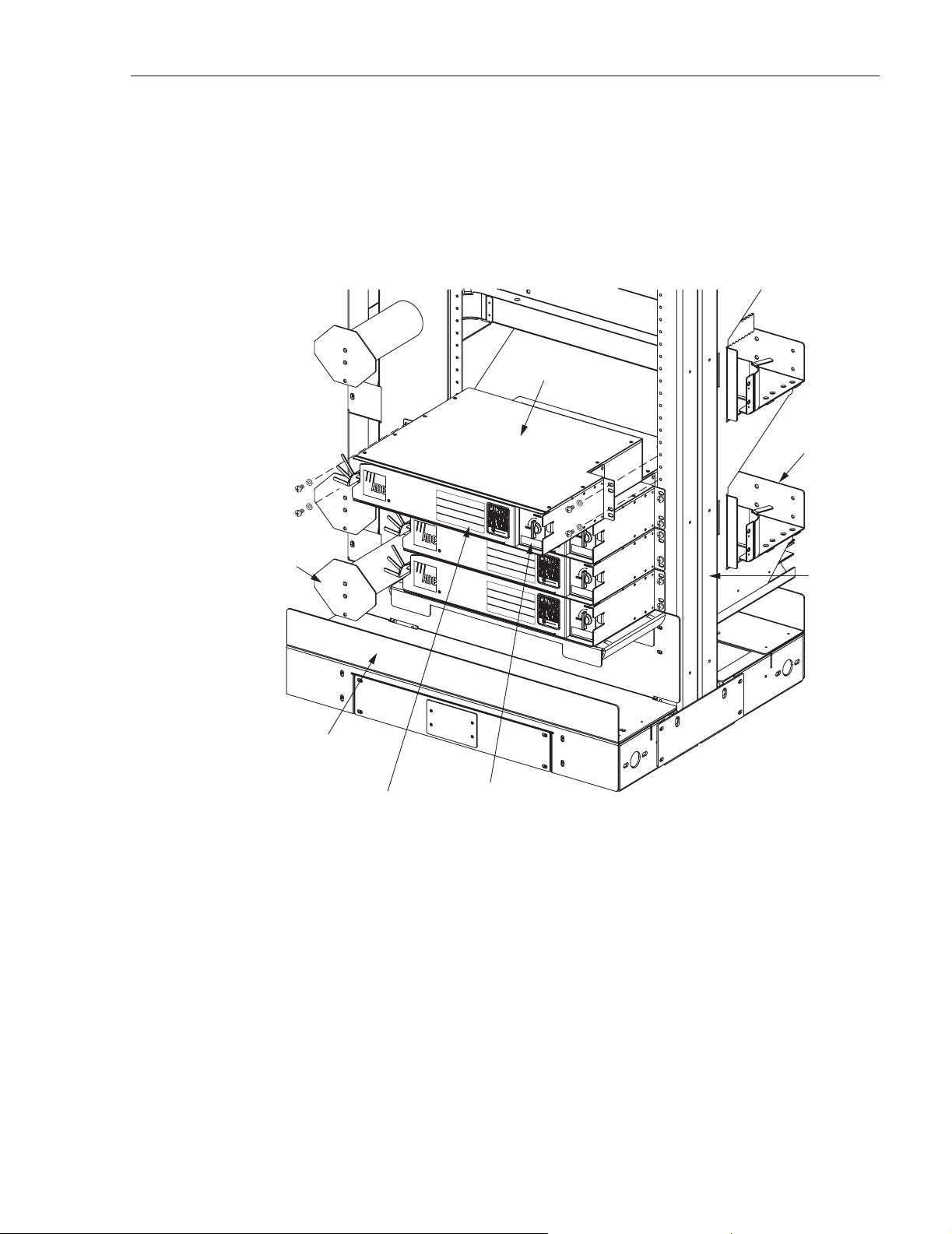

2.2 Mounting the NG3 Panel on the Frame

Use the following procedure to mount any NG3 panel on the NG3 frame:

1. Determine where the panel will be located on the frame.

2. Align the mounting holes in the panel with the mounting holes in the frame as shown in

Figure 7.

NG3

PANEL

ADCP-90-297 • Issue 7 • July 2006

REAR

TROUGH

SLACK

STORAGE

SPOOL

LOWER

TROUGH

GENERAL

PURPOSE

LABEL

AFFIX PANEL NUMBER

LABEL HERE. LABEL

SHEET PROVIDED

WITH FRAME.

18297-B

FRAME

Figure 7. Mounting the Panel on the Frame

3. Secure the panel to the frame using the four screws and washers provided with the panel.

4. Record the panel number and/or connector type on the general purpose label provided on

the front of the panel.

© 2006, ADC Telecommunications, Inc.

Page 9

Page 17

ADCP-90-297 • Issue 7 • July 2006

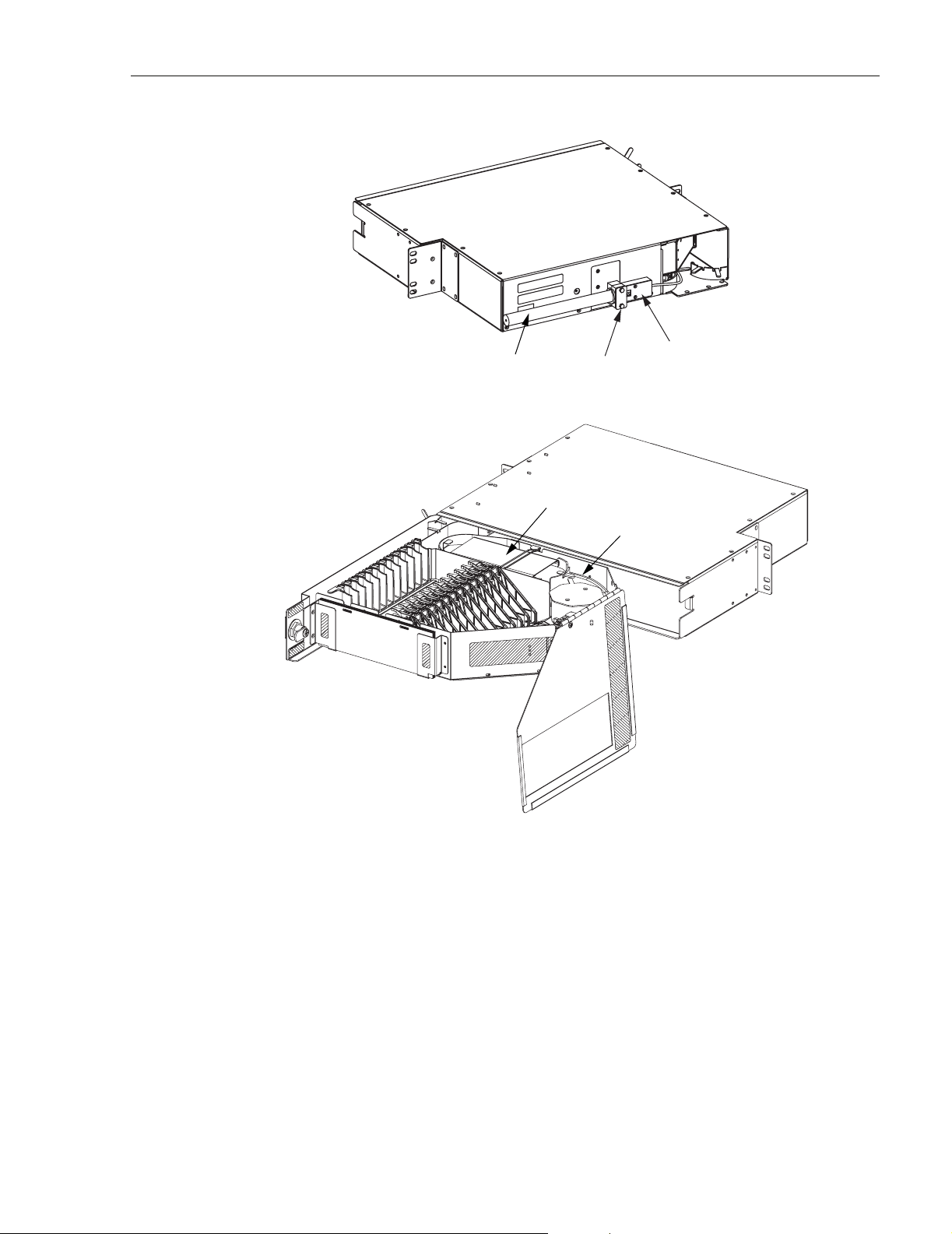

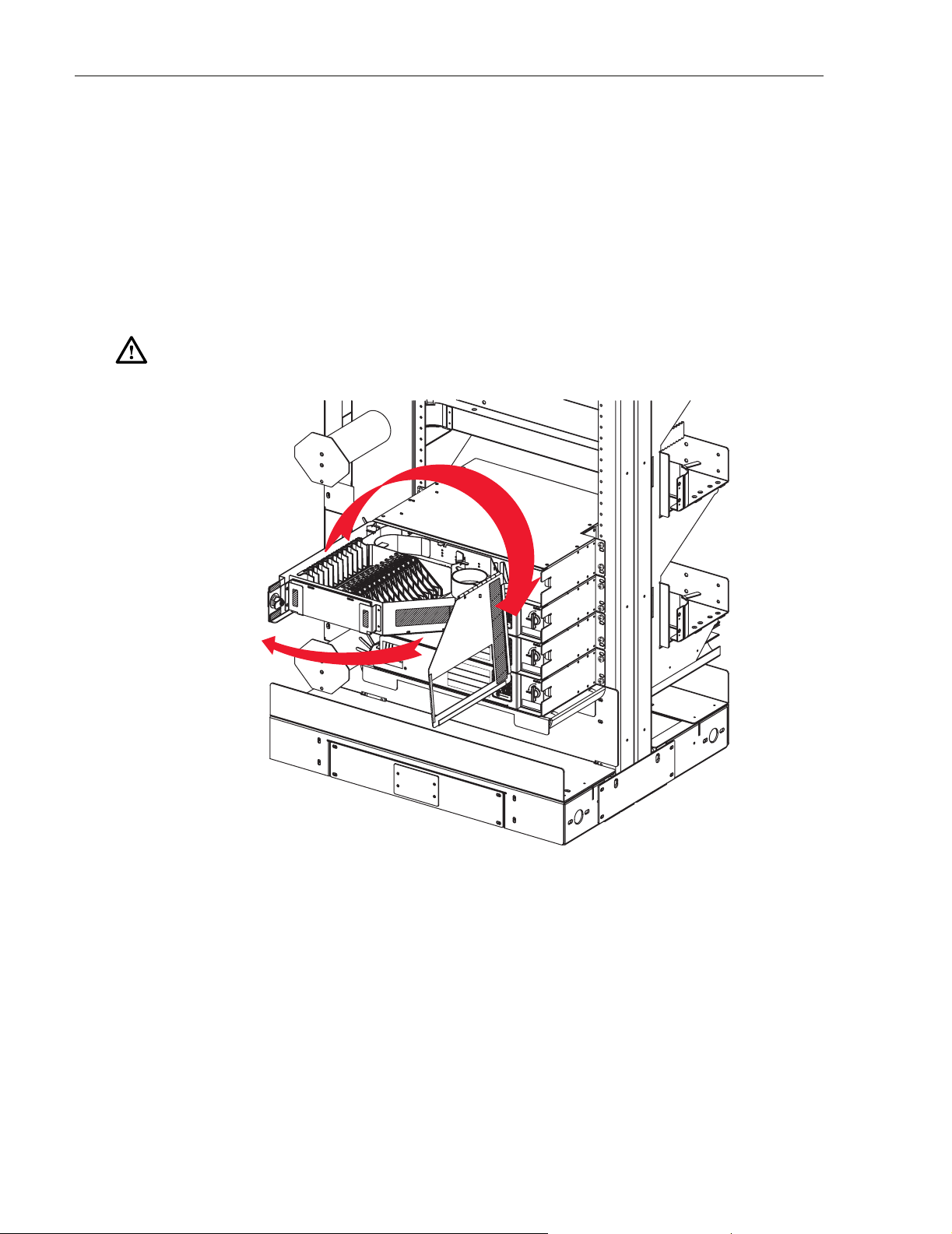

2.3 Opening the NG3 Panel

Use the following procedure to open any NG3 panel:

1. Rotate the door latch 90º counterclockwise.

2. Swing out the drawer as shown in Figure 8.

3. When the hinged drawer comes to rest in a position 90º out from the panel chassis, rotate

the top cover up and to the right. Allow the cover to hang down beside the drawer when

accessing the adapter packs or routing fibers within the drawer.

Caution: Placing a load in excess of 20 pounds onto an open drawer will result in

misalignment or damage to the drawer.

Figure 8. Opening the Hinged Drawer

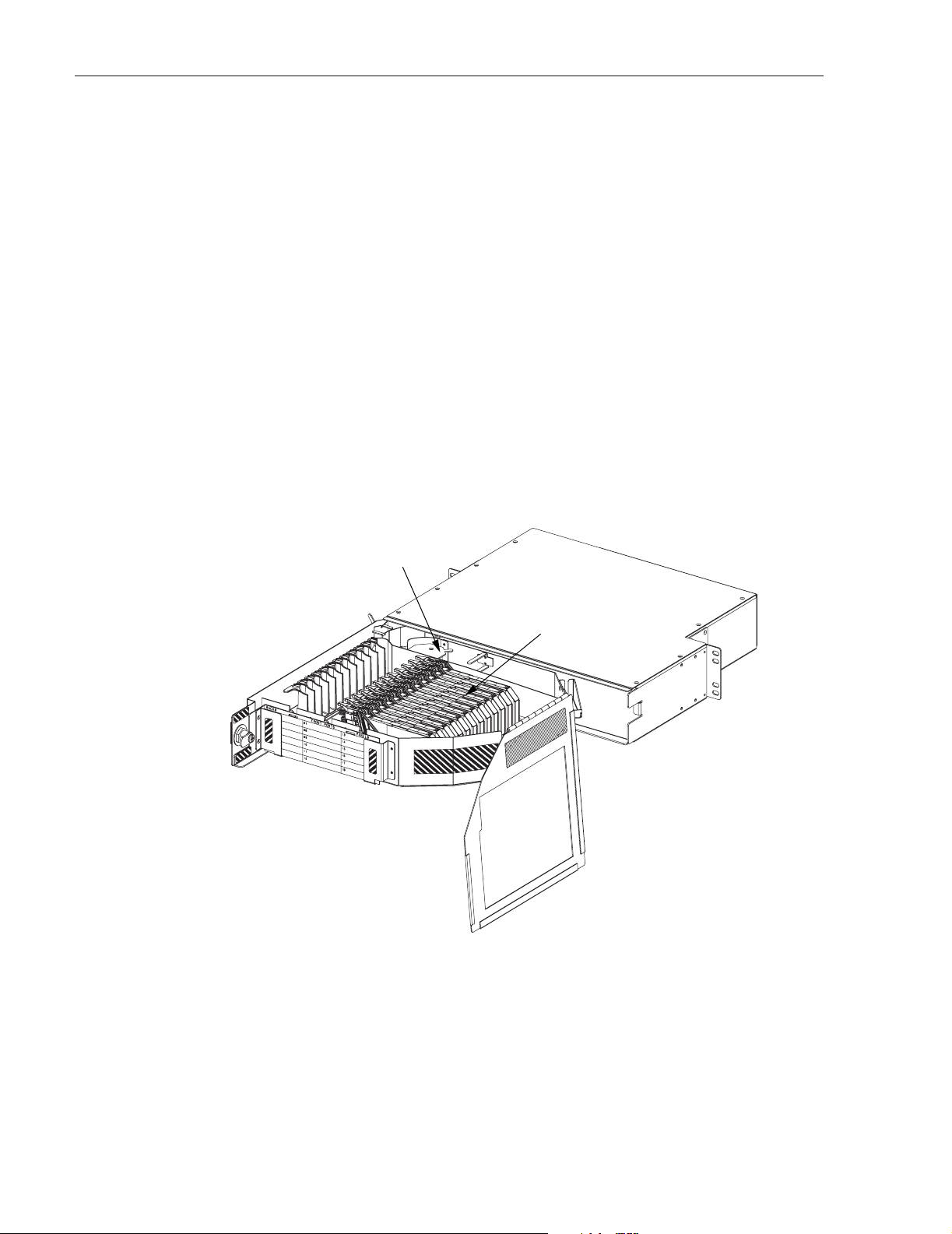

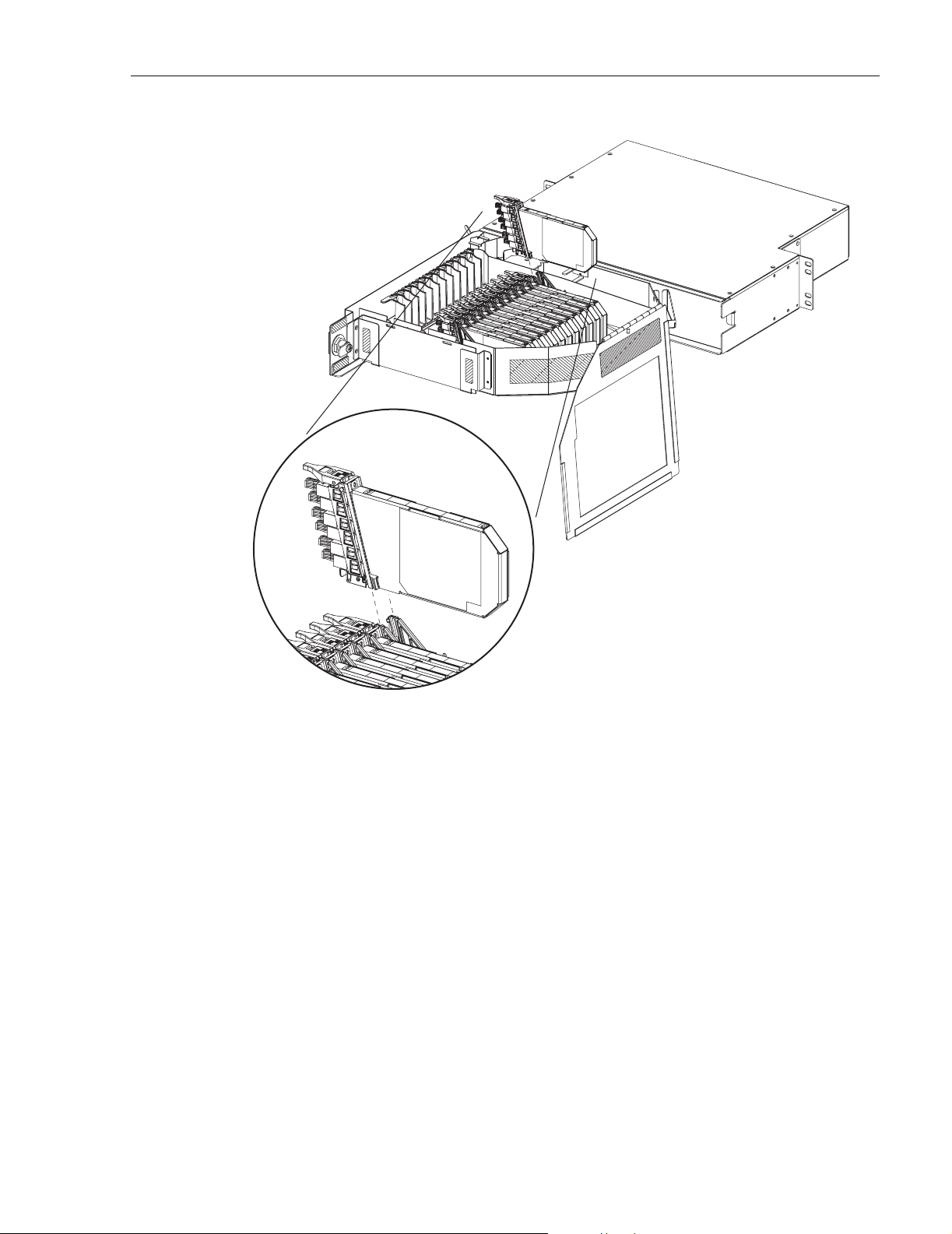

2.4 Installing Micro Value Added Modules

To prevent damage during shipment, all NG3 VAM panels are shipped without the micro VAMs

installed in the VAM panel mounting slots. Use the following procedure to install the micro

VAMs in the VAM panel:

1. Open the VAM panel as described in Subsection 2.3

2. Position the micro VAM about the selected mounting position as shown in Figure 9.

3. Slide the VAM down into the mounting slot.

Page 10

© 2006, ADC Telecommunications, Inc.

18298-C

Page 18

VALUE ADDED

MODULE ASSEMBLY

ADCP-90-297 • Issue 7 • July 2006

20288-A

Figure 9. Installing a Micro VAM

3 IFC CABLE ROUTING AND INSTALLATION

This section provides instructions for routing an IFC cable through an NG3 frame and installing

the cable in the appropriate NG3 panel. If the IFC cable is pre-installed in the panel, disregard

subsections 3.2 through 3.4. IFC cables may be of stranded or ribbon type construction.

3.1 General IFC Cable Routing Guidelines–All Panel Types

IFC cables are routed to the rear side of the frame from either above or below the NG3 panel.

Each IFC cable is routed vertically up or down the left rear side of the frame to the designated

panel as shown in Figure 10. The IFC cable is then routed horizontally from left to right to the

rear of the designated panel and into the opening on the right rear side of the panel. A clamp

secures the IFC cable to the rear side of the panel. The cable should also be secured to the frame

using wax lacing tied to the tie down bars located on the left rear side of the frame.

© 2006, ADC Telecommunications, Inc.

Page 11

Page 19

ADCP-90-297 • Issue 7 • July 2006

Caution: Applying excessive tension on lacing cables can cause physical damage and

attenuation of optical fibers.

The cable shall maintain a minimum bend radius of 1.5 inches or ten times the cable outside

diameter, which ever is greater, inside the cable raceways and within the NG3 frame. Secure the

cable to the overhead raceway per local practice. ADC does not recommend storing slack cable

on the NG3 frame. If cable storage is required, follow local practice.

IFC CABLE

IFC

TIE-DOWN

LOCATION

REAR VIEW

LACING

18304-D

Page 12

© 2006, ADC Telecommunications, Inc.

Figure 10. IFC Cable Routing on Rear of Frame

Page 20

3.2 Standard Termination Panel IFC Cable Installation

Use the following procedure to install a connectorized IFC cable in an unterminated (adapters

only) standard termination panel. A conversion kit (NG3-ACCIFCKIT) is required.

Note: This procedure is most efficiently done by two people, with one person at the front

of the panel and the other person at the rear.

1. Break out the cable according to the dimensions provided in Figure 11 (stranded cable) or

Figure 12 (ribbon cable). For ribbon cable, install protective tubing, fanouts, and upjackets

in the locations shown.

BREAKOUT LENGTH

65.0 IN. (165.1 CM)

+0.0 IN./-6.0 IN.

(+0.0 CM/-15.2 CM)

FANOUT LENGTH

37.0 IN. (93.9 CM)

+0.0 IN./-6.0 IN.

(+0.0 CM/-15.2 CM)

2.0 IN.

(5.1 CM)

ADCP-90-297 • Issue 7 • July 2006

IFC

CABLE

19786-B

CONNECTORS

SUBUNIT

DESIGNATION

LABEL

HEATSHRINK

6.0 IN. (15.2 CM)

CLAMP

Figure 11. Breakout Cable Dimensions for Stranded Cable Routed to Standard Termination Panel

CLAMP

BREAKOUT LENGTH

65.0 IN. (165.1 CM)

+0.0 IN./-6.0 IN.

(+0.0 CM/-15.2 CM)

FLARE

TUBE

INDIVIDUAL

PROTECTIVE

TUBING

SUBUNIT

DESIGNATION

LABEL

CLAMP POSITION

69.0 IN. (175.3 CM)

+0.0 IN./-6.0 IN.

(+0.0 CM/-15.2 CM)

FANOUT LENGTH

FANOUT

INDIVIDUAL

UPJACKETED

FIBER

38.0 IN. (96.5 CM)

+0.0 IN./-6.0 IN.

(+0.0 CM/-15.2 CM)

CONNECTORS

19787-B

Figure 12. Breakout Cable Dimensions for Ribbon Cable Routed to Standard Termination Panel

© 2006, ADC Telecommunications, Inc.

Page 13

Page 21

ADCP-90-297 • Issue 7 • July 2006

2. Locate the panel where the cable will be installed and position one person at the front of

the panel and another person at the rear.

3. At the front of panel, fully open the hinged drawer (refer to Subsection 2.3).

Caution: Placing a load in excess of 20 pounds onto an open drawer will result in

misalignment or damage to the drawer.

4. At the rear of the panel, insert the bundled connector end of the cable into the panel rear

entry hole, as shown in Figure 13, and slide it through to the front.

CLAMP POINT

SLIDE BUNDLED

FIBERS IN

FROM REAR

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

5. At the front of the panel, lift the cable up over the top edge of the hinged drawer and move

the cable to the cable entry hole on the left side of the drawer, as shown in Figure 14.

Page 14

© 2006, ADC Telecommunications, Inc.

20287-A

Figure 13. Routing IFC Cable Into Standard Termination Panel

Page 22

ADCP-90-297 • Issue 7 • July 2006

ROUTE FIBERS UNDER

PROTECTOR PLATE

LIFT CABLE

FIBERS

INTO CABLE

ENTRY HOLE

MOVE BUNDLED

FIBERS TO THE LEFT

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

20289-B

Figure 14. Positioning IFC Cable Within Standard Termination Panel

6. At the rear of the panel, clamp the cable to the panel using a cable clamp kit. The

components of the cable clamp kit are shown in Figure 15.

Note: Position the cable clamp on the cable at the point indicated in the cable breakout

diagrams. For ribbon cable, refer to Figure 11. For stranded cable, refer to Figure 12.

© 2006, ADC Telecommunications, Inc.

Page 15

Page 23

ADCP-90-297 • Issue 7 • July 2006

GROMMET

(IF NEEDED)

18431-B

PLATE

HEX

MOUNTING

SCREWS

YOKES

MOUNTING

HOLES

Figure 15. Clamping Cable to Standard Termination Panel

7. Route the cable fibers within the drawer as shown in Figure 16 (stranded cable) or

Figure 17 (ribbon cable).

8. Locate the assigned adapter and lift up the adapter pack. (refer to Subsection 5.1).

9. Remove the dust caps from the connectors and the rear side of the adapters and then insert

each connector into the appropriate adapter.

Note: Clean and inspect the connectors and adapters before mating them. For guidelines,

refer to Subsection 5.3.

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber connector or adapter. Exposure to invisible laser

radiation may result. An optical power meter should be used to verify active fibers. A protective

cap or hood MUST be immediately placed over any radiating adapter or optical fiber connector

to avoid the potential of dangerous amounts of radiation exposure. This practice also prevents

dirt particles from entering the adapter or connector.

Page 16

© 2006, ADC Telecommunications, Inc.

Page 24

ADCP-90-297 • Issue 7 • July 2006

10. Secure the cable to the drawer at the cable retention area using the O-ring provided with

the panel. Refer to Figure 16 or Figure 17 for details.

11. Return the adapter pack to its home position.

12. Continue routing and connecting any remaining connectors on the same cable.

13. When done, close the panel (refer to Subsection 5.5).

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

IFC CABLE

SLACK LOOP

CABLE

RETENTION

AREA

20290-A

CABLES SHOULD BE

LOOSE IN DRAWER.

FIBERS SHOULD NOT

BE TIGHT WHEN SAP

Figure 16. Stranded Cable Routing Within Standard Termination Panel

IS RAISED.

© 2006, ADC Telecommunications, Inc.

Page 17

Page 25

ADCP-90-297 • Issue 7 • July 2006

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

SLACK LOOPS

FANOUT

20291-A

CABLES SHOULD BE

LOOSE IN DRAWER.

FIBERS SHOULD NOT

BE TIGHT WHEN SAP

IS RAISED.

Figure 17. Ribbon Cable Routing Within Standard Termination Panel

Page 18

© 2006, ADC Telecommunications, Inc.

Page 26

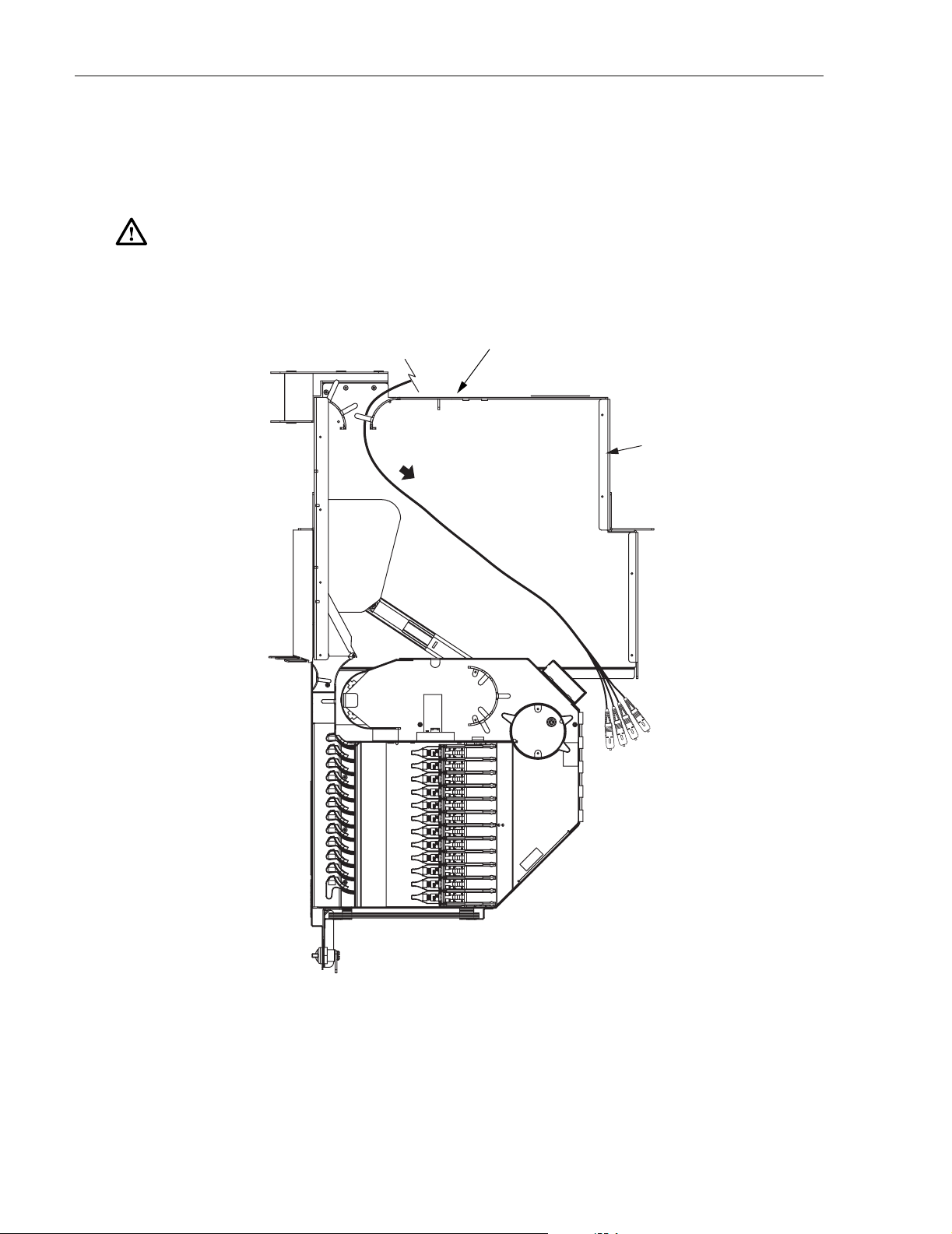

3.3 Termination and Splice Panel IFC Cable Installation and Splicing

The Termination and Splice Panel may be used to splice an unterminated 72-fiber ribbon-type

IFC cable to a connectorized cable assembly installed within the panel. Use the following

procedure to secure the IFC cable to the panel and to splice the IFC cable to the installed cable

assembly:

Note: This procedure is most efficiently done by two people, with one person at the front

of the panel and the other person at the rear.

1. Break out the cable and install the blocking kit (provided with panel) as shown in

Figure 18. Expose at least 156 inches (396 CM) of bare ribbon when assembling the

blocking kit. Refer to the Ribbon Blocking Kit Installation Instructions (ADCP-93-305)

for the kit assembly details.

ADCP-90-297 • Issue 7 • July 2006

EXPOSE AT LEAST

156 INCHES (396 CM)

WHEN ASSEMBLING

PLACE ALL SIX FIBER

RIBBONS WITHIN TUBING

OF BARE RIBBON

BLOCKING KIT

115 INCHES

(291 CM)

20209-A

Figure 18. Ribbon Blocking Kit Assembly

2. Locate the panel where the cable will be installed and position one person at the front of

the panel and another person at the rear.

3. At the front of panel, fully open the hinged drawer (refer to Subsection 2.3).

Caution: Placing a load in excess of 20 pounds onto an open drawer will result in

misalignment or damage to the drawer.

4. At the rear of the panel, insert the ribbon tube into the panel rear entry hole, as shown in

Figure 19, and slide it through to the front.

© 2006, ADC Telecommunications, Inc.

Page 19

Page 27

ADCP-90-297 • Issue 7 • July 2006

CLAMP POINT

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

SLIDE RIBBON

TUBE IN FROM REAR

20210-A

Figure 19. Routing Ribbon Tube into Termination and Splice Panel

5. At the front of the panel, lift the ribbon tube up over the top edge of the hinged drawer and

move the tube to the cable entry hole on the left side of the drawer, as shown in Figure 20.

Page 20

© 2006, ADC Telecommunications, Inc.

Page 28

ROUTE RIBBON

TUBE UNDER

PROTECTOR PLATE

LIFT RIBBON

TUBE INTO CABLE

ENTRY HOLE

MOVE RIBBON

TUBE TO LEFT

ADCP-90-297 • Issue 7 • July 2006

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

20211-B

Figure 20. Positioning Ribbon Tube Within Termination and Splice Panel

6. At the rear of the panel, clamp the cable to the panel using the cable clamp kit provided.

The components of the cable clamp kit are shown in Figure 21.

© 2006, ADC Telecommunications, Inc.

Page 21

Page 29

ADCP-90-297 • Issue 7 • July 2006

GROMMET

(IF NEEDED)

19991-C

YOKES

PLATE

MOUNTING

HOLES

HEX

MOUNTING

SCREWS

RIBBON

BLOCKING

KIT

Figure 21. Clamping IFC Ribbon Cable to Termination and Splice Panel

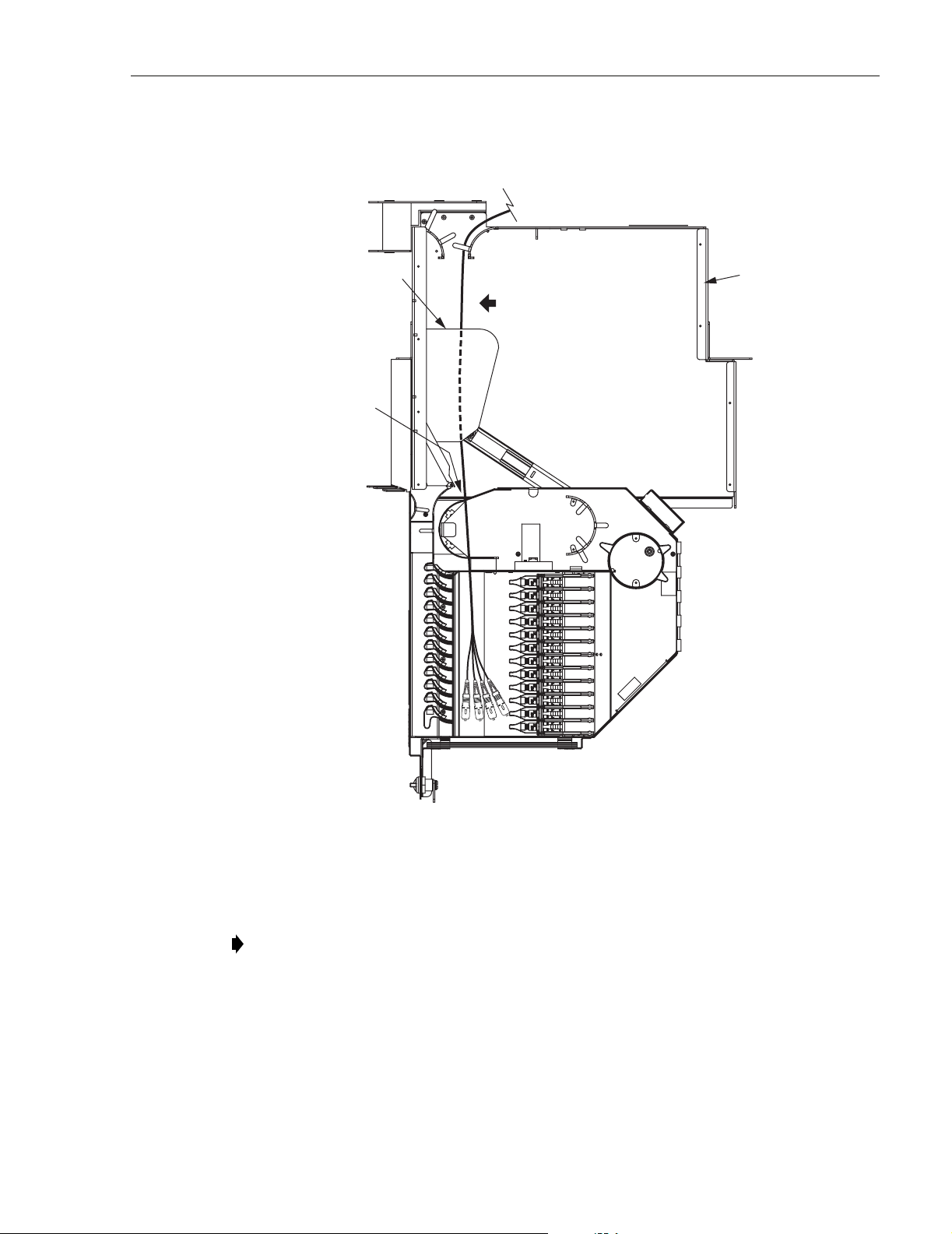

7. Route the ribbon tube once around and under the splice tray as shown in Figure 22.

ROUTE RIBBON

TUBE UNDER

PROTECTOR PLATE

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

Page 22

© 2006, ADC Telecommunications, Inc.

20212-A

Figure 22. Routing Ribbon Tube Around and Under Splice Tray

Page 30

ADCP-90-297 • Issue 7 • July 2006

8. Remove the splice tray cover and then secure the ribbon tube to the splice tray at the point

indicated in Figure 23. Use wax lacing to attach the ribbon tube to the splice tray.

SECURE TUBING

TO TRAY USING

WAX LACING

19990-A

Figure 23. Securing Ribbon Tube To The Splice Tray

9. Remove the splice tray from the drawer and uncoil the attached optical fibers from the

slack storage area around and under the splice tray.

10. Splice the IFC cable fibers to the cable assembly fibers following local splicing practice.

Two ribbon-type splice chips are attached to the bottom of the splice tray.

Note: ADC recommends that all splicing be done per Telecordia GR-1095-CORE and

GR-765 requirements.

11. When splicing is completed, re-install the splice tray cover on the splice tray and coil up

the excess slack from the attached optical fibers in the slack storage area.

12. Place the splice tray back in the panel and then close the drawer (refer to Subsection 5.5)

3.4 VAM Panel IFC Cable Installation

The VAM panel allows optical splitter or wavelength division multiplexing (WDM)

functionality to be incorporated into specified optical circuits at the NG3 frame. Use the

following procedure to install a connectorized stranded-type IFC cable in a VAM panel:

1. Break out the IFC cable according to the dimension shown in Figure 24.

2. Locate the panel where the cable will be installed and position one person at the front of

the panel and another person at the rear.

3. At the front of panel, fully open the hinged drawer (refer to Subsection 2.3).

Caution: Placing a load in excess of 20 pounds onto an open drawer will result in

misalignment or damage to the drawer.

4. At the rear of the panel, insert the bundled connector end of the cable into the panel rear

entry hole, as shown in Figure 25, and slide it through to the front.

© 2006, ADC Telecommunications, Inc.

Page 23

Page 31

ADCP-90-297 • Issue 7 • July 2006

CONNECTORS

BREAKOUT LENGTH

48.0 IN. (121.9 CM)

+0.0 IN./-3.0 IN.

(+0.0 CM/-7.6 CM)

2.0 IN.

(5.1 CM)

HEATSHRINK

6.0 IN. (15.2 CM)

Figure 24. Breakout Dimension for Stranded IFC Cable Routed to VAM Panel

CLAMP POINT

PANEL SHOWN

WITH TOP

SLIDE FIBERS IN

FROM REAR

REMOVED FOR

CLARITY

MULTI-FIBER IFC CABLE

2 MM MAX.

OUTSIDE DIAMETER

FOR SUBUNITS

CLAMP

20213-B

Page 24

© 2006, ADC Telecommunications, Inc.

20278-A

Figure 25. Routing IFC Cable Into VAM Panel

Page 32

ADCP-90-297 • Issue 7 • July 2006

5. At the front of the panel, lift the cable up over the top edge of the hinged drawer and move

the cable to the cable entry hole on the left side of the drawer, as shown in Figure 26.

PANEL SHOWN

ROUTE FIBERS UNDER

PROTECTOR PLATE

LIFT FIBERS INTO

CABLE ENTRY HOLE

MOVE FIBERS

TO LEFT

WITH TOP

REMOVED FOR

CLARITY

20279-B

Figure 26. Positioning IFC Cable Within VAM Panel

6. At the rear of the panel, clamp the cable to the panel using a cable clamp kit. The

components of the cable clamp kit are shown in Figure 27.

© 2006, ADC Telecommunications, Inc.

Page 25

Page 33

ADCP-90-297 • Issue 7 • July 2006

GROMMET

(IF NEEDED)

18431-B

PLATE

YOKES

HEX

MOUNTING

SCREWS

MOUNTING

HOLES

Figure 27. Clamping IFC Cable To VAM Panel

7. Route the cable fibers within the drawer as shown in Figure 28.

8. Locate the assigned VAM and lift it up to access the adapters (refer to Subsection 5.2).

9. Remove the dust caps from the connectors and the VAM adapters and then insert each

connector into the appropriate adapter.

Note: Clean and inspect the connectors and adapters before mating them. For guidelines,

refer to Subsection 5.3.

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber connector or adapter. Exposure to invisible laser

radiation may result. An optical power meter should be used to verify active fibers. A protective

cap or hood MUST be immediately placed over any radiating adapter or optical fiber connector

to avoid the potential of dangerous amounts of radiation exposure. This practice also prevents

dirt particles from entering the adapter or connector.

Page 26

© 2006, ADC Telecommunications, Inc.

Page 34

ADCP-90-297 • Issue 7 • July 2006

10. Store the excess slack by routing the cable fibers around the radius limiter provided (see

Figure 28).

11. Return the VAM to its home position.

12. Continue routing and connecting any remaining connectors on the same cable.

13. When done, close the panel (refer to Subsection 5.5).

PANEL SHOWN

ROUTE FIBERS

UNDER

PROTECTOR PLATE

IFC CABLE

SLACK LOOPS

WITH TOP

REMOVED FOR

CLARITY

20286-A

Figure 28. IFC Cable Installed In VAM Panel

© 2006, ADC Telecommunications, Inc.

Page 27

Page 35

ADCP-90-297 • Issue 7 • July 2006

3.5 Standard Termination Panel Breakout Cable Installation

Use the following procedure to install a connectorized breakout cable in an unterminated

(adapters only) standard termination panel. A conversion kit (NG3-ACCIFCKIT) is required.

Note: This procedure is most efficiently done by two people, with one person at the front

of the panel and the other person at the rear.

1. Break out the cable according to the dimensions provided in Figure 29.

BREAKOUT LENGTH

65.0 IN. (165.1 CM)

+0.0 IN./-6.0 IN.

(+0.0 CM/-15.2 CM)

CONNECTORS

HEATSHRINK

6.0 IN. (15.2 CM)

2.0 IN.

(5.1 CM)

MULTI-FIBER IFC CABLE

2 MM MAX.

OUTSIDE DIAMETER

FOR SUBUNITS

21430-A

CLAMP

Figure 29. Breakout Dimensions for Breakout Cable Routed to Standard Termination Panel

2. Locate the panel where the cable will be installed and position one person at the front of

the panel and another person at the rear.

3. At the front of panel, fully open the hinged drawer (refer to Subsection 2.3).

Caution: Placing a load in excess of 20 pounds onto an open drawer will result in

misalignment or damage to the drawer.

Page 28

© 2006, ADC Telecommunications, Inc.

Page 36

ADCP-90-297 • Issue 7 • July 2006

4. At the rear of the panel, insert the bundled connector end of the cable into the panel rear

entry hole, as shown in Figure 30, and slide it through to the front.

CLAMP POINT

PANEL SHOWN

WITH TOP

SLIDE BUNDLED

FIBERS IN

FROM REAR

REMOVED FOR

CLARITY

20287-A

Figure 30. Routing Breakout Cable Into Standard Termination Panel

© 2006, ADC Telecommunications, Inc.

Page 29

Page 37

ADCP-90-297 • Issue 7 • July 2006

5. At the front of the panel, lift the cable up over the top edge of the hinged drawer and move

the cable to the cable entry hole on the left side of the drawer, as shown in Figure 31.

ROUTE FIBERS UNDER

PROTECTOR PLATE

LIFT CABLE

FIBERS

INTO CABLE

ENTRY HOLE

MOVE BUNDLED

FIBERS TO THE LEFT

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

20289-B

Figure 31. Positioning Breakout Cable Within Standard Termination Panel

Page 30

© 2006, ADC Telecommunications, Inc.

Page 38

ADCP-90-297 • Issue 7 • July 2006

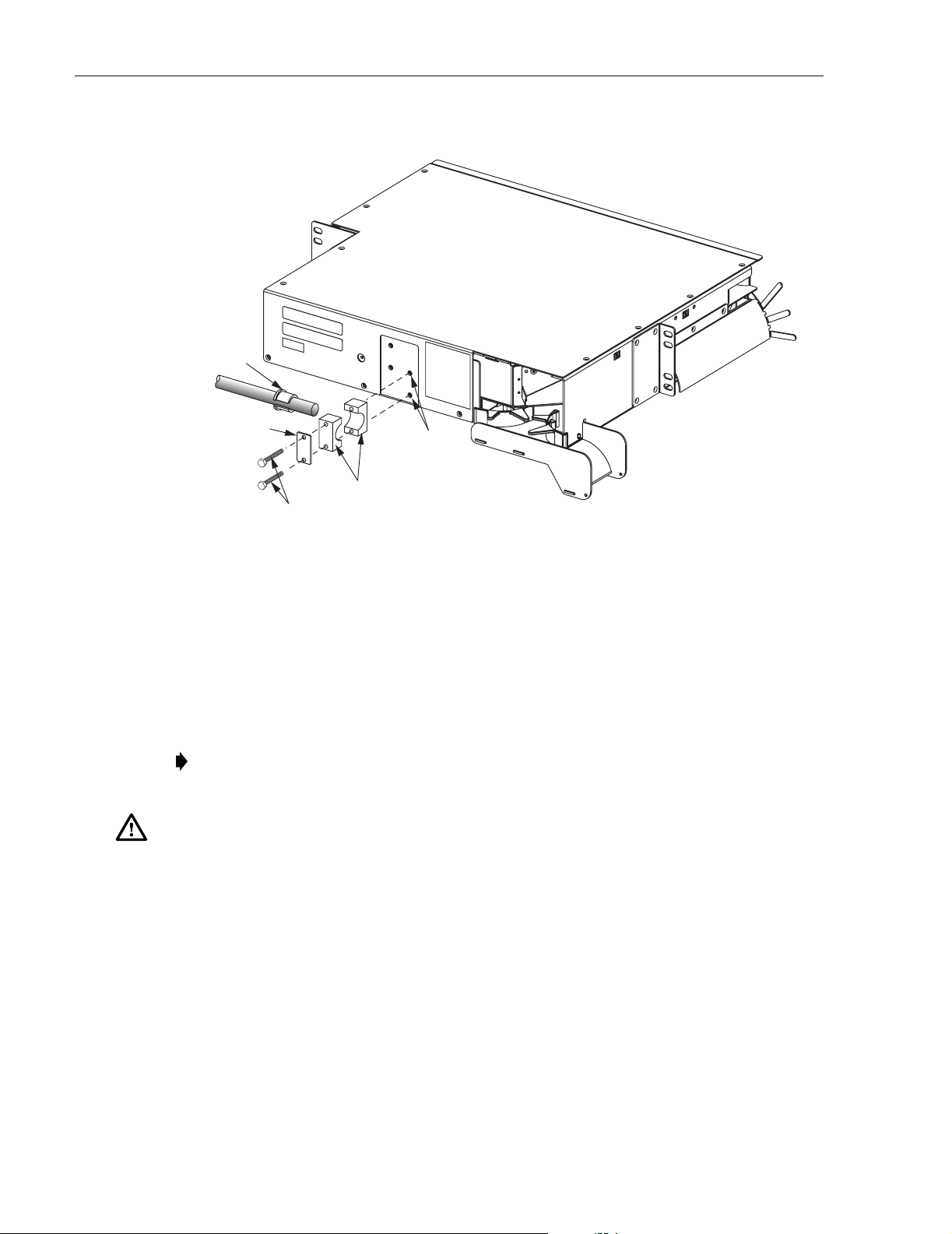

6. At the rear of the panel, clamp the cable to the panel using a cable clamp kit. The

components of the cable clamp kit are shown in Figure 32.

Note: Position the cable clamp on the cable at the point indicated in the cable breakout

diagrams.

GROMMET

(IF NEEDED)

18431-B

PLATE

HEX

MOUNTING

SCREWS

YOKES

MOUNTING

HOLES

Figure 32. Clamping Cable to Standard Termination Panel

7. Route the cable fibers within the drawer as shown in Figure 33.

8. Locate the assigned adapter and lift up the adapter pack. (refer to Subsection 5.1).

9. Remove the dust caps from the connectors and the rear side of the adapters and then insert

each connector into the appropriate adapter.

Note: Clean and inspect the connectors and adapters before mating them. For guidelines,

refer to Subsection 5.3.

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber connector or adapter. Exposure to invisible laser

radiation may result. An optical power meter should be used to verify active fibers. A protective

cap or hood MUST be immediately placed over any radiating adapter or optical fiber connector

to avoid the potential of dangerous amounts of radiation exposure. This practice also prevents

dirt particles from entering the adapter or connector.

© 2006, ADC Telecommunications, Inc.

Page 31

Page 39

ADCP-90-297 • Issue 7 • July 2006

10. Secure the cable to the drawer at the cable retention area using the O-ring provided with

the panel. Refer to Figure 33 for details.

11. Return the adapter pack to its home position.

12. Continue routing and connecting any remaining connectors on the same cable.

13. When done, close the panel (refer to Subsection 5.5).

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

BREAKOUT CABLE

SLACK LOOP

CABLE

RETENTION

AREA

21431-A

CABLES SHOULD BE

LOOSE IN DRAWER.

FIBERS SHOULD NOT

BE TIGHT WHEN SAP

Figure 33. Breakout Cable Routing Within Standard Termination Panel

IS RAISED.

Page 32

© 2006, ADC Telecommunications, Inc.

Page 40

4 FOT EQUIPMENT PATCH CORD ROUTING AND INSTALLATION

This section provides instructions for routing FOT equipment patch cords through an NG3

frame to the appropriate NG3 panel.

4.1 General FOT Equipment Patch Cord Routing - All Panel Types

Depending on the application, FOT equipment patch cords are routed to either the rear or front

side of the frame. When routed to the rear side, entry to the frame may be from either above or

below the NG3 panel. Each rear entry FOT patch cord is routed vertically up or down the right

rear side of the frame to the designated panel as shown in Figure 34. Storage for rear entry patch

cords may be provided by installing a Fiber Optic Terminal Storage Panel (FOTSP) between

each frame.

FOT PATCH CORDS

ADCP-90-297 • Issue 7 • July 2006

FOT PATCH

CORD ENTRY

NG3

PANELS

REAR VIEW

20216-A

Figure 34. Routing FOT Equipment Patch Cords to Rear Side of Frame

© 2006, ADC Telecommunications, Inc.

Page 33

Page 41

ADCP-90-297 • Issue 7 • July 2006

When routed to the front side, entry to the frame may be from above the NG3 panel only. Each

front entry patch cord is routed vertically down the left side of the frame to the designated panel

as shown in Figure 35. Storage for front entry patch cords is provided by the slack storage

spools on the left side of the frame.

FOT PATCH CORDS

DETAIL OF

PATCH CORD

ENTRY

The FOT patch cords must maintain a minimum bend radius of 1.5 inches or ten times the jacket

outside diameter (whichever is greater) inside cable raceways and within the NG3 frame. The

outside jacket diameter of the FOT patch cords should not exceed 2 mm.

Page 34

© 2006, ADC Telecommunications, Inc.

FRONT VIEW

20217-A

Figure 35. Routing FOT Equipment Patch Cords to Front Side of Frame

Page 42

4.2 Standard Termination Panel FOT Patch Cord Installation

The procedure that should be used for installing FOT equipment patch cords in the standard

termination panel is dependent on whether the panel is used in a cross-connect or interconnect

application. The following subsections provide the installation procedures for both applications.

Note: The photographs used in these procedures show an early version of the standard

termination panel. However, the basic routing instructions apply to both the early and

current versions of the panel.

4.2.1 Cross-Connect Application

In a cross-connect application, FOT patch cords are routed up or down the right rear side of the

frame and into the opening at the rear of the standard termination panel. Within the panel, each

patch cord is routed to the specified adapter pack (right side when drawer is open) and

connected to the appropriate adapter. Use the following procedure to install each FOT patch

cord in the standard termination panel:

1. Route the FOT patch cord to the rear of the panel as described in Subsection 4.1

ADCP-90-297 • Issue 7 • July 2006

2. Make sure the hinged drawer on the front of the panel is closed.

3. Locate the fiber transport on the rear of the panel as shown in Figure 36.

Note: When the hinged drawer is opened, the fiber transport moves to the front right

corner of the panel. The fiber transport holds the patch cord connector as it is pulled to the

front of the panel.

FIBER

TRANSPORT

Figure 36. Fiber Transport

18314-B

Page 35

© 2006, ADC Telecommunications, Inc.

Page 43

ADCP-90-297 • Issue 7 • July 2006

4. Hold the patch cord at its connector end and position it in an arc as shown in Figure 37.

Figure 37. Holding Patch Cord

5. Rotate the looped patch cord over and route it through the radius limiters just below the

fiber transport, as shown in Figure 38.

6. Place the patch cord connector in the fiber transport with the connector end facing to the

rear as shown in Figure 39. Be sure the patch cord has about 65 inches (165.10 cm) of

slack so it will not snag when pulled through from the front of the panel.

Page 36

© 2006, ADC Telecommunications, Inc.

Figure 38. Positioning Patch Cord in Radius Limiters

Page 44

ADCP-90-297 • Issue 7 • July 2006

Figure 39. Connector Oriented Correctly for Placement in Fiber Transport

7. Go to the front of the panel and open the hinged drawer. Locate the patch cord connector

in the fiber transport, now located in the rear right of the drawer, as shown in Figure 40.

Caution: Placing a load in excess of 20 pounds onto an open drawer will result in

misalignment or damage to the drawer.

Figure 40. Connector in Fiber Transport When Hinged Drawer is Opened

© 2006, ADC Telecommunications, Inc.

Page 37

Page 45

ADCP-90-297 • Issue 7 • July 2006

8. Lift up the connector and route the patch cord above and behind the rear top edge of the

hinged drawer and then through the opening on the rear left of the drawer as shown in

Figure 41.

Figure 41. Patch Cord Routed To Left Rear Side of Open Drawer

9. Route the patch cord around radius limiters and spool to the position shown in Figure 42

and Figure 43.

Page 38

© 2006, ADC Telecommunications, Inc.

Figure 42. Patch Cord Routed To Rear Side of Adapter Pack

Page 46

ADCP-90-297 • Issue 7 • July 2006

ROUTE UNDER

PROTECTOR

PLATE

FOT EQUIPMENT

PATCH CORD

PATCH CORD

SLACK LOOP

20292-A

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

CORDS SHOULD BE

LOOSE IN DRAWER.

FIBERS SHOULD NOT

BE TIGHT WHEN SAP

IS RAISED.

Figure 43. Routing FOT Patch Cords Within Standard Termination Panel - Cross-Connect Application

10. Locate and access the adapter pack and adapter (Subsection 5.1) where the patch cord will

be connected.

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber. Do not look directly into optical adapters or connectors.

Exposure to invisible laser radiation may result. An optical power meter should be used to

verify active fibers. A protective cap or hood MUST be immediately placed over any radiating

adapter or optical fiber connector to avoid the potential of dangerous amounts of radiation

exposure. This practice also prevents dirt particles from entering the adapter or connector.

11. Remove the dust cap from the adapter and connect the patch cord connector to the adapter.

Note: Always clean and inspect connectors and adapters before mating them. For

guidelines on cleaning connectors, refer to Subsection 5.3.

© 2006, ADC Telecommunications, Inc.

Page 39

Page 47

ADCP-90-297 • Issue 7 • July 2006

12. Adjust the patch cord to provide adequate slack within the drawer. Route extra slack out

through the back of the drawer and secure the patch cords in the cable retention area with

the O-ring provided.

Note: Make sure the patch cords are not pulled tight when the adapter pack is raised.

13. Close the top cover and shut the drawer.

14. Turn the door latch a quarter turn clockwise to secure the door in the closed position.

4.2.2 Interconnect Application

In an interconnect application, FOT patch cords are routed down the front side of the frame and

into the opening on the left side of the standard termination panel. Within the panel, each patch

cord is routed to a specified adapter pack (left side when drawer is open) and connected to the

appropriate adapter. Use the following procedure to install each FOT patch cord in the standard

termination panel:

1. Route the FOT patch cord to the front of the panel as described in Subsection 4.1.

2. Open the panel as described in Subsection 2.3.

Caution: Placing a load in excess of 20 pounds onto an open drawer will result in

misalignment or damage to the drawer.

3. Locate and access the adapter pack and adapter (Subsection 5.1) where the patch cord will

be connected.

Warn ing: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber. Do not look directly into the optical adapters or

connectors. Exposure to invisible laser radiation may result. An optical power meter should be

used to verify active fibers. A protective cap or hood MUST be immediately placed over any

radiating adapter or optical connector to avoid the potential of dangerous amounts of radiation

exposure. This practice also prevents dirt particles from entering the adapter or connector.

4. Remove the dust cap from the adapter and connect the patch cord connector to the adapter.

5. Route the patch cord within the panel as shown in Figure 44.

Note: Always clean connectors and adapters before mating them. For guidelines on

cleaning connectors, refer to Subsection 5.3.

6. Route the patch cord out and down from the panel as shown in Figure 45.

7. Close the top cover and shut the drawer.

8. Turn the door latch a quarter turn clockwise to secure the door in the closed position.

9. Use the front slack storage spools to take up patch cord slack.

Note: For additional instructions on routing patch cords, refer to the laminated cards

(ADCP-90-296) provided with the frame or the NG3 Fiber Distribution Frame System

User Manual (ADCP-90-298).

Page 40

© 2006, ADC Telecommunications, Inc.

Page 48

PLACE FIBER

UNDER TABS

AND ROUTING

FINGERS

ADCP-90-297 • Issue 7 • July 2006

IFC/OSP

FOT EQUIPMENT

CABLE SUBUNITS

PATCH CORDS

20296-A

Figure 44. Routing FOT Patch Cords Within Standard Termination Panel- Interconnect Applications

FRONT

UPPER

TROUGH

FRONT-TO-REAR

TRANSITION

TROUGH

ALWAYS ROUTE

PATCH CORD

DOWN OUT OF

PANEL

TYPICAL ROUTING OF

PATCH CORD OUT OF PANEL

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

REAR TROUGH

(NOT VISIBLE)

18288-B

Figure 45. Routing FOT Patch Cords Out of Panel - Interconnect Applications

© 2006, ADC Telecommunications, Inc.

Page 41

Page 49

ADCP-90-297 • Issue 7 • July 2006

4.3 Termination/Splice Panel FOT Patch Cord Installation

The termination and splice panel is primarily used in “tie panel” applications and is usually

linked to a standard termination panel with IFC cable. Tie panels are typically used to bridge

any gaps that may exist in between frames. If the termination and splice panel is used in an

application that makes it necessary to route FOT patch cords to the front of the panel, follow the

FOT patch cord routing procedures provided in Subsection 4.2.2.

4.4 VAM Panel FOT Patch Cord Installation

The VAM panel allows optical splitter or wavelength division multiplexing (WDM)

functionality to be incorporated into specified optical circuits at the NG3 frame. FOT patch

cords may be routed into the VAM panel from either the rear side or the front side of the frame.

Whether the FOT patch cords are routed into the VAM panel from the front or rear side is a

matter of convenience and is not related to whether the NG3 frame is used for an interconnect or

cross-connect application. The following subsections provide the procedures for both rear and

front entry FOT patch cord installation:

4.4.1 Rear Entry

For entry from the rear side, FOT patch cords are routed up or down the right rear side of the

frame and into the opening at the rear of the VAM panel. Within the panel, each patch cord is

routed to the specified VAM (left side when drawer is open) and connected to the appropriate

adapter. A label showing the VAM configuration is attached to the side of each VAM. Use the

following procedure when installing FOT patch cords from the rear side of the VAM panel:

1. Route the FOT patch cord to the rear of the panel as described in Subsection 4.1

2. Make sure the hinged drawer on the front of the panel is closed.

3. Locate the fiber transport on the rear side of the panel as shown in Figure 46.

Note: When the hinged drawer is opened, the fiber transport moves to the front right

corner of the panel. The fiber transport holds the patch cord connector as it is pulled to the

front of the panel.

4. Hold the patch cord at the connector and position it in an arc as shown in Figure 47.

Note: The photographs used in this procedure show an early version of the standard

termination panel. However, the basic routing instructions also apply to the current version

of the VAM panel.

Page 42

© 2006, ADC Telecommunications, Inc.

Page 50

FIBER

TRANSPORT

ADCP-90-297 • Issue 7 • July 2006

18314-B

Figure 46. Fiber Transport

Figure 47. Holding Patch Cord

© 2006, ADC Telecommunications, Inc.

Page 43

Page 51

ADCP-90-297 • Issue 7 • July 2006

5. Rotate the looped patch cord over and route it through the radius limiters just below the

fiber transport as shown in Figure 48.

Figure 48. Positioning Patch Cord in Radius limiters

6. Place the patch cord connector in the fiber transport with the connector end facing to the

rear as shown in Figure 49. Be sure the patch cord has about 65 inches (165.10 cm) of

slack so it will not snag when pulled through from the front of the panel.

Figure 49. Connector Oriented Correctly for Placement in Fiber Transport

Page 44

© 2006, ADC Telecommunications, Inc.

Page 52

ADCP-90-297 • Issue 7 • July 2006

7. Go to the front of the panel and open the hinged drawer. Locate the patch cord connector

in the fiber transport now located on the right rear side of the drawer as shown in

Figure 50.

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

FOT EQUIPMENT

PATCH CORD

CONNECTOR IN

FIBER TRANSPORT

20303-A

Figure 50. Connector in Fiber Transport When Hinged Drawer is Opened - Rear Entry

© 2006, ADC Telecommunications, Inc.

Page 45

Page 53

ADCP-90-297 • Issue 7 • July 2006

8. Lift up the connector and route the patch cord above and behind the rear top edge of the

hinged drawer and then through the opening at the rear left corner of the drawer as shown

in Figure 51.

FOT EQUIPMENT

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

PATCH CORD

ROUTE UNDER

PROTECTOR

PLATE

MOVE PATCH CORD

TO LEFT AND LIFT

INTO ENTRY HOLE

20305-A

Figure 51. Positioning Patch Cord Within VAM Panel - Rear Entry

9. Remove the dust caps from the connectors and the VAM adapters and then insert each

connector into the appropriate adapter.

Note: Clean and inspect the connectors and adapters before mating them. For guidelines,

refer to Subsection 5.3.

Page 46

© 2006, ADC Telecommunications, Inc.

Page 54

10. Route the patch cord within the drawer as shown in Figure 52.

PATCH CORD

SLACK LOOP

ADCP-90-297 • Issue 7 • July 2006

PANEL SHOWN

WITH TOP

REMOVED FOR

CLARITY

PLACE FIBER

UNDER ROUTING

FINGER

FOT EQUIPMENT

PATCH CORD

20307-A

Figure 52. Patch Cord Installed In VAM Panel - Rear Entry

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any active optical fiber connector or adapter. Exposure to invisible laser

radiation may result. An optical power meter should be used to verify active fibers. A protective

cap or hood MUST be immediately placed over any radiating adapter or optical fiber connector

to avoid the potential of dangerous amounts of radiation exposure. This practice also prevents

dirt particles from entering the adapter or connector.

11. Store the excess slack by routing the cable fibers around the radius limiter provided (see

Figure 52).

12. Return the VAM to its home position.

13. Continue routing and connecting any remaining connectors on the same cable.

14. When done, close the panel (refer to Subsection 5.5).

© 2006, ADC Telecommunications, Inc.

Page 47

Page 55

ADCP-90-297 • Issue 7 • July 2006

4.4.2 Front Entry

For entry from the front side, FOT patch cords are routed down the left front side of the frame

and into the opening on the left side of the VAM panel. Within the panel, each patch cord is

routed to the specified VAM (left side when drawer is open) and connected to the appropriate

adapter. A label showing the VAM configuration is attached to the side of each VAM. Use the

following procedure when installing FOT patch cords from the front side of the VAM panel:

1. Route the FOT patch cord to the front of the panel as described in Subsection 4.1.

2. Open the panel as described in Subsection 2.3.

Caution: Placing a load in excess of 20 pounds onto an open drawer will result in

misalignment or damage to the drawer.

3. Locate and access the VAM and adapter (Subsection 5.2) where the patch cord will be

connected.

Warn ing: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any active optical fiber. Do not look directly into the optical adapters or

connectors. Exposure to invisible laser radiation may result. An optical power meter should be

used to verify active fibers. A protective cap or hood MUST be immediately placed over any

radiating adapter or optical connector to avoid the potential of dangerous amounts of radiation

exposure. This practice also prevents dirt particles from entering the adapter or connector.

4. Remove the dust cap from the adapter and connect the patch cord connector to the adapter.

5. Route the patch cord within the panel as shown in Figure 53.

Note: Always clean connectors and adapters before mating them. For guidelines on

cleaning connectors, refer to Subsection 5.3.

6. Route the patch cord out and down from the panel as shown in Figure 54.

7. Close the top cover and shut the drawer.

8. Turn the door latch a quarter turn clockwise to secure the door in the closed position.

9. Use the front slack storage spools to take up patch cord slack.

Note: For additional instructions on routing patch cords, refer to the laminated cards

(ADCP-90-296) provided with the frame or the NG3 Fiber Distribution Frame System

User Manual (ADCP-90-298).

Page 48

© 2006, ADC Telecommunications, Inc.

Page 56

PLACE FIBER

UNDER TABS

AND ROUTING

FINGERS

ADCP-90-297 • Issue 7 • July 2006

FOT EQUIPMENT

PATCH CORD

20313-A

Figure 53. Routing FOT Patch Cords Within VAM Panel - Front Entry

FRONT

UPPER

TROUGH

FRONT-TO-REAR

TRANSITION

TROUGH

ALWAYS ROUTE

PATCH CORD

DOWN OUT OF

PANEL

TYPICAL ROUTING OF

PATCH CORD OUT OF PANEL

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

CAUTION

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXXXX

XXXXXXXXXXX

REAR TROUGH

(NOT VISIBLE)

18288-B

Figure 54. Routing Patch Cords Out of VAM Panel - Front Entry

© 2006, ADC Telecommunications, Inc.

Page 49

Page 57

ADCP-90-297 • Issue 7 • July 2006

5 OPERATION

Operation of the NG3 termination panel consists of tasks that are typically done after the panel

is installed. Operational tasks include accessing the adapter packs and VAM’s, cleaning

connectors and adapters, installing cross-connect patch cords, and updating designation cards.

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any active optical fiber. Do not look directly into the optical adapters of the

adapter packs. Exposure to invisible laser radiation may result. An optical power meter should

be used to verify active fibers. A protective cap or hood MUST be immediately placed over any

radiating adapter or optical fiber connector to avoid the potential of dangerous amounts of

radiation exposure. This practice also prevents dirt particles from entering the adapter or

connector.

5.1 Adapter Pack Access

Accessing an adapter pack is necessary in order to connect or disconnect a connector and