Page 1

ADC-EX108

YJ

ADC-M105

YJ

SERVICE MANUAL

STEREO CAR

CD CHANGER SYSTEM

This Service Manual is the "Revision Publishing" and replaces "Simple Manual"

ADC-EX108(YJ2)/ADC-M105(YJ), (S/M Code No. 09-008-404-5T9).

BASIC CD MECHANISM : 8ZG-4 RNF

S/M Code No. 09-009-404-5R9

REVISION

DATA

Page 2

SPECIFICATIONS

<Compact disc changer>

System Compact disc digital audio system

Frequency response 5 Hz - 20 kHz

Wow and flutter Below measurable limit

Signal to noise ratio 91 dB or more

Outputs Line output (for changer connector only)

Operating temperature -10 oC to 55 oC

Dimensions 254 x 83 x 173mm (w/h/d)

Weight 2.1 kg (4.62 lbs.)

Power requirement 12 V DC car battery

D/A converter 1 bit DAC, 8 times over sampling

Sampling rate 44.1 kHz

Disc size 120 mm

Design and specifications are subject to change without notice.

(10 x 3 3/8 x 6 7/8 in.)

(negative ground)

ACCESSORIES / PACKAGE LIST

PART NO.

NO.

1 8Z-KM3-919-010 IB,Y M105-B<M105>

1 8Z-KM3-918-010 IB,Y 108-B <EX108>

2 87-B10-208-010 VWWS+4-12 BLK

3 8Z-KM1-222-110 PLATE,UNIT ASSY

4 8Z-KM1-218-010 NUT,5 HEX-FLANGE

5 8Z-KM1-209-010 HLDR,UNIT 10A

6 8Z-KM1-216-010 HLDR,UNIT 10B

7 8Z-KM4-651-010 CABLE ASSY,13PIN-DIN

DESCRIPTIONREF. NO. KANRI

2

Page 3

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs laser. Therefore, be sure to follow carefully

the instructions below when servicing.

WARNING!!

WHEN SERVICING, DO NOT APPROACH THE LASER

EXIT WITH THE EYE TOO CLOSELY. IN CASE IT IS

NECESSARY TO CONFIRM LASER BEAM EMISSION.

BE SURE TO OBSERVE FROM A DISTANCE OF MORE

THAN 30cm FROM THE SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL PICK-UP BLOCK.

s Caution: Invisible laser radiation when

open and interlocks defeated avoid

exposure to beam.

s Advarsel: Usynlig laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa

mainitulla tavalla saataa altistaa käyt-täjän

turvallisuusluokan 1 ylittävälle näkymättömälle

lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som

specificeras i denna bruksanvising, kan användaren

utsättas för osynling laserstrålning, som överskrider

gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herin may result in

hazardous radiation exposure.

ATTENTION

Lutillisation de commandes, réglages ou procédures

autres que ceux spécifiés peut entraîner une dangereuse

exposition aux radiations.

ADVARSEL

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer

ude af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1

LASER product.

The CLASS 1 LASER PRODUCT label is located on the

rear exterior.

CLASS 1 LASER PRODUCT

KLASSE 1 LASER PRODUKT

LUOKAN 1 LASER LAITE

KLASS 1 LASER APPARAT

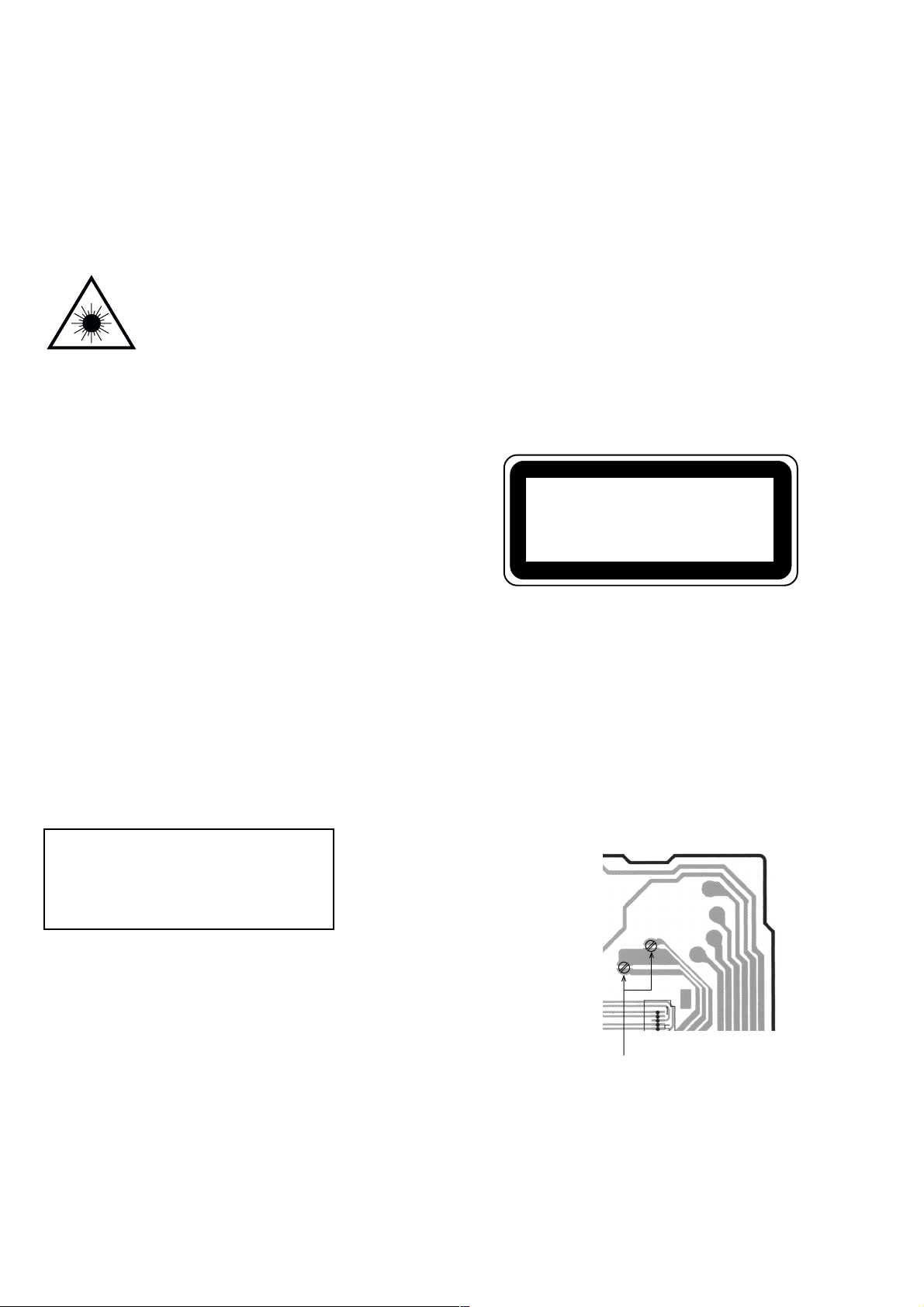

Precaution to replace Optical block

(KSS-710A)

Body or clothes electrostatic potential could

ruin laser diode in the optical block. Be sure

ground body and workbench, and use care the

clothes do not touch the diode.

1) After the connection, remove solder shown in

right figure.

PICK-UP ASSY

P.C.B

SOLDER

3

Page 4

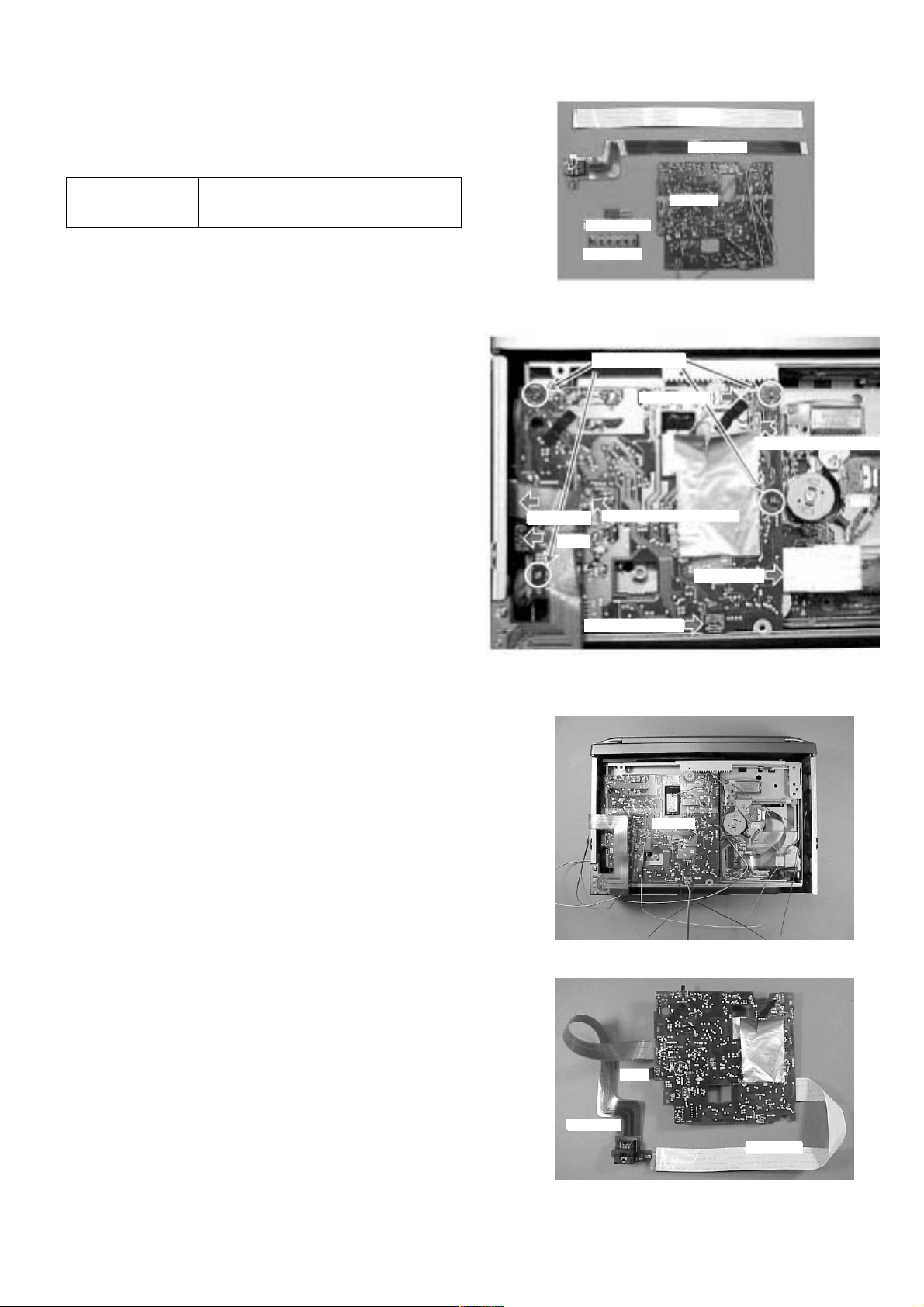

SERVICE JIG AND TOOLS

1. How to Use the Repair Jig

Use the following repair jig kit for servicing.

FFC

FFC

Part name Part code

For 10 CD changer JIG-ADC-EX106 SV-J00-090-010

The kit contains the following parts (Refer to Fig-1) ;

1. FFC (26P/25 cm) 1 pcs

2. P.W.B. FLEX 1 pcs

3. P.W.B. JIG 1 pcs

4. TRANSISTOR (2SD-2395) 1 pcs

5. P.W.B. KEY 1 pcs

(1) Remove the cabinet as follows;

1) Remove the CABI BOTTOM by removing the

four screws VTT+2.6-6B (Refer to Fig-2).

(2) Remove the P.W.B. MAIN as follows;

1) Remove all terminals of the transistor Q623

(2SD2395) by unsoldering them.

2) Remove the two motor wires (BLU/WHT).

3) Remove the two wires (BLK/BRN) of the sensor

(PD201).

4) Remove the P.W.B. MAIN from the unit by

removing the four screws V+2-3.

5) Disconnect the FFC of pickup from CN101.

6) Disconnect the PWB FLEX from CON1.

7) Remove the LED (LED201,GL380) from the

P.W.B. MAIN.

8) Remove the sensor (PS201,SENR GP1S94) from

P.W.B. MAIN.

PWB FLEX

Q623

PWB JIG

TRANSISTOR

PWB KEY

Fig-1

REMOVE SCREW

LED(LED201)

REMOVE MOTOR WIRE

REMOVE SENSOR WIRE

PICKUP FCC

SENSOR (PS201)

Fig-2

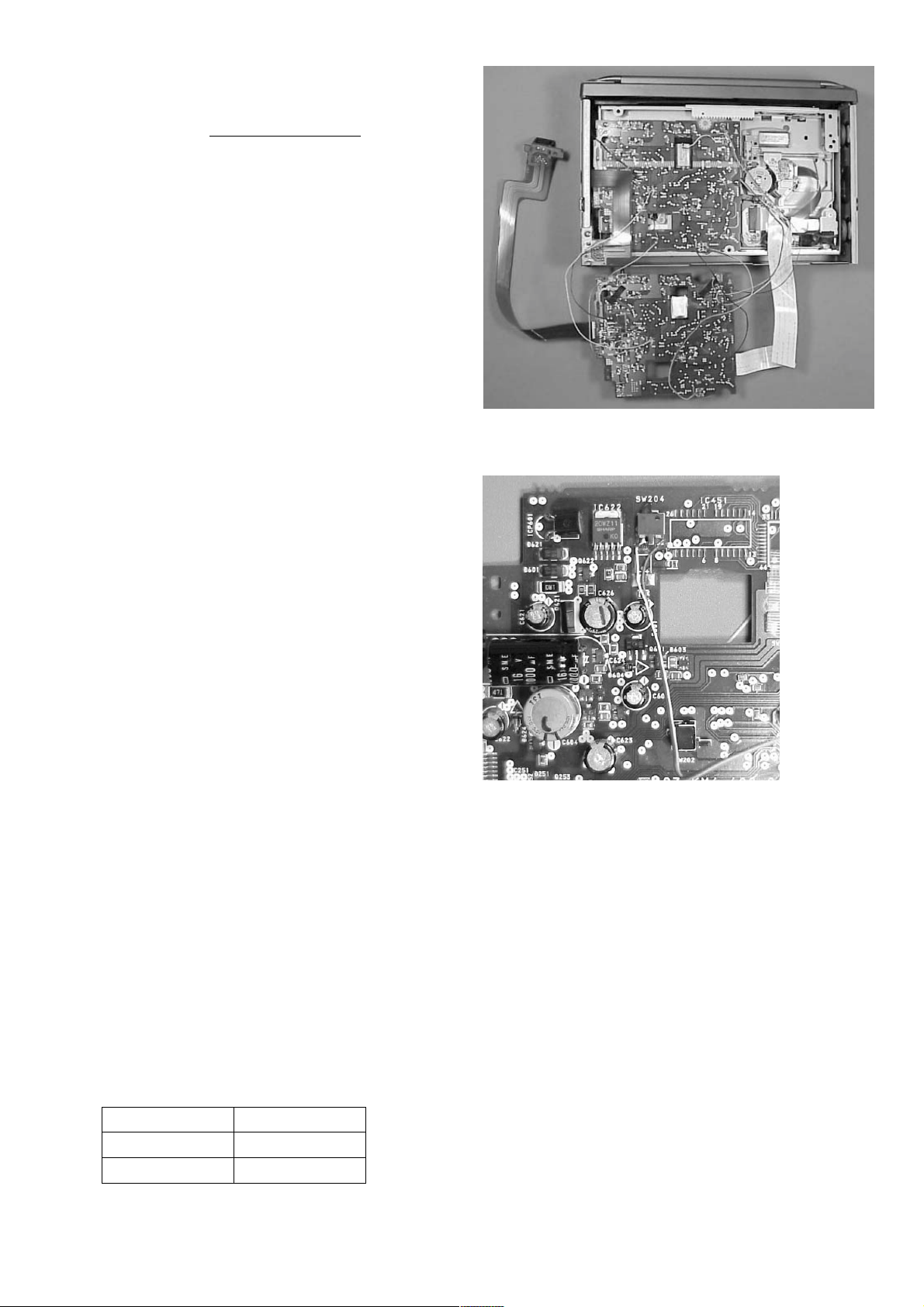

(3) Install the repair jig as follows;

1) Install the P.W.B. JIG into the unit and fix it with

screws. (Refer to Fig-3).

(4) Attach the parts as follows, (Refer to Fig-4);

1) Attach the supplied transistor to the location of the

P.W.B. MAIN from which Q623 is removed in

step (2).

2) Connect the supplied PWB FLEX to CON1.

When the CONTROL UNIT is not used, use the

P.W.B. KEY instead. (Refer to step (6), How to

use the repair jig.)

3) Connect the FFC cable to CON101 and pickup.

(The supplied FFC cannot be used because pitches

and number of pins are different.)

PWB JIG

Fig-3

Q623

PWB FLEX

FFC CABLE

Fig-4

4

Page 5

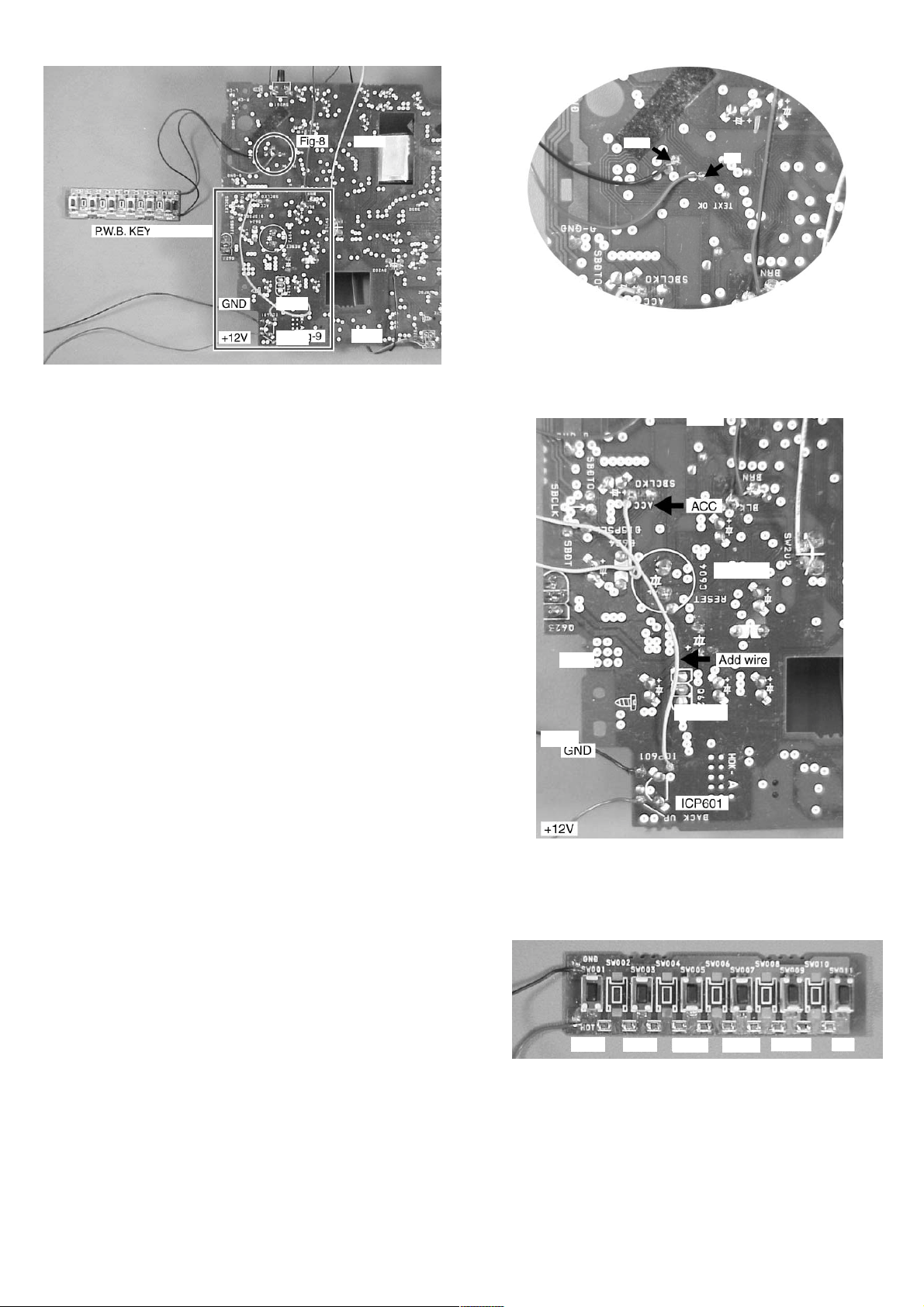

(5) Perform wirings to the C.Bs. Refer to Fig-5/-6;

Be sure to connect the wires coming from the

P.W.B. JIG to

MAIN C.B as follows.

1) Connect the motor wires and sensor (PD201)

wires that are removed in step (2) to the P.W.B.

JIG.

2) Connect all wires coming from the P.W.B. JIG to

the respective lands of the MAIN C.B by

soldering.

Connect the motor wires (BLU/WHT) of the

P.W.B. JIG to the motor wire connecting lands on

the MAIN C.B by soldering.

Connect the LED (LED201) wires (RED/GRY) of

the P.W.B. JIG to the LED wire connecting lands

on the MAIN C.B by soldering.

Connect the sensor wires (BRN/BLK) of the

P.W.B. JIG to the sensor wire connecting lands on

the MAIN C.B by soldering.

Connect the sensor (PS201) wires (YEL/ORG/

RED/BRN) of the P.W.B. JIG to the sensor wire

connecting lands on the MAIN C.B by soldering.

Connect the SW202 wire (WHT) of the P.W.B.

JIG to the SW202 wire connecting lands on the

MAIN C.B by soldering.

Connect the SW203 wire (BLK) of the P.W.B.

JIG to the SW203 wire connecting lands on the

MAIN C.B by soldering.

Connect the SW204 wires (BLU/WHT) of the

P.W.B. JIG to the leads of SW204 on the MAIN

C.B by soldering. Refer to Fig-6.

the same connecting points on the

Fig-5

(6) How to use the repair jig;

When the Control Unit (CDC/CT) is going to be used.

1) After all wires and connections are complete,

connect the Control Unit (CDC/CT) with the DIN

jack of the P.W.B. FLEX.

2) Connect external power +12 V to ACC/BACKUP

wire and ground (-) to the GROUND wire.

3) Perform the operation check.

When the Control Unit (CDC/CT) is not used.

1) Connect the supplied P.W.B KEY to the MAIN

C.B by performing all connections between them.

Refer to Fig-7/-8.

(Wires to be used for connecting the MAIN C.B

are not supplied.)

2) Connect the wires as follows. Refer to Fig-9.

P.W.B KEY MAIN C.B

HOT TO

GND GND

Fig-6

5

Page 6

PWB KEY

GND

Fig-8

GND

TO

+12V

Fig-9

Fig-7

3) Connect the wires as follows (Refer to Fig-9);

Connect wire for +12 V power to BACK UP of

ICP601 by soldering.

Connect ICP601 and ACC pattern land by soldering a

wire.

Connect GND by soldering a wire.

Connect the +12 V power to the ACC/BACK UP wire

and connect ground (-) to the GROUND wire of the

connector (Wires to be used for connection are not

supplied.)

Fig-8

ACC

Add wire

GND

ICP601

+12V

4) Perform the operation check (Refer to Fig-10).

6

STOP

PLAY

Fig-9

BSKIP

Fig-10

FSKIP

DOWN

UP

Page 7

ELECTRICAL MAIN PARTS LIST

PART NO. DESCRIPTIONREF. NO. KANRI

NO.

IC

87-A20-892-010 C-IC,CXD2588R

87-A21-467-010 C-IC,CXA2581N

8Z-KM3-692-010 C-IC,CXP84632-16 0Q

87-A21-158-040 C-IC,TC74HC365AF

87-017-888-080 IC,NJM4558MD

87-A20-574-010 C- IC,SM5902AF<EX108>

87-A21-160-040 C- IC,MSM5117400C-60SJ<EX108>

87-A21-161-040 C-IC,BA6392FP

87-A21-162-040 C-IC,BA6247FP

87-A21-102-040 C-IC,S-80828ANNP-EDR-T2

87-A21-190-040 C-IC,PQ20WZ1U

TRANSISTOR

87-A30-248-040 C-TR,2SB1197KQ

89-110-372-080 TR,2SA1037KR

87-026-648-080 C-TR,UPA608T

89-327-125-080 CHIP TR,2SC2712GR

87-A30-272-040 C-TR,DTA124EKA

87-A30-273-040 C-TR,DTC124EKA

87-A30-274-040 C-TR,2SD1622S-TD

87-A30-317-080 TR,2SA1702

89-423-952-010 TR,2SD2395E

87-A30-371-040 C-TR,2SD1623

87-A30-44 8-040 C-TR,DTA123JK<EX108>

DIODE

87-A40-250-040 CHIP-DIODE,DAN217

87-A40-196-080 C-ZENER,UDZ6.2B

87-020-331-080 CHIP-DIODE,DAN202K

87-A40-524-040 C-DIODE,1SR154-400

87-070-136-080 ZENER,MTZJ5.1B

87-A40-437-080 ZENER,MTZJ4.3B

MAIN C.B

C102 87-010-499-040 CAP,E 22-6.3 GAS

C103 87-A12-154-010 CAP,E 470-4 MA GAS

C104 87-016-669-080 C-CAP,S 0.1-25 K B

C105 87-016-669-080 C-CAP,S 0.1-25 K B

C106 87-016-669-080 C-CAP,S 0.1-25 K B

C107 87-010-184-080 C-CAP,S 3300P-50 KB

C108 87-016-526-080 C-CAP,S 0.47-16 BK

C109 87-012-156-080 C-CAP,S 220P-50 CH

C110 87-010-184-080 CHIP CAPACITOR 3300P(K)

C111 87-010-992-080 C-CAP,S 0.047-25 B

C112 87-016-669-080 C-CAP,S 0.1-25 K B

C115 87-012-154-080 C-CAP,S 150P-50 CH

C116 87-012-154-080 C-CAP,S 150P-50 CH

C117 87-010-176-080 C-CAP,S 680P-50 SL

C118 87-010-176-080 C-CAP,S 680P-50 SL

C151 87-A10-711-080 C-CAP,E 100-6.3 M MF

C152 87-016-669-080 C-CAP,S 0.1-25 K B

C153 87-A10-711-080 C-CAP,E 100-6.3 M MF

C155 87-016-669-080 C-CAP,S 0.1-25 K B

C156 87-016-669-080 C-CAP,S 0.1-25 K B

C157 87-012-156-080 C-CAP,S 220P-50 CH

C158 87-010-992-080 C-CAP,S 0.047-25 B

C159 87-012-156-080 C-CAP,S 220P-50 CH

C161 87-016-669-080 C-CAP,S 0.1-25 K B

C162 87-A12-031-080 C-CAP,E 33-10 M MF

C165 87-016-669-080 C-CAP,S 0.1-25 KB

C166 87-016-669-080 C-CAP,S 0.1-25 KB

C17 0 87-016-669-080 C-CAP,S 0.1-25 KB<EX108>

C171 87-010-500-040 CAP- E,33-4 M 5L SRE<EX108>

C201 87-016-669-080 C-CAP,S 0.1-25 K B

DESCRIPTIONREF. NO. KANRI

PART NO.

C202 87-016-669-080 C-CAP,S 0.1-25 K B

C251 87-010-197-080 C-CAP,S 0.01-25 KB

C252 87-012-140-080 C-CAP,S 470P-50 J CH

C301 87-010-552-040 CAP,E 22-16 GAS

C302 87-010-552-040 CAP,E 22-16 GAS

C303 87-010-318-080 C-CAP,S 47P-50 CH

C304 87-010-318-080 C-CAP,S 47P-50 CH

C305 87-015-696-040 CAP,E 2.2-50 SRA

C306 87-015-696-040 CAP,E 2.2-50 SRA

C307 87-010-178-080 CHIP CAP 1000P

C308 87-010-178-080 CHIP CAP 1000P

C321 87-010-555-040 CAP,E 100-10

C322 87-016-669-080 C-CAP,S 0.1-25 K B

C323 87-010-550-040 CAP,E 100-6.3 GAS

C324 87-016-669-080 C-CAP,S 0.1-25 K B

C325 87-010-550-040 CAP,E 100-6.3 GAS

C401 87-A10-711-080 C-CAP,E 100-6.3 M MF<EX108>

C402 87-016-669-080 C-CAP,S 0.1-25 KB<EX108>

C403 87-016-669-080 C-CAP,S 0.1-25 KB<EX108>

C404 87-010-178-080 CHIP CAP 1000P<EX108>

C452 87-016-669-080 C-CAP,S 0.1-25 KB<EX108>

C501 87-010-555-040 CAP,E 100-10 GAS

C503 87-016-669-080 C-CAP,S 0.1-25 K B

C505 87-010-178-080 CHIP CAP 1000P

C506 87-A11-257-010 CAP,E 470U-10M

C551 87-010-555-040 CAP,E 100-10 M 5L

C552 87-A11-257-010 CAP,E 470U-10M

C553 87-016-669-080 C-CAP,S 0.1-25 K B

C554 87-016-669-080 C-CAP,S 0.1-25 K B

C555 87-016-669-080 C-CAP,S 0.1-25 K B

C556 87-016-669-080 C-CAP,S 0.1-25 K B

C601 87-010-552-040 CAP,E 22-16 GAS

C602 87-A10-368-080 C-CAP,S 2.2-10 Z F

C603 87-010-552-040 CAP,E 22-16 GAS

C604 87-010-782-010 CAP,DL 0.047F-5.5 Z 70

C605 87-016-669-080 C-CAP,S 0.1-25 K B

C606 87-A10-368-080 C-CAP,S 2.2-10 Z F

C621 87-010-552-040 CAP,E 22-16 GAS

C622 87-010-555-040 CAP,E 100-10 M 5L

C623 87-010-555-040 CAP,E 100-10 M 5L

C624 87-010-260-080 CAP,E 47-25 M 11L SME

C625 87-016-669-080 C-CAP,S 0.1-25 K B

C626 87-016-044-040 CAP,E 100-16 GAS

C631 87-010-555-040 CAP,E 100-10 M 5L

C632 87-010-552-040 CAP,E 22-16 M 5L

C901 87-010-197-080 C-CAP,S 0.01-25 K B C2012

C902 87-016-669-080 C-CAP,S 0.1-25 K B

CN101 87-A61-155-080 C-CONN,30P H XF2H-3015-1

FC101 8Z-KM3-674-010 FF-CABLE, 30P 0.5 145MM- C

FC102 8Z-KM3-608-010 F-CABLE,2P (SENS KM3)

HL201 8Z-KM1-232-010 HLDR,LED

!

ICP601 87-A91-337-080 PROTECTOR,IC ICP-N75

L101 87-A50-536-080 C-COIL, 10UH K LQH3C24

L151 87-A50-536-080 C-COIL,10UH K LQH3C24

L152 87-A50-536-080 C-COIL,10UH K LQH3C24

L201 87-A50-536-080 C-COIL,10UH K LQH3C24

L301 87-A50-536-080 C-COIL,10UH K LQH3C24

L401 87-A50-536-080 C-COIL,10UH K LQH3C24<EX108>

L501 87-A50-536-080 C-COIL,10UH K LQH3C24

L551 87-A50-536-080 C-COIL,10UH K LQH3C24

LED201 87-070-288-010 LED,GL380

M8 01 87-A9 1-05 4-010 MOT,FF-050SK

PS201 87-A90-244-010 SNSR,GP1S94

SW201 87-A91-155-010 SW,TACT SKHHLQ

SW202 87-036-110-010 SW,MICRO SPPB62

SW203 87-036-110-010 SW,MICRO SPPB62

SW204 87-036-312-080 SW PUSH ESE102MH4-Q

X101 87-A70-163-080 C-VIB,CER 16.93MHZ CSTCVMXJ0C4

X200 87-A70-200-080 C-VIB,CER 12MHZ CSTCV12MTJ0C4

NO.

7

Page 8

PART NO. DESCRIPTIONREF. NO. KANRI

NO.

SENS C.B

PD201 87-026-674-010 P-TR,PT4850F

DIN C.B

J901 8Z-KM3-638-010 JACK,DIN 13 P TCS5125-014151

FLEX DIN C.B

8Z-KM3-617 -010 PWB,FLEX DIN (ZKM3)-C

DESCRIPTIONREF. NO. KANRI

PART NO.

NO.

CONNECT C.B

CON801 87-A61-155-080 C-CONN,30P H XF2H-3015-1

CON802 87-A61-240-080 C-CONN,16P H FLZ-RSM1-TB

M802 87-A91-054-010 MOT,FF-050SK

M803 87-A91-054-010 MOT,FF-050SK

M804 87-A90-926-010 MOT,RF-3L0PA

LIMIT C.B

SW803 87-036-312-080 C-SW,PUSH ESE102MH4-Q

W804 8Z-KM3-624-010 F-CABLE,2P (LIMIT)

SW C.B

SW801 87-036-269-080 C-SW,PUSH 1-1-1 ESE102MH2

SW802 87-036-312-080 C-SW,PUSH ESE102MH4-Q

W803 8Z-KM3-625-010 F-CABLE,4P (SWITCH)

LED C.B

CNA800 8Z-KM3-623-210 CONN ASSY,2P (LED)

CON803 87-009-863-010 CONN,2P WHT ZH

LED801 87-A40-319-080 C-LED,LT1E40A GRN

LED802 87-A40-320-080 C-LED,LT1H40A Y

LED803 87-A40-319-080 C-LED,LT1E40A GRN

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

CJ

CJ

CJ

FLEX PICK UP C.B

Figure

Value of resistor

Form

L

8Z-KM4-631-010 PWB,FLEX PICK UP (AK)

Dimensions (mm)

t

W

LW t

1.0 0.5 0.35 104

1.6 0.8 0.45

2 1.25 0.45

3.2

1.6

Resistor Code

0.55

: A

: A

108

118

128

TRANSISTOR ILLUSTRATION

C

B

E

2SA1037KR

2SB1197KQ

2SC2712GR

2SD1623

DTA124EKA

DTA123JKA

DTC124EKA

E1

B1

UPA608T

C2

C1

B2

E2

C

CBECB

2SD1622S

CBE

2SD2395E

E

2SA1702

8

Page 9

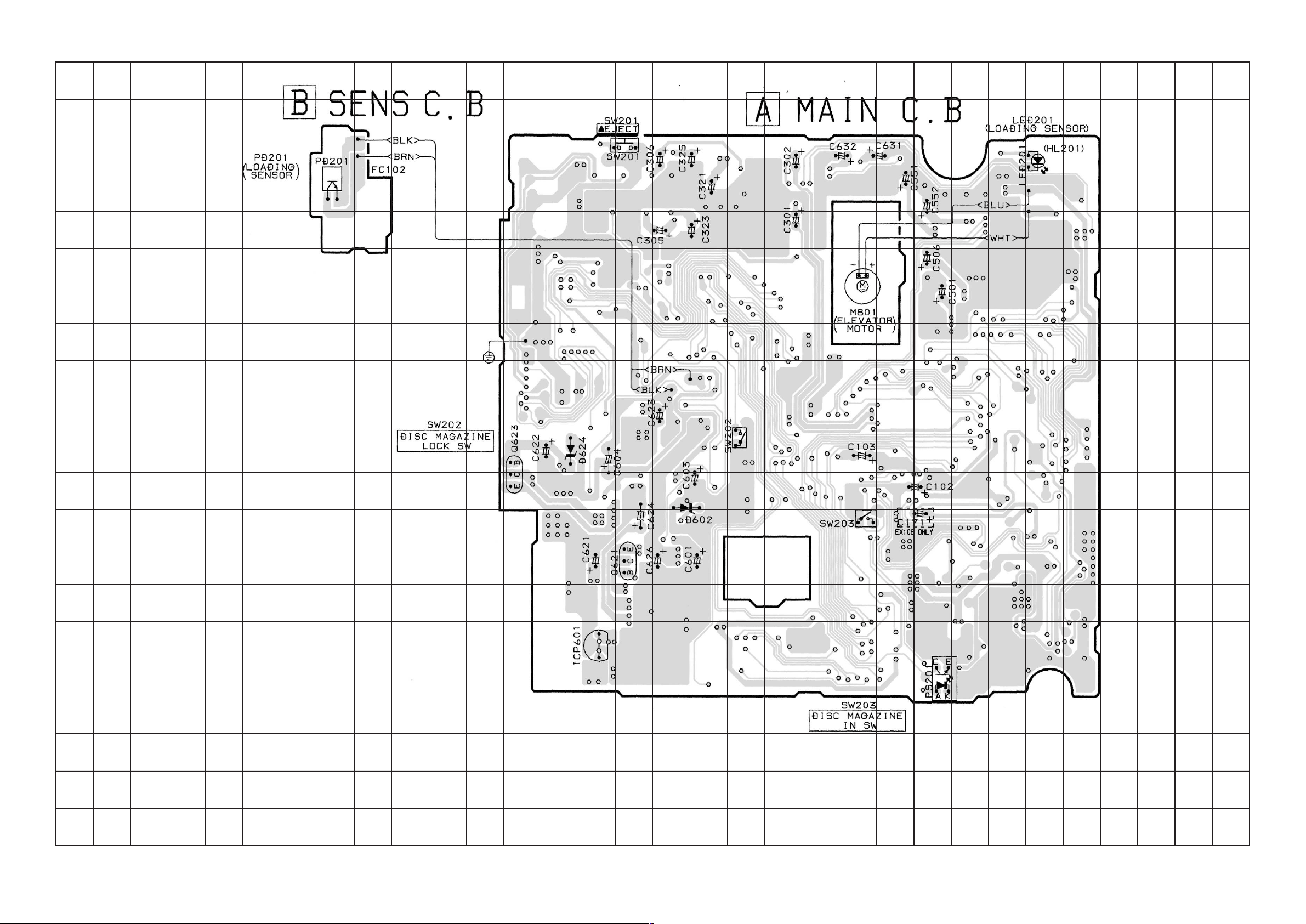

WIRING - 1 (MAIN / SENS) <1/2>

181920212223242526272829303132

17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 9 –

R

S

T

U

Page 10

WIRING - 1 (MAIN / DIN / FLEX DIN) <2/2>

A

B

C

D

E

F

G

H

151413121110987654321

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

I

J

K

L

M

N

O

P

Q

R

S

T

U

– 10 –

Page 11

WIRING - 2 (SW / LED / CONNECT / LIMIT / FLEX PICK UP)

101112131415161718192021222324

1234567892526272829303132

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 11 –

R

S

T

U

Page 12

SCHEMATIC DIAGRAM

12

Page 13

IC BLOCK DIAGRAM

13

Page 14

14

Page 15

IC DESCRIPTION

IC, CXP84632-160Q

Pin No. Pin Name I/O Description

1 ~ 4 NC Not connected.

5 EEPDI Connected to GND.

6 SCLK O SENS read clock out.

7 SENS I SENS in.

8 XLAT O DSP data latch out.

9 SYSM O DSP(DAC) system mute control. (H : MUTE).

10 DRST O DSP IC reset. (L : RESET).

11 EMPHA O DSP(DAC) DE EMPHASYS control. (H : ON).

12, 13 PWRCNT1, 2 O POWER control out 1, 2.

14 SENS I DISC IN detect sensor in.

15 RFSW O RFAMP GAIN select out. (H : CD - RW).

16 (EASSON) RFSEL O RFAMP Fs select out. (x2 speed : L). (Not used).

17 LEDCONT O LED on / off out. (H : ON).

18 ELCONT O MOTOR DRIVER control out 1.

19 LDCONT O MOTOR DRIVER control out 2.

20 MCONT O MOTOR DRIVER control out 3.

21 PHPWR O PHOTO SENSOR ON / OFF out. (H : ON).

22 EJECT I EJECT SW in. (Pull 22 ~ 28 SW L : ON).

23 INIT I INITIAL POSITION SW in.

24 MZIN I DISC MAGAZINE IN SW in.

25 MZLOCK I DISC MAGAZINE LOCK SW in.

26 UNLOAD I UNLOAD POSITION SW in.

27 LS I PU INNER POSITION SW in.

28 CHUCK I CHUCKING POSITION SW in.

29 CD6/10 I 6 / 10 DISC selector. (OPEN : 6 disc). (Connected to GND).

30 RESET IC RESET. (L : RESET).

31 EXTAL 12 MHz CLOCK.

32 XTAL 12 MHz CLOCK.

33 VSS IC GND.

34 TX Not used.

35 TEX Not used.

36 AVSS GND. (A/D in GND).

37 AVREF VDD. (A/D in Vref).

38 TEST0 I/O TEST MODE select (L) / TEST KEY connect.

39 ~ 42 TEST1 ~ 4 Not used.

43 TEST5 I CD TEXT FUNTION select. (L : NO TEXT). (M105 only)

44 TEST6 Not used.

45 TEST7 I EASS FUNCTION select. (L : NO EASS). (M105 only).

46 NC Not connected.

47 SQSI I SUBCODE CRC flag check.

48 SQCLK O SUBCODE READ CLOCK out.

15

Page 16

Pin No. Pin Name I/O Description

49 SQSI I SUBCODE DATA in.

50 NC Not connected.

51 DCLK O DSP / DRAM controller DATA CLOCK out.

52 ZSENS I DRAM controller DATA in. (EX108 only).

53 DATAO O DSP / DRAM controller DATA out.

54 PHSENS I PHOTO SENSOR in.

55 C2PO I C2 error flag in. (H : C2 error).

56 LOCK I LOCK in. (H : SPINDLE SERVO LOCK).

57 FOK I FOK in (H : FOCUS OK).

58, 59 NC Not connected.

60 ACCCNT I ACC CONT in. (H : ON).

61 CLKO O Adjust SERIAL CLOCK out.

62 CLKI I SERIAL CLOCK in.

63 SCOR I SUBCODE SYNC in.

64 DSPSEL I SERIAL BUS enable in.

65 SBCLKI I Adjust SERIAL CLOCK in.

66 SBDTI I SERIAL DATA in.

67 NC Not connected.

68 SBCLKO O SERIAL CLOCK out.

69 SBDTO O SERIAL DATA out.

70 NC Not connected.

71 BUCHK I Connected to VDD.

72 VDD IC VDD.

73 NC Connected to VDD.

74 AMUTE Not used.

75 SPCON O MOTOR DRIVER STANDBY control. (L : MUTE).

76 NRST O DRAM controller IC RESET. (L : RESET). (EX108 only).

77 YMLD O DRAM controller DATA LATCH out. (EX108 only).

78 LED1 O DISC detect sensor LED on / off. (L : ON).

79, 80 LED2, 3 Not used.

16

Page 17

VOLTAGE CHART

IC101, CXD2588R

PIN NO. CD x 1 CD x 2 RW x 1

1 DATA LINE DATA LINE DATA LINE

2 4.56 4.56 4.56

3 0.11 0.11 0.11

40 0 0

5 4.60 4.60 4.60

60 0 0

7 DATA LINE DATA LINE DATA LINE

8 4.59 4.59 4.59

9 4.57 4.57 4.57

10 0.03 0.03 0.03

11 4.61 4.61 4.61

12~14 4.06 4.06 4.06

15~18 0 0 0

19~20 2.03 2.03 2.03

21 1.92 1.92 1.92

22 4.06 4.06 4.06

23 0 0 0

24 0.05 0.05 0.05

25 1.92 1.92 1.92

26 2.00 2.00 2.00

27~28 0.01 0.01 0.01

29 0.04 0.04 0.04

30~31 4.06 4.06 4.06

32 2.25 2.25 2.25

33 0 0 0

34~35 2.25 2.25 2.25

36~41 DATA LINE DATA LINE DATA LINE

42~46 0 0 0

47 2.02 2.02 2.02

48 1.98 1.98 1.98

49~50 0 0 0

51 DATA LINE DATA LINE DATALINE

52 2.02 2.02 2.02

53 2.79 2.79 2.79

PIN NO. CD x 1 CD x 2 RW x 1

61 1.96 1.96 1.96

62 0 0 0

63~64 2.04 2.04 2.04

65~66 1.96 1.96 1.96

67 3.92 3.92 3.92

68 0 0 0

69~70 1.63 1.63 1.63

71 0.01 0.01 0.01

72~73 0 0 0

74 4.06 4.06 4.06

75 0.01 0.01 0.01

76 2.02 2.02 2.02

77~78 2.03 2.03 2.03

79 1.35 1.35 1.35

80 1.96 1.96 1.96

81 2.00 2.00 2.00

82 4.06 4.06 4.06

83 4.60 4.60 4.60

84 4.06 4.06 4.06

85 0 0 0

86 1.98 1.98 1.98

87 0 0 0

88 3.91 3.91 3.91

89 0 0 0

90~91 1.62 1.62 1.62

92~93 0 0 0

94 1.61 1.61 1.61

95 1.62 1.62 1.62

96 1.63 1.63 1.63

97 3.93 3.93 3.93

98~99 4.06 4.06 4.06

100 0 0 0

54 1.95 1.95 1.95

55 0 0 0

56 1.73 1.73 1.73

57 3.92 3.92 3.92

58 1.95 1.95 1.95

59 1.96 1.96 1.96

60 0.80 0.80 0.80

17

Page 18

IC151, CXA2581N

PIN NO. CD x 1 CD x 2 RW x 1

1 2.57 2.57 2.57

2 0.158 0.158 0.158

3 2.03 2.03 2.03

4 2.10 2.10 2.10

50 0 0

6 2.15 2.15 2.15

7 2.14 2.14 2.14

8~9 2.13 2.13 2.13

10~11 2.04 2.04 2.04

12 0 0 4.61

13 4.06 4.06 4.06

14 2.04 2.04 2.04

15 2.19 2.19 2.19

16 2.00 2.00 2.00

17 2.04 2.04 2.04

18 1.95 1.95 1.95

19 2.04 2.04 2.04

20 2.02 2.02 2.02

21 2.04 2.04 2.04

22 4.06 4.06 4.06

23 2.97 2.97 2.97

24 2.43 2.43 2.43

25 1.57 1.57 1.57

26 2.80 2.77 2.77

27 2.04 2.04 2.04

28 2.19 2.19 2.19

29 2.04 2.04 2.04

30 1.54 1.54 1.54

PIN NO. CD x 1 CD x 2 RW x 1

14 4.59 4.59 4.59

15 0 0 4.6

16 4.63 0.09 4.63x1 / 0.09x2

17 4.62 4.62 4.62

18~21 0 0 0

22~23 4.59 4.59 4.59

24~25 0 0 0

26~27 4.59 4.59 4.59

28~29 0 0 0

30 4.16 4.16 4.16

31 2.27 2.27 2.27

32 2.43 2.43 2.43

33 0 0 0

34 4.64 4.64 4.64

35~36 0 0 0

37 4.65 4.65 4.65

38 4.62 4.62 4.62

39~41 0 0 0

42 4.60 0 0

43 4.60 4.60 4.60

44 4.60 0 0

45~46 4.60 4.60 4.60

47 DATA LINE DATA LINE DATA LINE

48 4.56 4.56 4.56

49 DATA LINE DATA LINE DATA LINE

50 0 0 0

51 4.57 4.57 4.57

52~53 DATA LINE DATA LINE DATA LINE

54 4.64 4.64 4.64

IC201, CXP84632160Q

PIN NO. CD x 1 CD x 2 RW x 1

10 0 0

2~3 4.64 4.64 4.64

4~5 0 0 0

6 4.61 4.61 4.61

7 0.03 0.03 0.03

8 4.59 4.59 4.59

90 0 0

10~11 4.59 4.59 4.59

12~13 4.57 4.57 4.57

55 0 0 0

56~57 4.06 4.06 4.06

58~59 0 0 0

60 4.65 4.65 4.65

61 4.64 4.64 4.64

62 0 0 0

63 0.05 0.05 0.05

64 DATA LINE DATA LINE DATA LINE

65 4.64 4.64 4.64

66~67 0 0 0

68 4.64 4.64 4.64

18

Page 19

PIN NO. CD x 1 CD x 2 RW x 1

69 DATA LINE DATA LINE DATA LINE

70 0 0 0

71~73 4.65 4.65 4.65

74 0 0 0

75 4.59 4.59 4.59

76~77 4.63 4.63 4.63

78 4.00 4.00 4.00

79~80 0 0 0

IC251, TC74HC365AF

PIN NO. CD x 1 CD x 2 RW x 1

1~8 0 0 0

9~10 4.64 4.64 4.64

11~14 DATA LINE DATA LINE DATALINE

15 0 0 0

16 4.65 4.65 4.65

PIN NO. CD x 1 CD x 2 RW x 1

24 4.62 4.62 4.62

25 DATA LINE DATA LINE DATA LINE

26 4.56 4.56 4.56

27~28 DATA LINE DATA LINE DATA LINE

29 2.03 2.03 2.03

30 2.02 2.02 2.02

31~32 2.05 2.05 2.05

33 3.51 3.51 3.51

34 3.17 3.17 3.17

35~38 DATA LINE DATA LINE DATA LINE

39~40 2.40 2.40 2.40

41 2.01 2.01 2.01

42 1.94 1.94 1.94

43 2.04 2.04 2.04

44 2.08 2.08 2.08

IC301, NJM4558MD

PIN NO. CD x 1 CD x 2 RW x 1

1~3 6.30 6.30 6.30

40 0 0

5~7 6.30 6.30 6.30

8 10.65 10.65 10.65

IC401, SM5902AF <EX108 ONLY>

PIN NO. CD x 1 CD x 2 RW x 1

1 4.06 4.06 4.06

2~6 4.00 4.00 4.00

70 0 0

8 4.00 4.00 4.00

9 1.68 1.68 1.68

10 0 0 0

11 2.03 2.03 2.03

12 2.02 2.02 2.02

13 1.95 1.95 1.95

14 2.00 2.00 2.00

15 2.02 2.02 2.02

16 1.34 1.34 1.34

17 4.05 4.05 4.05

18 0 0 0

19 0.05 0.05 0.05

20 4.62 4.62 4.62

IC451, MSM5117400C-60SJ <EX108 ONLY>

PIN NO. CD x 1 CD x 2 RW x1

1 4.06 4.06 4.06

2~3 2.02 2.02 2.02

4 3.50 3.50 3.50

5 3.17 3.17 3.17

60 0 0

7- - -

8 DATA LINE DATA LINE DATA LINE

9 2.0 2.0 2.0

10 1.94 1.94 1.94

11 2.04 2.04 2.04

12 2.07 2.07 2.07

13 4.05 4.05 4.05

14 0 0 0

15~16 2.40 2.40 2.40

17~19 DATA LINE DATA LINE DATA LINE

20 - - -

21 DATA LINE DATA LINE DATA LINE

22 0 0 0

23 DATA LINE DATA LINE DATA LINE

24 2.03 2.03 2.03

25 2.00 2.00 2.00

26 0 0 0

21 DATA LINE DATA LINE DATA LINE

22 4.05 4.05 4.05

23 0 0 0

19

Page 20

IC501, BA6392FP

PIN NO. CD x 1 CD x 2 RW x 1

1 4.45 4.45 4.45

2 5.03 5.03 5.03

3 4.48 4.48 4.48

4~5 DATA LINE DATA LINE DATA LINE

6 4.75 4.75 4.75

7 4.77 4.77 4.77

80 0 0

9~10 DATA LINE DATA LINE DATALINE

11 4.73 4.73 4.73

12 4.71 4.71 4.71

13 4.76 4.76 4.76

14 0 0 0

15 4.59 4.59 4.59

16 4.78 4.78 4.78

17 4.69 4.69 4.69

18 4.76 4.76 4.76

IC622, PQ20WZ1U

PIN NO. CD x 1 CD x 2 RW x 1

1 13.10 13.10 13.10

2 4.57 4.57 4.57

3 11.11 11.11 11.11

4 2.67 2.67 2.67

50 0 0

19~20 DATA LINE DATA LINE DATA LINE

21~22 9.90 9.90 9.90

23 2.03 2.03 2.03

24 2.22 2.03 2.03

25 2.03 2.03 2.03

26 5.02 5.02 5.02

27 4.36 4.36 4.36

28 0 0 0

IC551, BA6247FP

PIN NO. CD x 1 CD x 2 RW x 1

1 0.55 0.55 0.55

2~4 0 0 0

5~6 DATA LINE DATA LINE DATA LINE

70 0 0

8 DATA LINE DATA LINE DATA LINE

9 10.33 10.33 10.33

10~15 0 0 0

16 10.33 10.33 10.33

17 0 0 0

18 0.55 0.55 0.55

19~21 0 0 0

22 0.55 0.55 0.55

23~25 0 0 0

20

Page 21

Q151, 2SB1197KQ

PIN CD x 1 CD x 2 RW x 1

E 3.18 3.18 3.18

C 2.18 2.18 2.18

B 2.54 2.54 2.54

Q253, 2SC2712GR

PIN CD x 1 CD x 2 RW x 1

E0 0 0

C0 0 0

B 0.68 0.68 0.68

Q152, DTA123JK <EX108 ONLY>

PIN CD x 1 CD x 2 RW x 1

E 4.05 4.00 4.05x1/4.00x2

C 2.77 3.96 2.77x1/3.96x2

B 4.60 0.09 4.60x1/0.09x2

Q153, 2SA1037K(R)

PIN CD x 1 CD x 2 RW x 1

E 2.80 2.80 2.80

C0 0 0

B 2.19 2.19 2.19

Q201, UPA608T

PIN CD x 1 CD x 2 RW x 1

E1 4.65 0 4.65

E2 0 4.64 0

C1 0 4.65 0

C2 4.64 0 4.64

B1 4.65 4.65 4.65

B20 0 0

Q601, 2SD1622S-TD

PIN CD x 1 CD x 2 RW x 1

E 4.65 4.65 4.65

C 13.10 13.10 13.10

B 5.23 5.23 5.23

Q621, 2SA1702

PIN CD x 1 CD x 2 RW x 1

E 13.10 13.10 13.10

C 13.05 13.05 13.05

B00 0

Q622, DTC124EKA

PIN CD x 1 CD x 2 RW x 1

E0 0 0

C 0.13 0.13 0.13

B 4.57 4.57 4.57

Q623, 2SD2395E

PIN CD x 1 CD x 2 RW x 1

E 4.62 4.62 4.62

Q202, 2SC2712GR

PIN CD x 1 CD x 2 RW x 1

E 2.15 2.15 2.15

C 4.63 4.63 4.63

B 2.83 2.83 2.83

Q251, 2SC2712GR

PIN CD x 1 CD x 2 RW x 1

E0 0 0

C0 0 0

B 0.64 0.64 0.64

Q252, DTA124EKA

PIN CD x 1 CD x 2 RW x 1

E 4.65 4.65 4.65

C 4.65 4.65 4.65

B00 0

C 13.03 13.03 13.03

B 4.07 4.07 4.07

Q631, 2SD1623

PIN CD x 1 CD x 2 RW x 1

E 11.06 11.06 11.06

C 11.10 11.10 11.10

B 11.65 11.65 11.65

PD201, PT4850F

PIN CD x 1 CD x 2 RW x 1

E0 0 0

C 4.58 4.58 4.58

21

Page 22

TEST MODE

There are two methods to perform operation check using test mode. One method uses the head unit. The other method uses the repair

jig. Because different operation buttons must be used for entering the operation modes and there are cases that unit does not run at all,

in the method that uses the head unit, the method using the repair jig is described as follows;

1. How to start up the CD test mode

Connect the P.W.B Key in accordance SERVICE JIG AND TOOLS step (6). How to use the repair jig - When the Control

Unit (CDC/CT) is not used .

1) While pressing the STOP button of the P.W.B Key, turn on the +12 V power of ACC/BACK UP.

2. How exit the CD test mode

1) Turn off the +12 V power of ACC/BACK UP.

3. Function description of CD test mode

Uses of the respective buttons of the P.W.B Key are

described in Fig-11.

Fig-11

Mode

Servo OFF

Search mode

Play mode

Sled mode

CD change

Operation key

STOP

FOCUS

FOCUS

V

SV ON

FWD

RVS

DISC UP

Operation

All servo off

Continuous focus search

Pickup lens repeats full swing (Note 1)

Normal playback

Pickup moves to outer circumference

Pickup moves to inner circumference

Disc unload

V

Magazine change

V

Disc load

Contents

APC circuit check

Laser current measurement

Focus error waveform check

Focus servo

Tracking servo

CLV servo

Sled servo

Sled servo

Mechanism operation check

Mechanism operation check (cyclic)

During the PLAY mode, the REV, FWD and DISC UP keys are invalid. Press the STOP key once.

When a Head Unit is connected, the Disc No. and the Track No. are shown on display in the same way as in the normal

operation.

Note 1: If the focus search operation is continued for 10 minutes or longer, the driver IC heats up sufficiently to trigger the

protection circuit, which stops the CD system. Turn off the main power and re-start operation about 10 minutes later.

22

Page 23

MECHANICAL EXPLODED VIEW 1 / 1

13

12

A

P.C.B

14

15

9

F

18

16

17

8ZG-4 RNF

15

A

20

21

A

14

19

H

13

P.C.B

PWB,FLEX DIN

(ZKM3)

H

7

I

A

6

4

B

5

4

8

G

10

G

B

6

MAIN C.B

11

F

WIRE ASSY

A

40 LUG

C

22

A

25

D

24

23

A

E

F

2

1

3

F

F

SH,BOTTOM 10

D

23

Page 24

MECHANICAL PARTS LIST 1 / 1

PART NO. DESCRIPTIONREF. NO. KANRI

NO.

1 8Z-KM1-003-010 PANEL,FRONT 10

2 8Z-KM1-004-010 WINDOW,FRONT 10

3 8Z-KM3-031-010 CABI,FRONT EX108<EX108 YJ2SF>

3 8Z-KM3-039-010 CABI,FRONT M105<M105 YJSF>

4 8Z-KM1-207-010 PLATE,MAG

5 8Z-KM3-034-010 WINDOW,DECK EX108<EX108 YJ2SF>

5 8Z-KM3-038-010 WINDOW,DECK M105<M105 YJSF>

6 8Z-KM1-220-010 MAGNET,HLDR ASSY

7 8Z-KM3-032-010 CABI,FRAME 10S

8 8Z-KM1-208-010 COVER, DECK 10

9 8Z-KM1-006-110 KEY,EJECT

10 8Z-KM1-230-010 PLATE,DECK

11 8Z-KM1-217-010 COVER, PLATE 10

12 8Z-KM1-203-010 HLDR,DECK L10

13 88-ZG3-371-010 DMPR,

14 8Z-KM1-202-010 SHAFT,FRAME

15 88-ZG4-542-010 SPR-E,DMPR 10

16 8Z-KM3-033-010 WINDOW,CD S

17 8Z-KM3-035-110 CABI,TOP 10S

18 8Z-KM3-608-010 F-CABLE,2P (SENS KM3)

DESCRIPTIONREF. NO. KANRI

19 8Z-KM1-204-010 HLDR,DECK R10

20 8Z-KM1-201-010 HLDR,CD

21 8Z-KM3-638-010 JACK,DIN 13 P TCS5125-014151

22 8Z-KM1-225-010 HLDR,REG

23 8Z-KM3-036-110 CABI,BOTTOM 10S

24 8Z-KM3-674-010 FF-CABLE,30P 0.5 145MM -C

25 8Z-KM1-232-010 HLDR,LED

A 87-B10-260-010 VTT+2.6-6 W/O SLOT BLK

B 8Z-KM1-223-010 S-SCREW,2-5 (BLK)

C 87-B10-255-010 U+2-3 W/O CR

D 8Z-KM1-215-010 S-SCREW,M3-5-12

E 8Z-KM1-224-010 S-SCREW,M3-7-11

F 87-571-032-410 VIT+2-3

G 87-B10-244-010 V+2-5 W/O BLK

H 87-B10-245-010 U+2.6-4 W/O CR

I 87-B10-097-010 W-M,3.2-8-0.188 W/ADH

PART NO.

NO.

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange GM Metallic Green

YM Metallic Yellow DM Metallic Orange PT Transparent Pink

24

Page 25

CD MECHANISM EXPLODED VIEW 1 / 2 (8ZG-4 RNF)

A

31

F

32

A

1

F

A

A

A

A

33

34

33

35

36

37

G

21

20

G

I

11

F

17

23

22

A

19

28

29

30

26

F

CHAS,REAR

2

27

H

5

25

D

C

E

9

D

E

24

D

B

10

3

A

4

H

E

A

A

5

6

7

8

SW C.B

12

A

D

13

38

LED C.B

B

PLATE ASSY

CKG-R

8ZG-8 RNF

25

17

16

18

14

15

A

A

A

Page 26

CD MECHANISM PARTS LIST 1 / 2 (8ZG-4 RNF)

PART NO.

1 88-ZG4-521-210 PLATE,SLIT 10

2 88-ZG4-513-110 PLATE,ELV-R 10

3 88-ZG4-501-110 CHAS ASSY,MAIN 10

4 88-ZG3-305-010 GEAR,ELV-R

5 88-ZG3-303-010 GEAR,ELV

6 88-ZG4-531-010 SHAFT,GATA 10

7 88-ZG4-512-110 PLATE,ELV-F 10

8 8Z-KM3-625-010 F-CABLE,4P (SWITCH)

9 88-ZG3-226-010 LEVER ASSY,SLD-1

10 88-ZG3-313-010 CAM,SLD

11 88-ZG3-002-210 MAGAZINE,B

12 88-ZG3-246-010 PLATE ASSY,CKG-R

13 88-ZG3-231-010 LEVER ASSY,CKG

14 88-ZG3-312-110 WORM-WHL,SLD

15 88-ZG3-221-010 HLDR ASSY,MOT ELV

16 88-ZG3-311-010 GEAR,WORM SLD

17 87-A91-054-010 MOT,FF-050SK

18 88-ZG3-211-110 CHAS ASSY,ELV

19 88-ZG3-314-010 GUIDE,F

20 88-ZG3-315-210 GUIDE,R

21 88-ZG3-236-010 ARM ASSY,

22 88-ZG3-266-110 CLAMP ASSY,

23 88-ZG3-276-310 SPR-P,CLAMP

24 88-ZG3-275-010 LEVER,SLD-2

25 88-ZG3-302-010 WORM-WHL,ELV

KANRI

NO.

DESCRIPTIONREF. NO.

PART NO.

NO.

26 88-ZG3-304-010 GEAR,ELV-F

27 88-ZG3-351-110 SPR-T,LEVER LOCK

28 88-ZG3-274-010 PLATE,LOCK SW

29 88-ZG3-352-010 SPR-E,LOCK SW

30 88-ZG3-301-010 GEAR,WORM ELV

31 88-ZG3-277-010 SPR-P,MAGAZINE

32 88-ZG4-506-110 CHAS ASSY,TOP 10

33 88-ZG4-541-010 SPR-E,EJECT 10

34 88-ZG3-278-010 PLATE,EJECT

35 88-ZG4-001-110 MAGAZINE,T 10

36 88-ZG4-514-110 SPR-P,TRAY 10

37 88-ZG3-003-210 TRAY,

38 8Z-KM1-214-010 HLDR,LED

A 87-262-545-310 V+2-2.5

B 87-261-031-410 V+2-2

C 87-B10-258-010 W-P,2.15-3.5-0.5

D 86-544-437-010 PW,1.5-3.5-0.5

E 87-B10-272-010 W-P,2.15-3.5-0.5 SLIT

F 87-571-032-410 VIT+2-3

G 87-067-869-010 V+1.7-8 HL BLK

H 87-067-310-010 PW,2.1-4-0.15 C

I 87-262-545-310 V+2-2.5

DESCRIPTIONREF. NO. KANRI

26

Page 27

CD MECHANISM EXPLODED VIEW 2 / 2 (8ZG-8 RNF)

21

20

19

LIMIT C.B

A

E

D

18

15

12

F

14

E

13

A

1

2

3

A

4

C

5

6

17

16

11

8

A

7

9

10

B

CONNECT C.B

A

27

Page 28

CD MECHANISM PARTS LIST 2 / 2 (8ZG-8 RNF)

PART NO.

NO.

1 88-ZG8-401-210 CHAS ASSY,MECHA

2 88-ZG8-425-010 GUIDE,PICKUP

3 88-ZG3-317-010 CLR,ELV

4 88-ZG8-426-010 HLDR,LEAD

5 88-ZG8-428-110 LEVER,PUSH SW

6 88-ZG8-412-010 SPR-P,PICKUP

7 87-A91-630-010 PICKUP,KSS-710A

8 8Z-KM4-631-010 PWB,FLEX PICK UP (AK)

9 88-ZG8-411-110 SPR-P,LEAD

10 87-A91-054-010 MOT,FF-050SK

11 88-ZG8-431-010 SHAFT,LEAD

12 88-ZG8-424-010 GEAR,MECHA 3

13 88-ZG3-332-010 CLR,LEVER ATK

14 88-ZG3-256-110 LEVER ASSY,ATK-F

15 88-ZG3-354-010 SPR-E,LEVER ATK

DESCRIPTIONREF. NO. KANRI

PART NO.

NO.

16 88-ZG8-427-010 HLDR,MOT MECHA

17 88-ZG8-422-010 GEAR,MECHA 1

18 88-ZG8-423-010 GEAR,MECHA 2

19 87-A90-926-010 MOT,RF-3L0PA

20 88-ZG8-421-010 TURN TABLE

21 8Z-KM3-624-010 F-CABLE,2P (LIMIT)

A 87-571-032-410 VIT+2-3

B 87-352-529-310 VT2+1.7-4.0 BLK

C 88-ZG8-432-010 S-SCREW,V+1.7-5 IB LOCK

D 87-262-547-310 V+2-3 BLK

E 87-078-018-010 PW 1.55-3.6-0.25

F 87-262-523-310 V+1.7-2 3 BLK

DESCRIPTIONREF. NO. KANRI

28

Page 29

211, IKENOHATA 1CHOME, TAITO-KU, TOKYO 110, JAPAN TEL:03 (3827) 3111

Printed in Singapore2000058 0251431

Loading...

Loading...