Page 1

ADCP-75-187

September 2006

Issue 3

Digivance® Street-Level Coverage Solution

800 MHz, 1900 MHz, and 800/900 MHz SMR

System Operation and Maintenance Manual

20576-A

1346357 Rev B

Page 2

ADCP-75-187

September 2006

Issue 3

Digivance® Street-Level Coverage Solution

800 MHz, 1900 MHz, 800/900 MHz SMR

System Operation and Maintenance Manual

1346357 Rev B

Page 3

ADCP-75-187 • Issue 3 • September 2006 • Preface

COPYRIGHT

© 2006, ADC Telecommunications, Inc.

All Rights Reserved

REVISION HISTORY

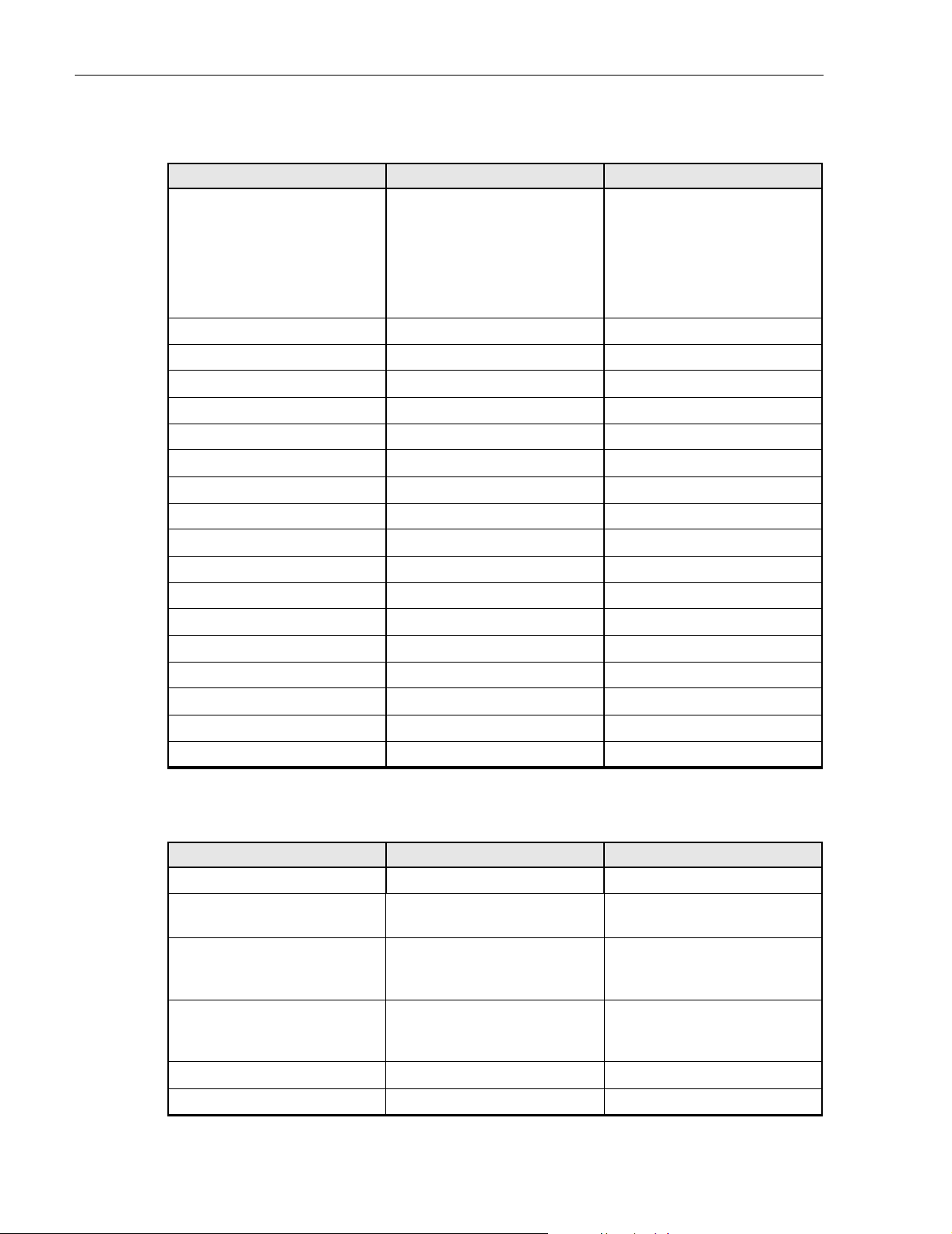

ISSUE DATE REASON FOR CHANGE

1 09/2005 Original issue.

2 06/2006 Release of single-band and dual-band remote units that support 800 and 1900 MHz operation and inclu-

3 09/2006 Non-technical changes for agency approvals.

sion of the RLM feature in the 800 and 1900 MHz remote units.

LIST OF CHANGES

The technical changes incorporated into this issue are listed below.

PAGE IDENTIFIER DESCRIPTION OF CHANGE

ix Standards Added FCC Part 15.5 statement.

2-25 Table 2-7 Deleted references to 1900 MHz Band G

TRADEMARK INFORMATION

ADC and Digivance are registered trademarks of ADC Telecommunications, Inc.

OptiTap is a trademark of Corning Incorporated.

Stargazer is a registered trademark of ADC DSL Systems, Inc.

Procomm Plus is a registered trademark of Quarterdeck Corporation.

Acrobat and Adobe are registered trademarks of Adobe Systems, Inc.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting ADC’s Technical Assistance Center at 1-800-366-3891, extension 73476

(in U.S.A. or Canada) or 952-917-3476 (outside U.S.A. and Canada), or by e-mail to wireless.tac@adc.com

Page ii

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 917-1717

Page 4

TABLE OF CONTENTS

Content Page

ABOUT THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

RELATED PUBLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

ADMONISHMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

GENERAL SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

STANDARDS CERTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

LIST OF ACRONYMS AND ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2 SCS SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2.1 Basic SCS System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2.2 Enhanced Base Transceiver Station Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2.3 Subscriber Unit Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2.4 Local Management Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2.5 Network Operations Center Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2.6 SNMP Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

3 SYSTEM FUNCTIONS AND FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

3.1 Fiber Optic Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

3.2 Control and Monitoring Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

3.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

3.4 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

3.5 Equipment Mounting and Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

4 DUAL-BAND REMOTE UNIT SCS SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

ADCP-75-187 • Issue 3 • September 2006 • Preface

SECTION 1:

OVERVIEW

SECTION 2:

DESCRIPTION

1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2 HOST UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1 Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.4 RF Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.5 RF Signal Level Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.6 Propagation Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.7 Optical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.8 Controller Area Network Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.9 Service Interface Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.10 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.11 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

© 2006, ADC Telecommunications, Inc.

Page iii

Page 5

ADCP-75-187 • Issue 3 • September 2006 • Preface

TABLE OF CONTENTS

Content Page

2.12 User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

3 REMOTE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3.1 Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.4 Antenna Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.5 RF Signal Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.6 Optical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.7 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.8 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

3.9 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

3.10 User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

4 ACCESSORY ITEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.1 Strand Mount Kit for RU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.2 Lightning Protector for RU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.3 Solar Shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

5 DIGIVANCE ELEMENT MANAGEMENT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

5.1 Digivance EMS Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

5.2 Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

5.3 Computer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

5.4 Digivance EMS Computer Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

5.5 Digivance Software User Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

6 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

1 BEFORE STARTING OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 Tools and Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 Readiness Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

2 TURN-UP SYSTEM AND VERIFY OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

2.1 Reference Procedure: Determine Forward Path Input Signal Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

2.2 Reference Procedure: Enter Site Name and Site Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

2.3 Reference Procedure: Enter Host Forward Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

2.4 Reference Procedure: Determine Output Signal Level at RU Antenna Port. . . . . . . . . . . . . . . . . . . . . . . . . 3-12

2.5 Reference Procedure: Enter Remote Forward Attenuation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

2.6 Reference Procedure: Enter Host Reverse Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

2.7 Reference Procedure: Enter Host Forward and Reverse Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Page iv

© 2006, ADC Telecommunications, Inc.

SECTION 3:

OPERATION

Page 6

TABLE OF CONTENTS

Content Page

1 SYSTEM MAINTENANCE OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

1.1 Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

2 FAULT DETECTION AND ALARM REPORTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

3 FAULT ISOLATION AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

3.1 Host Unit Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

3.2 RU Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4 TEST PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.1 Optical Power Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.2 Optical Loopback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

5 SCHEDULED MAINTENANCE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

ADCP-75-187 • Issue 3 • September 2006 • Preface

SECTION 4:

MAINTENANCE

SECTION 5:

GENERAL INFORMATION

1 WARRANTY/SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

2 SOFTWARE SERVICE AGREEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

3 REPAIR/EXCHANGE POLICY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

4 REPAIR CHARGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5 REPLACEMENT/SPARE PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

6 RETURNED MATERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

7 CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

© 2006, ADC Telecommunications, Inc.

Page v

Page 7

ADCP-75-187 • Issue 3 • September 2006 • Preface

TABLE OF CONTENTS

Content Page

Blank

Page vi

© 2006, ADC Telecommunications, Inc.

Page 8

ABOUT THIS MANUAL

This operation and maintenance manual provides the following information:

• An overview of the Digivance Street-Level Coverage Solution (SCS) system.

• A basic description of the system components including the Host Unit (HU), Remote Unit

(RU), and Digivance Element Management System (EMS).

• Procedures for turning-up the system and verifying that the system is functioning properly.

• Procedures for maintaining the system including scheduled maintenance tasks and fault

isolation and troubleshooting procedures.

• Product warranty, repair, return, and replacement information.

The procedures for installing the host unit, remote unit, and for installing and using the EMS

software are provided in other publications which are referenced in the Related Publications

section and at appropriate points within this manual.

RELATED PUBLICATIONS

Listed below are related manuals, their content, and their publication numbers. Copies of these

publications can be ordered by contacting the Technical Assistance Center at 1-800-366-3891,

extension 73476 (in U.S.A. or Canada) or 952-917-3476 (outside U.S.A. and Canada).

ADCP-75-187 • Issue 3 • September 2006 • Preface

Title/Description ADCP Number

Digivance LRCS and SCS Systems 800/900 MHz SMR Rear Access

Host Unit Installation and Maintenance Manual 75-180

Provides instructions for mounting the rear access host unit in an equipment

rack, installing and connecting the various cables, and replacing the cooling fans.

Digivance SCS System Interim Single-Band Remote Unit Installation Manual 75-190

Provides instructions for mounting the interim single-band remote unit and for

installing and connecting the various cables.

Digivance SCS System Single-Band Remote Unit Installation Manual 75-188

Provides instructions for mounting the single-band remote unit and for

installing and connecting the various cables.

Digivance SCS System Dual-Band Remote Unit Installation and

Maintenance Manual 75-189

Provides instructions for mounting the dual-band remote unit and for installing

and connecting the various cables.

Digivance Element Management System Version 7.0 User Manual 75-201

Provides instructions for installing the Digivance Element Management System

(EMS) software and for using both the Graphical User Interface (GUI) and the

Network Operations Center (NOC) versions of the software.

Digivance SNMP Agent Software Version 7.1 User Manual 75-202

Describes how to install, configure, and use the LRCS SNMP Proxy Agent.

© 2006, ADC Telecommunications, Inc.

Page vii

Page 9

ADCP-75-187 • Issue 3 • September 2006 • Preface

ADMONISHMENTS

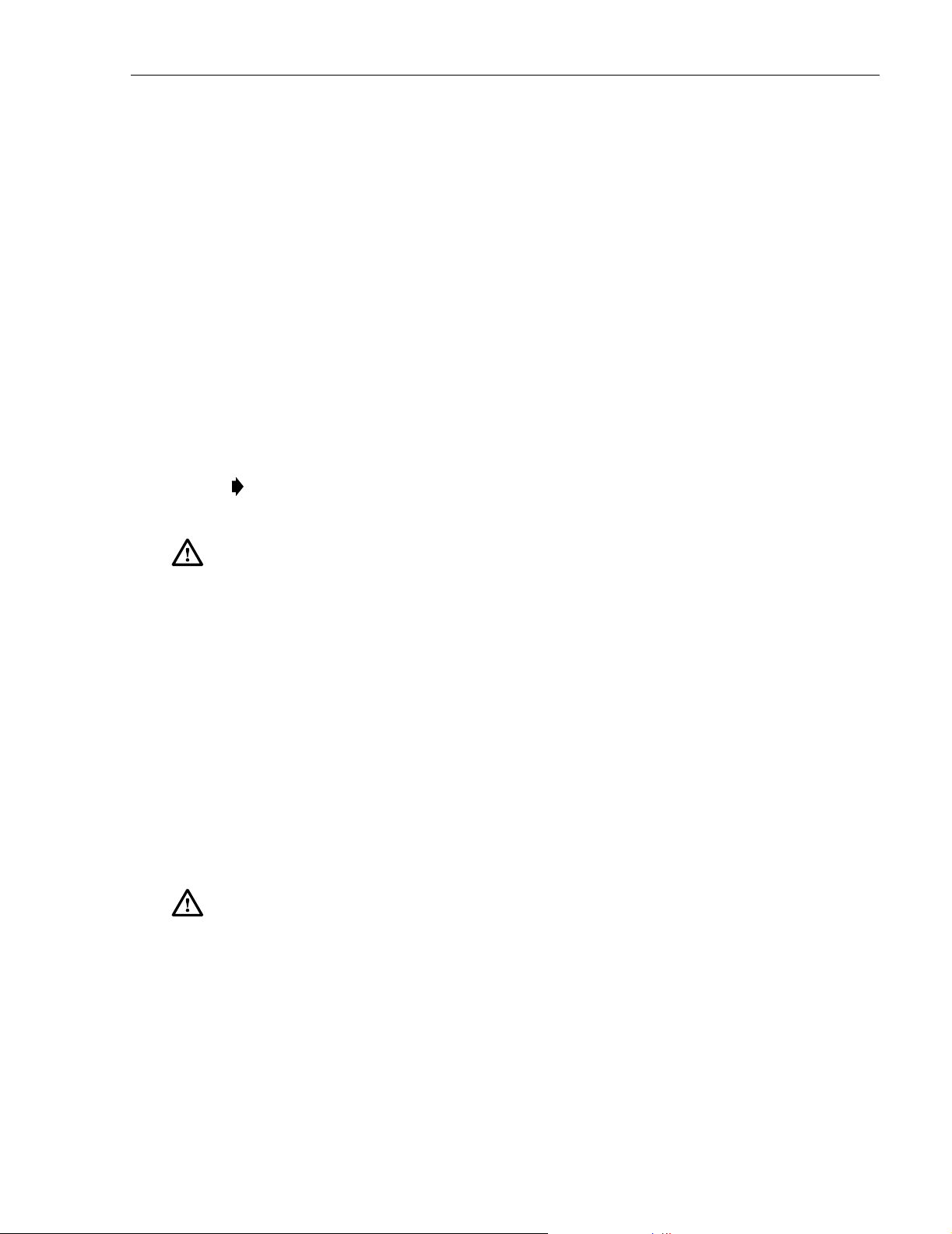

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below), and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warn ing: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

GENERAL SAFETY PRECAUTIONS

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the eye. Do not look into the ends of any optical fiber. Do not

look directly into the optical transceiver of any digital unit or exposure to laser radiation may

result. An optical power meter should be used to verify active fibers. A protective cap or hood

MUST be immediately placed over any radiating transceiver or optical fiber connector to avoid

the potential of dangerous amounts of radiation exposure. This practice also prevents dirt

particles from entering the adapter or connector.

Danger: Do not look into the ends of any optical fiber. Exposure to laser radiation may result.

Do not assume laser power is turned-off or the fiber is disconnected at the other end.

Danger: Wet conditions increase the potential for receiving an electrical shock when installing

or using electrically-powered equipment. To prevent electrical shock, never install or use

electrical equipment in a wet location or during a lightning storm.

Warn ing: The HU is powered by 48 VDC power which is supplied over customer-provided

wiring. To prevent electrical shock when installing or modifying the HU power wiring,

disconnect the wiring at the power source before working with uninsulated wires or terminals.

Caution: Always allow sufficient fiber length to permit routing of patch cords and pigtails

without severe bends. Fiber optic patch cords or pigtails may be permanently damaged if bent

or curved to a radius of less than 2 inches (50 mm).

Page viii

© 2006, ADC Telecommunications, Inc.

Page 10

STANDARDS CERTIFICATION

Each respective SMR, Cellular, and PCS system in the SCS platform is FCC and IC approved.

Information in this manual explains applicable portions of these systems.

FCC: The Digivance SCS system complies with the applicable sections of Title 47 CFR Parts

22, 24, and 90. Installation requirements the licensee needs to follow are listed in Title 47 CFR

90.635. This document may be found at the following website: http://www.access.gpo.gov/nara/

cfr/waisidx_03/47cfr90_03.html.

Caution: Modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

Part 15.5 General conditions of operation:

a. Persons operating intentional or unintentional radiators shall not be deemed to have

any vested or recognizable right to continue use of any given frequency by virtue of

prior registration or certificate of equipment.

b. Operation of an intentional, unintentional, or incidental radiator is subject to the

conditions that no harmful interference is caused and that interference must be

accepted that may be caused by the operation of an authorized radio station, by

another intentional or unintentional radiator, by industrial, scientific and medical

(ISM) equipment, or by an incidental operator.

ADCP-75-187 • Issue 3 • September 2006 • Preface

c. The operator of a radio frequency device shall be required to cease operating the

device upon notification by a Commission representative that the device is causing

harmful interference. Operation shall not resume until the condition causing the

harmful interference has been corrected.

UL/CUL: The Host Unit complies with UL and CUL 60950 Standard for Safety for

Information Technology Equipment including Electrical Business Equipment.

The Remote Unit complies with NEMA Type 6, UL and CUL 50, Standard for Enclosures for

Electrical Equipment.

The Remote Unit provides the degree of protection specified by IP67 as defined in IEC

(International Electrotechnical Commission) Publication 60529.

The Remote Unit complies with UL and CUL 60950 and UL 50 as Communication Service

Equipment under the DUZO category.

FDA/CDRH: This equipment uses a Class 1 LASER according to FDA/CDRH Rules. This

product conforms to all applicable standards of 21 CFR Part 1040.

IC: This equipment complies with the applicable sections of RSS-131. The term “IC:” before the

radio certification number only signifies that Industry Canada Technical Specifications were met.

© 2006, ADC Telecommunications, Inc.

Page ix

Page 11

ADCP-75-187 • Issue 3 • September 2006 • Preface

LIST OF ACRONYMS AND ABBREVIATIONS

The acronyms and abbreviations used in this manual are detailed in the following list:

AC Alternating Current

ASCII American Standard Code for Information Interchange

Att Attenuation

AW G American Wire Gauge

BER Bit Error Rate

C Centigrade

CAN Controller Area Network

CDRH Center for Devices and Radiological Health

CD-ROM Compact Disk Read Only Memory

COM Common

COMM Communication

Config Configuration

CUL Canadian Underwriters Laboratories

DC Direct Current

DCE Data Communications Equipment

DTE Data Terminal Equipment

EBTS Enhanced Base Transceiver Station

EIA Electronic Industries Association

EMS Element Management System

ESD Electrostatic Discharge

F Fahrenheit

FCC Federal Communications Commission

FDA Food and Drug Administration

FWD Forward

GUI Graphical User Interface

HU Host Unit

IC Industry Canada

IEC International Electrotechnical Commission

IP Internet Protocol

LED Light Emitting Diode

LPA Linear Power Amplifier

LRCS Long-Range Coverage Solution

MHz Mega Hertz

MIB Management Information Base

MPE Maximum Permissible Exposure

MTBF Mean Time Between Failure

NC Normally Closed

NEM Network Element Manager

NO Normally Open

NOC Network Operations Center

Page x

© 2006, ADC Telecommunications, Inc.

Page 12

OSP Outside Plant

PA Power Amplifier

PC Personal Computer

PCS Personal Communications System

Rev Reverse

RF Radio Frequency

RMA Return Material Authorization

RU Remote Unit

RX Receive or Receiver

SCS Street-Level Coverage Solution

SNMP Simple Network Management Protocol

SMR Specialized Mobile Radio

STM Spectrum Transport Module

TX Transmit or Transmitter

UL Underwriters Laboratories

VA C Volts Alternating Current

VDC Volts Direct Current

VSWR Voltage Standing Wave Ratio

WDM Wavelength Division Multiplexer

WECO Western Electric Company

ADCP-75-187 • Issue 3 • September 2006 • Preface

© 2006, ADC Telecommunications, Inc.

Page xi

Page 13

ADCP-75-187 • Issue 3 • September 2006 • Preface

Blank

Page xii

© 2006, ADC Telecommunications, Inc.

Page 14

SECTION 1: OVERVIEW

1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2 SCS SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2.1 Basic SCS System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2.2 Enhanced Base Transceiver Station Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2.3 Subscriber Unit Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2.4 Local Management Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2.5 Network Operations Center Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2.6 SNMP Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

3 SYSTEM FUNCTIONS AND FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

3.1 Fiber Optic Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

3.2 Control and Monitoring Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

3.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

3.4 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

3.5 Equipment Mounting and Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

4 DUAL-BAND REMOTE UNIT SCS SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

_________________________________________________________________________________________________________

ADCP-75-187 • Issue 3 • September 2006 • Section 1: OVERVIEW

1 INTRODUCTION

This section provides basic description, application, and configuration information about the

Digivance SCS system. Throughout this publication, all items referenced as “accessory items”

are not furnished with the basic product and must be purchased separately.

2 SCS SYSTEM OVERVIEW

The Digivance Long Range Coverage Solution (LRCS) system is an RF signal transport system

that provides long-range RF coverage to areas where it is impractical to place an Enhanced Base

Transceiver Station (EBTS) at the antenna site. High real estate costs and community

restrictions on tower and equipment locations often make it difficult to install the EBTS at the

same location as the antenna. The LRCS system overcomes equipment placement problems by

hubbing base stations at a central location and placing antennas at remote locations with

minimal real estate requirements. The LRCS system transports RF signals to remote locations to

expand coverage into areas not receiving service or to extend coverage into difficult to reach

areas such as canyons, tunnels, or underground roadways.

The SCS system provides the same functionality as the LRCS system but incorporates a low

profile, low power, low cost remote unit. The SCS system remote unit complements the high

power remote unit used with LRCS systems. The primary application includes urban areas

where multiple, strategically placed, low power remote units provide better coverage than high

power remote units.

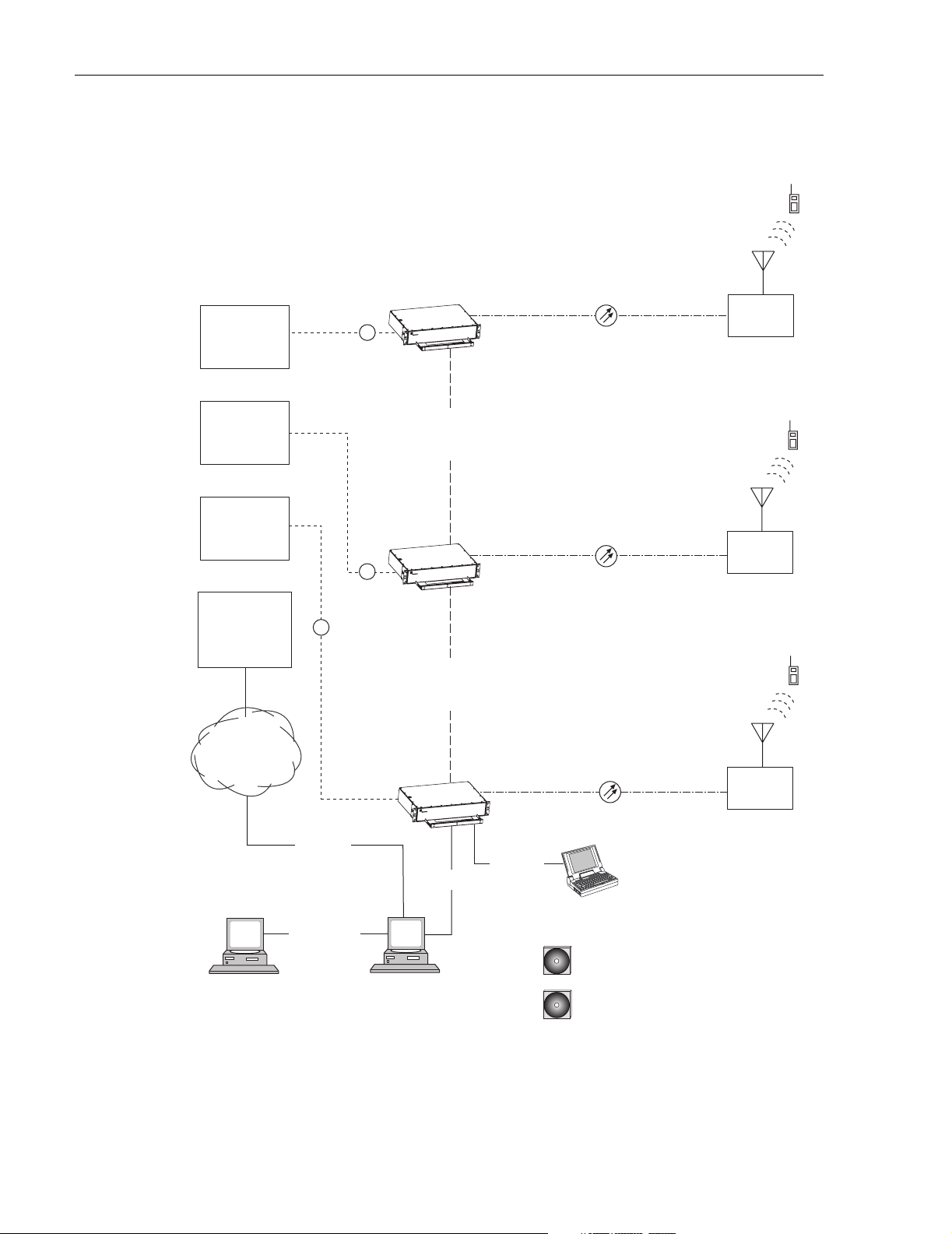

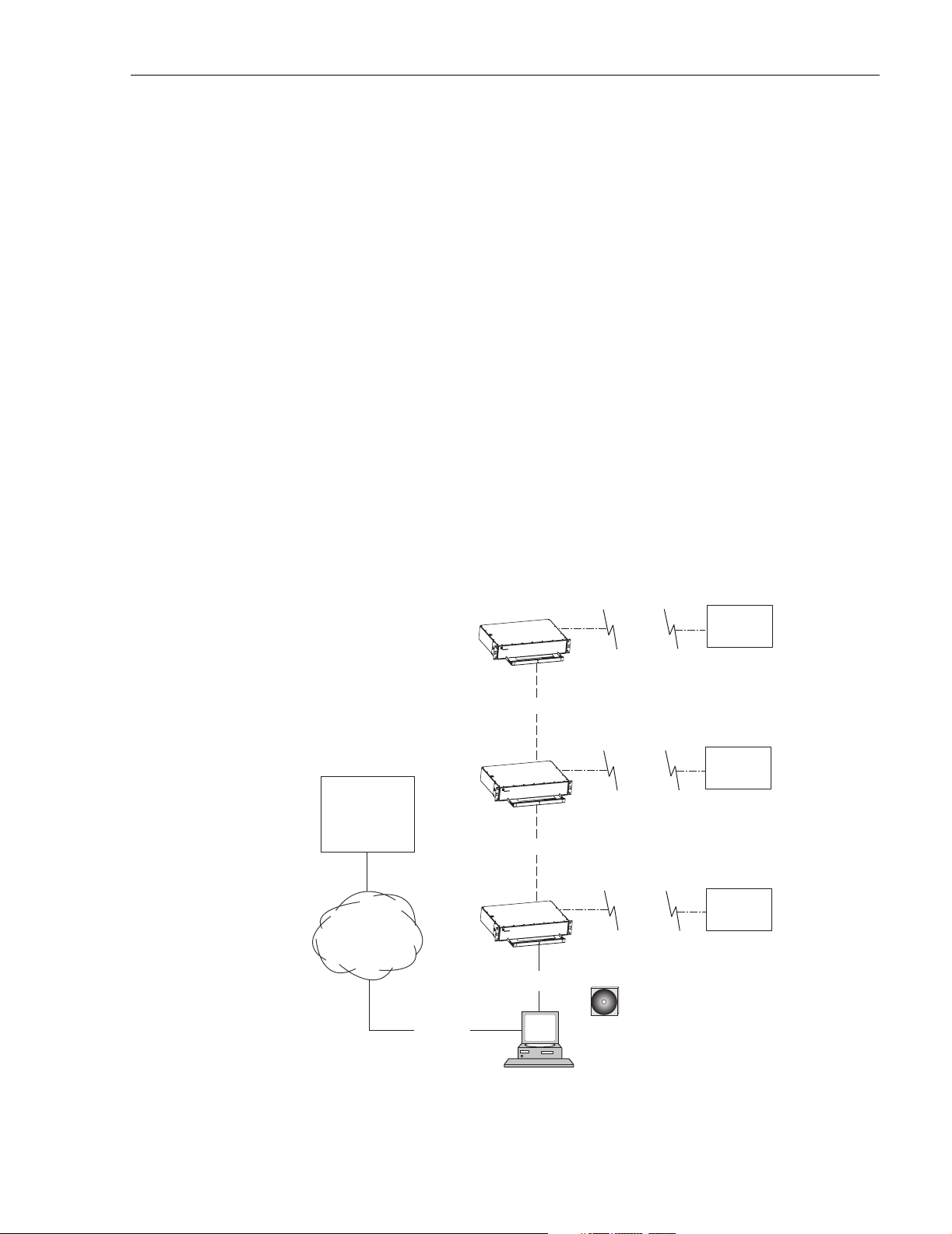

2.1 Basic SCS System Components

The basic components of a typical Digivance SCS system and their function are shown in

Figure 1-1. A basic SCS system consists of a Host Unit (HU) and a Remote Unit (RU). The HU

consists of a rack-mountable chassis that is designed for use in an indoor environment. The RU

consists of a sealed enclosure that is designed for use in an outdoor environment. Control and

monitoring functions are provided by the Digivance Element Management System (EMS).

© 2006, ADC Telecommunications, Inc.

Page 1-1

Page 15

ADCP-75-187 • Issue 3 • September 2006 • Section 1: OVERVIEW

HOST UNIT 1

ENHANCED

BASE

TRANSCEIVER

STATION 1

RF

REMOTE

UNIT 1

ENHANCED

BASE

TRANSCEIVER

STATION 2

ENHANCED

BASE

TRANSCEIVER

STATION 3

NETWORK

OPERATIONS

CENTER

(REMOTE

INTERFACE)

T1, DS0

WITH RS232

CONVERSION,

OR OTHER

MEDIUM

RF

RS-232

ASCII

HOST UNIT 2

RF

HOST UNIT 3

CONTROLLER

AREA

NETWORK

CONTROLLER

AREA

NETWORK

RS-232

RS-232

REMOTE

UNIT 2

REMOTE

UNIT 3

PC COMPUTER WITH EMS

(TEMPORARY CONNECTION)

NETWORK SNMP

MANAGER

Page 1-2

© 2006, ADC Telecommunications, Inc.

ETHERNET

LAN

PC COMPUTER WITH EMS

AND SNMP PROXY AGENT

(PERMANENT CONNECTION)

Figure 1-1. SCS System Overview Diagram

CD-ROM WITH SNMP PROXY

AGENT SOFTWARE (OPTIONAL)

CD-ROM WITH EMS

SOFTWARE

20564-B

Page 16

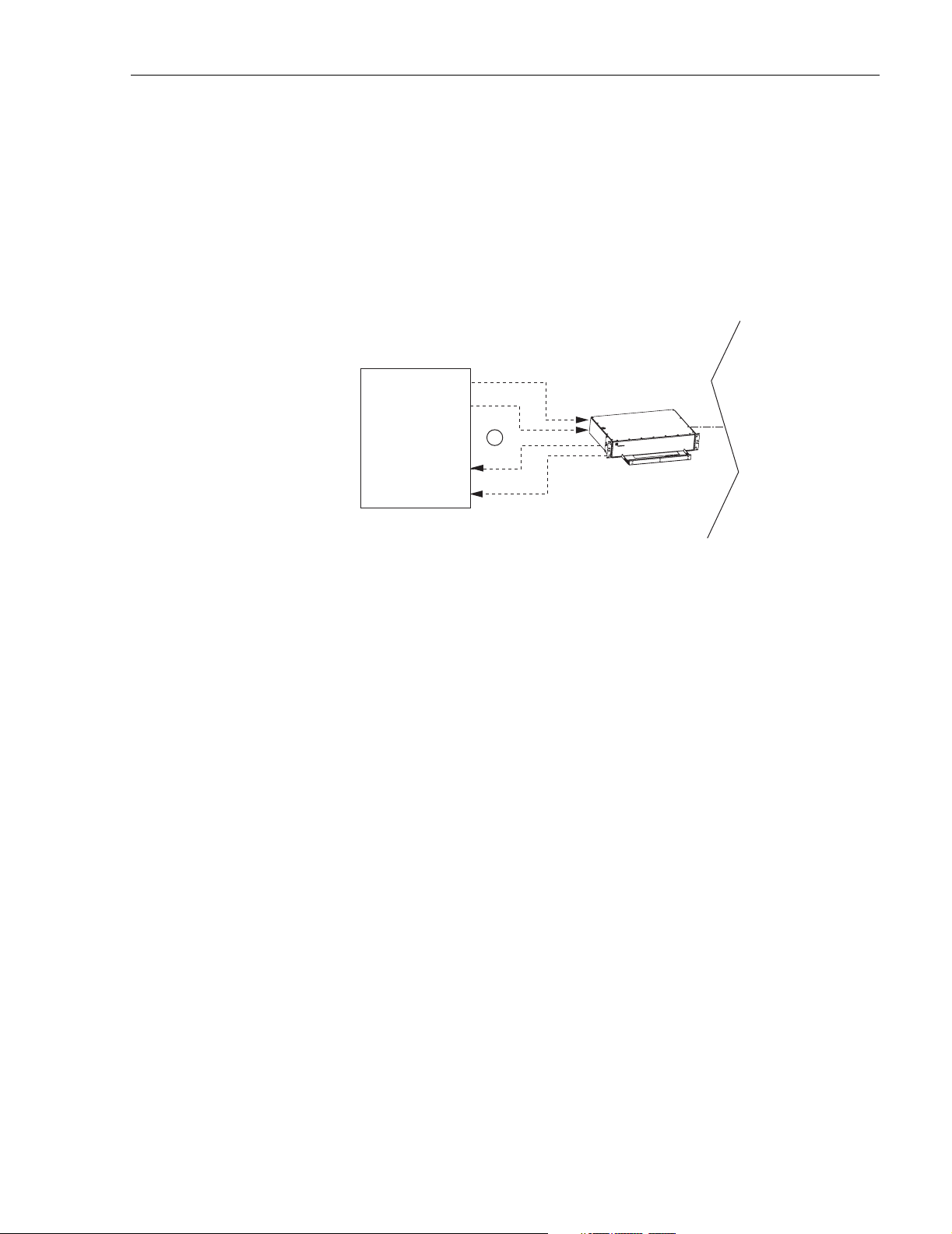

2.2 Enhanced Base Transceiver Station Interface

The HU is interfaced with an EBTS over coaxial cables as shown in Figure 1-2. The EBTS

provides the RF channel inputs and outputs for a designated sector. In the forward path, the HU

receives two RF inputs from the EBTS. The HU digitizes the RF spectrum and then converts it

to digital optical signals for transport to the RU. In the reverse path, the HU receives digital

optical signals from the RU. The HU converts the digital optical signals back to two RF outputs

which are supplied to the EBTS over the coaxial cable interface.

FORWARD

PATHS

ENHANCED

BASE

TRANSCEIVER

STATION

RF

REVERSE

PATHS

ADCP-75-187 • Issue 3 • September 2006 • Section 1: OVERVIEW

HOST UNIT

2.3 Subscriber Unit Interface

The RU interfaces with the subscriber units (cell phones) through an antenna. In the reverse

path, the RU receives RF spectrum from each subscriber unit (see Figure 1-1). The RU digitizes

the RF spectrum and then converts it to digital optical signals for transport to the HU over the

optical fiber link. In the forward path, the RU receives digital optical signals from the HU. The

RU converts the optical signals to RF spectrum for transmission to the subscriber units. The RU

is connected to an antenna (not provided) which transmits and receives the subscriber unit RF

spectrum.

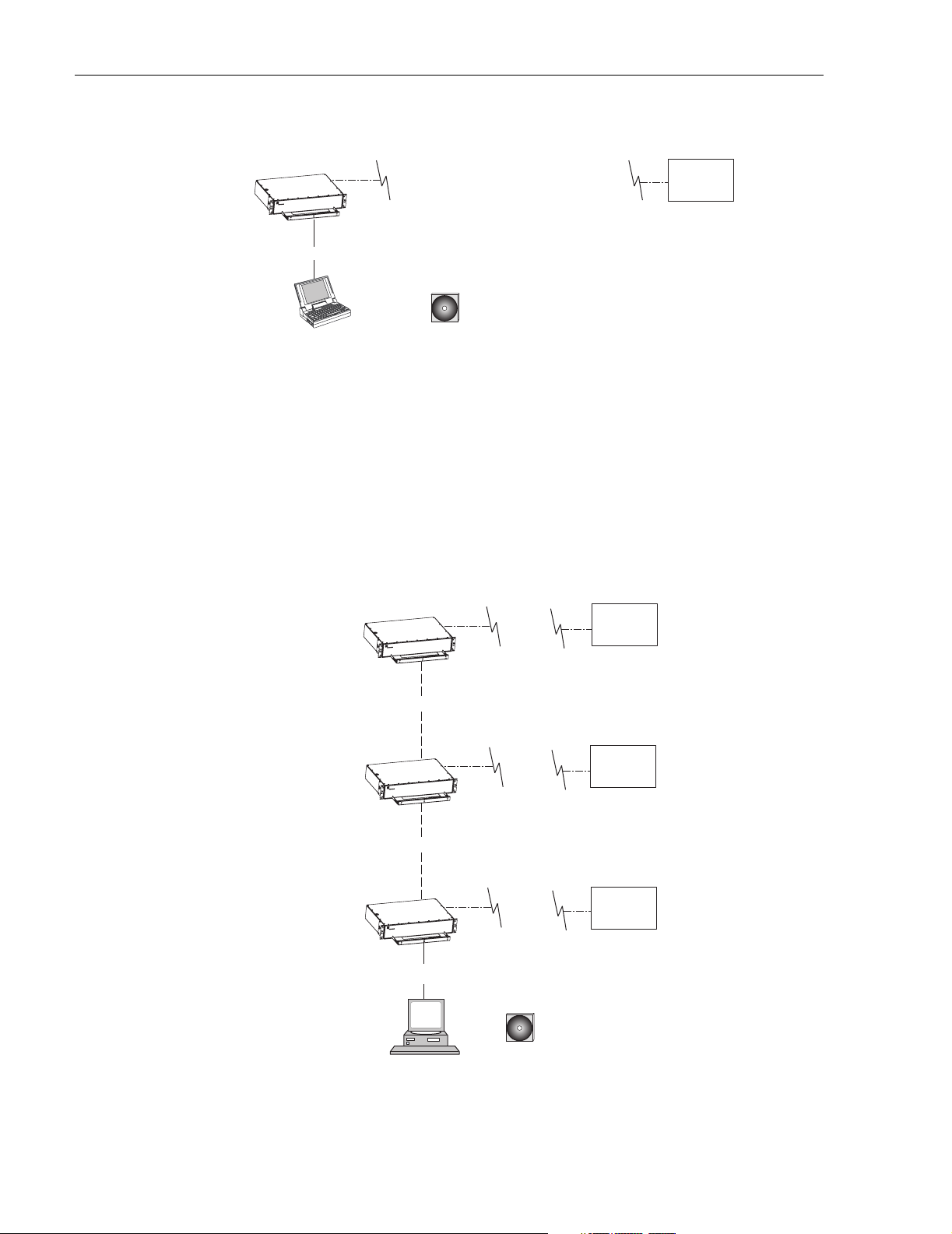

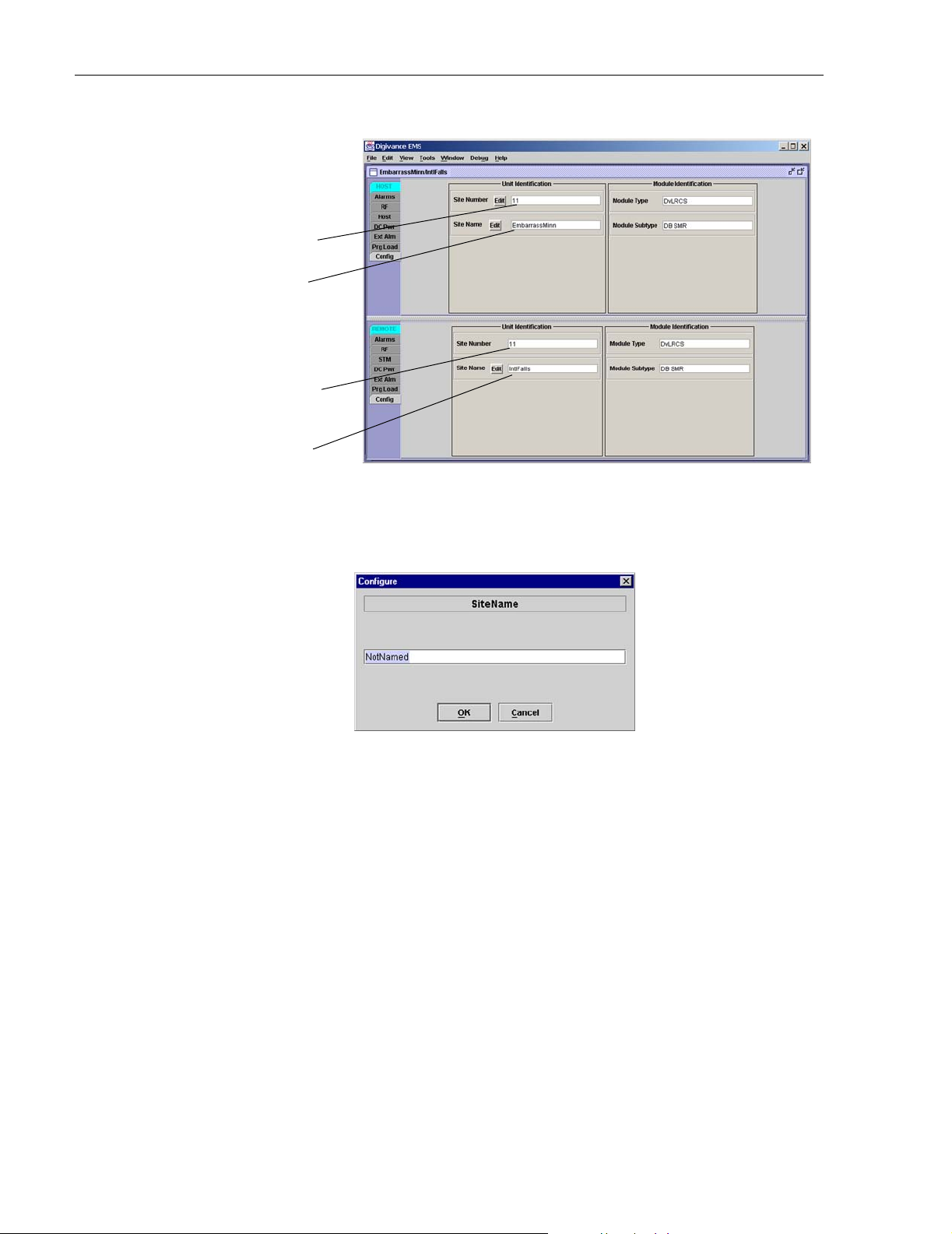

2.4 Local Management Interface

Communications with an individual Digivance system is supported through a local management

interface capability as shown in Figure 1-3. A local management interface requires a PC-type

computer loaded with the Digivance Element Management System (EMS) software. EMS

provides the various control and monitoring functions required to locally manage a Digivance

system. The EMS computer connects directly to the HU through the computer’s RS-232 port.

Operation is implemented through the EMS Graphical User Interface (GUI). The GUI consists

of a series of screens from which the user selects the desired option or function. An RS-232

service port is provided on the HU for connecting the EMS computer.

20856-A

Figure 1-2. EBTS/HU Interface

© 2006, ADC Telecommunications, Inc.

Page 1-3

Page 17

ADCP-75-187 • Issue 3 • September 2006 • Section 1: OVERVIEW

HOST UNIT

RS-232

REMOTE

UNIT

CD-ROM WITH DIGIVANCE

ELEMENT MANAGEMENT

SYSTEM (EMS) SOFTWARE

LAPTOP WITH EMS

(LOCAL INTERFACE)

20565-A

Figure 1-3. Local Management of a Single Digivance System

An EMS computer may be used to locally manage a networked group of multiple Digivance

systems as shown in Figure 1-4. A Controller Area Network (CAN) port is provided on each

HU. Up to twenty-four HU’s may be linked together through the CAN interface and controlled

by the same EMS computer. All the networked HU’s and the associated RU’s may be managed

by connecting the EMS computer to one HU. The EMS computer provides an RS-232 port (#1)

to support the interface with the networked HU’s.

HOST UNIT

REMOTE

UNIT

CAN

HOST UNIT

NOTE: THE SUM MAXIMUM

LENGTH FOR THE CAN BUS

CABLES IS 75 FEET

REMOTE

UNIT

PC COMPUTER WITH EMS

(LOCAL INTERFACE WITH

MULTIPLE SYSTEMS)

Page 1-4

© 2006, ADC Telecommunications, Inc.

CAN

HOST UNIT

REMOTE

UNIT

RS-232

NOTE: THE MAXIMUM LENGTH

FOR THE RS-232 CABLE IS 75 FEET

CD-ROM WITH DIGIVANCE

ELEMENT MANAGEMENT

SYSTEM (EMS) SOFTWARE

Figure 1-4. Local Management of Networked Digivance Systems

20857-A

Page 18

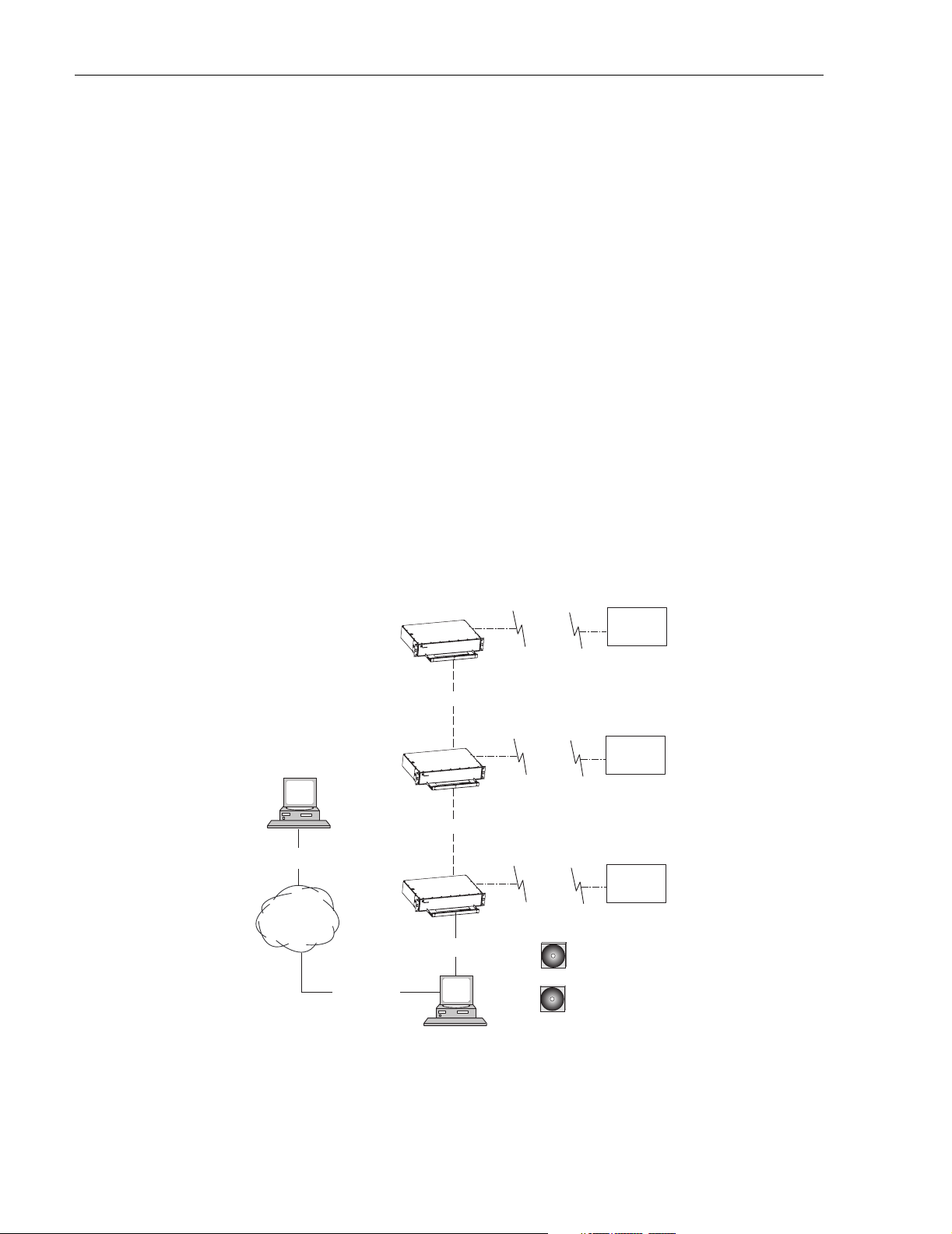

2.5 Network Operations Center Interface

Communications between a Network Operations Center (NOC) and a networked group of

multiple Digivance systems is supported by a NOC interface capability as shown in Figure 1-5.

To support the NOC interface, a PC-type computer loaded with the Digivance Element

Management System (EMS) software is required. EMS provides the various control and

monitoring functions required to remotely manage multiple Digivance systems through the

NOC interface.

A Controller Area Network (CAN) port is provided on each HU. Up to twenty-four HU’s may

be linked together through the CAN interface and controlled by the same EMS computer. All

the networked HU’s and the associated RU’s may be managed by connecting the EMS computer

to one HU. The EMS computer provides an RS-232 port (#1) to support the interface with the

networked HU’s.

The NOC can be linked to the EMS computer through a T1 system, DS0 with RS232

conversion, or some other medium. The EMS computer provides an RS-232 ASCII interface

port (#2) to support the interface with the NOC.

At the NOC, control and monitoring of the networked Digivance systems is implemented

through a Network Element Manager (NEM) interface which requires only a VT100 terminal/

emulator for operation. The NEM interface language consists of simple ASCII text strings. All

communications are input as either SET or GET commands which result in ASCII text string

responses from the specified system or systems.

ADCP-75-187 • Issue 3 • September 2006 • Section 1: OVERVIEW

NETWORK

OPERATIONS

CENTER

(REMOTE

INTERFACE)

T1, DS0

WITH RS232

CONVERSION,

OR OTHER

MEDIUM

RS-232

ASCII

HOST UNIT

HOST UNIT

HOST UNIT

CAN

CAN

RS-232

CD-ROM WITH EMS

SOFTWARE

PC COMPUTER WITH

EMS SOFTWARE

REMOTE

UNIT

REMOTE

UNIT

REMOTE

UNIT

20858-A

Figure 1-5. Remote Management of Networked Digivance Systems Through NOC Interface

© 2006, ADC Telecommunications, Inc.

Page 1-5

Page 19

ADCP-75-187 • Issue 3 • September 2006 • Section 1: OVERVIEW

2.6 SNMP Interface

Communications between an external Simple Network Management Protocol (SNMP) Manager

and a networked group of multiple Digivance systems is supported by an SNMP interface

capability as shown in Figure 1-6. To support the SNMP interface, a PC-type computer loaded

with both the Digivance Element Management System (EMS) software and the SNMP Proxy

Agent software is required. The EMS and SNMP Proxy Agent software plus the associated

Management Information Base (MIB) provide the various control (Set) monitoring (Get) and

trap functions required to remotely manage multiple Digivance systems using an SNMP

Manager.

A Controller Area Network (CAN) port is provided on each HU. Up to twenty-four HU’s may

be linked together through the CAN interface and controlled by the same EMS computer. All

the networked HU’s and the associated RU’s may be managed by connecting the EMS computer

to one HU. The EMS computer provides an RS-232 port (#1) to support the interface with the

networked HU’s.

The SNMP Manager may be linked with the EMS computer through a Local Area Network

(LAN). The EMS computer provides an Ethernet port to support the interface with the LAN.

The SNMP Proxy Agent supports two versions of the SNMP protocol: SNMPv1 and SNMPv2c.

A facility to Register/Unregister an SNMP Manager for receiving traps is also supported by the

SNMP Proxy Agent. The SNMP Manager is an option and must be ordered separately from

the EMS software.

NETWORK

SNMP

MANAGER

ETHERNET

LOCAL

AREA

NETWORK

HOST UNIT

CAN

HOST UNIT

CAN

HOST UNIT

RS-232

REMOTE

UNIT

REMOTE

UNIT

REMOTE

UNIT

CD-ROM WITH EMS

SOFTWARE

Figure 1-6. Remote Management of Networked Digivance Systems Through SNMP Manager

Page 1-6

© 2006, ADC Telecommunications, Inc.

ETHERNET

PC COMPUTER WITH EMS

AND SNMP PROXY AGENT

CD-ROM WITH SNMP

PROXY AGENT SOFTWARE

20859-A

Page 20

3 SYSTEM FUNCTIONS AND FEATURES

This section describes various system level functions and features of the Digivance system.

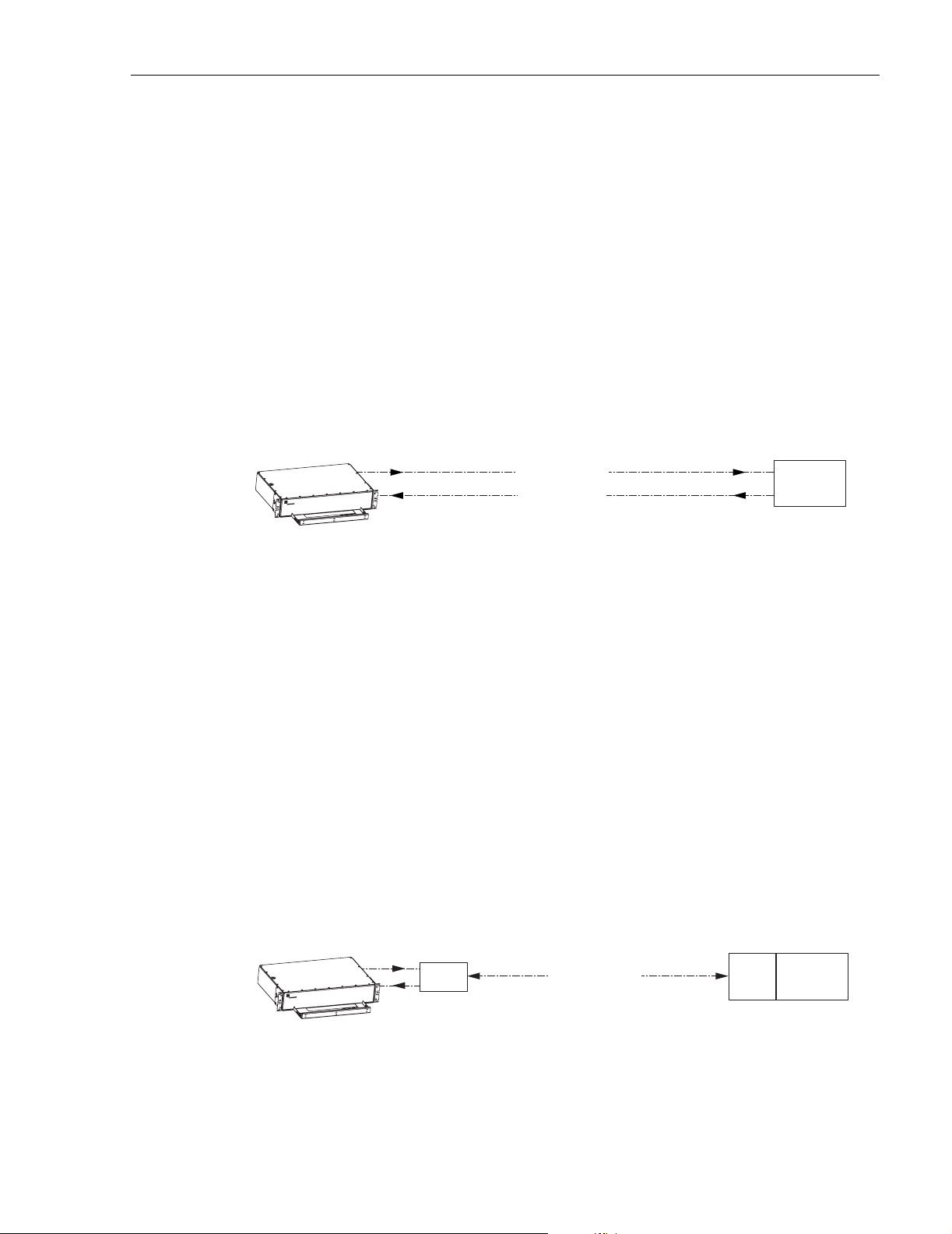

3.1 Fiber Optic Transport

In a typical Digivance LRCS system, the HU is connected to the RU over two single-mode

optical fibers. One fiber is used to transport the forward path optical signal. The other fiber is

used to transport the reverse path optical signal. Because the optical signal is digital, the input

and output RF signal levels at the HU or the RU are not dependent on the level of the optical

signal or the length of the optical fiber. A diagram of the fiber optic transport system for a

typical Digivance LRCS system is shown in Figure 1-7.

HOST UNIT

ADCP-75-187 • Issue 3 • September 2006 • Section 1: OVERVIEW

FIBER OPTIC

LINK

FORWARD PATH

REVERSE PATH

REMOTE

UNIT

18526-A

Figure 1-7. LRCS System Fiber Optic Transport - Typical

The maximum length of the optical links is dependent on the loss specifications of the optical

fiber, the losses imposed by the various connectors and splices, and the RF modulation protocol

response timing limitations. The basic system provides an optical budget of 25 dB (typical)

when used with 9/125 single-mode fiber.

In SCS applications, the forward path and reverse path optical signals from an HU/RU pair are

combined onto a single optical fiber. This is accomplished by using a passive bi-directional

Wavelength Division Multiplexer (WDM) system. The optical wavelengths used in the

Digivance system are 1550 nm for the forward path and 1310 nm for the reverse path. Because

different wavelengths are used for the forward and reverse paths, both signals can be combined

on a single optical fiber. A WDM module (accessory) is installed with the HU at the host site

The SCS RU, which is equipped with an internally mounted WDM, is installed at the remote

site as shown in Figure 1-8.

FIBER OPTIC LINK

HOST UNIT

WDM

FORWARD AND

REVERSE PATH

WDM

REMOTE

UNIT

20721-A

Figure 1-8. SCS System Fiber Optic Transport with Wavelength Division Multiplexer

© 2006, ADC Telecommunications, Inc.

Page 1-7

Page 21

ADCP-75-187 • Issue 3 • September 2006 • Section 1: OVERVIEW

3.2 Control and Monitoring Software

The EMS software and the SNMP Proxy Agent software provide control and monitoring

functions for the Digivance system through the local, NOC, and SNMP interfaces. The EMS

software package supports the local and NOC interfaces but does not include the SNMP Proxy

Agent software which must be ordered separately. Both the EMS and the SNMP Proxy Agent

software are required to support the SNMP interface. All software files are provided on CDROM’s. Software installation consists of copying the software files from the CD-ROM’s to a

designated directory on the hard-drive of the EMS computer.

The EMS software provides the capability to provision and configure the Digivance system for

operation. This includes selecting a site name, setting alarm thresholds, and setting forward and

reverse path RF gain adjustments. The EMS software also provides the capability to get alarm

messages (individual or summary), obtain data measurements, and to upgrade the HU/RU

system software. All control and monitor functions (except software upgrade which is not

supported by the NOC/NEM and SNMP interfaces and HU/RU pair site number assignment

which is not supported by the SNMP interface) may be implemented using the NOC/NEM

interface, the SNMP interface, or the EMS software GUI.

3.3 Fault Detection and Alarm Reporting

LED indicators are provided on the front panel of the HU and on the underside of the RU to

indicate if the system is normal or if a fault is detected. In addition, normally open and normally

closed alarm contacts (for both major and minor alarms) are provided at the HU for connection

to a customer-provided external alarm system. All alarms can also be accessed through the

NOC/NEM interface, SNMP manager, or the EMS software GUI.

3.4 Powering

The HU is powered by ±24 or ±48 VDC and must be hard-wired to a local DC power source

through a fuse panel. A screw-down terminal strip is provided on the rear side of the HU for the

power connections.

The RU is powered by 90 to 265 VAC (nominal 120 or 240 VAC), 47 to 63 Hz power. On an

optional basis, the RU may be powered by 60 to 89 VAC, 47 to 63 Hz power. A connector is

provided on the underside of the RU for the AC power connections. A 3-wire AC power cable

rated for outdoor use is included with the RU. The stub end of the cable must be hard-wired to

the AC power source.

3.5 Equipment Mounting and Location

The HU consists of a rack-mountable chassis assembly that is designed for mounting in a noncondensing indoor environment such as inside a wiring closet or within an environmentally-

controlled cabinet. The HU is usually installed within 20 feet of the EBTS and may be mounted

in either a 19- or 23-inch, WECO or EIA, equipment rack.

The RU consists of a sealed aluminum enclosure designed for mounting in either an indoor or

outdoor environment. The RU may be mounted from a pole or the exterior side of a building

with the standard mounting bracket or from a strand with an accessory bracket.

Page 1-8

© 2006, ADC Telecommunications, Inc.

Page 22

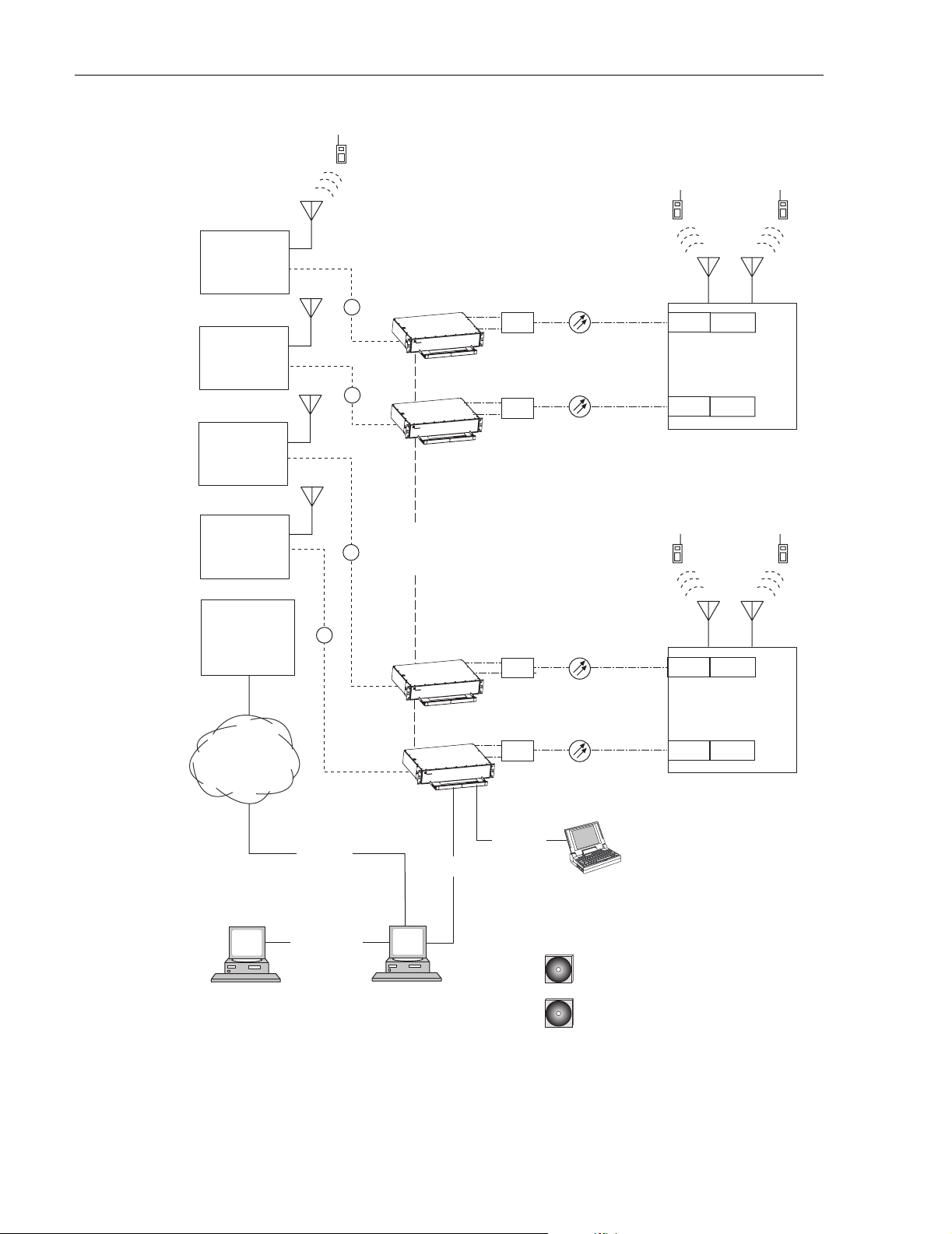

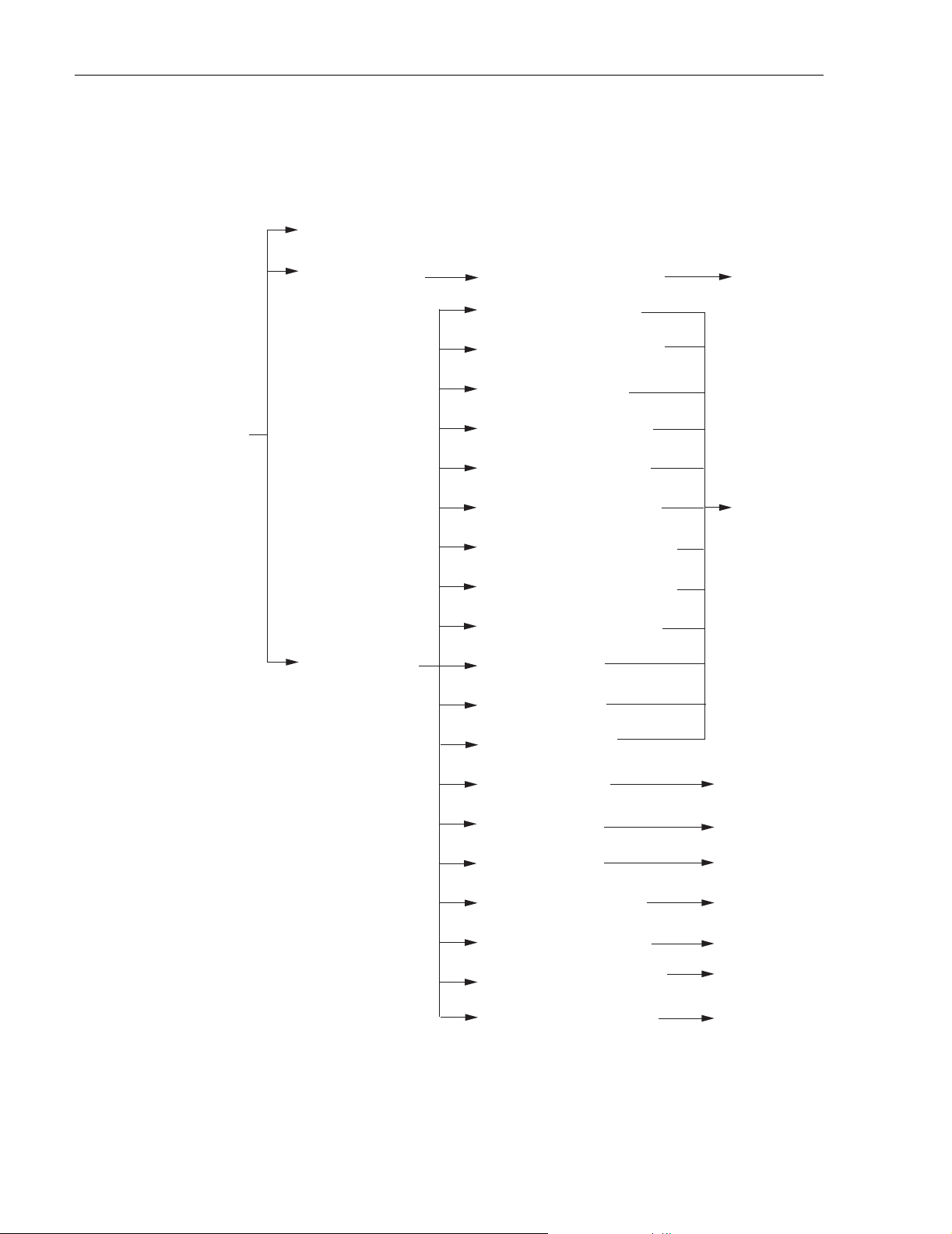

4 DUAL-BAND REMOTE UNIT SCS SYSTEMS

Sections 1 through 3 described the functions and features of a typical SCS system equipped with

one HU and the single-band RU. Each single-band RU is equipped with the electronics to

support one frequency band. If it is necessary to support two frequency bands (such as 800/900

MHz SMR and 1900 MHz) at the same remote location, a dual-band RU can be deployed. A

dual-band RU provides the electronic and optical functionality of two single-band RU’s except

that all the electronic and optical components are housed within a single enclosure.

A dual-band SCS system consists of two standard host units and a dual-band RU that are linked

together over two optical fibers. At the hub site, each HU is connected to a separate EBTS

facility. The dual-band RU supports the frequency bands (such as 800/900 MHz SMR and 1900

MHz) associated with the two connected HU’s. Each HU and the corresponding RU electronics

function independently of each other and may be managed separately using the same element

management system (EMS). Figure 1-9 shows a typical SCS system equipped with a dual-band

RU. One fiber is used to transport the forward/reverse path optical signals for one SCS system.

The other fiber is used to transport the forward/reverse path optical signals for the other SCS

system.

ADCP-75-187 • Issue 3 • September 2006 • Section 1: OVERVIEW

© 2006, ADC Telecommunications, Inc.

Page 1-9

Page 23

ADCP-75-187 • Issue 3 • September 2006 • Section 1: OVERVIEW

ENHANCED

BASE

TRANSCEIVER

STATION 1

ENHANCED

BASE

TRANSCEIVER

STATION 2

ENHANCED

BASE

TRANSCEIVER

STATION A

ENHANCED

BASE

TRANSCEIVER

STATION B

BASE STATION

ANTENNA

RF

RF

CONTROLLER

RF

HOST UNIT 1

HOST UNIT 2

AREA

NETWORK

WDM

WDM

BAND 1

800/900 MHZ SMR

WDM

DUAL-BAND

REMOTE UNIT

WDM

BAND A

800/900 MHZ SMR

BAND 2

1900 MHZ

UNIT 1

UNIT 2

BAND B

1900 MHZ

NETWORK

OPERATIONS

CENTER

T1, DS0

WITH RS232

CONVERSION,

OR OTHER

MEDIUM

NETWORK SNMP

MANAGER

Figure 1-9. SCS System With Dual-Band Remote Units Overview Diagram

RF

RS-232

ASCII

ETHERNET

LAN

PC COMPUTER WITH EMS

AND SNMP PROXY AGENT

(PERMANENT CONNECTION)

HOST UNIT A

HOST UNIT B

RS-232

WDM

WDM

RS-232

UNIT A

WDM

DUAL-BAND

REMOTE UNIT

UNIT B

WDM

PC COMPUTER WITH EMS

(TEMPORARY CONNECTION)

CD-ROM WITH SNMP PROXY

AGENT SOFTWARE

CD-ROM WITH EMS

SOFTWARE

20628-A

Page 1-10

© 2006, ADC Telecommunications, Inc.

Page 24

SECTION 2: DESCRIPTION

Content Page

1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2 HOST UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1 Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.4 RF Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.5 RF Signal Level Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.6 Propagation Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.7 Optical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.8 Controller Area Network Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.9 Service Interface Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.10 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.11 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.12 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

3 REMOTE UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

3.1 Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

3.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

3.4 Antenna Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.5 RF Signal Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.6 Optical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.7 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.8 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

3.9 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

3.10 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

4 ACCESSORY ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

4.1 Strand Mount Kit for RU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

4.2 Lightning Protector for RU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.3 Solar Shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

5 DIGIVANCE ELEMENT MANAGEMENT SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

5.1 Digivance EMS Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

5.2 Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

5.3 Computer Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

5.4 Digivance EMS Computer Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

5.5 Digivance Software User Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

6 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

_________________________________________________________________________________________________________

ADCP-75-187 • Issue 3 • September 2006 • Section 2: DESCRIPTION

© 2006, ADC Telecommunications, Inc.

Page 2-1

Page 25

ADCP-75-187 • Issue 3 • September 2006 • Section 2: DESCRIPTION

1 INTRODUCTION

This section describes the basic components of a typical Digivance SCS system including the

Host Unit (HU), Remote Unit (RU), element management system, and accessories. The system

specifications are provided in a table at the end of this section.

2 HOST UNIT

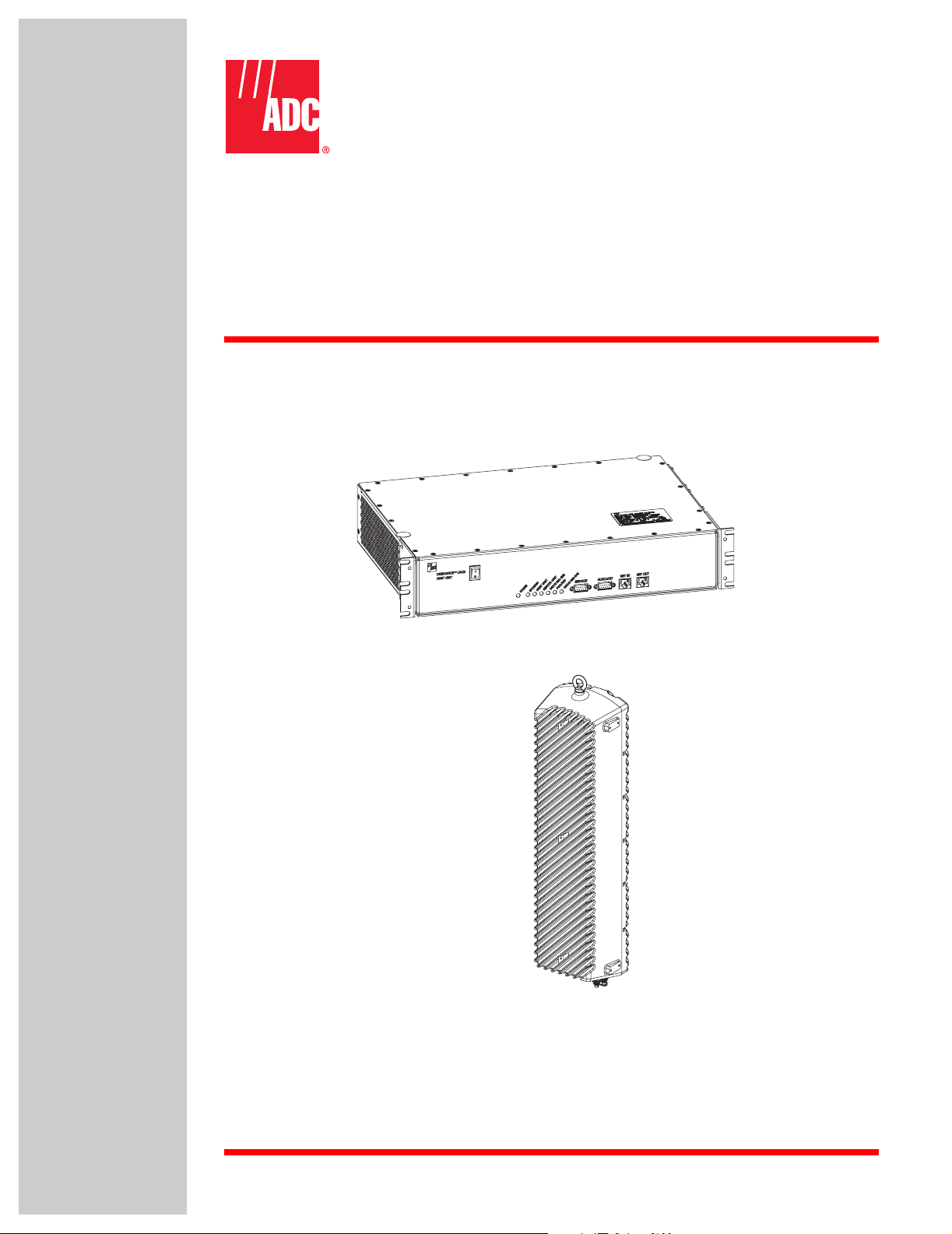

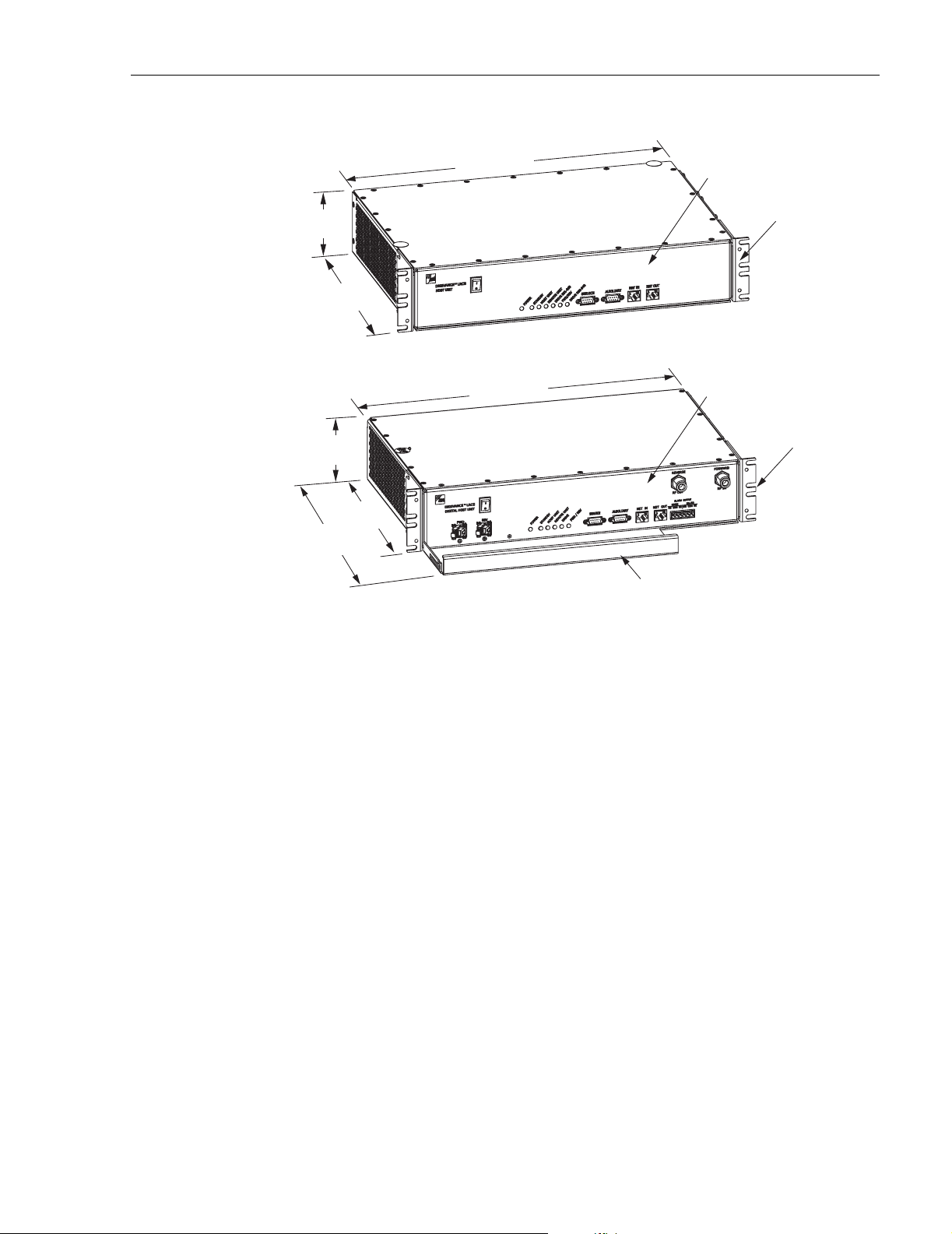

Two versions of the HU are available. The rear access HU, shown in Figure 2-1, is used with

800/900 MHz SMR systems. The front access HU, also shown in Figure 2-1, is used with 800

and 1900 MHz systems. Connection points for the RF, optical, and alarm cables are provided on

the rear side of the rear access HU and on the front side of the front access HU. Both HU

versions provide the following basic functions:

• Provides a limited adjustable RF interface with the BTS.

• Provides a fiber optic interface with the RU.

• Digitizes the two forward path composite RF signals.

• Converts the two digitized forward path RF signals to a digital optical signal.

• Converts the digitized reverse path optical signal to two digitized RF signals.

• Converts the two digitized reverse path RF signals to two composite RF signals.

• Sends alarm information to an external alarm system through relay contact closures

• Provides an RS-232 interface for connecting the EMS computer.

• Provides a CAN interface for networking multiple HUs.

2.1 Primary Components

The HU consists of an electronic circuit board assembly and a fan assembly that are mounted

within a powder-paint coated sheet metal enclosure. The enclosure provides a mounting point

for the circuit board and fan assemblies and controls RF emissions. The only user-replaceable

component is the fan assembly. The HU is designed for use within a non-condensing indoor

environment such as inside a wiring closet or cabinet. The front access HU is also equipped

with a front cable management tray and vertical cable guides.

2.2 Mounting

The HU is intended for rack-mount applications. A pair of reversible mounting brackets is

provided that allow the HU to be mounted in either a 19-inch or 23-inch EIA or WECO

equipment rack. When the rear access HU is installed, the front panel of the HU is flush with the

front of the rack. When the front access HU is installed, the front panel of the HU is flush with

the front of the rack and the cable management tray extends 3.9 inches (99 mm) beyond the

front panel. Screws are provided for securing the HU to the equipment rack.

Page 2-2

© 2006, ADC Telecommunications, Inc.

Page 26

3.5 INCHES

(88 mm)

12.2 INCHES

(311 mm)

ADCP-75-187 • Issue 3 • September 2006 • Section 2: DESCRIPTION

17.1 INCHES

(433 mm)

REAR ACCESS HOST UNIT

FRONT PANEL

MOUNTING

BRACKET

(BOTH SIDES)

3.5 INCHES

(89 mm)

11.4 INCHES

(290 mm)

15.3 INCHES

(389 mm)

Figure 2-1. Front View of Front and Rear Access Host Units

2.3 Fault Detection and Alarm Reporting

The HU detects and reports various internal and external faults including host unit fault, optical

fault, power fault, temperature fault, and RF fault. Various front panel Light Emitting Diode

(LED) indicators turn from green to red or yellow if a fault is detected. A set of alarm contacts

(normally open and normally closed) are provided for reporting an alarm to an external alarm

system when a fault is detected. Both major alarm (system operation seriously affected) and

minor alarm (system operation not affected or only slightly degraded) contacts are provided.

17.2 INCHES

(437 mm)

FRONT ACCESS HOST UNIT

FRONT PANEL

CABLE MANAGEMENT

TRAY

MOUNTING

BRACKET

(BOTH SIDES)

20666-A

Fault and alarm information may also be accessed locally through the EMS software GUI or

remotely through the NOC/NEM interface or SNMP interface. An alarm history file is

maintained by the EMS software so that a record is kept of all alarms as they occur. This is

useful when an alarm is reported and cleared before the reason for the alarm can be determined.

The status of the HU, the alarm state (major or minor), and other alarm information is

summarized and reported over the service interface, the CAN interface, and the optical interface

to the RU. In addition, the status of the RU is transmitted to the HU over the optical interface

and reported over the service interface and the CAN interface.

© 2006, ADC Telecommunications, Inc.

Page 2-3

Page 27

ADCP-75-187 • Issue 3 • September 2006 • Section 2: DESCRIPTION

2.4 RF Signal Connections

The RF signal connections between the rear access HU and the EBTS are supported through

four N-type female connectors. Two connectors are used for the forward path RF signals and

two connectors are used for the reverse path RF signals.

The RF signal connections between the front access HU and the EBTS are supported through

two N-type female connectors. One connector is used for the forward path RF signal and the

other connector is used for the reverse path RF signal.

In most installations, it is usually necessary to install external attenuators to support the RF

interface between the HU and the EBTS. The HU should be as close as possible to the EBTS to

minimize coaxial cable losses.

2.5 RF Signal Level Adjustments

The HU is equipped with several attenuators for adjusting the signal levels of the forward and

reverse path RF signals. The attenuators provide an attenuation adjustment range of 0 to 31 dB

and can be set in 1 dB increments. The attenuators are software controlled and are adjusted

through the EMS software GUI, NOC/NEM interface, or SNMP interface.

The host forward path attenuators adjust the level of the input RF signal(s) to the HU. Using

the forward path attenuator, an input signal with a nominal composite signal level of –9 dBm to

–40 dBm can be adjusted to produce maximum power output. Additional external attenuation

is required if the input signal level is greater than –9 dBm.

Note: The optimum composite RF input signal level for 800/900 MHz SMR systems is

–20 dBm.

The host reverse path attenuators adjust the level of the output RF signal(s) from the HU and

will add from –1 dB of gain (attenuator set to 31 dB) to +30 dB of gain (attenuator set to 0 dB)

to the RF output signal(s) at the HU.

2.6 Propagation Delay

The HU forward and reverse path propagation delays may be adjusted in 0.1 μsec increments

within a range of 0 to 63 μs. The propagation delay is software controlled and may be adjusted

through the EMS software GUI, NOC/NEM interface, or SNMP interface.

2.7 Optical Connection

Optical connections between the HU and the RU are supported through two optical ports

equipped with UPC/SC (flat) connectors. One port is used for the forward path optical signal

connection and the other port is used for the reverse path optical signal connection.

Page 2-4

© 2006, ADC Telecommunications, Inc.

Page 28

2.8 Controller Area Network Interface Connection

Controller Area Network (CAN) interface connections between multiple HUs are supported by

a pair of RJ-45 jacks. One of the jacks is designated as the network IN port and the other jack is

designated as the network OUT port. The CAN interface allows up to 24 HUs to be connected

together (in daisy-chain fashion) and controlled through a single EMS computer.

2.9 Service Interface Connection

The service interface connection between the HU and the EMS computer is supported by a

single DB-9 female connector. The service connector provides an RS-232 DTE interface. When

multiple HUs are networked together, the supporting EMS computer may be connected to the

service connector of any one of the networked HUs.

2.10 Powering

The HU is powered by ± 21 to ± 60 VDC power (nominal ± 24 or ± 48 VDC). The power is fed to

the HU through a screw-down type terminal strip located on the rear side of the unit. Power to

the HU must be supplied through a fuse panel such as the PowerWorx GMT Series Fuse Panel

(available separately). The power circuit for each HU must be protected with a 3 Amp GMT

fuse. An On/Off switch is provided on the HU front panel.

ADCP-75-187 • Issue 3 • September 2006 • Section 2: DESCRIPTION

2.11 Cooling

Continuous airflow for cooling is provided by dual fans mounted on the right side of the HU

housing. A minimum of 3 inches (76 mm) of clearance space must be provided on both the left

and right sides of the HU for air intake and exhaust. An alarm is generated if a high temperature

condition (>50º C/122º F) occurs. The fans may be field-replaced if either fan fails.

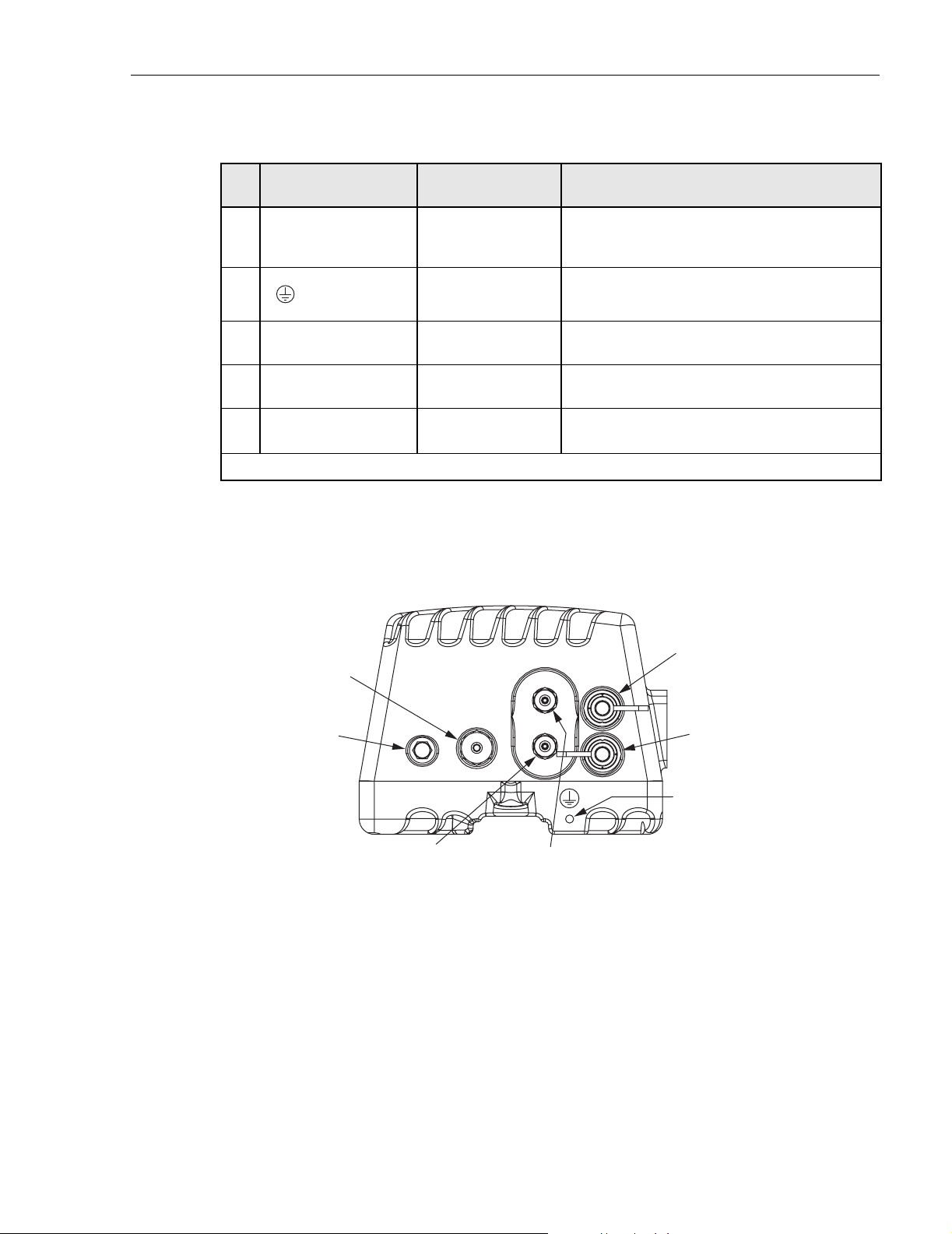

2.12 User Interface

The HU user interface consists of the various connectors, switches, terminals, and LEDs that are

provided on the HU front and rear panels. The rear access HU user interface points are

indicated in Figure 2-2 and described in Table 2-1. The front access HU user interface points

are indicated in Figure 2-3 and described in Table 2-2 .

© 2006, ADC Telecommunications, Inc.

Page 2-5

Page 29

ADCP-75-187 • Issue 3 • September 2006 • Section 2: DESCRIPTION

FRONT VIEW

(13) 806-824

REVERSE

(14) 896-901

REAR VIEW

(1) DC POWER

ON/OFF SWITCH

REVERSE

(9) SERVICE

INTERFACE

CONNECTOR

(10) AUXILIARY

CONNECTOR

(17) DC POWER

TERMINAL STRIP

LED INDICATORS

(15) 851-869

FORWARD

OUTPUT CONNECTOR

(16) 935-940

FORWARD

(19) ALARM

(REFERENCE

ITEMS 2 - 8)

Figure 2-2. Rear Access Host Unit User Interface

Table 2-1. Host Unit User Interface

(11) NET IN

CONNECTOR

(12) NET OUT

CONNECTOR

(18) COVER PLATE

(21)

(20)

REV

FWD

(22)

GROUNDING

STUD

20021-A

REF

NO

USER INTERFACE

DESIGNATION

1 I/0 On/Off rocker

2 POWER Multi-colored LED

3 STANDBY Multi-colored LED

4 HOST UNIT Multi-colored LED

5 REMOTE UNIT Multi-colored LED

6 DRIVE 851–869 Multi-colored LED

Page 2-6

© 2006, ADC Telecommunications, Inc.

DEVICE

switch

(green/yellow)

(green/yellow/red)

(green/yellow/red)

(green/yellow/red)

(green/yellow/red)

FUNCTIONAL

DESCRIPTION

Provides DC power on/off control.

Indicates if the HU is powered (green) or unpowered (off). See Note.

Indicates if the system is in the Normal (off),

Standby (blinking green), Test (blinking red), or

Program Load (blinking yellow) state. See Note.

Indicates if the HU is normal (green), overheated

(yellow), or faulty (red). See Note.

Indicates if no alarms (green), a minor alarm

(yellow), or a major alarm (red) is reported by the

RU. See Note.

Indicates if the level of the 851–869 MHz RF

input signal to the HU is normal (green), low

(yellow), or high (red). See Note.

Page 30

ADCP-75-187 • Issue 3 • September 2006 • Section 2: DESCRIPTION

Table 2-1. Host Unit User Interface, continued

REF

NO

USER INTERFACE

DESIGNATION

7FWD/REV

(PORT 1/PORT 2)

DEVICE

Multi-colored LED

(green/red)

Indicates if the reverse/forward path optical signals from the RU/HU are normal (green), if no

FUNCTIONAL

DESCRIPTION

signals are detected (red), or if excessive errors

are detected (red). See Note.

8 DRIVE 935–940 Multi-colored LED

(green/yellow/red)

Indicates if the level of the 935–940 MHz RF

input signal to the HU is normal (green), low

(yellow), or high (red). See Note.

9 SERVICE DB-9 connector

(female)

10 AUXILIARY DB-9 connector

(female)

Connection point for the RS-232 service interface cable.

Connection point for the RS-232 auxiliary interface cable. Not supported by SCS Remote Unit.

11 NET IN RJ-45 jack (female) Connection point for the CAN interface input

cable.

12 NET OUT RJ-45 jack (female) Connection point for the CAN interface output

cable.

13 806–824 REVERSE N-type female RF

coaxial connector

14 896–901 REVERSE N-type female RF

coaxial connector

15 851–869 FORWARD N-type female RF

coaxial connector

Output connection point for the 806–824 MHz

reverse path RF coaxial cable.

Output connection point for the 896–901 MHz

reverse path RF coaxial cable.

Input connection point for the 851–869 MHz forward path RF coaxial cable.

16 935–940 FORWARD N-type female RF

coaxial connector

17 POWER 24–48 VDC Screw-type terminal

Input connection point for the 935–940 MHz forward path RF coaxial cable.

Connection point for the DC power wiring.

strip

18 No designation Cover plate Covers the mounting slot for the wavelength divi-

sion multiplexer module.

19 ALARM OUTPUT Screw-type terminal

connector (14–26

AW G)

20 FWD (PORT 1) UPC/SC connector

(flat single-mode)

21 REV (PORT 2) UPC/SC connector

(flat single-mode)

Connection point for an external alarm system.

Includes normally open (NO), normally closed

(NC), and common (COM) wiring connections.

Output connection point for the forward path

optical fiber.

Input connection point for the reverse path optical fiber.

22 Chassis ground stud Connection point for a chassis grounding wire.

Note: A more detailed description of LED operation is provided in Section 4.

© 2006, ADC Telecommunications, Inc.

Page 2-7

Page 31

ADCP-75-187 • Issue 3 • September 2006 • Section 2: DESCRIPTION

(1) DC POWER

ON/OFF SWITCH

(2) PORT 1

OR FWD

CONNECTOR

NOTE: SHOWN WITHOUT

CABLE MANAGEMENT TRAY

(3) PORT 2

OR REV

CONNECTOR

(REFERENCE

ITEMS 4 - 9)

LED INDICATORS

(10) SERVICE

INTERFACE

CONNECTOR

(11) AUXILIARY INTERFACE

(NOT USED FOR SCS)

(15) REVERSE

RF OUT

CONNECTOR

(12) NET IN

CONNECTOR

(13) NET OUT

CONNECTOR

Figure 2-3. Front Access Host Unit User Interface

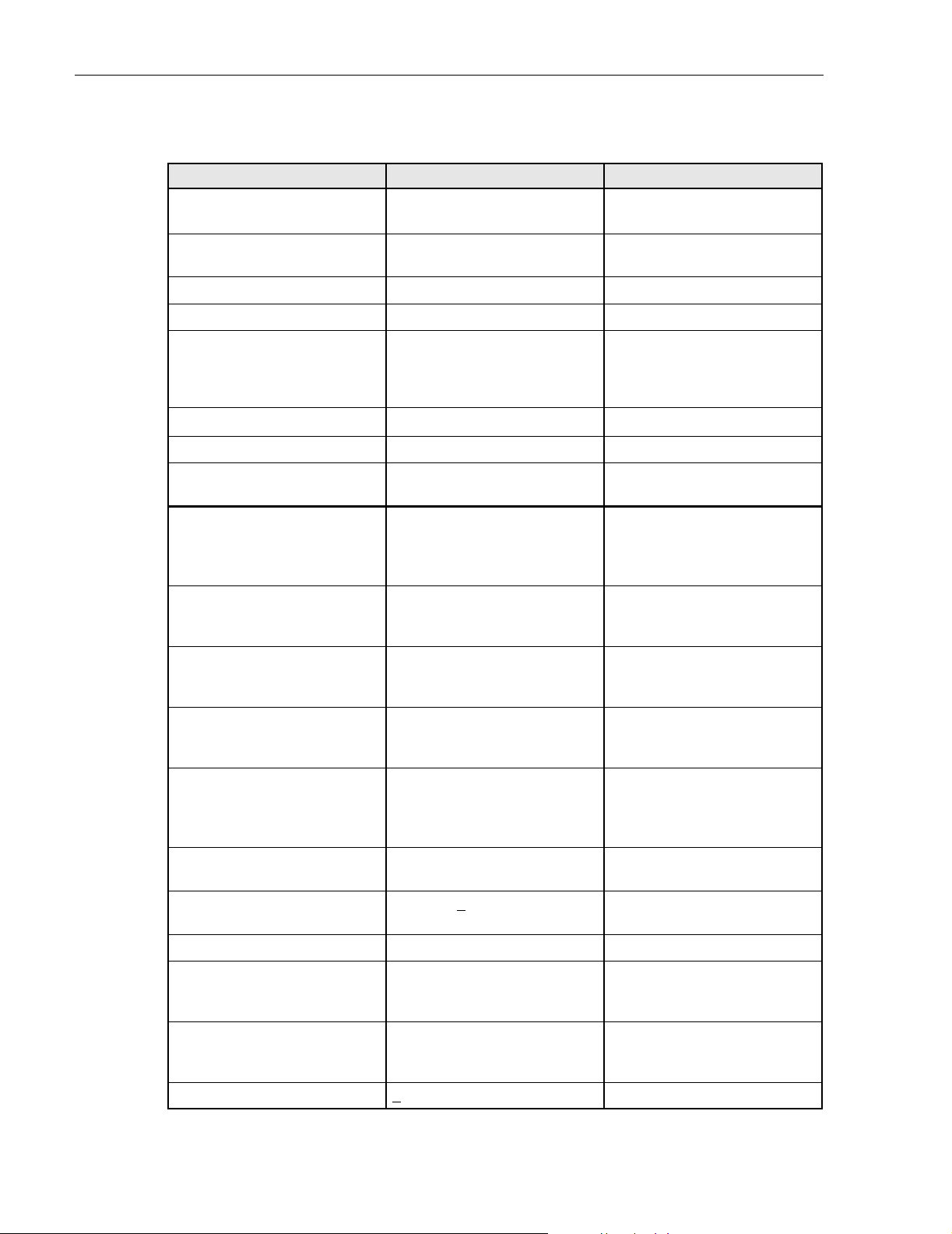

Table 2-2. Host Unit User Interface

REF

NO

USER INTERFACE

DESIGNATION

DEVICE

FUNCTIONAL

DESCRIPTION

1 I/0 On/Off rocker switch Provides DC power on/off control.

2 FWD SC connector

(single-mode)

Output connection point for the forward path

optical fiber.

(16) FORWARD

RF IN

(14) ALARM

OUTPUT

CONNECTOR

20667-A

3 REV SC connector

(single-mode)

4 POWER Multi-colored LED

(green/yellow)

5 STANDBY Multi-colored LED

(green/yellow/red)

6 HOST UNIT Multi-colored LED

(green/yellow/red)

7 REMOTE UNIT Multi-colored LED

(green/yellow/red)

8 DRIVE Multi-colored LED

(green/yellow/red)

9 FWD/REV Multi-colored LED

(green/red)

10 SERVICE DB-9 connector

(female)

11 AUXILIARY DB-9 connector

(female)

Input connection point for the reverse path primary optical fiber.

Indicates if the HU is powered (green) or unpowered (off). See Note.

Indicates if the system is in the Normal (off),

Standby (blinking green), Test (blinking red), or

Program Load (blinking yellow) state. See Note.

Indicates if the HU is normal (green), overheated

(yellow), or faulty (red). See Note.

Indicates if no alarms (green), a minor alarm

(yellow), or a major alarm (red) is reported by the

RU. See Note.

Indicates if the level of the RF input signal to the

HU is normal (green), low (yellow), or high

(red). See Note.

Indicates if the reverse path optical signals from

the STM are normal (green), if no signals are

detected (red), or if excessive errors are detected

(red). See Note.

Connection point for the RS-232 service interface cable.

Not used with SCS systems.

Page 2-8

© 2006, ADC Telecommunications, Inc.

Page 32

ADCP-75-187 • Issue 3 • September 2006 • Section 2: DESCRIPTION

Table 2-2. Host Unit User Interface, continued

REF

NO

12 NET IN RJ-45 jack (female) Connection point for the CAN interface input

13 NET OUT RJ-45 jack (female) Connection point for the CAN interface output

14 ALARM OUTPUT Screw-type terminal

15 REV RF OUT N-type female RF

16 FWD RF IN N-type female RF

Note: A more detailed description of LED operation is provided in Section 4.

USER INTERFACE

DESIGNATION

POWER 24–48 VDC

(Rear side - not shown)

(Rear side - not shown)

DEVICE

cable.

cable.

Connection point for an external alarm system.

connector (14–26

AW G)

coaxial connector

coaxial connector

Screw-type terminal

strip

Chassis ground stud Connection point for a chassis grounding wire.

Includes normally open (NO), normally closed

(NC), and common (COM) wiring connections.

Output connection point for the primary reverse

path RF coaxial cable.

Input connection point for the forward path RF

coaxial cable.

Connection point for the DC power wiring.

FUNCTIONAL

DESCRIPTION

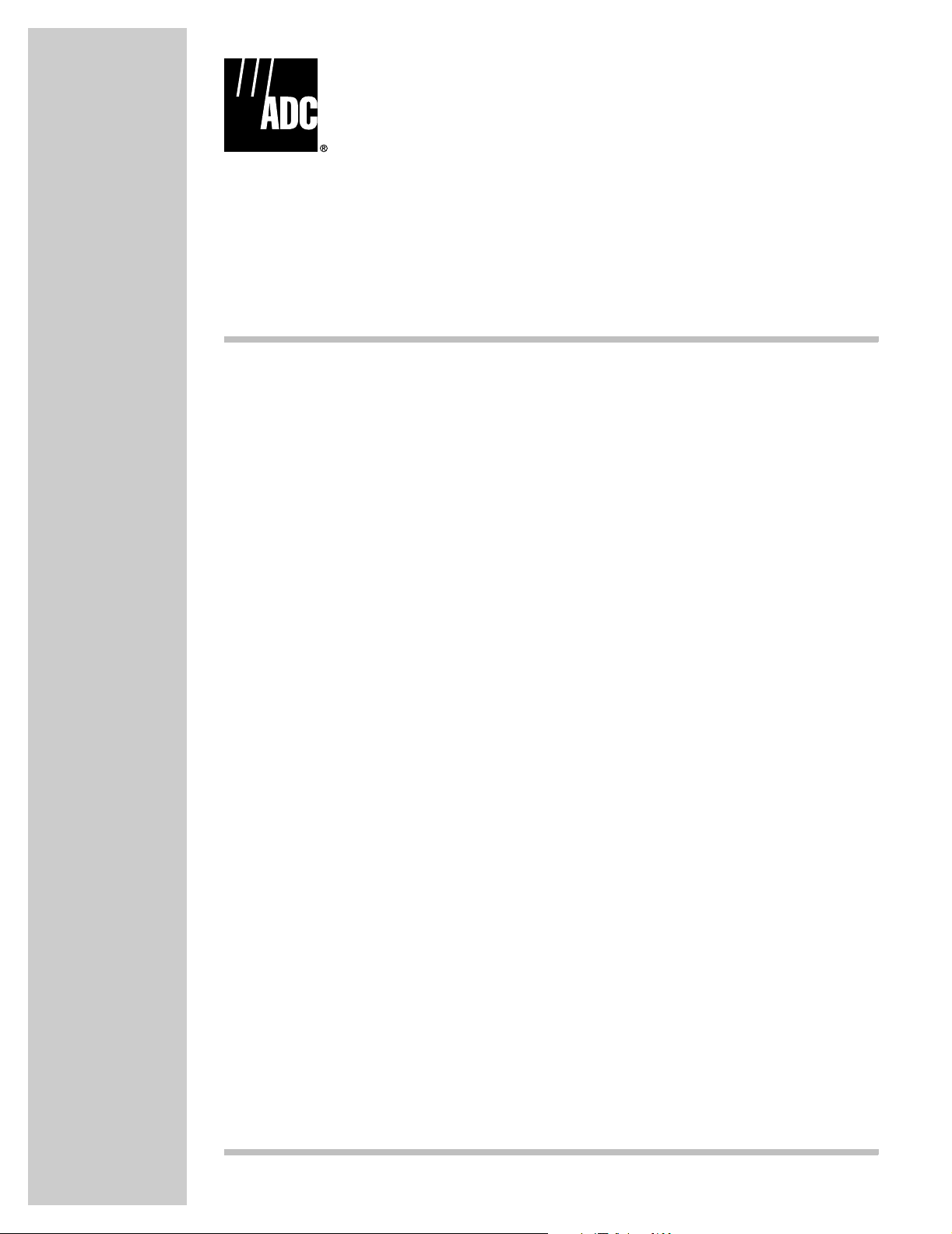

3 REMOTE UNIT

The RU is available in either a single-band or a dual-band version. Both versions of the RU

provide the following basic functions:

• Convert the digitized forward path optical signals to digitized RF signals.

• Convert the digitized forward path RF signals to composite RF signals.

• Digitize the reverse path composite RF signals.

• Convert the digitized reverse path RF signals to digitized optical signals.

• Provide an RF interface (antenna port) for the remote antenna(s).

• Provide an optical interface for the HU.

• Transport alarm, control, and monitoring information to the HU via the optical interface.

• Accept AC power input.

• Provide a visual indication of unit status

3.1 Primary Components

Depending on the version, the RU consists of either two or four electronic assemblies mounted

within an environmentally-sealed cast-aluminum enclosure. The Spectrum Transport Module

(STM) provides optical-to-RF and RF-to-optical conversion and digitizing functions; alarm,

control, and monitoring functions; power conversion functions; RF filtering and interface

functions. The Linear Power Amplifier (LPA) works in conjunction with the STM to amplify

© 2006, ADC Telecommunications, Inc.

Page 2-9

Page 33

ADCP-75-187 • Issue 3 • September 2006 • Section 2: DESCRIPTION

the forward path RF signal. The aluminum enclosure provides a mounting point for the

electronic assemblies, controls RF emissions, seals out dirt and moisture, and provides passive

cooling. The electronic assemblies are not user replaceable or accessible. All connectors and

indicators are mounted on the bottom of the RU enclosure for easy access.

The single-band version of the RU consists of one STM and one LPA mounted within the same

enclosure. The dual-band version, shown in Figure 2-4, consists of two STM’s and two LPA’s

mounted within the same enclosure. The dual-band version makes it possible to support two

separate frequency bands with a single RU.

Figure 2-4. Dual-Band Remote Unit

3.2 Mounting

The RU may be mounted on a flat vertical surface (such as the side of a building), on a utility pole,

or from a horizontal cable or overhead support. A combination wall/pole mounting bracket is

provided with each unit. A separate strand-mount kit (accessory item) is available if it is necessary

to mount the RU from a cable. Inside-pole mounting and underground vault installations are also

possible. Contact the Wireless TAC (see Section 5) for additional information.

3.3 Fault Detection and Alarm Reporting

The RU detects and reports various faults including remote unit fault, optical fault, output power

fault, temperature fault, and power amplifier fault. A single bottom-mounted Light Emitting

Diode (LED) indicator turns from off to red if a major fault is detected. The status of the STM

and LPA, the alarm state, and other fault information is summarized and reported over the

optical interface to the HU. Fault and alarm information may be accessed at the HU through the

EMS software GUI or remotely through the NOC/NEM interface or SNMP interface.

20568-C

Page 2-10

© 2006, ADC Telecommunications, Inc.

Page 34

3.4 Antenna Cable Connection

The antenna cable connection between the RU and the antenna is supported through either one

(single-band RU) or two (dual-band RU) 50-ohm N-type female connectors. The antenna cable/

cables carry the forward and reverse path RF signals between each antenna and RU. An

externally-mounted lightning protector is available as an accessory. The antenna connector on

the lightning protector may be either an N-type female connector or a 7/16 mm DIN connector.

The RU enclosure must be properly grounded for the lighting protector to function properly. On

an optional basis, the dual-band RU may be equipped with one N-type connector (and internal

diplexor) to support operation with a single antenna.

3.5 RF Signal Level Adjustment

The RU is equipped with digital attenuators for adjusting the signal level of the forward path RF

output signals. The remote forward path attenuators adjust the level of the two output RF

signals at the RU antenna port and will add from 0 to 31 dB of attenuation to the output signal

level. The attenuator can be set in 1 dB increments. The attenuator is software controlled and is

adjusted through the EMS software GUI, the NOC/NEM interface, or SNMP interface.

ADCP-75-187 • Issue 3 • September 2006 • Section 2: DESCRIPTION

3.6 Optical Connection

Fiber optic connections between the single-band RU and the associated HU are supported

through a single hardened optical port. All single-band RU’s are equipped with an internally