Preliminary

ADCP-75-179

Preliminary Issue A

September 2004

(Digivance

®

LRCS 800/900 MHz SMR System

with Version 3.01 EMS Software

(Operation and Maintenance Manual

20025-A

1304947 Rev 1

ADCP-75-179

Preliminary Issue A

September 2004

Digivance® LRCS 800/900 MHz SMR System

with Version 3.01 EMS Software

Operation and Maintenance Manual

1304947 Rev 1

ADCP-75-179 • Preliminary Issue A • September 2004 • Preface

COPYRIGHT

© 2004, ADC Telecommunications, Inc.

All Rights Reserved

Printed in the U.S.A.

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

A 09/2004 Original issue.

LIST OF CHANGES

The technical changes incorporat ed into this issue are lis ted below.

PAGE IDENTIFIER DESCRIPTION OF CHANGE

All Original issu e.

TRADEMARK INFORMATION

ADC and Digivance are regi s tered trademarks of A D C Telecommunications, Inc.

Stargazer is a registered t rademark of ADC DSL Systems, Inc.

Procomm Plus is a r egistered trademar k of Quarterdeck Corporation.

Acrobat and Adobe are register ed trademarks of Adobe Systems, Inc.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims an y and all liability for indirec t, incidental, special, consequen tial or other similar dam ages. This discl aimer of

liability applies to all products, publications and services during and after the warranty period.

This publ ication may be verified at any time by contacting ADC’s Technical Assistance Cent er at 1-800-366-3891, ex tension 73476

(in U.S. A . or Canada) or 952-9 17-3476 (outside U.S.A. and Canada), or by e-mai l t o w ire less.tac@adc.com

Page ii

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 917-1717

TABLE OF CONTENTS

Content Page

ABOUT THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

RELATED PUBLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

ADMONISHMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

GENERAL SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

STANDARDS CERTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

LIST OF ACRONYMS AND ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2 LRCS SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2.1 Basic System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2.2 Enhanced Base Transceiver Station Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2.3 Handset Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2.4 Local Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2.5 Network Operations Center Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2.6 SNMP Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

3 SYSTEM FUNCTIONS AND FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

3.1 Fiber Optic Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3.2 Control and Monitoring Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

3.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3.4 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

3.5 Equipment Mounting and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

ADCP-75-179 • Preliminary Issue A • September 2004 • Preface

SECTION 1:

OVERVIEW

SECTION 2:

DESCRIPTION

1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2 HOST UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1 Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 RF Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.5 RF Signal Level Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6 Propagation Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.7 Optical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.8 Controller Area Network Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.9 Service Interface Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.10 Auxiliary Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.11 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.12 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

© 2004, ADC Telecommunications , Inc.

Page iii

ADCP-75-179 • Preliminary Issue A • September 2004 • Preface

TABLE OF CONTENTS

Content Page

2.13 User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3 SPECTRUM TRANSPORT MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3.1 Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3.4 Antenna Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.5 RF Signal Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.6 Optical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.7 Service Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.8 Auxiliary Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.9 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.10 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.11 User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

4 35 WATT LINEAR POWER AMPLIFIER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

4.1 Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

4.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.4 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.5 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.6 User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

5 REMOTE UNIT MOUNTING SHELF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

5.1 Indoor Mounting Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

6 SLIM-STYLE REMOTE UNIT CABINETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

6.1 Slim-Style Single-STM Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

6.2 Slim-Style Dual-STM Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

7 ACCESSORY ITEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

7.1 Remote Unit Back-up Battery Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

7.2 Wavelength Division Multiplexer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

7.3 Coarse Wavelength Division Multiplexer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 25

8 DIGIVANCE ELEMENT MANAGEMENT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

8.1 Digivance EMS Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

8.2 Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

8.3 Computer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

8.4 Digivance EMS Computer Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

8.5 Digivance EMS User Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

9 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

1 BEFORE STARTING OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 Tools and Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Page iv

© 2004, ADC Telecommunications , Inc.

SECTION 3:

OPERATION

TABLE OF CONTENTS

Content Page

1.2 Readiness Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

2 TURN-UP SYSTEM AND VERIFY OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

2.1 Turn-Up Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

2.2 Check/Download HU and RU Control Program and FPGA Program Software . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

2.3 Determine Forward Path Input Signal Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

2.4 Enter Site Name and Site Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

2.5 Enter Host Forward Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

2.6 Determine Output Signal Level at STM Antenna Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

2.7 Enter Remote Forward Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

2.8 Enter Host Reverse Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

2.9 Enter Host Forward and Reverse Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

1 SYSTEM MAINTENANCE OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1 Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

2 FAULT DETECTION AND ALARM REPORTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

3 FAULT ISOLATION AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

3.1 Host Unit Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

3.2 STM Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

3.3 LPA Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4 TEST PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.1 Optical Power Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.2 Optical Loopback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

5 SCHEDULED MAINTENANCE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

ADCP-75-179 • Preliminary Issue A • September 2004 • Preface

SECTION 4:

MAINTENANCE

SECTION 5:

GENERAL INFORMATION

1 WARRANTY/SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2 SOFTWARE SERVICE AGREEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3 REPAIR/EXCHANGE POLICY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

4 REPAIR CHARGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5 REPLACEMENT/SPARE PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

6 RETURNED MATERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

7 CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

© 2004, ADC Telecommunications , Inc.

Page v

ADCP-75-179 • Preliminary Issue A • September 2004 • Preface

TABLE OF CONTENTS

Content Page

Blank

Page vi

© 2004, ADC Telecommunications , Inc.

ABOUT THIS MANUAL

This installati on and operation manual provides the following information:

• An overview of the Digivance 800/900 MHz SMR Long-Range Coverage Solution

(LRCS) system.

• A complete description of the basic system components including the Host Unit (HU),

Spectrum Transport Module (STM), Linear Power Amplifier (LPA), and Digivance

Element Management System (EMS).

• A basic description of the slim-style Remote Unit (RU) cabinets and indoor mounting

shelf.

• Procedures for tuning -up the system and verifying that the system is functioning properly.

• Procedures for maintaining the system including scheduled maintenance tasks and fault

isolation and trouble shooting procedures.

• Product warranty, repair, return, and replacement information.

The procedures for installing the remote unit modules and enclosures and for installing and

using the EMS software are provided in other publications which are referenced in the Related

Publications section and at appropriate points within this manual.

ADCP-75-179 • Preliminary Issue A • September 2004 • Preface

RELATED PUBLICATIONS

Listed below are related manuals, their content, and their publication numbers. Copies of these

publications can be ordered by contacting the Technical Assistance Center at 1-800-366-3891,

extension 73476 (in U.S.A. or Canada) or 952-917-3476 (outside U.S.A. and Canada).

Title/Description ADCP Number

Digivance LRCS System 800/900 MHz SMR Rear Access Host Unit

Installation and Maintenance Manual 75-180

Provides instructions for mounting the rear access host unit in an equipment

rack, installing and connecting the v arious cab les, and replacing t he cooling fans.

Digivance LRCS Dual-STM Systems Supplemental Manual 75-157

Provides supplemental information for LRCS systems that utilize one of the

dual-STM cabinets.

Digivance Element Management System V ersion 3.01 User Manual 75-151

Provides instr uctions for inst alling the Digiv a nce Element Management System

(EMS) software and for using both the Graphical User Interface (GUI) and the

Network Operations Center (NOC) versions of the software.

Digivance SNMP Agent Software User Manual 75-152

Describes how to install, configure, and use the LRCS SNMP Proxy Agent.

© 2004, ADC Telecommunications , Inc.

Page vii

ADCP-75-179 • Preliminary Issue A • September 2004 • Preface

ADMONISHMENTS

Important safety admonishments are used thr oughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below), and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause s evere personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

GENERAL SAFETY PRECAUTIONS

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the eye. Do not look into the ends of any optical fiber. Do not

look directly into the optical transceiver of any digital unit or exposure to laser radiation may

result. An optical power meter should be used to verify active fibers. A protective cap or hood

MUST be immediately placed ov er any radiating trans ceiv er or optical fiber connec tor to avoid

the potential of dangerous amounts of radiation exposure. This practice also prevents dirt

particles from entering the adapter or connector.

Danger: Do not look into the ends of any optical fiber. Exposure to laser radiation may result.

Do not assume laser power is turned-off or the fiber is disconnected at the other end.

Danger: Wet conditions increase the potential for receiving an electrical shock when installing

or using electrically-powered equipment. To prevent electrical shock, never install or use

electrical equipment in a wet location or during a lightning storm.

Warning: The HU is powered by 48 VDC power which is supplied over customer-provided

wiring. To prevent electrical shock when installing or modifying the HU power wiring,

disconnect the wiring at the power source before working with uninsulated wires or terminals.

Caution: Always allow sufficient fiber length to permit routing of patch cords and pigtails

without severe bends. Fiber optic patch cords or pigtails ma y be permane ntly damaged if be nt

or curved to a radius of less than 2 inches (50 mm).

Page viii

© 2004, ADC Telecommunications , Inc.

STANDARDS CERTIFICATION

FCC: This equipment complies with the applicable sections of Title 47 CFR Part 90.

Installation requirements the licensee needs to follow are listed in Title 47 CFR 90.635. This

document may be found at the following website: http://www.access.gpo.gov/nara/cfr/

waisidx_03/47cfr90_03.html.

UL/CUL: This equipment complies with UL and CUL 50 Standard for Enclosures for

Electrical Equipment. This equipment provides the degree of protection specified by IP43 as

defined in IEC Publication 529.

FDA/CDRH: This equipment uses a Class 1 LASER according to FDA/CDRH Rules. This

product conforms to all appli cable standards of 21 CFR Part 1040.

IC: This equipment complies with the applic able secti ons of RSS-131. The term “IC:” be fore the

radio ce rtif i cat io n number onl y signi f ie s th at Indu str y Cana da Technical Spec if ica tion s we re met.

LIST OF ACRONYMS AND ABBREVIATIONS

ADCP-75-179 • Preliminary Issue A • September 2004 • Preface

The acronyms and abbreviations used in this manual are detailed in the following list:

AC Alte rnat i ng Current

ASCII A me ri can St an dard Code for Inform at io n Interc h ang e

Att Attenuation

AWG American Wire Gauge

BER Bit Error Rate

C Centigrade

CAN Controller Area Network

CDRH Center for Devic es and Radiological Health

CD-ROM Compact Disk Read Only Memory

COM Common

COMM Communication

Config Configuration

CWDM Coarse Wavelength Division Multiplexer

CUL Canadian Underwriters La boratories

DC Direct Curren t

DCE Data Communications Equipment

DTE Data Terminal Equipment

EBTS Enhanced Base Transceiver Station

EIA Electronic Industries Association

EMS Element Management System

ESD Electrostatic Dischar ge

F Fahrenheit

FCC Federal Communications Commission

FDA Food and Drug Administration

© 2004, ADC Telecommunications , Inc.

Page ix

ADCP-75-179 • Preliminary Issue A • September 2004 • Preface

FSO Free Space Opti cs

Fwd Forward

GFCI Ground Fault Circuit Int errupter

GUI Graphi ca l Us er Inte rface

HU Host Unit

IC Industry Canada

IP Internet Protocol

LED Light Emitting Diode

LPA Linear Power Amplifier

LRCS Long-Range Cov erage Solution

MHz Mega Hertz

MIB Management Information Base

MPE Maximum Permissible Exposure

MTBF Mean Time Between Failu re

NC Normally Clo sed

NEM Network Element Manager

NO Normally Open

NOC Network Operations Cente r

NPT National Pipe Tapered

OSP Outsid e Plan t

PA Power Amplifier

PC Personal Computer

PCS Personal Communications System

Prg Program

Pwr Power

Rev Reverse

RF Radio Frequency

RIM Radio Interface Module

RMA Return Material Authorization

RU Remote U n it

RX Receive or Receiver

SNMP Simple Network Management Protocol

SMR Specialized Mobile Radio

STM Spectrum Transport Module

TX Transmit or Transmitter

UL Underwriters Laboratories

VAC Volts Alternating Current

VDC Volts Direct Cu rre nt

VSWR Voltage Standing Wave Ratio

WECO Western Electric Company

WDM Wavelength Division Multiplexer

Page x

© 2004, ADC Telecommunications , Inc.

SECTION 1: OVERVIEW

1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2 LRCS SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2.1 Basic System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2.2 Enhanced Base Transceiver Station Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2.3 Handset Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2.4 Local Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2.5 Network Operations Center Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2.6 SNMP Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

3 SYSTEM FUNCTIONS AND FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

3.1 Fiber Optic Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3.2 Control and Monitoring Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

3.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3.4 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

3.5 Equipment Mounting and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

_________________________________________________________________________________________________________

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 1: Overview

1 INTRODUCTION

This section provides basic description, application, and configuration information about the

Digivance Long-Range Coverage Solution (LRCS) system. Throughout this publication, all

items referenced as “accessory items” are not furnished with the basic product and must be

purchased s eparately.

2 LRCS SYSTEM OVERVIEW

The Digivance LRCS system is an RF signal transport system that provides long-range RF

coverage in areas where it is impractical to place an Enhanced Base Transceiver Station (EBTS)

at the antenna site. High real estate costs and community restrictions on tower and equipment

locations often make it difficult to install the EBTS at the same location as the antenna. The

Digivance LRCS system is design ed to overcome equi pment p lacement problem s by allowing

base stations to be hubbed at a central location while placing antennas at remote locations with

minimal real estate requirements. With the Digivance LRCS system, RF signals can be

transported to remote locations to expand coverage into areas not receiving service or to extend

coverage into difficult to reach areas such as canyons, tunnels, or underground roadways.

2.1 Basic System Components

The basic components of a typical Digivance LRCS system and their function are shown in

Figure 1-1. A basic LRCS system consists of a Host Unit (HU) and a Remote Unit (RU). The

HU consists of a single-unit assembly that mounts in a standard equipment rack. The RU

consists of multiple electronic and o ptical modules that mount i n either an outdoor cabinet or an

indoor mounting shelf. Control and monitoring functions are provided by the Digivance

Element Management System (EMS). In addition, various accessory items including a back-up

battery for the RU, a passive Wavelength Division Multiplexer (WDM) system, and an active

Coarse Wavelength Division Multiplexer (CWDM) system are available as accessories.

© 2004, ADC Telecommunications , Inc.

Page 1-1

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 1: Overview

BASE STATION

ANTENNA

HOST UNIT 1

ENHANSED

BASE

TRANSCEIVER

STATION 1

RF

WDM

WDM

REMOTE

UNIT 1

ENHANSED

BASE

TRANSCEIVER

STATION 2

ENHANSED

BASE

TRANSCEIVER

STATION 3

NETWORK

OPERATIONS

CENTER

(REMOTE

INTERFACE)

T1, DS0

WITH RS232

CONVERSION,

OR OTHER

MEDIUM

NETWORK SNMP

MANAGER

HOST UNIT 2

RF

RF

HOST UNIT 3

RS-232

ASCII

ETHERNET

LAN

PC COMPUTER WITH EMS

AND SNMP PROXY AGENT

(PERMANENT CONNECTION)

CONTROLLER

AREA

NETWORK

CONTROLLER

AREA

NETWORK

RS-232

CWDM

CWDM

RS-232

CWDM

CWDM

PC COMPUTER WITH EMS

(TEMPORARY CONNECTION)

CD-ROM WITH SNMP PROXY

AGENT SOFTWARE

CD-ROM WITH EMS

SOFTWARE

REMOTE

UNIT 2

REMOTE

UNIT 3

RS-232

20007-A

Page 1-2

© 2004, ADC Telecommunications , Inc.

Figure 1-1. System Overview Diagram

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 1: Overview

2.2 Enhanced Base Transceiver Station Interface

The HU is interfaced with an EBTS over coaxial cables as shown in Figure 1-2. The EBTS

provides the RF channel inputs and outputs for a designated sector. In the forward path, the HU

receiv es two RF inputs from the EBTS. The HU digitizes the RF signals and then conve rts them

to digital optical signals for tr ansport to the RU. In the reverse path, the HU receives digital

optical signals from the RU. The HU converts the digital optical signals back to two RF outputs

which are supplied to the EBTS ov er the coaxial cable interface.

FORWARD

PATHS

ENHANCED

BASE

TRANSCEIVER

STATION

RF

REVERSE

PATHS

HOST UNIT

2.3 Handset Interface

The RU interfaces with the handsets (cell phones) through an antenna. In the reverse path, the

RU recei v es RF signals from each handse t (see Figure 1-1). The RU digitizes the RF signals and

then con verts them to digital optical signals for transport to the HU over the optical fiber link. In

the forward path, the RU receives digi tal optical signals from the HU. The RU converts the

optical signals to RF signals for transmission to the handsets. The RU is connected to an

antenna (not provided) which transmits and receives the handset RF signals.

2.4 Local Interface

Communications with an individual Digivance system is supported through a local interface

capability as shown in Figure 1-3. A loca l interface requ ires a PC-ty pe compute r loaded with

the Digivance Element Management System (EMS) softw are. EMS provides the various control

and monitoring functions required to locally manage a Digivance system. The EMS computer

can be directly connected to either the HU or RU through the computer’s RS-232 port.

Operation is implemented through the EMS Graphical User Interface (GUI). The GUI consists

of a series of screens from which the user selects the desired option or function. An RS-232

service port is provided on both the HU and the RU for connecting the EMS computer.

20008-A

Figure 1-2. EBTS/HU Interface

© 2004, ADC Telecommunications , Inc.

Page 1-3

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 1: Overview

HOST UNIT

RS-232

REMOTE

UNIT

RS-232

CD-ROM WITH DIGIVANCE

ELEMENT MANAGEMENT

SYSTEM (EMS) SOFTWARE

LAPTOP WITH EMS

(LOCAL INTERFACE)

LAPTOP WITH EMS

(LOCAL INTERFACE)

18524-A

Figure 1-3. Local Management of a Single Digivance System

An EMS computer may be used to locally manage a networked group of multiple Digivance

systems as shown in Figure 1-4. A Controller Area Network (CAN) port is provided on each

HU. Up to twenty-four HU’s may be linked together through the CAN interface and controlled

by the same EMS computer. All the networked HU’s and the associated RU’s may be managed

by connecting the EMS computer to one HU. The EMS computer provides an RS-232 port (#1)

to support the interfa ce with the networked HU’s.

HOST UNIT

REMOTE

UNIT

CAN

HOST UNIT

REMOTE

UNIT

PC COMPUTER WITH EMS

(LOCAL INTERFACE WITH

MULTIPLE SYSTEMS)

Page 1-4

© 2004, ADC Telecommunications , Inc.

CAN

HOST UNIT

REMOTE

UNIT

RS-232

CD-ROM WITH DIGIVANCE

ELEMENT MANAGEMENT

SYSTEM (EMS) SOFTWARE

Figure 1-4. Local Management of Networked Digivance Systems

20009-A

2.5 Network Operations Center Interface

Communications between a Network Operations Center (NOC) and a networked group of

multiple Digivance systems is supported by a NOC interface capability as shown in Figure 1-5.

To support the NOC interface, a PC-type computer loaded with the Digivance Element

Management System (EMS) software is required. EMS provides the various control and

monitoring functions required to remotely manage multiple Digivance systems through the

NOC interface.

A Controller Area Network (CAN) port is provided on each HU. Up to twenty-four HU’s m ay

be linked together through the CAN interface and controlled by the same EMS computer. All

the networked HU’ s and the assoc iated RU’s may be managed by connecting the EMS computer

to one HU. The EMS computer provides an RS-232 port (#1) to support the interface with the

networked HU’s.

The NOC can be linked to the EMS computer through a T1 system, DS0 with RS232

conversion, or some other medium. The EMS computer provides an RS-232 ASCII interface

port (#2) to support the interface with the NOC.

At the NOC, control and monitoring of the networked Digivance systems is implemented

through a Network Element Manager (NEM) interface which requires only a VT100 terminal/

emulator for operation. The NEM interface language consists of simple ASCII text strings. All

communications are input as either SET or GET commands which result in ASCII text string

responses from the specified system or systems.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 1: Overview

NETWORK

OPERATIONS

CENTER

(REMOTE

INTERFACE)

T1, DS0

WITH RS232

CONVERSION,

OR OTHER

MEDIUM

RS-232

ASCII

HOST UNIT

HOST UNIT

HOST UNIT

CAN

CAN

RS-232

CD-ROM WITH EMS

SOFTWARE

PC COMPUTER WITH

EMS SOFTWARE

REMOTE

UNIT

REMOTE

UNIT

REMOTE

UNIT

20010-A

Figure 1-5. Remote Management of Networked Digivance Systems Through NOC Interface

© 2004, ADC Telecommunications , Inc.

Page 1-5

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 1: Overview

2.6 SNMP Interface

Communications between an e xterna l Simple Netw ork Management Prot ocol (SNMP) Manager

and a networked group of multiple Digivance systems is supported by an SNMP interface

capability as shown in Figure 1-6. To support the SNMP interface, a PC-type computer loaded

with both the Digivance Element Management System (EMS) software and the SNMP Proxy

Agent software is required. The EMS and SNMP Proxy Agent software plus the associated

Management Information Base (MIB) provide the various control (Set) and monitoring (Get)

functions required to remotely manage multiple Digivance systems using an SNMP Manager.

A Controller Area Network (CAN) port is provided on each HU. Up to twenty-four HU’s m ay

be linked together through the CAN interface and controlled by the same EMS computer. All

the networked HU’ s and the assoc iated RU’s may be managed by connecting the EMS computer

to one HU. The EMS computer provides an RS-232 port (#1) to support the interface with the

networked HU’s.

The SNMP Manager may be linked with the EMS computer through a Local Area Network

(LAN). The EMS computer provides an Ethernet port to support the interface with the LAN.

The SNMP Proxy Agent supports two ver sions of the SNMP protocol : SNMPv1 and SNMPv2c.

A facility to Register/Unregister an SNMP Manager for receiving traps is also supported by the

SNMP Proxy Agent. The SNMP Manager is not included with the EMS software and must be

provided separa tely.

NETWORK

SNMP

MANAGER

ETHERNET

LOCAL

AREA

NETWORK

ETHERNET

HOST UNIT

HOST UNIT

HOST UNIT

CAN

CAN

RS-232

REMOTE

UNIT

REMOTE

UNIT

REMOTE

UNIT

CD-ROM WITH EMS

SOFTWARE

CD-ROM WITH SNMP

PROXY AGENT SOFTWARE

Figure 1-6. Remote Management of Networked Digivance Systems Through SNMP Manager

Page 1-6

© 2004, ADC Telecommunications , Inc.

PC COMPUTER WITH EMS

AND SNMP PROXY AGENT

20011-A

3 SYSTEM FUNCTIONS AND FEATURES

This section describes various system level functions and features of the Digiva nce system.

3.1 Fiber Optic Transport

In a typical Digivance system, the HU is connected to the RU over two single-mode o ptical

fibers. One fiber is used to transport the forward path optical signal. The other fiber is used to

tran sport the reve rse p ath optical signal. Because the optical signal is digital, the input and

output RF signal levels at the HU or the RU are not dependent on the level of the optical signal

or the length of the optical fiber. A diagram of the fiber optic transport system for a typical

Digivance sy s tem is sh own in Figure 1-7.

HOST UNIT

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 1: Overview

FIBER OPTIC

LINK

FORWARD PATH

REVERSE PATH

REMOTE

UNIT

18526-A

Figure 1-7. Standard Fiber Optic Transport Application

The maximum length of the optical links is dependent on the loss specifications of the optical

fiber and the losses imposed by the various connectors and splices. The system provides an

optical budget of 25 dB (typical) when used with 9/125 single-mode fibe r.

In some applications, it may be desirable or necessary to combine the forward path and reverse

path optical signals from a single HU/RU pair onto a single optical fiber. This can be

accomplished by using a passive bi-directional Wavelength Division Multiplexer (WDM)

system. The optical wavelengths used in the Digivance syste m are 1550 nm for the forward path

and 1310 nm for the reverse path. Because different wavelengths are used for the forward and

reverse paths, both signals can be combined on a single optical fiber. One WDM module is

mounted with the HU and the other WDM module is mounted with the RU as shown in

Figure 1-8. The WDM system is available as an accesso ry item .

FIBER OPTIC

LINK

HOST UNIT

WDM

FORWARD AND

REVERSE PATH

WDM

REMOTE

UNIT

18527-A

Figure 1-8. Wavelength Division Multiplexer Application

© 2004, ADC Telecommunications , Inc.

Page 1-7

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 1: Overview

In some applications, it may be desirable or necessary to combine the forward and reverse path

optical signals from multiple HU’s and RU’s onto a single optical fiber. This can be

accomplished by using an active Coarse Wavelength Division M ultiplexer (CWDM) system. Up

to four Digivance systems may be configured to operate over a single optical fiber. A CWDM

module is mounted with each HU and RU. An example of a typical CWDM application is

shown in Figure 1-9.

HOST UNIT 1

HOST UNIT 2

HOST UNIT 3

HOST UNIT 4

CWDM

A

CWDM

B

CWDM

C

CWDM

D

FIBER OPTIC

LINK

FORWARD AND

REVERSE PATH

CWDM

A

CWDM

B

CWDM

C

CWDM

D

REMOTE

UNIT 1

REMOTE

UNIT 2

REMOTE

UNIT 3

REMOTE

UNIT 4

18528-A

A Free S p ace O p ti cs ( FSO ) s ys t em (t hat m eets the Di g ivance L RC S d at a rat e p erf or ma n ce an d

BER requirements) may be used in applications where it is desirable or necessary to bridge an

open span and where it is impractical to lay a f iber optic cable. One FSO transceiver unit may be

mounted on the HU side of the open span and the other FSO transceiver unit may be mounted

on the RU side of the open span. A system diagram of an FSO application is shown in

Figure 1-10. FSO systems are available from various equipment manufacturers.

HOST UNIT

Page 1-8

© 2004, ADC Telecommunications , Inc.

Figure 1-9. Coarse Wavelength Division Multiplexer Application

FREE SPACE OPTICS LINK

FORWARD PATH

REVERSE PATH

FSO

TX/RX

FSO

TX/RX

FORWARD PATH

REVERSE PATH

Figure 1-10. Free Space Optics Application

REMOTE

UNIT

18530-A

3.2 Control and Monitoring Software

The EMS software and the SNMP Proxy Agent software provide control and monitoring

functions for the Digivance system through the local, NOC, and SNMP interfaces. The EMS

and SNMP Proxy Agent software are stored on CD-ROM’s which are shipped in a separate

package along with the software user manuals. The EMS software package is available without

the SNMP Proxy Agent if the SNMP interface capability not required for the application.

Software installation consists of copying the software files from the CD-ROM’s to a designated

directory on the hard-drive of the EMS computer.

The EMS software provides the capability to provision and configure the Digivance system for

operation. This includes selecting a site name, setting alarm thresholds, and setting forward and

reverse path RF gain adjustments. The EMS software also provides the capability to get alarm

messages (individual or summary), obtain data measurements, and to upgrade the HU/RU

system software. All control and monitor functions (except software upgrade which is not

supported by the NOC/NEM and SNMP interfaces and HU/RU pair site number assignment

which is not supported by the SNMP interface) may be implemented using the NOC/NEM

interface, the SNMP interface, or the EMS software GUI.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 1: Overview

3.3 Fault Detection and Alarm Reporting

LED indicators are provided on the front panel of the HU and on the front panels of the RU

modules to indicate if the system is normal or if a fault is detected. In addition, normally open

and normally closed alarm contacts (for both major and minor alarms) are provided at the HU

for connection to a customer-provided external alarm system. All alarms can also be accessed

through the NOC/NEM interface , SNMP manager, or the EMS software GUI.

3.4 Powering

The HU is powered by ±24 or ±48 VDC and must be hard-wired to a local office battery power

source through a fuse panel. A screw-down terminal strip is provided on the rear side of the HU

for the power connections.

The RU is po wered b y 120 or 240 VAC power (50 or 60 Hz) and must be connected to a 20 Amp

AC powe r source. I f the R U modules are insta lled in an outdoor cabinet, the A C wiring is placed

in conduit and permanently connected to the internal cabinet wiring. If the RU modules are

installed in an indoor mounting shelf, a sta ndard three-conductor AC power cord is provided for

connection to a standard AC power outlet. A back-up battery system is available for specified

outdoor cabinets as an accessory. The battery-backup system powers the RU if the AC power

source is disconnected or fails.

3.5 Equipment Mounting and Configuration

The HU is a single-unit assembly that is designed for mounting in a non-condensing indoor

envir onment such as inside a wiring closet or within an environmenta lly-controlled cabinet. The

HU is intended for rack-mount applications and may installed (usually within 20 feet of the

EBTS) in either a 19- or 23-inch, WECO or EIA, equipment rack.

© 2004, ADC Telecommunications , Inc.

Page 1-9

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 1: Overview

The RU i s designed for mounting in ei ther an indoor or outdoor environment. The RU consists

of a Spectrum Transport Module (STM), a Linear Power Amplifier (LPA) module, WDM

remote module (accessory), CWDM remote module (accessory), and either an outdoor cabinet

or a indoor mounting shelf.

Several types of outdoor cabinets are available. Each outdoor cabinet is weather-tight but

contact with salt-air mist should be avoided as it may degrade the MTBF of the product. Outdoor cabinets can be mounted from a flat-vertical surface or a utility pole (requires pole-mount

kit). Slots are provided within each cabinet for mounting the STM and LPA modules and also

the WDM or CWDM remote modules. Storage spools are provided within the cabinet for

storing sh ort len gths of exces s fiber s lack. Speci fied cabi nets include a tray wi th a heated bas e

for mounting a back-up battery (accessory item).

A indoor mounting shelf for indoor use is also available. The indoor mounting shelf is designed

for installation in a non-condensing indoor environment such as inside a wiring closet or within

an environmentally-controlled cabinet. The indoor mounting shelf installs in a standard EIA or

WECO, 19- or 23-inch, equipment rack. Slots are provided within the mounting shelf for

mounting the STM and LPA modules and also the WDM or CWDM remote modules.

Page 1-10

© 2004, ADC Telecommunications , Inc.

SECTION 2: DESCRIPTION

Content Page

1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2 HOST UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1 Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 RF Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.5 RF Signal Level Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6 Propagation Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.7 Optical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.8 Controller Area Network Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.9 Service Interface Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.10 Auxiliary Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.11 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.12 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.13 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3 SPECTRUM TRANSPORT MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

3.1 Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

3.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

3.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3.4 Antenna Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.5 RF Signal Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.6 Optical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.7 Service Interface Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.8 Auxiliary Interface Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.9 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.10 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.11 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

4 35 WATT LINEAR POWER AMPLIFIER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

4.1 Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

4.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.4 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.5 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.6 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

5 REMOTE UNIT MOUNTING SHELF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

5.1 Indoor Mounting Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

6 SLIM-STYLE REMOTE UNIT CABINETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

6.1 Slim-Style Single-STM Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

6.2 Slim-Style Dual-STM Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

7 ACCESSORY ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

7.1 Remote Unit Back-up Battery Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

7.2 Wavelength Division Multiplexer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 2: Description

© 2004, ADC Telecommunications , Inc.

Page 2-1

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 2: Description

7.3 Coarse Wavelength Division Multiplexer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 25

8 DIGIVANCE ELEMENT MANAGEMENT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

8.1 Digivance EMS Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

8.2 Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

8.3 Computer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

8.4 Digivance EMS Computer Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

8.5 Digivance EMS User Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

9 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

_________________________________________________________________________________________________________

Page 2-2

© 2004, ADC Telecommunications , Inc.

1 INTRODUCTION

This section describes the basic components of a typical Digivance 800/900 MHz SMR LRCS

system including the Host Unit (HU) and Remote Unit (RU). The HU consists of a single rackmount chassis. The RU consists of a Spectrum Transport Module (STM); a 35 Watt Linear

Power Amplifier (LPA) module; and either an outdoor cabinet or an indoor mounting shelf.

Also described in this section are various accessory items that may be used with the HU and RU

including the Wavelength Division Multiplexer (WDM) system, Coarse Wavelength Division

Multiplex er (CWDM) system, and RU back-up battery kit.

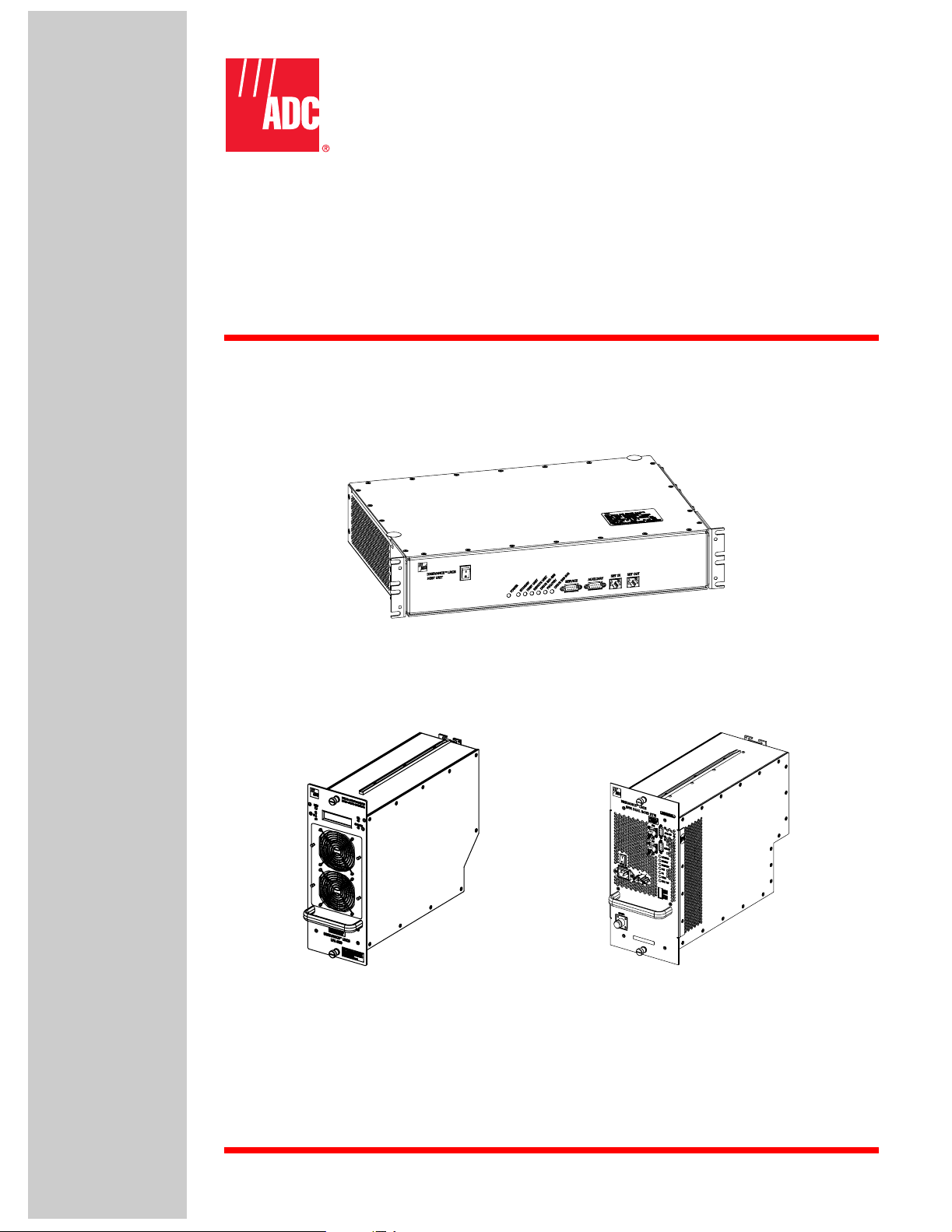

2 HOST UNIT

The HU, shown in Figure 2-1, provides the following basic functions:

• Provides an adjusta ble RF interface with the BTS.

• Provides a fiber optic interface with the RU.

• Digitizes the two forward path composite RF signals.

• Converts the two digitized forwar d path RF signals to a digital optical signal.

• Converts the digitized reverse path optical signal to two digitized RF signals.

• Converts the two digitized re verse path RF signals to two composite RF signals.

• Sends alarm information to an external alarm system through relay contact closures

• Provides an RS-232 interface for connecting the EMS computer.

• Provides an RS-232 interface for an auxiliary communications link with remote equipment.

• Provides a CAN interface for networking multiple HUs.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 2: Description

2.1 Primary Components

The HU consists of an electronic circuit board assembly and a fan assembly that are mounted

within a powder-paint coated sheet metal enclosure. The enclosure provides a mounting point

for the circuit board and fan assemblies and controls RF emissions. The only user-replaceable

component is the fan assembly. The HU is designed for use within a non-condensing indoor

environment such as inside a wiring closet or cabinet. The RF connectors, optical connectors,

alarm output connectors, DC power terminal strip, and grounding lug are mounted on the HU

rear panel. The On/Off power switch, LED indicators, service interface connector, and

Controller Area Network (CAN) connectors are mounted on the HU front panel.

2.2 Mounting

The HU is intended for rack-mount applications. A pair of reversible mounting brackets is

provided that allow the HU to be mounted in either a 19-inch or 23-inch EIA or WECO

equipment rack. When installed, the front panel of the HU is flush with the front of the rack.

Screws are provided for securing the HU to the equipment rack.

© 2004, ADC Telecommunications , Inc.

Page 2-3

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 2: Description

17.1 INCHES

(433 mm)

3.5 INCHES

(88 mm)

12.2 INCHES

(311 mm)

Figure 2-1. Host Unit

2.3 Fault Detection and Alarm Reporting

FRONT PANEL

MOUNTING

BRACKET

(BOTH SIDES)

20020-A

The HU detects and reports various internal and external faults including host unit fault, optical

fault, power fault, temperature fault, and RF fault. Various front panel Light Emitting Diode

(LED) indicators turn from green to red or yellow if a fault is detected. A set of alarm contacts

(normally open and normally closed) are provided for reporting an alarm to an external alarm

system when a fault is detected. Both major alarm (system operation se riously affected) and

minor alarm (system operati on not affected or only slightly degraded) contacts are provided.

Fault and alarm information may also be accessed locally through the EMS software GUI or

remotely through the NOC/NEM interface or SNMP interface. An alarm history file is

maintained by the EMS software so that a record is kept of all alarms as they occur. This is

useful when an alarm is reported and cleared before the reason for the alarm can be determined.

The status of the HU, the alarm state (major or minor), and other alarm information is

summarized and repor ted over the service interface, the CAN interface, and the optical interface

to the RU. In addition, the status of the RU is transmitted to the HU over the optical interface

and reported ove r the service interface and the CAN interfa ce.

2.4 RF Signal Connections

The RF signal connections between the HU and the EBTS are supported through four N-type

female connectors. Two connectors are used for the forward path RF signals. The other two

connectors are used for the reverse path RF signals. In most installations, it is usually necessary

to install external attenuators to support the RF interface between the HU and the EBTS. The

HU should be as close as possible to the EBTS to minimize coaxial cable losses.

Page 2-4

© 2004, ADC Telecommunications , Inc.

2.5 RF Signal Level Adjustments

The HU is equipped with several attenuators for adjusting the signal levels of the forward and

reverse path RF signals. The attenuators provide an attenuation adjustment range of 0 to 31 dB

and can be set in 1 dB increments. The attenuators are software controlled and are adjusted

through the EMS software GUI, NOC/NEM interface, or SNMP interface.

The host forward path attenuators adjust the level of the two input RF signals to the HU.

Using the forward path attenuator, an input signal with a nominal composite signal level of –12

dBm to –43 dBm can be adjusted to produce maximum power output. Additional external

attenuation is req uired if the input signal level is greater than –12 dBm.

The host reverse pa th attenuators adjust the level of the two output RF signals from the HU

and will add from –1 dB of gain (attenuator set to 31 dB) to +30 dB of gain (attenuator set to 0

dB) to the two RF output signals at the HU.

2.6 Propagation Delay

The HU forward and reverse path propagation delays may be adjusted in 0.1 µsec increments

within a range of 0 to 63 µs. The propagation delay is software controlled and may be adjusted

through the EMS softwa re GUI, NOC/NEM interface, or SNMP interface.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 2: Description

2.7 Optical Connection

Optical connections between the HU and the RU (STM) are supported through two SC-type

optical connector ports. One port is used for the forward path optical signal connection and the

other port is used for the reverse path optical signal connection.

2.8 Controller Area Network Interface Connection

Controller Area Network (CAN) interface connections between multiple HUs are supported by

a pair of RJ-45 jacks. One of the jacks is designated as the network IN port and the other jack is

designated as the network OUT port. The CAN interface allows up to 24 HUs to be connected

together (in daisy- chain fashion) and controlled through a single EMS computer.

2.9 Service Interface Connection

The service interface connection between the HU and the EMS computer is supported by a

single DB-9 female conne ctor. The ser vice connector provides an RS-232 DTE inte rface. When

multiple HUs are networked together, the supporting EMS computer may be connected to the

service connector of any one of the networked HUs.

2.10 Auxiliary Interface Connector

An auxiliary communication link is provided between the HU and the STM for customer use.

The auxiliary interface is supported by a single DB-9 female connector. The auxiliary connector

provides an RS-232 DTE interface. The auxiliary communications link can be used to remotely

monitor and control other network equipment t hat may be located at the remote unit site such as

the antenna.

© 2004, ADC Telecommunications , Inc.

Page 2-5

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 2: Description

2.11 Powering

The HU is powered by ± 21 to ± 60 VDC power (nominal ± 24 or ± 48 VDC). The power is fed to

the HU through a screw-down type terminal strip located on the rear side of the unit. Power to

the HU must be supplied through a fuse panel such as the PowerWorx GMT Series Fuse Panel

(available separately). The power circuit for each HU must be protected with a 3 Amp GMT

fuse. An On/Off switch is provided on the HU front panel.

2.12 Cooling

Continuous airflow for cooling is provided by dual fans mounted on the right side of the HU

housing. A minimum of 3 inches (76 mm) of clearance space must be provided on both the left

and right sides of the HU for air intake and exhaust. An alarm is generate d if a high temperature

condition (>50º C/122º F) occurs. The fans may be field-replaced if either fan fails.

2.13 User Interface

The HU user interface consi sts of the v arious connectors, switches, termi nals, and LEDs that are

provided on the HU front and rear panels. The HU user interface points are indicated in

Figure 2-2 and described in Table 2-1.

FRONT VIEW

(13) 806-824

REVERSE

(14) 896-901

REVERSE

REAR VIEW

Page 2-6

© 2004, ADC Telecommunications , Inc.

(1) DC POWER

ON/OFF SWITCH

(15) 851-869

FORWARD

OUTPUT CONNECTOR

(REFERENCE

ITEMS 2 - 8)

LED INDICATORS

(16) 935-940

FORWARD

(19) ALARM

(9) SERVICE

INTERFACE

CONNECTOR

(17) DC POWER

TERMINAL STRIP

(11) NET IN

CONNECTOR

(10) AUXILIARY

CONNECTOR

Figure 2-2. Typical Host Unit User Interface

(12) NET OUT

CONNECTOR

(18) COVER PLATE

(21)

(20)

REV

FWD

(22)

GROUNDING

STUD

20021-A

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 2: Description

Table 2-1. Host Unit User Interface

REF

NO

USER INTERFACE

DESIGNATION

DEVICE

1I/0 On/Off rocker

switch

2 P OW E R Mult i- color ed L ED

(green/yellow)

3 STANDBY Multi-colored LED

(green/yellow/red)

4 HOST UNIT Multi-colored LED

(green/yellow/red)

5 REMOTE UNIT Multi-colored LED

(green/yellow/red)

6 DRIVE 851–869 Multi-colored LED

(green/yellow/red)

7FWD/REV

(PORT 1/P ORT 2)

Mult i- c o lored LED

(green/red)

8 DRIVE 935–940 Multi-colored LED

(green/yellow/red)

9 SERVICE DB-9 connector

(female)

FUNCTIONAL

DESCRIPTION

Provides DC power on/off control.

Indicates if the HU is powered (green) or unpowered (off). See Note.

Indicate s if the system is in the Normal (off),

Standby (blinking green), Test (blinking red), or

Program Load (blinking yel low) state. See Note.

Indicates if the HU is normal (green), ov erheated

(yellow), or fault y (red). See Note.

Indica tes if no alar ms (green), a minor alarm

(yello w) , o r a majo r alar m ( re d) is r ep ort ed b y the

RU. See Note.

Indicates if the level of the 851–869 MHz RF

input signal to the HU is normal (green), low

(yellow), or high (red). See Note.

Indicates if the reverse/forward pat h optical signals from the STM/HU are normal (green), if no

signals are detected (red), or if excessive errors

are detected (red). See Note.

Indicates if the level of the 935–940 MHz RF

input signal to the HU is normal (green), low

(yellow), or high (red). See Note.

Connection point for the RS-232 service interface cable.

10 AUXILIARY DB-9 connector

(female)

Connection point for the RS-232 auxiliary interface cable.

11 NET IN RJ-45 jack (female) Connection point for the CAN interface input

cable.

12 NET OUT RJ-45 jack (female) Connection point for the CAN interface output

cable.

13 806–824 REVERSE N-type female RF

coaxia l connector

14 896–901 REVERSE N-type female RF

coaxia l connector

15 851–869 FORWARD N-type female RF

coaxia l connector

16 935–940 FORWARD N-type female RF

coaxia l connector

17 POWER 24–48 VDC Screw-type terminal

Output connection point for the 806–824 MHz

reverse path RF coaxial cable.

Output connection point for the 896–901 MHz

reverse path RF coaxial cable.

Input connection point for the 851–869 MHz forward path RF c oa x ial cable .

Input connection point for the 935–940 MHz forward path RF c oa x ial cable .

Connection point for the DC power wiring.

strip

18 No designation Cover plate Covers the mounting slot for the wavelength divi-

sion multiplexer module.

© 2004, ADC Telecommunications , Inc.

Page 2-7

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 2: Description

Table 2-1. Host Unit User Interface, continued

REF

NO

19 ALARM OUTPUT Screw-type terminal

20 FWD (PORT 1) SC connector

21 REV (PORT 2) SC connector

22 Chassis ground stud Connection point for a chassis grounding wire.

Note: A more detailed des cription of LED operation is provided in Section 4.

USER INTERFACE

DESIGNATION

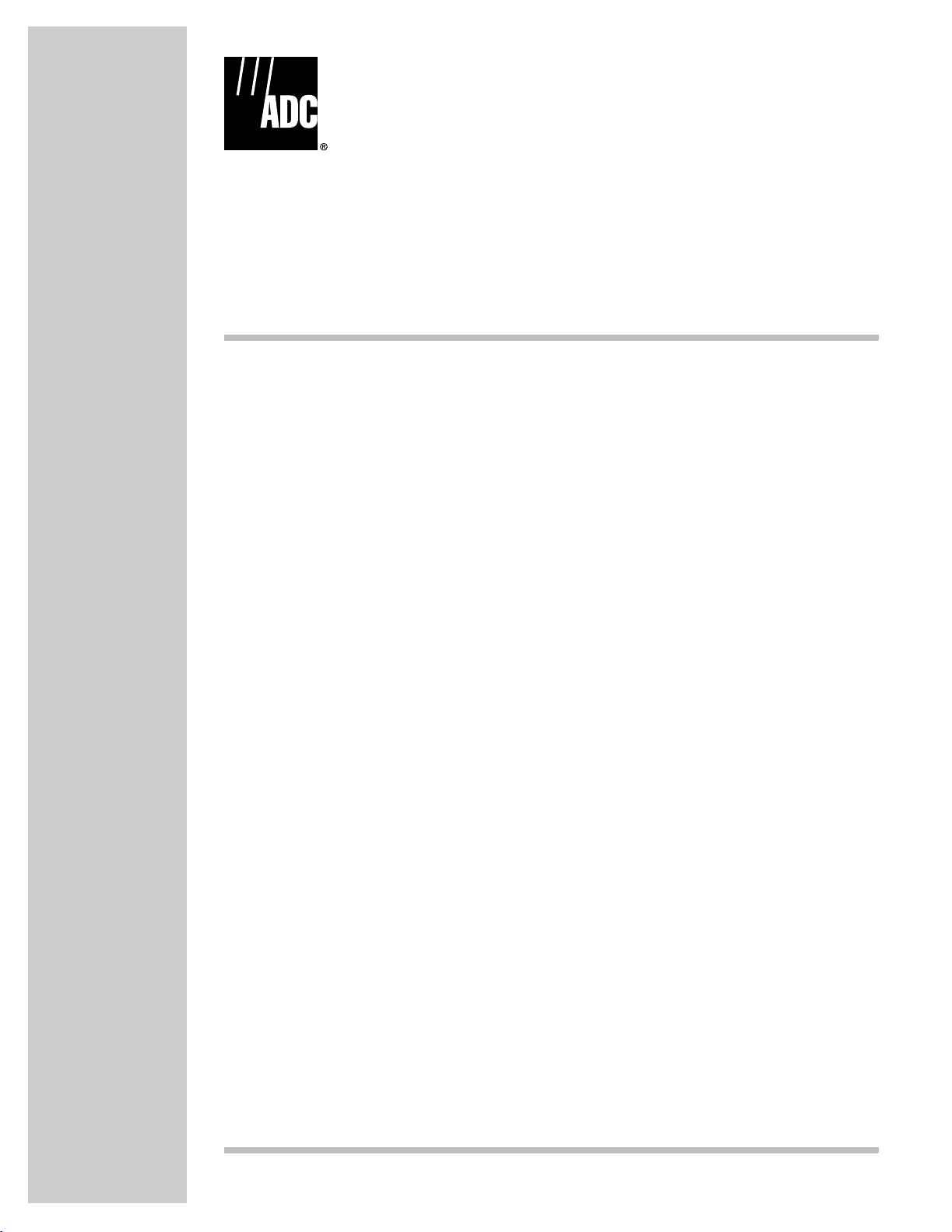

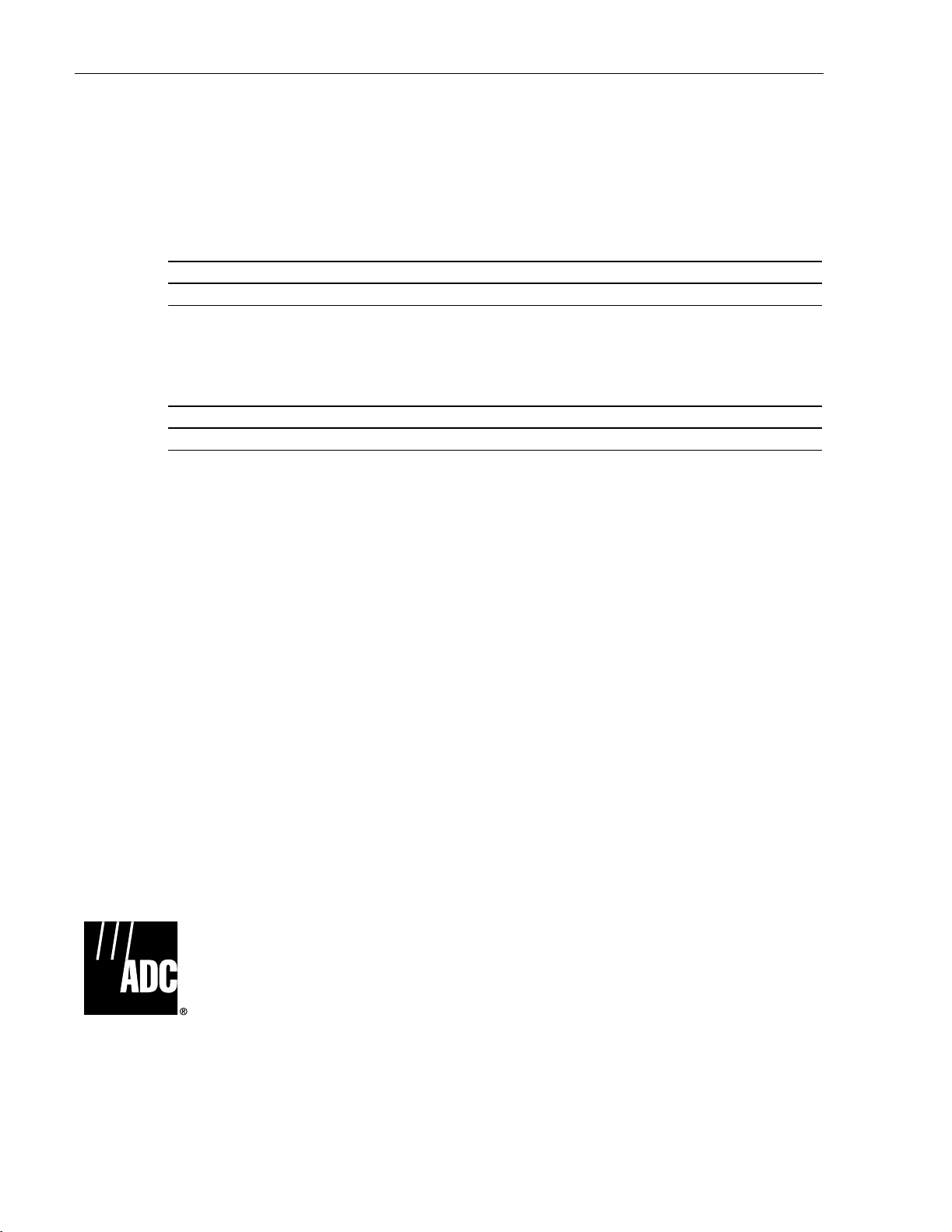

3 SPECTRUM TRANSPORT MODULE

The STM, shown in Figure 2-3, provides the following basic functions:

DEVICE

connector (14–26

AWG)

(single-mode)

(single-mode)

FUNCTIONAL

DESCRIPTION

Connection point for an external alarm system.

Includes normally open (NO), normally closed

(NC), and common (COM) wiring connections.

Output connection point for the forward path

optical fiber.

Input connection point for the reverse path primary optical fibe r.

• Provides an RF interfa ce (antenna port) for the remote antenna(s).

• Provides an optical interface for the HU.

• Converts the digitized forward path optical signal to digitized RF signals.

• Converts the digitized forward path RF signals to two composite RF signals.

• Digitizes the two reverse path composite RF signals.

• Converts the digitized re verse path RF signals to a digitized optical signal.

• Provides an RS- 2 32 interface for connecti n g a local EM S computer.

• Pro vide s an RS- 232 inte rf ace for an auxiliary communications link with remote equipment.

• Trans ports alarm, control, and monitoring information to the HU via the optical interface.

• Accepts AC power input and battery power input.

• Accepts external alarm input.

3.1 Primary Components

The STM consists of an electronic circuit board assembly, power supply, quadraplexer, and fan

assembly that are mounted within a powder-paint coated sheet metal enclosure. The metal

enclosure provides a mounting point for the electronic components and controls RF emissions.

Except for the fan unit, the electronic components are not user replaceable. The STM is

designed for use within the RU outdoor cabinet or indoor mounting shelf. Except for the LPA

interface connector, all controls, connectors, indicators, and switches are mounted on the STM

front panel for easy access. A carrying handle is provided on the front of the STM to facilitate

installation and transport.

Page 2-8

© 2004, ADC Telecommunications , Inc.

3.2 Mounting

The STM mounts within the RU outdoor cabinet or indoor mounting shelf. Runners on the top

and bottom of the STM mesh with tracks in the cabinet or mounting shelf. The runners and

tracks guide the ST M into the ins talled po sition . The e lectri cal inte rface betwe en t he STM and

LPA is supported by a D-sub female connector located on the rear side of the STM. A

corresponding D-sub male connector mounted at the rear of the RU cabinet or indoor mounting

shelf mates with the STM connector. Captive screws are provided for securing the STM in the

installed posit ion.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 2: Description

Figure 2-3. Typical Spectrum Transport Module

3.3 Fault Detection and Alarm Reporting

The STM detects and reports various faults including remote unit fault, optical fault, power

fault, temperature fault, power amplifier fault, and external (cabinet door open) fault. Various

front panel Light Emitting Diode (LED) indicators turn from green to red or yellow if a fault is

detected. The statu s of the STM , the al arm state (m ajor o r mino r), and ot her alarm informa tion

is summarized and reported over the optical interface to the HU and also over the service

interface. In addition, the alarm state of the HU is received over the optical interface and

reported to the service interface. Fault and alarm information may be accessed locally through

the EMS softwar e GU I or remote l y t hrou gh th e NOC /NEM inter face or SNMP in t e r fa ce.

20023-B

Page 2-9

© 2004, ADC Telecommunications , Inc.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 2: Description

3.4 Antenna Cable Connection

The antenna cable connection between the STM and the antenna is supported through a single

N-type female connector. The single connector is used for the antenna cable which carries both

the forward and primary reverse path RF signals.

3.5 RF Signal Level Adjustment

The STM is equipped with digital attenuators for adjusting the signal level of the forward path

RF output signals. The remote forward p a th a ttenuators adjust the level of the two output RF

signals at the RU antenna port and will add from 0 to 31 dB of attenuation to the output signal

level. The attenuator can be set in 1 dB increments. The attenuator is software controlled and is

adjusted through the EMS software GUI, the NOC/NEM interface, or SNMP interface.

3.6 Optical Connection

Fiber optic connections between the STM and the HU are supported through two SC-type

optical connector ports. One port is used for the forward path optical signal connection and the

other port is used for the reverse path optical signal connection.

3.7 Service Interface Connection

The service interface connection between the STM and a local laptop computer loaded with the

EMS software is supported by a single DB-9 female connector. The service interface connector

provides an RS-232 DTE interface. The STM service interface supports local communications

with both the STM and the corresponding HU.

3.8 Auxiliary Interface Connection

An auxiliary communication link is provided between the HU and the STM for customer use.

The auxiliary interface is supported by a single DB-9 female connector. The auxiliary connector

provides an RS-232 DTE interface. The auxiliary communications link can be used to remotely

monitor and control other network equipment t hat may be located at the remote unit site such as

the antenna.

3.9 Powering

The STM is powered by 120 or 240 VAC (50 or 60 Hz) power which is supplied through a

three-conductor AC power cord. The power cord is provided with the RU outdoor cabinet or

indoor mounting shelf. The power cord connects to a 3-wire AC c onne ctor mounted on the f ront

panel. A switch on the STM front panel provides AC power On/Off control.

The STM (and the connected LPA) may be powered by a 24 VDC back-up battery system

which is available as an accessory kit. A connector is provided on the STM front panel for the

back-up battery system wiring harness connection.

Page 2-10

© 2004, ADC Telecommunications , Inc.

3.10 Cooling

Continuous air-flow for c ooling is provide d by a single fan mounted on the rear side of the STM

housing. An alarm is generated if a high temperature condition (>50º C/122º F) occurs. If the

temperature falls below 32º F (0º C), the fan automatically shuts off. The fan may be field

replaced if it fails.

3.11 User Interface