Page 1

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 3: Operation

2. Click on the HOST Site Name Edit button (see Figure 3-6). The Site Name pop-up

screen will open as shown in Figure 3-7. Enter a unique name for the HOST. The name

may be up to 32 characters long and must not contain any spaces. The name may include

numbers, punctuation, and upper or lower case letters and must always begin with a letter.

Click on OK to close the screen and make the changes take effect.

Figure 3-7. HOST Site Name Pop-Up Screen

3. Click on the HOST Site Number Edit button (see Figure 3-6). The Site Num ber pop-up

screen will open. Enter any number (must be unique) between 1 and 24 and then click on

OK to close the screen and make the changes take effect.

4. Check the REMOTE Site Number field (see Figure 3-6). The REMOTE Site Number

does not have to be entered. When the HOST Site Number is entered, the system will

automatically enter the same number for the REMOTE Site Number.

5. Click on the REMOTE Site Name Edit button (see Figure 3-6). The Site Name pop-up

screen will open. Enter a unique name for the REMOTE. The name may be up to 32

characters long and must not contain any spaces. The name may include numbers,

punctuation, and upper or lower case letters and must always begin with a letter. Click on

OK to close the screen and make the changes take effect.

6. Open the Tools menu at the top of the main window and then select Refresh Catalog to

make the new Host and Remote sit e names appear in the View menu.

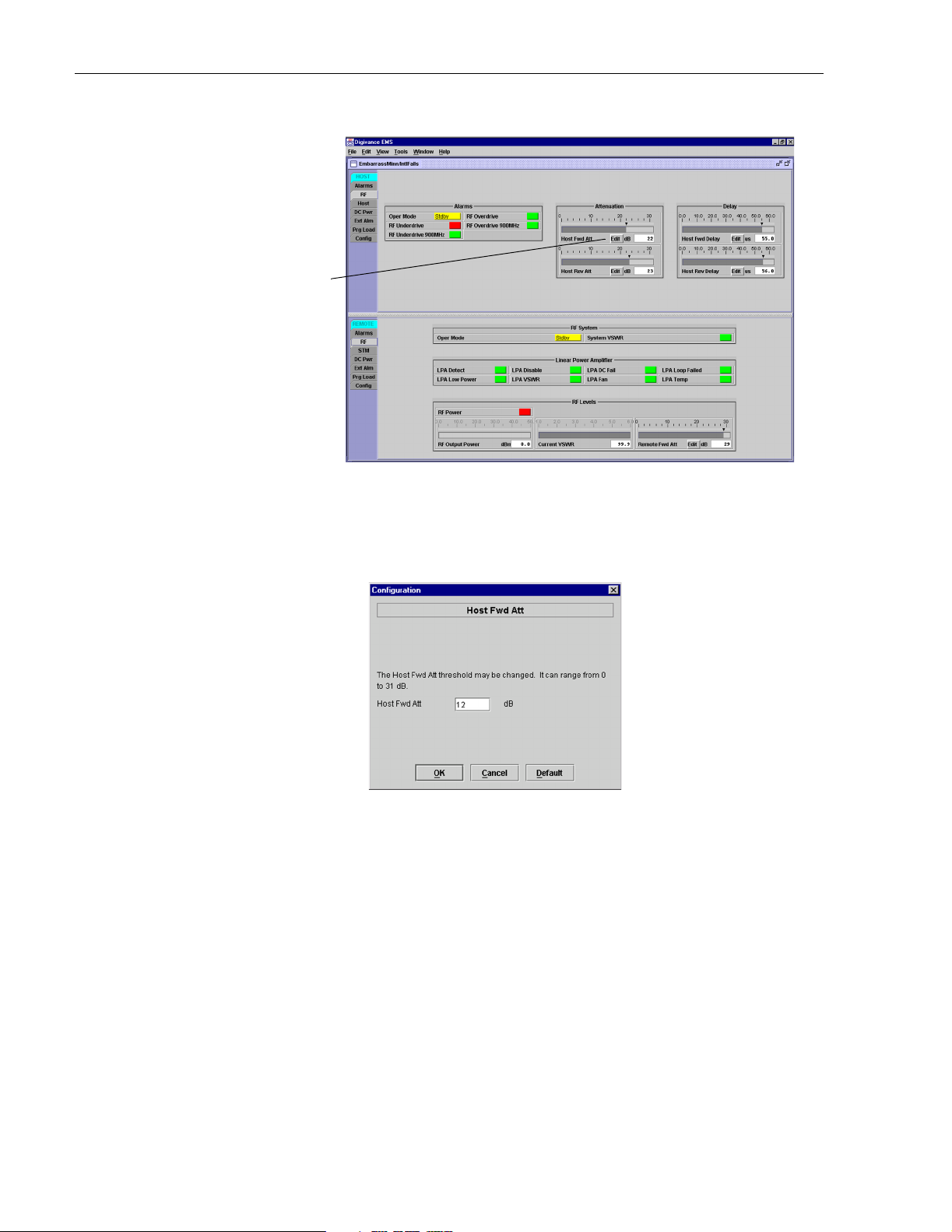

2.5 Enter Host Forward Attenuation

The HU internal forward path attenuator setting determines the maximum composite output

signal level at the STM antenna port. The appropriate attenuation value for any particular

system is based on the number of channels the system is transporting and the signal level of the

composite forward path signals input at the host units RF IN ports. By default, the forward path

attenuator is set to 31 dB.

The maximum output power that can be provided by the system is 43.4 dBm (22 Watts). The

total forward pa th gain that is pro vided by the system (with host and remote forw ard attenuators

set to 0 dB) is 85 dBm. Use the following procedure to set the forward path attenuation to

provide the maximum composite output signal level:

1. Click on the HOST RF tab. The HOST RF display will open within the EMS main

window as shown in Figure 3-8.

© 2004, ADC Telecommunications, Inc.

Page 3-11

Page 2

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 3: Operation

Click on Edit button

to open Host Fwd

Att pop-up screen

Figure 3-8. HOST RF Display

2. Click on the Host Fwd Att Edit button (see Figure 3-8). The Hos t Fw d At t pop-up screen

will open as shown in Figure 3-9.

Figure 3-9. Host Fwd Att Pop-Up Screen

3. Obtain the value of the total composite input signal level as determined in step 11 of

Section 2.3.

4. Determine the appropriate value to enter for the Host forward path attenuator by

subtracting the required system output level (per system design plan) from the system ga in

(85 dB) and then adding the composite input signal level. The result (see sample

calculation) is the amount of atte nuation required.

Atten = (System Gain) – (Required System Output Power) + (Composite Input Power)

5. Enter the attenuation value and click OK to close the pop-up screen and to make the

changes take effect.

Page 3-12

© 2004, ADC Telecommunications, Inc.

Page 3

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 3: Operation

2.6 Determine Output Signal Level at STM Antenna Port

The RF output signal level should be measured at the STM ANTENNA port to verify that

maximum composite signal level is at the required level. Use the following procedure to

determine the po wer level:

1. Verify that RF ON/OFF swi t c h on the LPA is in th e OFF position.

2. Disconnect the antenna cable from the STM ANTENNA port.

3. Connect a spectrum analyzer or RF power meter to the STM ANTENNA port. (Check the

input rating of the test equi pment. Insert a 30 dB 100 W attenuator if necessary.)

4. Place the RF switch on the LP A in the ON position.

5. If using a spectrum analyzer, proceed to step 6. If using a power meter, measure the

composite signal po wer from the STM and then proceed to step 8.

6. Measu re the RF level of a single ca rrier, such as the con trol channe l, in dBm. Mak e sure

the resolution bandwi dth of the spectrum analyzer is 30 kHz.

7. Calculate the total composite signal power using the fol lowing formula:

= Pc + 10Log N

P

tot

Where,

is the total composite powe r in dBm

P

tot

is the power per carrier i n dBm as meas u red in s tep 6, and

P

c

N is the total number of channels.

8. Record the result measured in step 5 or calculated in step 7.

9. Place the RF switch on the LP A in the OFF position.

10. Disconnect the spectrum analyzer or RF power meter from the STM ANTENNA port.

11. Re-connect the antenna cable to the STM ANTENNA port.

Note: To comply with Maximum Permissible Exposure (MPE) requirements, the

maximum composite output from the antenna cannot exceed 1000 Watts EIRP and the

antenna must be permanently installed in a fixed location that provides at least 6 meters

(20 feet) of separation from all persons.

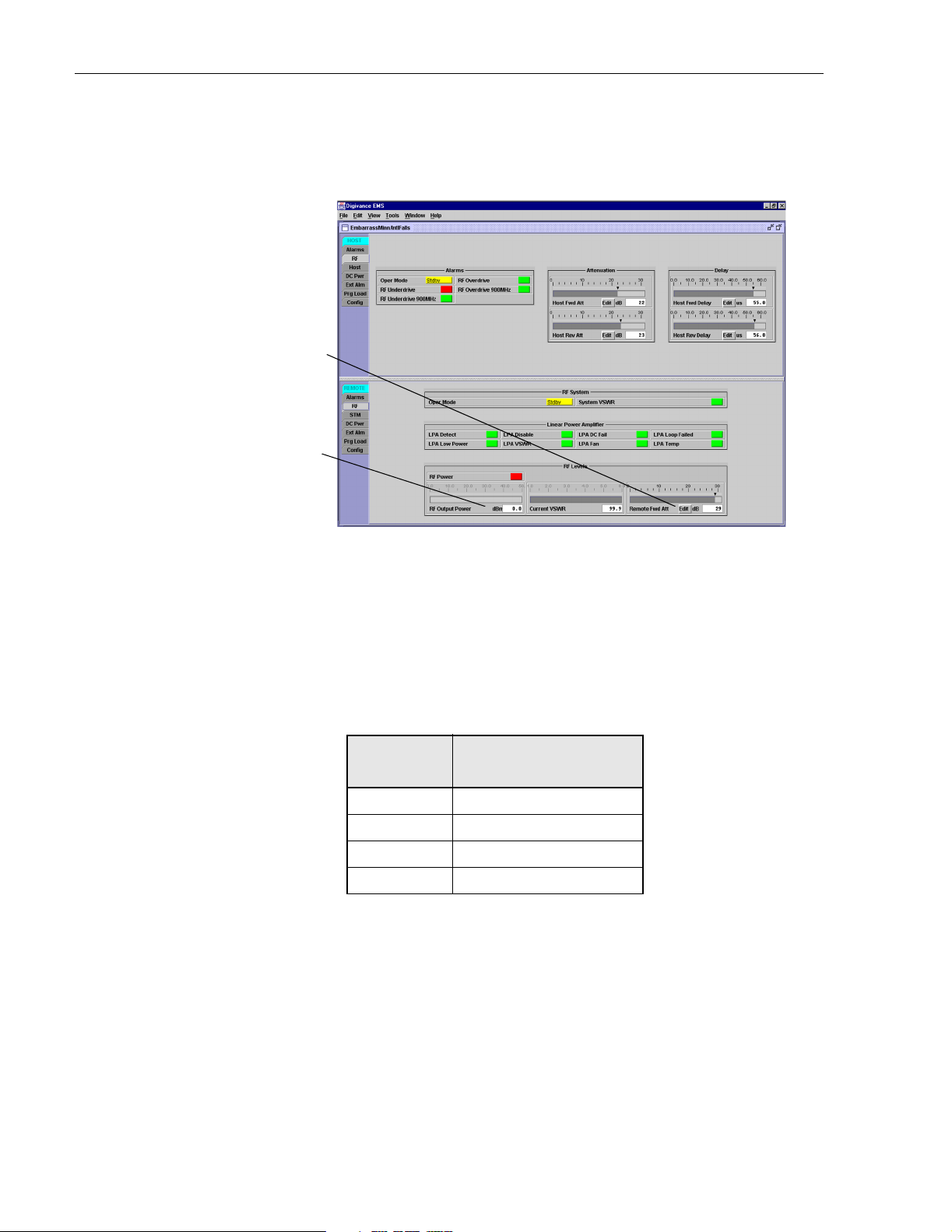

2.7 Enter Remote Forward Attenuation

The STM internal forward path attenuator setting is used to reduce the power level of the

composite output signals at the STM antenna port. The maximum composite output signal level

at the STM antenna port is set using the Host internal forward attenuator (see Section 2.5).

However, component variations may result in the output power at the STM antenna port being

slightly above or below the required power per channel. If this is the case, the STM forward

attenuator may be used in conjunction with the Host forward attenuator to add or remove

attenuation to produce the required output signal level. If less power is required, the STM

forward attenuator may be used to reduce the power level. The default setting is 31 dB. Use the

following procedure to change the STM forward attenuation:

© 2004, ADC Telecommunications, Inc.

Page 3-13

Page 4

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 3: Operation

1. Click on the REMOTE RF tab. The REMOTE RF display will open within the EMS main

window as shown in Figure 3-10.

Click Edit button to

open the Remote Fwd

Att pop-up screen

RF output signal

level (± 3 dB)

Figure 3-10. REMOTE LPA Display

2. Check the level of the RF output signal (as determined in Sectio n 2.6) ag ains t the sys tem

design plan specifications. Table 3-2 shows the output signal level required to provide 5

watts per channel for systems with 1 to 4 channels. The maximum output signal level

permitted for the system is 43.4 dBm (22 Watts).

Table 3-2. Composite Output Signal Levels

OUTPUT SIGNAL LEVEL

NUMBER OF

CHANNELS

REQUIRED TO PROVIDE 5

WATTS PER CHANNEL

137 dBm

240 dBm

342 dBm

443 dBm

3. Dete rmine i f mor e or l e ss a t tenu ati on is r equ ire d to pr o duce the r equi re d out put s ig nal le v el .

4. Click on the Remote Fwd Att field Edit bu t to n (s ee Figure 3-10). The Remote Fwd Att

pop-up screen will open as shown in Figure 3-11.

Page 3-14

© 2004, ADC Telecommunications, Inc.

Page 5

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 3: Operation

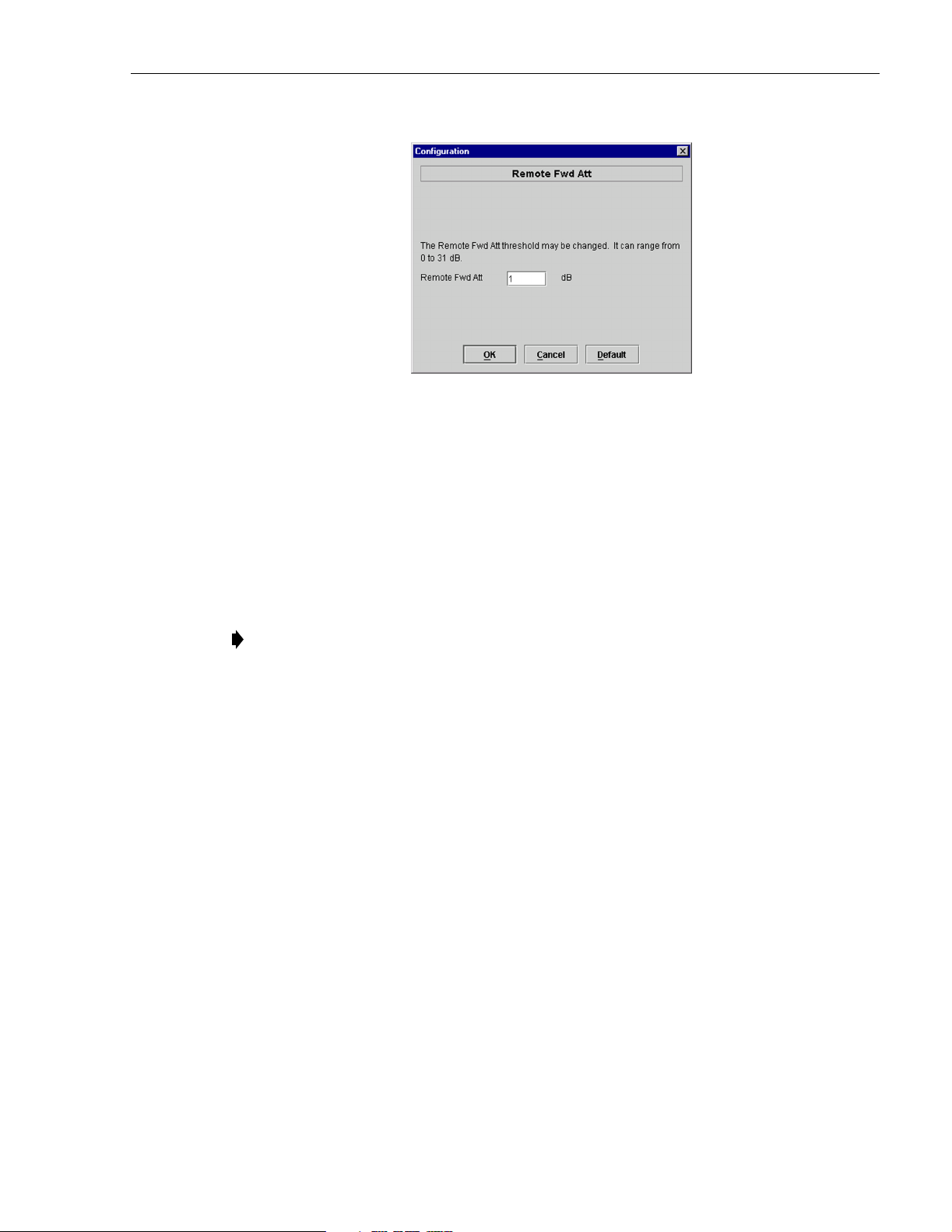

Figure 3-11. Remote Fwd Att Pop-Up Screen

5. Enter the required attenuation value and click OK to close the pop-up screen and to make

the changes take effect.

6. Verify that the appropriate RF output signal level appears in the RF Output Power field

(see Figure 3-10). This is primarily a reference value and should not take the place of

external test equipment when determining the power level of the composite RF output

signal. Depending on the modulation type and number of channels, the EMS softwar e may

report a power level that is higher or lower (± 3 dB) than the actual RF output signal.

Note: To comply with Maximum Permissible Exposure (MPE) requirements, the

maximum composite output from the antenna cannot exceed 1000 Watts EIRP and the

antenna must be permanently installed in a fixed location that provides at least 6 meters

(20 feet) of separation from all persons.

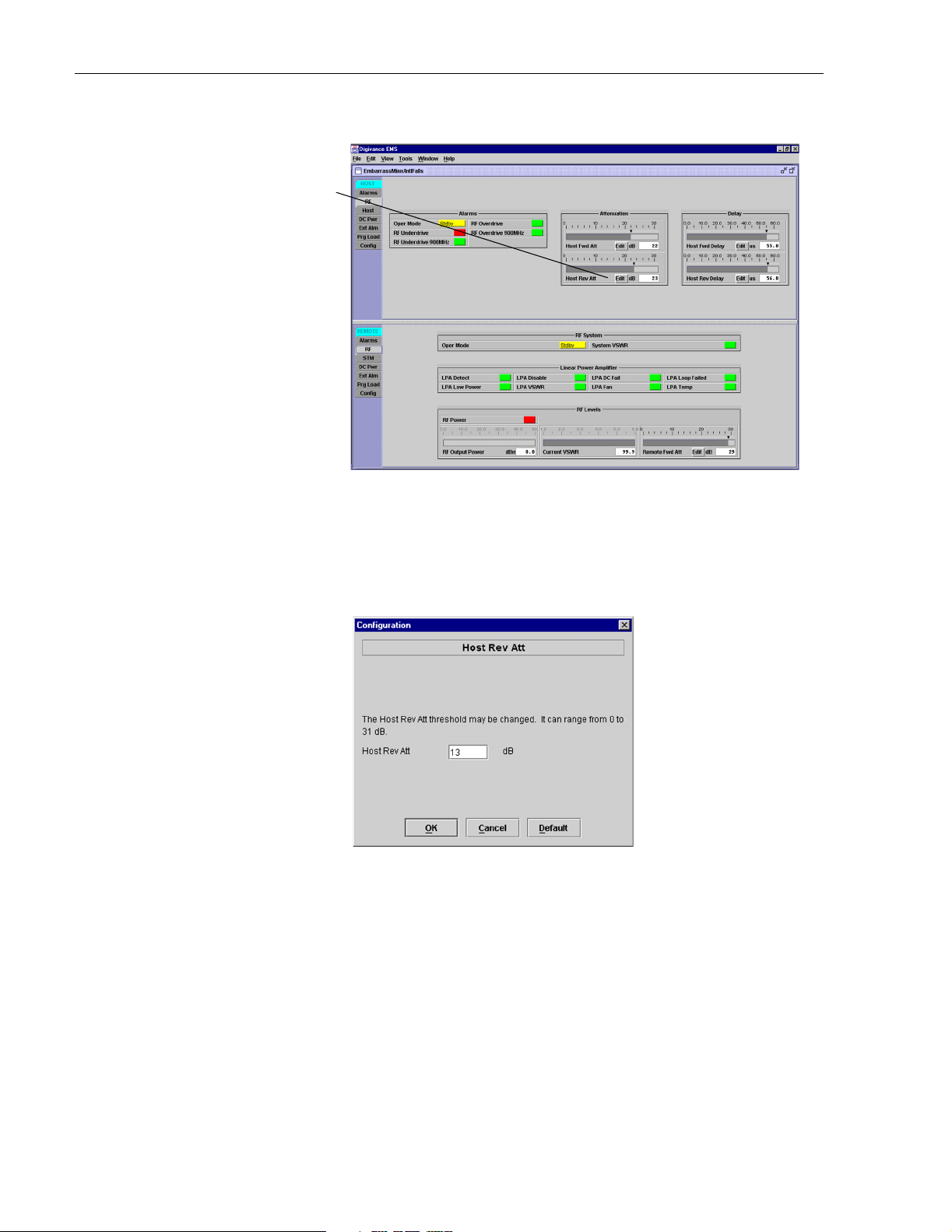

2.8 Enter Host Reverse Attenuation

The level of the RF signal that should be input to the EBTS will vary depending on the type of

EBTS, the receive distributi on, and the number of channels pre sent. To interf ace with the EBTS,

the reverse path signal level must be adjusted to provide the signal level required by the EBTS.

The HU provides from –1 to +30 dB of gain in the reverse path. By default, the host reverse

attenuator is set to –31 dB of attenuation which provides –1 dB of gain. Use the following

procedure to set the reverse path gain:

1. Check the EBTS manufacturer’s specifications to determine the composite signal level

required at the 806–824 MHz and 896–901 MHz reverse path input ports.

2. Determine the overall gain and loss imposed on the signal by the antenna, antenna cable,

and by the cables that connect the HU to the EBTS.

3. Determine the amount of gain required to raise the revers e path signal to the le vel required

at the EBTS.

4. Click on the HOST RF tab. The HOST RF display will open within the EMS main

window as shown in Figure 3-12.

© 2004, ADC Telecommunications, Inc.

Page 3-15

Page 6

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 3: Operation

Click Edit button to

open the Host Rev Att

pop-up screen

Figure 3-12. HOST RF Display

5. Click on the Host Rev Att field Edit button (see Figure 3-12). The Host Rev Att pop-up

screen will open as shown in Figure 3-13.

Figure 3-13. Host Rev Att Pop-Up Screen

6. Enter the attenuation value that will provide the required gain. Refer to Table 3-3 for the

attenuation values and the corresponding gain (nominal) values.

7. Click OK to close the pop-up screen and to make the changes take effect.

Page 3-16

© 2004, ADC Telecommunications, Inc.

Page 7

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 3: Operation

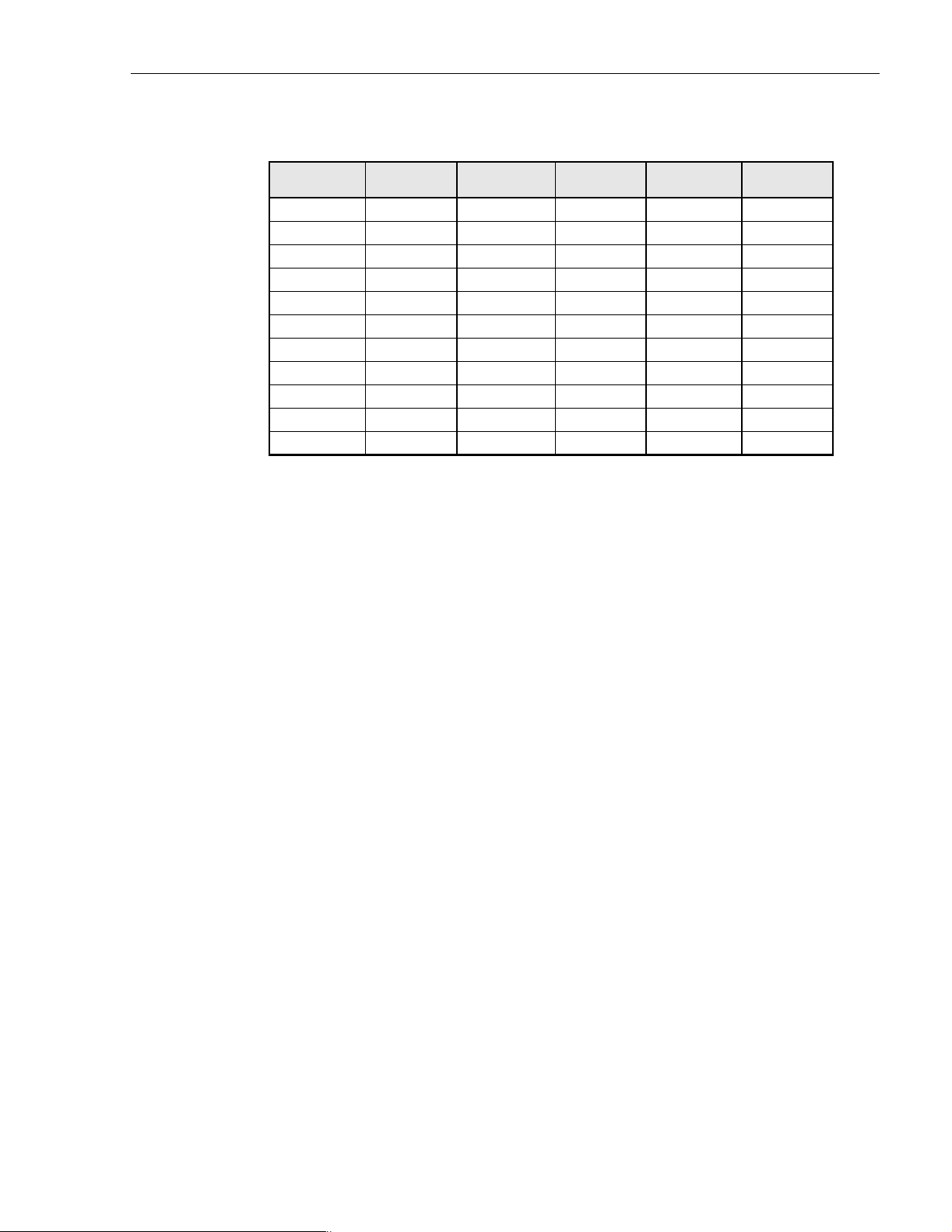

Table 3-3. Reverse Path Attenuation Setting and Nominal Gain Provided

ATTENUATION

SETTING

0 dB → 30 dB 11 dB → 19 dB 22 dB → 8 dB

1 dB 29 dB 12 dB 18 dB 23 dB 7 dB

2 dB 28 dB 13 dB 17 dB 24 dB 6 dB

3 dB 27 dB 14 dB 16 dB 25 dB 5 dB

4 dB 26 dB 15 dB 15 dB 26 dB 4 dB

5 dB 25 dB 16 dB 14 dB 27 dB 3 dB

6 dB 24 dB 17 dB 13 dB 28 dB 2 dB

7 dB 23 dB 18 dB 12 dB 29 dB 1 dB

8 dB 22 dB 19 dB 11 dB 30 dB 0 dB

9 dB 21 dB 20 dB 10 dB 31 dB –1 dB

10 dB 20 dB 21 9 dB

GAIN

PROVIDED

2.9 Enter Host Forward and Reverse Delay

The forward and reverse delay function allows entry of from 0 to 63 µsec of delay in the

forward and reverse path s. This featu re is used when mu ltiple sys tems are used to tran sport th e

same channel and the re is a significant differenc e in the path delay betwe en s ystems. Additional

delay may be e ntered to balance the overall system delay. The amount of delay requir ed must be

calculated by the RF engineer and should be included in the system design plan. The default

setting is 0 µsec. Use the following procedure to change the forward and reverse path delay:

ATTENUATION

SETTING

GAIN

PROVIDED

ATTENUATION

SETTING

GAIN

PROVIDED

1. Click on the HOST RF tab. The HOST RF display will open within the EMS main

window as shown in Figure 3-14.

2. Click on the Host Fwd D elay field Edit button (see Figure 3-14). T he Host Fwd Delay

pop-up screen will open as shown in Figure 3-15.

3. Obtain the value of the forward delay as specified in the system design plan. The delay is

adjustable in 0.1 µsec steps.

4. Enter the forward path delay value and click OK to close the pop-up screen and to make

the changes take effect.

5. Repeat the pr ocess for reverse delay by right-clicking on the appropriate delay section (see

Figure 3-14) and then entering the required delay value in the pop- up screen.

6. Click OK to close each pop-up screen and to make the changes take effect.

© 2004, ADC Telecommunications, Inc.

Page 3-17

Page 8

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 3: Operation

Click Edit button to

open the Host Fwd

Delay pop-up screen

Click Edit button to

open the Host Rev

Delay pop-up screen

Figure 3-14. HOST RF Display

Figure 3-15. Host Fwd Delay Pop-Up Screen

Page 3-18

© 2004, ADC Telecommunications, Inc.

Page 9

SECTION 4: MAINTENANCE

1 SYSTEM MAINTENANCE OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1 Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

2 FAULT DETECTION AND ALARM REPORTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

3 FAULT ISOLATION AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

3.1 Host Unit Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

3.2 STM Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

3.3 LPA Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4 TEST PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.1 Optical Power Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.2 Optical Loopback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

5 SCHEDULED MAINTENANCE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

_________________________________________________________________________________________________________

1 SYSTEM MAINTENANCE OVERVIEW

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

This section explains the Digivance system f ault detection and alarm reporting system, provides

a method for isolating and troubleshooting faults, and provides test procedures. The Digivance

system requires minimal regular maintenance to insure continuous and satisfactory operation.

Components that require regular replacement, cleaning, or testing include the HU fans, STM

fan, LPA fa ns, RU cabinet air-filter, and RU back- up battery.

Maintenance also includes diagnosing and correcting service problems as they occur. When an

alarm is repo rted, it will be necessary to follow a systemat ic troubleshooting procedure to locate

the problem. Once the source of the problem is isolated, the appropriate correctiv e action can be

taken to restore service. The only internal components that can be replaced are the cooling fans

which mount in the HU, RU, and LPA. The failure of any other internal component will require

replacem ent of the en ti re uni t.

1.1 Tools and Materials

The followi ng tools and materials are required in order to complete the maintenanc e proc edures

specified in this section:

•ESD wrist strap

• IR filtering saf ety glasses

• Patch cords with SC connectors

• 15 dB in-line SC optical attenuator s

• Optical power meter (15 50 and 1310 nm)

• TORX screwd river (with T10 b it)

• Battery maintenance tools (see PRC-SERIES OPERATING AND FIELD SERVICE

MANUAL for tool recommenda tions)

© 2004, ADC Telecommunications, Inc.

Page 4-1

Page 10

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

2 FAULT DETECTION AND ALARM REPORTING

The Digivance LRCS on-board embedded software de tects various unit and system faults which

generate et her a Maj or or M inor a larm. A Major alarm indicates that the syst em has failed in a

way that directly affects RF transport performance. When a major alarm occurs, all RF

functions are disabled and the system is out of service. A Minor alarm means that system

performance is not affected or in some cases, that the performance may no longer be optimal.

When a minor alarm occurs, RF functions continue and the system remains in service.

The following means are used to report Major and Minor alarms:

• HU alarm cont acts

• HU, STM, and LP A front panel LED’ s

• EMS soft ware G ra phi ca l Us er Int erfac e (G U I)

• Network Operations Center - Network Element Manager (NOC/NEM) interface

• SNMP interface

The HU is equipped with a set of both normally open (NO) and normally closed (NC) alarm

contacts which may be used to report both Major and Minor al arms to an exter nal alarm system.

The alarm cont acts summarize the i nputs so that any Major or Minor ala rm will trigger an a larm

repo r t to the external a larm system .

The HU, STM, and LPA front panel LED indicators show status and alarm information by

displaying various colors: Green, Red, Yellow, and Off. In addition to LED indicators, the 35

Watt LPA is also equipped with a Digital Display that provides text messages. A description of

the Host Unit, Spectrum Transport Module, and 35 Watt LPA LED indicators is provided

resp e ctively in Table 4-1, Table 4-2, and Table 4-3.

The EMS software GUI provides both a summary and a detailed list of alarm information that

includes unit and module level faults, circuit faults, and measured value faults such as voltages,

RF power, and temp erature. A s ummary showin g a list of all systems a nd their curre nt alarm

status is presented through the Alarm OverView display. A more detailed list of alarm

information is presente d through the HOST alarm display and the REMOTE alar m display. The

various fault conditions that trigger a major or minor alarm report are shown in the HOST and

REMOTE alarm dis pla y s.

The NOC/NEM interface provides the same summary and detailed listing of alarm information

as the EMS software GUI but in an ASCII text string format. Sending the command GET

ALARMSUMMARY produces a list of all systems and their current alarm status. Sending the

command GET ALARM ALL for a specific system will produce a detailed list of alarm

information for the specified system.

The SNMP interface provides alarm information to up to ten SNMP managers which must be

register ed with the SNMP agent. The SNMP interfac e allo ws the SNMP managers to rece iv e the

alarm and status information generated by the host and remote units. The presentation of the

alarm information is depe ndent on the features of the SNMP manager.

Page 4-2

© 2004, ADC Telecommunications, Inc.

Page 11

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

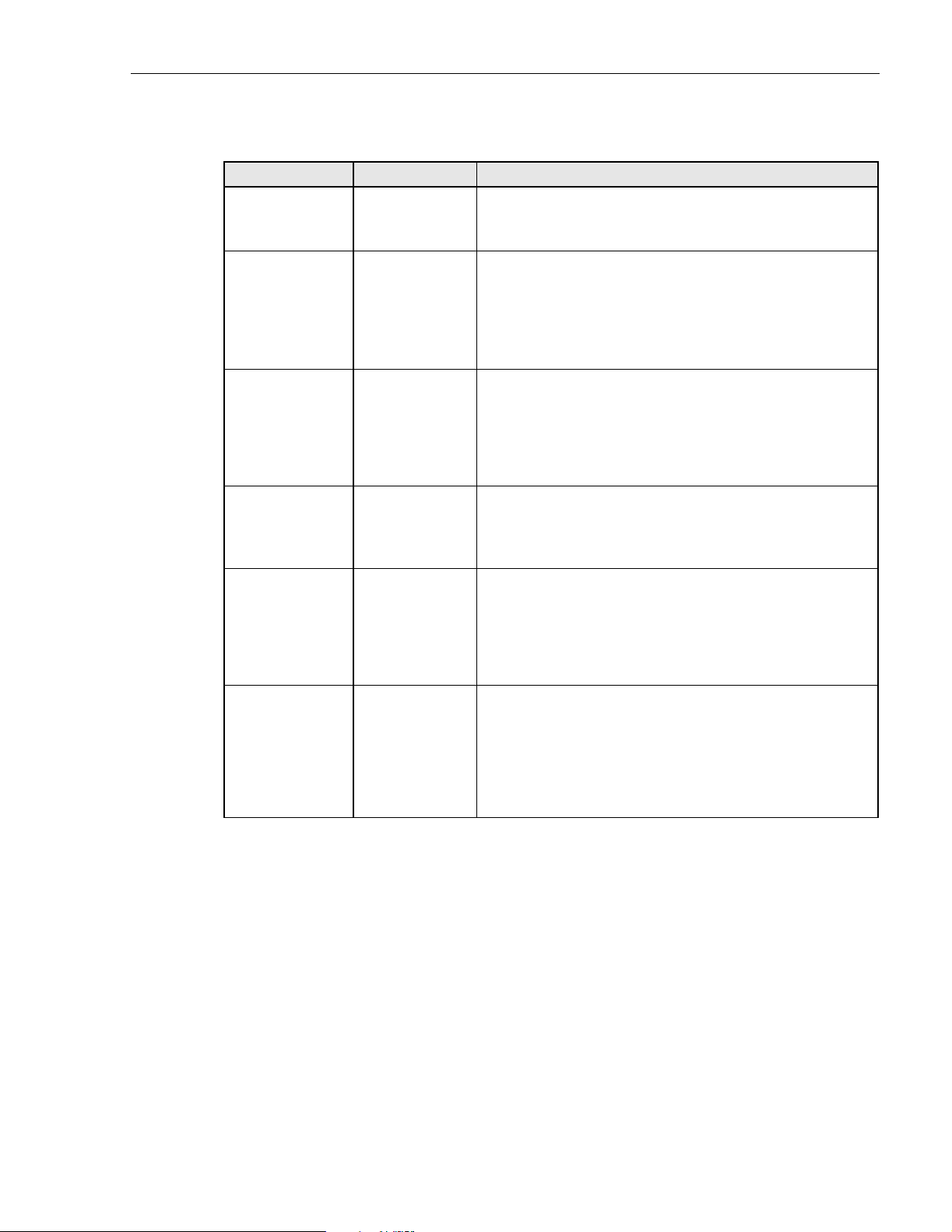

Table 4-1. Host Unit LED Indicators

INDICATOR COLOR DESCRIPTION

POWER

Green

Off

Indica tes if the HU is p owered or un- pow e red .

The DC power source is on.

The DC power source is off.

STANDBY

Indicates if the system is in the standby, normal, test, or

program load mode.

Green (blinking)

Yellow (blinking)

Red (blinking)

Off

HOST UNIT

The HU is in the standby m ode.

The HU is in the program loa d mode.

The HU is in the test mode .

The HU is in the normal mode.

Indicates if the HU is normal, over temperature, if an

internal fault is detected, or if there is an equipment mismatch.

Green

Yellow

Red

REMOTE UNIT

Green

Yellow

Red

DRIVE 851–869

and

DRIVE 935–940

Green

Yellow

Red

FWD/REV

(PORT 1/P ORT 2)

The HU is normal.

The HU is over temperature or d etects an internal fault.

The HU detects an internal fault or HU/RU band mismatch.

Indicates if an alarm is detected at the RU.

No alarms detected at the RU.

A minor alarm is detected at the RU.

A major alarm is detected at the RU.

Indicates if the specified forward path RF si gnal level is

norma l, abov e overdrive thresh o l d , or bel ow un derdrive

threshold.

The RF signal level is normal

The RF signal level is belo w the underdrive threshold.

The RF si g nal level is above the overdrive th r esho ld .

Indicates if the reverse path optical signals fr om the STM

are normal, if errors are detected, or if the optical signal is

not detected.

Green

Red

The reverse path optical signals are normal.

Excessive errors (see Note) are detected in the reverse path

optical s ignals or t he HU is not rece ivi ng a rev er se pa th optic al

signal.

Note: Excessive erro rs means the Bit Error Rate (BER) has exceeded 10

–6

(1 bit error per million bits) .

© 2004, ADC Telecommunications, Inc.

Page 4-3

Page 12

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

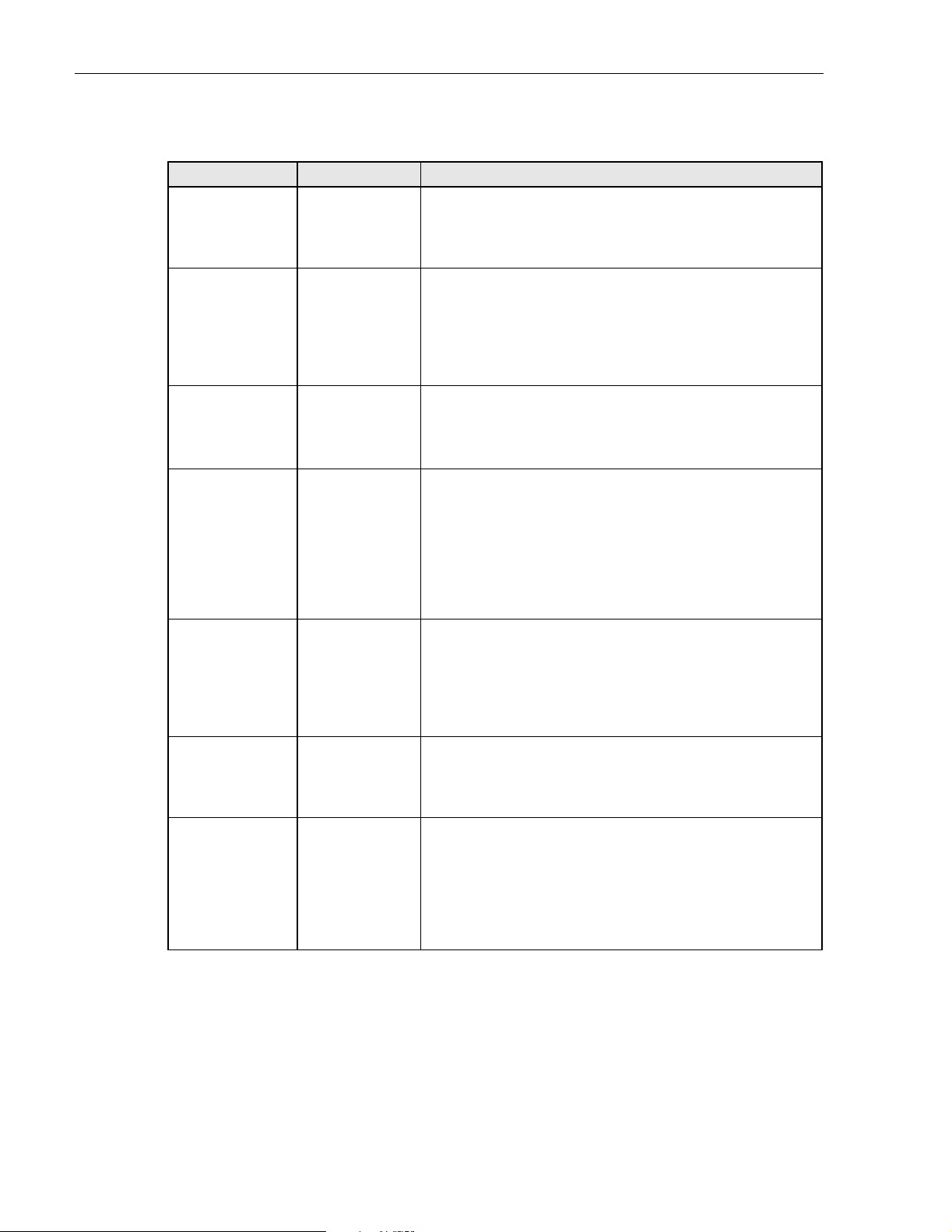

Table 4-2. Spectrum Transport Module LED Indicators

INDICATOR COLOR DESCRIPTION

AC POWER

Indicates if the STM is powered by the A C power source or

the back-up battery system.

Green

Red

STANDBY

The STM is powered by the AC power source.

The STM is powered by the back-up battery sys tem.

Indicates if the system is in the standby, normal, test, or

program load mode.

Green (blinking)

Yellow (blinking)

Red (blinking)

Off

The STM is in the standby mode.

The STM is in the program load mode.

The STM is in the test m o de.

The STM is in the normal mode.

HOST UNIT

Green

Yellow

Red

STM

Indicates if an alarm is detected at the HU.

No alarms detected at the HU.

A minor alarm is detected at the HU.

A major alarm is detected at the HU.

Indicates if the STM is normal, over temperature, if a battery fault is detected, if an internal fault is detected, or if

there is an equipment mismatch.

Green

Yellow

The STM is normal.

The STM is over te mperature due to high ambient tempera-

ture, th e fan ha s fa iled, or det ects an int er n al fau l t.

Red

The STM detects an internal fault, the backup battery voltage

is below threshold, or HU/RU band mismatch.

PA

Indicates if the LPA is normal, over temperature, has a fan

failure, has an internal fault, is shutdown, or not present.

Green

Yellow

Red

The LPA is normal.

The LPA is over temperature or the fan has failed.

Internal fau lt de tecte d in the LPA, the LPA RF po wer out put is

shutdown, or the LPA is not present.

VSWR

Indicates if the forward path VSWR is above or below the

threshold.

Green

Red

FWD/REV

(PORT 1/P ORT 2)

The VSWR is below the threshold.

The VSWR is ab ove the th r eshold.

Indicates if the forward path optical signals from the HU

are normal, if errors are detected, or if the optical signal is

not detected.

Green

Red

The forward pa th o pt ic al s ign al s are n or mal.

Excessive errors (see Note) are detected in the forward path

optical signal or the STM is not receiving the forward path

optical signal.

Note: Excessive erro rs means the Bit Error Rate (BER) has exceed ed 10

–6

(1 bit error per million bits) .

Page 4-4

© 2004, ADC Telecommunications, Inc.

Page 13

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

Table 4-3. 35 Watt LPA LED Indicators and Digital Display

INDICATOR COLOR DESCRIPTION

FAIL

Off

Yellow

Indicates if the LPA is normal or faulty.

The LPA is normal.

Internal fault detected in the LPA.

SHUTDOWN

Indicates if the LPA has an RF output or if the RF output

is shutdown.

Off

Red

DISPLAY MESSAGE 1ST LINE DESCRIPTION

The LPA RF output is on.

The LPA RF output is shutdown.

PA Initializi ng The LPA is initi alizing itself and is not rea dy for operation.

Normal Operation The LPA is en abled an d t r ansmitting RF.

Internal Shutdown The LPA is disabled due to a major fault and is not transmit -

ting RF.

Forced Shutdown The LPA is disabled by the front panel control switch or

through the EMS.

DISPLAY MESSAGE 2ND LINE DESCRIPTION

Over Power The LPA maximum RF output rating has been exceeded .

Over Temperature The LPA m aximum operating temperature has been exceeded.

VSWR The voltage standing wave ratio is greater than 3:1.

DC Fail The LPA internal DC power supply is out of specification.

Low Gain The LPA internal amplifier gain is too low.

Alarm: OK The LPA does not detect any faults that would cause an alarm.

Loop Fail The LPA internal loop gain in out of range.

Fan Fail One or both of the LPA cooling fans has failed.

© 2004, ADC Telecommunications, Inc.

Page 4-5

Page 14

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

3 FAULT ISOLATION AND TROUBLESHOOTING

Alarm information may be accessed using the HU and STM front panel LED indicators, the

EMS softwar e GUI, the NOC -NEM interfac e, or the SNMP manager. When an alarm occu rs,

use the unit LED indicators and any one of the specified software tools to determine which

Digivance system is affected, which unit (HU or ST M) reported the a larm, and the fault th at

generated the alar m. T hen re fer to e ither Section 3.1 Host Unit Troubleshooting or Section 3.2

STM Troubleshooting to isolate the problem and to determine the corrective a ction required. If

an LPA problem is reported by the STM, refer to Section 3.3 LPA Troubleshooting for the

troubleshooti ng procedures that apply to the LPA.

When attempting to isolate a problem, always determine the initial fault that generated the

alarm report. Some faults may cause additional faults to be reported which tends to obscure the

initial reason for the alarm. To help isolate faults, the EMS GUI provides an AlarmOverview

screen, shown in Figure 4-1, that indicates which Digivance system/unit is reporting the alarm.

Click to acknowledge

alarm and to open Alarm

History Info dialog box

Click to clear alarm

history fault indicator

and to close Alarm

History Info dialog box

Figure 4-1. AlarmOverView Screen

The AlarmOver view screen includes an ALARM HIST indi cator which the us er should click to

acknowledge that an alarm exists. Acknowledging the alarm opens the Alarm History Info

dialog box (also shown in Figure 4- 1) which directs the user to view the EMS Log file for

details. The EMS Log file lists t he various fa ults in the order in whic h they occurred. Cle ar each

fault starting with the initial fault. In most instances, clearing the initial fault will also clear any

remaining faults. For additional information on using the AlarmOverview screen, refer to the

Digivance Element Management System Version 3.01 User Manual (ADCP-75-151).

Note: It is recommended that if there are alarms at both the HU and STM, the op tical

faults shoul d be checked and cleared first. Because the HU and STM function as a system,

a fault in the fiber optic link will cause alarms to be reported by both the HU and STM.

Page 4-6

© 2004, ADC Telecommunications, Inc.

Page 15

3.1 Host Unit Troubleshooting

Use this section to troubleshoot alarms that originate with the Host Unit. When a Minor alarm

occurs, one (or more) of the Host Unit LED’s with turn yellow and the EMS software will

indicate a minor fault/alarm. When a Major alarm occurs, one (or more) of the Host Unit LED’s

will turn red and the EMS software will indicate a major fault/alarm. Locate the LED and the

corresponding software fault/status indicator in Table 4-4 and then take the corrective action

indicated.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

Table 4-4. Host Unit Fault/Alarm Isolation Diagram

Host Unit Front Panel LED

Green - Powered

Power

Off - Not powered

Green blinking - Standby

Yellow blinking Program load

Standby

Red blinking - Test

Off - Normal

Green - Normal

Yellow - Minor Alarm

Host

Unit

Red - Major Alarm

Software Fault/Status Indicator

No specific HU faults - Only

faults with no associated LED

are displayed

Oper Mode - Operational

mode of system

Temperature - Over temperature

LO Synth Lock - Local

oscillator synthesizer out of lock

Pri Rev Synth Lock - Reverse

primary synthesizer out of lock

8 Volt - Onboard 8 Volt power

supply below threshold

3.8 Volt - Onboard 3.8 Volt power

supply below threshold

Corrective Action

or Reference

Table 4-5

Problem A

Use EMS to

change system to

required mode

Table 4-5

Problem B

Replace HU

Pri Fwd Mux Lock - Forward primary

phase locked loop out-of-lock

Pri Laser Fail - Forward primary

laser failure

Hardware mismatch - Host and

Remote band mismatch

© 2004, ADC Telecommunications, Inc.

Replace HU or

STM with

correct unit

Continued

20013-A

Page 4-7

Page 16

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

Table 4-4. Host Unit Fault/Alarm Isolation Diagram, continued

Host Unit Front Panel LED Software Fault/Status Indicator Corrective Action

Green - Normal

Remote

Unit

Drive

851-869

Fwd/Rev

(Port 1/Port 2)

Drive

935-940

No Associated LED

Yellow - Minor Alarm at Remote Unit - See Table 4-6. Remote Unit Fault/Alarm Isolation Diagram

Red - Major Alarm at Remote Unit - See Table 4-6. Remote Unit Fault/Alarm Isolation Diagram

Green - Normal

Yellow - Minor Alarm

Red - Major Alarm

Green - Normal

Red - Major Alarm

Green - Normal

Yellow - Minor Alarm

Red - Major Alarm

RF Underdrive - 800 MHz forward

path RF signal level too low

RF Overdrive - 800 MHz forward

path RF signal level too high

Pri Rx Light - No light received

over optical reverse path

Pri Rx Errors - Excessive errors

received over optical reverse path

RF Underdrive 900 MHz - 900 MHz

forward path RF signal level too low

RF Overdrive 900 MHz - 900 MHz

forward path RF signal level too high

Minor Contact Output - Minor alarm

reported by HU or STM

Major Contact Output - Major alarm

reported by HU or STM

Remote Lost - The HU cannot

communicate with remote (STM)

EMS Link Status - The EMS cannot

communicate with HU

Table 4-5. Host Unit Fault/Alarm Corrective Action

or Reference

Table 4-5

Problem C

Table 4-5

Problem D

See Table 4-5

Problem E

See Table 4-5

Problem E

Table 4-5

Problem C

Table 4-5

Problem D

See specific

fault indicator

See specific

fault indiator

See Table 4-5

Problem E

See Table 4-5

Problem F

20014-A

PROBLEM A: The HU is not powered.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. The HU is tu r n ed off .

2. The fuse is open/removed from the fuse panel

or the DC power has failed.

PROBLEM B: The HU is overheating.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Air intake or exhaust opening to HU chassis

is blocked

2. Ambient tempera ture > 50º C/122º F.

3. Faulty fan.

4. The HU has failed.

Page 4-8

© 2004, ADC Telecommunications, Inc.

1. Place On/Off switch in the On position.

2. Check DC power source, repair as needed, and

replace or reinstall fuse at fuse panel.

1. Remov e cause of air-flow blockage.

2. Reduce ambient temperature.

3. Replace HU fan (See applicable manual).

4. Replace HU.

Page 17

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

Table 4-5. Host Unit Fault/Alarm Corrective Action, continued

PROBLEM C: The RF input signal level is below the underdrive threshold.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Composit e output sign a l from EBTS is t oo l o w.

1. Check EBTS composite output signal level and

adjust if too low.

2. Faulty coaxial connection between the HU

2. Correct EBTS cables if faulty.

and the EBTS.

3. Incorrect attenuation in forward path RF

coaxial li nk .

PROBLEM D: The RF input signal is above the overdrive threshold.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Composite output signal level from EBTS is

too high.

2. Incorrect attenuation in forward path RF

coaxial li nk .

PROBLEM E: No light received over the reverse path or excessive errors received over the reverse path

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Faulty reverse path optical fiber.

3. Check Host Forward Attenuator setting and

adjust if attenuation is to o hi gh.

1. Check EBTS composite output signal level and

adjust if too high.

2. Check Forward Attenuator setting and adjust if

attenuation is too low.

1. Test optical fiber. Clean connector if dirty. Repair

or replace optical fiber if faulty. (See Section 4.1).

2. Faulty optical transmit port at the STM;

or faulty optical receive port at the HU

PROBLEM F: The HU does not respond to control or monitoring commands sent by the EMS.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. The HU is not powered.

2. The cable connection between the HU and the

2. Test optical ports. Replace HU or STM if port is

faulty (See Section 4.2).

1. See Problem A this table.

2. Inspect EMS cable and repair or replace if faulty.

EMS computer is fa u lt y.

3. The CAN cable connections between the HUs

in a multiple HU installation are faulty.

3. Inspect each CAN cable and repair or replace if

faulty.

3.2 STM Troubleshooting

Use this section to troubleshoot alarms that originate with the STM. When a Minor alarm

occurs, one (or more) of the STM LED’s will turn yellow and the EMS software will indicate a

minor fault/alarm. When a Major alarm occurs, o ne (o r m o re) of t he ST M L E D’s will tur n red

and the EMS software will indicate a major fault/alarm. Locate the LED and the corresponding

fault/status indicator in Table 4-6 and then take the corrective action indicated.

© 2004, ADC Telecommunications, Inc.

Page 4-9

Page 18

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

Table 4-6. Remote Unit Fault/Alarm Isolation Diagram

Remote Unit Front Panel LED

Green - Powered by AC power

source

AC

Power

Standby

Host

Unit

STM

Red - Major Alarm

Off - Not powered

Green blinking - Standby

Yellow blinking Program load

Red blinking - Test

Off - Normal

Green - Normal

Yellow - Minor Alarm at Host Unit - See Table 4-4. Host Unit Fault/Alarm Isolation Diagram

Red - Major Alarm at Host Unit - See Table 4-4. Host Unit Faul/Alarm Isolation Diagram

Green - Normal

Yellow - Minor Alarm

Software Fault/Status Indicator

AC Fail - The AC power is off,

RU powered by back-up battery

Oper Mode - Operational mode

of system

Temperature - Over temperature

Converter - Power supply

converter failure

LO Synth Lock - Local

oscillator synthesizer out of lock

Pri Rev Synth Lock - Reverse

primary synthesizer out of lock

Corrective Action

or Reference

See Table 4-7

Problem A

Use EMS to

change system to

required mode

See Table 4-7

Problem B

Red - Major Alarm

Ref Synth Lock - Reference

synthesizer out of lock

8 Volt - Onboard 8 Volt power

supply below threshold

3.8 Volt - Onboard 3.8 Volt power

supply below threshold

Pri Rev Mux Lock - Reverse primary

phase locked loop out-of-lock

Pri Laser Fail - Reverse primary

laser failure

Hardware mismatch - Host and

Remote band mismatch

Battery Voltage - Battery

voltage below threshold

20015-A

Replace STM

Replace HU or

STM with

correct unit

See battery

manual

Continued

Page 4-10

© 2004, ADC Telecommunications, Inc.

Page 19

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

Table 4-6. Remote Unit Fault/Alarm Isolation Diagram, continued

Remote Unit Front Panel LED Software Fault/Status Indicator Corrective Action

or Reference

Green - Normal

LPA Fan - Fan failure

PA

VSWR

Fwd/Rev

(Port 1/Port 2)

Yellow - Minor Alarm

Red - Major Alarm

Green - Normal

Red - Major Alarm

Green - Normal

Red - Major Alarm

LPA Temp - Over temperature

LPA Detect - LPA

not installed

LPA Over Power - LPA

signal level too high

LPA VSWR - The LPA

VSWR is too high

LPA DC Fail - LPA DC

power supply failure

LPA Loop Failed - LPA

internal loop failure

LPA Low Power - LPA

internal amplifier failure

System VSWR - The VSWR at

the quadraplexer is too high

Pri Rx Light - No light received

over optical forward path

Pri Errors - Excessive errors

received over optical forward path

See Table 4-7

Check LPA. See

Check LPA. See

Check LPA. See

Check LPA. See

Check LPA. See

See Table 4-7

See Table 4-7

See Table 4-7

Replace

LPA fan

Problem C

Install LPA

Table 4-8

Table 4-8

Table 4-8

Table 4-8

Table 4-8

Problem D

Problem E

Problem E

No Associated LED

Host Lost - The STM cannot

communicate with Host (HU)

EMS Link Status - The EMS cannot

communicate with STM

Minor Extern Input - Minor external

alarm reported by STM

Major Extern Input - Major external

alarm reported by STM

RF Power - No RF power detected

at quadraplexer (STM)

LPA Disable - The LPA is shut down

© 2004, ADC Telecommunications, Inc.

See Table 4-7

Problem E

See Table 4-7

Problem F

See Table 4-7

Problem G

See Table 4-7

Problem G

See Table 4-7

Problem H

Check LPA. See

Table 4-8

20016-A

Page 4-11

Page 20

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

Table 4-7. STM Fault/Alarm Corrective Action

PROBLEM A: The RU is powered by the battery back-up system.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. The AC po wer s ystem circuit breaker is open

or the AC power has fail ed.

2. The STM has failed.

PROBLEM B: The STM is overheating.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Air intake or exhaust opening to the remote

unit cabinet is blocked

2. Ambient tempera ture > 50º C/122º F.

3. Faulty fan.

4. The STM has failed.

PROBLEM C: The LPA is overheating.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Air intake or exhaus t opening to the remote

unit cabinet is blocked

2. Ambient tempera ture > 50º C/122º F.

3. Faulty fan.

PROBLEM D: The forward path VSWR is above threshold.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Faulty antenna or antenna system.

2. Faulty antenna cable.

3. The STM qudraplexer has failed.

PROBLEM E: No light received over the forward path or excessive errors received over the forward path

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Faulty forward path optical fiber.

2. Faulty optical transmit port at the HU;

or faulty optical recei ve port at the STM.

PROBLEM F: The STM does not respond to control or monitoring commands sent by the EMS.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. The cable connection between the STM and

the EMS computer is faulty.

PROBLEM G: An external fault is detected at the Remote Unit.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. The RU cabinet door is open.

2. Customer specified ext ernal fault at RU

1. Check the AC power sy stem, repair as need ed,

and reset circuit breaker.

2. Replace the STM.

1. Remov e cause of air-flow blockage.

2. Reduce ambient temperature.

3. Replace STM f an (See applicable manual).

4. Replace STM.

1. Remov e cause of air-flow blockage.

2. Reduce ambient temperature.

3. Replace LPA fan (See applicable manual).

1. Check the antenna system for shorts or opens

(including lightning protector).

2. Check the antenna cable for fault y conne ctions.

3. Replace the STM.

1. Test optic al fiber. Clean conn ector if dirty. Repair

or replace optical fiber if faulty. (See Section 4.1).

2. Test optical ports. Replace HU or STM if port is

faulty (see Section 4.2).

1. Inspect EMS cable and repair or replace if faulty.

1. Close R U ca binet door.

2. Check RU and correct specified externa l fault.

Page 4-12

© 2004, ADC Telecommunications, Inc.

Page 21

3.3 LPA Troubleshooting

During normal operation of the 35 Watt LPA, all LED’s should be Off. When troubleshooting

the LPA, always check the LPA front panel display for messages before initiating a reset or

replacing the LPA. The display will generally indicate the reason for the alarm.

LED: FAIL Color: Yellow Alarm Type: Major

PROBLEM: Internal fault detected in the LPA.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. The STM to LPA connecti ng cable is faulty.

2. The LPA has failed.

LED: SHUTDOWN Color: Red Alarm Type: Major

PROBLEM: The RF output from the LPA is shutdown.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

Table 4-8. 35 Watt LPA Fault Isolation and Corrective Action

1. Inspect cabl e and repair or replace if faulty.

2. Replace LPA

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1.Th e RF ON/OF F s w it ch is in th e O FF p osition

2. The LPA is in the forced shutdown mode

(single front fan unit) or internal shutdown

mode (dual front fan unit).

1. Place RF ON/OFF switch in the ON position

2. Watch the LED Display and note reason for the

forced shutdown. Refer to the Display Message

section of this table for the re com m ended correc tive action.

3. Breaker switch on LPA is open

4. The LPA is faulty.

DISPLAY MESSAGE FORCED/INTERNAL SHUTDOWN Alarm Type: LOOP FAIL

PROBLEM: Internal fault detected in the LPA.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

3. Reset breaker switch.

4. Replace LPA.

1. The LPA has failed. 1. Replace LPA

DISPLAY MESSAGE FORCED/INTERNAL SHUTDOWN Alarm Type: DC FAIL

PROBLEM: Internal fault detected in the LPA.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. The LPA has failed. 1. Replace LPA

DISPLAY MESSAGE FORCED/INTERNAL SHUTDOWN Alarm Type: LOW POWER ALARM

PROBLEM: Internal fault detected in the LPA.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. The LPA has failed. 1. Replace LPA

DISPLAY MESSAGE FORCED/INTERNAL SHUTDOWN Alarm Type: FANFAIL

PROBLEM: Internal fault detected in the LPA.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Both LPA fans have failed. 1. Replace both LPA fans. To reset, use EMS to

place Digiv ance system in standby mod e and

then pl ac e s y ste m b ac k in no rmal mode .

© 2004, ADC Telecommunications, Inc.

Page 4-13

Page 22

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

Table 4-8. 35 Watt LPA Fault Isolation and Corrective Action, continued

DISPLAY MESSAGE FORCED/INTERNAL SHUTDOWN Alarm Type: OVER POWER ALARM

PROBLEM: Output power from the LPA exceeds the maximum rating.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. The power level of the RF forwar d path

composite input signal at the HU is too high.

2. The LPA has failed.

DISPLAY MESSAGE FORCED/INTERNAL SHUTDOWN Alarm Type: VSWR ALARM

PROBLEM: The VSWR exceeds threshold setting of 3:1.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. The interface cable between the LP A and STM

is faulty or the interface cable co n nectors are

faulty.

2. The antenna cable or antenna cable connectors

are faulty.

1. Check the power level of the RF composite input

signal at the H U and adjust to correct level. To

reset, use EMS to place Digivance system in

standby mode and then place system back in

normal mode.

2. Replace LPA.

1. Inspe ct interface cable and connectors and repair

or replace as needed.To reset, use EMS to place

Digi vance syst em in standby mode and then place

system back in normal mode.

2. Inspect ante nna cable and connectors and repair

or replace as needed.To reset, use EMS to place

Digi vance syst em in standby mode and then place

system back in normal mode.

3. The antenna or antenna s ystem is faulty.

4.The STM qudraplexer has failed.

5. The LPA has failed.

3. Check the antenn a ci rcuit for shorts or opens

(in cluding lightning protector). To reset, use EMS

to place Digiv ance system in standb y mode and

then place sy stem back in no r mal mode.

4. Replace STM.

5. Replace LPA

Page 4-14

© 2004, ADC Telecommunications, Inc.

Page 23

4 TEST PROCEDURES

This section provides procedures for common troubleshooting and maintenance tests. Refer to

these proced ures as need ed when s peci fied in the Fault/A larm Isolation Diag r ams in Section 3.

4.1 Optical Power Test

A break in an optical fiber or a fault with the optical connector will interrupt communications

between linked compon ents or generate excessive errors. Use the following procedu re to isolate

a problem with an optical f iber or connector .

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the ey e. Do not look into the e nds of any optical fiber. Do not

look directly into the optical transmitter of any unit or exposure to laser radiation may result.

An optical power meter should be used to verify active fibers. A protective cap or hood MUST

be immediately placed over any radiating transmitter or optical fiber connector to avoid the

potential of dangerous amounts of radiation exposure. This practice also prevents dirt particles

from ente ring the connector.

1. Put on the IR filtering sa fety glasses.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

2. Notify the NOC or alarm monitoring system oper ator that the system is going offline.

3. At the HU and at the STM, place the On/Off switches in the OFF position (press O).

Note: Turning off the HU and STM disables the respective lasers which is necessary in

order to safely inspect and clean the optical connectors.

4. Disconnect the optical fiber connectors for the fiber to be tested at the HU and the STM.

5. Inspect the optical connectors. Verify that connectors are clean and that no scratches or

imperfections are visible on the fiber end. Clean and polish the optical connectors if necessary .

6. Connect the optical power meter to the output (rece iver) end of the o pt ic al fiber as shown

in Figure 4-2. If an attenuator was included in the fiber link, make sure the attenuator is

installed.

FORWARD PATH OPTICAL FIBER

TEST SET UP

FORWARD PATH

OPTICAL FIBER

REVERSE PATH

OPTICAL FIBER TEST SET UP

REVERSE PATH

PATH OPTICAL FIBER

ATTENUATOR

(IF USED)

(PORT 1)

OPTICAL POWER

FWD

METER

-15 TO -25 dBm

STM

REV

(PORT 2)

20017-A

FWD

(PORT 1)

OPTICAL POWER

-13 TO -25 dBm

HOST UNIT

REV

(PORT 2)

METER

ATTENUATOR

(IF USED)

Figure 4-2. Forward and Reverse Path Optical Fiber Test Set Up

© 2004, ADC Telecommunications, Inc.

Page 4-15

Page 24

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

7. Connect the input (transmitter) end of the optical fiber to the transmitting HU or STM

(see Figure 4-2).

8. At the transmitting HU or STM, place the On/Off switch in the ON position (press I).

9. Using the transmitting HU or STM as an optical light source, measure the optical power

at the receiver end of the optical fiber. The power level of the optical input signal at the

HU or STM must fall within the follo wing ranges:

Forward Pa th Signal at the STM: –15 to –25 dBm (with attenuator installed)

Reverse Path Signal at the HU: –13 to –25 dBm (with attenuator installed)

If the power level of the recei ved optical signal is within the specified range, the optical

fiber and the far end unit are good. If the power level of the received signal is not with

the specif ied range, e ither the opt ical f iber is faulty or the far end unit optica l transmitt er

is faulty. Continue with test pr ocedure to isolate the problem

10. At the transmitting HU or STM, place the On/Off switch in the OFF position (press O).

11. Disconnect the optica l power meter from the receiver end of the optical fiber.

12. Use a 1 meter patch cord to connect the optical power meter to the transmitting HU or

STM as shown in Figure 4-3.

FWD

(PORT 1)

OPTICAL POWER

+2 +/- 1 dBm

Figure 4-3. Host Unit and STM Optical Transmitter Test Set Up

HOST UNIT

HOST UNIT OPTICAL TRANSMITTER

REV

(PORT 2)

STM OPTICAL TRANSMITTER

METER

1 METER PATCH CORD

TEST SET UP

1 METER PATCH CORD

TEST SET UP

OPTICAL POWER

FWD

(PORT 1)

METER

0 +/- 1 dBm

STM

REV

(PORT 2)

20018-A

13. At the transmitting HU or STM, place the On/Off switch in the ON position (press I).

14. Measure the optical output power of the transmitting HU or STM. The power level of the

optical output signal from the HU or STM must meet the following specification:

Forward Path Signal at the HU: 0 +

Reverse Path Signal at the STM: +2 +

If the power level of the optical output signal is within specifications with a 1 meter

patch cord installed, the fiber optic link is faulty. If the power level of the optical signal

is not within specifications, the far end HU or STM optical transmitter is faulty.

Page 4-16

© 2004, ADC Telecommunications, Inc.

1 dBm

1 dBm

Page 25

15. At the transmitting HU or STM, place the On/Off switch in the OFF position (press O).

16. Disconnect the optica l power meter from the receiver end of the optical fiber.

17. Reconnect the optical fibers to the receiving HU or STM.

18. Repeat steps 3 through 17 for each optical fiber that requires testing.

19. When ready to put the system back into service, place the On/Off switch in the ON

position (press I) at both the HU and STM.

20. Notify the NOC or alarm monitoring servi ce that the system is going back online.

4.2 Optical Loopback Test

The following procedures provide tests to determine if an optical port fault exists with the Host

Unit or with the STM.

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the ey e. Do not look into the e nds of any optical fiber. Do not

look directly into the optical transmitter of any unit or exposure to laser radiation may result.

An optical power meter should be used to verify active fibers. A protective cap or hood MUST

be immediately placed over any radiating transmitter or optical fiber connector to avoid the

potential of dangerous amounts of radiation exposure. This practice also prevents dirt particles

from ente ring the connector.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

1. Put on the IR filtering sa fety glasses.

2. Notify the NOC or alarm monitoring system oper ator that the system is going offline.

3. At the HU or STM (whichever unit is being tested), place the On/Off switch in the OFF

position (press O).

4. Disconnect the optical fiber connectors from the FWD (PORT 1) and REV (PORT 2)

optical ports and place a dust cap over each connector.

5. Plug a 15 dB in-line optical attenuator into the FWD (PORT 1) optical port as shown in

Figure 4-4.

HOST UNIT OR STM

FWD

(PORT 1)

15 dB

ATTENUATOR

1 METER PATCH CORD

Figure 4-4. Host Unit and STM Loopback Test

REV

(PORT 2)

20019-A

© 2004, ADC Telecommunications, Inc.

Page 4-17

Page 26

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

6. Connect a 1 meter patch cord between the optical attenuator and the REV (PORT 2)

optical port.

7. Place the On/Off switch in the ON position (press I) and observe the FWD/REV (PORT 1/

POR T 2) LED indicator.

8. The FWD/REV (POR T 1/PORT 2) LED indicator will turn either red or green. If the LED

turns red, either the FWD (PORT 1) optical transmitter or the REV (PORT 2) receiver is

faulty. If the LED turns green, both the FWD (PORT 1) and the REV (PORT 2) optical

ports are good.

9. Place the On/Off switc h in the OFF position (press O).

10. Remove the dust caps from the optical fiber connectors.

11. Clean each connector (follow connector supplier’s recommendations) and then insert each

connector into the appropriate optical port.

12. When ready to put the unit back into service, place the On/Off switch in the ON position

(press I).

13. Notify the NOC or alarm monitoring servi ce that the system is going back online.

Page 4-18

© 2004, ADC Telecommunications, Inc.

Page 27

5 SCHEDULED MAINTENANCE REQUIREMENTS

Table 4-9 specifies the system maintenance requirements and the recommended maintenance

interval for each maintenance task. Refer to the manual specified in the table for the required

maintenance procedure.

Table 4-9. Scheduled Maintenance

INTERVAL ITEM REQUIREMENT

1 month Battery* Check float voltage.

6 months Battery* Perform 1 month scheduled maintenance tasks.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

Check system ambi en t temperature.

Check system float current.

Check individual battery te rmi nal temperature.

Check individual battery float voltages .

12 months Bat tery *

Perform 1 and 6 month scheduled maintenance tasks

Complete detailed physical inspection.

Re-torque terminal connections.

Perform general system maintenance.

Perform cabinet maintenance.

RU cabinet filter**

Remov e and clean the RU cabinet fi lter. Refer to the appropriate Rem ote Unit Ins t alla tio n and Ma int enanc e Ma nual (s ee

Related Manuals se ction) for the required procedures.

24 months Battery* Perform 1, 6, and 12 month scheduled maintenance tasks.

Test battery system for rat ed capacity.

60 months HU Fans

STM Fan

LPA Fans

Remove and replace the cooling fans in the HU, STM, and

LPA. Refer to the appropriate Installation and Maintenance

Manual (see Related Manuals section) for the require d pr oce dures.

* Refer to the PRC-SERIES OPERATING AND FIELD SERVICE MANUAL (provided with the

back-up battery system) for the specified battery maintenance procedures.

**Though it is not recomm ended tha t the RU be installed i n a salt -air environment , if done s o, clean the

cabinet filter on a monthly basis instead of on a 12 month basis. In addit ion, the RU should be

inspected for corrosion due to salt, partic ularly near the fans and around the connectors. The MTBF of

the RU may be im pacted if the RU is exp o sed to salt-air.

© 2004, ADC Telecommunications, Inc.

Page 4-19

Page 28

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 4: maintenance

Blank

Page 4-20

© 2004, ADC Telecommunications, Inc.

Page 29

SECTION 5: GENERAL INFORMATION

Content Page

1 WARRANTY/SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2 SOFTWARE SERVICE AGREEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3 REPAIR/EXCHANGE POLICY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

4 REPAIR CHARGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5 REPLACEMENT/SPARE PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

6 RETURNED MATERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

7 CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

_________________________________________________________________________________________________________

1 WARRANTY/SOFTWARE

The Product and Software warranty policy and warranty period for all ADC Products is

published in ADC’s Warranty/Software Handbook. Contact the Technical Assistance Center at

1-800-366-3891, extension 73476 (in U.S.A. or Canada) or 952-917-3476 (outside U.S.A. and

Canada) for warranty or software information or for a copy of the Warranty/Software

Handbook.

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 5: General Information

2 SOFTWARE SERVICE AGREEMENT

ADC software service agreements for some ADC Products are available at a nominal fee.

Contact the Technical Assistance Center at 1-800-366-3891, extension 73476 (in U.S.A. or

Canada) or 952-917-3476 (outside U.S.A. and Canada) for software service agreement

information.

3 REPAIR/EXCHANGE POLICY

All repairs of ADC Products must be done by ADC or an authorized representative. Any

attempt to repair or modify ADC Products without written authorization from ADC voids the

warranty.

If a malfunction cannot be resolved by the normal troubleshooting procedures, call the

Technical Assistance Center at 1-800-366-3891, extension 73476 (in U.S.A. or Canada) or

952-917-3476 (outside U.S.A. and Canada). A telephone consultation can sometimes resolve a

problem without the need to repair or replace the ADC Product.

If, during a telephone consultation, ADC determines the ADC Product needs repair, ADC will

authorize the return of the affected Product for repair and provide a Return Material

Authorization number and complete return shipping instructions. If time is critical, ADC can

arrange to ship the replacement Product immediately. In all cases, the defecti ve Product must be

carefully pack a g ed and ret urn ed to AD C.

© 2004, ADC Telecommunications, Inc.

Page 5-1

Page 30

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 5: General Information

4 REPAIR CHARGES

If the defect and the necessary repairs are covered by the warranty, and the applicable warranty

period has not e xpired, the Buyer’s only payment obl igation is to pay the shi pping cost to return

the defective Product. ADC will repair or replace the Product at no charge and pay the return

shipping charges.

Otherwise, ADC will charge a percentage of the current Customer Product price for the repair

or NTF (No Tr ouble Found). If an advance replacement is requested, the full price of a new unit

will be charged initially. Upon receipt of the defective Product, ADC will credit Buyer with 20

percent of full price charged for any Product to be Out-of-Warranty. Products must be returned

within thirty (30) days to be eligible for any advance replacement credit. If repairs necessitate a

visit by an ADC re presentative, ADC will charge the current price of a field visi t plus round trip

transportation charges from Minneapolis to the Buyer’s site.

5 REPLACEMENT/SPARE PRODUCTS

Replacement parts, including, but not limited to, button caps and lenses, la mps, fuses, and patch

cords, are ava il able from ADC on a special order basis. Contact the Technical Assistance Center

at 1-800-366-3891, extension 73476 (in U.S.A. or Canada) or 952-917-3476 (outside U.S.A.

and Canada) for additional information.

Spare Products and accessories can be purchased from ADC. Contact Sales Administration at

1-800-366-3891, extension 73000 (in U.S.A. or Canada) or 1-952-938-8080 (outside U.S.A.

and Canada) for a price quote and to place your order.

6 RETURNED MATERIAL

Contact the ADC Product Return Department at 1-800-366-3891, exte nsion 73748 (in U.S.A. or

Canada) or 952-917-3748 (outside U.S.A. and Canada) to obtain a Return Material

Authorization number prior to returning an ADC Product.

All returned Products must have a Return Material Authorization (RMA) number clearly

marked on t he outside of t he package. The Return Material Aut horization number is valid for 90

days from authorizati on.

Page 5-2

© 2004, ADC Telecommunications, Inc.

Page 31

ADCP-75-179 • Preliminary Issue A • September 2004 • Section 5: General Information

7 CUSTOMER INFORMATION AND ASSISTANCE

PHONE:

EUROPE

Sales Administration: +32-2-712-65 00

Technical Assistance: +32-2-712-65 42

EUROPEAN TOLL FREE NUMBERS

Germany:

UK:

Spain:

France:

Italy: 0800 782374

U.S.A. OR CANADA

Sales: 1-800-366-3891 Extension 73000

Technical Assistance: 1-800-366-3891

Connectivity Extension 73475

Wireless Extension 73476

ASIA/PACIFIC

Sales Administration: +65-6294-9948

Technical Assistance: +65-6393-0739

ELSEWHERE

Sales Administration: +1-952-938-8080

Technical Assistance: +1-952-917-3475

WRITE:

ADC TELECOMMUNICATIONS, INC

PO BOX 1101,

MINNEAPOLIS, MN 55440-1101, USA

0180 2232923

0800 960236

900 983291

0800 914032

ADC TELECOMMUNICATIONS (S'PORE) PTE. LTD.

100 BEACH ROAD, #18-01, SHAW TOWERS.

SINGAPORE 189702.

ADC EUROPEAN CUSTOMER SERVICE, INC

BELGICASTRAAT 2,

1930 ZAVENTEM, BELGIUM

PRODUCT INFORMATION AND TECHNICAL ASSISTANCE:

connectivity_tac@adc.com

wireless.tac@adc.com

euro_tac@adc.com

asiapacific_tac@adc.com

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice.

In no event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period. This publication may be

verified at any time by contacting ADC's Technical Assistance Center.

© 2004, ADC Telecommunications, Inc.

13944-L

All Rights Reserved

Printed in U.S.A .

Page 5-3

Page 32

Blank

Page 33

Page 34

www.adc.com

i

Loading...

Loading...