Page 1

FCC ID: F8I-DISSMRAA, Partial User Manual, 3 of 4

5.

Insert the optical transceiver into the socket until it locks into place.

6.

Replace the optical transceiver dust cap if it was removed for installation.

7.

Repeat procedure for each optical transceiver that requires installation.

8.

Install a port cover (see Figure 18) over each unused optical transceiver socket.

4.8 Ports 1–6 Optical Connections

ADCP-75-136 • Issue 1 • November 2002

The optical interface between the DHU and each DEU or DRU is supported by six optical

ports. Each of the six optical ports provides a duplex LC-type optical transceiver which is

mounted on the DHU front panel. One side of the transceiver provides the optical fiber

connection for the forward path (downlink) signal. The other side of the transceiver provides

the optical fiber connection for the reverse path (uplink) signal. Use the following procedure to

install the forward and reverse path optical fibers and to connect them to the DHU:

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the eye. Do not look into the ends of any optical fiber. Do

not look directly into the optical transceiver of any digital unit or exposure to laser radiation

may result. An optical power meter should be used to verify active fibers. A protective cap or

hood MUST be immediately placed over any radiating transceiver or optical fiber connector

to avoid the potential of dangerous amounts of radiation exposure. This practice also prevents

dirt particles from entering the transceiver or connector.

1.

Obtain the required lengths of single- or multi-mode fiber optic cable.

2.

Route the fiber optic cable between the DHU and the DEU or DRU (if not already

routed) and cut to required length. Allow sufficient slack for dressing and organizing the

cables at each unit. Maintain a minimum bend radius of 2 inches (50 mm).

Note: The maximum path lengths for the optical fibers are as follows: 500 meters (1,641

feet) for 62.5 micron core multi-mode fiber, 750 meters (2,461 feet) for 50 micron core

multi-mode fiber, and 10 km (32,808 ft) for 9 micron core single-mode fiber.

3.

Terminate each optical fiber with a field-installable LC type fiber optic connector as

shown in Figure 19. Follow the instructions provided by the connector manufacturer for

installing the connector.

4.

Test each fiber for optical loss as described in Subsection 6.4.2 of this manual.

5.

Designate one of the fibers as the forward path fiber and the other as the reverse path

fiber and label both ends of each fiber with the path designation.

6.

Use the plastic joiner provided with the LC connectors to join the DHU Port 1 forward

and reverse path connectors together (see Figure 19). Make sure the forward path and

reverse path connectors are oriented as shown.

Note: When viewing any Port 1-6 optical transceiver from the front, the forward path port is

on the left and the reverse path port is on the right as shown in Figure 20. In addition, singlemode transceivers are colored blue and multi-mode transceivers are colored black or beige.

Both single- and multi-mode transceivers may be mounted on the same DHU.

© 2002, ADC Telecommunications, Inc.

Page 33

Page 2

ADCP-75-136 • Issue 1 • November 2002

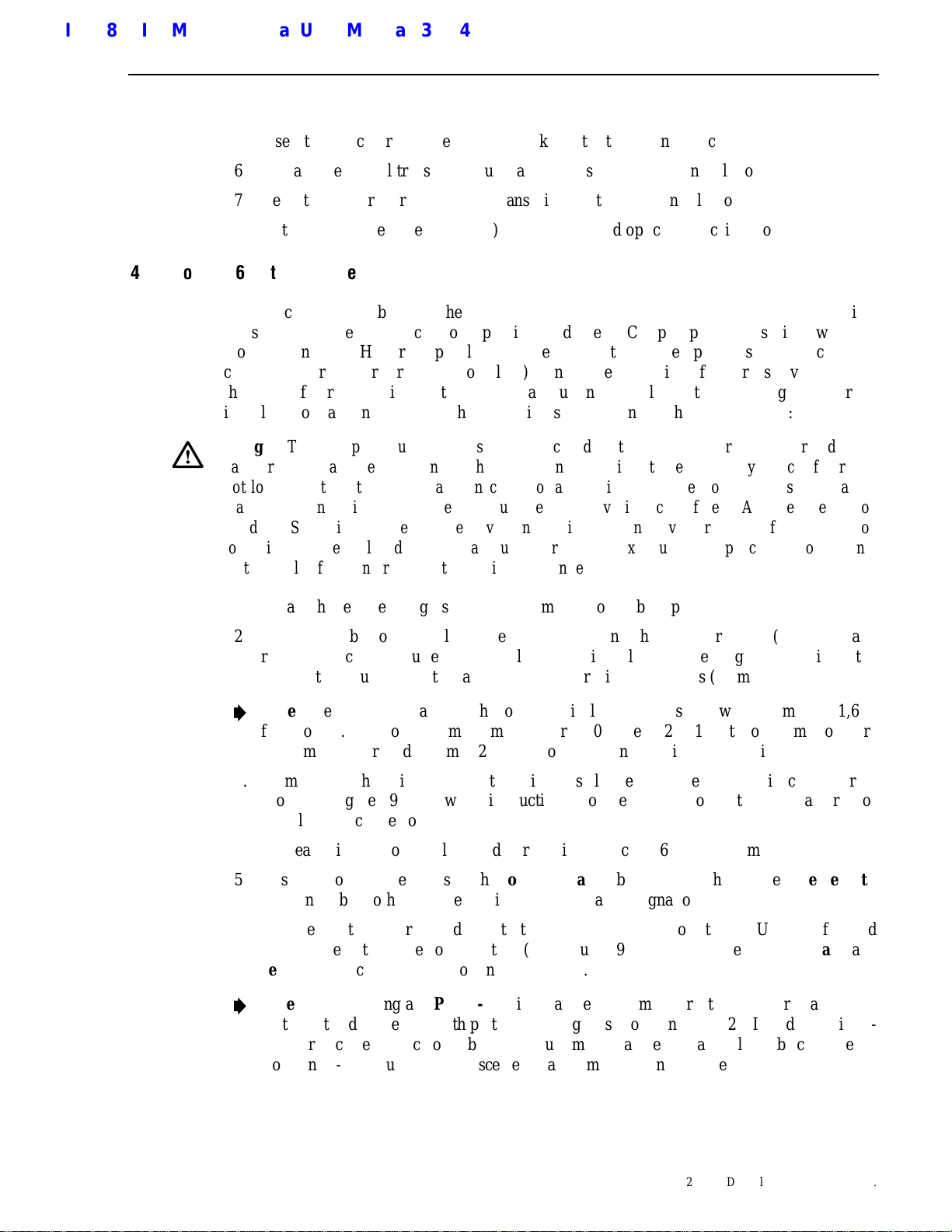

FORWARD PATH (TX)

CONNECTOR

REVERSE PATH (RX)

CONNECTOR

OPTICAL CONNECTOR

ASSEMBLY DETAIL

OPTICAL

CONNECTOR

PORT 1

OPTICAL

TRANSCEIVER

CABLE GUIDE

DETAIL

DESIGNATION CARD AND

HOLDER DETAIL

Figure 19. Ports 1–6 Fiber Optic Cable Connections

TRANSCEIVER COLOR CODE

BLUE = SINGLE-MODE (9 MICRON)

BLACK/

BEIGE = MULTI-MODE (50 OR 62.5 MICRON)

CLEAR

PLASTIC

COVER

CARD

HOLDER

CABLE

GUIDES

17274-A

17150-A

FORWARD

PATH (TX)

Page 34

© 2002, ADC Telecommunications, Inc.

REVERSE

PATH (RX)

DUST CAP (LEAVE IN PLACE

UNTIL READY TO INSTALL CONNECTOR)

DETAIL DRAWING OF

OPTICAL PORT

Figure 20. Optical Transceiver Designations

Page 3

7.

Remove the dust caps from the optical fiber connectors and the port 1 optical transceiver.

Note: Leave the dust cap in place on any unused optical transceiver.

8.

Clean each connector (follow connector supplier’s recommendations) and then insert the

optical fiber connector pair into DHU optical port 1 (see Figure 19).

9.

Place the optical fibers within the cable guides provided on the cable management tray (see

Figure 19) and then dress and secure the fibers at the DHU per standard industry practice.

10. Connect the forward and reverse path optical fibers to the DEU or the DRU as specified

in the instructions provided with that unit.

11. Use the designation card provided (see Figure 19) to indicate the location and name of

the DRU or DEU that is connected to each optical fiber pair. The designation card holder

may be attached to any convenient flat surface such as the DHU cable management tray

12. Repeat steps 1–11 for each remaining optical port.

4.9 DC Power Connections

ADCP-75-136 • Issue 1 • November 2002

The DC power interface between the DHU and each DRU is supported by six RJ-45 female

connectors. Each DHU RJ-45 connector provides nominal 48 Vdc power for the associated

DRU except when the DRU is powered with an ac/dc converter. A category 3 or 5 twisted pair

cable is used to feed the power from the DHU to the DRU. Use the following procedure to

install the DC power cable and to connect it to the DHU.

1.

Obtain the required length of category 3 or 5 twisted pair cable.

2.

Route the cable between the DHU and the DRU (unless already routed) and then cut to

required length. Allow sufficient slack for dressing and organizing the cable at the DHU.

Note: The maximum distance for routing power cable is 500 meters (1,641 feet).

3.

Terminate each end of the cable with a male RJ-45 connector. Match the wire color to

the connector pin as specified in Table 6.

Caution: The DRU will be damaged if the RJ-45 connector is wired incorrectly.

4.

Perform a continuity test to verify that each wire is properly connected to the terminating

RJ-45 connector and check the connector for correct polarity (see diagram in Table 6).

Table 6. RJ-45 Connector Pin Designations

PIN NUMBER WIRE COLOR CONNECTOR PINS

1

2

3

4

5

6

7

8

White/Green

Green

White/Orange

Orange

White/Blue

Blue

White/Brown

Brown

+48 VDC ON PINS 1, 3, 5, AND 7

RETURN ON PINS 2, 4, 6, AND 8

PIN

PIN

8

1

16180-A

© 2002, ADC Telecommunications, Inc.

Page 35

Page 4

ADCP-75-136 • Issue 1 • November 2002

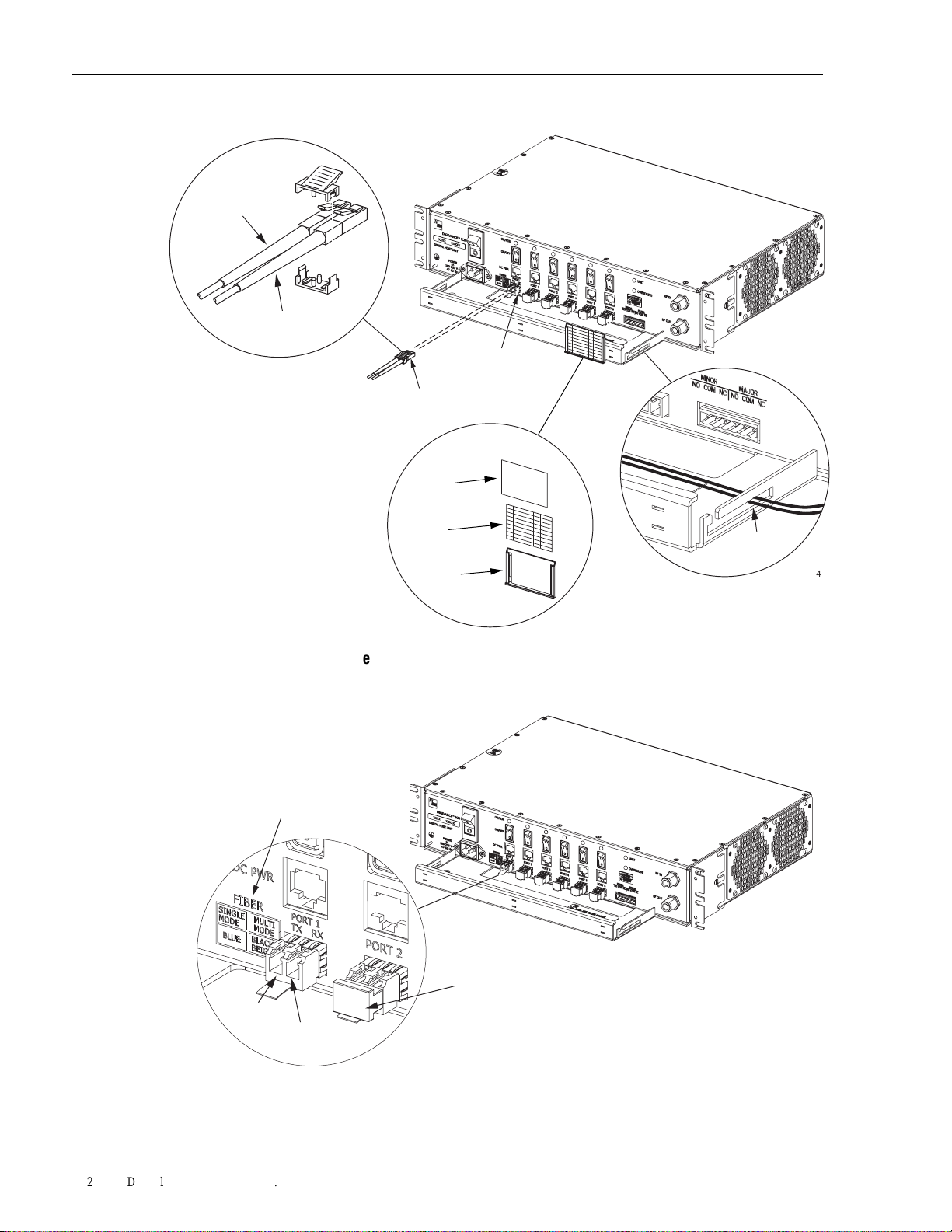

5.

Connect the DC power cable to the DHU port 1 DC PWR jack as shown in Figure 21.

6.

Place the DC power cable within the cable guides provided (see Figure 21) and then

dress and secure the cable at the DHU per standard industry practice.

RJ-45 CONNECTOR

DETAIL

1

8

CONNECTOR

Figure 21. 48 Vdc Power Cable Connection

7.

Connect the DC power cable to the DRU as specified in the instructions provided with

that unit.

8.

Repeat steps 1–7 for each remaining DRU that will be powered by the DHU.

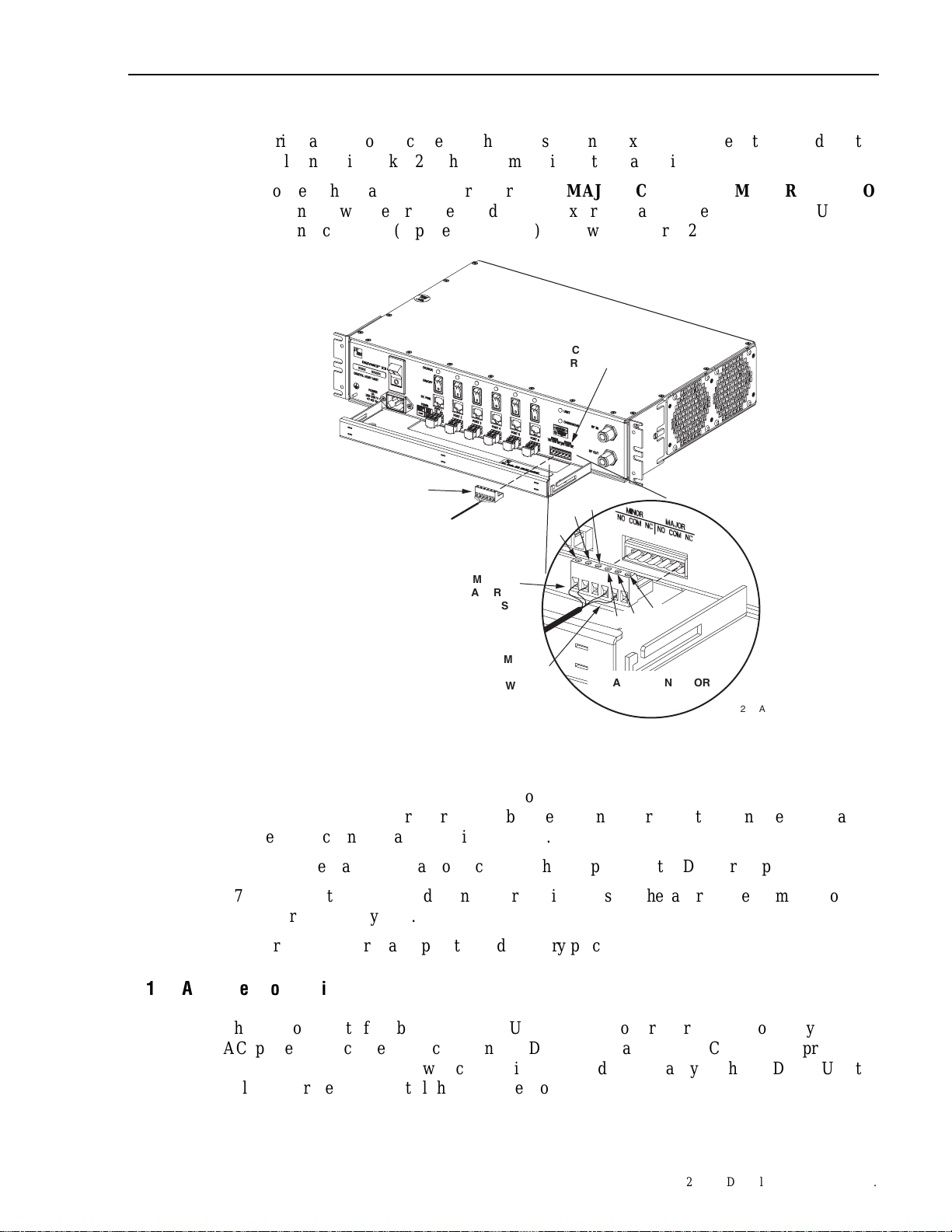

4.10 External Alarm System Connections

The alarm interface between the DHU and an external alarm system is supported by a sixterminal plug (with screw-type terminals) that connects to a receptacle mounted on the DHU

front panel. The terminal plug provides connections to normally open (NO) and normally

closed (NC) dry type alarm contacts for both minor and major alarms. A category 3 or 5 cable

is typically used to connect the DHU to the external alarm system. Use the following

procedure to install the alarm wiring and connect it to the DHU:

RJ-45

PORT 1

DC POWER

CONNECTOR

CABLE GUIDE

DETAIL

17275-A

CABLE

GUIDES

1.

Obtain the required length of category 3 or 5 cable.

2.

Route the cable between the DHU and the external alarm system (if not already routed)

and then cut to required length. Allow sufficient slack for dressing and organizing the

cable at the DHU.

Page 36

© 2002, ADC Telecommunications, Inc.

Page 5

ADCP-75-136 • Issue 1 • November 2002

3.

Strip back the outer cable sheath and insulation to expose the wires at both ends of the

cable and strip back 0.2 inches (5 mm) of insulation each wire.

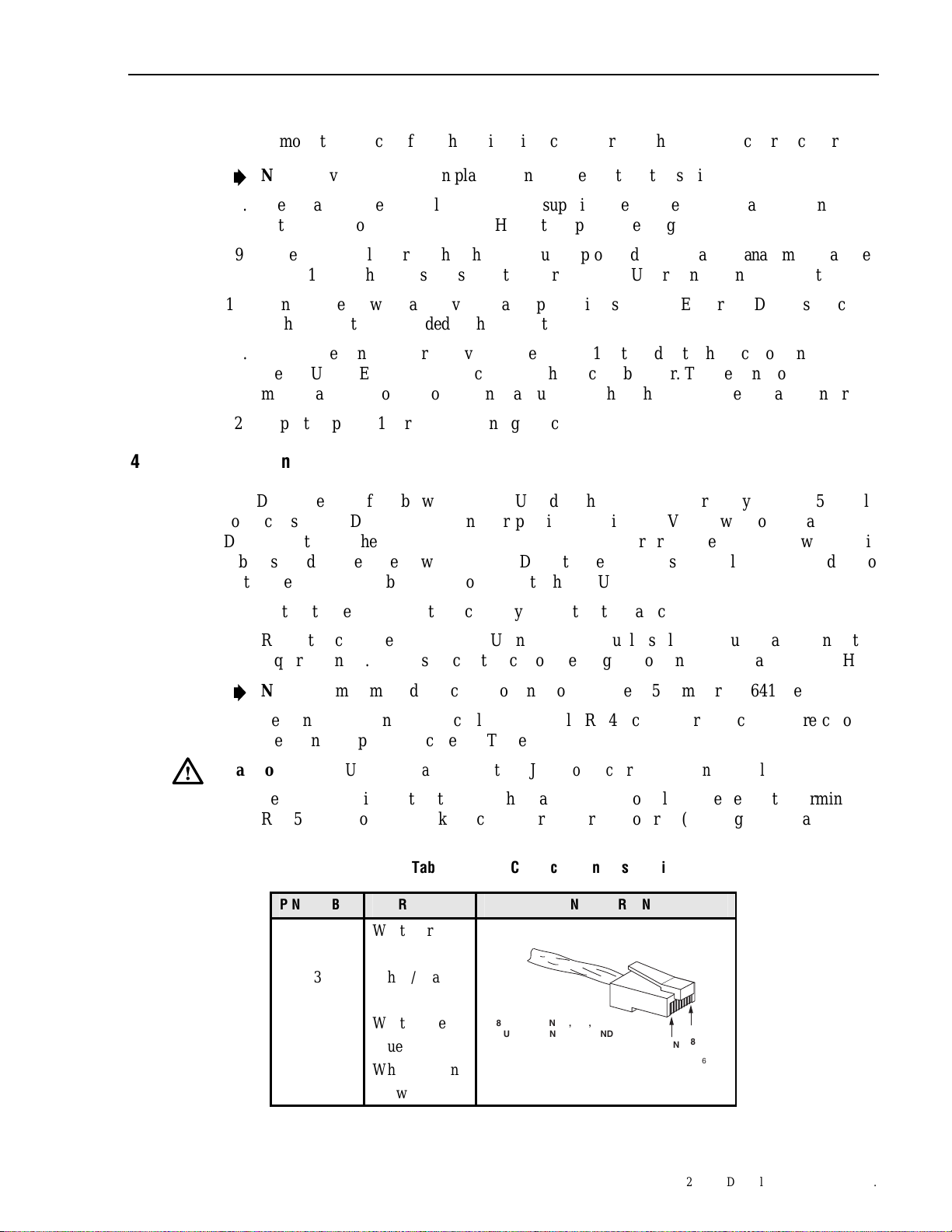

4.

Connect the Major alarm wire pair to the MAJOR COM/NC or MAJOR COM/NO

terminals (whichever is required by the external alarm system) on the DHU alarm

terminal connector (supplied with DHU) as shown in Figure 22.

ALARM

CONNECTOR

RECEPTACLE

ALARM

CONNECTOR

MINOR

ALARM

WIRES

MAJOR

ALARM

WIRES

NO

MINOR

NC

COM

NO

ALARM CONNECTOR

COM

MAJOR

DETAIL

NC

17278-A

Figure 22. External Alarm System Connections

5.

Connect the Minor alarm wire pair to the MINOR COM/NC or MINOR COM/NO

terminals (whichever is required by the external alarm system) on the DHU alarm

terminal connector as shown in Figure 22.

6.

Insert the alarm terminal connector into the receptacle on the DHU front panel.

7.

Connect the Major and Minor alarm wire pairs to the appropriate terminals on the

external alarm system.

8.

Dress and secure cable per standard industry practice.

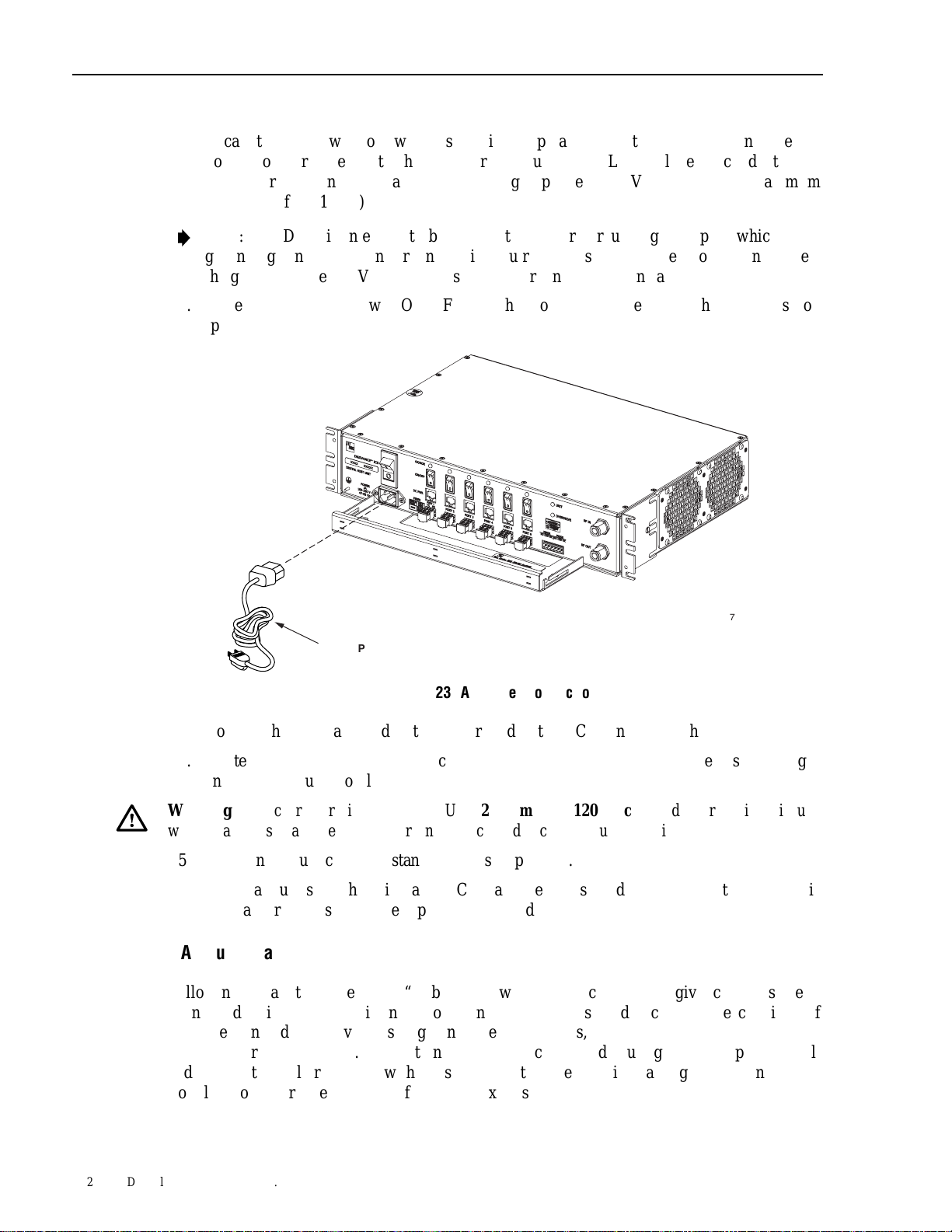

4.11 AC Power Connections

The AC power interface between the DHU and the AC power source is supported by a 3-wire

AC power cord connector located on the DHU front panel. The AC connector provides a

connection point for the power cord which is provided separately with the DHU. Use the

following procedure to install the AC power cord:

© 2002, ADC Telecommunications, Inc.

Page 37

Page 6

ADCP-75-136 • Issue 1 • November 2002

1.

Locate the AC power cord which is provided separately with the DHU. Use only the AC

power cord provided with the DHU or an equivalent UL/CUL listed 3-conductor, 18

AWG cord terminated in a molded-on plug cap rated 125 V, 15 A with a maximum

length of 6 feet (1.8 m).

Note: The DHU is intended to be used with a 3-wire grounding type plug which has a

grounding pin. Equipment grounding is required to ensure safe operation. Do not defeat

the grounding means. Verify DHU is reliably grounded when installed.

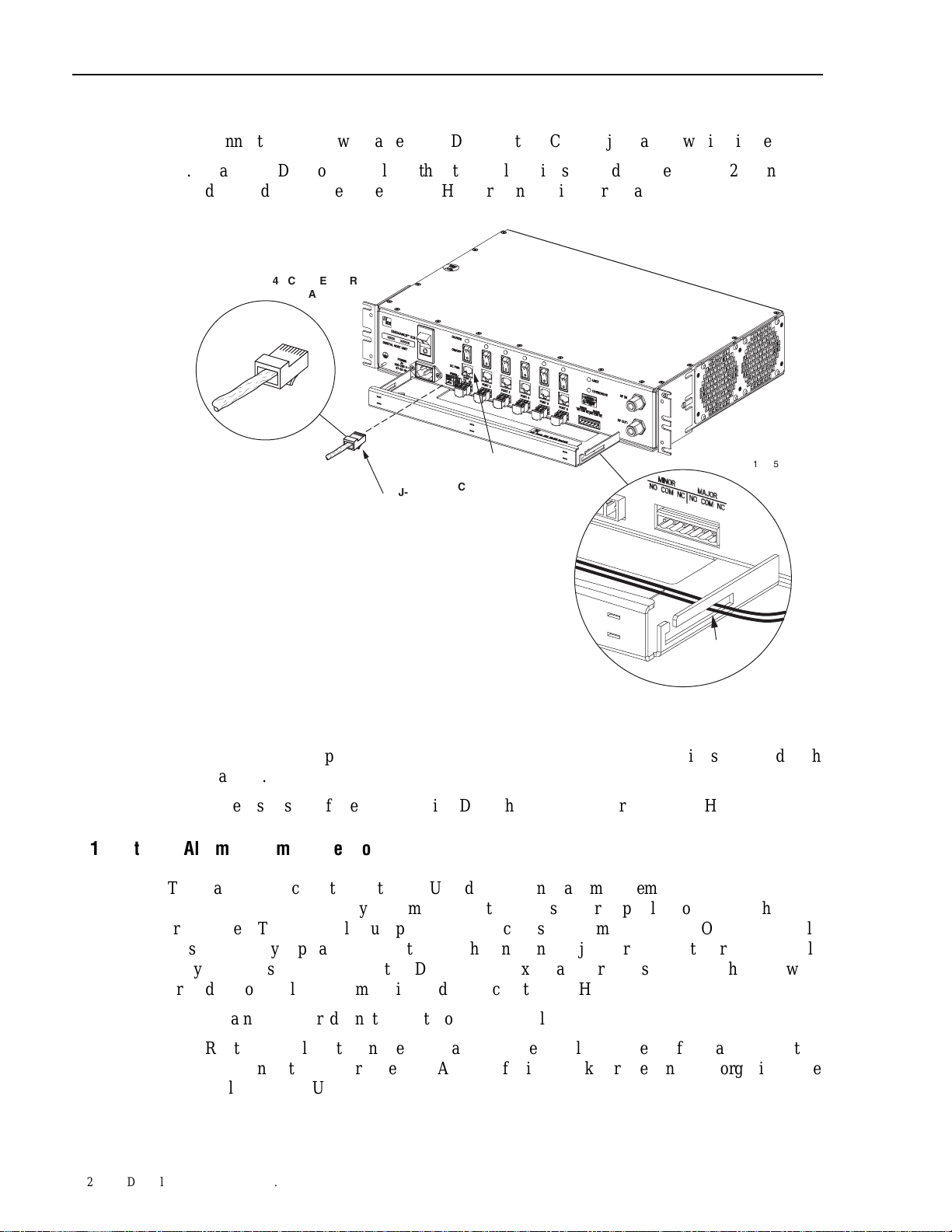

2.

Place the DHU AC power ON/OFF switch, shown in Figure 23, in the OFF position

(press O).

3.

Connect the receptacle end of the power cord to the AC connector on the DHU.

4.

Route the plug end of the power cord to the specified AC outlet (per the system design)

and connect plug to outlet.

Warning: The current rating of the DHU is 2.0 Amps at 120 Vac. Avoid overloading circuits

which may cause damage to over-current protection devices and supply wiring.

5.

Dress and secure cable per standard industry practice.

6.

When all units of the Digivance ICS have been installed, refer to Section 4 of this

manual for the system power up and test procedures.

4.12 Create As-Built Drawing

Following installation, create an “as-built” drawing of the complete Digivance ICS system.

Using a drawing of the building floor plan, show the installed location of each piece of

equipment including the various Digivance electronic units, the antennas, the interface units,

and the microcell (if used). In addition, show the location and routing of all copper, coaxial,

and fiber optic cable runs used with the system. Retain the as-built drawing for reference when

troubleshooting or when planning for system expansion.

17276-A

AC POWER CORD

Figure 23. AC Power Connection

Page 38

© 2002, ADC Telecommunications, Inc.

Page 7

5 SYSTEM OPERATION

ADCP-75-136 • Issue 1 • November 2002

This section provides guidelines for turning-up the Digivance ICS, verifying that all units are

operating properly, testing to ensure that all performance requirements are satisfied, and

correcting any installation problems. This process assumes that the various units that comprise

the Digivance ICS have been installed in accordance with the system design plan and the BTS

interface device has been installed and tested.

5.1 Tools and Materials

The following tools and materials are required in order to complete the procedures in this

section:

• Portable spectrum analyzer

• Portable test transmitter

• Cell phone

• Pencil or pen

• Writing pad

5.2 Turn-Up System and Verify Operation

The process of turning-up the system and verifying operation involves powering up the

various system components and then verifying that the LED indicators show normal operation.

Refer to Tables 7, 8, and 9 as needed for a complete description of the unit LED indicators.

Use the following procedure to power-up the system. If any unit does not respond as

described, refer to Subsection 5.3 for the correction procedures.

1.

Temporarily disconnect the alarm system or notify alarm system provider that testing is

in progress.

2.

Verify that each AC powered unit is connected to the appropriate outlet.

3.

Place the ON/OFF switch on the DHU in the ON position (press I).

4.

Verify that the UNIT LED and the OVERDRIVE LED on the DHU turn yellow (for

approximately 6 seconds) and then green.

5.

Place the PORT 1 ON/OFF switch on the DHU in the ON position (press I).

6. If a

DEU is connected to port 1, proceed to step 7. If a DRU is connected to port 1, skip

steps 7 and 8 and proceed to step 9.

7.

Place the ON/OFF switch on the DEU in the ON position (press I).

8.

Verify that the UNIT LED on the DEU turns yellow (for approximately 6 seconds) and

then green.

9.

Verify that the PORT 1 OK/NOK LED on the DHU turns yellow (for approximately 6

seconds) and then green.

10. If a DEU is connected to PORT 1, proceed to step 11. If a DRU is connected to PORT 1,

skip steps 11 through 13 and proceed to step 14.

© 2002, ADC Telecommunications, Inc.

Page 39

Page 8

ADCP-75-136 • Issue 1 • November 2002

11. Verify that the HOST PORT LED on the DEU turns green.

12. Place the PORT 1 ON/OFF switch on the DEU in the ON position (press I).

13. Verify that the PORT 1 OK/NOK LED on the DEU turns yellow (for approximately six

seconds) and then green.

14. Verify that the STATUS LED on the DRU connected to PORT 1 turns yellow (for

approximately six seconds) and then green.

15. Repeat the procedure covered in steps 5 through 14 for each of the remaining DHU

optical ports (ports 2 through 6) that is connected to a DEU or a DRU.

16. Reconnect the alarm system and notify alarm system provider that system is operational.

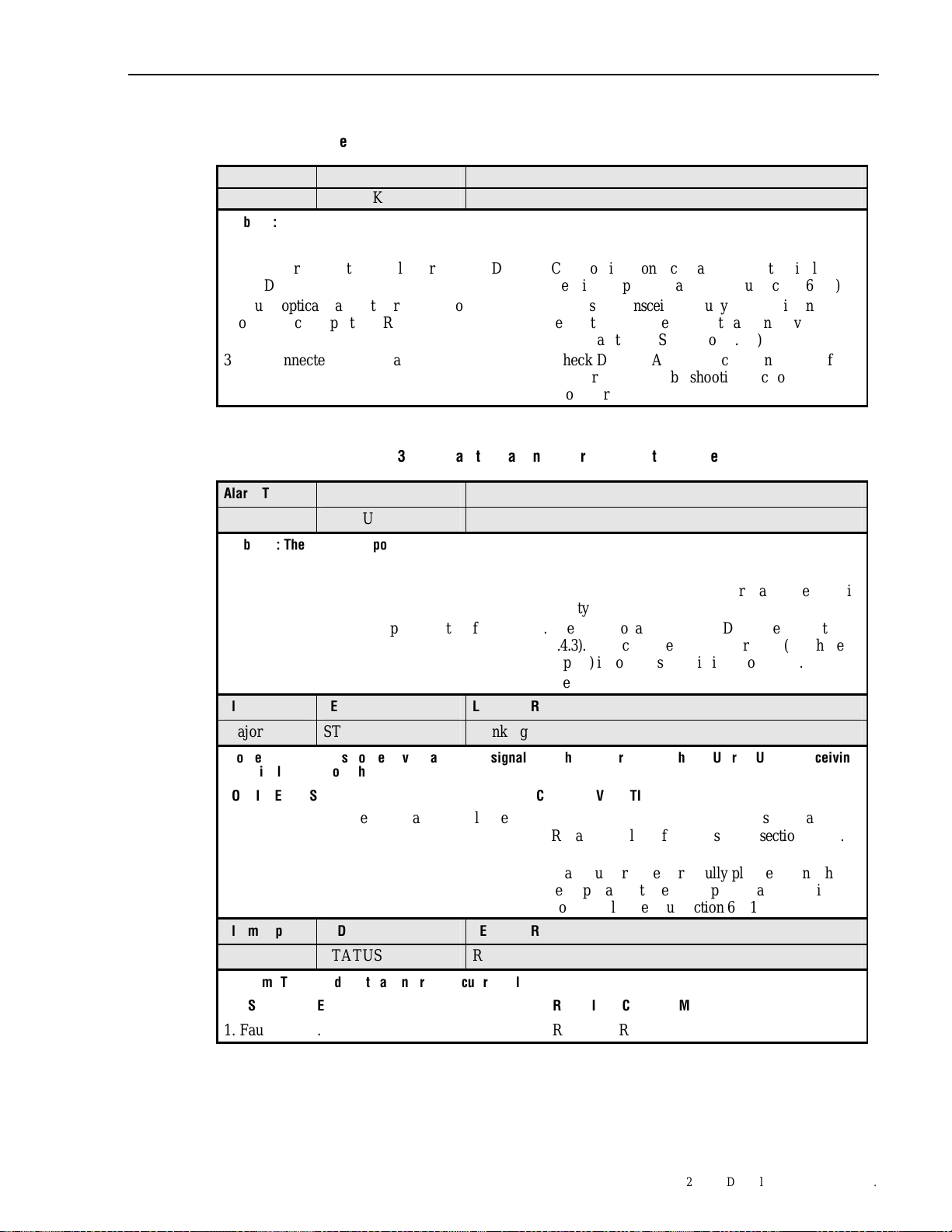

INDICATOR COLOR DESCRIPTION

Table 7. Digital Host Unit LED Indicators

UNIT

LED

PORT 1–6

OK/NOK

LEDs

OVERDRIVE

LED

Note: Detection of any fault will generate an alarm. A high temperature fault will generate a minor

alarm (yellow LED). All other types of faults will generate a major alarm (red LED).

Green

Yellow

Red

Off

Green

Yellow

Red

(steady)

Red

(blinking)

Off

Green

Red

Indicates when the DHU is normal or faulty.

DHU in normal state, no faults detected.

DHU high temperature fault detected. (see Note)

DHU fault detected (see Note).

AC power off to DHU or DHU internal fault.

Indicates if any connected DEU or DRU is normal or faulty or if the

optical inputs from any connected DEU or DRU are normal or lost.

All connected units in normal state, no faults detected.

High temperature fault detected in connected DEU. (see Note)

Fault detected in a connected DEU or DRU. (see Note)

No reverse path optical signal detected from a connected DEU or DRU or

excessive reverse path errors detected from a connected DEU or DRU.

(see Note)

Port disabled (via front panel switch) or DHU internal fault.

Indicates when the forward path RF input is below or above the

overdrive threshold.

RF input signal level at DHU below overdrive threshold.

RF input signal level at DHU above overdrive threshold.

Page 40

© 2002, ADC Telecommunications, Inc.

Page 9

ADCP-75-136 • Issue 1 • November 2002

Table 8. Digital Expansion Unit LED Indicators

INDICATOR COLOR DESCRIPTION

UNIT

LED

HOST PORT

LED

PORT 1–6

OK/NOK

LEDs

Green

Yellow

Red

Off

Green

Red

(blinking)

Off

Green

Yellow

Red

(steady)

Red

(blinking)

Off

Indicates when the DEU is normal or faulty.

DEU in normal state, no faults detected.

DEU high temperature fault detected. (see Note)

DEU internal fault detected. (see Note)

AC power off to DEU or DEU internal fault.

Indicates when the optical inputs from the DHU or supporting

DEU are normal or lost.

DHU or supporting DEU in normal state, no faults detected.

No forward path optical signal detected from DHU or supporting DEU

or excessive forward path errors detected from DHU or supporting

DEU. (see Note).

DEU internal fault.

Indicates if any connected DEU or DRU is normal or faulty or if the

optical inputs from any connected DEU or DRU are normal or lost.

DRU or remote DEU in normal state, no faults detected.

High temperature fault detected in connected DEU. (see Note)

Fault detected in a connected DEU or DRU. (see Note)

No reverse path optical signal detected from a connected DEU or DRU

or excessive reverse path errors detected from a connected DEU or

DRU.

Port disabled (via front panel switch) or DEU internal fault.

Note: Detection of any fault will generate an alarm. A high temperature fault will generate a minor

alarm (yellow LED). All other types of faults will generate a major alarm (red LED).

Table 9. Digital Remote Unit LED Indicator

INDICATOR COLOR DESCRIPTION

STATUS

LED

Green

Red

(steady)

Red

(blinking)

Off

Note: Detection of any fault will generate an alarm. A high temperature fault will generate

Indicates if the DRU is normal or faulty or if the forward path optical

inputs to the DRU are normal or lost.

DRU in normal state, no faults detected.

DRU internal fault detected. (See Note)

No forward path optical signal from the DHU or DEU detected.

DC power off to DRU or DRU internal fault.

a minor alarm (yellow LED). All other types of faults will generate a major alarm (red LED).

© 2002, ADC Telecommunications, Inc.

Page 41

Page 10

ADCP-75-136 • Issue 1 • November 2002

5.3 Test System Performance

Testing the performance of the system involves completing various RF tests and telephone

service tests that verify if the system is functioning properly. Use the following procedure to

test the system performance:

1. Verify that the forward path (downlink) input signal level at the DHU is optimized. The peak

COMPOSITE forward path input signal level at the DHU should be set at –20 dBm.

Note: In a CDMA system, the power level is dependent on the traffic. For optimum

operation in a CDMA system, the input signal level should be set below the level of the

pilot signal.

2.

Verify that the reverse path (uplink) signal level at the local BTS or donor antenna is

optimized. Note that the reverse path output signal level required is dependent on service

provider signal to noise requirements, ICS system noise floor, the service provider

equipment, and the system configuration.

3.

Check and record the Received Signal Strength Indication (RSSI) and any spurious

emission levels at and between all DRU antennas. Analyze all DRU’s and the DHU

interface using a spectrum analyzer.

4.

Plot the RSSI levels on a floor plan of the building and check against the pre-installation

RSSI levels to determine the overall and average RSSI improvement attributed to the

Digivance ICS. Check the entire Digivance coverage area.

5.

Verify call processing and voice quality within the coverage areas. Initiate and receive

multiple long and short duration calls. Document the performance and address any issues

as calls are processed within the entire coverage area. Assuming a properly functioning

server RF link and BTS and a properly designed and optimized ICS system, there should

be no clicks, mutes, clipping, or crackles within the coverage area. In a wireless office

application, hand off will not occur.

6. If

the DHU interfaces with a local BTS (microcell), verify the handoff function by

placing a call and confirming handoffs between the Digivance/microcell coverage area

and the outdoor macrocell coverage area (macro system) and vice versa. The handoff

should take place without any noticeable call quality or performance issues.

7. If

the DHU interfaces with a remote BTS through a donor antenna, verify call quality by

placing a call and then walking between the Digivance coverage area and an area

receiving good coverage directly from the cell site base station. There should be no

noticeable difference in call quality.

8.

Following service provider guidelines, test the 411 and 911 links to verify the routing of

emergency and special services calls on local BTS configurations.

9.

Verify that the alarm reporting system functions properly by turning the DHU off. This

should generate a major and minor alarm and operate both the major and minor alarm

contacts. Check for alarm confirmation from the service provider’s local switch and

Network Operations Center (NOC). Note that this tests only the external alarm system

and does not verify operation of the Digivance alarm reporting system.

Page 42

© 2002, ADC Telecommunications, Inc.

Page 11

6 SYSTEM MAINTENANCE PROCEDURES

ADCP-75-136 • Issue 1 • November 2002

This section explains the alarm reporting system, provides a method for isolating and

troubleshooting faults, and provides procedures for replacing the modular transceivers and the

DHU or DEU cooling fans.

The Digivance ICS requires no regular maintenance to insure continuous and satisfactory

operation. Maintenance, as it applies to the Digivance ICS, primarily involves diagnosing and

correcting service problems as they occur. When an alarm is reported, it will be necessary to

follow a systematic troubleshooting procedure to locate the problem. Once the source of the

problem is isolated, the appropriate corrective action can be taken to restore service. The only

unit components that can be replaced are the cooling fans that mount in the DHU and DEU

and the modular optical transceivers. The failure of any other component within a unit will

require replacement of that unit.

6.1 Tools and Materials

The following tools and materials are required in order to complete the procedures in this

section:

• ESD wrist strap

• IR filtering safety glasses

• Optical loopback device (such as Stratos Lightwave LC5 series) and LC duplex adapter

• Optical power meter

• Magnification device for inspecting LC connectors

• Laser light source

• Multimeter

• Cell phone

• RJ-45 circuit access tool (such as the Harris 8-wire Banjo Adapter)

• Medium and small size flat-bladed screwdrivers

• TORX screwdriver (T10)

6.2 Fault Detection and Alarm Reporting

Detection of a fault by the Digivance ICS will generate an external alarm response. LED

indicators are provided on the front panel of the various units to indicate when a fault is

detected. In addition to LED indicators, the DHU also provides normally open (NO) and

normally closed (NC) dry alarm contacts for reporting minor and major alarms to an external

alarm system. A minor alarm is defined as a high temperature condition. A major alarm is

defined as any fault condition except high temperature.

When the DHU alarm contacts are connected to an external alarm system, detection of a fault

will generate an alarm at the Network Operations Center (NOC). However, various types of

faults may not generate an alarm response. In this case, the first indication of a problem will

probably be from cell phone users reporting a loss of service or poor service. Whenever a

problem is reported, whether by a external alarm system or by a call from a user, refer to

Subsection 6.3 to isolate and correct the fault.

© 2002, ADC Telecommunications, Inc.

Page 43

Page 12

ADCP-75-136 • Issue 1 • November 2002

6.3 Fault Isolation and Troubleshooting

Fault isolation and troubleshooting guidelines are provided in Tables 11, 12, 13, and 14. When an

alarm is reported, determine the type of alarm generated (minor or major) and then check the LED

indicators on the DHU and note any that are red, yellow, or off. If any of the Port 1–6 OK/NOK

LED indicators on the DHU are red or yellow, also check the LED indicators on the connected

DEU’s and/or DRU’s and note if any are red or yellow. Start the troubleshooting process at the

DHU and then work toward the unit where the alarm originated. The troubleshooting tables are

organized according to unit type. Locate the problem in the appropriate table, check out the

suggested possible causes, and take corrective action as required.

Figure 24 shows two basic ICS system configurations. The troubleshooting tables list possible

causes for various problems. If the cause of a particular problem is specific to either of the two

system configurations shown in Figure 24, the type of system configuration (1 or 2) will be

referenced in the table.

DIGITAL HOST UNIT

REV

DRU

(1)

FWD

REV

DIGITAL EXPANSION UNITDIGITAL HOST UNIT

REV

DRU

(2)

FWD

FWD

17962-A

Figure 24. ICS System Basic Configurations

Table 11. DHU Fault Isolation and Troubleshooting Guidelines

Alarm Type LED LED COLOR

Minor

Problem : The DHU is overheating.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Air intake or exhaust openings to DHU

chassis blocked.

2. Ambient temperature > 50º C/122º F.

3. Faulty fan.

Alarm Type LED LED COLOR

Major

Problem : The DHU detects an internal circuitry fault.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Faulty DHU.

UNIT

UNIT

Yellow

1. Remove cause of air-flow blockage.

2. Reduce ambient temperature.

3. Replace fan (see Subsection 6.5).

Red

1. Replace DHU.

(Continued)

Page 44

© 2002, ADC Telecommunications, Inc.

Page 13

ADCP-75-136 • Issue 1 • November 2002

Table 11. DHU Fault Isolation and Troubleshooting Guidelines (Continued)

Alarm Type LED LED COLOR

Major

Problem: Forward path RF input level too high.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Incorrect attenuation in forward path RF

coaxial link.

Alarm Type LED LED COLOR

Minor

Problem: The DHU is receiving a minor alarm signal from the DEU.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. The connected DEU is overheating (2).

Alarm Type LED LED COLOR

Major

Problem: The DHU is not receiving an optical signal from the DRU or DEU.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Forward and reverse path optical fibers

reversed between DHU and DRU (1); or

between DHU and DEU (2).

2. Faulty reverse path optical fiber between DHU

and DRU (1).

3. Faulty optical receive port at DHU or faulty

optical transmit port at DRU (1).

4. Faulty forward or reverse path optical fiber

between DHU and DEU (2).

Alarm Type LED LED COLOR

Major

Problem: The DHU is receiving a major alarm signal from the DRU.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Faulty forward path optical fiber between

DHU and DRU (1).

2. Faulty optical transmit port at DHU or faulty

optical receive port at DRU (1).

3. The DRU is faulty (1 and 2).

4. Faulty forward or reverse path optical fiber

between the DEU and DRU (2).

OVERDRIVE

OK/NOK

OK/NOK

OK/NOK

Red

1. Adjust attenuation at interface device.

Yellow

1. Check DEU UNIT indicator and then refer to the

Blinking Red

1. Check fiber connections for correct polarity and

appropriate troubleshooting section for procedures.

reverse connectors at either unit if mismatched.

2. Clean optical connector and then test optical fiber.

Repair or replace if faulty (see Subsection 6.4.2).

3. Make sure transceiver is fully plugged in and then

Red

test optical port. Replace optical transceiver if

port is faulty (see Subsection 6.4.1).

4. Clean optical connectors and then test optical

fibers. Repair or replace if faulty (see Subsection

6.4.2).

1. Clean optical connector and then test optical fiber.

Repair or replace if faulty (see Subsection 6.4.2).

2. Make sure transceiver is fully plugged in and then

test optical port. Replace optical transceiver if

port is faulty (see Subsection 6.4.1).

3. Check DEU UNIT indicator or DRU STATUS

indicator and then refer to appropriate troubleshooting section for procedures.

4. Check the status of the OK/NOK LED on the

DEU and then Refer to Table 12.

© 2002, ADC Telecommunications, Inc.

Page 45

Page 14

ADCP-75-136 • Issue 1 • November 2002

Alarm Type LED LED COLOR

Minor

Problem : The DEU is overheating.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

UNIT

1. Air intake or exhaust openings to DEU

chassis blocked.

2. Ambient temperature > 50º C/122º F.

3. Faulty fan.

Alarm Type LED LED COLOR

Major

Problem : The DEU detects an internal circuitry fault.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Faulty DEU.

Alarm Type LED LED COLOR

Major

Problem: The DEU is not receiving an optical signal from the DHU.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

UNIT

HOST PORT

1. Faulty forward path optical fiber between DEU

and DHU (2).

2. Faulty optical receive port at DEU or faulty

optical transmit port at DHU (2).

Alarm Type LED LED COLOR

Minor

Problem: The DEU is receiving a minor alarm signal from a connected DEU.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

OK/NOK

1. The connected DEU is overheating.

Alarm Type LED LED COLOR

Major

Problem: The DEU is not receiving an optical signal from the DRU.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

OK/NOK

1. Forward and reverse path optical fibers

reversed between DEU and DRU.

2. Faulty reverse path optical fiber between DEU

and DRU.

3. Faulty optical receive port at DEU or faulty

optical transmit port at DRU.

Table 12. DEU Fault Isolation and Troubleshooting Guidelines

Yellow

1. Remove cause of air-flow blockage.

2. Reduce ambient temperature.

3. Replace fan (see Subsection 6.5).

Red

1. Replace DEU.

Blinking Red

1. Clean optical connector and then test optical fiber.

Repair or replace if faulty (see Subsection 6.4.2).

2. Make sure transceiver is fully plugged it and then

Yellow

Blinking Red

test optical port. Replace optical transceiver if

port is faulty (see Subsection 6.4.1).

1. Check DEU UNIT indicator and then refer to the

appropriate troubleshooting section for procedures.

1. Check fiber connections for correct polarity and

reverse connectors at either unit if mismatched.

2. Clean optical connector and then test optical fiber.

Repair or replace if faulty (see Subsection 6.4.2).

3. Make sure transceiver is fully plugged in and then

test optical port. Replace optical transceiver if

port is faulty (see Subsection 6.4.1).

(Continued)

Page 46

© 2002, ADC Telecommunications, Inc.

Page 15

ADCP-75-136 • Issue 1 • November 2002

Table 12. DEU Fault Isolation and Troubleshooting Guidelines (Continued)

Alarm Type LED LED COLOR

Major

Problem: The DEU is receiving a major alarm signal from the connected DRU.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Faulty forward path optical fiber between DEU

and DRU.

2. Faulty optical transmit port at DEU or faulty

optical receive port at DRU.

3. The connected DRU is faulty.

OK/NOK

Red

1. Clean optical connector and then test optical fiber.

Repair or replace if faulty (see Subsection 6.4.2).

2. Make sure transceiver is fully plugged in and then

test optical port. Replace optical transceiver if

port is faulty (see Subsection 6.4.1).

3. Check DRU STATUS indicator and then refer

to

appropriate troubleshooting section for

procedures.

Table 13. DRU Fault Isolation and Troubleshooting Guidelines

Alarm Type LED LED COLOR

Major

Problem : The DRU is not powered.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. DC power cable open.

2. No power or insufficient power output from

ac/dc power converter, DHU (1), or DEU (2).

3. Faulty DRU.

Alarm Type LED LED COLOR

Major

Problem : The DRU is not receiving an optical signal from the DHU or DEU; or the DHU or DEU is not receiving

an optical signal from the DRU.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Faulty forward or reverse path optical fiber

between DHU and DRU (1), DEU and

DRU (2), or DEU and DHU (2).

2. Faulty optical transmit or receive port at the

DHU (1) or DEU (2); or faulty optical

transmit or receive port at DRU (1 and 2).

Alarm Type LED LED COLOR

Major

Problem: The DRU detects an internal circuitry fault.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

1. Faulty DRU.

STATUS

STATUS

STATUS

Off

Blinking Red

Red

1. Test cable for continuity and repair or replace if

faulty.

2. Check DC voltage level at the DRU (see Subsection

6.4.3). Replace converter, DHU, or DEU (whichever

applies) if voltage is not within 34 to 48 Vdc.

3. Replace DRU.

1. Clean optical connector and then test optical fiber.

Repair or replace if faulty (see Subsection 6.4.2).

2. Make sure transceiver is fully plugged it and then

test optical port. Replace optical transceiver if

port is faulty (see Subsection 6.4.1).

1. Replace DRU.

© 2002, ADC Telecommunications, Inc.

Page 47

Page 16

ADCP-75-136 • Issue 1 • November 2002

Alarm Type LED LED COLOR

None

Problem: Loss of phone service from one DRU. Service normal at all other DRU’s.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

All

1. DRU antenna cable disconnected.

2. DRU antenna obstructed or misdirected.

3. DRU antenna faulty.

4. DRU faulty.

Alarm Type LED LED COLOR

None

Problem: Loss of phone service from all DRU’s.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

All

1. Faulty coaxial connection between DHU

and the interface device.

2. Faulty coaxial connection between interface

device and the BTS or donor antenna.

3. Faulty interface equipment.

4. Faulty DHU

5. Fault with cellular network or equipment.

Alarm Type LED LED COLOR

None

Problem: Calls may be originated and terminated but service is noisy.

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

All

1. Some electrical device in the immediate

vicinity is creating interference.

Alarm Type LED LED COLOR

None

Problem: Sudden high rate of blocked calls (delay dial tone).

POSSIBLE CAUSE CORRECTIVE ACTION/COMMENTS

All

1. Too many users for the number of channels

available.

2. Faulty DHU, DEU, or DRU.

Table 14. System Fault Isolation and Troubleshooting Guidelines

Normal

Normal

Normal

Normal

1. Re-connect DRU antenna cable to DRU.

2. Remove antenna obstruction or re-orient antenna.

3. Replace antenna.

4. Replace DRU.

1. Check forward path signals at the DHU. Check

reverse path signals at the interface device.

2. Check forward path signals at the interface

equipment. Check reverse path signals at the BTS or

antenna.

3. Adjust or replace interface equipment.

4. Replace DHU.

5. Contact cell service provider and verify that

cellular network and equipment is operational.

1. Try turning off each device that may be causing

interference and see if problem corrects itself.

1. Wait a few minutes and try dialing again. Upgrade

service if additional channels are required.

2. Replace defective unit.

Page 48

© 2002, ADC Telecommunications, Inc.

Page 17

6.4 Test Procedures

6.4.1 Optical Loopback Test Procedure

ADCP-75-136 • Issue 1 • November 2002

Dirty optical connectors, a faulty optical transceiver, a break in an optical fiber, or a fault in an

optical connector will interrupt communications between fiber-linked components. Use the

following procedure to determine if a fault exists with an optical port or with an optical fiber:

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the eye. Do not look into the ends of any optical fiber. Do

not look directly into the optical transceiver of any digital unit or exposure to laser radiation

may result. An optical power meter should be used to verify active fibers. A protective cap or

hood MUST be immediately placed over any radiating transceiver or optical fiber connector

to avoid the potential of dangerous amounts of radiation exposure. This practice also prevents

dirt particles from entering the transceiver or connector.

1.

Put on the IR filtering safety glasses.

2. At

the DHU or supporting DEU, place the PORT ON/OFF switch for the fiber port or

fiber to be tested in the OFF position (press O).

3.

Disconnect the optical connectors for the fiber port to be tested and place a dust cap over

each connector.

4.

Plug a loopback into the optical port to be tested as shown in Figure 25.

OPTICAL LOOPBACK

CONNECTION DETAIL

5. At

(press I).

17277-A

PORT 1

OPTICAL

TRANSCEIVER

OPTICAL

LOOPBACK

Figure 25. DHU/DEU Loopback Test

the DHU or supporting DEU, place the PORT ON/OFF switch in the ON position

Page 49

© 2002, ADC Telecommunications, Inc.

Page 18

ADCP-75-136 • Issue 1 • November 2002

6.

The PORT OK/NOK LED will turn either blinking red or green. If the LED turns

blinking red, the optical port is faulty. Replace the optical transceiver and then recheck

system operation. If the LED turns green, the optical port is good. Proceed to step 7 to

continue the test procedure.

7.

Place the PORT ON/OFF switch in the OFF position (press O).

8.

Disconnect the loopback from the DHU or supporting DEU.

9.

Clean and then reconnect the optical fiber connectors to the DHU or DEU optical port.

10. Disconnect the optical connectors at the DRU optical port or remote DEU host port (far

end of fiber).

11. Clean the optical fiber connectors and then using an LC optical adapter, connect the

loopback to the connectors as shown in Figure 26.

NOTE: iF THE DISTANCE BETWEEN THE DHU/DEU AND THE

DRU EXCEEDS THE DISTANCE SHOWN BELOW, THE

REMOTE LOOPBACK TEST WILL NOT WORK.

62.5 MICRON MULTI-MODE FIBER - 250 METERS

50 MICRON MULTI-MODE FIBER - 375 METERS

9 MICRON SINGLE-MODE FIBER - 5 KILOMETERS

OPTICAL

LOOPBACK

16768-B

OPTICAL

ADAPTER

OPTICAL

CONNECTOR

Figure 26. Optical Fiber Loopback Test

12. Insert a dust plug into the DRU optical port or remote DEU host port.

13. At the DHU or supporting DEU, place the PORT ON/OFF switch in the ON position

(press I).

14. The PORT OK/NOK LED will turn either blinking red or green. If the LED turns

blinking red, one of the optical fibers is faulty. Refer to Subsection 6.4.2 to isolate which

fiber is at fault. If the LED turns green, the optical fibers are good. Proceed to step 14 to

finish the test procedure.

15. At the DHU or supporting DEU, place the PORT ON/OFF switch in the OFF position

(press O).

16. Disconnect the loopback and the optical adapters from the optical fiber connectors.

17. Place a dust cap over the connector for each optical fiber

18. Remove the dust plug from the DRU optical port or remote DEU host port.

19. Plug the loopback into the DRU optical port or DEU host port as shown in Figure 27.

20. If testing a DRU that is powered by the DHU or by a supporting DEU, place the PORT

ON/OFF switch in the ON position (press I).

Page 50

© 2002, ADC Telecommunications, Inc.

Page 19

ADCP-75-136 • Issue 1 • November 2002

OPTICAL LOOPBACK

CONNECTION DETAIL

17282-A

OPTICAL

OPTICAL

LOOPBACK

Figure 27. DRU Loopback Test

21. The DRU STATUS LED or DEU HOST LED will turn either blinking red or green. If

TRANSCEIVER

the LED turns blinking red, the optical port is faulty and the optical transceiver must be

replaced. If the LED turns green, the optical port is good.

22. At the DHU or supporting DEU, place the PORT ON/OFF switch in the OFF position

(press O).

23. Remove the loopback from the DRU optical port or remote DEU host port.

24. Clean the optical fiber connectors and then reconnect the optical fibers to the DRU

optical port or remote DEU host port.

25. At the DHU or supporting DEU, place the PORT ON/OFF switch in the ON position

(press I).

26. Verify that the PORT OK/NOK LED turns green.

6.4.2 Optical Loss Test Procedure

A break in an optical fiber or a fault with the optical connector will interrupt communications

between linked components. Use the following procedure to isolate a problem with an optical

fiber or optical connector:

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the eye. Do not look into the ends of any optical fiber. Do

not look directly into the optical transceiver of any digital unit or exposure to laser radiation

may result. An optical power meter should be used to verify active fibers. A protective cap or

hood MUST be immediately placed over any radiating transceiver or optical fiber connector

to avoid the potential of dangerous amounts of radiation exposure. This practice also prevents

dirt particles from entering the transceiver or connector.

1.

Put on the IR filtering safety glasses.

2. At

the DHU or supporting DEU, place the PORT ON/OFF switch for the optical fiber to

be tested in the OFF position (press O) if not already off.

© 2002, ADC Telecommunications, Inc.

Page 51

Page 20

ADCP-75-136 • Issue 1 • November 2002

3.

Disconnect the optical connectors at the DHU or supporting DEU and at the

corresponding DRU or remote DEU.

4.

Inspect the optical connectors. Verify that each connector is clean and that no scratches

or imperfections are visible on the fiber end. Clean and polish the optical connector if

necessary.

5.

Connect a laser light source to one end of the first optical fiber and an optical power

meter to the other end.

6.

Verify that the power loss is within specifications (8 dB loss) for the length of the fiber

installed. If the power loss is not within specifications, repair or replace the optical fiber

and/or connector per local practice.

7.

Repeat steps 5 and 6 for the second optical fiber.

8.

Reconnect the optical connectors at the DHU or supporting DEU and the corresponding

DRU or remote DEU.

9. At

the DHU or supporting DEU, place the PORT ON/OFF switch for the fiber that was

tested in the ON position (press I).

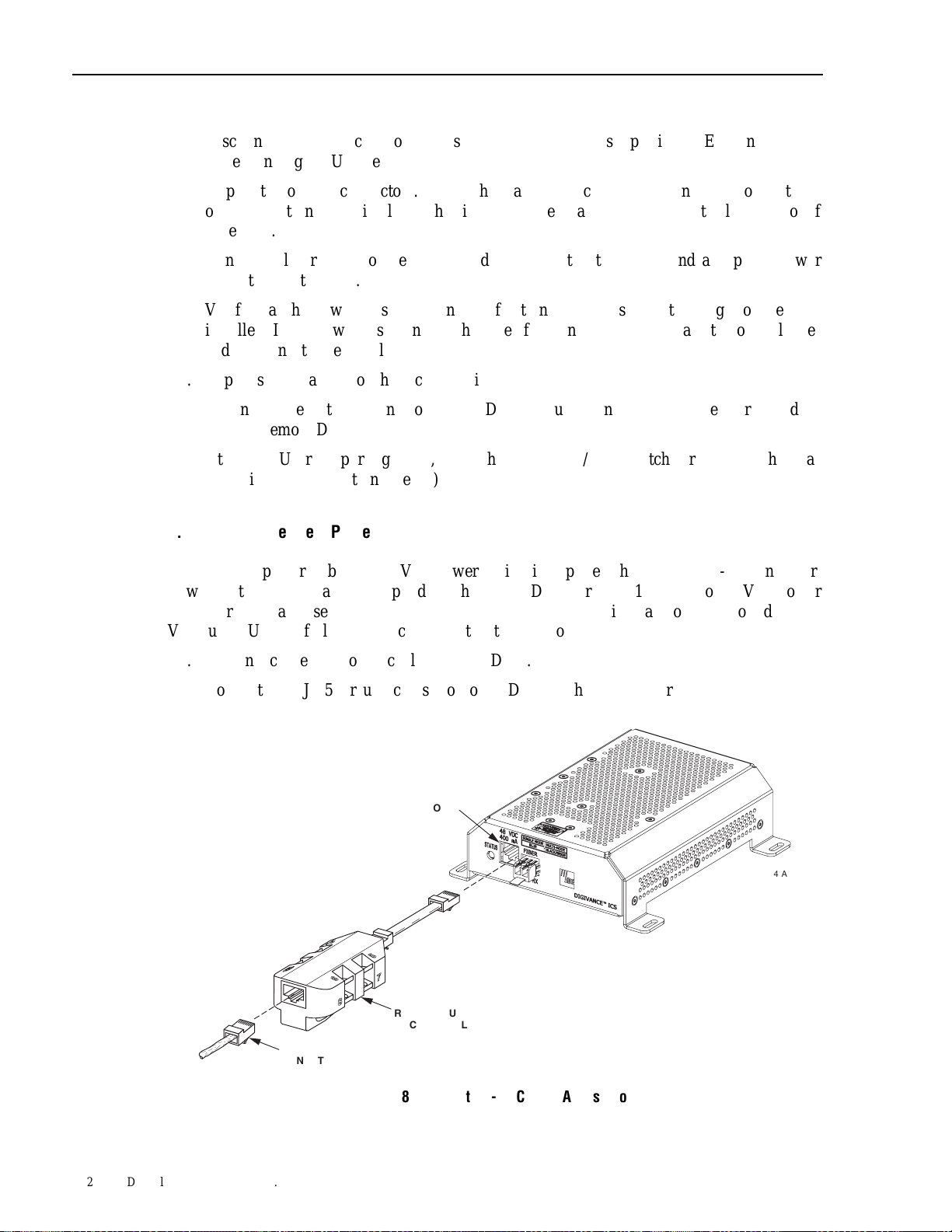

6.4.3 DC Power Test Procedure

The DRU is powered by 34–48 Vdc power which is supplied through the RJ-45 connector.

Power to the DRU may be supplied by the DHU, DEU, or by a 120 Vac to 48 Vdc power

converter (available separately as an accessory item) plugged into a properly grounded 120

Vac outlet. Use the following procedure to test the DC power cable:

1.

Disconnect the DC power cable from the DRU.

2.

Connect the RJ-45 circuit access tool to the DRU as shown in Figure 28.

POWER

PORT

17284-A

Page 52

© 2002, ADC Telecommunications, Inc.

POWER

CONNECTOR

RJ-45 CIRCUIT

ACCESS TOOL

Figure 28. Connect RJ-45 Circuit Access Tool

Loading...

Loading...