Page 1

3.6 System Expansion Planning

The DEU enables 6-way expansion of any optical port. This makes it possible to add more

DRU’s without having to install additional DHU’s. Each DHU is equipped with six optical

ports. If more than six DRU’s are required by the application, a DEU may be connected to one

of the optical ports at the DHU which expands that port to six ports. If still more optical ports

are required, then a second DEU may be connected to the DHU or a second DEU may be

connected to the first DEU. The ability to cascade DEU’s in parallel or in series provides

unlimited flexibility. It is physically possible to connect an unlimited number DRU’s to the

DHU through the installation of DEU’s.

The total number of DRU’s that can be served is limited by the cumulative noise effect caused

by antenna combining. This number cannot be determined until the radius distance of coverage

required at the DRU antenna is determined and the path loss attributed to the structure are

known. The system design requires that the carrier to noise differential be greater than the

customer’s desired signal to noise ratio.

If it is likely that the system will be expanded in the future, locate the DHU in such a way that it can

be used as a hub for an expanded system. It should be noted that a DEU can be used as an optical

regenerator. A DRU may sometimes need to be located at a point that is beyond the distance

limitation imposed by the optical fiber. The solution is to install a DEU at the maximum optical

fiber length from the DHU. This provides an additional 500 m, 750 m, or 10 km (depending on the

fiber type) of optical fiber length beyond the DEU for connecting the DRU.

ADCP-75-132 • Issue 2C • August 2006

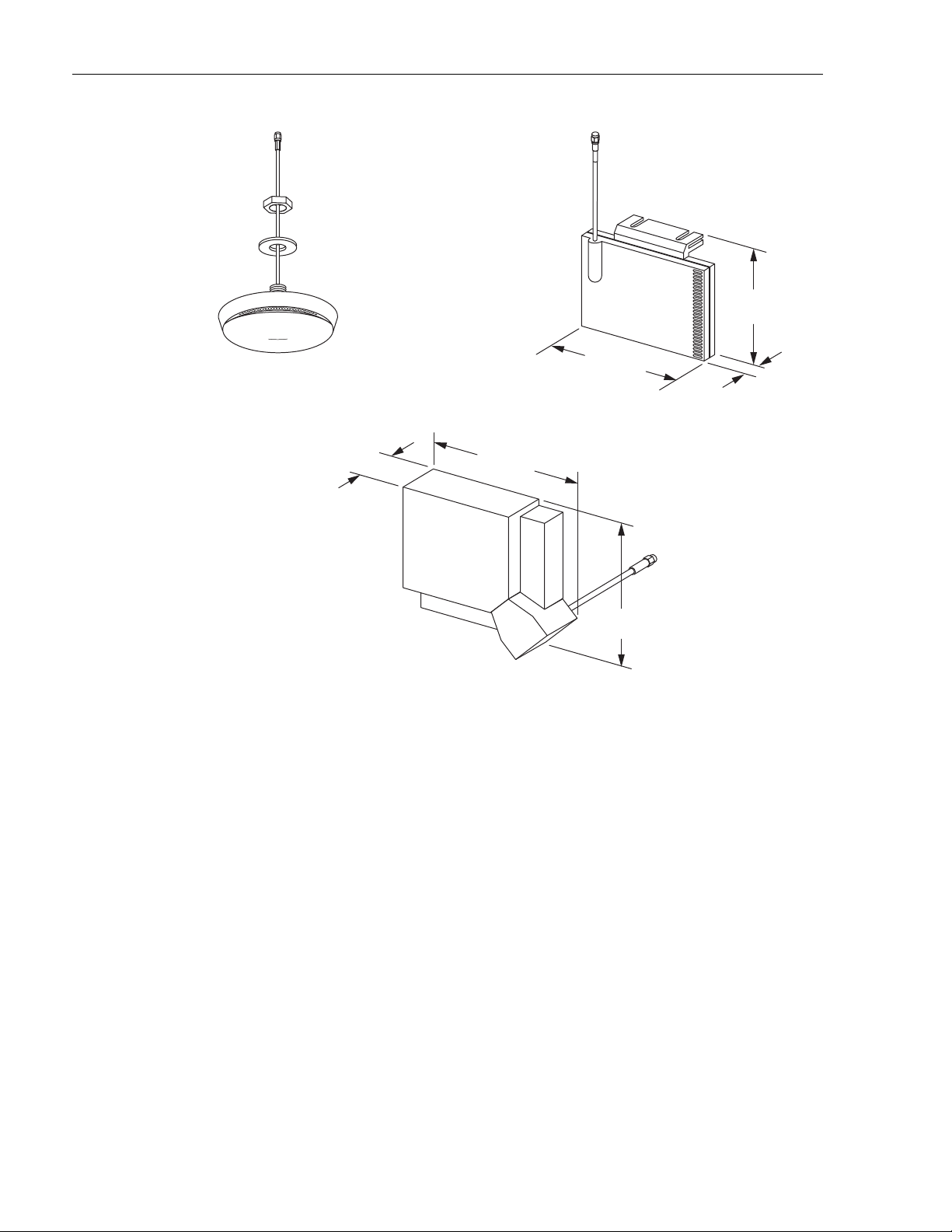

3.7 DRU Antenna Options

Various antennas, shown in Figure 12, are available from ADC for use with the DRU. All

antennas include a 6-foot (1.8 m) long 50-ohm coaxial cable (equipped with SMA male

connector) for connection to the DRU. The DRU is equipped with an SMA female connector

for connecting the antenna cable.

The DRU antennas are designed for unobtrusive mounting within an office environment. Each

type of antenna provides a specific coverage pattern in order to accommodate the shape of the

area where coverage is required. The ceiling-mount omni directional antenna is designed to

mount in the center of the coverage area. The directional panel antenna is designed to mount

vertically on one side of the coverage area or in the corner of the coverage area. The ceiling

mount hallway antenna is designed to mount in the center of long corridors. Non-ADC

antennas may also be used with the DRU to meet various application requirements, but must

comply with equipment authorization for RF exposure compliance.

Note: To comply with Maximum Permissible Exposure (MPE) requirements, antennas must

be installed to provide at least 20 centimeters (8 inches) of separation from all persons per

FCC 47 CFR part 2.1091 and IC RSS-102, Section 2.5.2.

© 2006, ADC Telecommunications, Inc.

Page 23

Page 2

ADCP-75-132 • Issue 2C • August 2006

MOUNTING STUD

LENGTH - 1.5 INCHES (38 mm)

DIAMETER - 0.875 INCHES (22 MM)

4 dBi GAIN

CEILING-MOUNT

HALLWAY

DIAMETER - 4.2 INCHES (106.7 MM)

DEPTH - 0.91 INCH (23 MM)

2.5 dBi GAIN CEILING-MOUNT

OMNIDIRECTIONAL

1.4 INCHES

(36 MM)

INCLUDES ADJUSTABLE

MOUNTING BRACKET

(NOT SHOWN)

3 INCHES

(75 MM)

6 INCHES

(152 MM)

5.5 INCHES

(140 MM)

8 dBi GAIN

90 DEGREE DIRECTIONAL PANEL

(WALL/CORNER-MOUNT)

Figure 12. 1900 MHz DRU Antenna Options

18079-A

2.4 INCHES

(61 MM)

0.29 INCH

(7.4 MM)

3.8 External Alarm System Reporting Requirements

The DHU provides normally open (NO) and normally closed (NC) form C dry alarm relay

contacts for reporting minor and major alarms to an external alarm system. A minor alarm is

defined as a high temperature condition. A major alarm is defined as any fault condition

except high temperature. Connections to the alarm contacts are provided through a screw-type

terminal strip. Category 3 or 5 cable should be used for the alarm wires. If an external alarm

system is not in use, no alarm connections are required.

3.9 Maintenance Requirements

The Digivance ICS requires no regular maintenance to insure continuous and satisfactory operation.

Maintenance, as it applies to the Digivance ICS, primarily involves diagnosing and correcting

service problems as they occur. Faults and failures arising from within the Digivance ICS will

generate an external alarm response which includes lighting an LED indicator(s) and closing or

opening a set of alarm contacts. When an alarm is reported, it will be necessary to isolate the source

Page 24

© 2006, ADC Telecommunications, Inc.

Page 3

of the problem by observing the LED indicators on each unit and then performing various tests to

isolate the problem. Once the source of the fault is isolated, the appropriate action can be taken to

correct the problem. The only unit components that can be replaced are the cooling fans which are

mounted in the DHU and the DEU and the modular optical transceivers. The failure of any other

component within a unit will require replacement of the unit. Basic trouble-shooting procedures are

provided in Section 6 of this manual.

3.10 System Design Recommendations

Follow a systematic process when designing an in-building coverage solution. The following

sub sections outline the four phases of the in-building coverage solution design process.

System design and planning services are available from ADC if required. Refer to Section 7 of this

manual for additional information.

3.10.1 Phase One – Initial Evaluation

Qualify the Installation: Confirm that there are no extenuating circumstances that would

prevent a successful installation such as: extreme cellular system issues (blocking, severe

interference, site problems, etc.), building issues, power issues, or safety issues (site should

not present any hazards or conditions that would make operation of the equipment unsafe).

ADCP-75-132 • Issue 2C • August 2006

Analyze the RF Situation: Determine how the system RF link to the outside world will be

provided. Will it be a direct feed from a BTS (microcell) or an over-the-air connection via a

donor antenna? If it is a donor antenna, is the customer within the coverage footprint of a

serving cell or better? The coverage can be determined during the preliminary walkthrough by

checking the downlink Received Signal Strength Indication (RSSI) outside the building with a

unity gain sampling antenna. Sometimes a rooftop reading is needed to obtain a sufficient

signal level. Note that it is an FCC violation to expand the normal coverage footprint of a

cellular site with an in-building product without prior approval of the service provider. In

addition, consider the impact the system will have on traffic, especially the busy hour.

Confirm with the service provider that the expected increase in the volume of calls will be

addressed (if needed), possibly with additional equipment such as additional channels or a

microcell.

Determine the Amount of Building Attenuation: If a donor antenna will provide the RF link

to the BTS, determine if there is enough signal isolation between the donor antenna and the inbuilding system to avoid a feedback loop and signal degradation. This step can often be

accomplished during the preliminary walkthrough.

Discuss Installation with Building Management and Engineering: Discuss all initially

anticipated Digivance ICS coverage areas (including any obviously desirable cable routings,

equipment installations, power and mechanical requirements) with the authorized client and

building personnel for an initial approval/confirmation. This gives a good estimate of the

extent of the system work needed. Occasionally, some of the system design work can be

accomplished at this point.

© 2006, ADC Telecommunications, Inc.

Page 25

Page 4

ADCP-75-132 • Issue 2C • August 2006

3.10.2 Phase Two – System Design

Determine forward and reverse path loss and then design for unity gain on the uplink

and maximum power out of the DRU on the downlink: The overall purpose of the

Digivance ICS is to transparently overcome attenuation losses, not to provide additional gain

beyond what is required to bring the signal to unity gain. Complete the following steps to

make this determination:

1. Determine the in-building reverse path (uplink) losses at typical operating frequencies

and distances from the subscriber handset (terminal) to the DRU. This information will

be used to determine the optimal uplink signal level to the outside world.

2. Determine the typical composite cell site Effective Radiated Power (ERP) into the

system. Calculate the interface adjustment required to feed the required downlink signal

level to the DHU in order to drive the DRU output signal at the desired level.

Determine the location of the DHU and its RF and AC power sources: Complete the

following steps to make this determination:

1. Determine where and how the DHU will be mounted.

2. Determine the location of the DHU AC power source.

3. Determine the RF source (local interface with BTS or remote interface with BTS through

donor antenna) for the DHU.

4. If local interface connection with the BTS is required, determine the distance to the

DHU.

5. If a remote interface connection with the BTS is required, determine what type of

antenna is needed and where it can be mounted.

6. Determine the attenuation or amplification requirements for the DHU to BTS interface.

Discuss the design of the Digivance ICS installation with building management and

engineering: Explain the proposed system design with building management and engineering

personnel and obtain final design approval prior to installation.

3.10.3 Phase Three – Installation

Use industry standard practices for cabling, installation, and powering to complete the

following:

1. Install the DHU as described in Section 3 of this manual and adjust the RF interface

levels based on the system design specifications. Additional information concerning the

DHU to BTS interface is provided in the Digivance ICS Remote Interface Unit User Manual

(ADCP-75-178) and in the Digivance ICS 800 and 1900 MHz High Power Conditioning

Panel User Manual (ADCP-75-175).

2. Install a DRU as described in the Digital Remote Unit Installation Instructions (ADCP 75-112). If a donor antenna is used, install the DHU and RIU close to the donor antenna.

Page 26

© 2006, ADC Telecommunications, Inc.

Page 5

ADCP-75-132 • Issue 2C • August 2006

3. Conduct an initial performance evaluation and complete the following:

a) Confirm proper isolation, signal quality, and power levels.

b) Make test calls from DRU service area and evaluate call quality (confirm with

service provider if desired).

c) Address performance issues as needed.

4. Install the remaining DRU’s and also any DEU’s as described in the Digital Expansion

Unit Installation Instructions (ADCP-75-111). Test call quality and range of each DRU

as needed.

5. Check powering and alarm functions of entire system per Digivance ICS specifications.

3.10.4 Phase Four - Performance Evaluation

Complete the following to evaluate the performance of the Digivance ICS:

1. Evaluate the forward path (downlink) and reverse path (uplink) RF signal levels and

quality.

2. Make continuous calls from DRU to DRU, checking all service areas, seams, and coverage

boundaries for call quality (both DL and UL). Address all quality issues as needed.

3. Place calls both leaving and entering the building(s), in parking lots, etc. Address all

quality issues as needed.

4. Contact client/service provider to inform them when the Digivance ICS is operational.

© 2006, ADC Telecommunications, Inc.

Page 27

Page 6

ADCP-75-132 • Issue 2C • August 2006

4 DIGITAL HOST UNIT INSTALLATION PROCEDURE

This section provides the installation procedures for the DHU. Installation of the DEU(s) and

DRU(s) may proceed separately from the installation of the DHU. The installation procedures

for the DEU are provided in the Digital Expansion Unit Installation Instructions (ADCP -75-

111) which are shipped with the DEU. The installation procedures for the DRU, the DRU

antennas, and the AC/DC converter (optional DRU accessory) are provided in the Digital

Remote Unit Installation Instructions (ADCP-75-112) which are shipped with the DRU. When

all units of the Digivance ICS have been installed, refer to Section 5 of this manual for the

system power up and test procedures.

4.1 System Plan Review and Pre-Installation Cable Routing

Before beginning the installation, review the system plan with the system engineer. Make sure

each equipment installation site is identified and located and all cable runs are mapped out.

The coaxial, DC power, and fiber optic cables may be routed between the various equipment

locations before the equipment is installed. Whenever possible, route fiber optic cables

through conduit or a guideway such as the FiberGuide system. Avoid routing fibers through

ladder type cable racks or troughs that do not provide sufficient support to limit bending or

prevent accidental damage. Tie-wrapping is not recommended as a means of securing fiber

optic cables. Make sure to leave sufficient slack at each equipment location for connectorizing

and cable management. The procedures for terminating the cables and for connecting the

cables to the DHU are provided in the sections that follow.

4.2 Tools and Materials

The following tools are required in order to complete the procedures in this section:

• Box cutter

• Pencil or scribe

• Medium and small size flat-bladed screwdrivers

• TORX screwdriver (T20 bit)

• Pliers

• Wire cutters

• Wire stripper

• Tool kit for attaching RJ-45 male connectors to category 3 or 5 cable

• Tool kit for attaching N-type male connectors to coaxial cable

• Tool kit for attaching LC connectors to multimode fiber optic cable

• Drill and assorted drill bits (wall-mount installations only)

• Multimeter

• Optical power meter

• Laser light source

• ESD wrist strap

Page 28

© 2006, ADC Telecommunications, Inc.

Page 7

The following materials are required in order to complete the procedures in this section:

• Wall-mount fasteners (wall-mount applications only)

• #22 AWG (0.40 mm) category 3 or 5 cable (for power cable and external alarm connections)

• RJ-45 male connectors (for power cable)

• #18 AWG (1.00 mm) insulated stranded copper wire (for chassis grounding wire)

• Ring terminal for #18 wire (for chassis ground wire connection)

• 50 or 62.5 micron core multi-mode or 9 micron core single-mode fiber optic cable

• LC-type field installable connectors

• High performance, flexible, low loss 50-ohm coaxial cable

• N-type male connectors

• Wire ties

4.3 Unpacking and Inspection

This subsection provides instructions for opening the shipping boxes, verifying that all parts

have been received, and verifying that no shipping damage has occurred. Use the following

procedure to unpack and inspect the DHU:

ADCP-75-132 • Issue 2C • August 2006

1. Open the shipping carton and carefully unpack the DHU from the protective packing

material.

2. Check the DHU for broken or missing parts. If there are any damages, contact ADC (see

Section 6 at the end of this manual) for an RMA (Return Material Authorization) and to

reorder if replacement is required.

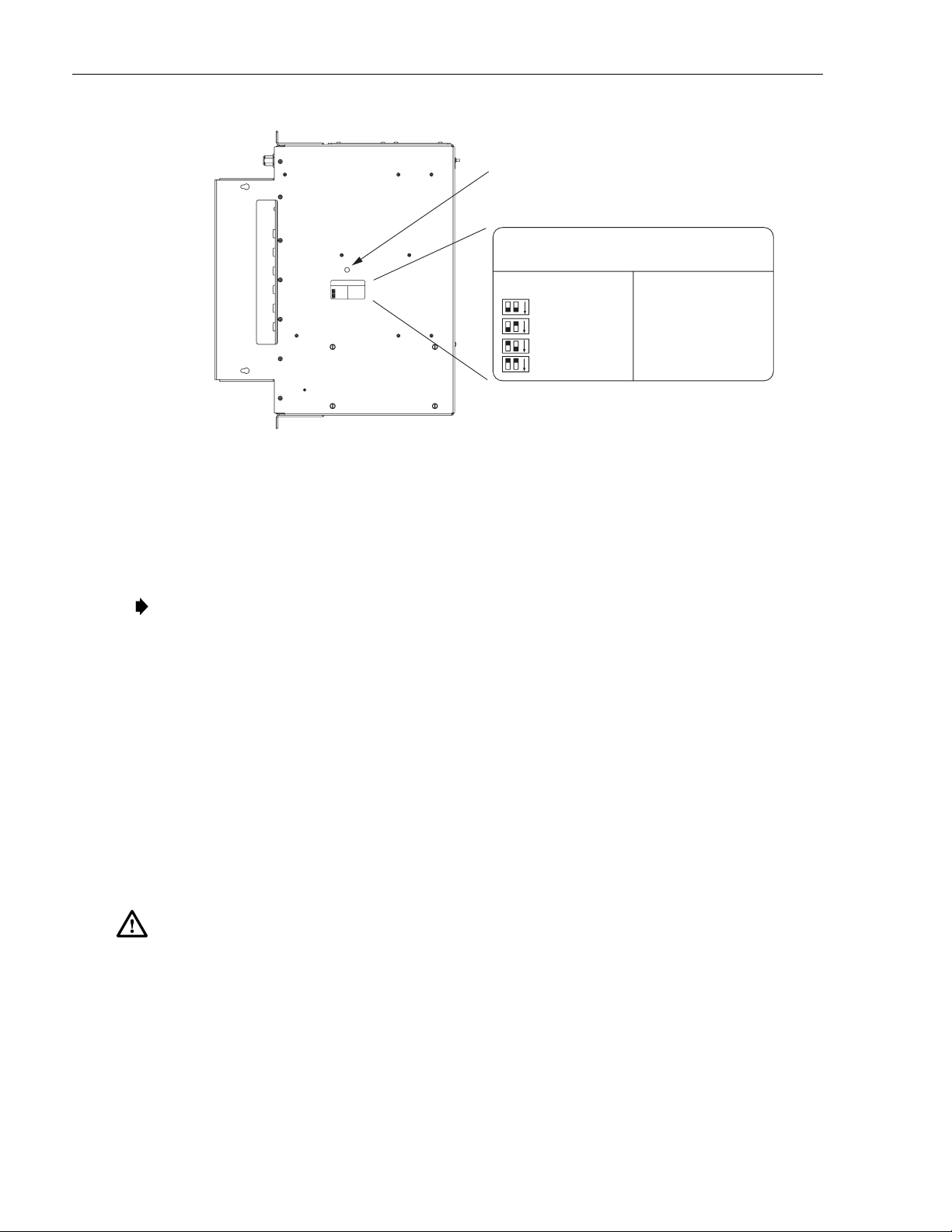

4.4 Frequency Band Selection Procedure

The 1900 MHz version of the DHU may be configured to operate at any one of four frequency

bands. A DIP switch is provided on the underside of the DHU for selecting the required

frequency band. Use the following procedure to set the DIP switch to provide the required

1900 MHz frequency band:

1. Determine the required frequency band for the DHU (AD, DBE, BEF, or EFC) as

specified in the system design plan.

2. Orient the DHU as shown in Figure 13 and then locate the small hole in the bottom of

the DHU that provides access to the band select DIP switch.

3. Use a non-conductive probe to align the DIP switch sliding handles to provide the

required frequency band (see Figure 13).

Caution: The DIP switches on the connected DRU’s must be set to the same frequency band as the

DHU. Any DRU that is set to a different frequency than the DHU will not function properly.

4. Place the copper sticker provided with the DHU over the small opening that provides

access to the DIP switch.

Note: The copper sticker provides EMI/RFI shielding. Do not use some other type of material

to cover the DIP switch access hole.

© 2006, ADC Telecommunications, Inc.

Page 29

Page 8

ADCP-75-132 • Issue 2C • August 2006

4.5 Mounting Procedure

ALIGN DIP SWITCH HANDLES AS

SHOWN ON THE LABEL TO PROVIDE

SPECIFIED FREQUENCY BAND

SWITCH POSITIONS AS SEEN THROUGH HOLE

MOVABLE TAB SHOWN WHITE

SWITCH POSITIONS AS SEEN THROUGH HOLE

MOVABLE TAB SHOWN WHITE

FORWARD

REVERSE

1930-1950

1850-1870

BLOCK A,D

1945-1970

1865-1890

BLOCK D,B,E

1950-1975

1870-1895

BLOCK B,E,F

1965-1990

1885-1910

BLOCK E,F,C

BLOCK A,D

BLOCK D,B,E

BLOCK B,E,F

BLOCK E,F,C

Figure 13. 1900 MHz Frequency Band Selection

FORWARD

1930-1950

1945-1970

1950-1975

1965-1990

REVERSE

1850-1870

1865-1890

1870-1895

1885-1910

16816-B

The DHU may be either rack-mounted or wall-mounted. Of the procedures that follow, use

whichever procedure is appropriate for the installation:

Note: To insure that all optical connectors and transceivers remain dust-free during

installation, leave all dust caps and dust protectors in place until directed to remove

them for connection.

4.5.1 Rack Mount Installation

The DHU may be mounted in either a 19-inch or 23-inch EIA or WECO equipment rack. Both US

standard and metric machine screws are included for rack mounting the DHU. When loading the

DHU in a rack, make sure the mechanical loading of the rack is even to avoid a hazardous

condition such as a severely unbalanced rack. The rack should safely support the combined weight

of all the equipment it holds and be securely anchored. In addition, the maximum recommended

ambient temperature for the DHU is 50º C (122º F). Allow sufficient air circulation or space

between units when the DHU is installed in a multi-unit rack assembly because the operating

ambient temperature of the rack environment might be greater than room ambient.

Warning: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrically-powered equipment. To prevent electrical shock, never install

or use electrical equipment in a wet location or during a lightning storm.

Use the following procedure to install the DHU in the equipment rack:

1. The DHU is shipped with the mounting brackets installed for 19-inch rack installations.

If mounting the DHU in a 19-inch rack, proceed to step 4. If mounting the DHU in a 23inch rack, proceed to step 2.

2. Remove both mounting brackets from the DHU (requires TORX screwdriver with T20 bit)

Page 30

© 2006, ADC Telecommunications, Inc.

Page 9

ADCP-75-132 • Issue 2C • August 2006

3. Reinstall both mounting brackets so the long side of the bracket is flush with the DHU

front panel as shown in Figure 14. Use the screws removed in step 2 to re-attach the

brackets to the DHU enclosure.

4. Position the DHU in the designated mounting space in the rack (per system design) as

shown in Figure 15.

REMOVE AND REINSTALL MOUNTING

BRACKETS AS SHOWN FOR

INSTALLATION IN 23-INCH RACKS

17271-A

Figure 14. Installing the Mounting Brackets for 23-Inch Rack Installations

17281-A

Figure 15. DHU Rack Mount Installation

5. Secure the mounting brackets to the rack using the four machine screws provided (use

#12-24 screws or M6 x 10 screws, whichever is appropriate).

Note: Provide a minimum of 3 inches (76 mm) of clearance space on both the left and right

sides of the DHU for air intake and exhaust.

© 2006, ADC Telecommunications, Inc.

Page 31

Page 10

ADCP-75-132 • Issue 2C • August 2006

4.5.2 Wall-Mount Installation

The DHU may be mounted from any flat vertical surface. It is recommended that a backer

board such as 3/4-inch plywood be applied over the mounting surface to provide a secure base

for attaching the DHU. Two mounting holes are provided in the cable management tray for

securing the DHU to the mounting surface. The fasteners must be provided by the installer.

Use the following procedure to wall-mount the DHU:

Warning: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrically-powered equipment. To prevent electrical shock, never install

or use electrical equipment in a wet location or during a lightning storm.

1. Obtain the appropriate fasteners (lag bolts, screw anchors, etc.) for securing the DHU to

the mounting surface.

2. Position the DHU on the mounting surface in the specified location (per the system

design) with the front panel facing up as shown in Figure 16.

Note: Provide a minimum of 3 inches (76 mm) of clearance space on both the left and right

sides of the DHU for air intake and exhaust.

BACKER BOARD SUCH

AS 3/4-INCH PLYWOOD

3. Using the DHU as a template, mark the location of the mounting holes on the mounting

surface.

Note: The mounting holes in the DHU cable management tray are spaced 11-21/32 inches

(296 mm) center to center.

Page 32

© 2006, ADC Telecommunications, Inc.

Figure 16. DHU Wall-Mount Installation

17272-A

Page 11

4. Set the DHU aside and then drill appropriately sized holes in the mounting surface for

the fasteners.

5. Partially install the fasteners in the drilled holes. Leave the head of each fastener

protruding about 1/4 inch (6 mm) from the mounting surface.

6. Hang the DHU from the fasteners and then securely tighten each fastener.

4.6 Chassis Ground Connections

A stud is provided on the front side of the chassis for connecting a grounding wire to the

chassis. Use the following procedure to connect the grounding wire to the chassis and to route

the grounding wire to an approved earth ground source:

1. Obtain a length of #18 AWG (1.00 mm) insulated stranded copper wire for use as a

chassis grounding wire.

2. Terminate one end of the wire with a ring terminal.

3. Locate the chassis ground stud at the front of the DHU as shown in Figure 17.

ADCP-75-132 • Issue 2C • August 2006

17279-A

Figure 17. Chassis Ground Stud

4. Secure the ring end of the wire to the chassis ground stud (see Figure 17) using the nut

and two star washers provided.

5. Route the free end of the chassis grounding wire to an approved (per local code or

practice) earth ground source.

6. Cut the chassis grounding wire to length and connect it to the approved ground source as

required by local code or practice.

Note: Be sure to maintain reliable grounding for rack and wall mounted equipment. Pay

particular attention to ground source connections.

© 2006, ADC Telecommunications, Inc.

Page 33

Page 12

ADCP-75-132 • Issue 2C • August 2006

4.7 Coaxial Cable Connections

The RF interface between DHU and the BTS is supported through a pair of type N female

connectors mounted on the DHU front panel. One connector provides the coaxial cable

connection for the forward path (downlink) signal. The other connector provides the coaxial

cable connection for the reverse path (uplink) signal. Coaxial cables link the DHU to the BTS

through an interface device such as the HPCP or the RIU. Use the following procedure to

install the forward and reverse path coaxial cables and connect them to the DHU:

1. Obtain the required lengths of high performance, flexible, low loss 50-ohm coaxial

communications cable (RG 400 or equivalent) for all coaxial connections.

2. Route the forward path and reverse path coaxial cables (if not already routed) between

the DHU and the specified interface device (per system design) and cut to the required

length. Allow sufficient slack for dressing and organizing cables at the DHU.

3. Terminate each cable with a type N male connector following the connector supplier’s

recommendations.

4. Connect the forward path cable to the RF IN connector on the DHU front panel as

shown in Figure 18.

5. Connect the reverse path cable to the RF OUT connector on the DHU front panel.

TYPE-N MALE CONNECTOR

Figure 18. Forward and Reverse Path Coaxial Cable Connections

RF IN CONNECTOR

(FORWARD PATH)

RF OUT CONNECTOR

(REVERSE PATH)

17273-A

6. Dress and secure cables at the DHU per standard industry practice.

7. Adjust the RF signal levels and complete the remaining the forward and reverse path

coaxial cable connections as specified by the following:

Local Interface Using High Power Conditioning Panel: Refer to the High Power

Conditioning Panel User Manual (ADCP-75-175) for adjustment and connection procedure.

Remote Interface Using Remote Interface Unit: Refer to the Remote Interface Unit

User Manual (ADCP-75-178) for adjustment and connection procedure.

Local or Remote interface using ancillary interface device: Refer to Section 5.2,

Turn-Up System and Verify Operation, for adjustment and connection procedure.

Page 34

© 2006, ADC Telecommunications, Inc.

Page 13

4.8 Modular Optical Transceiver Installation

The modular optical transceivers are available separately and may or may not be installed in

the DHU depending on the configuration ordered. If the optical transceivers are factory

installed in the DHU, skip this section and proceed to Section 4.9. If the optical transceivers

are not factory installed, use the following procedure to install each transceiver:

1. Slip on an Electro-Static Discharge (ESD) wrist strap and connect the ground wire to an

earth ground source such as the grounding stud on the DHU front panel. Wear the ESD

wrist strap while completing the optical transceiver installation procedure.

ADCP-75-132 • Issue 2C • August 2006

Warning: Electronic components can be damaged by static electrical discharge. To prevent

ESD damage, always wear an ESD wrist strap when handling electronic components.

2. Locate the appropriate transceiver socket on the front of the DHU as shown in Figure 19

and remove the port cover from the socket.

RELEASE

LEVER

T

X

R

X

TYPE A

TRANSCEIVER

TYPE B

TRANSCEIVER

RELEASE TAB

DETAIL DRAWING

OF TYPE A AND TYPE B

MODULAR OPTICAL

TRANSCEIVERS

DUST CAPS

TRANSCEIVER COLOR CODE

BLUE = SINGLE-MODE (9 MICRON)

BLACK/

BEIGE = MULTI-MODE (50 OR 62.5 MICRON)

T

X

R

X

OPTICAL

TRANSCEIVER

SOCKET

PORT

COVER

DETAIL DRAWING OF

OPTICAL TRANSCEIVER

SOCKETS

17258-A

Figure 19. Optical Transceiver Installation

3. Select the optical transceiver that corresponds to the type of fiber (single- or multi-mode)

required for the installation. The color of the transceiver (see transceiver color code in

Figure 19) corresponds to the fiber type.

4. Remove the transceiver from the anti-static packaging and orient for installation (see

Figure 19.).

Note: Two types of optical transceivers, type A and type B, are available. Both types

provide the same functionality. On the type A optical transceiver, the release lever (see

Figure 19) must be closed for installation.

© 2006, ADC Telecommunications, Inc.

Page 35

Page 14

ADCP-75-132 • Issue 2C • August 2006

5. Insert the optical transceiver into the socket until it locks into place.

6. Replace the optical transceiver dust cap if it was removed for installation.

7. Repeat procedure for each optical transceiver that requires installation.

8. Install a port cover (see Figure 19) over each unused optical transceiver socket.

4.9 Ports 1–6 Optical Connections

The optical interface between the DHU and each DEU or DRU is supported by six optical

ports. Each of the six optical ports provides a duplex LC-type optical transceiver which is

mounted on the DHU front panel. One side of the transceiver provides the optical fiber

connection for the forward path (downlink) signal. The other side of the transceiver provides

the optical fiber connection for the reverse path (uplink) signal. Use the following procedure

to install the forward and reverse path optical fibers and to connect them to the DHU:

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser

radiation can seriously damage the retina of the eye. Do not look into the ends of any optical

fiber. Do not look directly into the optical transceiver of any digital unit or exposure to laser

radiation may result. An optical power meter should be used to verify active fibers. A

protective cap or hood MUST be immediately placed over any radiating transceiver or optical

fiber connector to avoid the potential of dangerous amounts of radiation exposure. This

practice also prevents dirt particles from entering the transceiver or connector.

1. Obtain the required lengths of single- or multi-mode fiber optic cable.

2. Route the fiber optic cable between the DHU and the DEU or DRU (if not already

routed) and cut to required length. Allow sufficient slack for dressing and organizing the

cables at each unit. Maintain a minimum bend radius of 2 inches (50 mm).

Note: The maximum path lengths for the optical fibers are as follows: 500 meters (1,641

feet) for 62.5 micron core multi-mode fiber, 750 meters (2,461 feet) for 50 micron core

multi-mode fiber, and 10 km (32,808 ft) for 9 micron core single-mode fiber.

3. Terminate each optical fiber with a field-installable LC type fiber optic connector as

shown in Figure 20. Follow the instructions provided by the connector manufacturer for

installing the connector.

4. Test each fiber for optical loss as described in Subsection 6.4.2 of this manual.

5. Designate one of the fibers as the forward path fiber and the other as the reverse path

fiber and label both ends of each fiber with the path designation.

6. Use the plastic joiner provided with the LC connectors to join the DHU Port 1 forward

and reverse path connectors together (see Figure 20). Make sure the forward path and

reverse path connectors are oriented as shown.

Note: When viewing any Port 1-6 optical transceiver from the front, the forward path port is

on the left and the reverse path port is on the right as shown in Figure 21. In addition, singlemode transceivers are colored blue and multi-mode transceivers are colored black or beige.

Both single- and multi-mode transceivers may be mounted on the same DHU.

Page 36

© 2006, ADC Telecommunications, Inc.

Page 15

FORWARD PATH (TX)

CONNECTOR

REVERSE PATH (RX)

CONNECTOR

OPTICAL CONNECTOR

ASSEMBLY DETAIL

OPTICAL

CONNECTOR

PORT 1

OPTICAL

TRANSCEIVER

ADCP-75-132 • Issue 2C • August 2006

CABLE GUIDE

DETAIL

DESIGNATION CARD AND

HOLDER DETAIL

Figure 20. Ports 1–6 Fiber Optic Cable Connections

TRANSCEIVER COLOR CODE

BLUE = SINGLE-MODE (9 MICRON)

BLACK/

BEIGE = MULTI-MODE (50 OR 62.5 MICRON)

CLEAR

PLASTIC

COVER

CARD

HOLDER

CABLE

GUIDES

17274-A

17150-A

FORWARD

PATH (TX)

REVERSE

PATH (RX)

DUST CAP (LEAVE IN PLACE

UNTIL READY TO INSTALL CONNECTOR)

DETAIL DRAWING OF

OPTICAL PORT

Figure 21. Optical Transceiver Designations

© 2006, ADC Telecommunications, Inc.

Page 37

Page 16

ADCP-75-132 • Issue 2C • August 2006

7. Remove the dust caps from the optical fiber connectors and the port 1 optical transceiver.

Note: Leave the dust cap in place on any unused optical transceiver.

8. Clean each connector (follow connector supplier’s recommendations) and then insert the

optical fiber connector pair into DHU optical port 1 (see Figure 20).

9. Place the optical fibers within the cable guides provided on the cable management tray (see

Figure 20) and then dress and secure the fibers at the DHU per standard industry practice.

10. Connect the forward and reverse path optical fibers to the DEU or the DRU as specified

in the instructions provided with that unit.

11. Use the designation card provided (see Figure 20) to indicate the location and name of

the DRU or DEU that is connected to each optical fiber pair. The designation card holder

may be attached to any convenient flat surface such as the DHU cable management tray

12. Repeat steps 1–11 for each remaining optical port.

4.10 DC Power Connections

The DC power interface between the DHU and each DRU is supported by six RJ-45 female

connectors. Each DHU RJ-45 connector provides nominal 48 VDC power for the associated

DRU except when the DRU is powered with an AC/DC converter. A category 3 or 5 twisted

pair cable is used to feed the power from the DHU to the DRU. Use the following procedure

to install the DC power cable and to connect it to the DHU.

1. Obtain the required length of category 3 or 5 twisted pair cable.

2. Route the cable between the DHU and the DRU (unless already routed) and then cut to

required length. Allow sufficient slack for dressing and organizing the cable at the DHU.

Note: The maximum distance for routing power cable is 500 meters (1,641 feet).

3. Terminate each end of the cable with a male RJ-45 connector. Match the wire color to

the connector pin as specified in Table 6.

Caution: The DRU will be damaged if the RJ-45 connector is wired incorrectly.

4. Perform a continuity test to verify that each wire is properly connected to the terminating

RJ-45 connector and check the connector for correct polarity (see diagram in Table 6).

Table 7. RJ-45 Connector Pin Designations

PIN NUMBER WIRE COLOR CONNECTOR PINS

1

2

3

4

5

6

7

8

White/Green

Green

White/Orange

Orange

White/Blue

Blue

White/Brown

Brown

+48 VDC ON PINS 1, 3, 5, AND 7

RETURN ON PINS 2, 4, 6, AND 8

PIN

PIN

8

1

16180-A

Page 38

© 2006, ADC Telecommunications, Inc.

Page 17

ADCP-75-132 • Issue 2C • August 2006

5. Connect the DC power cable to the DHU port 1 DC PWR jack as shown in Figure 22.

6. Place the DC power cable within the cable guides provided (see Figure 22) and then

dress and secure the cable at the DHU per standard industry practice.

RJ-45 CONNECTOR

DETAIL

1

8

CONNECTOR

Figure 22. 48 VDC Power Cable Connection

7. Connect the DC power cable to the DRU as specified in the instructions provided with

that unit.

8. Repeat steps 1–7 for each remaining DRU that will be powered by the DHU.

4.11 External Alarm System Connections

The alarm interface between the DHU and an external alarm system is supported by a sixterminal plug (with screw-type terminals) that connects to a receptacle mounted on the DHU

front panel. The terminal plug provides connections to normally open (NO) and normally

closed (NC) dry type alarm contacts for both minor and major alarms. A category 3 or 5 cable

is typically used to connect the DHU to the external alarm system. Use the following

procedure to install the alarm wiring and connect it to the DHU:

RJ-45

PORT 1

DC POWER

CONNECTOR

CABLE GUIDE

DETAIL

17275-A

CABLE

GUIDES

1. Obtain the required length of category 3 or 5 cable.

2. Route the cable between the DHU and the external alarm system (if not already routed)

and then cut to required length. Allow sufficient slack for dressing and organizing the

cable at the DHU.

© 2006, ADC Telecommunications, Inc.

Page 39

Page 18

ADCP-75-132 • Issue 2C • August 2006

3. Strip back the outer cable sheath and insulation to expose the wires at both ends of the

cable and strip back 0.2 inches (5 mm) of insulation each wire.

4. Connect the Major alarm wire pair to the MAJOR COM/NC or MAJOR COM/NO

terminals (whichever is required by the external alarm system) on the DHU alarm

terminal connector (supplied with DHU) as shown in Figure 23.

ALARM

CONNECTOR

RECEPTACLE

ALARM

CONNECTOR

MINOR

ALARM

WIRES

MAJOR

ALARM

WIRES

NO

MINOR

NC

COM

NO

ALARM CONNECTOR

COM

MAJOR

DETAIL

NC

17278-A

Figure 23. External Alarm System Connections

5. Connect the Minor alarm wire pair to the MINOR COM/NC or MINOR COM/NO

terminals (whichever is required by the external alarm system) on the DHU alarm

terminal connector as shown in Figure 23.

6. Insert the alarm terminal connector into the receptacle on the DHU front panel.

7. Connect the Major and Minor alarm wire pairs to the appropriate terminals on the

external alarm system.

8. Dress and secure cable per standard industry practice.

4.12 AC Power Connections

The AC power interface between the DHU and the AC power source is supported by a 3-wire

AC power cord connector located on the DHU front panel. The AC connector provides a

connection point for the 120 VAC power cord which is provided separately with the DHU.

Use the following procedure to install the AC power cord:

Page 40

© 2006, ADC Telecommunications, Inc.

Page 19

ADCP-75-132 • Issue 2C • August 2006

1. Locate the 120 VAC power cord which is provided separately with the DHU. Use only

the AC power cord provided with the DHU or an equivalent UL/CUL listed 3-conductor,

18 AWG cord terminated in a molded-on plug cap rated 125 V, 15 A with a maximum

length of 6 feet (1.8 m).

Note: The DHU is intended to be used with a 3-wire grounding type plug which has a

grounding pin. Equipment grounding is required to ensure safe operation. Do not defeat

the grounding means. Verify DHU is reliably grounded when installed.

2. Place the DHU AC power ON/OFF switch, shown in Figure 24, in the OFF position

(press O).

3. Connect the receptacle end of the power cord to the AC connector on the DHU.

4. Route the plug end of the power cord to the specified AC outlet (per the system design)

and connect plug to outlet.

Warning: The current rating of the DHU is 2.0 Amps at 120 VAC. Avoid overloading circuits

which may cause damage to over-current protection devices and supply wiring.

5. Dress and secure cable per standard industry practice.

6. When all units of the Digivance ICS have been installed, refer to Section 4 of this

manual for the system power up and test procedures.

4.13 Create As-Built Drawing

Following installation, create an “as-built” drawing of the complete Digivance ICS system.

Using a drawing of the building floor plan, show the installed location of each piece of

equipment including the various Digivance electronic units, the antennas, the interface units,

and the microcell (if used). In addition, show the location and routing of all copper, coaxial,

and fiber optic cable runs used with the system. Retain the as-built drawing for reference

when troubleshooting or when planning for system expansion.

17276-A

AC POWER CORD

Figure 24. AC Power Connection

© 2006, ADC Telecommunications, Inc.

Page 41

Page 20

ADCP-75-132 • Issue 2C • August 2006

5 SYSTEM OPERATION

This section provides guidelines for turning-up the Digivance ICS, verifying that all units are

operating properly, testing to ensure that all performance requirements are satisfied, and

correcting any installation problems. This process assumes that the various units that comprise

the Digivance ICS have been installed in accordance with the system design plan and the BTS

interface unit (HPCP or RIU) has been installed and tested. The procedures for installing and

testing the HPCP or RIU are provided in the user manual that is shipped with the unit.

5.1 Tools and Materials

The following tools and materials are required in order to complete the procedures in this

section:

• Portable spectrum analyzer

• Portable test transmitter

• Cell phone

• Pencil or pen

• Writing pad

5.2 Turn-Up System and Verify Operation

The process of turning-up the system and verifying operation involves powering up the

various system components and then verifying that the LED indicators show normal

operation. Refer to Tables 8, 9, and 10 as needed for a complete description of the unit LED

indicators. Use the following procedure to power-up the system. If any unit does not respond

as described, refer to Subsection 5.4 for the correction procedures.

1. Temporarily disconnect the alarm system or notify alarm system provider that testing is

in progress.

2. Verify that each AC powered unit is connected to the appropriate outlet.

3. Place the ON/OFF switch on the DHU in the ON position (press I).

4. Verify that the UNIT LED and the OVERDRIVE LED on the DHU turn yellow (for

approximately 6 seconds) and then green.

5. If DHU will be connected to an ancillary interface device, adjust the level of the RF

input and output signals at the DHU and complete all remaining coaxial cable

connections as described in Section 5.3.

6. Place the PORT 1 ON/OFF switch on the DHU in the ON position (press I).

7. If a DEU is connected to port 1, proceed to step 8. If a DRU is connected to port 1, skip

steps 8 and 9 and proceed to step 10.

8. Place the ON/OFF switch on the DEU in the ON position (press I).

9. Verify that the UNIT LED on the DEU turns yellow (for approximately 6 seconds) and

then green.

Page 42

© 2006, ADC Telecommunications, Inc.

Page 21

ADCP-75-132 • Issue 2C • August 2006

10. Verify that the PORT 1 OK/NOK LED on the DHU turns yellow (for approximately 6

seconds) and then green.

11. If a DEU is connected to PORT 1, proceed to step 12. If a DRU is connected to PORT 1,

skip steps 12 through 14 and proceed to step 15.

12. Verify that the HOST PORT LED on the DEU turns green.

13. Place the PORT 1 ON/OFF switch on the DEU in the ON position (press I).

14. Verify that the PORT 1 OK/NOK LED on the DEU turns yellow (for approximately six

seconds) and then green.

15. Verify that the STATUS LED on the DRU connected to PORT 1 turns yellow (for

approximately six seconds) and then green.

16. Repeat the procedure covered in steps 6 through 15 for each of the remaining DHU

optical ports (ports 2 through 6) that is connected to a DEU or a DRU.

17. Reconnect the alarm system and notify alarm system provider that system is operational.

Table 8. Digital Host Unit LED Indicators

INDICATOR COLOR DESCRIPTION

UNIT

LED

PORT 1–6

OK/NOK

LEDs

OVERDRIVE

LED

Note: Detection of any fault will generate an alarm. A high temperature fault will generate a minor alarm

(yellow LED). All other types of faults will generate a major alarm (red LED).

Green

Yellow

Red

Off

Green

Yellow

Red

(steady)

Red

(blinking)

Off

Green

Red

Indicates when the DHU is normal or faulty.

DHU in normal state, no faults detected.

DHU high temperature fault detected. (see Note)

DHU fault detected (see Note).

AC power off to DHU or DHU internal fault.

Indicates if any connected DEU or DRU is normal or faulty or if the

optical inputs from any connected DEU or DRU are normal or lost.

All connected units in normal state, no faults detected.

High temperature fault detected in connected DEU. (see Note)

Fault detected in a connected DEU or DRU. (see Note)

No reverse path optical signal detected from a connected DEU or DRU or

excessive reverse path errors detected from a connected DEU or DRU.

(see Note)

Port disabled (via front panel switch) or DHU internal fault.

Indicates when the forward path RF input is below or above the

overdrive threshold.

RF input signal level at DHU below overdrive threshold.

RF input signal level at DHU above overdrive threshold.

© 2006, ADC Telecommunications, Inc.

Page 43

Page 22

ADCP-75-132 • Issue 2C • August 2006

INDICATOR COLOR DESCRIPTION

Table 9. Digital Expansion Unit LED Indicators

UNIT

LED

HOST PORT

LED

PORT 1–6

OK/NOK

LEDs

Green

Yellow

Red

Off

Green

Red

(blinking)

Off

Green

Yellow

Red

(steady)

Red

(blinking)

Indicates when the DEU is normal or faulty.

DEU in normal state, no faults detected.

DEU high temperature fault detected. (see Note)

DEU internal fault detected. (see Note)

AC power off to DEU or DEU internal fault.

Indicates when the optical inputs from the DHU or supporting

DEU are normal or lost.

DHU or supporting DEU in normal state, no faults detected.

No forward path optical signal detected from DHU or supporting DEU or

excessive forward path errors detected from DHU or supporting DEU.

(see Note).

DEU internal fault.

Indicates if any connected DEU or DRU is normal or faulty or if the

optical inputs from any connected DEU or DRU are normal or lost.

DRU or remote DEU in normal state, no faults detected.

High temperature fault detected in connected DEU. (see Note)

Fault detected in a connected DEU or DRU. (see Note)

No reverse path optical signal detected from a connected DEU or DRU or

excessive reverse path errors detected from a connected DEU or DRU.

Port disabled (via front panel switch) or DEU internal fault.

Off

Note: Detection of any fault will generate an alarm. A high temperature fault will generate a minor alarm

(yellow LED). All other types of faults will generate a major alarm (red LED).

INDICATOR COLOR DESCRIPTION

STATUS

LED

Note: Detection of any fault will generate an alarm. A high temperature fault will generate

a minor alarm (yellow LED). All other types of faults will generate a major alarm (red LED).

Page 44

© 2006, ADC Telecommunications, Inc.

Green

Red

(steady)

Red

(blinking)

Off

Table 10. Digital Remote Unit LED Indicator

Indicates if the DRU is normal or faulty or if the forward path optical

inputs to the DRU are normal or lost.

DRU in normal state, no faults detected.

DRU internal fault detected. (See Note)

No forward path optical signal from the DHU or DEU detected.

DC power off to DRU or DRU internal fault.

Page 23

5.3 RF Input and Output Signal Level Adjustments

The DHU may be connected to either a donor antenna or a base transceiver station through an

ancillary interface device. The following sections provide general guidelines for using the

interface device to adjust the forward and reverse path signals to the correct level.

5.3.1 Forward Path RF Signal Level Adjustment

Use the following procedure to adjust the level of the forward path composite RF signal input

to the DHU so that the maximum RF output signal level is provided at the DRU:

1. Complete all remaining forward path coaxial cable connections between the BTS and the

local interface device or between the antenna and the remote interface device as

specified in the instructions provided with the equipment.

2. Connect a spectrum analyzer or power meter to the forward path output port on the

interface device.

Note: Check the input rating of the test equipment and the output rating of the interface

device. To avoid burning out the spectrum analyzer or power meter, it may be necessary

to insert a 30 dB 100W (or similar) attenuator between the interface device and test

equipment.

ADCP-75-132 • Issue 2C • August 2006

3. Adjust the interface device to provide the maximum RF signal level at the output port.

4. If using a spectrum analyzer, proceed to step 5. If using a power meter, measure the

composite signal power from the interface device and then proceed to step 7.

5. Measure the RF level of a single carrier, such as the control channel, in dBm. Make sure

the resolution bandwidth of the spectrum analyzer is 30 kHz.

6. Calculate the total composite signal power from the interface device using the following

formula:

P

= Pc + 10Log N – (see Note)

tot

Where,

P

P

is the total composite power in dBm

tot

is the power per carrier in dBm as measured in step 4

c

N is the total number of channels.

Note: If calculating the composite power for a CDMA system, reduce the initial result

by 16.23 dBm.

7. Adjust the interface device to provide a composite RF signal level of approximately –20

dBm at the interface device RF output port.

8. Disconnect the test equipment from the interface device

9. Connect the forward path cable (attached to the RF IN connector on the DHU) to the

interface device RF output port.

© 2006, ADC Telecommunications, Inc.

Page 45

Page 24

ADCP-75-132 • Issue 2C • August 2006

10. Use the interface device to slowly increase the level of the forward path RF signal

supplied to the DHU. Make all adjustments to the signal level in 1 dB increments.

Caution: Do not supply the DHU with an RF input signal that is 0 dBm or greater or the

system could be damaged.

11. Continue to increase the forward path RF signal level until the DHU overdrive LED just

begins to turn red.

12. Reduce the level of the RF input signal by 1 dB and then verify that the DHU Overdrive

LED stays green.

5.3.2 Reverse Path RF Signal Level Adjustment

The level of the reverse path composite RF signal output from the interface must be adjusted

so that the correct RF signal level is input to the BTS or the antenna. When the level of the

reverse path signal at the DRU antenna port is at a composite maximum of –40 dBm, the level

of the RF output signal from the DHU will be –30 dBm. This equals a system gain of 10 dB.

Use the following procedure to adjust the reverse path RF signal level:

1. Complete all remaining reverse path coaxial cable connections .

2. Determine the maximum acceptable DRU path loss per the system design specifications.

3. Determine the total cable loss that will be imposed by the reverse path coaxial cables and

any other devices (splitters, connectors, etc) that will impose a lose on the signal.

4. Determine the total gain that will be provided by the DRU antenna and by the donor

antenna (if present).

5. Use the following formula to calculate the total gain or loss that must be added by the

interface device to provide unity gain:

Reverse Path Gain/Loss Required = [∑ System Insertion Loss + Designed Path Loss*] –

[System Gain (10 dB) + ∑ Antenna Gain]

*Designed path loss is defined as the loss between a BTS antenna and a donor site antenna.

6. Adjust the interface device to provide the amount of gain or loss required per the

calculation in step 5.

5.4 Test System Performance

Testing the performance of the system involves completing various RF tests and telephone

service tests that verify if the system is functioning properly. Use the following procedure to

test the system performance:

1. Verify that the forward path (downlink) input signal level at the DHU is optimized. Refer to

the High Power Conditioning Panel User Manual (ADCP-75-175) or the Remote Interface

Unit User Manual (ADCP-75-178) for the adjustment procedure.

Note: In a CDMA system, the power level is dependent on the traffic. For optimum

operation in a CDMA system, the input signal level should be set below the level of the

pilot signal.

Page 46

© 2006, ADC Telecommunications, Inc.

Page 25

ADCP-75-132 • Issue 2C • August 2006

2. Verify that the reverse path (uplink) signal level at the local BTS or donor antenna is

optimized. Note that the reverse path output signal level required is dependent on service

provider signal to noise requirements, ICS system noise floor, the service provider

equipment, and the system configuration.

3. Check and record the Received Signal Strength Indication (RSSI) and any spurious

emission levels at and between all DRU antennas. Analyze all DRU’s and the DHU

interface using a spectrum analyzer.

4. Plot the RSSI levels on a floor plan of the building and check against the pre-installation

RSSI levels to determine the overall and average RSSI improvement attributed to the

Digivance ICS. Check the entire Digivance coverage area.

5. Verify call processing and voice quality within the coverage areas. Initiate and receive

multiple long and short duration calls. Document the performance and address any issues

as calls are processed within the entire coverage area. Assuming a properly functioning

server RF link and BTS and a properly designed and optimized ICS system, there should

be no clicks, mutes, clipping, or crackles within the coverage area. In a wireless office

application, hand off will not occur.

6. If the DHU interfaces with a local BTS (microcell), verify the handoff function by

placing a call and confirming handoffs between the Digivance/microcell coverage area

and the outdoor macrocell coverage area (macro system) and vice versa. The handoff

should take place without any noticeable call quality or performance issues.

7. If the DHU interfaces with a remote BTS through a donor antenna, verify call quality by

placing a call and then walking between the Digivance coverage area and an area

receiving good coverage directly from the cell site base station. There should be no

noticeable difference in call quality.

8. Following service provider guidelines, test the 411 and 911 links to verify the routing of

emergency and special services calls on local BTS configurations.

9. Verify that the alarm reporting system functions properly by turning the DHU off. This

should generate a major and minor alarm and operate both the major and minor alarm

contacts. Check for alarm confirmation from the service provider’s local switch and

Network Operations Center (NOC). Note that this tests only the external alarm system

and does not verify operation of the Digivance alarm reporting system.

© 2006, ADC Telecommunications, Inc.

Page 47

Loading...

Loading...