Page 1

Digivance® NXD

Radio Access Node (RAN)

Installation and Maintenance Manual

ADCP-75-210

Issue 1

March 2007

21227-A

1356011 Rev A

Page 2

ADCP-75-210 • Issue 1 • March 2007 • Preface

COPYRIGHT

© 2006, ADC Telecommunications, Inc.

All Rights Reserved

Printed in the U.S.A.

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

1 02/2007 Original.

TRADEMARK INFORMATION

Digivance is a registered trademark of ADC Telecommunications, Inc.

ADC is a trademark of ADC Telecommunications, Inc.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting ADC’s Technical Assistance Center at 1-800-366-3891, extension 73475

(in U.S.A. or Canada) or 952-917-3475 (outside U.S.A. and Canada), or by e-mail to connectivity_tac@adc.com.

Page ii

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 917-1717

Page 3

TABLE OF CONTENTS

Content Page

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

RELATED PUBLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

AdmonishmentS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Safe Working Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

STANDARDS CERTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

LIST OF ACRONYMS AND ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

1 PRODUCT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 System Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 High-Level View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Dimensions and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 RAN Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.7 RAN Chassis and Electronic Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.8 Rectifier Shelf. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.9 Power Amplifier Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.10 Multiplexer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.11 Circuit Breaker Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.12 Backup Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.13 Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2 STANDARD INSTALLATION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.1 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.2 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

ADCP-75-210 • Issue 1 • March 2007 • Preface

1.6.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6.2 Fiber Optic Cable Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6.3 Antenna Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6.4 AC Power Wiring Entry and Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6.5 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.7.1 cPCI Power Supply Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.7.2 Central Processing Unit (CPU) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.7.3 System Interface (STF2) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.7.4 Synchronous Interface (SIF) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.7.5 Small Form-Factor Pluggable (SFP) Optical Transceiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.7.6 RAN Down Converter (RDC or RDC2) Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.7.7 RAN Up Converter (RUC2.X or RUC3) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.7.8 Fan Access Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.7.9 800 MHz Multicoupler (C/MCPLR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.7.10 1900 MHz Multicoupler (P/MCPLR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.8.1 Rectifier Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.8.2 Low Voltage Disconnect (LVD) Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

© 2007, ADC Telecommunications, Inc.

Page iii

Page 4

ADCP-75-210 • Issue 1 • March 2007 • Preface

TABLE OF CONTENTS

Content Page

2.3 Required Materials and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.4 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.4.1 Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.4.2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.4.3 Antenna Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.4.4 RF Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.4.5 Fiber Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.5 Installing a RAN Cabinet on a Wooden Utility Pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.5.1 Site Requirements Unique to Pole Mounting Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.5.2 Pole Loading Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.5.3 Installing the Cabinet Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.5.4 Mounting the RAN Cabinet on the Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.5.5 Installing the Rain Shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.6 Installing a RAN Cabinet on a Concrete Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.6.1 Pouring a Concrete Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.6.2 Mounting the Cabinet on a Concrete Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.6.3 Installing the Pedestal Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.7 Other Standard Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.7.1 Installing a Solar Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.7.2 Installing a Ground Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.7.3 Installing RF Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.7.3.1 Weatherproofing RF Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.7.3.2 Routing and Securing RF Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.7.4 Installing Pre-Connectorized Indoor/Outdoor Fiber Optic Cable . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.7.5 Installing AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.7.6 Installing Backup Batteries (Extended or Glitch) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.7.6.1 Battery Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.7.6.2 Battery Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3 INSTALLING AN EXTENSION RAN (POLE MOUNT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4 NON-STANDARD INSTALLATION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.1 Installing an Electronic Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.1.1 Installing a Central Processing Unit (CPU) Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.1.2 Installing a Systems Interface (STF2) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.1.3 Installing a Synchronous Interface (SIF) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.1.4 Installing a Small Form-Factor Optical Transceiver (SFP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.1.5 Installing a RAN Down Converter (RDC or RDC2) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.1.6 Installing a RAN Up Converter (RUC2.X or RUC3) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.2 Installing cPCI Chassis Air Baffles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.3 Installing a Rectifier Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.4 Installing a Compact PCI Power Supply (cPCI P/S) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.5 Installing a Power Amplifier Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Page iv

© 2007, ADC Telecommunications, Inc.

Page 5

TABLE OF CONTENTS

Content Page

5 MAINTENANCE PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.1 cPCI Fan Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.2 Cleaning or Replacing an Air Inlet Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6 CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

ADCP-75-210 • Issue 1 • March 2007 • Preface

© 2007, ADC Telecommunications, Inc.

Page v

Page 6

ADCP-75-210 • Issue 1 • March 2007 • Preface

TABLE OF CONTENTS

Content Page

Page vi

© 2007, ADC Telecommunications, Inc.

Page 7

ABOUT THIS MANUAL

This manual provides the following information:

• An overview of the Digivance NXD system;

• A description of the NXD system Radio Access Node (RAN);

• Installation procedures for the RAN;

• Maintenance procedures for the RAN;

• Product support information.

Procedures for installing and operating other NXD system components including the system

“Hub” and the EMS software that provides a user interface for the system, are available in other

ADC publications, listed under “Related Publications” below, and at appropriate points within

this manual.

RELATED PUBLICATIONS

ADCP-75-210 • Issue 1 • March 2007 • Preface

Listed below are related manuals, their content, and their publication numbers. Copies of these

publications can be ordered by contacting the Technical Assistance Center at 1-800-366-3891,

extension 73476 (in U.S.A. or Canada) or 952-917-3476 (outside U.S.A. and Canada). All ADC

technical publications are available for downloading from the ADC web site at www.adc.com.

Title/Description ADCP Number

Digivance CXD/NXD Hub Installation and Maintenance Manual 75-193

Provides instructions for installing and operating the NXD system Hub.

Digivance CXD/NXD SNMP Agent and Fault Isolation User Guide 75-195

Describes how to troubleshoot the system using the parameters accessed

through the NXD system SNMP agents.

Digivance CXD/NXD Element Management System User Manual 75-199

Provides instructions for installing and using the Element Management System

(EMS) software for the NXD system.

Digivance NXD Multi-Band Distributed Antenna System Operation Manual 75-209

Provides instructions for turning up and operating NXD equipment.

2 in. O.D. Quad Cellular/PCS Omni-Directional Antenna Installation Manual 75-215

Provides instructions for installing an RF antenna for the NXD system

9 in. O.D. Quad Cellular/PCS Omni-Directional Antenna Installation Manual 75-221

Provides instructions for installing an RF antenna for the NXD system

© 2007, ADC Telecommunications, Inc.

Page vii

Page 8

ADCP-75-210 • Issue 1 • March 2007 • Preface

ADMONISHMENTS

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times.

These warnings are flagged by use of the triangular alert icon (seen below), and are listed in

descending order of severity of injury or damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warn ing: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

GENERAL SAFETY PRECAUTIONS

-

Warn ing: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrically-powered equipment. To prevent electrical shock, never install or

use electrical equipment in a wet location or during a lightning storm.

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the eye. Do not look into the ends of any optical fiber. Do not

look directly into the optical transceiver of any digital unit or exposure to laser radiation may

result. An optical power meter should be used to verify active fibers. A protective cap or hood

MUST be immediately placed over any radiating transceiver or optical fiber connector to avoid

the potential of dangerous amounts of radiation exposure. This practice also prevents dirt

particles from entering the adapter or connector.

Caution: This system is a RF Transmitter and continuously emits RF energy. Maintain 3 foot

(91.4 cm) minimum clearance from the antenna while the system is operating. Wherever

possible, shut down the RAN before servicing the antenna.

Caution: Always allow sufficient fiber length to permit routing of patch cords and pigtails

without severe bends. Fiber optic patch cords or pigtails may be permanently damaged if bent

or curved to a radius of less than 2 inches (5.1 cm).

Caution: Exterior surfaces of the RAN may be hot. Use caution during servicing.

Page viii

© 2007, ADC Telecommunications, Inc.

Page 9

SAFE WORKING DISTANCES

The Digivance NXD antenna, which is mounted on top of a pole, radiates radio frequency

energy.

For the occupational worker, safe working distance from the antenna depends on the workers

location with respect to the antenna and the number of wireless service providers being serviced

by that antenna.

Emission limits are from OET Bulletin 65 Edition 97-01, Table 1 A.

STANDARDS CERTIFICATION

FCC: The Digivance NXD complies with the applicable sections of Title 47 CFR Part 15, 22,

24 and 90.

The Digivance NXD Hub has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications.

ADCP-75-210 • Issue 1 • March 2007 • Preface

Changes and modifications not expressly approved by the manufacturer or registrant of this

equipment can void your authority to operate this equipment under Federal Communications

Commissions rules.

In order to maintain compliance with FCC regulations, shielded cables must be used with this

equipment. Operation with non-approved equipment or unshielded cables is likely to result in

interference to radio & television reception.

ETL: This equipment complies with ANSI/UL 60950-1 Information Technology Equipment.

This equipment provides the degree of protection specified by IP24 as defined in IEC

Publication 529. Ethernet signals are not for outside plant use.

FDA/CDRH: This equipment uses a Class 1 LASER according to

FDA/CDRH Rules. This

product conforms to all applicable standards of 21 CFR Part 1040.

IC: This equipment complies with the applicable sections of RSS-131. The term “IC:” before

the radio certification number only signifies that Industry Canada Technical Specifications

were met.

Wind Loading: The NXD RAN is able to withstand wind loads up to 150 mph.

© 2007, ADC Telecommunications, Inc.

Page ix

Page 10

ADCP-75-210 • Issue 1 • March 2007 • Preface

LIST OF ACRONYMS AND ABBREVIATIONS

The acronyms and abbreviations used in this manual are detailed in the following list:

AC Alternating Current

ANT Multiband Antenna

BIM Base Station Interface Module

BTS Base Transceiver Station

C Centigrade

CDRH Center for Devices and Radiological Health

C/MCPLR Cellular SMR Multicoupler

CM Centimeter

cPCI CompactPCI

CPU Central Processing Unit

CXD Compact RAN

DAS Distributed Antenna System

dB(FS) decibals (Full Scale – digital reading)

DC Direct Current

Div Diversity

EMS Element Management System

ESD Electrostatic Discharge

F Fahrenheit

FDA U.S. Food and Drug Administration

FCC U.S. Federal Communications Commission

GPS Global Positioning System

IC Industry Canada

IN Inch

IP Internet Protocol

KG Kilogram

LED Light Emitting Diode

LSE Location Services Equipment

LV D Low Voltage Disconnect

MHz Mega Hertz

MTBF Mean Time Between Failure

MUX Multiplexer

Node Any CPU in the Digivance NXD system

NXD Digivance Neutral Host Product Line

OSP Outside Plant

PA Power Amplifier

PAA Power Amplifier Assembly

PC Personal Computer

PCI Peripheral Component Interconnect bus

PIC PA Interface Controller

Page x

© 2007, ADC Telecommunications, Inc.

Page 11

ADCP-75-210 • Issue 1 • March 2007 • Preface

P/MCPLR PCS Multicoupler

RAN Radio Access Node

RDC RAN Down Converter

RDC2 RAN Down Converter Version 2

RF Radio Frequency

RUC RAN Up Converter

RUC2.X RAN Up Converter Version 2.X

RUC3 RAN Up Converter Version 3

SFP Small Form-Factor Pluggable Optical Transceiver

SIF Sonet Interface Module

SNMP Simple Network Management Protocol

SONET Synchronous Optical Network

STF2 System Interface Module

UL Underwriters Laboratories

VA C Volts Alternating Current

VDC Volts Direct Current

VSWR Voltage Standing Wave Ratio

WDM Wave Division Multiplex

WSP Wireless Service Provider

© 2007, ADC Telecommunications, Inc.

Page xi

Page 12

ADCP-75-210 • Issue 1 • March 2007 • Preface

Page xii

© 2007, ADC Telecommunications, Inc.

Page 13

1 PRODUCT DESCRIPTION

This section describes the Digivance Neutral Host (NXD) Radio Access Node (RAN).

1.1 General Description

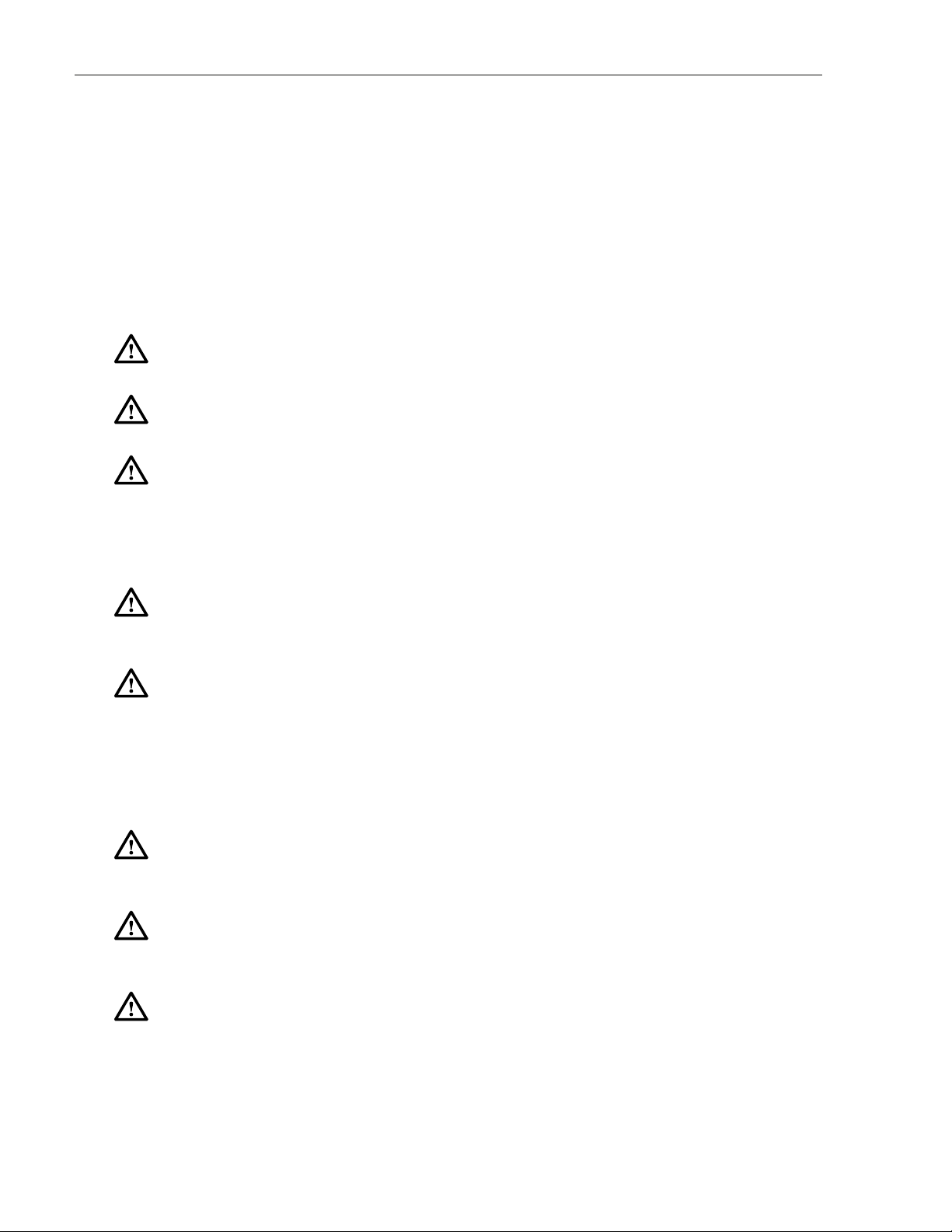

The RAN, shown in Figure 1, is the remote component in the Digivance NXD Multi-Band

Distributed Antenna System. The RAN is a pole-mounted or pad-mounted, weather-resistent

cabinet, housing electronic modules that operate on an internal cPCI backplane. Included are a

central processing unit, a system interface, an optical interface, optical to RF data converters,

RF multicouplers, and DC power supplies. The RAN also houses rectifiers, backup batteries,

power amplifiers, and optical wave division multiplexers. Optical and RF functions are both

required because the RAN exchanges data with the system Hub using an optical link and

exchanges data with wireless users using RF signals. Each RAN provides the system with an RF

antenna and can accommodate up to four bands (

RANs installed at the same location can accommodate up to eight bands using a common

antenna.

ADCP-75-210 • Issue 1 • March 2007

PCS A-F, SMR A, Cell A”/A, or Cell B/B’). Dual

Figure 1. NXD RAN

21227-A

Page 1

© 2007, ADC Telecommunications, Inc.

Page 14

ADCP-75-210 • Issue 1 • March 2007

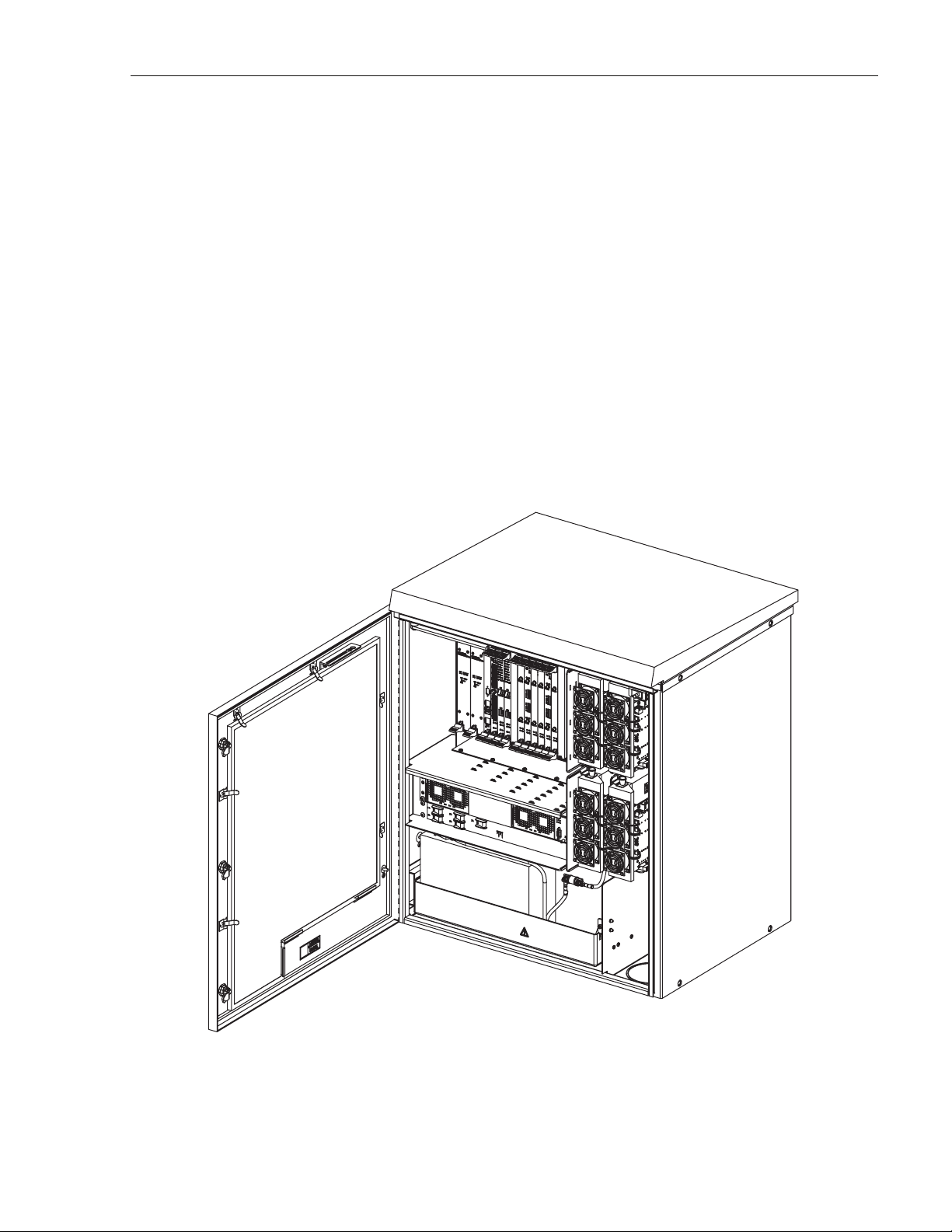

1.2 System Function

The NXD Distributed Antenna System (DAS), in which the RAN is the remote component, is a

multi-frequency, multi-protocol RF access network providing microcellular Cellular and PCS

coverage via a distributed RF access system. In a typical configuration, such as shown in

Figure 2, multiple RANs are connected to a central Hub where multiple Base Transceiver

Station (BTS) interfaces are located. Signals received at the Hub are distributed to the RANs in

digital form by way of a fiber optical link. Within the RANs, the signals are converted from

digital to RF format to be transmitted from the RAN antennas. Signals also travel in a reverse

direction, from the RANs to the Hub, with a reverse data conversion.

Physically, the DAS consists primarily of electronic modules located in the Hub and RANs. At

the Hub, these modules are mounted in an equipment rack typically housed in a common

telecommunications structure with the base station electronics for Wireless Service Providers

(WSPs), either in the same room or nearby. These modules include high power attenuators, base

station modules, a power distribution unit, an Ethernet hub, a Hub reference module, an RF

chassis, and one or more digital chassis. The RAN electronic modules, mounted in the RAN

cabinet, perform the remote system functions of optical to RF data conversion and RF access.

These modules are described in subsequent topics within this product description. Digivance

Element Management System (EMS) software, running on a computer located at the Hub,

provides a graphical user interface to monitor system performance.

RF

SIGNALS

Access

WIRELESS

SERVICE

PROVIDERS

(WSPs)

Radio

Node

Digital

Fiber

Distribution Hub - EMS Server,

located on Hub Master, monitors

Hub Nodes and RANs

BTS BTS BTS BTS

21013-A

Page 2

© 2007, ADC Telecommunications, Inc.

Figure 2. System Function

Page 15

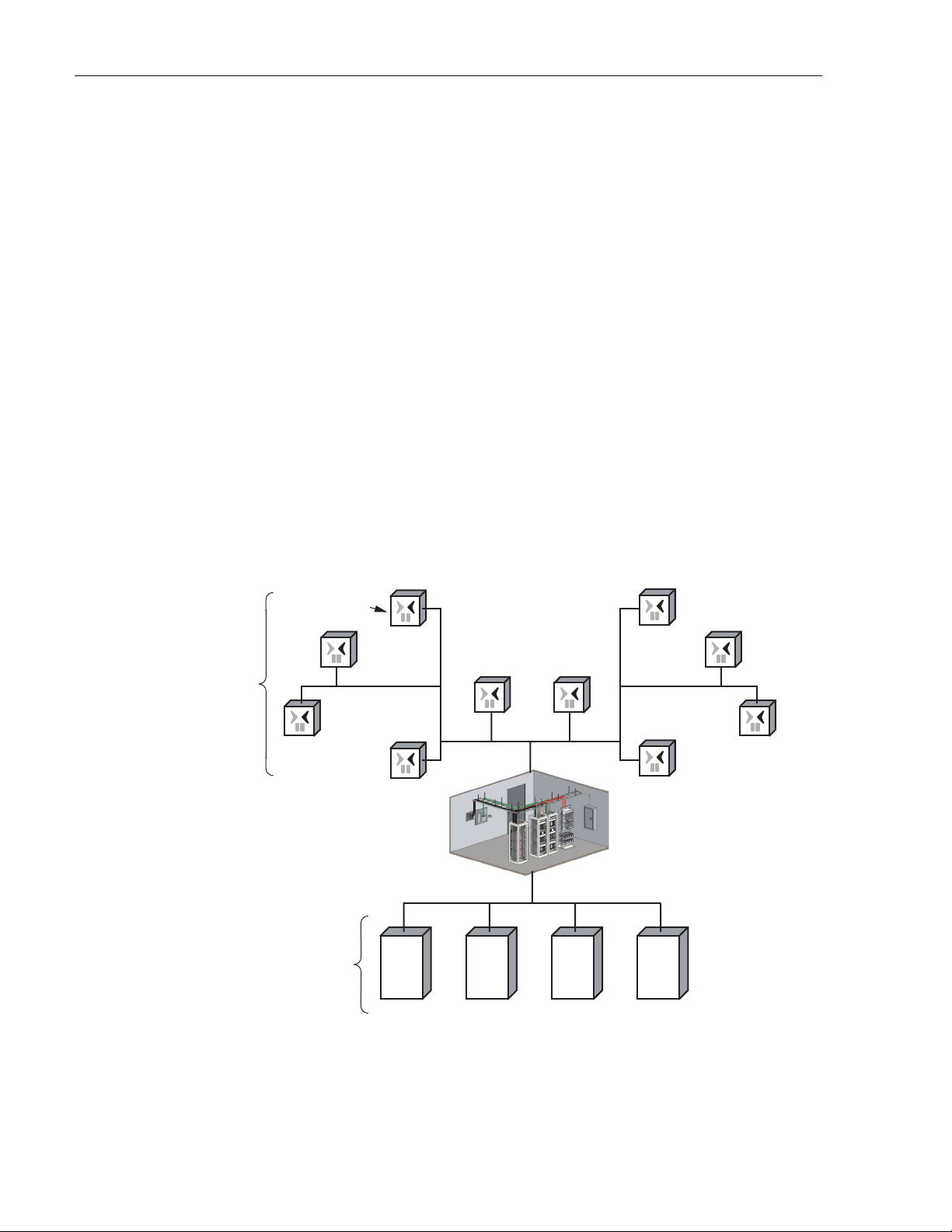

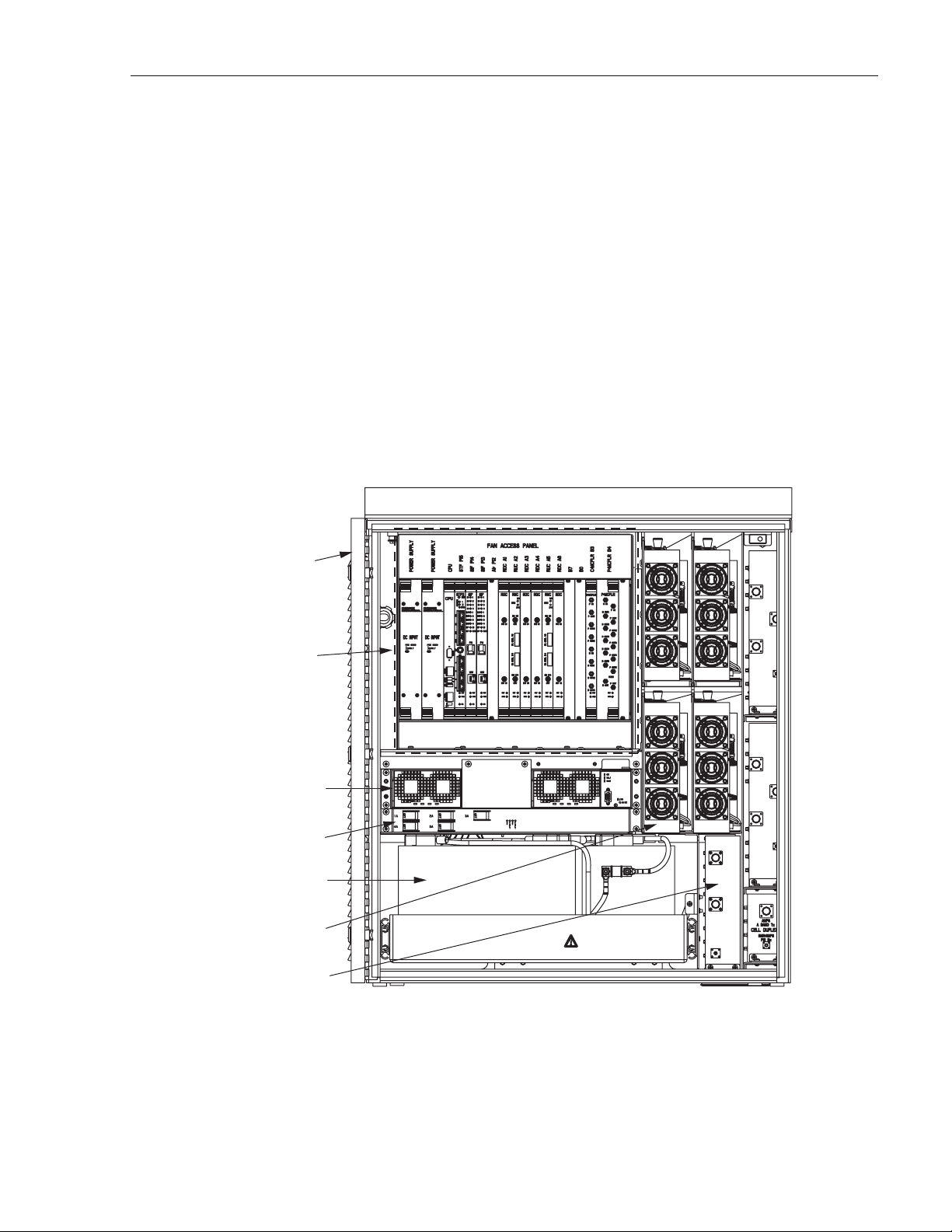

1.3 High-Level View

The RAN consists of the main components shown in a high-level view in Figure 3. These

components include:

• RAN Cabinet: exterior shell of the RAN containing cable connection points, ground

studs, and slots or shelves supporting other RAN components.

• RAN Chassis: standard Compact PCI (cPCI) shelf capable of housing 21 industry

standard cPCI circuit card modules. The modules are plugged into a common backplane

providing data bussing between them.

• Related Electronics: including rectifiers, Power Amplifier Assemblies (PAAs), batteries,

multiplexers, and a circuit breaker panel.

All components called out in the figure except for the multiplexers are separately installable in

the field. In most cases, however, the RAN is shipped with a basic set of components having

been ordered in advance by the customer and installed in the factory.

ADCP-75-210 • Issue 1 • March 2007

RAN

CABINET

RAN CHASSIS

AND ELECTRONIC

MODULES

RELATED

ELECTRONICS:

RECTIFIERS

CIRCUIT

BREAKER

PANEL

BACKUP

BATTERIES

POWER

AMPLIFIER

ASSEMBLIES

(PAAs)

MULTIPLEXERS

21281-A

Figure 3. High Level View

© 2007, ADC Telecommunications, Inc.

Page 3

Page 16

ADCP-75-210 • Issue 1 • March 2007

1.4 User Interface

The RAN user interface consists of the various connectors, fittings, mounting slots, power

cords, switches, and indicators that are of relevance to the user in installation and operation

procedures. The user interface is shown in Figure 4 and described in Tabl e 1.

FAN ACCESS

PANEL (1)

RECTIFIER

COMPARTMENT

(UP TO 3)

ELECTRONIC

MODULES (21)

COMPARTMENT

(UP TO 4)

POWER AMPLIFIER

ASSEMBLIES (4)

RF

CABLES

MUXs BATTERY

GPS

PCS-P

PCS-D

CELL/

SMR-D

CELL/

SMR-P

FIBER

PORT

PRIME

POWER

PORT

EARTH

GROUND

STUDS

REAR FRONT

DOOR

ALARM

(1)

Page 4

© 2007, ADC Telecommunications, Inc.

AIR INLET

FILTER (1)

21290-A

KNOCK-OUTS FOR

2nd RAN WIRING FROM

RAN A TO RAN B

Figure 4. User Interface

Page 17

ADCP-75-210 • Issue 1 • March 2007

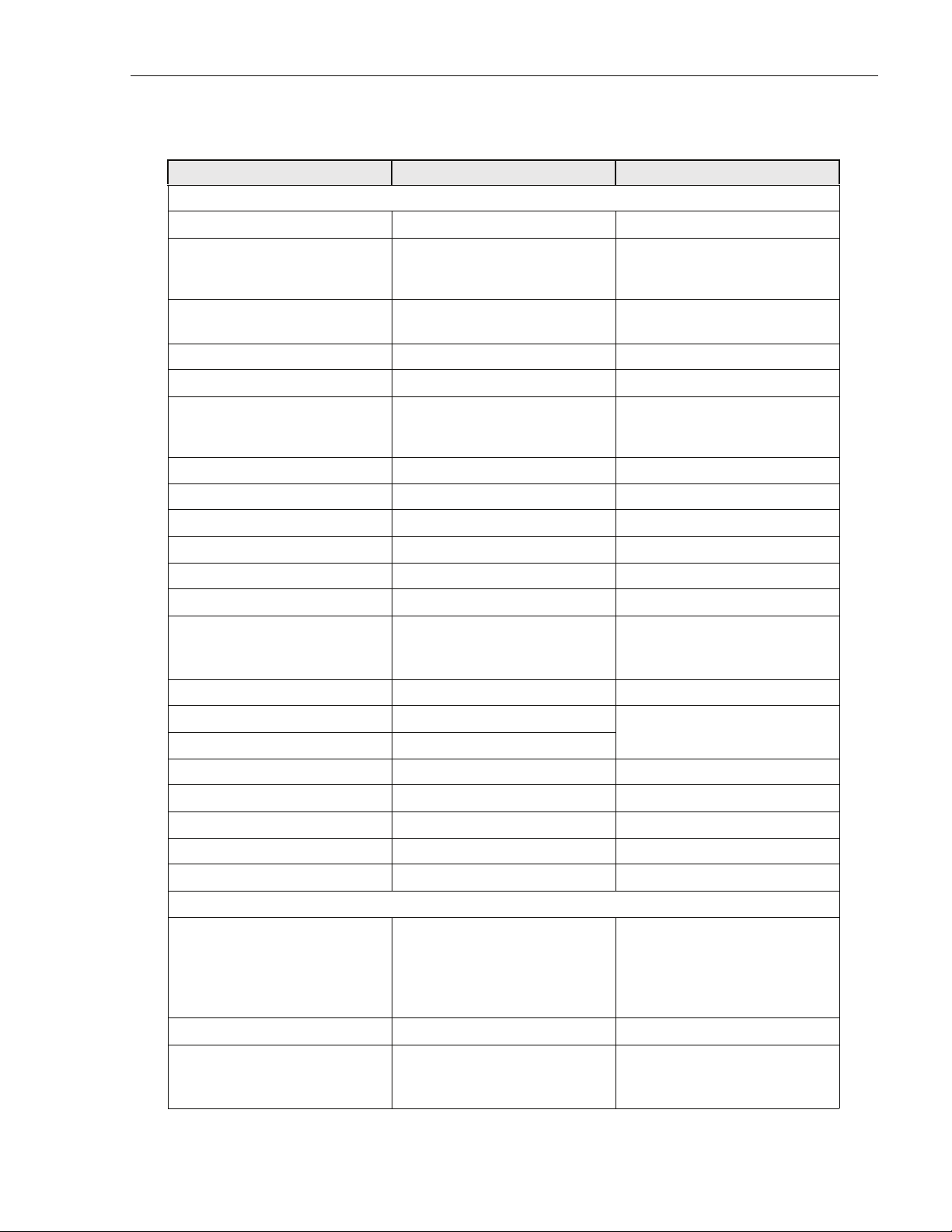

Table 1. RAN Cabinet User Interface

COMPONENT WHY RELEVANT FOR MORE INFORMATION

Front View

Fan Access Panel Panel swings down providing access to

Section 1.7.8 on Page 20

internal fan compartment; fans can be

replaced as required

Electronic Modules Electronic modules have indicators

Section 1.7 on Page 10

monitored by the user

Electronic modules can be installed and

Section 4.1 on Page 57

replaced as required

Interconnection diagram summarizes

connections between modules

Power Amplifier Assemblies PAAs have indicators monitored by

Figure 40 on Page 58;

Figure 41 on Page 59

Section 1.9 on Page 25

user

PAAs can be installed or replaced as

Section 4.5 on Page 68

required

Rectifier Compartment Rectifiers have four unmarked LEDs Section 1.8 on Page 23

Rectifiers can be individually installed

Section 4.3 on Page 66

and replaced as required

Battery Compartment Batteries are packaged separately and

Section 2.7.6 on Page 50

installed in a standard installation; they

can be replaced as required

Rear Access

GPS, PCS-P, PCS-D,

CELL/SMR-D,

CELL/SMR-P

Connection points for RF cables connecting RAN with GPS antenna and RF

antenna.

Section 2.7.3 on Page 45;

Table 21 on page 47

Fiber Optic Cables Connection

Point

Prime Power Contact Contact point for power ingress. RAN

Connection point for fiber optic cable

from Hub

Section 2.7.4 on Page 47

Section 2.7.5 on Page 49

requires 240 VAC, single phase, 20

Amps service, typically routed from a

pole- or pad-mounted junction box

Earth Ground Studs Connection point for ground wires Section 2.7.2 on Page 44

Oblique View

Air Inlet Filter Filters are replaced per maintenance

Section 5.2 on Page 70

schedule

Door Alarm Replaceable switch

Knock-Outs for 2nd RAN Wiring from RAN A to RAN B

When two RANs are installed at the

same location, an omnibus cable is

Section 3 on Page 54

routed from RAN A to RAN B through

these knockout holes

© 2007, ADC Telecommunications, Inc.

Page 5

Page 18

ADCP-75-210 • Issue 1 • March 2007

1.5 Dimensions and Specifications

FRONT SIDE

36.5 IN.

(92.7 CM)

31.0 IN.

(78.7 CM)

Figure 5. NXD RAN Dimensions

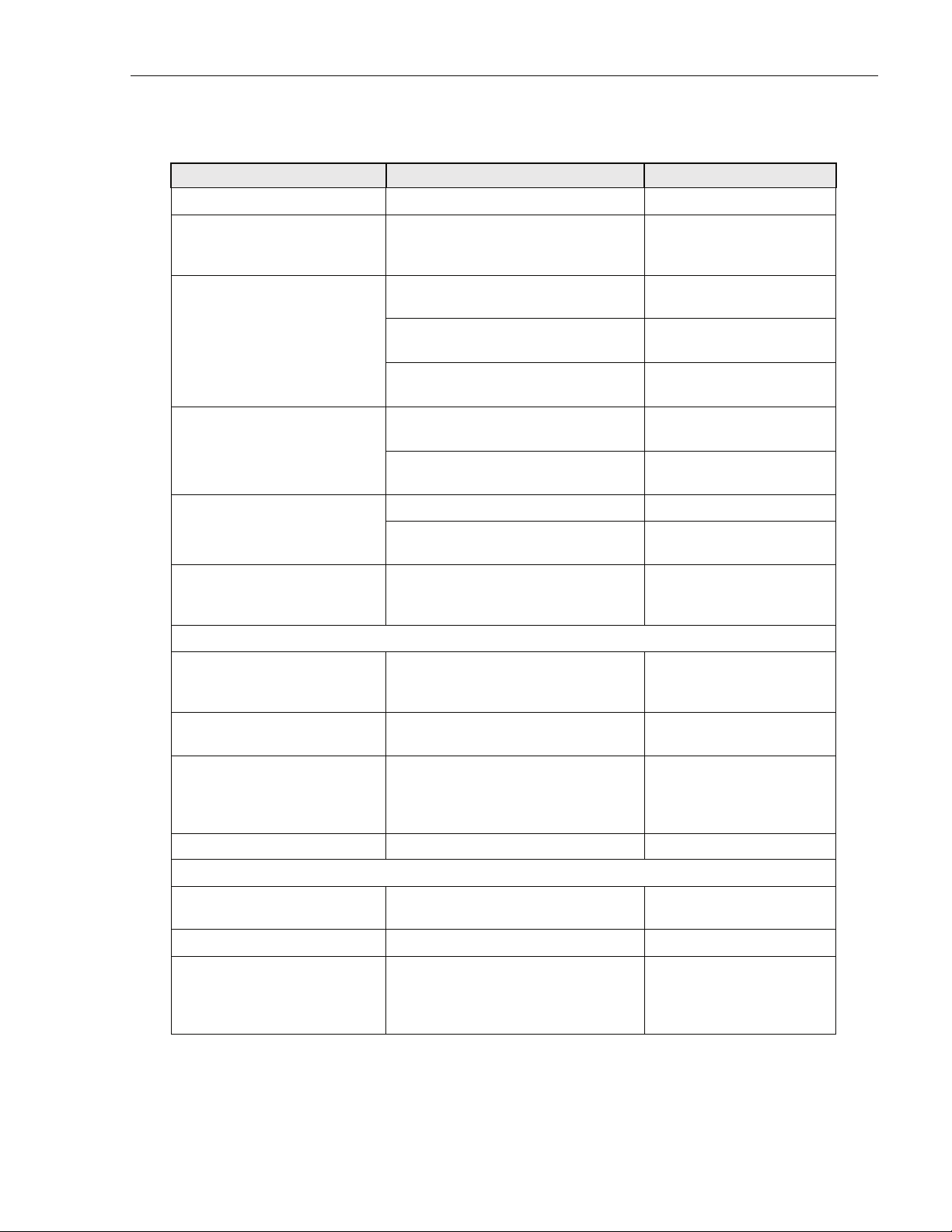

Table 2. RAN Specifications

ITEM SPECIFICATION COMMENT

Physical and Mechanical

Dimensions (HxWxD) 36.5 x 31.0 x 24.0 inches

See also Figure 5

(92.7 x 78.7 x 60.1 cm)

Weight

with extended batteries (4)

300 lbs. (136.4 kg)

625 lbs. (284.1 kg)

RAN without batteries

Total RAN + 4 batteries

Color Putty white

Bands per box

Boxes per RAN site

RF connections

Up to 4

Up to 2 RANs

RAN cabinet has

5 Type N plugs

Cable type: CommScope PN

540ANM or equivalent

Environmental and Thermal

24.0 IN.

(60.1 CM)

21228-A

Box thermal management External air Variable speed fans (PIC/PA

Assembly and cPCI)

Operating temperature -40 to +50 degrees C -40 to 122 degrees F

Cold-start temperature -20 to +50 degrees C -4 to 122 degrees F

Storage temperature -40 to +85 degrees C -40 to 185 degrees F

Internal air temperature 0 to 60 degrees C 32 to 140 degrees F

Weather resistance NEMA-3R

Operational humidity 95%

Acoustic emissions 63 dBA

Page 6

© 2007, ADC Telecommunications, Inc.

Page 19

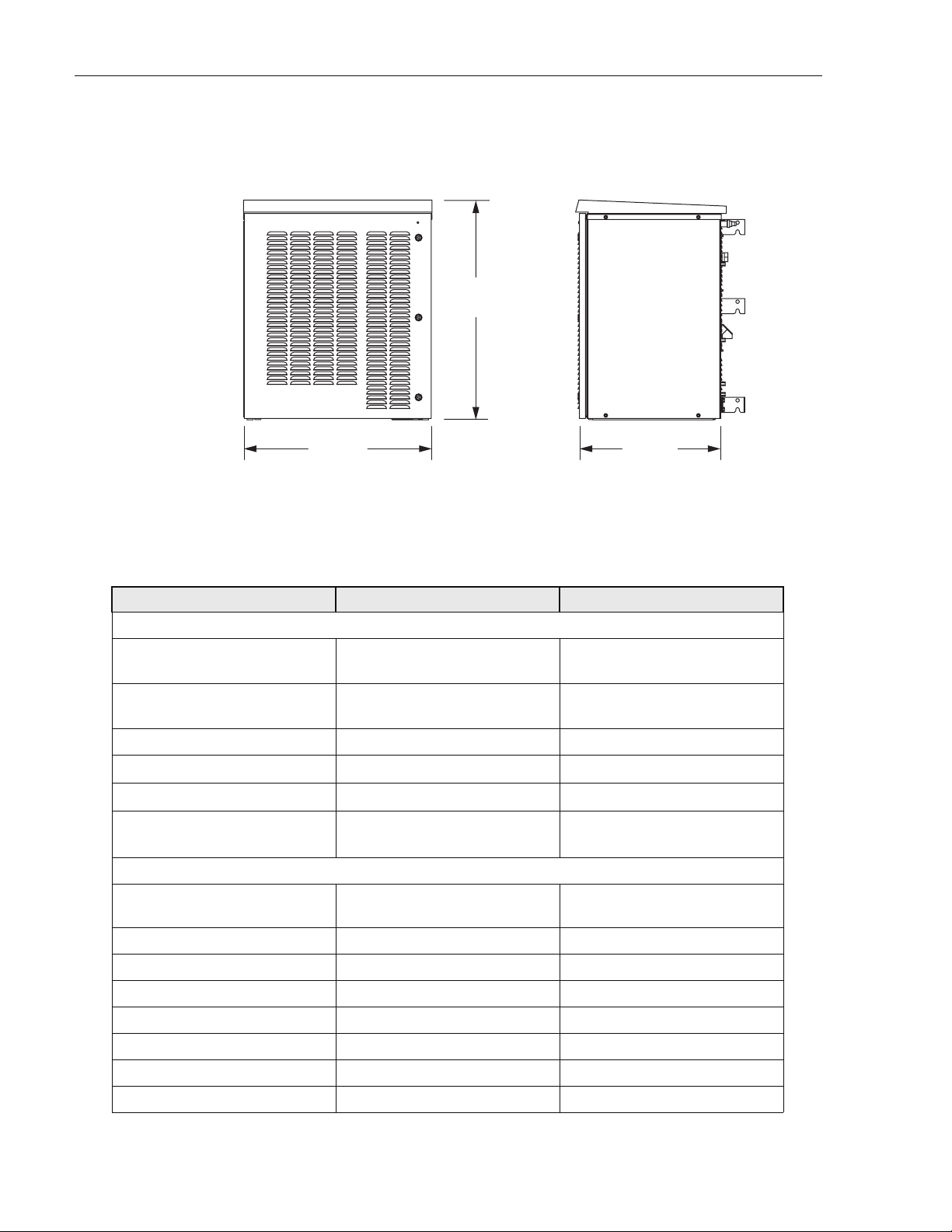

Table 2. RAN Specifications

ITEM SPECIFICATION COMMENT

Power

AC power ingress 240 VAC, 20 Amps, single phase

ADCP-75-210 • Issue 1 • March 2007

Battery backup options

extended

glitch

120 minutes

5 minutes

-48 volts

@25 degrees C (degrees F)

for four bands

RAN box power use 2700 Watts Max.

16 Amps Max.

cPCI rack power -48 VDC

Optical

Fiber cable ingress Nylon connector accommodates

cable diameters in range 0.38-

For larger cable sizes, refer to the

note in Section 1.6.2 on Page 9.

0.50 inches (0.97-1.27 cm).

Fiber type Corning SMF-28 or equivalent

Optical connectors LC Standard on SFP transceivers

Insertion loss 0.2 dB Typical, 0.4 dB Max.

Number of fibers required 1-4 fiber runs per RAN

Fiber configuration Star (point to point) or ring Ran ring limited to 3 SIFs

Fiber data link protocol OC-48

Wavelengths per fiber

with WDM option

with CWDM option

1 (1310 nm)

2 (1310/1550)

8 (1470-1610)

Without WDM/CWDM option

20 nm increments (ITU-GRID)

Optical transceiver type SFP Dual LC connector

Optical Tx power -3 dBm Max, -10 dBm Min. Finistar FTRJ-1320-1

Optical Rx sensitivity -22 dBm Typical, -18 dBm Max.

(or equivalent)

Optical link margin 2 dB Estimated

Optical link loss 6 dB Estimated

Optical Rx saturation level -3 dBm Min. Max. operational power

Optical Rx damage level -3 dBm Min. Max survivable power

Optical safety class 1 ANSI Z 136.2

RF

Tuning frequency

PCS band

Cellular band

SMR 800 band

SMR 900 band

Receive Path

1850-1910 MHz

824-849 MHz

806-824 MHz

896-901 MHz

Transmit Path

1930-1990 MHz

869-894 MHz

851-869 MHz

935-940 MHz

Instantaneous bandwidth 15 MHz

Receiver noise figure

PCS band

Cellular band

6 dB

5 dB

Measured at Hub output connector (BIM, RxP) without BTS at 10

dB gain and a single RAN

© 2007, ADC Telecommunications, Inc.

Page 7

Page 20

ADCP-75-210 • Issue 1 • March 2007

Table 2. RAN Specifications

ITEM SPECIFICATION COMMENT

Input IP3 -21 dBm Two tone tests at -56 dBm

Received signals

In band

Out of band +/- 8.5 MHz

Out of band +11/-13 MHz

Out of band +13/-16 MHz

-41 dBm

-3 dB

-43 dB

-83 dB

RDC capability (at cabinet input)

A/D clip level, single RF channel

Selectivity

Selectivity

Selectivity

(function of SAW filter)

Automatic gain control

Detector integration time

Attack time

Decay time

Gain control range

Gain in series with BTS -10 to +10 dB Lower limit for simulcast with a

Gain parallel to BTS 0 to +30 dB Allows injection after BTS

Gain stability +/- 2dB Over temperature, frequency, and

System Bandwidth

Forward Path

Reverse Path

Impedance 50 ohm

Output Power

Cellular/SMR 10 Watt MCPA

PCS 20 Watt MCPA

Gain resolution 1 dB

Gain measurement Configured at startup using fac-

10 usec

0 usec

0 usec

30 dB

15 MHz block increments

15 MHz block increments

6.5 Watts (+38 dBm) composite

12.5 Watts (+41 dBm) composite

Activated if A/D clips, changes

gain of A/D and gain in digits.

Design ensures analog gain and

digital gain change will be timed

correctly. 15 dB noise figure at

-14 dB gain

host tower site, the max reduces

effect of cascaded noise figure

amplifiers

aging valid for input signals

below AGC threshold

At antenna port

At antenna port

tory calibration of modules and

user data

Note: The Manufacturer’s rated output power of this equipment is for single carrier

operation. For situations when multiple carrier signals are present, the rating would have

to be reduced by 3.5 dB, especially where the output signal is re-radiated and cause

interference to adjacent band users. The power reduction is to be by means of input power

or gain reduction and not by an attenuator at the output of the device.

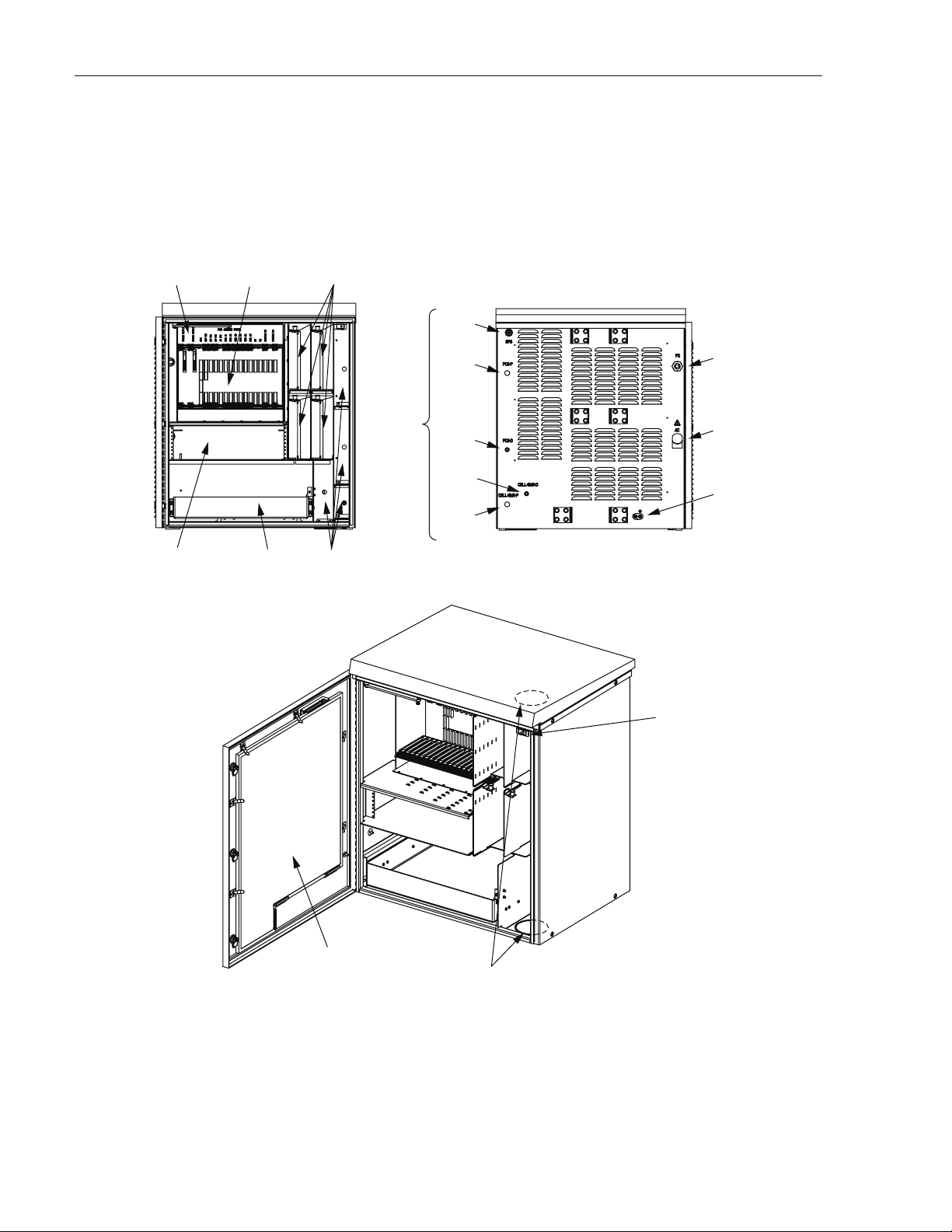

1.6 RAN Cabinet

The RAN cabinet is a NEMA-3R enclosure designed to protect its electronic components from

weather and human tampering. The cabinet is weather-tight but contact with salt-air mist should

be avoided as it may decrease the mean time between failure of some components. The cabinet

has ventilation openings to allow entry of cool air and escape of hot air. The cabinet provides

Page 8

© 2007, ADC Telecommunications, Inc.

Page 21

ADCP-75-210 • Issue 1 • March 2007

termination points for the coaxial antenna cable, fiber optic cable, ground cable, and AC cable.

The cabinet has inbuilt AC power surge protection and limited storage for fiber optic cables.

1.6.1 Mounting

The RAN cabinet may be mounted on a wood pole or on a concrete pad. Mounting bracket kits

(available from ADC) are required for each type of installation.

1.6.2 Fiber Optic Cable Entry

A nylon connector is provided on the rear of the RAN cabinet for routing a fiber optic cable into

the cabinet. The cord connector provides cable strain relief and a watertight seal at the fiber

optic cable entry point. As the connector nut is tightened, a soft neoprene bushing compresses to

tightly grip the cable without applying excessive force to the fibers. The connector

accommodates cables of a diameter in the range .38 to .50 inches (.97 to 1.27 cm).

Note: If the installer has a larger cable, the manufacturer (Hubbell Inc.) makes bushings

that fit this connector in the following size ranges: .500-.625, .625-.750, .750-.875, .875-

1.00, 1.00-1.125 inches.

In a typical installation, the connectorized end of a multi-fiber OSP cable is routed into the

cabinet through the cord connector and the individual fibers are connected to the optical

transceiver on the Synchronous Interface Card (SIF). Excess slack is stored inside the cabinet.

The stub end of the cable is routed to an external splice enclosure (not provided) for splicing to

the outside plant fiber optic cable.

1.6.3 Antenna Cable Connections

Five N-type plugs are provided on the rear of the RAN cabinet for connecting the antenna

coaxial cables. On the inside of the cabinet, coaxial jumper cables (included with the cabinet)

are used for connecting to the antenna port on the appropriate multiplexer.

1.6.4 AC Power Wiring Entry and Grounding

The NXD RAN uses 240 VAC power. A one inch (2.54 cm), 90 degree rigid elbow conduit

fitting is provided on the rear of the cabinet. The conduit should be routed to an external

junction box (not provided). It is suggested that an external AC outlet (not provided) be installed

near the cabinet to power test equipment and power tools. The AC source should supply 50/60

Hz, single-phase power through a circuit breaker rated at 20 Amps.

1.6.5 Ventilation

Ventilation openings are provided in the front door of the RAN cabinet to permit entry of air for

cooling. A filter removes dirt particles so that only clean air enters the cabinet. The heated air

exits the cabinet through the rear side. The four PAAs are each equipped with three cooling fans

that pull air through the module and exhaust it to the rear of the cabinet. A fan assembly at the

top of the RAN chassis forces the air out the rear side of the cabinet.

© 2007, ADC Telecommunications, Inc.

Page 9

Page 22

ADCP-75-210 • Issue 1 • March 2007

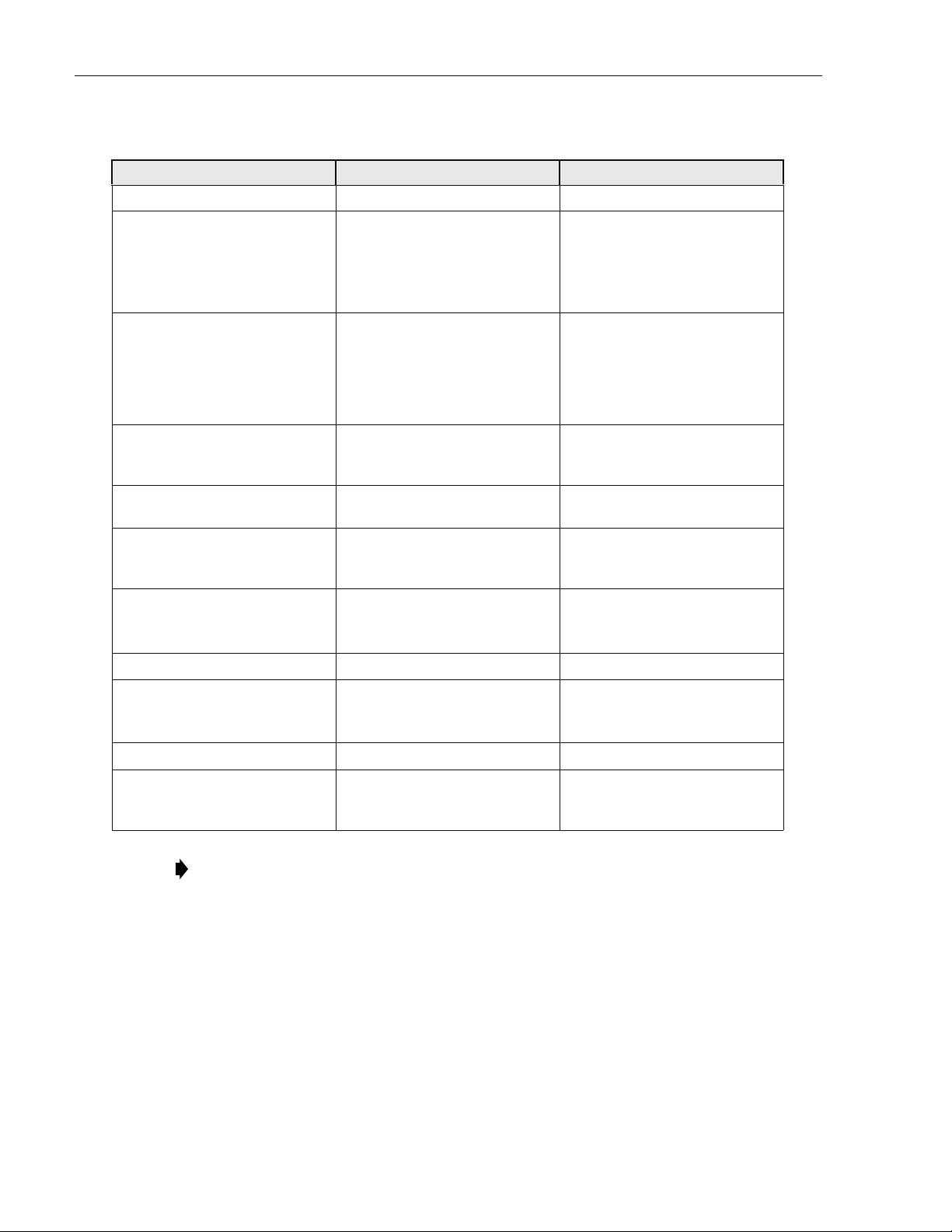

1.7 RAN Chassis and Electronic Modules

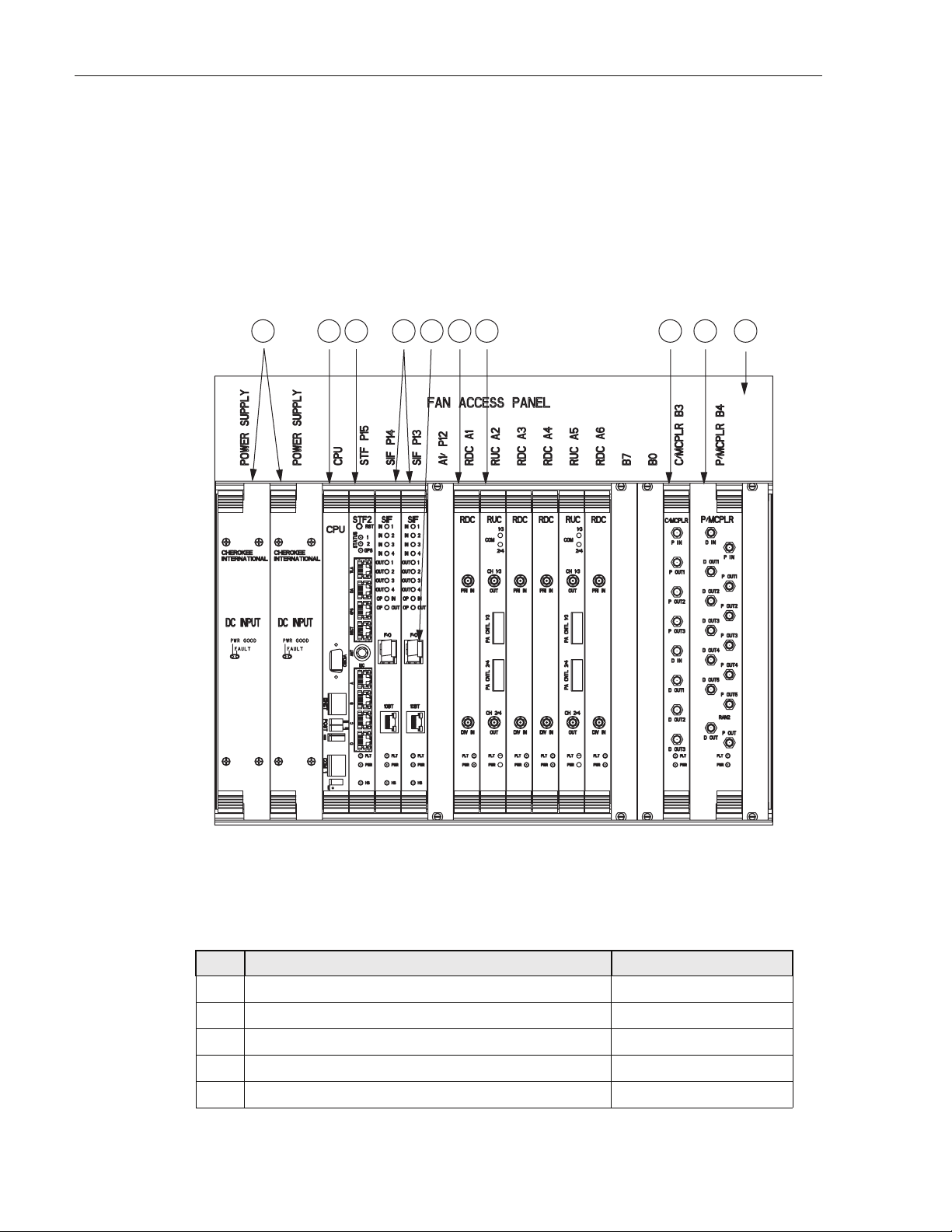

The RAN chassis, shown in Figure 6, is a standard Compact PCI (cPCI) shelf capable of

housing 21 industry standard cPCI circuit cards (called “electronic modules” in this manual).

The backplane supports the basic cPCI functions and it has been extended to allow the routing

TM

of DIF

cooling fans within the Fan Access Panel on the top of the chassis. Tab le 3 identifies the

electronic modules using the callout reference numbers from Figure 6.

, reference clocks and I2C signals between I2C modules. The RAN chassis also houses

123 67 891045

REF # MODULE NAME FOR DETAILS REFER TO

1 cPCI Power Supplies Section 1.7.1 on Page 12

2 Central Processing Unit (CPU) Section 1.7.2 on Page 13

3 System Interface (STF2) Section 1.7.3 on Page 14

4 Synchronous Interface (SIF) Section 1.7.4 on Page 15

5 Small Form-Factor Pluggable Optical Transceiver (SFP) Section 1.7.5 on Page 17

Page 10

© 2007, ADC Telecommunications, Inc.

21282-A

Figure 6. RAN Chassis

Table 3. RAN Chassis Electronic Modules

Page 23

ADCP-75-210 • Issue 1 • March 2007

U

Table 3. RAN Chassis Electronic Modules

REF # MODULE NAME FOR DETAILS REFER TO

6 RAN Down Converter (RDC or RDC2) Section 1.7.6 on Page 17

7 RAN Up Converter (RUC2.X or RUC3) Section 1.7.7 on Page 19

8 800 MHz Multi-Coupler Section 1.7.9 on Page 20

9 1900 MHz Multi-Coupler Section 1.7.10 on Page 22

10 Fan Access Panel Section 1.7.8 on Page 20

Figure 7 is a schematic showing the data flow in the RAN chassis, as represented by the PCS-A

band. As shown, data flows in two directions, from the Hub through the RAN to the antenna,

and from the antenna through the RAN back to the Hub. In each direction, data conversion

occurs, with optical data “upconverted” to RF data in the up direction in the schematic, and RF

data “downconverted” to optical data in the down direction. In an up direction, the RUC module

converts Digitized Intermediate Frequency (DIF) data into PCS, Cellular, and SMR frequency

RF bands. The RF signals are amplified and then transmitted from the RF antenna. In the down

direction, the RDC module converts PCS, Cellular, and SMR frequency bands into DIF data.

The overall series of events is managed by the CPU using an Ethernet connection to the chassis

backplane.

RAN

MB

ANT

1900-P 1900-D

ANT

PCS QUADPLEXER

AB FRX

MCPA

RF

RUC RDC

DIF

SIF

Fiber Fiber

ANT

PCS QUADPLEXER

DECRX

Pri Div

1900

MUL

66

Pri Div

DIF

DIF

Ethernet

RAN = Radio Access Node

DIF = Digital Intermediate

Frequency

SIF = Synchronous Interface

RUC = RAN Up Converter

MCPA = Munti-Carrier Power

Amplifier

MB ANT = Multi Band Antenna

MUL = Multi-Coupler

RDC = RAN Down Converter

CPU

21777-A

B

H

Figure 7. RAN Chassis Schematic

© 2007, ADC Telecommunications, Inc.

Page 11

Page 24

ADCP-75-210 • Issue 1 • March 2007

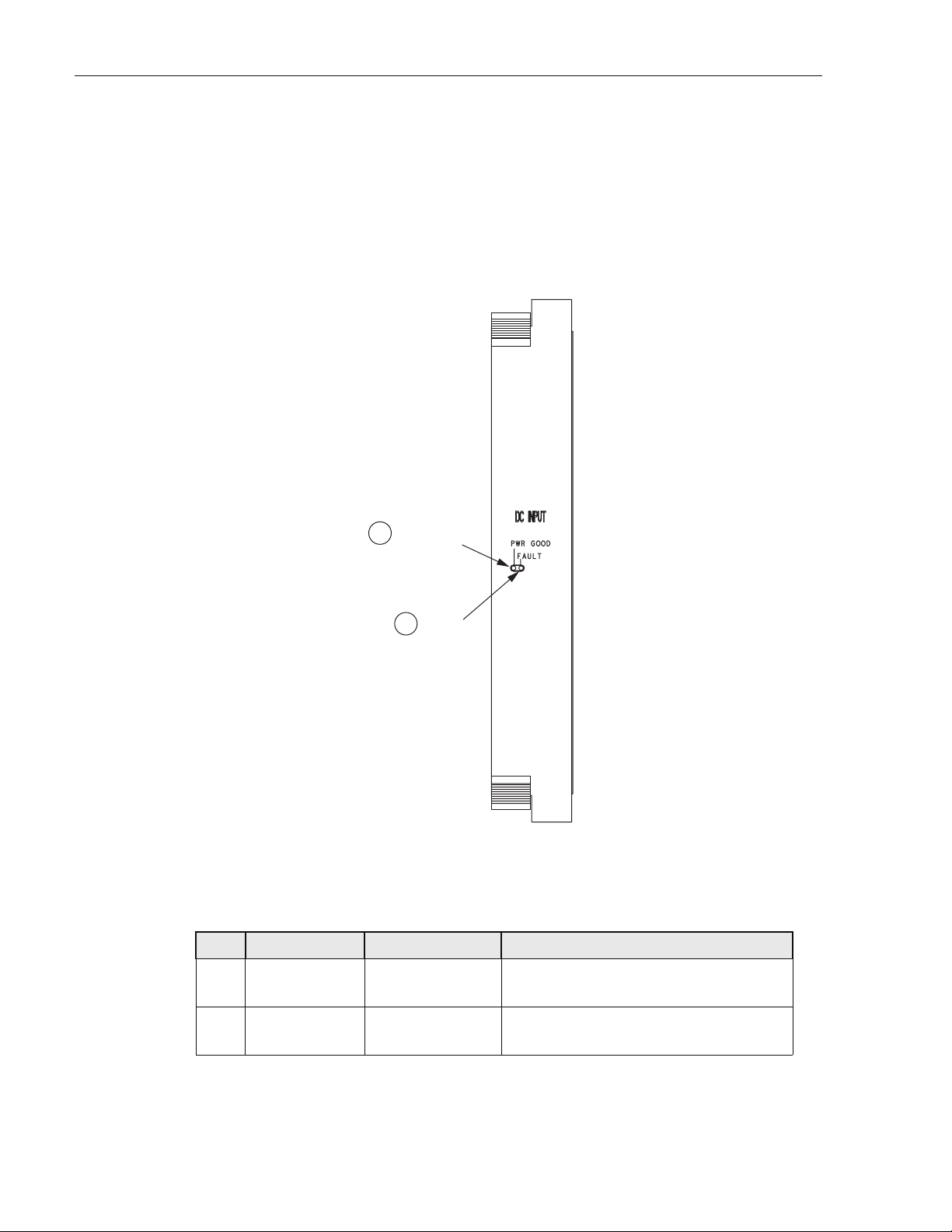

1.7.1 cPCI Power Supply Modules

The Compact PCI (cPCI) Power Supply Modules provide +/-12V, 5V, and 3.3V DC power to

the cPCI backplane for use by the cPCI electronic modules. Each RAN requires one power

supply module. Two modules can be used to provide redundancy if desired. These modules are

hot swappable. Figure 8 shows the cPCI Power Supply Module faceplate. Table 4 describes the

faceplate components called out in the figure.

POWER

1

GOOD LED

FAULT

2

LED

21240-A

Figure 8. cPCI Power Supply Module Faceplate

CPU

Table 4. cPCI Power Supply Module Faceplate

Ref #

DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 PWR GOOD Single-color LED

(green)

2 FAULT Single-color LED

(red)

Power Good. Turns green when module has

power

Fault. Turns red when module has

insufficient power to perform its function

Page 12

© 2007, ADC Telecommunications, Inc.

Page 25

ADCP-75-210 • Issue 1 • March 2007

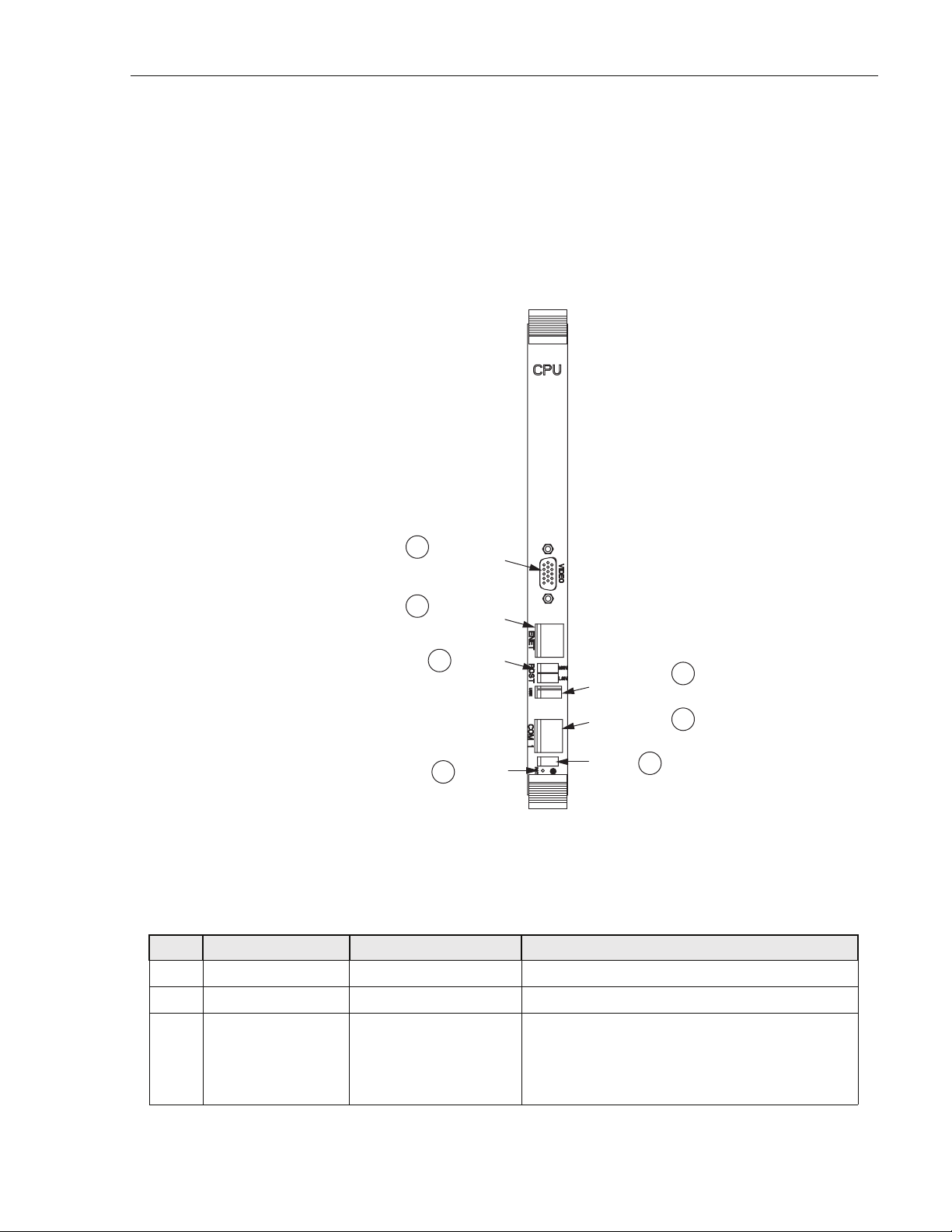

1.7.2 Central Processing Unit (CPU) Module

The Central Processing Unit (CPU) Module is a cPCI-based, single-board x86 computer with

disk running on a Linux operating system. Each RAN chassis has one CPU module. The CPU

runs a process management program that manages all RAN hardware including RF and digital

equipment. The program also manages RF signal gain and monitors signal presence and quality.

Figure 9 shows the CPU module faceplate. Tab le 5 describes the faceplate components called

out in the figure.

VIDEO

7

CONNECTOR

ETHERNET

6

CONNECTOR

ACTICITY

5

4

LEDs

RESET

BUTTON

21251-A

UNIVERSAL

SERIAL BUS

CONNECTOR

COM 1

CONNECTOR

STATUS

LEDs

3

1

2

Figure 9. CPU Module Faceplate

CPU

Table 5. CPU Module Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 USB1 USB connector Front panel input/output for USB connectivity

2 COM 1 RJ-11C connector Front panel interface for COM1

3 (Unmarked) Status LEDs LED 1 is POST (red on start-up, turns green on

successful completion of start-up self test); LED 2

& 3 are undefined; LED 4 (blinking green) indicates

disk or flash memory activitity

© 2007, ADC Telecommunications, Inc.

Page 13

Page 26

ADCP-75-210 • Issue 1 • March 2007

Table 5. CPU Module Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

4 RST Recessed switch Reset. Used to manually reset the CPU

5 POST Single-color LEDs

(yellow)

Post. Top four LEDs give status of CPU during initial

boot process; bottom four give board operation status

6 ENET RJ-45 connector with

single-color LEDs (green

and yellow)

Ethernet. 10 BaseT. Connects to RJ-45 connector on

SIF module (10BT port) using cable 1001478P001.

Connection status (green) and 100 BT (yellow)

7 VIDEO 15-PIN VGA connector Video. Not used by Digivance system

1.7.3 System Interface (STF2) Module

The System Interface (STF2) Module is a cPCI electronic module that provides the CPU and

other electronic modules with the ability to communicate with one another using the four I2C

buses on the cPCI backplane. One STF2 is used per RAN. The STF2 also has the GPS antenna

input port located in the center of the module faceplate. STF2 modules are specified according

to the number of qualifying communications devices being utilized. Tab le 6 describes the

module faceplate components. Figure 10 shows the location of the faceplate components.

Table 6. System Interface Module Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 RST Recessed switch Reset. Used to halt operation of the CPU operating system. A

power ON reset is required to restart the CPU

2 STATUS 1 Single-color LED

(yellow)

3 STATUS 2 Single-color LED

(yellow)

Reserved for future use. Indicator turns yellow when the CPU is

not installed or has malfunctioned

Reserved for future use. Indicator turns yellow when the CPU is

not installed or has malfunctioned

4 STATUS GPS Single-color LED

(green)

Indicator showing that 1PPS signal is available. Led toggles once

per second (RAN only)

5 DA RJ-45 connector Door Alarm. Input using cable 1001474P001; small LED on this

connector lights (red) when door is open

6 GPS RJ-45 connector Not used

7 RECT RJ-45 connector Rectifier. Communications to rectifier using cable 1001476P001

8 (Unmarked) Single-color LED

(red)

9 (Unmarked) Single-color LED

(green)

10 FLT Single-color LED

(red)

Page 14

© 2007, ADC Telecommunications, Inc.

I2C Error LEDs. One on each I2C RJ-45 connector. Indicator turns

red when there is no response on port

I2C Comm LEDs. One on each I2C RJ-45 connector. Indicator

turns green when an I2C message sent on the port

Fault. Indicator turns red when module has failed or upon startup

until the module has completed initialization

Page 27

Table 6. System Interface Module Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

11 HS Single-color LED

Not used

(blue)

ADCP-75-210 • Issue 1 • March 2007

12 PWR Single-color LED

Power. Indicator turns green when module has power

(green)

13 I2C A-D RJ-45 connectors I2C (Bus). Connectors to I2C buses

14 ANT SMA connector Antenna. Input for GPS antenna signal

15 TLA RJ-45 connector Tower Light Alarm (unused)

RESET

1

TOWER LIGHT

15

ALARM CONNECTOR

GPS ANTENNA

CONNECTOR

14

(RAN ONLY)

SWITCH

GPS

4

LED

STATUS

LED 1

STATUS

LED 2

DOOR ALARM

CONNECTOR

GPS COMMS

CONNECTOR

CONNECTOR

I2C ERROR LED

2

3

RECTIFIER

COMMS

5

6

7

8

9

10

11

13

CONNECTOR

POWER LED

12

I2C COMM LED

I2C

FAULT LED

HOT SWAP LED

21253-A

n

Figure 10. System Interface Module Faceplate

1.7.4 Synchronous Interface (SIF) Module

The Synchronous Interface (SIF) Module provides the optical interface between the Hub and

the RAN. This interface provides for exchange of digitized RF signal information and 10BaseT

Ethernet command and control information. Each RAN can have up to two SIFs, each handling

two bands with diversity receive paths.

© 2007, ADC Telecommunications, Inc.

Page 15

Page 28

ADCP-75-210 • Issue 1 • March 2007

The SIF module is equipped with a small form-factor pluggable optical transceiver (SFP)

module. (For more information on the SFP, see Section 1.7.5.) Figure 11 shows the SIF module

faceplate. Ta ble 7 describes the faceplate components.

OPTICAL

9

INPUT LED

OPTICAL

8

OUTPUT LED

SFP FIBER

7

CONNECTOR

6

5

OPTIC

FAU LT

LED

POWER

LED

DIF INPUT

LED 1-4

DIF OUTPUT

LED 1-4

ETHERNET

CONNECTOR

HOT SWAP

LED

21238-A

1

2

3

4

Figure 11. Synchronous Interface Module Faceplate

Table 7. Synchronous Interface Module Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 IN 1-4 Tri-color LED

(green/yellow/red)

In. Indicates if DIF input is not enabled (off), good (green),

degraded (yellow), clock issue (blinking), or no DIF tone

lock or unused channel (red)

2 OUT 1-4 Tri-color LED

(green/yellow/red)

Out. Indicates if DIF output is not enabled (off), good

(green), degraded (yellow), clock issue (blinking), or bad

data on output of unused channel (red)

3 10BT RJ-45 connector 10BaseT (Ethernet). Communications between SIF and CPU

using cable 1001478P001

4 HS Blue LED Not used

5 PWR Green LED Power. Lights when module has power

6 FLT Red LED Fault. Lights when module has failed and during start-up

until module is initialized

Page 16

© 2007, ADC Telecommunications, Inc.

Page 29

ADCP-75-210 • Issue 1 • March 2007

Table 7. Synchronous Interface Module Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

7 F/O Dual-LC connectors Fiber/Optics. Optics connector on SFP optical transceiver

8 OP IN Tri-color LED

(green/yellow/red)

9 OP OUT Tri-color LED

(green/yellow/red)

Optical In. Indicates input status of the SFP interface: not

enabled (off), good (green), degraded (yellow), or bad output

signals (red)

Optical Out. Indicates output status of SFP interface: not

enabled (off), good (green), degraded (yellow), or bad framing, bad parity, no signal, or no signal lock (red)

1.7.5 Small Form-Factor Pluggable (SFP) Optical Transceiver

The Small Form-Factor Pluggable (SFP) Optical Transceiver, located on the SIF module and

shown in Figure 12, provides the optical interface between the Hub equipment and the RAN

hardware. The SFP has a laser transmitter and an optical receive detector.

The Digivance NXD system uses industry standard SFP optics which offer a number of

configuration options depending on the requirements of the project. The SFP modules are

available separately and may or may not be installed in the SIF depending on the configuration

ordered. The SFP module is specified as up to two per RAN and is able to support two bands

with receive diversity.

The standard SFP module has an optical budget of 9 dB. The SFP module is factory and field

replaceable with optical transceivers having extended optical budgets up to 26 dB or Coarse

Wave-Division Multiplexing (CWDM) optical wavelengths.

21316-A

Figure 12. Small Form-Factor Optical Transceiver

1.7.6 RAN Down Converter (RDC or RDC2) Module

The RAN Down Converter (RDC or RDC2) Module is a cPCI electronic module housing a

dual-diversity wideband RF receiver. This module takes PCS, Cellular, SMR A, and SMR B

signals from a primary and secondary antenna (via the appropriate multicoupler) and converts

the signals to Digitized Intermediate Frequency (DIF).

© 2007, ADC Telecommunications, Inc.

Page 17

Page 30

ADCP-75-210 • Issue 1 • March 2007

This module also provides a CW test tone for use in reverse continuity testing. The RF signals

are input into the module by way of coax cables terminated with SMA connectors on the

faceplate (at the ports labeled PRI IN and DIV IN). Figure 13 shows the module faceplate.

Tab le 8 describes the module faceplate components called out in the figure.

PRIMARY

DIVERSITY

FAULT

LED

POWER

LED

21236-A

1

IN

IN

2

3

4

Figure 13. RAN Down Converter Module Faceplate

Table 8. RAN Down Converter Module Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 PRI IN SMA connector Primary In. Receives RF primary output from either C/PMC-

PLR or P/MCPLR module. Connection is made using cable

1955000P081

2 DIV IN SMA connector Diversity In. Receives RF diversity output from either C/

PMCPLR or P/MCPLR module. Connection is made using

cable 1955000P081

3 FLT Red LED Fault. Lights when module has failed and during start-up until

module has initialized; blinks after module receives a system

clock and is awaiting initialization

4 PWR Green LED Power. Lights when module has power

Page 18

© 2007, ADC Telecommunications, Inc.

Page 31

ADCP-75-210 • Issue 1 • March 2007

1.7.7 RAN Up Converter (RUC2.X or RUC3) Module

The RAN Up Converter (RUC2.X or RUC3) Module is a cPCI electronic module that takes

Digitized Intermediate Frequency (DIF) signals from a DIF signal generated by the SIF and

converts the signals to RF (PCS, Cellular, SMR A, and SMR B frequency bands). Each module

supports two simultaneous bands via wideband outputs. The RUC also provides clocking for its

neighboring RDC. For module faceplate and callouts, see Figure 14 and Tab le 9 .

1

8

CHANNEL

1/3 OUT

CHANNEL

2/4 OUT

COM 1/3

COM 2/4

PA CNTL 1/3

PA CNTL 2/4

FAULT LED

POWER LED

21234-A

2

3

4

5

6

7

Figure 14. RAN Up Converter Module Faceplate

Table 9. RAN Up Converter Module Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 CH 1/3 OUT SMA connector Channel 1/3 Out*

2 COM 1/3 Yellow LED COM Port 1/3. Turns yellow when DIF is locked to SIF channel

1 or 3*

3 COM 2/4 Yellow LED COM Port 2/4. Turns yellow when DIF is locked to SIF channel

2 or 4*

4 PA CNTL 1/3 I2C flatpack

connector

PA Control Channel 1 or 3. Outputs control data to the PIC card

on the PAA for the channel being provided (using cable

1955000P079)*

© 2007, ADC Telecommunications, Inc.

Page 19

Page 32

ADCP-75-210 • Issue 1 • March 2007

Table 9. RAN Up Converter Module Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

5 PA CNTL 2/4 I2C flatpack

connector

PA Control Channel 2 or 4. Outputs control data to the PIC card

on the PAA for the channel being provided (using cable

1955000P079)*

6 FLT Red LED Fault. Turns red when the module has failed. Indicator is lit dur-

ing start-up until module has initialized. Indicator will blink

after module receives system clock and is awaiting initialization

7 PWR Green LED Power. Turns green when module has power

8 CH 2/4 OUT SMA connector Channel 2 or 4 OUT*

* An RUC in slot A2 will connect to PAAs 1 and 2. An RUC in slot A5 will connect to PAAs 3 and 4.

Therefore, the RUC front panel indicators of 1/3 and 2/4 will map to PAAs 1 and 2 connections in slot

A2 and PAA 3 and 4 connections in slot A5.

1.7.8 Fan Access Panel

The Fan Access Panel, shown in Figure 15, has a hinged front panel that swings down providing

access to the two fans cooling the RAN chassis. These fans are user-replaceable. This panel has

labels identifying the electronic modules located in the cPCI shelf below the panel.

LABELS FOR CPCI

ELECTRONIC MODULES

21318-A

Figure 15. Fan Access Panel

1.7.9 800 MHz Multicoupler (C/MCPLR)

The 800 MHz (C/MCPLR) Module is a cPCI electronic module that houses the dual-diversity,

receive unit for the 800 MHz bands. This module interfaces to the multiplexer system and

contains the front end low noise amplifiers for the reverse path. The module has six outputs

(Cell bands A, B, and 800 MHz, with diversity).

Figure 16 shows the location of the faceplate components. Tab le 10 describes the faceplate

components.

Page 20

© 2007, ADC Telecommunications, Inc.

Page 33

ADCP-75-210 • Issue 1 • March 2007

Table 10. C/MCPLR Modules Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 P IN SMA connector Primary In. Receives RF primary reverse path input from primary

antenna

2 D IN SMA connector Diversity In. Receives RF diversity reverse path input from second-

ary antenna

3 P OUT SMA connectors Primary Out. 3 primary outputs (Cell bands A, B, and SMR-A). Each

output being used connects to one RDC electronic module, either in

the same RAN or in the extension RAN if present. Connection is

made using cable 1955000P081

4 D OUT SMA connectors Diversity Out. 3 diversity outputs (Cell bands A, B, and SMR-A).

Each output being used connects to one RDC electronic module,

either in the same RAN or in the extension RAN if present. Connec-

tion is made using cable 1955000P081

5 FLT Red LED Fault. Lights when module has failed and during start-up until mod-

ule has initialized

6 PWR Green LED Power. Lights when module has power

PRIMARY IN

CONNECTOR

PRIMARY OUT

CONNECTORS

DIVERSITY IN

CONNECTOR

DIVERSITY OUT

CONNECTORS

1

3

2

4

FAULT LED

POWER LED

21242-A

5

6

Figure 16. C/MCPLR Module Faceplate

© 2007, ADC Telecommunications, Inc.

Page 21

Page 34

ADCP-75-210 • Issue 1 • March 2007

1.7.10 1900 MHz Multicoupler (P/MCPLR)

The 1900 MHz (P/MCPLR) Module is a cPCI electronic module that houses the dual-diversity,

receive unit for the PCS band. This module interfaces to the multiplexer system and contains the

front end low noise amplifiers for the reverse path. The PCS band has 12 outputs (bands A-F,

with diversity). Figure 17 shows the location of the faceplate components. Tab le 1 1 describes

the module faceplate components.

DIVERSITY OUT

4

CONNECTORS

DIVERSITY IN

CONNECTOR

PRIMARY IN

CONNECTOR

PRIMARY OUT

CONNECTORS

FAULT LED

POWER LED

21245-A

2

1

3

5

6

Figure 17. P/MCPLR Modules Faceplates

Table 11. P/MCPLR Modules Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 P IN SMA connector Primary In. Receives RF primary reverse path input from primary

antenna

2 D IN SMA connector Diversity In. Receives RF diversity reverse path input from secondary

antenna

3 P OUT SMA connectors Primary Out. 6 primary outputs (bands A-F); each output being used

connects to one RDC module, in either same RAN or extension RAN

if present. Connection is made using cable 1955000P081

Page 22

© 2007, ADC Telecommunications, Inc.

Page 35

ADCP-75-210 • Issue 1 • March 2007

Table 11. P/MCPLR Modules Faceplate Components

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

4 D OUT SMA connectors Diversity Out. 6 diversity outputs (bands A-F); each output being

used connects on one RDC module, in either same RAN or extension

RAN if present. Connection is made using cable 1955000P081

5 FLT Red LED Fault. Lights when module has failed and during start-up until mod-

ule has initialized

6 PWR Green LED Power. Lights when module has power

1.8 Rectifier Shelf

The Rectifier Shelf, shown in Figure 18, is a chassis/backplane device that contains rectifier

modules and a Low Voltage Disconnect (LVD) unit. The shelf interconnects the rectifier

modules and LVD unit, and provides an interface to external connectors.

Typically, the rectifier shelf contains two rectifier modules. The center panel on the shelf can be

removed to add a third rectifier, providing N+ redundancy as more equipment is added to the

RAN chassis.

LOW VOLTAGE

DISCONNECT

(LVD) UNIT

21319-A

OVER

TEMPERATURE

PROTECTION

LED

AC OK

LED

RECTIFIER

DC OK

LED

PROTECTION

21

OVER

VO LTAGE

LED

34

Figure 18. Rectifier Shelf

1.8.1 Rectifier Module

The rectifier module converts 240 VAC prime power into -48 VDC for use within the RAN.

Each rectifier has four LEDs, shown in Figure 18 and described in Tab le 12. The rectifiers are

controlled by the LVD unit under command of the STF2 module.

© 2007, ADC Telecommunications, Inc.

Page 23

Page 36

ADCP-75-210 • Issue 1 • March 2007

Table 12. Rectifier Indicators

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 (Unmarked) Green LED AC OK. Lights when AC power is present

2 (Unmarked) Green LED DC OK. Lights when rectifier is limiting current

3 (Unmarked) Red LED Over Voltage Protection. Lights when rectifier has failed

4 (Unmarked) Red LED Over Temperature Protection. Lights when over temperature compen-

sation circuit is active

1.8.2 Low Voltage Disconnect (LVD) Unit

The Low Voltage Disconnect (LVD) Unit (Figure 19) disconnects power automatically when

the RAN voltage falls below a specified minimum. The LVD unit also manages the backup

batteries (extended or glitch).

OK LED

1

2

MAJOR FAULT LED

3

MINOR FAULT LED

4

LVD ON LED

6

21334-A

5

Figure 19. Low Voltage Disconnect Unit

Table 13. LVD Indicators

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 OK Green LED Okay. Lights when power system is functioning correctly

2 MAJ Red LED Major Fault. Lights when a major fault exists

3 MIN Yellow LED Minor Fault. Lights when a minor fault exists

4 (Unmarked) 9-pin connector Connector for cable 1001476P001 to the RECT (RJ45 connector)

port on the STF module

5 LVD Red LED Low Voltage Disconnect. Lights when switch has closed due to low

voltage

6 DISC Switch Disconnect. Pressing this switch disconnects the backup batteries

Page 24

© 2007, ADC Telecommunications, Inc.

Page 37

1.9 Power Amplifier Assembly

The Power Amplifier Assembly (PAA) is an electronic device that amplifies RF signals in the

forward path just before they are transmitted to the RAN antenna. Up to four PAAs may be

mounted in the RAN, each providing one band. Each PAA consists of a Power Amplifier (PA), a

control board called the PA Interface Controller (PIC), and a cooling system. The PA is multichannel. Different units are used for PCS, Cellular, and SMR 800 bands.

The PIC interfaces to the discrete signals of the PA. The PIC also provides DC power to the PA

by converting from -48 VDC to +12 VDC or +28 VDC depending upon which PA is being used.

Each PA has its own PIC. The PIC is managed is managed by the CPU over an I2C connection

through its corresponding RUC. The cooling system consists of a heat sink and three fans that

provide cooling for the PA by blowing external air across the heat sink. The fans are softwarecontrolled. The PIC module monitors the tachometer outputs of the fan.

Figure 20 shows the PA assembly connection points and indicators. Tabl e 14 describes the items

called out in the figure.

ADCP-75-210 • Issue 1 • March 2007

PIC LED

INDICATORS

1

DC_ FAULT

2

3

DC_ IN

DC_ OUT

8

RF IN

48V

5

PWR

12C

4

21276-A

RF

OUT

POWER

AMPLIFIER

6

7

Figure 20. Power Amplifier Assembly

Page 25

Page 38

ADCP-75-210 • Issue 1 • March 2007

Table 14. PAA Connection Points and Indicators

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 DC_IN Green LED DC In. Lighted when PIC has -48 VDC input

2 PA _FAU LT Red LED PA Fault. Lighted when PA has failed

3 DC_OUT Green LED DC Out. Lighted when PIC has +28 VDC output

4 I2C RJ-45 connector

(J1)

I2C (Bus). Connection to RUC module P/A CNTRL using

cable 1001475P001

5 48V PWR Positronic 3-pin

connector (J2)

6 RF OUT SMA connector RF Out. Output of PA for cable 1955000P080 to one of the

7 (Unmarked) Power Amplifier Power amplifier (see description on preceding page)

8 RF IN SMA connector RF In. Input from RUC for cable 19559999P079

48 Volt DC Power. Input to PIC for -48 VDC using PIC

power harness 1001471P001

four plexers (depending on band), connector port TX

1.10 Multiplexer System

The NXD RAN multiplexer system consists of four units that interface to the antenna, PAs, and

multicouplers:

• Quadplexer Primary (PCS Bands A, B, F), interfaces to PCS primary antenna;

• Quadplexer Diversity (PCS Bands D, E, C), interfaces to PCS diversity antenna;

• Triplexer Primary, either of two types:

– Type one (Cellular Band B, SMR800 Band), interfaces to 800 MHz primary antenna;

– Type two (SMR800 Band, SMR900 Band), interfaces to 800 MHz primary antenna;

• Diplexer Diversity (Cellular Band A), interfaces to 800 MHz diversity antenna.

For a schematic of the PCS multiplexers, see Figure 21. For a schematic of the Cellular/SMR

multiplexers, see Figure 22 (showing Cellular B, SMR800 triplexer) or Figure 23 (showing

SMR800, SMR900 triplexer).

Page 26

© 2007, ADC Telecommunications, Inc.

Page 39

ADCP-75-210 • Issue 1 • March 2007

Quadplexer

PCS Band

A/B/F

Rx

1850-1910

Rx

A

B

C

D

E

F

Primary

Tx

1930-1945

MCPA

Tx

A

RUC

Primary

Antenna

Antenna Assembly

Tx

1950-1965

MCPA

Tx

B

RUC

Multicoupler

1850/1910

Tx

1970-1975

MCPA

Tx

F

RUC

Figure 21. PCS Multiplexers

Rx

1850-1910

Rx

A

B

C

D

E

F

Diversity

Tx

1945-1950

MCPA

Tx

D

RUC

Diversity

Antenna

Tx

1965-1970

MCPA

Tx

E

RUC

Quadplexer

PCS Band

D/E/C

Tx

1975-1990

MCPA

Tx

C

RUC

21270-A

Duplexer

800 Mhz Band

Rx

810-849Tx869-880

Rx

SMR

A”

A

B

B’

Figure 22. Cell/SMR Multiplexers (With Cell/SMR 800 Triplexer)

Primary

Antenna

MCPA

Tx

A” A

RUC

Antenna Assembly

Multicoupler

810-849

Rx

810-849

Rx

SMR

A

CELL

A”

A

B

Diversity

Antenna

Tx

855-866

MCPA

Tx

SMR-A

RUC

Triplexer

800 Mhz Band

Tx

880-894

MCPA

Tx

B B’

RUC

21271-B

© 2007, ADC Telecommunications, Inc.

Page 27

Page 40

ADCP-75-210 • Issue 1 • March 2007

Duplexer

800 Mhz Band

Rx

810-849Tx869-880

Rx

SMR A

A”

A

Primary

Antenna

Diversity

Antenna

Antenna Assembly

Rx

810-901Tx851-869

MCPA

Tx

A” A

RUC

Rx

SMR A

SMR B

A”

A

MCPA

Tx

SMR-A

RUC

Multicoupler

810-901

Figure 23. SMR Multiplexers (With SMR 800/900 Triplexer)

Triplexer

800 Mhz Band

Tx

935-940

MCPA

Tx

SMR-B

RUC

21779-A

1.11 Circuit Breaker Panel

The Circuit Breaker Panel, shown in Figure 24, contains five circuit breakers. It distributes the

RAN’s -48 VDC power and protects the RAN’s electronics. Table 15 gives the circuit breaker

functions. Table 16 describes the panel LEDs.

CIRCUIT

BREAKER

(5 PLACES)

SYSTEM OK

12

LEDs

FAULT

LEDs

21320-A

Figure 24. Circuit Breaker Panel

Page 28

© 2007, ADC Telecommunications, Inc.

Page 41

REF # DESIGNATION DEVICE FUNCTIONAL DESCRIPTION

1 OK Green LED Okay. Lights when AC power is present

2 FAU LT Red LED Fault. Lights when rectifier is limiting current

1.12 Backup Batteries

ADCP-75-210 • Issue 1 • March 2007

Table 15. Circuit Breaker Functions

BREAKER FUNCTION

1A PA1

2A PA2

3A PA3

4A PA4

5A cPCI chassis

Table 16. Circuit Breaker Panel LEDs

The NXD RAN has two backup battery options:

1.13 Antenna

ADC provides a pole-mount antenna kit for use when the RAN is mounted on a wooden utility

pole. The kit must be separately ordered from the RAN. Pole mounting is the most common

type of RAN installation.

The antenna offered interfaces with the PCS and Cellular/SMR bands and supports two branch

diversity receive paths. Also included in the kit is the GPS antenna used by the RAN.

The RAN may also be mounted outdoors on a concrete pad. This type of installation may use a

conventional directional antenna in either a sector or quasi-omni antenna configuration,

depending on the coverage objective and design. Proper antenna selection and the mounting

installation are the responsibility of the design engineer.

Antenna installation is covered in separate publications, available for downloading from the

ADC web site, www.adc.com. Refer to RELATED PUBLICATIONS on Page vii.

• Extended Batteries: provide backup protection for up to two hours. These are four 12V,

85-100 AH internal batteries connected in series for a -48V system. The four batteries

together with associated wiring and hardware weigh 325 pounds (147.7 kg).

• Glitch Batteries: provide backup protection for up to five minutes. These are small,

motorcycle type batteries connected in a series configuration.

© 2007, ADC Telecommunications, Inc.

Page 29

Page 42

ADCP-75-210 • Issue 1 • March 2007

2 STANDARD INSTALLATION PROCEDURES

This section provides the standard procedures for a typical installation. The RAN may be

installed either on a wooden pole or on a concrete pad.

This section is organized as follows:

• Sections 2-1 through 2-4 provide information that is relevant before installing the cabinet.

These subsections contain an installation overview, unpacking instructions, a list of

required material and tools, and site preparation guidelines.

• Section 2-5 tells how to install a cabinet on a wooden utility pole. Included are instructions

for installing the pole mount bracket and then installing the cabinet on the bracket. Also

included are instructions for installing the rain shields.

• Section 2-6 tells how to install the RAN on a concrete pad. Included are instructions for

pouring the concrete pad, mounting the RAN on the pad, and installing the pedestal

enclosure.

• Section 2-7 contains other standard procedures typically done at every installation. These

procedures describe how to install the solar shield, grounding wire, RF cables, fiber optic

cable, AC power, and backup batteries.

Note: Section 3 contains instructions for installing a second RAN at the same location.

Section 4 provides information on non-standard installation procedures such as installing

an electronic module.

Installation of the RAN cabinet may proceed separately from the installation of the

corresponding Hub equipment. When the installation of the RAN is completed, refer to the

Digivance NXD Multi-Band Distributed Antenna System Operation Manual (ADCP-75-209)

for system turn-up and test procedures.

The procedures in this section assume that the required Outside Plant (OSP) fiber optic cable

has already been routed between the Hub and the RAN, that the required antenna has been

installed, and that a coaxial cable terminated with an N-type connector has been routed to the

RAN from the antenna.

Danger: Wet conditions increase the potential for receiving an electrical shock when installing

or using electrically-powered equipment. To prevent electrical shock, never install or use

electrical equipment in a wet location or during a lightning storm.

Caution: Always allow sufficient fiber length to permit routing of patch cords and pigtails

without severe bends. Some fiber optic patch cords or pigtails may be permanently damaged if

bent or curved to a radius of less than 2 inches (50 mm).

2.1 Installation Overview

A standard (typical) installation of the RAN consists of the following steps:

Warn ing: Electronic components can be damaged by static electrical discharge. To prevent

ESD damage, always wear an ESD wrist strap when handling electronic components.

Page 30

© 2007, ADC Telecommunications, Inc.

Page 43

ADCP-75-210 • Issue 1 • March 2007

Note: To insure that all optical connectors and optical ports remain dust-free during

installation, leave all dust caps and dust protectors in place until directed to remove them

for installation.

1. Checking out and preparing the installation site.

2. Unpacking and inspecting the shipped items.

3. Installing a pole mount frame or pedestal mount.

4. Installing the RAN cabinet on the pole or pad.

5. Installing the rain shields (pole mount) or pedestal enclosure (pad mount).

6. Installing the solar shield.

7. Installing a ground wire.

8. Connecting RF cables between the antenna and RAN.

9. Installing the fiber optical cable that connects the RAN to the Hub.

10. Installing AC power.