Page 1

Appendix

– Cables, Connectors, and

A

Accessories

This section provides information about cables, connectors, and accessories that an

LGCell application might require. LGC Wireless can provide these components, or

the customer can. If the customer provides them, they must be on-site when LGC

Wireless personnel arrive.

Information in this section includes the following topics:

• A description of the cables and connectors needed for the installation

• Relative system gain over varying cable lengths

Contents

Appendix A – Cables, Connectors, and Accessories

Cables and Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

LGCell Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Page 2

A-2 Appendix A – Cables, Connectors, and Accessories

Page 3

Cables and Connectors

The following cables and connectors are required for connecting

not provided with the LGC

prior to the LGC

and connectors.

Determine which cables (and their length) and connectors you need, then order

them through a cable vendor or installer.

installation. LGC wireless can provide and install these cables

ell

equipment and must be on site or installed at the site

ell

LGCell.

Coaxial Cable – RF Transmission

Standard Coaxial Cable for Duplex RF Connections

• Connects the Main Hub to a roof-mounted antenna, repeater, or duplex MBS.

• Provides bi-directional downlink and uplink transmission with one cable for

duplex RF connections.

Standard Coaxial Cable for Simplex RF Connections

• Connects a Main Hub to a simplex MBS, a simplex roof-mounted antenna, or

repeater.

• Provides unidirectional downlink and uplink signals on separate cables for

simplex RF connections.

They are

MMF Cable with ST-Connectors –

RF Transmission (Vertical Run)

Standard Multi-Mode Fiber Optic Cable

• Connects Main Hub to Expansion Hubs

a028

• Transmits (downlink) and receives (uplink)

MMF

Cable

• Accommodates distances up to 1 km.

cellular and/or PCS signals.

A-3

Page 4

UTP/STP Cable with RJ-45 connectors –

RF Transmission (Horizontal Run)

RJ-45

Connector

Standard Category 5 Unshielded or Shielded Twisted

Pair

• Connects the Expansion Hub to the RAUs.

• Transmits (downlink) and receives (uplink) cellular

and PCS signals.

UTP/STP

Cable

• Delivers electrical power to RAUs.

a029

• Accommodates distances up to 60 meters.

LGC Wireless recommends plenum-rated CAT 5 UTP/STP cable and connectors.

A-4 Appendix A – Cables, Connectors, and Accessories

Page 5

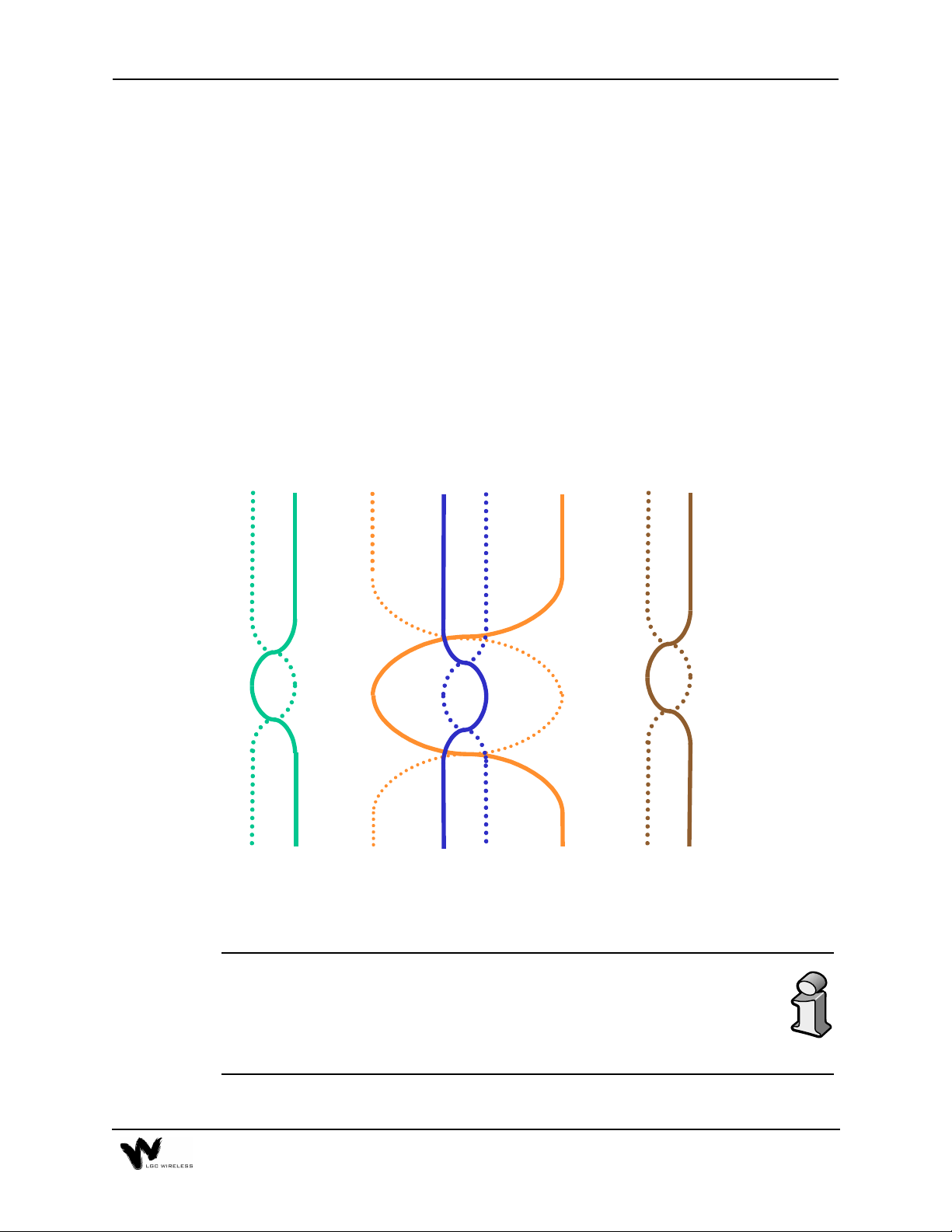

Unshielded Twisted Pair Cable Termination

All UTP (Unshielded Twisted Pair) shall be terminated according to the TIA/EIA

568-A standard. The following diagram describes how the four pairs should be

terminated.

Top View of the Wiring Map for Category 5 (CAT 5) UTP Cable

(TIA/EIA 568-A Standard)

Straight Connect

12 3 45 6 78

Green/

White

Green Orange

The UTP/STP cable can be any length from 10 meters up to 60 meters. (Per

TIA/EIA specifications, UTP/STP cable must be at least 10 meters.) For

cables longer than 60 meters, system specifications are slightly degraded.

When using high quality UTP/STP cable, lengths up to 60 meters can be

used without degrading system performance.

Orange/

White

Blue

Blue/

White

Brown/

White

Brown

A-5

Page 6

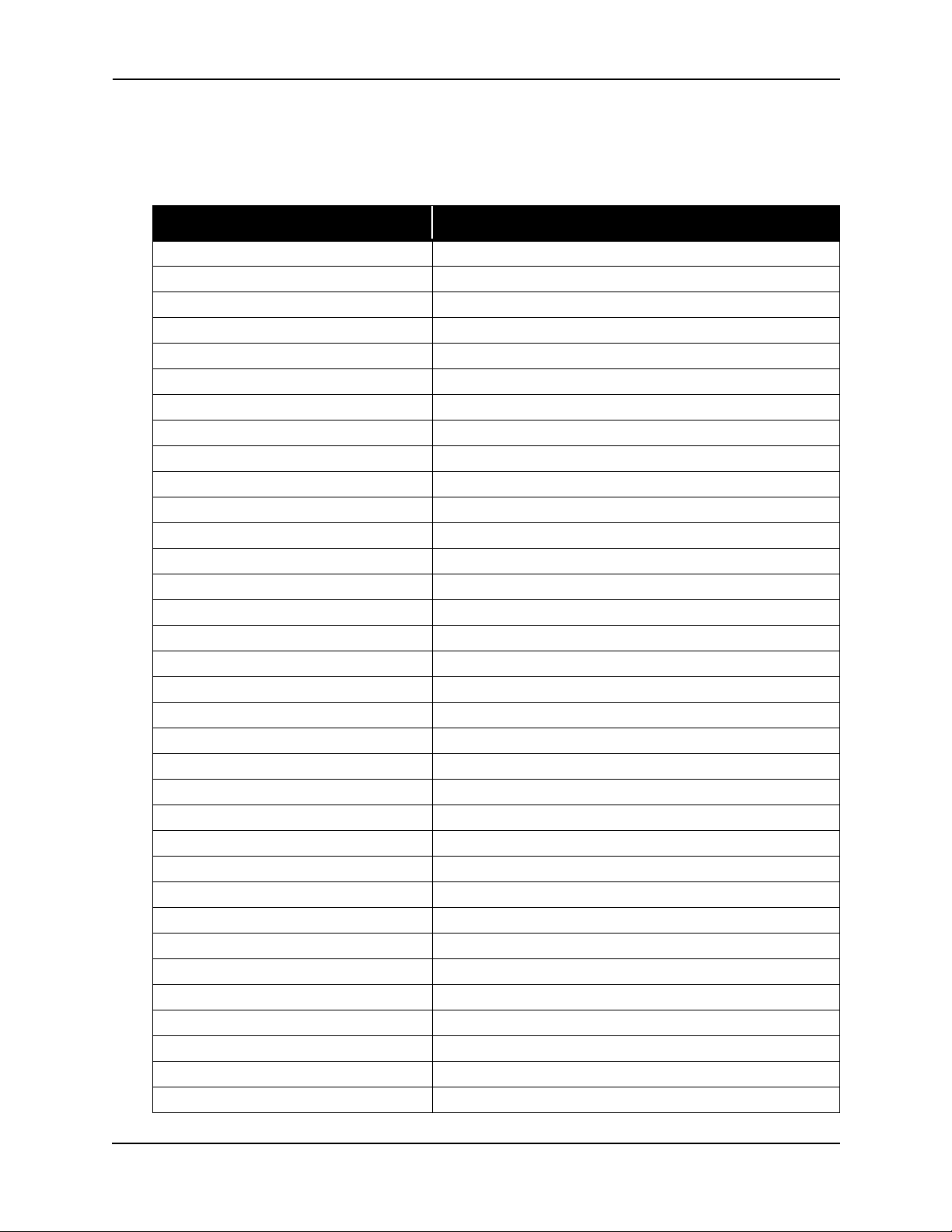

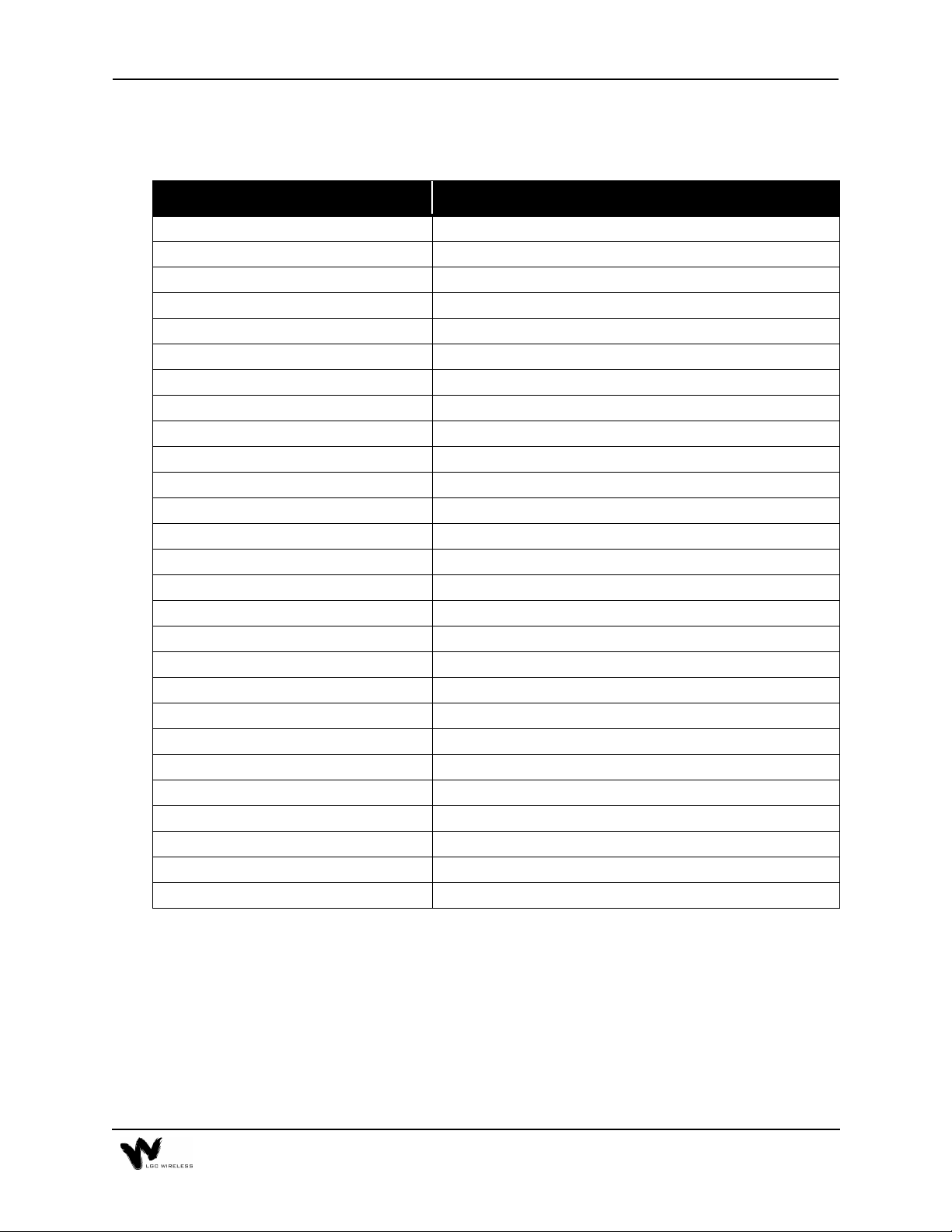

The next two tables show how system gain on the uplink and downlink vary as a

function of cable length (horizontal run, measured with 1 km of Multi-Mode Fiber).

LGCell System Gain vs. UTP/STP Cable Length (800 MHz, iDEN, 900 MHz)

UTP Cable Length (feet) Relative System Uplink and Downlink Gain (dB)

0 No change in gain

10 No change in gain

20 No change in gain

30 No change in gain

40 No change in gain

50 No change in gain

60 No change in gain

70 No change in gain

80 No change in gain

90 No change in gain

100 No change in gain

110 No change in gain

120 No change in gain

130 No change in gain

140 No change in gain

150 No change in gain

160 No change in gain

170 No change in gain

180 -0.6

190 -1.3

200 -2.0

210 -2.7

220 -3.4

230 -4.1

240 -4.8

250 -5.5

260 -6.2

270 -6.9

280 -7.6

290 -8.3

300 -9.0

310 -9.7

320 -10.4

330 -11.1

A-6 Appendix A – Cables, Connectors, and Accessories

Page 7

LGCell System Gain vs. UTP/STP Cable Length

for 1800 MHz or 1900 MHz

(Horizontal run, measured with 1 km of Multi-Mode Fiber)

UTP Cable Length (feet) Relative System Uplink and Downlink Gain (dB)

0 No change in gain

10 No change in gain

20 No change in gain

30 No change in gain

40 No change in gain

50 No change in gain

60 No change in gain

70 No change in gain

80 No change in gain

90 No change in gain

100 No change in gain

110 No change in gain

120 No change in gain

130 No change in gain

140 No change in gain

150 No change in gain

160 No change in gain

170 No change in gain

180 -0.6

190 -1.3

200 -2.0

210 -2.7

220 -3.4

230 -4.1

240 -4.8

250 -5.5

260 -6.2

LGC

ell

Accessories

LG

provides a full range of accessories that might be required for LG

Cell

applications. Please see your LG

for the accessory list.

Price Book or contact your account manager

Cell

Cell

A-7

Page 8

A-8 Appendix A – Cables, Connectors, and Accessories

Page 9

Appendix

This appendix is a summary of the TIA/EIA 568-A Commercial Building

Telecommunications Cabling Standard.

The TIA/EIA 568-A commercial building cabling standard addresses the need for

a common criterion covering cabling in commercial buildings. The standard was

drafted to ensure support for a wide variety of applications, devices, and vendor

products.

The TIA/EIA 568-A standard assures a flexible cabling scheme which permits the

planning and installation of communications cable without prior knowledge of the

user's needs. This is especially valuable for new building construction and

renovation where it is less costly and less disruptive to install a universal cabling

system prior to occupancy.

The need for a building cabling standard was recognized in the early 1980s. It

resulted from the changes brought on by new technologies. The purpose of the

original drafting committee was to provide a non-proprietary cabling system for

both new and existing facilities.

– TIA/EIA 568-A Cabling Standard

B

In 1985, the Computer Communications Industry Association approached the

Electronic Industry Association (EIA) in regard to the market's confusion over

cabling systems. The EIA and later its offspring, the Telecommunications Industry

Association (TIA), addressed this via technical working groups comprised of

industry participants. The resulting standard 568 addressed performance and safety

issues related to technology and utilized many recognized and proven standards.

The TIA/EIA 568-A standard defines the categories of UTP cabling, the categories

of connecting hardware, patch cables, and provides guidelines on cabling practices.

The TIA/EIA 568-A standard describes six sub-systems within a facility

telecommunications cabling system summarized below. (This is intended as a

summary only and is meant to provide a better comprehension of the standard. The

complete TIA/EIA 568-A standard is available for purchase. Call 1-800-854-7179.)

Page 10

Horizontal Wiring

The horizontal cable is the portion of the cabling system which extends from the

work area outlet to the telecommunications closet. The horizontal cabling is a star

topology, with a maximum cabling run of 90 meters (295 feet), independent of

media type.

Voice Data

4-pair 100 ohm UTP cable 4-pair 100 ohm UTP/STP

2-pair 150 ohm STA

62.5/125 µm fiber optic cable

The horizontal cable amounts to the greatest quantity of individual cables in the

building. Although the TIA/EIA 568-A standard helps limit cabling options,

consideration should be given to media type in order to support possible future

needs. The cable selected should accommodate more than one network planning

period.

Backbone Wiring

The backbone cabling provides the interconnection between the telecommunications closets and the equipment rooms and entrance facilities. The

backbone cabling is also a star topology with the maximum cable length being

media and applications dependent.

The backbone cable is typically second to horizontal cables in terms of amount of

cable deployed. The cable selected should accommodate a minimum of one to

several network planning periods.

B-2 Appendix B – TIA/EIA 568-A Cabling Standard

Page 11

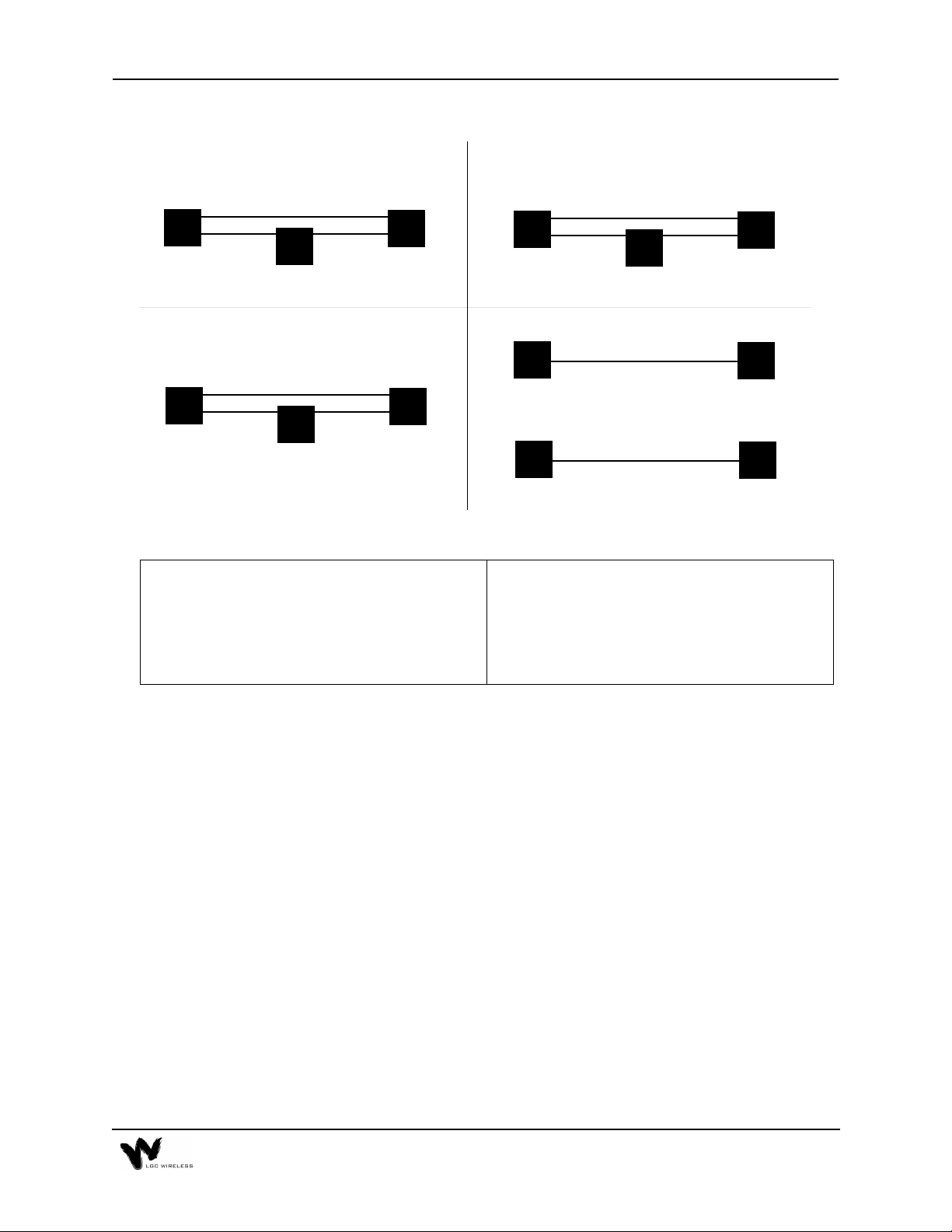

Multi-Mode Optical Fiber Cable

62.5/125 micron Optical Fiber Cable

62.5/125 µm Optical Fiber Cable

3000m (9843 ft.)

HC

500m

(1640 ft.)

100Ohm UTP Cable for Voice

IC

2500m

(8202 ft.)

800m (2624 ft)

Maximum

TC

500m

(1640 ft.)

Maximum

HC Horizontal Cross-Connect MC Main Cross-Connect IC Intermediate Cross-Connect

Note 1

When the HC to IC distance is less than maximum,

the IC to MC distance for optical fiber can be

increased accordingly but the total distance from the

HC to the MC shall not exceed the maximum of

2000m (6560 ft.).

IC

300m

(984 ft.)

Note 2

MC

MC

HC

100Ohm UTP Cable for Data

HC

150Ohm STP-A Cable for Data

HC

Note 2

When the HC to IC distance is less than maximum,

the IC to MC distance for UTP cable can be

increased accordingly but the total distance from the

HC to the MC shall not exceed the maximum of

800 m (2624 ft). For voice applications only.

2000m (6560 ft.)

Maximum

500m

(1640 ft.)

Maximum

90m (295 ft)

Maximum

90m (295 ft)

Maximum

IC

MC

1500m

(4920 ft.)

Note 1

IC/

MC

IC/

MC

Work Area

The work area interconnects the horizontal cabling at the wall outlet to the desktop

devices. The maximum allowable distance for patch cables is three meters (9.8

feet), based on the cable being of the same type as the horizontal cable.

Telecommunications Closet

The telecommunications closet is the area in a building dedicated to

telecommunication equipment. The functions which take place in the closet include

the interconnection point between horizontal and backbone cabling systems, the

interconnection of two or more backbone cabling systems, and/or the

interconnection of the entrance facility to the overall telecommunications cabling

system.

B-3

Page 12

Equipment Room

The equipment room is the area in a building where telecommunications equipment

is located. Parts of or all of the telecommunications cabling system terminate here.

Entrance Facilities

The entrance facility is where outside telecommunications service enters the

building, and interconnects with the building's internal telecommunications

systems. In a campus or mul ti-building environment, t he entranc e facilit y may also

contain the building's backbone interconnects.

Unshielded Twisted Pair Cable Termination

All UTP (Unshielded Twisted Pair) shall be terminated according to the TIA/EIA

568-A standard.

B-4 Appendix B – TIA/EIA 568-A Cabling Standard

Page 13

Appendix

– Compliance Information

C

All LGCell systems comply with Optical Fiber Safety Standard IEC/EM60825-2.

The LGCell distributed antenna system is rated as a Class 1 laser hazard system. It

has an absolute maximum output power of -11.5 dBm at 1300 nanometers (nm).

There are no restriction on the location or use of an LGCell system. No special

precautions are required if standard work practices are followed. Additional

information on the safe use of optical fiber communications systems is at the end of

this appendix.

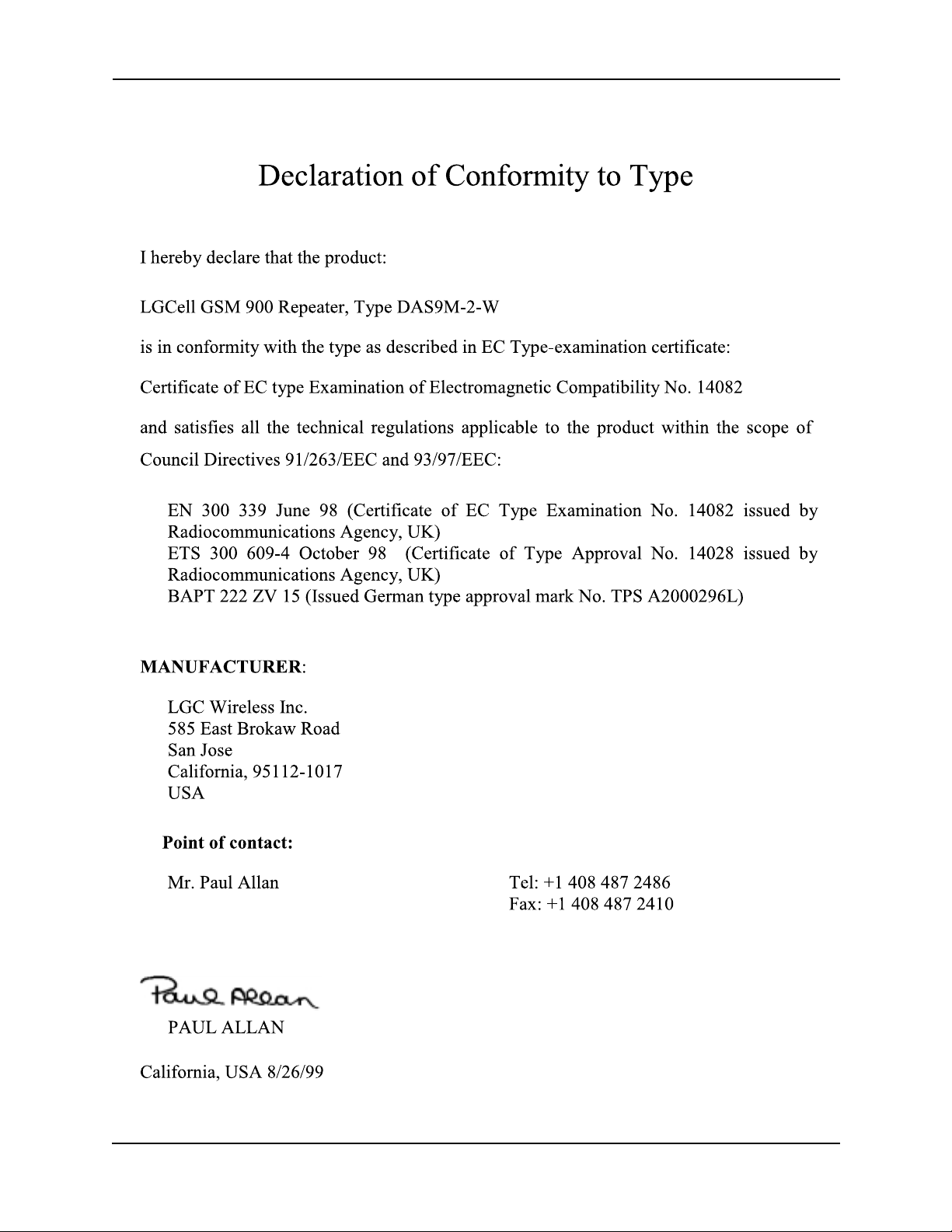

The following provides LGC Wireless’ LGCell system approval status for various

countries around the world. Some European countries require National Type

Approval to their national standards (such as Germany).

DAS9M-2-W:

Telecom: A200296L (BAPT 222 ZV 15/ETS 300 609-4) and ETS 300 609-4,

October 1998

EMC: EN 300 339, June 1998, EN 61009-4-6, 1996, and EN55022/CISPR

22 Class B

Safety: Power Supplies, Astec International Ltd., Model LPS 43, Universal

Micro Electronics Co. Ltd., Model UPO651S-02, and International

Power Sources, Inc., Model UPO651S-02 all have CB scheme

certifications.

Markings: The German Type Approval mark is required as well as the UK

approval number. The CE mark is also required.

DAS18M-2-W:

Telecom: ETS 300 609-4, October 1998

EMC: EN 300 339, June 1998

Safety: Power Supplies, Astec International Ltd., Model LPS 43, Universal

Micro Electronics Co. Ltd., Model UPO651S-02, and International

Power Sources, Inc., Model UPO651S-02 all have CB scheme

certifications.

Markings: The UK approval number and the CE mark are required.

Page 14

DAS8M-2-W:

Telecom: FCC: NOO-DAS800-1 (FCC Part 22.901d) Non-Broadcast

Transmitter

Industry Canada: 3077281151A for the “Cellular 800” (RSS128,

Issue 1)

EMC: FCC: Class A, Part 15, Subpart B

Industry Canada: Same as FCC

Safety: UL 1950, 3rd Edition and the cUL mark for the Canadian equivalent.

NEBS: This is a customer driven conformance certification and typically

desired of equipment that is intended to be installed in a Central

Office environment. LGC products are intended as Customer

Premise Equipment and it is not anticipated that they will be

installed in a Central Office environment, therefore NEBS

conformance certification has not been pursued at this time.

Markings: The FCC approval number and the FCC logo are required. The word

Canada followed by the Canadian approval number is required. The

UL mark is required.

DAS19M-2-W:

Telecom: FCC: NOO-DAS800-1 (FCC Part 24E) Distributed Antenna System

(Repeater)

Canada: 3077331163A for the “PCS 1900” (RSS-133, Issue 1)

EMC: FCC: Class A, Part 15, Subpart B

Industry Canada: Same as FCC

Safety: UL 1950, 3rd Edition and the cUL mark for the Canadian equivalent.

NEBS: This is a customer driven conformance certification and typically

desired of equipment that is intended to be installed in a Central

Office environment. LGC products are intended as Customer

Premise Equipment and it is not anticipated that they will be

installed in a Central Office environment, therefore NEBS

conformance certification has not been pursued at this time.

Markings: The FCC approval number and the FCC logo are required. The word

Canada followed by the Canadian approval number is required. The

UL mark is required.

C-2 Appendix C – Compliance Information

Page 15

FCC Regulatory Notice:

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including interference that

may cause undesired operation.

Industry Canada Regulatory Notice:

This Class B (or Class A, if so indicated on the registration label) digital apparatus

meets the requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numerique de la Classe B (ou Classe A, si ainsi indique sur l’etiquette

d’enregistration) respecte toutes les exigences du Reglement sur le Materiel

Brouilleur du Canada.

C-3

Page 16

C-4 Appendix C – Compliance Information

Page 17

C-5

Page 18

IEC/EN 60825-2 - Safe Use of Optical Fiber

Communication Systems

Part 2 of IEC 60825 provides requirements and specific guidance for the safe use of

optical fiber communications where optical power may be accessible at some

distance from the optical source. In this part of IEC 825, light emitting diodes

(LED’s) are included whenever the word “laser” is used.

Description of LG

The LG

A Main Hub, which is connected by dual mode fiber optic cables to one or more

Expansion Hubs. Each Expansion Hub is connected by UTP CAT 5 cable to a

Remote Antenna Unit. Because LED’s are used to send a signal over the fiber optic

cable, the LG

is a distributed antenna system. It consists of three main components.

Cell

Cell

System

is covered under the IEC 60825 specification.

Cell

Requirements under IEC 60825

Under IEC 60825, LGC Wireless is required to determine the Class of operation of

the LG

instructions that must be included in an operators manual as well as any warning

labels that may be required on the LG

The LG

3.2 enclosed system:

radiation is totally enclosed, by light proof cabinets, components, total internal

reflection or optical fiber cables and connectors.

3.3 end user:

the manner the system was designed to be used. The user cannot necessarily control

the power generated and transmitted within the system.

system, the Hazard level of the LG

Cell

system.

Cell

is covered only under these definitions of section 3 of 60825

Cell

A system in which, during normal operation, the optical

The person or organization using the optical fiber communication in

system and any special

Cell

.

3.4 hazard level 1:

communication system at which, under reasonably foreseeable circumstances,

human access to laser radi ation in excess of the accessible emission limits (AEL) of

class 1 for the applicable wavelengths and emission duration will not occur.

3.10 light emitting diode (LED):

to produce electromagnetic optical radiation in the wavelength range from 180nm

to 1mm. (The optical radiation is produced by the process of spontaneous emission,

although some stimulated emission may be present.)

3.13 location with controlled access:

housing (enclosure) is controlled and is accessible only to authorized persons who

have received adequate training in laser safety and servicing of the system involved.

Examples include optical cable ducts and switching centers.

C-6 Appendix C – Compliance Information

A hazard level 1 is allocated to any part within an optical fiber

Any semiconductor device which can be made

A location where access to the protective

Page 19

3.14 location with restricted access:

housing is restricted and not open to the public. Examples include industrial and

commercial premises, PBX rooms, computer system rooms, and optical test sets.

Distributed fiber networks may pass through unrestricted public areas, restricted

areas within premises, as well as controlled areas or they may be deployed entirely

within restricted business premises.

A location where access to the protective

3.18 optical fiber communication system:

generation, transference, and reception of optical radiation arising from lasers in

which the transference is by means of optical fiber for communication purposes.

3.19 reasonable foreseeable event:

circumstances can be predicted fairly accurately, and the occurrence of which is a

possibility. Examples of reasonably foreseea ble events might include the following:

fiber cable break, optical connector disconnection, operator error or inattention to

safe working practices. Reckless use or use for completely inappropriate purposes

is not to be considered as a reasonably foreseeable event.

An event, the occurrence of which under given

An engineered assembly for the

Installation Notes

The LGCell is covered under these parts of section 5 of 60825

5.2.1.3 Test Equipment:

system, only test equipment of laser Class 1 should be used.

5.2.1.5 Installation Rules:

optical fiber cable communication system should observe all rules, procedures and

practices established for the safe operation of optical fiber communication systems.

During installation or testing of an optical fiber cable or

Each person engaged in the installation or service of an

Evaluation of LGC System

The LGCell is covered under Annex A of 60825

The LG

communication system that would be safe under normal operating conditions

because the optical radiation is totally enclosed and contained under intended

operation. However, because of the extended nature of the system, the optical

power may be accessible a kilometer from the optical source. The LG

contains LED's, which are the source of radiation covered under IEC 825. Usually

a whole fiber optical communication system would not be classified under IEC 8252 in the same way required under IEC 825-1. This is because, under intended

operation, the optical power is totally enclosed, and it could be argued that an

interpretation of IEC 825-1 would give a class 1 to all systems, which may not

accurately reflect the hazard potential of some systems. If the emitter can be

operated separately, it should be classified according to IEC 825-1. However, the

power output level of the LG

1 hazard level even under 100% modulation conditions. The absolute maximum

allowed at 1300nm is +9.5 dBm. The absolute maximum accessible output of the

system is a self contained product that contains an optical fiber

Cell

system is so low that it always falls into the c lass

Cell

Cell

system

C-7

Page 20

LG

location of use of the LG

fiber optic system is -11.5 dBm. Therefore there is no restriction as to

Cell

Cell

Suggested Work Practices

system and there is no labeling requirement.

The LG

is covered under these parts of section D7 of 60825

Cell

The following working practices are suggested for working on the LG

Viewing Fiber:

•

Do not stare with unprotected eyes at the connector ends of the

fibers or the ports of the hub.

Test Fibers Cables:

•

When using test fiber optical cables, the optical power

source shall be the last to be connected and the first to be disconnected.

Fiber ends:

•

Any unconnected fiber ends should be covered with an approved

cap. Do not use tape.

Broken Fiber Cables:

•

Do not stare with unprotected eyes at any broken ends

of the fibers. Report and have any broken fiber cables replaced.

Cleaning:

•

Modification:

•

Use only approved methods for cleaning optical fiber connectors.

Do not make any unauthorized modifications to this fiber

optical system of associated equipment.

Live work:

•

Signs:

•

Test Equipment:

•

No warning signs are required.

Live work is permitted on the LG

Use class 1 test equipment.

as it is a class 1 hazard.

Cell

Cell

system:

C-8 Appendix C – Compliance Information

Page 21

Appendix

– Services

D

This appendix gives an overview of services that LGC Wireless provides.

LGC Wireless offers a full range of professional services to ensure cost-effective

and timely deployment of wireless networks. The seasoned staff of dedicated

service professionals at LGC Wireless combine wireless system design and

implementation expertise with a commitment to customer satisfaction unequalled

in the industry. LGC offers a “Coverage Guarantee” and full access to its experts

any time, 7 days a week and 24 hours a day.

For both small and large installations, LGC can deliver specific services or a full,

turnkey package that frees the customer from all the implementation details. LGC

Wireless offers the following services:

• Application Development

• Preliminary System Design

• Site Surveys

• Installation and Commissioning

• Project Management

• Turnkey Implementation

• Maintenance

Page 22

Page 23

Appendix

This appendix describes the Alarm Report Monitor (ARM2000) system, an option

that you can order separately, for monitoring LGCell, PCS Extender, and Fiber

Extender alarms.

If your LGCell is connected to a microcellular base station, see the Integration

Module Installation and Reference Manual for installation and operation of alarm

devices and connectivity for that system.

– Alarm Report Monitor (ARM2000)

E

Contents

Appendix E – Alarm Report Monitor (ARM2000)

Description of the ARM2000 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ARM2000 System Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ARM2000-RU (Remote Unit) Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PCARM Installation for ARM2000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Security Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Alarm and Device Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PCARM Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Page 24

E-2 Appendix E – Alarm Report Monitor (ARM2000)

Page 25

Description of the ARM2000 System

The Alarm Report Monitor (ARM2000) software is used to display, manage, and

record the alarm monitoring activity of one or more remote-ARM (ARM2000-RU)

alarm monitoring and remote control units. The software provides a graphical

display of up to 255 of these units and enables the user to identify and acknowledge

alarm events, reset alarms, maintain event history, and page field service personnel.

The system supports multiple users and tracks responsibility through log-in and logout procedures, using four security levels to protect critical system functions.

Alarm Report Monitor Features

The ARM2000 system has the following features:

•

Graphic Color Status Display

front panels with animation of all alarm reporting functions.

•

Remote System Reset Control

status is color keyed for on/off and pulsing conditions.

•

Alarm History and Control Logs

view and print reports for the entire system, one specific device, or one channel

of any unit.

•

Security Code Management

system. Four levels of security are available, with log-in and log-out

procedures to track responsibility.

•

Journal Printer

All activity is time and date stamped.

option keeps an active record of all alarm and control events.

shows the entire system and individual device

uses point-and-click mouse control. Reset

keep track of all system events. You can

allows restrictions to sensitive areas of the

Hardware and Operating System Requirements

To run ARM2000, you need the following hardware and operating system:

• IBM Pentium or compatible PC

• Windows 95 or Windows 98 with MS-DOS prompts

• VGA card with a minimum of 1024 Kbytes video RAM

• 8 Mbytes of conventional memory

• Hard disk storage space: at least 10 Mbytes. Additional storage space allows

larger history logs.

• One Com port

• US Robotics External 56Kbps modem (connects to COM1 port)

• Mouse

• Parallel printer (optional)

E-3

Page 26

ARM2000 System Basics

The ARM2000 system is an alarm monitoring, reporting, and remote control

system. Up to 8,160 individual alarm points can be mo nitored, displayed and logged

by the system. The system consists of up to 255 remote-ARM monitoring units that

can monitor up to 2,040 LGC systems (LG

a Pentium PC running the ARM software.

These remote-ARM units communicate with the ARM software through dial-up

modem connections. Each remote-ARM unit can use an external or internal

modem. A database of these devices is set up in the PC, each device having a unique

address. This address is set on the device and programmed into the PC using the

Device Setup utilities of the software.

The next figure illustrates both the direct connection of a single ARM unit and

multiple units connected via a dial network.

Multiple Remote-ARM Over Dial-up Network

Cell

, PCS Extender, Fiber Extender) and

Remote ARM with Internal Modem

Dial-up

Network

Remote ARM with Internal Modem

ARM2000-RU (Remote Unit) Installation

The ARM2000-RU is rack mounted in the same rack as the LG

This remote-ARM unit has an “octopus” cable that enables it to monitor up to 8

LG

it will monitor due to the cable length.

The ARM unit has an external power supply that requires a 110 VAC receptacle.

Connect the power to the ARM unit after all cable and telephone connections are

completed.

Main Hubs. The ARM unit needs to be within 4 feet of each Main Hub that

Cell

Cell

Main Hub(s).

E-4 Appendix E – Alarm Report Monitor (ARM2000)

Page 27

Modem Connections

Communications to or from the remote ARM can be configured in either of two

ways:

• Internal modem (inside remote-ARM unit)

The internal modem must be a North American qualified modem for use in

telephone networks that use North American standard call progress tones. This

modem is inside the remote-ARM unit and requires an analog phone line

connection with an RJ-11 male connector. Connect the phone line to the port

marked “Line” in COM1, at the back of the remote ARM.

• External modem (via RS-232 COM1)

LGC Wireless recommends a US Robotics External modem qualified in the

country of use. To install this modem, you need a DB-25 to RJ-45 converter

cable and a cable with RJ-45 male connectors on both ends.

If you are in a country that does not use North American standard call progress

tones, you need to use an external modem with the ARM2000-RU unit.

If you use the US Robotics External modem, you need to prepare the modem with

initialization commands before you use it, as “Preparing the PC Modem” on page 7

describes. Take the following steps to install the modem:

1

Connect the phone line to the phone line marking at the rear of the modem.

2

If you choose to be notified by a phone ring of an incoming call, then connect

the phone to the phone marking at the rear of the modem via RJ-11 male

connectors on both ends.

3

Connect the DB-25 to RJ-45 converter at the rear of the modem.

4

Run the other end of the RJ-45 cable to the RS-232 COM1 port at the rear of

the remote ARM.

Alarm Cable Connections

To connect the LG

connector cable. Make the following connections to monitor the following alarms:

Connector

J1 Alarms 1,2 - Main Hub 1

J2 Alarms 3,4 - Main Hub 2

J3 Alarms 5,6 - Main Hub 3

J4 Alarms 7,8 - Main Hub 4

Main Hub(s) to the remote ARM, use the two-to-eight-port

Cell

Alarm Monitored

J5 Alarms 9,10 – Main Hub 5

E-5

Page 28

J6 Alarms 11,12 – Main Hub 6

J7 Alarms 13,14 – Main Hub 7

J8 Alarms 15,16 – Main Hub 8

Input Alarm input to ARM unit

Output Remote Reset from ARM unit

Alarm Cable and Connectors

Test Setup

After the ARM unit is powered up, the unit should be reset and ready for

communicating to the PCARM system for final programing.

When the ARM is powered, wait 15 seconds and then press the TEST button on the

left front of the unit. All 16 circuit alarm LEDs on the front panel should light and

toggle to green momentarily. If this does not occur, power down the ARM unit for

15 seconds and start over.

The LED final state should be green to indicate a proper connection and a no-fault

condition for each Main Hub that is also powered up. Each Main Hub has 2 LEDs

assigned to it. Alarm circuits that do not have an “octopus” cable connected will be

red.

E-6 Appendix E – Alarm Report Monitor (ARM2000)

Page 29

PCARM Programming Information

If multiple ARM200-RU units are installed that will be controlled by one PCARM

system, then each ARM200-RU unit must be configured with a unique device ID

(1-255) for programming by the PCARM system. Each ARM unit must have a

different device ID if it will be controlled by one PCARM system. There is a label

on each ARM unit that indicates what device ID it has be configured for. The device

number and which Main Hub(s) it has been connected to, is important information

that must be provided to the person programming the PCARM.

PCARM Installation for ARM2000

The PCARM software runs the ARM2000 system. This section describes how to

install the PCARM software and configure it for running the ARM2000, with a

subsection on each of the following steps:

1

PC modem preparation

2

Remote programming of a remote-ARM unit

3

PCARM software installation

4

Modem connections

5

Testing of communications between PCARM and a remote-ARM unit

Preparing the PC Modem

To communicate with the internal modem of the remote-ARM unit (ARM2000RU), prepare the US Robotics 56K external modem for the Intel Pentium PC that

will be running the PCARM software via the following steps:

1

Install the US Robotics 56K external modem in the COM1 port of the Intel

Pentium PC. (Follow the installation instructions that accompany the modem.)

2

Enter the AT comma nds to initializ e the 56K modem to communic ate with the

internal modem of the remote ARM.

To enter the AT commands

1

Choose Accessories from Programs on the Start menu.

2

Click HyperTerminal.

3

Double click HyperTerminal.exe.

4

Enter a name of connection (“Test”, for example).

5

When prompted to enter a phone number, select direct to COM1 from the

“CONNECT USING

COM 1 properties.

” pull-down menu and click OK. Then click OK on

E-7

Page 30

Once connected to COM1, enter AT and press Enter. (You will see OK displayed

at this point and will not see any characters.) Then enter the following AT

commands.

•“AT&F”

•“AT&A0”

•“AT&B1”

•“AT&K0”

•“AT&M0”

•“AT&N3”

•“AT&W”

After you enter these commands, your PCARM modem is ready for communication

with the internal modem of the remote ARM. Exit HyperTerminal. (You do not

need to save this session).

Remote Programming of a Remote-ARM Unit

To program the remote-ARM unit with the phone number to dial out to the PCARM

modem when an alarm condition occurs, make sure that the remote-ARM unit is

connected to an analog dial-up line and is powered up. Call from the PCARM,

taking the following steps. (Make sure the US Robotics 56K modem is installed in

the PCARM before programming.)

1

Click Start.

2

Click Programs.

3

Click Accessories.

4

Click HyperTerminal.

5

Double click HyperTerminal.exe.

6

Type connection name (“TEST”, for example) and click Enter.

7

Type the phone number of the line to which the remote-ARM unit is

connected.

8

Click OK.

9

Click Connect.

When a connection is established to the remote-ARM unit, the HyperTerminal

status bar will indicate the connection time.

10

After a connection is established, type “P” and then press the Enter key.

A prompt appears on the screen asking you to enter the phone number:

(ENTER PHONE NUMBER)

E-8 Appendix E – Alarm Report Monitor (ARM2000)

Page 31

Enter the dial-up number (the PCARM modem number) that the remote ARM

11

will dial to establish communications with the PCARM. If you need to enter a

digit to access an outside line (such as 9), separate this digit from the phone

number with a comma for a pause. Enter 1 for long distance if required.

End the session by entering “ATH0”.

12

Exit HyperTerminal. You do not have to save the session.

13

PCARM Software Installation

To install the PCARM files

Place the PCARM disk in the A (or appropriate) drive.

1

Open Windows Explorer from the Program menu under the START Button.

2

Make directory PCARM under the C drive.

3

Make two sub-directories in the PCARM folder, labeled ARCHIVE and

4

BACKUP.

Exit Windows Explorer.

5

From the START Button RUN A:\PCARM.exe. Press OK.

6

The WinZip program will extract and unzip the PCARM files.

Save the unzipped PCARM files to the C:\PCARM directory.

7

Close the WinZip window.

8

Take out the PCARM disk and store in a safe place.

9

After you install these files, verify that the files are in the PCARM directory

10

via Windows Explorer, then exit Explorer.

To create a shortcut for PCARM

Right click the mouse on the Windows 95 desktop.

1

Place the mouse pointer over NEW.

2

Another menu pops up.

Click Shortcut.

3

Click Browse.

4

Double click PCARM.exe.

5

Click Next.

6

Click Next (again).

7

Double click the desired icon.

8

A “PCARM.exe” icon appears on the desktop.

E-9

Page 32

To set up PCARM software

Double click the PCARM.exe shortcut icon that you created.

1

The System View screen appears.

Click setup.

2

Click Configure ARM Manager (change the configurations to desired

3

settings). Make sure “use modem” is YES. Once changes have been made,

save the changes and exit.

Click Setup (again).

4

Click Device.

5

Click Remote Arm.

6

Enter the device address (0001, for example).

7

Enter the location (LGC Wireless, for example).

8

Enter the phone number for the remote-ARM unit (assigned to that hardware

9

device number).

Enter appropriate alarm names, short names, alarm & clear states, and pager.

10

Select no for pager for all alarms entered. (See Inputs sample screen.) If you

are in Device 0001, alarm names are already set. This is the default database.

Save the data you entered. (You will not see any indicator of saved data.)

11

Click Program Outputs.

12

Enter the appropriate number of devices, and Energize and De-Energize states.

13

(See Outputs sample screen). If you are in Device 0001, there is default data

present.

Save data once entered.

14

Once data has been saved, exit out of setup. (This will take you to the Device

15

View screen.)

To receive alarms from the remote-ARM unit or units, leave the PCARM running

continuously on the PC. The System View screen indicates the status of each device

(REMOTE ARM UNIT).

E-10 Appendix E – Alarm Report Monitor (ARM2000)

Page 33

Modem Connections

Communications to or from the remote-ARM unit can be configured in either of

two ways:

• The internal modem (inside the remote-ARM unit) uses North American call

progress tones.

• External Modem (via RS-232 COM1) used for International locations when

North American call progress tones are not used.

Internal Modem:

ends)

The internal modem is situated inside the remote-ARM unit. The phone line

connection is connected to the port marked, “Line” in COM1, at the back of remoteARM unit.

External Modem:

RJ-45 converter, cable with RJ-45 male connectors on both ends)

If you choose to use an external modem, use a US Robotics 56K external modem.

If this modem is used, plea se prepa re the m odem with the i nitia liz ation comm ands

given in the modem preparation section prior to usage. Connect the phone line to

the phone line marking at the rear of the modem. Connect the DB-25 to RJ-45

converter at the rear of the modem, and run the other end of the RJ-45 cable to the

RS-232 COM1 port at the rear of the remote-ARM unit. Verify that you are using

a remote-ARM unit that does not have an internal modem (part number ARM2000RU-EXT).

(Required parts: cable with RJ-11 male connectors on both

(Required parts: US Robotics External modem, DB-25 to

Testing Communications Between PCARM and Remote-ARM Unit

To test communications between the two modems, the PCARM software needs to

be running. (Install the software and configure it, if not done.)

1

Turn on the PC and wait for Windows 95 to load.

2

Click the PCARM.exe shortcut icon to run the PCARM program.

This puts you at the System View screen.

3

On the System View screen, click the device with which you want to

communicate.

This puts you at the Device View screen. To find the device, place the mouse

pointer over the cell for the device.

4

On the Device View screen, click Test to test communications between the

PCARM and the remote-ARM unit.

An alarm condition prompts the remote-ARM unit to dial the PCARM (alternate

method of test).

E-11

Page 34

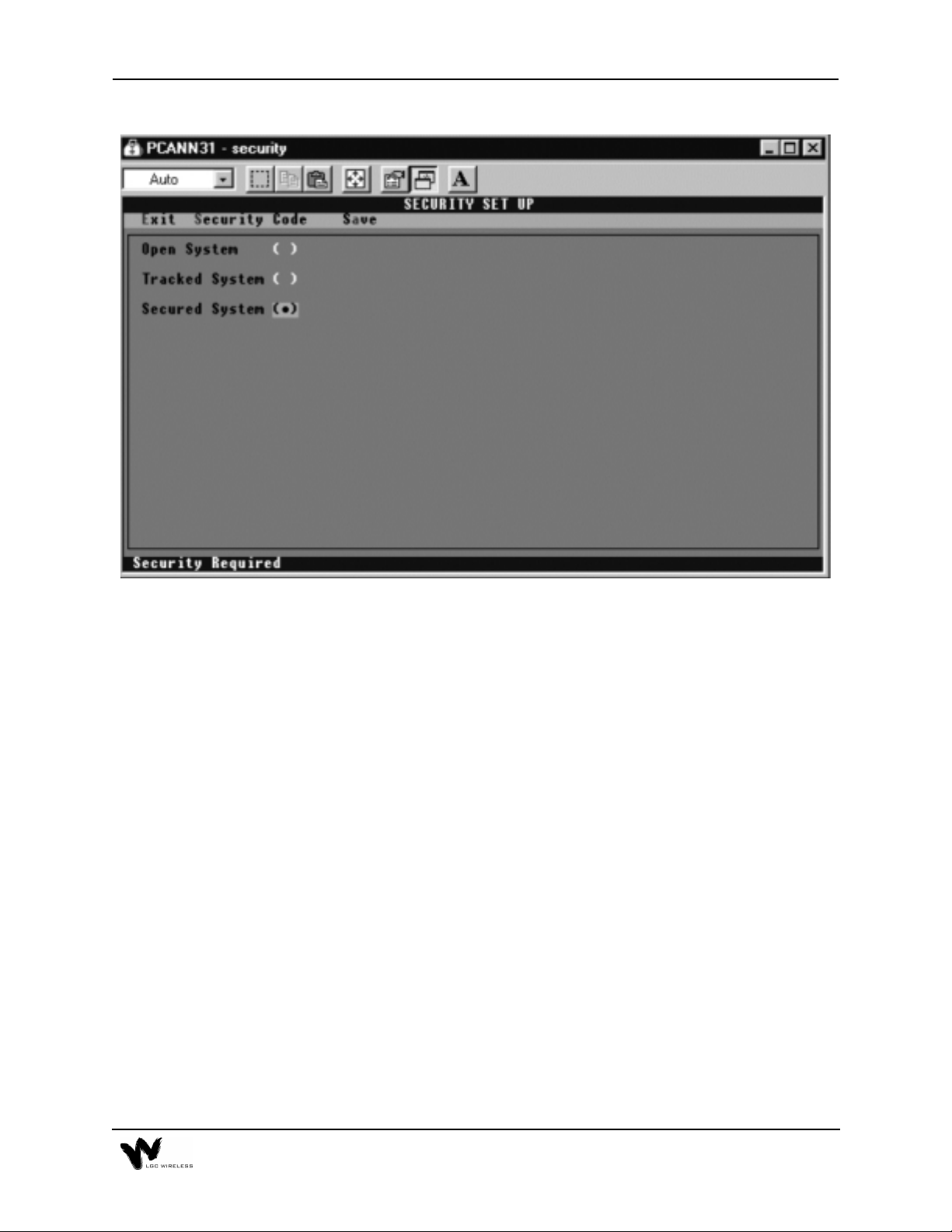

Security Setup

To access the security utility, click Setup on the Device View or System View

screen. Choose the desired security system by placing the cursor in the appropriate

box and clicking. For a secure system you will need to enter a name, password

(security code), and clearance level for each individual who will use the system. In

a secure system at least one operator must have a Level 3 security clearance. If the

system is set up to be Tracked, or Secured, an operator can log on and log off from

the Setup menu on the Device View or System View screen.

E-12 Appendix E – Alarm Report Monitor (ARM2000)

Page 35

Security Setup Utility Overview

The Security Setup Utility enables the user to setup the various security feature s of

the ARM. It is made up of two different screens. One to select the system wide

security options and the other to enter the system operators.

Access to the Security Setup Utility

You can access the Security Setup Utility from the System View or Device View

screen or the Control Panel. From any of th ese, select Setup / Security. If the system

is in tracked or secured mode, you must have Level 3 security clearance. If the

operator who is currently logged on does not have Level 3 clearance, an error

message is displayed. In a secured system, you need to enter a second security code

to access this utility.

E-13

Page 36

Security Options Screen

Security Options Fields

To select a Security Setup field, use the SPACEBAR key or position the cursor over

the field you want and click the left mouse button. You can set up the security of

the system in one of three ways:

• Open system

In an open system, all functions are availa ble a t all time s. No log-on or lo g-off

procedure is required. This is the least secure system.

• Tracked system

In a tracked system, each user is assigned a security level and an access code.

There are four levels of security, each with progressively more access to the

system. After a user logs on at a given level, all functions for that level are

available to the user.

• Secure system

A secure system functions in the same way as a tracked system, except that level

3 functions (archive and system management) require reentry of the security

code.

E-14 Appendix E – Alarm Report Monitor (ARM2000)

Page 37

Security Codes Screen

The Security Codes screen enables the system supervisor (highest security, Level

3) to change or add operator names and security codes and assign individual

security levels.

Security Code Levels

• Level 0

Allows a user to view status and history screens and to print reports. At this

level, the user will not be able to acknowledge alarms. Any attempt to perform

a function will result in a prompt for a higher security code or log on.

• Level 1

All of Level 0 plus the ability to acknowledge alarms.

• Level 2

All of Level 1 plus the ability to control the remote-ARM relays.

• Level 3

Manager Level. Unrestricted access to all system functions. This level is

required for all setup functions.

E-15

Page 38

Alarm and Device Setup

During the initial test after you complete the setup, PCARM displays the

appropriate clear and alarm conditions. To acknowledge these conditions, click the

ACK button on the Device View screen. During initial setup, all 16 devices are

assumed to be enabled.

Disabling Alarms and Devices

To disable an alarm, place the mouse pointer over the alarm and right click.

PCARM displays a dialog box that asks if you want to be reminded to enable after

an elapsed time. Make your selection of time and press Enter. The alarm is disabled

at this point, both in PCARM and on the REMOTE UNIT display panel.

You can also enable a device in this manner from the System View screen.

Enabling Alarms and Devices

To enable an alarm, place the mouse pointer over the desired alarm and right click.

PCARM displays a dialog box that gives you options to enable or cancel. Click the

enable options, or press E on the keyboard to enable them. (If you attempt to enable

an alarm when appropriate conditions have not been met, the alarm indicator (red

LED) flashes and the PC buzzer sounds.)

You can also enable a device in this manner from the System View screen.

E-16 Appendix E – Alarm Report Monitor (ARM2000)

Page 39

E-17

Page 40

Resetting the Main Hub Remotely

The remote-ARM unit is designed not only to monitor the alarm conditions, but also

to reset the Main Hub from a remote site. When an alarm condition occurs, you can

clear the alarm from the PCARM via the control menu and then reset the Main Hub.

To reset an alarm condition remotely

1

From the Device View screen, click Control Menu to go to the Control Panel

screen.

2

Choose a hub to reset by clicking that hub.

PCARM displays the Control Relay dialog box, which gives you the option to

pulse or change the state of the relay.

3

Click Pulse to reset the hub.

PCARM displays the Pulse Duration dialog box, which asks you for a pulse

time and displays the following message:

ONLY ONE (1) SECOND PULSE IS REQUIRED TO RESET THE HUB.

E-18 Appendix E – Alarm Report Monitor (ARM2000)

Page 41

Choose your time and press Enter

4

If the alarm condition has cleared, the PC buzzer sounds and a status box

appears on your screen.

Click Go To.

5

PCARM displays the Device View screen, on which the cleared alarm(s) flash

green.

To acknowledge the clear condition, click ACK.

6

The flashing green indicator or indicators become solid green.

Control Relay Dialog Box

E-19

Page 42

Pulse Duration Dialog Box

Control Panel Status Box

E-20 Appendix E – Alarm Report Monitor (ARM2000)

Page 43

PCARM Operations

To display, manage, and record alarm monitoring activity in PCARM, you can

perform operations from the System View, Device View, and Alarm View screens.

You can also enable and disable alarms and devices from the System View and

Device View screens.

System View Screen

Overview of the System View Screen

The System View screen displays the current status for all of devices in the entire

system. On the screen, 255 windows display the status for each device in the

system. When no alarms are present, the windows for all of the active devices are

green. If an alarm occurs, the window of the particular device flashes red and the

PC’s buzzer sounds. A status bar at the bottom of the screen displays the current

status of the communications port and operator. At the top of the s creen is a menu

bar for program navigation.

E-21

Page 44

Window Status Indicators

Window State Condition

Green All circuits clear and acknowledged.

Red Alarm condition on one or more channels. All alarms are acknowl-

edged.

Green Flashing Unacknowledged clear event on one or more channels.

Red Flashing Unacknowledged alarm on one or more channels.

Red/Green Flashing Both alarms and clears that are unacknowledged.

Blue Flashing Unit is not responding to polls.

Yellow The device is output only.

Gray Unit is not programmed.

Black Device has been disabled.

Device Selection

To view a particular device, position the cursor over the window of the device and

click the right button. This transfers the program into the device view mode. See

“Device View Screen” on page 25.

Disabling Devices

You can disable devices to allow maintenance of the monitored equipment

without receiving false alarms. To disable a device, position the cursor over the

device and click the right mouse button. PCARM displays a dialog box that

prompts you to enter a reminder time. Enter a desired amount for timer (in

minutes) to be reminded that the device has been disabled, or 0 for no reminder.

Enabling Devices

To enable a device, position the mouse over the desired disabled device and

click the right mouse button. This will cause a confirmation dialog box to be

displayed. To enable the device, click the Enable button on the dialog box or

press the ‘E’ on the keyboard. To cancel, click the Cancel button, press the

‘ESC’ or ‘C’ key on the keyboard.

E-22 Appendix E – Alarm Report Monitor (ARM2000)

Page 45

Status Bar

The status bar is located on the bottom of the System View screen. It displays the

current status of the system. It has three status windows. The function of each of

these windows is described in the following sections:

Communications Port Status

This window is used to display the current status of the communications port. If the

system is configured to be directly connected to a device it will display “Direct

Connect”. If the system is configured to use a modem it displays the current status

of the modem.

Operator Status:

This window is used to display the operator status. In an open system, it displays

“Open System”. In tracked and secured systems, it displays the name of the operator

that is currently logged on or “Please Log On” if no operator is logged on.

System View Menus

The System View menus are located on top of the screen. Descriptions of the menu

choices follow:

•

File

This selection displays a pull down menu with the following choices:

Archive

This selection displays a sub-menu that allows clearing the active Alarm and/or

Control Log and saving the current contents to an Archive file. The data from

the Alarm and/or Control Log are stored in the sub directory archive. These files

are Dbase III compatible. In a tracked or secured system, the user must have a

Level 3 security code.

Exit

This selection terminates the ARM program and returns to DOS.

•

History

This selection displays an Alarm History Screen that lists a full chronological

history of all events (alarms\clears) for the entire system.

E-23

Page 46

•

Setup

This selection displays a pull down menu with the following five choices:

Config ARM

:

This selection accesses the ARM configuration utility.

Device

:

This selection displays a sub-menu that allows access to the device setup

utilities as described below.

REMOTE-ARM

:

This selection accesses the remote-ARM setup utility.

Security

:

This selection accesses the Security Setup utility.

Log On

:

This selection displays the Log On Dialog Box.

Log Off

:

This selection displays the Log Off Dialog Box.

•

Operator Log

This selection displays an Operator History Log that lists a full chronological

history of all operators that have logged into and logged out of the system.

•

Print Current Alarms

This selection generates a report showing all current alarm conditions in the

system.

E-24 Appendix E – Alarm Report Monitor (ARM2000)

Page 47

Device View Screen

Overview of the Device View Screen

The Device View screen displays a Graphic Color Status Display of any individual

front panel with animation of all alarm reporting functions. Each Device View has

the location name of the device printed at the top of the screen (LGC Wireless in

the example above). When no alarms are present all channel LED’s are green, there

is a message ‘ALL CLEAR’, and the time. Each LED has an associated name

(Short Name) printed above it. There is a status bar at the bottom of the screen that

displays the system status. There is a menu bar at the top of the screen for program

navigation.

When an alarm occurs, its associated LED begins to flash red and the PC’s buzzer

sounds until the alarm is acknowledged. Below the front panel, the alarm name,

status, and time/date the alarm occurred is displayed.

When the alarm clears, its associated LED flashes green and the PC’s buzzer

sounds three beeps. When the clear is acknowledged, the channel LED is steady

green.

E-25

Page 48

When you are at the Device View screen, if an event occurs on another device, a

New Event dialog box will pop up over the Device View screen. The New Event

dialog box offers the following choices:

•

Go To

Select to display the device that is alarming.

•

System View

Select to display System View screen.

•

Continue

Select to continue with the device that is presently displayed.

Acknowledging Alarms

Alarms and Clears are both acknowledged in the same manner. Simply position the

cursor over the ACK button and click the left mouse button. If the system has been

configured as an open system and the Require Initials on Acknowledgment option

has been enabled, the Enter Initials dialog box will be displayed. Simply enter your

initials followed by the enter key and the alarm is acknowledged. In tracked and

secured systems, an operator with a security level of one or greater must be logged

on in order to acknowledge and alarm or clear. If no one has logged on prior to

clicking the acknowledge button, the Log on dialog box will be displayed. The ESC

key will cancel the log on procedure without acknowledging the alarm.

Disabling Channels

Individual alarm channels can be disabled to allow equipment maintenance without

causing false alarms. To disable an alarm channel, position the cursor over the

desired disabled channel’s LED and click the right mouse button. A dialog box will

then pop prompting to enter a reminder time. Enter the desired timer (in minutes)

for the disabled reminder to pop up. Enter 0 if no reminder is required.

Enabling Channels

To enable the channel, position the cursor over the desired channe l’s LED and click

the right mouse button. This will cause a confirmation dialog box to be displayed.

To enable the channel, click the Enable button or press the E key. To cancel, click

the Cancel button or press the ESC or C key.

Alarm View Dialog Box

The Alarm View dialog box has been provided as a quick way of viewing the last

two events that occurred on a given channel. To display the Alarm View dialog

box, position the cursor over the desired channel’s LED and click the left mouse

button. This is a non modal dialog box, clicking another channel or anything else

on the screen will close the dialog box and perform the selected function. If the

selected channel has no alarms an error box will be displayed.

E-26 Appendix E – Alarm Report Monitor (ARM2000)

Page 49

Communications Test Function

A communications test function has been provided to test communications between

ARM and the remote-ARM unit and update the status. This should be done after a

new device is installed. To test a device, position the cursor over the test butt on and

click the left mouse button and ARM will call the remote-ARM unit. When the test

is complete a dialog box stating the result of the test will be displayed.

Status Bar

There is a status bar located at the bottom of the screen. This status bar displays the

current status of the system.

Alarm View Screen Overview

The Alarm View Screen provides a quick view of all the alarms (acknowledged and

unacknowledged) in the entire system. The alarms are displayed in chronological

order from the newest to the oldest. The unacknowledged alarms are displayed in

red, and the acknowledged alarms are displayed in blue. Clicking any of the alarms

in this view causes the program to switch to the device view of the selected alarm.

A scroll bar on the right hand side of the screen is provided to scroll through the

alarm list. A menu bar, at the top of the screens, is provided to navigate to other

screens. The contents of this screen can be printed to a printer or file.

E-27

Page 50

Reports

You can display the following reports in PCARM:

• Alarm History Log

• Alarm History by Device

• Alarm Detail

Alarm History Log

The Chronological Alarm History screen displays the entire contents of the Alarm

History Log in chronological order (newest to oldest). A scroll bar on the right hand

side of the screen is provided to scroll through the alarm log. The scroll bar thumb

shows the current position in the file. A menu bar located on the top of the screen

is provided to navigate through the program.

This screen shows the location of the alarm, channel name, and status. For a more

detailed view of an individual alarm, position the cursor over the desired alarm and

click the left mouse button. This causes the Alarm Detail dialog box to be displayed.

In addition to the alarm information, this screen also displays any loss of

communications and restoration of communications.

Alarm History by Device

The Device History screen displays the chronological alarm history (newest to

oldest) of one specific remote-ARM device. A scroll bar on the right hand side of

the screen is provided to scroll through the alarms. The thumb of the scroll bar

shows the position in the file. A menu bar located at the top of the screen is provided

to navigate through the ARM.

This screen shows the channel name, status, and time the event occurred. For a more

detailed view of the event, position the cursor over the desired event and click the

left mouse button and the Alarm Detail Dialog Box will be displayed.

Alarm Detail Dialog Box

The Alarm Detail dialog box is displayed when you click any event in the Alarm

History logs. This dialog box displays the following information for the selected

event:

• Location name

• Channel name

• Status of the channel

• Time the event occurred

E-28 Appendix E – Alarm Report Monitor (ARM2000)

Page 51

• Time the event was acknowledged

• Initials of who acknowledged the event

Operator Log

The Operator Log is a chronological history (newest to oldest) of the operators who

have logged on to the system. This screen contains columns to display the operator

name, time logged on, and the time logged off.

You can access the Operator Log only from the System View screen. Select

Operator Log from the main menu.

Report Printing

PCARM provides the ability to print any of the Alarm, Control, and Operator logs

to either a printer (connected to LPT1) or a file. To print a log, select Print from the

menu of the displayed log. This pops up the following dialog box.

In this dialog box, click the square button next to either LPT1 or FILE. To start

printing, click the OK button. If you select FILE, PCARM displays a second dialog

box in which you can enter the name of the file (up to 13 characters).

When printing begins (to file or printer), PCARM displays the Print Progress dialog

box. You can abort the print job at any time by clicking the Cancel button.

E-29

Page 52

Alarm Logs

To print an alarm log, select the log you want and then select Print from the log

screen’s menu.

Control Logs

To print a control log, display the log and then select Print from the log screen’s

menu.

Current Alarms

ARM provides the ability to print a list of all current alarms (acknowledged and

unacknowledged) to a printer. To print all current alarms, select Print Current

Alarms from the menu on the System View screen.

Operator Log

To print the Operator Log, select Print from the Operator Log menu.

E-30 Appendix E – Alarm Report Monitor (ARM2000)

Loading...

Loading...