Page 1

USER MANUAL

Soneplex

DS3 Loop Extender (D3LX) CO Module

Product: D3LXC-FCA100, D3L XC-SCA100

CLEI Code: SOCPG2GB, SOCPG2KB

Soneplex

DS3 Loop Extender (D3LX) RMT Module

Product: D3LXR-FCA100, D3LXR-SCA100

CLEI Code: SOCPG2HB, SOCPG2JB

Page 2

LTPS-UM-8013-03

Revision History of This Manual

To order copies of this document, use document catalog number LTPS-UM-8013-03.

Issue Release Date Revisions Made

1 January 11, 2002 Initial release

2 March 21, 2002 Updated BNC cable/cabling instructions

3 August 30, 2002 Updated BNC Tip and Ring illustration

Related Documentation

Soneplex Remote Terminal Enclosure Installation Manual ADCP-61-704

Soneplex Two-Position D3LX Remote Chassis Installation Instructions LTPS-AD-8029-xx

Soneplex Four-Position Remote Terminal Cabinet Installation Addendum for D3LX Systems LTPS-AD-8030-xx

Soneplex QLX/WQLXR and Four-Position Remote Terminal Cabinet Description Manual ADCP-61-151

Soneplex System Installation Manual LTPS-UM-8010-xx

Soneplex Loop Extender System Operation and Maintenance Manual ADCP-61-494

Soneplex TL1 Interface Specification for D3LX-Based Systems LTPS-UM-8027-xx

Soneplex D3LX Remote Craft Access Module (D3RCAM) User Manual LTPS-UM-8017-xx

Copyright

August 30, 2002

© 2002 ADC DSL Systems, Inc. All rights reserved.

Trademark Information

ADC and Soneplex are registered trademarks of ADC Telecommunications, Inc. No right, license, or interest to such trademarks is

granted hereunder, and you agree that no such righ t, license, or interest shall be asserted by you with re spect to such trademark.

Other product names mentioned in this manual are used for identification purposes only and may be trademarks or registered

trademarks of their respective companies.

Disclaimer of Liability

Information contained in this do cume nt is compan y private to ADC DSL Systems, Inc., and shall not be modified, used, copied,

reproduced or discl osed in whole or in part without the written consent of AD C.

Contents herein are curr ent as of th e date of publi catio n. ADC re serv es the right to ch ange the cont ents wi tho ut prio r no tice. In no

event shall ADC be liable for any d amages resulti ng from l oss of da ta, loss of us e, or los s of prof its, and ADC furthe r discl aims any

and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of liability applies to all

products, publications and services during and after the warranty period.

ii August 30, 2002 D3LX CO and RMT Modules

Page 3

LTPS-UM-8013-03 Using This Manual

USING THIS MANUAL

The following conventions are used in this manual:

• Monospace type indicates screen text.

• Keys you press are indicated by small icons such as or . Key combinations to be pressed

simultaneously are indicated with a plus sign as follows: + .

Y ENTER

CTRL ESC

• Items you select are in bold.

• Three types of messages, identified by icons, appear in text.

Notes contain information about special circumstances.

Cautions indicate the possibility of personal injury or equipment damage.

The Electrostatic Discharge (ESD) symbol indicate s that a device or as sembly is susc eptible to

damage from electrostatic discharge.

INSPECTING SHIPMENT

Upon receipt of the equipment:

• Unpack each container and inspect the contents for signs of damage. If the equipment has been damaged in

transit, immediately report the extent of damage to the transportation company and to ADC DSL Systems,

Inc. Order replacement equipment, if necessary.

• Check the packing list to ensure complete and accurate s hipmen t of each listed item. If the shipment is short

or irregular, contact ADC DSL Systems, Inc. as described in “Appendix C - Pr odu ct Su pport ” on page41. If

you must store the equipment for a prolonged period, store the equipment in its original container.

D3LX CO and RMT Modules August 30, 2002 iii

Page 4

Inspecting Shipment LTPS-UM-8013-0 3

iv August 30, 2002 D3LX CO and RMT Modules

Page 5

LTPS-UM-8013-03 Table of Contents

TABLE OF CONTENTS

Overview ____________________________________________________________________________ 1

Front-Panel Description________________________________________________________________ 3

Protection Switching..........................................................................................................................4

Automatic Switching...........................................................................................................5

Manual Switching................................................................................................................5

Applications.......................................................................................................................................5

Preparing to Install D3LX Modules______________________________________________________ 6

Installing the BNC Panel _______________________________________________________________ 7

Overview............................................................................................................................................7

Installation of the Panel......................................................................................................................7

Installing a D3LX CO Module in an LEC _________________________________________________ 9

Power Verification................... ..... ...... ...... .................................. ..... ...... ..........................................12

Verification of Electrical DS3 Power Level......................................................................12

Verification of D3LX CO Optical Power..........................................................................13

Installing a D3LX RMT Module in a Remote Cabinet______________________________________ 14

Four-Position Remote Terminal Cabinet Installation......................................................................14

Two-Position QLX Remote BNC Chassis Installation....................................................................16

Power Verification................... ..... ...... ...... .................................. ..... ...... ..........................................16

Verification of Electrical DS3 Power Level......................................................................16

Verification of Optical Power............................................................................................17

Provisioning_________________________________________________________________________ 18

Manual .............................................................................................................................................18

Automatic.........................................................................................................................................18

Other Provisioning Considerations..................................................................................................19

Alarm Setting During Provisioning...................................................................................19

D3 Remote Craft Access Module (D3RCAM) Option .....................................................19

Setting Up System Options ____________________________________________________________ 19

Connecting a Maintenance Terminal to the SCU Craft Port ...........................................................19

Connecting a Maintenance Terminal to the D3RCAM Craft Port...................................................20

Navigating Through Craft Interface Menus...................................................... ...... ..... ....................22

Local Configuration__________________________________________________________________ 23

Configuring the D3LX System Through the SCU...........................................................................23

Configuring D3LX Alarms..............................................................................................................25

Setting Alarm Levels.........................................................................................................25

Displaying D3LX Status..................................................................................................................27

Viewing Loopback Status and Performing Loopback Commands..................................................28

D3LX CO and RMT Modules August 30, 2002 v

Page 6

Table of Contents LTPS-UM-8013-0 3

Performance Monitoring ................................................................................................................. 29

Performing System Maintenance .................................................................................................... 30

Logging Off..................................................................................................................................... 31

Removing D3LX Modules.............................................................................................................. 32

Remote Configuration _________________ ___ _________________ __ ___ _________________ ___ __33

D3RCAM Menu..............................................................................................................................34

Unit Configuration...........................................................................................................................34

Troubleshooting _____________________________________________________________________36

Appendix A - Specifications____________________________________________________________ 37

D3LX Card-Edge Connector............................. .................................. ...... ..... .................................38

Appendix B - Cleaning and Mating Fiber-Optic Systems____________________________________39

Cleaning...........................................................................................................................................39

Mating.............................................................................................................................................. 40

Appendix C - Product Support _________________________________________________________41

Appendix D - Abbreviations ___________________________________________________________ 42

Certification and Warranty _____________________________________________ Inside Back Cover

vi August 30, 2002 D3LX CO and RMT Modules

Page 7

LTPS-UM-8013-03 List of Figures

LIST OF FIGURES

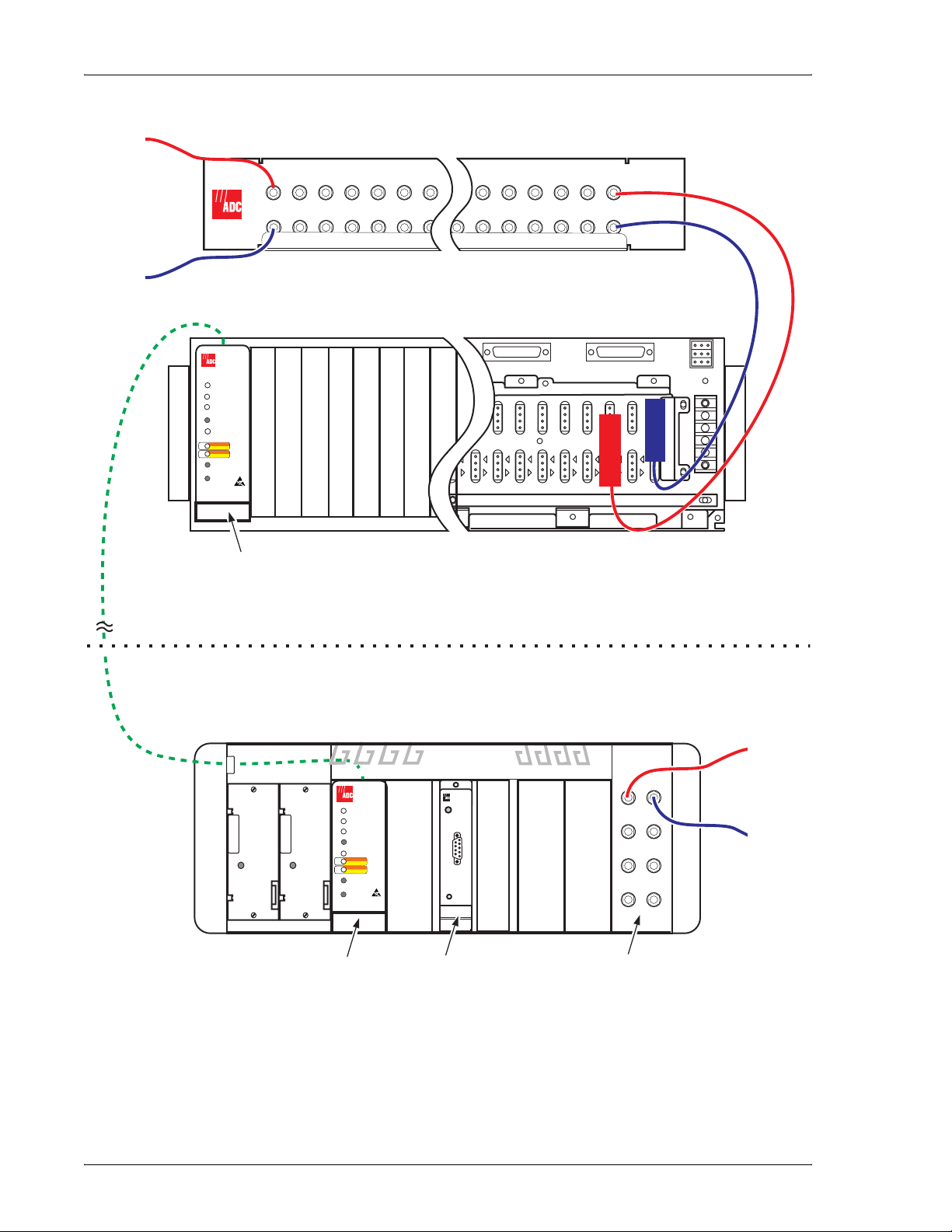

1. D3LX CO and D3LX RMT Modules.............................................................................................................1

2. System Overview............................................................................................................................................2

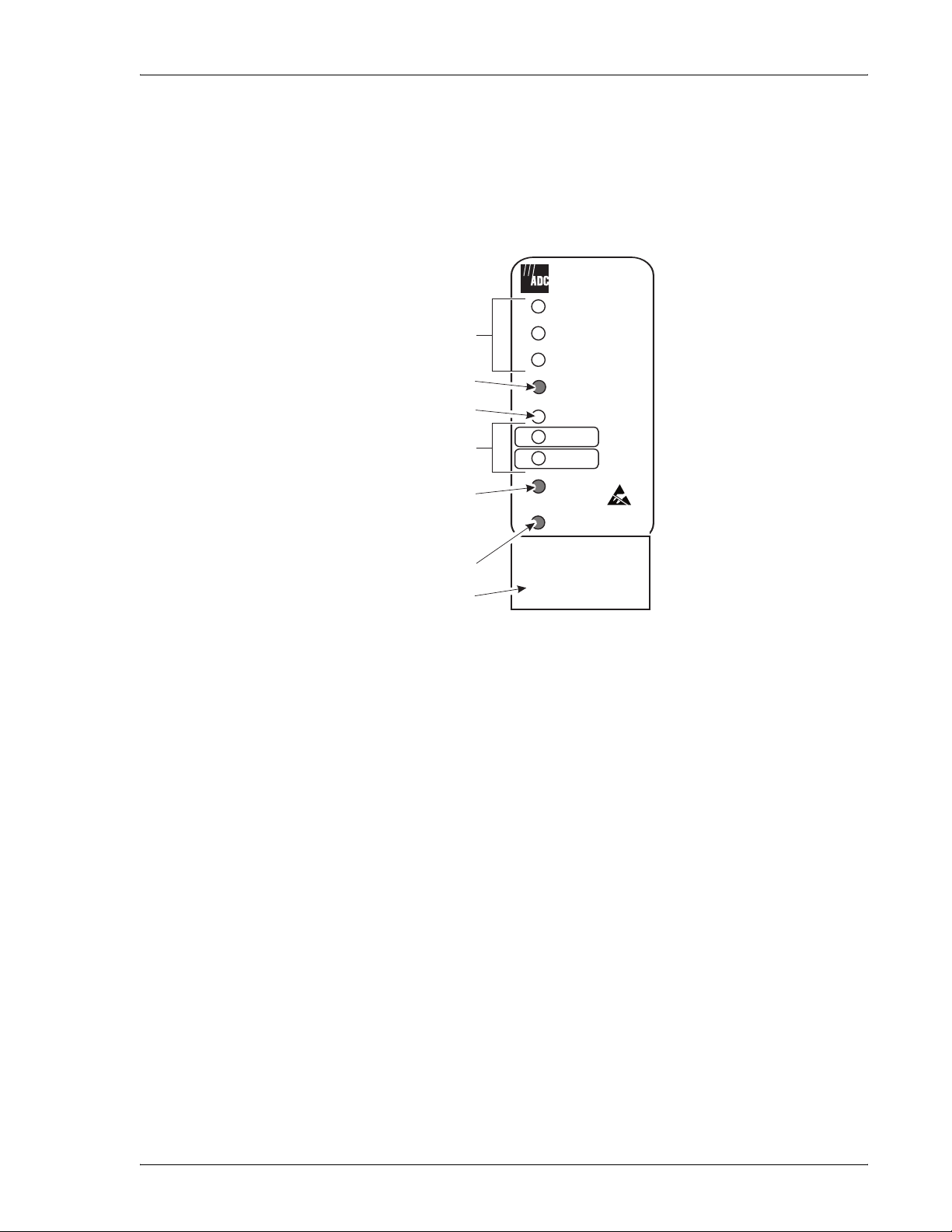

3. D3LX CO Front Panel....................................................................................................................................3

4. Mounting the BNC Panel and Connecting ADC Adapter Cables (LEC Shown)...........................................8

5. Routing the Fiber Patch Cord....................................................................................................................... 10

6. D3LX Module Locations in Loop Extender Chassis....................................................................................11

7. Installing the D3LX CO ...............................................................................................................................12

8. Routing the Fiber Through a Four-Position Remote Terminal Cabinet.......................................................14

9. D3LX RMT Module Locations in a Four-Position Remote Terminal Cabinet............................................15

10. D3LX RMT Module Locations in a Two-Position QLX Remote BNC Chassis......................................... 16

11. Connecting a Maintenance Terminal to the SCU.........................................................................................20

12. Connecting a Maintenance Terminal to the D3RCAM................................................................................21

13. D3LX Configuration Screen.........................................................................................................................23

14. D3LX Alarm Setting Menu..........................................................................................................................26

15. Display D3LX Status....................................................................................................................................27

16. Loopback Status and Commands .................................................................................................................28

17. Performance Monitoring Menu–DS3/E3 PM Configuration Shown...........................................................29

18. System Maintenance–Trouble Isolation Screen Shown...............................................................................31

19. Removing a D3LX Module–D3LX CO Shown...........................................................................................32

20. D3RCAM Craft Interface Main Menu ................................................................................ ..... ...... . .............33

21. D3RCAM Menu Tree...................................... ...... ..... .................................................................................. 34

22. Unit Configuration Screen...................................................... ......................................................................34

23. D3LX Card-Edge Connector........................................................................................................................38

24. Cleaning Materials........................................................................................................................................39

D3LX CO and RMT Modules August 30, 2002 vii

Page 8

List of Tables LTPS-UM-8013-03

LIST OF TABLES

1. D3LX Front-Panel Description and Status LEDs..........................................................................................4

2. Tip and Ring Assignments for Protection Switching Applications ...............................................................8

3. Chassis Port Description .............................................................................................................................. 19

4. Navigational Keys for the Craft Interface Screens During Telnet Sessions................................................22

5. D3LX CO Configuration Fields–SCU V3.7 or later.................................................................................... 24

6. D3LX Alarm Level Defaults........................................................................................................................ 26

7. Un it Configu ration Fields–D3RCAM Version 1.0 or later..........................................................................35

8. Troubleshooting ...........................................................................................................................................36

9. D3LX Module Specifications....................................................................................................................... 37

viii August 30, 2002 D3LX CO and RMT Modules

Page 9

LTPS-UM-8013-03 Overview

OVERVIEW

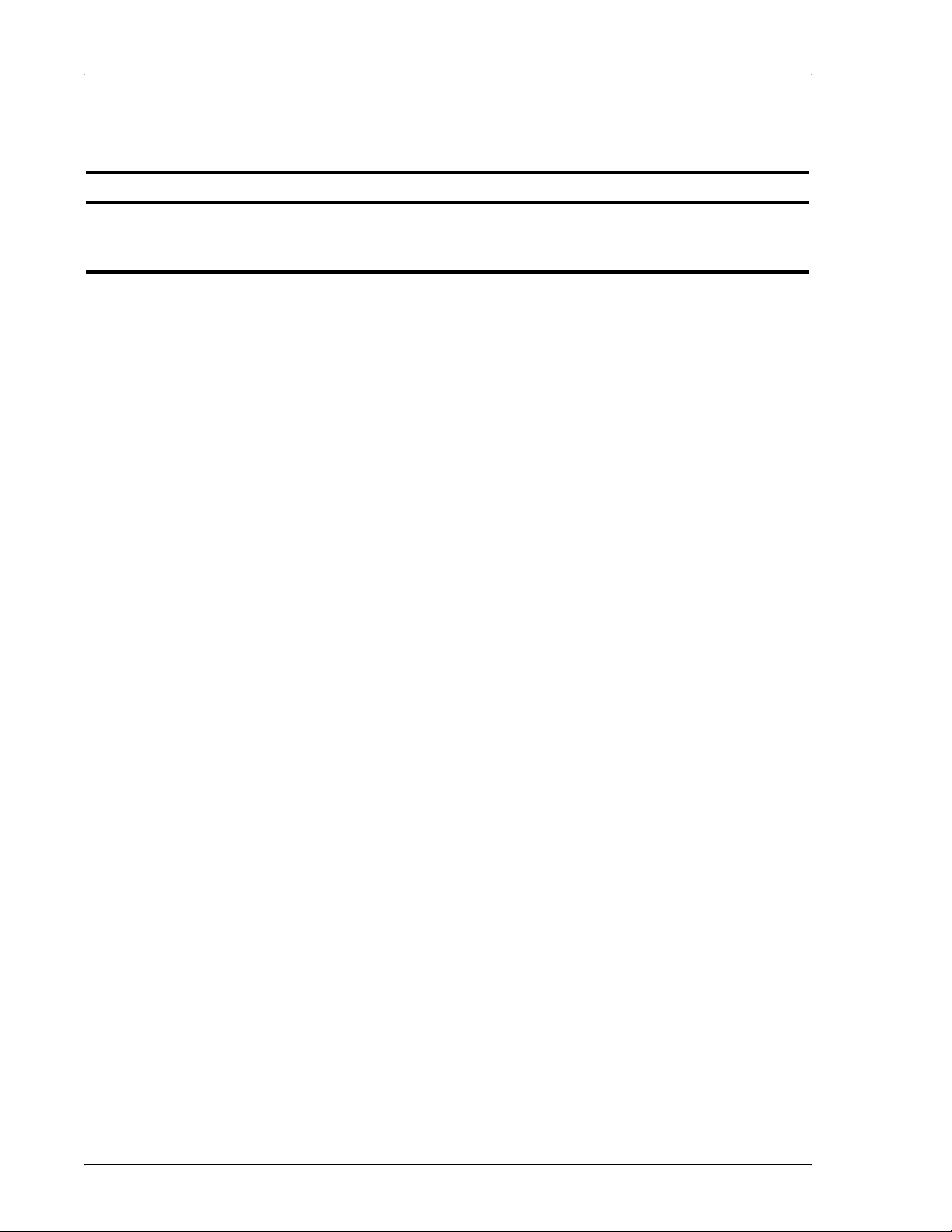

The Soneplex® DS3 Loop Extender

(D3LX) modules sho wn in Figure 1 are a pair of fiber-optic units that provide

DS3 service. The D3LX CO resides at the Central Office (CO) site, and the D3 LX RMT reside s at th e Custom er

Premises Equipment (CPE) or remote site.

D3LX

STATUS

FAR END

DS3 STATUS

ENABLE

DS3 ONLINE

C

O

D3LX

STATUS

FAR END

DS3 STATUS

ENABLE

DS3 ONLINE

R

M

T

Figure 1. D3LX CO and D3LX RMT Modules

The D3LX CO module occupies two card slots in a local, Soneplex Loop Extender Chassis (LEC). The D3LX

RMT module occupies two card slots in a Four-Position Remote Terminal Cabinet, or Two-Position QLX Remote

BNC Chassis. A D3LX Remote Craft Access Module (D3RCAM) may also installed to provide maintenance

terminal access at the remote site. For more information on the D3RCAM, refer to LTPS-UM-8017-xx, the

Four-Position Remote Terminal Cabinet, refer to ADCP-61-151, or the Two-Position QLX Remote BNC Chassis,

refer to LTPS-UM-8029-xx.

The D3LX modules are part of a system that converts a metallic DS3 circuit at the CO site into a DS3 optical signal

that uses Wavelength Division Multiplexing (WDM) to transmit a signal across one single-mode fiber to a D3LX

RMT via a D3LX LTU at the CPE site. The D3LX RMT mo dule converts the optical sign al back into an electrical

DS3 and transmits the signal back to the D3LX CO residing in the LEC as shown in Figure 2 on page 2.

The D3LX modules perform the following functions:

• Exchange status, alarm, and protection switching information.

• Perform bit error rate monitoring of the optical link.

• Monitor the optical input for Loss-Of-Signal (LOS) and Loss-Of-Frame (LOF).

• Monitor the laser bias for degradation.

• Retrieve remote module status.

• Provide 1+1 Protect mode (line protection).

D3LX CO and RMT Modules August 30, 2002 1

Page 10

Overview LTPS-UM-8013-03

CO - Local

DS3 out

(transmit)

2 3 4 5 6 7 56 4 3 2 1

1

DS3 out

DS3 in

(receive)

DS3 in and out

D3LX CO

STATUS

FAR END

DS3 STATUS

R=FAULT

G=O.K.

FLASH=LBK

ENABLE

OFF=UNEQPP

DS3 ONLINE

G=ONLINE

OFF=OFFLINE

FAIL

OPT

BER

LOCKOUT

APS

FORCE

LMPTST/

APS

RESET

D3LX CO

15

BNC panel - front

Loop Extender - front

21

T

R

T1

R1

19 18 17 16 1520 21 2016 17 18 19

BNC panel - rear

PORT 2 DTE RS-232

2-4

2-3

T

T

L1

L1

L1

R

R

T1

T1

L2

L2

L2

R1

R1

T

T

R

R

T1

T1

R1

R1

PORT 3 DTE RS-232

2-2

2-1

1-4

T

T

L1

R

R

T1

T1

L2

R1

R1

T

T

R

R

T1

T1

R1

R1

1-3

T

T

L1

L1

L1

R

R

T1

T1

L2

T1

L2

L2

R1

R1

R1

T

T

R

R

T1

T1

T1

R1

R1

R1

Loop Extender - rear

DS3 in

1-2

T

L1

R

L2

T

R

ADC

adapter

cables

SHIELD GND

FRAME GND

1-1

T

R

T1

R1

T

R

T1

R1

–48V

RTN

A

B

A

B

DS3 in and out

POWER

CPE - Remote

DS3 out

(transmit)

1-1

AC/DC

AC/DC

POWER

D3LX RMT

STATUS

FAR END

DS3 STATUS

R=FAULT

G=O.K.

FLASH=LBK

ENABLE

OFF=UNEQPP

DS3 ONLINE

G=ONLINE

OFF=OFFLINE

FAIL

OPT

BER

LOCKOUT

APS

FORCE

LMPTST/

APS

RESET

D3LX RMT

D3RCAM

STATUS

C

R

A

F

T

RESET

D3RCAM

TX RX

1-3

TX RX

2-1

TX RX

2-3

TX RX

D3LX LTU

jack block

DS3 in

(receive)

Four-Position Remote Cabinet - front

Figure 2. System Overview

2 August 30 , 20 02 D3LX CO and RMT Modules

Page 11

LTPS-UM-8013-03 Front-Panel Description

FRONT-PANEL DESCRIPTION

Figure 3 shows the D3LX CO front panel. Table 1 on page 4 describes the LEDs and other front-panel

components. For pinout diagrams of the D3LX card-edge connector, refer to “D3LX Card-Edge Connector” on

page 38.

D3LX CO

STATUS

Status LEDs

Enable pushbutton

Online status LED

Fiber-optic

status LEDs

OPT

APS

Lamp test force/

Automatic protection

switching pushbutton

Reset pushbutton

Retaining latch

Figure 3. D3LX CO Front Panel

FAR END

DS3 STATUS

ENABLE

DS3 ONLINE

FAIL

BER

LOCKOUT

FORCE

LMPTST/

APS

RESET

R=FAULT

G=O.K.

FLASH=LBK

OFF=UNEQPP

G=ONLINE

OFF=OFFLINE

D3LX CO and RMT Modules August 30, 2002 3

Page 12

Front-Panel Description LTPS-UM-8013-0 3

Table 1. D3LX Front-Panel Description and Status LEDs

Name Function

LEDs The LEDs can report the following conditions:

Activity Color Status

STATUS Off Not lit Blown fuse

On (solid) Green Normal operation.

On (solid) Yellow Module initializing or performing self test diagnostics or LED test.

On (solid) Red Module fault detected.

FAR END Off Not lit Remote alarms inactive (no alarm).

On (solid) Yellow Remote alarm on D3LX CO.

DS3 STATUS Off Not lit Unequipped.

On (solid) Green DS3 active.

On (flashing) Green DS3 in loopback, output AIS.

On (solid) Red DS3 fault (LOS).

On (flashing) Red DS3 in loopback, output AIS.

DS3 ONLINE Off Not lit DS3 offline.

On (solid) Green DS3 active.

OPT Off Not lit Optical link active (normal operation).

On (solid) Yellow BER fault.

On (solid) Red Optical link failure (OOF)

APS Off Not lit No protection switching (normal operation).

On (solid) Yellow Force manual protection enabled.

On (solid) Red Protection switching limit.

ENABLE

pushbutton

LMPTST/APS

pushbutton

RESET

pushbutton

Retaining latch Secures the D3LX when it is firmly seated in the backplane of the chassis and the latch is in the upright position

Pressed with APS In a protected system, the active DS3 are force switched to that module.

Note: The ENABLE pushbutton is pressed first and released last.

Pressed with RESET Cold start reset (service affecting).

Note: The ENABLE pushbutton is pressed first and released last.

Pressed Lights front-panel LEDs yellow, except for STATUS and DS3 STATUS which light red.

Pressed with ENABLE In a protected system, the active DS3 are force switched to that module.

Note: The ENABLE pushbutton is pressed first and released last.

Pressed Warm start reset (non-service affecting).

Pressed with ENABLE Cold start reset (service affecting).

Note: The ENABLE pushbutton is pressed first and released last.

PROTECTION SWITCHING

The D3LX system may be configured for either protected or non-protected mode. For protected mode, two

modules are installed: working and protect. The working module carries the signal, while the protect module is in

standby. Each working module uses 1 group, physically occupying 2 slots. Each protected module occupies an

additional 2 slots; there are four slots required for each D3LX system.

In protected mode, the offline module is switched into service whenever the D3LX determines that a service fault

has occurred in the online module.

4 August 30 , 20 02 D3LX CO and RMT Modules

Page 13

LTPS-UM-8013-03 Front-Panel Description

Automatic Switching

The 1:1 (Line) Protect mode transmits identical traffic across two parallel systems. The working and protect D3LX

modules provide Automatic Protection Switching (APS) compatible with the rem ote D3LX module. APS is

non-revertive and bidirectional and may be forced or disabled through the front-panel pushbuttons or the SCU

software.

Service is automatically switched from the online D3LX module to the offline module when one or more of the

following events occur:

• Offline module detects a failure in the online module.

• Online module detects an optical failure. (LOS, LOF, or BER threshold is exceeded.)

APS is completed within 50 msec of the initiation of a switch. After the occurrence of three automatic switches

within a 24-hour period, APS is locked out. APS may be enabled again through the front panel interface or the

craft interface.

APS to the offline module can be disabled. To do this, simultaneously press the LMPTST/APS and ENABLE

pushbuttons on the online module’s front panel. APS can be restored by pressing both pushbuttons a second time.

BER Monitoring

The optical link is continuously monitored for bit errors. If the bit errors exceed a predetermined threshold, and

the D3LX is configured for protection, protection switching occurs and an alarm is indicated. The optical alarm

is indicated when the threshold exceeds 10

between 10

-4

and 10

-10

(default is 10-6).

-6

to 10

-10

(default is 10-8). The optical switch threshold may be set

Manual Switching

Service can be manually switched from the online D3LX module to the offline module by simultaneously pressing

the LMPTST/APS and ENABLE pushbuttons located on the offline module’s front panel. This disables the APS

causing the APS LED to turn yellow. The ONLINE LED of the new online module (formerly the protect module)

turns green, indicating a successful transfer of service. The ONLINE LED of the new offline module (formerly

the working module) is not lit, indicating it is in standby mode and not carrying the DS3 service.

APPLICATIONS

D3LX modules can be used in a number of solutions:

• Switched Multimegabit Data Service (SMDS) Applications—D3LX modules support th e tr ans mi ssion of

SMDS service through the network.

• Private Line Interconnect Applications—D3LX modules provide private point-to-point LAN interconnect

services through the use of the D3LX.

• DS3 Video Distance Learning Applications—D3LX modules provide high quality video signal transmission

that is the most cost-effective solution for DS3 video transport.

• DS3 Asynchronous Transport Mode (ATM) Applications—D3L X modules provide high spe ed ATM

services using D3LX at a fraction of the cost of an OC-3 multiplexer.

D3LX CO and RMT Modules August 30, 2002 5

Page 14

Preparing to Install D3LX Modules LTPS-UM-8013-03

PREPARING TO INSTALL D3LX MODULES

Prior to installing D3LX modules in chassis confirm that:

• chassis are installed for each module (an LEC for the D3LX CO and a Four-Position Remote Terminal

Cabinet or Two-Position QLX Remote BNC Chassis for the D3LX RMT).

• a BNC Patch Panel with ADC adapter cables is installed in the CO rack and at the remote site. For more

information about this operation, refer to “Installing the BNC Panel” on page 7.

• protection switching is enabled (if you plan to employ it). For more information about protection switching,

refer to “Setting Up System Options” on page 19.

• a meter and variable line attenuator are available.

• fiber-optic patch cords are of appropriate length and that the connectors are of appropriate type (SC or FC)

for your application.

• the optical components receive the proper cleaning p rocedures. For more inf ormation about cleaning, refer to

“Appendix B - Cleaning and M ating Fiber-Optic Systems” on page 39.

• a Soneplex Controller Unit (SCU) version 3.7 or greater is installed in the LEC.

• any other optional equipment that needs to be installed prior to the D3LX modules, such as an Alarm

Processing Unit (APU) or D3LX Remote Access Module (D3RCAM), is installed. Refer to the optional

equipment documentation for installation information.

6 August 30 , 20 02 D3LX CO and RMT Modules

Page 15

LTPS-UM-8013-03 Installing the BNC Panel

INSTALLING THE BNC PANEL

OVERVIEW

The ADC BNC Panel consists of 14 pairs of 75Ω BNC connectors that are part of a system that converts an

electrical DS3 circuit at the CO site into an optical signal that uses WDM to transmit a signal across one

single-mode fiber to a CPE site. The BNC Panel can support 7 working D3LX lines and 7 protection D3LX lines.

(Table 2 on page 8 lists each working slot location as labelled on the front panel of the chassis and its

corresponding protection slot.)

The D3LX CO (CO module) converts the optical signal at the CO site and the D3LX RMT (remote module)

converts the optical signal back into an electrical DS3 and transmits the signal back to the D3LX CO residing in

the Loop Extender Chassis (LEC).

A BNC Panel and ADC adapter cables are required when D3LX modules are installed. Prior to ordering ADC

adapter cables, measure the distance between the BNC Panel and the chassis. For more information about

installing D3LX modules, refer to “Installing a D3LX CO Module in an LEC” on page 9.

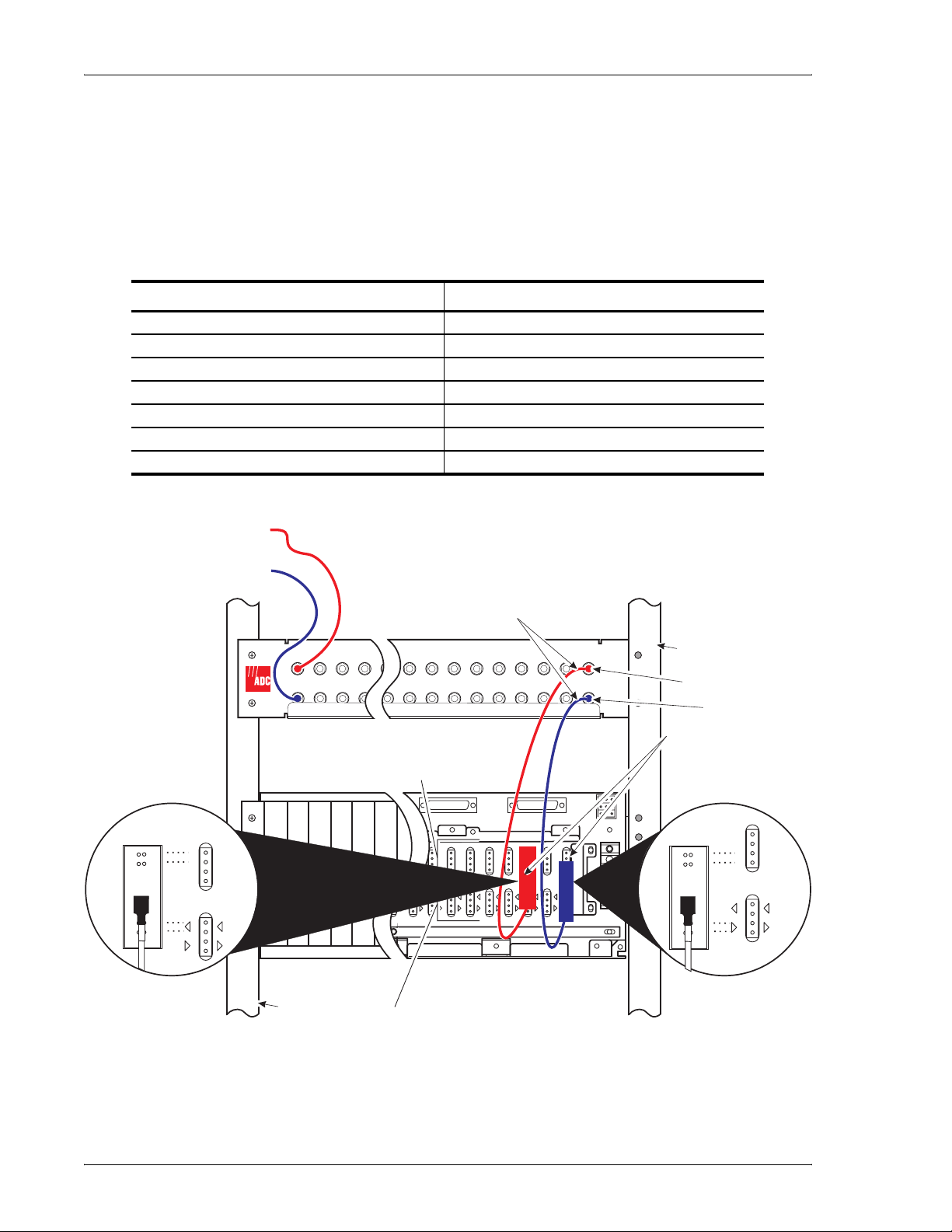

INSTALLATION OF THE PANEL

Prior to installing the ADC adapter cables (BNC-3-CBL-WW), remove any existing wires from the

LINE wire-wrap row on the back of the LEC.

1 Mount the panel in the rack.

2 Secure the panel to the rack by using the provided screws.

3 On the front of the panel, connect the DS3 IN (transmit) and DS3 OUT (receive) coax cables as shown in

Figure 4 on page 8. Note the connector numbers on the BNC panel.

In every group of 4 slots, such as 1-1 through 1- 4, the right mo st two slots have cables plugged into the bottom

2 wire-wrap pins (T1 and R1), and the two left most slots have cables plugged into the top 2 wire-wrap pins

(T and R). If it is a protected system or a single D3LX module, then sl ot s 1-2 and 1-4 do not have cables.

For exampl e, a D3LX CO module plugged into slo t 1-1 of the chassis or in a 2 D3LX protected system:

• The DS3 receive cable plugs into the botto m 2 pins T1 and R1 of slot 1-1. This is the DS3 that the D3LX

receives.

• The DS3 transmit cable is plugged into the top 2 pins T and R of slot 1-3. This is the DS3 that the D3LX

transmits.

In another example, for a D3LX CO module plugged into slot 1-3 of the chassis in an unprotected system:

• The DS3 receive cable plugs into the botto m 2 pins T1 and R1 of slot 1-2. This is the DS3 that the D3LX

receives.

• The DS3 transmit cable plugs into the top 2 pins T and R of slot 1-4. This is the DS3 that the D3LX

transmits.

4 From the rear of the panel, con nect the coax end of an ADC adapter cable to the DS3 IN (receive) conn ector.

The connector number must match the connector number on the front of the panel.

5 Connect the wire-wrap conversion block e nd of the same ADC adapter cable to the T and R EQUIP wire-wrap

posts on the back of the LEC as shown in Figure 4 on page 8. The top of the conversion block mates with the

T and R LINE wire-wrap posts to prevent improper connection.

D3LX CO and RMT Modules August 30, 2002 7

Page 16

Installing the BNC Panel LTPS-UM-8013-0 3

6 From the rear of the panel, connect the coax end of an ADC adapter cable to the DS3 OUT (transmit).

connector. The connector number must match the connector number on the front of the panel.

7 Connect the wire-wrap conversion block en d of the same ADC adapter cable to the T and R EQUIP wire-wrap

posts on the back of the LEC as shown in Figure 4 on page 8. The top of the conversion block mates with the

T1 and R1 LINE wire-wrap posts to prevent improper connection.

8 Repeat this entire procedure for each D3LX module installed.

Table 2. Tip and Ring Assignments for Protection Switching Applications

Working Card Slot TX/RX BNC Connector Pair Protect Card Slot TX/RX BNC Connector Pair

1-1 1/15 1-3 2/16

2-1 3/17 2-3 4/18

3-1 5/19 3-3 6/20

4-1 7/21 4-3 8/22

5-1 9/23 5-3 10/24

6-1 11/25 6-3 12/26

7-1 13/27 7-3 14/28

DS3 out

(transmit)

DS3 in

(receive)

ADC adapter

cables (coax end)

2 3 4 9 8 56 4 3 2 1

1

15

7

19 18 17 16 1523 22 2016 17 18 19

21

CO rack - rear

DS3 out

DS3 in

BNC panel - front

BNC panel - rear

LINE wire-wrap row

PORT 2 DTE RS-232

1-3

T

L1

R

T1

L2

R1

T

R

T1

R1

Loop Extender - front

2-4

T

L1

L1

R

T1

T1

L2

L2

R1

R1

T

T

R

R

T1

T1

T1

R1

R1

R1

2-3

T

L1

R

T1

L2

R1

T

R

T1

R1

Loop Extender - rear

PORT 3 DTE RS-232

2-2

2-1

1-4

1-3

T

T

L1

L1

R

R

T1

L2

L2

R1

T

T

R

R

T1

R1

1-2

T

T

T

L1

L1

R

R

R

T1

T1

T1

L2

L2

R1

R1

R1

T

T

T

R

R

R

T1

T1

T1

R1

R1

R1

SHIELD GND

FRAME GND

1-1

T

L1

R

T1

L2

R1

T

R

T1

R1

A

–48V

B

A

RTN

B

ADC adapter

cables

(conversion block end)

1-1

T

L1

R

T1

L2

R1

T

R

T1

R1

CO rack - front

EQUIP wire-wrap row

Figure 4. Mounting the BNC Panel and Connecting ADC Adapter Cables (LEC Shown)

8 August 30 , 20 02 D3LX CO and RMT Modules

Page 17

LTPS-UM-8013-03 Installing a D3LX CO Module in an LEC

INSTALLING A D3LX CO MODULE IN AN LEC

Avoid exposure to invisible laser radiation.

• Do not look into the end s of any o ptical fib er or directly into the m odule fib er connec tors as

exposure to invisible laser radiation may result.

• Use a meter to verify active fibers.

• Do not insert module edge connectors into the chassis connectors before connecting the

optical fiber to the module. Verify that LED indicators are not lit, and the module is not

engaged with the chassis connectors before proceeding.

When using D3LX CO modules in a group, never install other Soneplex modules in any of the

unused slots in the same group.

Remove any existing wire wraps from the LEC backplane prior to installing any ADC adapter

cables (BNC-3-CBL-WW) for the groups that are being used for D3LX modules.

Use the following procedure to install D3LX CO modules in LECs:

1 Select the fiber-optic patch cord with the appropriate length (the measured distance from the Fiber

Distribution Frame or equivalent d i stribution device) and the appropriate type optical connector (SC or FC

type).

2 Route the fiber patch cord through the top of the chassis, along the heat baff le/fiber management panel. Lower

the cord through the FiberGuide vertical duct to the location reserved for the D3LX CO module as shown in

Figure 5 on page 10. The protective cover must remain on the fiber connector to prevent dust and damage to

the connection. The fiber should be tagged to identify the circuit.

3 Open the front panel of the LEC into which the D3LX CO will be installed.

D3LX CO and RMT Modules August 30, 2002 9

Page 18

Installing a D3LX CO Module in an LEC LTPS-UM-8013-0 3

Fiber patch cord

FiberGuide vertical duct

Heat baffle/fiber management panel

Figure 5. Routing the Fiber Patch Cord

4 Locate the mounting slots designated for the D3LX CO modules in the chassis.

5 Refer to Figure 6 on page 11 for D3LX CO module locations chassis and slot corresponding to the DS3

signal.

– If no protection switching is required, proceed to the next step.

– If protection switching is required, a working module may be installed in the first slot of any quad group,

such as 1-1, 2-1, 3-1, 4-1, 5-1, 6-1, or 7-1. The protection module is installed in the slot to its immediate

right in the order of 1-3, 2-3, 3-3, 4-3, 5-3, 6-3, or 7-3. For more informati on on protection switching,

refer to “Protection Switching” on page 4.

Install the working module first, then the protect module.

10 August 30, 2002 D3LX CO and RMT Modules

Page 19

LTPS-UM-8013-03 Installing a D3LX CO Module in an LEC

Use #1 mounting slots for working D3LX units

Use #3 mounting slots for protect D3 unitsLX

1-3

2-3

3-3

4-3

5-3

6-3

7-3

D3LX

Working unit

D3LX

Protect unit

1-1

OPT

APS

1

1

STATUS

FAR END

DS3 STATUS

DS3 ONLINE

FAIL

BER

LOCKOUT

FORCE

D3LX CO

R=FAULT

G=O.K.

FLASH=LBK

ENABLE

OFF=UNEQPP

G=ONLINE

R=LINELOCK

OFF=OFFLINE

LMPTST/

APS

RESET

2-1

2

2

D3LX CO

STATUS

FAR END

DS3 STATUS

R=FAULT

G=O.K.

FLASH=LBK

ENABLE

OFF=UNEQPP

DS3 ONLINE

G=ONLINE

R=LINELOCK

OFF=OFFLINE

FAIL

OPT

BER

LOCKOUT

APS

FORCE

LMPTST/

APS

RESET

3-1

4-1

35467

5-1

6-1

7-1

SCU APU

Figure 6. D3LX Module Lo cations in Loop E xtender Chassis

6 Remove a new module from its protective ESD packaging. If the module is installed, remove it and inspect

for physical damage.

7 Align the module with the slot and slide the module into the chassis until about 3 inches protrude fr om the

front of the chassis as shown in Figure 7 on page 12. Do not seat module in connector at this tim e.

8 Remove the protective dust cap from the connector on the D3LX CO module.

S

C

U

STATUS

CR

O

ETH

MJ

S

X.25

S

MN

C

R

A

ACO

F

T

PWR

RESET

HSKP

RMT

ALM

DISP RMT

LMPTST

D3LX CO and RMT Modules August 30, 2002 11

Page 20

Installing a D3LX CO Module in an LEC LTPS-UM-8013-0 3

Fiber patch cord

Fiber clip

D3LX CO

Figure 7. Installing the D3LX CO

9 After removing the protective cover from a fiber patch cord, clean the fiber-optic connector and adapter as

directed in “Appendix B - Cleaning and Mating Fiber-Optic Systems” on page 39.

POWER VERIFICATION

Verification of Electrical DS3 Power Level

1 Apply power to the D3LX CO.

2 Attach the fiber patch cord from the D3LX CO to a meter.

3 Confirm that the readings are within the specification (-5 dBm to -23 dBm).

If the reading is not within the specification, check all fiber-optic connections to the D3LX CO.

If the reading is still not within the specification, replace the module.

4 Once the readings are within specification, disconnect the patch cord from the meter.

Now that the DS3 power level meets optical specifications, verify the D3LX CO module.

12 August 30, 2002 D3LX CO and RMT Modules

Page 21

LTPS-UM-8013-03 Installing a D3LX CO Module in an LEC

Verification of D3LX CO Optical Power

1 Connect an attenuator in series:

• Connect a patch cord from the meter to the attenuator.

• Connect a meter patch cord from the attenuator to the module.

2 Using the retaining latch, press the module into the chassi s until it is properly seated.

3 Is the STATUS indicator lit green?

• If Yes, continue to next step.

• If No, repeat steps 1 through 3 with a new D3LX CO module.

4 On the APU, as shown in Figure 6 on page 11, press the LMPTST/APS pushbutton. Did all D3LX CO

indicators light?

• If Yes, continue to next step.

• If No, repeat steps 1 through 3 with a new D3LX CO module.

The module laser is transmitting when power is applied to the module.

5 Confirm that the transmit power is -7 dBm ± 2 dBm.

If the reading is not within this specification, replace the module.

6 Reduce the voltage on the attenuator and confirm that the receive dynamic range is -5 dBm to 123 dBm.

If the reading is not within this specification, replace the module.

Verify that unit is completely disconnected from the chassis connectors before removing the

optical fiber from the plug-in unit. Verify that the far end transmitter is off before proceeding.

Exposure to invisible laser radiation from the optical fiber is possible if the far end transmitter

is transmitting. Verify that all LEDs are off (not illuminated).

7 Release the retaining latch on the D3LX CO module and slide the module out about 3 inches.

8 Disconnect the meter patch cord from the D3LX CO module.

9 Route the fiber out the top of the chassis and adjust as required to remove any excess slack.

10 Guide the fiber with one hand while sliding the module slowly back into the chassis.

Always allow sufficient fiber length to permit routing without severe bends. Fibers may be

permanently damaged if bent/curved to a radius of less than 1.5 inches (3.81 cm).

11 Using the retaining latch, press the module into the chassis until it is properly seated.

12 Did the STATUS indicator light green? (If ther e is no DS3 signal p resent, th e OPT FAIL indicator is lit red.)

• If Yes, continue to next step.

• If No, repeat steps 1 through 10 with a new D3LX CO module.

13 If this is to be a DS3 protected system, repeat the preceding steps to install the protect module in the slot

adjacent to the working module.

14 Repeat entire procedure for each D3LX CO module to be installed.

15 Store excess fiber at the fiber storage device specified in the work instruction.

D3LX CO and RMT Modules August 30, 2002 13

Page 22

Installing a D3LX RMT Module in a Remot e Ca bin et LTPS-UM-8013-0 3

INSTALLING A D3LX RMT MODULE IN A

REMOTE CABINET

Avoid exposure to invisible laser radiation.

• Do not look into the end s of any o ptical fib er or directly into the modul e fiber con nectors a s

exposure to invisible laser radiation may result.

• Use a meter to verify active fibers.

• Do not insert module edge connectors into the chassis connectors before connecting the

optical fiber to the module. Verify that LED indicators are not lit, and the module is not

engaged with the chassis connectors before proceeding.

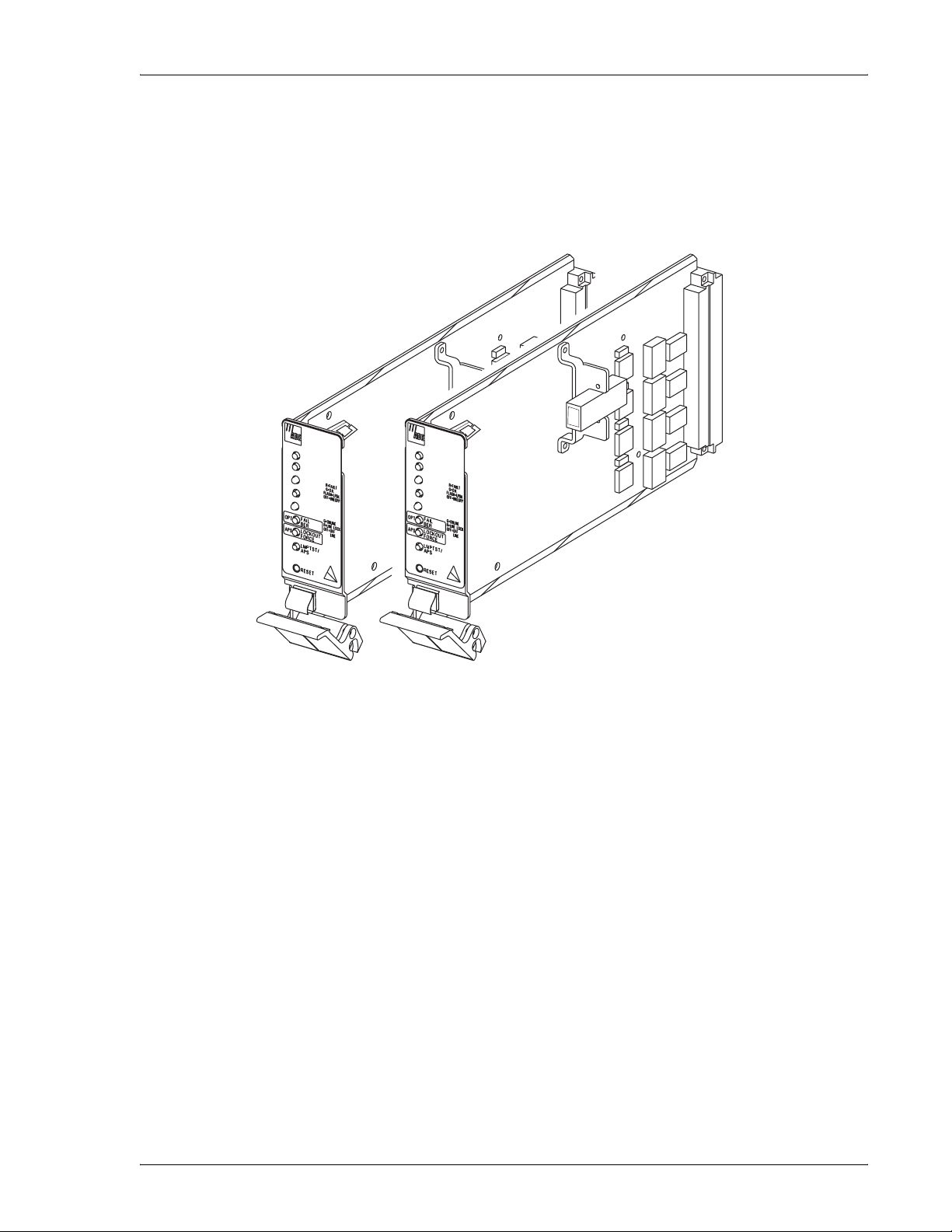

Use the following procedure to install D3LX RMT modules in a Four-Position Remote Terminal Cabinet or

Two-Position QLX Remote BNC Chassis. After installing the D3LX RMT modules in either chassis, proceed to

“Power Verification” on page 16.

FOUR-POSITION REMOTE TERMINAL CABINET INSTALLATION

To install first the working module, and then the protect module (if installing D3LX RMT modules in protection

switching applications):

1 Open the front panel of the remote terminal into which the D3LX RMT will be inst alled.

2 Route the fiber patch cord through the to p of the chassis and around the rad ius limiters as shown in Figure 8.

The protective cover must remain on the fiber connector to prevent dust and damage to the connection. The

fiber should be tagged to identify the circuit.

Fiber-optic patch cord

Fiber-optic loop

Radius limiters

Figure 8. Routing the Fiber Through a Four-Position Remote Terminal Cabinet

14 August 30, 2002 D3LX CO and RMT Modules

Page 23

LTPS-UM-8013-03 Instal ling a D 3LX R MT Module in a Remote Cabinet

3 Locate the mounting slots designated for the D3LX RMT modules in the chassis. If protection switching is

required, a working module installs in the first slot of a quad group, such as 1-1 or 2-1. The protection module

installs in the slot to the right of the working module, slot 1-2 or 2-2.

4 Refer to Figure9 for D3LX RMT module locations chassis and slot corresponding to the DS3 signal.

– If no protection switching is required, proceed to the next step.

– If protection switching is required, a working module may be installed in the first slot of any quad group,

such as 1-1 or 2-1. The protection module is installed in the slot to its immediate right in the order of 1-3

or 2-3. For more information on protection swit ching, refe r to “Protection Switching” on page 4.

Install the working module first, then the protect module.

5 Remove a new module from its protective ESD packaging. If the module is installed, remove it and inspect

for physical damage.

6 Align the module with the slot and slide the module into the chassis until about three inches pr otru de fr om

the front of the chassis. Do not seat module in connector at this time.

7 Remove the protective dust cap from the connector on the D3LX RMT module.

Fiber clip

Fiber

management

enclosure

AC/DC

POWER

Fiber patch cord

AC/DC

POWER

OPT

APS

D3LX RMT

STATUS

FAR END

DS3 STATUS

ENABLE

DS3 ONLINE

FAIL

BER

LOCKOUT

FORCE

LMPTST/

APS

RESET

R=FAULT

G=O.K.

FLASH=LBK

OFF=UNEQPP

G=ONLINE

OFF=OFFLINE

OPT

APS

Fiber guides

D3LX RMT

STATUS

FAR END

DS3 STATUS

R=FAULT

G=O.K.

FLASH=LBK

ENABLE

OFF=UNEQPP

DS3 ONLINE

G=ONLINE

OFF=OFFLINE

FAIL

BER

LOCKOUT

FORCE

LMPTST/

APS

RESET

1-1

D3RCAM

D3LX RMT modules

C

R

A

F

T

APS/LMPTST

DS3 CAM

D3RCAM

STATUS

STATUS

ENABLE

APS

FAIL

ERROR

FAIL

ERROR

CRAFT

RESET

A

P

U

D3LX RMT

CR

STATUS

MJ

NET

EOP

DISP RMT

LMPTST

FAR END

MN

DS3 STATUS

R=FAULT

G=O.K.

FLASH=LBK

ENABLE

OPT

APS

DS3 ONLINE

FAIL

BER

LOCKOUT

FORCE

LMPTST/

APS

RESET

OFF=UNEQPP

G=ONLINE

R=LINELOCK

OFF=OFFLINE

ACO

PWR

HSKP

RMT

ALM

OPT

APS

STATUS

FAR END

DS3 STATUS

ENABLE

DS3 ONLINE

FAIL

BER

LOCKOUT

FORCE

LMPTST/

APS

RESET

2-1 2-31-3

APU

D3LX RMT

R=FAULT

G=O.K.

FLASH=LBK

OFF=UNEQPP

G=ONLINE

R=LINELOCK

OFF=OFFLINE

Fiber clip

1-1

TX RX

1-3

TX RX

2-1

TX RX

2-3

TX RX

D3LX LTU

jack block

Figure 9. D3LX RMT Module Locations in a Four-Position Remote Terminal Cabinet

8 After removing the protect ive co ver fro m a fiber patch cord, confirm that the fiber-optic connector is free of

debris as directed in “Appendix B - Cleaning and Mating Fiber-Optic Systems ” on page 39.

9 Proceed to “Power Verification” on page 16 .

D3LX CO and RMT Modules August 30, 2002 15

Page 24

Installing a D3LX RMT Module in a Remot e Ca bin et LTPS-UM-8013-0 3

TWO-POSITION QLX REMOTE BNC CHASSIS INSTALLATION

To install first the working module, and then the protect module (if installing D3LX RMT modules in protection

switching applications):

1 Open the front panel of the remote terminal into which the D3LX RMT will be inst alled.

2 Route the fiber patch cord through the left side of the fiber management enclosure located on the remote

terminal as shown in Figure 10. The protective cover must remain on the fiber connector to prevent dust and

damage to the connection. The fiber should be tagged to identify the circuit.

CR

MJ

P

U

D3RCAM

MN

PWR

HSKP

ACO

RMT

ALM

DISP RMT

STATUSSTATUS

C

R

RESET

A

F

T

D3LX RMT

STATUS

FAR END

G=ONLINE

OFF=OFFLINE

R=FAULT

G=O.K.

FLASH=LBK

OFF=UNEQPP

FAIL

BER

LOCKOUT

ENABLE

DS3 ONLINE

OPT

APS

FORCE

LMPTST/

APS

RESET

DS3 STATUS

D3LX RMT

STATUS

FAR END

G=ONLINE

OFF=OFFLINE

R=FAULT

G=O.K.

FLASH=LBK

OFF=UNEQPP

FAIL

BER

LOCKOUT

ENABLE

DS3 ONLINE

OPT

APS

FORCE

LMPTST/

APS

RESET

DS3 STATUS

A

Fiber

management

enclosure

D3RCAM

APU

D3LX RMT modules

Figure 10. D3LX RMT Module Locations in a Two-Position QLX Remote BNC Chassis

3 Locate the mounting slots designated for the D3LX RMT modules in the chassis.

4 Refer to Figure 10 for D3LX RMT module locations chassis and slot corresponding to the DS3 signal.

5 Remove a new module from its protective ESD packaging. If the module is installed, remove it and inspect

for physical damage.

6 Align the module with the slot and slide the module into the chassis until about three inches pr otru de fr om

the front of the chassis. Do not seat module in connector at this time.

7 Remove the protective dust cap from the connector on the D3LX RMT module.

8 After removing the protect ive co ver fro m a fiber patch cord, confirm that the fiber-optic connector is free o f

debris as directed in “Appendix B - Cleaning and Mating Fiber-Optic Systems” on page 39.

9 Proceed to “Power Verification” on page 16.

POWER VERIFICATION

Verification of Electrical DS3 Power Level

1 Apply power to the D3LX RMT.

2 Attach the fiber patch cord from the D3LX RMT to a meter.

3 Confirm that the readings are within the specification (-5 dBm to -23 dBm).

If the reading is not within the specification, check all fiber-optic connections to the D3LX RMT.

If the reading is still not within the specification, replace the module.

4 Once the readings are within specification, disconnect the patch cord from the meter.

Now that the DS3 power level meets optical specifications, verify the D3LX RMT module.

16 August 30, 2002 D3LX CO and RMT Modules

Page 25

LTPS-UM-8013-03 Instal ling a D 3LX R MT Module in a Remote Cabinet

Verification of Optical Power

1 Connect an attenuator in series:

• Connect a patch cord from the meter to the attenuator.

• Connect a meter patch cord from the attenuator to the module.

2 Using the retaining latch, press the module into the chassis until it is properly seated.

3 Is the STATUS indicator lit green?

• If Yes, continue to next step.

• If No, repeat step s 1 through 3 w ith a new D3LX RMT modul e.

4 On the APU, as shown in Figure 9 on p age 15, press the LMPTST/APS pushbutton. Did all D3LX RMT

indicators light?

• If Yes, continue to next step.

• If No, repeat steps 1 through 3 with a new D3LX RMT module.

The module laser is transmitting when power is applied to the module.

5 Confirm that the transmit power is -7 dBm ± 2 dBm.

If the reading is not within this specification, replace the module.

6 Reduce the voltage on the attenuator and confirm that the receive dynamic range is -5 to -23 dBm.

If the reading is not within this specification, replace the module.

Verify that unit is completely disconnected from the chassis connectors before removing the

optical fiber from the plug-in unit. Verify that the far end transmitter is off before proceeding.

Exposure to invisible laser radiation from the optical fiber is possible if the far end transmitter

is transmitting. Verify that all LEDs are off (not illuminated).

7 Release the retaining latch on the D3LX RMT module and slide the module out about 3 inches.

8 Disconnect the meter patch cord from the D3LX RMT module.

The D3LX RMT module optical power level specification is now verified.

9 Route the fiber out the top of the chassis and adjust as required to remove any excess slack.

10 Guide the fiber with one hand while sliding the module slowly back into the chassis.

Always allow sufficient fiber length to permit routing without severe bends. Fibers may be

permanently damaged if bent/curved to a radius of less than 1.5 inches (3.81 cm).

11 Using the retaining latch, press the module into the chassis until it is properly seated. If there is excessiv e

resistance, withdraw the module and check for alignment or obstructions.

12 Did the STATUS indicator light green? (If ther e is no DS3 signal p resent, th e OPT FAIL indicator is lit red.)

• If Yes, continue to next step.

• If No, repeat steps 1 through 10 with a new D3LX RMT module.

13 If this is to be a DS3 protected system, repeat the preceding steps to install the protect module in the slot

adjacent to the working module.

14 Repeat entire procedure for each D3LX RMT module to be installed.

D3LX CO and RMT Modules August 30, 2002 17

Page 26

Provisioning LTPS-UM-8013-03

15 Store the remaining slack fiber on the left side of the fiber management enclosure within the remote cabinet,

leaving 5 to 6 inches of slack fiber above the upper card guide to provide a service loop.

PROVISIONING

In D3LX systems, provisioning occurs automatically if a remote module is inst alled. In the event that a remote

module is not installed or properly functioning, refer to the manual provisioning process below.

MANUAL

Manual provisioning of the D3LX system may be performed locally through the SCU (version 3.7 or later) or

remotely through the D3RCAM. Craft interface software provides a user-fr iendly menu driven program to option

the modules in the system and maintain a provisioning database at the central office. In the chassis with the SCU,

provisioning instructions pass to resident modules through communication channels embedded in the backplane

of the chassis.

Perform manual provisioning through the craft interface of the D3LX module after installation or when changes

occur in the network system configuration. For complete information about manual p rov isioning, refer to the

Soneplex Loop Extender System Operation and Maintenance Manual (Version S1.0), document ADCP-61-494

and Soneplex Shelf Controller User Manual (V3.7).

AUTOMATIC

Automatic provisioning occurs in a previously provisioned system when replacing the D3LX module or when

power to the module is lost and then restored. In systems with D3LXs at the CO, the SCU provides provisioning

data to the module (slot) that powers up, based on the database established when the system was previously

provisioned.

When an SCU is replaced at the CO, the new SCU module requests provisioning data from the

D3LX CO modules in the local chassis and from the remote modules optically connected to

them. Additionally, the SCU retains its p rovisionin g databas e up to 24 hours after power is los t.

The following items are configured during provisioning:

• Protect or Non-Protect operation

-6

-10

• BER Minor Alarm Threshold (range, 10

• BER Switch Threshold (range, 10

• Equipped/Unequipped state

• Line State

– In-Service (IS)

– Out of Service (OOS)

-4

to 10

to 10

-10

)

)

• Alarm reporting options. For more information, see “Alarm Setting During Provisioning” on page 19.

• Line Buildout (range: two segments between 0 - 450 ft)

18 August 30, 2002 D3LX CO and RMT Modules

Page 27

LTPS-UM-8013-03 Setting Up System Options

OTHER PROVISIONING CONSIDERATIONS

Alarm Setting During Provisioning

The D3LX generates alarms on conditions occurring in the D3LX CO modules DS3 facility. The severity of the

alarm conditions as Critical, Major, Minor, or Event is selected while provisioning. The alarms are handed off to

an Alarm Processing Unit (APU) which acts as an interface between the D3LX modules and the customer alarm

monitoring equipment. For more information on alarms, see “Configuring D3LX Alarms” on page 25.

D3 Remote Craft Access Module (D3RCAM) Option

The D3RCAM is a plug-in module for the D3LX system which provides a craft interface at the remote site.

Additionally, the D3RCAM works in conjunction with the APU and the D3LX modules to display alarm

information for the remote chassis or terminal.

SETTING UP SYSTEM OPTIONS

To configure D3LX system options , you must connect a maintenance terminal to an available craft port. You may

select either the SCU or Ports 2 or 3 (local) or the D3RCAM (remote) craft port.

• If you are using the SCU, refer to “Connecting a Maintenance Terminal to the SCU Craft Port” on page 19.

• If you are using the D3RCAM, refer to “Connecting a Maintenance Ter minal to the D3RCAM Craft Port” on

page 20.

CONNECTING A MAINTENANCE TERMINAL TO THE SCU CRAFT PORT

Connect the VT100 compatible terminal or host computer to the interface port as follows:

1 For initial setup, connect the local maintenance terminal to the SCU craft port (on front panel). After

configuration, the SCU may be con nected to ports 2 o r 3 on the back plane of the LEC. For more informat ion

on Ports 2 and 3 located on the LEC, refer to Soneplex Loop Extender System Operation and Maintenance

Manual, ADCP-61-494. See Table 3 for chassis port description s.

Table 3. Chassis Po rt De scription

SCU Front-Panel Craft Port Ports 2 and 3

Function—DCE connection on the installed SCU module (see Figure 11 on

page 20)

Cable Type—Straight-through cable (26 AWG or larger, stranded pairs,

overall shielding, common for all leads).

Connector—Type DB-9 receptacle. Type DB-25 receptacle.

DTE connections on the chassis backplane. Ports

provide an RS (EIA-232) interface.

A null-modem cable or adapter.

2 Connect one end of the interface cable to the main tenance terminal a nd the o ther end to th e craft po rt located

on the front of the SCU as shown in Figure 11.

3 Start a terminal emulation program such as Procomm that emulates a VT100 terminal.

4 Configure the maintenance terminal to the following communication settings:

D3LX CO and RMT Modules August 30, 2002 19

Page 28

Setting Up System Options LTPS-UM-8013-0 3

• 9600 baud

• No parity

• 8 data bits

• 1 stop bit

• Hardware flow control to OFF

Maintenance

terminal

Serial

COM port

LEC

Craft port

Interface cable

Figure 11. Connecting a Maintenance Terminal to the SCU

The default port configuration for the SCU craft port is CRAFT. Ports 2 and 3 must be configured

for CRAFT before the craft interface may be accessed via these ports.

5 At the maintenance terminal, press . The Enter User Name field appears.

ENTER

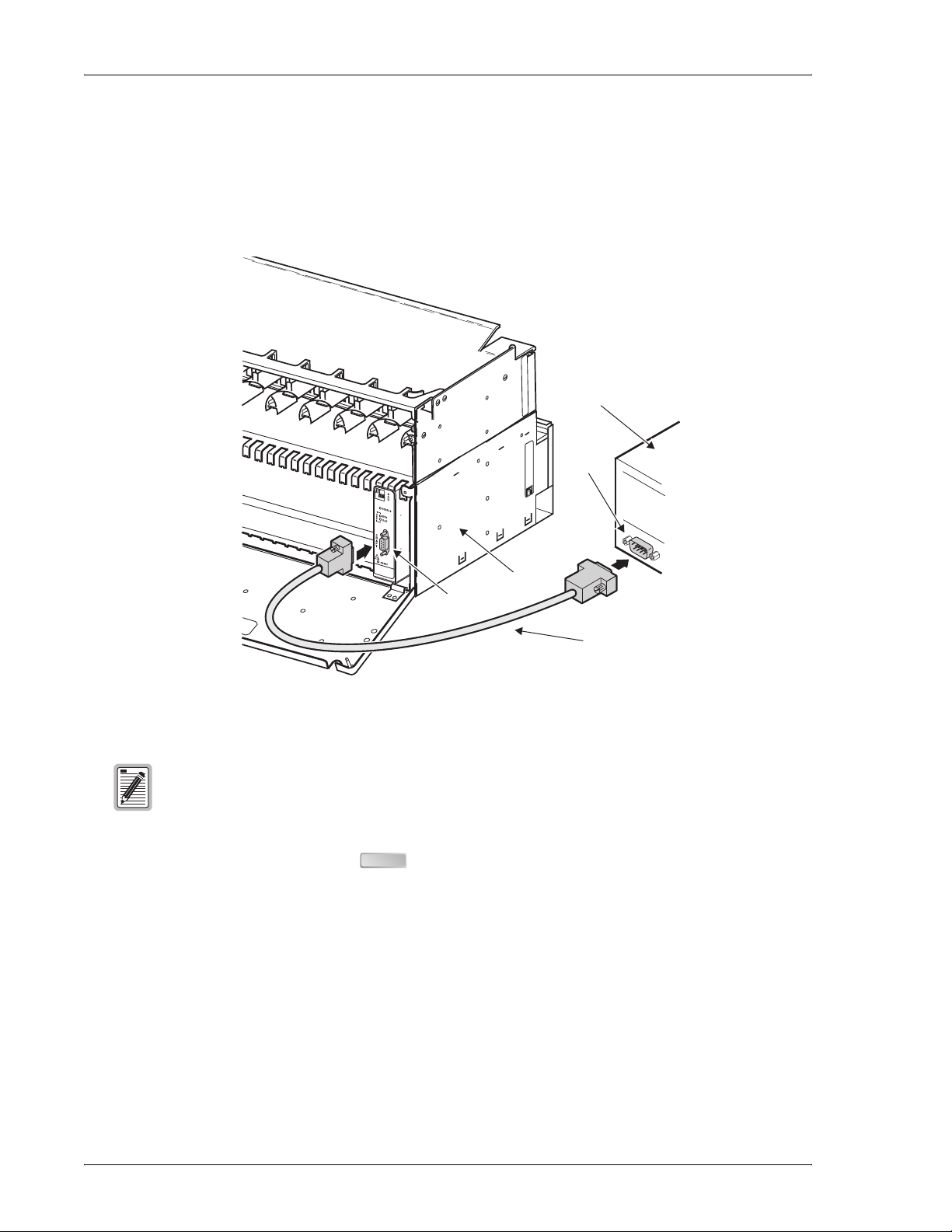

CONNECTING A MAINTENANCE TERMINAL TO THE D3RCAM CRAFT

ORT

P

1 Locate the D3RCAM in the remote cabinet. The D3RCAM craft port is located o n the front of the D3RCAM.

2 Select the cable for use between the craft port and the maintenance terminal with a DB-9 (male) connector at

one end and a maintenance terminal connector at the other end.

3 Connect one end of the interface cable to the maintenance terminal and the other end to the D3RCAM craft

port as shown i n Figure 12.

4 Start a terminal emulation program such as Procomm that emulates a VT100 terminal.

20 August 30, 2002 D3LX CO and RMT Modules

Page 29

LTPS-UM-8013-03 Setting Up System Options

5 At the maintenance terminal, press . The Enter User Name field appears.

ENTER

Maintenance

Serial

S

T

AT

U

S

C

R

A

F

T

R

E

S

E

T

COM port

Four-position remote

terminal chassis

Craft port

Interface cable

Figure 12. Connecting a Maintenance Terminal to the D3RCAM

terminal

D3LX CO and RMT Modules August 30, 2002 21

Page 30

Setting Up System Options LTPS-UM-8013-0 3

NAVIGATING THROUGH CRAFT INTERFACE MENUS

Many of the operations that follow require the use of the craft interface.

To select a menu from the craft interface, do one of the following:

• Press the number of the menu.

• Use the arrow keys to select the menu and press .

← →

ENTER

Table 4 summarizes the navigational keys, which are also listed in the on-screen Help menu.

Table 4. Navigational Keys for the Craft Interface Screens During Telnet Sessions

(a)

Key

SPACEBAR

ENTER

Returns to the previous menu.

ESC

↑

↓

→

Selects the next page or item to the right of the current one.

←

Menu number Selects the menu or item.

+ Returns to Main menu.

CTRL T

+ Returns to previous menu.

CTRL P

+ Terminates the session (logout).

CTRL D

+ Displays the Help menu.

CTRL A

+ Jumps to Active Alarm menu.

CTRL E

+ Jumps to Shelf Status screen.

CTRL G

+ Refreshes the screen.

CTRL R

(a) Legacy managemen t units require the use of control keys instead of arrow keys.

Function

Cycles through selections.

Activates the current setting or choice, or display a menu.

Selects the line or item above the current one.

Selects the line or item below the current one.

Selects the previous page or item to the left of the current one or returns to the previous menu.

Most VT100 emulation programs support a print screen option. For Windows-based prog rams ,

such as Procomm or HyperTerminal, see the Help menu for instructions.

22 August 30, 2002 D3LX CO and RMT Modules

Page 31

LTPS-UM-8013-03 Local Configuration

LOCAL CONFIGURATION

A D3LX system can be configured locally by an SCU (version 3.7 or later) with a D3LX CO module in an LEC.

It can also be configured remotely by a D3RCAM with a D3LX RMT module installed in a remote chassis. See

“Remote Configuration” on page 33 for the procedure configuring remotely using the D3RCAM.

The following details the local configuration procedure.

CONFIGURING THE D3LX SYSTEM THROUGH

3. Unit Configuration

THE SCU

Use the craft interface system menu to view or edit the configuration for

each D3LX module in the chassis. This menu can also be used to equip,

provision, assign thresholds, and assign service state.

1 Connect a maintenance terminal to the craft port on the SCU front panel and log on to the craft interface

system as described in “Connecting a Maintenance Terminal to the SCU Craft Port” on page 19.

See “Nav igating Throug h Craft Interfac e Menus” o n page 22 for detailed information on making

selections.

2 From the Main menu, select 3. Unit Configuration.

3 From the Unit Configuration menu, select 4. D3LX Configuration.

The D3LX Configuration appears as shown in Figure 13.

4. D3LX Configuration

Figure 13. D3LX Configuration Screen

D3LX CO and RMT Modules August 30, 2002 23

Page 32

Local Configuration LTPS-UM-8013-03

Press + for assistance when making selections.

4 Configure the fields as detailed in the Table 5 and assign the selections by pressing .

CTRL A

ENTER

5 Repeat Steps 2 through 5 for each D3LX system installed in the chassis.

Table 5. D3LX CO Configuration Fields–SCU V3.7 or later

Field Name Type Options Description Default

Unit Equip State Toggle EQUIPPED Establishes communication with SCU. Module

must be set to EQUIPPED before remaining

selections are allowed.

UNEQUIPPED No communication with SCU.

Unit Service State Toggle IN SERVICE Places the unit in service and allows equipment

alarm reporting by the SCU. Must be set to IS

for reporting of equipment alarms.

OUT OF SERVICE Removes unit from service and stops

equipment alarm reporting by the SCU.

Unit Protect State Toggle PROTECTED Line protection Unprotected

UNPROTECTED No protection

Optical Service State Toggle IN SERVICE Places facility in service and enables T2 alarm

reporting by the D3LX CO.

OUT OF SERVICE Removes facility from service and stops T2

alarm reporting by the D3LX CO.

Optical BER Alarm

Threshold

Toggle Set to OFF or set

between 10

-6

and 10

The average Bit Error Ratios of both the

-10

incoming optical signals are monitored by the

D3LX CO. By monitoring BERs, the D3LX CO is

capable of triggering a minor alarm when any of

the monitored signals degrades below the BER

threshold level.

Optical BER Switch

Threshold

DS3 Provisioned

(set for each T1)

Toggle Range from 10-4 to

10

-10

Sets the threshold at which the APS will be

executed.

Toggle YES Brings up T1 default settings and allows

configuration changes.

NO No configuration changes allowed.

DS3 Service State Toggle IN SERVICE Select IS after completing the remaining con-

figurations.

OUT OF SERVICE Leave this field at OUT OF SERVICE (versus IN

SERVICE) at this time to avoid undesirable

reporting of alarms.

DS3 Transmit LBO

Local

Toggle 0–225 ft., 226–450 ft. The DS1 signal output provides standard DSX

signal levels which can be compensated for at

various distances, such as cable length.

DS3 Transmit LBO

Remote

Toggle 0–225 ft., 226–450 ft. The DS1 signal output provides standard DSX

signal levels which can be compensated for at

various distances, such as cable length.

UNEQUIPPED

OOS

OOS

-8

10

-6

10

NO

OOS

0–225 ft.

0–225 ft.

Continued

24 August 30, 2002 D3LX CO and RMT Modules

Page 33

LTPS-UM-8013-03 Local Configuration

Table 5. D3LX CO Configuration Fields–SCU V3.7 or later (Continued)

Field Name Type Options Description Default

Housekeeping Lab els

1 and 2

* This field shows as N/A if D3RCAM is not installed at the Four-Position Remote Terminal Cabinet or Two-Position QLX Remote BNC

Chassis.

CONFIGURING D3LX ALARMS

Input Enter up to 8

alphanumeric

characters.

Enter the remote housekeeping alarm label you

want for each field; the fields can be edited to

create customized labels. When a

housekeeping alarm occurs, for example, door

ajar, water on the floor, or fire alarm, the name

assigned is displayed in the condition column

of the Alarm History and Active Alarms screens.

1. Alarms

SCU V3.7 = Blank

Use this procedure to set alarm indicators for equipment, optical

facilities, and DS3 facilities groups for each D3LX CO module. You

6. Set Alarm Levels

can select CRITICAL (CR), MAJOR (MJ), MINOR (MN), EVENT

(EV), or NOT RPTD (not reported) for each field.

7. Set D3LX Alarm Levels

Setting Alarm Levels

1 From the Main menu, select 1. Alarms.

2 From the Alarms menu, select 6. Set Alarms Levels.

3 From the Set Alarm Levels menu, select 7. Set D3LX Alarm Levels.

The D3LX CO Alarm Levels screen appears as shown in Figure 14 on page 26.

4 In the Group toggle field, use to select the group number (1-7).

SPACEBAR

5 From the Equipment Alarms, Optical Facility Alarms, and DS3 Facility Alarms fields, select CRITICAL

(CR), MAJOR (MJ), MINOR (MN), EVENT (EV), or NOT RPTD (not reported) for each field. Default

alarm levels are shown in Table 6 on page 26. Assign the selections by pressing

Abbreviations of the alarm field options (except NOT RPTD) appear in the Active Alarms and

Alarm History screens. The option you selec t for a particular type of alarm determines whether

you will be notified when that type alarm occurs: critical, major, and minor alarms are audible

and visual notifications, events are system actions without audible and visual notifi cations, and

not reported alarms do not require notification.

ENTER

D3LX CO and RMT Modules August 30, 2002 25

Page 34

Local Configuration LTPS-UM-8013-03

Figure 14. D3LX Alarm Setting Menu

Table 6. D3LX Alarm Level Defaults

Condition Alarm Level Default

Equipment Alarms

BOARD FAIL Major

COMM FAIL Major

CONFIG MISMATCH Minor

HSKP1, HSKP2 Minor

PROTECT COMM FAIL Minor

OPTICAL COMM FAIL Minor

VERSION MISMATCH Minor

Optical Facility Alarms

APS LIMIT Minor

FORCE TO WORK Minor

FORCE TO PROT Minor

LASER DEGRADE Minor

OPTICAL LOF Major

OPTICAL LOS Major

T-BER Minor

DS3 Facility Alarm

LOOPED BACK Minor

RECEIVE LOS Major

TRANSMIT LOS Minor

RECEIVE AIS Major

26 August 30, 2002 D3LX CO and RMT Modules

Page 35

LTPS-UM-8013-03 Local Configuration

DISPLAYING D3LX STATUS

Use this procedure to display the status of both working and protect

2. Display Status

5. Display D3LX Status

modules in local and remote sites.

1 From the Main menu, select 2. Display Status.

2 From the Alarms menu, select 5. Display D3LX Status (as shown in Figure 16).

3 Use , , , ,

SPACEBAR

← →

and to select the group and slot to display.

↓ ↑

Figure 15. Display D3LX Status

D3LX CO and RMT Modules August 30, 2002 27

Page 36

Local Configuration LTPS-UM-8013-03

VIEWING LOOPBACK STATUS AND

ERFORMING LOOPBACK COMMANDS

P

Use this procedure to view loopbacks and send loopback

6. System Maintenance

4. Loopback Status Commands

commands for a specific D3LX system.

1 From the Main menu, select 6. System Maintenance.

1. High/Low Speed

S

2 From the System Maintenance menu, select

4. Loopback Status Commands.

3 From the Loopback Status/Commands menu, select 1. High/Low Speed Loopback

Status/Commands (as shown in Figure 16) to view the status of current loopbacks and to enable new

loopback tests for low-speed modules and their associated components.

4 Use , , , ,

SPACEBAR

← →

to your requirements, then assign the selections by pressing .

and to select the group and slot to display, populate each data field according

↓ ↑

ENTER

tatus Commands

Loopback

Figure 16. Loopback Status and Commands

28 August 30, 2002 D3LX CO and RMT Modules

Page 37

LTPS-UM-8013-03 Local Configuration

PERFORMANCE MONITORING

Use this procedure to monitor the performance of modules on both

the near and far end of D3LX systems.

1 From the Main menu, select 7. Performance

Monitoring.

2 From the Performance Monitoring menu, select

DS3/E3 PM Configuration (as shown in Figure 17).

3 In PM Reports, select DS3/E3 Far End PM Configuration.

To change the type of report, select the Group and Circuit, then select Local or Remote, 15 Minute, Daily, or

Summary.

4 Use , , , ,

SPACEBAR

to your requirements, then assign the selections by pressing .

← →

and to select the group and slot to display, populate each data field according

↓ ↑

7. Performance Maintenance

1. PM Configuration

2. PM Reports

ENTER

Figure 17. Performanc e Monitoring Menu–DS3/E 3 PM Configuration Shown

D3LX CO and RMT Modules August 30, 2002 29

Page 38

Local Configuration LTPS-UM-8013-03

PERFORMING SYSTEM MAINTENANCE

Use this procedure to perform the system maintenance commands

listed.

1 From the Main menu, select 6. System Maintenance.

2 From the System Maintenance menu, select

• 1. Force/APS Commands, and then select

1. Commands for Optical Facilities to view

and force line protection for the available circuits,

• 2. Reset/LED Test Commands to reset the selected

D3LX module or verify that its LEDs are working properly,

• 4. Loopback Status Commands, and then select 1,

High/Low Speed Loopback Status/Commands

to view the loopback status or perform loopbacks on the

selected D3LX, or

• 8. Trouble Isolation (as shown in Figure 18 on

page 31), and then select the Group and Slot.

3 Use , , , ,

SPACEBAR

← →

display, populate each data field according to your require ments,

then assign the selections by pressing .

and to select t he grou p and slot to

↓ ↑

ENTER

6. System Maintenance

1. Force/APS Commands

2. Reset/LED Test Commands

3. Execute ACO (Alarm Cut-Off)

4. Loopback Status/Commands

5. Display Inventory

6. Display Circuit IDs

7. SCU-860 Data Transfer

8.Trouble Isolation

9. Metallic Loop Qualification

(MLQ Capable Chassis Required)

30 August 30, 2002 D3LX CO and RMT Modules

Page 39

LTPS-UM-8013-03 Local Configuration

Figure 18. System Maintenance–Trouble Isolation Screen Shown

LOGGING OFF

To log off from anywhere on the system during a Telne t session, press + .

CTRL D

D3LX CO and RMT Modules August 30, 2002 31

Page 40

Local Configuration LTPS-UM-8013-03

REMOVING D3LX MODULES

D3LX CO

STATUS

FAR END

DS3 STATUS

ENABLE

DS3 ONLINE

LEC

Optical receptical

Optical connector

Fiber patch cord

D3LX module

Figure 19. Removing a D3LX Module–D3LX CO Shown

Do not look into the ends of any optical fiber or into any plug-in module conn ector. Exposure to

invisible laser radiation may cause permanent eye damage. A meter should be used to verify

active fibers.

1 For SC-type connectors: pull down on the retaining latch and withdraw the unit halfway ou t of th e chass is

while preventing the fiber-optic cord from binding. Release the fiber-optic patch cord from the optical

receptacle by gently pulling back on the locking mechanism and remove the cord as shown in Figure 19.

2 For FC-type connectors: unscrew the threaded cap counterclockwise and withdraw the unit halfway out of

the chassis while preventing the fiber-optic cord from binding.

3 Replace the protective cap on the optical connector located on the circuit board.

32 August 30, 2002 D3LX CO and RMT Modules

Page 41

LTPS-UM-8013-03 Remote Configuration

REMOTE CONFIGURATION

Use the D3RCAM craft interface system menu to view or edit the configuration for each D3LX RMT module in

the chassis. This menu can also be used to equip, provision, assign thresholds, and assign service state. The

D3RCAM Configuration menu is shown in Figure 22 on page 34.

1 Connect a maintenance terminal to the craft port on the D3RCAM front panel. Logon to the craft interface

system as described in “Connecting a Maintenance Terminal to the D3RCAM Craft Port” on page 20.

The Main Menu appears, as shown in Figure 20. If the Main Menu does not appear, check the terminal

communication parameters (or computer software interface) and retry this procedure.

Figure 20. D3RCAM Craft Interface Main Menu

D3LX CO and RMT Modules August 30, 2002 33

Page 42

Remote Configuration LTPS-UM-8013-03

D3RCAM MENU

The D3RCAM Main Menu (as shown in Figure 21) displays following configuration options:

System

Date/Time

System

Maintenance

Protection Switch Status/Commands

D3LX Group 1

D3LX Group 2

Reset/LED Test Command

Execute ACO (Alarm Cut-Off)

Loopback Status/Commands

Display Inventory

Alarms

Display Active Alarms

Display Alarm Summary

Display Alarm History

Clear Alarm History

Display

Status

Display Shelf Status

Display D3LX Status

Unit Configuration

Figure 21. D3RCAM Menu Tree

UNIT CONFIGURATION

Use this procedure to configure each D3LX RMT module installed in the remote ch assis. Refer to your work order

for configuration settings.

Please note that it is not nece ssary to configure each card in a w orking and protect system. Both

working and protect cards are provisioned at the same time. Provisioning can be done from

either the CO or remote end.