Page 1

ADCP-75-214

September 2006

ClearGain® 1800 MHz and 2100 MHz Dual

Inline Tower Mounted Amplifier System

User Manual

Issue 2

1383772 Rev A

Page 2

ADCP-75-214 • Issue 2 • September 2006 • Preface

COPYRIGHT

© 2006, ADC Telecommunications, Inc.

All Rights Reserved

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

1 06/2006 Original

2 09/2006 Add support for 1800MHz System

TRADEMARK INFORMATION

ADC and ClearGain are registered trademarks of ADC Telecommunications, Inc.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting ADC Technical Assistance Center at 1-800-366-3891, extension 63475

(in U.S.A. or Canada) or 952-946-3475 (outside U.S.A. and Canada), or by e-mail to bcg_tac@adc.com.

Page ii

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 946-3292

Page 3

TABLE OF CONTENTS

Content Page

ABOUT THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

ADMONISHMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

LIST OF ACRONYMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

1 PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 SYSTEM INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Masthead Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 PDU Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Bias-T Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 TROUBLESHOOTING 4-PORT CLEARGAIN DUAL INLINE DUAL DUPLEX TOWER MOUNTED AMPLIFIERS . . . . . . . . . . . 12

4.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Troubleshooting Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Troubleshooting Flowchart (For Systems With Three-Port MHUs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Troubleshooting Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Return Loss Sweep Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 1800 Masthead Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 2100 Masthead Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 PDU (Power Distribution Unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4 Bias-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ADCP-75-214 • Issue 2 • September 2006 • Preface

© 2006, ADC Telecommunications, Inc.

Page iii

Page 4

ADCP-75-214 • Issue 2 • September 2006 • Preface

Blank

Page iv

© 2006, ADC Telecommunications, Inc.

Page 5

ABOUT THIS MANUAL

This document describes the ADC ClearGain 1800 and 2100 MHz Dual Inline Tower Mounted

Amplifier (TMA) Systems and provides complete instructions for installing these products on a

communications tower.

ADMONISHMENTS

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below), and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

ADCP-75-214 • Issue 2 • September 2006 • Preface

Warn ing: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

CERTIFICATION

The ClearGain

requirements of EN60950.

The ClearGain

applicable CE Directives.

STANDARDS

The following is a listing of applicable regulatory standards:

Safety EN60950

EMC ETSI 300-342-2

1800 and

1800 and

2100 MHz

2100 MHz

Dual Inline TMA

Dual Inline TMA

have been tested and found to comply with the

have been tested and found to comply with all

Storage ETSI 300 019-1-1

Transport ETSI 300 019-1-2

Operation ETSI 300 019-1-4

© 2006, ADC Telecommunications, Inc.

Page v

Page 6

ADCP-75-214 • Issue 2 • September 2006 • Preface

LIST OF ACRONYMS

AISG – Antenna Interface Standards Group

ANT – Antenna

AW G – American Wire Gauge

BTS – Base Transceiver Station

LED – Light Emitting Diode

LNA – Low Noise Amplifier

MHU – Masthead Unit

OOK – On/Off Key

PDU – Power Distribution Unit

RET – Remote Electrical Tilt

RF – Radio Frequency

TMA – Tower Mounted Amplifier

Page vi

© 2006, ADC Telecommunications, Inc.

Page 7

1 PRODUCT OVERVIEW

1.1 General Description

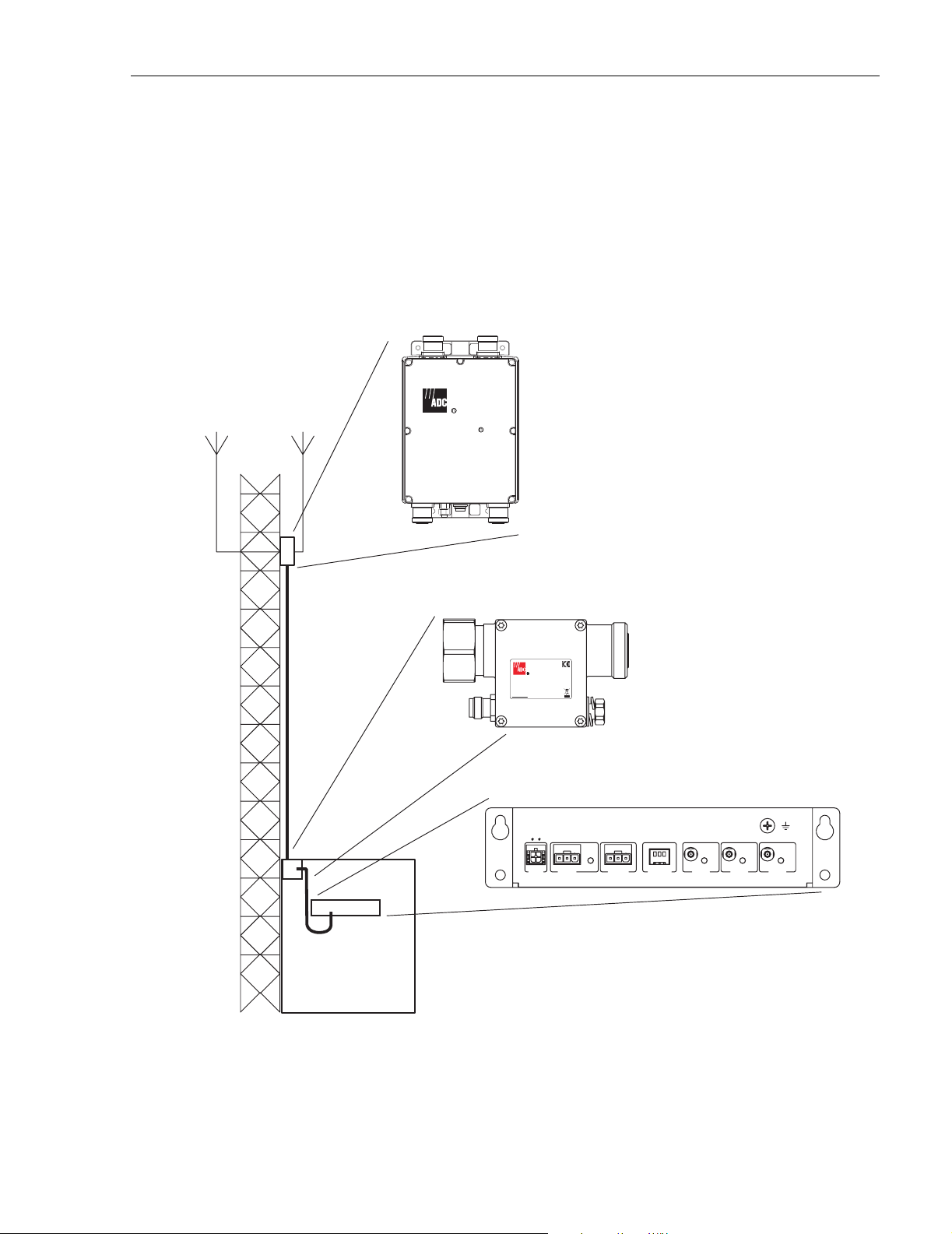

The ClearGain 1800 or 2100 MHz Dual Inline Tower Mounted Amplifier (TMA) system are

composed of some combination of three functional components: a ClearGain Power Distribution

Unit (PDU), a Masthead Unit (MHU) / Tower Mounted Amplifier (TMA), and a Bias-T.

shows where these components are located in a typical application on a communications tower.

ADCP-75-214 • Issue 2 • September 2006

Figure 1

MASTHEAD UNIT (MHU)

ClearGain

DUAL

INLINE

BIAS-T

BTS ANT

Bias-T kit

Freq: 800 - 2200MHz

Temp: -40 to +65 C

ASSEMBLED IN

Input: 5 to 24VDC

KOREA

Max Current: 2A

Date: YYYY/MM/DD

P/N: 1344027

S/N: XXXXXXXXX

DC

ClearGain PDU

G

W

R

B

- +

INPUT

NO COM NC FAIL

ALARM

RS485

BG

A

MHU

CONNECT

BASE

TRANSCEIVER

STATION

Figure 1. Functional Components of a ClearGain TMA System

OK OK OK

MHU 1 MHU 2 MHU 3

21297-B

One PDU may support up to three dual inline MHUs of the same frequency. Each MHU requires

a separate Bias-T. The ClearGain TMA system also includes power cables and alarm cables.

© 2006, ADC Telecommunications, Inc.

Page 1

Page 8

ADCP-75-214 • Issue 2 • September 2006

1.2 Functional Description

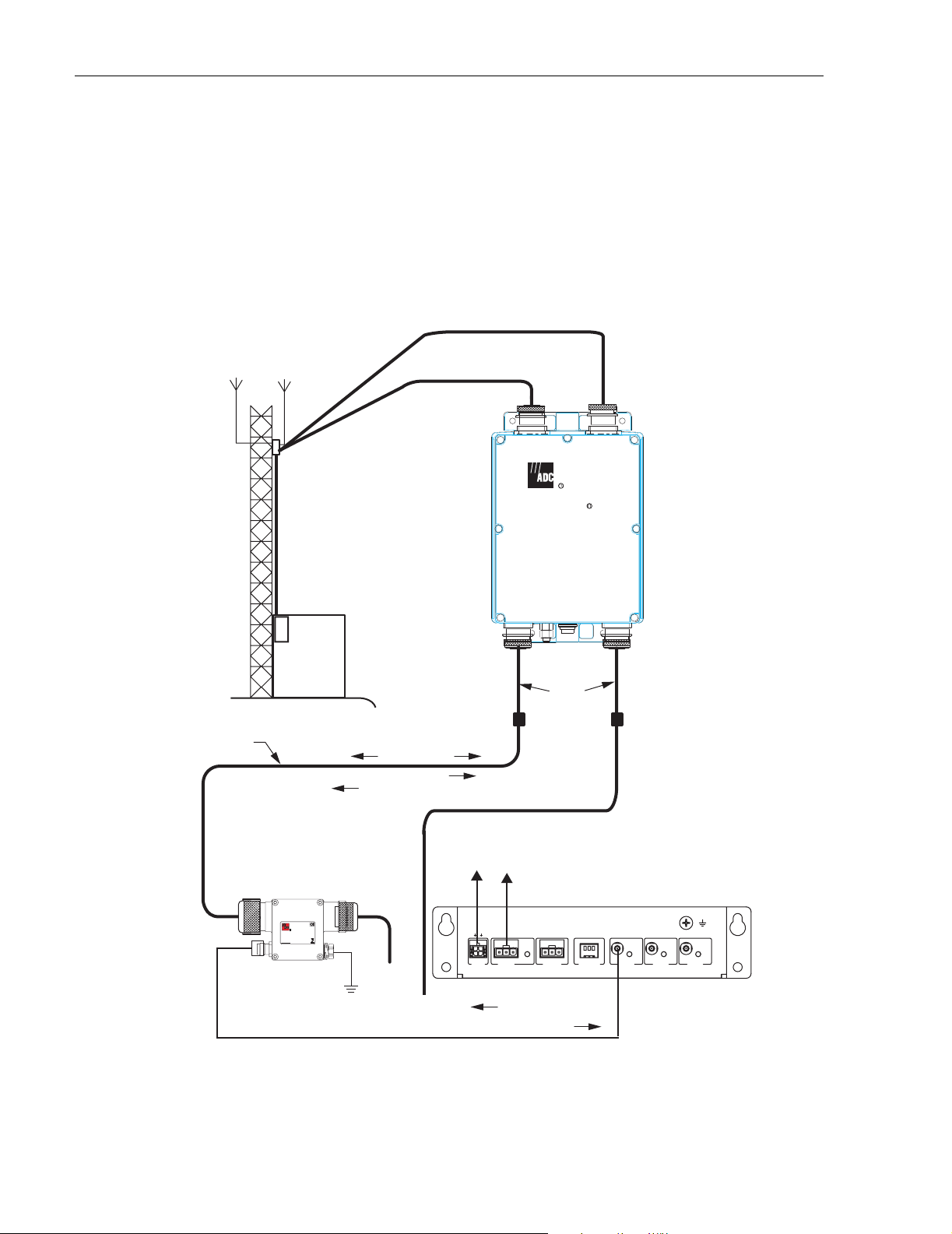

The basic purpose of a ClearGain Dual Inline TMA system is to amplify the uplink signal just

after the antenna. This is done to compensate for the loss in signal strength that occurs in

passage of the signal through the coaxial cable to the Base Transceiver Station (BTS) at the base

of the tower. The ClearGain TMA system improves the performance of the BTS by providing

12dB of uplink (reverse path) gain with a low noise figure. The ClearGain TMA system

provides visual and dry contact output alarming and lightning protection. Figure 2 depicts how

the system components are involved in system function.

COAXIAL

CABLE

ANTENNA

STATION

BASE

COAXIAL CABLE

TO ANTENNA

RF SIGNALS

DC POWER

FAULT DETECTION

ANT A

BTS A

JUMPER

CABLES

ANT B

ClearGain

MHU

BTS B

Page 2

© 2006, ADC Telecommunications, Inc.

BTS ANT

Bias-T kit

Freq: 800 - 2200MHz

Temp: -40 to +65 C

ASSEMBLED IN

Input: 5 to 24VDC

KOREA

Max Current: 2A

Date: YYYY/MM/DD

P/N: 1344027

S/N: XXXXXXXXX

DC

GROUND

INPUT

G

B

- +

W

R

SITE

ALARM

NO COM NC FAIL

ALARM

POWER

RX/TX (A)

RX/TX (B)

DC POWER

FAULT DETECTION

Figure 2. System Function

ClearGain PDU

ABG

RS485 MHU 1 MHU 2 MHU 3

CONNECT

OK OK OK

MHU

21305-B

Page 9

ADCP-75-214 • Issue 2 • September 2006

MHU – located as close to the antenna as possible, performs the amplifier function on the

uplink signal. Three subcomponents of the MHU, two RF cavity filters, and a Low Noise

Amplifier (LNA), are involved in the amplifier function. Downlink signal is not amplified but

passed through an RF cavity filter.

PDU

– located in the base station, provides DC current to power the LNAs and On/Off Key (OOK)

modem signal for use in the Remote Electrical Tilt (RET). The PDU outputs the DC current through

a front port from which it travels by way of a short linkage cable to the Bias-T. The injection of the

DC power onto the coaxial cable will not cause interference with signal transmission.

The PDU monitors the MHUs simultaneously by sensing their current draws. If any of the

MHUs fail, or if there is a cut or short circuit in the coaxial cable, the PDU sends an alarm to the

BTS. The PDU thus also monitors the condition of the coaxial cable, not just the MHU. The

PDU also has built-in lightning protection.

The PDU has a connector for RET communication with the BTS. The data bus is a two-wire bidirectional configuration and can be used for RS-485 communications link between the BTS

and PDU. The OOK modem is AISG standard compliant.

Bias-T – located on the coaxial cable, is a passive device that physically injects DC power onto

the coaxial cable to provide powering for the MHU. Bias-T may be installed indoors or

outdoors. There are four Bias-T connector options:

• 7/16 DIN male to the BTS; 7/16 DIN female to the ANT

• 7/16 DIN female to the BTS; 7/16 DIN male to the ANT

• N male to the BTS; N female to the ANT

• N female to the BTS; N male to the ANT

A single PDU supports three dual inline MHUs (with one Bias-T required for each dual inline

MHU). The Bias-T may be plugged into either of the RF cables to power the MHU.

2 SYSTEM INSTALLATION

2.1 Installation Overview

Installation consists of three main steps:

1. Installing the MHU: mechanical attachment, coaxial cables and ground cable.

2. Installing the PDU: mechanical attachment, operation power, alarms and ground cable.

3. Installing the Bias-T: mechanical attachment, coaxial cables, power cable and ground cable.

2.2 Masthead Unit Installation

Pole mounting kits are provided for installing the MHU. See Figure 3. Before any installation,

check that the ClearGain MHU has no visible damages or defects. Place ClearGain MHU as

close to the antenna as possible.

© 2006, ADC Telecommunications, Inc.

Page 3

Page 10

ADCP-75-214 • Issue 2 • September 2006

Note: All hardware is specified in metric units. The threads are sensitive to damage.

Figure 3. Typical MHU Clamp Mounting Kit Components

1. When installing on a pole a clamp kit (Figure 3) is required. The kit is designed for tube

diameters of 30 to 140 mm.

2. Before going up to the mast, temporarily remove the connector protector plugs, inspect the

7/16 DIN connectors for damage, and return the connector protector plugs to their

respective connectors.

3. Install clamps on pole and route through the mounting openings near the center of the MHU.

4. Position MHU at the desired location and tighten clamps securely.

2.2.1 Installing the MHU Ground Cable

Good grounding of the ClearGain MHU is important to protect the unit against voltage surges.

These surges may be caused by lightning or inadvertent contact with high voltage power lines.

Install the ground cable as follows:

1. Connect the ground cable to MHU bottom using M8 star washer and nut.

2. Connect the other end of the cable to a good ground (site ground) with a reliable joint.

Page 4

© 2006, ADC Telecommunications, Inc.

Page 11

ADCP-75-214 • Issue 2 • September 2006

GROUNDING and BONDING CONSIDERATIONS

• Grounding is very important in tower top applications. Shipped with each MHU, is a 4mm

(#6 AWG), one-meter (39-inch) ground cable with single hole crimp lug connectors on

both ends. Installation hardware is provided to attach one end to the MHU.

• Keep ground wire as short and direct (no loops or knots) as possible, secure it to a good

ground point (metal to metal).

• Always follow local grounding practices. The single hole lug is typically used to attach a

dedicated tower ground bus.

• In the absence of a dedicated ground, the tower structure itself can be used by using a

exothermic weld joint (not very common) or a mechanical ground clamp. If a clamp is

used, it must be very tight and protected from corrosion effects with a corrosion

preventative compound. It is recommended that the ground integrity/resistance at any

mechanical junction be checked during periods of regular tower maintenance. Always

follow local grounding practices.

• If the ground cable length is too short, customer may make a longer ground cable using

4mm (#6 AWG) wire as long as all the mechanical connections are tight and clean. Keep

ground cables as short as possible.

2.2.2 Installing Coaxial Cables

Caution: Before connecting any coaxial cables, ensure that the BTS transmitter output is

turned off and that precautions are taken to ensure that the transmitter cannot be activated

during the equipment installation.

Four short coaxial jumpers should be pre-made. Two will connect the BTS ports to the hard line

and the other two will connect the ANT ports to the antenna.

Caution: Remote Electrical Tilt (RET) connector on MHU must be covered with protective cap

if a cable is not connected to meet IP65 rating.

Most installations require four good quality flexible coax jumpers, normally terminated with 7/16

DIN-7/16 DIN connectors. Check gender of hard line and determine if antenna pigtail is present,

adjust accordingly for a correct match.

The coaxial feeder that runs from the base station to the antenna should be attached to the BTS

port of the MHU using a jumper cable. The reason for the jumper cable is to ensure that

mechanical forces caused by temperature change will not damage the MHU connectors. Tighten

connectors to 25–30 Nm (18.43–22.13 ft. lbs.) torque.

To improve connection reliability the connector joint can be protected. This is done, by

installing specific weatherproof tape over the cable connectors. Loose cable should be secured

to the tower using cable brackets.

© 2006, ADC Telecommunications, Inc.

Page 5

Page 12

ADCP-75-214 • Issue 2 • September 2006

2.3 PDU Installation

2.3.1 Mechanical Attachment of PDU

Warn ing: Never install the Power Distribution Unit in a wet location or during a lightning

storm. When installing or modifying communication lines, disconnect lines at the interface

before working with uninsulated lines or terminals to prevent electrical shock.

The PDU should be mounted in accordance with local code using appropriate hardware. The

PDU has two mounting holes on either side, as shown in Figure 4. Below are guidelines for

standard wall mount, masonry wall mount, and rack mount of the PDU.

2.3.1.1 Standard Wall Mount

When mounting the PDU on a wooden or metal surface, it is recommended that it be installed

on a secure surface.

2.3.1.2 Masonry Wall Mount

When mounting the PDU on a masonry surface, it is important that the bolts (especially the

upper bolts) be located as close as possible to the center of bricks or blocks. Masonry mounting

screws are not provided.

Page 6

© 2006, ADC Telecommunications, Inc.

Figure 4. Example of PDU Standard Wall Mount

Page 13

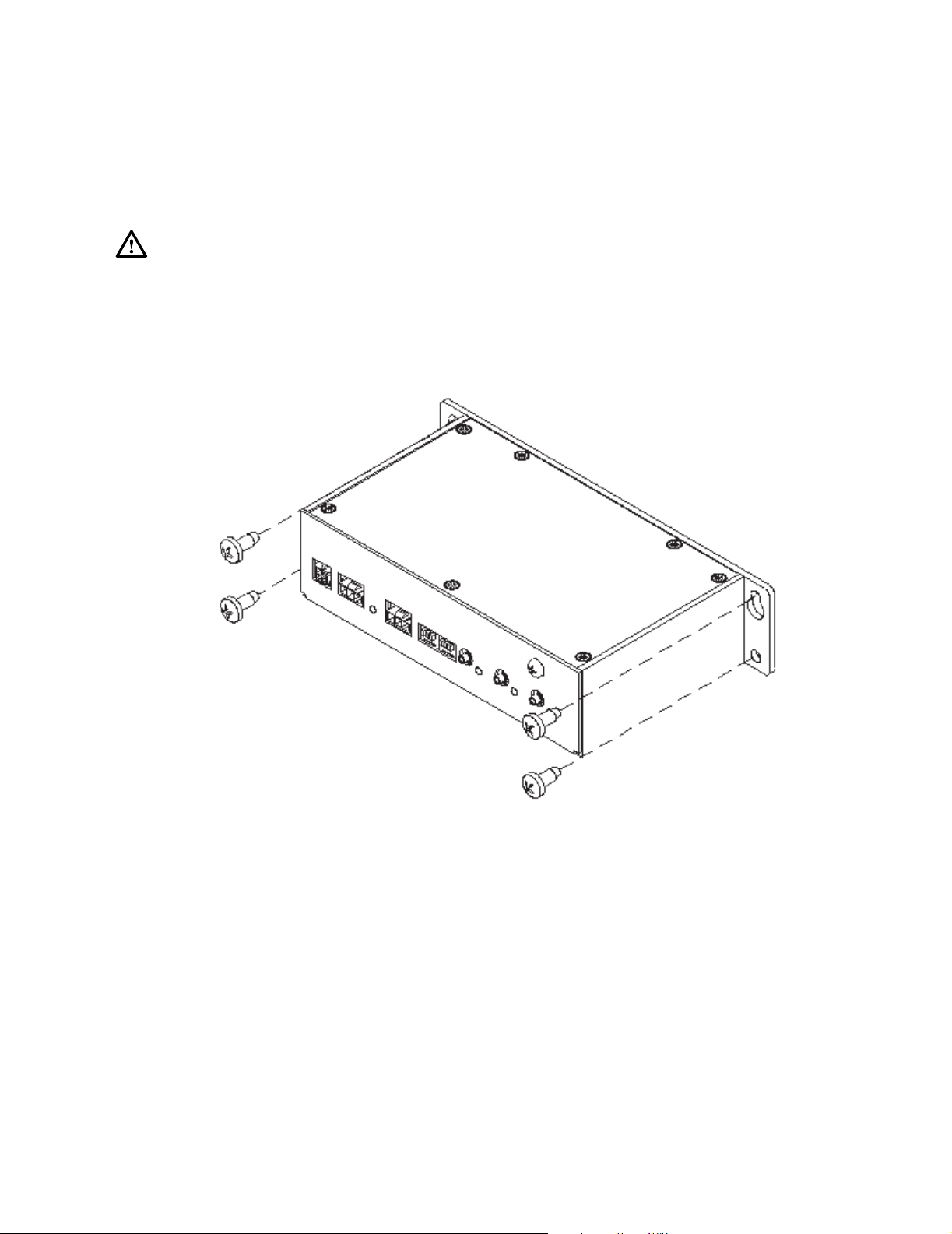

2.3.1.3 Rack Mount (Optional)

ADCP-75-214 • Issue 2 • September 2006

A mounting bracket, shown in

Figure 5

is available that allows the PDU to be mounted in a rack. If

mounting PDU in a rack, refer to the installation drawing provided with the mounting bracket

RACK

MOUNTING

BRACKET

21300-A

Figure 5. PDU Rack Mount Bracket

2.3.2 Installation of PDU Cables

.

There are fife PDU cables:

• Power cable

•Alarm cable

• Communication cables

• MHU (Bias-T) cables

• Ground cable.

© 2006, ADC Telecommunications, Inc.

Page 7

Page 14

ADCP-75-214 • Issue 2 • September 2006

Figure 6 shows the cable terminations on the front of the PDU. Connect the cables as follows:

(Left to Right: Power Cable, Alarm Cable, RS-485, Three MHU (Bias-T) Cables, and Ground Cable)

Figure 6. Cable Terminations on Front of PDU

1. Connect the ground cable under the grounding screw on the PDU front panel. Connect the

other end of the cable to the site-grounding pole.

2. Connect the alarm cable leads to the base station or site alarm system. Use either

“Normally Open” or “Normally Closed” contacts. Figure 7 shows the PDU alarm logic.

3. Connect the other end of the alarm cable to the PDU “ALARM” connector.

4. Connect communication cable leads to the base station or site control systems to control

RET. The data bus is a two-wire bi-directional configuration and is used for the RS-485

communications link. Figure 7 shows the RS-485 connection.

5. Connect the power cable to the site DC power source. (The power cable has four leads.

Red is positive, Black is negative, and White/Green is for ground.)

6. Connect the power cable to the “INPUT” connector on the PDU front panel.

Page 8

© 2006, ADC Telecommunications, Inc.

Page 15

DC

INPUT

POWER DISTRIBUTION UNIT

PDU

ALALRM

LOG IC

ADCP-75-214 • Issue 2 • September 2006

OUTPUT

21307-B

NO

(NO RM ALLY

OPEN)

COM

(CO MMO N)

NC

(NO R MA LLY

CLOSED)

GND

RS485A RS 485B

Figure 7. PDU Alarm Logic and RS-485 Connections

2.3.3 Setting the DIP Switch on the PDU

PDU has one set of dip switches to enable or disable the MHU ports. To disconnect unused MHU

output (see

Figure 8

). For the MHU outputs that are used, the DIP switch must be in the “down”

position or “ON”. Unused outputs must be disconnected by setting DIP switch in the “up” position.

(Switch 1 and 3 Set to “ON” to Indicate Use of MHU Ports 1 and 3)

Figure 8. Example of DIP Switch Setting on the PDU

© 2006, ADC Telecommunications, Inc.

Page 9

Page 16

ADCP-75-214 • Issue 2 • September 2006

2.4 Bias-T Installation

2.4.1 Mechanical Attachment and Cable Connections

Caution: Prior to installing any Bias-T unit, ensure that the BTS transmitter output is turned off

and that precautions are taken to ensure that the transmitter cannot be activated during the

equipment installation.

The Bias-T is installed either inline with the antenna feeder cable or directly to the BTS antenna

port. Integrated lightning protection is built into each Bias-T unit. There is no additional

mounting hardware required. Bias-T can be installed in either of the two antenna feeder cables

for each MHU. Connect the Bias-T as follows:

1. Connect the Bias-T “BTS” connector inline with the antenna feeder cable or directly in the

BTS antenna port.

Note: Orientation of the Bias-T is critical, BTS end should face the BTS and ANT should

face the antenna.

2. Connect the coaxial run going to the MHU to the “ANT” port of the Bias-T.

3. Connect the mini coax cable to the TNC connector of the Bias-T unit.

4. Connect the other end of the mini coax cable to the PDU front panel SMB connector

MHU1…3 (whichever is being used).

5. Connect the ground cable to the Bias-T ground terminal (see Figure 9).

6. Connect the other end of the ground cable to the site-grounding pole.

BTS ANT

Bias-T kit

Freq: 800 - 2200MHz

Temp: -40 to +65 C

ASSEMBLED IN

Input: 5 to 24VDC

KOREA

Max Current: 2A

Date: YYYY/MM/DD

P/N: 1344027

S/N: XXXXXXXXX

DC

GROUND TERMINAL

21298-A

Figure 9. Bias-T Ground Cable Connection

2.4.2 Additional Lightning Protection

ADC recommends that the operator install further lightning protection between the MHU and

Bias-T. It must allow the DC voltage to pass through the lightning protector, if it does not then

the Bias-T should be mounted on the antenna side of the protection.

Page 10

© 2006, ADC Telecommunications, Inc.

Page 17

3 TROUBLESHOOTING

When a fault occurs with the system, the red alarm LED on the PDU and the PDU dry-alarm

contact are activated. In such a case, troubleshoot for problems as follows:

1. Check that power is present at the PDU. The PDU will not operate if DC is not present,

polarity is incorrect, or the DC presented is out of specifications (–56 to –20 VDC or +20

to +56 VDC).

2. Each MHU output has a status LED. Status LED for each MHU that is in use should be

GREEN.

3. Disable or disconnect any unused MHU ports to prevent false alarm conditions.

4. Verify that DC voltage is present at the MHU port on the PDU. Disconnect the MHU

(Bias-T) cable and measure output voltage using a multimeter (Voltage measurement,

DC). Nominal DC output power should be 14–16 VDC.

5. Verify that DC voltage is present at the antenna side of the Bias-T. Disable RF transmit

power or disconnect it from the BTS. Disconnect antenna feeder cable from ANT side of

Bias-T and measure voltage using a multimeter (Voltage measurement, DC). Nominal DC

output power should be 14–16 VDC.

ADCP-75-214 • Issue 2 • September 2006

© 2006, ADC Telecommunications, Inc.

Page 11

Page 18

ADCP-75-214 • Issue 2 • September 2006

4 TROUBLESHOOTING 4-PORT CLEARGAIN DUAL INLINE DUAL DUPLEX

TOWER MOUNTED AMPLIFIERS

Trouble is visually indicated by LED's or no LED illumination on a specific MHU, swap Bias-T

cables on PDU ports to see if trouble remains or moves (reference Figure 8). See Figure 10 for

possible trouble points.

ANTENNA

JUMPER

FEEDLINE

JUMPERS

ANTENNA

JUMPER

MASTHEAD

UNIT (MHU)

NOTE: COMMON FAILURE

POINTS ARE THE ANTENNA

AND FEEDLINE JUMPERS/

CONNECTORS.

HARD LINE

SHELTER

TEST

POINT

CHECK IF EXTERNAL JUMPERS

OR SURGE PROTECTORS ARE PRESENT.

IF A SURGE PROTECTOR IS ANYWHERE

BETWEEN THE BIAS-T AND THE MHU

IT MUST BE ABLE TO PASS DC.

Figure 10. Tower Mounted Amplifiers

HARD LINE

21299-A

Page 12

© 2006, ADC Telecommunications, Inc.

Page 19

4.1 Troubleshooting

1. Observe and record PDU LED status. Disable or disconnect RF from BTS. Remove any surge

protectors. Disconnect Bias-T from the antenna feedline / hardline / jumper / protector.

2. Multimeter checks:

a. Measure voltage on the Bias-T _______ VDC. Normal is 15 VDC.

ADCP-75-214 • Issue 2 • September 2006

FEED LINE

PDU

PDU

b. Measure resistance of the feedline _______ Ohms. Normal is High or Very high Ω

(KΩ/ΜΩ).

FEED LINE

3. Antenna/cable analyzer checks. Measure the in-band RL/VSWR of the system ______ dB

or ratio. Check distance to Fault for anomalies.

© 2006, ADC Telecommunications, Inc.

Page 13

Page 20

ADCP-75-214 • Issue 2 • September 2006

4. Re-connect Bias-T with a T adapter. Verify voltage on the T adapter _______ VDC.

Normal is 15 VDC.

PDU

5. Re-connect to original configuration and return to service. PDU should illuminate a green

LED for each active TMA if there are no faults in the system.

6. Check with operators for improved performance.

4.2 Troubleshooting Hints

• If voltage is outside of the normal range, trace it back towards the fault.

• If no resistance or low resistance, check protector, feedline, jumpers and MHU.

• If an infinite resistance reading (sometimes indicated by OL), check to see if MHU is

installed or for a discontinuity exists up to the MHU.

• Normal in-band RL should be greater than 18dB. If less than 18dB, check protector,

feedline, jumpers and antenna.

• Mark receive and transmit bands to verify correct filtering.

• Check the distance to fault to identify any anomalies on the feedline.

Page 14

© 2006, ADC Telecommunications, Inc.

Page 21

4.3 Troubleshooting Flowchart (For Systems With Three-Port MHUs)

If directed by the flowchart, refer to the troubleshooting matrix in Section 4.4 or to the return

loss sweep guide in Section 4.5.

START

• CHECK SUPPLY IS -56 to -20 VDC or +20 to +56 VDC.

ANY

LIGHTS ON

THE PDU?

YES

NO

The red lead is connected to the higher potential.

• CHECK SUPPLY FUSE/BREAKER IS OK. (5A RATING)

• CHECK DC CABLE AND CONNECTION.PROBLEM

The red Fail led should come on when any MHU

select dip switch is pushed to the down position. If

the bias-t connection is not made.

ADCP-75-214 • Issue 2 • September 2006

OFF

PDU OR

CONNECTIVITY

PROBLEM

RED

MHU

led

YELLOW

SOLID

ONE

PAT H

FAILING

REFER TO TROUBLESHOOTING MATRIX

ALARM

led

OFF

MHU

led

GREEN

TTA ACTIVE

The red Alarm led should come on

when any MHU select dip switch

OFF

is pushed to the down position. If

the bias-t connection is not made.

• CHECK DC CONNECTIVITY

TO THE

• CHECK MHU PORT FOR 18VDC.

IF NOT PRESENT, REPLACE PDU.

• CHECK BIAS-T CABLE FOR

18VDC. IF NOT

PRESENT,

REPLACE BIAS-T CABLE.

• CHECK BIAS-T FOR 18VDC.

IF NOT

PRESENT, REPLACE BIAS-T.

• CHECK RESISTANCE OF

FEEDLINE.

- LO OHMS OR

SHORTED;

PROBLEM TOP SIDE.

- HI OHMS OR OPEN IS

NORMAL

BUT ALSO MAY INDICATE A

DISCONTINUITY.

21401-A

Page 15

© 2006, ADC Telecommunications, Inc.

Page 22

ADCP-75-214 • Issue 2 • September 2006

4.4 Troubleshooting Matrix

If directed in Section 4.3 to consult a troubleshooting matrix, see Tab le 1 below.

Note: ClearGain PDU DIP switches must be in the down position for each active MHU!

Note:

ClearGain PDU input voltage must be in the range –56 to –20 VDC or +20 to +56 VDC.

Table 1. Troubleshooting Matrix

PARAMETER SPECIFICATION EXPLANATION

GREEN/YELLOW

OK LED

RED GENERAL

ALARM LED

Electronic Load

Each Path OFF < 180 mA Fail OFF ON

Each Path ON 180 – 220 mA OK GREEN OFF

Total Fail 370 – 400 mA Fail OFF ON

Short Circuit

Protection

1.5 A ± 10% Fail GREEN ON

Short state of MHU path does not affect other path. After generating Green alarm,

the short state is held for ten seconds then Red alarm is generated by the PDU.

Circuit Fluctuation Min 180 mA

One path failed. YELLOW ON

Max 380 mA

Input Voltage

–56 to –20 VDC /

OK GREEN OFF

+20 to +56 VDC

Output Voltage 15 V, 4% Total failure. OFF ON

Page 16

© 2006, ADC Telecommunications, Inc.

Page 23

4.5 Return Loss Sweep Guide

RETURN LOSS SWEEP GUIDE FOR THE RECEIVE SECTION OF THE MHUs.

ADCP-75-214 • Issue 2 • September 2006

0

-5

-10

-15

-20

RL dB

-25

-30

-35

-40

-45

NORMAL IN-SYSTEM SWEEP. TYPICAL. DEGRADATION FROM NORMAL SYSTEM SWEEP.

GOOD BAD

v1 v2 v1 v2

RL IS STILL GOOD IN RX BAND.

RECOMMEND CONNECTOR/LINE/ANTENNA CHECKS

DURING NEXT SCHEDULED MAINTENANCE PERIOD WHEN

TOWER CREW AVAILABLE.

RESISTANCE LOOKING INTO THE FEEDLINE SHOULD INDICATE HIGH OR INFINITE OHMS.

0

GOOD BAD

-5

-10

-15

-20

RL dB

-25

-30

-35

-40

-45

v1 v2 v1 v2

ANTENNA PORT: TERMINATED WITH 50 OHM LOAD.

"PERFECT ANTENNA" < 50 OHM LOAD >

ANTENNA PORT: ANTENNA CATASTROPHICALLY

FAILED "OPEN".

ANTENNA PORT: ANTENNA CATASTROPHICALLY

FUSED "SHORT".

18270-A

© 2006, ADC Telecommunications, Inc.

Page 17

Page 24

ADCP-75-214 • Issue 2 • September 2006

5 SPECIFICATIONS

5.1 1800 Masthead Unit

Tab le 2 provides typical specifications for the 1800 Masthead Unit.

CATEGORY PARAMETER SPECIFICATION

Filters RX (up link) frequency range 1710–1785 MHz

LNA with filter Gain 12 ± 1 dB

Table 2. 1800 Masthead Unit Specifications

TX (down link) frequency range 1805–1880 MHz

Tx path Insertion Loss 0.7 dB

Power Handling Capability 200W

Return Loss 18 dB

Noise Figure < 1.6 dB

IIP3 > + 13 dBm

Bypass Loss < 2.0 dB

Physical Dimensions (W x H x D) 189.0 x 336.0 x 90.0 mm

(7.4 x 13.2 x 3.5 inches)

Weight 6.9 kg (15.2 lbs.)

Color Gray Metallic

Connectors Antenna Connector 7/16 DIN Female

BTS Connector 7/16 DIN Female

Intermodulation Intermodulation < –115dBm (2x20W)

Power Operation Voltage 15 VDC

Operation Current 220 mA

Environmental Operating Temperature –40°C to +65°C (–40°F to +149°F)

Outdoor Protection IP65

Quality MTBF >500,000 hours

Lightning Protection IEC 61000-4-5

Page 18

© 2006, ADC Telecommunications, Inc.

Page 25

5.2 2100 Masthead Unit

Tab le 3 provides typical specifications for the 2100 Masthead Unit.

CATEGORY PARAMETER SPECIFICATION

Filters RX (up link) frequency range 1920–1980 MHz

LNA with filter Gain 12 ± 1 dB

Physical Dimensions (W x H x D) 166.0 x 210.0 x 80.0 mm

ADCP-75-214 • Issue 2 • September 2006

Table 3. 2100 Masthead Unit Specifications

TX (down link) frequency range 2110–2170 MHz

Tx path Insertion Loss 0.5 dB

Power Handling Capability 200W

Return Loss 18 dB

Noise Figure < 1.7 dB

IIP3 > + 13 dBm

Bypass Loss < 2.0 dB

(6.5 x 8.3 x 3.2 inches)

Weight 4.2 kg (9.3 lbs.)

Color Gray Metallic

Connectors Antenna Connector 7/16 DIN Female

BTS Connector 7/16 DIN Female

Intermodulation Intermodulation < –106dBm (2x20W)

Power Operation Voltage 15 VDC

Operation Current 220 mA

Environmental Operating Temperature –40°C to +65°C (–40°F to +149°F)

Outdoor Protection IP65

Quality MTBF >500,000 hours

Lightning Protection IEC 61000-4-5

© 2006, ADC Telecommunications, Inc.

Page 19

Page 26

ADCP-75-214 • Issue 2 • September 2006

5.3 PDU (Power Distribution Unit)

Tab le 4 provides typical specifications for the PDU.

Table 4. Power Distribution Unit (PDU) Specifications

CATEGORY PARAMETER SPECIFICATION

Electrical Input voltage range 20–56VDC positive/negative ground

Output voltage 15V, 4% (Over voltage protection)

Output voltage accuracy 4% in 20mA – 400mAMAX 10% in 1.5A

Output ripple 100mV pk – pk

PDU Inrush Current ETS300132-2, Part 2

Short circuit protection 1500mA, 10%

(Input polarization protected)

Connector and

LED

Outputs for TMA's SMB connector Male (3 pcs)

Input connector Molex Micro-fit 43045 - 0400

General alarm connector Molex Mini-Fit 39-30-3035

Communications link between BTS

Molex Mini-Fit 39-30-3035

and RET

Indicators Two color LED (3 pcs) (green and yellow)

Red LED 1 pcs

Physical Dimensions (W x H x D) 194.4 x 43.6 x 100.0 mm

(7.7 x 1.7 x 3.9 inches)

Weight 0.5 Kg (1.2 lbs.)

Color Gray Metallic

Communication Pin Number Signal Comments

1 RS485 A RET control command AISG Layer2. ISO/

IEC 8482:1993 (RS485).

2RS485 B

3 RS485 GND

PDU only receives control command from BTS and modulates 2.176MHz Modem

Signal and transmit to TMA through SMB connector, and vice versa.

Resistance between RS485 A and

> 1k Ohm

RS485 B

Resistance between RS485 A or

> 1k Ohm

RS485 B and DC return / RS485 GND

Page 20

© 2006, ADC Telecommunications, Inc.

Capacitance between RS485 A or

RS485 B

Capacitance between RS485 A or

RS485 B and DC/RS485 GND

< 1nF

< 1nF

Page 27

5.4 Bias-T

ADCP-75-214 • Issue 2 • September 2006

Tab le 5 provides typical specifications for the Bias-T.

Table 5. Bias-T Specification

CATEGORY PARAMETER SPECIFICATION

RF Path Frequency Rangy (MHz) 800–2200

Insertion Loss (max) 0.2 dB

Return Loss (min) 19 dB

Power Handling (max) 500W RMS

Isolation (RF to DC port) > 30 dB

Inter modulation (3rd order) 2x20W tones <–108 dBm

DC Path DC Input Voltage 5–24 V

Input Current 0–2 A

DC Path Resistance < 1 Ohm

Physical Dimension (HxWxD) mm 55.5 x 95.0 x 40.0mm

(2.2 x 3.7 x 1.6 inches)

Weight 0.3 Kg (0.7 lbs.)

Color Gray Metallic

Housing Aluminum

Environmental Operating Temperature –40 to +65º C (–40°F to +149°F)

Storage Temperature –40 to +70º C (–40°F to +158°F)

Outdoor Protection IP65

Quality MTBF 500,000 hours

Lightning

Protection

Current Peak 10 KA

Raising Time (10–90) 8 ns

Peak Half Voltage Time 50–50) 20 ns

© 2006, ADC Telecommunications, Inc.

Page 21

Page 28

ADCP-75-214 • Issue 2 • September 2006

6 CUSTOMER INFORMATION AND ASSISTANCE

PHONE:

U.S.A. OR CANADA

Sales: 1-800-366-3891 Extension 73000

Technical Assistance: 1-800-366-3891

Connectivity Extension 73475

Wireless Extension 73476

EUROPE

Sales Administration: +32-2-712-65 00

Technical Assistance: +32-2-712-65 42

EUROPEAN TOLL FREE NUMBERS

Germany:

UK:

Spain:

France:

Italy: 0800 782374

ASIA/PACIFIC

Sales Administration: +65-6294-9948

Technical Assistance: +65-6393-0739

ELSEWHERE

Sales Administration: +1-952-938-8080

Technical Assistance: +1-952-917-3475

WRITE:

ADC TELECOMMUNICATIONS, INC

PO BOX 1101,

MINNEAPOLIS, MN 55440-1101, USA

0180 2232923

0800 960236

900 983291

0800 914032

ADC TELECOMMUNICATIONS (S'PORE) PTE. LTD.

100 BEACH ROAD, #18-01, SHAW TOWERS.

SINGAPORE 189702.

ADC EUROPEAN CUSTOMER SERVICE, INC

BELGICASTRAAT 2,

1930 ZAVENTEM, BELGIUM

PRODUCT INFORMATION AND TECHNICAL ASSISTANCE:

connectivity.tac@adc.com

wireless.tac@adc.com

euro.tac@adc.com

asiapacific.tac@adc.com

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice.

In no event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period. This publication may be

verified at any time by contacting ADC's Technical Assistance Center.

© 2006, ADC Telecommunications, Inc.

13944-M

All Rights Reserved

Page 22

Loading...

Loading...