Page 1

UltraWAVE BTS

Installation and Commissioning

Guide

Release 6.5

Part Number 680208-00

1/03 Version A

Page 2

The products described in this docume nt are products of interWAVE Communications, Inc. or its lice nsers.

No part of this document may be photocopied, reproduced, translated, transfe rred, disclosed or otherwise

provided to third parties without the prior written consent of an officer of interW AVE Communications, Inc.

This document applies to the interWAVE Communications, Inc. release of the GSM product line and to all

subsequent versions and releases of the hardware or software unless otherwise indicated in a new version or

an update package for this edition.

Publications requests should be addressed to your local sales support office.

interWAVE Communications, Inc. reserves the ri ght to make changes to a ny products described herei n at any

time without notice. interWAVE Communications International, Ltd. and interWAVE Communications, Inc. do

not assume any responsibility or liability arising out of the application or use of any product described herein,

except as expressly agreed to in writing by interWAVE Communications, Inc. nor does the purchase or use of

a product from interWAVE Communications, Inc. convey a licen se under any patent rights, copyrights,

trademark rights, or any other of the intellectual property rights of interWAVE Communications International,

Ltd. or third parties.

Use, duplication, or disclosure by the U.S. Government is subject to restrictions of FAR 52.227-14 (g) (2) (6/

87) and FAR 52.227-19 (6/87), or DFAR 252.227-7015 (b) (6/95) and DFAR 227.7202-3 (a).

The software described in this document is furnished under a license agreement or nondisclosure

agreement. The software may be used or co pied only in accordance with the terms of the agreement. It is a

violation of inter WAVE Communications International, Ltd. proprietary rights to co py the software on any

medium except as sp ecifically allowed in t he license or nondisclosure agreement . interWAVE's produ c ts are

patented by one or more of the following United States Patents: No. 5,781,582, No . 5,682,4 03, No.

5,734,979, No. 5,734,699, No. 5,999,813, No. 5,953,651, No. 5,887,256, No. 5,577,029, No.

5,761,195, No. 5,842,138, No. 5,818,824, No. 5,957,464, No. 6,078,823, No. 6,070,071, No.

6,101,400, No. USP D 391,967, No. USP D 391,968, No. USP D 397,693.

Trademark Acknowledgment

interWAVE, WAVEXpress, MicroXpress, WAVEXchange, WAVEView, GSM Network in a Box, and

TurboWAVE are trademarks or registered trademarks of interWAVE Communications International, Ltd. All

other trademarks, service marks and product names mentioned in this document a re the property of their

respective owners.

©2003 interWAVE Communications, Inc. All Rights Reserved.

ii UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 3

United States Federal Communications Commission Required User Information

Located on the equipment is a label that contains, among other information, the FCC registration number. If

requested, this information must be provided to the telephone company.

The UltraWAVE BTS Series AUAC series complies with Part 22 of the FCC Rules.

The 1900 MHz WAVEXpress Series M50 complies with Part 24 of the FCC Rules.

This equipment cannot be used on the telephone company-provided coin service. Connec tion to Party Line

Service is subject to State Tariffs.

If this equipment causes harm to the telephone network, the telephone company will notify you in advance

that temporary discontinuance of servic e may be required. If advance notice isn’t practical, the telephone

company will notify the customer as soon as possible. Also, you will be advised of your right to file a

complaint with th e FCC if you believe it is ne cessary.

The telephone company may make changes in its facilities, equipme nt, operations, of pr ocedures that could

affect the operation of the equipment. If this happens, the telephone company will provide advance notice in

order for you to make the necessary modifications in order to maintain uninterrupted service .

If trouble is experienced with this equipment, please contact:

interWAVE Communications, Inc.

312 Constitution Drive

Menlo Park, CA 94025

Phone: 650.838.2117

If the trouble is causing harm to the telephone network, the telephone company may request you to remove

the equipment from the network until the problem is resolved.

It is recommended that the customer insta ll an AC surge arrester in the AC outlet to which that device is

connected. This is to avoid damaging th e equipment caused by local lightning strikes and other electrical

surges.

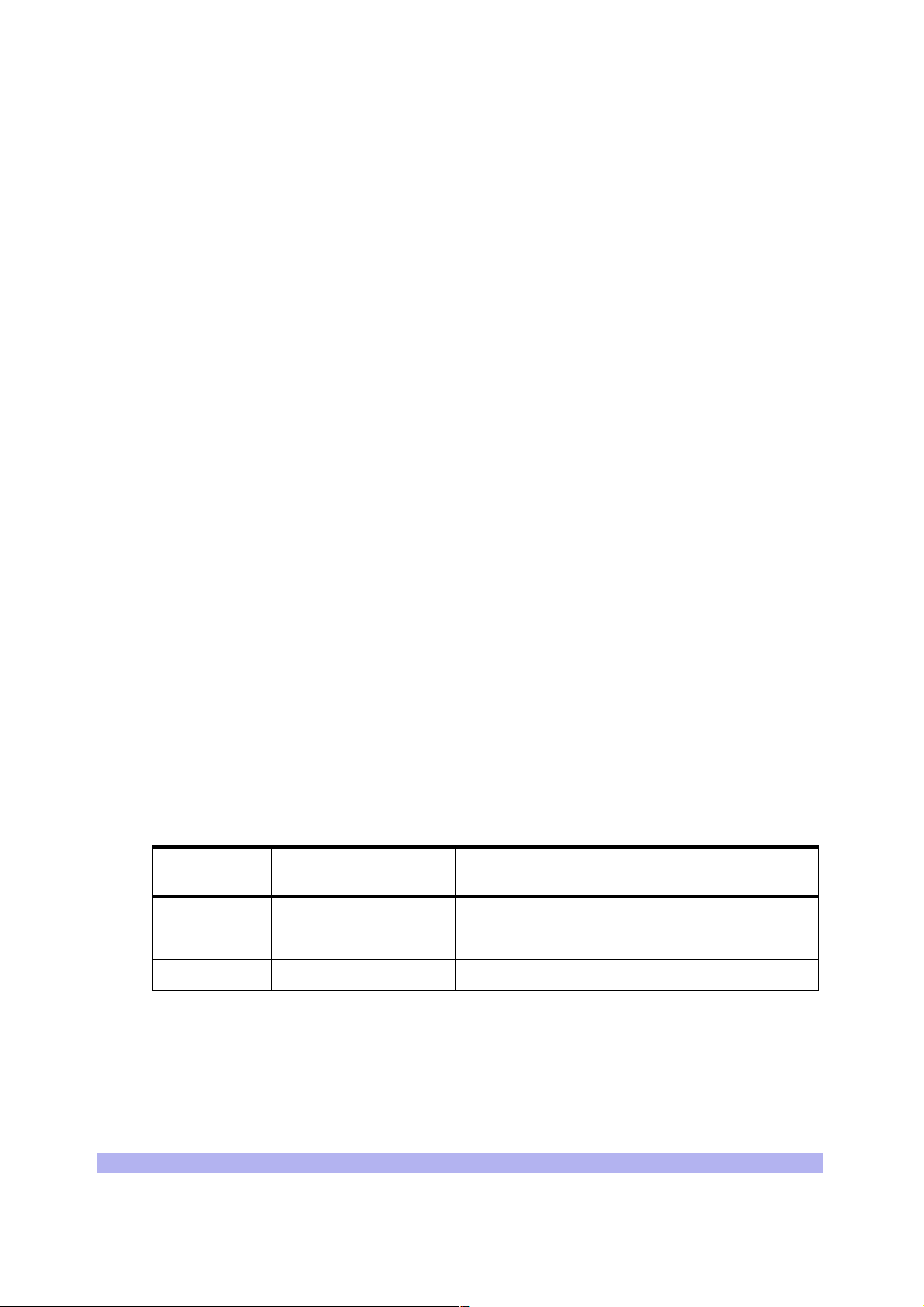

This equipment uses the following USOC jacks and codes:

Model Name Facility Interface Code Service Order Code Jack Type

340122 04DU9-BN 6.ON RJ-48C

340122 04DU9-DN 6.ON RJ-48C

340122 04DU9-1KN 6.ON RJ-48C

340122 04DU9-1SN 6.ON RJ-48C

340122 04DU9-1ZN 6.ON RJ-48C

Note: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection agains t

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential are a is likely to cause harm ful interference in which case the user will be required to correct the

interference at his own expense.

iii

Page 4

Changes of modificat ions not expressly approv ed by interWAVE Communicat ions, Inc. can void the user’s

authority to ope rate the equipment.

Industry Canada Required User Inform ation

CP-O1, Issue 8, Part 1, Section 14.1

NOTICE: The Industry Canada label ide ntifies certified equipm ent. This certification means that the

equipment me e ts certain telecommunicati ons network protective, ope rational and safety require m ents as

prescribed in the appropriate Terminal Equipment Technical Requirements document(s). The Department

does not guarantee the equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of

the local telecommunications company. The equipment must also be installed using an acceptable method of

connection. The customer should be aware that compliance with the above conditions may not prevent

degradation of service in some situations.

Repairs to certified equipment should be coordinated by a representative designated by the supplier. Any

repairs or alterations made by the user to th is equipment, or equipm ent malfunctions, may give the telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility,

telephone lines and internal metallic water pipe system, if present, are connected together. This precaution

may be particularly important in rural areas.

CAUTION: Users should not attempt to make such connections themselves, but should contact the

appropriate elect ric inspection authority, or electrician, as appropriate.

The standard connecting arrangement (telephone jack type) for this equipme nt is CA81A.

CP-01, Issue 8, Part 1, Section 14.2

NOTICE: The Ringer Equivalence Number (R EN) assigned to each terminal device provides an indication of

the maximum number of terminals allowed to be connected to a telephone interface. The termination of an

interface may consist of any combination of de vices subject only to the requirement that the sum of the

Ringer Equivalence Numbers of all the devi ces does not exceed 5.

This Class A digital a pparatus complies with Canadian ICES-003.

Cet appareil numerique de la classe A est conforme a la norme NMB-003 du Canada.

This device complies with Industry Canada RSS-133 and SRSP-510.

iv UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 5

Table of Contents

Welcome! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Assumptions, Purpose, and Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Customer Support Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Return Materials Authorization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xii

Chapter 1 Unpacking and Configuration Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1-1 Unpacking and Inspecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2 Inspect Components and Record Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2.1 Identifying the Syst em Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2.2 Identifying Module Part and Serial numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-3 Verifying and Documenting Cards and Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3.1 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3.2 RF Subrack Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3.3 Baseband Subrack Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-4 Internal Cabling Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2-1 Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

2-1.1 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1.2 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1.3 Chassis Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-2 Mounting the BTS Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-3 Configuring the E1 or T1 Trunk Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-3.1 Configure Ground Jumpers on 75 Ohm E1 Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-3.2 Configure Cable Length DIP Switch Settings on T1 Cards . . . . . . . . . . . . . . . . . . . . . 23

2-4 Connecting Power and Ground Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-4.1 Connecting the Grounding Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-4.2 Connecting the Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-5 Connecting E1 or T1 Trunk Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-5.1 E1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-5.2 T1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-5.3 Connecting E1 or T1 Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-5.4 Direct Cabling Between Multiple UltraWAVE or WAVEXpress Systems . . . . . . . . . . . 31

2-5.5 Cabling External BTSs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-6 Connecting Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-6.1 Omni 1 TRX (O1) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2-6.2 Omni 2 TRX (O2) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-6.3 Omni 3 TRX (O3) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-6.4 Omni 4 TRX (O4) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

v

Page 6

2-6.5 Omni 5 TRX (O5) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2-6.6 Omni 6 TRX (O6) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-6.7 Omni 5 (05) and Omni 6 (O6) 25 Watt Configuration . . . . . . . . . . . . . . . . . . . . . . . .36

2-6.8 Sectorized Two TRX (S11) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2-6.9 Sectorized Three TRX (S111) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 7

2-6.10 Two Sector Four TRX (S22) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

2-6.11 Three Sector Four TRX (S211) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2-6.12 Three Sector Five TRX (S221) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2-6.13 Three Sector Six TRX (S222) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 9

2-6.14 Two Sector Five TRX (S32) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

2-6.15 Two Sector Six TRX (S33) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

2-6.16 Two Sector Six TRX (S42) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

2-6.17 RF Radiation Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

2-7 Connecting External Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

2-8 Post Installation Cabling and Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Chapter 3 Off-Line Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3-1 Pre Off-Line Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3-1.1 Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3-2 Off-Line Commissioning the UltraWAVE BTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

3-2.1 Connecting the Craft PC to the ICP Processor Card . . . . . . . . . . . . . . . . . . . . . . . . . .50

3-2.2 Starting XWindows Using the Craft PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3-2.3 Power-On LED Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

3-2.4 Establishing Serial Communications with the BTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3-2.5 Verifying/Changing Boot Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

3-3 Software verification using Craft PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3-3.1 Verifying the Current Software Version and Patch Level . . . . . . . . . . . . . . . . . . . . . . . 58

3-3.2 Checking the Flash Version Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

3-3.3 Running E1 or T1 POST Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

3-3.4 Verifying Telnet Co mmunications with the BTS over Ethernet . . . . . . . . . . . . . . . . . .60

3-3.5 Running TRX POST Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3-3.6 Reviewing POST Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

3-3.7 Rebooting the BTS after Running POST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 4

3-3.8 Terminating Serial Communications with the BTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3-4 Exiting XWindows on the Craft PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

3-5 Upgrading the BTS Software Version (Flash) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

3-6 Post Off-Line Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Chapter 4 Off-Line Commissioning of a Daisy Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4-1 Prerequisites to Daisy Chaining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4-2 Setting the Abis LAPD Signaling Timeslot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Chapter 5 On-Line Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

5-1 Pre On-Line Commissioning Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

5-2 On-Line Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

5-3 Antenna Cabling and Power Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

vi UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 7

5-3.1 Voltage Standing Wave Ratio (VSWR) Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5-3.2 Verifying BTS RF Performance without Racal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5-3.3 Verifying TRX Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5-3.4 RX BER Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 9

5-4 Post On-Line Commissioning Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Checklist 1 Site Readiness Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Checklist 2 Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Checklist 3 Commissioning Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

vii

Page 8

(this page intentionally left blank)

viii UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 9

Welcome!

Welcome to the UltraWAVE BTS Installation and Commissioning Guide. This guide is written to provide

the user with installation guidelines and procedures which will be required to set-up and initially

configure the BTS.

Assumptions, Purpose, and Audience

This document is intended for an interWAVE trained field service engineer (FSE) or operator who

performs local installation and commissioning at a customer sit e. The FSE or operator should be

equipped with the necessary tools for installation and commissioning, and a basic understanding of the

GSM cellular network. The FSE or Operator should also be familiar with the use of Craft PC and

procedures conducted using the Craft PC.

interWAVE assumes that pre-installation project planning has occurred, and is documented via a site

survey report. This site survey should include items such as the location of antennas, chassis, power

connections and other interface accesses and temperature control equipment.

Preface

Microwave Radio Radiation Warning

Although interWAVE prod ucts do not u se microwave ra dio antennas , the equi pment is o ften mounted in

the vicinity of microwave radio antennas. Under normal operating conditions, microwave radio

equipment complies with the limits for human exposure to radio frequency (RF) fields adopted by the

Federal Communications Commission (FCC). All interWAVE Communications, Inc. microwave radio

equipment is designed so that under normal working conditions, microwave radiation directly from the

radio is negligible when compared w it h the permissible limit of continuo us daily exposure

recommended in the United States by ANSI/IEEE C95 .1-1991 (R1997), Safety Levels with Respect to

Human Exposure to Radio Frequency Electromagnetic Fields, 3 kHz to 300 GHz.

Microwave signal levels that give rise to hazardous radiation levels can exist within transmitter power

amplifiers, associated RF multi plex ers, and antenna systems.

Never look into the open end of a waveguide or any other open RF

connection as eyes are particularly vulnerable to radiation. Do not

disconnect RF coaxial conn ecto r s, op en mi cro w ave un its, or break down

any microwave screening while the radio equipment is operating.

Related Documentation

All manuals are availab l e on a documentation CD-ROM in Adobe portable document format or in an

online format via our protected Internet site. To order documentation, please contact interWAVE

Communications, Inc. Sales department online at http://www.iwv.com.

ix

Page 10

Updates to this manual will be posted on the interWAVE Communicati on s, In c. Customer Service

Website at http://www.iwv.com/custsupport. Registered interWAVE customers can access the

interWAVE on-line information and support service, available 24 hours a day, seven days a week. The

interWAVE on-line servi ce provides users with a wealth of up-t o-date infor mation, with docum ents being

added or updated each month.

Customer Support Services

interWAVE has regional customer service centers that handle day-to-day customer issues. Each center

is staffed with a local technical support group. The exact services to be performed by the interWAVE

Customer Service department are s pecified in a support contract. Below is an example of the ty pes of

services available:

• telephone support

• site surveys

• installations

• off-line and on-line commissioning

• network integration activities

• troubleshooting and fault isolation

• escalation of problems to appropriate interWAVE techn i c a l departments

interWAVE can physically perfor m all or a portion of these processes for the operator, as specified in

the support contract. The Customer Service department can also provide documentation outlining

corrective and preventive maintenance procedures and troubleshooting guides for fault isolation.

Contact your local Sales Support office

http://www.iwv.com.

If possible, please have the following information available when making a call:

• site number or name

• full description of product(s) (e.g., model and part number) and configuration

• serial number of product(s)

• purchase order number

For support on installin g or configuring all interWAVE GSM, DCS or PCS equipment, contact your

Regional interWAVE Customer Service Center

• +852.2574.1922 or asia_support@iwv.com.hk -- Asia and Pacific Rim

• +1.866.306.1263 or usa_support@iwv.com -- North and South America, Europe, Africa,

and Middle East

, or interWAVE headquarters directly via the Internet at

at:

or via the Internet at http://www.iwv.com/custsupport.

x UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 11

Return Materials Author iz ation

In the event that a depot repair or hardware replacement is required after contacting Customer Service,

please contact interWAVE for return authorization. The following information is required by interWAVE:

• full description of the product(s): model and part number

• serial number of the product(s)

• purchase order number

• quantity that needs to be returned to interWAVE, if applicable

• description of observed problem

All interWAVE products carry a one year manufacturing warranty from the dat e of shipment. At the time

of a request for a return authorization, if the product has exceeded the warranty period, interWAVE will

require a new purchase order number to cover the cost of non-warranty repair.

Contact Sales Operations via the Internet at http://www.iwv.com or email at rma@iwv.com.

Training

interWAVE has devel ope d a n ext e ns ive s er i es of tr ai n in g c ours es designed to teach you how to use our

products. The course s are devel oped by a combinati on of subj ect matt er experts an d traini ng specia lists

in order to create highly technical material s in modern training format. Each of our course offerings are

designed around specific learning objectives that keep our classes on track to learning specific job skills

related to interWAVE products.

The interWAVE training ca ta lo g conta i ns a l is ti ng of t he in terWAVE training services available along with

descriptions of each course. Our training materials are divided into specific subsystem training series,

depending upon the topic and job requirements.

Contact Customer Service via the Intern et at ht tp://www.iwv.com or email at training@iwv.com.

xi

Page 12

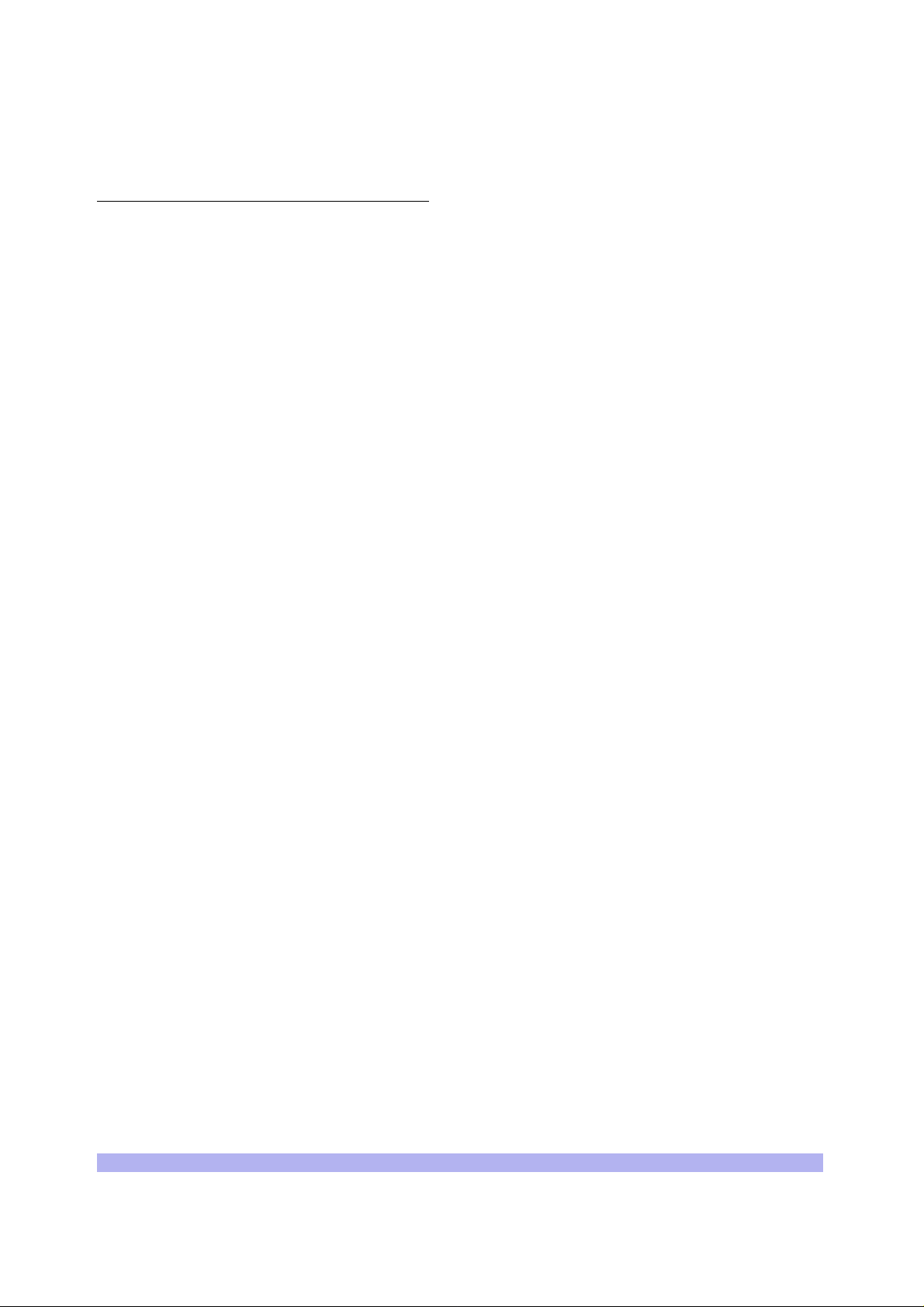

Conventions Used in this Manual

The following type and style conventions are used in this manual:

Table 1 Conventions Used in This Manual

Convention Meaning

Body text

Used for regular body text

Bold Indicates a menu or button choice

Command Indicates computer gene ra ted text and prompts

User Input Indicates user input

<hostname> In command syntax, indicates user-specified command line parameters

<variable> In body text, indicates user-specified command line parameters

[BRACKETS] Indicates a key on the keyboard or instrument

Provides relevant additional information

Provides important warning information that may affec t operation of or

maybe a potential threat to the system

Used to tell the reader to

important instructions that are vital to prevent equipment or software

damage

STOP what they are doing and to read

xii UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 13

One

Unpacking and Configuration Veri fication

This chapter provides instructio ns for opening the shipping container and inspecti ng the contents.

When you have completed the procedu res in this chapter you will have confirm e d that the hardware

arrived undamaged, and that everything you ordered is present and configured correctly.

The procedures in this chapter include:

• Unpacking and inspecting the system. See Section 1-1.

• Inspect the system identification label and verify that this is the system you ordered. See

Section 1-2.

• Inspect the system components, verify and record the part numbers. See Section 1-3.

1-1 Unpacking and Inspecting

Your interWAVE system was packed with great care, and all containers were inspected before shipment.

Upon receipt of these packages, immediately inspect the outside of the shipping containers. If there is

any visible damage, insist that a representative of the carrier be present when unpacking the contents.

10000

Carefully inspect the system as it is unpacked. If any damage, such as dents or broken connections, is

noticeable immediately notify the car rier as well as interWAVE Customer Servi ce.

Store the shipping containers for future use. If the unit has to be returned for upgrade or service, the

specially designed shipping containers assure adequate protection for the equipment. If for some

reason the contai ner s ar e n ot r eusa b le or if they are misplaced, please contact interWAVE to order new

containers.

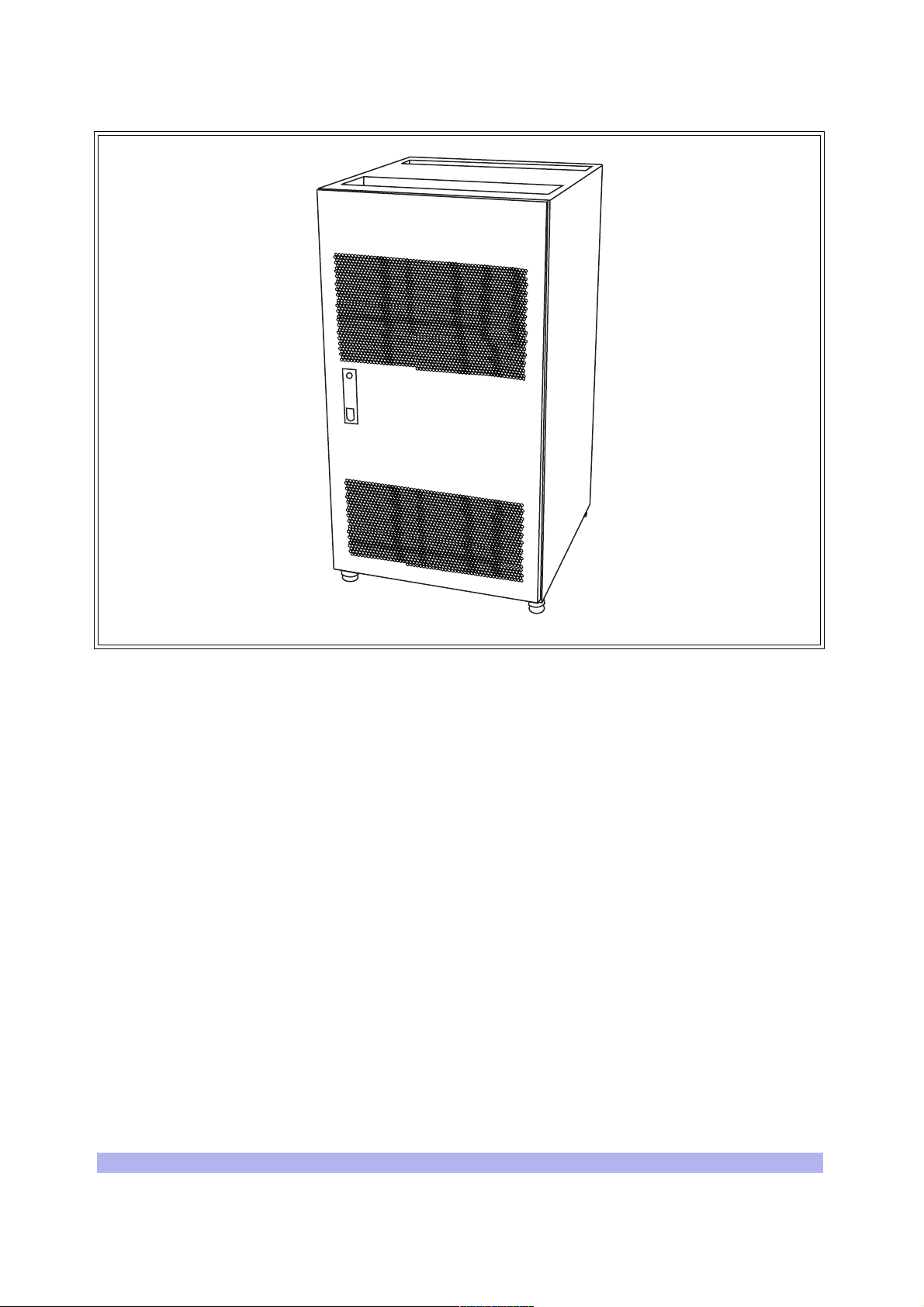

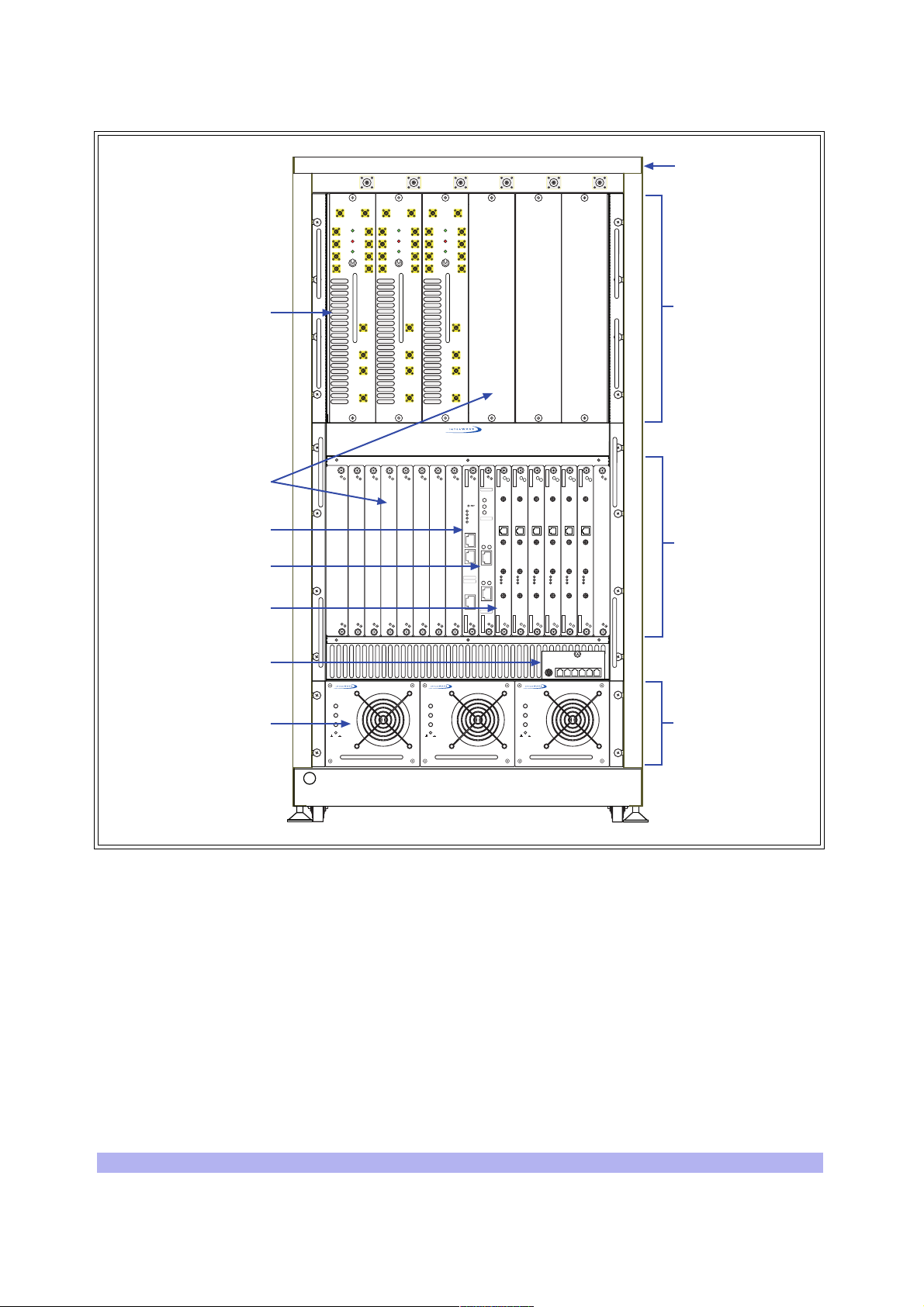

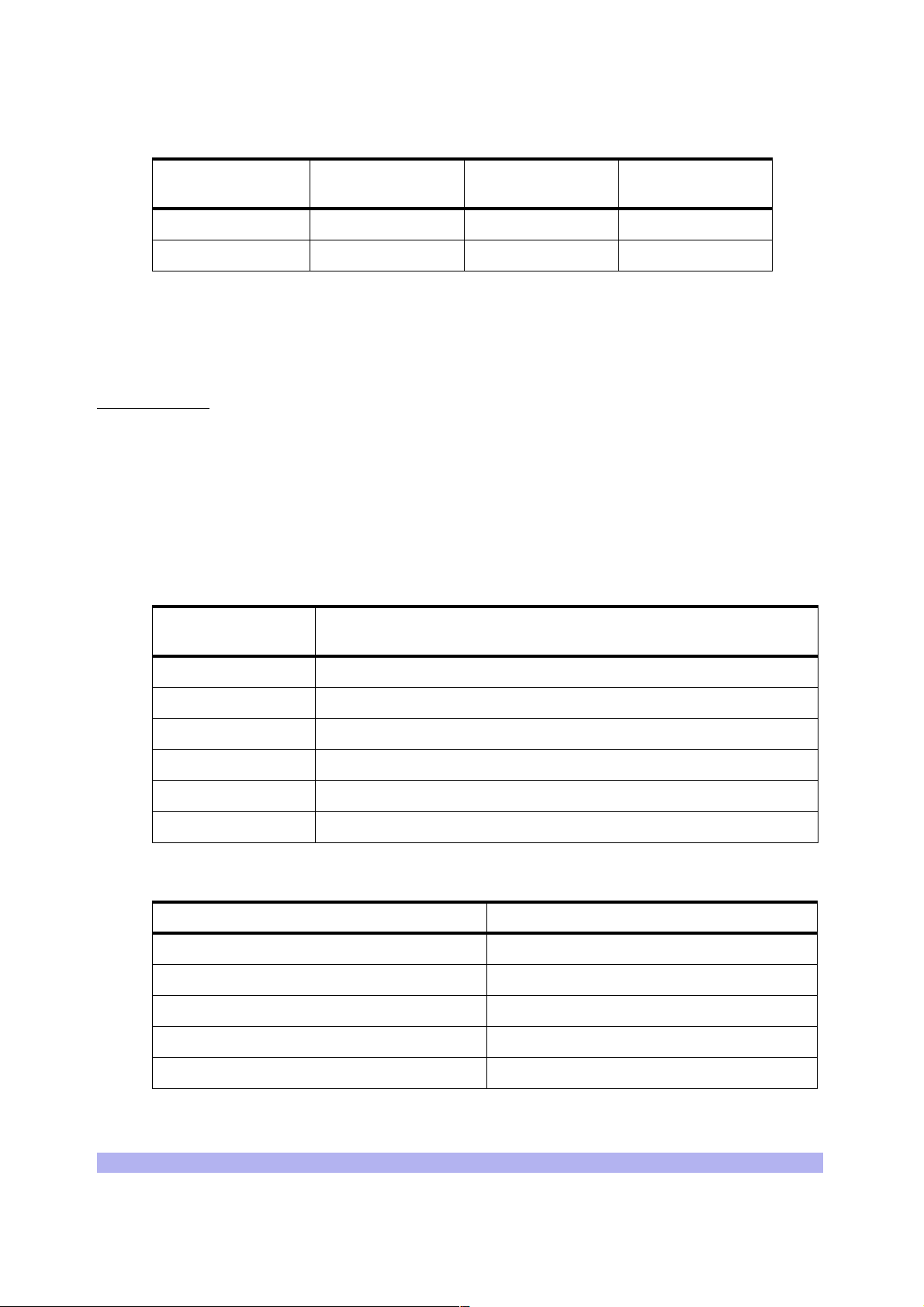

The UltraWAVE BTS is shipped pre-configured in a locking cabinet assembly, shown in Figure 1-1.

Unpacking and Configuration Verification 1

Page 14

Figure 1-1 Locking Cabinet

Doors are provided for access to the front and rear of the internal assemblies. To open the doors:

1 Insert the key provided into the lock and turn to unlock.

2 Depress the lock mechanism to release the door latch handle.

3 Turn the door handle to unlatch and open the door.

IW007302

2 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 15

1-2 Inspect Components and Record Part Numbers

The UltraWAVE BTS is tested with all cards and modules installed in the chassis as ordered by t he

customer. In this section you will:

• Identify and record part and serial numbers

• Determine your system configuratio n

The unit is shipp ed assembled to your location. The as sem bl ed c abi net and subracks are pre-cabled for

your configuration with the exception of the power su pplies which will need to be installe d. The

individual components of the unit include:

• Cabinet (20U) with locking doors and external I/O int erface ports

• RF subrack assembly

• Baseband subrack assembly

• Power supply subrack assembly

• PC cards and blank panels

• RF cards and modules

• Internal cabling

• Power supply modules

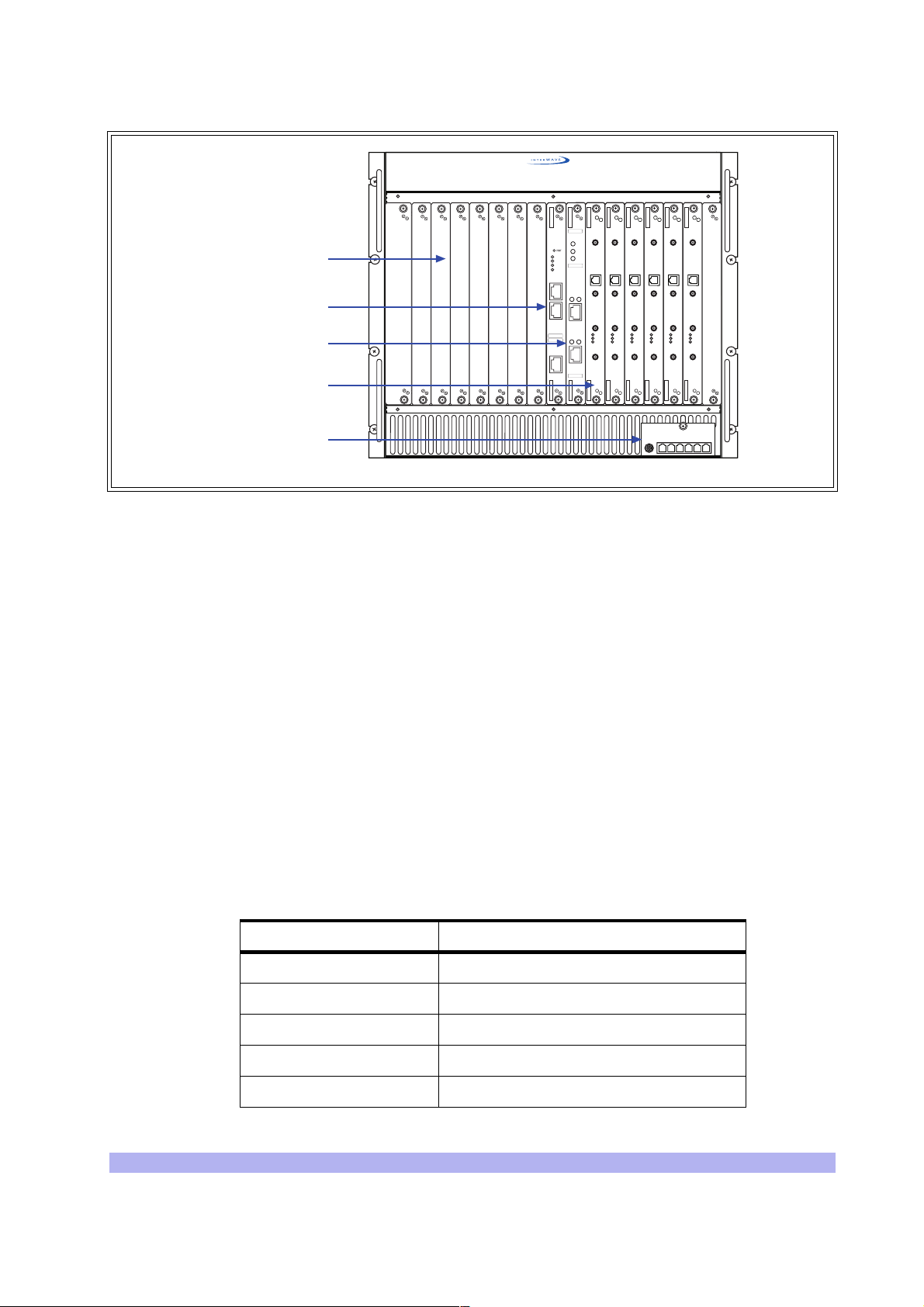

These components appear assembled without internal cabling in Figure 1-2.

Unpacking and Configuration Verification 3

Page 16

01 23 54

ANT

DIV

PWR

FLT

RX1

ON LINE

RX2

ON

RX3

OFF

RX4

MAIN

MAIN

DIV

PWR

FLT

RX1

RX1

ON LINE

RX2

RX2

ON

RX3

RX3

OFF

RX4

RX4

ANT

ANT

ANT

ANT

ANT

MAIN

DIV

PWR

FLT

RX1

RX2

RX3

RX4

RX1

RX1

ON LINE

RX2

RX2

ON

RX3

RX3

OFF

RX4

RX4

Cabinet (20U)

RF modules

Blank panels

Processor card

E1 or T1 trunk card

TRX cards

Clock module

Power supply modules

OUTPUT

OFF ON

RF subrack

TX1

DET

PA1

IN

TX2

DET

PA2

IN

DET

DET

PA1

PA1

IN

TX2

DET

PA2

IN

IN

TX2

DET

PA2

IN

TX1

TX1

012345678

IIIIIIIIIIIIIIIIIIIIIIIII

P/N XXXXXX

PWR

ON

LINE

PWR

FLT

ONLINE

FLT

120 OHM

SCN

ENET

ALARMS

12

CON

PORT 0

ALARMS

IIIIIIIIIIIIIIIIIIIIIIIII

P/N XXXXXX

12

IIIIIIIIIIIIIIIIIIIIIIIII

S/N XXXXXX

PORT 1

IIIIIIIIIIIIIIIIIIIIIIIII

S/N XXXXXX

INPUT

FAULT

OUTPUT

OFF ON

INPUT

FAULT

TX

TX

TX

OUT

OUT

OUT

13 MHZ

13 MHZ

13 MHZ

CLK

CLK

CLK

RX-A

RX-A

RX-A

DET

DET

DET

IN

IN

IN

PWR

PWR

PWR

ON LINE

ON LINE

ON LINE

FLT

FLT

FLT

RX-B

RX-B

RX-B

INPUT

OUTPUT

FAULT

OFF ON

TX

TX

TX

OUT

OUT

OUT

13 MHZ

13 MHZ

13 MHZ

CLK

CLK

CLK

RX-A

RX-A

RX-A

DET

DET

DET

IN

IN

IN

PWR

PWR

PWR

ON LINE

ON LINE

ON LINE

FLT

FLT

FLT

RX-B

RX-B

RX-B

assembly

Baseband subrack

assembly

Power supply

subrack assembly

IW006301

Figure 1-2 UltraWAVE BTS Components

1-2.1 Id entifying the System Configuration

Many configurations of the UltraWAVE BTS are available, from an omni one TRX (O1) to a three sector

two TRX per sector (S222) system. Use this section to verify the configuration of your BTS.

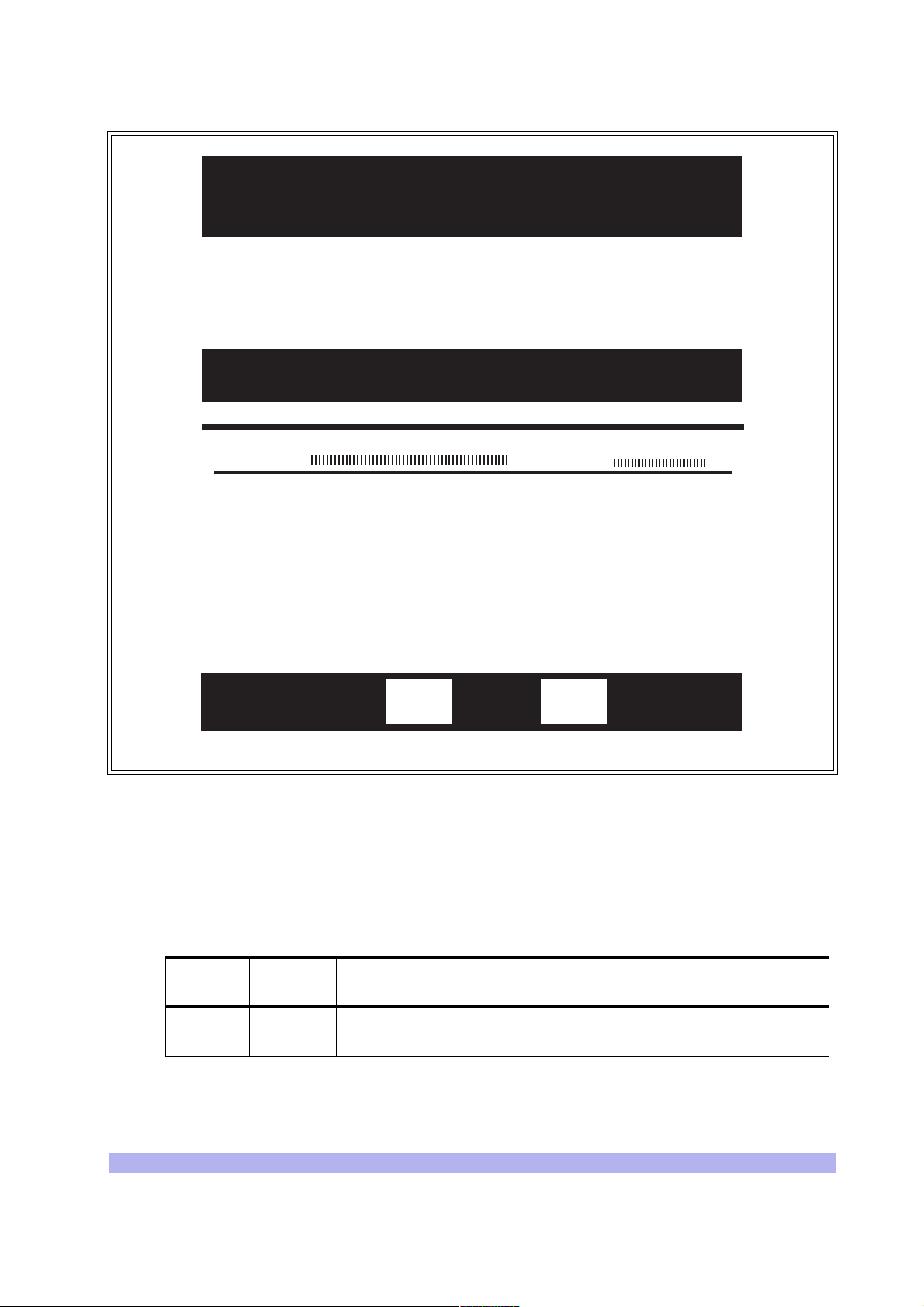

1 Locate the main configuration label on the exterior of your shipping container as shown in

Figure 1-3.

This configuration label details the system configurat ion and all of the modules an d cards

contained in the system.

4 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 17

interWAVE Communications

312 Constitution Drive

Menlo Park, CA 94025-1164 USA

Ship To

Your Company

123 Main St.

Your Town, Province

Country

Equipment List

Model:

part number

xxxxxx-xxx

xxxxxx-xxx

xxxxxx-xxx

xxxxxx-xxx

xxxxxx-xxx

xxxxxx-xxx

AUACS241855075223A

module or card description

module or card description

module or card description 00xxxxxxx

module or card description 00xxxxxxx

module or card description 00xxxxxxx

module or card description 00xxxxxxx

module or card description 00xxxxxxx

- UltraWAVE BTS

SALES ORDER# XXXXXX

S/N:

000xxxxx

serial number

00xxxxxxx

Box

Figure 1-3 Main Configuration Label

2 Locate the model number and using Table 1-1 decode the first seven digits for the chassis

type and system c onfiguration of th e BTS.

The first four letters denote the type of interWAVE system, in this case an UltraWAVE BTS.

The next two o r three digits denote the BTS configuration.

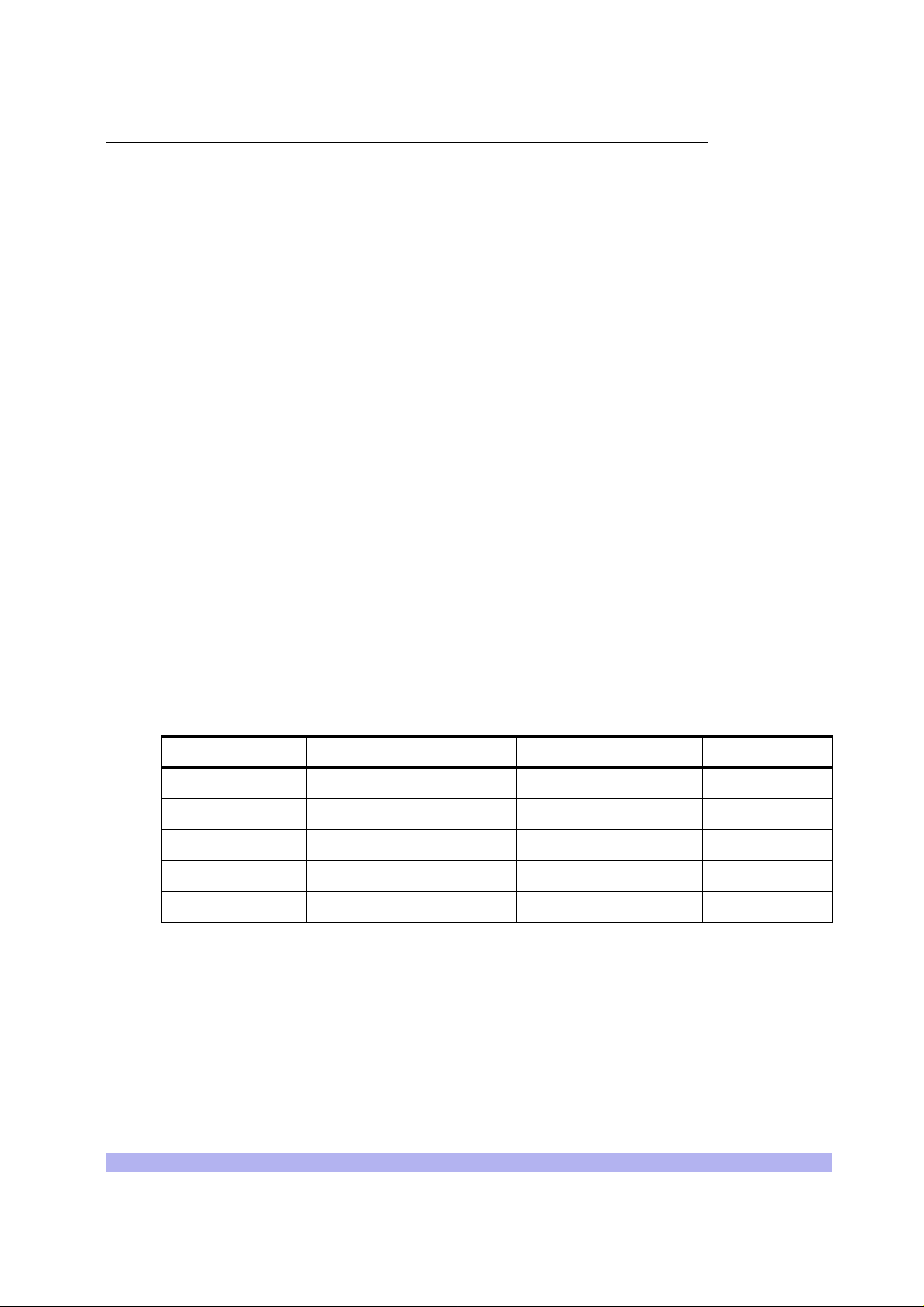

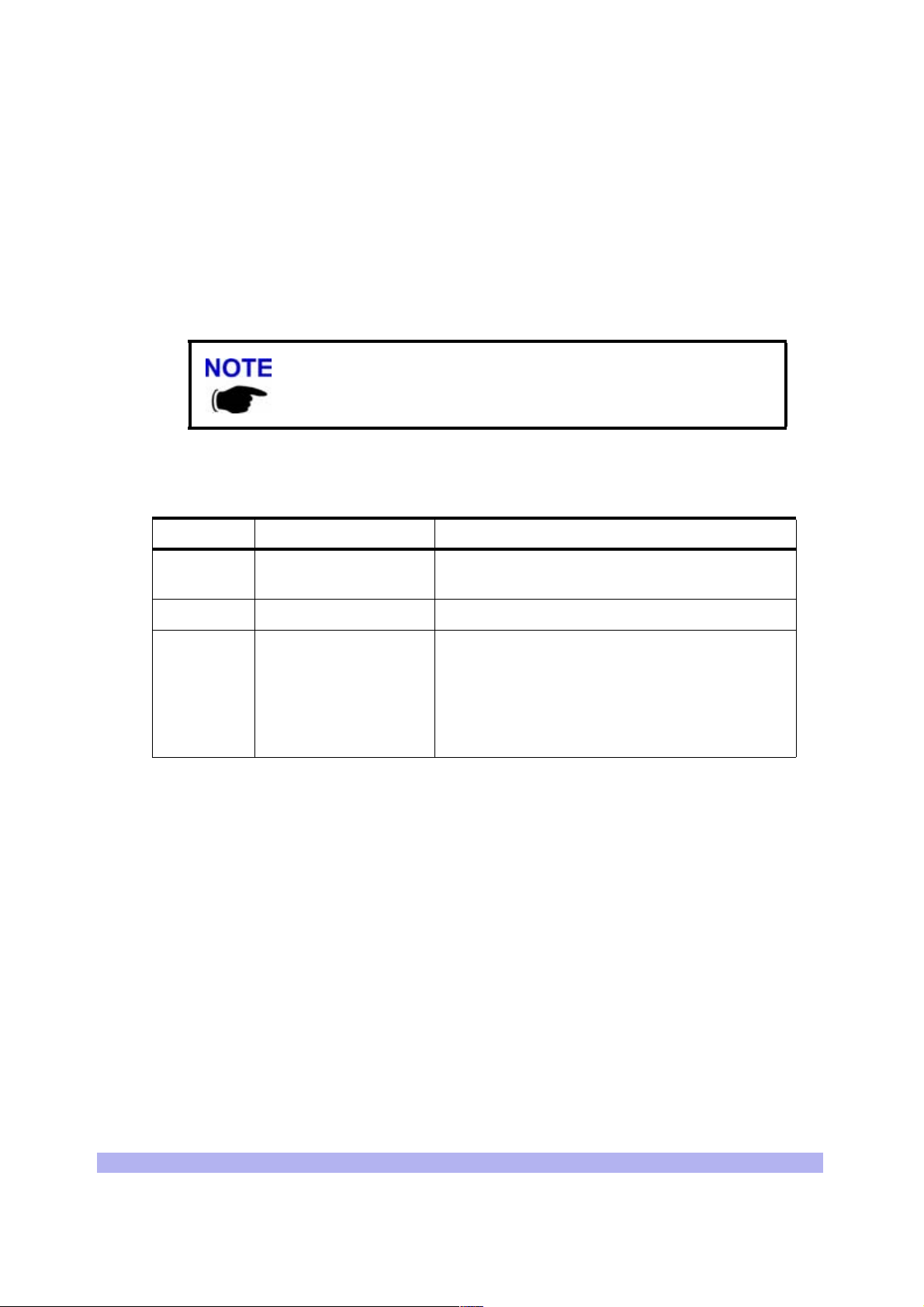

Table 1-1 Model Number Details

Digit

Location

First four

letters

Contents Configuration

AUAC UltraWAVE BTS

of

IW007301

Unpacking and Configuration Verification 5

Page 18

Table 1-1 Model Number Details (continued)

Digit

Location

Next two

or three

digits

Contents Configuration

O1 Omni single TRX (O1); 50 watts, 2 antennas

O2 Omni two TRX (O2); 50 watts, 2 antennas

O3 Omni three TRX (O3); 25 watts, 2 antennas

O4 Omni four TRX (O4); 25 watts, 2 antennas

O5 Omni five TRX (O5); 15 watts, 2 antennas or 25 watts, 3 antennas

O6 Omni six TR X (O6); 15 watts, 2 antennas or 25 watts, 3 antennas

S11 Two sector, one TRX per sector (S11); 50 watt, 4 antennas

S13 Three sector, one TRX per sector (S111); 50 watt, 6 antennas

S21 Two sector, two TRXs per sector (S22); 50 watt, 4 antennas

S22

S23

S24 Three sector, two TRXs per secto r (S 22 2); 50 watt, 6 an tenn as

Three sector, two TRXs in one sector and one TRX in two sectors

(S211); 50 watt, 6 antennas

Three sector, two TRXs in two sectors and one TRX in one sector

(S221); 50 watt, 6 antennas

S32

S33 Two sector, three TRXs per sector (S33); 25 watt, 4 antennas

S41

Two sector, th ree TRXs in one sector and two in the other (S32); 25

watt, 4 antennas

Two sector, four TRXs in one sector, two in the ot her (S42); 25 watt,

4 antennas

Using the example in Figure 1-3, the model number is AUACS24 which corresponds to an

UltraWAVE BTS configured for three sectors with two TRXs per sector (S222).

3 Record your model number and co nf iguration in the Installation Checklist.

1-2.2 Identifying Module Part and Serial numbers

The factory plac es up to four configuration labels on the f r ont of each BTS card, module, and ch a ssis to

help identify the system configuration . The labels identify the:

• Part description

• Part number

• Revision or dash number

• Serial number

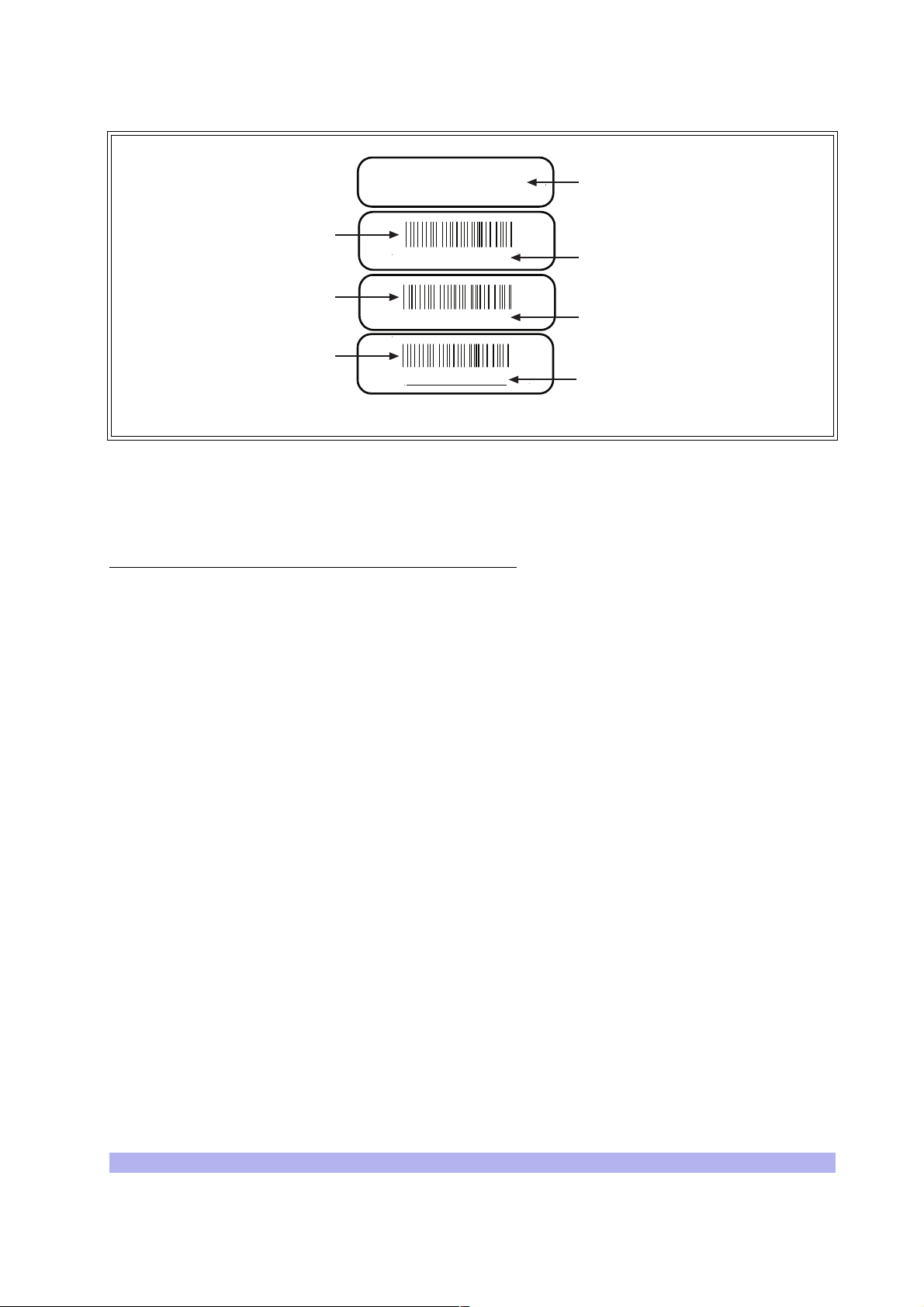

An example of the configuration labe ls appears in Figure 1-4:

6 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 19

E1

LH, 2 PORT, ETH

Barcode identifier of

the part number

P/N 340127

Barcode identifier of

the rev number

-200

Barcode identifier of

the serial number

S/N 00719500

Figure 1-4 Sample Configuration Labels

The part numbers on the BTS car ds and mo dules s hould be compar ed to the m ain confi gurati on label as

instructed in the following sections.

Part Numbers, Revision Numbers and Serial Numbers

The verification proce dures requ ire y ou to re cor d each components’ part number, revision number and

serial number. These numbers are displayed on labels attached to th e front plate of each component:

Description of part

Part number

Dash or revision number

Serial number

IW048901

• Part Number -- The part number identifies the type of c omponent. All identical components

have the same part number. Part numbers use the format:

P/N NNNNNN

• Revision Number -- Revision numbers record minor changes in design. Revision numbers

use the format:

-NNN

• Serial Number -- Each individual component has its own unique serial number. Serial

numbers use the format:

S/N NNNNNNNN

Unpacking and Configuration Verification 7

Page 20

1-3 Verifying and Documenting Cards and Modules

The cabinet contains three subrack assemblies:

• The RF subrack contains the BTS RF modules which are responsible for RF power amplifica-

tion, duplexing and combining when requi r ed for each c onf iguration.

• The baseband subrack assembly contains the main processing, trunking and TRX cards.

• The power supply subrack assembly contains up to three power supply modules.

1-3.1 Required Equipment

To verify and record your system configuration, you need:

• A copy of the Shipping Checklist . It should be one of the papers inside the shipping

container.

• A copy of Checklist 2

1-3.2 RF Subrack Assembly

The RF subrack pr o vid es s i x slots, starting on the left wi th sl ot 0. Depending on your BTS configurat i on ,

up to three slots will be required for RF modules. These modules are shipped pre-installed and cabled

from the factory.

1 Locate the configuration part and serial numbers on your RF modules. Figure 1-4 illustrates a

sample of these labels.

2 Write down the pa rt numbe r, re vis ion n umber a nd seri al number i n the Ins talla tion Check list.

3 Compare the part numbers to the RF module part numbers on the main configuration label

and shipping ch ecklist.

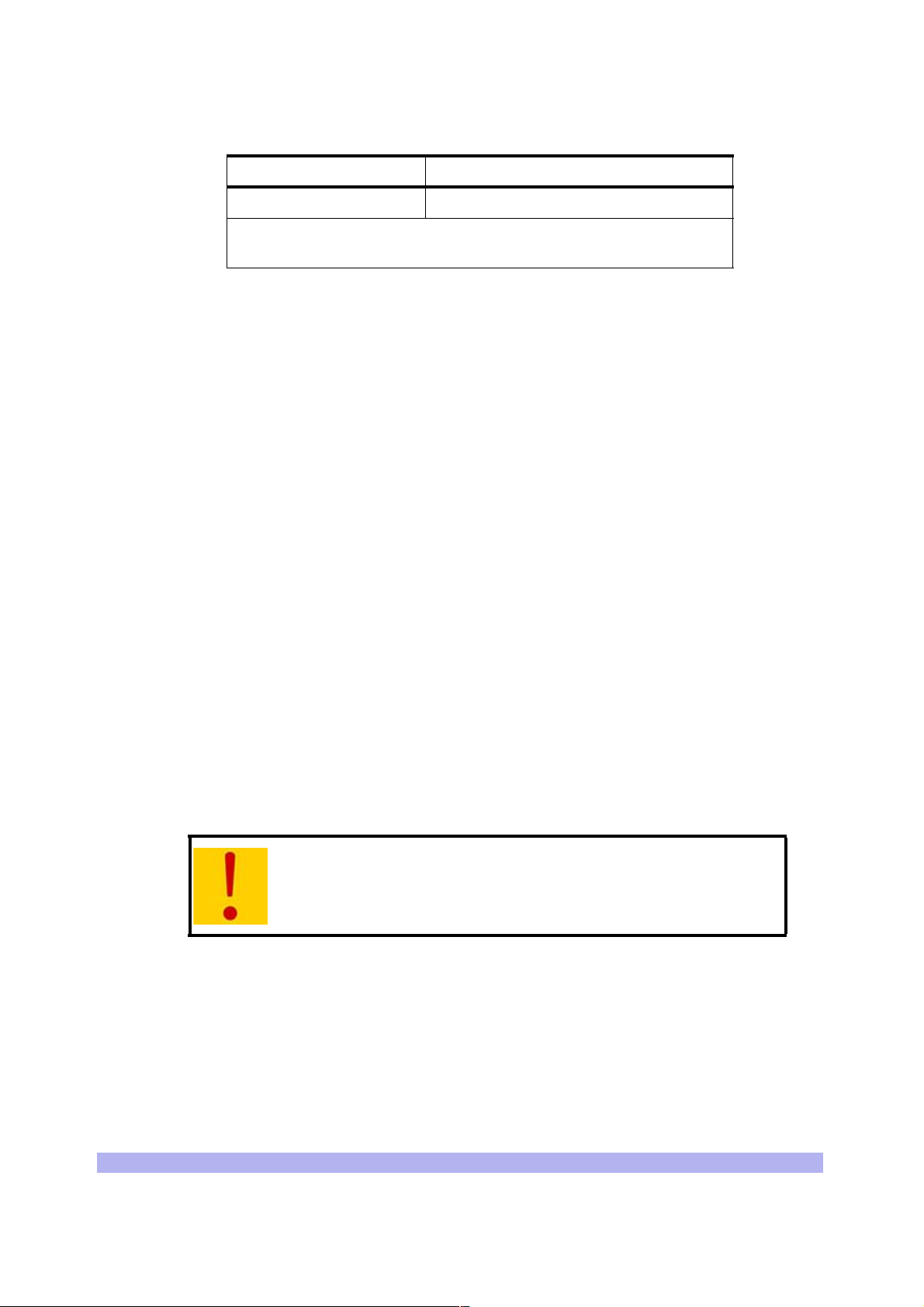

1-3.3 Baseband Subrack Assembly

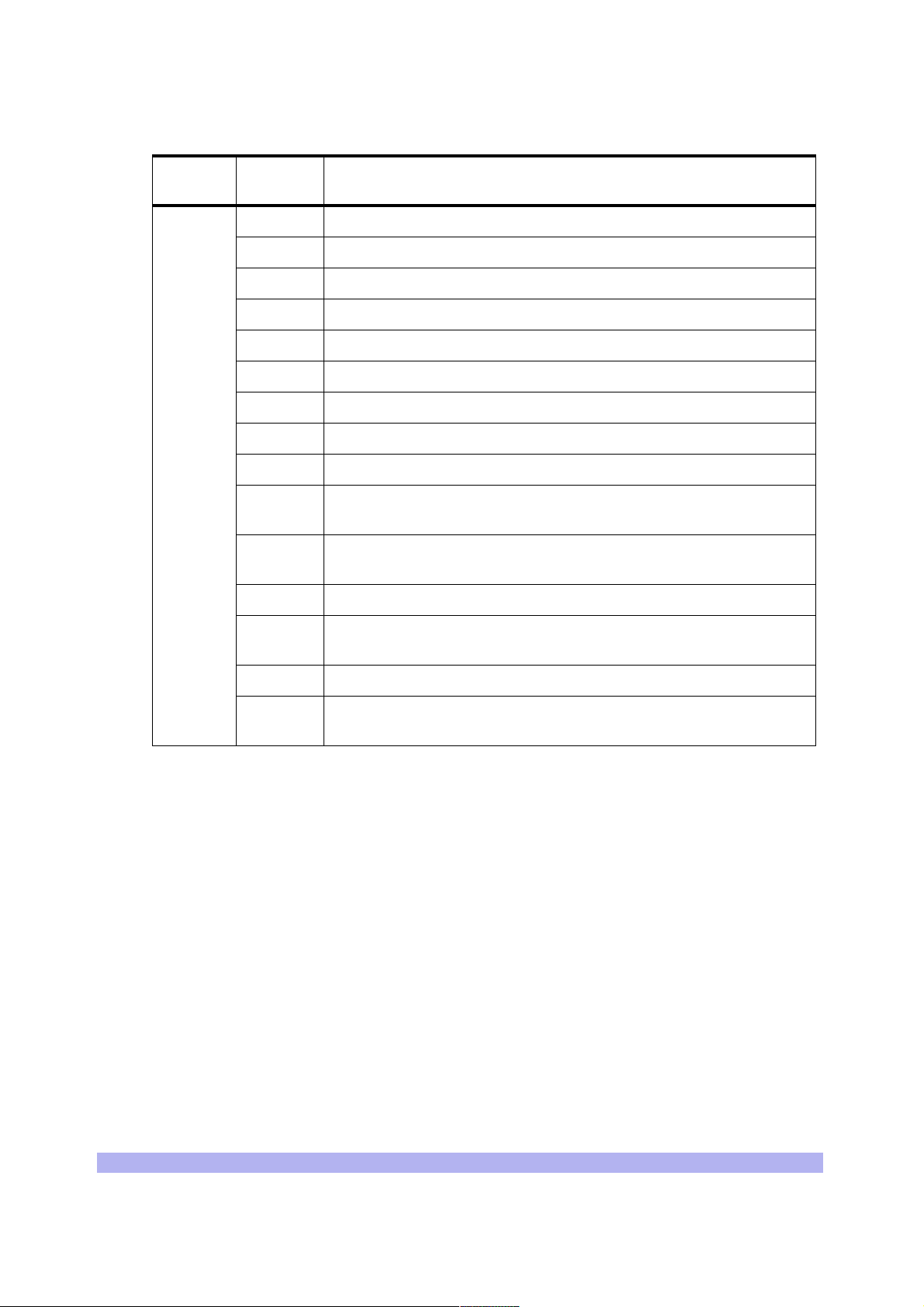

The baseband subrack provides nine slots, starting on the left with slot 0. The following table shows the

card cage assignments in the baseband subrack assembly:

Table 1-2 Card Cage Slot Assignments

Card Slots

Processor card 0 1 This is an ICP processor card.

E1 or T1 1 1 E1 or T1 card provides 2 E1 or T1 lines

TRX 2, 3, 4, 5, 6, 7 1 Each TRX manages 8 radi o channels.

Use the following procedure to identify and record your system components. See Figure 1-5 for

component locations:

Width

(Slots)

Function

8 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 21

Blank panels

Processor card

E1 or T1 trunk card

TRX cards

Clock module

Figure 1-5 Baseband Subrack Assembly

1 Locate slot 0 and write down the processor card part number, revision numbe r and serial

number in the installation checklist. The processor card part number for the BTS is 340150.

2 Slot 1 should contain an E1 or T1 card. Verify that the part number on the card identifies the

card as the correct type, as specified by the main configuration label, and write down the

part number, re vision number and serial number in the installation checklis t.

012345678

IIIIIIIIIIIIIIIIIIIIIIIII

P/N XXXXXX

PWR

ON

LINE

PWR

FLT

ONLINE

FLT

120 OHM

SCN

ENET

ALARMS

12

CON

PORT 0

ALARMS

IIIIIIIIIIIIIIIIIIIIIIIII

P/N XXXXXX

12

IIIIIIIIIIIIIIIIIIIIIIIII

S/N XXXXXX

PORT 1

IIIIIIIIIIIIIIIIIIIIIIIII

S/N XXXXXX

TX

TX

TX

OUT

OUT

OUT

13 MHZ

13 MHZ

13 MHZ

CLK

CLK

CLK

RX-A

RX-A

RX-A

DET

DET

DET

IN

IN

IN

PWR

PWR

PWR

ON LINE

ON LINE

ON LINE

FLT

FLT

FLT

RX-B

RX-B

RX-B

TX

TX

TX

OUT

OUT

OUT

13 MHZ

13 MHZ

13 MHZ

CLK

CLK

CLK

RX-A

RX-A

RX-A

DET

DET

DET

IN

IN

IN

PWR

PWR

PWR

ON LINE

ON LINE

ON LINE

FLT

FLT

FLT

RX-B

RX-B

RX-B

IW007303

The BTS will contain one of three types of E1 or T1 cards:

• 75 Ohm E1 -- Part Number 340122-075

• 120 Ohm E1 -- Part Number 34 0122-120

• 100 Ohm T1 -- Part Number 34 0122-100

3 Verify that your system has the correct number of TRX cards as determined by the main

configuration label.

4 Using Table 1-3, verify that they are in the correct slots. TRX cards fill the card cage

assembly from left to r i ght . For exa m ple, i f y our con fi gur a ti on ha s th r ee TRX s , slots 2, 3 and

4 would contain the TRXs.

Table 1-3 TRX Slot Assignments

TRX Card # Slots

12

23

34

45

56

Unpacking and Configuration Verification 9

Page 22

Table 1-3 TRX Slot Assignments

TRX Card # Slots

67

Note: Systems equipped with less than six TRXs will have blank panels

covering the empty slots.

5 For each TRX card, write down the part number, revision number and serial number in the

installation checklist.

6 Verify that all empty slots have blank panels covering them.

7 Check the shipping invoice and verify that the system has the correct number of power

modules (2 or 3). If the third power module is not installed, verify that the slot is covered by

a blank panel.

8 For each power mo dule, write down the part numb er, revision number and seri a l n u m ber in

the installation checklist.

9 Verify that the clock module is installed. Write down its part number, revision number and

serial number in the installation checklist.

10 Verify all empty sl ots are covered by blank panels. These are necessary for cooling and to

meet RF emission standards.

1-4 Internal Cabling Overview

Cabling inside the BTS cabinet i s routed to connectors accessible on the outside of the cabinet

assembly. The internal cabling connects the E1 or T1 card to the external interface cable plate interface.

Antenna connections are also routed interna lly to provide an N-type connector on the top of the

cabinet.

The internal cabling of the BTS depends on the configur ation ordered by th e c ustomer. It is completed

by the manufacturer. Due to its complexity, it is not recommended for you to move or disconnect

internal cabling. Schematics of the int er nal RF cabling are provided in Appendix 1.

Extreme care should be used when working around SMA cables, as

misalignment or loosening of the cable with the connectors can

damage both parts and degrade the cable's performance.

Proceed to Chapter Two to install your BTS.

10 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 23

Two

This chapter provides instructions for installing and configuring the hardware. This includes:

• Verifying site requirements

• Mounting the chassis in i ts permanent location

• Configuring the E1 or T1 trunk card(s)

• Making the external connections to the BTS

2-1 Site Requirements

Before a si te is chosen or equipment installed, a site survey must be carried o ut. The site survey

checklist assists the surveyor with the inspection and the collection of site specific information such as

environmental conditions, electrical requirements, and mechanical requirements

The site survey checklist must be completed before installation begins. Note that the necessary steps

for site readiness are listed in Checklist 1.The interWAVE Network Implementation Manual

additional det a iled site requirements.

Installation

20000

provides

The site readiness c heck l i st as sists the field service engineer or operator to ensure that the site is ready

for equipment installatio n. It includes information about:

• Environmental conditions

• Electrical requirements

• Chassis require m ents

The site readiness checklist is located in Checklist 1, it must be completed as part of the installation

process.

2-1.1 Environmental Conditions

The BTS is designed to operate indoors only. To facilitate long-term operability an d durability of the

BTS, observe specific environmental constraints.

Before installing the BTS, ensure that the operating environment maintains a temperature within the

range shown in Table 2-1.

Make sure the ambient temperature around the unit (which may be

higher than the room temperature) is within the limit specified for the

unit.

Installation 11

Page 24

Table 2-1 Operating Environment

Humidity

(non-condensing)

Maximum 90% 55 degrees 131 degrees

Minimum 10% -5 degrees 23 degrees

2-1.2 Electrical R equirements

The BTS is specifie d to op er at e on either AC or DC power. Requirements for the BTS are dependent on

the number of TRX cards supported.

Power Options

Main power supply options for the BTS are:

• 110 VAC, 50-60 Hz

• 220 VAC, 50-60 Hz

• -48 VDC

Table 2-2 shows the typical current requirements for the BTS AC power mains.

Table 2-2 Input Power Requirements

Product

configuration

Temperature

(Celsius)

Requirement for 120 or 220 VAC

Temperature

(Fahrenheit)

One TRX 410 watts

Two TRXs 715 watts

Three TRXs 1010 watts

Four TRXs 1320 watts

Five TRXs 1630 watts

Six TRXs 1925 watts

Table 2-3 Power Specifications

Power Requirements Specification

BTS voltage range: 115 VAC 90 to132 VAC, 47 to 63 Hz

BTS power protection: 115 VAC Dedicated 20 amp circuit breaker

BTS voltage range: 230 VAC 187 to 264 VAC, 47 to 63 Hz

BTS power protection: 230 VAC Dedicated 10 amp circuit breaker

BTS voltage range: -48 VDC -41 to -60 VDC

12 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 25

Table 2-3 Power Specifications (continued)

WHEEL_FV

CAB_F

RUBFE

RUBFE

Power Requirements Specification

BTS power prote ction: -48 VDC dedicated 45 amp fuse/circuit breaker

2-1.3 Chassis Requirements

Before installing the BTS, ensure that adequate clearing space is allowed around the unit. The BTS

should be installed away from salt spray and in an area where there are min imal vibrations. Table 2-4

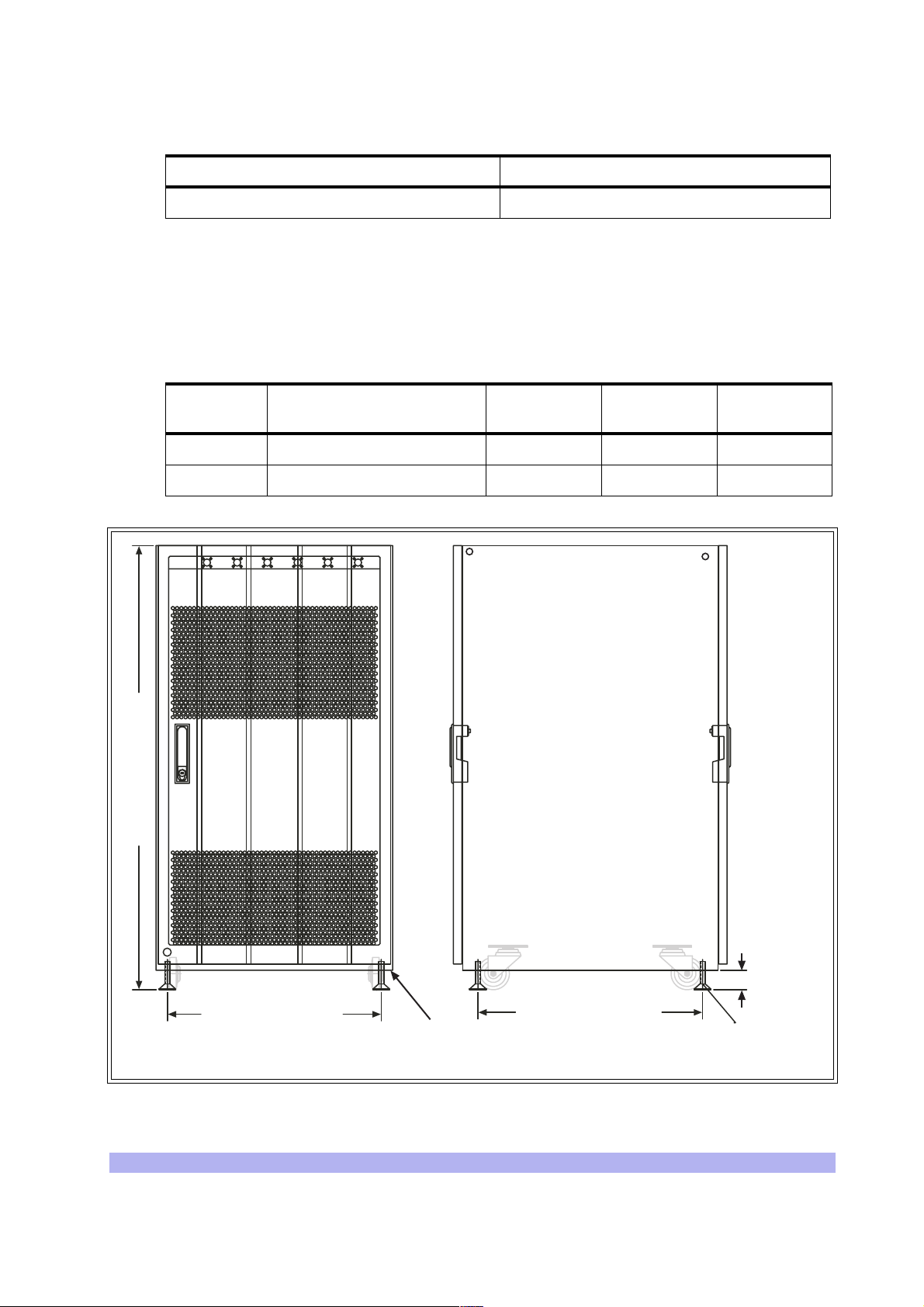

shows the dimensions of the BTS. For detailed cabinet dimensions, see Sect ion 2-2.

Table 2-4 BTS Cabinet Dimensions

Weight

(Maximum Configuration)

Height Width Depth

Metric 213 Kg 105.1cm 56.0 cm 64.77 cm

Imperial 470 lbs 41.38 inches 22.05 inches 25.5 inches

10 32 54

41.375 in. [105.09 cm]

DOOR_

DOOR_

FV

CAB_F

V

WHEEL_FV

RUBFE

ET

WHEEL_FV

RUBFE

ET

19.925 in. [50.61 cm]

SV

CAB_S

WHEEL_SV

V

RUBFE

ET

20.925 in. [53.15 cm]

M10 Tap Holes

(each corner)

WHEEL_SV

RUBFE

ET

M12-1.75

(each corner)

DOOR_

SV

1.808 in

[4.59 cm]

IW008301

Figure 2-1 Cabinet Dimensions

Installation 13

Page 26

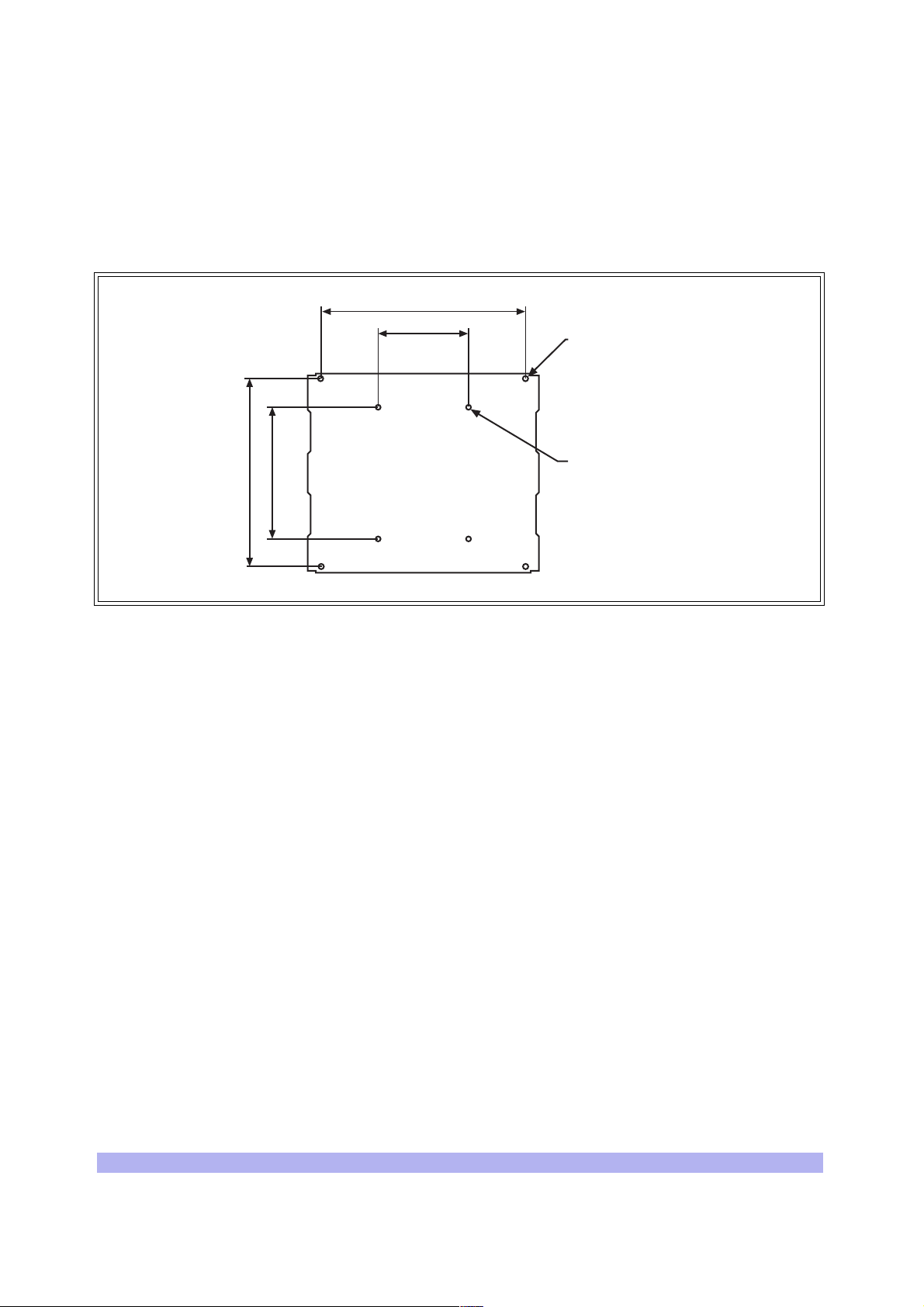

2-2 Mounting the BTS Chassis

The BTS chassis sho uld be mount ed on a concre te pa d of s uffic ien t densi ty t o supp ort t he weig ht of t he

cabinet assembly. Alignment pins may be installed in the concrete pad at the locations provided in

Figure 2-2. The alignment pins should be 0.5 inch (1.27 cm) in diameter and protrude from 4.1 in. to

4.4 in. (10.41 cm to 11.18 cm) from the concrete pad.

22.63 in. [57.48 cm]

[25.40 cm]

14.567 in.

[37.00] cm

20.898 in. [53.08 cm]

10.00 in.

Rubber feet

Mounting hole

M16-2 x4 places

Alignment holes

0.551 in. [1.40 cm]

IW021301

Figure 2-2 Cabinet Footprint

Enough clearance should be provided from the front and back of the cabinet to fully open the doors.

This requires at least 24 inches (61 cm) from the front and rear doors. The minimum clearance required

on either side of the cabinet is 4.5” (11.4 cm) and the minimum clearance required below the cabinet is

1.8 inches (4.59 cm). The mounting site should also have ample clearance for the trunk and antenna

cables to be attached to the connectors at the top of the cabinet.

The required footprint for your cabinet installation must be at least 73.5 inches (186.7 cm) by 31.5

inches (80 cm). Be sure there is sufficient airflow around the unit.

14 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 27

20.547 in.

[52.19 cm]

Tapped hole

M10-1.5 x4 places

22.280 in.

[56.59 cm]

0.750 in.

[1.91] cm

40.904 in.

[103.90 cm]

21.280 in.

[54.05 cm]

Tapped hole

M10-1.5

x4 places

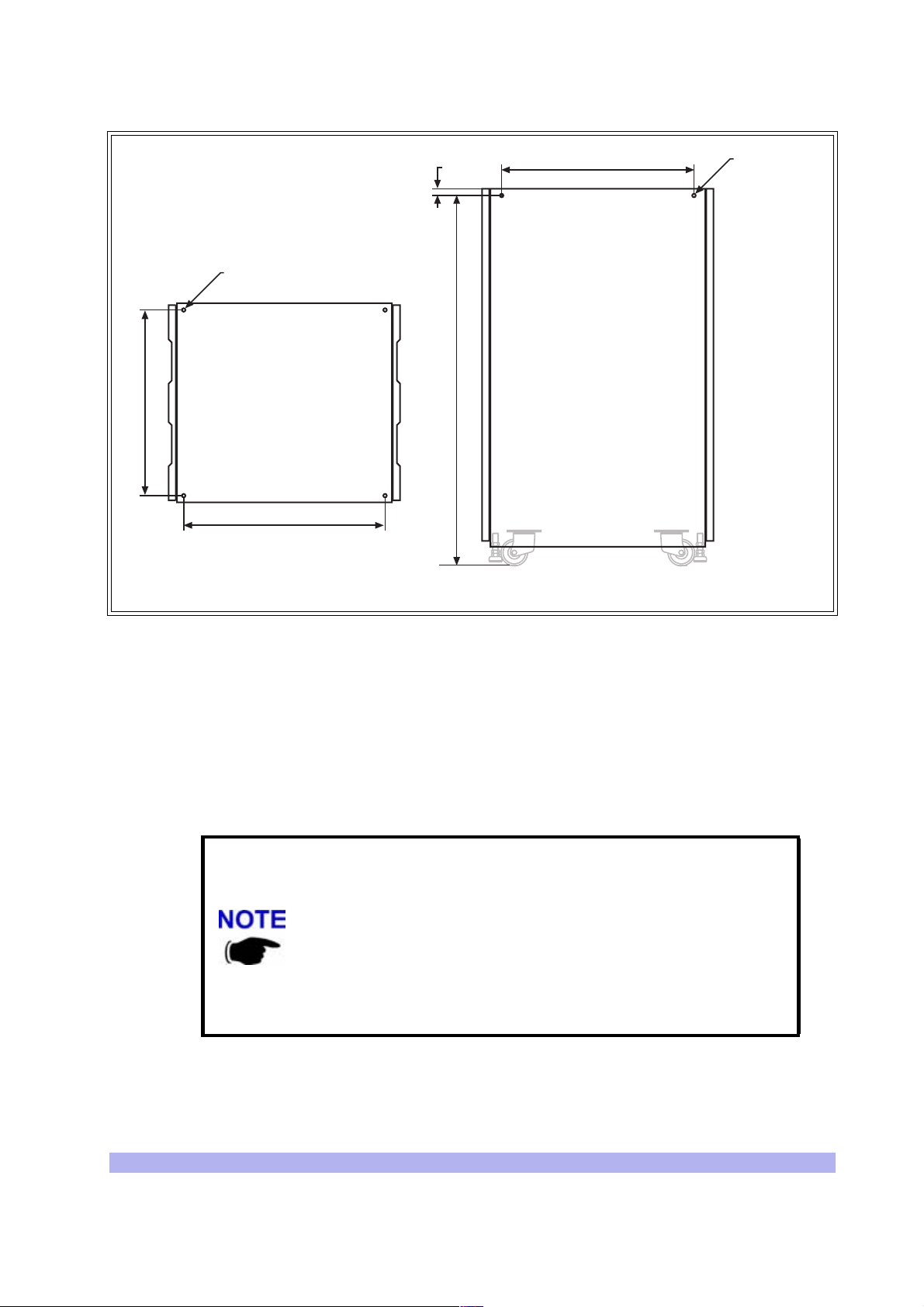

Figure 2-3 Cabinet Dimensions

The cabinet is mounted on casters and may be carefully moved from the unpacking site to its final

mounting location. The cabinet has four rubber which will raise the cabinet off of the castors. The

dimensions for the engagement height of the rubber feet is shown in Figure 2-1. If you have alignment

pins mounted in your concrete pad, use the procedure in this section.

If you do not have the alignment pins, Figure 2-3 illustrates the location of eight M10 tap holes which

may be used for addition al mount ing stu ds, eye hooks or angle bra ckets for securi ng t he BTS cabinet in

its final location.

• Make sure the ambient temperature around the unit (which may be

higher than the room temperature) is within the limit specified for the

unit.

• Make sure there is sufficient airflow around the unit.

• Make sure electrical circuits are not overloaded - consider the

nameplate rating of all the connected equipment, and make sure you

have over current protection.

• Make sure the equipment is properly grounded.

• Make sure no objects place on top of unit.

Cabinet (side)Cabinet (top)

IW021302

Installation 15

Page 28

Required Materials

• Angle brackets

• Four M10 machine screws and washers

Required Tools

• 15 mm open end wrench

Installation Instructions

1 Move the cabinet into its final location. If using alignment pins to prevent movement, move

the cabinet into position over the pins.

2 Lower the each of the rubber feet until each reaches the concrete pad.

3 Using the 15 mm open end wrench, lower each foot until the casters are raised from the

concrete floor, approximately 0.25 in. (0.65 cm).

4 Remove the casters from the bottom of the cabinet.

5 Lower the cabinet to within 4.1 in. to 4.4 in. (10.41 cm to 11.18 cm) of the concrete pad. If

you are using alignment pins, lower the cabinet until the pins should enter the alignment

holes no more than 0.25 in. (0.6 cm). Do not lowe r the cabinet too far over alignment pins

as they may puncture internal components.

6 Secure locking nuts on foot studs.

7 Secure the cabinet using customer-provided 10 mm studs.

Rack Mount Advisory

To prevent bodily injury when mounting or servicing this unit in a rack, you must take specia l

precautions to ensure that the system remains stable. The following guidelines are provided to ensure

your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the top

with the heaviest comp onent at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting or

servicing the unit in the rack.

Attention: Pour év iter tou te bl essure corp orell e pend ant l es opér ati ons de mo ntage ou de ré parat ion de

cette unité en casier, il convient de prendre des précautions spéciales afin de mainten ir la stabilité du

système. Les directives ci-dessous sont destinées à assurer la protection du personnel :

You may use the additional M10 tap holes to secure the cabinet as

site-specific conditions allow.

• Si cette unité constitue la seule unité montée en casier, elle doit être placée dans le bas.

16 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 29

• Si cette unité est montée dans un casier partiellement rempli, charger le casier de bas en

haut en plaçant l'élément le plus lourd dans le bas.

• Si le casier est équipé de dispositifs stabilisateurs, installer les stabilisateurs avant de monter

ou de réparer l'unité en casier.

Warnung: Zur Vermeidung von K örp erverletzung beim Anbringen oder Warten dieser Einheit in einem

Gestell müssen Sie besondere Vorkehrungen treffen, um sicherzustellen, daß das System stabil bleibt.

Die folgenden Richtlinien sollen zur Gewährleistung Ihrer Sicherheit dienen:

• Wenn diese Einheit die einzige im Gestell ist, sollte sie unten im Gestell angebracht werden.

• Bei Anbringung dieser Einheit in einem zum Teil gefüllten Gestell ist das Gestell von unten

nach oben zu laden, wobe i das schwerste Bauteil unten im Gestell anzubringen ist.

• Wird das Gestell mit Stabi lisierungszubehör geliefert, sin d zuerst die Stabilisatoren zu in stall-

ieren, bevor Sie die Einheit im Gestell anbringen oder sie warten.

Installation 17

Page 30

2-3 Configuring the E1 or T1 Trunk Card

This section describes how to configure E1 or T1 trunk cards.

These procedures designed for E1 or T1 cards that are shipped pre-configured in a system. To

configure E1 or T1 card s that a re ship ped as confi gured or unconfigured replacements, see Ap pendix 1.

Your system is shipped from the manufacturer configured with the correct cards for your site-specific

application. These can be 100 Ohm T1, 75 Ohm E1, or 120 Ohm E1. All cards are shipped with th e

appropriate connectors.

Cable runs of greater than 600 meters (1968 feet) are not supported

directly from the card. If you are attempting a longer cable run between

interWAVE chassis please contact Customer Service to determine if you

need a repeater for your application.

Table 2-5 list s the cards and the procedures that apply to each card type.

Table 2-5 Trunk Cards and Procedures

Label Description Operation

75 Ohm 75 Ohm E1 board

120 Ohm 120 Ohm E1 Board No configuration is required

100 Ohm 100 Ohm T1 Board

Set the ground to the Transmit or Receive side

using the jumpers. See Section 2-3.1

Configure the DIP switch based on cable length

to the DSX-1 demarcation point. See

Section 2-3.2.

NOTE: No configuration is required unless

connecting to a DSX1 demarcation point greater

than 133 ft.

2-3.1 Configure Ground Jumpers on 75 Ohm E1 Cards

Two types of dual port 75-Ohm E1 cards exist. They are differentiated only by their connector types—

either BNC or RJ-45 — on the front pa nel of the card.

1 Open the front cabinet door and locate the 75 Ohm E1 card in the baseband subrack

assembly.

2 Identify your E1 card and proceed to the appropriate subsection. For RJ-45 cards, continue

with the procedure below. For BNC cards, proceed to “BNC Connector Cards” on page 22.

18 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 31

PWR

ON

LINE

FLT

ALARMS

12

E1-0

PWR

ON

LINE

FLT

RS-232

RX

Figure 2-4 Identify 75 Ohm E1 Cards

RJ-45 Connector Cards:

1 Ensure that anti-static precautions are taken.

2 Make note of the orientation of the cables and disconnect them from the selected card.

3 Using a Phillips screwdriver, fully loosen the two screws located at the top and bottom of the

card.

PORT 0

ALARMS

12

PORT 1

RJ-45

E1-1

BNC

IW093203

TX

RX

TX

4 Remove the card by firmly pulling the two white tabs locat e d at the top and bottom of the

card.

5 See Figure 2-5 to locate jumpers P8 through P11.

6 Set the signal grounding to the Transmit or Receive Side.

Jumpers P8, P9, P10 and P11 control the signal grounding. Placing the jumper across Pins 1

and 2 sets the corresp onding ground; otherwise the jumper shou ld be pl a ced a c ros s Pi ns 2

and 3.

The following table shows the jumper assignments:

Installation 19

Page 32

Table 2-6 Ground Jumpers

Ground Selection Port Jumper Positions

Receive Side

Transmit Side

Port 0 P8 = 1 to 2 P9 = 2 to 3

Port 1 P10 = 2 and 3 P11 = 1 and 2

Port 0 P8 = 2 to 3 P9 = 1 to 2

Port 1 P10 = 1 and 2 P11 = 2 and 3

interWAVE recommends grounding the receive (RX) side on 75 Ohm boards.

Only one side of the transmission link should be grounded. To ensure

that only the one side is grounded you should check the settings at the

far end of the E1 transmission link when possible. These settings should

be identified by experie nced personnel.

7 Place the card into the slot and slide in the card until it completely rests inside the slot. Push

the card firmly into place.

8 Using a Phillips screwdriver, tighten the two captive screws into the chassis through the

trunk card.

20 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 33

Figure 2-5 shows the location of the grounding jumpers

J7

12 435678

ON

RX

Ground

Port 0

Ground

RX

Ground

Port 1

Ground

TX

TX

RJ45

RJ45

P8P11P10 P9

2940

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE FUSE

FUSE

555-

RELAY

+

RELAY

+

RELAY

+

RELAY

+

2940

555-

NONC

NONC

NONC

NONC

1:1.36

PE68822

1:2

1:2

PE68822

1:1.36

Jumper

Item No.0015

61

X

T

41

61

X

T

41

80

RX

BT-8370

80

RX

BT-8370

1

..... HOST .....

21

1

..... HOST .....

21

Jumper Position 1,2

For P8-P11

IW068004

Figure 2-5 Ground Jumpers (P8 through P11)

Installation 21

Page 34

BNC Connector Cards

By placing a jumpe r between pins 1 a nd 2 of headers P4 (port 1) and P6 ( port 2), t he outer c onductor of

the dual port BNC 75 Ohm E1 card is grounded. This adheres to the ITU G.703 specification, which

states that the receive coaxial pair must be floating, but with the option to ground.

The BTS is shipped with 4 jumpers in place which ground both the transmit and the receive coaxial pair.

It is mandatory that the transmit pair is grounded. However, whether the receive pair is grounded is

determined by the customer equipment to which th e BSC is connected.

The configuration of these jumpers can be changed at this point.

Tools Required

• Phillips screwdriver

• Electrostatic wrist strap, provided with the BTS

Procedure

1 Place the supplied electrostatic wrist st rap around your wrist. Attach the metallized tape of

the wrist strap to the closest ground, fo r example, to the chassis of the BTS.

2 Unscrew the 75 Ohm dual port E1 card from the chassis, and pull it halfway out.

3 Look for the four jumpers silk-screened P3, P4, P5, and P6, located next to the external

connectors on the dual port E1 card. See Figure 2-6

• A jumper connects pins 1 and 2 of P4 and P6. Th is ensures that the out er conductor is

grounded. It is mandatory that these jumpers be installed in this configuration.

• A jumper connects pins 1 and 2 of P3 and P5. Remove these jumpers if the receive

pair must be floating. Keep these jumpers inst alled if the receive pair is to be

grounded.

.

Jumper

Item No.0015

P3

Receive

J1

J2

P4

Transmit

P6

Transmit

J3

J4

P5

Receive

Jumper Position 1,2

For P3-P6

IW272806

Figure 2-6 Placement of the Jumper for Ports P3-P6

22 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 35

After the E1 card jumpers are checked for their correct placement, reinsert the dual port E1 card in the

chassis, and screw it into place.

2-3.2 Configure Cable Length DIP Switch Settings on T1 Cards

To configure the DIP switch settings on a T1 card:

1 Ensure that anti-static precautions are taken.

2 Make note of the orientation of the cables and disconnect them from the selected card.

3 Using a Phillips screwdriver, fully loosen the two screws located at the top and bottom of the

card.

4 Remove the T1 card by firmly p ulling th e two w hite tabs l ocated a t the to p and bo ttom of th e

card.

5 See Figure 2-7 to locate the DIP switch.

6 On T1 cards, the DIP switch setting is determined by the cable distance from the card to the

DSX-1 demarcation point. The following table provides the appropriate Port 0 and Port

DIP switch settings for DSX-1 d e marcation points located wi th in various cable distance

.

ranges

In Table 2-7, the first setting (0-133 ft.) is the default and should be

used for all T1 applications unless

point beyond 133 ft. When connecting two WAVEXpress chassis you will

always use the first setting regardless of distanc e (up to 600 m).

connecting to a DSX-1 demarcation

1

Table 2-7 T1 DIP Switch Settings

Port 0

Switch Setting

1-2-3-4

OFF-ON-ON-ON OFF-ON-ON-ON 0-133 (0-40.57)

OFF-OFF-ON-ON OFF-OFF-ON-ON 133-266 (40.57-81.13)

OFF-ON-OFF-ON OFF-ON-OFF-ON 266-399 (81.13-121.7)

OFF-OFF-OFF-ON OFF-OFF-OFF-ON 399-533 (121.7-162.57)

OFF-ON-ON-OFF OFF-ON-ON-OFF 533-655 (162.57-199.78)

Port 1

Switch Setting

5-6-7-8

Cable distance from T1 Card to

DSX-1 Demarcation Point

Feet (Meters)

Note: ON refers to the DIP switch pin being in the “UP” position and OFF refers to the DIP

switch pin being in the “DOWN” position. X = either ON or OFF.

7 Place the card into the slot and slide in the card until it completely rests inside the slot. Push

the card firmly into place.

8 Using a Phillips screwdriver, tighten the two captive screws into the chassis through the

trunk card.

Installation 23

Page 36

The following figure shows the location of the DIP switch.

ON

12 435678

J4

12 435678

ON

J6

Figure 2-7 Location of DIP switch on a Trunk Card

J8

J7

J9

IW180001

24 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 37

2-4 Connecting Power and Ground Cables

Use this section to c onnect your earth ground and power cables to the BTS cabinet.

2-4.1 Connecting the Grounding Cable

The cabinet should be grounded to the site earth ground ring. Complete the following to connect an

earth ground to the chassis.

1 Route a customer-supplied 10 AWG (2.5 mm) or larger copper wire to a grounding lug

inserted into one of the M10 tap holes shown in Figure 2-3.

2 Connect the other end of the lead stud to the closest grounding bus.

CAUTION: GROUNDING CIRCUIT CONTINU ITY IS VITAL FOR SAFE

OPERATION OF MACHINE. NEVER OPERATE MACHINE WITH

GROUNDING CONDUCTOR DISCONNECTED.

ATTENTION: UN CIRCUIT DE TERRE CONTINU EST ESSENTIEL EN VUE

DU FONCTIONNEMENT SÉCURITAIRE DE L'APPAREIL. NE JAMAIS METRE

L'APPAREIL EN MARCHE LORSQUE LE CABLE DE MISE À LA TERRE EST

DÉBRANCHE.

Warnung: Achtung , Hoher Ableitstrom! S chutzleiteranschluß vor dem

Netzanschluß herstelle n.

2-4.2 Connecting the Power Supplies

In this section, you will connect the BTS to your power source. Refer to the appropriate subsection to

make either AC or DC power connections.

Warning: This product relies on the building's installation for

short-circuit (overcurrent) protection. Ensure that a fuse or circuit

breaker no larger than 120 VAC, 15A U.S. (240 VAC, 10A int ernational)

is used on the phase conductors (all current-carrying conductors).

Attention Pour ce qui est de la protection contre les courts-circ uits

(surtension), ce produit dépend de l'installation électrique du local.

Vérifier qu' un fusible ou qu'un disjoncteur de 120 V alt., 15 A U.S.

maximum (240 V alt ., 1 0 A intern a tion al) es t ut il isé s ur les co nd uct eurs

de phase (conducteurs de charge).

Warnung Dieses Produkt ist darauf angewiesen, daß im Gebäude ein

Kurzschluß- bzw. Überstromschutz installiert ist. Stellen Sie sicher, daß

eine Sicherung oder ein Unterbrecher von nicht mehr als 240 V

Wechselstrom, 10 A (bzw. in den USA 120 V Wechselstrom, 15 A) an

den Phasenleitern (alle n strom fü h ren den Leitern) verwendet wir d.

Installation 25

Page 38

AC Operation

The BTS is shipped from the factory wi th the in terna l cablin g rout ed fro m the AC po wer s upp l y sub rack

assembly to a molex connector on the top rear of the cabinet. A power supply cable is included with the

BTS which should be used to connect to your AC power supply or battery backup system.

Make connections from the AC power supply to the cabinet as follows:

1 Verify the ground connection you made in Section 2-4.1 is secure.

2 Make sure that the power button located on all power supply modules is in the raised OFF

position. See Figure 2-8 for the location of the power supply power buttons.

INPUT

OUTPUT

FAULT

OFF ON

INPUT

OUTPUT

FAULT

OFF ON

ON/OFF Buttons

Figure 2-8 Power Supply ON/OFF Buttons

3 Plug the molex power connector into the power connection on the top of the cabinet.

Secure the connector by twistin g the connect or sleeve until the lines on the cable connector

and chassis connector align.

4 Plug the power cable into the electrical ma ins. Do not a pply power to th e chassis at this tim e.

Wait until you are performing th e off-line commissioning procedures in the next chapter.

CAUTION: THE POWER SUPPLY CORD IS USED AS THE MAIN

DISCONNECT DEVICE, ENSURE THAT THE SOCKET-OUTLET IS

LOCATED/INSTALLED NEAR THE EQUIPMENT AND IS EASILY

ACCESSIBLE.

INPUT

OUTPUT

FAULT

OFF ON

IW008302

ATTENTION: LE CORDON D'ALIMENTATION EST UTILISÉ COMME

INTERRUPTEUR GÉNÉRAL. LA PRISE DE COURANT DOIT ÊTRE SITUÉE

OU INSTALLÉE À PROXIMITÉ DU MATÉRIEL ET ÊTRE FACILE D'ACCÉS.

Warnung: Das Netzkabel dient als Netzschalter. Stellen Sie sicher, das

die Steckdose einfach zugänglich ist.

26 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 39

-48 VDC Operation

The BTS is shipped from the factory with the internal cabling routed from the DC power supply subrack

assembly to a molex connector on the top rear of the cabinet. A power suppl y cabl e is in cl uded with the

BTS which should be used to connect to your DC power supply or battery backup syste m .

Use the following procedure:

1 Verify the ground connection you made in Section 2-4.1 is secure. The cabinet power

supply is grounded through this connection. It is critical that this connection is made

properly.

2 Make sure that the power button located on all power supply modules is in the raised OFF

position. See Figure 2-8 for the location of the power supply power buttons.

3 Verify that the-48 VDC power source is off.

4 The -48 VDC power cable has two wi res fo r the pos itive ( +) connec tion and two wire s for the

negative (-) connection. This spreads the curr ent draw across two pins of the molex

connector for each connection.

The power main must be a Safe Extra-Low Voltage (SELV), -48 VDC

supply as defined in IEC950 and EN60950.

Attach the two positive (+) cables to the positive side of your -48 VDC power source.

5 Attach the two negative (-) cables to the negative side of your -48 VDC power source.

6 Plug the molex power connector into the power connecti on on the top of the cabinet.

Secure the connector by twistin g the connect or sleeve until the lines on the cable connector

and chassis connector align.

Do not use the DC power supply circuit breaker to apply power to the

chassis at this time. Wait until you are performing the off-line

commissioning procedures in the next chapter.

CAUTION: THE POWER SUPPLY CORD IS USED AS THE MAIN

DISCONNECT DEVICE, ENSURE THAT THE SOCKET-OUTLET IS

LOCATED/INSTALLED NEAR THE EQUIPMENT AND IS EASILY

ACCESSIBLE.

ATTENTION: LE CORDON D'ALIMENTATION EST UTILISÉ COMME

INTERRUPTEUR GÉNÉRAL. LA PRISE DE COURANT DOIT ÊTRE SITUÉE

OU INSTALLÉE À PROXIMITÉ DU MATÉRIEL ET ÊTRE FACILE D'ACCÉS.

Warnung: Das Netzkabel dient als Netzschalter. Stellen Sie sicher, das

die Steckdose einfach zugänglich ist.

Installation 27

Page 40

2-5 Connecting E1 or T1 Trunk Cables

External trunk cabling depends on the configuration that the customer ordered and the site-specific

requirements. These cables will be supplied by the customer. Failure to use electrically compliant T1 or

E1 cables may cause transmission errors. Please refer to the appropriate subsections to determine your

cable requirements.

The E1 or T1 trunk cables are routed internally from the E1 or T1 trunk card in the baseband sub rack

assembly to the top rear of the BTS cabinet. All three types of signaling (E1 75 Ohm, 120 Ohm and T1

100 Ohm) are termina ted at the cabinet with RJ-48C port connectors. The pinout of this connector is

illustrated in Figure 2-9.

E1 or T1 Port

Connector

Pin Numbers

Figure 2-9 Cabinet Trunk Port Pinout

2-5.1 E1 Cables

E1-75 Ohm

This is coaxial cable with a nominal impedance of 75 Ohm +/-5% at 1 MHz. The maximum allow able

cable distance depends directly on the insertion loss of the cable at 1 MHz. In this mode, the E1 trunk

card can accommodate up to 6 dB of cable loss.

E1-120 Ohm

8

7

6

5

4

3

2

1

Pin 8: PCB Signal Ground

Pin 5: Transmit Tip

Pin 4: Transmit Ring

Pin 2: Receive Tip

Pin 1: Receive Ring

IW009301

This cable is individually shielded twisted pair with a nominal impedance of 120 Ohm +/-5% at 1 MHz .

The maximum allowable cable distance depends directly on the insertion loss of the cable at 1 MHz. In

this mode, the E1 trunk card can accommodate up to 9 dB of cable loss.

Table 2-8 provides a de script ion of cables re quired fo r inst alla tion an d connect ion t o an E1 networ k, but

not supplied wit h the BTS:

28 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 41

Table 2-8 Customer-Supplied E1 Cabling

Cable Identity Cable Type Corresponding Cable Plug

E1, 120 Ohm Shielded, Twisted, 2- Pair RJ-48C, Male

E1, 75 Ohm Shielded, Twisted, 2-Pair RJ-48C, Male

Note: The number of cables required depends on the ordered configuration of the BTS.

Conversion Cables

If you are connecting into an existing E1 network with standard BNC or DSUP connectors, a conversion

cable for either the 75 Ohm or 120 Ohm will be required. To purchase these cables from interWAVE,

contact your local sales support representative.

Before connecting E1 lines to the BTS, it is assumed that the quality of

the lines has been verified. It is recommended that bit error ratio tests

-8

be completed to ensure that the BER is less than 10

.

J2

RECEIVE

TRANSMIT

J3

J2

BLUE/WHITE

WHITE/BLUE (R-TIP)

ORANGE/WHITE

WHITE/ORANGE

J3

Figure 2-10 75 Ohm BNC Conversion Cable

Figure 2-10 illustrates the pinout for an RJ-48C to 75 Ohm BNC conversion cable.

(R-RING)

(T-RING)

(T-TIP)

J1

Pin 1

Pin 8

J1

1

2

3

4

5

6

7

8

IW009302

Installation 29

Page 42

Pin 15 Pin 8

Pin 9

Pin 1

J2

Pin 1

Pin 8

J1

J2

11

3

9

1

BLUE/WHITE

WHITE/BLUE (R-TIP)

ORANGE/WHITE

WHITE/ORANGE

Figure 2-11 120 Ohm DSUB Conversion Cable

Figure 2-11 illustrates the p inout for the RJ-48C to DSUB 120 Ohm conversion cable.

2-5.2 T1 Cables

T1-100 Ohm

For T1 connections, the proper cable is individually shielded twisted pair with a nominal impedance of

100 Ohm +/-5% at 772 kHz. The maximum allowable cable distance depends directly on the insertion

loss of the cable at 772 kHz. The T1 card can accommodate up to 9 dB of cable loss. When using

22 AWG ABAM cable, 9 dB of loss is approximately 2000 feet. When using Belden type 9729 (with a

cable loss of 6 dB per 1000 feet at 7 72 kHz) the maximum cable di stance is approximately 1500 feet.

(R-RING)

(T-RING)

(T-TIP)

J1

1

2

3

4

5

6

7

8

IW009303

Table 2-9 provides a description of cables required for installation and connecti on to a T1 network, but

not supplied wit h the BTS:

Before connecting T1 lines to the BTS, it is assumed that the quality of

the lines has been verified. It is recommended that bit error rate tests

-8

be completed to ensure that the BER is less than 10

.

Table 2-9 Customer-Supplied T1 Cabling

Cable Identity Cable Type Corresponding Cable Plug

T1, 100 Ohm Shielded, Twisted, 2-Pair RJ-48C, Male

Note: The number of cables required depends on the ordered configuration of the BTS.

30 UltraWAVE BTS Installation and Commissioning Guide, Release 6.5A

Page 43

2-5.3 Connecting E1 or T1 Lines

All E1 or T1 cable routing should be installed per the site survey documentation in conjunction with the

information identified in the interWAVE Network Implementation Manual

.

• Using the approp riate customer-sup plied cables, connect the Abis interface E1 and/or T1

cables to the local E1 or T1 provider.

2-5.4 Direct Cabling Between Multiple UltraWAVE or WAVEXpress Systems

This section provides info rmation for cabling between WAVEXpress equipment. The external cabling