Page 1

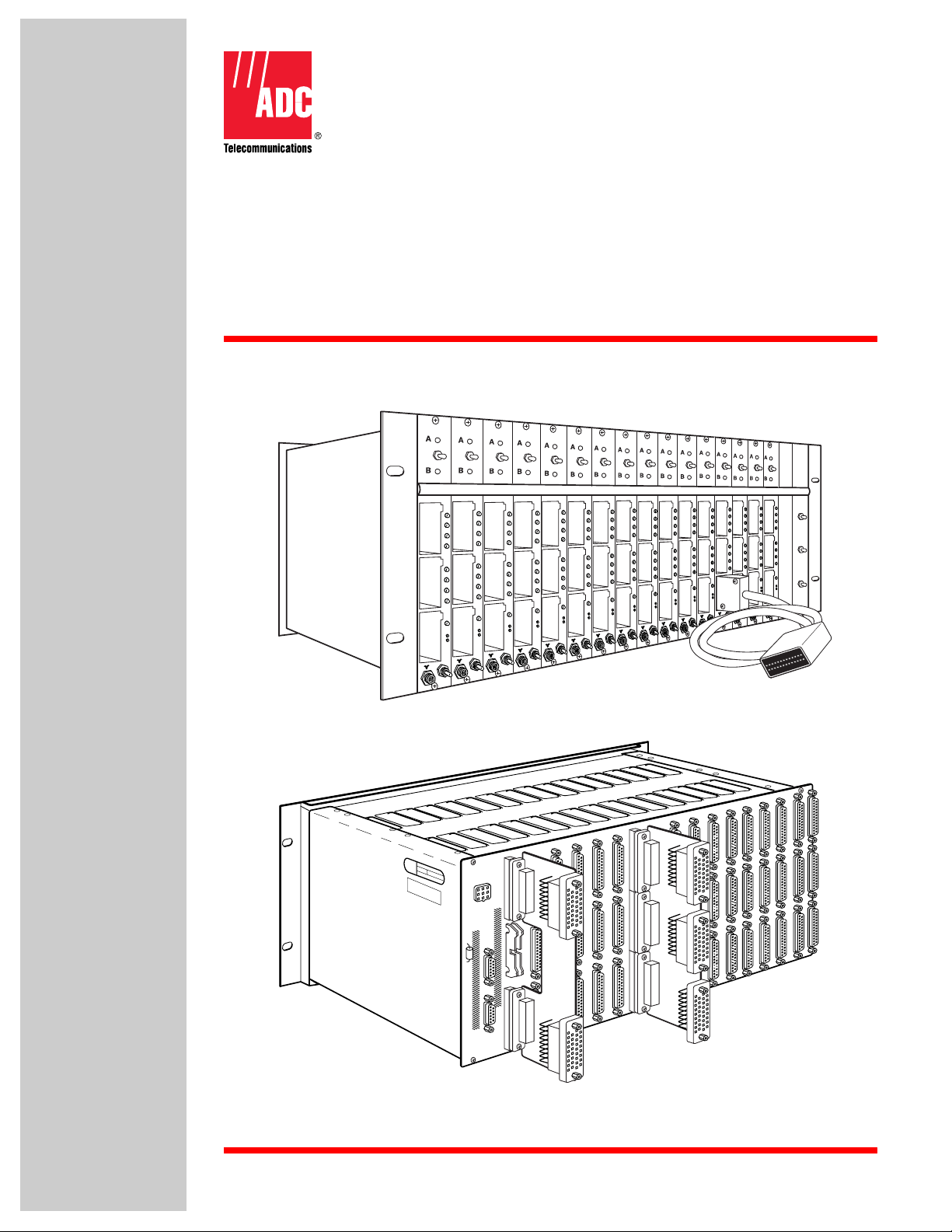

RS-232/V.24, X.21

and V.35 PatchSwitch

User Manual

ADCP-50-304

Issue 19

June 1999

COMP

MODEM

MON

ADC

MADE IN USA

P/N

REV

DATE CODE

TD

TD

RD

RD

DCD

DCD

SQ

SQ

RTS

RTS

CTS

CTS

DSR

DSR

DTR

DTR

ALM

ALM

RST

RST

L

A

0

E

L

DLY

F

L

D

A

M

0

F

E

DLY

L

F

D

M

F

DLY

S/N

TD

TD

RD

RD

DCD

DCD

SQ

SQ

RTS

RTS

CTS

CTS

DSR

DSR

DTR

DTR

ALM

ALM

RST

RST

L

A

0

E

L

F

L

A

D

0

M

F

E

L

F

DLY

D

M

F

RD

RD

DCD

DCD

SQ

SQ

RTS

RTS

CTS

CTS

DSR

DSR

DTR

DTR

ALM

ALM

RST

RST

0

F

L

A

0

F

E

L

DLY

F

L

A

D

0

M

F

E

L

DLY

F

D

M

F

DLY

RD

RD

RD

DCD

DCD

DCD

SQ

SQ

SQ

RTS

RTS

RTS

CTS

CTS

CTS

DSR

DSR

DSR

DTR

DTR

DTR

ALM

ALM

ALM

RST

RST

RST

L

A

0

E

L

F

DLY

L

A

0

D

M

F

E

L

F

DLY

L

A

D

M

F

E

L

DLY

D

M

RD

RD

RD

DCD

DCD

DCD

SQ

SQ

SQ

RTS

RTS

RTS

CTS

CTS

CTS

DSR

DSR

DSR

DTR

DTR

DTR

ALM

ALM

ALM

RST

RST

RST

L

A

0

E

L

F

L

A

0

D

M

F

E

L

F

DLY

L

A

0

D

M

F

E

L

F

DLY

D

M

F

RD

RD

RD

DCD

DCD

DCD

SQ

SQ

SQ

RTS

RTS

RTS

CTS

CTS

CTS

DSR

DSR

DSR

DTR

DTR

DTR

ALM

ALM

ALM

RST

RST

RST

L

A

0

E

L

L

F

A

0

D

M

E

F

L

L

A

F

0

DLY

D

E

M

L

F

F

DLY

D

M

F

DLY

TD

TD

COMP

RD

B

DCD

MASTER

SQ

RTS

MODEM

CTS

ENABLE

DSR

DTR

ALM

MON

RST

ALARM

RESET

L

A

0

E

L

F

D

M

F

DLY

1586-A

A

TD

TD

TD

TD

TD

TD

TD

TD

TD

TD

1587-A

1059311 Rev A

Page 2

ADCP-50-304 • Issue 19 • June 1999 • Preface

COPYRIGHT

© 1999, ADC Telecommunications, Inc.

All Rights Reserved

Printed in the U.S.A.

TRADEMARK INFORMATION

ADC and ADC Telecommunications are registered trademarks of ADC Telecommunications, Inc.

DISCLAIMER OF LIABILITY

Contents herein are cu rrent a s of the da te of p ublic atio n. ADC r eserves the ri ght to chan ge t he co ntent s wi thout prior no tice . In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting AD C’s Technical Assistance Center at 1-800-366-3891, extension 3223

(in U.S.A. or Canada) or 612-946-3223 (outside U.S.A. and Canada), or by writing to ADC Telecommunications, Inc., Attn:

Technical Assistance Center, Mail Station #77, P.O. Box 1101, Minneapolis, MN 55440-1101, U.S.A.

Page ii

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (612) 938-8080

Fax: (612) 946-3292

Page 3

TABLE OF CONTENTS

Content Page

1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2 PURPOSE AND SCOPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2.1 PatchSwitch Assembly Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2.2 PatchSwitch Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3.1 DMPS-10 AC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2 PATCHING WITH IN-LINE A/B SWITCHING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3 A/B SWITCHING WITH OFF-LINE MONITOR ACCESS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

3.1 PS Control Module (RDM-15). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3.2 LED/Alarm Patch Module with A/B Switching and In-Line Patch Access (PSM-01) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3.3 Patch Module with A/B Switching and In-Line Patch Access (PSM-02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

4 A/B SWITCHING MODULE (PSM-03) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

5 LED/ALARM PATCH MODULE WITH A/B SWITCHING AND OFF-LINE ACCESS (PSM-04) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

6 PATCH MODULE WITH A/B SWITCHING AND OFF-LINE ACCESS (PSM-05) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

7 LED/ALARM PATCH INTERFACE (PSM-07) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

7.1 Patch Interface (PSM-08) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

8 TEST MODULE (PSM-12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

9 TEST MODULE (PSM 13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

10 PS RS-422/RS-232 INTERFACE CONVERTER MODULE (PSR-06) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

11 PS CHASSIS POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

ADCP-50-304 • Issue 19 • June 1999 • Pre fa ce

SECTION 1

INTRODUCTION

SECTION 2

FUNCTIONAL DESCRIPTION

SECTION 3

PATCHSWITCH V.35

1 PRODUCT OFFERING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2 APPLICATION WITH EXISTING UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3 FUNCTION SELECTION-MODULES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4 FUNCTIONAL SELECTION—CONVERSION BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

5 HARDWARE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

6 RECOMMENDED MATING CONNECTOR PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

© 1999, ADC Telecommunications, Inc.

Page iii

Page 4

ADCP-50-304 • Issue 19 • June 1999 • Preface

TABLE OF CONTENTS

Content Page

1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2.1 PSM-812001 X.21 LED/Alarm Patch Module with A/B Switching and Off-Line Patch Access . . . . . . . . . . . . . . . . . . . . . 4-2

2.2 PSM-813001 X.21 PatchSwitch Module with A/B Switching and Off-Line Patch Access . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

2.3 PSM-832001 X.21 LED/Alarm PatchSwitch Interface Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

2.4 PSM-83301 X.21 PatchSwitch Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

2.5 PSM-832002 X.21 LED/Alarm PatchSwitch Test/Status Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

2.6 PSO-839001 Backplane Adapter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

2.7 PSO-836001 Backplane Adapter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

2.8 PSO-839002 Backplane Adapter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

3 FUNCTIONAL DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

3.1 A/B Switch Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

3.2 Switch Module Interlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

3.3 Monitor, Patch, and Access Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

3.4 Status Indication Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

3.5 Alarm Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

3.6 Alarm Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

3.7 Alarm Time Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

3.8 B Alarm Enable/Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

3.9 PSM-832002 Module Quiescent State Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4 POWER REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

5 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

6 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

6.1 Interlock Jumper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

6.2 Alarm Jumper Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

6.3 Alarm Time Delay Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

6.4 Adapter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

6.5 Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

6.6 Cable Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

SECTION 4

PATCHSWITCH X.21

1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2 SPACE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3 ENVIRONMENTAL CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

4 POWER REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Page iv

© 1999, ADC Telecommunications, Inc.

SECTION 5

SITE PREPARATION

Page 5

TABLE OF CONTENTS

Content Page

1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1 PatchSwitch Chassis Installation (For PatchSwitch V.35 Installation, see Section 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.2 PatchSwitch Module Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

1.3 Blank Panel Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

1.4 Chassis Power Supply Connection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

1.5 Communications Network Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

1.6 Control Module DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

2 CONTROL MODULE AUTOFALLBACK JUMPER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

3 CONTROL MODULE REMOTE CONTROL JUMPER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

4 PS MODULE JUMPER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

4.1 Interlock Jumper Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

4.2 Alarm Jumper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

4.3 Automatic Alarm Reset Jumper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

ADCP-50-304 • Issue 19 • June 1999 • Pre fa ce

SECTION 6

INSTALLATION

SECTION 7

OPERATION

1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2 PATCHING — IN-LINE ACCESS MODULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2.1 Monitor Patching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2.2 Intrusive Patching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

3 PATCHING — OFF-LINE ACCESS MODULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

4 INTERFACE MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

4.1 Test Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

5 SWITCHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

6 CONTROL MODULE SWITCHING (LOCAL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

6.1 Interface Converter Module (PSR-06A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

6.2 Single Channel Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

6.3 Bank Switching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

6.4 Reset Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

6.5 DC Pulse Control Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

6.6 Remote Control Switching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

6.7 Remote Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

6.8 Command Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

6.9 Command Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

6.10 Command Interpretation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

6.11 Command Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

6.12 Command Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

6.13 Select PS Chassis Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

6.14 GO Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

© 1999, ADC Telecommunications, Inc.

Page v

Page 6

ADCP-50-304 • Issue 19 • June 1999 • Preface

TABLE OF CONTENTS

Content Page

6.15 Request Software Revision Level (REV) Command) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

6.16 Request Status (UPdate Command). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

6.17 Status Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

6.18 TLKxx Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

6.19 TLKxx Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

6.20 SPKxx Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

6.21 Reset Alarm Status (IN Command). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

6.22 Enable/Disable Alarm Status Reporting (AL Command) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

6.23 Request Switching (AB Command). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

6.24 Request Super Chassis Command (SC Command) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

6.25 De-Select The PS Chassis (UNT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

6.26 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

6.27 Testing The Communications Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

SECTION 8

GENERAL INFORMATION

1 WARRANTY/SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2 REPAIR/ADVANCE REPLACEMENT POLICY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

3 REPAIR CHARGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

4 REPLACEMENT/SPARE PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

5 RETURNED MATERIAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

6 CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Page vi

© 1999, ADC Telecommunications, Inc.

Page 7

REVISION HISTORY

EDITION/ISSUE DATE REASON FOR CHANGE

1st Edition, Issue 1 02/83 Original.

1st Edition, Issue 2 03/83 Technical changes.

1st Edition, Issue 3 03/83 Warranty changes.

1st Edition, Issue 4 07/83 Technical changes.

2nd Edition, Issue 1 02/84 Incorporation of remote control.

2nd Edition, Issue 2 10/84 Technical changes.

3rd Edition, Issue 1 03/86 Incorporated PSM-12 and PSM-13 Test Modules.

3rd Edition, Issue 2 05/86 Edited Com munications Network Interface Connections paragraph for clarification an d

4th Edition, Issue 1 07/86 Incorporated PSM-1 2 and PSM-13 Test Modules. Added autofailback feature and super

5th Edition, Issue 1 12/86 Delete references to PSM-14 CTRL Module.

6th Edition, Issue 1 06/88 Technical changes and clarification.

7th Edition, Issue 1 10/88 Added V.35 modules and conversion boards.

7th Edition, Issue 2 08/89 Changed Figure 3-6.

8th Edition, Issue 1 05/90 Added new information on PSM-15.

8th Edition, Issue 2 06/90 Ch an ged DIP Switch Settings in Figure 5-3 and in Control Module DIP Switch Set ti ngs

9th Edition, Issue 1 09/91 General technical changes and added X.21 modul es.

9th Edition, Issue 2 05/92 Add ed DMP S-10 Power Supply.

10th Edition, Issue 1 03/93 Added DC control.

Issue 19 06/99 Update to current forma t st andards.

ADCP-50-304 • Issue 19 • June 1999 • Pre fa ce

corrected connect ors designations in Figure 4-1.

chassis selection (SC comman d) to Remote Control Module, st at us response for TLK

(terminal) selection, and Ver tical interlock to PSM-01, PSM-02, and PSM-03. Added PSM04, PSM-05 Patch Modules with off-line access, and RS-422/RS-232 Data Converter Module.

paragraph.

ABOUT THIS MANUAL

This user manual describes the RS-232/V.24 and V.35 PatchSwitch equipment. The manual

provides information necessary to install and operate these units. The manual is intended fo r use

at communications network facilities and users who monitor and maintain the network. Section 1

provides a general description of the ADC equipment. Section 2 provides a functional

description of the equipment components. Section 3 provides a complete description of V.35

modules. Section 4 provides a description of X.21 modules. Sections 5 and 6 describe the

equipment site preparation an d installation. Sectio n 7 describes the op eration of the equipm ent.

General Information Section explains the equipment warranty, repair/exchange policy, charges,

replacement/spare parts, returned material and customer suppor t services.

Portions of the Patch Modules are covered by U.S. Pat. No. 4,363,941 and corresponding

foreign Letters Patent.

© 1999, ADC Telecommunications, Inc.

Page vii

Page 8

ADCP-50-304 • Issue 19 • June 1999 • Preface

RELATED PUBLICATIONS

Listed below are all the related manuals, their content, and their publication numbers. Copies of

these publications can be ordered by contacting the ADC Technical Assistance Center at

1-800-366-3891 (in U.S.A. or Canada) or 612-946-3000, extension 3223 (outside U.S.A. and

Canada.

Title ADCP Number

Network Control Products Catalog 517

PatchSwitch Remote Control Unit User Manual ADCP-50-302

PatchSwitch V.35 Installation and User Guide ADCP-50-311

Remote Test Access (RTA) Espion 500 System User Manual ADCP-50-100

Remote Test Access (RTA) System User Manual ADCP-50-101

ADMONISHMENTS

Important safety admoni shmen ts are used throughou t thi s manual to warn of possi ble haza rds to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below), and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

Page viii

© 1999, ADC Telecommunications, Inc.

Page 9

GENERAL SAFETY PRECAUTIONS

Danger: To prevent electrical shock, never install telephone equipment in a wet location or

during a lightning storm. When installing or modifying telephone lines, disconnect lines on the

network side before working with uninsulated lines or terminals.

Danger: The chassis must be properly grounded to ensure equipment and human safety.

Danger: Electric modules can be damaged by electrostatic discharge (ESD). Before handling

modules, wear an anti-static discharge wrist strap to prevent damage to electronic components.

Place modules in anti-static packing material when transporting or storing. When working on

modules, always place them on an approved anti-static mat that is electrically grounded.

FCC COMPLIANCE STATEMENT

This product has been certified to comply with the requirements for class A computing devices

per part 15 of the FCC regulations.

ADCP-50-304 • Issue 19 • June 1999 • Pre fa ce

Danger: This equipment generates, uses, and can radiate radio frequency energy and if not

installed and used in accordance with the user manual, may cause interference to radio

communications. It has been tested and found to comply with limits for a Class B computing

device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to provide reasonable

protection against such interference when operated in a commercial environment. Operation of

this equipment in a residential area is likely to cause interference in which case the user, at his

own expense, will be required to take whatever measures may be required to correct the

interference.

© 1999, ADC Telecommunications, Inc.

Page ix

Page 10

INTRODUCTION

Page 11

SECTION 1: INTRODUCTION

Content Page

1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2 PURPOSE AND SCOPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

2.1 PatchSwitch Assembly Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

2.2 PatchSwitch Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1- 5

3 SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

3.1 DMPS-10 AC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

_________________ ___________________ ______________________________________ _______________________________

1 GENERAL

ADC PatchSwitch Digital Patching with RS-232/V.24, X.21, and V.35 Switching equipment,

hereinafter refe rr ed t o a s PatchSwitch or PS, p rovides conveni ent ac ces s t o RS- 232 (ANSI/EIA-

232) or CCITT V.24, X.21, or V.35 circuits for patching or switching to allow monitoring,

testing, and reconfiguring of a communications network. The V.35 description is located in

Section 3. The X.21 description is located in Section 4.

ADCP-50-304 • Issue 19 • June 199 9 • Sec tion 1: In troduction

Note:

The PatchSwitch equipment described in this manual conforms to EIA/CCITT (RS232/Recommendation V.24), interfa ce between Data Terminal Equipment (DTE) and Data

Communication Equipment (DCE) known as the Serial Binary Data Int er change or SBDI.

The PatchSwitch product line is a flexible, modular system providing the following features:

1. Monitoring of digital communications leads without circuit interruption;

2. Line access and switching on data communications circuit directed toward two (A/B)

equipments at the DTE end and as directed toward the modem at the DCE end;

3. Loss of monitored signal alarming circuits which identify the down circuit with either or

both visual and audible indications;

4. Optional signal monitoring and alarming of eight different RS-232 signal lines;

5. Optional interlocking in groups of two to 16 modules with A/B switching;

6. Optional interlocking in groups of two to 16 chassis with A/B switching;

7. Optional test module with three (3) RS-232 female ports for convenient interface with

compatible test equipment, with or without lead status monitoring LEDs (8-leads

monitored);

8. Flexibility of t he modular system appr oach al lo ws th e additi on of chas sis and modul es and

the interchange of modules on a single line basis;

9. Module replacement or removal with no need for rear cable disconnection;

10. All female DTE and DCE connectors or female DTE and male DCE connectors;

11. High density chassis occupies 7 inches (17.78 cm) in height within a standard 19-inch

(48.26 cm) wide rack;

© 1999, ADC Telecommunications, Inc.

Page 1-1

Page 12

ADCP-50-304 • Issue 19 • June 1999 • Section 1: Introduction

12. Remote switching and alarm c ontrol opera tion up to 1,0 00 fee t a way from t he P at chSwit ch

chassis rack;

13. Remote operator control via ser ial da ta communic ation s circ uits e mploy ing eit her RS-2 32,

RS-422 or V.35 standards;

14. Optional autofallback to either A/B switch position on detection of an alarm;

15. Local or remote bank switching using manual or serial control;

16. 0, +5V and –5 to –48 Vdc pulse controlled bank switching, and

17. Direct test access to off-line devices.

2 PURPOSE AND SCOPE

The purpose of this manual is to provide the user with information necessary to install and

operate the PatchSwitch equipment. Section 1 is a general description of the PatchSwitch

equipment.

2.1 PatchSwitch Assembly Configurations

Prepackaged standard product PS assemblies are configured as listed in Table 1-1. All

assemblies contain 16 PS modules in the leftmost 16 positions of the 18 position chassis. The

17th position contains a blank panel and the 18th position contains the PS Chassis Control

Module. Each of the 16 modules provides patching and/or A/B (A channel DTE or B channel

DTE) fallback switching for all 23 leads of an RS-232/V.24 or V.35 circuit. Bank switching,

switching operation enab le, and mast er ala rm reset are al l pro vid ed for in t he Control Module of

the PS Chassis. Each module may be configured as part of an interlocked group.

Only one module of an interlock ed gr oup can be in the B stat e at one time. Eac h ass embly has a

blank designation strip for operator labeling of the circuits. The PS assembly has two main

functions. First, it allows a user to select from two DTE channels to be connected to a DCE.

Secondly, it allows the user to monitor and restore data channels through the use of manual

patching. The PS assembly gives positive indication of the current DTE channel in use and

allows the operato r to switch all 16 channel s in the PS assembly with a si ngle switch (bank

switch). With user selectable serial remote control, the switching function can be located up to

1,000 feet away for the PS chassis assembly. With user selectable dc controlled bank switching,

the bank switching function can be located up to 500 feet away.

Page 1-2

© 1999, ADC Telecommunications, Inc.

Page 13

ADCP-50-304 • Issue 19 • June 199 9 • Sec tion 1: In troduction

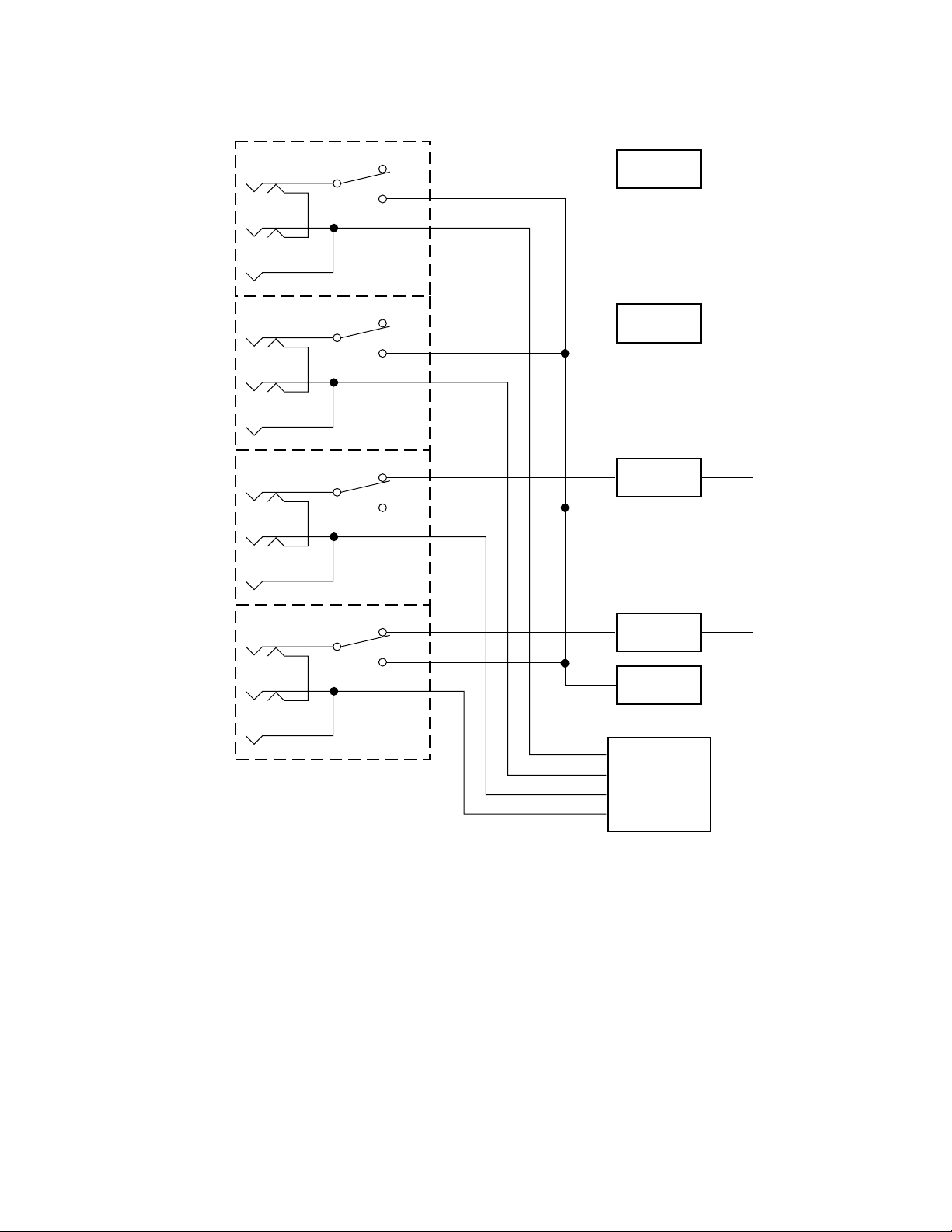

The Interlocked group feature protects a device used as a substitute. A spare device may be

connected to the DTE-B port of several A/B switching modules as shown in Figure 1-1. The A/B

Interlock Jumper of each module in the group m ust be in the same position. When one device

fails, the spare device may be substituted. Now, If another device fails, the interlocked group

feature prevents the spare from being substituted for the second failed device.

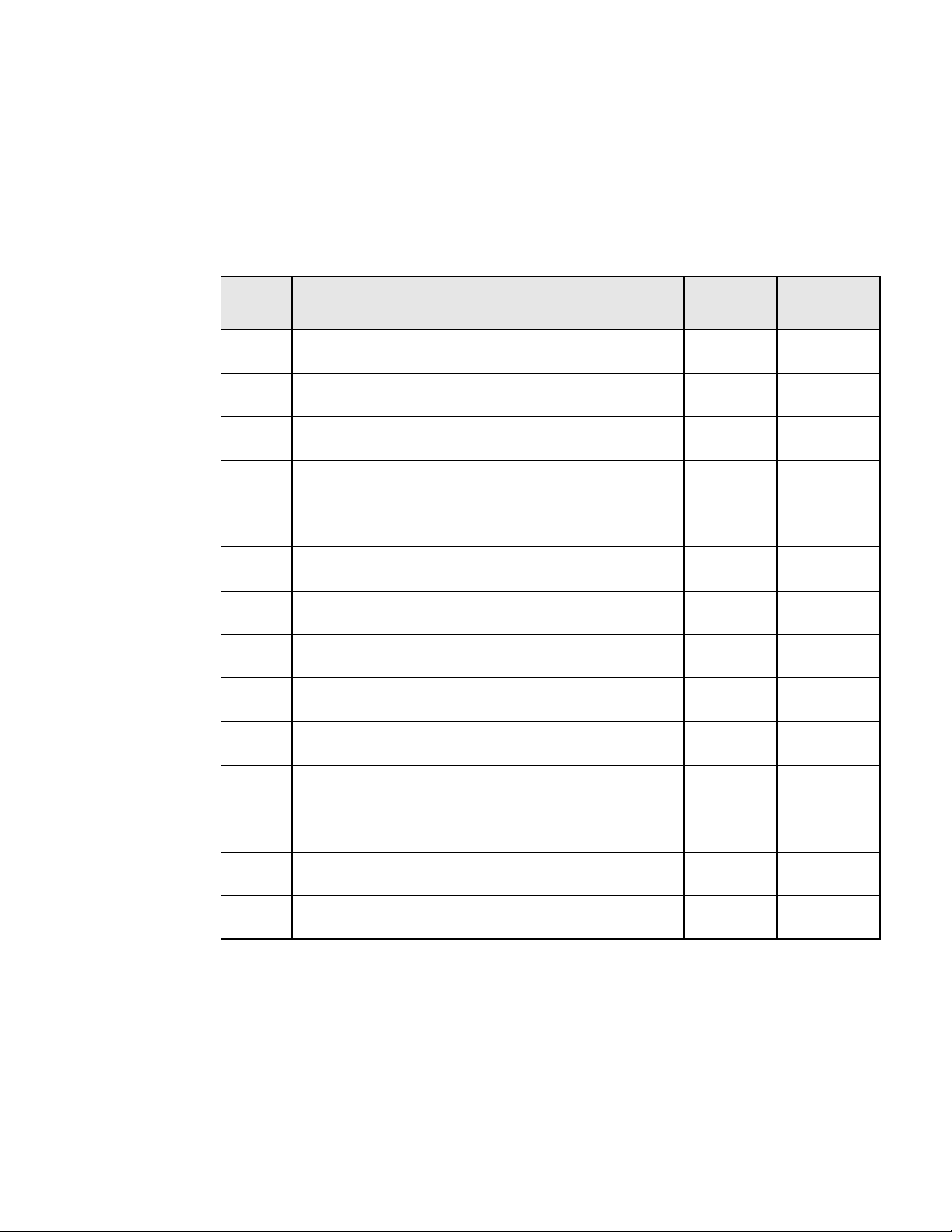

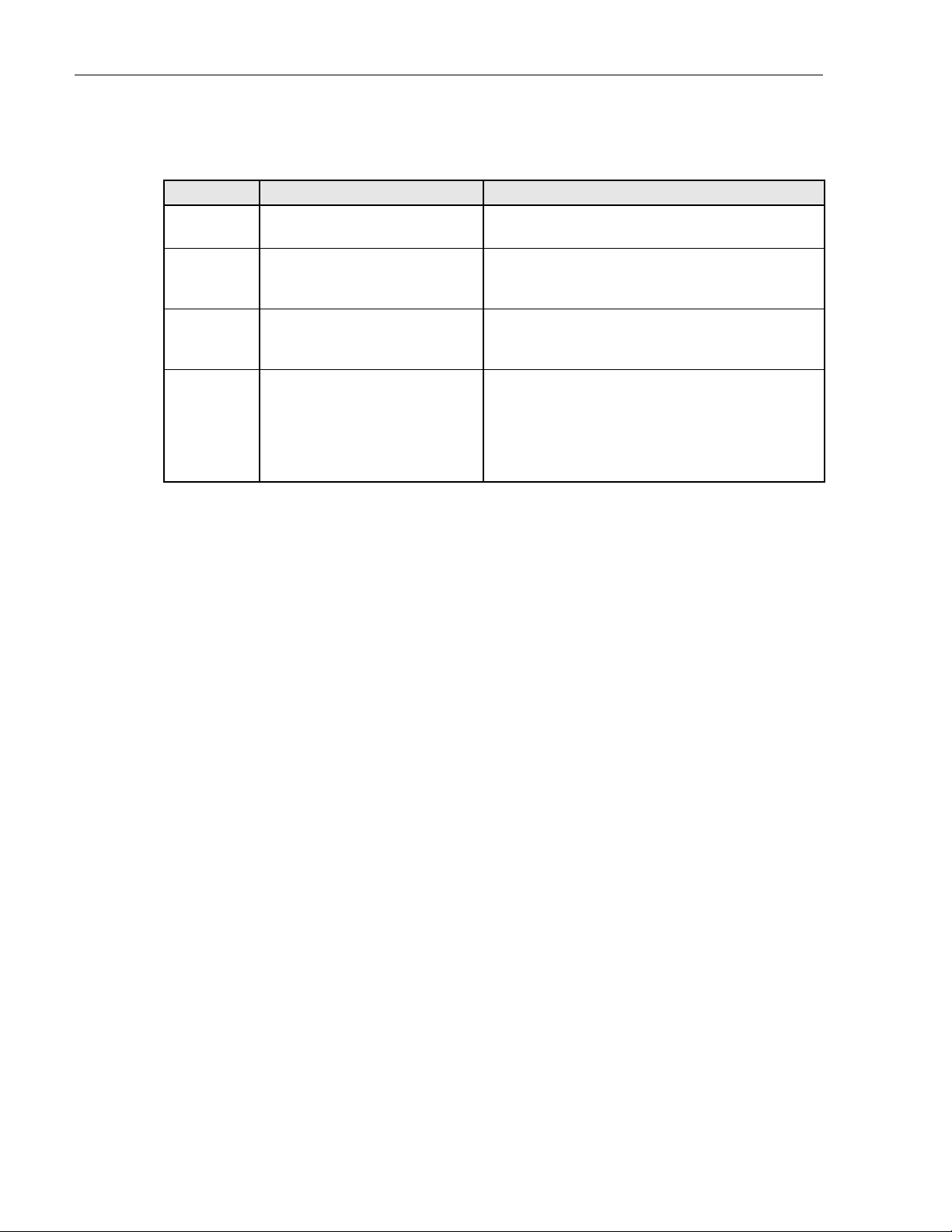

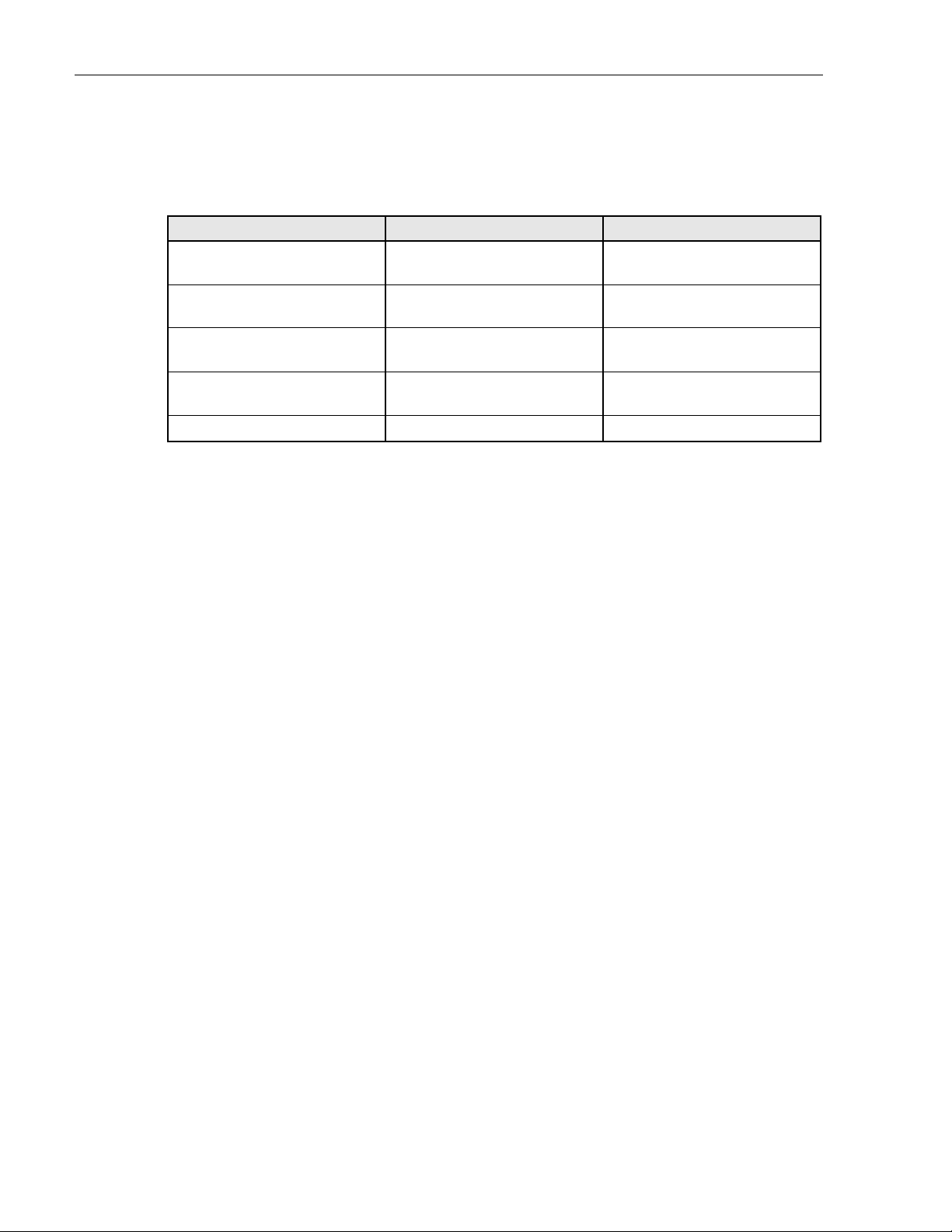

Table 1-1. PatchSwitch (PS) Assembly Configurations

ADC

NUMBER DESCRIPTION

PSA-01

RS-232 16 Line LED/Alarm Patching with A/B Switching

(Female DTE/DCE Connectors

)

PSA-02 RS-232 16 Line LED/Alarm Patching with A/B Switching

(Female DTE and Male DCE Connectors)

PSA-03 RS-232 16 Line Patching with A/B Switching

(Female DTE/DCE Connectors)

PSA-04 RS-232 16 Line Patching with A/B Switching

(Female DTE and Male DCE Connectors)

PSA-05 RS-232 16 Line A/B Switching

(Female DTE/DCE Connectors)

PSA-06 RS-232 16 Line A/B Switching

(Female DTE and Male DCE Connectors)

PSA-07 RS-232 16 Line LED/Alarm A/B Switching with

Off-Line Patch Access (Female DTE/DCE Connectors)

PSA-08 RS-232 16 Line LED/Alarm A/B Switching with Off-Line

Patch Access (Female DTE and Male DCE Connectors)

PSA-09 RS-232 16 Line A/B Switching with Off-Line Patch Access

(Female DTE/DCE Connectors)

PSA-10 RS-232 16 Line A/B Switching with Off-Line Patch Access

(Female DTE and Male DCE Connector)

PSA-11 V.35, 16 Line LED/Alarm A/B Switching with Off-Line

Patch

CHASSIS

MODULES

16 PSM-01

1 PSM-09

16 PSM-01

1 PSM-09

16 PSM-02

1 PSM-09

16 PSM-02

1 PSM-09

16 PSM-03

1 PSM-09

16 PSM-03

1 PSM-09

16 PSM-04

1 PSM-09

16 PSM-04

1 PSM-09

16 PSM-05

1 PSM-09

16 PSM-05

1 PSM-09

16 PSM-16

1 PSM-09

CHASSIS*

WITH CONTROL

MODULE ONLY

RDC-01

RDC-02

RDC-01

RDC-02

RDC-01

RDC-02

RDC-01

RDC-02

RDC-01

RDC-02

RDC-01

PSA-12 V.35, 16 Line LED/Alarm A/B Switching with Off-Line

Patch

16 PSM-16

1 PSM-09

PSA-13 V.35, 16 Line A/B Switching with Off-Line Patch 16 PSM-17

1 PSM-09

PSA-14 V.35, 16 Line A/B Switching with Off-Line Patch 16 PSM-17

1 PSM-09

* Requires Power Supply

© 1999, ADC Telecommunications, Inc.

RDC-02

RDC-01

RDC-02

Page 1-3

Page 14

ADCP-50-304 • Issue 19 • June 1999 • Section 1: Introduction

MODULE 1

MODULE 2

MODULE 3

A

B

A

B

A

B

MODEM

1

MODEM

2

MODEM

3

MODULE 4

A

B

MODEM

SPARE

MODEM

FRONT

PROCESSOR

Figure 1-1. Typical Hot Spare Mo dem Configuration

4

END

1588-A

Page 1-4

© 1999, ADC Telecommunications, Inc.

Page 15

2.2 PatchSwitch Equipment

The PS equipment consists of a chassis with a control module and associated power supply,

modules forpatching and/or switching and interfacing, blank panel and patch cords. Table 1-2 lists

the PS equipment.

(V.35 Modules are described in Section 3. X.21 Modules are described in Section 4)

ADC NUMBER DESCRIPTION COMMENTS

RDC-01 PatchSwitch Chassis,

16 position

RDC-02 PatchSwitch Chassis,

16 position

ADCP-50-304 • Issue 19 • June 199 9 • Sec tion 1: In troduction

Table 1-2. PatchSwitch Equipment

Standard rack mounted chassis which includes a

control module. Requi res Power Supply. Chassis can

hold up to 16 PS modules and one patch interface,

test data converter , or blank module. Provides female

DCE and DTE connectors.

Same as RDC-01 except provides male DCE

connectors.

PSM-01 LED/Alarm Patch Module with

A/B Switching

A/B electromechanical switching between two data

communications devi ces ; and co mpu ter, modem and

monitor patching functions. Also includes RS232/

V.24 LED and Alarm functions.

PSM-02 Patch Model with A/B Switching Same as PSM-01 except no LED and alarm

functions.

PSM-03 Module with A/B Switching Only A/B electromechanical switching between two data

communications devices.

PSM-04 LED/Alarm Patch Module with

Off-Line Access

Same as PSM-01 except it provides direct test access

to off-line device when module is in either A or B

(sub) state.

PSM-05 Patch Module with Off-Line

Same as PSM-04 except no LEDs or alarm.

Access

PSM-07 LED Alarm Patch Interface Connects one o r two data ports to other test equip-

ment via patch cords. Also includes RS-232/V.24,

LEDs and alarm.

PSM-08 Patch Interface Same as PSM-07 except no LEDs and alarm.

PSM-09 Blank Panel Covers unused card slots.

PSM-12 RS-232/V.24 LED/Alarm

Tes t Module

Provides an interface port for test equipment requir-

ing RS-232/V.24 circuit compatibility. Normally

positioned in slot 17 of RDC-01 and RDC-02.

However, this PS module may be mounted in any

slot, except for 18, of the above PS chassis. Includes

eight LEDs for RS-232 lead status monitoring,

an adjustable alarm and patch jack port.

PSM-13 Test Module Same as PSM-12 without LEDs and alarm

circuitry.

PSM-15 Control Module Chassis control module permitting local, or

dc pulse serial remote switch and alarm control.

PSW-000001 PatchSwitch Power Supply

(6 pin in-line connector)

Dual output supply used with PSC-01/PSC-02

chassis with input power source from 90 to 240 Vac,

48-63 Hz.

© 1999, ADC Telecommunications, Inc.

Page 1-5

Page 16

ADCP-50-304 • Issue 19 • June 1999 • Section 1: Introduction

Table 1-2. PatchSwitch Equipment, continued

(V.35 Modules are described in Section 3. X.21 Modules are described in Section 4)

ADC NUMBER DESCRIPTION COMMENTS

PSW-000002 PatchSwitch Power Supply

(9 pin in-line connector)

PSW-000003 PatchSwitch Power Supply

(9 pin in-line connector)

PSR-06 Data Converter Module Converts signals to provide RS-232/RS-422

Dual output supply used with RDC-01/RDC-02

chassis with input power source –48 Vdc.

Dual output supply used with RDC-01/RDC-02

chassis with input power source from 90 to

240 Vac, 48-63 Hz.

compatibility for remotely controlled PatchSwitch

equipment.

PMPC-2

PMPC-3

PMPC-4

PMPC-6

PMPC-8

PMPC-10

Standard Patch Cord, 2-feet

Standard Patch Cord, 3-feet

Standard Patch Cord, 4-feet

Standard Patch Cord, 6-feet

Standard Patch Cord, 8-feet

Standard Patch Cord, 10-feet

Patch cords are 26 conductor cable with ADC

patching connectors on both ends. For use with

PSM-01, PSM-02, PSM-04, PSM-05, PSM-07,

PSM-08, PSM-1 2 and PSM-13.

2.2.1 PatchSwitch Chassis

The PS chassis is the stan dard EI A 19-in ch rack moun ted uni t wit h a ba ckplane and s pace f or 18

modules. The early chassis (PSC-01 and PSC-02) can be identified by the six pin in-line power

connector located on the back upper left corner of the chassis. The later chassis (RDC-01 and

RDC-02) can be identified by the nine pin square power connector located on the back upper

left corner of the chassis.

The RDC-01/02 backplane consists of a printed circuit board assembly with eighteen 96-pin

connectors on the inside of the card cage and 50 D-subminiature (DB) 25-pin connectors, two

(DB) 9-pin connectors , one 20-pin dual in-lin e (DI N ) con nector and one 9-pin squar e co nnector

on the back of the board.

2.2.2 PatchSwitch Control Module (RDM-15B)

Manual operation of the PatchSwitch Control Module switches provides local control of the

switch and alarm functions. The Control Module is microprocessor-based and provides the

interfacing cap abilities for b oth m anua l, dc pulse bank swit ching and remote cont rol operations.

A four-position DIP switch on the Control Module encodes the chassis identification number.

Remote control devices use this number to select the PS chassis (see Table 6-1). The Control

Module is located in position 18 (slot 18) of all PatchSwitch chassis.

Page 1-6

© 1999, ADC Telecommunications, Inc.

Page 17

ADCP-50-304 • Issue 19 • June 199 9 • Sec tion 1: In troduction

2.2.3 Data Converter Module (PSR-06)

This module is a printed circuit board assembly with components, a front panel with four LED

status indicators and a rear 96-pin DIN connector. The module interfaces with the ADC Remote

Control Unit, a user's CRT terminal, or computer, and converts signals providing RS-422/RS232 compatib ility to permit remote s erial control for PatchSwitch equipm ent to be co nnected to

RS-232 modem or CRTs.

2.2.4 LED/Alarm Patch Module with A/B Switching (PSM-01)

This PS module is a printed circuit board assembly with components, a front panel (two toggle,

one rotary and one touch switch, three patch 26-pin connectors, and 11 LEDs), and rear 96-pin

DIN connector. It may be mounted in any of the first 16 module positions.

2.2.5 Patch Module with A/B Switching (PSM-02)

This PS module has the same features as PSM-01 except without RS-232/V.24 lead status

indicators and alarming.

2.2.6 A/B Switching Module (PSM-03)

This PS module is a printed circuit board assembly with components, a front panel (one toggle

switch and two LEDs) and a rea r 96-pin DIN conne ctor. It may be mounted in any of the first 16

module positions.

2.2.7 Led/Alarm Patch Module with A/B Switching and Off-Line Access (PSM-04)

This module is the same as PSM-01 except that when it is in A or B state, the off-line port

provides direct test access to the off-line device.

2.2.8 Patch Module with A/B Switching and Off-Line Access (PSM-05)

Same as PSM-04 except this module has no LEDs or alarm.

2.2.9 LED/Alarm Patch Interface (PSM-07)

This module (normally mounted in the 17th position of the chassis but may be mounted in the

1st through 16th position) is a patch interface module with LED and alarm; the model is a

printed circuit board assembly with components, a front panel (one toggle, one rotary and one

touch switch, two patch 26-pin connectors and nine LEDs), and a rear 96-pin DIN connector.

2.2.10 Patch Interface (PSM-08)

This module (normally mounted in the 17th position of the chassis but may be mounted in the

1st through 16th position) is a patch interface module; the module is a printed circuit board

assembly with a front panel (two patch 26-pin connectors) and rear 96-pin connector.

© 1999, ADC Telecommunications, Inc.

Page 1-7

Page 18

ADCP-50-304 • Issue 19 • June 1999 • Section 1: Introduction

2.2.11 Blank Panel (PSM-09)

This panel is used in chassis module positions in lieu of a module. The panel is a two piece

assembly secured to the chassis by two mounting screws.

2.2.12 Test Module (PSM-12)

Test Module PSM-12 is normally mounted in the slot position 17 of the PS chassis, but may be

mounted in any slot to the left of position 17 (1 through 16). This module provide the user with

RS-232/V.24 interface capabilities and status monitoring for eight (8) leads and alarm

conditions. The module contains three female RS-232/V.24 ports (one on the front panel and

two on the rear of the module) and a patch jack. All four connectors are hardwired in parallel.

The eight RS-232/V.24 leads monitored for status include: TD; RD; DCD; SQ; RTS; CTS;

DSR; and DTR. Each lead contains an associated LED indicator, located on the front panel,

which turns on when the signal is active (or high). An adjustable alarm circuit with associated

LED (ALM) is also provided to inform the user when a preselected alarm condition exits. After

an alarm conditions occurs, the alarm circuit may be reset by the operator touching the finger

reset (RST) switch. A toggle switch is also provided to enable/disable the alarm LED.

2.2.13 Test Module (PSM-13)

Test Module PSM-13 is normally mounted in slot 17 of the PS chassis, but may be mounted in

any slot to the left of position 17 (1 through 16). This module provides the user with interface

capabilities to spare devices or test equipment. The front panel of the Test Module contains one

female DB25 port and one patch jack. The rear of the module at slot position 17 contains two

female RS-232/V.24 ports. All four connectors are hardwired in parallel.

2.2.14 PatchSwitch Chassis AC Power Supply (PSW-000001)

This power supply is a plug-in unit used when the power source is from 90 to 240 Vac, 48-63

Hz. This power s uppl y has a six pin in-line c onne ct or f or use wi th chassis PSC-01 and PSC-02.

2.2.15 PatchSwitch Chassis AC Power Supply (PSW-000003)

This power supply is a plug-in unit used when the power supply source is from 90 to 240 Vac,

48-63 Hz. This power supply has a nine pin square connector for use with chassis RDC-01 and

RDC-02.

2.2.16 Standard Patch Cords (PMPC-X)

The standard patch cords used with the PC chassis modules are described in Table 1-2.

Page 1-8

© 1999, ADC Telecommunications, Inc.

Page 19

3 SPECIFICATIONS

Physical Character is ti cs

PS Chassis

Environmental Conditions

Ambient Temperature:

Relative Humidity:

Power Requirements

PS Chassis:

ADCP-50-304 • Issue 19 • June 199 9 • Sec tion 1: In troduction

Height: 7 inches (17.78 cm)

Width: 19 inches (48.3 cm)

Depth: 12 inches (30.12 cm)

Operating: +32° F to +122° F (0° C to +50° C)

Storage: –40° F to +158° F (–40° C to +70° C)

Operating:10% to 80% noncondensing

Storage: 5% to 90% noncondensing

+5 Vdc @ 3 amps

+12 Vdc @ 1 amp (switching)

3.1 DMPS-10 AC Power Supply

The DMPS-10 AC Power Supply provides all dc operating voltages and current required by up to

four fully-populated RDC-01 or RDC-02 chassis. The rack mounted power supply plugs directly

into a standard 110 Vac primary power source outlet. This power supply can also be set for use

with 240 Vac. The power supply comes equipped with one nine-conductor power cord and an AC

line cord. The DMPS-10 will power one PS assembly and can house up to three additional

DMPS-10 EXP expansion power modules to supply power for four PS chassis assemblies.

© 1999, ADC Telecommunications, Inc.

Page 1-9

Page 20

DESCRIPTION

FUNCTIONAL

Page 21

SECTION 2: FUNCTIONAL DESCRIPTION

Content Page

1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2 PATCHING WITH IN-LINE A/B SWITCHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

3 A/B SWITCHING WITH OFF-LINE MONITOR ACCESS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

3.1 PS Control Module (RDM-15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

3.2 LED/Alarm Patch M odule with A/B Switching and In- Line Patch Access (PSM-01). . . . . . . . . . . . . . . . . . . . .2-7

3.3 Patch Module with A/ B Swit ching and In-Line Patch Acc es s (PSM -02) . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

4 A/B SWITCHING MODULE (PSM -0 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

5 LED/ALARM PATCH MODULE WITH A/B SWITCHING AND OFF-LINE ACCESS (PSM-04) . . . . . . . . . . . . . . . . . . . . . .2-13

6 PATCH MODULE WITH A/B SWITCHING AND OFF-LINE ACCESS (PSM-05) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

7 LED/ALARM PATCH INTERFACE (PSM-07). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

7.1 Patch Interface (PSM -08) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

8 TEST MODULE (PSM-12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

9 TEST MODULE (PSM 13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

10 PS RS-422/RS-232 INTER FACE CONVERTER MOD ULE (PSR-06). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

11 PS CHASSIS POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

_________________ ___________________ ______________________________________ _______________________________

ADCP-50-304 • Issue 19 • June 1999 • Se ct ion 2: Fun ct i ona l Description

1 GENERAL

This section describes how the PatchSwitch equipment functionally operates in a data

communications netw ork. The PS equipment pro vide s two main f uncti ons. A user selec ts one o f

two DTE data cha nnel s to connect to a DCE. Add it ion al ly, the user can monitor an d r es tor e dat a

channels with a manual patch.

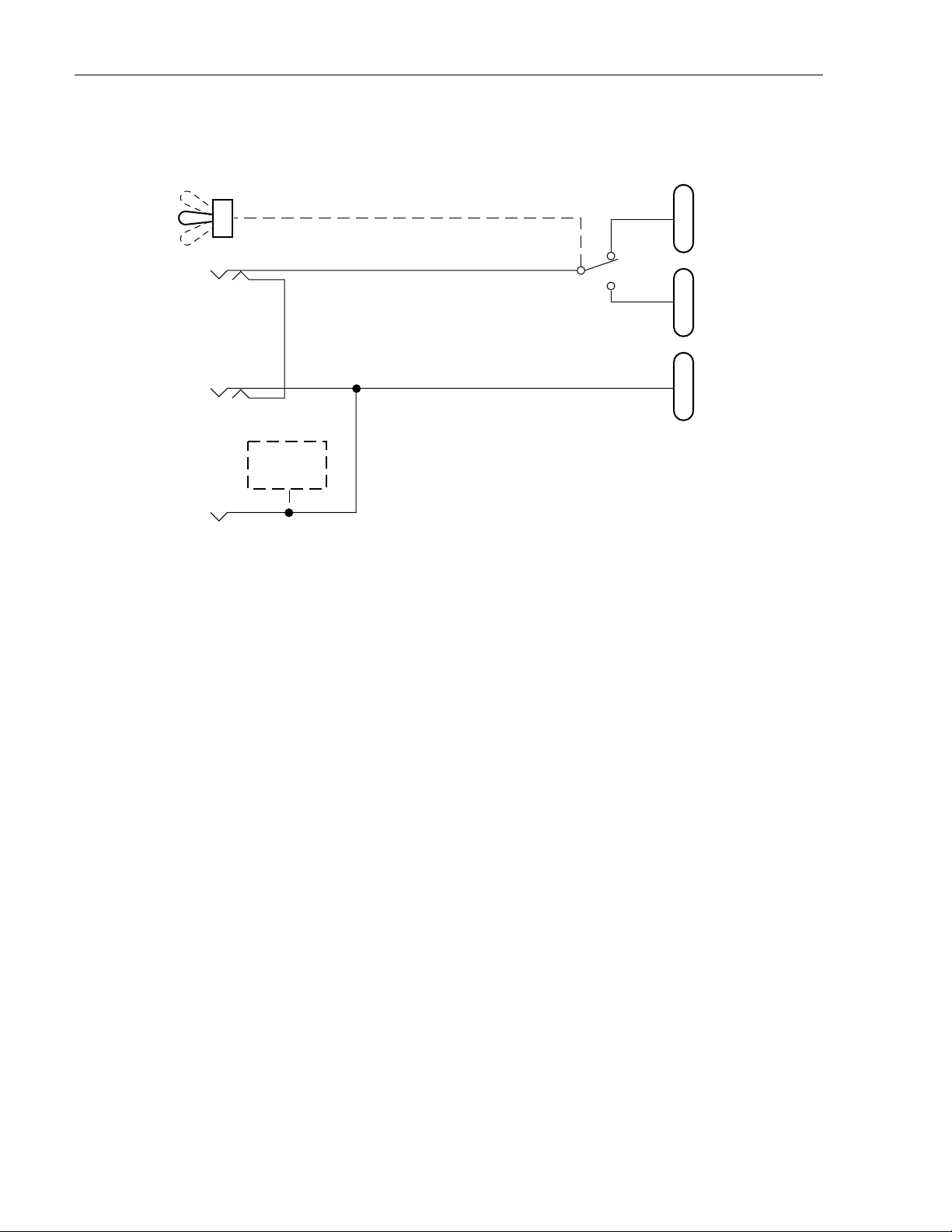

2 PATCHING WITH IN-LINE A/B SWITCHING

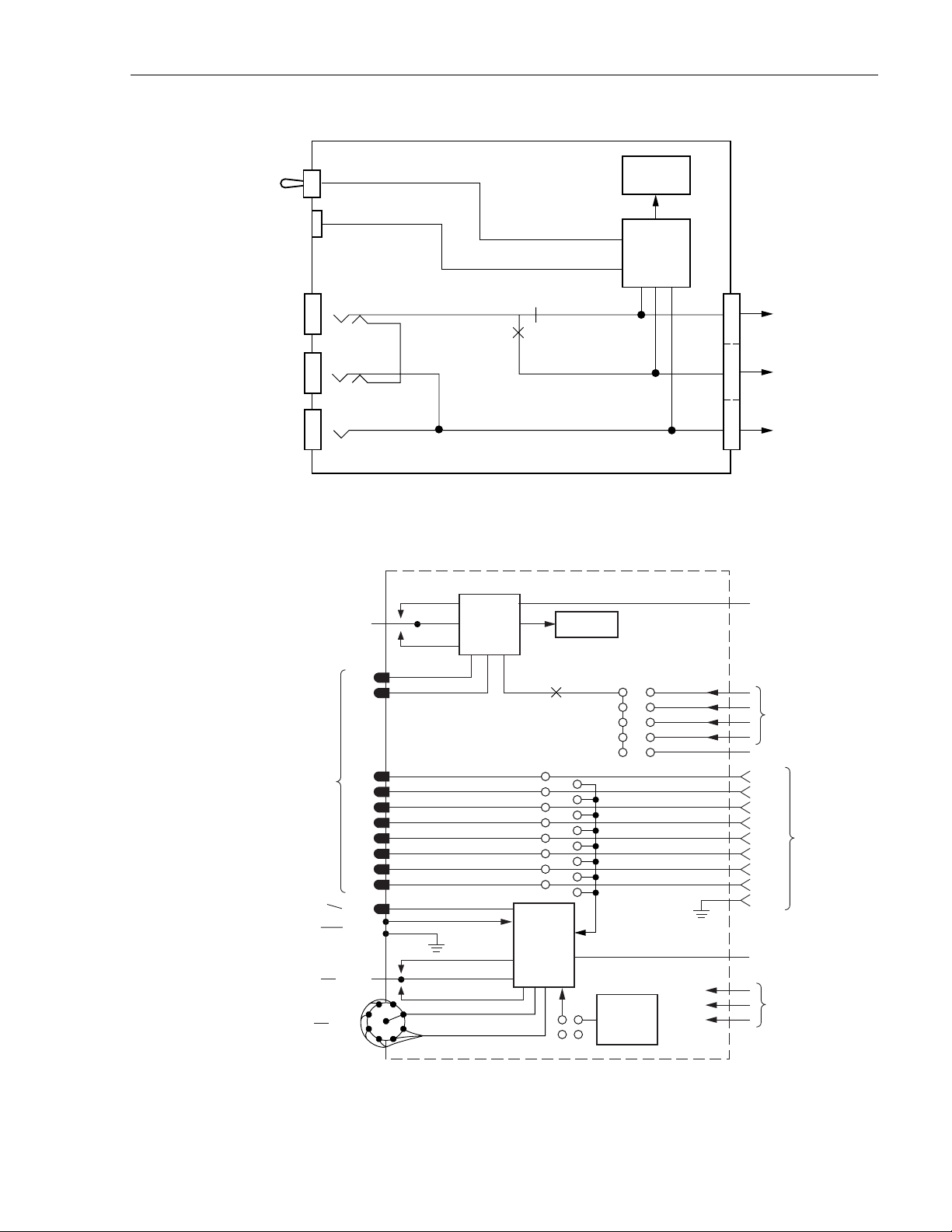

A functiona l diagram illustrati ng patching wi th in-line A/B swit ching is shown in Figure 2-1.

Computer access is through the COMPUTER patch cord jack and either the DTE-A or DTE-B

jack. Modem connection is through the MODEM patch cord jack and the DCE jack. Monitor

connection is through the MONITOR patch cord jack.

© 1999, ADC Telecommunications, Inc.

Page 2-1

Page 22

ADCP-50-304 • Issue 19 • June 1999 • Section 2: Functional Description

FRONT PANEL

CONNECTIONS

COMPUTER

MODEM

MONITOR

LED/ALARM

ELECTRONICS

(PSM-01

ONLY)

Figure 2-1. PatchSwitch with In-Line Access (PSM-01, PSM-02)

BACKPLANE

CONNECTIONS

A

B

J1 DTE-A

J2 DTE-B

J3 DCE

1607-A

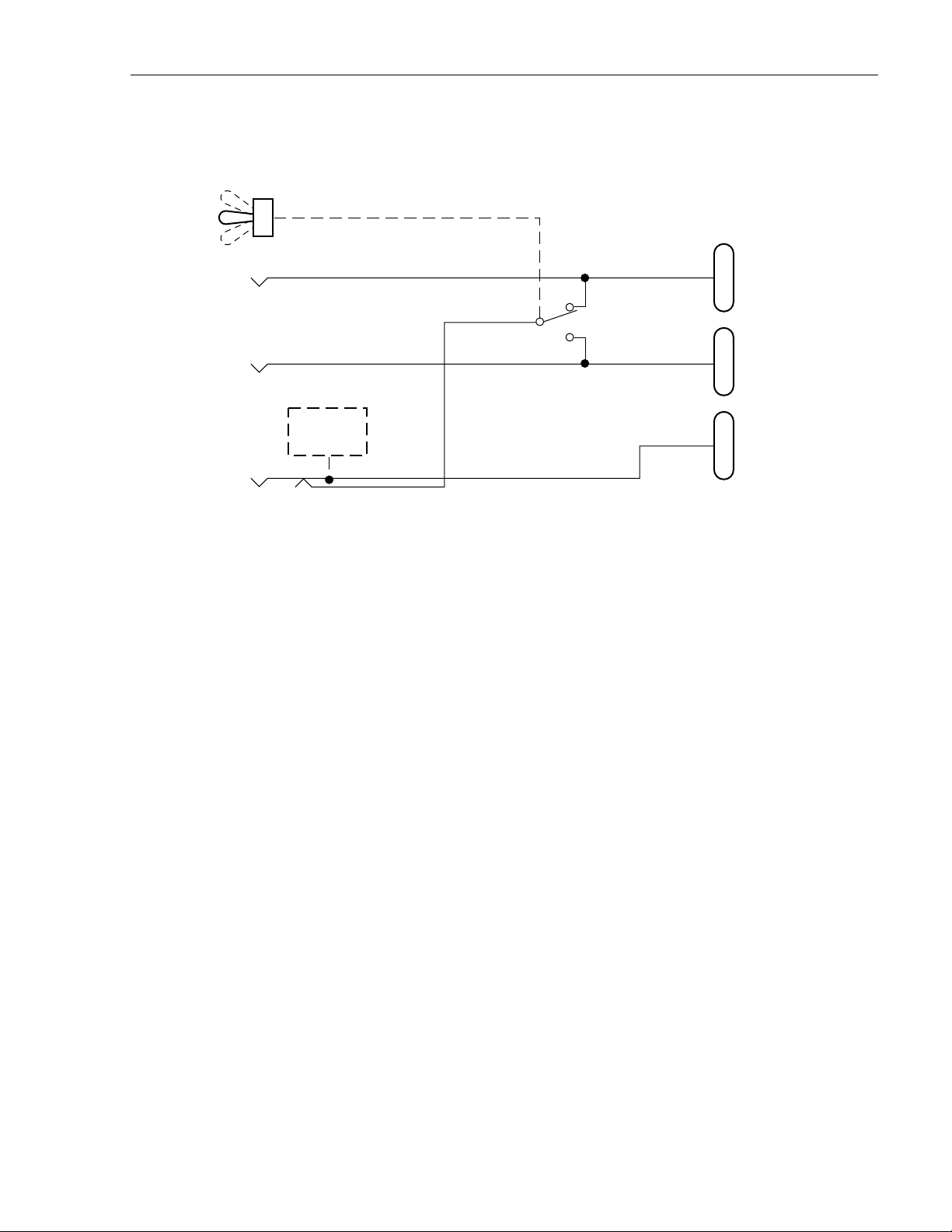

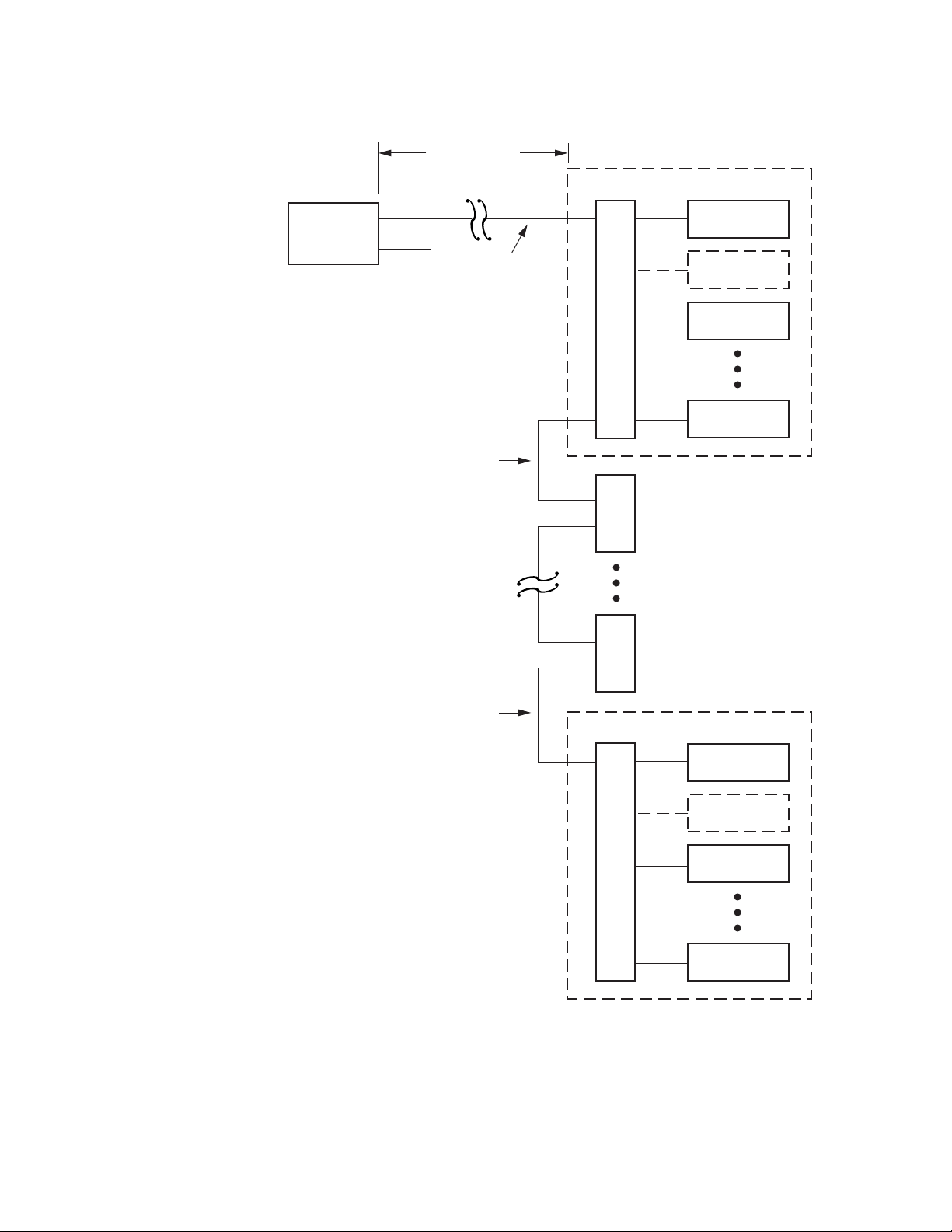

3 A/B SWITCHING WITH OFF-LINE MONITOR ACCESS

The capability for accessing the off-line DTE device is illustrated in Figure 2-2. The upper port

(A) provides patch cord access to the upper “D” subminiature connector (J-1) on the chassis

rear panel. When the module is in the “A” or normal state, this provides a monitor function. If

the module is in the “B” or “sub” state, this provides direct test access to the off-line device.

The middle port (B) functions in the same manner for the middle connector (J-2) on the chassis

backplane; “B” state, monitor access. “A” state, test access to the off-line “B” device.

The lower port (C) provides “intrusive” test access to the lower (J-3) connector on the chassis

backplane. Insertion of a patch cord in this port, regardless of switch status, breaks the circuit

and connects the patch cord to the common (DCE) device.

Page 2-2

© 1999, ADC Telecommunications, Inc.

Page 23

FRONT PANEL

CONNECTIONS

A

B

ADCP-50-304 • Issue 19 • June 1999 • Se ct ion 2: Fun ct i ona l Description

BACKPLANE

CONNECTIONS

A

B

LED/ALARM

ELECTRONICS

(PSM-04

ONLY)

C

Figure 2-2. PatchSwitch with Off-Line Access (PSM-04, PSM-05)

3.1 PS Control Module (RDM-15)

The PS Contro l Mod ule (C M) c ontro ls the overall manu al o pera tions of th e mod ules cont ained

in the PS chassis. Three toggle switche s l oca ted on the front panel have the fo ll owing functi ons:

1. Bank switch all PS modules to either the “A” or “B” position. That is, switch all modules

at the same time to either the “A” position or “B” position.

A

B

J1 DTE-A

J2 DTE-B

J3 DCE

1608-A

2. Enable the bank switch and the individual module A/B switches.

3. Reset all of the modules' alarm circuits.

The audible alarm circuitry is in the CM. It activates when an individual PS module detects an

alarm condition (according to the alarm selection configuration on the module). Alarm

conditions are detected only by modules which contain circuitry. The alarm circuitry must also

be conditioned by proper strapping (jumper) of the individual PS chassis module.

When the alarm conditi on occurs, the individual module energizes it s ye ll ow LED indicator and

the CM audible alarm sounds. The operator toggles the reset switch to reset the alarm circuitry.

The PS Control Module is equipped with a selectable remote control feature. Depending on the

strap position the CM will either accept serial RS-422 or dc level (pulse) signals through the 9pin D-subminiature connector. The CM is shipped strapped for RS-422 control.

With the CM strapped for serial RS-422 remote control, the CM provides an interface between

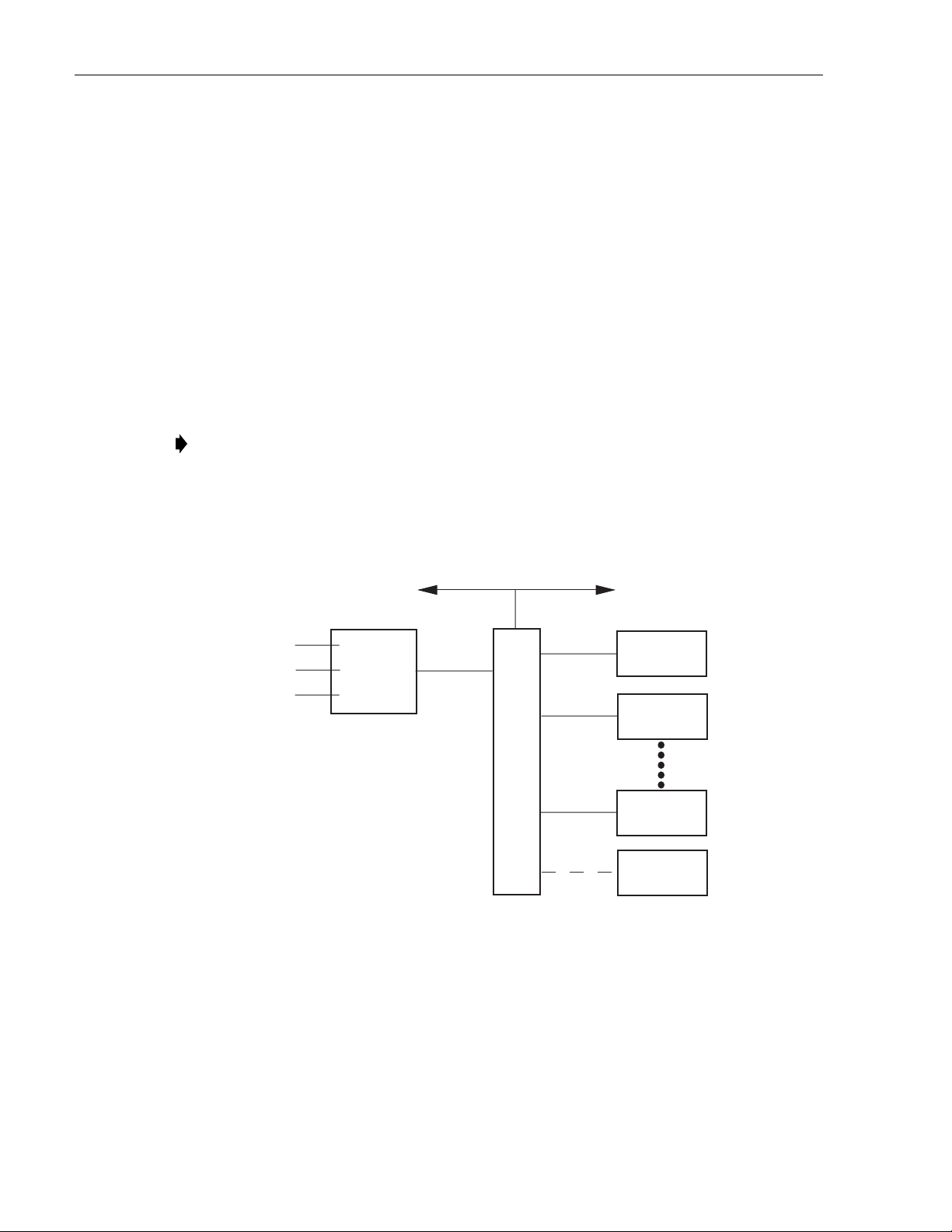

the PS chassis modules and a remote control device (see Figure 2-3 and Figure 2-4). The

following devices can be used for remote control of a PS chassis.

1. PatchSwitch Remote Control Unit (RCU, PSR-03) (See ADCP-50-302 User Manual.)

2. Terminal or computer (asynchronous ASCII device).

© 1999, ADC Telecommunications, Inc.

Page 2-3

Page 24

ADCP-50-304 • Issue 19 • June 1999 • Section 2: Functional Description

A remote control device can control the operation of up to 16 full PS chassis assemblies (16

modules each) using a dedicated communications channel. This channel has four signals:

1. Transmit Data (TD)

2. Receive Data (RD)

3. Clear-To-Send (CTS)

4. Request-To-Send (CTS)

Each of the abo ve signals ha s t he same function as th e corresponding sig nal s defined by the RS232 standard.

The communications channel transmission medium is a cable consisting of four twisted wires

within an overall shield. The shield is ground potential.

Note:

The electrical characteristics of the communications channel cable (9-wire)

conform to RS-422A/V.11 (X.27) standards.

COMMUNICATIONS

CHANNEL**

MASTER A/B

ENABLE

RESET

REMOTE

CONTROL DEVICE

CONTROL

MODULE*

SLOT 18

* STANDARD

CONTROL OR

REMOTE

CONTROL

** USED ONLY

BY REMOTE

CONTROL

MODULE

P/S

C

H

A

S

S

S

B

A

C

K

P

L

A

N

E

TO NEXT P/S CHASSIS

MODULE 0

SLOT 1

MODULE 1

I

SLOT 2

P/S MODULES

2 THROUGH 14

(SLOT 3-15)

MODULE 15

SLOT 16

SLOT 17

1609-A

Figure 2-3. Control Module, Simplified Block Diagram (Standard and Remote)

Page 2-4

© 1999, ADC Telecommunications, Inc.

Page 25

UP TO 1000 FT.

(304 M)

ADCP-50-304 • Issue 19 • June 1999 • Se ct ion 2: Fun ct i ona l Description

PATCHSWITCH CHASSIS 0

REMOTE

CONTROL

UNIT

RS-422

RS-232

COMMUNICATION

RS-422

COMMUNICATION

CHANNEL

RS-422

CHANNEL

B

A

C

K

P

L

A

N

E

PS CHASSIS 1

PS CHASSIS 6

CM 0

SLOT 18

SLOT 17

PS MODULE

SLOT 16

SLOTS

2 – 15

PS MODULE

SLOT 1

PS CHASSIS

2 – 5

RS-422

COMMUNICATION

CHANNEL

PATCHSWITCH CHASSIS 7

B

A

C

K

P

L

A

N

E

SLOTS

2 – 15

CM 7

SLOT 18

SLOT 17

PS MODULE

SLOT 16

PS MODULE

SLOT 1

1610-A

Figure 2-4. RCU to Local PatchSwtich Chassis, Interconnection Block Diagram

© 1999, ADC Telecommunications, Inc.

Page 2-5

Page 26

ADCP-50-304 • Issue 19 • June 1999 • Section 2: Functional Description

The cable connectors are 9-pin, D-subminiature. Both end-connectors are male. The cable may

be up to 1,000 feet in length. Connector pin assignments are detailed in Table 2-1.

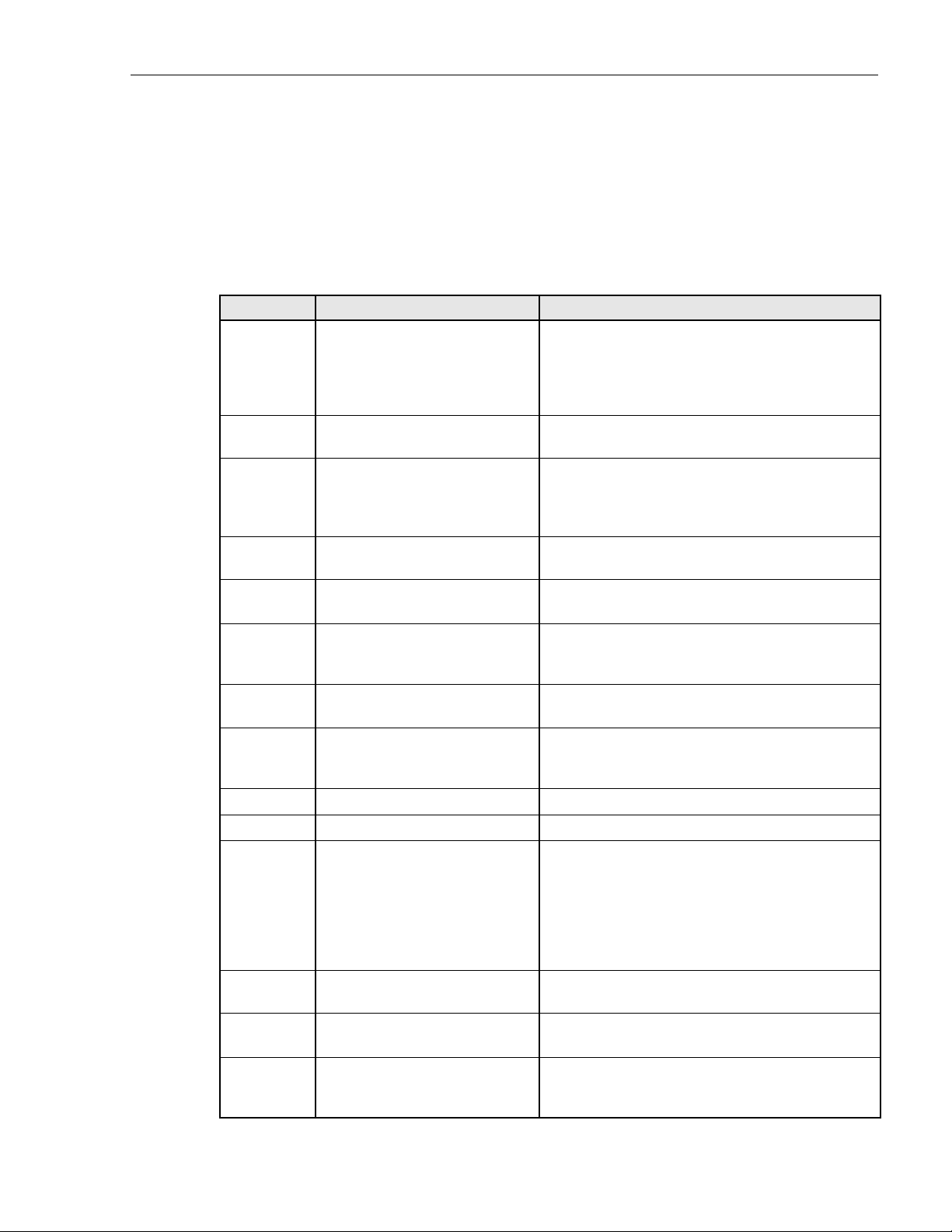

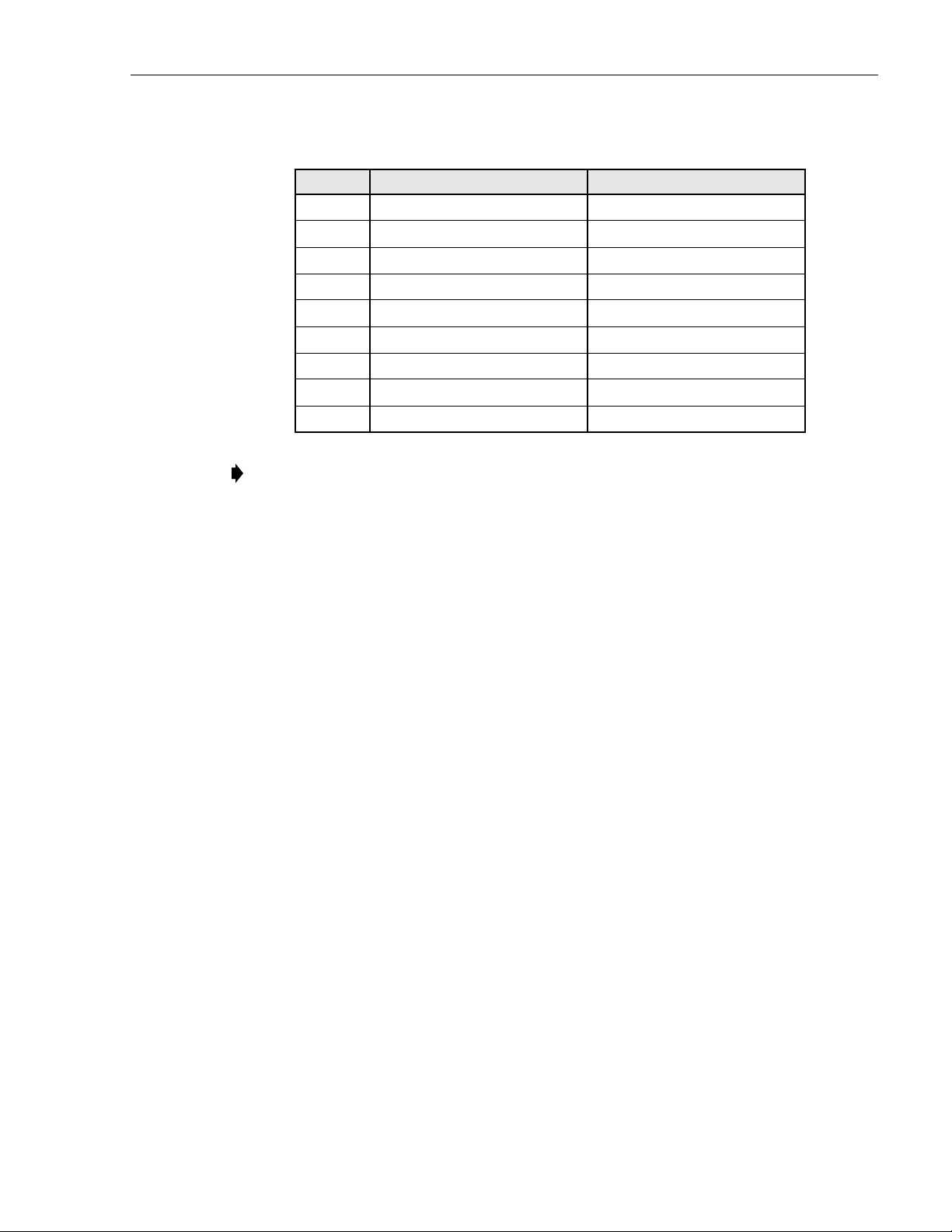

Table 2-1. Communications Channel Connector Pin Assignments

SIGNAL NAME PIN NUMBER DIRECTION OF SIGNAL

TD +

TD –

6

7

Input

Input

RD +

RD –

CTS +

CTS –

RT S +

RT S –

GRD – 1Ground

2

3

4

5

8

9

Output

Output

Output

Output

Input

Input

Each PS chassis contains two female 9-pin D-subminiature connectors wired in parallel. A

cable connects one PS chassis to another in daisy-chain fashion. A long cable connects the

remote contro l device to the first (or last) P S chassis i n the chai n. Up to 16 PS chass is may be

interconnected via the communications cable to a remote control device.

All transmissions between the PatchSwitch Control Module and the remote control device must

use the ASCII character set. The PS chassis is a DCE device and has the following data

transmission characteristics:

1. Speed of 1200 bits per second

2. Asynchronous transmission

3. Bit-serial ASCII data (8 bit no parity)

4. One Stop bit.

During normal operations, only one (of the possible 16) PS chassis CM may transmit on the

communications channel at one time. When a PS Chassis is selected by the remote control

device, all other PS chassis connected on the same channel are disabled (de-selected). All

manual controls on a CM are always functional.

With the CM strapped for dc pulse control, the CM provides capability to bank switch PS chassis

modules by application of 0V (GND), +5V or –5 V to –48V dc voltage levels on the 9- pin Dsubminiature connector. The connector pin assignments are detailed in Table 2-2.

Page 2-6

© 1999, ADC Telecommunications, Inc.

Page 27

ADCP-50-304 • Issue 19 • June 1999 • Se ct ion 2: Fun ct i ona l Description

Table 2-2. DB-9 Pinout and Signal Characteristics

PIN OULTAGE INPUT CHANNEL (SWITCHED TO)

1 Chassis Ground N/A

2 –48V +5% (–5V min) B

3+5V +5% B

4 Remote Ground In B

5 Signal Return N/A

6 –48V +5% (–5V min) A

75V +5% A

8 Remote Ground In A

9 Signal Return N/A

The dc voltages indicated in Table 2-2 must be present for a minimum of 250 msec

Note:

to ensure switching.

Up to four (4) PS chassis can be bank switched by daisy chaining the CMs via the 9-pin Dsubminiature and ensuring that each CM is strapped for dc pulse control.

The CM is also equipped with a selectable Autofallback feature. When an alarm condition is

detected, automatic switching is performed between the “A” and “B” sides of the PS modules.

The “A” to “B” side, or “B” to “A” automatic switching operation is selected by installing a

jumper on the CM circuit board. After configuring the Autofallback option, the PS module

detecting the alarm swi tc hes to t he designated side (dep endi ng on the strap install ed) , it re mains

in the switched position regardless of subsequent alarm status.

Alarm indications are automatically reset after the module detecting the alarm switches to the

appropriate side if the module is strapped for “Automatic Reset” (recommended). When the

front panel alarm (

ALM

) selection is posi ti one d in the

OFF

position, the autof al lback feature is

disabled for that module.

3.2 LED/Alarm Patch Module with A/B Switching and In-Line Patch Access (PSM-01)

This PS module provides patching and switching functions together with lead status, switch

status, and alarm indications. A simplified circuit of this module is shown in Figure 2-5.

The A/B switch activates relays to connect the computer patch cord jack either the DTE-A port

or the DTE-B port. The indicators show A/B switch position, alarm and RS-232 lead status.

Figure 2-6 shows a more detailed diagram of the module. In addition to switching between

DTE-A or DTE-B, th e rel ay s als o swit ch in th e int er lo ck ju mp er. Interlockin g is use d to pro te ct

the user from accidentally switching a common backup piece of equipment onto two or more

different data lines. This is accomplished by allowing only the first module in that group to

switch. The remaining modules r emain in the “no rmal sta te” or the “A” position. Modules in the

“B” position once switched to “A” will remain in the “A” position.

© 1999, ADC Telecommunications, Inc.

Page 2-7

Page 28

ADCP-50-304 • Issue 19 • June 1999 • Section 2: Functional Description

The three classes of interlock groups available are:

1. Global Interlock: Groups 1 and 2 are global and may be extended to all chassis in a

system, using a 20-p in i nt er cha ssi s i nt er loc k cable. W it h t hi s gr ouping, all modules having

a jumper placed on group 1 make up one group, and all modules with a ju mp er on gr oup 2

make up the other group. Interchassis interlock cables must be installed between chassis.

Each module interlock group may have no more than one jumper installed at a time.

2. Horizontal Interlock: Groups 3 and 4 are horizontal and they include only modules in the

individual chassis. With this grouping, all modules having a jumper placed on group 3

make up one group, and all modules with a jumper on group 4 make up the other group.

These groupings do not extend out of the chassis and are not affected by the interchassis

interlock cable. Each module interlock group jumper block may have no more than one

jumper installed at a time.

3. Vertical Interlock: The vertical in terl ock ju mper po siti on is la beled V. Placi ng a jump er in

this position interlocks all modules in the same slot location in other chassis having a

jumper install ed on the same V position . Interchassis interlo ck cables must be installe d

between chassis. The interchassis interlock cable is a 20 position ribbon cable (4WC-03)

with a 20-pin connector for each chassis. Each module interlock group jumper block may

have no more than one jumper installed at a time.

LEDs show the status of eight RS-232 leads. Each lead has a jumper connection to the alarm

circuit control logic. The alarm is thus user selectable for any of eight leads. The EIA RS-232/

CCITT V.2 4 modem interface signal l eads are shown in Table 2-3. The al arm circuit control

logic supplies the alarm signal to the control module and an alarm indicator. This logic is also

controlled by the RST (Reset) touch switch, toggle switch OFF (LED off, audible alarm off),

ALM (LED and audible alarm on) and LED (LED on, audible alarm off), and rotary switch

DLY (alarm time delay setting). The alarm may be automatically reset if the automatic alarm

reset jumper is in place. LED status indicators with their color and signal definition is shown in

Table 2-4. Table 2-5 shows the alarm delay settings.

Caution: The bank switching feature is not compatible with the group interlock feature. If no

module in an interlocked group is in the B state when a bank switch to the B state is initiated,

only the first module in this group will switch to the B state. Data may be lost when more than

one module is in the B state of an interlocked group. If one module in an interlocked group is in

the B state when a bank switch is initiated, the rest of the modules in that interlocked group do

not switch to the B state; consequently, the system maintains its integrity

.

Page 2-8

© 1999, ADC Telecommunications, Inc.

Page 29

ADCP-50-304 • Issue 19 • June 1999 • Se ct ion 2: Fun ct i ona l Description

A/B

SWITCH

1641-A

INDICATORS

COMPUTER

MODEM

MONITOR

A/B

RELAY

A/B

RELAYS

A/B

DTE AND

ALARM

LOGIC

DTE

(A)

DTE

(B)

DCE

UPPER

INTERFACE

PORT

LOWER

INTERFACE

PORT

Figure 2-5. LED/Alarm Patch Module with A/B Switchin g Simplified Circuit Diagram

STATUS

INDICATORS

ALARM

INDICAT OR

TOUCH

SWITCH

TOGGLE

SWITCH

ROTARY

SWITCH

TOGGLE

SWITCH

ALM

DL Y

TD

RD

DCD

SQ

RTS

CTS

DSR

DTR

ALM

RST

A

B

OFF

LED

A

B

A/B

SWITCH

LOGIC

A/B SWITCH CONTROL

A/B

RELAYS

INTERLOCK

A/B

RELAYS

ALARM

JUMPER

ALARM

CIRCUIT

CONTROL

LOGIC

AUTOMA TIC

ALARM

RESET

STORE

A/B

JUMPER

GROUP 1

2

3

4

V

ALARM

+5 Vcd

GND

+12 Vcd

1611-A

CONTROL

MODULE

PIN 2

PIN 3

PIN 8

PIN 21

PIN 4

PIN 5

PIN 6

PIN 20

PIN 7

CONTROL

MODULE

BACKPLANE

RS-232

LEADS

BACKPLANE

Figure 2-6. LED/Alarm Patch Module with A/B Switching Detailed Circuit Diagram

© 1999, ADC Telecommunications, Inc.

Page 2-9

Page 30

ADCP-50-304 • Issue 19 • June 1999 • Section 2: Functional Description

Table 2-3. RS-232 Modem Terminal Interface

PIN NAME SOURCE FUNCTION CIRCUIT CCITT/EIA

1* FG — Frame Ground 101 (AA)

2* TD DTE Transmitted Data 103 (BA)

3* RD DCE Received Data 104 (BB)

4* RTS DTE Request To Send 105 (CA)

5* CTS DCE Clear To Send 106 (CB)

6* DSR DCE Data Set Ready 107 (CC)

7* SG — Signal Ground 102 (AB)

8* DCD DCE Data Carrier Detect 109 (BA)

9* DCE Positive DC Test Voltage

10* DCE Negative DC Test Voltage

11*

12* SRLSD DCE Sec Data Carrier Detect 122 (SCF)

13* (S)CTS DCE Sec Clear To Send 121 (SCB)

14* STD DTE Sec Transmittal Data 128 (SBA)

15* TC DCE Transmitter Clock 114 (DB)

16* SRD DCE Sec Received Data 119 (SBB)

17* RC DCE Receiver Clock 115 (DD)

18*

LL DTE Local Loopback 141 (LL)

19* SRTS DTE See Request To Send 120 (SCA)

20* DTR DTE Data Terminal Ready 108/2 (CD)

21* SQ DCE Signal Quality Detect 110 (CG)

22* RI DCE Ring Indicator 125 (CE)

23* DTE Data Rate Selector 111 (CH)

Data Rate Selector 112 (CI)

24* ETC DTE Ext Transmitter Clock 113 (DA)

25* TM DCE Test Mode 142 (TM)

Page 2-10

© 1999, ADC Telecommunications, Inc.

Page 31

ADCP-50-304 • Issue 19 • June 1999 • Se ct ion 2: Fun ct i ona l Description

Table 2-4. LED Status Indicators

LED STATUS INDICATOR COLOR SIGNAL DEFINITION

A Red DTE-A

B Green DTE-B

TD Green Transmitted Data

RD Green Received Data

DCD Green Data Carrier Detect

SQ Green Signal Quality Detect

RTS Red Request To Send

CTS Red Clear To Send

DSR Red Data Set Ready

DTR Red Data Terminal Ready

ALM Yellow Alarm On

Table 2-5. Alarm Time Delay Settings

TIME DELAY

ARC LENGTH 50 HZ AND 60 HZ ENVIRONMENT

γ

1 µsec

Shortest 64 msec

256 msec

0.51 sec

1.02 sec

8.19 sec

32.75 sec

Longest 65.5 sec

3.3 Patch Module with A/B Switching and In-Line Patch Access (PSM-02)

This PS module operates similarly to the PSM-01 by providing patching, switching, and switch

status indicatio n, e xcept it does no t cont ain LED statu s indi cator s and alar m ci rcuitry. A detailed

circuit diagram of this module is shown in Figure 2-7.

© 1999, ADC Telecommunications, Inc.

Page 2-11

Page 32

ADCP-50-304 • Issue 19 • June 1999 • Section 2: Functional Description

4 A/B SWITCHING MODULE (PSM-03)

This module provides A/B swit ching only. A simplified circuit diagr am of t his module is show n

in Figure 2-8.

The A/B switch activates the A/B relays. The A/B relays complete the channel between the DCE

and either DTE-A or DTE-B. The re lays also switc h in the interl ock jumper. Interlocking from

the control mod ule protects the user fr om accidentally switchin g common backup equip ment

onto two or more different data lines. The thre e classes of interlo ck groups available are:

1. Global Interlock: Groups 1 and 2 are global and may be extended to all chassis in a

system, using a 20-p in i nt er cha ssi s i nt er loc k cable. W it h t hi s gr ouping, all modules having

a jumper placed on group 1 make up one group, and all modules with a ju mp er on gr oup 2

make up the other group. Interchassis interlock cables must be installed between chassis.

Each module interlock group may have no more than one jumper installed at one time.

2. Horizontal Interlock: Groups 3 and 4 are horizontal and they include only modules in the

individual chassis. With this grouping, all modules having a jumper placed on group 3

make up one group and all modules with a jumper on group 4 make up the other group.

These groupings do not extend out of the chassis and are not affected by the interchassis

interlock cable. Each module interlock group jumper block may have no more than one

jumper installed at a time.

3. Vertical Interlock: The vertical in terl ock ju mper po siti on is la beled V. Placi ng a jump er in

this position interlocks all modules in the same slot location in other chassis having a

jumper instal led on the came V position. Interch assis interlock c ables must be inst alled

between chassis. The interchassis interlock cable is a 20 position ribbon cable (4WC-03)

with a 20-pin connector for each chassis. Each module interlock group jumper block may

have no more than one jumper installed at a time.

TOGGLE

SWITCH

INDICATORS

A

B

A

B

Figure 2-7. Patch Module with A/B Switching Detailed Circuit Diagram

A/B

SWITCH

LOGIC

A/B

REPLAYS

A/B

REPLAYS

ALARM

A/B

INTERLOCK

JUMPER

GROUP 1

2

3

4

V

1612-A

BACKPLANE

Page 2-12

© 1999, ADC Telecommunications, Inc.

Page 33