Page 1

UltraWAVE Micro BTS

Commissioning Guide

Installation and

SW Release 7.2

July 2006

P/N 214323

Page 2

Legal Rights

The material contained herein is proprietary, privileged, and confidential and

owned by Alvarion or its third party licensors. No disclosure thereof shall be made

to third parties without the express written permission of Alvarion Ltd.

This document applies to the Alvarion release of the GSM or CDMA product lines

and to all subsequent versions and releases of the hardware or software thereof

unless otherwise indicated in a new version or an update package for the current

edition dated November 2005.

Publications requests should be addressed to your local sales support office.

Alvarion Ltd. reserves the right to alter the equipment specifications and

descriptions in this publication without prior notice. No part of this publication

shall be deemed to be part of any contract or warranty unless specifically

incorporated by reference into such contract or warranty.

Use, duplication, or disclosure by the U.S. Government is subject to restrictions of

FAR 52.227-14 (g) (2) (6/87) and FAR 52.227-19 (6/87), or DFAR 252.227-7015

(b) (6/95) and DFAR 227.7202-3 (a).

The software described in this document is furnished under a license agreement.

The software may be used or copied only in accordance with the terms of the

agreement. It is a violation of Alvarion Ltd. proprietary rights to copy the software

on any medium except as specifically allowed in the license agreement. The

material contained herein is Alvarion proprietary, privileged, and confidential. No

disclosure thereof shall be made to third parties without the express written

permission of Alvarion.

The information contained in this manual is subject to change without notice.

Alvarion Ltd. shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of

this manual or equipment supplied with it.

Alvarion's products are patented by one or more of the following United States

Patents: No. 5,781,582, No. 5,682,403, No. 5,734,979, No. 5,734,699, No.

5,999,813, No. 5,953,651, No. 5,887,256, No. 5,577,029, No. 5,761,195, No.

5,842,138, No. 5,818,824, No. 5,957,464, No. 6,078,823, No. 6,070,071, No.

6,101,400, No. USP D 391,967, No. USP D 391,968, No. USP D 397,693.

Trademark Acknowledgment

Alvarion®, BreezeCOM®, WALKair®, WALKnet®, BreezeNET®, BreezeACCESS®,

BreezeMANAGE™, BreezeLINK®, BreezeConfig™, BreezeMAX™, AlvariSTAR™,

MGW™, eMGW™, WAVEXpress™, MicroXpress™, WAVEXchange™,

WAVEView™, GSM Network in a Box and TurboWAVE™ and/or other products

and/or services referenced here in are either registered trademarks, trademarks

or service marks of Alvarion Ltd. All other names are or may be the trademarks of

their respective owners.

©2006 Alvarion, Ltd. All Rights Reserved.

United States Federal Communications Commission Required User Information

Located on the equipment is a label that contains, among other information, the

FCC registration number. If requested, this information must be provided to the

telephone company.

The UltraWAVE BTS Series AUAC series complies with Part 22 of the FCC Rules.

ii UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 3

Legal Rights

The 1900 MHz WAVEXpress Series M50 complies with Part 24 of the FCC Rules.

The Breeze2000 BS Plus 800 MHz complies with Part 22 of the FCC Rules.

The Breeze2000 Pico BS Plus (800 MHz and 1900 MHz) comply with Part 22 and

Part 24 of the FCC Rules and UL 1950 safety certification.

This equipment cannot be used on the telephone company-provided coin service.

Connection to Party Line Service is subject to State Tariffs.

If this equipment causes harm to the telephone network, the telephone company

will notify you in advance that temporary discontinuance of service may be

required. If advance notice isn’t practical, the telephone company will notify the

customer as soon as possible. Also, you will be advised of your right to file a

complaint with the FCC if you believe it is necessary.

The telephone company may make changes in its facilities, equipment,

operations, of procedures that could affect the operation of the equipment. If this

happens, the telephone company will provide advance notice in order for you to

make the necessary modifications in order to maintain uninterrupted service.

If trouble is experienced with this equipment, please contact:

Alvarion, Inc.

2495 Leghorn Drive

Mountain View, CA 94043-1611 U.S.A.

If the trouble is causing harm to the telephone network, the telephone company

may request you to remove the equipment from the network until the problem is

resolved.

It is recommended that the customer install an AC surge arrester in the AC outlet

to which that device is connected. This is to avoid damaging the equipment

caused by local lightning strikes and other electrical surges.

This equipment uses the following USOC jacks and codes:

USOC Jacks and Codes

Model Name Facility Interface Code Service Order Code Jack Type

340122 04DU9-BN 6.ON RJ-48C

340122 04DU9-DN 6.ON RJ-48C

340122 04DU9-1KN 6.ON RJ-48C

340122 04DU9-1SN 6.ON RJ-48C

340122 04DU9-1ZN 6.ON RJ-48C

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B iii

Page 4

Legal Rights

cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Changes of modifications not expressly approved by Alvarion can void the user’s

authority to operate the equipment. FCC and IC certification labels denoting the

product specific certification numbers may be found on the product.

Industry Canada Required User Information

CP-O1, Issue 8, Part 1, Section 14.1

NOTICE: The Industry Canada label identifies certified equipment. This

certification means that the equipment meets certain telecommunications

network protective, operational and safety requirements as prescribed in the

appropriate Terminal Equipment Technical Requirements document(s). The

Department does not guarantee the equipment will operate to the user’s

satisfaction.

Before installing this equipment, users should ensure that it is permissible to be

connected to the facilities of the local telecommunications company. The

equipment must also be installed using an acceptable method of connection. The

customer should be aware that compliance with the above conditions may not

prevent degradation of service in some situations.

Repairs to certified equipment should be coordinated by a representative

designated by the supplier. Any repairs or alterations made by the user to this

equipment, or equipment malfunctions, may give the telecommunications

company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground

connections of the power utility, telephone lines and internal metallic water pipe

system, if present, are connected together. This precaution may be particularly

important in rural areas.

CAUTION: Users should not attempt to make such connections themselves, but

should contact the appropriate electric inspection authority, or electrician, as

appropriate.

The standard connecting arrangement (telephone jack type) for this equipment is

CA81A.

CP-01, Issue 8, Part 1, Section 14.2

NOTICE: The Ringer Equivalence Number (REN) assigned to each terminal device

provides an indication of the maximum number of terminals allowed to be

connected to a telephone interface. The termination of an interface may consist of

any combination of devices subject only to the requirement that the sum of the

Ringer Equivalence Numbers of all the devices does not exceed 5.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numerique de la classe A est conforme a la norme NMB-003 du

Canada.

This device complies with Industry Canada RSS-133 and SRSP-510 or RS132 &

SRPS-503.

iv UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 5

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Chapter 1 - Unpacking and Configuration Verification . . . . .1

1.1 Unpacking and Inspecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.1.1 Unpacking the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.1.2 Opening the Cabinet Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.1.3 Unpacking and Inspecting the Rack Assembly . . . . . . . . . . . . . . . . . . . . . .7

1.2 Electrostatic Discharge (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.3 Inspecting Components and Recording Part Numbers . . . . . . . . . . . . . . . . . . . .8

1.3.1 Identifying the System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.3.2 Verifying System Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.4 Verifying and Documenting Cards and Modules . . . . . . . . . . . . . . . . . . . . . . . . .12

1.4.1 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1.4.2 Micro Subrack Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1.4.3 Slot Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

1.4.4 Verification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

1.5 Verifying Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

1.5.1 Verifying Internal Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

1.5.2 Verifying Enclosure Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Chapter 2 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.1 Analyzing Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Page 6

Table of Contents

2.2 Mounting the Micro BTS Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3 Configuring the E1 or T1 Trunk Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.4 Connecting Ground Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.1.1 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1.2 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1.3 Chassis Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2.1 Rack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2.2 Enclosure Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.3.1 Configuring Ground Jumpers on 75 Ohm E1 Cards . . . . . . . . . . . . . . . . . 32

2.3.2 Configuring Cable Length DIP Switch Settings on T1 Cards . . . . . . . . . . 34

2.4.1 Connecting the Grounding Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4.2 Grounding the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.5 Connecting Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.5.1 Connecting AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.5.2 Connecting DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.6 Connecting E1 or T1 Trunk Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.6.1 E1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.6.2 T1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.6.3 Connecting E1 or T1 Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.6.4 Direct Cabling Between Multiple UltraWAVE or WAVEXpress Systems . 50

2.7 Connecting Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.7.1 Omni 1 TRX (O1) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2.7.2 Omni 2 TRX (O2) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2.7.3 Omni 3 TRX (O3) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.7.4 Sectorized Three TRX (S111) Configuration . . . . . . . . . . . . . . . . . . . . . . 57

2.7.5 Three Sector Six TRX (S222) Configuration . . . . . . . . . . . . . . . . . . . . . . . 58

2.7.6 RF Radiation Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

vi UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 7

Table of Contents

2.8 Connecting External Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.9 Making a Serial Connection to the Processor Card . . . . . . . . . . . . . . . . . . . . . . 64

2.10 Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.11 Post Installation Cabling and Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

2.11.1 Connecting the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

2.11.2 Verifying External Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Chapter 3 - Off-Line Commissioning . . . . . . . . . . . . . . . . . . 67

3.1 Pre Off-Line Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3.1.1 Visual Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3.2 Off-Line Commissioning of the Micro BTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.2.1 Starting XWindows Using the Craft PC . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.2.2 Connecting the Craft PC to the ICP Processor Card . . . . . . . . . . . . . . . . 72

3.2.3 Setting Up a Serial Connection via the ICP Processor Card Serial Port . 73

3.2.4 Power-On LED Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.2.5 Configuring Boot Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.2.6 Setting Up an Ethernet Connection to the ICP Processor Card

Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.2.7 Verifying Telnet Communications with the Micro BTS over Ethernet . . . . 81

3.3 Software Verification using Craft PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3.3.1 Verifying the Current Software Version and Patch Level . . . . . . . . . . . . . 83

3.3.2 Checking the Flash Version Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.3.3 Running E1 or T1 POST Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3.3.4 Running TRX POST Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.3.5 Reviewing POST Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3.3.6 Rebooting the Micro BTS after Running POST . . . . . . . . . . . . . . . . . . . . 89

3.3.7 Terminating Serial Communications with the Micro BTS . . . . . . . . . . . . . 89

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B vii

Page 8

Table of Contents

3.3.8 Exiting XWindows on the Craft PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.4 Upgrading the Micro BTS Software Version (Flash) . . . . . . . . . . . . . . . . . . . . . 90

3.5 Post Off-Line Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.5.1 Post Off-Line Commissioning Procedures at the Staging Area . . . . . . . . 92

3.5.2 Post Off-Line Commissioning Procedures On-Site . . . . . . . . . . . . . . . . . . 92

Chapter 4 - Off-Line Commissioning of a Daisy Chain . . . 107

4.1 Prerequisites to Daisy Chaining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

4.2 Setting the Abis LAPD Signaling Timeslot . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Chapter 5 - On-Line Commissioning . . . . . . . . . . . . . . . . . 111

5.1 Pre On-Line Commissioning Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5.2 On-Line Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

5.2.1 Unlocking the Abis Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

5.2.2 Commissioning the Micro BTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

5.2.3 Recovery Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

5.2.4 External Alarm Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

5.2.5 TCH Timeslot Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

5.3 Antenna Cabling and Power Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

5.3.1 Setting up Power Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

5.3.2 Verifying TRX Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

5.3.3 Voltage Standing Wave Ratio (VSWR) Check . . . . . . . . . . . . . . . . . . . . 126

5.3.4 RX Signal Quality Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

5.4 Post On-Line Commissioning Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

viii UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 9

Table of Contents

Checklist 1 - Site Readiness Checklist . . . . . . . . . . . . . . . 129

Checklist 2 - Installation Checklist . . . . . . . . . . . . . . . . . . 131

Checklist 3 - Commissioning Checklist . . . . . . . . . . . . . . . 133

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B ix

Page 10

Table of Contents

(this page intentionally left blank)

x UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 11

Welcome!

Welcome to the UltraWAVE Micro BTS Installation and Commissioning Guide. This

guide describes how to perform local installation and commissioning of the Micro

BTS at the customer’s site.

Assumptions, Purpose, and Audience

This document is intended for an Alvarion trained field service engineer (FSE) or

operator who performs local installation and commissioning at a customer site.

The FSE or operator should be equipped with the necessary tools for installation

and commissioning, and a basic understanding of the GSM cellular network. The

FSE or Operator should also be familiar with the use of Craft PC and procedures

conducted using the Craft PC.

Alvarion assumes that pre-installation project planning has occurred, and is

documented via a site survey report. This site survey should include items such as

the location of antennas, chassis, power connections and other interface accesses

and temperature control equipment.

Preface

Microwave Radio Radiation Warning

Although Alvarion products do not use microwave radio antennas, the equipment

is often mounted in the vicinity of microwave radio antennas. Under normal

operating conditions, microwave radio equipment complies with the limits for

human exposure to radio frequency (RF) fields adopted by the Federal

Communications Commission (FCC). All Alvarion microwave radio equipment is

designed so that under normal working conditions, microwave radiation directly

from the radio is negligible when compared with the permissible limit of

continuous daily exposure recommended in the United States by ANSI/IEEE

C95.1-1991 (R1997), Safety Levels with Respect to Human Exposure to Radio

Frequency Electromagnetic Fields, 3 kHz to 300 GHz.

Microwave signal levels that give rise to hazardous radiation levels can exist within

transmitter power amplifiers, associated RF multiplexers, and antenna systems.

Page 12

Preface

Never look into the open end of a waveguide or any other open RF

connection as eyes are particularly vulnerable to radiation. Do not

disconnect RF coaxial connectors, open microwave units, or break

down any microwave screening while the radio equipment is

operating.

Related Documentation and Services

All manuals are available on a documentation CD-ROM in Adobe portable

document format or in an online format via our protected Internet site. To order

documentation, please contact Alvarion Sales department online at http://

www.alvarion.com.

Updates to this manual will be posted on the Alvarion Customer Service Website

at http://www.alvarion.com. Registered Alvarion customers can access the

Alvarion on-line information and support service, available 24 hours a day, seven

days a week. The Alvarion on-line service provides users with a wealth of

up-to-date information, with documents being added or updated each month.

Customer support services, such as technical support, RMAs, and training, are

described in the Customer Support Services document.

Warranties and Disclaimers

All Alvarion Ltd. (“Alvarion”) products purchased from Alvarion or through any of

Alvarion's authorized resellers are subject to the following warranty and product

liability terms and conditions.

Exclusive Warranty

(a) Alvarion warrants that the Product hardware it supplies and the tangible

media on which any software is installed, under normal use and conditions, will

be free from significant defects in materials and workmanship for a period of

fourteen (14) months from the date of shipment of a given Product to Purchaser

(the “Warranty Period”). Alvarion will, at its sole option and as Purchaser's sole

remedy, repair or replace any defective Product in accordance with Alvarion's

standard R&R procedure.

(b) With respect to the Firmware, Alvarion warrants the correct functionality

according to the attached documentation, for a period of fourteen (14) month from

invoice date (the “Warranty Period”). During the Warranty Period, Alvarion may

release to its Customers firmware updates, which include additional performance

improvements and/or bug fixes, upon availability (the “Warranty”). Bug fixes,

temporary patches and/or workarounds may be supplied as Firmware updates.

xii UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 13

Disclaimer

Preface

Additional hardware, if required, to install or use Firmware updates must be

purchased by the Customer. Alvarion will be obligated to support solely the two (2)

most recent Software major releases.

ALVARION SHALL NOT BE LIABLE UNDER THIS WARRANTY IF ITS TESTING

AND EXAMINATION DISCLOSE THAT THE ALLEGED DEFECT IN THE PRODUCT

DOES NOT EXIST OR WAS CAUSED BY PURCHASER'S OR ANY THIRD

PERSON'S MISUSE, NEGLIGENCE, IMPROPER INSTALLATION OR IMPROPER

TESTING, UNAUTHORIZED ATTEMPTS TO REPAIR, OR ANY OTHER CAUSE

BEYOND THE RANGE OF THE INTENDED USE, OR BY ACCIDENT, FIRE,

LIGHTNING OR OTHER HAZARD.

(a) The Software is sold on an “AS IS” basis. Alvarion, its affiliates or its licensors

MAKE NO WARRANTIES, WHATSOEVER, WHETHER EXPRESS OR IMPLIED,

WITH RESPECT TO THE SOFTWARE AND THE ACCOMPANYING

DOCUMENTATION. ALVARION SPECIFICALLY DISCLAIMS ALL IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE AND NON-INFRINGEMENT WITH RESPECT TO THE SOFTWARE.

UNITS OF PRODUCT (INCLUDING ALL THE SOFTWARE) DELIVERED TO

PURCHASER HEREUNDER ARE NOT FAULT-TOLERANT AND ARE NOT

DESIGNED, MANUFACTURED OR INTENDED FOR USE OR RESALE IN

APPLICATIONS WHERE THE FAILURE, MALFUNCTION OR INACCURACY OF

PRODUCTS CARRIES A RISK OF DEATH OR BODILY INJURY OR SEVERE

PHYSICAL OR ENVIRONMENTAL DAMAGE (“HIGH RISK ACTIVITIES”). HIGH

RISK ACTIVITIES MAY INCLUDE, BUT ARE NOT LIMITED TO, USE AS PART OF

ON-LINE CONTROL SYSTEMS IN HAZARDOUS ENVIRONMENTS REQUIRING

FAIL-SAFE PERFORMANCE, SUCH AS IN THE OPERATION OF NUCLEAR

FACILITIES, AIRCRAFT NAVIGATION OR COMMUNICATION SYSTEMS, AIR

TRAFFIC CONTROL, LIFE SUPPORT MACHINES, WEAPONS SYSTEMS OR

OTHER APPLICATIONS REPRESENTING A SIMILAR DEGREE OF POTENTIAL

HAZARD. ALVARION SPECIFICALLY DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY OF FITNESS FOR HIGH RISK ACTIVITIES.

(b) PURCHASER'S SOLE REMEDY FOR BREACH OF THE EXPRESS

WARRANTIES ABOVE SHALL BE REPLACEMENT OR REFUND OF THE

PURCHASE PRICE AS SPECIFIED ABOVE, AT ALVARION'S OPTION. TO THE

FULLEST EXTENT ALLOWED BY LAW, THE WARRANTIES AND REMEDIES SET

FORTH IN THIS AGREEMENT ARE EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, EITHER IN FACT OR BY

OPERATION OF LAW, STATUTORY OR OTHERWISE, INCLUDING BUT NOT

LIMITED TO WARRANTIES, TERMS OR CONDITIONS OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, SATISFACTORY QUALITY,

CORRESPONDENCE WITH DESCRIPTION, NON-INFRINGEMENT, AND

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B xiii

Page 14

Preface

ACCURACY OF INFORMATION GENERATED. ALL OF WHICH ARE EXPRESSLY

DISCLAIMED. ALVARION' WARRANTIES HEREIN RUN ONLY TO PURCHASER,

AND ARE NOT EXTENDED TO ANY THIRD PARTIES. ALVARION NEITHER

ASSUMES NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR IT ANY

OTHER LIABILITY IN CONNECTION WITH THE SALE, INSTALLATION,

MAINTENANCE OR USE OF ITS PRODUCTS.

Limitation of Liability

(a) ALVARION SHALL NOT BE LIABLE TO THE PURCHASER OR TO ANY THIRD

PARTY, FOR ANY LOSS OF PROFITS, LOSS OF USE, INTERRUPTION OF

BUSINESS OR FOR ANY INDIRECT, SPECIAL, INCIDENTAL, PUNITIVE OR

CONSEQUENTIAL DAMAGES OF ANY KIND, WHETHER ARISING UNDER

BREACH OF CONTRACT, TORT (INCLUDING NEGLIGENCE), STRICT LIABILITY

OR OTHERWISE AND WHETHER BASED ON THIS AGREEMENT OR

OTHERWISE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

(b) TO THE EXTENT PERMITTED BY APPLICABLE LAW, IN NO EVENT SHALL

THE LIABILITY FOR DAMAGES HEREUNDER OF ALVARION OR ITS EMPLOYEES

OR AGENTS EXCEED THE PURCHASE PRICE PAID FOR THE PRODUCT BY

PURCHASER, NOR SHALL THE AGGREGATE LIABILITY FOR DAMAGES TO ALL

PARTIES REGARDING ANY PRODUCT EXCEED THE PURCHASE PRICE PAID

FOR THAT PRODUCT BY THAT PARTY (EXCEPT IN THE CASE OF A BREACH OF

A PARTY'S CONFIDENTIALITY OBLIGATIONS).

Important Notice

This user manual is delivered subject to the following conditions and restrictions:

This manual contains proprietary information belonging to Alvarion Ltd. Such

information is supplied solely for the purpose of assisting properly authorized

users of the respective Alvarion products.

No part of its contents may be used for any other purpose, disclosed to any

person or firm or reproduced by any means, electronic and mechanical,

without the express prior written permission of Alvarion Ltd.

The text and graphics are for the purpose of illustration and reference only.

The specifications on which they are based are subject to change without

notice.

The software described in this document is furnished under a license. The

software may be used or copied only in accordance with the terms of that

license.

Information in this document is subject to change without notice. Corporate

and individual names and data used in examples herein are fictitious unless

otherwise noted.

xiv UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 15

Preface

Alvarion Ltd. reserves the right to alter the equipment specifications and

descriptions in this publication without prior notice. No part of this publication shall be deemed to be part of any contract or warranty unless specifically

incorporated by reference into such contract or warranty.

The information contained herein is merely descriptive in nature, and does not

constitute an offer for the sale of the product described herein.

Any changes or modifications of equipment, including opening of the equip-

ment not expressly approved by Alvarion Ltd. will void equipment warranty

and any repair thereafter shall be charged for. It could also void the user's

authority to operate the equipment.

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B xv

Page 16

Preface

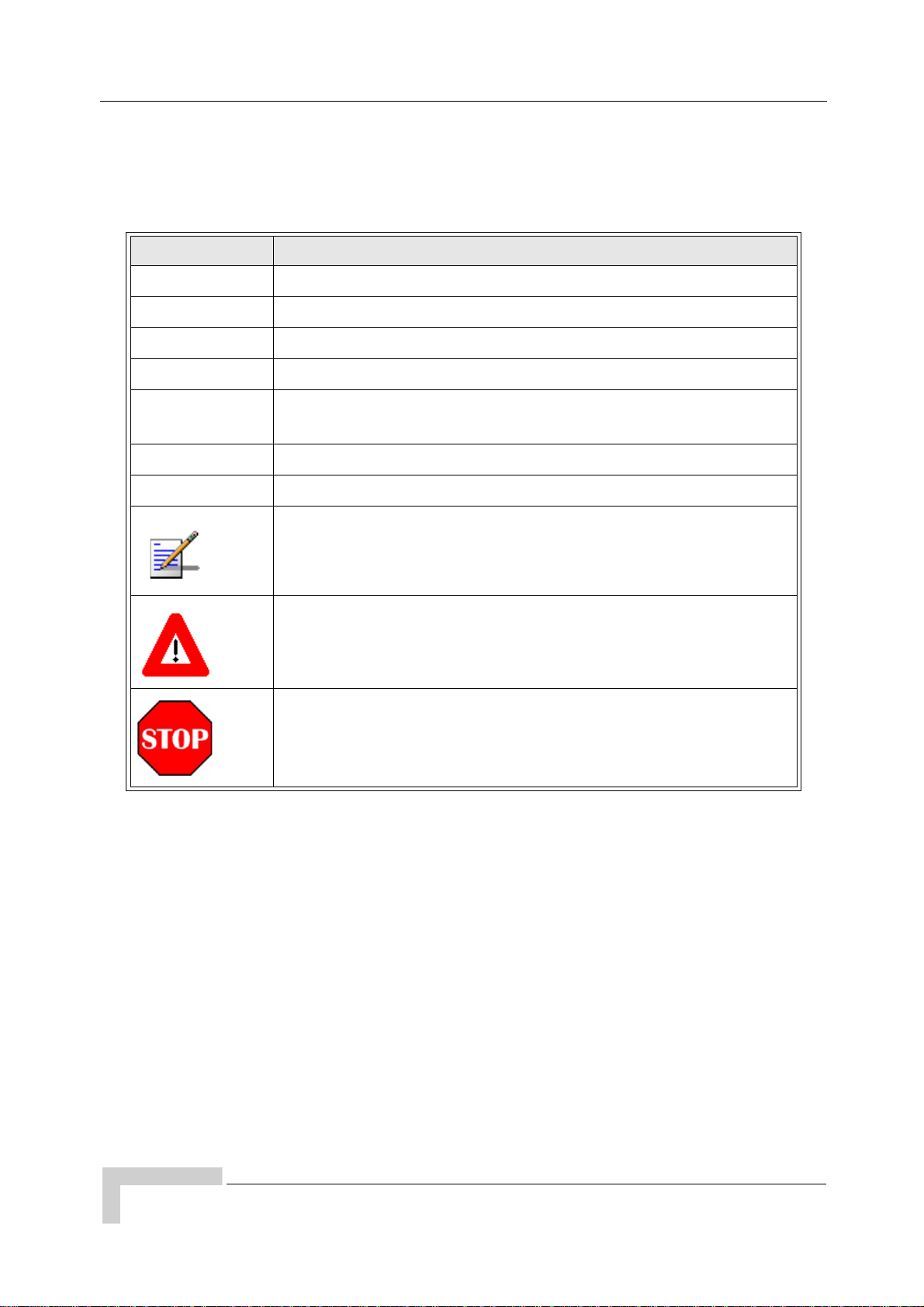

Conventions Used in This Manual

The following type and style conventions are used in this manual:

Conventions Used in This Manual

Convention Meaning

Body Text Used for regular body text

Bold Indicates a menu or button choice

Command Indicates computer generated text and prompts

User Input Indicates user input

<hostname>

<variable> In body text, indicates user-specified command line parameters

[BRACKETS] Indicates a key on the keyboard or instrument

In command syntax, indicates user-specified command line

parameters

Provides relevant additional information

Provides important warning information that may affect operation

of or maybe a potential threat to the system

Used to tell the reader to STOP what they are doing and to read

important instructions that are vital to prevent equipment or

software damage

xvi UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 17

1

Chapter 1 - Unpacking and Configuration Verification

In this Chapter:

“Unpacking and Inspecting” on page 2

“Electrostatic Discharge (ESD)” on page 7

“Inspecting Components and Recording Part Numbers” on page 8

“Verifying and Documenting Cards and Modules” on page 12

“Verifying Cabling” on page 15

This chapter provides instructions for opening the shipping container and

inspecting the contents. When you have completed the procedures in this chapter,

you will have confirmed that the hardware arrived undamaged and that everything

you ordered is present and configured correctly.

Page 18

Chapter 1 - Unpacking and Configuration Verification

1.1 Unpacking and Inspecting

The UltraWAVE Micro BTS is packed with great care, and all containers are

inspected prior to shipment.

Micro BTS components that are shipped separately include:

Micro subrack assembly

Power supplies

Power supply subrack assembly

The Micro subrack assembly includes RF Module(s), processor card, E1 or T1

card, TRX card(s) and the clock module.

Upon receipt of these packages, immediately inspect the outside of the shipping

containers. If there is any visible damage, insist that a representative of the

carrier is present when unpacking the contents.

Carefully inspect the system as it is unpacked. If any damage, such as dents or

broken connections, is noticeable, immediately notify the carrier as well as

Alvarion Customer Service.

Store the shipping containers for future use. If the unit has to be returned for

upgrade or service, the specially designed shipping containers assure adequate

protection for the equipment. If for some reason the containers are not reusable or

if they are misplaced, please contact Alvarion to order new containers.

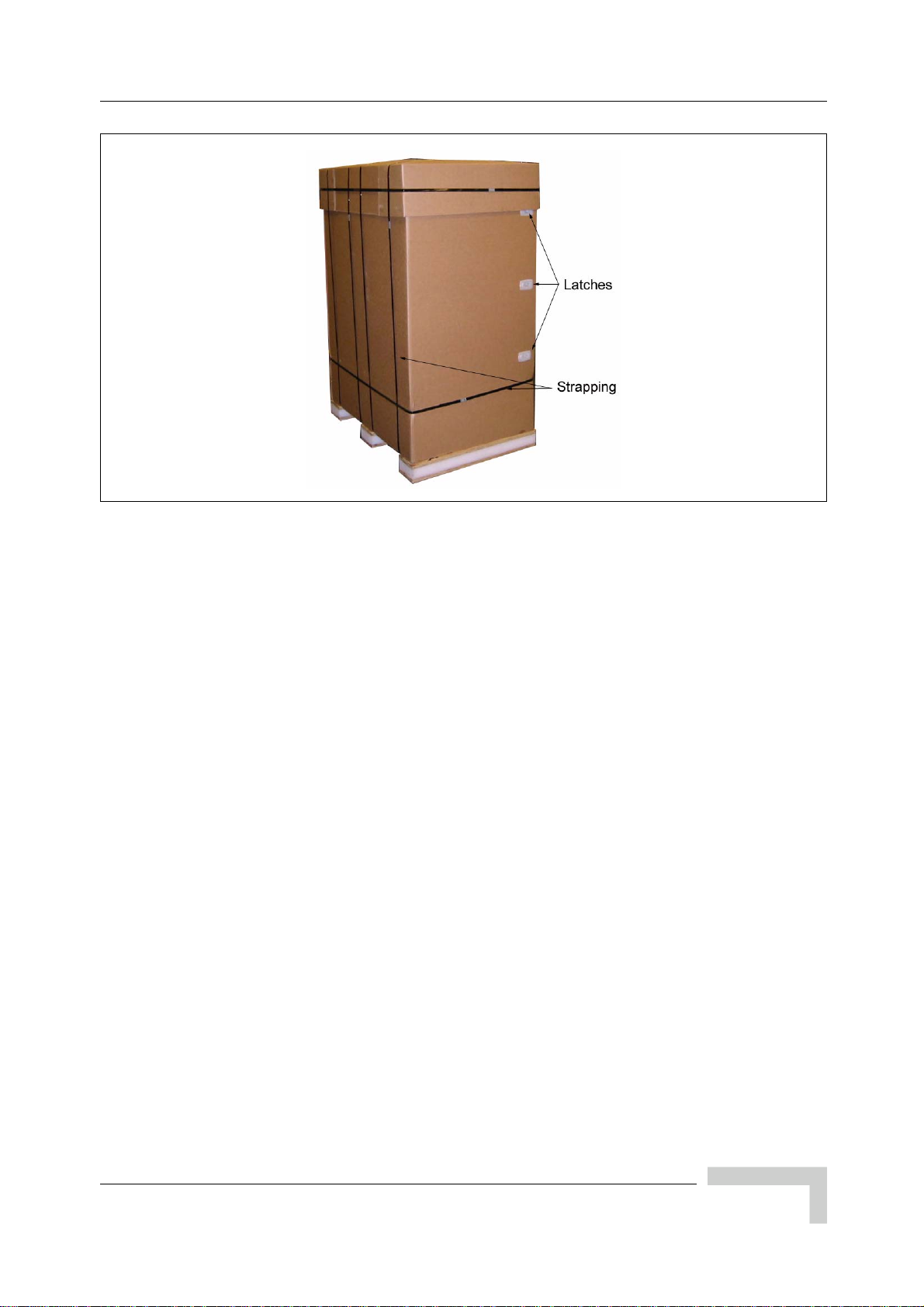

1.1.1 Unpacking the Cabinet

The UltraWAVE Micro BTS is shipped in a specially designed carton. The cabinet

should remain in the packaging until shipped to its final destination. Use this

procedure to unpack your cabinet.

1 Move the cabinet to a level, well illuminated area.

2 Cut all of the strapping on the outside of the shipping container. See

Figure 1-1.

2 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 19

Figure 1-1: UltraWAVE Packaging

Unpacking and Inspecting

3 Remove the cardboard top and set aside.

4 Locate the plastic latches, shown in Figure 1-1. Pull on each latch to release

the cardboard side.

5 Remove the cardboard enclosing the cabinet assembly.

6 Carefully remove the two boxes from the top of the cabinet assembly. These

boxes contain the power supply units.

7 Remove the insulating material from the top and sides of the cabinet.

8 Cut the strapping which secures the cabinet to the pallet and remove the

protective plastic.

9 Using an adjustable wrench, raise the rubber feet located at each corner on

the bottom of the cabinet. See Figure 1-2.

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 3

Page 20

Chapter 1 - Unpacking and Configuration Verification

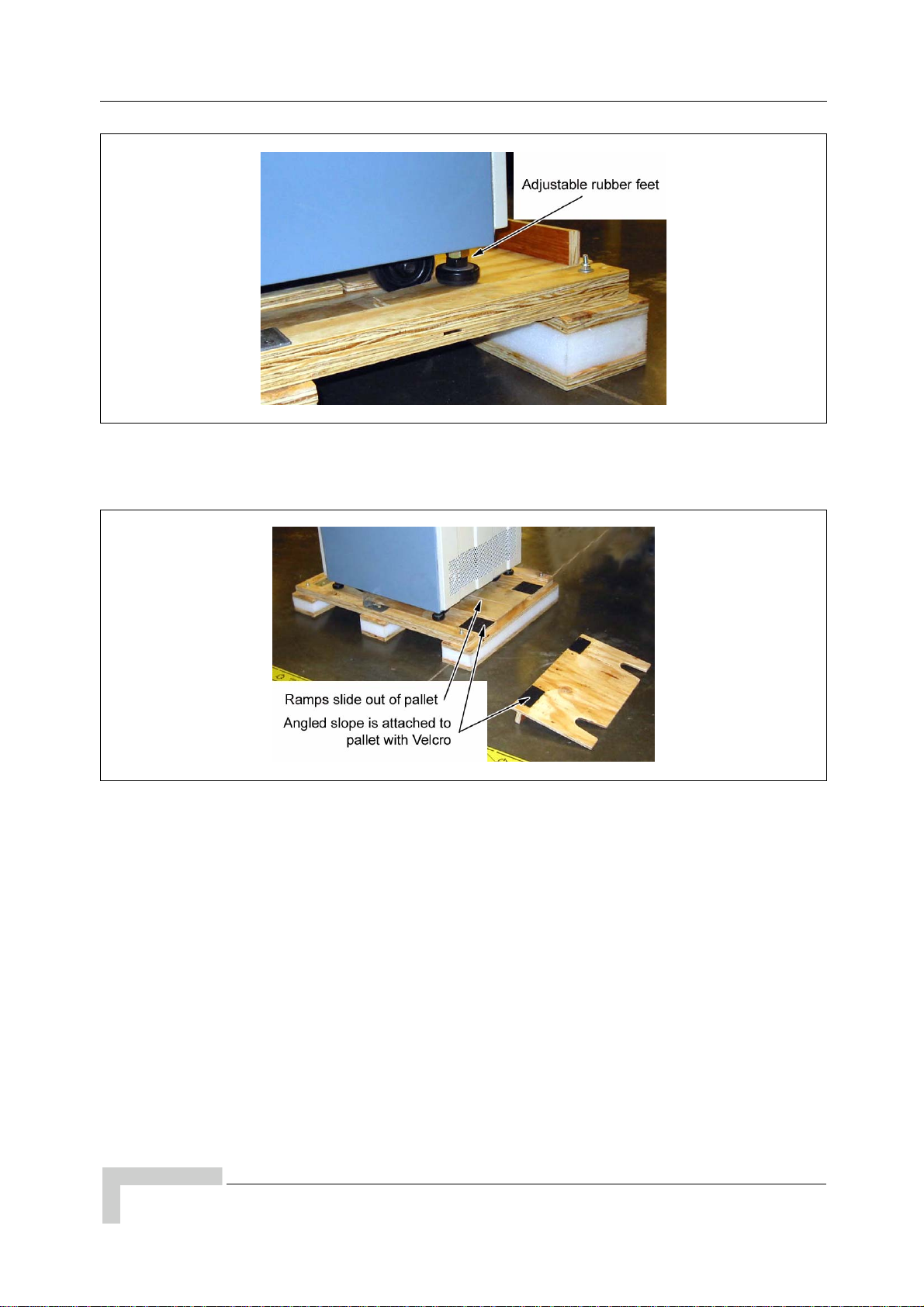

Figure 1-2: Adjustable Feet

10 Remove the angled slope and ramps from the pallet. See Figure 1-3.

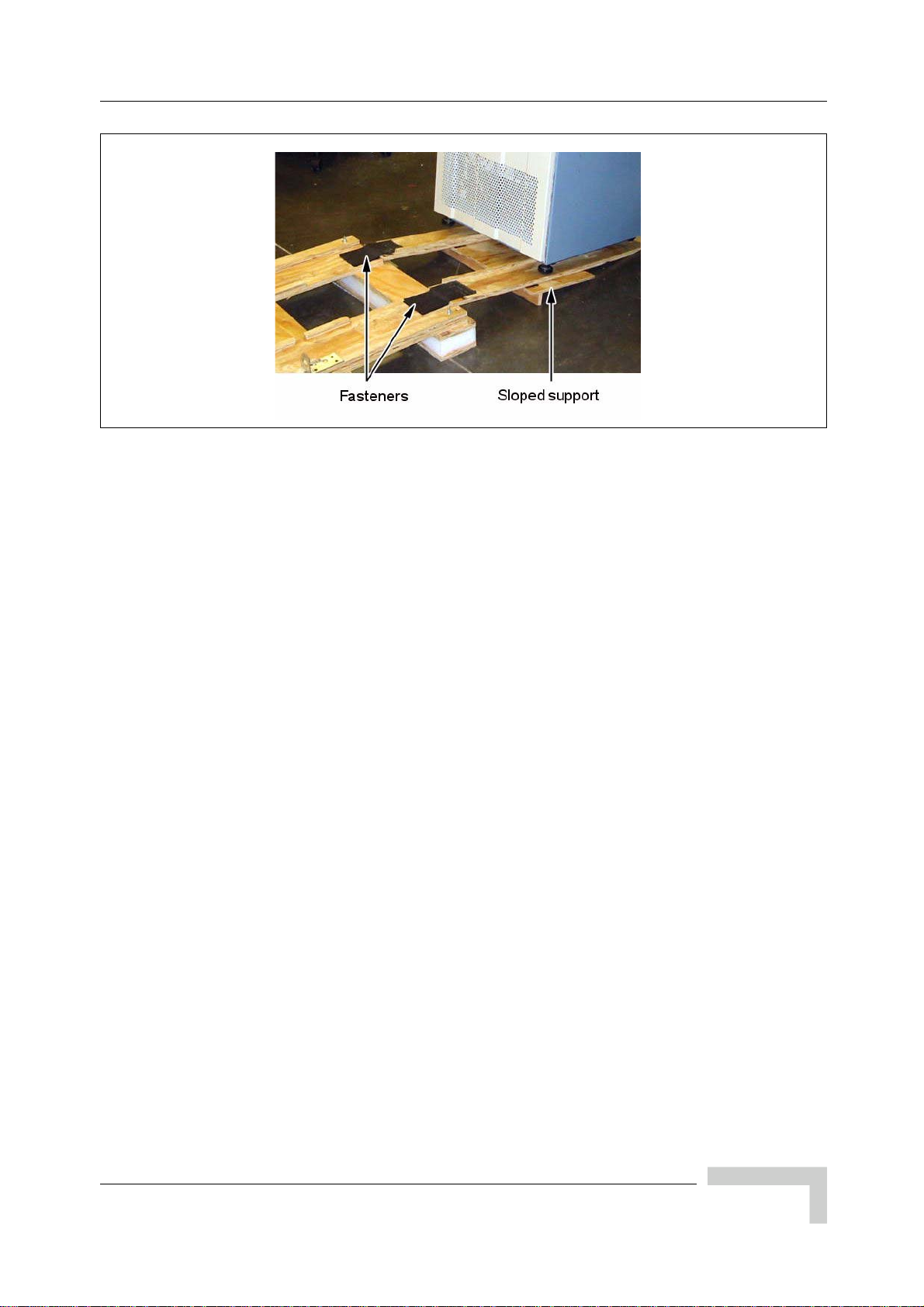

Figure 1-3: Pallet Accessories

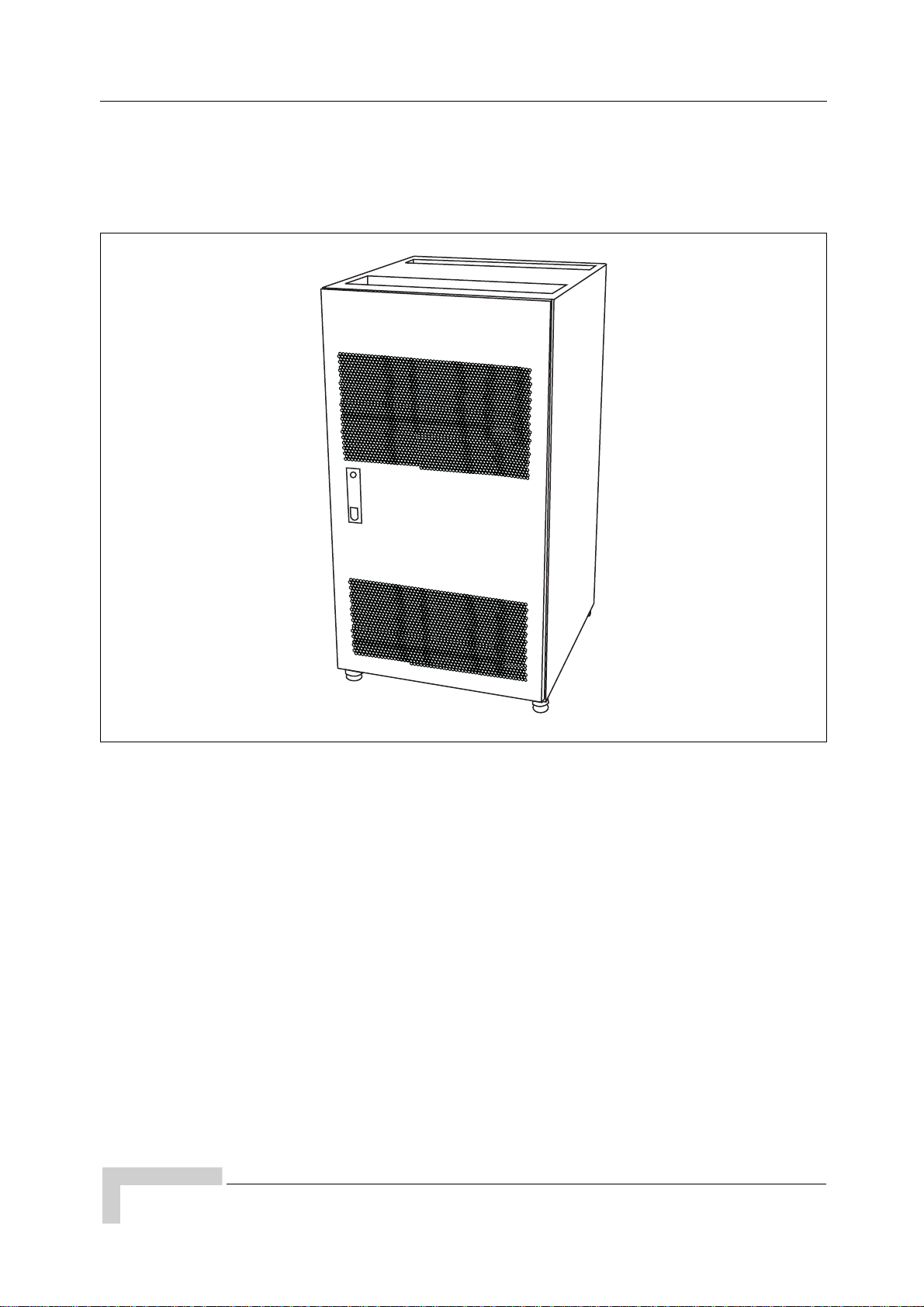

11 Attach ramps to pallet using loop and hook fasteners and slide the sloped

support underneath the ramps. See Figure 1-4.

4 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 21

Unpacking and Inspecting

Figure 1-4: Pallet Ramps

12 Carefully roll the cabinet down the ramps and off of the pallet.

13 Store all packaging material in a safe, dry location.

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 5

Page 22

Chapter 1 - Unpacking and Configuration Verification

1.1.2 Opening the Cabinet Assembly

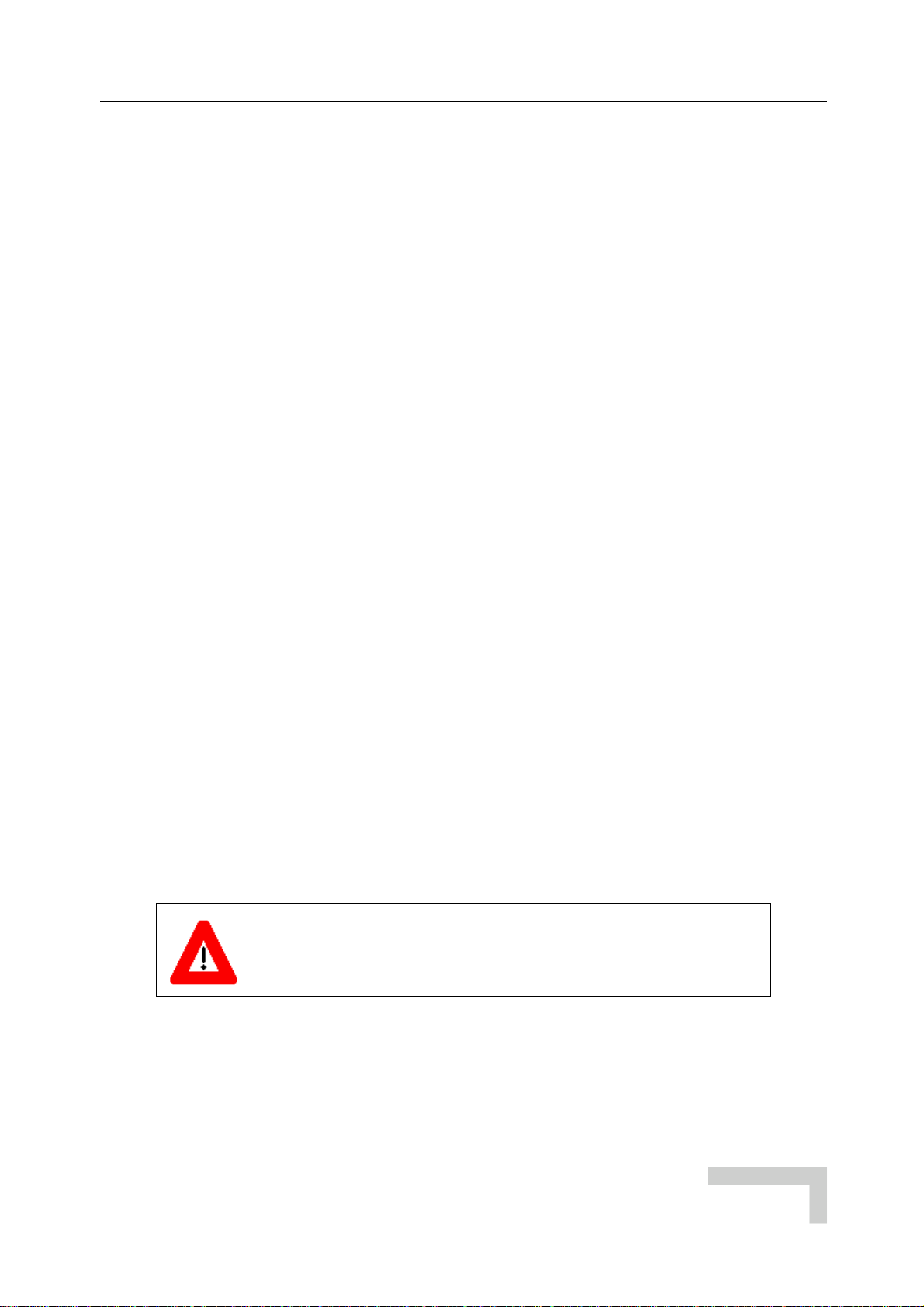

The UltraWAVE Micro BTS is shipped pre-configured in a locking cabinet

assembly as shown in Figure 1-5.

IW007302

Figure 1-5: Locking Cabinet

Doors are provided for access to the front and rear of the internal assemblies. To

open the doors:

1 Insert the key provided into the lock and turn to unlock.

2 Depress the lock mechanism to release the door latch handle.

3 Turn the door handle to unlatch and open the door.

4 Carefully remove the packaging material from inside the cabinet.

6 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 23

Electrostatic Discharge (ESD)

1.1.3 Unpacking and Inspecting the Rack Assembly

The Micro BTS may be shipped in a standard 19 inch rack assembly. Carefully

inspect the system as it is unpacked. Ensure that the required cabling is

included. If you notice any damage such as dents or broken connections,

immediately notify the carrier as well as Alvarion Customer Service.

Store the shipping containers for future use. If the unit has to be returned for

upgrade or service, the specially designed shipping containers assure adequate

protection of the equipment. If for some reason the shipping containers are not

reusable or if they are misplaced, please contact Alvarion to order new containers.

1.2 Electrostatic Discharge (ESD)

Electrostatic discharge is the movement of normally motionless electrical charges

which can destroy common electrical and electronic equipment.

Alvarion recommends that you use an anti-static wrist strap when handling

boards and components.

By using an anti-static wrist-strap, static electricity is constantly dispersed, via

the snug-fitting wrist-band, down the cable and to the grounded connection at the

other end, leaving hands free to work.

Use either the provided anti-static wrist-strap or an ESD mat.

Otherwise, touch the metal chassis to drain off any static electricity before

touching the cards.

Do not wear wool or polyester clothing.

Dry air can prevent dangerous charges from harmlessly dissipating. Alvarion

recommends a relative humidity of 50-60% when working on this equipment.

Handle the cards as little as possible and only by the edges.

Before starting any of the following procedures, the Field Service

Technician needs to ensure that anti-static precautions are taken.

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 7

Page 24

Chapter 1 - Unpacking and Configuration Verification

1.3 Inspecting Components and Recording Part Numbers

The Micro BTS is shipped with all RF modules and cards installed in the Micro

subrack assembly as ordered by the customer. The Micro BTS components

include:

Micro subrack assembly

Processor card

E1 or T1 card

TRX cards

RF modules

Fan assemblies (located on the back of the chassis)

Clock module

Internal cabling

Blank panel(s)

Power supply modules and subrack assembly

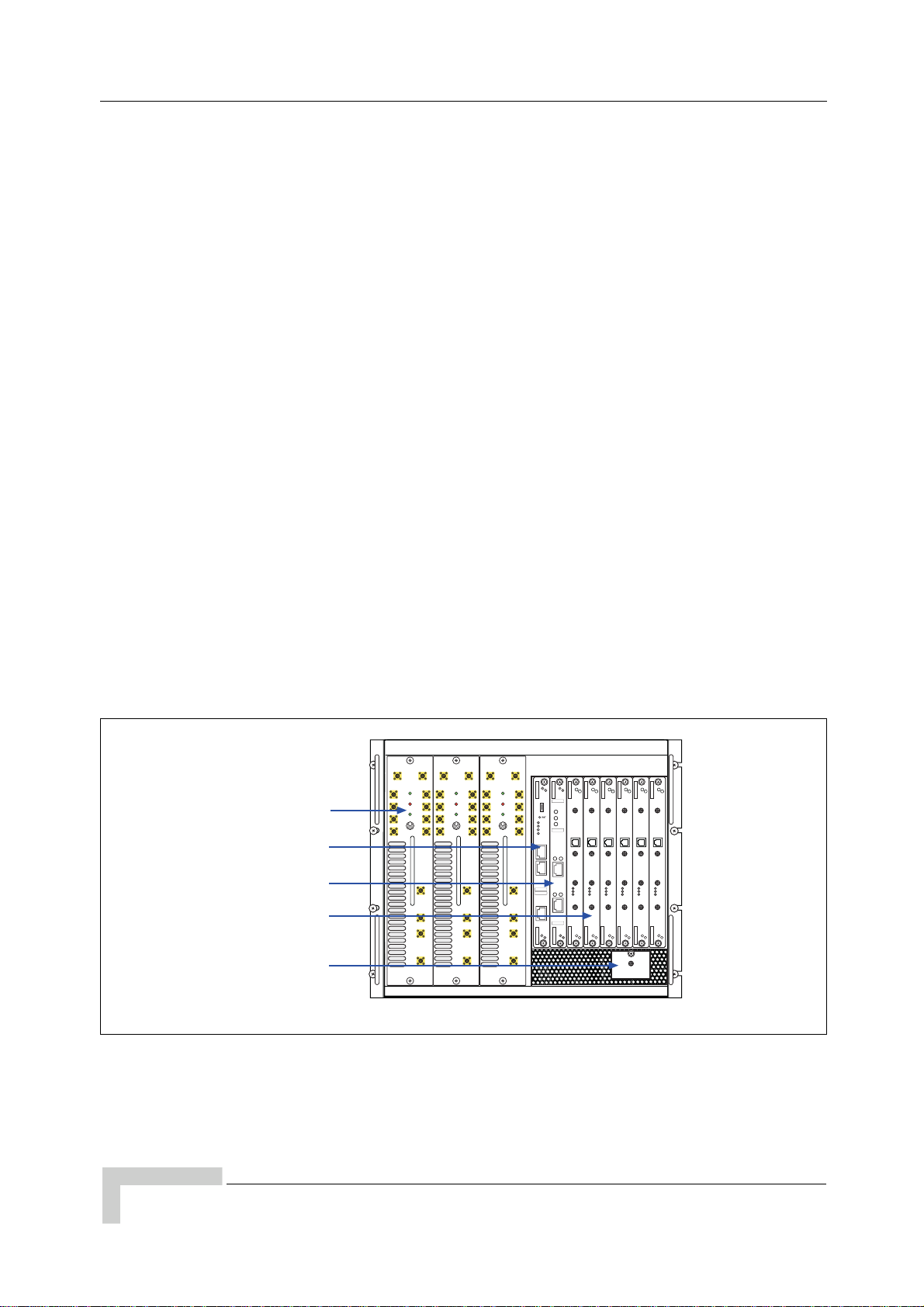

Some of these components appear in Figure 1-6.

ANT

ANT

MAIN

DIV

RX1

RX1

ON LINE

RX2

RX2

RX3

RX3

RX4

RX4

TX1

DET

PA1

IN

TX2

DET

PA2

IN

01234567

PWR

FLT

RX1

RX2

ON

PWR

RX3

ONLINE

FLT

OFF

SCN

RX4

ENET

CON

IIIIIIIIIIIIIIIIIIIIIIIII

TX1

P/N XXXXXX

IIIIIIIIIIIIIIIIIIIIIIIII

DET

S/N XXXXXX

PA1

IN

TX2

DET

PA2

IN

C

RF Modules

Processor Card

E1 or T1 Trunk Card

TRX Cards

Clock Module

ANT

DIV

PWR

FLT

RX1

ON LINE

RX2

ON

RX3

OFF

RX4

A

MAIN

MAIN

DIV

PWR

FLT

RX1

RX1

ON LINE

RX2

RX2

ON

RX3

RX3

OFF

RX4

RX4

TX1

DET

PA1

IN

TX2

DET

PA2

IN

B

ANT

ANT

ANT

IIIIIIIIIIIIIIIIIIIIIIIII

P/N XXXXXX

I2C

ALARMS

ALARMS

120 OHM

12

PORT 0

12

PORT 1

IIIIIIIIIIIIIIIIIIIIIIIII

S/N XXXXXX

PWR

ON

LINE

FLT

TX

TX

TX

OUT

OUT

OUT

13 MHZ

13 MHZ

13 MHZ

CLK

CLK

CLK

RX-A

RX-A

RX-A

DET

DET

DET

IN

IN

IN

PWR

PWR

PWR

ON LINE

ON LINE

ON LINE

FLT

FLT

FLT

RX-B

RX-B

RX-B

TX

TX

TX

OUT

OUT

OUT

13 MHZ

13 MHZ

13 MHZ

CLK

CLK

CLK

RX-A

RX-A

RX-A

DET

DET

DET

IN

IN

IN

PWR

PWR

PWR

ON LINE

ON LINE

ON LINE

FLT

FLT

FLT

RX-B

RX-B

RX-B

IW132601

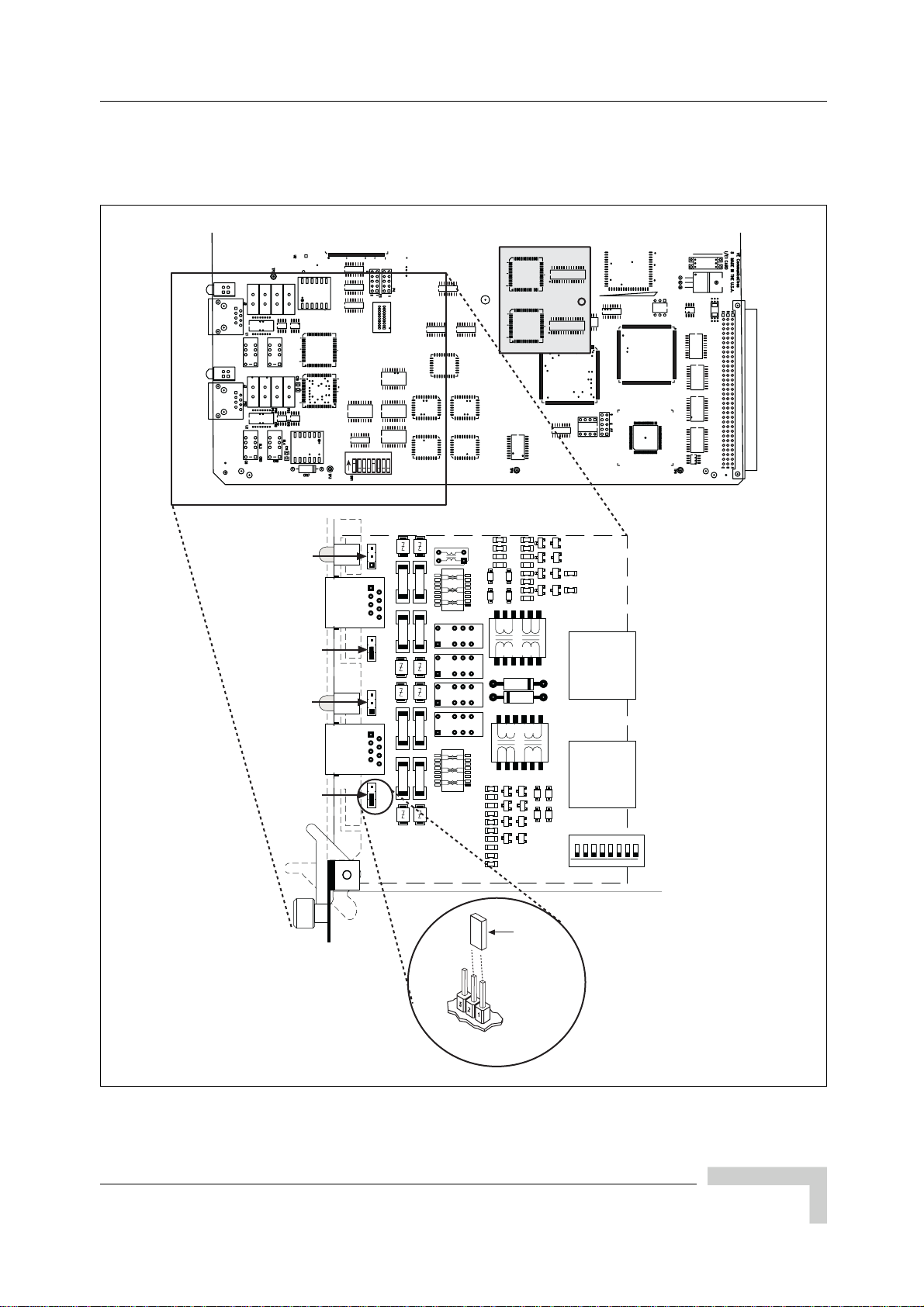

Figure 1-6: UltraWAVE Micro Subrack Assembly

8 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 25

Inspecting Components and Recording Part Numbers

1.3.1 Identifying the System Configuration

The UltraWAVE Micro BTS is available in a number of different configurations.

Micro BTS available configurations are listed in Table 1-1. Use this section to

verify the configuration of your UltraWAVE Micro BTS.

Locate the main configuration label on the exterior of your shipping container or

on the back of the Micro subrack assembly.

MODEL: AKAD

MODEL NUMBER: AKADO21902512482B

INPUT POWER:

MFG DATE: JUL 11, 2006

-48VDC, 10A

SERIAL:

REVISION:

P/N:

00xxxxx

612872

B

IW192603

Figure 1-7: Configuration Label

The main configuration label includes the following details:

Serial number (00xxxxxx).

P/N (xxxxxx).

Revision letter (X).

Model (example: AKAD) - denotes the type of Alvarion system, in this case an

UltraWAVE Micro BTS.

Factory configuration number.

Input Power (example: -48VDC, 10A).

Manufacturing date (month, date, year).

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 9

Page 26

Chapter 1 - Unpacking and Configuration Verification

Table 1-1 lists Micro BTS configuration types and details.

Table 1-1: Configuration Type and Details

Configuration

Type

01

02

03

Configuration Details

Omni single TRX (01); 15 Watt, 25 Watt, 40 Watt or

50 Watt, two antenna configuration

Omni two TRX (02); 15 Watt, 25 Watt, 40 Watt or

50 Watt, two antenna configuration

Omni three TRX (03); 15 Watt or 25 Watt, two

antenna configuration

Three sector, one TRX per sector (S111); 15 Watt,

S111

25 Watt, 40 Watt or 50 Watt, six antenna

configuration

Three sector, two TRXs in one sector and one TRX in

S222

the other two sectors (S222), 15 Watt, 25 Watt,

40 Watt or 50 Watt, six antenna configuration

Record your model and configuration details in Checklist 2 - Installation

Checklist.

10 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 27

Inspecting Components and Recording Part Numbers

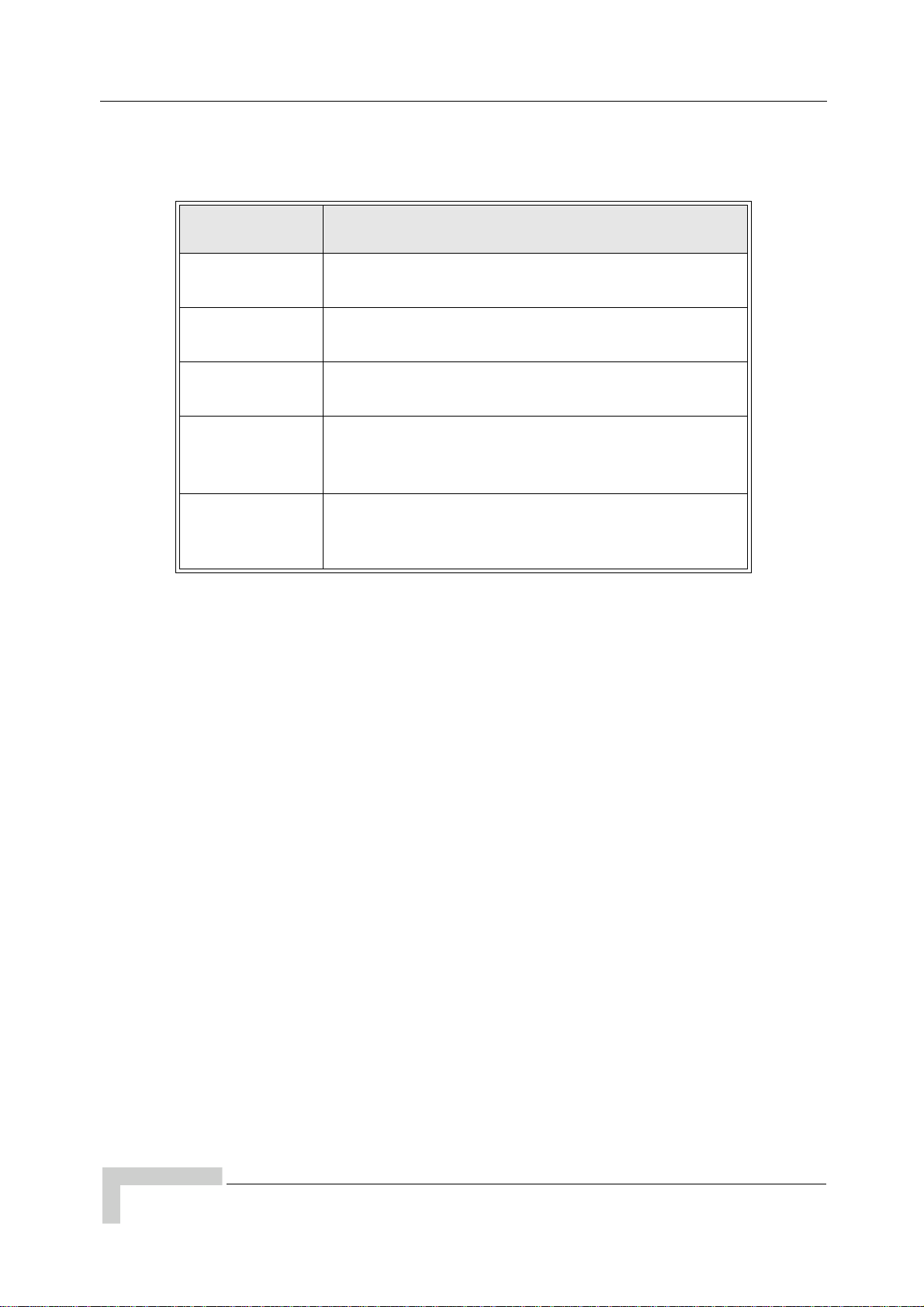

1.3.2 Verifying System Labels

This procedure requires you to record each components’ part number, revision

number and serial number in Checklist 2 - Installation Checklist. The factory

places up to three configuration labels on the front of each Micro BTS card,

module and chassis to help identify the system’s configuration. These labels

identify the following:

Part number -- Part number identifies the type of component. All identical

components have the same part number. Part numbers use the format:

P/N NNNNNN

Revision or dash number -- Revision numbers record minor changes in design.

Revision numbers use the format:

-NNN

Serial number -- Each individual component has its own unique serial

number. Serial numbers use the format:

S/N NNNNNNNN

An example of the configuration labels appears in Figure 1-8.

Barcode identifier of

the part number

Barcode identifier of

the rev number

Barcode identifier of

the serial number

P/N 340127

-200

S/N 00719500

Part number

Dash or revision number

Serial number

Figure 1-8: Sample Configuration Labels

IE168405

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 11

Page 28

Chapter 1 - Unpacking and Configuration Verification

1.4 Verifying and Documenting Cards and Modules

The cabinet contains two subrack assemblies.

The Micro contains:

RF modules responsible for RF power amplification, duplexing and

combining when required

Processor Card, E1 or T1 trunk card, TRX cards, and clock module

The power supply consists of up to two power supply modules and a third slot

covered with a blank panel.

1.4.1 Required Equipment

To verify and record your system configuration, you need:

A copy of the Shipping Checklist. It is one of the papers inside the shipping

container.

A copy of Checklist 2 - Installation Checklist.

1.4.2 Micro Subrack Assembly

The Micro subrack assembly provides three RF slots, starting on the left with slot

A. Depending on your Micro BTS configuration, up to three slots will be required

for RF modules. These modules are shipped pre-installed and cabled from the

factory.

1 Locate the configuration part and serial numbers on your RF modules.

Figure 1-8 illustrates a sample of these labels.

2 Write down the part number, revision number and serial number in Checklist

2 - Installation Checklist.

12 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 29

1.4.3 Slot Assignments

Beside the RF slots, the Micro BTS chassis layout provides eight standard slots,

starting on the left with slot 0. See Figure 1-9.

Verifying and Documenting Cards and Modules

Processor Card

E1 or T1 Trunk Card

Clock Module

Table 1-2 shows the Micro BTS slot assignments in the Micro subrack assembly.

Card Slots

RF Modules

TRX Cards

Figure 1-9: Micro BTS Chassis Layout

Table 1-2: Micro BTS Slot Assignments

Width

(slots)

ANT

ANT

MAIN

DIV

PWR

FLT

RX1

RX1

ON LINE

RX2

RX2

ON

RX3

RX3

OFF

RX4

RX4

TX1

DET

PA1

IN

TX2

DET

PA2

IN

A

Function

ANT

ANT

MAIN

DIV

PWR

FLT

RX1

ON LINE

RX2

ON

RX3

OFF

RX4

B

ANT

ANT

MAIN

DIV

RX1

RX1

ON LINE

RX2

RX2

RX3

RX3

RX4

RX4

TX1

DET

PA1

IN

TX2

DET

PA2

IN

01234567

PWR

FLT

ON

OFF

IIIIIIIIIIIIIIIIIIIIIIIII

RX1

P/N XXXXXX

I2C

PWR

RX2

ON

LINE

PWR

FLT

RX3

ONLINE

FLT

120 OHM

SCN

RX4

ENET

ALARMS

12

CON

PORT 0

ALARMS

IIIIIIIIIIIIIIIIIIIIIIIII

TX1

P/N XXXXXX

12

IIIIIIIIIIIIIIIIIIIIIIIII

DET

S/N XXXXXX

PORT 1

PA1

IN

IIIIIIIIIIIIIIIIIIIIIIIII

S/N XXXXXX

TX2

DET

PA2

IN

TX

OUT

OUT

OUT

13 MHZ

13 MHZ

13 MHZ

CLK

CLK

CLK

RX-A

RX-A

RX-A

DET

DET

DET

IN

IN

IN

PWR

PWR

PWR

ON LINE

ON LINE

ON LINE

FLT

FLT

FLT

RX-B

RX-B

RX-B

OUT

OUT

OUT

13 MHZ

13 MHZ

13 MHZ

CLK

CLK

CLK

RX-A

RX-A

RX-A

DET

DET

DET

IN

IN

IN

PWR

PWR

PWR

ON LINE

ON LINE

ON LINE

FLT

FLT

FLT

RX-B

RX-B

RX-B

TX

TX

TX

TX

TX

C

IW132601

RF Modules A, B, C 1 RF power amplification, duplexing and combining.

Processor

card

0 1 ICP processor card.

E1 or T1 1 1 Each E1 or T1 card provides 2 E1 or T1 lines.

TRX

Clock

Module

2, 3, 4, 5, 6,

7

1 Each TRX manages 8 radio channels.

NA NA

The clock module is located directly underneath the

TRX cards, and provides synchronization for the

Air-interface and E1/ T1 modules.

The minimum configuration consists of a processor card in slot 0, one E1 or T1

card in slot 1, one TRX in slot 7, a clock module and an RF module in slot C. Any

unused slots must be covered by a blank panel.

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 13

Page 30

Chapter 1 - Unpacking and Configuration Verification

1.4.4 Verification Procedure

Use the following procedure to identify and record your system components.

Compare components against those listed in the shipping checklist. See

Figure 1-9 for Micro BTS chassis component locations.

1 Verify that the subrack assembly has four fan assemblies on the power

amplifier side on the rear of the chassis and two fans on the VME bus cards

side on the rear of the chassis. Verify that the fans are securely fastened to the

chassis.

2 Verify that the Micro BTS rack assembly contains an one or more RF modules

in slots A, B and/or C of the Micro rack assembly. Write down the part

number, revision number and serial number of each RF module in Checklist 2

- Installation Checklist.

3 Verify that the chassis contains an ICP processor card in slot 0 of the Micro

subrack assembly. Write down the processor card part number, revision

number and serial number in Checklist 2 - Installation Checklist.

4 Slot 1 of the Micro subrack assembly should contain an E1 or T1 card. From

the shipping checklist, write down the part number, revision number and

serial number of the E1 or T1 card in Checklist 2 - Installation Checklist.

5 Slots 2 to 7 should contain one or more TRXs. Verify how many are required

from the shipping checklist, then verify that they are all there. Write down the

part number, revision number and serial number of each TRX card in Check-

list 2 - Installation Checklist.

6 Check the shipping checklist and verify that the power supply subrack

assembly has one or two power supply modules and power supply fan assemblies. One or two power supply modules are required depending on your

configuration. Verify that a third slot and any other open slot is covered with a

blank panel.

For each power supply module, write down the part number, revision number

and serial number in Checklist 2 - Installation Checklist.

7 Verify that all empty slots are covered by blank panels. These are necessary for

cooling, and to meet RF emission standards.

14 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 31

1.5 Verifying Cabling

In this section, you inspect the internal cabling and verify that it is configured

correctly.

1.5.1 Verifying Internal Cabling

When the Micro BTS assembly and the power supply rack assembly are mounted

in the rack enclosure, all E1 or T1 interfaces are routed directly to the trunk cards

through a dust protector on the rack. The interface access area is mounted in the

rear recessed area of the rack enclosure. The internal cabling also connects the

power supply modules to the Micro subrack assembly and provides a plug on the

exterior of the cabinet for connection to the power source.

The internal cabling of the Micro BTS is included for the rack enclosure

configuration only, and is completed by the manufacturer. Due to its complexity,

it is not recommended for you to move or disconnect internal cabling.

Verifying Cabling

1.5.2 Verifying Enclosure Cabling

When the Micro subrack assembly and power supply modules are mounted in the

rack enclosure, it is necessary to verify that the following cables are connected:

Alarm cable and I

Power supply cables

Ensure that:

The alarm cable is connected to the power supply subrack assembly and the

Micro assembly.

A USB style cable is connected from the I

the front of the ICP processor card.

The power supply subrack assembly power cables are connected to the Micro

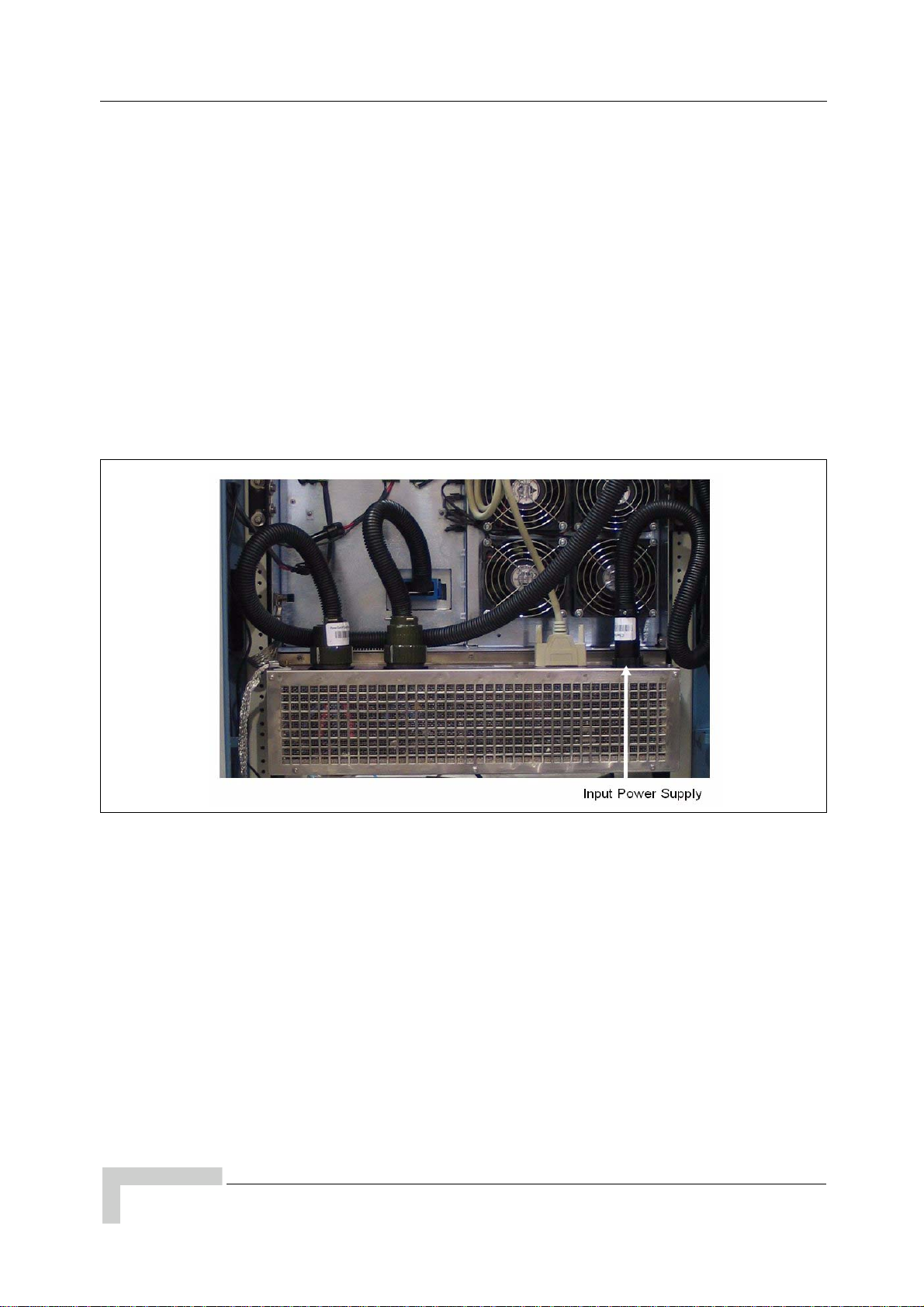

subrack assembly. See Figure 1-10, Power Supply Cable 1 and Power Supply

Cable 2.

The external power supply cable (Input Power Supply) is connected to the

power supply subrack assembly.

2

C interface cable

2

C interface to the I2C connector on

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 15

Page 32

Chapter 1 - Unpacking and Configuration Verification

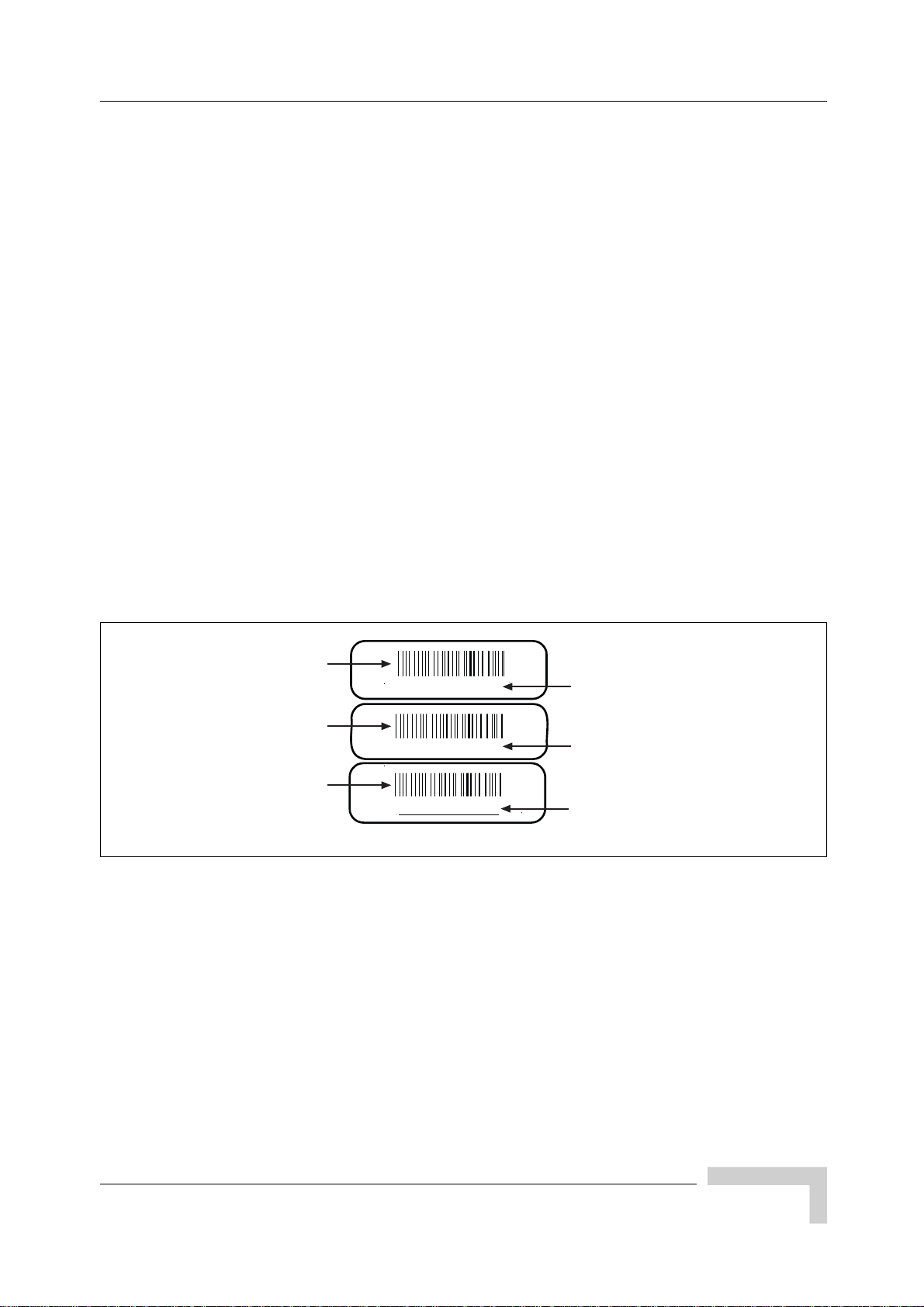

Figure 1-10: Micro Subrack and Power Supply Assembly Rear View

Figure 1-10 shows the location of the following components from the rear view of

the Micro subrack assembly and power supply assembly:

Fan Assemblies

External Alarm Interface

Mounting Brackets

Power Supply 1 cable for slots A through C

Power Supply 2 cable for slots 0 through 7

Processor Card Interface

The ICP processor card uses an I

USB style cable between the processor card interface connector and the I

2

C interface and connects physically with a

2

C

connector on the front of the ICP processor card.

Input Power Supply cable connection

Please proceed to Chapter 2 - Installation to install your Micro BTS.

16 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 33

Chapter 2 - Installation

In this Chapter:

“Analyzing Site Requirements” on page 18

“Mounting the Micro BTS Chassis” on page 22

“Configuring the E1 or T1 Trunk Card” on page 31

“Connecting Ground Cables” on page 36

“Connecting Power Supplies” on page 38

2

“Connecting E1 or T1 Trunk Cables” on page 47

“Connecting Antennas” on page 52

“Connecting External Alarms” on page 60

“Making a Serial Connection to the Processor Card” on page 64

“Network Connections” on page 65

“Post Installation Cabling and Checks” on page 66

This chapter provides instructions for installing and configuring the Micro BTS

hardware.

Page 34

Chapter 2 - Installation

2.1 Analyzing Site Requirements

Before a site is chosen or equipment installed, a site survey must be carried out.

The site survey checklist assists the surveyor with the inspection and the

collection of site specific information such as environmental conditions, electrical

requirements, and mechanical requirements.

The site survey checklist must be completed before installation begins. The

necessary steps for site readiness are listed in Checklist 1 - Site Readiness

Checklist. The GSM Network Implementation Manual

site requirements.

The site readiness checklist assists the field service engineer or operator to ensure

that the site is ready for equipment installation. It includes information about:

Environmental conditions

Electrical requirements

provides additional detailed

Chassis requirements

The site readiness checklist is located in Checklist 1 - Site Readiness Checklist. It

must be completed as part of the installation process.

2.1.1 Environmental Conditions

The Micro BTS is designed to operate indoors only. To facilitate long-term

operability and durability of the Micro BTS, observe specific environmental

constraints.

Before installing the Micro BTS, ensure that the operating environment maintains

a temperature and humidity within the ranges shown in Table 2-1.

Make sure the ambient temperature around the unit (which may

be higher than the room temperature) is within the specified limit

for the unit.

Table 2-1: Micro BTS Operating Environment

Scale

Maximum 90% 55 degrees 131 degrees

Minimum 10% -5 degrees 23 degrees

18 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Humidity

(non-condensing)

Temperature

(Celsius)

Temperature

(Fahrenheit)

Page 35

2.1.2 Electrical Requirements

The Micro BTS is specified to operate on either AC or DC power. Requirements for

the Micro BTS are dependent on the number of TRX cards supported.

Power Options

Main power supply options for the Micro BTS are:

110 VAC to 220 VAC auto-ranging, 30 A, 50-60 Hz

-40 VDC to -60 VDC (-48 VDC nominal), 40 A

Table 2-2 shows the estimated power requirements for the different TRX

configurations for the Micro BTS.

Table 2-2: Estimated Power Requirements for TRX Configurations

Analyzing Site Requirements

Product

Configuration

One TRX 261 Watts 350 Watts 345 Watts

Two TRXs 531 Watts 700 Watts 690 Watts

Three TRXs 801 Watts 1050 Watts 1035 Watts

Four TRXs 1071 Watts 1400 Watts 1380 Watts

Six TRXs 1611 Watts 2100 Watts 2070 Watts

Table 2-3 shows Micro BTS Power Specifications.

Power Requirements Specification

Micro BTS voltage range: 110 VAC 90 to 264 VAC

Micro BTS power protection: 110 VAC Dedicated 30 amp circuit breaker

Micro BTS voltage range: 220 VAC 90 to 264 VAC

Micro BTS power protection: 220 VAC Dedicated 15 Amp circuit breaker

Micro BTS DC voltage range: -48 VDC -40 to -60 VDC

-48 VDC 110 VAC 220 VAC

Table 2-3: Micro BTS Power Specifications

Micro BTS DC power protection: -48 VDC Dedicated 40 Amp fuse/circuit breaker

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 19

Page 36

Chapter 2 - Installation

2.1.3 Chassis Requirements

Before installing the Micro BTS, ensure that adequate clearance space is allowed

around the unit. Enough clearance should be provided from the front and back of

the cabinet to fully open the doors. This requires at least 24 inches (61 cm) from

the front and rear doors. The minimum clearance required on either side of the

cabinet is 4.5 inches (11.4 cm) and the minimum clearance required below the

cabinet is 1.8 inches (4.59 cm). The mounting site should also have ample

clearance for the trunk and antenna cables to be attached to the connectors at the

top of the cabinet.

The Micro BTS should be installed away from salt spray and in an area where

there are minimal vibrations.

Table 2-4 lists the dimensions of the Micro BTS chassis.

Table 2-4: Micro BTS Chassis Dimensions

Scale Height Width Depth

Metric 39.93 cm 48.26 cm 43.82 cm

Imperial 15.72 inches 19.0 inches 17.25 inches

Table 2-5 lists the weight and dimensions of the power supply rack.

Table 2-5: Power Supply Rack Weight and Dimensions

Weight

Scale

Metric 23.8 kg

Imperial 52.35 lbs

(Maximum

Configuration)

Table 2-6 and Figure 2-1 provide the dimensions of the BTS cabinet. For detailed

cabinet dimensions, refer to Section 2.2.

Table 2-6: Micro BTS Cabinet Weight and Dimensions

Height Width Depth

12.5 cm (AC)

48.26 cm 51.44 cm

13 cm (DC)

5 inches (AC)

19.0 inches 20.25 inches

5.2 inches (DC)

Scale

Metric 166 kg 105.1 cm 56.0 cm 64.77 cm

Imperial 365 lbs 41.38 inches 22.05 inches 25.5 inches

20 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Weight

(Maximum Configuration)

Height Width Depth

Page 37

Analyzing Site Requirements

WHEEL_SV

WHEEL_SV

WHEEL_FV WHEEL_FV

DOOR_

FV

CAB_F

V

RUBFE

ET

RUBFE

ET

CAB_S

V

DOOR_SVSV

DOOR_SVSV

RUBFE

ET

RUBFE

ET

When fully loaded, two people are required to lift the chassis. (The

two man lift requirement applies to loads of over 80 kg.)

41.375 in. [105.09 cm]

DOOR_

FV

CAB_F

V

WHEEL_FV

RUBFE

ET

19.925 in. [50.61 cm]

The steps for site readiness are listed in Checklist 1 - Site

Readiness Checklist.

DOOR_

CAB_S

V

RUBFE

ET

RUBFE

ET

20.925 in. [53.15 cm]

M10 Tap Holes

(each corner)

Figure 2-1: Cabinet Footing Dimensions

DOOR_

RUBFE

ET

M12-1.75

(each corner)

1.808 in

[4.59 cm]

IW008301

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 21

Page 38

Chapter 2 - Installation

2.2 Mounting the Micro BTS Chassis

The Micro BTS is offered in two different configurations:

19 inch (48.26 cm) rack assembly

Cabinet enclosure assembly

Upon ordering the Micro BTS, the desired type of mounting must be specified, as

a separate mounting kit is supplied for each option.

This section describes all the necessary steps for installing a Micro BTS. It is

divided into two subsections. These two sections are:

Rack installation. Section 2.2.1

Enclosure mounting. Section 2.2.2

Each of these sections contain complete instructions on how to install the Micro

BTS in different configurations. Please refer to the appropriate section.

Ensure that:

• The ambient temperature around the unit (which may be higher

than the room temperature) is within the limit specified for the

unit.

• There is sufficient airflow around the unit.

• The electrical circuits are not overloaded - consider the name

plate rating of all the connected equipment and make sure you

have over current protection.

• The equipment is properly grounded.

• No objects are placed on top of the unit.

22 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 39

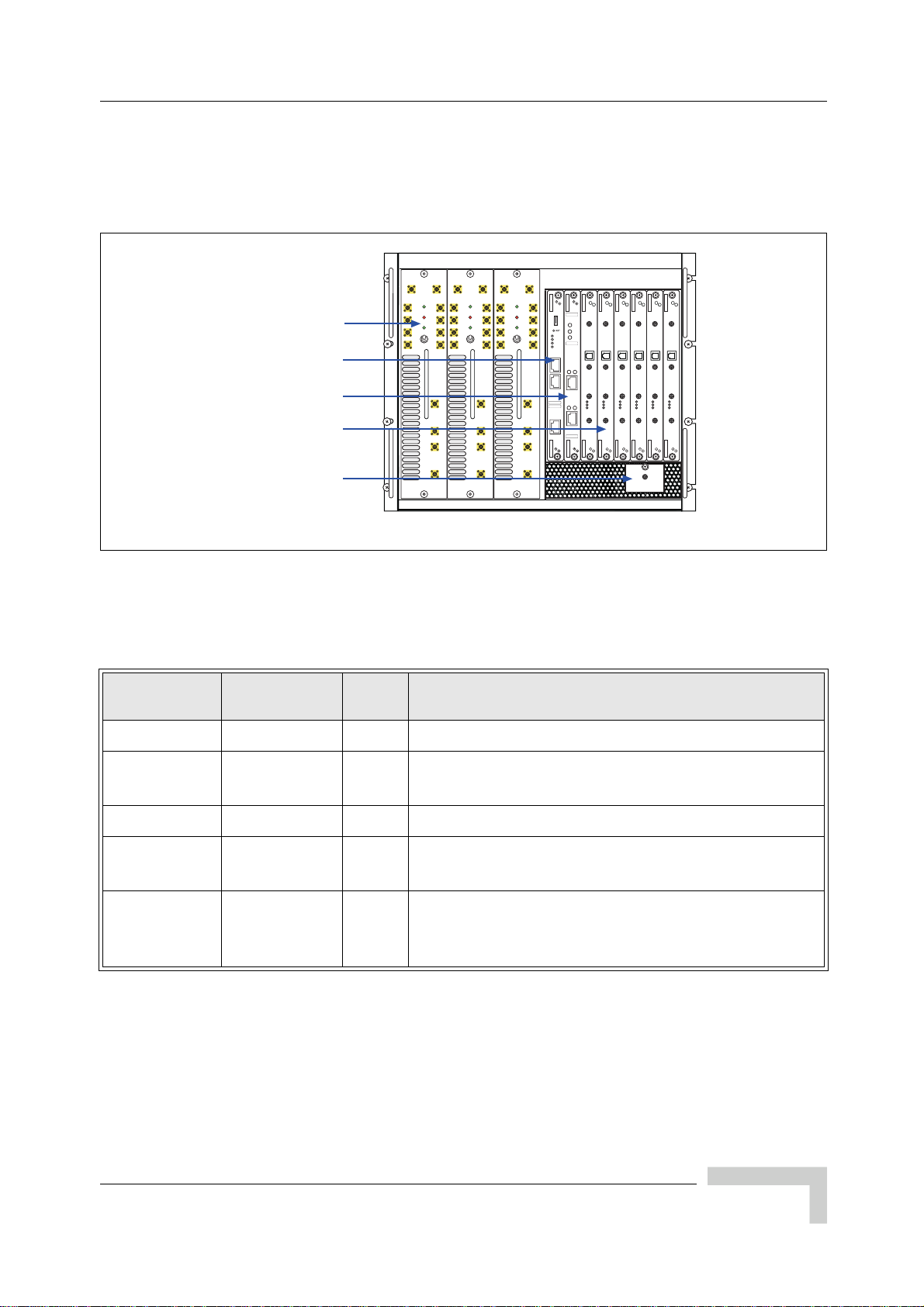

2.2.1 Rack Installation

The Micro BTS may be ordered with or without a standard EIA 19 inch rack

enclosure as defined in EIA standard RS-310-D Racks, Panels and Associated

Equipment. If you ordered the rack enclosure, the Micro subrack assembly and

the power supply subrack assembly will be mounted inside the rack enclosure

with cable access to the outside of the enclosure.

The minimum clearance required above and below the chassis is 1.0" (2.54 cm)

and the minimum clearance required behind the chassis is 1.0" (2.54 cm). The

mounting site should also have ample clearance for the trunk cables to be

attached to the front panel connectors.

Required Materials

12 standard customer-provided rack mount screws

Optional Materials

One standard 19" (48.26 cm) rack mount shelf assembly

Mounting the Micro BTS Chassis

Required Tools

Rack mount screwdriver

Rack Mount Advisory

To prevent bodily injury when mounting or servicing this unit in a rack, you must

take special precautions to ensure that the system remains stable. The following

guidelines are provided to ensure your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in

the rack.

When mounting this unit in a partially filled rack, load the rack from the

bottom to the top with the heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before

mounting or servicing the unit in the rack.

Attention: Pour éviter toute blessure corporelle pendant les opérations de montage

ou de réparation de cette unité en casier, il convient de prendre des précautions

spéciales afin de maintenir la stabilité du système. Les directives ci-dessous sont

destinées à assurer la protection du personnel:

Si cette unité constitue la seule unité montée en casier, elle doit être placée

dans le bas.

Si cette unité est montée dans un casier partiellement rempli, charger le casier

de bas en haut en plaçant l'élément le plus lourd dans le bas.

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 23

Page 40

Chapter 2 - Installation

Si le casier est équipé de dispositifs stabilisateurs, installer les stabilisateurs

avant de monter ou de réparer l'unité en casier.

Warnung: Zur Vermeidung von Körperverletzung beim Anbringen oder Warten

dieser Einheit in einem Gestell müssen Sie besondere Vorkehrungen treffen, um

sicherzustellen, daß das System stabil bleibt. Die folgenden Richtlinien sollen zur

Gewährleistung Ihrer Sicherheit dienen:

Wenn diese Einheit die einzige im Gestell ist, sollte sie unten im Gestell ange-

bracht werden.

Bei Anbringung dieser Einheit in einem zum Teil gefüllten Gestell ist das

Gestell von unten nach oben zu laden, wobei das schwerste Bauteil unten im

Gestell anzubringen ist.

Wird das Gestell mit Stabilisierungszubehör geliefert, sind zuerst die Stabilisa-

toren zu installieren, bevor Sie die Einheit im Gestell anbringen oder sie

warten.

Installation Instructions

1 Allocate nine rack units of space in your 19" rack for the Micro subrack

assembly and three rack units of space for the power supply subrack

assembly.

2 The rack mount brackets have cutouts to accommodate the rack screws.

Using two people, carefully align the Micro subrack assembly with the rack

holes.

3 Mount the Micro BTS subrack assembly in the rack using customer-provided

screws.

4 Using the same procedure, align and mount the power supply subrack

assembly below the Micro BTS subrack assembly, as shown in Figure 2-2.

Optionally, you can mount a rack mount shelf assembly and use

the shelf to support the two rack assemblies. Both assemblies

must also be secured to the rack unit.

24 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 41

Mounting the Micro BTS Chassis

.

ANT

ANT

MAIN

DIV

PWR

FLT

RX1

RX1

ON LINE

RX2

RX2

ON

RX3

RX3

OFF

RX4

RX4

A

ANT

ANT

MAIN

DIV

PWR

FLT

RX1

RX1

ON LINE

RX2

RX2

ON

RX3

RX3

OFF

RX4

RX4

TX1

DET

PA1

IN

TX2

DET

PA2

IN

B

INPUT

OUTPUT

FAULT

ON

OFF

UNLOCK

ANT

ANT

MAIN

DIV

RX1

ON LINE

RX2

RX3

RX4

TX1

DET

PA1

IN

TX2

DET

PA2

IN

01234567

PWR

FLT

ON

OFF

IIIIIIIIIIIIIIIIIIIIIIIII

RX1

P/N XXXXXX

I2C

RX2

RX3

RX4

PWR

TX

ON

OUT

LINE

PWR

FLT

ONLINE

FLT

120 OHM

13 MHZ

SCN

CLK

ENET

ALARMS

12

RX-A

DET

CON

IN

PORT 0

ALARMS

PWR

IIIIIIIIIIIIIIIIIIIIIIIII

TX1

P/N XXXXXX

12

ON LINE

IIIIIIIIIIIIIIIIIIIIIIIII

DET

S/N XXXXXX

FLT

RX-B

PORT 1

PA1

IN

IIIIIIIIIIIIIIIIIIIIIIIII

S/N XXXXXX

TX2

DET

PA2

IN

TX

OUT

OUT

13 MHZ

13 MHZ

CLK

CLK

RX-A

RX-A

DET

DET

IN

IN

PWR

PWR

ON LINE

ON LINE

FLT

FLT

RX-B

RX-B

OUT

OUT

OUT

13 MHZ

13 MHZ

13 MHZ

CLK

CLK

CLK

RX-A

RX-A

RX-A

DET

DET

DET

IN

IN

IN

PWR

PWR

PWR

ON LINE

ON LINE

ON LINE

FLT

FLT

FLT

RX-B

RX-B

RX-B

TX

TX

TX

TX

C

INPUT

OUTPUT

FAULT

ON

OFF

UNLOCK

Figure 2-2: Attaching the Subrack Assemblies

Rack Screws

x8

Rack Screws

x4

IE027601

5 Connect the alarm cable between the power supply subrack assembly and the

Micro subrack assembly. See Figure 2-3. Secure the cable by tightening the

phillips screws.

6 Connect Power Supply Cable 1 and Power Supply Cable 2 between the power

supply subrack assembly and the Micro BTS subrack assembly. See

Figure 2-3. The connector to the Micro subrack assembly will snap into place,

while you must tighten the round quick disconnect connector by twisting the

connector housing.

Refer to Section 1.5 for more information on cabling and on verifying that cables

are connected correctly.

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 25

Page 42

Chapter 2 - Installation

USB Cable to

Processor Card

External Alarm

Interface

Power Supply

Cable 2

Power Supply

Cable 1

EP1 EP2 EP3 EP4 EP5 EP6 EP7 EP8 EP9 EP10 EP11 EP12 EP13 EP14 EP15 EP16

EP17 EP18 EP19 EP20

Figure 2-3: Power Cabling and Alarm Cabling

7 You have completed the hardware installation. Proceed to Section 2.3 to

continue the Micro BTS configuration.

Alarm Cable

Input Power

Supply

IW144601

26 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 43

2.2.2 Enclosure Mounting

The Micro BTS chassis should be mounted on a concrete pad of sufficient density

to support the weight of the cabinet assembly. Alignment pins may be installed in

the concrete pad at the locations provided in Figure 2-4. The alignment pins

should be 0.5 inches (1.27 cm) in diameter and protrude from 4.1 inches to

4.4 inches (10.41 cm to 11.18 cm) from the concrete pad.

22.63 in. [57.48 cm]

10.00 in.

[25.40 cm]

14.567 in.

[37.00] cm

Mounting the Micro BTS Chassis

Rubber feet

Mounting hole

M16-2 x4 places

Alignment holes

0.551 in. [1.40 cm]

20.898 in. [53.08 cm]

IW021301

Figure 2-4: Cabinet Footprint

Enough clearance should be provided from the front and back of the cabinet to

fully open the doors. This requires at least 24 inches (61 cm) from the front and

rear doors. The minimum clearance required on either side of the cabinet is

4.5 inches (11.4 cm) and the minimum clearance required below the cabinet is

1.8 inches (4.59 cm). The mounting site should also have ample clearance for the

trunk and antenna cables to be attached to the connectors at the top of the

cabinet.

The required footprint for your cabinet installation must be at least 73.5 inches

(186.7 cm) by 31.5 inches (80 cm). Be sure there is sufficient airflow around the

unit.

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 27

Page 44

Chapter 2 - Installation

20.547 in.

[52.19 cm]

Tapped hole

M10-1.5 x4 places

22.280 in.

[56.59 cm]

0.868 in.

[2.21] cm

40.904 in.

[103.90 cm]

19.780 in.

[50.24 cm]

Cabinet (side)Cabinet (top)

Tapped hole

M10-1.5

x4 places

IW021302

Figure 2-5: Cabinet Dimensions

The cabinet is mounted on casters and may be carefully moved from the

unpacking site to its final mounting location. The cabinet has four rubber feet

which will raise the cabinet off of the casters. The dimensions for the engagement

height of the rubber feet is shown in Figure 2-1. If you have alignment pins

mounted in your concrete pad, use the procedure in this section.

If you do not have the alignment pins, Figure 2-5 illustrates the location of eight

M10 tap holes which may be used for additional mounting studs, eye hooks or

angle brackets for securing the Micro BTS cabinet in its final location.

• Make sure the ambient temperature around the unit (which

may be higher than the room temperature) is within the

specified limit.

• Make sure there is sufficient airflow around the unit.

• Make sure electrical circuits are not overloaded - consider the

nameplate rating of all the connected equipment, and make

sure you have over current protection.

• Make sure the equipment is properly grounded.

• Make sure no objects are placed on the top of the unit.

28 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 45

Required Materials

Angle brackets

Four M10 machine screws and washers

Required Tools

15 mm open end wrench

Installation Instructions

1 Move the cabinet into its final location. If using alignment pins to prevent

movement, move the cabinet into position over the pins.

2 Lower each of the rubber feet until each reaches the concrete pad.

3 Using the 15 mm open end wrench, lower each foot until the casters are raised

from the concrete floor, approximately 0.25 inches (0.65 cm).

4 Remove the casters from the bottom of the cabinet.

Mounting the Micro BTS Chassis

5 Lower the cabinet to within 4.1 inches to 4.4 inches (10.41 cm to 11.18 cm) of

the concrete pad. If you are using alignment pins, lower the cabinet until the

pins enter the alignment holes no more than 0.25 inches (0.6 cm). Do not

lower the cabinet too far over alignment pins as they may puncture internal

components.

6 Secure locking nuts on foot studs.

7 Secure the cabinet using customer-provided 10 mm studs.

You may use the additional M10 tap holes to secure the cabinet

as site-specific conditions allow.

Rack Mount Advisory

To prevent bodily injury when mounting or servicing this unit in a rack, you must

take special precautions to ensure that the system remains stable. The following

guidelines are provided to ensure your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in

the rack.

When mounting this unit in a partially filled rack, load the rack from the

bottom to the top with the heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before

mounting or servicing the unit in the rack.

UltraWAVE Micro BTS Installation and Commissioning Guide, Version B 29

Page 46

Chapter 2 - Installation

Attention: Pour éviter toute blessure corporelle pendant les opérations de montage

ou de réparation de cette unité en casier, il convient de prendre des précautions

spéciales afin de maintenir la stabilité du système. Les directives ci-dessous sont

destinées à assurer la protection du personnel:

Si cette unité constitue la seule unité montée en casier, elle doit être placée

Si cette unité est montée dans un casier partiellement rempli, charger le casier

Si le casier est équipé de dispositifs stabilisateurs, installer les stabilisateurs

Warnung: Zur Vermeidung von Körperverletzung beim Anbringen oder Warten

dieser Einheit in einem Gestell müssen Sie besondere Vorkehrungen treffen, um

sicherzustellen, daß das System stabil bleibt. Die folgenden Richtlinien sollen zur

Gewährleistung Ihrer Sicherheit dienen:

Wenn diese Einheit die einzige im Gestell ist, sollte sie unten im Gestell ange-

dans le bas.

de bas en haut en plaçant l'élément le plus lourd dans le bas.

avant de monter ou de réparer l'unité en casier.

bracht werden.

Bei Anbringung dieser Einheit in einem zum Teil gefüllten Gestell ist das

Gestell von unten nach oben zu laden, wobei das schwerste Bauteil unten im

Gestell anzubringen ist.

Wird das Gestell mit Stabilisierungszubehör geliefert, sind zuerst die Stabilisa-

toren zu installieren, bevor Sie die Einheit im Gestell anbringen oder sie

warten.

30 UltraWAVE Micro BTS Installation and Commissioning Guide, Version B

Page 47

Configuring the E1 or T1 Trunk Card

2.3 Configuring the E1 or T1 Trunk Card

This section describes how to configure E1 or T1 trunk cards.

These procedures are designed for E1 or T1 cards that are shipped pre-configured

in a system. To configure E1 or T1 cards that are shipped as configured or

unconfigured replacements, refer to the GSM Field Maintenance Guide

Your system is shipped from the manufacturer configured with the correct cards

for your site-specific application. These can be 75 Ohm E1, 120 Ohm E1 or

100 Ohm T1 cards. All cards are shipped with the appropriate connectors.

Cable runs of greater than 600 meters (1968 feet) are not

supported directly from the card. If you are attempting a longer

cable run between UltraWAVE chassis please contact Customer

Service to determine if you need a repeater for your application.

.

Table 2-7 lists the cards and the procedures that apply to each card type.

Table 2-7: Trunk Cards and Procedures

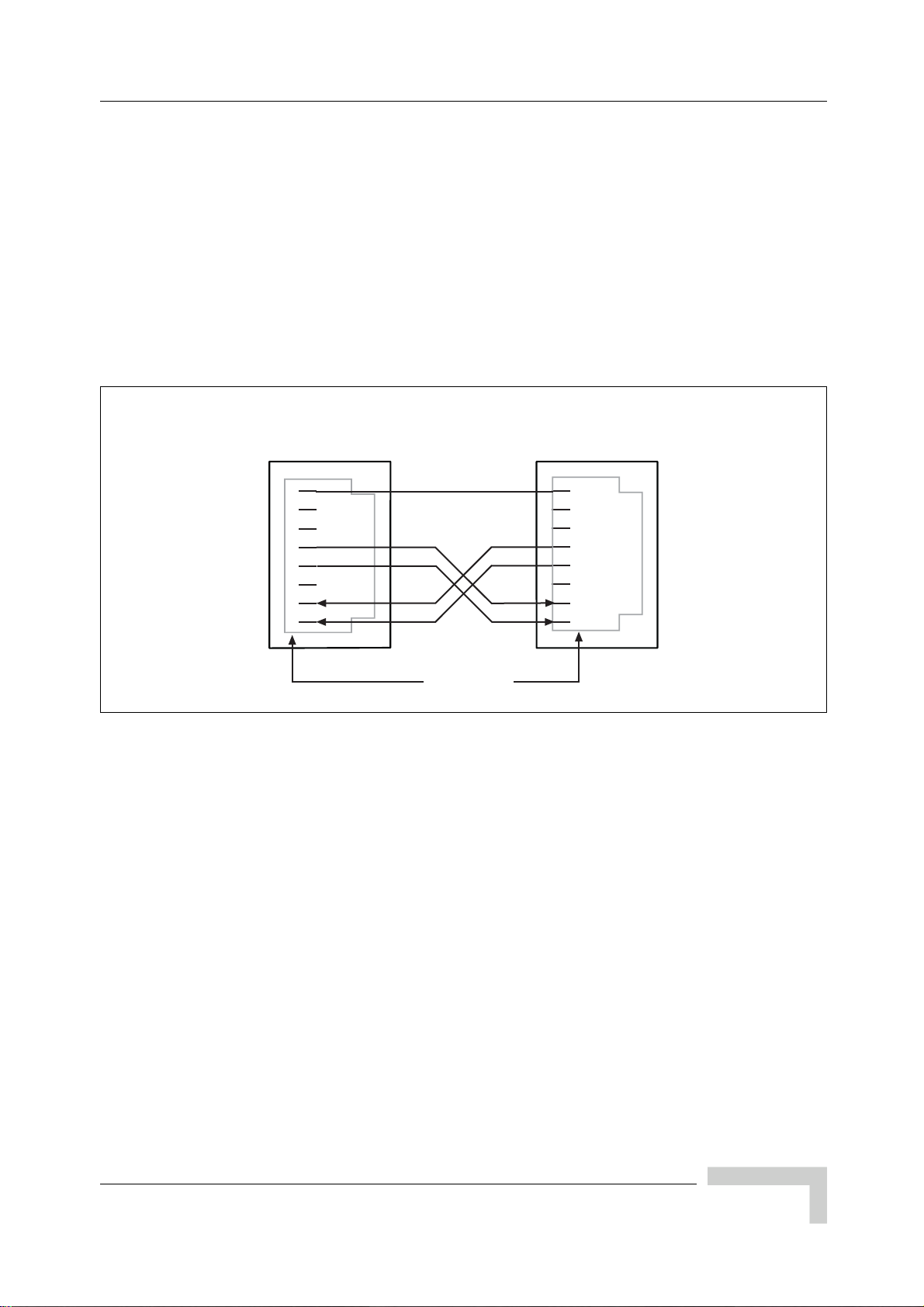

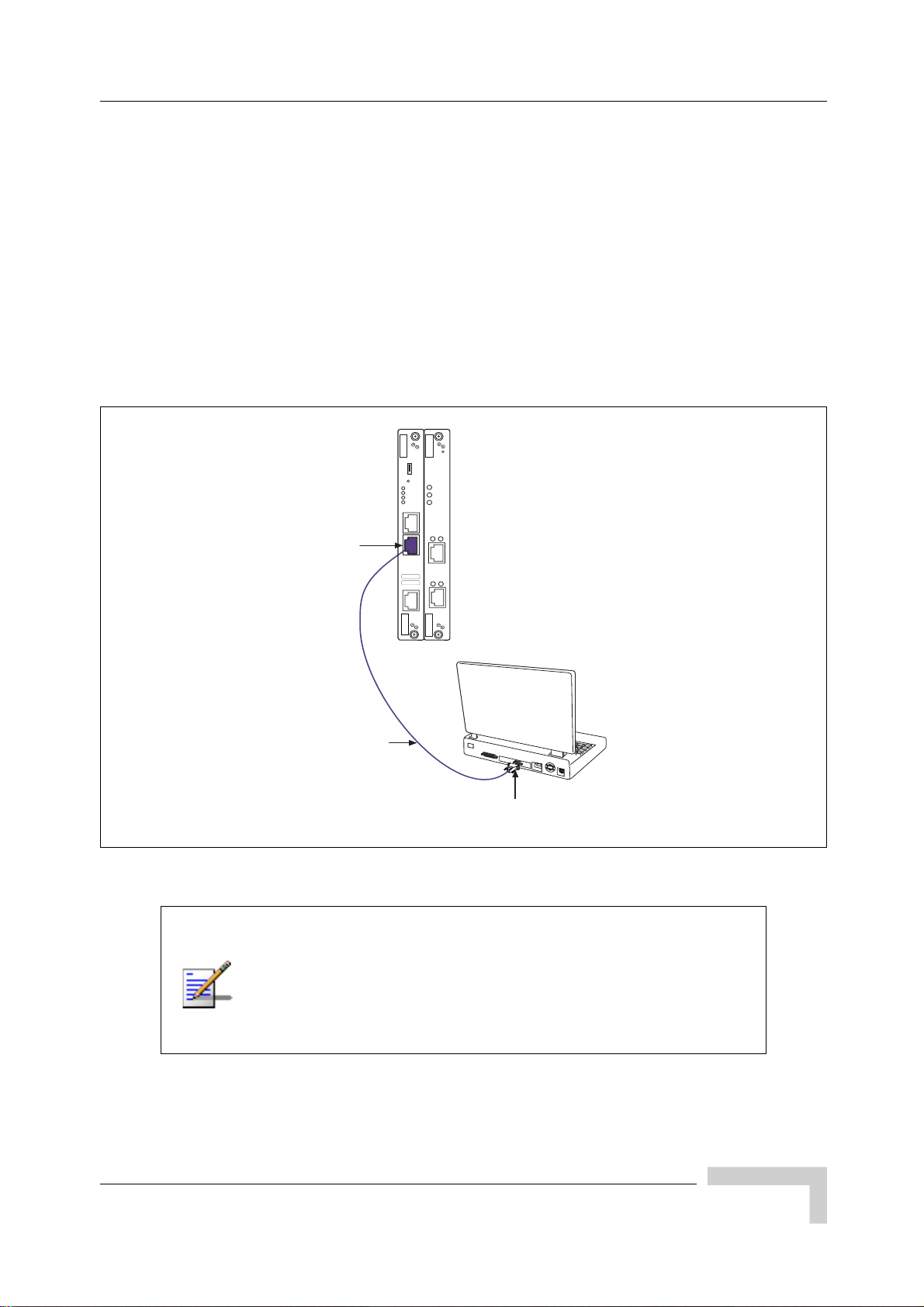

Label Description Operation