Page 1

ADG-35i/ADG-50i/ADG-80i

MG-50p/MG-80p

Installation/Operator Manual

RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

WFR115735A

Page 2

Dryer Safety

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

■

It is recommended that the owner post, in a prominent location, instructions for the customer’s use in the event the customer

smells gas. This information should be obtained from your gas supplier.

■

Post the following warning in a prominent location.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

FOR YOUR SAFETY

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death, or property

damage.

–

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this

or any other appliance.

–

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Clear the room, building, or area of all occupants.

•

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

•

instructions.

If you cannot reach your gas supplier, call the re department.

•

–

Installation and service must be performed by a qualied installer, service agency, or

the gas supplier.

2

Page 3

In the State of Massachusetts, the following installation instructions apply:

■ Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gas fitter qualified or licensed by

the State of Massachusetts.

■ Acceptable Shut-off Devices: Gas Cocks and Ball Valves installed for use shall be listed.

■ A flexible gas connector, when used, must not exceed 4 feet (121.9 cm).

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, Part 1, CSA C22.1.

Important Information

IMPORTANT: A means of restraint must be used to avoid

straining of the gas supply when the dryer is moved.

An external means of power removal (disconnect device) must be

provided by the installer.

The dryer must be used only for drying water washed fabrics.

The dryer must never be operated with any of the back guards or

service panels removed.

The wiring diagram for the dryer is located behind the front

control panel.

Caution: Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper operation.

List of Acronyms

N.P.T. National Pipe Thread

HVAC Heating, Ventilating, and Air-Conditioning

in WC Inches of Water Column

UL Underwriters Laboratory

S.A.F.E Sensor Activated Fire Extinguishing

FSS Fire Suppression System

Table of Contents

ADG-35i Specifications .............................................. 4

ADG-50i / MG-50P Specifications ............................. 6

ADG-80i / MG-80P Specifications ............................. 8

Installation Instructions ............................................. 10

Location Requirements .............................................. 10

Dryer Enclosure Requirements ................................. 11

Fresh Air Supply Requirements ................................. 11

Exhaust Requirements ............................................... 12

Electrical Information ................................................. 15

Gas Information .......................................................... 16

Water Information for Optional Wet Fire

Suppression System ................................................... 18

Preparation For Operation / Start-Up ....................... 19

Preoperational Test .................................................... 20

Operating Instructions ............................................... 20

Shutdown Instructions ................................................ 21

Service / Parts Information ........................................ 21

Routine Maintenance ................................................. 21

Adjustments ................................................................ 22

Data Label Information .............................................. 22

Programming .............................................................. 23

3

Page 4

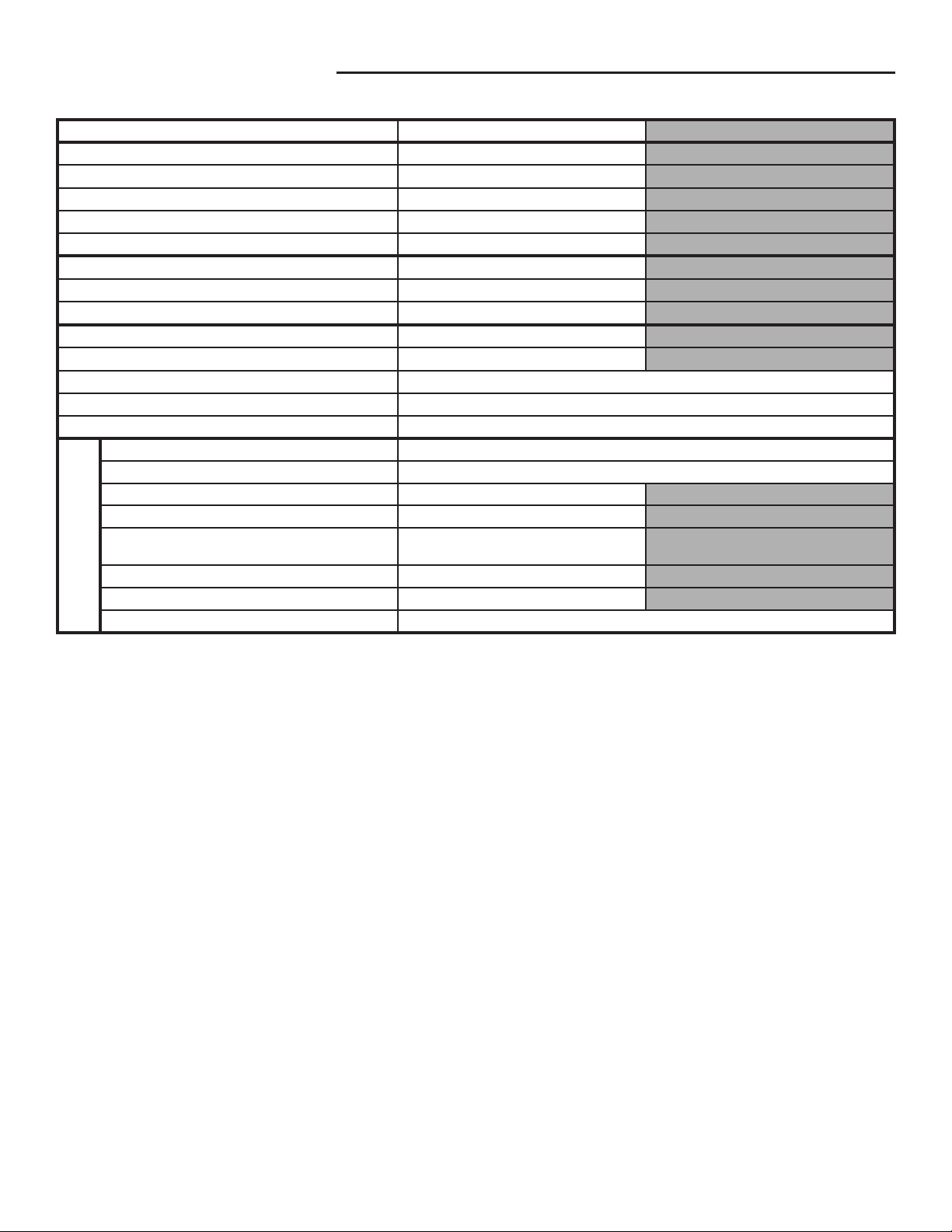

ADG-35i Specifications

MAXIMUM CAPACITY (DRY WEIGHT) 35 lb 15.87 kg

TUMBLER DIAMETER 30" 76.20 cm

TUMBLER DEPTH

TUMBLER VOLUME 12 cu ft 339.80 L

TUMBLER / DRIVE MOTOR 1 hp 0.74 kW

BLOWER / FAN MOTOR 1/2 hp 0.37 kW

CABINET WIDTH

CABINET DEPTH 43" 109.22 cm

CABINET HEIGHT

DOOR OPENING (DIAMETER) 21½" 54.61 cm

DOOR SILL HEIGHT

WATER CONNECTION 3/4"-11.5 NH

DRYERS PER 20'/40' CONTAINER 10/22

DRYERS PER 48'/53' TRUCK 32/36

AIRBORNE SOUND LEVEL 64 dB(A)

VOLTAGE AVAILABLE 120 V 1ø 2w 60 Hz

APPROXIMATE NET WEIGHT 552 lb 250.38 kg

APPROXIMATE SHIPPING WEIGHT 585 lb 265.35 kg

AIRFLOW 60

GAS

Hz

HEAT INPUT 70,000 Btu/hr 17,639 kcal/hr

EXHAUST CONNECTION (DIAMETER) 6" / 8" 15.24 cm / 20.32 cm

INLET PIPE CONNECTION 1/2" N.P.T. (Male)

293/8"

317/8"

677/8"

309/16"

440 cfm 12.46 cmm

74.61 cm

80.96 cm

172.40 cm

77.62 cm

Shaded areas are stated in metric equivalents.

4

Page 5

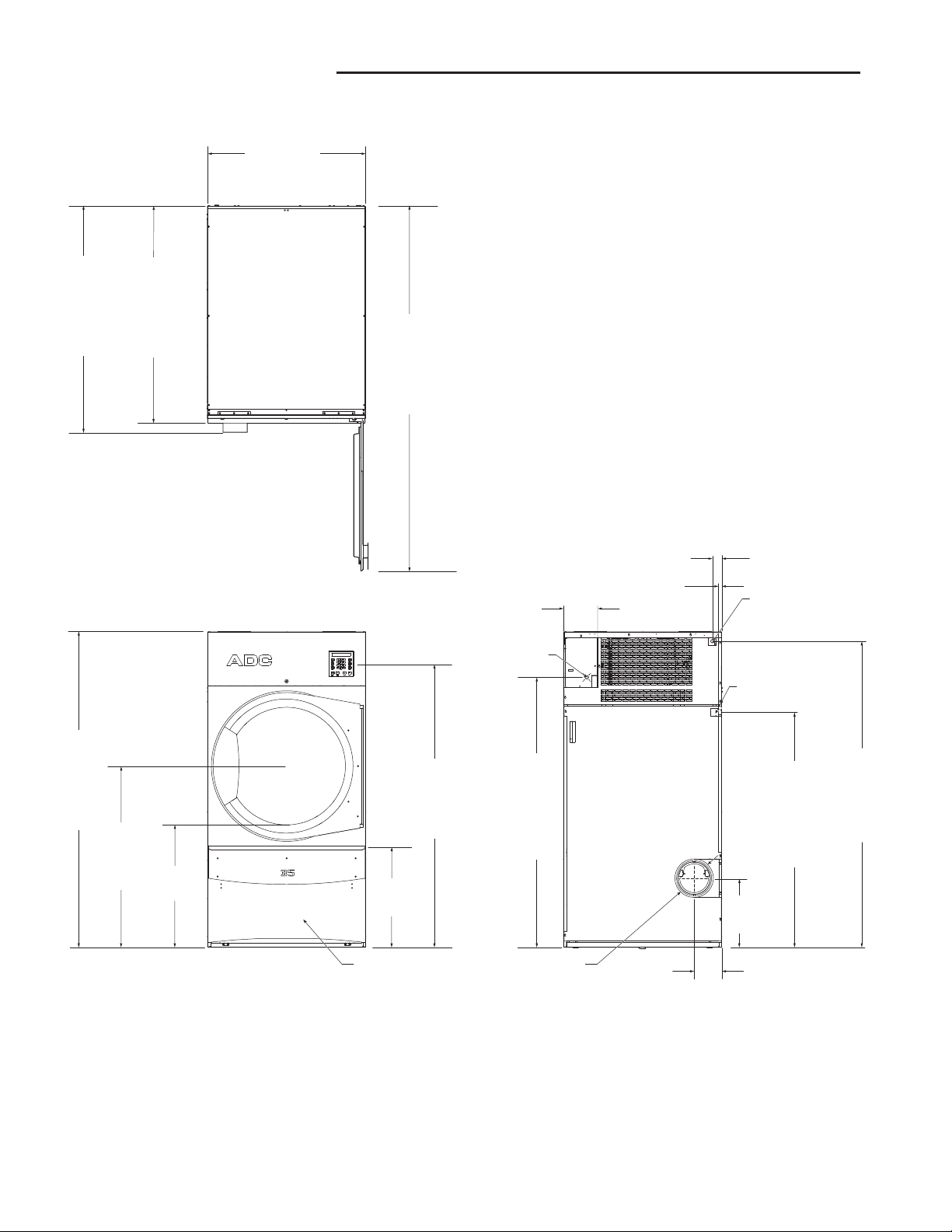

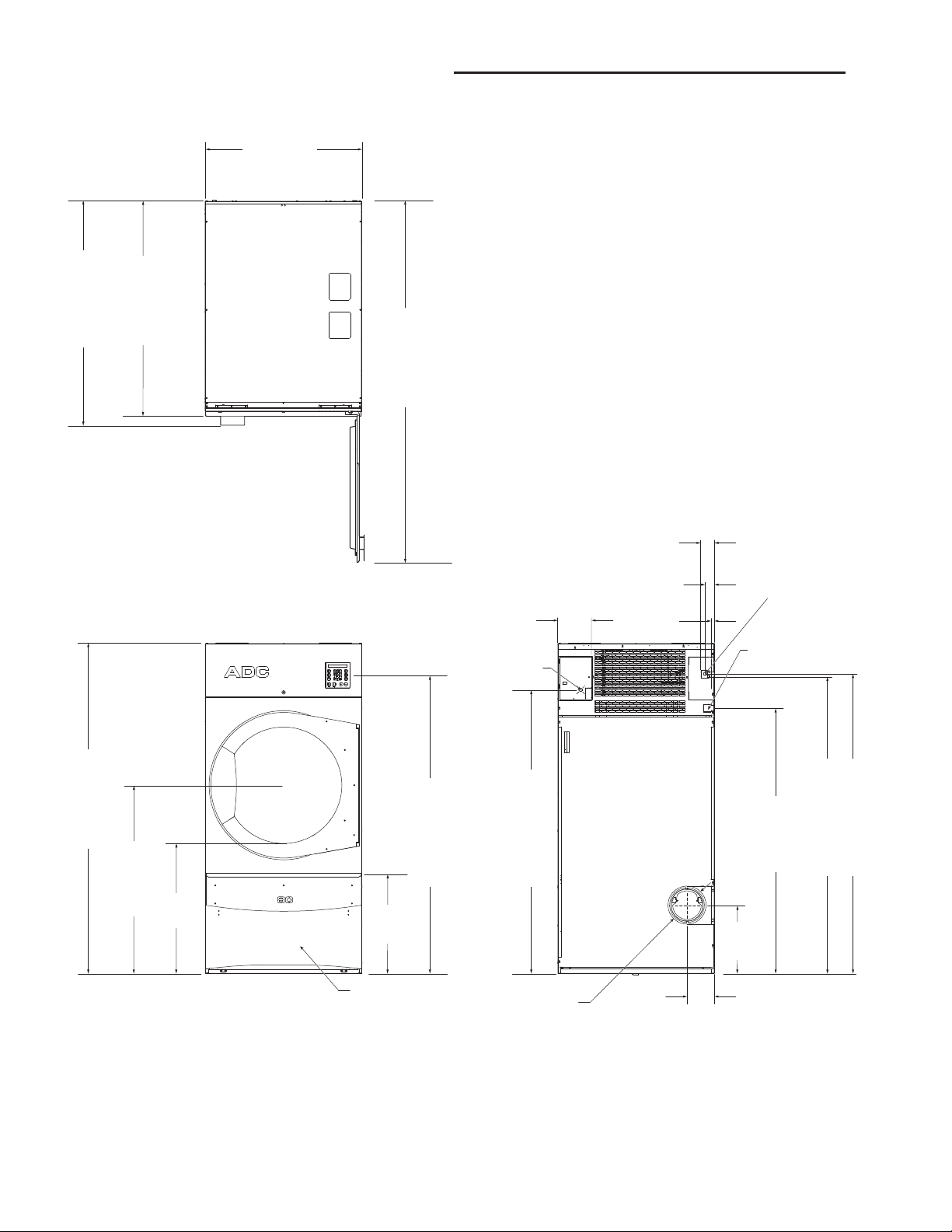

ADG-35i Specifications

31 7/8"

(81 cm)

45 1/16"

(114.5 cm)

43"

(109.2 cm)

70 1/2"

WITH

MAIN

DOOR

(179)

OPEN

ELECTRICAL CONNECTION

7 1/2"

(19.1 cm)

1 3/4"

(4.4 cm)

3 3/8"

(8.6 cm)

GAS INLET CONNECTION

1/2" N.P.T. (MALE)

WATER CONNECTION

3/4" - 11.5 NH

67 7/8"

(172.5 cm)

(104.8 cm)

41 1/4"

30

9/16"

(77.7 cm)

25 5/8"

(65.1 cm)

LINT DOOR

7/16"

62

(158.6 cm)

6" (15.2 cm)

CONNECTION FOR OPTIONAL

58 3/8"

(148.3 cm)

8" (20.3 cm) DIA ALSO PROVIDED

DIA EXHAUST

6 3/16"

(15.7 cm)

(127.5 cm)

17 5/8"

(44.8 cm)

50 3/16"

66 3/8"

(156.6 cm)

5

Page 6

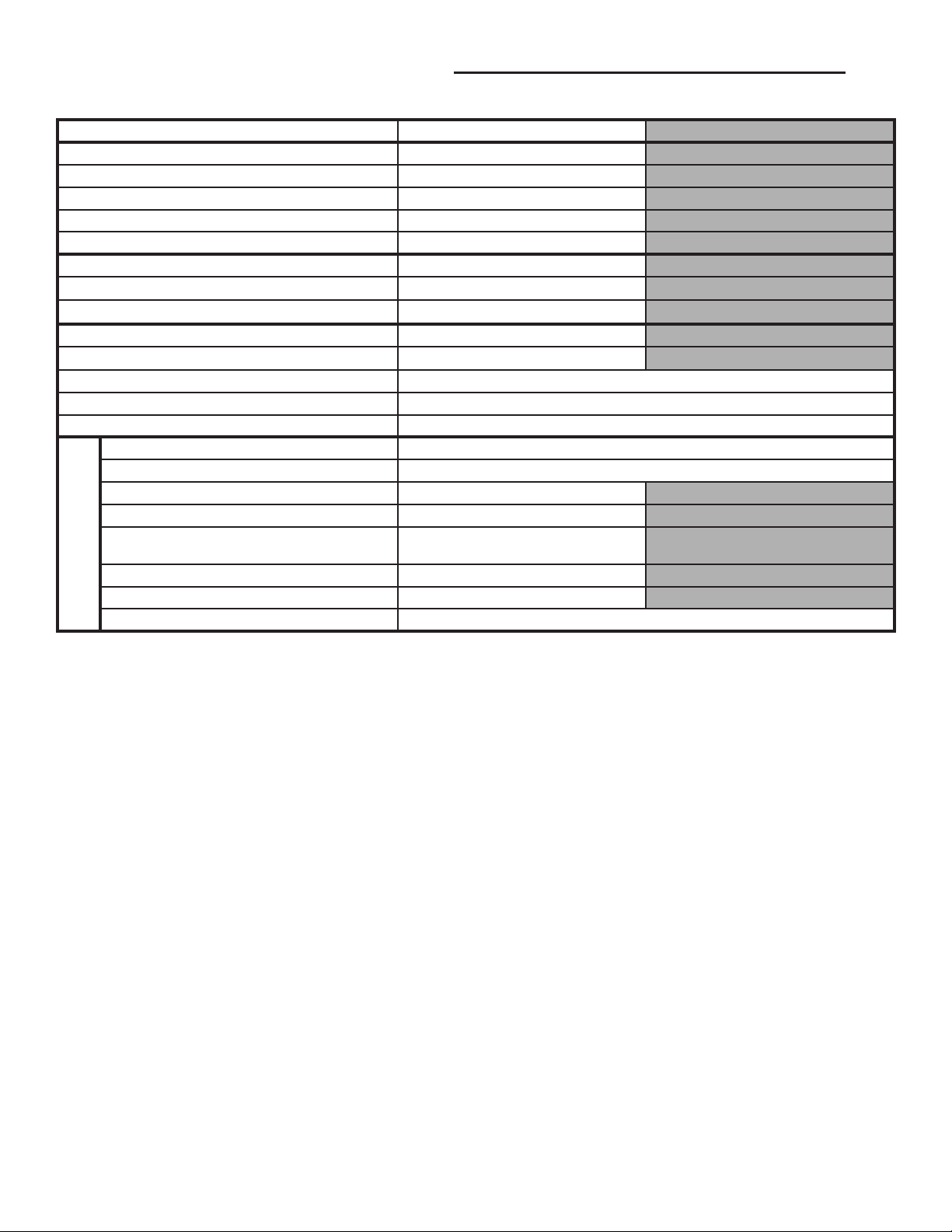

ADG-50i / MG-50p Specifications

MAXIMUM CAPACITY (DRY WEIGHT) 50 lb 22.67 kg

TUMBLER DIAMETER 32¾" 83.18 cm

TUMBLER DEPTH 37½" 95.25 cm

TUMBLER VOLUME 18.3 cu ft 518.19 L

TUMBLER / DRIVE MOTOR 1 hp 0.74 kW

BLOWER / FAN MOTOR 3/4 hp 0.56 kW

CABINET WIDTH 34½" 87.63 cm

CABINET DEPTH

CABINET HEIGHT

DOOR OPENING (DIAMETER) 27" 68.58 cm

DOOR SILL HEIGHT

WATER CONNECTION 3/4"-11.5 NH

DRYERS PER 20'/40' CONTAINER 10/20

DRYERS PER 48'/53' TRUCK 25/28

AIRBORNE SOUND LEVEL 64 dB(A)

VOLTAGE AVAILABLE 120 V 1ø 2w 60 Hz

APPROXIMATE NET WEIGHT 655 lb 297.10 kg

APPROXIMATE SHIPPING WEIGHT 710 lb 322.05 kg

AIRFLOW 60

GAS

Hz

HEAT INPUT 125,000 Btu/hr 31,500 kcal/hr

EXHAUST CONNECTION (DIAMETER) 8" 20.32 cm

INLET PIPE CONNECTION 1/2" N.P.T.

493/8"

735/8"

291/8"

850 cfm 24.06 cmm

125.41 cm

187.10 cm

74 cm

Shaded areas are stated in metric equivalents.

6

Page 7

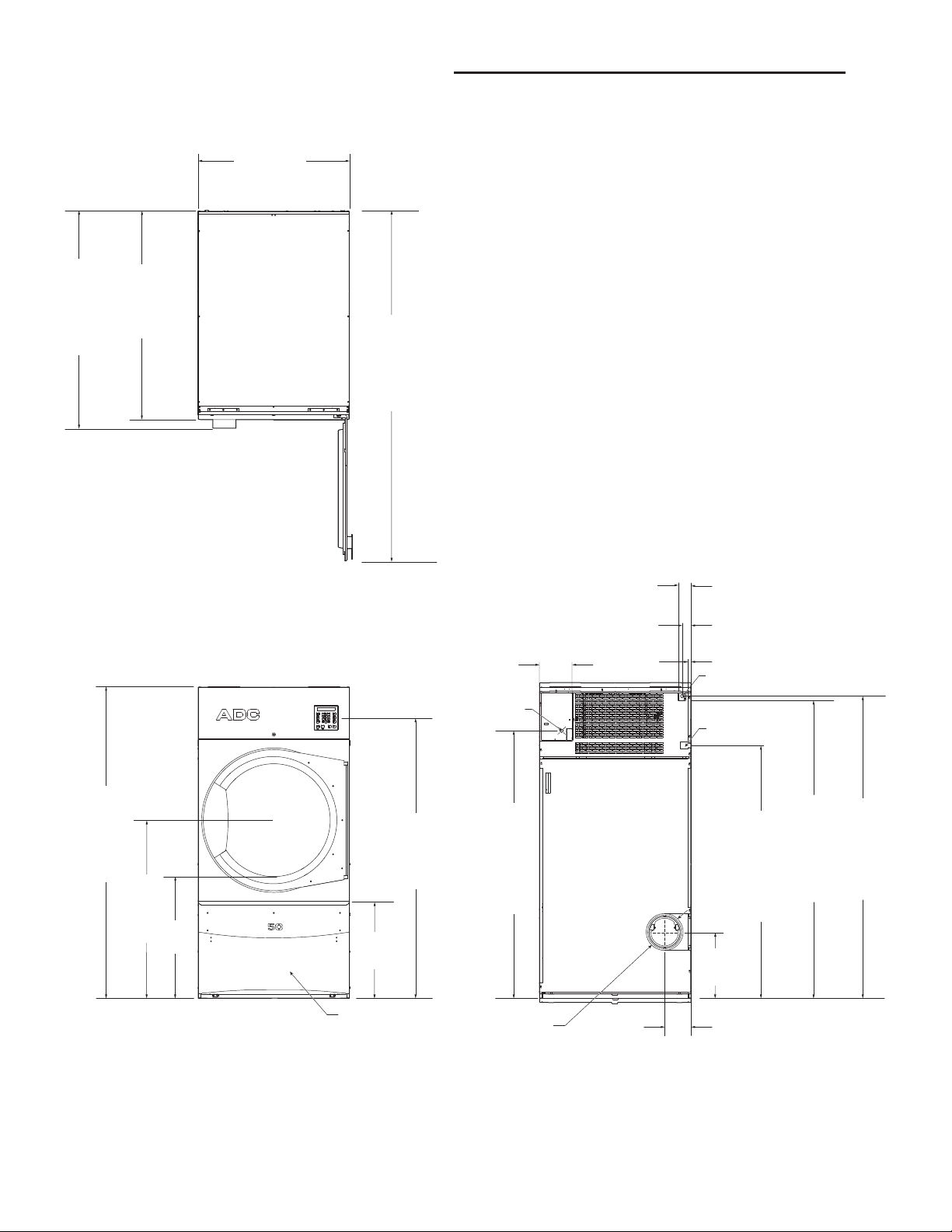

ADG-50i / MG-50p Specifications

34 1/2"

(87.6 cm)

51 1/2"

(130.8 cm)

49 3/8"

(125.5 cm)

81 7/8"

(207.9 cm)

ELECTRICAL CONNECTION

WITH

MAIN

DOOR

OPEN

7 1/2"

(19.1 cm)

4 5/8"

(11.7 cm)

3 1/2"

(8.9 cm)

1 3/4"

(4.4 cm)

GAS INLET CONNECTION

1/2" N.P.T. (MALE)

WATER CONNECTION

3/4"- 11.5 NM

73 5/8"

(187.1 cm)

(108.2 cm)

42 5/8"

(74 cm)

29 1/8"

25 1/16"

(63.7 cm)

LINT DOOR

65 3/4"

(167 cm)

8"

(20.3 cm)

61 5/8"

(156.5 cm)

DIA EXHAUST

5 11/16"

(14.4 cm)

18 5/8"

(47.3 cm)

57 5/8"

(146.4 cm)

69 3/8"

(176.2 cm)

70 7/16"

(178.9 cm)

7

Page 8

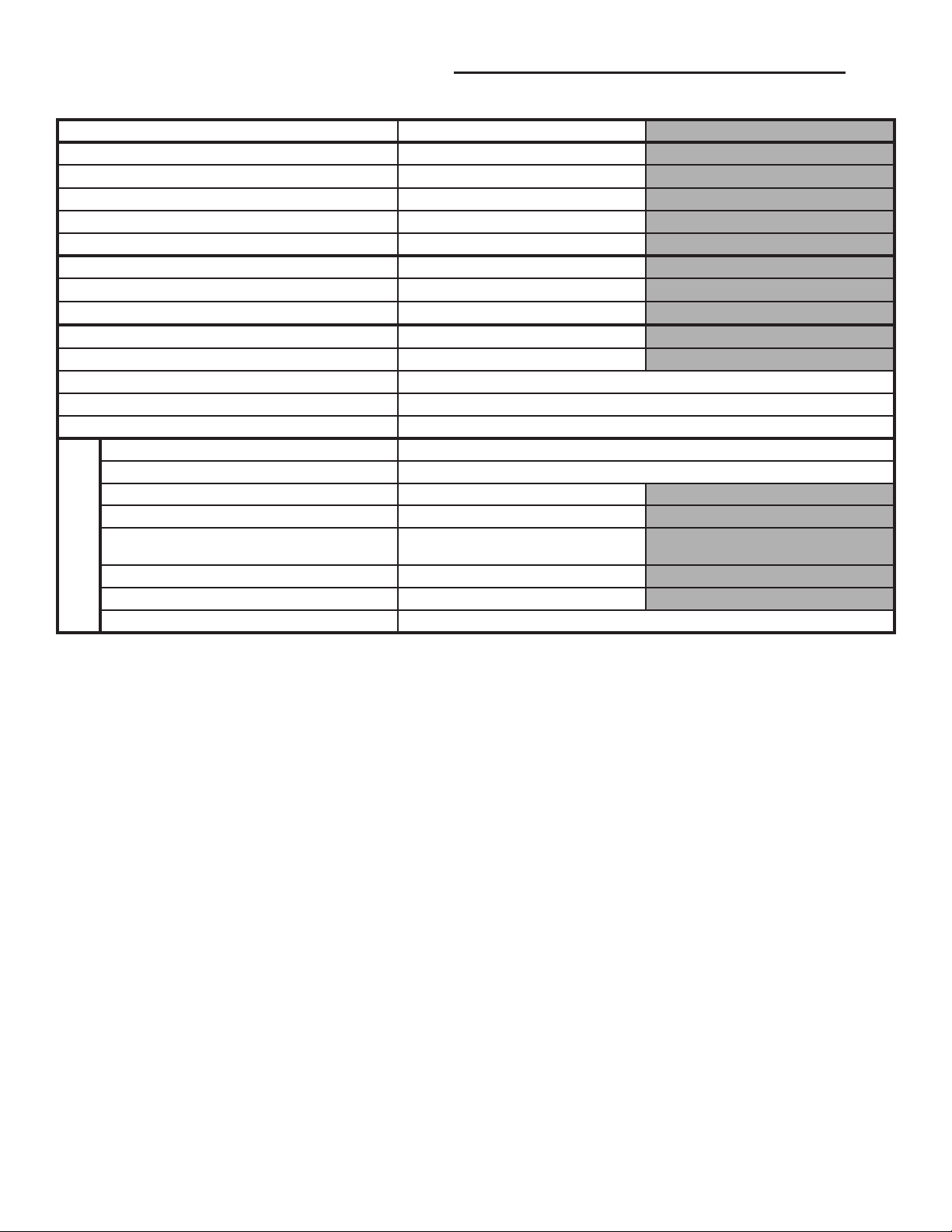

ADG-80i / MG-80p Specifications

MAXIMUM CAPACITY (DRY WEIGHT) 80 lb 36.28 kg

TUMBLER DIAMETER 37" 93.98 cm

TUMBLER DEPTH

TUMBLER VOLUME 22.05 cu ft 624.39 L

TUMBLER / DRIVE MOTOR 1 hp 0.74 kW

BLOWER / FAN MOTOR 3/4 hp 0.56 kW

CABINET WIDTH 39" 99.06 cm

CABINET DEPTH

CABINET HEIGHT

DOOR OPENING (DIAMETER)

DOOR SILL HEIGHT 29 74 cm

WATER CONNECTION 3/4"-11.5 NH

DRYERS PER 20'/40' CONTAINER 8/16

DRYERS PER 48'/53' TRUCK 22/26

AIRBORNE SOUND LEVEL 64 dB(A)

VOLTAGE AVAILABLE 120 V 1ø 2w 60 Hz

APPROXIMATE NET WEIGHT 700 lb 317.52 kg

APPROXIMATE SHIPPING WEIGHT 720 lb 326.59 kg

AIRFLOW 60

GAS

Hz

HEAT INPUT 135,000 Btu/hr 34,019 kcal/hr

EXHAUST CONNECTION (DIAMETER) 8" 20.32 cm

INLET PIPE CONNECTION 1/2" N.P.T. (Male)

357/16"

523/8"

777/8"

311/8"

920 cfm 26.05 cmm

90.01 cm

133.03 cm

197.80 cm

73.66 cm

Shaded areas are stated in metric equivalents.

8

Page 9

ADG-80i / MG-80p Specifications

39"

(99.1 cm)

54 1/2"

(138.4 cm)

W

52 3/8"

(133.1 cm)

W/O

90 1/16"

(228.7 cm)

ELECTRICAL CONNECTION

WITH

MAIN

DOOR

OPEN

7 1/2"

(19.1 cm)

3 1/2"

(8.9 cm)

2 5/16"

(5.8 cm)

1 3/4"

(4.4 cm)

GAS INLET CONNECTION

1/2

" N.P.T. (MALE)

SAFE WATER CONNECTION

3/4" - 11.5 NH

77 7/8"

(197.9 cm)

44 3/4"

(113.7 cm)

(73.7 cm)

29"

25 1/16"

(63.7 cm)

LINT DOOR

70"

(177.8 cm)

65 15/16"

(167.4 cm)

8"

(20.4 cm)

DIA EXHAUST

6 13/16"

(17.2 cm)

(157.5 cm)

17 1/16"

(43.3 cm)

62"

70 3/8"

(178.8 cm)

73 5/8"

(186.9 cm)

9

Page 10

Installation Instructions

Location Requirements

WARNING

Excessive Weight Hazard

Use two or more people and mechanical equipment to

lift, move and install dryer.

Failure to do so can result in back or other injury.

Installation should be performed by qualified professional in

accordance with local, state, and country codes. In the absence

of these codes, the installation must conform to applicable

American National Standards: ANSI Z223.1-LATEST EDITION

(National Fuel Gas Code) or ANSI/NFPA NO. 70-LATEST

EDITION (National Electrical Code) or in Canada, the installation

must conform to applicable Canadian Standards: CAN/CGAB149.1-M91 (Natural Gas) or CAN/CGA-B149.2-M91 (Propane

Gas) or LATEST EDITION (for General Installation and Gas

Plumbing) or Canadian Electrical Codes Parts 1 & 2 CSA C22.11990 or LATEST EDITION (for Electrical Connections).

Tools Required

■

Utility Knife to remove packaging.

■

1/2" Box wrench or 1/2" socket to remove pallet bolts.

■

Pipe wrench for gas connections.

■

TORX T20 to remove back guard to access leveling feet.

■

1/4” socket or 1/4” open end wrench to adjust leveling feet.

■

8 mm (5/16”) socket or open end wrench to remove lint trap

shipping bracket.

Moving to Final Location

1. Move the dryer near the point of installation.

2. Use the Utility Knife to make a cut in the plastic film.

3. Remove all plastic wrap and corrugated shipping material.

4. Dispose of/recycle all packaging material.

Leveling Dryer

The dryer is equipped with 4 leveling legs, 1 at each corner of

thebase. For optimum performance the dryer should be level

front- to-back and side-to-side.

Removing Lint Trap Shipping Bracket

1. In the lint compartment at the bottom of the dryer a bracket is

installed on the lint trap to protect it during shipping. Prior to

operating the dryer open the lint door to access the bracket.

2. Using the wrench or screwdriver, remove the (2) screws.

3. Dispose of/recycle the bracket and screws.

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Failure to do so can result in death, explosion, or fire.

IMPORTANT: The dryer must be installed on noncombustible

floor only.

The dryer is for use in noncombustible locations.

Before installing the dryer, be sure the location conforms to

local codes and ordinances. In the absence of such codes or

ordinances the location must conform with the National Fuel

Gas Code ANSI.Z223.1 LATEST EDITION, or in Canada, the

installation must conform to applicable Canadian Standards:

CAN/CGA-B149.1-M91 (Natural Gas) or CAN/CGA-B149.2-M91

(L.P. Gas) or LATEST EDITION (for General Installation and Gas

Plumbing).

The operation of this dryer may affect the operation of other

types of gas dryers, which take their air for safe combustion from

the same room. If in doubt, consult the dryer manufacturer(s).

The dryer must be installed on a sound level floor capable of

supporting its weight. Carpeting must be removed from the floor

area that the dryer is to rest on.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Provisions for adequate air supply must be provided as noted in

this manual (refer to Fresh Air Supply Requirements section).

Clearance provisions must be made from combustible

construction as noted in this manual (refer to Dryer Enclosure

Requirements section).

Provisions must be made for adequate clearances for servicing

and for operation as noted in this manual (refer to Dryer

Enclosure Requirements section).

The dryer must be installed with a proper exhaust duct

connection to the outside as noted in this manual (refer to

Exhaust Requirements section).

The dryer must be located in an area where correct exhaust

venting can be achieved as noted in this manual (refer to Exhaust

Requirements section).

IMPORTANT: The dryer should be located where a minimum

amount of exhaust ducting will be necessary.

The dryer must be installed with adequate clearance for air

openings into the combustion chamber.

IMPORTANT: The dryer must be installed in a location/

environment, which the ambient temperature remains between

40°F (4.44°C) and 130°F (54.44°C).

†TORX and T20 are trademarks of Acument Intellectual Properties, LLC.

10

Page 11

Reversing the Main Loading Door Hinge Side

CLEARANCE

ALL AROUND

I

The dryer is shipped with the main door hinge on the right hand

side as standard. The swing of the door is field reversible. If

required, the front panel can be reversed so that the door hinges

on the left-hand side.

Tools Required

1. 3/16" Allen Wrench.

2. TORX T-25 Screw Driver.

3. Ratchet wrench, 7/16" socket, optional 3" extension; or 7/16"

box end wrench.

Procedure for reversing the Front Panel

1. Disconnect the power to the dryer.

2. Remove the main loading door from the front panel. Use the

3/16" Allen wrench to remove the top hinge block. Support

the door during this operation so that it does not fall. Now lift

the door off the bottom hinge.

3. Remove the bottom hinge block. Remove the plastic washer

from the bottom hinge block and place it in the same location

on the top hinge block.

4. Open the lint door and using the T-25 screwdriver, remove the

three screws retaining the bottom of the front panel. Swing

the bottom of the front panel away from the dryer about three

inches. Reach behind the front panel and disconnect the door

switch plug located in the lower right corner.

5. Open the control door and remove the four screws retaining

the top of the front panel. Be careful that the front panel does

not fall when the last screw is removed.

6. Remove the front panel from the machine and place it face

down on a flat surface.

7. On the dryer there is a second plug for the door switch,

located inside the upper left corner of the dryer. This plug

is similar to the one in the lower right disconnected earlier,

except there is a jumper on this plug. Remove the jumper and

install it on the plug in the lower right.

8. Reinstall the front panel on the dryer. Check that the mounts

for the door hinge are on the left-hand side. Be sure to

connect the door switch plug now in the upper left corner of

the dryer.

9. Reinstall the retaining screws, top and bottom.

10. The handle and hinge location on the door have to be

reversed. Position the door on a flat surface with the hinge

on the right, the handle on the left, and the warning labels

facing up. Use the 7/16" wrench to remove the hinge bracket,

handle, and magnet stops, from the door ring. Move the hinge

to the left side, and the handle and magnet stops to the right

side. Reinstall and tighten all bolts.

11. Reinstall the bottom hinge block. This was the top hinge

block and now has the plastic washer on it.

12. Reinstall the main loading door, and the top hinge block. The

top hinge block was the bottom hinge block, now with no

plastic washer on it.

13. Check that the door swings properly and that all warning

signs on the inside of the door are right side up.

14. Close all doors and panels. Then reconnect the power to the

dryer.

15. Check that the dryer starts with no errors.

16. Check that the dryer stops when the door is opened.

NOTE: Some doors have a custom logo bar inside. If the

instructions above have been followed correctly the logo bar

will be right side up. If not, follow instructions 2 through 10 for

removing the door and reversing the hinge side.

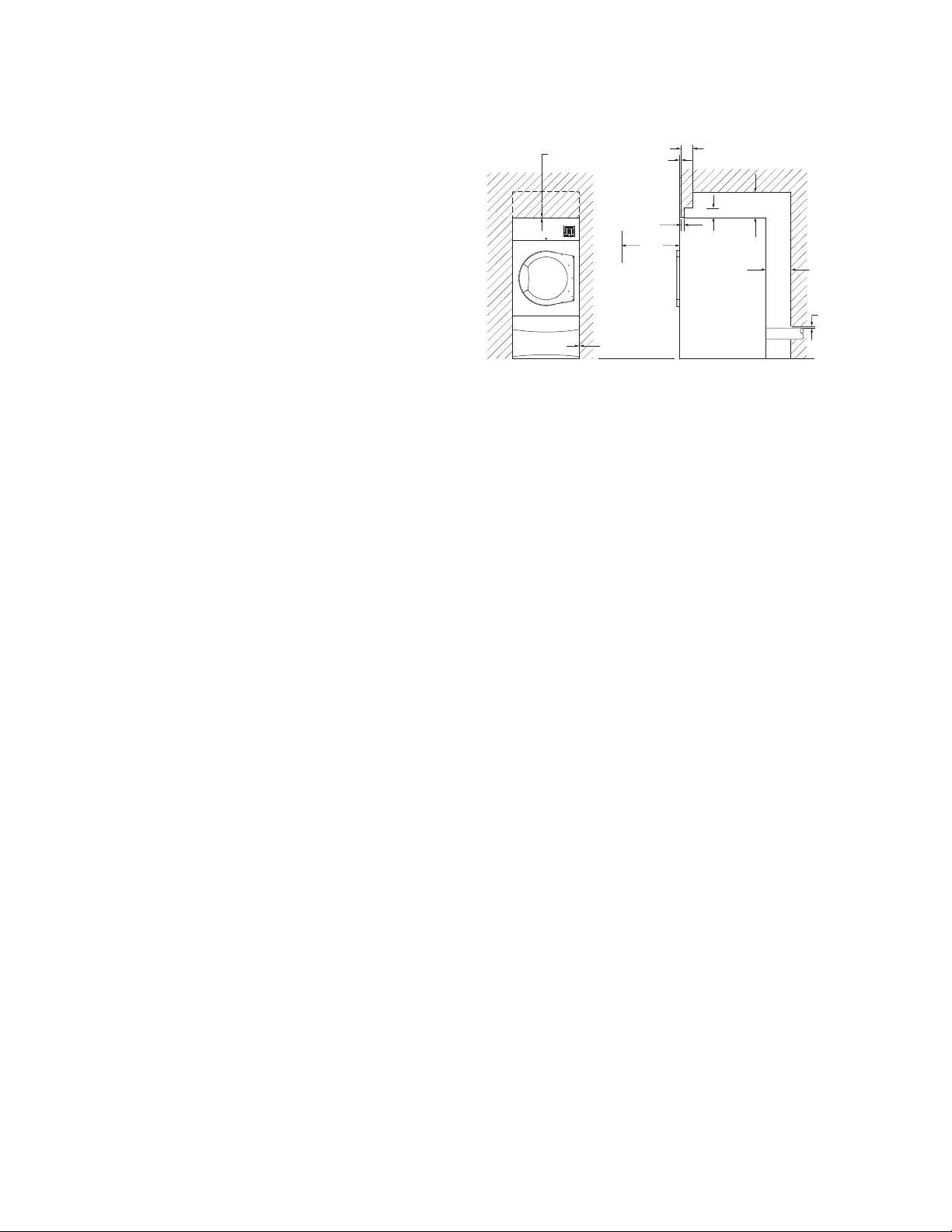

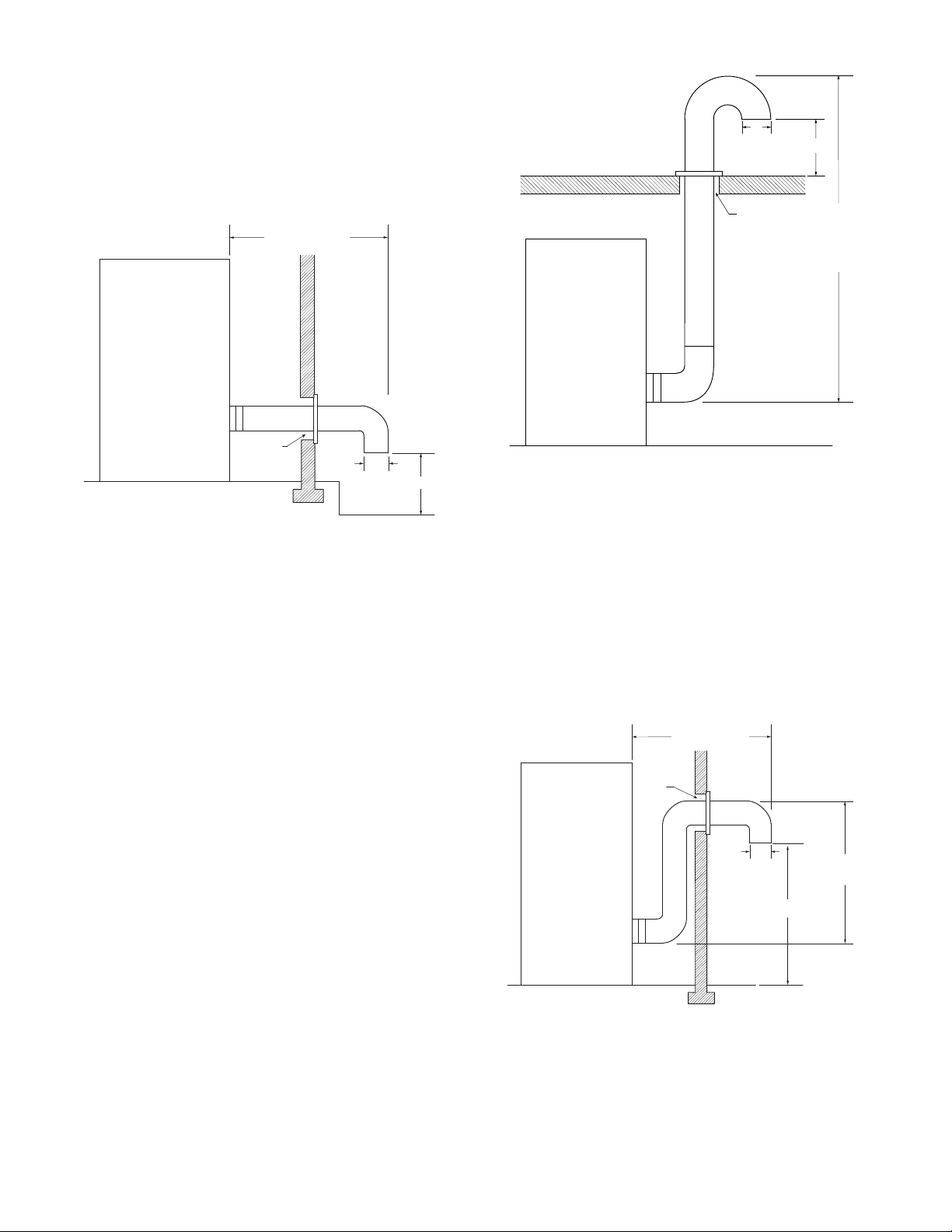

Dryer Enclosure Requirements ___

Bulkheads and partitions should be made of noncombustible

material.

NOTE: Allowances must be made for opening the control door.

D

E

A. The requirement to allow the loading door to open completely

for the AD-35i is 33" (83.8 cm), AD-50i/M-50p is 36" (91.4

cm), and AD-80i/M-80p is 40" (101.6 cm).

B. A minimum overhead clearance of 12" (30.48 cm) is required.

18" (45.72 cm) is recommended.

C. Dryer should be positioned a minimum of 12" (30.48 cm) away

from the nearest obstruction. 24" (60.96 cm) is recommended

for ease of installation, maintenance, and service.

D. 1/16" (0.15875 cm) minimum is required.

E. E Dryers may be positioned sidewall to sidewall, however

a 1/16" (0.15875 cm) minimum allowance must be made

for the opening and closing of the lint door, along with the

removal of panels during maintenance.

F. Dryer must protrude 1" (2.54 cm) from the surface of any

bulkhead or partition around the dryer to allow the control

door to open.

G. The maximum thickness of any bulkhead or partition from the

header down to the top of the dryer is 1" (2.54 cm).

H. The minimum clearance from the top of the dryer to the

header of any bulkhead or partition located directly above the

dryer is 4"(10.16 cm).

I. The maximum thickness of any bulkhead or partition above

the header is 4" (10.16 cm).

F

B

G

A

H

C

2" (5.08 cm)

Fresh Air Supply Requirements ___

When the dryer is operating, it draws in room air, heats it, passes

this air through the tumbler, and exhausts it out of the building.

Therefore, the room air must be continually replenished from the

outdoors. If the make-up air is inadequate, drying time and drying

efficiency will be adversely affected. Ignition problems and sail

switch “fluttering” problems may result, as well as premature

motor failure from overheating. The dryer must be installed with

provisions for adequate combustion and makeup air supply.

Air supply (make-up air) must be given careful consideration to

ensure proper performance of each dryer. Fresh air ventilation

openings shall not be blocked and/or sealed. As a general rule,

an unrestricted air entrance from the outdoors of 70 in.2 (451 cm2)

for each AD-35i, 125 in.2 (806 cm2) for each AD-50i/M-50p, and

135in.2 (870 cm2) is required for each AD-80i/M-80p. (Based on

1in.2 [6.5 cm2] per 1,000 Btu [252 kcal].)

It is not necessary to have a separate make-up air opening for

each dryer. Common make-up air openings are acceptable.

However, they must be set up in such a manner that the makeup

air is distributed equally to all the dryers.

To compensate for the use of registers or louvers used over the

openings, this area must be increased by approximately 33%.

Makeup air openings should not be located in an area directly

near where exhaust vents exit the building.

Allowances must be made for remote or constricting

passageways or where dryers are located at high altitudes or

predominantly low pressure areas.

11

Page 12

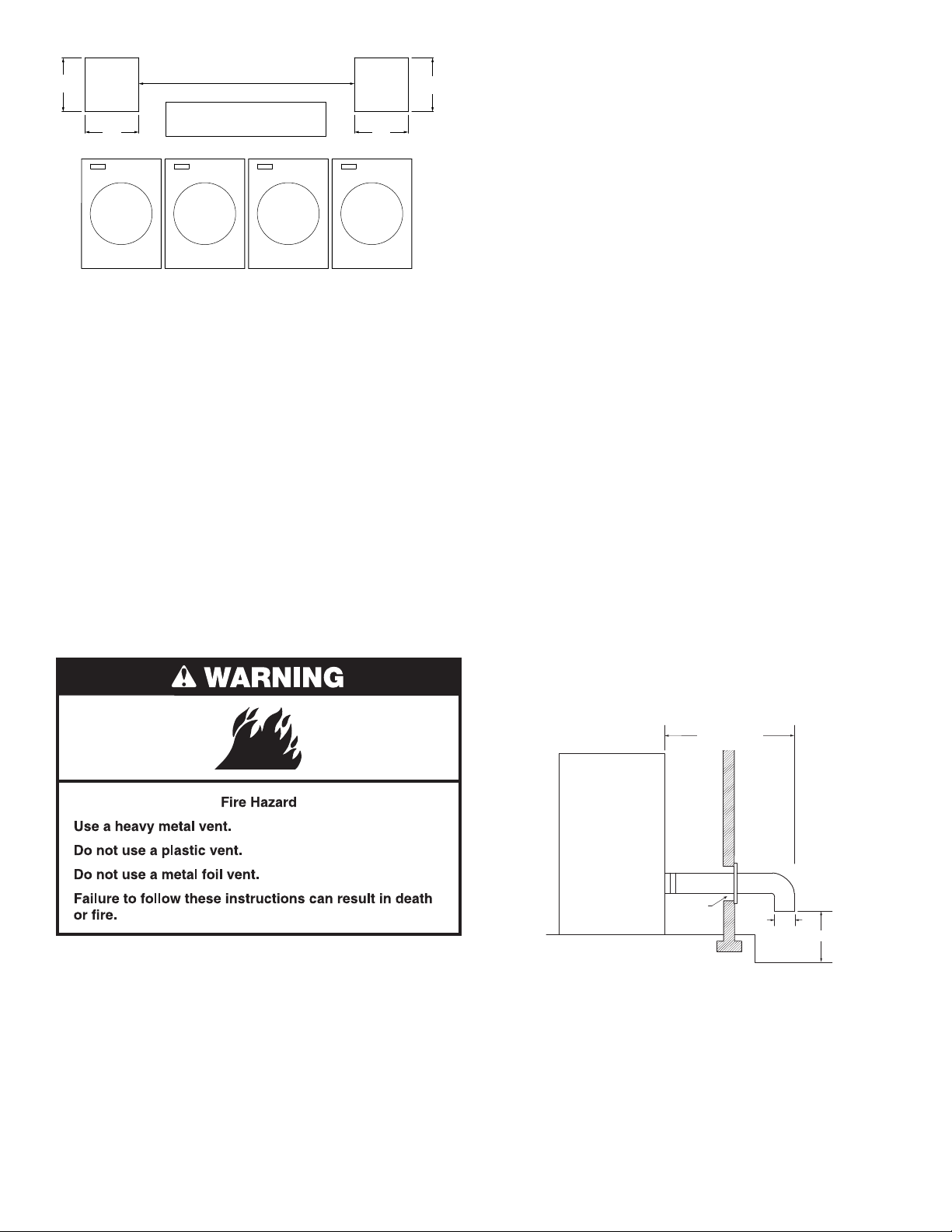

A

B B

MAKE-UP AIR OPENINGS

A = 12" (30.5 cm)

B = 12" (30.5 cm)

A

EXAMPLE: For a bank of four AD-35i dryers, two unrestricted

openings measuring 12" by 12" (30.5 cm by 30.5 cm) are

acceptable.

To compensate for the use of registers or louvers used over the

openings, this area must be increased by approximately 33%.

Make-up air openings should not be located in an area directly

near where exhaust vents exit the building.

IMPORTANT: Make-up air must be free of dry cleaning solvent

fumes. Make-up air that is contaminated by dry cleaning solvent

fumes will result in irreparable damage to the motors and other

dryer components.

NOTE: Component failure due to dry cleaning solvent fumes will

void the warranty.

Exhaust Requirements___________

Exhaust ductwork should be designed and installed by a qualified

professional. Improperly sized ductwork will create excessive

back pressure, which results in slow drying, increased use of

energy, and shutdown of the burner by the airflow (sail) switch,

burner hi-limits, or lint chamber hi-limit protector thermostat. The

dryer must be installed with a proper exhaust duct connection to

the outside.

lint. When adding ducts, overlap the duct being connected. All

ductwork joints must be taped to prevent moisture and lint from

escaping into the building. Inspection doors should be installed

at strategic points in the exhaust ductwork for periodic inspection

and cleaning of lint from the ductwork.

IMPORTANT: Exhaust back pressure measured by a manometer/

magnehelic in the exhaust duct must be no less than 0 and must

not exceed 0.6 in WC (1.5 mb).

NOTE: It is recommended that exhaust or booster fans not be

used in the exhaust ductwork system except where necessary

to maintain exhaust back pressure (in the exhaust duct) between

zero and 0.6" water column. Where employed, booster fans must

not activate the dryer airflow proving switch (sail switch) when the

dryer is not in operation.

When the exhaust ductwork passes through a wall, ceiling, or

roof made of combustible materials, the opening must be 2" (5.08

cm) larger than the duct (all the way around). The duct must be

centered within this opening.

The ductwork for this dryer must be suitable for the appliance

category in accordance with national installation regulations of

the country of destination.

Outside Ductwork Protection

To protect the outside end of the horizontal ductwork from the

weather, a 90° elbow bent downward should be installed where

the exhaust exits the building. If the ductwork travels vertically

up through the roof, it should be protected from the weather by

using a 180° turn to point the opening downward. In either case,

allow at least twice the diameter of the duct between the duct

opening and the nearest obstruction (refer to the diagram).

IMPORTANT: Do not use screens, louvers, or caps on the

outside opening of the exhaust ductwork.

Single Dryer Venting (AD-35i)

IMPORTANT: For the AD-35i, a minimum exhaust duct size of

6"(15.24 cm) must be used.

For a 6" (15.24 cm) horizontal run where a maximum of one

elbow is used, the ductwork from the dryer outlet must not

exceed 25feet(7.6 meters). Refer to the following illustration.

AD-35i ONLY

HORIZONTAL SINGLE DRYER VENTING

6" (15.24 CM) DUCTING

As per the National Fuel Gas Code, “Exhaust ducts for type

2 clothes dryers shall be constructed of sheet metal or other

noncombustible material. Such ducts shall be equivalent in

strength and corrosion resistance to ducts made of galvanized

sheet steel not less than 26 gauge (0.0195" [0.50 mm]) thick.”

The ductwork should be laid out in such a way that the ductwork

travels as directly as possible to the outdoors with as few turns

as possible. There should be a minimum 6" (15.24 cm) clearance

between the back guard and the first bend in the ductwork

for ease of servicing. Single or independent dryer venting is

recommended. It is suggested that the use of 90° turns be

avoided; use 30° and/or 45° bends instead. The radius of the

elbows should preferably be 1-1/2 times the diameter of the

duct. All ductwork should be smooth inside with no projections

from sheet metal screws or other obstructions, which will collect

12

25 FEET

7.6 METERS

SIDE VIEW OF DRYER

(SECTION VIEW)

6" (15.24 cm)

DIAMETER

DUCT MIN.

SEE

NOTE 1

D

2 x D

NOTE 1: WHEN PASSING THROUGH COMBUSTIBLE MATERIAL

THE OPENING MUST BE 2" (5.08 CM) LARGER THAN THE

DUCT (ALL THE WAY AROUND). THE DUCT MUST BE

CENTERED WITHIN THIS OPENINGS.

If the length of the duct run or quantity of elbows used exceeds

the above noted specifications, the cross-sectional area of the

ductwork may need to be increased.

IMPORTANT: For extended ductwork runs, the cross section

area of the ductwork can only be increased to an extent. When

the ductwork approaches the maximum limits noted in this

manual, a professional HVAC firm should be consulted for proper

venting information.

Page 13

Single Dryer Venting (AD-35i, AD-50i/M-50p,

AD-80i/M-80p)

IMPORTANT: A minimum exhaust duct size of 8" (20.32 cm)

must be used.

For an 8" (20.32 cm) horizontal run where a maximum of one

elbowis used, the ductwork from the dryer outlet must not

exceed 50 feet (15.2 meters). Refer to the following illustration.

HORIZONTAL SINGLE DRYER VENTING

SIDE VIEW OF DRYER

(SECTION VIEW)

NOTE 1: WHEN PASSING THROUGH COMBUSTIBLE MATERIAL

THE OPENING MUST BE 2" (5.08 CM) LARGER THAN THE

DUCT (ALL THE WAY AROUND). THE DUCT MUST BE

CENTERED WITHIN THIS OPENINGS.

NOTE 2: THE AD35I HAS A REMOVABLE 6" DIA EXHAUST

TRANSITION. REMOVE THIS TRANSITION TO INSTALL AN 8"

DIA EXHAUST.

If the length of the duct run or quantity of elbows used exceeds

the above noted specifications, the cross-sectional area of the

ductwork may need to be increased.

IMPORTANT: For extended ductwork runs, the cross section

area of the ductwork can only be increased to an extent. When

the ductwork approaches the maximum limits noted in this

manual, a professional HVAC firm should be consulted for proper

venting information.

For an 8" (20.32 cm) vertical run with three 90° elbows, the

ductwork from the dryer to the outside outlet cannot exceed

30feet(9.2 meters). Refer to the following illustration.

8" (20.32 CM) DUCTING

50 FEET

15.2 METERS

8" (20.32 cm)

DIAMETER

DUCT MIN.

SEE

NOTE 1

D

2 x D

VERTICAL SINGLE DRYER VENTING

D

2 x D

SEE NOTE 1

30 FEET

9.2 METERS

SIDE VIEW OF DRYER

(SECTION VIEW)

8" (20.32 cm) DIAMETER DUCT MIN.

NOTE 1: WHEN PASSING THROUGH COMBUSTIBLE MATERIAL

THE OPENING MUST BE 2" (5.08 CM) LARGER THAN THE

DUCT (ALL THE WAY AROUND). THE DUCT MUST BE

CENTERED WITHIN THIS OPENINGS.

NOTE 2: THE AD35I HAS A REMOVABLE 6" DIA EXHAUST

TRANSITION. REMOVE THIS TRANSITION TO INSTALL AN 8"

DIA EXHAUST.

Combined Vertical and Horizontal Dryer

Venting

For an 8" (20.32 cm) combined vertical and horizontal run, the

dryer to the outside outlet cannot exceed the sum of dimensions

“A” and “B” in the following illustration.

This calculation of “A” and “B” compensates or allows for the

use of a maximum of 3 elbows including one elbow, which is the

outside outlet protection. Refer to the illustration below.

“A” DIMENSION

SEE

NOTE 1

SIDE VIEW OF DRYER

(SECTION VIEW)

8" (20.32 cm)

DIAMETER DUCT MIN.

D

2 x D

“B”

DIMENSION

NOTE 1: WHEN PASSING THROUGH COMBUSTIBLE MATERIAL

THE OPENING MUST BE 2" (5.08 CM) LARGER THAN THE

DUCT (ALL THE WAY AROUND). THE DUCT MUST BE

CENTERED WITHIN THIS OPENINGS.

NOTE 2: “A” DIMENSION + “B” DIMENSION SHOULD NOT

EXCEED 30 FEET (9.2 METER).

NOTE 3: THE AD35I HAS A REMOVABLE 6" DIA EXHAUST

TRANSITION. REMOVE THIS TRANSITION TO INSTALL AN 8"

DIA EXHAUST.

13

Page 14

IMPORTANT: For extended ductwork runs, the cross-sectional

2

WHEN PASSING THROUGH COMBUSTIBLE MATERIAL THE OPENING MUST BE 2-INCHES (5.08 cm) LARGER

THAN THE DUCT (ALL THE WAY AROUND). THE DUCT MUST BE CENTERED WITHIN THIS OPENING.

40 FEET (12.2 METERS)

THAN THE DUCT (ALL THE WAY AROUND). THE DUCT MUST BE CENTERED WITHIN THIS OPENING.

2

WHEN PASSING THROUGH COMBUSTIBLE MATERIAL THE OPENING MUST BE 2-INCHES (5.08 cm) LARGER

20 FEET (16.1 METERS)

THAN THE DUCT (ALL THE WAY AROUND). THE DUCT MUST BE CENTERED WITHIN THIS OPENING.

area of the ductwork can only be increased to an extent. When

the ductwork approaches the maximum limits as noted in this

manual, a professional HVAC firm should be consulted for proper

venting information.

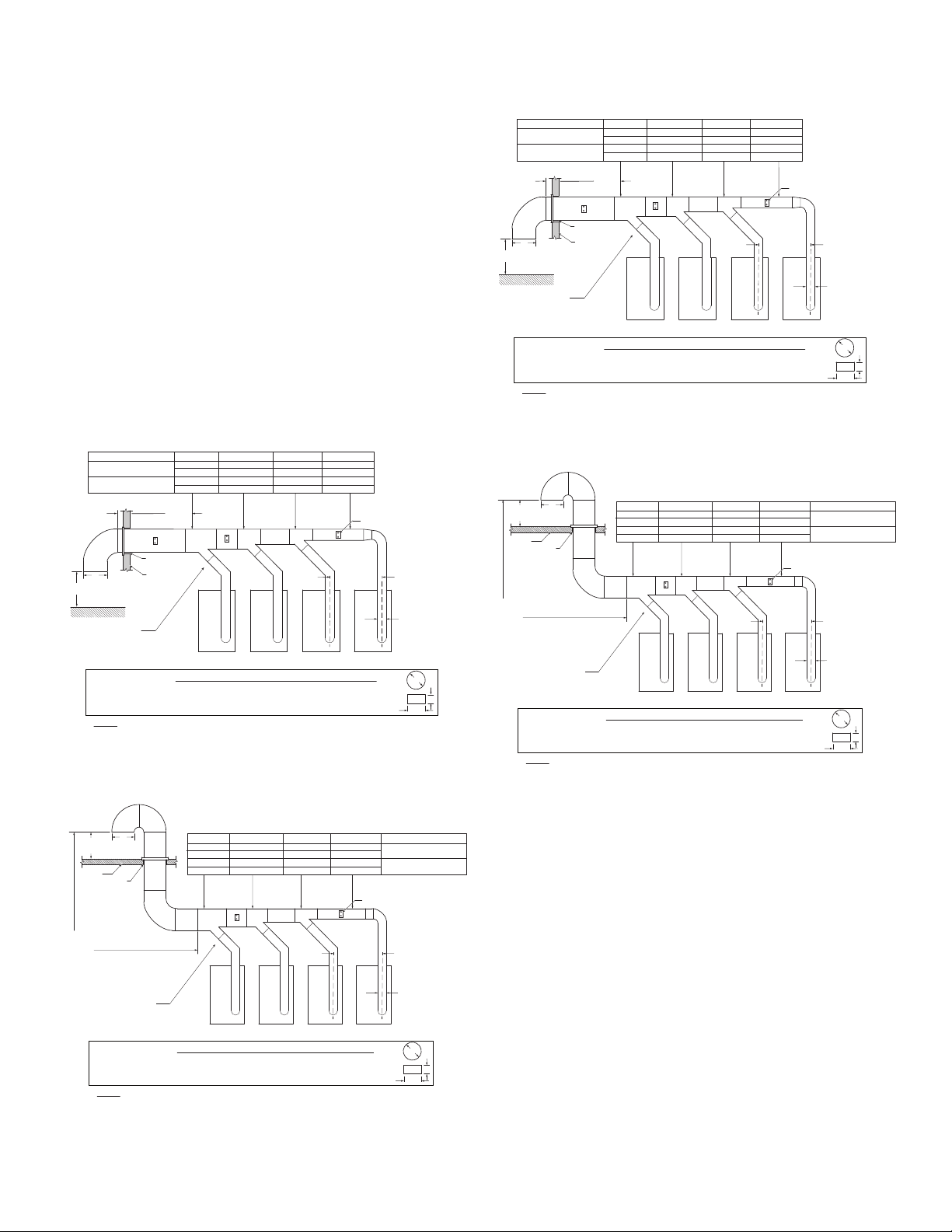

Multiple Dryer (Common) Venting

If it is not feasible to provide separate exhaust ducts for each

dryer, ducts from individual dryers may be channeled into a

“common main duct.” The individual ducts should enter the

bottom or side of the main duct at an angle not more than 45º in

the direction of airflow. The main duct should be tapered, with the

diameter increasing before each individual duct is added.

IMPORTANT: No more than four dryers should be connected to

one main common duct.

The main duct may be any shape provided that the minimum

cross-sectional area is maintained. The illustration below shows

the minimum cross-sectional area for multiple dryer venting.

These figures must be increased if the main duct run from the last

dryer to where it exhausts to the outdoors is unusually long (over

30' [9.1 m]) or has numerous elbows (more than one) in it.

AD-35i

NO. OF DRYERS

MINIMUM CROSS (SQ.IN.)

SECTION AREA (SQ.CM)

MINIMUM ROUND(IN.)

DUCT DIAMETER (CM.)

D

X D CLEARANCE

HORIZONTAL MULTI DRYER VENTING

24.4 METERS

(15.24 CM) DUCTING

80 FEET

NOTE A

WALL

MAXIMUM

1058

35.6

4

164

14

120

774

12

30.5

3

2

80

516

10

25.4

54

348

8

20.3

1

INSPECTION

DOORS

28 1/2-60” (72-142cm)

DISTANCES BETWEEN

DUCTS

AD-50i/M-50p, AD-80i/M-80p

HORIZONTAL MULTI DRYER VENTING

8 (20.32 CM) DUCTING

NO. OF DRYERS

MINIMUM CROSS (SQ.IN.)

SECTION AREA (SQ.CM)

MINIMUM ROUND(IN.)

DUCT DIAMETER (CM.)

20 FEET

6.1 METERS

D

X D CLEARANCE

TUMBLER EXHAUST MUST

ENTER MAIN EXHAUST

DUCT AT A 45º ANGLE

IMPORTANT: NO MORE THAN 4 DRYERS CAN BE CONNECTED TO ONE COMMON DUCT ( VENT ).

CROSS SECTIONAL AREA OF A ROUND DUCT = .785 X D² Where D = DIAMETER OF THE DUCT.

CROSS SECTIONAL AREA OF A RECTANGULAR DUCT = W

NOTE A:

THAN THE DUCT (ALL THE WAY AROUND). THE DUCT MUST BE CENTERED WITHIN THIS OPENING.

4

201

1297

16

40.6

MAXIMUM

NOTE A

WALL

FORMULAS TO CALCULATE DUCTING CROSS SECTIONAL AREA

164

1058

14

35.6

3

2

120

774

12

30.5

X H Where W = WIDTH AND H = HEIGHT.

VERTICAL MULTI DRYER VENTING

8 (20.32 CM) DUCTING

2 X D

CLEARANCE

WALL

NOTE A

D

315

2030

20

50.8

4

3 2

225

1644

18

45.7

164

1058

14

35.6

1

60

516

10

25.4

1

60

516

10

25.4

INSPECTION

DOORS

28 1/2-60” (72-142cm)

DISTANCES BETWEEN

DUCTS

NO. OF DRYERS

MINIMUM CROSS (SQ.IN.)

SECTION AREA (SQ.CM)

MINIMUM ROUND(IN.)

DUCT DIAMETER (CM.)

INSPECTION

DOORS

MINIMUM DUCT SIZE

8” (20.3 cm)

D

H

W

TUMBLER EXHAUST MUST

ENTER MAIN EXHAUST

DUCT AT A 45º ANGLE

IMPORTANT: NO MORE THAN 4 DRYERS CAN BE CONNECTED TO ONE COMMON DUCT ( VENT ).

CROSS SECTIONAL AREA OF A ROUND DUCT = .785 X D² Where D = DIAMETER OF THE DUCT.

CROSS SECTIONAL AREA OF A RECTANGULAR DUCT = W

NOTE A:

FORMULAS TO CALCULATE DUCTING CROSS SECTIONAL AREA

X H Where W = WIDTH AND H = HEIGHT.

VERTICAL MULTI DRYER VENTING

(15.24 CM) DUCTING

D

2 X D

CLEARANCE

WALL

NOTE A

TOTAL STRIAGHT

TUMBLER EXHAUST MUST ENTER

MAIN EXHAUST DUCT AT A 45º ANGLE

IMPORTANT: NO MORE THAN 4 DRYERS CAN BE CONNECTED TO ONE COMMON DUCT ( VENT ).

CROSS SECTIONAL AREA OF A ROUND DUCT = .785 X D² Where D = DIAMETER OF THE DUCT.

CROSS SECTIONAL AREA OF A RECTANGULAR DUCT = W

NOTE A: WHEN PASSING THROUGH COMBUSTIBLE MATERIAL THE OPENING MUST BE 2-INCHES (5.08 cm) LARGER

164

1058

14

35.6

FORMULAS TO CALCULATE DUCTING CROSS SECTIONAL AREA

3

120

774

12

30.5

2

80

516

10

25.4

X H Where W = WIDTH AND H = HEIGHT.

1

54

348

8

20.3

INSPECTION

DOORS

MINIMUM DUCT SIZE

6” (15.2 cm)

D

H

W

NO. OF DRYERS4

MINIMUM CROSS (SQ.IN.)

SECTION AREA (SQ.CM)

MINIMUM ROUND(IN.)

DUCT DIAMETER (CM.)

28 1/2-60” (72-142cm)

DISTANCES BETWEEN

DUCTS

MINIMUM DUCT SIZE

6” (15.2 cm)

D

H

W

TOTAL STRIAGHT

TUMBLER EXHAUST MUST ENTER

MAIN EXHAUST DUCT AT A 45º ANGLE

IMPORTANT: NO MORE THAN 4 DRYERS CAN BE CONNECTED TO ONE COMMON DUCT ( VENT ).

CROSS SECTIONAL AREA OF A ROUND DUCT = .785 X D² Where D = DIAMETER OF THE DUCT.

CROSS SECTIONAL AREA OF A RECTANGULAR DUCT = W

NOTE A: WHEN PASSING THROUGH COMBUSTIBLE MATERIAL THE OPENING MUST BE 2-INCHES (5.08 cm) LARGER

FORMULAS TO CALCULATE DUCTING CROSS SECTIONAL AREA

X H Where W = WIDTH AND H = HEIGHT.

28 1/2-60” (72-142cm)

DISTANCES BETWEEN

DUCTS

MINIMUM DUCT SIZE

8” (20.3 cm)

D

H

W

14

Page 15

Electrical Information

TYPICAL STRAN RELIEF

Electrical Requirements

All electrical connections must be made by a properly licensed

and competent electrician. This is to ensure that the electrical

installation is adequate and conforms to local, state, and

national regulations or codes of the country of destination. In the

absence of such codes, all electrical connections, materials, and

workmanship must conform to the applicable requirements of the

National Electrical Code ANSI/NFPA NO. 70-LATEST EDITION

or in Canada, the Canadian Electrical Codes Parts 1 & 2 CSA

C22.1-1990 or LATEST EDITION.

IMPORTANT: Failure to comply with these codes or ordinances,

and/or the requirements stipulated in this manual can result in

personal injury or component failure.

NOTE: Component failure due to improper installation will void

the warranty.

Each pocket should be connected to an independently protected

branch circuit. The dryer must be connected with copper wire

only. Do not use aluminum wire. The copper conductor wire/cable

must be of proper ampacity and insulation in accordance with

electric codes for making all service connections.

NOTE: The use of aluminum wire will void the warranty.

An individual ground circuit must be provided to each pocket, do

not daisy chain.

Component failure due to improper voltage application will void

the warranty.

The manufacturer reserves the right to make changes in

specifications at any time without notice or obligation.

IMPORTANT: A separate protected circuit must be provided to

each pocket.

It is necessary to have a power disconnect for each pocket.

These disconnects must be located within 30 feet (9 meters) of

the dryer.

The dryer must be connected to the electric supply shown on the

data label.

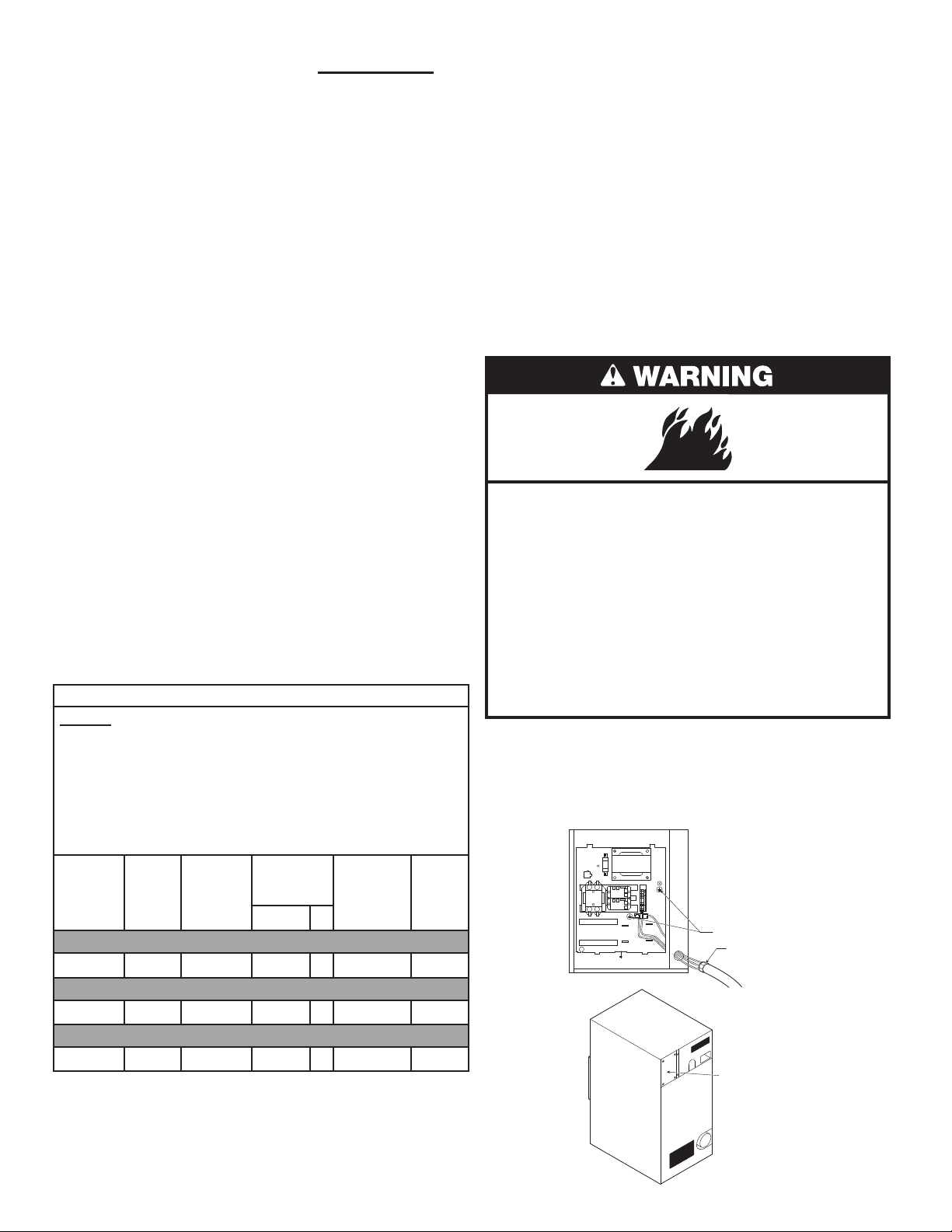

Electrical Service Specifications

Gas Models Only

ELECTRICAL SERVICE SPECIFICATIONS (PER POCKET)

NOTES:

SERVICE

VOLTAGE

120 1ø 2 10.2 15 14

120 1ø 2 9.8 15 14

120 1ø 2 9.8 15 14

A. When fuses are used they must be dual element,

time delay, current limiting, class RK1 or RK5 ONLY.

Calculate/determine correct fusevalue, by applying

either local and/or National Electrical Codes to listed

appliance amp draw data.

B. Circuit breakers are thermal-magnetic (industrial)

motor curve typeONLY. For others, calculate/verify

correct breaker size according to appliance amp

draw rating and type of breaker used.

PHASE WIRE

SERVICE

APPROX.

AMP

DRAW

CIRCUIT

BREAKER

MIN

WIRE

GAUGE

60 Hz

AD-35i

AD-50i/ M-50p

AD-80i/ M-80p

Grounding

A ground (earth) connection must be provided and installed in

accordance with local, state, and national regulations or codes

of the country of destination. In the absence of these codes,

grounding must conform to applicable requirements of the

National Electrical Code ANSI/NFPA NO. 70-LATEST EDITION,

or in Canada, the installation must conform to applicable Canada

Standards: Canadian Electrical Codes Parts 1 & 2 CSA C22.11990 or LATEST EDITION. The ground connection may be to a

proven earth ground at the location service panel.

Electrical Connections

A wiring diagram is located behind the control panel for

connection data.

If local codes permit, power to the dryer can be made by the use

of a flexible UL listed power cord/pigtail (wire size must conform

to rating of dryer), or the dryer can be hard wired directly to the

service breaker panel. In both cases, a strain relief must be

installed where the wiring enters the dryer.

Fire Hazard

Use appropriate gauge of copper wire (See chart in

"Electrical Requirements" section).

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Electrically ground appliance per installation

instructions.

Securely tighten all connections.

Failure to do so can result in death, fire, or electrical

shock.

Single-Phase (1ø) Gas Wiring Connections/

Hookup

The electrical input connections on all single-phase (1ø) gas

dryers are made into the rear service box located at the upper left

area of the dryer.

GROUND CONNECTION

ELECTRIC SERVICE

BOX COVER

15

Page 16

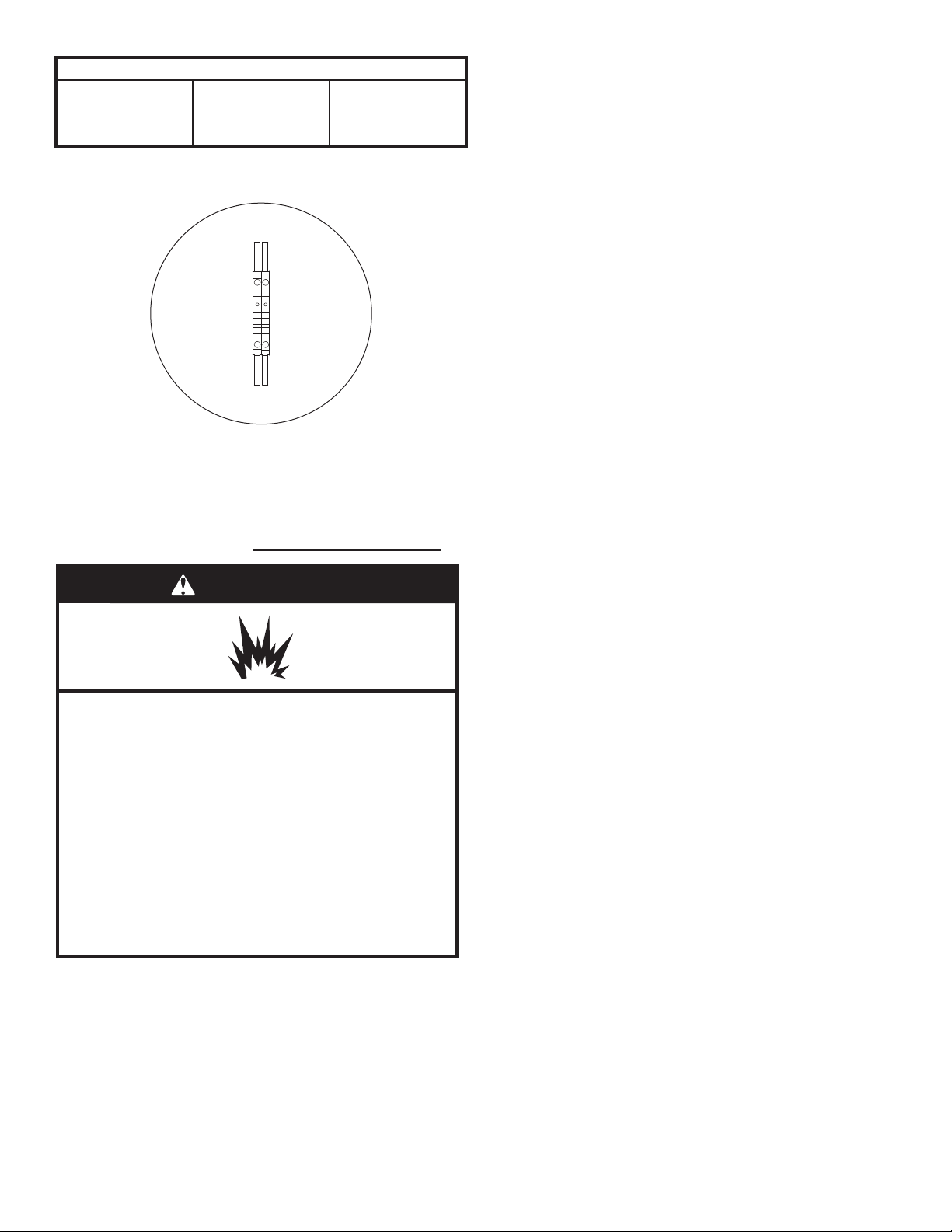

SINGLE-PHASE ELECTRICAL LEAD CONNECTIONS

Black

+

Positive

or L1

For 120 V Applications

White

+

Neutral

or N

Green

+

Ground

PANEL WIRING

SERVCE WIRING

Input connection wiring must be sized properly to handle the

dryer’s current draw. This information is printed on the dryer’s

rating plate.

IMPORTANT: A strain relief must be used where the input wiring

enters the electric box.

Gas Information

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

(Propane Gas) or LATEST EDITION.

It is important that gas pressure regulators meet applicable

pressure requirements, and that gas meters be rated for the total

amount of all the dryer Btu being supplied.

For ease of service, the individual gas supply line of each dryer

must have its own manual shutoff valve.

The dryer must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any pressure

test of the gas supply system at test pressures equal to or less

than 1/2psig (3.5 kPa).

The dryer and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2 psig (3.5 kPa).

Failure to isolate or disconnect the dryer from supply as noted

can cause irreparable damage to the gas valve, voiding the

warranty.

NOTE: Undersized gas piping will result in ignition problems,

slow drying, increased use of energy.

The input ratings shown on the rating plate are for elevations

up to 2,000 feet (610 meters), unless elevation requirements of

over 2,000 feet (610 meters) were specified at the time the dryer

order was placed with the factory. The adjustment or conversion

of dryers in the field for elevations over 2,000 feet (610 meters)

is made by changing each burner orifice. If this conversion is

necessary, contact the reseller who sold the dryer or contact the

manufacturer.

IMPORTANT: If connection to this appliance is made with a

flexible hose, it must be suitable for the appliance category in

accordance with national installation regulations of the country of

destination, and if in doubt the installer must contact the supplier.

The manufacturer of this appliance does not recommend the use

of flexible gas supply line/ hose. An external gas supply shutoff

must be provided.

Pipe joint compounds that resist the action of natural,

propane, and butane gases must be used on all tapered thread

connections.

In the U.S.A.: An individual manual shutoff valve must be

installed within 6 feet (1.8 meters) of the dryer in accordance with

the National Fuel Gas Code, ANSI Z223.1.

In Canada: An individual manual shutoff valve must be installed

in accordance with the B149.1, Natural Gas and Propane

Installation Code. It is recommended that an individual manual

shutoff valve be installed within 6 feet (1.8 meters) of the dryer.

The dryer must be connected to the type of heat/gas indicated

on the rating plate and pressure must be confirmed. If this

information does not agree with the type of gas available, do

not operate the dryer. Contact the reseller who sold the dryer or

contact the manufacturer.

It is your responsibility to have all plumbing connections,

materials, and workmanship conform to local and state

regulations or codes of the country of destination. In the

absence of such codes, all plumbing connections, materials, and

workmanship must conform to the applicable local requirements

In the USA this is the National Fuel Gas Code ANSI Z223.1LATEST EDITION, or in Canada, the Canadian Installation Codes

CAN/CGA-B149.1-M91 (Natural Gas) or CAN/CGAB149.2-M91

16

Page 17

Heat Input / Gas Consumption / Orifice (Injector) Data

GAS WATER HEATERS

DRYERS

GAS SPECIFICATIONS

Nominal

Model Gas Type

Heating

Value

Btu/ft3 in WC Btu/hr kW DMS mm in WC

AD-35i

AD-50i

AD-80i

Natural 1,000 7.0-13.0 70,000 20.5 22 3.988 1 3.5

*Propane 2,500 11.0 70,000 20.5 41 2.438 1 10.5

Natural 1,000 7.0-13.0 125,000 36.64 5 5.22 1 3.5

*Propane 2,500 11.0 125,000 36.64 30 3.264 1 10.5

Natural 1,000 7.0-13.0 135,000 39.53 2 5.613 1 3.5

*Propane 2,500 11.0 135,000 39.53 29 3.454 1 10.5

Shaded areas are stated in metric equivalents

*Gas valve’s internal regulator disabled.

**Consult factory for elevations over 2,000 feet (610 meters) for correct orifice size.

Supply

Pressure

Gross Heat Input Orifice Size*

Piping / Connections

Orifice

(Injector)

Quantity

Manifold

Pressure

AD-35i AD-35i / M-50p AD-80i / M-80p

1/2" 1/2" 1/2"

All connections are N.P.T (Male)

There should be a minimum 6-inch (15.24 cm) clearance between

the back guard and the first bend in the gas piping for ease of

servicing. It is recommended that a gas shutoff valve be provided

to the gas supply line of each dryer for ease in servicing.

The size of the main gas supply line (header) will vary depending

on the distance this line travels from the gas meter or, in the case

of propane gas, the supply tank, other gas-operated appliances

on the same line, etc. Specific information regarding supply line

size should be determined by the gas supplier.

NOTE: Undersized gas supply piping can create a low or

inconsistent pressure, which will result in erratic operation of the

burner ignition system.

TYPICAL NATURAL GAS INSTALLATION

GAS SHUTOFF

VALVE

DRYERS

GAS SERVICE LINE TAP

GAS LOOP

GAS WATER HEATERS

GAS METER

IN-LINE PRESSURE REGULATOR

(ONLY WHEN LINE PRESSURE

EXCEEDS 13 INCHES (32.34 MB

WATER COLUMN)

TYPICAL PROPANE GAS INSTALLATION

PRESSURE REGULATOR

(OPTIONAL)

GAS SHUTOFF

VALVE

GAS LOOP

GAS SERVICE LINE TAP

PRESSURE REGULATOR

PROPANE SUPPLY TANK

Consistent gas pressure is essential at all gas connections. It is

recommended that a 3/4" (19.05 mm) pipe gas loop be installed

in the supply line servicing a bank of dryers. An in-line pressure

regulator must be installed in the gas supply line (header) if the

(natural) gas pressure exceeds 13.0 in WC (3.23 kPa) pressure.

A minimum 1/8" N.P.T. plugged tap, accessible for a pressure

gauge connection, must be installed in the main gas supply line

immediately upstream of the dryer.

Test all connections for leaks by brushing on a soapy water

solution (liquid detergent works well).

17

Page 18

Gas Pressure Test Procedure

35i, 50i

Gas Pressure Adjustment

1. Disconnect power to the dryer.

2. Turn off gas supply using the shutoff valve that supplies the

dryer.

3. Locate the output pressure tap screw on the gas valve and

unscrew 4 to 5 full turns.

UNION

CONNECTION

GAS VALVE

OUTLET

PRESSURE TAP

INLET

PRESSURE TAP

REGULATOR

CAP

VALVE MOUNTING

SCREWS

MANIFOLD

ORIFICE

80i

INLET

PRESSURE TAP

4. Connect the airtight hose to pressure tap post. (Airtight hose

will attach between pressure tap post and manometer.)

5. Connect opposite end of hose to manometer.

6. Turn on gas supply using the shutoff valve that supplies the

dryer and reconnect the power.

7. Start the dryer in Heat Mode and wait for ignition.

8. Record the manometer reading. Check the reading against

the Burner Pressure column in the Gas Specification chart

on page18. Measured value should be within .30" W.C.

of that value. If not, see the next section on Gas Pressure

Adjustment.

9. Once test is complete, disconnect power to the dryer.

10. Turn off gas supply using the shutoff valve that supplies the

dryer.

11. Disconnect manometer.

12. Remove hose from pressure tap post. Tighten screw inside

the pressure tap or install plug.

REGULATOR CAP

OUTLET PRESSURE

TAP

1. Disconnect electrical power to the dryer.

2. Turn off gas supply using the shutoff valve that supplies the

dryer.

3. Remove the regulator cap with a screwdriver to gain access

gas valve’s internal regulator adjusting screw.

4. Use a small flat blade screwdriver to turn the plastic

adjustment screw in the valve. Turn the screw clockwise to

raise pressure and counterclockwise to lower pressure.

NOTE: Outlet pressure is measured with the burner in operation

for all burner adjustment conditions. Therefore, once the

necessary adjustments have been made, the dryer must be

operated in a heating cycle to verify that the pressure is correct.

5. Turn on gas supply using the shutoff valve that supplies the

dryer and reconnect the power.

6. Run the dryer and check the outlet pressure. Compare the

reading to the value shown in Burner Pressure column of the

Gas Specification chart on page 18. Measured value should

be within .30" W.C. of that value. If the pressure is not correct,

disconnect the power to the dryer and repeat steps 1 to 4. Do

this as many times as necessary to achieve the correct burner

pressure.

7. Once the adjustment of the valve is complete, the regulator

cap must be replaced and sealed with, for example, paint to

prevent tampering by the user.

Leak Check

1. Be sure the gas supply is turned on.

2. Turn on dryer.

3. Brush or spray an approved noncorrosive leak-detection

solution onto all connections and inspect for leaks indicated

by growing bubbles.

4. If dryer was moved during testing, use the same method

to check for leaks in the flexible gas supply line and fittings

between the dryer and the gas supply pipe.

5. If any bubbles are present, turn off gas supply, tighten the

leaking connection and retest for leaks.

Water Information for Optional

Wet Fire Suppression System

Before You Start

Check Local Codes and Permits

Call your local water company or the proper municipal authority

for information regarding local codes.

IMPORTANT: It is your responsibility to have all plumbing

connections made by a qualified professional to ensure that the

plumbing installation is adequate and conforms to local, state,

and federal regulations or codes.

It is the installer’s, or owner’s responsibility to see that

the required water pressure, pipe size, or connections are

provided. The manufacturer assumes no responsibility if the fire

suppression system is not connected, installed, or maintained

properly.

18

Page 19

Installation

Electrical Requirements

No independent external power source or supply connection

is necessary. The 24 V power to operate the fire suppression

system is accomplished internally in the dryer (from the dryer

controls).

IMPORTANT: Electrical power must be provided to the dryer

at all times. If the main electrical power supply to the dryer is

disconnected, the Fire Suppression System is inoperative.

Water Supply

If equipped, the wet fire suppression system must be supplied

withcold water, through a minimum 1/2" (12.7 mm) size pipe, at

40psi +/- 20 psi (2.75 bar +/- 1.37 bar) of pressure.

If the rear area of the dryer or the water supply is located in an

area where it will be exposed to cold/freezing temperatures,

provisions must be made to protect these water lines from

freezing.

IMPORTANT: If the water in the supply line or water solenoid

valve freezes, the Wet Fire Suppression System will be

inoperative.

Water Connections

The water connection is 3/4" 11.5 NH. A flexible supply line/

coupling must be used in an effort to avoid damaging the electric

water solenoid valve. Solenoid valve failure due to hard plumbing

connections will void warranty.

NOTE: The 3/4" 11.5 NH is a standard hose coupling screw

thread. It is not to be confused with 3/4" N.P.T., or 3/4" B.S.P. The

sealing of an NH connection is made with a washer as opposed

to the mating threads of an N.P.T. or B.S.P. assembly. The 3

thread designs are not compatible.

It is recommended that a filter or strainer be installed in the water

supply line.

The dryer is to be connected to the water mains using a new

hose set. An old hose set should not be reused.

Connect the hose to the S.A.F.E. (FSS) system.

1. Disconnect power from the dryer.

2. Install filter or strainer to the water supply line.

3. Connect the new flexible supply line/coupling with washers to

the 3/4" 11.5 NH hose adapter.

• Screw coupling on by hand until seated on the hose

adapter.

• Using slip-joint pliers, tighten the coupling with an additional

two-thirds turn.

NOTE: Do not overtighten. Damage to coupling can result.

3/4-11 NH Connection

Solenoid Valve

To Spray Nozzle

Minimum 1/2 (12.7mm) Size

Flexible Pipe (By Customer)

Water Pressure Sensor

4. Connect the other end of the new flexible supply line/coupling

with new washers to the water supply valve.

• Screw coupling on by hand until seated on the supply valve.

• Using slip-joint pliers, tighten the coupling with an additional

two-thirds turn.

5. Turn water supply to dryer on.

6. Check for leaks.

• Check for leaks at the flexible supply line/coupling,

the3/4"-11.5 NH hose adapter (both ends).

7. Reconnect the power.

NOTE: Do not overtighten. Damage to coupling can result.

S.A.F.E. (FSS) Fire Suppression Systems

Both OPL and COIN models are protected by wet and dry

S.A.F.E. (FSS) fire suppression routines. The microprocessor

controller (computer) display will read “S.A.F.E. or FSS

ACTIVATED”, and the horn/tone will sound when a fire has been

detected, and is actively being suppressed by either method.

Restarting the Dryer After the S.A.F.E. (FSS)

System Has Been Activated (All Models)

WARNING: ELECTRICAL SHOCK HAZARD

Electrical shock can result in death or

serious injury.

If the water dispensing system is activated

do not attempt to operate the dryer.

If the water dispensing system is activated

have the dryer inspected by a qualified

agency before operating the dryer.

If the water based S.A.F.E. (FSS) routine was activated:

After the microprocessor controller (computer) determines that

the situation is under control and shuts off the water being

injected into the basket (tumbler), the microprocessor controller

(computer) display will read “S.A.F.E. or FSS was ACTIVATED”,

and the horn/tone will sound until turned off manually. To turn off

the horn/tone press and hold the “O” or “X” key on the keyboard

(touch pad).

If the dry S.A.F.E. (FSS) routine was activated:

After the microprocessor controller (computer) determines that

the situation is under control and stops the basket (tumbler), the

microprocessor controller (computer) display will read “S.A.F.E. or

FSS was ACTIVATED”, and the horn/tone will sound until turned

off manually. To turn off the horn/tone press and hold the “O” or

“X” key on the keyboard (touch pad).

Once the microprocessor controller (computer) displays “S.A.F.E.

(FSS) WAS ACTIVATED”, a service call to your local dealer is

required to reset the microprocessor controller (computer).

Qualified personnel will inspect the dryer and, if it is found to be

safe for operation, reset the control.

Preparation for Operation /

Start-Up

The following items should be checked before attempting to

operate the dryer:

• Read all “CAUTION,” “WARNING,” “IMPORTANT,” and

“INSTRUCTION” labels attached to the dryer. Read all

instructions before using the dryer.

• Check incoming supply voltage to be sure that it is the same as

indicated on the rating plate.

• Check to ensure that the dryer is connected to the type of heat/

gas indicated on the dryer rating plate.

• Be sure that all gas shutoff valves are in the open position.

• Be sure all back panels (guards) and electric box covers are in

place.

• Be sure the service doors are closed and securely in place.

• Be sure the lint door/drawer is securely in place.

• Rotate the tumbler (drum) by hand to be sure it moves freely.

19

Page 20

• Check bolts, nuts, screws, terminals, and fittings for tightness

and security.

• Check that the vent is connected to the dryer and is exhausted

to the outdoors.

Preoperational Test

All dryers are thoroughly tested and inspected before leaving

the factory. However, a preoperational test should be performed

before the dryer is publicly used. It is possible that adjustments

have changed in transit or due to marginal location (installation)

conditions.

Turn on electric power to the dryer.

Refer to the Operating Instructions for starting your particular

model dryer.

Open all shutoff valves.

When a gas dryer is first started (during initial start-up), it has

a tendency not to ignite on the first ignition attempt. This is

because the gas supply piping is filled with air, so it may take a

few minutes for the air to be purged from the lines.

NOTE: During the purging period, check to be sure that all gas

shutoff valves are open.

A gas pressure test should be taken at the gas valve pressure tap

of each dryer to ensure that the water column pressure is correct

and consistent. See the “Gas Pressure Test Procedure’’ section

for instructions.

NOTE: Water column pressure requirements (measured at the

pressure tap of the gas valve body) must be verified.

IMPORTANT: In most cases there is no regulator provided in a

propane dryer. The water column pressure must be regulated

at the source (propane tank), or an external regulator must be

added to each dryer.

Operating Instructions

Tumbler Coating

The tumbler is treated with a protective coating. We suggest

dampening old garments or cloth material with a solution of

water and nonflammable mild detergent and tumbling them in the

tumbler to remove this coating.

Dryer should be operated through one complete cycle to

ensure that no further adjustments are necessary and that all

components are functioning properly.

Microprocessor Programs / Selections

Each microprocessor controller (computer) has been

preprogrammed by the factory with the most commonly used

parameter (program) selections. If computer program changes

are required, refer to the programming sections at the back of

this manual.

IMPORTANT: For more detailed information regarding the

microprocessor controller (computer), refer to the microprocessor

programming sections at the back of this manual.

Coin Models

Microprocessor Controller (Computer)

When the microprocessor controller (computer) is in the ready

state, the L.C.D. screen will display “Ready, Insert $XX.XX

(amount) to Start”.

Insert coin(s). Once the correct “Amount to Start” has been

inserted, the L.C.D. will display “Select Temperature”.

Select temperature by pressing “HI,” “MED,” or “LO.” The cycle

will start and the L.C.D. will display the Dry Cycle selected and

the remaining time.

The dryer will continue through the drying and cooling cycles,

until the vended time has expired.

NOTE: To stop the dryer, open main door. Continuation of the

cycle will resume only after the door has been closed and any

one of the three temperature selections is pressed.

Non-Coin Models

Microprocessor Controller (Computer)

The L.E.D. display reads “READY” (no cycle in progress).

Press the letter on the keypad corresponding to the cycle desired

(e.g. key “D”).

The dryer will then start (i.e. blower, tumbler, and heat).

The L.E.D. display will read MANUAL DRYING CYCLE D, ___MIN

REMAIN.

20

Page 21

NOTE: The dryer can be stopped at any time by pressing the

“STOP/CLEAR” key, at this time the dryer will go into a cycle

pause. If the “STOP/CLEAR” key is pressed again at this point,

the cycle that was in progress will be cancelled and returned to

the “READY” state.

When the programmed drying time has expired, the non-coin

microprocessor controller (computer) may proceed into the Cool

Down Cycle.

Once the Cool Down Cycle begins at the end of the heat

cycle, the L.E.D. display will read COOL DOWN TEMP ___/___

MINUTES remaining. At the end of the heat cycle, the dryer will

shut off the heat and continue the fan and tumbler until the Cool

Down Time or temperature is reached.

Shutdown Instructions

If the dryer is to be shutdown (taken out of service) for a period of

time, the following must be performed:

Disconnect power to the dryer either at the external disconnect

switch or the circuit breaker.

Disconnect the gas supply: close external gas shutoff valve. Also

close two internal gas shutoff valves.

If the dryer is to be removed from service or discarded, before

doing so remove the door to the drying compartment.

Shut off and disconnect the water line if wet S.A.F.E. system is

installed.

Service / Parts Information

Service

Service must be performed by a qualified trained technician.

If service is required, contact the reseller from whom the

equipment was purchased. If the reseller cannot be contacted or

is unknown, contact the Service Department for a reseller in your

area.

NOTE: When contacting the Service Department, be sure to give

them the correct model number and serial number so that your

inquiry is handled in an expeditious manner.

Parts

Replacement parts should be purchased from the reseller from

whom the equipment was purchased. If the reseller cannot be

contacted or is unknown, contact the Parts Department for a

reseller in your area. Parts may also be purchased directly from

the factory by calling the Parts Department at +1 (269)-923-3000

or you may FAX in your order at +1 (508) 678-9447.

NOTE: When ordering replacement parts from the reseller or the

manufacturer, be sure to give them the correct model number

and serial number so that your parts order can be processed in

an expeditious manner.

Routine Maintenance

Cleaning

A program should be established for the inspection and cleaning

of lint in the burner area, exhaust ductwork, and area around the

back of the dryer. The frequency of inspection and cleaning can

best be determined from experience at each location.

Exhaust duct outlet should be checked periodically for

blockages, and if any found, removed.

A program and/or schedule should be established for periodic

inspection, cleaning, and removal of lint from various areas of the

dryer, as well as throughout the ductwork system. The frequency

of cleaning can best be determined from experience at each

location.

Maximum operating efficiency is dependent upon proper airflow.

The accumulation of lint can restrict this airflow.

When cleaning the dryer cabinet, avoid using harsh abrasives. A

product intended for the cleaning of appliances is recommended.

When cleaning the dryer cabinet, avoid using harsh abrasives. A

product intended for the cleaning of appliances is recommended.

NOTE: Suggested time intervals shown are for average usage,

which is considered 6 to 8 operational (running) hours per day.

IMPORTANT: Be sure to reinstall all parts removed during

cleaning.

Every 6 months, inspect the exhaust ducting and remove any lint

buildup.

Suggested Cleaning Schedule Every Third of

Fourth Load

Clean the dryer’s internal lint screen about every third or fourth

load. A clogged lint screen will reduce the airflow, and cause poor

dryer performance. The screen is located behind the lint door just

below the main loading door. Open the lint door and brush the lint

off the screen.

Inspect the lint screen and replace if torn.

NOTE: To remove the lint screen from the dryer, open the lint

door at least 90 degrees. Located just above the lint screen is

a clamp retained by two screws. Use a 5/16" (8mm) wrench to

remove the two screws and the clamp. The lint screen is mounted

in a track. Slide the lint screen out of the track.

To replace it, reverse the above procedure.

Weekly

Clean lint accumulation from the lint chamber, thermostat

and microprocessor temperature sensor area. The thermostat

and microprocessor temperature sensor area is located in

the ductwork just above the lint screen. All of these areas are

accessed by opening the lint door.

90 Days

Remove lint from the gas valve burner area with a dusting brush

or vacuum cleaner. The gas valve burner area is located behind

the control door just above the main loading door.

NOTE: To prevent damage, avoid cleaning and/or touching

21

Page 22

igniter/flame-probe assembly.

SECHEUSES, VOL.2

INPUT(ENTREE) =

ORIFICE =

ORIFICE

MOD

SER

INPUT (0 TO 2,000 FT.)

(ENTREE (0 A` 610M))*

HEAT(CHALEUR) TYPE

120V/60HZ/1PH/2W 16A

MANIFOLD PRESSURE(PRESSION A LA TUBULURE D`ALIAMENTATION)

USE WITH(UTILISER AVEC DU ) GAS(GAZ)

CLOTHES DRYERS, VOL.II

ANSI Z21.5.2-2013 CSA 7.2-2013

MIN. SUPPLY PRESSURE(PRESSION) MAX. SUPPLY PRESSURE(PRESSION)

*FOR CANADIAN INSTALLATIONS WITH ELEVATIONS BETWEEN 2,000 AND 4,500 FT.

(POUR LES INSTALLATIONS CANADIENNES AVEC DES ELEVATIONS ENTRE 610 A` 1372M)

Assembled in (Assemble aux) USA

Whirlpool Corporaon TEL: (269) 923-3000

88 Currant Road FAX: (508) 678-9447

Fall River, MA 02720-4781 mdl-service@whirlpool.com

WWW.WHIRLPOOL.COM

"NRTL"

3

MAN8402

7

6

5

4

1

2

Clean any lint accumulation in and around the motor(s) casing

openings. The motors are located at the back of the dryer. The

dryers back guard must be removed to access this area. 6

Months Inspect and remove lint accumulation in the dryer’s air

handling systems. This includes customer furnished make-up

air openings, exhaust ductwork systems, and from the dryer’s

internal exhaust ducting.

NOTE: The buildup of lint in the air handling systems can reduce

the flow of combustion, exhaust and ventilation gases, reducing

dryer performance.

Months

Inspect and remove lint accumulation in the dryer’s air handling

systems. This includes customer furnished make-up air openings,

exhaust ductwork systems, and from the dryer’s internal exhaust

ducting.

NOTE: The buildup of lint in the air handling systems can reduce

the flow of combustion, exhaust and ventilation gases, reducing

dryer performance.

Cleaning of the dryer’s internal exhaust may require removing

the lint screen. See the instructions above for removing the lint

screen. Check any back draft dampers in the exhaust ductwork.

Inspect and remove any lint which can cause the damper to bind

or stick. A back draft damper that is sticking partially closed

can result in slow drying and the shutdown of heat circuit safety

switches and thermostats.

7 Days After Installation and Every 12 Months

Thereafter

Inspect bolts, nuts, screws, setscrews, grounding connections

and nonpermanent gas connections (unions, shutoff valves, and

orifices). The belt should be examined. A cracked or seriously

frayed belt should be replaced. Complete an operational check of

controls and valves. Complete an operational check of all safety

devices (lint drawer switch, door switches, sail switch, and hilimit thermostats).

A lit green L.E.D. diagnostic indicator indicates dryer controller is

calling for heat and that all interlocks have been satisfied.

Manual Reset Hi-Limit Instructions

This dryer was manufactured three hi-limit manual reset

thermostats. One is located on the burner and two in the exhaust.

The burner hi-limit thermostat is located in the front center of the

dryer behind the control door. The exhaust hi-limits are located in

the duct above the lint trap.

To reset the burner high limit, disconnect the power, open the

control door and support it with the prop rod. Remove the two

screws that secure the left side of the burner heat deflector.

Swing the heat deflector to the right and out of the way to gain

access to the thermostat. Push the red button in the center to

reset. Replace the heat deflector. Close the control door. Restore

the power.

To reset the exhaust hi-limits, disconnect the power and open the

lint door. Above the lint trap and in the duct below the tumbler are

four sensors. The flat ones on the far left are the hi-limits. These

thermostats are redundant, so both have to be checked. Remove

the two screws securing each thermostat and remove them. Push

the red button in the center to reset. Replace the thermostats.

Close the lint door. Restore the power.

Data Label Information

Standard Label

Adjustments

DSI Module

Theory of Operation: Start the drying cycle. When the gas

burner ignites within the chosen trial for ignition time (8-seconds),

the flame sensor detects gas burner flame and signals the DSI

module to keep the gas valve open as long as there is a call for

heat. The DSI module will “LOCKOUT” if the gas burner flame

is not sensed at the end of the trial for ignition period. The trial

for ignition period will be repeated for a total of three retries/

trials (the initial try and two more retries/trials). If the flame is

not sensed at the end of the third retry/trial (inter-purge period

of 30-seconds), the DSI module will “LOCKOUT” (a red L.E.D.

diagnostic indicator will flash).

An unlit red L.E.D. diagnostic indicator indicates normal

operation.

When contacting ADC, the information on the rating plate is

required to ensure proper service/parts assistance. The rating

plate is located on the upper left side panel of the dryer, behind

the control panel.

1. Model Number – This describes the style of dryer and type of

heat (gas, electric, or steam).

2. Serial Number – Allows the manufacturer to gather

information on your particular dryer.

3. Type of Heat – This describes the type of heat for your

particular dryer, gas (either natural gas or propane gas)

4. Heat Input (For Gas Dryers) – This describes the heat input

in British thermal units per hour (Btu/hr) or kilowatts (kW).

5. Orifice Size (For Gas Dryers) – Gives the number drill size

used.

6. Electric Service – This describes the voltage and current

rating for a particular model.

7. Gas Manifold Pressure (For Gas Dryers) – This describes

the manifold pressure taken at the gas valve tap.

22

Page 23

Programming

EXHAUST HIGH LIMIT FAULT – Temp. disk under tumbler is

open.

SAIL SWITCH CLOSED FAULT – Sail switch is closed – should be

open at the start of a cycle.

SAIL SWITCH OPEN FAULT – Sail switch remained open after the

cycle started. Should have closed.

BURNER HIGH LIMIT FAULT – Burner temp. disk has opened.

BURNER IGNITION CONTROL – No signal to gas valve from (DSI)

module during trial for ignition time. DSI module is bad.

IGNITION FAULT – Gas valve did not remain open after trial for

ignition. Indicates that no flame was detected.

FLAME FAULT – Flame was detected during trial for ignition but

failed later.

ROTATION FAULT – Indicates the tumbler is not rotating.

OPEN EXHAUST TEMPERATURE PROBE – Indicates the exhaust

temperature probe is open or shorted.

OPEN FIRE SUPPRESSION SYSTEM (F.S.S.) PROBE FAULT –

Indicates the temperature probe for the F.S.S. is open or shorted.

LOW VOLTAGE FAULT – Volt dropped below the operating value.

EE PROM FAULT ### – Error in memory location. Fault

correction: First cycle power to get the display to read “ENTER

PASSWORD”. Next press the keys FAA, then press the ENTER

key. Press the UP ARROW then “YES” will be displayed. Now

press the ENTER key and the display should return to ready.

Inputs (Red L.E.D. on control board)

All indications are with L.E.D. lit

ESTOP – Indicates E-STOP has been pressed.

GAS_V – Indicates the gas valve is open (ON).

BRHL – Indicates the burner high limit disk is closed.

SAIL – Indicates the sail switch is closed.

EXHL – Indicates the exhaust high limit disk is closed

(temperature below 190° F [87.8° C]).

MAIN – Indicates the status of main door is closed.

LINT – Indicates the lint drawer is closed.

FUSE – Indicates the status of the control voltage after POWER

ON button has been pressed.

Outputs (Green L.E.D. on control board)

All indications are with L.E.D. lit

AUX – This is for a spare output to be programmed.

_HEAT – Indicates the status of the heat output.

AIR – Indicates the status of the air jet output.

REV – Indicates the status of the tumbler reverse direction

output.

If the request to tumble the drum in the reverse direction is made,

then the L.E.D. is ON.

FWD – This L.E.D. will indicate the status of the tumbler forward

direction output.

FAN – This L.E.D. will indicate the status of the fan output.

Phase 7.2.2 OPL Diagnostic Codes

MAIN DOOR OPENED – A main door or door circuit is open.

EXHAUST HIGH TEMP FAULT – Tumbler is above 180°F (82.2°C).

LINT ACCESS OPEN – Lint drawer or lint door circuit is open.

23

Page 24

Phase 7.3.2 Coin Programming

Enter the programming mode by placing the switch on the Phase

7 board in the up position while no cycle is in progress. “Program