Page 1

Digivance® LRCS System

Rear Access Host Unit

Installation and Maintenance Manual

ADCP-75-169

Issue 1

June 2004

19717-A

1284820 Rev A

Page 2

ADCP-75-169 • Issue 1 • June 2004 • Preface

COPYRIGHT

© 2004, ADC Telecommunications, Inc.

All Rights Reserved

Printed in the U.S.A.

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

1 06/2004 Original release.

LIST OF CHANGES

The technical changes incorporat ed into this issue are lis ted below.

PAGE IDENTIFIER DESCRIPTION OF CHANGE

All Original release

TRADEMARK INFORMATION

ADC, Digi vance, PowerWorx, and FiberGuide are registered trademarks of A D C Telecommunications, Inc.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims an y and all liability for indirec t, incidental, special, consequen tial or other similar dam ages. This discl aimer of

liability applies to all products, publications and services during and after the warranty period.

This publ ication may be verified at any time by contacting ADC’s Technical Assistance Cent er at 1-800-366-3891, ex tension 73475

(in U.S. A . or Canada) or 952-9 17-3475 (outside U.S.A. and Canada), or by e-mail to bcg_tac@adc. com .

Page ii

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 917-1717

Page 3

TABLE OF CONTENTS

Content Page

ABOUT THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

ADMONISHMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

GENERAL SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

STANDARDS CERTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

LIST OF ACRONYMS AND ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 HOST UNIT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.2 RF Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 Optical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4 Controller Area Network Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.5 Service Interface Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.6 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.7 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 HOST UNIT ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Interface Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Wavelength Division Multiplexer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Coarse Wavelength Division Multiplexer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 INSTALLATION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Before Starting Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 OSP Fiber Cable Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4 HU Mounting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5 Chassis Ground Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.6 Coaxial Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.7 WDM Mounting Procedure (Accessory). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.8 Optical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.9 Controller Area Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.10 EMS Computer Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.11 External Alarm System Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.12 DC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.13 Installation Complete. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Host Unit Fan Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ADCP-75-169 • Issue 1 • June 2004 • Preface

© 2004, ADC Telecommunications , Inc.

Page iii

Page 4

ADCP-75-169 • Issue 1 • June 2004 • Preface

TABLE OF CONTENTS

Content Page

Blank

Page iv

© 2004, ADC Telecommunications , Inc.

Page 5

ABOUT THIS MANUAL

This publication pro vides a basic descripti on of the Digi v ance LRCS rear access Host Unit (HU)

plus the installation and maintenance procedures. Also described are various accessories that

may be used with the HU. An overview of the Digivance System, a complete description of the

system components, the system turn-up and test procedures, and the system troubleshooting

procedures are provided in the applicable Digivance System Operation and Maintenance

Manual (see Related Publications section). The rear access HU is installed in conjunction with

the Digivance Remote Unit.

RELATED PUBLICATIONS

Listed below are related manuals and their publication numbers. Copies of these publications

can be ordered by contacti ng the ADC T e chnical Assi stance Center at 1-800-366- 389, ext ension

73475 (in U.S.A. or Canada) or 1-952-917-3475 (outside U.S.A. and Canada).

Title ADCP Number

ADCP-75-169 • Issue 1 • June 2004 • Preface

Digiv ance LRCS SMR System with Version 3.01 EMS Software Operat ion

and Maintenance Manual 75-170

Digiv ance LRCS SMR Interface Panels User Manual 75-143

Digiv ance Coarse Wavelength Di vision Multiplex er User Manual 75-142

Digiv ance LRCS Dual-STM Systems Supplemental Manual 75-157

ADMONISHMENTS

Important safety admonishments are used thr oughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below) and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause s evere personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

© 2004, ADC Telecommunications , Inc.

Page v

Page 6

ADCP-75-169 • Issue A • June 2001 • Preface

GENERAL SAFETY PRECAUTIONS

Warning: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrically-powered equipment. To prevent electrical shock, never install or

use electrical equipment in a wet loca tion or during a lightning storm.

STANDARDS CERTIFICATION

FCC: This equipment complies with the appl icable sections of Title 47 CFR Part 90 (SMR).

UL/CUL: This equipment complies with UL and CUL 50 Standard for Enclosures for

Electrical Equipment. This equipment provides the degree of protection specified by IP43 as

defined in IEC Publication 529.

FDA/CDRH: This equipment uses a Class 1 LASER according to FDA/CDRH Rules. This

product conforms to all appli cable standards of 21 CFR Part 1040.

IC: This equipment complies with the applic able secti ons of RSS-131. The term “IC:” be fore the

radio ce rtif i cat io n number onl y signi f ie s th at Indu str y Cana da Techn ica l Spe cif i cat io ns were met.

LIST OF ACRONYMS AND ABBREVIATIONS

The acronyms and abbreviations used in this manual are detailed in the following list:

AWG American Wire Gauge

C Centigrade

CAN Controller Area Network

CDRH Center for Devic es and Radiological Health

CUL Canadian Underwriters La boratories

CWDM Coarse Wavelength Division Multiplexer

DC Direct Curren t

DCE Data Communications Equipment

DIV Diversity

DTE Data Terminal Equipment

EBTS Enhanced Base Transceiver Station

EIA Electronic Industries Association

EMS Element Management System

ESD Electrostatic Dischar ge

F Fahrenheit

FCC Federal Communications Commission

FDA Food and Drug Administration

FWD Forward

HU Host Unit

IC Industry Canada

Page vi

© 2004, ADC Telecommunications , Inc.

Page 7

ADCP-75-169 • Issue 1 • June 2004 • Preface

LED Light Emitting Diode

LPA Linear Power Amplifier

LRCS Long-Range Cov erage Solution

MHz Mega Hertz

MPE Maximum Permissible Exposure

MTBF Mean Time Between Failure

NEM Network Element Manager

NEMA National Electrical Manufacturers Association

NO Normally Open

NOC Network Operations Cente r

OSP Outsid e Plan t

PA Power Amplifier

REV Reverse

RF Radio Frequency

RMA Return Material Authorization

RU Remote U n it

SMR Specialized Mobile Radio

STM Spectrum Transport Module

UL Underwriters Laboratories

VDC Volts Direct Current

VSWR Voltage Standing Wave Ratio

WECO Western Electric Company

WDM Wave Divis i on Multiplexe r

© 2004, ADC Telecommunications , Inc.

Page vii

Page 8

ADCP-75-169 • Issue A • June 2001 • Preface

Blank

Page viii

© 2004, ADC Telecommunications , Inc.

Page 9

1 INTRODUCTION

The rear access Host Unit serves as the EBTS servicing unit for the Digivance LRCS system. A

typical LRCS system consists of a Host Unit (HU) and a R emote Unit (RU). The HU consists of

an electro nic chassis as sembly that m ounts in a st andard equipm ent rack. Th e RU consists of

multiple electronic and optical modules that mount in either an outdoor cabinet or an indoor

mounting shelf. The HU and the RU together comp rise an L RCS system. Various ac cessory

items are also available for use with the basic L RC S s ystem. All items refe renced as “accessory

items” are not furnished with the basi c system and must be purchased separately.

2 HOST UNIT DESCRIPTION

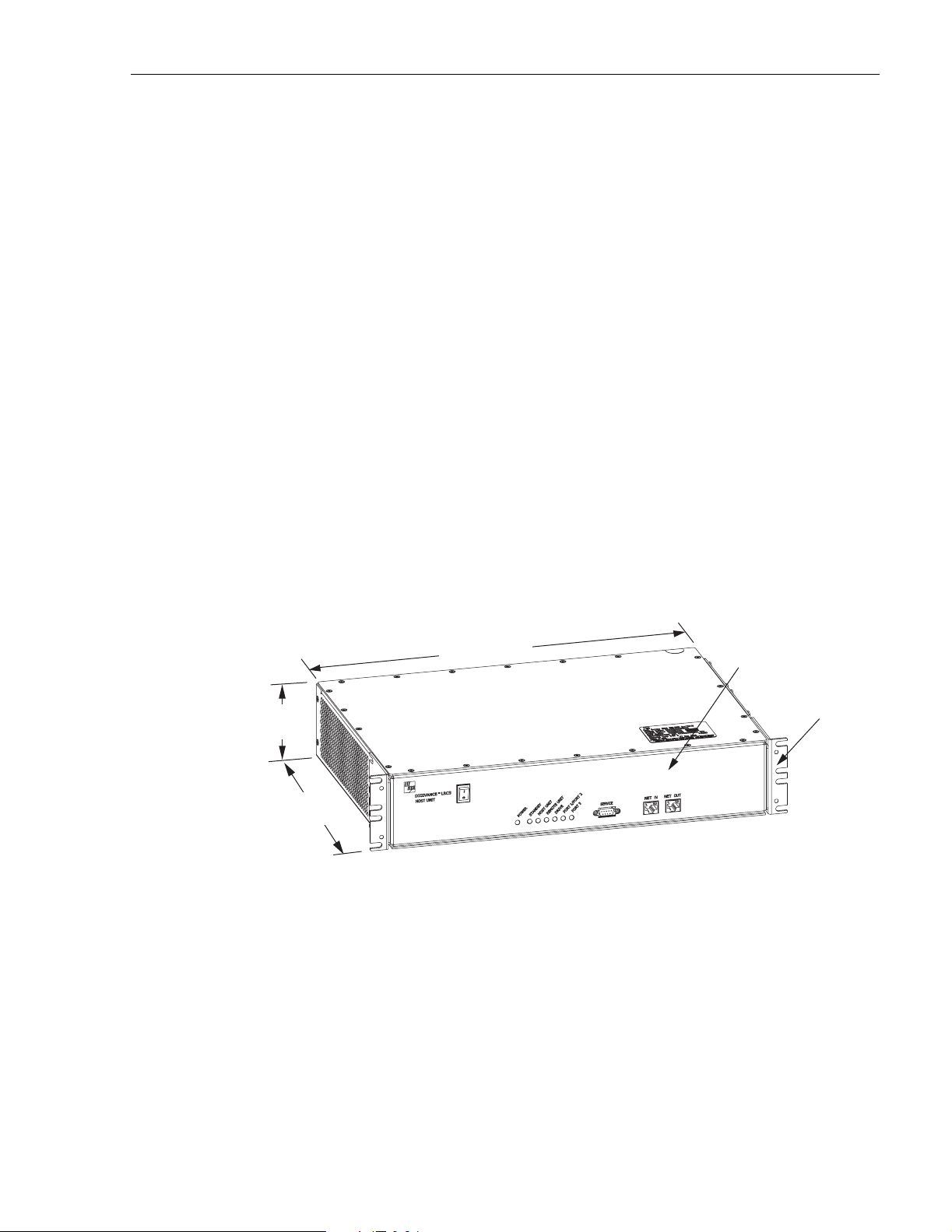

The HU, shown in Figure 1, consists of an electronic circuit board assembly and a fan assembly

that are m oun t ed within a powd er-pai n t co at ed s heet metal en cl os u re. Th e en cl osur e p ro vides a

mounting point for the circuit board and fan assemblies and controls RF emissions. The only

user-replaceable component is the fan assembly. The HU is designed for use within a noncondensing indoor environment such as inside a wiring closet or cabinet. The RF connectors,

optical connectors, alarm output connectors, DC power terminal strip, and grounding lug are

mounted on the HU rear side. The On/Off power switch, LED indicators, service interface

connector , and Contr oller Area Networ k (CAN) connectors are mounted on the HU front panel.

ADCP-75-169 • Issue 1 • June 2004

2.1 Mounting

The HU is intended for rack-mount applications. A pair of reversible mounting brackets is

provided that allow the HU to be mounted in either a 19-inch or 23-inch EIA or WECO

equipment rack. When installed, the front panel of the HU is flush with the front of the rack.

Screws are provided for securing the HU to the equipment rack.

3.5 INCHES

(88 mm)

12.2 INCHES

(311 mm)

17.1 INCHES

(433 mm)

Figure 1. Host Unit

FRONT PANEL

MOUNTING

BRACKET

(BOTH SIDES)

17857-A

© 2004, ADC Telecommunications , Inc.

Page 1

Page 10

ADCP-75-169 • Issue 1 • June 2004

2.2 RF Signal Connections

The RF signal connections between the HU and the EBTS are supported through either two

(non-diversity unit) or three (diversity unit) N-type female connectors. On non-diversity units,

one connector is used for the forward path RF signal. The other connector is used for the reverse

path RF signal. On diversity units, a third connector is used for the diversity path RF signal. In

installations where multiple EBTS’s will be connected to a single HU, it will usually be

necessary to install a Primary Interface Panel and an Expansion Panel (accessory items) to

support the interface between the HU and the EBTS. The HU should be as close as possible to

the EBTS to mini mize cab le losses.

2.3 Optical Connection

Optical connections between the HU and the RU (STM) are supported through either two (nondiversity unit) or three (diversity unit) SC-type optical connector ports. On non-diversity units,

one port is used for connecting the forward path optical signal and the other port is used for

connecting the primary reverse path optical signal. On diversity units, a third optical port is used

for connecting the di versity reverse path optical signal.

2.4 Controller Area Network Interface Connection

Controller Area Network (CAN) interface connections between multiple HU’s are supported by

a pair of RJ-45 jacks. One of the jacks is designated as the network IN port and the other jack is

designated as the network OUT port. The CAN interface allows up to 24 HU’s to be connected

together (in daisy- chain fashion) and controlled through a single EMS computer.

2.5 Service Interface Connection

The service interface connection between the HU and the EMS computer is supported by a

single DB-9 female conne ctor. The ser vice connector provides an RS-232 DTE inte rface. When

multiple HU’s are networked together, the supporting EMS computer may be connected to the

service connector of any one of the networked HU’s.

2.6 Powering

The HU is powered by ± 21 to ± 60 VDC power (nominal ± 24 or ± 48 VDC). The power is fed to

the HU through a screw-down type terminal strip located on the rear side of the unit. Power to

the HU must be supplied through a fuse panel such as the PowerWorx 20-position GMT fuse

panel (available separately). The power circuit for each HU must be protected with a 3 Amp

GMT fuse. An On/Off switch is provided on the HU front panel.

2.7 User Interface

The HU user interface consi sts of the v arious connectors, switches, termi nals, and LEDs that are

provided on the HU front a nd rear panels. The HU user interface points are indicated in Figure 2

and described in Table 1.

Page 2

© 2004, ADC Telecommunications , Inc.

Page 11

ADCP-75-169 • Issue 1 • June 2004

FRONT VIEW

(12) REVERSE 1

RF OUT

(1) DC POWER

ON/OFF SWITCH

(13) REVERSE 2

RF OUT

(REFERENCE

ITEMS 2 - 8)

LED INDICATORS

(14) FORWARD

RF IN

REAR VIEW

(17) ALARM

OUTPUT CONNECTOR

Figure 2. Host Unit User Interface

Table 1. Host Unit User Interface

REF

NO

USER INTERFACE

DESIGNATION

DEVICE

1I/0 On/Off rocker

switch

(9) SERVICE

INTERFACE

CONNECTOR

(15) DC POWER

TERMINAL STRIP

(18)

PORT 1

(19)

PORT 2

(10) NET IN

CONNECTOR

(20)

PORT 3

(11) NET OUT

CONNECTOR

(16) COVER PLATE

(21) GROUNDING

FUNCTIONAL

DESCRIPTION

Provides DC power on/off control.

19722-A

STUD

2 P OW E R Mult i- color ed L ED

(green/yellow)

3 STANDBY Multi-colored LED

(green/yellow/red)

4 HOST UNIT Multi-colored LED

(green/yellow/red)

5 REMOTE UNIT Multi-colore d LED

(green/yellow/red)

6 D R I V E Mult i- c o lored LED

(green/yellow/red)

Indicates if the HU is powered (green) or unpowered (off). See Note.

Indicate s if the system is in the Normal (off),

Standby (blinking green), Test (blinking red), or

Program Load (blinking yel low) state. See Note.

Indicates if the HU is normal (green), ov erheated

(yellow), or fault y (red). See Note.

Indica tes if no alar ms (green), a minor alarm

(yello w) , o r a majo r alar m ( re d) is r ep ort ed b y the

RU. See Note.

Indicate s if the level of the RF input signal to the

HU is normal (green), low (yellow), or high

(red). See Note.

Page 3

© 2004, ADC Telecommunications , Inc.

Page 12

ADCP-75-169 • Issue 1 • June 2004

Table 1. Host Unit User Interface, continued

REF

NO

USER INTERFACE

DESIGNATION

DEVICE

7 PORT 1/PORT 2 Multi-colored LED

(green/red)

Indicates if the reverse/forward path optical signals from the STM/HU are normal (green), if no

FUNCTIONAL

DESCRIPTION

signals are detected (red), or if excessive errors

are detected (red). See Note.

8PORT 3

(diversity unit only)

Mult i- c o lored LED

(green/yellow)

Indicates if the diversity reverse path optical signal

from the RU is normal (green), if no signal is

detected (yellow), or if excessive errors are

detected (yellow). See Note.

9 SERVICE DB-9 connector

(female)

Connection point for the RS-232 service interface cable.

10 NET IN RJ-45 jack (female) Connection point for the CAN interface input

cable.

11 NET OUT RJ-45 jack (female) Connection point for the CAN interface output

cable.

12 REV RF OUT N-type female RF

coaxia l connector

13 REV DIV RF OUT N-type female RF

coaxia l connector

14 FWD RF IN N-type female RF

coaxia l connector

Output connection point for the primary reverse

path RF coax ial cable.

Output connection point for the diversity reverse

path RF coax ial cable.

Input connection point for the forward path RF

coaxial cable.

15 POWER 24–48 VDC Screw-type terminal

Connection point for the DC power wiring.

strip

16 No designation Cover plate Covers the mounting slot for the wavelength divi-

sion multiplexer module.

17 ALARM OUTPUT Screw-type terminal

connector (14–26

AWG)

18 PORT 1 SC connector

(single-mode)

19 PORT 2 SC connector

(single-mode)

20 PORT 3

(diversity unit only)

SC connector

(single-mode)

Connection point for an external alarm system.

Includes normally open (NO), normally closed

(NC), and common (COM) wiring connections.

Output connection point for the forward path

optical fiber.

Input connection point for the reverse path primary optical fibe r.

Input connection point for the reverse path diversity optical f iber.

21 Chassis ground stud Connection point for a chassis grounding wire.

Note: A more detailed description of LED operation is provided in the applicable System Operat ion and

Maintenance Manual.

Page 4

© 2004, ADC Telecommunications , Inc.

Page 13

3 HOST UNIT ACCESSORIES

This section p rovides a brief description of various accessory items tha t a re available separately.

The accessory items may or may not be required depending on the application.

3.1 Interface Panels

The interf ace panels are accessory items that are used when multiple EBTS’ s require connection

to a single HU. Two types of panels are available: the Primary Interface Panel and the

Expansion Panel. The Primary Interface Panel, shown in Figure 3, provides combining and

splitting (as need ed) of the forwa rd and rev e rse path RF signal. The Primary Inte rface Panel also

provides atte nuation of the forward path signal to the level required for input to the HU. Up to 6

EBTS’s may be connected to a single HU using the Primary Interface Panel.

ADCP-75-169 • Issue 1 • June 2004

18221-A

Figure 3. Primary Interface Panel

The Expansion Panel, shown in Figure 4, is used in conjunction with the Primary Interface

Panel when more than 6 EBTS’ s must be connected to a single HU. The Primary Interface Panel

can support two Expansion Panels and each Expansion Panel can support up to six EBTS’s. For

complete information about the SMR Interface Panels, refer to the Digivance Long Range

Coverag e Solution SMR Interface Panels User Manual (ADCP-75-143).

© 2004, ADC Telecommunications , Inc.

Page 5

Page 14

ADCP-75-169 • Issue 1 • June 2004

Figure 4. Expansion Panel

3.2 Wavelength Division Multiplexer System

The Wavelength Division Multiplexer (WDM) system is an accessory product that is used when

it is desirable or necessary to combine the forward and reverse path optical signals from one

Digiv ance syst em onto a single optica l fi ber. Each WDM system consists of a host module and a

remote module. The HU provides a mounting slot for installing a WDM host module. Both the

RU outdoor cabinet the RU indoor mounting shelf provide a mounting slot for installing a

WDM remote module.

18824-A

Each WDM module consists of a bi-directional wavelength division multiplexer mounted

within a power-paint coated sheet metal enclosure. A straight SC-type optical connector port is

provided for connecting the forward/reverse path optical fiber to the WDM module. A pair of

pigtail leads with SC-type connectors are provided for connecting the WDM module to the

forward and reverse path optical ports on the HU or STM. The WDM host/remote module is

shown in Figure 5.

17013-A

Figure 5. WDM Host/Remote Module

Page 6

© 2004, ADC Telecommunications , Inc.

Page 15

3.3 Coarse Wavelength Division Multiplexer System

The Coarse Wavelength Division Multiplexer (CWDM) system is an accessory product that is

used when it is desirable or necessary to combine the forward and reserve path optical signals

from up to four Digivance systems onto a single optical fiber. Each CWDM system consists of a

Host Module, Host Module mounting shelf, and Remote Module. The CWDM Host Module

mounting shelf can support up to three CWDM Host Modules. The RU single-STM mounting

shelf and the outdoor cabinet s provide a mount ing slot for installing a CWDM Remote Module.

The CWDM Host Module and Host Module Mounting Shelf are shown in Figure 6. The

CWDM Remote Module is shown in Figure 7. For complete information about the CWDM

system, refer to the Digivance System Coarse Wavelength Division Multiplexer User Manual

(ADCP-75-142).

ADCP-75-169 • Issue 1 • June 2004

18647-A

Figure 6. CWDM Host Module and Host Module Mounting Shelf

18648-A

Figure 7. CWDM Remote Module

© 2004, ADC Telecommunications , Inc.

Page 7

Page 16

ADCP-75-169 • Issue 1 • June 2004

4 INSTALLATION PROCEDURES

This section provides the installation procedures for the HU and the WDM host module

(accessory item). The installation procedures for the Interface Panels are provided in the

Digiv ance Long Range Cove rage Solution SMR Interface Panels User Manual (ADCP-75-143).

The installation procedures for the CWDM Host Module and the Host Module Mounting Shelf

are provided in the Digivance System Coarse Wavelength Division Multiplexer User Manual

(ADCP-75-142). Installation of the RU components may proceed separately from installation of

the HU.

4.1 Before Starting Installation

Before beginning the installation, review the system design plan with the system engineer.

Make sure each equipment installation site is identified and located and all cable runs are

mapped out. Also identify all tools and materials that are required to complete the ins tallation.

4.1.1 Tools and Materials

The following tools are required to complete the procedures in this section:

• Box cutter

• Pencil or scribe

• Medium size flat-bladed screwdriver

• Phillips scre wdriver (#2)

• TORX screwdriver (T20 bit)

• Pliers

• Wire cutters

• Wire stripper

• Tool kit for attaching N-type male connectors to coaxial cable

• Multimeter

• Optical power meter

The followin g materials are required to complete the procedures in this se ction:

• #18 AWG (1.0 mm) insulated stranded copper wire (for chassis grounding wire)

• #18 AWG (1.0 mm) red and black insulated copper wire (for DC power wires)

• Category 3 or 5 cable (for external alarm system wires)

• #6 ring terminal (1) for #18 wire (for chassis gr ound wire connection)

• #6 fork terminals (2) for #18 wire (fo r DC power wiring connection)

• Single-mode patch cord(s) with SC connectors (1, 2 or 3 depending on the application)

• High performance, flexible, low-loss 50- ohm coaxial cable

• N-type male connectors

• Wire ties

Page 8

© 2004, ADC Telecommunications , Inc.

Page 17

4.2 Unpacking and Inspection

This section provides instructions for opening the shipping boxes, verifying that all parts have

been received, and verifying that no shipping damage has occurred. Use the following

procedure to unpack and inspec t the HU and any acce ssories:

1. Open the shipping cartons and carefully unpack each component from the protective

packing material.

2. Check each component for broken or missing parts. If there are damages, contact ADC

(see section 6 at the end of this manual) for an RMA (Return Material Authorization) and

to reorder if replacement is required.

4.3 OSP Fiber Cable Installation Guidelines

The outside plant (OSP) fiber optic cables should be routed between the HU and RU and

terminated befor e the equipment is installed. A diagram of a typi cal OSP cable routing is shown

in Figure 8. At the HU, the OSP cable should be terminated at a fiber distribution panel and

spliced to pigtails. Jumper patch cords may then be used to link the HU optical ports to the OSP

cable terminations. Whenever possible, a guideway such as the FiberGuide system should be

provided to protect the fiber optic patch cords from damage and to prevent excessive bending.

The procedures for conn ectin g the OSP cable opt ical fi bers to the HU is provi ded in Section 4.8.

ADCP-75-169 • Issue 1 • June 2004

SPLICE

X

TERMINATION

PATCH

CORDS

INDOOR

REMOTE SITE

PATCH

CORDS

FIBER DISTRIBUTION

PANEL

STM

HOST UNIT

FIBER DISTRIBUTION

PANEL

HOST SITE

X

OUTSIDE PLANT

OUTDOOR

REMOTE SITE

INDOOR

MOUNTING

SHELF

STM

INDOOR/OUTDOOR

X

X

CABLE

OUTDOOR

CABINET

CABLE WITH

PIGTAIL LEADS

SPLICE

ENCLOSURE

18626-B

Figure 8. Typical Fiber Optic Cable Routing

© 2004, ADC Telecommunications , Inc.

Page 9

Page 18

ADCP-75-169 • Issue 1 • June 2004

When routed to the RU outdoor cabinet, the OSP fiber optic cable should be spliced to a

connectorized outdoor-rated cable (consisting of individual jacketed pigtails) which is then

routed into the outdoor cabinet. The individual pigtails can then be connected directly to the

STM optical ports. A connector is provided on the bottom of the RU outdoor cabinet to seal the

cable entry point and provide strain relief. The procedure for routing the fiber cable into an

outdoor cabinet in provi ded in the applic able Remote Unit Installat ion and Maintenance Manual

(see Related Publicat ions section).

When routed to the RU indoor mounti ng sh elf, the OSP cable should be terminated at a fiber

distribution panel and spliced to pigtails. Jumper patch cords may then be used to link the STM

optical ports to the OSP cable terminations. Whenever possible, a guideway such as the

FiberGuide sys tem should be provi ded to protect the fiber optic patc h cords from damage and to

prevent excessive bending. The procedure for connecting the OSP optical fibers to an STM

mounted in the indoor mounting shel f is provide d in the applicable Remote Unit Insta llatio n and

Maintenance Manual (see Related Publications section).

4.4 HU Mounting Procedure

The HU may be mounted in either a 19-inch or 23-inch EIA or WECO equipment rack. Both

US standard and metric machine screws are included for rack mounting the HU. When loading

the HU in a rack, make sure the mechanical loading of the rack is even to avoid a hazardous

condition such as a severely unbalanced rack. The rack should safety support the combined

weight of all the equipment it holds. In addition, maximum recommended ambient temperature

for the HU i s 50º C (1 22º F). Al low sufficient air circu lation or s pace betw een units when th e

HU is installed in a multi-rack assembly because the operating ambient temperature of the rack

environment might be greater than room ambient.

Warning: Wet conditions increase the potential for receiving an electrical shock when

installing o r using el ectrica lly pow ered equipmen t. To prevent electrica l shock, never inst all or

use electrical equipment in a wet loca tion or during a lightning storm.

Note: To insure that all optical connectors remain dust-free during installation, leave all dust

caps and dust protectors in pla ce until directed to remove them for connect ion.

Use the following pr ocedure to install the HU in the equipment rack:

1. The HU is shipped with the mounting brackets installed for 19-inch rack installations. If

mounting the HU in a 19-inch rack, proceed to step 4. If mounting the HU in a 23-inch

rack, proceed to step 2.

2. Remove both mounting brackets from the HU (requires TORX screwdriver with T20 bit)

and save screws for reuse.

3. Reinstall both mounting brackets so the long side of the bracket is flush with the HU front

panel as shown in Figure 9. Use the screws removed in step 2 to re-attach the brackets to

the HU chassis.

Page 10

© 2004, ADC Telecommunications , Inc.

Page 19

ADCP-75-169 • Issue 1 • June 2004

FOR INSTALLATION IN 23-INCH

RACKS, REMOVE AND REINSTALL

MOUNTING BRACKETS AS SHOWN

17864-A

Figure 9. Installing the Mounting Brackets for 23-Inch Rack Installations

4. Position t he HU in the designated mount ing space in the rack (pe r system design plan) and

then secure ( but do not ti ghten) the HU to the rack using the four mac hine screws provided

(use #12-24 or M6 x 10 screws, whichever is appropriate) as shown in Figure 10.

Note: Provide a m inimum of 3 inches (76 mm) of clear ance space on both the left and

right sides of the HU for air intake and exhaust.

17865-A

Figure 10. HU Rack Mount Installation

© 2004, ADC Telecommunications , Inc.

Page 11

Page 20

ADCP-75-169 • Issue 1 • June 2004

4.5 Chassis Ground Connection

A stud is provide d on the rear side of the chassis for connecting a grounding wire to the chassis.

Use the following procedure to connect the grounding wire to the chassis and to route the

grounding wire to an appro ved earth ground source.

1. Obtain a length of #18 AWG (1.00 mm) insulated stranded copper wire for use as a

chassis grounding wire.

2. Terminate one end of the wire with a ring terminal.

3. Locate the chassis gr ound stud at the rear of the HU as shown in Figure 11.

4. Attach the ring end of the wire to the chassis ground stud (see Figure 11).

5. Route the free end of the chassis grounding wire to an approved (per local code or

practice) earth gr ound source.

6. Cut the chassis grounding wire to length and connect it to the approved ground source as

required by local code or practice.

Note: Be sure to maintain reliable grounding. Pay particular attention to ground source

connections.

4.6 Coaxial Cable Connections

The RF interface be tween the HU and the EBTS is supported through either two (non-diversity)

or three (diversity) type N female connectors mounted on the HU rear panel. On non-diversity

units, one connector provides the coaxial cable connection for the forward path (downlink)

signal and the other connector provides the coaxial cable connection for the reverse path

(uplink) signal. On diversity units, a third connector provides the coaxial cable connection for

the dive rsity reverse path (uplink) signal.

17866-A

Figure 11. Chassis Ground Stud

In most installations, it is usually necessary to insert an external attenuator into th e for ward

path link between the HU and the EBTS. A signal level that is greater than –9 dBm will

overdrive and possibly damage the HU re ceiver. Before completing the forward path connection

at the EBTS, verify that the composite forward path RF signal level at the HU is between –9

Page 12

© 2004, ADC Telecommunications , Inc.

Page 21

ADCP-75-169 • Issue 1 • June 2004

and –40 dBm. Refer to the applicable System Operation and Maintenance Manual for the

procedure to determine the forward path input signal level. If the Primary Interface Panel and

Expansion Panel are required, refer to the Digivance LRCS SMR Interface Panels User Manual

(ADCP-75-143) for the coaxial cable installation procedures.

The HU should be mounted as close as possible to the EBTS to minimize cable losses. Use the

following pr ocedur e to r oute and co nnect t he forw ard and reverse path coax ial cabl es to the HU:

1. Obtain the required lengths of high performance, flexible, low loss 50-ohm coaxial

communications cable (RG-400 or equivalent) for all coaxial connections.

2. Route the forward and reverse path coaxial cables and the diversity reverse path cable (if

the HU supports diversity) between the HU and the EBTS interface (per system design

plan) and cut to the required length. Allow sufficient slack for dressing and organizing

cables at the HU and for installing an external attenuator in the forward path link.

3. Terminate each cable wi th an N-type male con nector following the conn ector supplier’s

recommendations.

4. If required, install an external attenuator in the forward path.

Note: The composite forward path RF signal level at the HU must be between –9 and

–40 dBm. Do not con nect the forward path cabl e until the composite fo rward path RF

signal le vel is measured and the amount of external attenuation required is determined.

5. Connect the forward path cable to the FORWARD RF IN connector on the HU front

panel as shown in Figure 12.

6. Connect the reverse path cable to the REVERSE 1 RF OUT connector on the HU front

panel (see Figure 12).

REVERSE 1

RF OUT CONNECTOR

(REVERSE PATH)

REVERSE 2

RF OUT CONNECTOR

(DIVERSITY

REVERSE PATH)

19719-A

FORWARD RF IN

CONNECTOR

(FORWARD PATH)

TYPE-N MALE

CONNECTOR

Figure 12. Forward and Reverse Path Coaxial Cable Connections

© 2004, ADC Telecommunications , Inc.

Page 13

Page 22

ADCP-75-169 • Issue 1 • June 2004

7. If the HU supports diversity, connect the diversity reverse path cable to the REVERSE 2

RF OUT connector on the HU front panel (see Figure 12).

8. Dress and secure cables at the HU.

9. Complete all remaining coaxial connections as specified in the system design plan.

4.7 WDM Mounting Procedure (Accessory)

A bi-directional wavelength division multiplexer (WDM) module is available as an accessory

item for the Digivance system. If the application does not require the use of a WDM system,

skip this section and proceed to Section 4.8. The WDM mounts in a slot that is provided at the

rear side of the HU.

Use the following pr ocedure to install the WDM:

1. Remove the cover plate from the WDM mounting slot located on the rear side of the HU

as shown in Figure 13.

2. Slide the WDM into the mounting slot.

3. Push inward on the two Push/ Pull fasteners to secure the WDM to the HU.

4. Carefully coil up the two WDM pigtails to protect them from damage prior to connection

to the HU optical ports.

WDM MODULE

REMOVE COVER PLATE

FOR WDM MODULE

INSTALLATION

Figure 13. WDM Installation

19720-A

4.8 Optical Connections

The optical interface between the HU and the RU is supported by either two (non-diversity) or

three (diversity) optical ports. Each optical port consists of an SC optical adapter which is

mounted on the HU front panel. The PORT 1 port provides the optical connection for the

forward path ( downlink) signal. The PORT 2 port provide the optical connection for the rev erse

Page 14

© 2004, ADC Telecommunications , Inc.

Page 23

ADCP-75-169 • Issue 1 • June 2004

path (uplink) signal. The PORT 3 port provides the optical connection for the diversity reverse

path (uplink) signal .

The optical connections are dependent on whether or not a WDM host module (accessory) or

CWDM host module (accessory) is installed:

• If the installation does not include either a WDM or CWDM module, proceed to

Section 4.8.1 for the optical connections procedure.

• If the installation includes a WDM module, proceed to Section 4.8.2 for the optical

connections procedure.

• If the installation includes a CWDM module, refer to the Digivance System Coarse

Wavelength Division Multiple xe r User Manual (ADCP-75-142) for the optical connection

procedure.

Danger: This equipment uses a Class 1 Laser according to FDA/CDRH rules. Laser radiation

can seriously damage the retina of the eye. Do not look into the ends of any optical fiber. Do not

look directly into the optical transmitter of any unit or exposure to laser radiation may result.

An optical power meter should be used to verify active fibers. A protective cap or hood MUST

be immediately placed over any radiating transmitter or optical fiber connector to avoid the

potential of dangerous amounts of radiation exposure. This practice also prevents dirt particles

from ente ring the connector.

4.8.1 Optical Connections Without WDM or CWDM System

Use the following procedure to connect the optic al fi bers when a WDM is not installed with the HU:

1. Obtain two (non-diversity) or three (diversity) patch cords that are of sufficient length to

reach from the HU to the fiber dist ribution panel.

2. Designate one of the patch cords as the for war d pa th link and the other as the reverse

path link and attach an identification label or tag next to the connector. For diversity

systems, designate and label or tag a third patch cord as the diver sity reve r s e p a t h link.

3. Remove the dust caps from the HU optical ports and from the patch cord connectors that

will be connected to the HU.

4. Clean each patch cord connector following the patch cord supplier’s recommendations.

Note: To protect the optical receivers, insert a 15 dB attenuator in each optical path. When

the system is turned-up and test ed, the attenuator may be resized or removed.

5. Insert each patch cord connector into the appropriate optical port as shown in Figure 14

and as specified by the followin g :

PORT 1 - Forward path patch cord

PORT 2 - Reverse path patch cord

PORT 3 - Diversity reverse path patch cord

© 2004, ADC Telecommunications , Inc.

Page 15

Page 24

ADCP-75-169 • Issue 1 • June 2004

PORT 1

FORWARD PATH

PORT 2

REVERSE PATH

19721-A

PORT 3

DIVERSITY

REVERSE PATH

Figure 14. Fiber Optic Cable Connections To Host Unit

6. Route the patch cords from the HU to the fiber distribution panel.

Note: The HU o p tic al adapters are angled to t he left. Therefore, always route patch cords

to the HU from the left side of the rack. Routing patch cords to the HU from the right may

exceed the bend radius limitations for the optical fiber.

7. At the fiber distribution panel, identify the OSP cable optical fiber terminations that

correspond to the forwa rd , reverse, and diversity reve rse (if supported) paths.

8. Remove the dust caps from the OSP cable optical fiber adapters and from the patch cord

connectors.

9. Clean each pat ch cord connector (follow patch cord supplier’s recommendations) and then

mate the connector with the appropriate OSP cable adapter.

10. Store any excess patch cord slack at the fiber distribution panel.

4.8.2 Optical Connections With WDM System

Use the following procedure to connect the optical fibers when a WDM module is installed with

the HU:

1. Obtain a patch cord tha t is of sufficient length to reach from the WDM module to the fiber

distribution panel.

2. Remove the dust cap from the optical port (Port 1) on the WDM module and from the

patch cord connector that will be connected to the WDM module.

Page 16

© 2004, ADC Telecommunications , Inc.

Page 25

ADCP-75-169 • Issue 1 • June 2004

3. Clean the patch cord connector (follow patch cord supplier’s recommendations).

Note: To protect the optical receivers, insert a 15 dB attenuator in each optical path. After

the optical powe r has been measured, the attenuator may be resized or removed.

4. Insert the connec tor into one of the WDM module’s optical port (port 1).

5. Route the patch cord from the WDM to the fiber distribution panel.

6. Identify the OSP cable opt ical fiber termination that corresponds to the RU.

7. Remove the dust cap from the OSP cable optical adapter and from the patch cord

connector.

8. Clean the patch cord connector (follow patch cord supplier’s recommendations) and then

mate the connector with the appropriate OSP cable adapter.

9. Store any excess patch cord slack at the fiber distribution panel.

10. Remove the dust caps from the HU optical ports and from the WDM pigtails that will be

connected t o the HU.

11. Clean each pigtai l connector (follow the procedures provided with the WDM module) and

then insert the connector into the appropriate optical port on the HU as shown in Figure 14

and as diagramed in Figure 15.

Note: The HU opt i cal ad ap ters are angled t o the left. Therefore, pigtails should always be

routed to the HU from the left side of the rack. Routing pigtails to the HU from the right

side of the rack may exceed the bend radius limitations for the optical fiber.

HOST UNIT

WAVELENGTH

DIVISION

MULTIPLEXER

BI-DIRECTIONAL

FIBER LINK WITH

REMOTE UNIT

PORT1PORT

FORWARD

PATH

WDM

PIGTAILS

123

Figure 15. Fiber Optic Connections To WDM Module

2

REVERSE

PATH

PORT

3

REVERSE PATH

(IF SUPPORTED)

DIVERSITY

FIBER DISTRIBUTION

PANEL

X

X

FROM STM

TO/FROM REMOTE

WDM MODULE

19718-A

12. If the HU supports diversity, follow steps 2–5 in Section 4.8.1 for routing and connecting

the dive rsity reverse path link.

© 2004, ADC Telecommunications , Inc.

Page 17

Page 26

ADCP-75-169 • Issue 1 • June 2004

4.9 Controller Area Network Connections

Controller area Network (CAN) interface connections between multiple HU’s are supported by

a pair of RJ-45 jacks. One of the jacks is designated as the NET IN port and the other jack is

designated as the NET OUT port. The CAN interface allows up to 24 HU’s to be connected

together (in daisy-chain fashion) and controlled through a single Digivance EMS computer. A

one meter long cable is available (accessory) for CAN connections. Use the following

procedure to connect CAN interf ace cables between multiple HU’s:

1. Connect one end of the CAN interface cable (accessory) to either the NET IN or NET

OUT port on HU #1 as shown in Figure 16.

2. Route the CAN interface cable to HU #2 and connect the cable’s free end to the port that is

the logical opposite of the CAN interface connection at HU #1.

Note: Connect OUT to IN and IN to OUT. If connected to a NET OUT port at HU #1,

connect to the NET IN port at HU #2. If connected to a NET IN port at HU #1, connect to

a NET OUT port at HU #2.

3. If a third HU will be connected to the network, connect a second CAN interface cable to

the remaining network por t on HU #2.

NET IN

NET OUT

17869-B

RJ-45 CONNECTOR

DETAIL

Figure 16. Controller Area Network Connections

4. Route the second CAN interface cable to HU #3 and connect the cable’s free end to the

port that is the logical opposite of the CAN interface connection at HU #2.

5. Repeat step s 3 and 4 for each additional HU that is added to the network up to a total of 24

HU’s. A diagram of typical CAN interface connections is shown in Figure 17.

Page 18

© 2004, ADC Telecommunications , Inc.

Page 27

ADCP-75-169 • Issue 1 • June 2004

HOST UNIT 1 HOST UNIT 2 HOST UNIT 3

NET IN NET OUT NET IN NET OUT NET IN NET OUT

Figure 17. Configuring CAN Connections with Multiple Host Units

4.10 EMS Computer Connection

The service interface connection between the HU and the EMS computer is supported by a

single DB-9 female connector. The service connector provides an RS-232 DTE interface. A

three meter long straight-through RS-232 interface cable is available (accessory) for connecting

the EMS computer to the HU. Use the following procedure to install the service interface cable:

1. Connect one end of the service interface cable (accessory) to the SERVICE port as shown

in Figure 18.

2. Route th e service inter face cable to the EMS computer an d connect the free end of the

cable to the computer’s RS-232 DCE port. Refer to the user manual provided with the

computer to locate and configure the specified port.

CONTROLLER AREA NETWORK

INTERFACE CABLES

16900-B

TO NEXT HOST UNIT

(NOTE: LAST HOST HAS NO

CONNECTION AT NET OUT)

Figure 18. Service Interface Connection

17870-A

Page 19

© 2004, ADC Telecommunications , Inc.

Page 28

ADCP-75-169 • Issue 1 • June 2004

4.11 External Alarm System Connections

The alarm interfac e between the HU and an exte rnal alar m system is suppor ted by a six- termina l

plug (with screw-type terminals) that connects to a receptacle mounted on the HU front panel.

The terminal plug provides connections to normally open (NO) and normally closed (NC) dry

type alarm contacts for both major and minor al arms. A categ ory 3 or 5 cable is typic ally use d to

connect th e HU to the external alarm system. U se the foll owing proced ure to instal l the alarm

wiring and connect it to the HU:

1. Obtain the required le ngth of category 3 or 5 cable.

2. Route the cable between the HU and the external alarm system (if not already routed) and

then cut t o the required length. Allow sufficient slack for dressi ng a nd organizing the cable

at the HU.

3. Strip back the outer cable sheath and insulation to expose the wires at both ends of the

cable and strip back 0.2 inches (5 mm) of insulation from each wire.

4. Connect the Major alarm wire pair to the MAJOR COM/NC or MAJOR COM/NO

terminals (whic hever is requ ired by the ex ternal a larm sys tem) on th e HU alarm termi nal

connector (supplied with HU) as shown in Figure 19.

NO

COM

NC

MINOR ALARM WIRES

ALARM

CONNECTOR

NC

COM

NO

MAJOR ALARM WIRES

Figure 19. External Alarm System Connections

17871-A

5. Connect the Minor alarm wire pair to the MINOR COM/NC or MINOR COM/NO

terminals (whic hever is requ ired by the ex ternal a larm sys tem) on th e HU alarm termi nal

connector (s ee Figure 19).

Page 20

© 2004, ADC Telecommunications , Inc.

Page 29

6. Connect the Major and Minor alarm wire pairs to the appropriate terminals on the external

alarm system.

7. Dress and secure cable per standard industry practice.

4.12 DC Power Connections

The HU is powered by ± 21 to 60 VDC power (nominal ± 24 or ± 48 VDC). The power is fed to

the HU through a screw-down type terminal strip located on the rear side of the unit. Power to

the HU must be supplied through a fuse panel such as the 20 position PowerWorx GMT Fuse

Panel (available separately) and the power must be protected with a 3 Amp GMT fuse. Use the

following pr ocedure to install the power wiring:

1. Obtain one pair of #18 AWG (1.00 mm) red and black insulated copper wire for use as the

power wiring.

2. Terminate one end of each wire with a fork terminal as shown in Figure 20.

3. Connect the power wires to the power terminal strip at the rear of the HU.

4. Route the free ends of the wires to the fuse panel and locat e the terminals that will be used

for the power feed. Refer to the user manual provided with the fuse panel for specific

information.

ADCP-75-169 • Issue 1 • June 2004

5. Remove the fuse from the circuit that will power the HU.

+ (BLACK)

FORK

TERMINALS

– (RED)

#18 AWG

(1.0 mm)

COPPER

WIRE

17872-B

Figure 20. DC Power Connections

© 2004, ADC Telecommunications , Inc.

Page 21

Page 30

ADCP-75-169 • Issue 1 • June 2004

6. Connect the power wires to the appropriate terminals as specified in the fuse panel user

manual.

Note: When connecting the equipment to the supply circuit, be sure to check equipment

nameplate ratings to avoid overloading circuits which may cause damage to over-current

protection de vices and supply wiring.

7. Dress and secure the power wiring at the fuse panel and the HU. The procedure for

checking the voltage level and verifying that the HU is ready to power up is provided in

the applicable System Operation and Maintenance Manual (see Related Publications

section).

4.13 Installation Complete

When the installation is complete, refer to the applicable System Operation and Maintenance

Manual (see Related Publications section) for the system turn-up and test procedures.

5 MAINTENANCE

This section provides the HU maintenance procedures. Refer to this section when scheduled

maintenance is required. The fault isolation and troubleshooting procedures are provided in the

applicable System Opera tion and Maintenance Manual (see Related Publications se ction).

5.1 Host Unit Fan Replacement Procedure

The HU is equipped with two cooling fans which are located on the right side of the HU

enclosure. The cooling fans blow cool ai r into the enclosure. Heated air is exhausted through the

vent openings on the left side of the enclosure. Replacement of the fans requires that the HU be

turned off for a sh o rt pe ri od of t im e. Th e rec o mm en d ed replacement i nte rval is 60 m o n ths. U s e

the follo wing procedure to remove and replace the HU cooling fans:

1. Before working on the HU or handling a fan, slip on an Electro-Static Discharge (ESD)

wrist strap and connect the ground wire to an earth ground source. Wear the ESD wrist

strap while completin g each sect ion of the fan installation procedure.

Warning: Electronic components can be damaged by static electrical discharge. To prevent

ESD damage, always wear an ESD wrist strap when working on the HU, STM, or LPA and

when handling electronic components.

2. Notify the NOC or alarm monitoring syste m operator that the system is going offline.

3. Place the HU On/Off switc h in the OFF position (press O).

4. Remove the six flat-head screws (requires TORX screwdriver with T10 bit) that secure the

fan/grill assembly to the right side of the HU enclosure as shown in Figure 21. Save

screws for reuse.

5. Carefully withdraw the fan/grill assembly from the enclosure until the wiring harness is

exposed and the connector s are accessible.

Page 22

© 2004, ADC Telecommunications , Inc.

Page 31

ADCP-75-169 • Issue 1 • June 2004

17873-A

Figure 21. Host Unit Fan/Grill Assembly Removal

6. Lift the small latch on each wiring harness connector and carefully unplug each connector

from the circuit board connector.

7. Remove the plastic rivets that secure each fan to the grill by pushing outward on the rivet

center post until the rivet can be withdrawn from the grill as shown in Figure 22.

16173-B

Figure 22. Removing Host Unit Fans From Grill

8. Remove both f ans from the grill

9. Use the ri vets remov ed in step 7 to secure the replacement fans to the grill. Orient each fan

so the wiring harness is on the top and the arrow on the fan points into the enclosure.

10. Connect the two wiring harness connectors to the circuit board connectors.

11. Secure the f an/grill assembly to the side of the enclosure (see Figure 21) using the six flathead screws removed in step 4.

12. Place the H U On/ O ff switch i n the ON position (press I).

13. Verify that the fans run properly following powe r-up.

14. Notify the NOC or alarm monit oring syst em operator that the syste m is going ba ck online.

© 2004, ADC Telecommunications , Inc.

Page 23

Page 32

ADCP-75-169 • Issue 1 • June 2004

6 CUSTOMER INFORMATION AND ASSISTANCE

PHONE:

EUROPE

Sales Administration: +32-2-712-65 00

Technical Assistance: +32-2-712-65 42

EUROPEAN TOLL FREE NUMBERS

Germany:

UK:

Spain:

France:

Italy: 0800 782374

U.S.A. OR CANADA

Sales: 1-800-366-3891 Extension 73000

Technical Assistance: 1-800-366-3891

Connectivity Extension 73475

Wireless Extension 73476

ASIA/PACIFIC

Sales Administration: +65-6294-9948

Technical Assistance: +65-6393-0739

ELSEWHERE

Sales Administration: +1-952-938-8080

Technical Assistance: +1-952-917-3475

WRITE:

ADC TELECOMMUNICATIONS, INC

PO BOX 1101,

MINNEAPOLIS, MN 55440-1101, USA

0180 2232923

0800 960236

900 983291

0800 914032

ADC TELECOMMUNICATIONS (S'PORE) PTE. LTD.

100 BEACH ROAD, #18-01, SHAW TOWERS.

SINGAPORE 189702.

ADC EUROPEAN CUSTOMER SERVICE, INC

BELGICASTRAAT 2,

1930 ZAVENTEM, BELGIUM

PRODUCT INFORMATION AND TECHNICAL ASSISTANCE:

connectivity_tac@adc.com

wireless.tac@adc.com

euro_tac@adc.com

asiapacific_tac@adc.com

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice.

In no event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period. This publication may be

verified at any time by contacting ADC's Technical Assistance Center.

© 2004, ADC Telecommunications, Inc.

All Rights Reserved

13944-L

Printed in U.S.A.

Page 24

Loading...

Loading...