Page 1

Advanced Control Equipment

ACE

Document No. 96A0245

Issued: February 27, 2001

Rev.D: Aug 17, 2011

ADB Airfield Solutions, LLC

977 Gahanna Parkway

Columbus, OH 43230

USA

Copyright 2001 by ADB Airfield Solutions, LLC. All rights reserved.

Tel: +1 (614) 861-1304

Fax: +1(614) 864-2069

www.adb-airfieldsolutions.com

Page 2

Advanced Control Equipment ACETM Record of Changes

Record of Changes

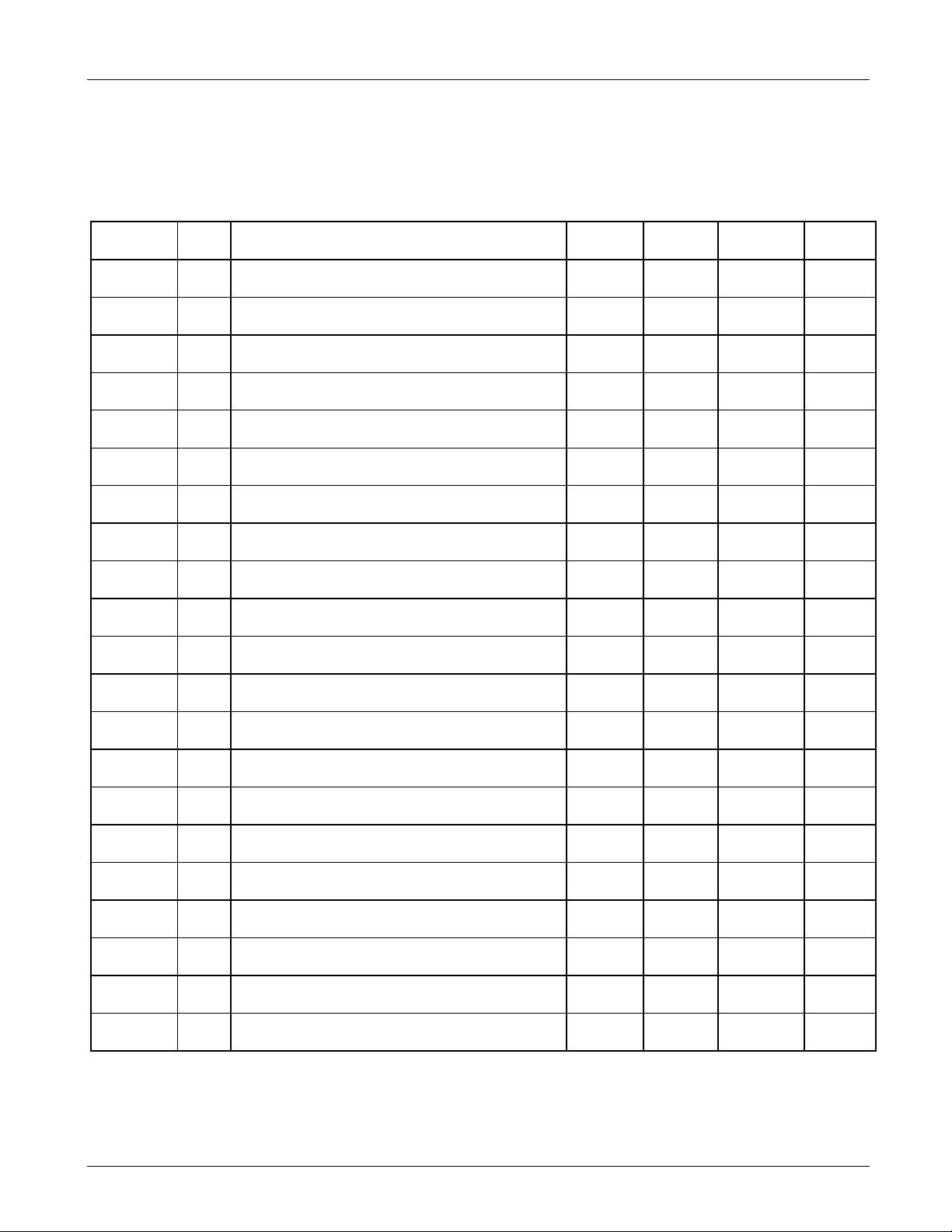

Page Rev Description EC No. Checked Approved Date

A Released Manual.

Title page B Changed to Siemens sans font. 00696 JY WT 5/16/01

all C Updated to new format

all D Updated for Corey

00646 WT EPD 2/27/01

RH JC 8/17/11

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D ii

Page 3

Advanced Control Equipment ACETM Table of Contents

Table of Contents

Record of Changes ........................................................................................ ii

Table of Contents ......................................................................................... iii

Warranties .................................................................................................... iv

1. Safety ....................................................................................................... 1

Safety Symbols ..................................................................................... 1

Qualified Personnel .............................................................................. 2

Intended Use ........................................................................................ 2

Installation ............................................................................................ 3

Operation .............................................................................................. 3

Maintenance and Repair ....................................................................... 4

2. Description ............................................................................................... 6

ACE™ Power Supply Circuit Board ................................................... 7

ACE™ Input / Output Circuit Board ................................................... 7

ACE™ Processor Circuit Board .......................................................... 8

ACE™ Lamps Out Circuit Board ........................................................ 8

ACE™ Front Panel Display Circuit Board .......................................... 8

3. Theory of Operation ............................................................................... 10

ACE™ Communication ..................................................................... 10

ACE™ Input / Output ........................................................................ 11

ACE™ Failsafe Functionality ............................................................ 11

4. Installation Instructions .......................................................................... 12

ACE™ Mounting Location ................................................................ 12

ACE™ Mounting Orientation ............................................................ 12

ACE™ Mounting Instructions ........................................................... 13

ACE™ Cable Entry and Wiring ......................................................... 16

ACE™ Wiring ................................................................................... 17

5. ACE™ Troubleshooting ........................................................................ 19

6. Parts ........................................................................................................ 21

Introduction ........................................................................................ 21

Using the Illustrated Parts List ........................................................... 21

ACE™ Part Numbering System ......................................................... 22

Spare Parts .......................................................................................... 24

2001 ADB Airfield Solutions, LLC

All rights reserved

Issued 5/01

96A0245D

Page 4

Advanced Control Equipment ACETM Warranties

Products of Siemens Airfield Solutions manufacture are guaranteed against

Warranties

Disclaimers

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

mechanical, electrical, and physical defects (excluding lamps) for a period

of one year from the date of installation or a maximum of two years from

the date of shipment and are guaranteed to be merchantable and fit for the

ordinary purposes for which such products are made.

Siemens Airfield Solutions will correct by repair or replacement, at its

option, equipment or parts which fail because of mechanical, electrical or

physical defects, provided that the goods have been properly handled and

stored prior to installation, properly installed and properly operated after

installation, and provided further that Buyer gives Siemens Airfield

Solutions written notice of such defects after delivery of the goods to

Buyer.

Siemens Airfield Solutions reserves the right to examine goods upon which

a claim is made. Said goods must be presented in the same condition as

when the defect therein was discovered. Siemens Airfield Solutions furthers

reserves the right to require the return of such goods to establish any claim.

Siemens Airfield Solutions’s obligation under this guarantee is limited to

making repair or replacement within a reasonable time after receipt of such

written notice and does not include any other costs such as the cost of

removal of defective part, installation of repaired product, labor or

consequential damages of any kind, the exclusive remedy being to require

such new parts to be furnished.

Siemens Airfield Solutions’s liability under no circumstances will exceed

the contract price of goods claimed to be defective. Any returns under this

guarantee are to be on a transportation charges prepaid basis. For products

not manufactured by, but sold by Siemens Airfield Solutions, warranty is

limited to that extended by the original manufacturer.

This is Siemens Airfield Solutions’s sole guarantee and warranty with

respect to the goods; there are no express warranties or warranties of fitness

for any particular purpose or any implied warranties of fitness for any

particular purpose or any implied warranties other than those made

expressly herein. All such warranties being expressly disclaimed.

This manual could contain technical inaccuracies or typographical errors.

Siemens Airfield Solutions reserves the right to revise this manual from

time to time in the contents thereof without obligation of Siemens Airfield

Solutions to notify any person of such revision or change.

Details and values given in this manual are average values and have been

compiled with care. They are not binding, however, and Siemens Airfield

Solutions disclaims any liability for damages or detriments suffered as a

result of reliance on the information given herein or the use of products,

processes or equipment to which this manual refers. No warranty is made

that the use of the information or of the products, processes or equipment to

which this manual refers will not infringe any third party’s patents or rights.

The information given does not release the buyer from making their own

experiments and tests.

96A0245D iv

Page 5

Advanced Control Equipment ACETM Safety

TM

Advanced Control Equipment ACE

1. Safety

Safety Symbols

This section contains general safety instructions for using your Siemens

Airfield Solutions equipment. Task- and equipment-specific warnings are

included in other sections of this manual where appropriate. Note all

warnings and follow all instructions carefully. Failure to do so may result

in personal injury, death, or property damage.

To use this equipment safely,

refer to the FAA Advisory Circular AC 150/5340-26, Maintenance of

Airport Visual Aids Facilities, for instructions on safety precautions.

observe all safety regulations. To avoid injuries, always remove power

prior to making any wire connections and touching any parts. Refer to

FAA Advisory Circular AC 150/5340-26.

read and become familiar with the general safety instructions provided

in this section of the manual before installing, operating, maintainin g,

or repairing this equipment.

read and carefully follow the instructions given throughout this manual

for performing specific tasks and working with specific equipment.

store this manual within easy reach of personnel installing, operating,

maintaining, or repairing this equipment.

follow all applicable safety procedures required by your company,

industry standards, and government or other regulatory agencies.

obtain and read Material Safety Data Sheets (MSDS) for all materials

used.

Become familiar with the safety symbols presented in this section. These

symbols will alert you to safety hazards and conditions that may result in

personal injury, death, or property and equipment damage.

WARNING: Failure to observe this warning may result in

personal injury, death, or equipment damage.

WARNING: Risk of electrical shock. Failure to observe this

warning may result in personal injury, death, or equipment

damage.

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 1

Page 6

Advanced Control Equipment ACETM Safety

Safety Symbols (contd.)

Qualified Personnel

Intended Use

The term qualified personnel is defined here as individuals who thoroughly

understand the equipment and its safe operation, maintenance, and repair.

Qualified personnel are physically capable of performing the required tasks,

familiar with all relevant safety rules and regulations and have been trained

to safely install, operate, maintain, and repair the equipment. It is the

responsibility of the company operating this equipment to see that its

personnel meet these requirements.

Siemens Airfield Solutions cannot be responsible for injuries or damages

resulting from nonstandard, unintended applications of its equipment. This

equipment is designed and intended only for the purpose described in this

manual. Uses not described in this manual are considered unintended uses

and may result in serious personal injury, death, or property damage.

Unintended uses may result from taking the following actions:

making changes to equipment that have not been recommended or

failing to make sure that auxiliary equipment complies with approval

using materials or auxiliary equipment that are inappropriate or

allowing unqualified personnel to perform any task

WARNING: Disconnect equipment from line voltage. Failure

to observe this warning may result in personal injury, death, or

equipment damage.

WARNING: Wear safety goggles. Failure to observe may

result in serious injury.

CAUTION: Failure to observe may result in equipment

damage.

WARNING: Use of this equipment in ways other than

described in this manual may result in personal injury, death, or

property and equipment damage. Use this equipment only as

described in this manual.

described in this manual or using parts that are not genuine Siemens

Airfield Solutions replacement parts

agency requirements, local codes, and all applicable safety standards

incompatible with your Siemens Airfield Solutions equipment

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 2

Page 7

Advanced Control Equipment ACETM Safety

Installation

Operation

Read the installation section of all system component manuals before

installing your equipment. A thorough understanding of system

components and their requirements will help you install the system safely

and efficiently.

WARNING: Failure to follow these safety procedures can

result in personal injury or death.

Allow only qualified personnel to install Siemens Airfield Solutions

and auxiliary equipment. Use only approved equipment. Using

unapproved equipment in an approved system may void agency

approvals.

Make sure all equipment is rated and approved for the environment in

which you are using it.

Follow all instructions for installing components and accessories.

Install all electrical connections to local code.

Use only electrical wire of sufficient gauge and insulation to handle the

rated current demand. All wiring must meet local codes.

Route electrical wiring along a protected path. Make sure they will not

be damaged by moving equipment.

Protect components from damage, wear, and harsh environment

conditions.

Allow ample room for maintenance, panel accessibility, and cover

removal.

Protect equipment with safety devices as specified by applicable safety

regulations.

If safety devices must be removed for installation, install them

immediately after the work is completed and check them for proper

functioning.

Only qualified personnel, physically capable of operating the equipment

and with no impairments in their judgment or reaction times, should operate

this equipment.

Read all system component manuals before operating this equipment. A

thorough understanding of system components and their operation will help

you operate the system safely and efficiently.

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 3

Page 8

Advanced Control Equipment ACETM Safety

Operation (contd.)

Maintenance and Repair

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

Before starting this equipment, check all safety interlocks, fire-

detection systems, and protective devices such as panels and covers.

Make sure all devices are fully functional. Do not operate the system if

these devices are not working properly. Do not deactivate or bypass

automatic safety interlocks or locked-out electrical disconnects or

pneumatic valves.

Never operate equipment with a known malfunction.

Do not attempt to operate or service electrical equipment if standing

water is present.

Use this equipment only in the environments for which it is rated. Do

not operate this equipment in humid, flammable, or explosive

environments unless it has been rated for safe operation in these

environments.

Never touch exposed electrical connections on equipment while the

power is ON.

Allow only qualified personnel to perform maintenance, troubleshooting,

and repair tasks. Only persons who are properly trained and familiar with

Siemens Airfield Solutions equipment are permitted to service this

equipment.

Always use safety devices when working on this equipment.

Follow the recommended maintenance procedures in your equipment

manuals.

Do not service or adjust any equipment unless another person trained in

first aid and CPR is present.

Connect all disconnected equipment ground cables and wires after

servicing equipment. Ground all conductive equipment.

Use only approved Siemens Airfield Solutions replacement parts.

Using unapproved parts or making unapproved modifications to

equipment may void agency approvals and create safety hazards.

96A0245D Page 4

Page 9

Advanced Control Equipment ACETM Safety

Maintenance and Repair

(contd.)

Check interlock systems periodically to ensure their effectiveness.

Do not attempt to service electrical equipment if standing water is

present. Do not service electrical equipment in a high-humidity

environment.

Use tools with insulated handles when working with electrical

equipment.

When replacing or servicing the ACE

TM

, turn the main circuit off until

the operation is complete and personnel are no longer handling

equipment.

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 5

Page 10

Advanced Control Equipment ACETM Description

2. Description

The ACE

distributed computer control system. Siemens Airfield

Solutions’s Advanced Control Equipment ACE

TM

is at the heart of Siemens Airfield Solutions’s

TM

(Figure 1) is

the remote interface between the ALCS and any controlled

element in the airfield lighting vault.

The ACE

TM

is a universal device that can be used to control any

type of CCR and/or controlled element regardless of the

manufacturer. Each CCR and Controllable item will be

connected to an ACE

TM

. The ACETM is a microprocessor based

module that includes all of the communication, control

commands, input/output interface, and failsafe functionality

(Figure 2) for the controlled element.

.

F

IGURE 1. Advanced Control Equipment ACE

TM

1. Top Mounting Holes 2. Bottom Mounting Holes 3. ACE

4. ACETM Control/Monitor Display 5. Bottom Cable Access Plate

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 6

TM

Front Cover

Page 11

Advanced Control Equipment ACETM Description

2

2. Description (contd.)

3

5

6

4

1. Bottom Access Plate (Conduit Entry) 2. Ground Lug 3. Power Supply Printed Circuit Board

4. Input/Output Printed Circuit Board 5. Processor Printed Circuit Board 6. Lamps Out Printed Circuit Board

IGURE 2. Advanced Control Equipment ACE

F

TM

Internals

ACE™ Power Supply

Circuit Board

Each ACE

components. The following is a summary of the internal

components of the ACE

The ACE

figure 2) provides each of the printed circuit boards with a

TM

will have identical and interchangeable internal

TM

.

TM

Power Supply Printed Circuit Board (Shown in

regulated and isolated power source.

ACE™ Input / Output Circuit

Board

The ACE

figure 2) provides the interface for all control and monitoring

connections. This board incorporates a distribution bus for

TM

Input / Output Printed circuit board (Shown in

interfacing internal boards. In addition, the quick-disconnect

terminal blocks provide an easy to service point of connection.

The Input / Output Printed circuit board contains eight (8)

discrete latching relay outputs and eight (8) discrete input lines.

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 7

Page 12

Advanced Control Equipment ACETM Description

2. Description (contd.)

ACE™ Processor Circuit Board

ACE™ Lamps Out Circuit

Board

ACE™ Front Panel Display

Circuit Board

The ACE

is the brain behind the design. It provides an interface for the

redundant communication network, RCN, which is how ACE

TM

Processor Printed Circuit Board (Shown in figure 2)

™

receives and transmits data to the ALCS vault computer. For

easy access when connecting the redundant communication

network to the ACE™, the board includes both RJ-45 plugs and

quick-disconnects. In addition, the processor board contains a

fiber optic interface for the optional Insulation Resistance

Monitoring System.

The ACE™ Lamps Out Printed Circuit Board (Optional, Shown

in figure 2) consists of a processor which interfaces, over a fiber

optic serial communications link, with up to three Current and

Voltage sensor modules. Siemens Airfield Solutions’s Current

and Voltage Sensor Module, which is mounted inside the CCR

and is required with the Lamps Out monitoring option, measures

current and voltage waveforms. In addition to RMS voltage,

RMS current, apparent power (VA), true power, and power

factor, the Lamps Out Printed Circuit Board, in turn, calculates

the number of lamps burnt out (Up to 16) at each brightness

level. The Lamps Out Board can be expanded, from single

circuit monitoring capability, to monitoring of up to nine (9)

circuits (Additional Circuit Boards).

TM

The ACE

Control/Monitor Display (Shown in figure 1)

provides a local control and monitoring interface for each

controllable element. The display consists of several LEDs that

give status indication of the ACE

™

, CCR brightness step, CCR

remote/local status, CCR primary power, circuit current or

voltage readings, and RCN channel status.

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 8

Page 13

Advanced Control Equipment ACETM Description

2. Description(contd.)

CONTROL

COMMANDS

FROM TOWER

VAULT

COMPUTER

COMMUNICATION

SERVER

ACE

ACE

CONFIRMATION OF

COMMANDS SENT TO

TOWER

REDUNDANT

COMMUNICATIONS

NETWORK

TYPICAL RUNWAY CCRs

ACE ACE ACE

TYPICAL TAXIWAY CCRs

ACE ACE

ACE

OTHER CONTROLLABLE DEVICES

(BEACON, WINDCONE, etc.)

ACE ACE ACE

A. Lighting commands are generated in the tower cab by air traffic controllers.

B. Lighting commands are communicated, over the main airfield lighting communications network, to the electrical vault

computer.

C. The electrical vault computer, in turn, passes the lighting commands to the communication server.

D. The communications server broadcasts the lighting commands over the ACE™ Redundant Communications Network.

E. Finally, the ACE™ unit with the corresponding address that the lighting command is directed to executes the command.

F. The command is internally confirmed by the ACE™ and a confirmation is sent back to the tower computer.

IGURE 3. Signal Flow Diagram of Typical Airfield Lighting Electrical Vault

F

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 9

Page 14

Advanced Control Equipment ACETM Theory Of Operation

3. Theory of Operation:

ACE™ Communication:

The ACE

airfield lighting distributed control system. Distributed control

technology has many advantages over traditional central control,

including; Cost effectiveness; System expandability; Ease of

maintenance; Ease of installation; Interchangeable parts; Ease of

troubleshooting. In a distributed control scenario, each ACE

unit is locally installed at or near a controllable item (CCR,

Generator, ATS, etc.). Each ACE

airfield lighting control network and execute remote lighting

commands (Figure 3). The number of ACE™ units that can be

daisy-chained together is virtually unlimited, thus system

expansion is made easy.

The ACE

type of CCR and/or controlled element regardless of the

manufacturer. The ACE

inside a small and rugged environmental enclosure that can be

wall mounted or directly attached to the door of a CCR. The

ACE

includes all of the communication, control commands,

input/output interface, and failsafe functionality for the

controlled element.

Each of the ACE

controllable device will have a unique factory set address and a

field programmable communication address. These addresses

are used by the ALCS to direct lighting commands to the

corresponding ACE

commands and returns the operational status of the element back

to the ALCS.

Each ACE™ is connected to redundant communication

networks via duel resident RS-422 serial communication ports

located on the processor printed circuit board. The ACE™

network is comprised of a communications server and all the

daisy-chained ACE™ units in the lighting vault. The

communications server stays in constant communication with all

the ACE™ units in both of the networks while at the same time

staying in constant contact with the main ALCS network. This

communications protocol dictates that the local ACE™ store all

data and parameters specific to the controlled element. This

characteristic frees up the ALCS computers from having to store

the parameters for each of the controlled elements. The result of

this is real-time communication between all of the ACE™ units

and the rest of the ALCS even if one of the ACE™ network

connections fails.

TM

represents the heart of Siemens Airfield Solutions’s

TM

would, in turn, talk with the

TM

is a universal device that can be used to control any

TM

printed circuit boards are mounted

TM

consists of a microprocessor-based module(s) that

TM

units connected to a CCR or other

TM

. The ACETM in turn executes the

TM

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 10

Page 15

Advanced Control Equipment ACETM Theory Of Operation

3. Theory of Operation: (contd.)

ACE™ Input/output interface:

ACE™ Failsafe Functionality:

The ACE

TM

design is modular in nature. The input/output board

incorporates a distribution bus for interfacing additional internal

printed circuit boards. Adding additional boards give the

ACE™ the potential of full FAA L - 827 CCR monitoring.

In addition, the quick-disconnect terminal blocks provide an

easy-to-service point of connection. The input / output printed

circuit board contains eight (8) discrete latching relay outputs

and eight (8) discrete input/output lines.

The latching output relays can be configured to control

brightness steps of CCRs or simple ON/OFF control as required

by the controlled element. The input lines can be configured to

monitor any external event that is determined by a discrete

contact closure. Some examples include generator monitoring,

monitoring of Automatic Transfer Switch position, and control

of Circuit Selector Switch loops. In addition, the ACE

TM

can be

expanded to perform CCR output voltage and current

monitoring (OPTIONAL) as well as field circuit cable Insulation

Resistance Monitoring (OPTIONAL).

Each ACE™ unit will provide a self-contained failsafe feature.

This feature will insure default airfield lighting operation in the

event of an ALCS component failure or even a complete ALCS

failure. In addition, each ACE™ monitors its outputs and

verifies proper commands are executed. The failsafe system

also permits maintenance of portions of the control system

without changing the operational status of the lighting system.

The failsafe mode of each ACE™ unit is defined per the

requirements of the airport/owner. The failsafe modes are as

follows:

CTIVE FAILSAFE MODE: This mode is executed as follows:

A

If the CCR was switched ON before the failure, it will remain

ON at the same brightness level.

If the CCR was switched OFF before the failure, it will

switch ON to a pre-determined brightness level.

ASSIVE FAILSAFE MODE: This mode is executed as follows:

P

If the CCR was switched ON before the failure, it will remain

ON at the same brightness level.

If the CCR was switched OFF before the failure, it will

remain OFF.

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 11

Page 16

Advanced Control Equipment ACETM Installation Instructions

4. Installation Instructions

ACE™ Mounting Location:

ACE™ Mounting Orientation:

Locate each ACE™ unit as close as possible to each of the

controllable elements (i.e. Regulator, Generator etc.). Exact

locations should be coordinated with the Airport / Engineer.

Each ACE™ must be mounted flush against a wall or on U-rails

that will support all four (4) corners. The unit must be oriented

as seen in

Figure 4.

Top Mounting Holes (Slotted)

Figure 4: Advanced Control Equipment

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 12

Bottom Mounting Holes (Round)

Page 17

Advanced Control Equipment ACETM Installation Instructions

4. Installation Instructions (contd.)

ACE™ Mounting Instructions:

D. Remove the six (6)

screws that attach the

BOTTOM access

plate to the enclosure

as seen in Figure 5.

There are three (3)

screws on each side.

Important Note: The ACE™ enclosure is designed such that

the unit can be replaced easily without having to remove any of

the mounting hardware. Follow these instructions closely.

A. Position the enclosure flush on its mounting surface and

mark the mounting holes in all four (4) corners. Make sure to

mark the top portion of the slotted mounting hole as seen in

Figure 4. Mounting hardware must fit through lower opening

of the top slotted mounting holes as seen in Figure 4.

B. Drill out th e marked holes and insert anchor hardware as

required.

C. Carefully remove the lid of the enclosure and disconnect

the grounding strap from the main enclosure.

Figure 5: Bottom access plate screw removal

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 13

Page 18

Advanced Control Equipment ACETM Installation Instructions

4. Installation Instructions (contd.)

E. Remove the BOTTOM

access plate from the

main enclosure as seen

in Figure 6, and put

aside temporarily.

F. Mount the MAIN

enclosure using the top,

slotted mounting holes

and secure as seen in

Figure 7.

Figure 6: Removal of bottom access plate

Place large opening over screw and pull down

securing the top mounting holes.

Figure 7: Securing the main enclosure

G. Re-attach the BOTTOM access plate to the main enclosure

using the six (6) screws.

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 14

Page 19

Advanced Control Equipment ACETM Installation Instructions

4. Installation Instructions (contd.)

Mount the BOTTOM access

H.

plate using the bottom, round

mounting holes as seen in

Figure 8.

Figure 8: Securing the bottom access plate

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 15

Page 20

Advanced Control Equipment ACETM Installation Instructions

4. Installation Instructions (contd.)

ACE™ Cable Entry and Wiring:

A. Attach all conduit as

required to the bottom

access plate ONLY as seen

in Figure 9.

Siemens Airfield

Solutions

removing the MAIN

enclosure while drilling

and attaching conduit to the

BOTTOM access plate.

Make sure not to damage

internal electronic

components during

installation of enclosure.

DO NOT blow out

enclosures as metal

shavings can damage the

electronics.

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

recommends

Figure 9: Conduit and Cable entry locations

Important Note: All conduit and wiring must only enter the

ACE™ enclosure through the bottom access plate. This will

facilitate quick maintenance and replacement of the ACE™

unit.

Top

Conduit and Cabling

through bottom access plate only

96A0245D Page 16

Page 21

Advanced Control Equipment ACETM Installation Instructions

N

N

4. Installation Instructions (contd.)

ACE™ Wiring:

GND

Pull control, monitor and power wiring as required and terminate as

indicated on the “System External Wiring Diagrams” which are

included with ALCS system prints.

120VAC

A

TB 1

TB 2

Primary Network Connection

CHA

CHB

To Next ACE Un it

To Next ACE Un it

Secondary Network Connection

B

TB 3

120VAC 120VAC 120VAC 120VAC

TB 4

CC B1 B2 B3 B4 B5 CCI

ADB

CCR Terminal Block

A. Terminal blocks TB1 and TB2 are system latching relay ou tp uts that are used to control brightness steps of a CCR.

These output can also be configured to control any element that requires an ON/OFF contact closure. In addition, these

terminal blocks can be configured to control both CCR brightness steps and a L – 847 – X Circuit Selector Switch.

B. Terminal blocks TB3 and TB4 accept any discrete contact closure that uses a 120VAC control voltage. Examples of

useful inputs are: CCR Over Current, CCR Over Voltage, CCR Primary Power, CCR Remote Local, CCR Open Circuit,

CCR Access Door, etc.

Figure 10. Generic Terminal Block wiring example with terminal block definitions

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 17

Page 22

Advanced Control Equipment ACETM Installation Instructions

4. Installation Instructions (contd.)

CH

CH

A

B

ACE Communications Server

12345678

ABCH

RJ4

5

RJ45

Vault Computer

Figure 11. ACE™ communications network generic wiring diagram. For specific wiring diagrams of these connections

please consult “System External Wiring Diagrams” which are included with ALCS system prints.

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 18

Page 23

Advanced Control Equipment ACETM ACE™ Troubleshooting

5. ACE™ Troubleshooting

In the unlikely event that an ACE™ unit is determined to be

malfunctioning, the following guide will help to diagnose the

problem and provide a solution to quickly get the unit

functioning properly. Before beginning, remember improper or

incorrect wiring is the cause of most problems. So, first check

all wiring for lose connections or possible electrical

shorts/opens.

Problem Possible Solution

Make sure the main power LEDs on the input/output printed circuit

board are illuminated. If these LEDs are not illuminated then

power to the ACE™ is not being supplied. Make sure the ACE™

Power supply printed circuit board (Figure 10) is receiving 120VAC

at the main power quick disconnect terminal block. Make sure that

all wire connections are secure.

ACE™ Front Panel Status LED not

illuminated

ALCS reporting failed communication

with a specific ACE™

Channel A LED not Flashing

If the main power LEDs on the input/output printed circuit board

are illuminated, make sure the ribbon cable that connects the front

panel display to the ACE™ processor board is secure.

The ACE™ design allows for additional printed circuit boards to be

added to the basic system. Due to the nature of how the additional

boards are connected to the existing boards it is necessary to make

sure that the additional printed circuit boards are seated in their

connector.

Check for power indication. If all of the boards have power, refer to

the Processor board LED description table (Table 1) for normal

operation of each of the LEDs: If any of the LEDs are not

functioning as described in the table, cycle ACE™ power and

recheck. If problem still occurs contact your Siemens Airfield

Solutions service representative.

Cycle power to the ACE™ unit. If the problem still persists turn off

the power to the ACE™ and inspect all wires and wire terminations

for loose or degrading wire. Check the continuity of the wire

connecting the defective ACE™ and the next device in the ACE™

network. If the problem still persists contact your Siemens Airfield

Solutions service representative.

Cycle power to the ACE™ unit. If the problem still persists turn off

the power to the ACE™ and inspect all wires and wire terminations

Channel B LED not Flashing

for loose or degrading wire. Check the continuity of the wire

connecting the defective ACE™ and the next device in the ACE™

network. If the problem still persists contact your Siemens Airfield

Solutions service representative.

Either of the Internal Processor Board

Diagnostic LEDs is frozen on or off.

If either of the LEDs is frozen, cycle the power to the ACE™. If

the problem still persists contact your Siemens Airfield Solutions

service representative

Make sure the power LED, on the lamps out board, is on. If it is not,

turn the power to the ACE™ off. Check the integrity of the header

Lamps out board LED not flashing

connection on the lamps out board. Turn the power to the ACE™

on. If the problem still persists contact you Siemens Airfield

Solutions service representative.

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 19

Page 24

Advanced Control Equipment ACETM ACE™ Troubleshooting

5. ACE™ Troubleshooting (contd.)

All of the ACE™ printed circuit boards have power indication

LEDs. There is a bank of three LEDs located on the input /

output board. These LEDs indicate the status of the raw DC

voltage, regulated DC voltage, and board Reset status. All three

of these LEDs should be on when there is power to the ACE™.

The second bank of LEDs indicate communication status and

internal processor board diagnostic status. The following table

summarizes the function of these LEDs. This bank of LEDs

also form binary error codes. These codes are used by Siemens

Airfield Solutions to determine board level problems.

Circuit Board Label LED description Normal working operation

D10 Processor board Power Always on

D6 Internal Processor Board Diagnostics Flashing

D7 Internal Processor Board Diagnostics Flashing

D8 Only used for error codes Off

D9 Only used for error codes Off

D2 Local Debug Communications Port Status Flashing If Laptop is connected

D3 Lamps Out Board communications Port Status

D4 Channel B Communications Port Status Flashing

D5 Channel B Communications Port Status Flashing

Table 1: Processor board LED description

Flashing If lamps out board is

connected

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 20

Page 25

Advanced Control Equipment ACETM Parts

6. Parts

Introduction

Using the Illustrated Parts List

Item Description Part Number Quantity Note

S1 Assembly

NS Part

H1 Part or Assembly

Part/Assembly for option 1 xxxxxxxx 2

Part/Assembly for option 2

T1 Assembly xxxxxxxx 1

Part

NOTE A

Part

To order parts, call Siemens Airfield Solutions Customer Service or your

local Siemens Airfield Solutions representative. Use this five-column parts

list, and the accompanying illustration, to describe and locate parts

correctly.

This subsection describes how to use the illustrated parts list covered later

in this section. It does not provide the actual parts list.

The Item column numbers correspond to the numbers that identify parts in

illustrations following each parts list. NS (not shown) indicates that a listed

part is not illustrated.

The Description column gives the part name, as well as its dimensions and

other characteristics when appropriate. Indentions show the relationships

between assemblies, subassemblies, and parts.

The Part Number column gives the Siemens Airfield Solutions part number.

The Quantity column contains the quantity required per unit, assembly, or

subassembly. The code AR (As Required) is used if the part number is a

bulk item ordered in quantities or if the quantity per assembly depends on

the product version or model.

The Note column contains letters that refer to notes at the end of each parts

list. Notes contain special ordering or product/part version information.

xxxxxxxx 1 A

xxxxxxxx 1

xxxxxxxx 2

xxxxxxxx 1

xxxxxxxx 2

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 21

Page 26

Advanced Control Equipment ACETM Parts

ACE™ Part Numbering System

44A6016 - X X X X

Figure 12: ACE™ with Hinged Enclosure Part Numbers

Figure 12 shows how to determine the part number for an ACE with hinged

enclosure. Figure 13 shows how to determine the part number for an ACE

without hinged enclosure.

Display Board

0 = With Display Board

1 = Without Display Board

Input Power Monitoring

0 = Without Input Power

Monitoring

1 = With Input Power Monitoring

Field Circuit Monitoring

0 = No Field Circuit Monitoring

1 = Monitors 1 Field Circuit

2 = Monitors 2 Field Circuits

3 = Monitors 3 Field Circuits

4 = Monitors 4 Field Circuits

5 = Monitors 5 Field Circuits

6 = Monitors 6 Field Circuits

7 = Monitors 7 Field Circuits

8 = Monitors 8 Field Circuits

I/O PCB Assembly

A= I/O PCB Assembly, De-populated:

8

Input, 8 Output

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 22

Page 27

Advanced Control Equipment ACETM Parts

ACE™ Part Numbering System

(contd.)

44A4830 - X X X X

Figure 13: ACE™ without Hinged Enclosure Part Numbers

Display Board

0 = With Display Board

1 = Without Display Board

Input Power Monitoring

0 = Without Input Power

Monitoring

1 = With Input Power Monitoring

Field Circuit Monitoring

0 = No Field Circuit Monitoring

1 = Monitors 1 Field Circuit

2 = Monitors 2 Field Circuits

3 = Monitors 3 Field Circuits

4 = Monitors 4 Field Circuits

5 = Monitors 5 Field Circuits

6 = Monitors 6 Field Circuits

7 = Monitors 7 Field Circuits

8 = Monitors 8 Field Circuits

I/O PCB Assembly

A= I/O PCB Assembly, De-populated:

8

Input, 8 Output

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 23

Page 28

Advanced Control Equipment ACETM Parts

Spare Parts

Siemens Airfield

Part Description

The following tables describe part number assignments for the

ACE™ unit. Since the ACE™ is modular in design, Table 2

shows what Siemens Airfield Solutions part numbers to use in

the event a whole ACE™ is to be ordered. The second table

shows individual component part numbers of the ACE™ unit.

Solutions Part

Number

44A4830/1000 Basic ACE™ wall mount unit. This part number alone does not include the lamps out

monitoring printed circuit board.

44A4830/1000

94A0259/XX

44A4830/1000

94A0260/XX

44A4830/1000

94A0259/XX

94A0260/XX

Siemens Airfield

Basic ACE™ wall mount unit including XX (X ranges from 01 to 09) number of field circuits to

monitor current and voltage. This part number will also include the Current and Voltage Field

Sensor Unit.

Basic ACE™ wall mount unit including XX (X ranges from 01 to 09) number of field circuits to

monitor Insulation Resistance. These part numbers will also include the Field Sensor Unit.

Basic ACE™ wall mount unit including XX (X ranges from 01 to 09) number of field circuits to

monitor current and voltage, and number of field circuits to monitor Insulation Resistance

Table 2 Complete ACE™ assembly part numbers

Part Description

Solutions Part

Number

44A4801 ACE™ Processor Printed Circuit Board

44A4800 ACE™ Input / Output Printed Circuit Board

44A4850 ACE™ Power Supply Printed Circuit Board

44A44A4802/1 ACE™ Lamps Out Printed Circuit Board Populated for 1 field circuit

44A44A4802/2 ACE™ Lamps Out Printed Circuit Board Populated for 2 field circuits

44A44A4802/3 ACE™ Lamps Out Printed Circuit Board Populated for 3 field circuits

44A4803 ACE™ Front Display Printed Circuit Board

44A5904 ACE™ Front Display Lexan Overlay with Overlay Switches

70A0525/03 ACE™ Power Printed Circuit Board Power Connector Plug, 3 Position

70A0525/06 ACE™ Processor Printed Circuit Board Primary and Redundant Communications port

Connector Plug, 6 Position

70A0525/08 ACE™ Input / Output Printed Circuit Board Connector Plug, 8 Position

56A0386 ACE™ Enclosure Assembly

Table 3 ACE™ assembly part numbers

2001 ADB Airfield Solutions, LLC

All rights reserved Issued 5/01

96A0245D Page 24

Loading...

Loading...