Page 1

z Allen Products Co., Inc. Signal Hill, Ca 90755 (562) 424-1100 Rev. 00 8/20/12

Gridlink TM One-Way-Array SAS-1WA-30

Work Instruction

1. Read and understand the procedure before starting. If you have any questions, ask engineering.

2. Make sure to have all the parts and materials for packing.

Qty: Description Qty: Description

2 pc Universal Cross Arm 1 pc Hardware kit

1 pc ATM logo, 1.5 OD round 4 pcs Inserts, end caps, black

1 pc Hex bolt, ½-13 x 4.5” long with cross drill hole (grd 8) 4 pcs 1/4-20 x 3/4” long screw, black

2 pcs 1/2” Fender washer, black 8 pcs 1/4” Flat washer, black

1 pc Nylon friction washer, 1.5” OD x .5” ID x .125” thk, white 4 pcs 1/4-20 Nylock nut, black

1 pc Product/Lot label 4 pcs 5/16-18 Eyebolt, black

2 pcs Barcode label 8 pcs 5/16” Flat washer, black

1 pc Package label 4 pcs 5/16-18 Nylock nut, black

1 pc Carton (5 X 5 X 36) 1 pcs Cotter Pin, 3/32” dia., silver

3. Check the arms for dimensions, holes, and cosmetics. Any defect is cause for rejection and/or rework.

4. Apply a product/lot label “SAS-1WA-30” on the inside of one

cross arm.

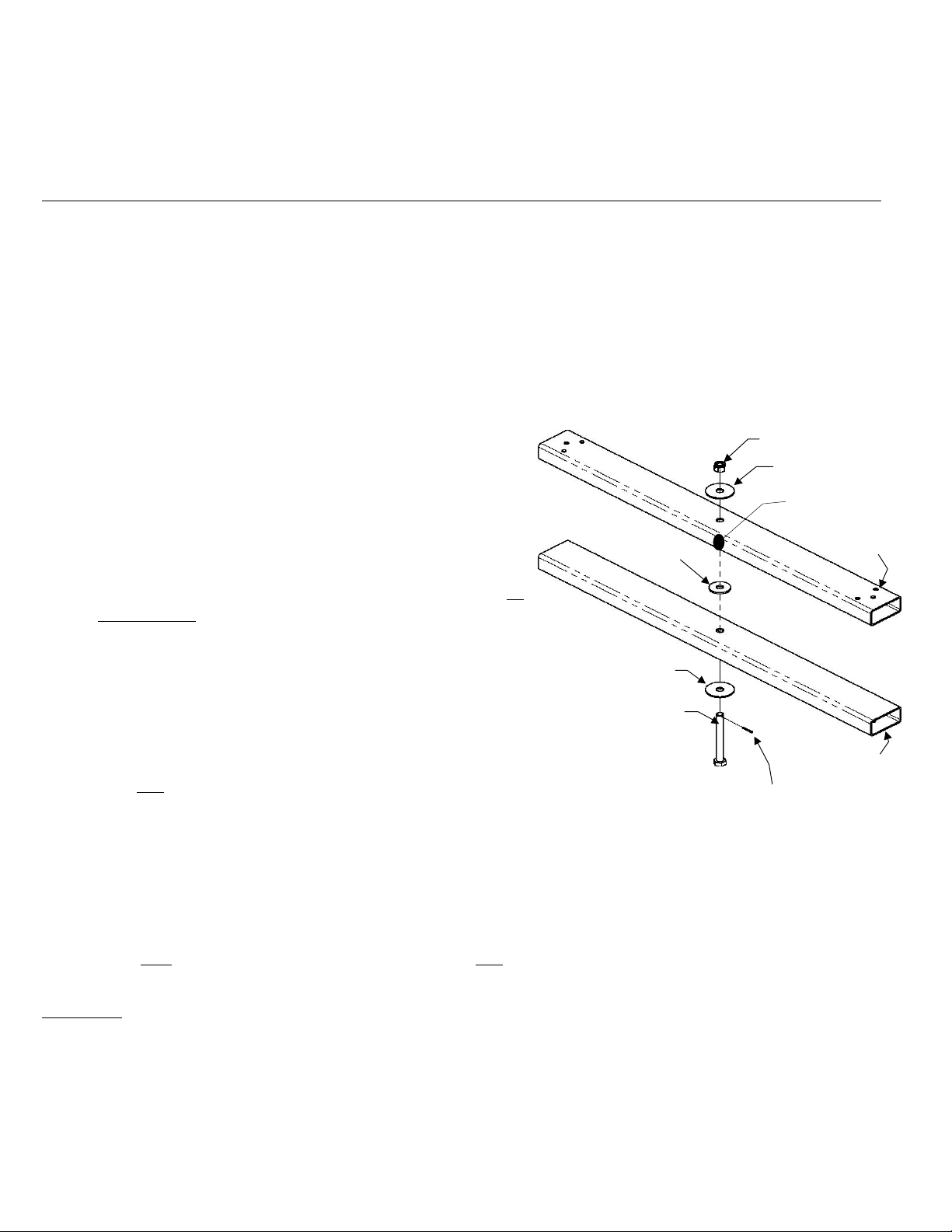

5. With the series of cross arm holes facing away from each

other, assemble the cross arms together with the nylon washer

in between the arms. Insert the bolt through the center of the

cross arms and the nylon washer then secure the bolt with flat

washers and nylock nut (Figure 1). Tighten bolt and nut to 20

ft-lbs torque. Insert cotter pin in hole in 1/2-13 bolt and bend

over end of cotter pin.

6. Apply an ATM logo on the center front of the upper tube of the

One-way array assembly (Figure 1).

7. Insert One-way array into a polytube and seal both ends.

8. Tape one hardware kit securely to one end of the One-way array.

9. Place the One Way Array

TM

into a 36 x 5 x 5 carton.

10. Insert a folder One Way Array

TM

installation instruction sheet into the carton.

11. Make sure the assembly is secure and does not rattle before closing the carton. Seal both ends of the carton.

12. Place one barcode label on each end of the carton and one product label on the top right/rear of the carton.

Important:

Wear gloves to avoid finger printing the painted parts

Be careful to avoid scratching the paint.

Keep finished products clean and protect against scratches and chipping.

DO NOT Place cartons/finished parts on bare floor

Figure 1

FENDER WASHER

1/2-13 NYLOCK NUT

FENDER WASHER

ATM LOGO CENTERED

HOLES

ON TOP

HOLES ON

BOTTOM

NYLON

WASHER

1/2-13 X 4-1/2 BOLT

COTTER PIN is installed AFTER BOLT is inserted

through assembly and AFTER NUT is tightened

Loading...

Loading...