Page 1

HoverTrack® Series 4X2-X462-4X-FS

Assembly Installation Guide 4 Wide Video Wall Floor Stand

This video wall floor stand display the NEC X461 and

X462 monitors in a 4 wide by 2 deep or 4 wide x 3 deep

landscape configuration. The video frame easily attaches to

vertical column by way of bolts and nuts. The floor stand

comes with adjustable feet to compensate for any

unleveled flooring.

Important: Installing video displays is a serious endeavor

that requires experienced professionals. Improperly

assembled floor stands and other structures as well as

the equipment being installed can result in property

damage, injury, death and/or liability to the installing

contractor. Do not proceed if any part of the installation is

in doubt.

Caution: Due to the wide variety of structures,

environments, materials and installation methods, the

installing contractor must exercise good judgment in

selecting the proper area. The base structure must be flat

and capable of supporting the height of the video wall

display. Consult local building codes for further guidance.

Follow these instructions for the most efficient and

safest mounting results.

Package Contents:

3 pcs 4X2-X462-4X-FS-A Vertical column Assembly

8 pcs 4X2-X462-4X-FS-B Horizontal Brace Assembly

6 pcs Adjustable leveler foot, ½-13 thread

13 pcs Hex bolt, 3/8-16 x 5” long, black

48 pcs Hex bolt, 3/8-16 x 3.25” long, black

122 pcs Flat washer, 3/8 SAE,black

61 pcs Nyloc nut, 3/8-16, black

6 pcs End cap, 2 x4, black

Step 1:

Before starting assembly, check included parts list to make

sure all hardware are accounted for.

Step 2:

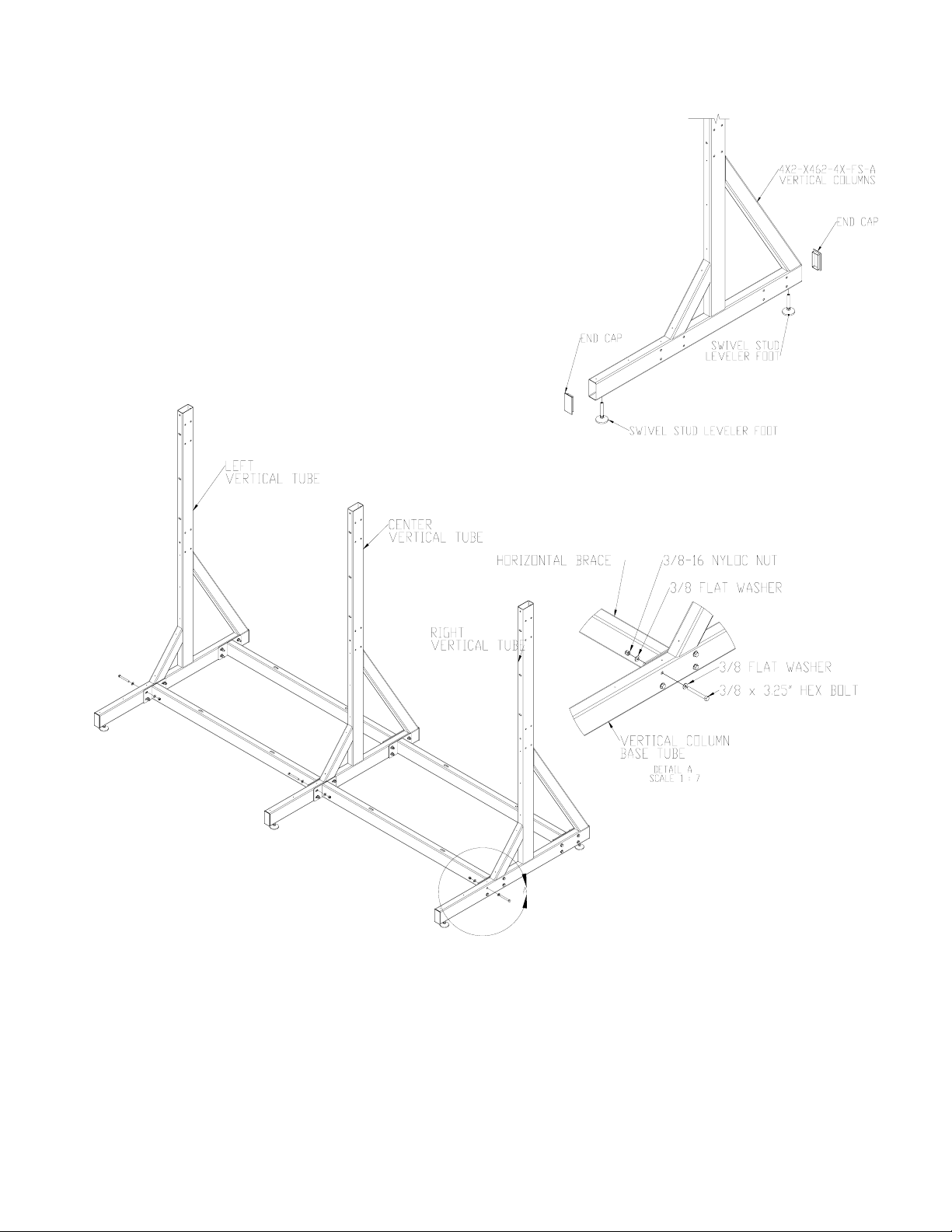

Attach the end caps to both ends of the base tubes (Figure 1).

Step 3:

Screw in the Adjustable leveler foot into the two weld nut under the base tube (Figure 1).

Step 4:

Connect two horizontal brace’s plates to the bottom side of the right vertical columns using the provided 3/8-16 x 3.25” long hex bolt, flat

washer and nuts. Snugly tighten bolts (Figure 2).

4X2-X462-VWD Video Wall on a Floor Stand

© 2012 Adaptive Technologies Group, Signal Hill, CA 90755 USA (562) 424-1100 Rev.00-01/12

Page 2

Step 5:

Attach the other end of the horizontal brace’s plate to the center vertical

column side. Insert bolts through the horizontal brace’s plate and into the

side holes of the vertical column’s base. Position another horizontal brace

on the other side of the center verticals column then secure three pieces

together using the provided bolts, washers and nuts. Snugly tighten bolts

(Figure 2)

Step 4:

Attach the left vertical column to the end of the horizontal brace’s plate and

the secure with the included bolts, washer and nuts (Figure 2).

Step 5:

Attach a horizontal brace to the middle and top of the vertical columns

(Figure 3). Snugly tighten bolts.

Figure 1

Figure 2

Step 6:

Adjust the horizontal braces so they will line up with each other. The slots on the middle horizontal brace must line up with the holes on

the vertical columns (Figure 4). Use a Level to horizontally level the horizontal braces.

Step 7:

Line up the fronts of the three vertical columns. You can stretch the string from the left vertical column to the right vertical column and

they should be straight and evenly touches the fronts of the tubes. Once they are line up tighten bolts permanently.

© 2012 Adaptive Technologies Group, Signal Hill, CA 90755 USA (562) 424-1100 Rev.00-01/12

Page 3

Step 8:

Adjust the adjustable leveler foot to level

and plum of the stand.

Step 9: Install Video Wall Frame

Lift the assembled Video frame to the front

of the stand. Align and match the holes

and slots of the video frames outer most

vertical channels and the center channel to

the stand vertical columns’ holes. Secure

the frame to the stand permanently using

the provided bolt, washers and nuts as

shown figure 5. Use three bolts, washer

and nuts per vertical channel (Figure 5).

Secure the two vertical channels closes to

the center to the stand’s horizontal brace

(Figure 5).

Figure 3

Figure 5

Figure 4

© 2012 Adaptive Technologies Group, Signal Hill, CA 90755 USA (562) 424-1100 Rev.00-01/12

Loading...

Loading...