Page 1

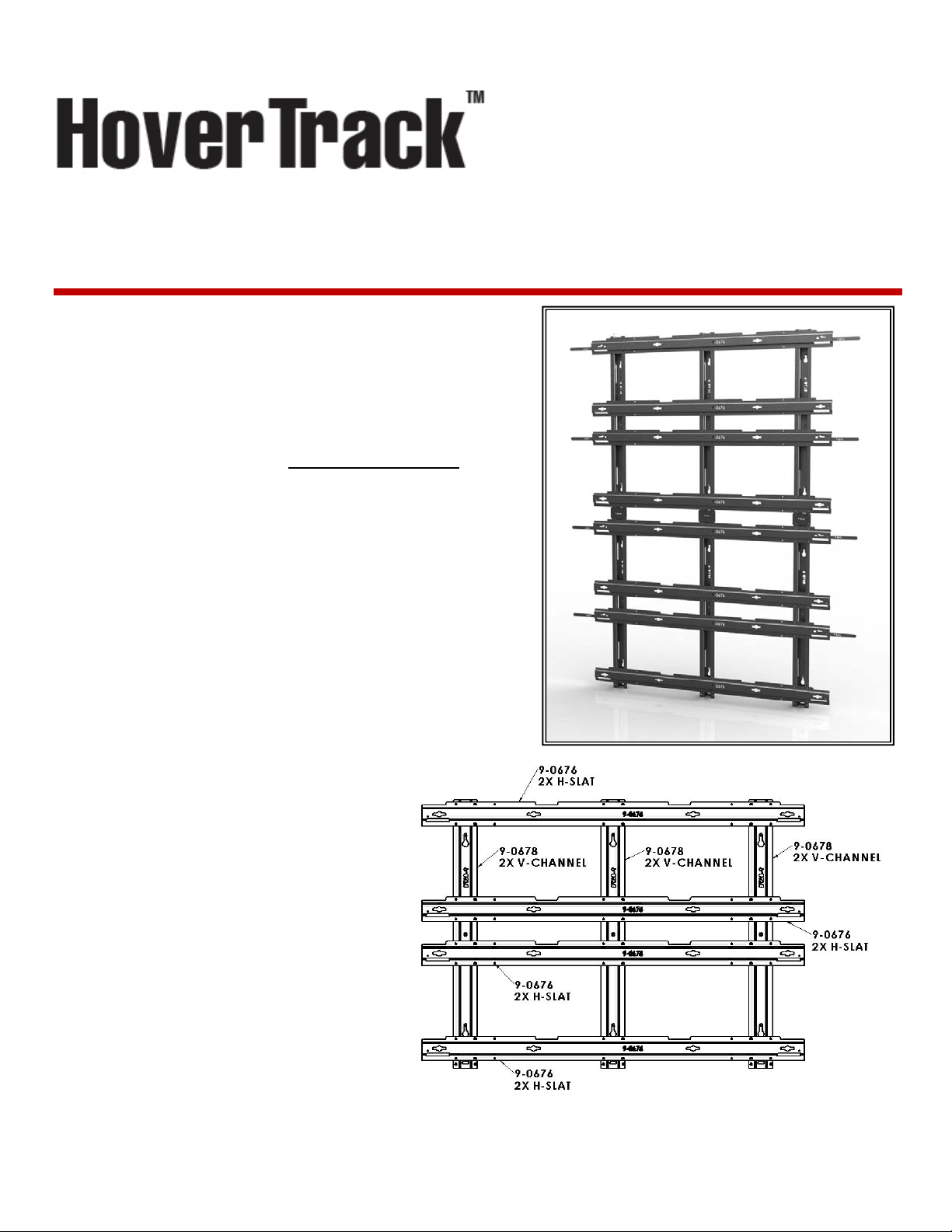

2X4-UE46A -VWD

Assembly Installation Guide

Important: Assembling video displays is a serious endeavor that requires

experienced professionals. Improperly assembled equipment can result in

property damage, injury and/or liability to the installing contractor. Do not

attempt to install this equipment if any part of the assembly is in doubt.

Follow these instructions for the most efficient and safest assemble results.

Do not attempt to install this product if any of the parts listed below are

missing. If parts are missing, contact sales@adapttechgroup.com;

Package Contents:

8 pcs 9-0676 2X H-Slat

3 pcs 9-0678 2X V-Channel Assy.

3 pcs 9-0640 2x lower v-channel assy.

8 pcs 9-0696 Lock Arm Bracket w/ hrdwr

3 pcs 9-0644 vertical Joiner plate

32 pcs M8 adjustable VESA buttons (long shaft)

1 pc Adjustment wrench

18 pcs Adjustable Wood screw Hanger stud

108 pcs Flat head phil. Screw, M6x20mm long

Step 1: Assemble Upper Frame

Place all of the parts in figure 1 on the floor. Start with three 9-0678 2X Vchannels with their open side facing up and with the narrow part of the key

holes slots facing up in all in the same direction.

Place four 9-0676 H-Slats over the 2X V-channels

with the keyhole surface facing up and the four-hole

patterns lining up with that of the V-channels (Figure

1). Rectangular slots in the ends of the H-slats should

be at the outer edge of the frame. (See figure 4).

Step 2: Assemble Lower Frame:

Place all of the parts in figure 2 on the floor. Start

with three 9-0640 2X Lower V-channels with their

open side facing up with the narrow part of the key

holes slots facing up and all in the same direction.

Place four 9-0676 2X H-Slats over the 4X lower Vchannels with the keyhole surface facing up and the

four-hole patterns lining up with that of the channels

(Figure 2). Rectangular slots in the ends of the slats

should be at the outer edge of the frame. (See figure

4).

Upper Frame (Figure 1)

© 2013 Adaptive Technologies Group, Signal Hill, CA 90755 USA (562) 424-1100 Rev.00-02/18/13

Page 2

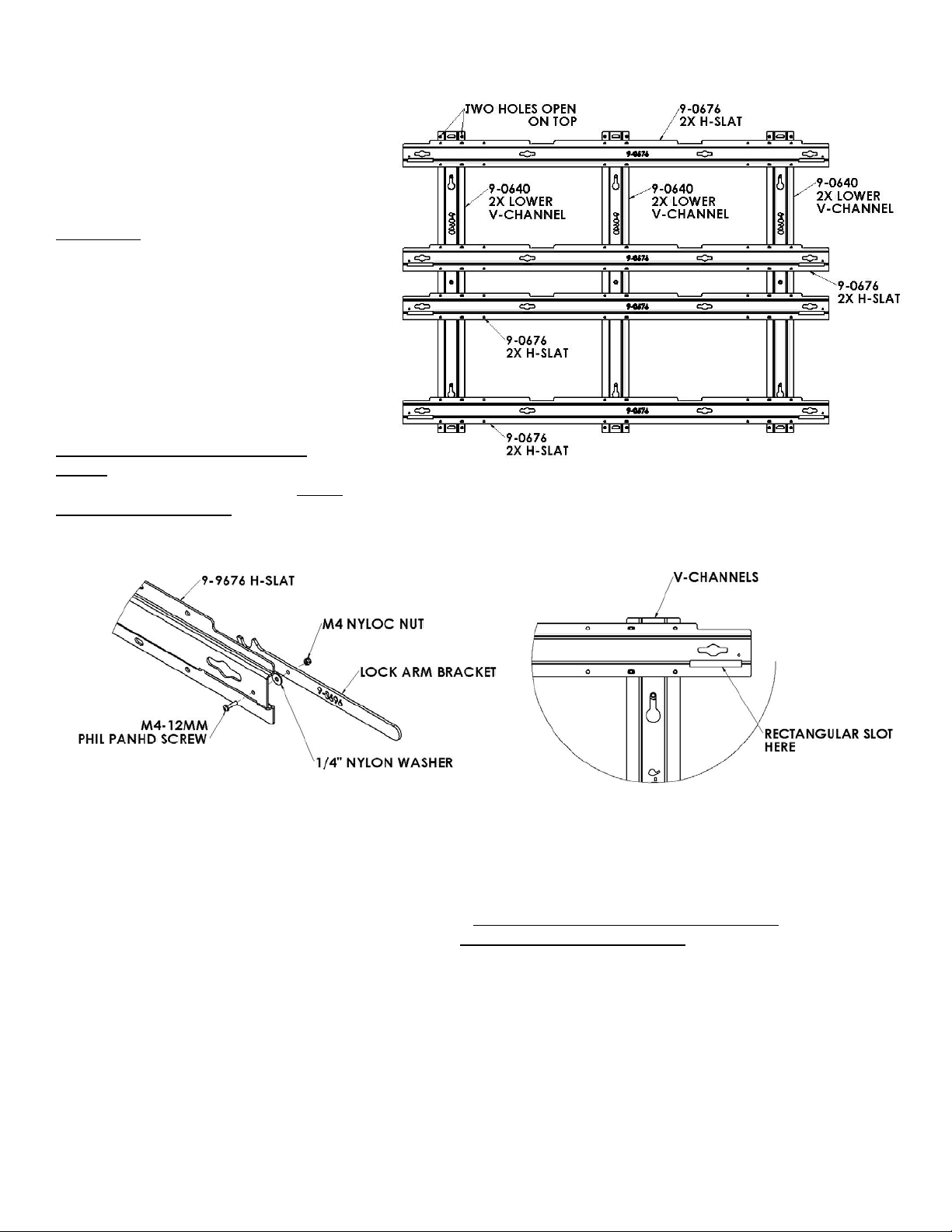

Step 3: Install Locking Arm brackets

Assemble the 9-0696 locking arm bracket on

TWO of the Upper framed 9-0676 H-slat and two

on the Lower frame’s 9-0676 H-slat near the

rectangular slot using the provided M4 screws,

nylon washer and nylock nut (Figure 3). The

locking arm brackets must be installed on the

first and third horizontal H-slats of the upper and

lower frame starting from the top. Make sure the

hook of the locking arm bracket faces up (Figure

3). Tighten screw to increase locking arm

friction.

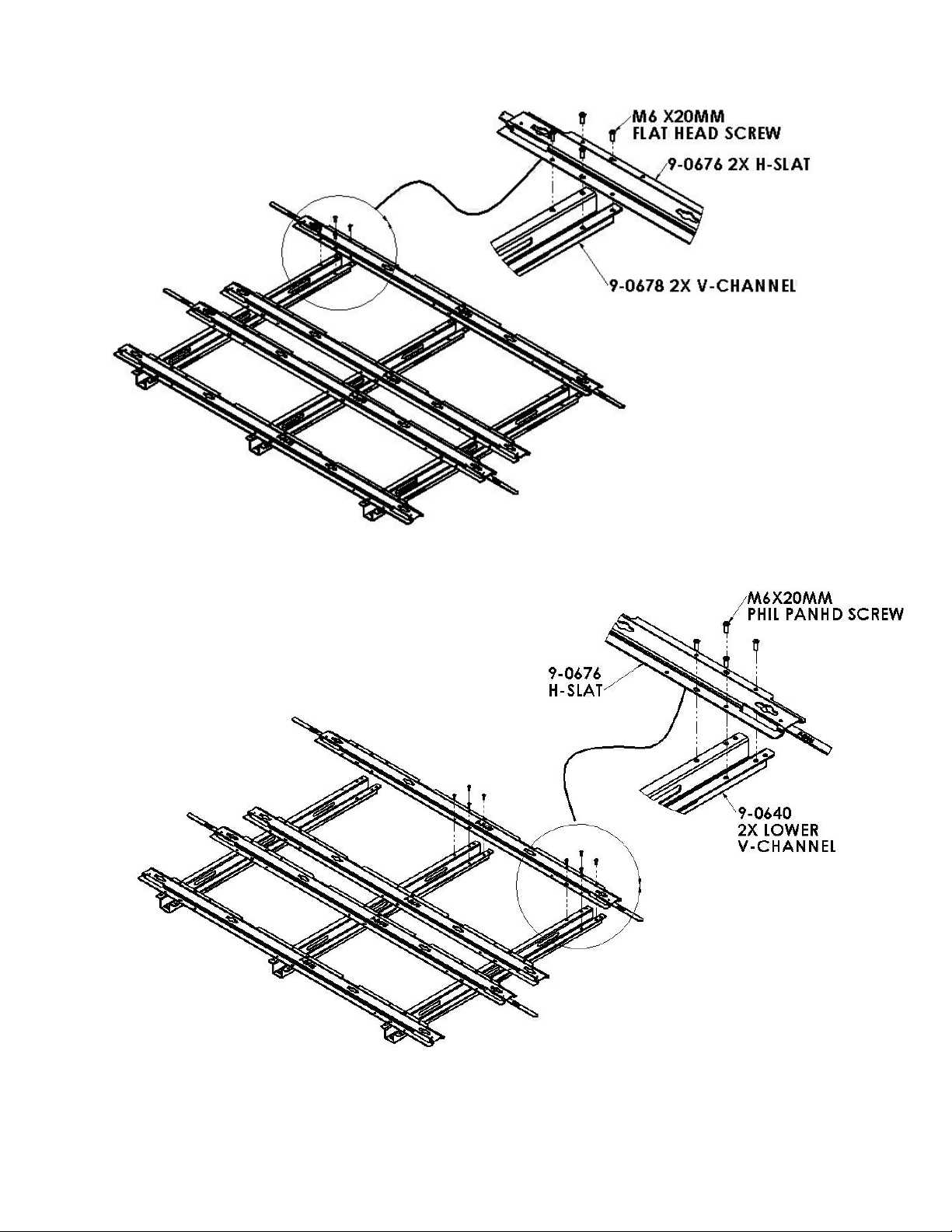

Step 4: Assemble the Upper Frame

Assemble the top upper frame by attaching the

horizontal H-slats, (9-0676 to the 2X V-channels

(9-0678) using the provided M6x20mm long flat

head screws. Screw-in all screws half way first,

do not tighten screws until all screws are

installed. Check for squareness by measuring

corners to corners then tighten screws starting

with the screws on the holes then the screws on

the slots of the H-slats (Figure 5).

Figure 4

Lower Frame (Figure 2)

Figure 3

Figure 4

Step 5: Assemble the Lower Frame

Assemble the top lower frame by attaching the horizontal H-slats, (9-0676 to the 2X lower V-channels (9-0640) using the provided

M6x20mm long flat head screws. Screw-in all screws half way first, do not tighten screws until all screws are installed. Check for

squareness by measuring corners to corners then tighten screws starting with the screws on the holes then the screws on the slots of

the H-slats (Figure 6).

Step 6:

Join the upper frame and the lower frame together using the 9-0644 vertical joiner plate (Figure 7 and main illustration). Tighten

screws permanently.

Step 7:

For wall installation, refer to product installation guide.

© 2013 Adaptive Technologies Group, Signal Hill, CA 90755 USA (562) 424-1100 Rev.00-02/18/13

Page 3

Figure 5

Figure 6

© 2013 Adaptive Technologies Group, Signal Hill, CA 90755 USA (562) 424-1100 Rev.00-02/18/13

Page 4

Figure 7

© 2013 Adaptive Technologies Group, Signal Hill, CA 90755 USA (562) 424-1100 Rev.00-02/18/13

Page 5

2X4-UE46A-VWD

2 Wide x 4 Deep Video Wall Display Installation Guide

This display kit mounts the Samsung UE46A LCD monitors in a 4

wide by 2 deep landscape configurations. The frame attaches to a wall

and receives the LCD monitors by way of four machined fittings (per

monitor) that thread into the monitor’s VESA holes. These fittings then

insert into the frame’s channels. The monitor’s fittings secure to the

frame with locking arms that provide an easy way to remove the

monitors for service.

Important: Installing video displays is a serious endeavor that

requires experienced professionals. Improperly prepared walls and

other structures as well as the equipment being installed can

result in property damage, injury, death and/or liability to the

installing contractor. Do not proceed if any part of the installation is

in doubt.

Caution: Due to the wide variety of structures, environments,

materials and installation methods, the installing contractor must

exercise good judgment in selecting the proper mounting area. The

mounting structure must be capable of supporting at least 5 times the

load of the installed equipment. Consult local building codes for further

guidance.

For a flat mounting surface and adequate support , ALWAYS

install a ¾” backing plywood.

Follow these instructions for the most efficient and safest

mounting results.

Package Contents:

1 pc Frame Assembly w/ locking arms

32 pcs M8 Adjustable VESA button (black)

18 pcs Adjustable Lag bolts, 5/16”x1.5” long

18 pcs Hex nuts, 5/16”

18 pcs Flat washer, 5/16

1 pc Installation guide sheet

Notes:

Hardware to mount frames to wall is included.

© 2013 Adaptive Technologies Group, Signal Hill, CA 90755 USA (562) 424-1100 Rev.00-02/18/13

Page 6

Step 1: Mount Video Frame to Wall

Scribe a horizontal line on the wall showing the exact

location of where the top edge corner of the upper left

monitor will be. Measure down 6.2” (157.5mm) from that

line and scribe another horizontal line showing where the

horizontal location of the first adjustable lag bolt will be

(Figure 1).

Scribe a vertical line showing where the top left side of

the upper monitor will be. Measure to the right 15.9”

(403.9mm) and scribe another vertical line showing where

the vertical location of the first adjustable lag bolts

(Figure 1). Mark the intersection of the vertical and

horizontal lines.

Measure 49.3” (1252.2mm) to the right for the location of

the second adjustable lag bolt. Use a long level to make

sure the second location is horizontally aligned and

leveled to the first lag bolt location (Figure 1). Mark the

second lag bolt location.

Pre-drill the marked lag bolt locations using a 3/16” or

5mm drill bit. Install the first and second adjustable lag

bolts to the pre-drilled holes until the hex part of the bolt is

flush to the wall. A deep socket wrench maybe required.

Figure 1

Figure 2

Step 2:

Hang the frame from the top keyholes to the adjustable lag

bolts (Two people minimum required). Install the provided

hex nut and flat washer over the adjustable lag bolts, level

frame then tighten the hex nuts.

Use the frame as a template to mark the other locations of

the adjustable lag bolts (18 plcs). Use three (3) per Vchannel, two keyholes and the center hole (Figure 2).

Loosen and remove the hex nut and flat washer securing the

frame to the wall then place the frame back on the floor. Predrill marked holes using the 3/16” or 5mm drill bit then install

the other adjustable lag bolts until the hex part of the bolt is

flush to the wall (Figure 2).

Hang the upper frame back onto the adjustable lag bolts

mounted on the wall. Install hex nut and flat washer then

snugly tighten hex nuts. DO NOT TIGTHEN permanently

until the entire video frame is installed and adjusted (Figure

3).

Step 3:

Use a long level to plumb the frame by rotating the adjustable

lag bolts on the V-channels using the provided adjustment

wrench starting from one side of the frame. Rotate counter

clockwise to pull the frame forward and clockwise to push the

© 2013 Adaptive Technologies Group, Signal Hill, CA 90755 USA (562) 424-1100 Rev.00-02/18/13

Page 7

frame back towards the wall (Figure 4). Use a long level, a straight edge or a piece of string secured on each side of the frame to make

g

the horizontal H-slats straight by adjusting the adjustable lag bolts closest to the H-slat. Once the frame is plumbed and leveled, tighten

all hex nuts permanently.

ure 4

Fi

Figure 3

Step 5: Install Monitors to the Left Column

Lift up the locking arms on the left side of the frame. Starting

with the upper left monitor, connect power and signal wires to

each monitor then align its four M8 Adjustable VESA buttons

with the four large slots in the H-slats then slide the monitor

from left to right until it stops. Pull down the locking arm to lock

monitor into place (Figure 6). Repeat step 5 for the lower

monitors.

Step 4: Install Adjustable VESA buttons to monitors

Thread the M8 adjustable VESA buttons to the VESA mounting holes in

the back of each monitor using a Phillips head screw driver (Figure 5).

Figure 5

Step 6: Note on alignment:

While installing monitors, check for front and side alignment of the

monitors. The surfaces of all monitors must be aligned and flush to each

other. If one or more screens are tilted more than others use the

Figure 6

adjustment wrench to reach the hex portion of the M8 adjustable VESA

buttons at the rear of the monitor then rotate counter clockwise to pull the

front of the monitor forward or clockwise to push it back towards the wall. If access to the rear is not accessible remove the screen(s)

and depending whether the monitor needs to be tilted forward or backward rotate the buttons using the adjustment wrench, a phillips

head screw driver or fingers (Figure 7). Reinstall and recheck surface alignments. Repeat where necessary.

© 2013 Adaptive Technologies Group, Signal Hill, CA 90755 USA (562) 424-1100 Rev.00-02/18/13

Page 8

Step 7: Install Monitors to the right Column

Starting with the top monitor, connect the power and signal wires to

each monitor then align its four M8 adjustable VESA buttons with

the four large slots in the H-slats. Slide the monitor from right to left

until it is snug against the left column monitor (Figure 8). Repeat

step 7 for the lower monitor. Check for front and side alignmentsrefer to Step 6.

Servicing Tips

Left Column Monitor Removal

Reach fingers between the left side wall and the monitor and lift the

locking arm to unlock. Slide monitor to the LEFT about 1.00”

(25.4mm) until its VESA buttons disengage from the frame, lift a

little to support the weight of the monitor then slowly pull to remove

(Figure 9).

Right Column Monitor Removal

Reach fingers between the wall and the monitor and lift the locking

arm to unlock. Slide the monitor to the RIGHT until its VESA

buttons disengage from the frame, lift a little to support the weight

of the monitor then slowly pull to remove (Figure 9).

Figure 7

Figure 9

Figure 8

© 2013 Adaptive Technologies Group, Signal Hill, CA 90755 USA (562) 424-1100 Rev.00-02/18/13

Loading...

Loading...