Page 1

Page 2

Declarations

Declarations

Directive 2006/95/EC: Low Voltage Directive

974-0001 E12

975-0001 E15

992-0007 E218

994-0001 E219

Directive 2006/42/EC: Machinery Directive

974-0001 E12

975-0001 E15

992-0007 E218

994-0001 E219

930-0004 E-Frame with Extender Beam

931-0009 E12/E15 - SpekTrix Underhang

938-0015 E12 Dolly

938-0004 E15 Dolly

938-0016 E218 Dolly

938-0020 E219 Dolly

938-0014 Dolly Stacking Legs

BUILT. STRONG.

E-Series | Declaration of Conformity

Page 2

Page 3

WARNING

SAFETY RISK

PAY SPECIAL ATTENTION

PINCH POINT

CAN CAUSE SEVERE

PERSONAL INJURY

TIP HAZARD

ALWAYS MOVE LOADED

DOLLY ON THE LONG EDGE

ATTENTION

IMPORTANT OPERATING

INSTRUCTIONS

Section A

Warning & Safety Symbols

Throughout this manual the potential risks are indicated by these symbols.

ATTENTION

It is compulsory to read this manual before using

the E-Series system. Supervision and competency

are the responsibility of the system owners and

operators. All intersections, joints and rigging hard

ware must be inspected regularly. Operators must

not assume rigging has been inspected prior to use

by someone else.

-

E-Series | Warning & Safety Symbols

Page 3

Page 4

Section A

Safety Precautions

English

• Read these instructions, keep them available for reference, they can

be downloaded any time from https://www.adamsonsystems.com/

index.php/support . Heed all warnings and follow all instructions.

• Servicing is required when the loudspeaker has been damaged in any

way, such as when the loudspeaker has been dropped; or when for

undetermined reasons the loudspeaker does not operate normally.

• Protect the cabling from being walked on or pinched.

• Use only with the rigging frames/accessories specied by Adamson,

or sold with the loudspeaker system.

• This speaker enclosure is capable of creating a strong magnetic

eld. Please use caution around the enclosure with data storage

devices such as hard drives.

• Handles are for moving the system only.

ATTENTION

IMPORTANT OPERATING

INSTRUCTIONS

Francais

• Lire les instructions ci dessous, maintenez-les disponibles pour

référence. Ils peuvent être téléchargés à tout moment à cette

adresse. https://www.adamsonsystems.com/index.php/support

.Tenez compte de tous les avertissements et suivez toutes les

instructions.

• Une maintenance s’avère nécessaire lorsqu’une enceinte a été

endommagé de quelque façon que ce soit. Que celle ci soit tombé

ou qu’elle ne fonctionne pas normalement pour des raisons

indéterminées.

• Protéger le câblage contre l’écrasement.

• Utiliser uniquement les accessoires d’accrochage fourni par

ADAMSON ou vendu avec les enceintes.

• Cette enceinte acoustique génère des champs magnétiques

intenses. Prenez les précautions nécessaires avec les appareilles de

stockage de données comme les disques durs.

• Les poignées ne doivent servir qu’à déplacer l’enceinte.

Espanol Deutsch

• Lea estas instrucciones y téngalas a mano cuando las necesite.

Puede descargarlas cuando desee desde https://www.

adamsonsystems.com/index.php/support. Preste atención a todas

las recomendaciones y siga las instrucciones.

• Debe reparar el altavoz cuando haya algún desperfecto de cualquier

tipo, por ejemplo cuando haya caído o en ocasiones indeterminadas

en que el altavoz no funcione correctamente.

• Proteja el cableado para que no sea pisado o aplastado.

• Utilice solamente los Rigging Frames y accesorios especicados

por Adamson o que vengan con el equipo original de Adamson.

• Este recinto acústico es capaz de generar fuertes campos

magnéticos. Tenga especial cuidado al utilizar dispositivos de

almacenamiento de datos magnéticos como Discos Duros etc.

• Las agarraderas son solo para mover el sistema.

• Lesen sie diese Anleitung und bewahren Sie sie auf. Sie kann jederzeit

unter https://www.adamsonsystems.com/index.php/support

heruntergeladen werden. Beachten Sie alle Warnungen und folgen

Sie allen Anweisungen.

• Service ist notwendig wenn der Lautsprecher in irgendeiner Art

beschädigt wurde, z.B. weil er heruntergefallen ist oder wenn er aus

anderen Gründen nicht ordnungsgemäß funktioniert.

• Schützen Sie die Lautsprecherkabel davor gequetscht oder geknickt

zu werden.

• Verwenden Sie ausschließlich das von Adamson für dieses

Lautsprechersystem spezizierte bzw. das zusammen mit dem

System erworbene Rigging-Zubehör.

• Dieser Lautsprecher kann ein starkes magnetisches Feld erzeugen.

Bitte seien Sie in der Nähe des Lautsprechers z.B. mit Datenspeichern

wie Festplatten entsprechend vorsichtig .

• Die Griffe dienen ausschließlich zum Transport des Lautsprechers

E-Series | Safety Precautions

Page 4

Page 5

E-Series User Manual

Table of Contents

Sections

Introduction & Product Details

1.1 Overview 6

1.2 Predictive Software 7

1.3 E15 Spec Sheet 8

1.4 E12 Spec Sheet 9

1.5 E218 Spec Sheet 10

1.6 E219 Spec Sheet 11

1.7 Cardioid Subs 12

System Configuration

2.0 E-Rack Description 13

2.1 E-Rack Overview 14

2.2 Configuration Example 15

2.3 Wiring Diagrams 16

Rigging

3.0 The 4 Stack Dolly 18

3.1 Rigging Overview 19

3.2 Rear Rigging 24

3.3 Front Rigging 25

3.4 Rigging Sticker Legend 27

3.5 Setting Angles 28

3.6 Attaching the Rigging Frame 29

3.7 Consequent Arrays 31

3.8 Highly Curved Arrays 33

3.9 Lowering the Array 34

3.10 Rigging the E Sub 35

3.11 Attaching Tops to Subs 36

Ground Stacking

4.0 Ground Stacking Legs 38

Truck Pack

5.0 Possible Configurations 39

E-Series | Table of Contents

Page 5

Page 6

Introduction & Product Details

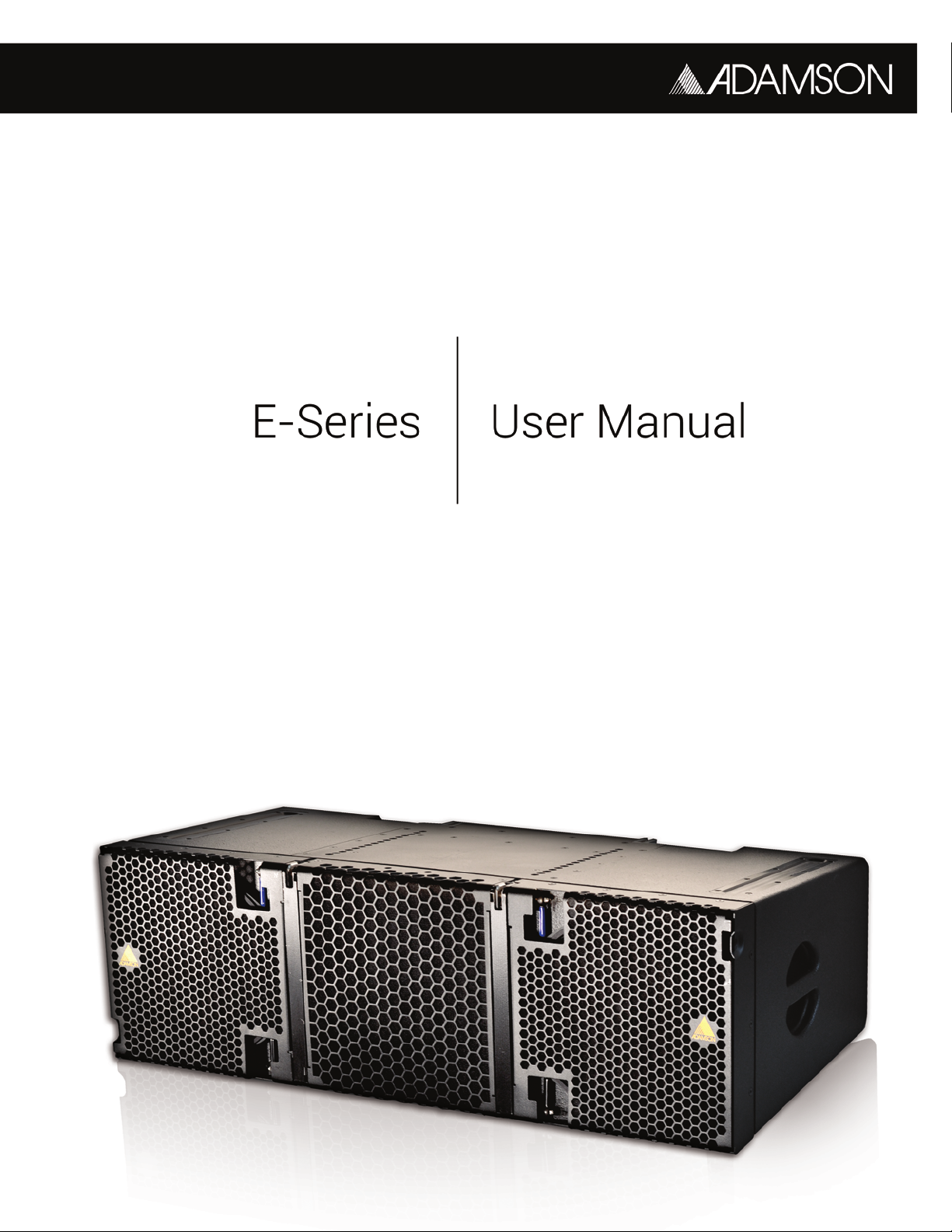

1.0 Introduction

This manual is designed to give the E-Series user the necessary information to accurately fly or

stack E-Series loudspeakers in all the available congurations, as well as the proper deployment

and use of E-Series loudspeakers. Safe step by step rigging procedures will be outlined, as well

as example system congurations, correct wiring and amplication and transport.

1.1 Overview

At Adamson, we believe that loudspeakers need to be built from the ground up. This means

having total control over every aspect of the design and manufacturing process. The E-Series

is the culmination of decades of research that has allowed us to deliver the highest performing,

large format line array on the planet.

At the heart of the E-Series is the E-Capsule. It houses the patented Co-Linear Drive Module - a

revolutionary dual chamber waveguide concept capable of virtually eliminating mid-frequency

lobing in line source designs. The patented Autolock™ rigging system is mounted to this core

rather than the cabinet exterior. One engineer can set angles and hoist the system in tight

quarters using the smallest and lightest rigging frame in the industry. In true Adamson tradition,

Kevlar cones are essential to the design and a part of an unmistakable sonic signature of

unmatched vocal clarity, power and punch.

We’ve set the modern touring standard by using only rugged, durable and light weight materials.

From Marine Grade Baltic birch to Air Craft Grade aluminium and Kevlar Neodymium drivers.

The entire system is designed to maximize use of space in a standard North American or

European truck pack. It features the fastest and most intuitive rigging system available.

E-Series | Introduction & Product Details

Page 6

Page 7

Introduction & Product Details

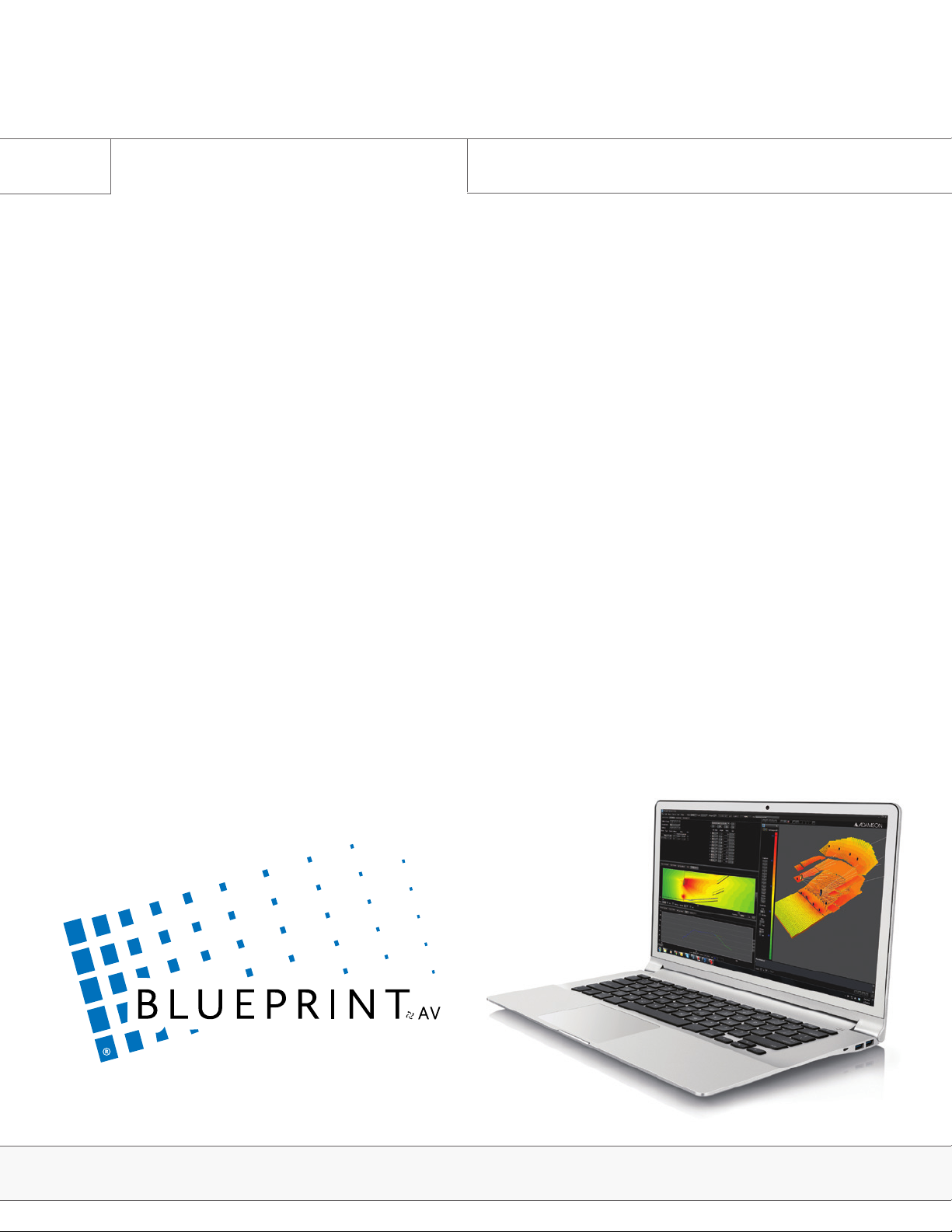

1.2 Predictive Software

Blueprint AV

Blueprint AV is a 2D & 3D modeling suite which offers a fast and intuitive work-flow, without sacricing

precision. The E-Series is included, along with all of Adamson’s other Line Array products. Design is simple

and easy, yet complex simulation options are at your nger tips.

Use basic geometric shapes to design anything from a basic eld to a complex structure. Multi-point

extrude and revolve surfaces allow for intuitive arena or stadium design.

Depending on your time constraints, Blueprint AV can be easily switched from in-depth 3D operation to

streamlined 2D operation, saving on simulation time.

Once your hang is designed, Blueprint gives you all pertinent mechanical information needed to correctly

fly the system.

Blueprint AV is now available as a native Java-run program for both PC and Mac platforms. Please contact

blueprint@adamsonsystems.com for license information and technical support.

E-Series | Introduction & Product Details

Page 7

Page 8

Introduction & Product Details

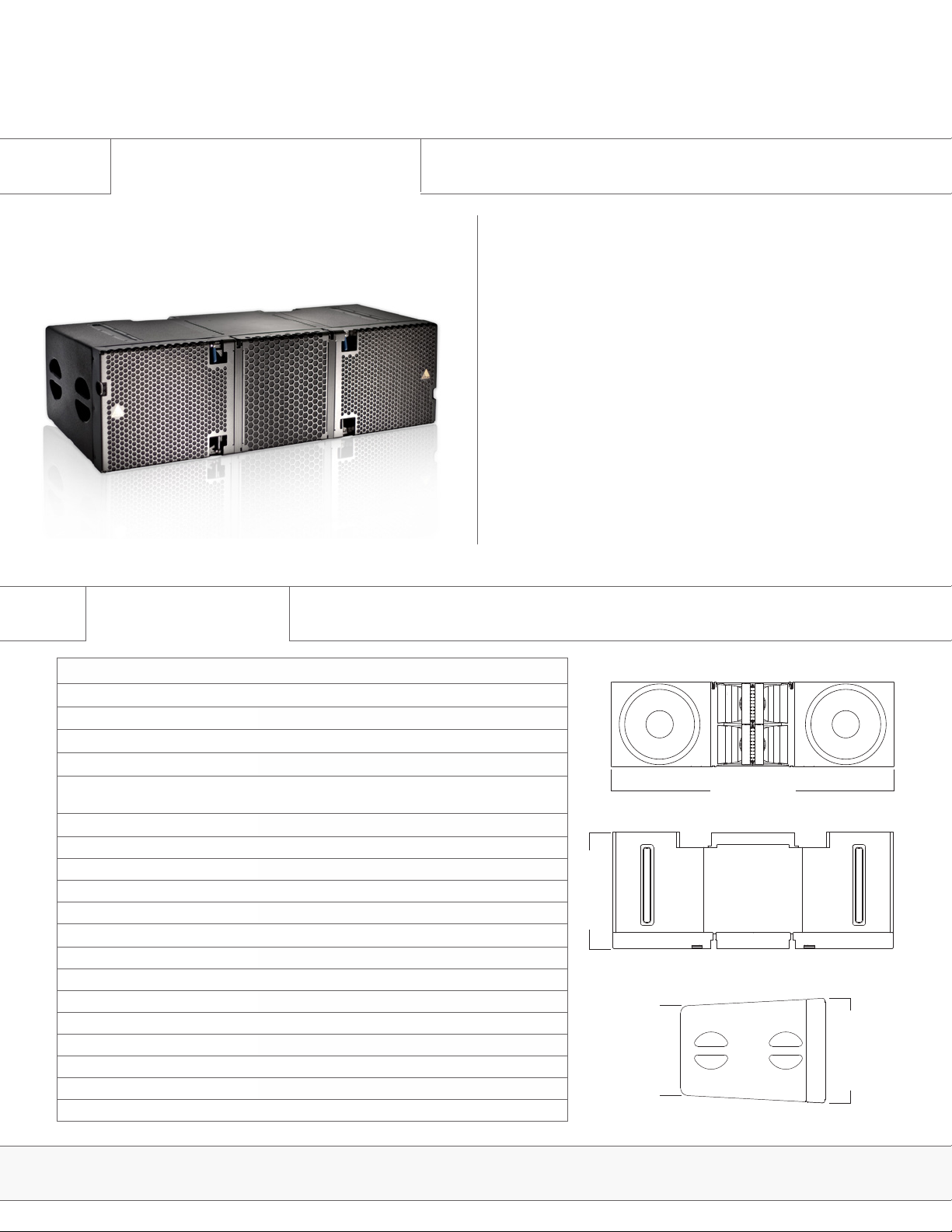

1.3 E15 Spec Sheet

E15

The Adamson E15 is a 3 way, true line source enclosure, incorporating proprietary transducer and waveguide technology which reduces weight and minimizes the footprint. The heart of the E15 is the

E-Capsule, which is precisely engineered and constructed of lightweight

aluminum. The patent pending skeletal structure provides an accurate

and rigid frame for mounting the modular aircraft grade steel Auto-

lock™ rigging system, while simultaneously housing a series of efcient

mid-high components coaxially mounted on Adamson’s pioneering

Co-Linear Drive Modules.

Two vector corrected low-excursion 7” Kevlar Neodymium midrange

transducers paired with two next generation 4” HF compression drivers

energize the drive modules and provide seamless mid-high energy

with no audible distortion at very high SPL levels. Critically optimized

waveguides based on a prolate-spheroidal geometry ensure precise

pattern control and minimum THD, producing a dispersion pattern of

90° x 6° (H x V). The E-Capsule is flanked with two separate birch ply

enclosures, each containing Adamson’s proprietary Kevlar Neodymium

15” woofer, capitalizing on the advantages of Adamson’s Advanced

Cone Architecture and optimized heat dissipation management of the

4” voice coil.

Specications

Frequency Range (+/-3 dB) 60 Hz - 18 kHz

Nominal Directivity (-6 dB) H x V 90° x 6°

Maximum Peak SPL

Components LF 2x ND15-L 15” Kevlar Neodymium Driver

Components MF 2x YX7 7” Kevlar Neodymium Driver

Components HF 2x NH4TA2 4” Diaphragm / 1.5” Exit Compression

Nominal Impedance LF 2x 8 Ω

Nominal Impedance MF 16 Ω

Nominal Impedance HF 16 Ω

Power Handling (AES / Peak) LF 2x 800 / 2x 3200 W

Power Handling (AES / Peak) MF 700 / 2800 W

Power Handling (AES / Peak) HF 320 / 1280 W

Connection 2x Speakon™ NL8

Height Front (mm / in) 391 / 15.4

Height Back (mm / in) 333 / 13.125

Width (mm / in) 1306 / 51.4

Depth (mm / in) 544 / 21.4

Weight (kg / lbs) 79.8 / 176

**

12 dB crest factor pink noise at 1m, free eld, using specied processing and amplication

Processing Lake

**

147 dB

Driver

Rigging Autolock™ Rigging System

1305 mm / 51.4 in

543 mm / 21.4 in

333 mm / 13.125 in

391 mm / 15.4 in

E15 | Spec Sheets

Page 8

Page 9

Introduction & Product Details

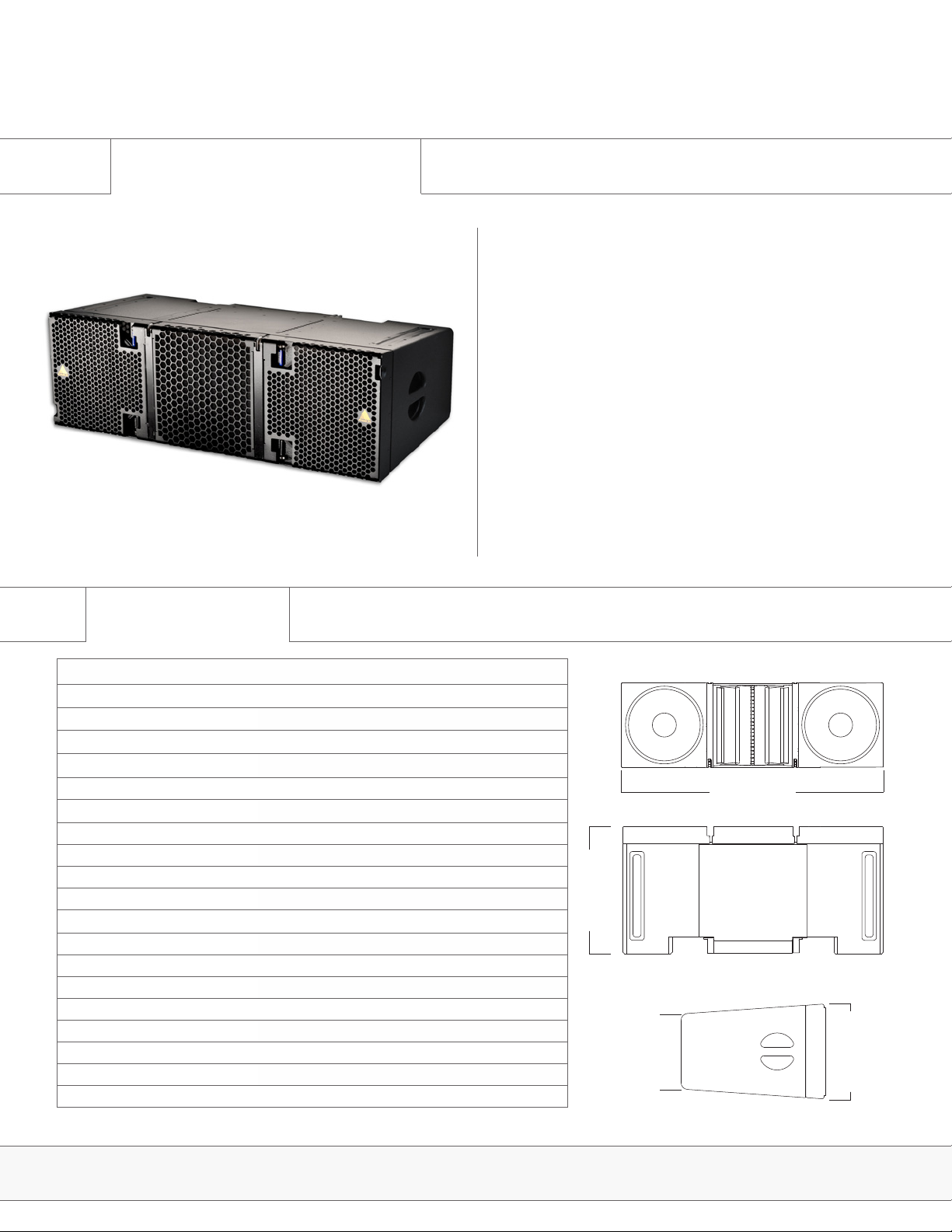

1.4 E12 Spec Sheet

E12

The Adamson E12 is a 3 way, true line source enclosure, incorporating proprietary transducer and waveguide technology which reduces weight and minimizes its footprint. The heart of the E12 is the

E-Capsule, which is precisely engineered and constructed of lightweight

aluminum. The patent pending skeletal structure provides an accurate

and rigid frame for mounting the modular aircraft grade steel Autolock™

rigging system, while simultaneously housing ultra-efcient mid-high

components coaxially mounted on Adamson’s newly modied E12

Co-Linear Drive Module.

A vector corrected low-excursion 7” Kevlar Neodymium midrange

transducer paired with a next generation 4” HF compression driver

energize the drive module and provide seamless mid-high energy with

no audible distortion at very high SPL levels. The critically optimized

waveguide, based on a prolate-spheroidal geometry ensure precise

pattern control and minimum THD, producing a dispersion pattern of

110° x 8° (H x V). The E-Capsule is flanked with two separate birch ply

enclosures, each containing Adamson’s proprietary Kevlar Neodymium

12” woofer, capitalizing on the advantages of Adamson’s Advanced

Cone Architecture and optimized heat dissipation management of the

4” voice coil.

Specications

Frequency Range (+/-3 dB) 60 Hz - 18 kHz

Nominal Directivity (-6 dB) H x V 110° x 8°

Maximum Peak SPL

Components LF 2x ND12-S 12” Kevlar Neodymium Driver

Components MF YX7 7” Kevlar Neodymium Driver

Components HF NH4TA2 4” Diaphragm / 1.5” Exit Compression Driver

Nominal Impedance LF 2x 8 Ω

Nominal Impedance MF 8 Ω

Nominal Impedance HF 8 Ω

Power Handling (AES / Peak) LF 2x 800 / 2x 3200 W

Power Handling (AES / Peak) MF 350 / 1400 W

Power Handling (AES / Peak) HF 160 / 640 W

Connection 2x Speakon™ NL8

Height Front (mm / in) 358 / 14.1

Height Back (mm / in) 282 / 11.1

Width (mm / in) 1111 / 43.75

Depth (mm / in) 543 / 21.4

Weight (kg / lbs) 59.9 / 132

Processing Lake

**

12 dB crest factor pink noise at 1m, free eld, using specied processing and amplication

**

145 dB

Rigging Autolock™ Rigging System

1111 mm / 43.75 in

543 mm / 21.4 in

281 mm / 11.1 in

358 mm / 14.1 in

E12 | Spec Sheets

Page 9

Page 10

Introduction & Product Details

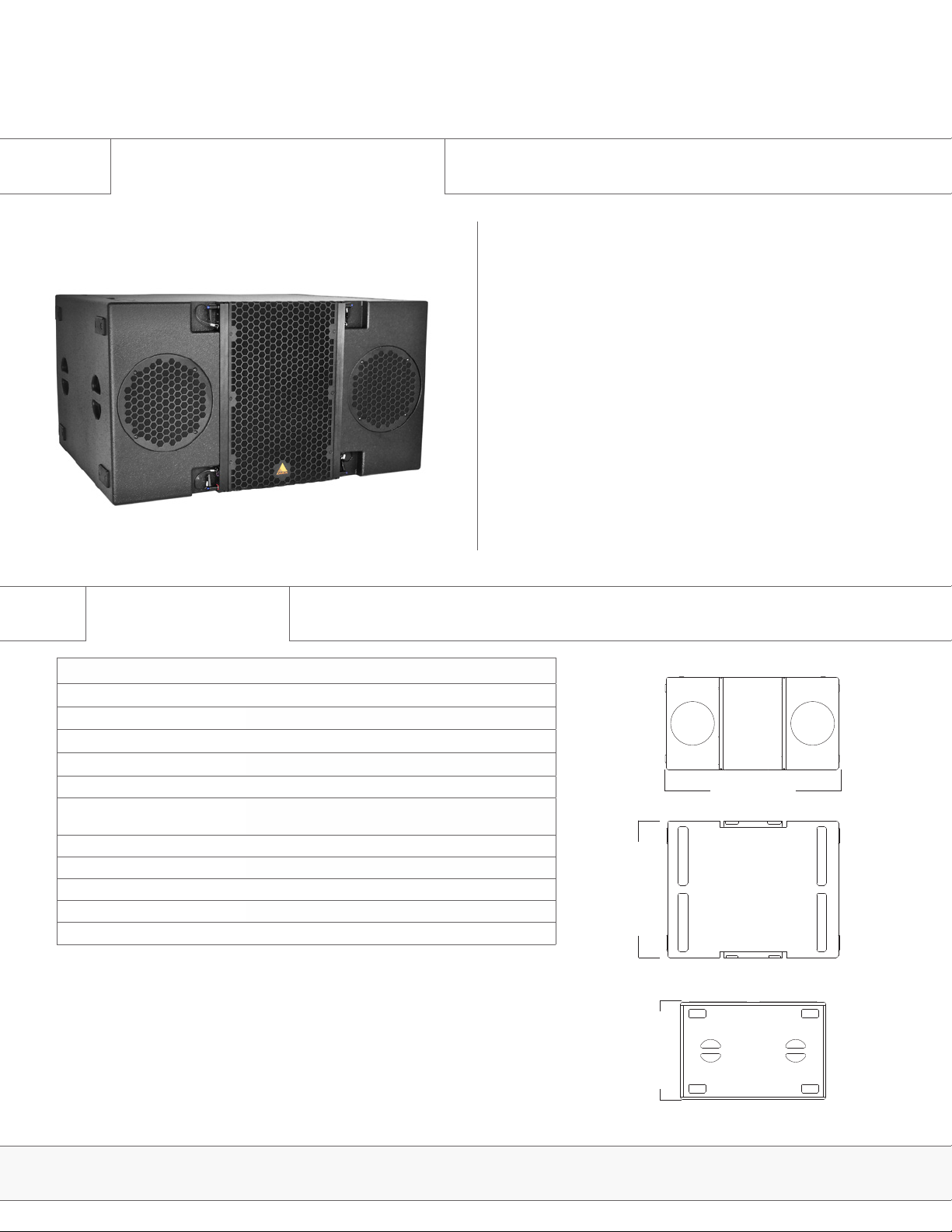

1.5 E218 Spec Sheet

E218

The E218 subwoofer was developed to pair with the E12 or E15

enclosures. Two light-weight, long excursion ND18-S Kevlar Neodymium drivers which utilize Adamson’s Advanced Cone Architecture are

mounted in an efcient band-pass subwoofer. The design achieves a

remarkable reduction of the rearward radiated energy without dedicated

cardioid setups and algorithms. A typical user would appreciate the

sonic attack of this design.

The E218 can be used ground stacked or flown utilizing the E-Frame

Full Line. The frame also allows the E218, E219 and E12/E15 enclosures to be flown in the same array.

The E218 is constructed of (marine) birch plywood as well as aircraft

grade steel and aluminum and is equipped with three Speakon NL8

connectors, two parallel in / out plugs and one dedicated output con-

nection point for efcient cable usage. The integrated rigging system

allows for either 0° or 3° splay between adjacent enclosures.

Specications

Frequency Range (+/- 3dB) 30 Hz - 110 Hz

Maximum Peak SPL

Components LF 2x ND18-S 18” Neodymium Kevlar Driver

Nominal Impedance LF 2x 8 Ω

Power Handling (AES / Peak) LF 2x 800 / 3200 W

Connection 3x Speakon™ NL8: 2x Rear Parallel (Pins 1 +/-) and 1x

Height Front (mm / in) 597 / 23.5

Width (mm / in) 1111 / 43.75

Depth (mm / in) 870 / 34.25

Weight (kg / lbs) 86 / 190

Processing Lake

**

12 dB crest factor pink noise at 1m, half space, using specied processing and amplication

**

142 dB

Rigging Flyable with E-Frame Full Line

Rear Output (Pin 2 to 1)

1111 mm / 43.75 in

870 mm / 34.25 in

597 mm / 23.5 in

Page 10E218 | Spec Sheets

Page 11

Introduction & Product Details

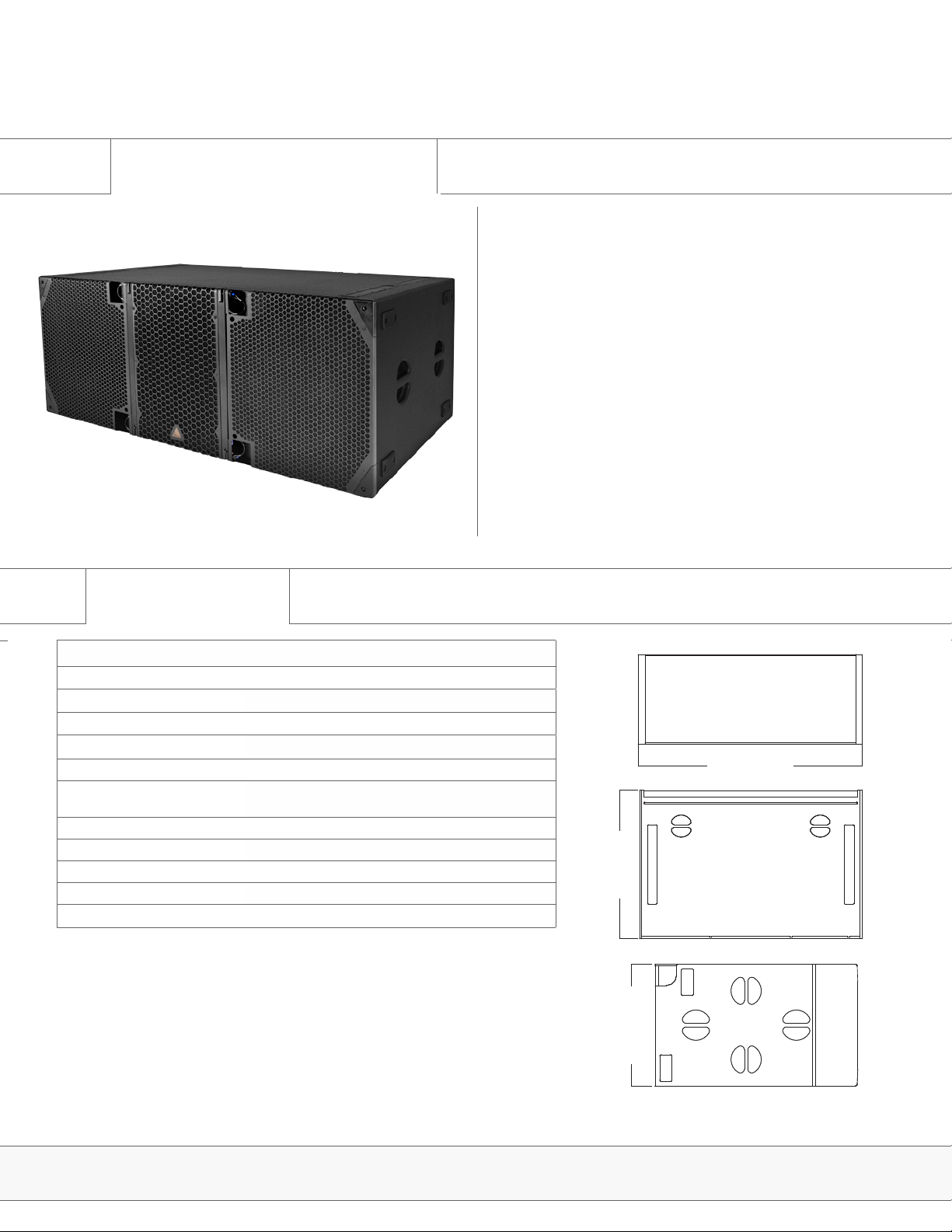

1.6 E219 Spec Sheet

E219

The E219 Subwoofer was developed to bolster the low-end of the

E-Series line of products. The enclosure is loaded with two light weight,

long excursion, 19” SD19 Kevlar Neodymium drivers utilizing Adamson’s Advanced Cone Architecture and Symmetrical Drive Technology.

The drivers employ dual 5” voice coils for exceptional power handling,

with a dual-spider suspension system for extra stability even under

extreme excursion. They are mounted in an ultra-efcient front-loaded

enclosure, designed to reproduce clean, musical low frequency information. A typical user would appreciate the lower fundamental notes of

this design.

The E219 can be ground stacked or flown utilizing the E-Frame FUll

Line. The cabinet construction uses marine grade birch plywood as

well as aircraft grade steel and aluminum, and is equipped with three

Speakon™ NL8 connectors, two parallel In/Out plugs and one dedicated

output connection to optimize speaker cabling. The integrated rigging

system allows for either 0° or 3° splay between adjacent cabinets.

Specications

Frequency Range (+/- 3dB) 28 Hz - 90 Hz

Maximum Peak SPL

Components LF 2x SD19 19” Kevlar Neodymium Driver

Nominal Impedance LF 2x 5 Ω

Power Handling (AES / Peak) LF 2x 1600 / 2x 6400 W

Connection 3x Speakon™ NL8: 2x Rear Parallel (Pins 1 +/-) and 1x

Height Front (mm / in) 597 / 23.5

Width (mm / in) 1418 / 55.83

Depth (mm / in) 889 / 35

Weight (kg / lbs) 112.9 / 249

Supported Processing Lake

**

12 dB crest factor pink noise at 1m, half space, using specied processing and amplication

**

144 dB

Rigging Flyable with E-Frame Full Line

Rear Output (Pin 2 to 1)

1418 mm / 55.83 in

889 mm / 35 in

597 mm / 23.5 in

Page 11E219 | Spec Sheets

Page 12

Introduction & Product Details

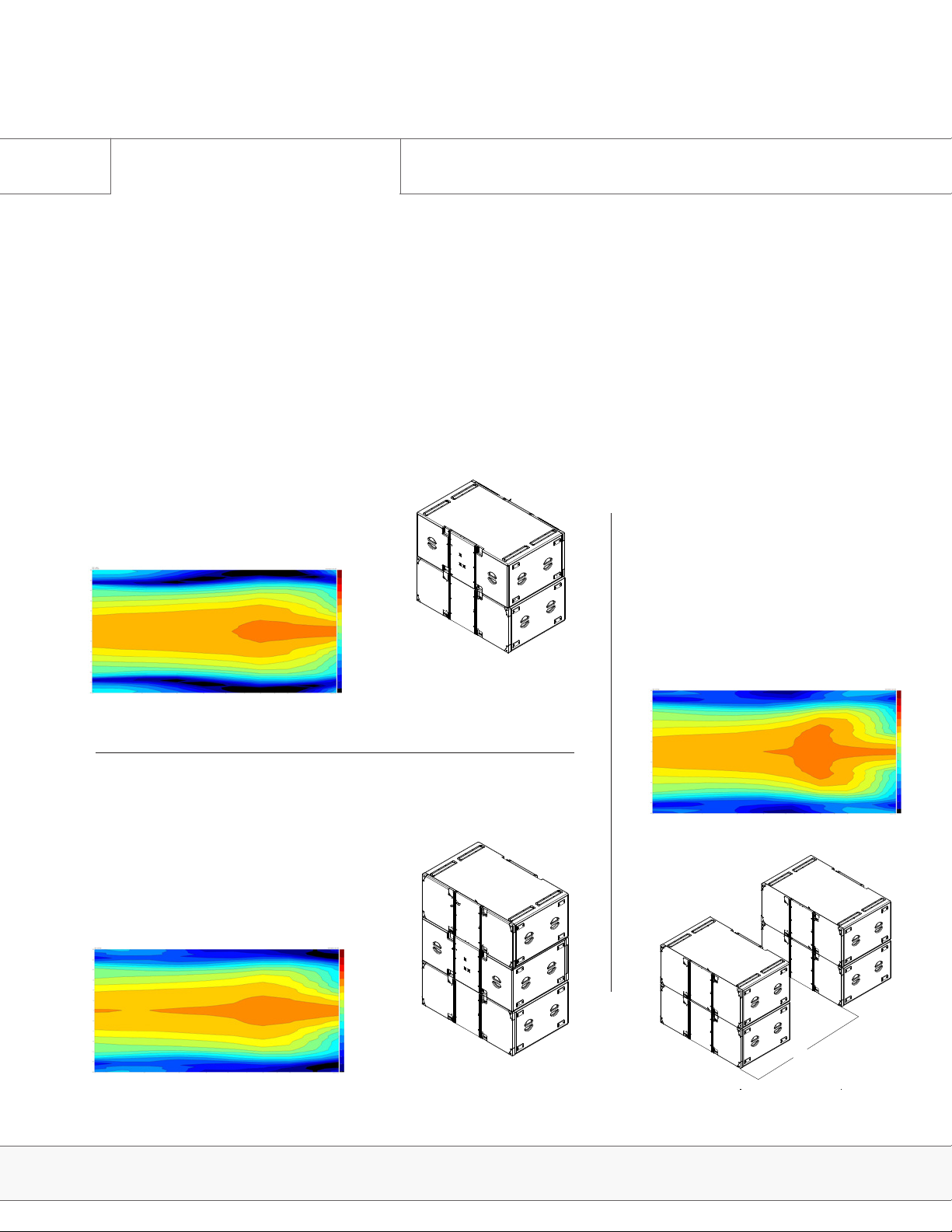

1.7 Cardioid Subs

Every Adamson subwoofer has specifically designed cardioid presets. Adamson utilizes three

configurations ranging from a minimal footprint and minimized rear rejection to larger setups

that eliminate virtually all audio energy behind the array. Please refer to the Lake Preset Loading

Manual for further instructions.

Front-Back

The FB preset should be used in situations

where a minimal footprint is desired.

Only 2 enclosures stacked ensures that

sightlines will not be impaired.

End-Fire 66

The EF66 preset should be used

in situations where the most

rear cancellation is desired.

Unlike traditional end-fire

arrays, Adamson’s proprietary

preset eliminates a wide range

of frequencies in the rear of the

array.

Front-Back-Front

The FBF preset exhibits higher output from

the front of the array. A similar footprint

to the FB configuration, this stack is 3

enclosures high.

E-Series | Cardioid Subs

66"

Page 12

Page 13

System Conguration

2.0 E-Rack Description

Adamson Touring Rack

Adamson has developed a unified

rack solution, configured to

interface seamlessly with our line of

loudspeaker products. All E-Racks

are equipped with two or three Lab.

gruppen PLM+ series amplifiers,

featuring Lake processing and Dante

audio networking functionality. The

Adamson Audio Panel provides

Analog and AES inputs, Speakon NL8

and Socapex outputs, and etherCON

RJ45 connections, designed for dual

redundant Dante setups. A managed

Gigabit Ethernet switch and an AC

distribution panel available in 120

V or 230 V versions complete the

hardware. The entire package fits into

a compact and lightweight 10U rack,

designed with interior suspension,

hinged doors and extra rails for

secure & efficient use of space.

E-Rack elements are comprised of:

• 10U suspended rack with hinged, sliding front and rear doors

• Up to three Lab.gruppen PLM 20K44 ampliers (8 and 12-Channel versions available)

• Adamson Audio Panel

• Adamson AC Panel, 120 V or 230 V (region specic)

• Cisco SG300-20 managed switch

• Includes one Personal License per rack

E-Series | System Conguration

Page 13

Page 14

System Conguration

2.1 E-Rack Overview

Adamson has developed a unied rack solution congured to interface seamlessly with our

line of Loudspeaker products. For more information on the E-Rack, please refer to the E-Rack

brochure available on the Adamson Systems website.

2 or 3x Lab.gruppen PLM 20K44

1x Adamson Audio Panel, incl. Analog and

PUSHPUSHPUSH

PUSHPUSHPUSH

AES in and thru-puts (XLR), Speaker outputs (NL8 and Socapex), Gigabit Network

Ports (Ethercon RJ45)

1x AC Distribution Panel, L21-30 input or

CEE 32A 3-Phase 400V/230V 3L+N+PE

(Red CEE connector), depending on region

1x DANTE Certied Switch (Rear Side)

E-Series | System Conguration

Page 14

Page 15

System Conguration

2.2 Configuration Example

This example conguration demonstrates the efciency of the system. For further information regarding congurations, please refer to the Adamson Document E-Series Conguration Brochure.

E12 | System Conguration

Page 15

Page 16

System Conguration

2.3 Wiring Diagrams

E12

3-way line source enclosure [974-0001]

LF - 2x 12” ND12-S[940-0022], MF - 1x 7” YX7 [940-0020], HF - 1x 4”NH4 [140-0004]

Autolock™ rigging system

E15

3-way line source enclosure [975-0001]

LF - 2x 15” ND14-L[940-0013], MF - 2x 7” YX7 [940-0020], HF - 2x 4”NH4 [140-0004]

Autolock™ rigging system

E-Series | Wiring Diagrams

Page 16

Page 17

System Conguration

2.3 Wiring Diagrams

E218

[992-0007]

Subwoofer: LF - 2x 18” ND18-S [940-0023]

Integrated rigging system

E219

[994-0001]

Subwoofer: LF - 2x 19” SD19-ND [940-0024]

Integrated rigging system

E-Series | Wiring Diagrams

Page 17

Page 18

Rigging

3.0 The 4 Stack Dolly

Transporting the 4 Stack Dolly

There is a tip hazard when transporting a 4 stack on uneven ground or on a ramp. To avoid tipping the dolly,

It should always travel with sides of the cabinet to the front or back.

*On the 4 stack dolly, the bottom cabinet is held in place by the rear, red autolock mechanism..

TIP HAZARD

ALWAYS MOVE LOADED

DOLLY ON THE LONG EDGE

E-Series | Rigging

Page 18

Page 19

Rigging

3.1 Rigging Overview

TIP HAZARD

ALWAYS MOVE LOADED

DOLLY ON THE LONG EDGE

The Autolock Rigging System™

The Autolock Rigging System™ is the main attachment for all of the points in the E15/E12 system. The idea is

to only guide the latches to the right spot, where a spring-loaded bolt snaps into place, and is then secured with

the very same lever by turning it into its lock down position. Caution should be taken while connecting cabinets to

ensure hands are out of the way.

The order of operation of the rigging system is: prep angles, arm pins, guide into place (pinning happens

automatically) and secure rigging parts manually to ‘closed’ position.

The levers are color coded for ease of use. All front rigging have black levers at bottom and and blue levers on top,

the rear levers are red.

The black bottom levers hold and release the rigging bar from the

box above, the blue top lever receives the rigging frame, as well as

the above box’s rigging bars and locks them into place. The black

lever only has one function; to release rigging bar either to put into

use or to store it away. Pull it to release, let it go and it flips back

into place.

Fig. 1

The Autolock™ Rigging features a ‘peep

hole’ where you can see the rigging bar

when it is locked. When it is unlocked you

will see a clear avenue. To be sure, make

sure you can set all blue and red levers to

‘Closed’ position (down).

The blue and red levers have 3 functions: Closed, Spring, and Open.

(pages 25-26)

All rigging levers feature a ‘peep hole’(Fig. 1) where you can assure

the the pin is fully ejected and is in fact in its proper place. Always

make sure your red and blue levers are set to ‘Closed’ position.

E-Series | Rigging

Page 19

Page 20

Rigging

3.1 Rigging Overview

ATTENTION

IMPORTANT OPERATING

INSTRUCTIONS

The rear of the E-Capsule also features an angle chart

with a knob lever which adjusts the angles. (Fig. 2) All

angles are set while the cabinets are stacked on the dolly,

ensuring that a single technician can prep the cabinets

for rigging. For a more detailed look at the rigging sticker,

please refer to section 3.4.

Fig. 2

0 0°

1 0.5°

2 1.0°

3 2.0°

4 3.0°

5 4.5°

6 6.3°

7 8°

in enclosure

R

Fig. 3 E12 E15Fig. 4

E-Series | Rigging

0 0°

1 0.3°

2 0.6°

3 1.3°

4 2.0°

5 3.1°

6 4.4°

7 6°

in enclosure

R

There are 8 angles, 0 to 7, and an additional ‘R’ being the

‘idle’ or ‘rest’ position, when the rigging hardware is all the

way down and the boxes aren’t connected. It is applicable

when the enclosure is not in use, to protect the rigging

hardware from damage. To keep the system intact for

transport, leave the angles pinned in.

The angles are numbered as well as color coded to mark

which slot should be pinned with the attached push-pin.

The following rigging positions are equal to the following

degrees for the E12 (Fig. 3) and the E15 (Fig.4).

Page 20

Page 21

Rigging

3.1 Rigging Overview

ATTENTION

IMPORTANT OPERATING

INSTRUCTIONS

The E-Frame with Extender Beam is designed for use with the E12 and E15 cabinets. It

consists of a steel frame, paired with an extension beamof which there are several combination

congurations. Always refer to Blueprint AV™ for correct rigging instructions.

In standalone mode (Fig. 1), the frame can be

used to lift flat to slightly-angled arrays. Two

rigging plates are provided for dual motor

operation, and if two motors are not available,

one lifting plate may be repositioned towards

the center of the frame. Please refer to

Blueprint AV™ when determining proper lifting

plate location.

Fig. 1

Fig. 2

In order to attach the extended beam, the

lifting plates must be removed and replaced

with Extended Beam plates, characterized as

having a rectangular shape and two smaller

holes at the top of each plate. (Fig. 2)

As arrays get longer and more curved, the

center of gravity will shift, making it necessary to position the rigging beam and rigging

pieces so that the motors carry equivalent

weight. The ‘Mechanical’ tab in Blueprint AV™

will aid the user in choosing the correct rig-

ging frame conguration. (Fig. 3)

Fig. 3

E-Series | Rigging

Page 21

Page 22

Rigging

3.1 Rigging Overview

ATTENTION

IMPORTANT OPERATING

INSTRUCTIONS

For arrays with little to no

incline, the extension beam

centered will usually provide

the best weight dispersion.

Fig. 1

Fig. 2

Fig. 3

For arrays with negative incline,

the extension beam positioned

towards the back of the frame

will provide the best weight

dispersion.

For arrays with positive incline,

the extension beam positioned

towards the front of the frame

will provide the best weight

dispersion.

E-Series | Rigging

Page 22

Page 23

Rigging

3.1 Rigging Overview

The E-Frame Full Range is designed for use with all E-Series enclosures. It consists of a steel

frame, long enough to not need the addition of an extension beam. It can be congured as

a standalone frame to hang any cabinet, or as an adapter frame to hang top cabinets under

flown subs, or to stack top cabinets on ground stacked subs. Always refer to Blueprint AV™ for

correct rigging instructions.

ATTENTION

IMPORTANT OPERATING

INSTRUCTIONS

The frame faces one direction while in stacking mode and is reversed when in hanging mode. If

the E218/E219 and E12/E15 are to be flown in the same array, two frames are needed. Please

refer to sections 3.10 and 3.11 for detailed descriptions of how to deploy the frame.

E-Series | Rigging

Page 23

Page 24

Rigging

3.2 Rear Rigging

Rear Autolock Rigging - Red Lever

The 3 different modes of the red lever:

1. Closed (Locked)

2. Spring Mode

3. Open (Locked)

Fig. 1

ATTENTION

IMPORTANT OPERATING

INSTRUCTIONS

In the ‘Closed’ mode (Fig. 1) the lever is in and turned

upward or downward (both up and down lock the

system - decide which way you’ll be using it, and close

all the enclosures the same way for uniformity.

Fig. 2

Fig. 3

The lever is pulled out and parallel to the ground in

‘Spring’ mode (Fig. 2)

The lever is out and turned downward or upward in

‘Open’ mode (Fig. 3). This mode is used when taking

the system down ie on boxes 4-8-12-16... This mode

can also be used on all enclosures when separating

4-stacks into individual enclosures.

E-Series | Rigging

Page 24

Page 25

Rigging

3.3 Front Rigging

Front Autolock Rigging - Blue Lever

The 3 different modes of the blue lever:

1. Closed (Locked)

2. Spring Mode

3. Open (Locked)

Fig. 1

ATTENTION

IMPORTANT OPERATING

INSTRUCTIONS

‘Closed’ (Fig. 1)- the lever is in and turned downward to

lock the system.

Fig. 2

Fig. 3

The lever is pulled out and parallel to the ground in ‘Spring’

mode (Fig. 2)

The lever is pulled out and turned downward. This ‘Open’

mode (Fig. 3) is used in taking the system apart. ie on

boxes 1-5-9-13. Also on all enclosures when separating 4

stacks for maintenance etc.

E-Series | Rigging

Page 25

Page 26

Rigging

3.3 Front Rigging

Front Autolock Rigging - Black Lever

There is only 1 mode of use for the black lever:

Fig. 1

ATTENTION

IMPORTANT OPERATING

INSTRUCTIONS

The lever is pulled out and parallel to the ground in temporary

‘Open’ mode (Fig. 1)- this releases the rigging bars from

inside the enclosure. The lever snaps back into place ready to

be fastened to ’Closed’ mode. To place the rigging bars back

into the enclosure just pull lever out again and push gear back

into place.

Fig. 2

Make sure system is fully fastened in the ‘Closed’ mode

(Fig.2) by using the ‘peep hole’ prior to lifting.

E-Series | Rigging

Page 26

Page 27

Rigging

3.4 Rigging Sticker Legend

Rear Autolock Rigging Sticker Legend

* When releasing and pulling the system apart (to enclose rigging bars) let

knob slide down to ‘rest’ position (green), and place attached push pin to green

slot (above) If you’re dividing into 4 stacks, perform this task on every 4th box

only.

* When needing a zero degrees angle (such as the top boxes of longer arrays)

use magenta slot. Position 1 uses the purple slot, positions 2 and 4 use the

yellow slot, position 3 uses the blue slot, positions 5 and 7 use the green slot

and position 6 uses the beige slot.

ATTENTION

IMPORTANT OPERATING

INSTRUCTIONS

* Idle Stack Pin slot is used when stacking mode is not in use. It is also used in

a hanging rigging conguration where gravity allows all the angles to shift to

the desired position.

* Stack pin slot is used when stacking the E15/E12 system, or needing a rigid

flown array. (ie when the system is arrayed in a manner that gravity cannot

sustain the desired angles). The user must ensure this pin is set on both sides

of each cabinet.

Note: E12 sticker shown

E-Series | Rigging

Page 27

Page 28

Rigging

3.5 Setting Angles

ATTENTION

IMPORTANT OPERATING

INSTRUCTIONS

Setting the angles on all 4-stacks and basic preparation.

Before attaching cabinets together, use Blueprint AV™ to plan your cabinet angles for desired coverage. Prepare all

the cabinet angles before beginning to attach and lift the array. The top cabinet, which attaches to the rigging frame

is number 1, and the cabinets gain numerically as the descend. Make sure you are setting the correct angle on both

sides of the E-Capsule.

1. The front blue levers on the top cabinets of each 4-up dolly are on

‘Spring’ mode.

2. Red levers in the rear on the BOTTOM cabinet of each 4-stack are in

‘Spring’ mode, abling the hook-up of the next cabinet stack.

3. Remove the angle pin. (Fig. 1)

Fig. 1

4. Raise the sliding knob to the angle specied by corresponding

Blueprint AV design and place the angle pin in the corresponding colorcoded slot. (Fig. 2)

Fig. 2

Fig. 3

Fig. 4

E-Series | Rigging

5. Remember to check that all cabinets are fully bolted through and

locked by conrming that all levers can be placed in ‘Closed’ mode.

(Fig. 3) Make sure to perform this every time even with enclosures

which are already pinned, to guarantee than no one has changed the

mode of the levers during set-up, tear-down or transport.

6. Stack pin should always be in “Idle Stack Pin” mode unless you’re

ground stacking the system or need a rigid array.(Fig. 4)

Page 28

Page 29

Rigging

3.6 Attaching the Rigging Frame

The rigging Frame contains 4 pins: 2 in the front which are xed in place and 2 in the rear, one of which needs to be

pinned manually using attached push pin. The system ideally uses 2 motors: one in front, one in back of the frame

for easy adjustment once the array has been flown. For flying from a single point, you’ll need to rmly decide the

angle of the frame prior to rigging all the cabinets.

1. Place top enclosure’s blue levers to ‘Spring’ position on both sides.

2. The rear angle should be set to “2” or “Yellow” to successfully

connect the top box to the rigging frame.

3. Lower frame and guide the front rigging to place. (Fig. 1)

Fig. 1

PINCH POINT

CAN CAUSE SEVERE

PERSONAL INJURY

WARNING

SAFETY RISK

PAY SPECIAL ATTENTION

Fig. 2

E-Series | Rigging

4. Conrm through peephole that front rigging is locked into place,

and the levers (blue) on both sides of the enclosure are in ‘Locked’

position.

5. Manually pin rear of frame to rst enclosure using attached push

pin. (Fig. 2)

Page 29

Page 30

Rigging

Fig. 3

3.6 Attaching the Rigging Frame

6. Ensure the rear red pin that connects to the dolly on the bottom

cabinet is in the open position. (Fig. 3)

PINCH POINT

CAN CAUSE SEVERE

PERSONAL INJURY

WARNING

SAFETY RISK

PAY SPECIAL ATTENTION

Fig. 4

E-Series | Rigging

7. Lift cabinet stack up, release and lift off dolly. (Fig. 4)

Page 30

Page 31

Rigging

3.7 Consequent Arrays

Fig. 1

PINCH POINT

CAN CAUSE SEVERE

PERSONAL INJURY

WARNING

SAFETY RISK

PAY SPECIAL ATTENTION

Attaching the second and consequent arrays

1. Lift Frame with the attached 4 enclosures high enough to clear the

next 4 -stack underneath. (they should all have their angles set)

2. Place rear rigging (red levers on box #4, 8, 12, 16...28) to ‘Spring’

mode, make sure the same cabinets’ front rigging bars are released

using black levers. (Fig. 1)

Fig. 2

Fig. 3

3. Place front rigging’s blue levers (box #5, 9, 13, 17...29)... (rst box in

the new 4-stack to be suspended) to ‘Spring’ mode (Fig. 2)

4. Pull front rigging’s black lever (box #4,8,12,16...28) allowing the

rigging piece to drop. (Fig. 3)

E-Series | Rigging

Page 31

Page 32

Rigging

Fig. 4

3.7 Consequent Arrays

PINCH POINT

CAN CAUSE SEVERE

PERSONAL INJURY

5. If dealing with a large amount of cabinets and high rigging

points, its best to keep the lower stack pushed slightly back to

allow for any spring in the motor and top rigging. Trying to lower

an array that is not lined up properly can damage the cabinets.

Once the upper array is at the desired position, wheel the lower

stack into position so the front rigging points are lined up in the

slot. Lower the front of the cabinets until the rigging latches

catch, and continue to lower until the rear pin latches. (Fig. 4)

WARNING

SAFETY RISK

PAY SPECIAL ATTENTION

6. Place all levers to ‘Closed’ position. (Fig. 5,6 &7)

7. Make sure that all rigging is latched properly through the

‘peephole’ or by conrming that all levers are in ‘Closed’ mode.

8. Continue and repeat process until you have hung the total

amount of desired cabinets.

Fig. 5

Fig. 6 Fig. 7

E-Series | Rigging

Page 32

Page 33

Rigging

3.8 Highly Curved Arrays

Connecting a 4 stack to a highly curved array

When connecting a 4 stack of cabinets to a steep flown array,

it may not be safe or practical to continue to lower the array to

make the rear attachment (once the fronts are connected). It is

also not recommended to tip the lower dolly forward as this can

be dangerous. The easiest connection method is as follows:

1. Place ALL rear red levers on the 4 stack on the ground to the

“open” position. (Fig. 1)

Fig. 1

PINCH POINT

CAN CAUSE SEVERE

PERSONAL INJURY

WARNING

SAFETY RISK

PAY SPECIAL ATTENTION

Fig. 2

Fig. 3

2. Set the front blue levers on the top cabinet of the 4 stack to the

“Spring” position (Fig. 2)

3. Connect the front of the upper array to the 4 Stack in the same

manner as outlined in section 3.7, #5.

4. Lift the motor slightly so that there is minimal weight on the

dolly of the 4 stack - without actually lifting the dolly from the

ground

5. Ensure the rear red lever on the bottom cabinet of the flown

array is set to “spring” mode. (Fig. 3) Lift the top cabinet in the

stack by hand, so it meets the upper array. The rear red lever

should automatically latch in place. This should be relatively easy

with two people. If the cabinet seems very heavy- there is too

much weight on the cabinet- and the motors must be raised

slightly.

6. Set the next rear red lever to “spring” mode

7. Repeat steps 4-6 until all cabinets are connected at the rear.

NOTE: With enough stage hands, this process can be carried out

with two cabinets at a time- meaning only the red lever connecting

the backs of the 2nd & 3rd cabinet need be disconnected. Please

ensure safe lifting practices are being adhered to to avoid injury.

If straining to lift cabinets - use more stage hands or try lifting the

motors slightly.

E-Series | Rigging

Page 33

Page 34

Rigging

3.9 Lowering the Array

Fig. 1

Fig. 2 Fig. 3

PINCH POINT

CAN CAUSE SEVERE

PERSONAL INJURY

WARNING

SAFETY RISK

PAY SPECIAL ATTENTION

To Lower a Steep Angled Array

1. Lower the array until it is just above the floor. (Fig. 1)

2. Make sure the rear red lever on the bottom box is set to “spring” mode

to receive the dolly.

3. Connect the dolly to the bottom cabinet.

4. If the bottom cabinets are at a steep angle and it is unsafe to continue

to lower the array, two crew members should be used to support the

weight of the cabinet at all times; before the dolly has ground contact,

(the dolly should never tip over as in (Fig. 3) push the hang to the front

in order to prevent the dolly to tip over, then proceed lowering the array

(Fig.2); release the red lever above this cabinet to free the rear of the

bottom cabinet.

5. All front levers should stay connected. This will allow you to raise the

motors until the frame is no longer steeply angled. (Fig. 4)

6. Set front blue lever on top cabinet in 4 stack to open. and allow the

bottom 4 cabinets to separate from the array.

7. Lift the array just above the 4 stack and wheel 4 stack out from under

array. (Fig. 5)

Fig. 4

Fig. 5

Fig. 6

If the bottom cabinet in the array is still at a steep angle - repeat this

procedure.

To Lower a Moderately Angled Array

1. Lower the array till it is just above the floor. (Fig. 1)

2. Make sure the rear red lever on the bottom box is set to “spring” mode

to receive the dolly.

3. Connect the dolly to the bottom cabinet.

4. Lower the array till all the rear angles collapse in the bottom 4 stack.

5. Set the front blue lever on the top enclosure of the 4 stack to open.

6. Set the rear red lever on the bottom of the upper array to open.

7. Lift the array above the 4 stack (Fig. 5)

8. Wheel 4 stack out of the way

Repeat procedure until done. (Fig. 6)

E-Series | Rigging

Page 34

Page 35

Rigging

3.10 Rigging the E Sub

The E218 an E219 rigging system is based on the same concept as the Energia Autolock™ system, but simplied. A

less complex system without spring loaded locking mechanisms allows the user to quickly connect and fly a multitude

of E-Series Subwoofer cabinets.

The E-Frame Full Line has two modes; flying and stacking. A tray for the Adamson Laser Inclinometer exists at one

end of the frame. If the tray is facing forward, the frame is in flying mode. If the tray is facing backwards, the frame

is in stacking mode.

Four rigging pieces drop down from the center capsule to connect

another E218, E219 , or an E-Frame Full Line to adapt for use with

an E12 as well. Four chambers at the top of the center capsule

allow connection between 2 E218 Steps to rigging the E-Series

Subwoofers:

1. Set the angle of all cabinets to be flown to either 0° or 3° splay, as

specied in your Blueprint AV™ design. (Note that in order to connect

the top box to the rigging frame, the angle must be set to 0°)

2. Attach the E-Frame Full Line to the top E218 or E219 cabinet and

secure in place with the push pins provided (Fig. 1)

Fig. 1

PINCH POINT

CAN CAUSE SEVERE

PERSONAL INJURY

WARNING

SAFETY RISK

PAY SPECIAL ATTENTION

Fig. 2

Fig. 3

3. Due to the depth of the E-Frame Full Line, no external beam is

needed. Attach rigging plates to the rigging frame in the positions

specied in the Mechanical page of your Blueprint AV™ design.

(Fig. 2)

4. Lift the Frame with the E-Series Subwoofer attached. (Fig. 3) If

more E218 or 219 are to be flown, repeat step 1 for the next dolly,

lower the already rigged Subwoofers to the next set, position the

rigging pieces and secure them using the push pins.

E-Series | Rigging

Page 35

Page 36

Rigging

3.11 Attaching Tops to Subs

The E-Frame Full Line is designed to allow all members of the E-Series family to be safely rigged to one another,

whether it is in a ground-stacked or flown scenario.

PINCH POINT

CAN CAUSE SEVERE

PERSONAL INJURY

WARNING

SAFETY RISK

PAY SPECIAL ATTENTION

Ground Stacked

1. Place E218 cabinets where the Blueprint AV™ design

species.

2. Attach the E-Frame Full Line to the top E218 cabinet and secure in place with the push pins provided with the E218. (Fig. 1)

Fig. 1

3. Make sure the Stacking Plates are in the up position, and secured with the push pins provided. The position of the Stacking

Plates is adjustable, follow what the Blueprint AV™ mechanical

tab displays. (Fig. 2)

Fig. 2

Fig. 3

Fig. 4

4. Set the E12/E15 red lever to “Spring” mode and place the

cabinet on the rigging frame, conrm the rear rigging is locked.

(Fig. 3)

5.Release the front rigging pieces by opening the black levers on

the front of the E12/E15.

6. Secure in place to the E-Frame Full Line using the top, front

push pin. (Fig. 4)

7. Add cabinets as specied by the Blueprint AV™ design.

E-Series | Rigging

Page 36

Page 37

Rigging

3.11 Attaching Tops to Subs

Note: The steps in section 3.10 must be complete before going any further

PINCH POINT

E12 / E15 as an Underhang

Pictures shown are E12 and E218, the same principles apply to

the E15 and E219.

1. Set all E12 angles while still on the dolly.

2. Set blue levers on the top E12 box to ‘Spring’ mode.

3. Move front lower rigging pieces on the E-Frame Full Line to the

inner channel and secure in place with the push pins provided.

Fig. 1

Fig. 2

(Fig. 1)

4. Place E-Frame Full Line on the E12 and conrm the front rigging is locked.

5. Set the rear knob lever to 0 and lock in place using the push pin.

(Fig. 2)

6. Remove Rigging and Stacking Plates from the Energia Modular

Rigging Frame.

7. Release the lower rigging pieces of the suspended E218 and

remove the upper push pin from each corner of the E-Frame Full

Line. (Fig. 3)

CAN CAUSE SEVERE

PERSONAL INJURY

WARNING

SAFETY RISK

PAY SPECIAL ATTENTION

Fig. 3

Fig. 4

E-Series | Rigging

8. Lower and guide the suspended E218 onto the rigging frame,

securing the rigging pieces to the E-Frame Full Line, using the

push pins previously removed. (Fig. 4)

9. Lift the array and add full range enclosures as specied by

Blueprint AV™ (Fig. 5)

Fig. 5

Page 37

Page 38

Ground Stacking

4.0 Ground Stacking Legs

Dolly Stacking Legs (938-0014)

Fig. 1

TIP HAZARD

ALWAYS MOVE LOADED

DOLLY ON THE LONG EDGE

Available as an accessory, the Ground Stacking Legs allow users

to angle the E12 or E15 in positive or negative increments while

situated on the E12 or E15 Dolly.

1. Make sure all wheel locks are engaged and the dolly is situated

where the design has specied.

2. Insert stacking leg into rectangular chamber directly above the

dolly wheel. (Fig. 1)

3. Insert rst push pin into the hole directly above the dolly wheel. (Fig.

2)

4. Insert second push pin into the hole above and behind the dolly

wheel. (Fig. 3)

5. Repeat procedure for all four stacking legs.

6. Turn handle until all stacking legs are rmly planted on the ground.

(Fig. 4)

7. If a negative inclination is desired, tighten the back two stacking legs

until desired incline is achieved.

8. If a positive inclination is desired, tighten the front two stacking legs

until desired incline is achieved. (Fig. 5)

Fig. 2

Fig. 3 Fig. 4 Fig. 5

E-Series | Ground Stacking Conguration

Page 38

Page 39

Truck Pack

63.8"

92.9"

45.3"

2.4m

1.2m

92.9"

2.4m

1.6m

76.5"

99.4"

45"

63.8"

92.9"

45.3"

2.5m

1.9m

99.4"

2.5m

1.1m

2.4m

1.2m

92.9"

2.4m

1.6m

90.8"

5.0 Possible Congurations

The E-Series system has been designed to t standard truck widths in several different congu-

rations. This section shows some of the options.

90.8"

2.3m

36.3"

76.5"

0.9m

2x E218 Wide

Two 3-high E218 dollies are tight packed end-to end

for a width of approximately 91”, and a depth of approximately 36”.

1.9m

4x E12/E15 Symmetrical

Four 4-high E12 dollies are packed front to back

for a width of approximately 93”, and a depth of

approximately 45”.

2x E218, 1 x E12

Two 3-high E218 dollies flank a single 4-high E12

dolly with a width of approximately 99” and a depth of

approximately 45”.

E-Series | Truck Pack

Page 39

Page 40

Loading...

Loading...