Page 1

SMT Breadboard Prototyping Using Breakout PCBs

Created by Ladyada

Page 2

2

3

4

6

Guide Contents

Guide Contents

Overview

Required Tools

Soldering an SOIC

© Adafruit Industries http://learn.adafruit.com/smt-prototyping-using-breakout-pcbs Page 2 of 8

Page 3

Overview

Nothing is as fast and fun as prototyping on a breadboard, but at some point you will find that

the chips you want to work with are only available in non-breadboard-friendly SMT/SMD (Surface

Mount Technology/Surface Mount Device). Unlike most DIP chips and resistors, SMT parts do

not have the leads going through holes in the PCB. Instead, they 'float' on top, with oftenrectangular solder pads.

Although you may one day decide to use CAD software for laying out a custom PCB for these

parts, you can do yourself a favor and prototype with SMT breakout/adapter PCBs. In this mini

tutorial we'll go over how to use these. It's not hard, once you have the experience!

© Adafruit Industries http://learn.adafruit.com/smt-prototyping-using-breakout-pcbs Page 3 of 8

Page 4

Required Tools

With ALL SMT work, having the right tools is essential! You will need tweezers. Either straight-

tip style (available here) (http://adafru.it/421)

Or curved (available here) (http://adafru.it/422)

You'll also need a soldering iron with a fine tip. Although a good iron is a little expensive, its the

most important tool and we suggest investing in a good one. Our favorite is the Hakko FX-

888D (http://adafru.it/1204) with the fine SMT tip (http://adafru.it/1249)

© Adafruit Industries http://learn.adafruit.com/smt-prototyping-using-breakout-pcbs Page 4 of 8

Page 5

© Adafruit Industries http://learn.adafruit.com/smt-prototyping-using-breakout-pcbs Page 5 of 8

Page 6

Soldering an SOIC

We'll start by showing how to solder an SOIC component. Although we have many different

'package' versions available (such as SOIC/TSSOP/QFP/QFN) SOIC is the easiest to start with

and its the chip I needed to work with today so that's what we're going to do :)

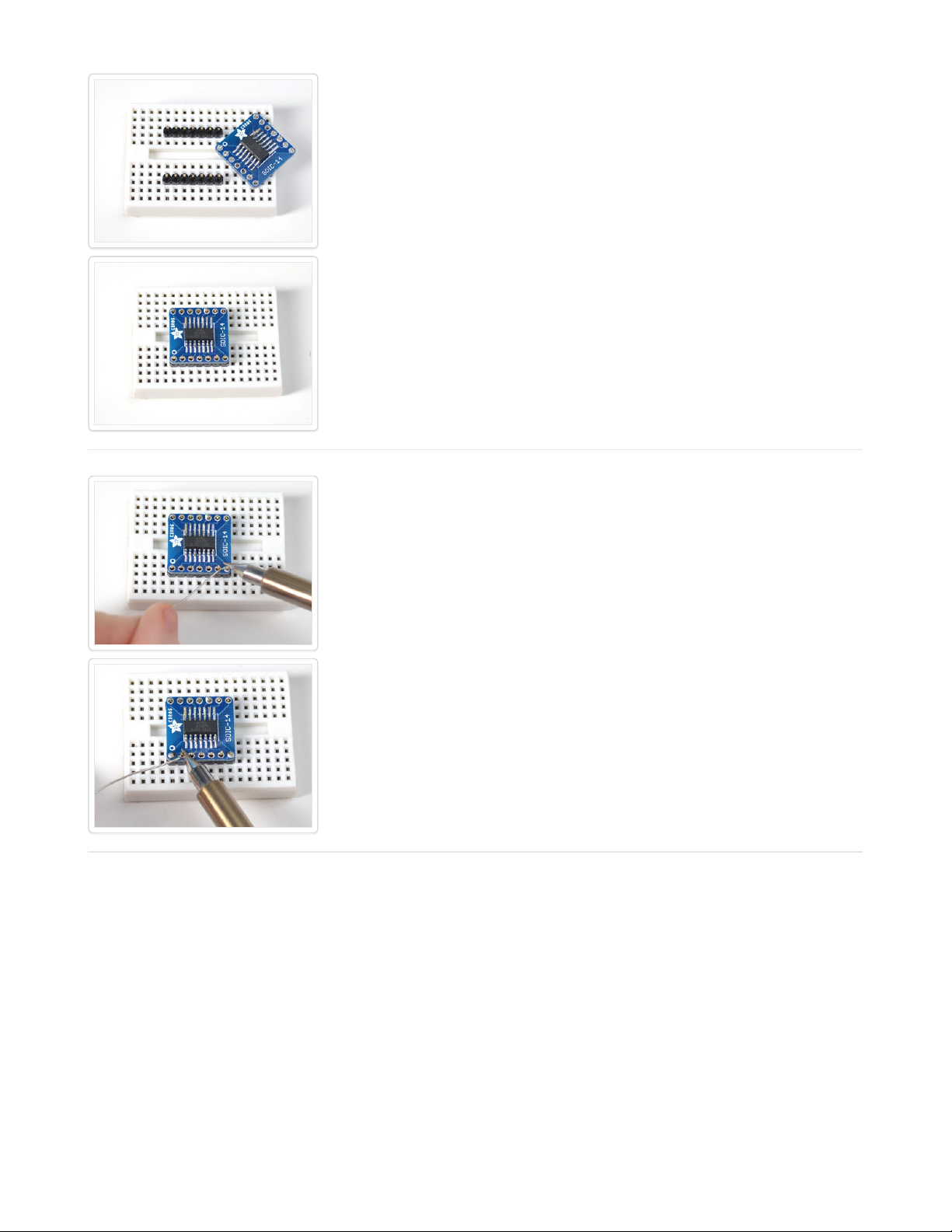

Begin by placing the breakout adapter

into your vise/third hand to keep it

steady.

We'll start by melting a little solder on

one corner pad. I like going with the top

right corner. Melt just a tiny bit on, so its

rounded but not blobby

Next you need to place the part onto the

pads, and you'll want to get the

orientation right. You can look for a dot

(indicating pin #1). In some cases, look

for a flattened corner (on the left side

here) which indicates which side is on the

left

© Adafruit Industries http://learn.adafruit.com/smt-prototyping-using-breakout-pcbs Page 6 of 8

Page 7

Once you've identified which is pin 1,

hold the chip with the tweezers over the

pads and then re-heat the corner pad

you soldered onto a few steps ago.

Now you can 'fix' the chip in place by

soldering in the opposite corner. The one

pin you soldered will keep the chip in

place mostly, so you just have to solder

the other pin a little to make the setup

secure

Go ahead and solder the remaining pins

now

© Adafruit Industries http://learn.adafruit.com/smt-prototyping-using-breakout-pcbs Page 7 of 8

Page 8

The hard part's done! Now we can solder

on regular 0.1" spaced male header. We

like the break-away kind so its easy to

get just the right amount. (You can get

some at the adafruit shop if you don't

have any!) (http://adafru.it/392)

Break two pieces the same length as the

pads on either side of the PCB and place

them into a breadboard, long pins down.

They should be parallel and the same

distance as the PCB pads so that you can

place the PCB on top with ease

Almost done, now all you have to do is

solder each header pin into the

corresponding hole to make a secure

connection

© Adafruit Industries Last Updated: 2013-03-31 09:30:21 PM EDT Page 8 of 8

Loading...

Loading...