320 / 420 / 600 / 800

Installation, Operating and

Servicing Instructions

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

661Y0700.B

EN • 1

INDEX

WARNINGS 3

Who should read these instructions 3

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Symbols 3

Recommendations 3

Applicable standards 3

Warnings 3

Packing 3

INTRODUCTION 4

Description of the specifications 4

Description of operation 4

TECHNICAL CHARACTERISTICS 5

Operating condition 5

Wiring diagram 5

INSTALLATION INSTRUCTIONS 6

Dimensions 6

Domestic hot water connections 6

Installation 6

Central heating connections 7

COMMISSIONING 8

Filling the tank 8

Check to be carried out before start-up 8

Setting the thermostat 8

MAINTENANCE 9

Periodic checks by the user 9

Annual service 9

Emptying 9

SPARE PARTS 10

661Y0700.B

EN • 2

WARNINGS

WHO SHOULD READ THESE INSTRUCTIONS

These instructions should be read by:

- the specifying engineer

- the installer

- the user

- the service engineer

SYMBOLS

The following symbols are used in this manual:

Essential instruction for

the correct operation of

the installation.

Essential instruction for

the safety of persons

and the environment.

Danger of electrocution.

• It is important to switch the tank OFF before carrying out

any work.

• There are no user accessible parts inside the tank casing.

APPLICABLE STANDARDS

The appliances carry the CE mark in accordance with the

standards in force in the various countries.

WARNINGS

This documentation is part of the information delivered with the

appliance and must be given to the user and stored in a safe

place!

An approved installer must carry out the assembly, commissioning,

maintenance and repair of the system, in accordance with current

standards in force.

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Danger of burns

RECOMMENDATIONS

• Please, read carefully this manual before installing and

commissioning the tank.

• It is prohibited to carry out any modifications to the inside of

the appliance without the manufacturer’s prior and written

agreement.

• The product must be installed and serviced by trained

engineers, in compliance with current standards.

• The installation must comply with the instructions in this

manual and with the codes and standards governing systems

for the production of hot water.

• Any failure to follow instructions relating to tests and test

procedures may result in personal injury or risks of pollution.

• To guarantee safe and correct operation of the appliance, it

is important to have it serviced and maintained every year by

an approved installer or maintenance company.

ACV shall not accept any responsibility for damage caused by noncompliant location of the system or by use of the parts or

connections not approved by ACV for this application.

The manufacturer reserves the right to change the

technical characteristics and specification of its

products without notice.

The availability of some versions and their accessories is

market dependant.

PACKING

Units are shipped ready to install, tested and packaged in a carboard box.

Contents of the package

• One hot water tank.

• One multilingual technical instruction manual.

• In case of anomaly, please call your service engineer.

• The parts may only be replaced by genuine factory parts. You

will find a list of the spare parts and their reference number

ACV to the end of this document.

661Y0700.B

EN • 3

INTRODUCTION

DESCRIPTION OF THE SPECIFICATIONS

“Tank-in-Tank” system

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

“Tank-in-Tank” is a heat exchanger with a built-in accumulator, made

up of two concentric tanks: the inner tank contains domestic water

to be reheated (secondary) and the outer tank contains the heating

fluid (primary) which circulates between the two tanks and transfers

its heat to the domestic water.

Hot water exchanger accumulator

The inner tank is the heart of the tank: it is subject to the

aggressiveness of the supply water, to high pressures and to

variations in temperature. This tank is made of solid chromenickel stainless steel (stainless steel 304 or duplex), fully welded

under argon protection using the Tungsten Inert Gas (T.I.G.)

technique.

Before assembly, the convex bottoms are pickled and passivated in

order to improve the tank’s lifespan and in particular its resistance to

corrosion. The shell is corrugated all the way up using an exclusive

manufacturing process. This design gives considerable resistance to

pressure and limits the adherence of lime scale by allowing the tank

to expand and contract.

Outer tank

The outer tank containing water from the primary circuit arriving

from the boiler, is made of carbon steel STW 22.

Thermal Insulation

This is carried out using high densit y injected polyurethane

foam, 50 mm containing no CFCs.

Lining

The tank is covered using polypropylene, a plastic material which

offers a high resistance to shocks and which is also very pleasing

to the eye.

DESCRIPTION OF OPERATION

Operating cycle

The thermostat is triggered and starts up the pump which loads the

heating fluid. This fluid circulates around the inside tank and heats

up the domestic water. When the required temperature is reached,

the thermostat stops the loading pump.

OFF Reheating Running Tepping

Cold Water

Domestic hot water

Heating fluid

Losses when shut down in Watt

Models

SL 320 ΔT = 50 K 94,4

SL 420 ΔT = 50 K 102,8

SL 600 ΔT = 50 K 110,5

Losses in

[Watt]

1 8

2

3

4

5

6

SL 800 ΔT = 50 K 121,7

Temperature losses with ambient T° of 20°C

9

1. A uxil i a r y c on n e c t io n DH W

2. Domestic cold water inlet

3. Poly ur ethane foam insulation 50 mm

4. Flow connection [primary circuit]

5. Stainless steel (304 or Duplex) inner tank

6. Return connection [primary circuit]

7. Out er steel tank [primar y circuit]

10

8. Manual air val ve

9. Domestic ho t water outle t

10. Polypropylene top lid

11. Polypropylene shell

12. Polypropylene bottom lid

11

7

661Y0700.B

12

EN • 4

TECHNICAL CHARACTERISTICS

OPERATING CONDITION

Maximum service pressure [tank filled with water]

- Heating circuit: Smart 320 / 420 / 600 / 800 4 bar

Smart 320 / 420 Duplex 6 bar

Smart 600 / 800 Duplex 5 bar

- DHW circuit: 10 bar

Operating temperature

- Maximum temperature: 90°C

Water quality

• Chlorides: < 150 mg/L [304 Stainless steel]

< 2000 mg/L [Duplex]

• 6 ≤ ph ≤ 8

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

SL

Tank characteristics

Total capacity L 318 413 606 755

Primary capacity L 55 55 161 184

Primary fl uid fl ow rate L/h 6200 6400 7200 7500

Primary pressure drop mbar 90 95 92 175

Heating surface m

2

Tank performances

Peak fl ow at 40°C L/10’ 922 1195 1345 1820

Peak fl ow at 45°C L/10’ 790 1012 1153 1474

Peak fl ow at 60°C L/10’ 504 620 706 948

Peak fl ow at 40°C L/60’ 2666 3151 3437 4039

Peak fl ow at 45°C L/60’ 2285 2608 2946 3263

Peak fl ow at 60°C L/60’ 1368 1513 1733 1811

Constant fl ow at 40°C L/h 2093 2536 2511 2888

Constant fl ow at 45°C L/h 1794 2058 2152 2347

Constant fl ow at 60°C L/h 1037 1153 1232 1306

Pre-heating time minutes 23 24 35 66

Puissance puisée kW 73 88 88 96

Running conditions: 85°C Water intake T°: 10°C

320

2,65 3,24 3,58 4,36

SL

320

SL

420

SL

420

SL

600

SL

600

SL

800

SL

800

WIRING DIAGRAM

1. Co n t r o l t h e r mos t a t [6 0/9 0 °C]

2. Lo ad pump [in option]

3. Manual reset high limit thermostat [103°C max.]

Bk

2

1

c

t

1

c

3

t

1

c

t

1

1

2

OrOr

Y/Gr

Bk

Y/Gr

L1 N

Br

W

Bk

T2 S3T1NL1

R

Or

Br

Y/Gr

B

NL1

Y/Gr

T2S3 T1 NL1

2

PH

NO

NC

SL 320 - 420

SL 320 - 420

SL 600 - 800

B. Blue

Bk. Black

Br. Brown

R. Red

Or. Orange

W. W h ite

Y/ Gr . Ye l l o w/ G r ee n

(UK version)

661Y0700.B

EN • 5

INSTALLATION INSTRUCTIONS

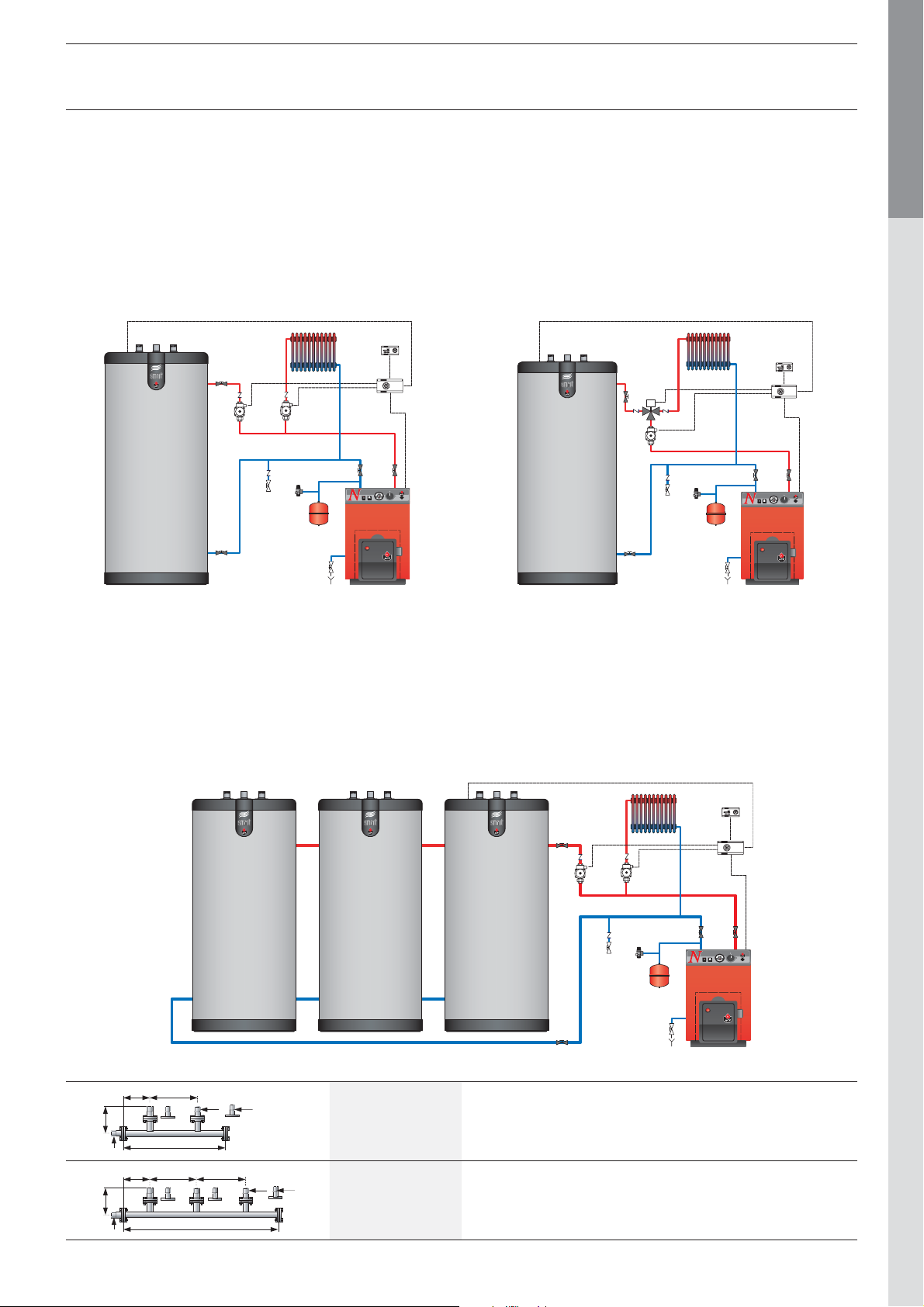

DIMENSIONS

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

A mm 1593 2018 1892 2292

B mm 1280 1705 1583 1983

C mm 250 250 255 255

D mm 660 660 817 817

Weight empty [kg] 141 167 238 280

A

SL

320

B

C

SL

420

SL

600

135

DOMESTIC HOT WATER CONNECTIONS

The installation of a domestic safety unit is compulsory.

In order to avoid water dropping on the tank, the

domestic safety unit should not be placed directely

above the tank.

The third domestic water outlet can be used as a

return from the domestic hot water circulation loop.

SL

800

INSTALLATION

This hot water tank should not be installed where it will be exposed

to outside weather conditions.

Choose the most appropriate location according to the position of

the boiler and the proximity of the domestic hot water distribution

system, in order t o reduce hea t losses and minimise the pressure

drops.

Only for floor-standing installation.

135

D

HYDRAULIC CONNECTIONS

Models Heating connections

SL 320 / 420 Ø 1”1/2 [F]

135

SL 600 / 800 Ø 2" [F]

Models DHW connectons

SL 320 / 420 / 600 / 800 Ø 1”1/2 [M]

8

2

1

33

4

1

5

1

7

9

3

1 1

1

10

Mains water kits could be in some countries due to

approval regulations.

Recommendations

• The pipe feeding the tank with cold water must be fitted

with a safety unit comprising at least the following:

- An isolating valve [1]

- a non-return valve [3]

- a safety valve [4]:

- a sanitary expansion vessel of appropriate dimensions.

• When the operating pressure exceeds 6 bar a pressure

reducer [2] must be installed before the safety unit.

• Union fittings are recommended for easy removal of the

connections. Ideally the “dielectric” version is preferable

in order to protect the connections against corrosion in

the presence of dissimilar metals such as copper and

galvanised steel.

• The installation of an expansion vessel avoids safety valve

runoff (loss of water).

• Domestic hot water expansion vessel capacit y:

18 Litres: for the following models: 320

24 Litres: for the following models: 420

35 Litres: for the following models: 600 / 800

(set to < 10 bar)

6

1. Is o l a t i n g v a l v e

2. Pressure reducer

3. Non-r et urn valve

4. Expansion tank

5. Saf et y valve

6. Drain cock

7. A i r v e n t

8. Thermo st at ic mi xing v alve

9. Circulation pump

10. Drawoff point

Please see the technical instruction manual of the

expansion vessel’s manufacturer for further details.

661Y0700.B

EN • 6

INSTALLATION INSTRUCTIONS

CENTRAL HEATING CONNECTIONS

1. System filling valve

2. Safety valve calibrated to 3 bar

3. Expan sion v essel

4. Drain cock

5. Isolation valve, heating system

6. Room thermos tat

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

7. Optional boiler control [BC 01 or BC 03]

8. Boiler pump

9. Heating pump

10. 3-ways motorized mixing valve

Tank wit h lo a d pu mp

5

8

5

9

1

2

3

Tank wit h th r ee w ays

motorized mixing valve.

6

6

7

10

5

8

5 5

1

2

3

5

4

4

7

5 5

425 850

235

2"

425 850 850

235

2"

1700

2550

2" 1

1/2

"

2" 1

Battery formation of 3 indirect water heaters

10800128 Kit battery 2x SL 320 - 420 - 600 - 800

1/2

"

10800129 Kit battery 3x SL 320 - 420 - 600 - 800

6

5

8

9

1

2

3

5

4

7

5 5

661Y0700.B

EN • 7

COMMISSIONING

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Before pressurising the central heating tank (primary)

you should first pressurise the domestic hot water

tank (secondary).

Both the domestic hot water tank and the central

heating tank must be filled before using the tank.

FILLING THE TANK

Domestic hot water tank

1. Close the drain cock [6] of the DHW circuit.

2. Open the isolating valve [1] of the DHW circuit for the filling.

3. Bleed the air in the circuit by turning on a nearby hot water

tap [10] Fill the tank until the flow rate stabilises.

4. Turn off the hot water tap [10].

8

2

1

33

4

1

5

6

1

7

9

3

1 1

1

CHECKS TO BE CARRIED OUT BEFORE START-UP

• Safety valves (domestic hot water) and (central heating)

correctly installed and discharge connected to the drains.

• Domestic hot water tank and primary circuit filled with

water.

• Air bleed correctly carried out on both circuits.

• Air valve sealed.

• Both hot and cold water pipes correctly connected to the

tank’s hot water circuit.

• Heating feed and return correctly connect ed to the tank.

• The electrical cabling is correct.

• The tank’s thermostat is set according to the instructions

shown in § “Setting the thermostat”.

• Connections checked and free of leaks.

SETTING THE THERMOSTAT

Factory settings

10

The thermostat of the tank is factory preset to the minimum

recommended by the standards, over a range of settings from

60 to 90°C.

To increase the temperature: turn the button clockwise.

To reduce the temperature: turn the button anticlockwise.

When adjusting the tank’s thermostat, make sure that the

boiler temperature is set to a value at last 10°C higher than

tank’s thermostat.

Central heating tank

1. Close the drain cock [4] on the tank’s primary circuit.

2. Open the isolation valves [5] on the central heating circuit

connected to the boiler.

3. Bleed the air in the circuit by opening the air vent located on

the upper part of the tank.

4. Follow the instructions supplied with the boiler for filling.

5. When the tank is full and the air has been removed, the

bleed valve should be closed.

6

5

8

9

1

2

5

3

Ensure that the bleed valve is properly sealed.

6. If any antifreeze is needed in the primary circuit it must be

compatible with Public hygiene rules and not be toxic.

A food-type Propylene Glycol is recommended.

Consult the manufacturer to ensure that the antifreeze is

compatible with the tank’s construction materials.

7

5 5

4

Recommendations

There is a risk that bacteria including “Legionella

pneumophila” may develop if a minimum temperature

of 60°C is not maintained both in storage and in the

hot water distribution network.

There is a risk of scalding from hot water!

ACV recommends the use of a thermostatic mixing

valve set to provide water at 60 °C or less.

• The water heated to wash clothes, dishes and for other

purposes can burn and cause serious injury.

• Children, the elderly, the sick or the disabled are the most at

risk from burns due to very hot water. Never leave them on

their own in a bath or under the shower. Never allow young

children to turn on hot water taps or fill their own baths.

• Set the water temperature appropriately according to the

intended use and plumbing codes.

When repeatedly drawing small amounts of hot water,

a “stratification” effect may develop in the tank.

The upper layer of hot water may then reach very high

temperatures. A thermostatic mixing valve will stop

water at excessivly high temperatures reaching the

outlets.

Never use car antifreeze or undiluted antifreeze.

This can cause serious injury, death or damage to the

premises.

661Y0700.B

EN • 8

MAINTENANCE

PERIODIC CHECKS BY THE USER

• Check the pressure of the boiler’s pressure gauge: it should

be between 0.5 and 1.5 bar.

• Carry out a monthly visual inspection of the valves,

connections and accessories in order to detect any leaks

or malfunctions.

• Periodically check the air valve located on the upper part of

the tank to make sure that it is not leaking.

• If you notice anything unusual, contact a technician or your

heating engineer.

ANNUAL SERVICE

The annual service, carried out by a technician, must include

the following:

• Checking the air valve:

The air bleed can lead t o water being added to the system.

Check the pressure on the boiler’s pressure gauge.

• Manually activate the domestic hot water safety valve once

a year. This operation will lead to a discharge of hot water.

Before drawing any hot water through the safety unit,

make sure that the discharge goes directly to the drain

in order to avoid any risk of burning or damage.

• The discharge pipe should be open to the atmosphere.

• If the safety unit occasionally “drips” this may be due to an

expansion problem or to clogging of the valve.

• Follow the circulator’s maintenance instructions.

• Check that the valves, cocks, controllers and any electrical

accessories installed are working properly (see the

manufacturer’s instructions if necessary)

.

Domestic hot water tank

To empty the domestic hot water tank:

1. Switch off the electrical power supply to the tank.

2. Close the isolation valve [1].

3. Open the drain cock [6] and the air vent [7].

4. Allow the water to flow out into the drain.

5. After emptying, return the valves to their initial positions.

In order to allow emptying, the drain valve [6] must be

located at the lowest point on the tank.

8

2

1

33

4

1

5

6

1

7

9

3

1 1

1

10

Central heating tank

To empty of f the primary circuit:

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

EMPTYING

Recommendations

Empty the tank if it is to be switched off during

the winter and there is a risk of frost conditions

exposure.

If the central heating water (primary circuit) contains

any antifreeze, only the domestic hot water should

be drained.

Before draining off the domestic hot water, insulate

the tank to reduce the central heating pressure

(primary circuit) to 1 bar, in order to protect the

tank against a risk of collapsing.

If the central heating circuit does not contain any

antifreeze, both the central heating and hot water

circuits should be drained.

1. Switch off the electrical power supply to the tank.

2. Close the shut-off valves [5] on the primary circuit.

3. Connect a hose to the drain valve [4].

4. Open the drain valve [4] and drain the hot wat er off.

5. To speed up the process, open the air vent located on the

upper part of the tank.

6. When the emptying is finished, close the drain cock again

then screw the air valve up again.

6

5

8

9

1

2

3

5

7

5 5

4

661Y0700.B

EN • 9

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

A01

N°

SL

320

SL

420

SL

600

SL

800

A02

A03

A04

SL 320 - 420

A01

A02

A03

A04

497B5001 497B5001 497B5007 497B5007

39438047 39438049 39438030 39438049

49410089 497B0029 49410044 497B0029

497B5000 497B5000 497B5006 497B5006

SL 320 - 420 (UK)

SL 600 - 800

55445006 55445006

54442045 54442045

54764021 54764021

24614154

54764020

661Y0700.B

24614152

EN • 10

Loading...

Loading...