ACV SLE 210 Plus, SLE 210, SLE 300, SLE 300 Plus, SLE 240 Plus Installation, Operating And Maintenance Instructions

...Page 1

Smar t Line SLE - SLE Plu s : 661Y2100 • A

EN

FR

NL

ES

IT

DE

PL

RU

INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS

SLE

130 - 160 - 210 - 240 - 300

SLE Plus

210 - 240 - 300

SMART Line

Page 2

EN

FR

NL

ES

IT

DE

PL

RU

en

2

Smar t Line SLE - SLE Plu s : 661Y2100 • A

TABLE OF CONTENTS

USER'S GUIDE .............................................................................................5

Control panel

............................................................................................................................................................. 5

APPLIANCE DESCRIPTION ........................................................................6

TECHNICAL CHARACTERISTICS ..............................................................7

Main characteristics

............................................................................................................................................. 7

Dimensions .................................................................................................................................................................. 7

Heating connections ...........................................................................................................................................8

Domestic hot water connections .............................................................................................................. 8

Domestic hot water performances ..........................................................................................................9

Maximum operating conditions ................................................................................................................ 9

Electrical characteristics ................................................................................................................................10

INSTALLATION ........................................................................................11

Package contents

................................................................................................................................................. 11

Tools required for the installation........................................................................................................... 11

Safety instructions ............................................................................................................................................... 12

Connection ................................................................................................................................................................ 14

Connection to the DHW circuit ................................................................................................................. 15

Connection to the primary circuit .......................................................................................................... 16

Examples of possible combinations of the SLE and SLE Plus ...........................................17

Tank used as electric DHW tank only ................................................................................................... 18

Page 3

en

3

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

TABLE OF CONTENTS

STARTING UP ...........................................................................................19

Safety instructions to ll the tank

........................................................................................................... 19

Filling ..............................................................................................................................................................................20

Checks before starting up .............................................................................................................................22

Starting up .................................................................................................................................................................22

MAINTENANCE ........................................................................................23

Periodic checks by the user

.........................................................................................................................23

Annual maintenance .........................................................................................................................................23

Draining ........................................................................................................................................................................ 24

Bringing back into service after maintenance .............................................................................25

Fault nding ..............................................................................................................................................................26

Page 4

NOTES

• This manual contains important information with respect to the installation, the starting up

and the maintenance of the hot water tank.

• This manual must be provided to the user, who will read it carefully and keep it in a safe

place.

• The availability of certain models as well as their accessories may vary according to the markets.

• The manufacturer reserves the right to change the technical characteristics and features of

its products without prior notice.

We accept no liability should any damage result from the failure to comply with theinstructions contained in this technical manual.

Essential instructions forthe safety of persons and the environment

• It is strictly prohibited to bring any modification to the appliance, without

themanufacturer’s prior written approval.

• The appliance must be installed by a qualified installer, in accordance with

applicable regulations.

• The installation must comply with the instructions contained in this manual and

with the regulations applicable to installations.

• Failure to follow the instructions in this manual could result in personal injury or a

risk of environmental pollution.

• The manufacturer declines all liability for any damage caused as a result of

incorrect installation or in the event of the use of appliances or accessories that are

not approved by the manufacturer.

Essential instructions forthecorrect operation oftheinstallation

• In order to ensure that the appliance operates correctly, it is essential to have it

serviced by a certified installer or maintenance contractor every year.

• In case of problem, please contact your installer for advice.

• Faulty parts must only be replaced with genuine parts.

• Our domestic hot water tanks are designed and manufactured exclusively for the

heating and storage of domestic hotwater.

• The domestic hot water heaters must only be heated using hot water in a closed

circuit.

• The part number (N° Art.) and serial number (N° Ser.) of the tank are indicated on

its rating plate and must be provided to ACV in case of warranty claim. Failure to

do so will make the claim void.

EN

FR

NL

ES

IT

DE

PL

RU

en

4

Smar t Line SLE - SLE Plu s : 661Y2100 • A

GENERAL RECOMMENDATIONS

Page 5

en

5

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

USER'S GUIDE

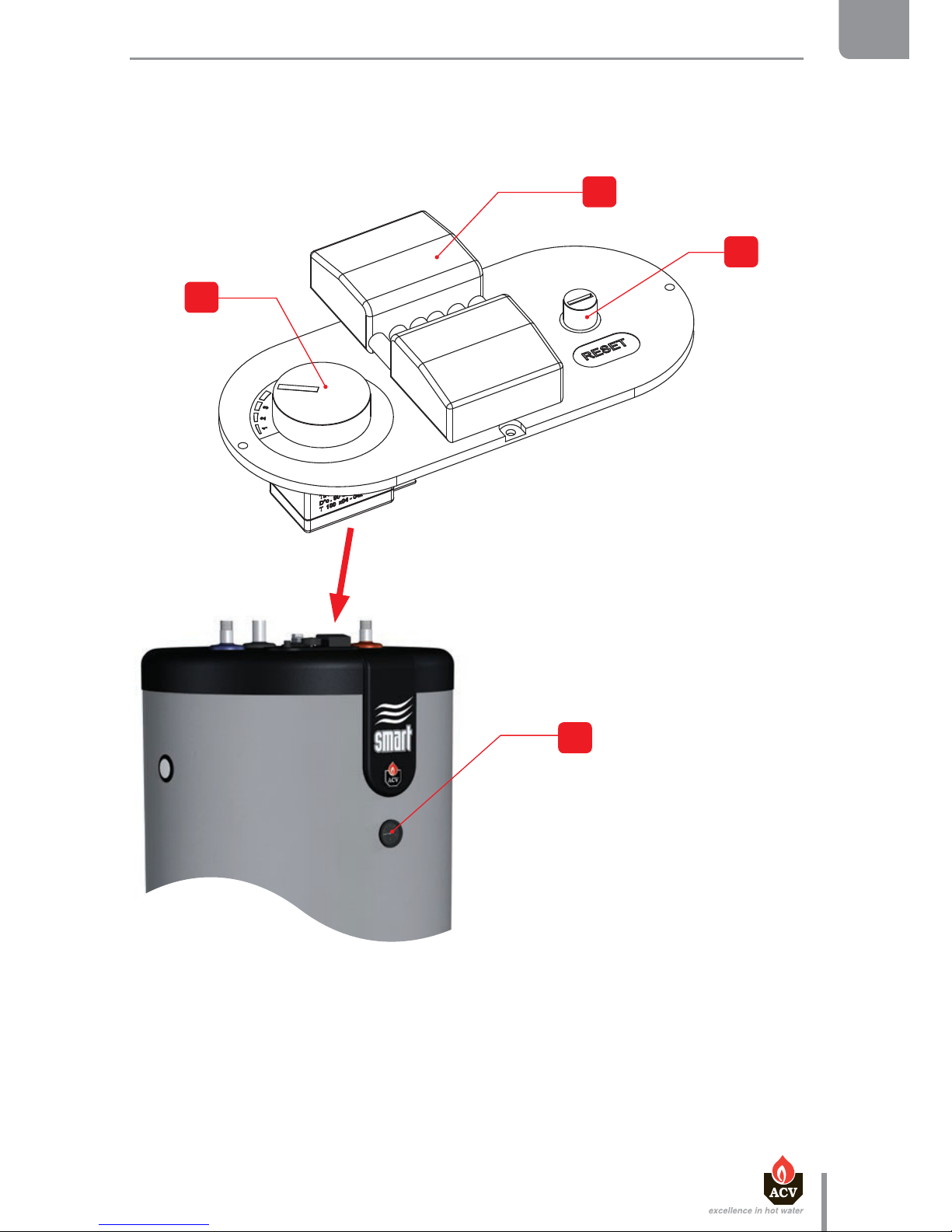

CONTROL PANEL

Key :

1. Control thermostat [60/90°C] - to set the domestic hot water (DHW) temperature.

2. Manual reset high limit thermostat - to restart the tank after overheating of the primary circuit.

3. Connection plug - to connect the electrical power supply.

4. Thermometer - indicates the temperature of the DHW.

4

1

3

2

Page 6

EN

FR

NL

ES

IT

DE

PL

RU

en

6

Smar t Line SLE - SLE Plu s : 661Y2100 • A

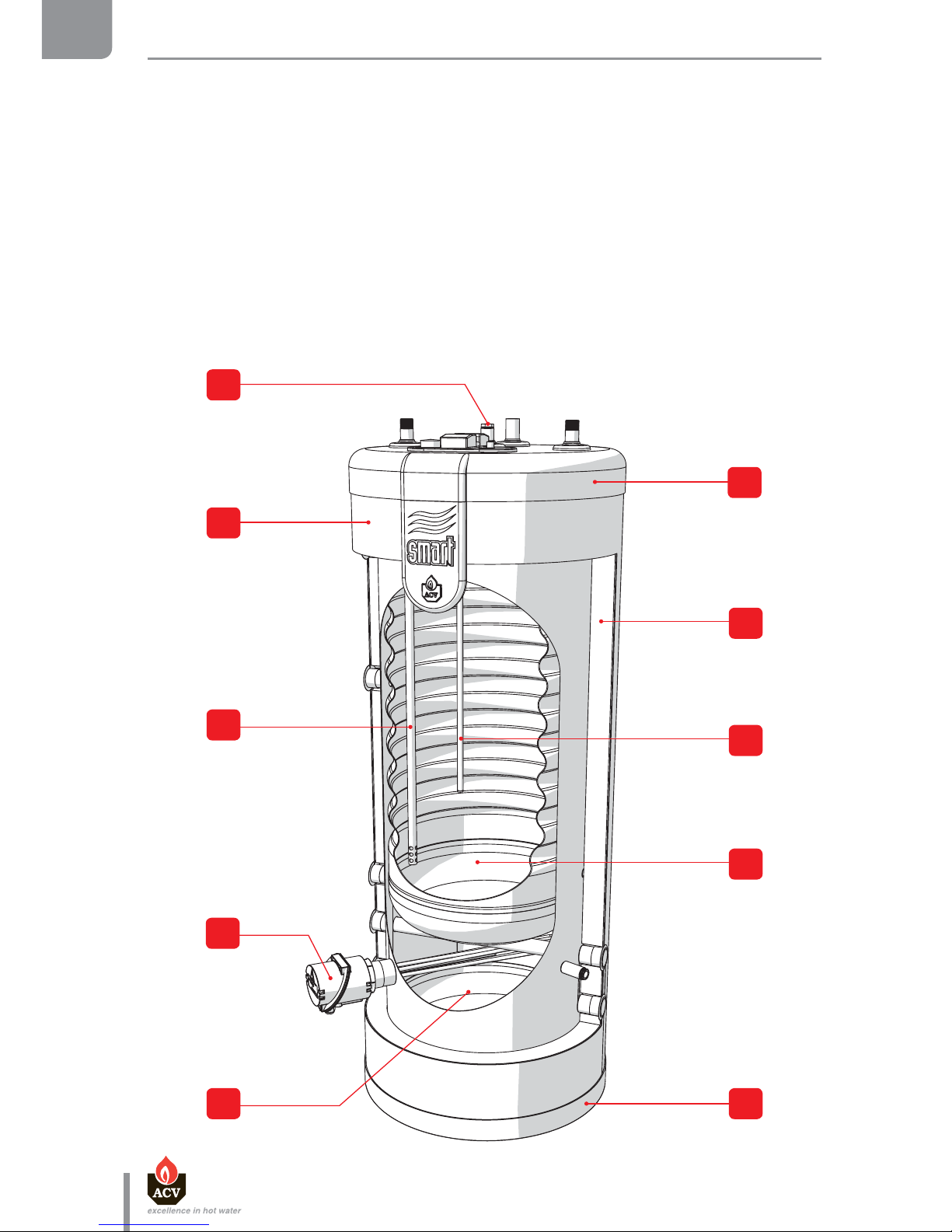

APPLIANCE DESCRIPTION

MODELS SLE / SLE Plus

High efficiency storage water tanks, to be installed on the floor. Possibility to heat by transfer fluid

or independently with an optional electric resistance.

1. Manual air bleed valve

2. Polypropylene shell

3. Dip tube

4. Electrical heating element (optional)

5. Outer steel tank (primary circuit)

6. Polypropylene top lid

7. Polyurethane foam insulation

8. Dry well

9. Stainless steel tank (DHW)

10. Polypropylene bottom lid

6

2

1

3

5

4

7

9

8

10

Page 7

en

7

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

TECHNICAL CHARACTERISTICS

TECHNICAL CHARACTERISTICS

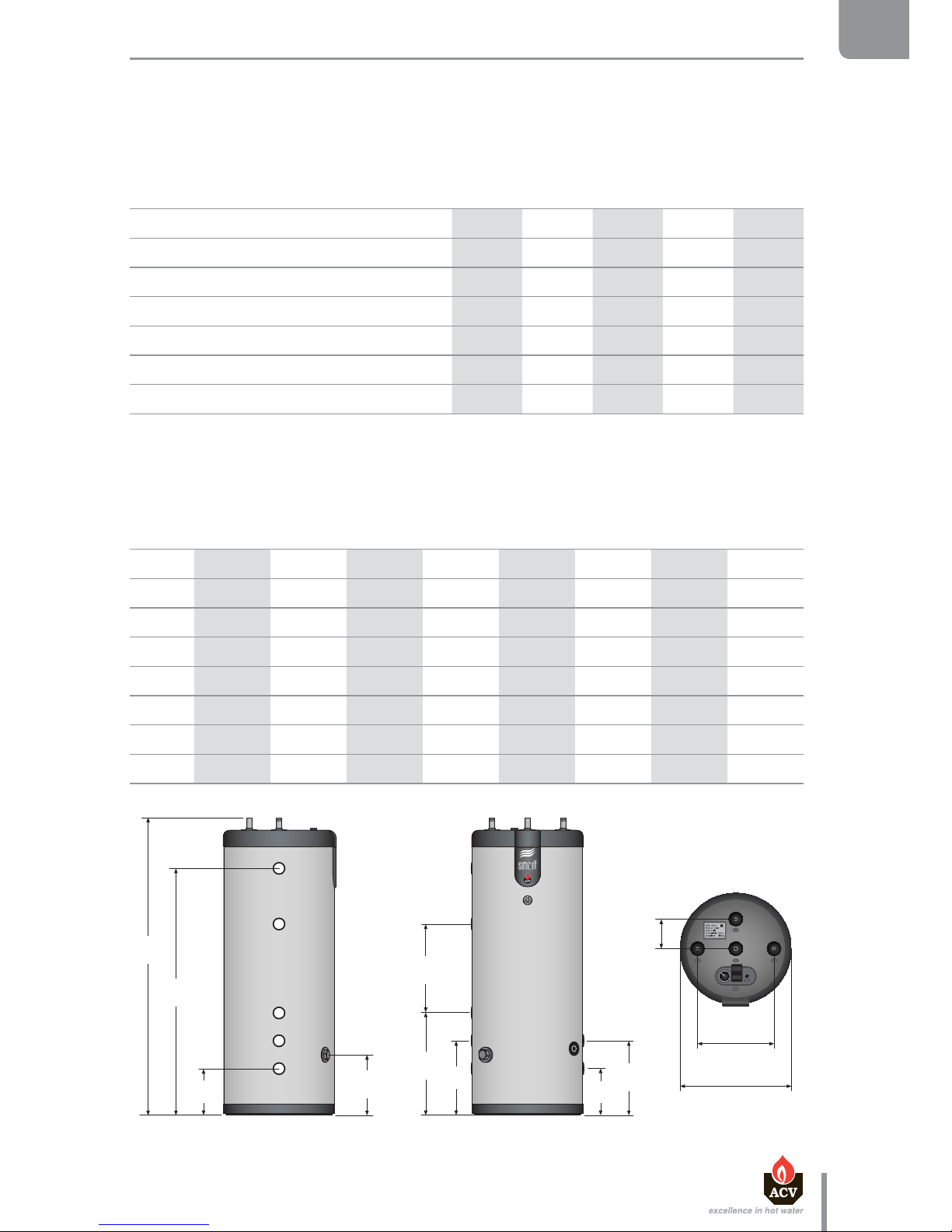

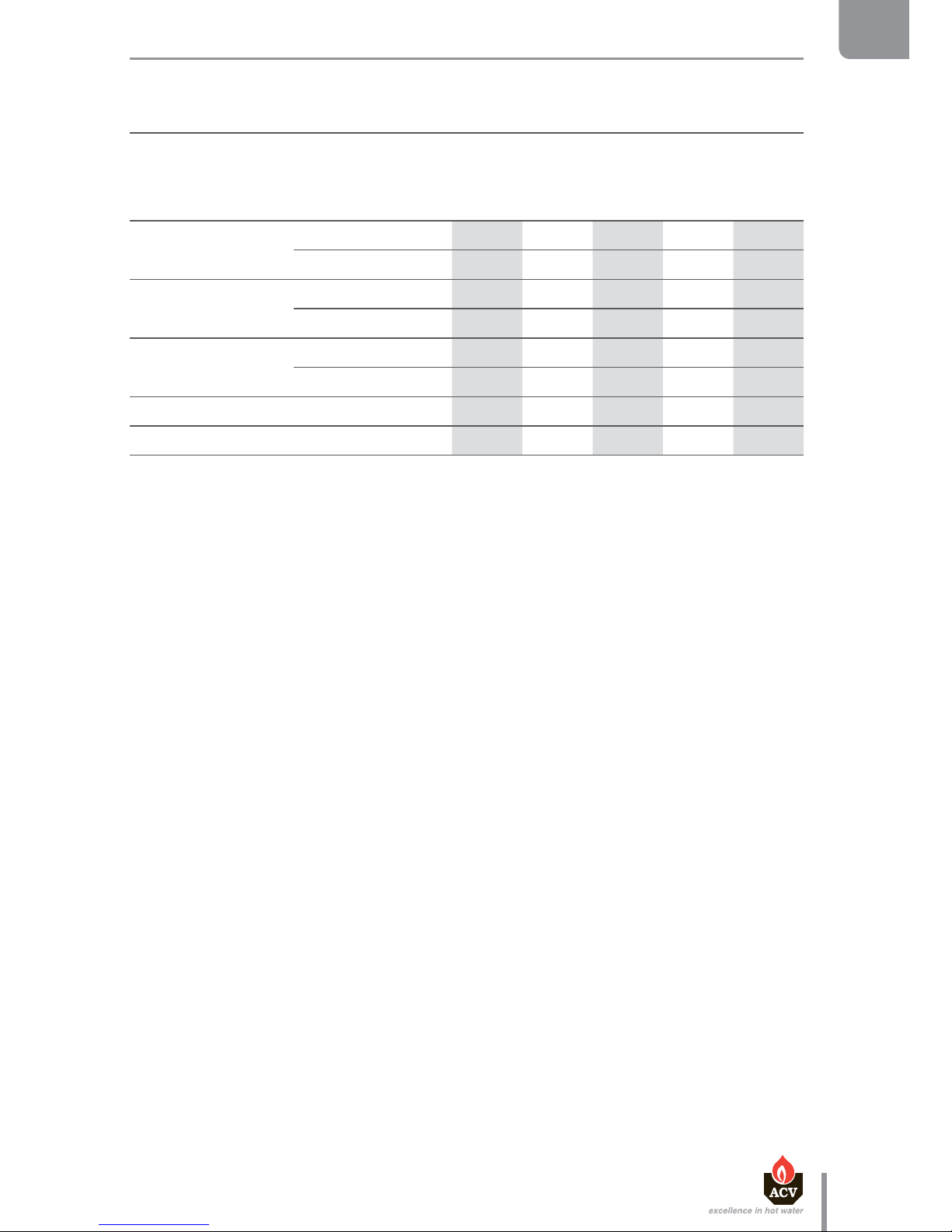

MAIN CHARACTERISTICS

MAIN CHARACTERISTICS

SLE

130

SLE

160

SLE /

SLE Plus

210

SLE /

SLE Plus

240

SLE /

SLE Plus

300

Total capacity L 130 161 203 242 293

Primary circuit capacity (heating) L 55 62 77 78 93

Sanitary circuit capacity L 75 99 126 164 200

Primary uid ow rate L/h 2100 2600 3500 4200 5500

Primary pressure drop mbar 17 22 37 45 51

Tank heating surface m² 1,03 1,26 1,54 1,94 2,29

Empty weight kg 45 54 66 76 87

DIMENSIONS

SLE

130

SLE

160

SLE

210

SLE

240

SLE

300

SLE Plus

210

SLE Plus

240

SLE Plus

300

A (mm)

1025 1225 1495 1740 2045 1495 1740 2050

B (mm)

760 960 1230 1480 1780 1230 1480 1785

C (mm)

235 235 235 235 230 235 235 235

D (mm)

235 235 335 340 405 315 305 340

E (mm)

— — — — — 940 1070 1280

F (mm)

— — — — — 475 455 525

G (mm)

— — 375 375 405 355 345 380

H (mm)

— — 235 235 230 235 235 235

A

B

C

D

E

F

G

H

G

360

150

565

Page 8

EN

FR

NL

ES

IT

DE

PL

RU

en

8

Smar t Line SLE - SLE Plu s : 661Y2100 • A

TECHNICAL CHARACTERISTICS

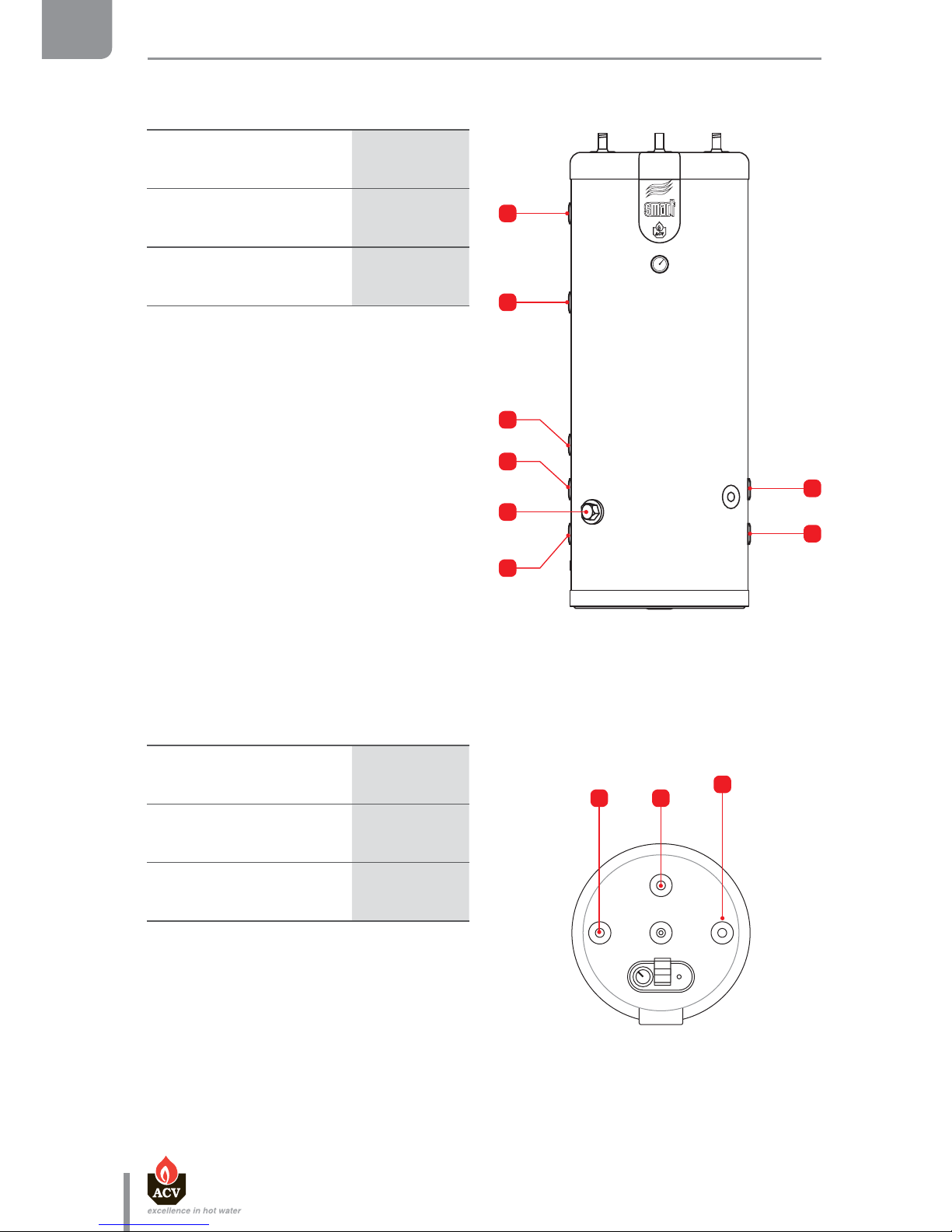

HEATING CONNECTIONS

DOMESTIC HOT WATER CONNECTIONS

1. Heating ow connection (tank loading)

2. Auxiliary heating return

(only SLE Plus)

3. Auxiliary heating return

(only SLE Plus)

4. Heating ow connection / heat pump

(except SLE 130 - 160)

5. Optional electrical heating element connection

6. Heating return connection / heat pump

7. Flow heating circuit

(except SLE 130 - 160)

8. Return heating circuit

(except SLE 130 - 160)

1. Cold water inlet connection

2. Auxiliary connection (DHW)

3. Domestic hot water connection

Connections

dimensions

SLE /

SLE Plus

Heating connection Ø 1" [F]

Optional electrical heating

element connection

Ø 1"½ [F]

Connections

dimensions

SLE /

SLE Plus

Cold / hot water

connections

Ø 3/4" [M]

Auxiliary

connections

Ø 3/4" [F]

1

2

3

4

6

5

7

8

21

3

Page 9

en

9

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

TECHNICAL CHARACTERISTICS

DOMESTIC HOT WATER PERFORMANCES

DHW performance :

Heating source = External boiler

connected to tank *

SLE

130

SLE

160

SLE /

SLE Plus

210

SLE /

SLE Plus

240

SLE /

SLE Plus

300

Peak ow at

40°C [∆T = 30K]

L/10' 236 321 406 547 800

60°C [∆T = 50K]

L/10' 117 161 209 272 370

Constant ow at

40°C [∆T = 30K]

L/h 658 890 1132 1527 2100

60°C [∆T = 50K]

L/h 320 465 576 769 970

Peak ow 1

st

hour at

40°C [∆T = 30K]

L/60' 784 1063 1349 1820 2360

60°C [∆T = 50K]

L/60' 384 549 689 913 1100

Maximum absorbed power kW 23 31 39 53 68

Reheat time Minutes 22 22 20 20 22

* Conditions : Primary circuit temperature : 85°C, water intake temperature : 10°C

MAXIMUM OPERATING CONDITIONS

Maximum Service Pressure [tank full of water]

- Primary circuit : .................................................3 bar

- DHW water circuit : ......................................8,6 bar

Maximum Temperature

- Maximum DHW temperature : ....................90°C

Supply Pressure (DHW circuit)

- Max. 6 bar without requiring a pressure reducing valve

Water Quality

- Chlorides < 150 mg/L

- 6 ≤ pH ≤ 8

- If the water hardness is > 20°fH, the installation of a water softener is recommended.

Page 10

EN

FR

NL

ES

IT

DE

PL

RU

en

10

Smar t Line SLE - SLE Plu s : 661Y2100 • A

TECHNICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

Main characteristics SLE / SLE Plus

Rated voltage V~ 230

Rated frequency Hz 50

Optional heating element

The models SLE / SLE Plus can be installed with a self- controlled heating element with builtin control safety thermostats. The control thermostat of the tank can not control the heating

element. To be mounted with an external box with a switch and a circuit breaker - not included

in the delivery.

Volt Amp Power Code

1 x 230 V 13 3 kW 10800081

3 x 400 V + N 4.4 3 kW 10800082

1 x 230 V 26 6 kW 10800083

3 x 400 V + N 8.8 6 kW 10800084

Wiring diagram

1. Manual reset high limit thermostat

2. Control thermostat [60/90°C]

Bk. Black

Br. Brown

Or. Orange

R. Red

W. White

Y/Gr. Yellow/Green

1

Y/Gr

Br

Y/Gr

R

W

Or

Bk

T2S3 T1 NL1

T2 S3T1NL1

t

2

c

1

2

t

c

1

L

N/C

N/O

Page 11

en

11

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

INSTALLATION

PACKAGE CONTENTS

The appliances are delivered assembled, tested and packed.

At product reception and after removal of packaging,

check the package contents and that the appliance is

free of damages.

Contents packaging :

• A domestic hot water tank.

• A technical manual

TOOLS REQUIRED FOR THE INSTALLATION

General remarks

Make sure to place the rating plate on the outer casing of the tank, so that it is easily

accessible and readable.

The manufacturer reserves the right to change the technical characteristics and

features of its products without prior notice.

The availability of certain models as well as their accessories may vary according to

the markets.

Page 12

SAFETY INSTRUCTIONS

General remark

• Connections (electrical, hydraulic) must be carried out in accordance with

applicable standards and regulations.

• If the water drawing off point is far from the tank, installing an auxiliary DHW loop

can allow to get hot water more quickly at all times.

Essential instructions forthecorrect operation oftheinstallation

• The tank must be installed in a dry and protected area.

• Install the appliance to ensure easy access at all times.

• To avoid any risk of corrosion, connect the stainless steel tank directly to the earth.

• Make sure to install a pressure reducing valve set at 4.5 bar in the DHW circuit if the

supply pressure is higher than 6 bar.

• On the DHW circuit, install an approved safety group, comprised of a safety valve

set at 7 bar, a check valve and a stop valve.

• Make sure that the outlet of the safety unit goes directly to the sewer to avoid any

potential damage.

• Do not install the safety group above the tank to avoid water discharge on to the

tank.

EN

FR

NL

ES

IT

DE

PL

RU

en

12

Smar t Line SLE - SLE Plu s : 661Y2100 • A

INSTALLATION

Page 13

Essential instructions forthe safety of persons and the environment

• Hot water can burn!

In the event of small amounts of hot water repeatedly being drawn off, a

stratification effect can develop in the tank. The upper hot water layer may then

reach very high temperatures.

• ACV recommends using apre-set thermostatic mixing valve in order to provide

hot water at a maximum of 60°C.

• Water heated to wash clothes, dishes and for other uses can cause serious burns.

• In order to avoid exposure to extremely hot water that can cause serious burns,

never leave children, old people, disabled or handicapped people in the bath

orshower alone.

• Never allow young children to turn on the hot water or fill their own bath.

• Adjust the water temperature in accordance with usage and plumbing regulations.

•

The risk of developing bacteria exists, including “Legionella pneumophila”,

ifaminimum temperature of 60°C is not maintained in both the DHW tank andthe

hot water distribution network.

Essential instructions for the electrical safety

• Only an approved installer is authorized to carry out the electrical connections.

• Install a 2-way switch and a fuse or circuit breaker of the recommended rating

outside the appliance, so as to be able to shut power down when servicing the

appliance or before performing any operation on it.

• Shut down external electrical supply of the appliance before performing any

operation on the electrical circuit.

• This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge,

unless supervised or unless they have been given instruction concerning the use

of the appliance by a person responsible for their safety.

en

13

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

INSTALLATION

Page 14

CONNECTION

Essential instructions forthe safety of persons and the environment

• Refer to the safety instructions for the installation. Failure to comply with these

instructions can result in damages to the installation, severe injuries or death.

• Hot water can burn! ACV recommends using a pre- set thermostatic mixing valve

in order to provide hot water at a maximum of 60°C.

Essential instructions forthecorrect operation oftheinstallation

• The filling circuit of the DHW tank must be equipped with a safety group,

comprised at least of a stop valve, a check valve, a safety valve set at 7 bar, and

possibly, an expansion vessel of the appropriate size. Make sure that the circuit

between the tank and the safety valve is always open.

• The third DHW tank connection, if any, can be used for the auxiliary DHW loop.

If the connection is not used, replace the protective plug by a brass plug of the

appropriate size.

General remarks

• In certain countries the domestic kits must be approved.

• The circuit illustrations are basic principle diagrams only.

EN

FR

NL

ES

IT

DE

PL

RU

en

14

Smar t Line SLE - SLE Plu s : 661Y2100 • A

INSTALLATION

• To protect the primary circuit when the stop valves are closed, a safety valve and

expansion vessel are imperative between the tank and the stop vales.

Page 15

en

15

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

INSTALLATION

CONNECTION TO THE DHW CIRCUIT

1. Filling valve

2. Pressure reducing valve (set at 4.5 bar)

3. Check valve

4. DHW expansion vessel

5. Safety valve (set at 7 bar)

6. Drain valve

7. Draw-o tap

8. Pressure gauge

9. Grounding

10. Stop valve

11. Thermostatic mixing valve

12. Air vent

Cold water

Hot water

Domestic hot water kit (option)

1. Thermostatic mixing valve

2. Mixed water outlet - Ø 3/4" [M]

3. DHW expansion vessel connection - Ø 3/4" [M]

4. Safety unit (7 bar)

5. Outlet hot water tank - Ø 3/4" [F]

6. Inlet cold water tank - Ø 3/4" [F]

7. Cold water inlet - Ø 3/4" [M]

8. Drain connection - Ø 1" [M]

2

7

1

5 6

3 4

8

The drain connection 8 must be connected to the sewer system to avoid hot water

projections on the top cover of the tank.

1102

3

4

8

5

9

10

7

6

11

2

7

1

5 6

3 4

8

12

Page 16

EN

FR

NL

ES

IT

DE

PL

RU

en

16

Smar t Line SLE - SLE Plu s : 661Y2100 • A

INSTALLATION

CONNECTION TO THE PRIMARY CIRCUIT

1. Primary circuit lling valve

2. Charging pump

3. Check valve

4. Primary circuit stop valve

5. Expansion vessel

6. Pressure gauge

7. Safety valve (set at 3 bar)

8. Drain valve

9. Stop valve

Cold water

Hot water

1 2 3 4

8

5

9

7

6

4

Page 17

en

17

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

INSTALLATION

EXAMPLES OF POSSIBLE COMBINATIONS OF THE SLE AND SLE PLUS

SLE Plus combined with a heat pump and floor heating system.

SLE 210 / 240 / 300 combined with a boiler and floor heating system.

Prestige

Page 18

EN

FR

NL

ES

IT

DE

PL

RU

en

18

Smar t Line SLE - SLE Plu s : 661Y2100 • A

INSTALLATION

TANK USED AS ELECTRIC DHW TANK ONLY

Do not power the heating element if the outside tank is not filled and bled.

1. System lling valve

2. Safety valve (set at 3 bar)

3. Expansion vessel

4. Isolation valve, heating system

5. Pressure gauge

Essential instruction for the correct operation of the installation

• Connections must be carried out in accordance with applicable standards and

regulations.

4

1

2

3

5

Plug all unused

connections

Plug all unused

connections

Page 19

SAFETY INSTRUCTIONS TO FILL THE TANK

Essential instructions forthe safety of persons and the environment

• The DHW tank must always be filled and pressurised before filling and pressurising

the primary circuit.

• Do not use vehicle antifreeze. This can cause serious injury or death, or damage

facilities.

• If antifreeze is needed in the primary circuit, it must comply with Public

Hygiene Regulations and must be non-toxic. A food-grade Propylene Glycol is

recommended. It must be diluted according to the ratio recommended in the local

regulations.

• Consult the manufacturer to determine the compatibility of the antifreeze with the

tank's construction materials.

Essential instructions forthecorrect operation oftheinstallation

• Before bringing the tank into service, check the connections to avoid any risk

ofleaks during filling.

• Only use drinking water to check that the DHW tank is watertight. The on-site

testpressure must not exceed a pressure surge of 8,6 bar.

• Using antifreeze in the primary circuit will lead to a reduction in the heating

performance. The higher the concentration of antifreeze in the circuit, the lower

the performance.

en

19

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

STARTING UP

Page 20

FILLING THE DHW TANK Figure 1

General remark

• Connect the safety valve outlet to the sewer.

1. To fill the tank, open a hot water tap (2) located at the highest point of the installation. It

enables to bleed the air from the installation.

2. Open the filling valve (1) and the stop valves (3) to fill the DHW tank.

3. Close the hot water tap (2), after the water flow has stabilised and the air has been

completely evacuated.

4. Check all the connections of the installation for leaks.

FILLING THE PRIMARY CIRCUIT Figure 2

General remark

• If the tank is used within a heating installation, refer to the heating boiler manual.

FILLING

Essential instructions forthecorrect operation oftheinstallation

• The DHW t ank must always be filled and pressurised b efore filling and pressurising

the primary circuit.

1. Check that the drain valve (3) of your primary circuit is tightly closed.

2. Open the stop valves (1) and (2) of the primary circuit connected to the heating boiler.

3. Open the air bleed valve (4) located on the top of the hot water tank.

4. Connect the filling pipe to the valve (3) and open the valve to start filling the heating circuit.

5. Once the system is bled from air, close the airbleed valve (4). Make sure the air bleed valve

is tight.

6. Once the desired pressure is reached, close the valve (3) and disconnect the filling pipe from

the valve (3).

EN

FR

NL

ES

IT

DE

PL

RU

en

20

Smar t Line SLE - SLE Plu s : 661Y2100 • A

STARTING UP

Page 21

en

21

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

STARTING UP

Cold water

Hot water

Figure 1

1

3

3

2

Figure 2

1 2

4

3

1 2

Page 22

CHECKS BEFORE STARTING UP

• Check that the safety valves (DHW and primary) are correctly installed and that the outlets are

connected to the sewer.

• Check that the DHW tank and the primary circuit are filled with water.

• Check that the air has been correctly bled from both circuits.

• Check that the tank’s upper air bleed valve is tight.

• Check that the water side and heat source side pipes are correctly connected and not leaking.

• Check that the sensor of the thermostat is correctly positioned in the dry well (see figures

below).

STARTING UP

If the tank is used as electric DHW tank only:

1. Put the electric plug into the mains socket

2. Adjust the required temperature using the control thermostat integrated in the electrical

resistance.

If the tank is used within a heating installation:

To put the installation into service, refer to the heating boiler manual.

1. Adjust the required temperature using the control thermostat of the tank.

EN

FR

NL

ES

IT

DE

PL

RU

en

22

Smar t Line SLE - SLE Plu s : 661Y2100 • A

STARTING UP

Page 23

PERIODIC CHECKS BY THE USER

• Check the pressure of the primary circuit pressure gauge: it should be between 0.5 and 1.5 bar.

• Visually inspect, on a regular basis, the valves, connections and accessories in order to detect

any leaks or malfunction.

• Periodically check the air bleed valve located on the tank top to ensure that itisnot leaking.

• Check that the DHW water circuit safety valves are in good operating condition.

• In the event of a problem, please contact an engineer or your installer.

ANNUAL MAINTENANCE

Essential instructions forthecorrect operation oftheappliance

• The discharge pipe of the safety unit must be open to the outside. If the safety

unit drips periodically, it may be due to an expansion problem or clogging ofthe

valve.

• For internal inspections, the hand hole can be used. If there is none, use one of the

water connections to insert the appropriate inspection equipment. If necessary,

drain the tank before inspection.

The annual maintenance service, performed by an engineer, must include:

• A check of the air bleed valve: the bleeding of air can lead to the need for adding water to

the system.

• A check of the primary and DHW circuit pressure gauges.

• The manual activation of the storage water circuit safety valve once a year. This operation

will lead to a discharge of hot water.

• A check of the correct operation of valves, taps, control units and accessories that are

possibly installed [refer to the manufacturer's instructions if necessary].

en

23

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

MAINTENANCE

Page 24

DRAINING

Essential instructions forthe safety of persons and the environment

• The water coming out of the drain valve is very hot and can cause very severe

burns. Make sure the area around the hot water flow is clear of people.

Essential instructions for the electrical safety

• Shut down the external electrical supply of the installation before draining.

Essential instructions forthecorrect operation oftheinstallation

• Drain the tank if it is not used in winter and is at risk from exposure to ice. If the

primary circuit water contains antifreeze, only the DHW tank must be drained. If

the heating circuit does not contain antifreeze, the heating circuit and domestic

water must be drained.

• Before draining the DHW, isolate the tank and lower the pressure of the heating

circuit to 1 bar, in order to prevent the DHW tank from being crushed.

DRAINING THE PRIMARY CIRCUIT Figure 3

To drain the primary circuit of the hot water heater:

1. Stop the charging pump.

2. Isolate the hot water primary circuit byclosing the stop valves (1).

3. Connect the drain valve (2) to the sewer using a flexible hose.

4. Open the drain valve (2) and drain thewater from the primary circuit tothedrain.

5. Open the tank’s air bleed valve (3) toaccelerate drainage.

6. Close the drain valve (2) and air bleed valve (3) after draining the tank.

EN

FR

NL

ES

IT

DE

PL

RU

en

24

Smar t Line SLE - SLE Plu s : 661Y2100 • A

MAINTENANCE

Cold water

Hot water

Figure 3

1

2

1

3

Page 25

DRAINING THE DHW TANK Figure 4

To drain the hot water heater’s DHW tank:

1. Open fully the hot water tap (3) for at least 60 minutes to make sure the DHW tank has cooled

down sufficiently.

2. Close the filling valve (1) and the stop valve (4).

3. Connect the drain valve (2) to the sewer using a flexible hose.

4. Open the drain valve (2) and the air vent (5) to drain the water from the DHW tank to the

sewer.

5. Close the drain valve (2) and the air vent (5) after having drained the DHW tank.

en

25

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

MAINTENANCE

BRINGING BACK INTO SERVICE AFTER MAINTENANCE

Refer to chapter "Starting up", page 19

Figure 4

1

4

2

3

Cold water

Hot water

4

5

Page 26

EN

FR

NL

ES

IT

DE

PL

RU

en

26

Smar t Line SLE - SLE Plu s : 661Y2100 • A

MAINTENANCE

1

Check the power supply, when the tank operates as electric DHW tank only

(electrical resistance activated).

2

Check the proper operation of the boiler and the

control thermostat of the tank.

3

Check if the charging pump works properly and replace if necessary

4

Check the safety thermostat on the tank and/or the electric

heating element and reset or replace if necessary.

5

Check the electric heating element and

replace if necessary.

Models

SLE / SLE Plus

SLE / SLE Plus + electric heating element

FAULT FINDING

What to do if the domestic hot water is not heated anymore?

Page 27

en

27

EN

FR

NL

ES

IT

DE

PL

RU

Smar t Line SLE - SLE Plu s : 661Y2100 • A

RATING PL ATE

:

Type :

Year :

N° Art. :

T. max.

:

99999

12345678

Name of product

2014

90°C

3 bar

230 V 50Hz

8,6 bar

KERKPLEIN N° 39

1601 RUISBROEK

BELGIUM

www.acv.com

(21) 99999 (91) 12345678 (92) 2014

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Max. :

Max. :

N° Ser. :

SPECIMEN

Page 28

EN

FR

NL

ES

IT

DE

PL

RU

en

28

Smar t Line SLE - SLE Plu s : 661Y2100 • A

Loading...

Loading...