Page 1

P R E S T I G E

TECHNICAL

excellence in hot waterexcellence in hot water

Page 2

A place for the cd containing all the diagrams

presented in this book. Diagrams are in

AutoCad format.

Page 3

TABLE OF

CONTENTS

Description

INTRODUCTION

Page

04

HEAT EXCHANGER

CONSTRUCTION

WORKING PRINCIPLE

Technical characteristics

TECHNICAL DATA

DIMENSIONS

Connections

HEATING CONNECTIONS

PRESSURE DROP DIAGRAM - HEATING

HOT WATER CONNECTIONS

PRESSURE DROP DIAGRAM - HOT WATER

ELECTRICAL CONNECTIONS

CHIMNEY CONNECTIONS

Burner, regulator, cascade

BURNER

05

06

07

TABLE OF CONTENTS

08

09

10

10

11

11

12

15

16

REGULATOR ACV / MCBA

CASCADE OF BOILERS

Samples of installation

LEGEND

SCHEME 1

SCHEME 2

SCHEME 3

SCHEME 4

SCHEME 5

SCHEME 6

SCHEME 7

SCHEME 8

Prestige 50 - 75 Solo for 1 heating circuit and hot water production, weather dependent

regulation by the boiler MCBA and the room thermostat

Prestige Solo for 1 heating circuit and hot water production, weather dependent

regulation by the boiler MCBA and the Room Unit

Prestige Solo for 2 heating circuits and hot water production, regulated by the

boiler MCBA and the AM 3-11 module

Prestige Solo for 2 heating circuits and hot water production, regulated by the

boiler MCBA and the ZMC-1 module

Prestige Solo for 2 heating circuits and hot water production, regulated by the

Control Unit

Prestige Solo with solar system and SLME cylinder for 2 heating circuits

and hot water production, regulated by the Control Unit

Prestige Solo with solid fuel boiler for 2 heating circuits and hot water

production, regulated by the Control Unit

Cascade of 2 Prestige

regulated by the Control Unit

50 - 75

50 - 75

50 - 75

50 - 75

50 - 75 - 120

50 - 75 - 120

50 - 75 - 120 Solo for 2 heating circuits and hot water production,

16

16

17

20

21

22

24

26

28

30

32

SCHEME 9

SCHEME 10

SCHEME 11

SCHEME 12

SCHEME 13

Cascade of 3 Prestige Solo with solar system for 2 heating circuits and hot

water production, regulated by the Control Unit

Cascade of 2 Prestige Solo for 4 heating circuits and hot water production,

regulated by the 2 Control Unit

Cascade of 2 Prestige Solo with HeatMaster 201 (hot water production) for

3 heating circuits, regulated by the Control Unit

Cascade of 2 Prestige Solo with cascade of 2 HeatMasters’ 201 (hot water

production) for 3 heating circuits, regulated by the 2 Control Unit

Cascade of 8 Prestige 50 - 75 - 120 Solo, regulated by the Control Unit

50 - 75 - 120

50 - 75 - 120

50 - 75 - 120

50 - 75 - 120

34

36

38

40

42

Page 4

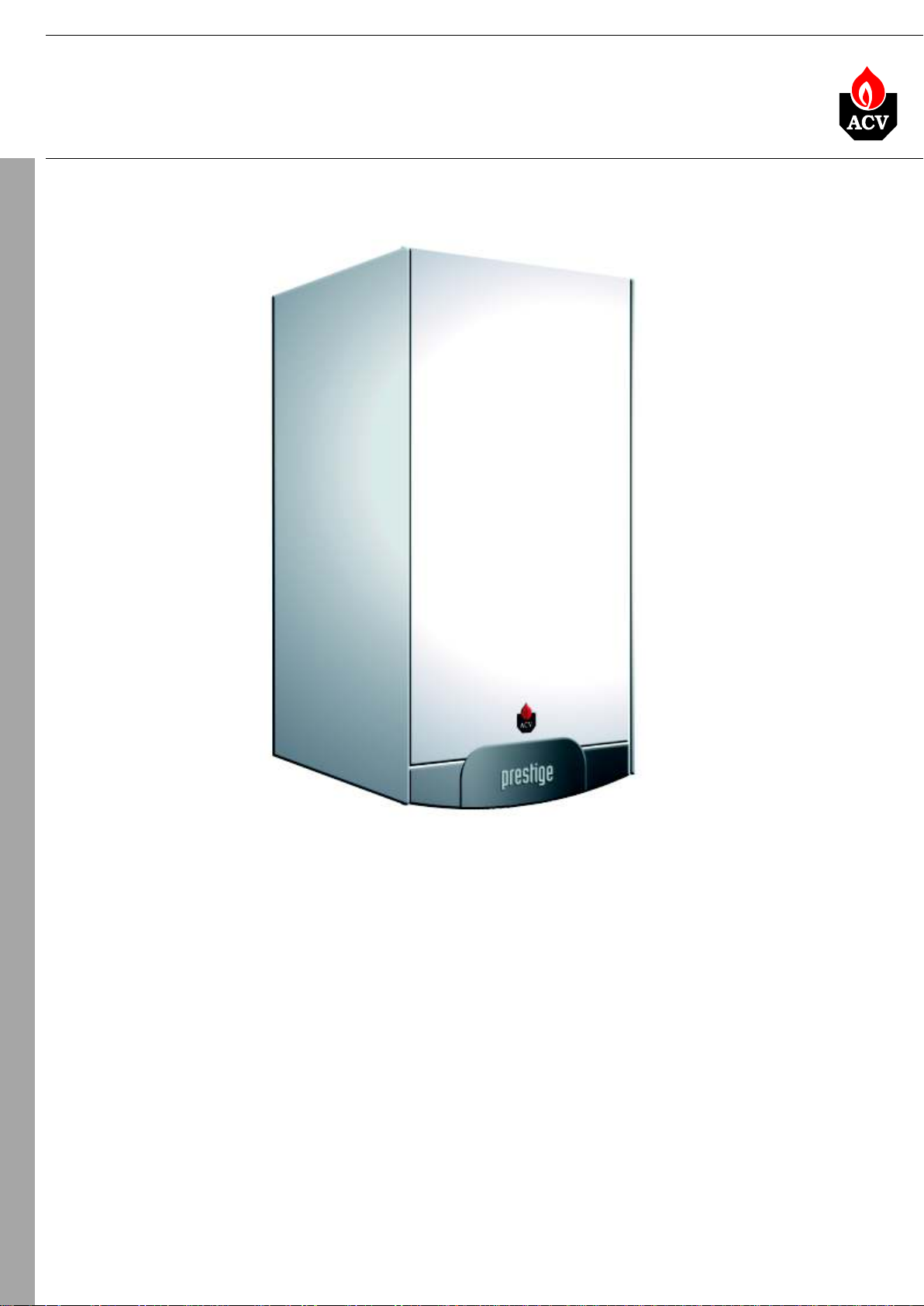

04

DESCRIPTION

INTRODUCTION

PRESTIGETECHNICAL

excellenceinhotwaterexcellenceinhotwater

Excellent

resistance to

corrosion and

very economic,

quite operation.

Prestige is a wall-mounted gas condensing boiler with very high efficiency. At

the heart of the Prestige is a new, specially designed stainless steel heat

exchanger, developed after intensive research and laboratory testing. Designed

using ACV’s 80 years experience in the manufacture of heating and hot water

products. Stainless steel offers very high resistance to corrosion eighter from

water or condensed combustion gases. In this unique construction combustion

gases pass downwards through the heat exchanger tubes, making maximum

use of the energy available from the combustion process. Moreover, as the

condensate runs down the heat exchanger tubes, it cleans any traces of

combustion residue, this ensures that the boiler continues to function at

maximum efficiency throughout its life.

The Prestige burner can operate for both natural gas and propane, they are

very quite with low NOx emission. An integrated weather dependent regulator

controls the burner power which increases boiler efficiency and reduces gas

consumption. The boilers are very compact and lightweight. Can be connected

in cascade to increase output or installed together with HeatMaster or ACV

tank-in-tank for hot water production. Prestige can fulfill the needs of both the

individual and highly specialised user.

®

Page 5

05

HEAT EXCHANGER

EXCELLENT RESISTANCE TO

CORROSION

Stainless steel offers a high

resistance to corrosion from the

internal primary water which could

contain system additives and

impurities. It is also resistant to the

acidity of condensate which forms in

the flue ways, and even to the

presence of sulfpher traces in natural

gas or propane.

HIGH EFFICIENCY

The stainless steel heat exchanger

flue tubes are designed to reach an

optimal heat exchange over their

entire length. The Prestige maintain

an exceptional continuous output

throuhout the life of the boiler, since

no oxidation occurs in the heat

exchanger. Furthermore the fuel

consumption of the boiler is

improved thanks to the reduced

pressure loss in the flue tubes.

LIGHTWEIGHT

Due to the exceptional corrosion

resistant properties of stainless steel,

an equivalent aluminium heat

exchanger would be much thicker

and therefore much heavier than the

stainless steel heat exchanger of the

Prestige.

excellenceinhotwaterexcellenceinhotwater

LOW MAINTENANCE

The stainless steel heat

exchanger of the Prestige is self -

cleaning, as the condensate runs

down the exchanger tubes it

cleans any possible traces of

combustion residue. This ensures

that the boiler continues to

function at maximum efficiency

throughout its life, and therefore

maintenance requirements for the

heat exchanger are reduced.

STABLE BOILER

TEMPERATURE CONTROL

Most boilers use a water tube for

the combustion process, however

the stainless steel heat

exchanger of the Prestige has

flue tubes running through the

sealed water jacket. This

increases the volume of water in

the system, the benefit is that it

allows stable temperature control

of the boiler and minimizes the

risk of overheating due to varying

water flow rates.

DESCRIPTION

Special construction of the

heat exchanger allows better

heat exchange from

combustion gases to the

water

Page 6

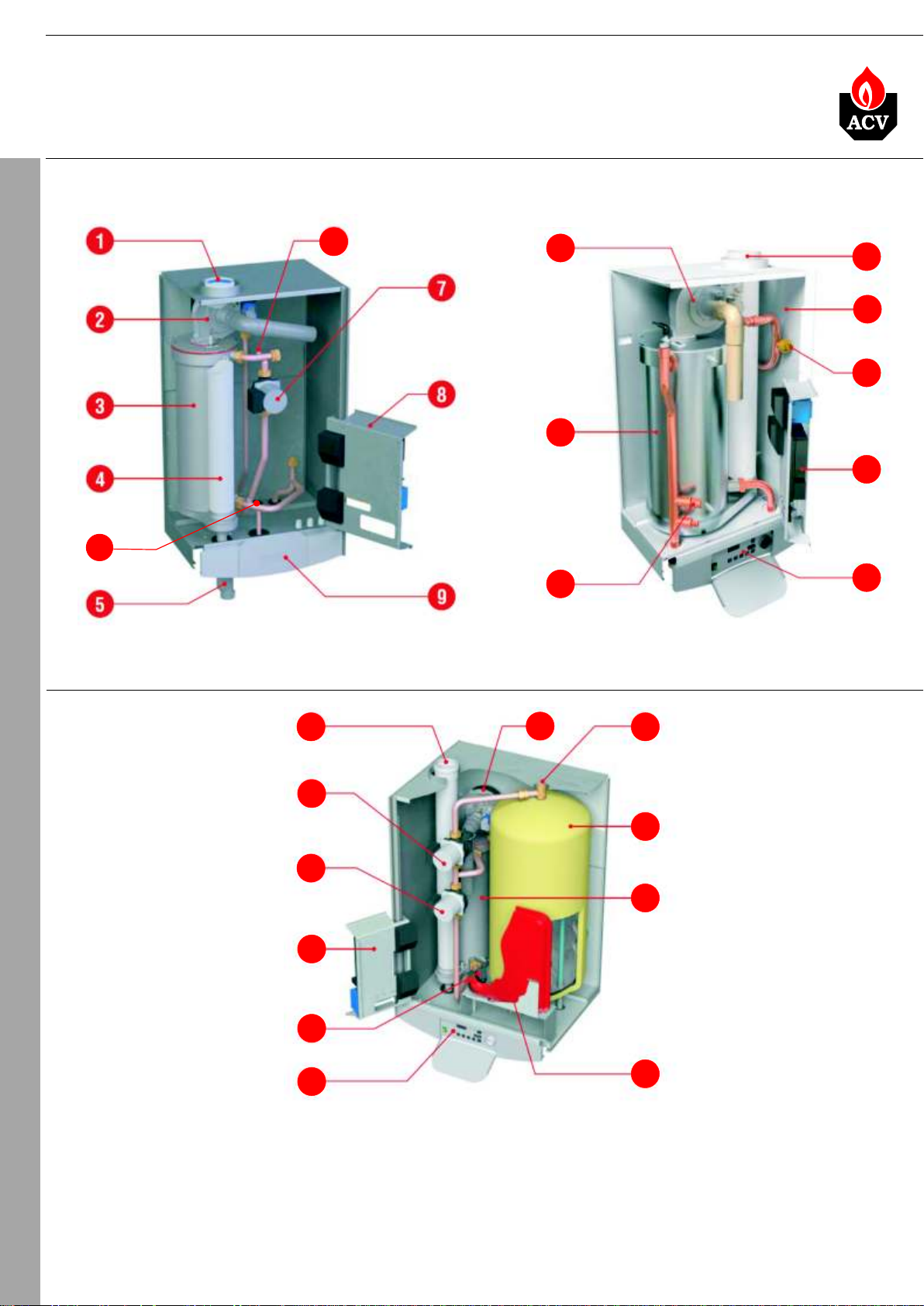

06

DESCRIPTION

CONSTRUCTION

PRESTIGE SOLO

PRESTIGETECHNICAL

14

24 - 32 50 - 75 - 120

11

2

3

14

excellenceinhotwaterexcellenceinhotwater

1

15

6

8

9

PRESTIGE EXCELLENCE

1

10

7

8

14

9

2

11

12

3

13

LEGEND:

1. Chimney connection

2. Burner

3. Stainless steel heat exchanger

4. Flue tubes

5. Condensate trap

6. Low gas pressure switch

7. CH primary pump

8. Electrical plate

9. Control panel

10. Hot water primary pump

11. Air vent

12. Stainless steel hot water tank

13. Expansion vessel

14. Low pressure water switch

15. Casing

Page 7

07

WORKING PRINCIPLE

CONDENSATION

During natural gas or propane combustion, CO2 and water vapour is created. The temperature of

combustion gases that leave a non-condensing boiler can be more than 150 C, which means that

during stable boiler operation, water vapour will not condese. These combustion gases are hot,

and this heat is lost to the atmosphere.

The Prestige is a condensing boiler, which means that the water vapour from combustion gases

will condense and this heat will be recovered. Condensing boilers convert latent vapour energy

contained in flue gases back to water, exploiting its thermal energy and therefore reducing fuel

consumption.

This is how the standard output of a condensing boiler reaches 109% measured on the

combustion gas LHV (Low Heating Value), which immiediately translates into an energy saving of

25-30% compared to a traditional system.

Contrary to traditional boilers, a condensing boiler not only uses the heat produced in combustion

but also converts the latent heat of the vapour.

The Prestige features incredibly low emissions of nitrogen oxygen (NOx) and carbon monoxide

(CO): emissions are 30% lower than the most stringent environment protection standards.

excellenceinhot waterexcellencein hotwater

0

DESCRIPTION

OPERATION

Working principle

Pre-mixed gas and air is blown by the fan to the burner head, where it ignites on the burner tube.

The number of fan revolutions are regulated to allow for fluent power modulation of the burner.

The flue gases pass downwards through the flue tubes of the heat exchanger and in the lower part

the water vapour from flue gases is condensed, the condensate flows down to the trap below the

boiler.

Special construction of the flue tubes allows for efficient heat exchange to the water, when the

condensate flows down through the heat exchanger, it cleans it automatically. The primary water

is pumped across the heat exchanger, in the Prestige 24-32 these pumps are located under the

front casing.

The Prestige Excellence is also equipped with a 54 litre cylinder for hot water production. The

cylinder is made using ACV tank-in-tank system. You know all the advantages of ACV tank-intank system ...

Boiler management

Boiler operation is managed by the MCBA. The control manages all the gas burner and boiler

functions, including its safety parameters and flame modulation, as well as monitoring and

controlling the water temperature (outlet/inlet) and the combustion gases. It can also work as a

weather dependent regulator when the outside temperature sensor is connected.

With the MCBA you can also regulate a DHW tank or with further enhacements control multiple

heating circuits and communicate with other boilers and controls.

Page 8

08

TECHNICAL CHARACTERISTICS

TECHNICAL DATA

Fuel

Input min/max

Output min/max

Efficiency 30% (EN677)

Flue - max. pressure drop

CO in combustion gases

2

Max NOx emission

Max CO emission

G20 gas flow rate

G31 gas flow rate

Weight

Heating circuits

Heating connections

Hot water connections

Max. operating temperature

PRESTIGETECHNICAL

Total capacity

Boiler water capacity

Hot water tank capacity

Capacity of the expansion vessel

Max. operating pressure heating/hot water

Hot water peak flow Dt=30 C

Hot water peak flow Dt=25 C

Electrical connection

Supply voltage

Maximum absorbed electrical power

Class

0

0

Type

kW

kW

%

max Pa

%

mg/kWh

mg/kWh

3

m /h

3

m /h

kg

0

litr

litr

litr

bar

l/min

l/min

V/Hz

IP

Prestige Solo

24

G20, G31

5,9/24*

5,8/23,4*

109

130

max 9,3*

66*

45/20*

2,5

0,98**

48

1”

-

C

A

90

8

8

-

-

3/-

-

-

230/50

0,8

30

Prestige Excellence

24

G20, G31

5,9/24*

5,8/23,4*

109

130

max 9,3*

66*

52/20*

2,5

0,98**

92

1”

3/4”

90

70

16

54

1x12 litr

3/10

17,5

21,0

230/50

0,8

30

Prestige Solo

32

G20, G31

5,9/32*

5,8/31,0*

109

130

max 9,3*

66*

45/20*

3,4

1,3**

48

1”

-

90

8

8

-

-

3/-

-

-

230/50

0,8

30

[*] gaz G20 values

**] Prestige with propane has P in the name

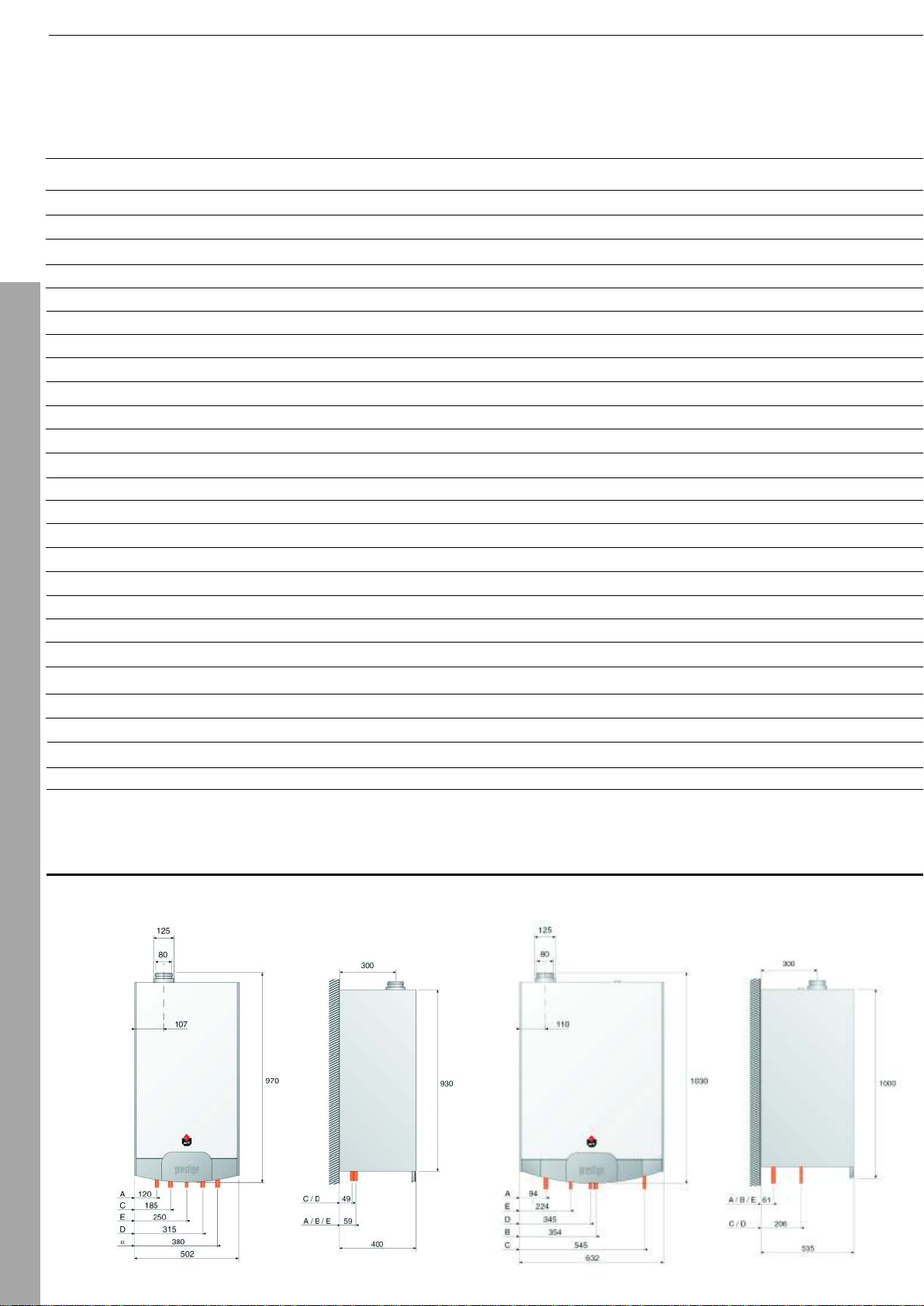

DIMENSIONS

PRESTIGE SOLO 24 - 32

PRESTIGE EXCELLENCE 24 - 32

Page 9

09

Prestige Excellence

32

G20, G31

5,9/32*

5,8/31,0*

109

130

max 9,3*

66*

52/20*

3,4

1,3**

92

1”

3/4”

90

70

16

54

1x12 litr

3/10

22,4

27,0

230/50

0,8

30

Prestige Solo

50

G20, G31

15/49,9*

14,7/48,4*

107,8

150

max 9,4*

66*

45/20*

5,3

2,0**

58

1 1/4”

90

20

20

-

4/-

-

-

230/50

1,1

30

Prestige Solo

75

G20, G31

18,3/72*

17,9/69,9*

107,8

150

max 9,4*

62*

52/20*

7,6

2,8**

58

1 1/4”

90

17

17

-

-

4/-

-

-

230/50

1,1

30

Prestige Solo

120

G20, G31

45/80-126*

36,3/78,1-116,6*

150

max 9,5*

47*

106/*

12,7

5,1**

83

1 1/2”

90

28

28

-

-

4/-

-

-

230/50

1,1

30

TECHNICAL DATA

Type

kW

kW

%

max Pa

%

Efficiency 30% (EN677)

Flue - max. pressure drop

CO in combustion gases

2

mg/kWh

mg/kWh

3

m /h

3

m /h

kg

Hot water connections

0

C

Max. operating temperature

litr

litr

litr

Hot water tank capacity

Capacity of the expansion vessel

Max. operating pressure heating/hot water

bar

l/min

l/min

Hot water peak flow Dt=30 C

Hot water peak flow Dt=25 C

Electrical connection

V/Hz

A

Maximum absorbed electrical power

IP

Input min/max

Output min/max

Max NOx emission

Max CO emission

G20 gas flow rate

G31 gas flow rate

Heating circuits

Heating connections

Total capacity

Boiler water capacity

Supply voltage

Fuel

Weight

0

0

Class

TECHNICAL CHARACTERISTICS

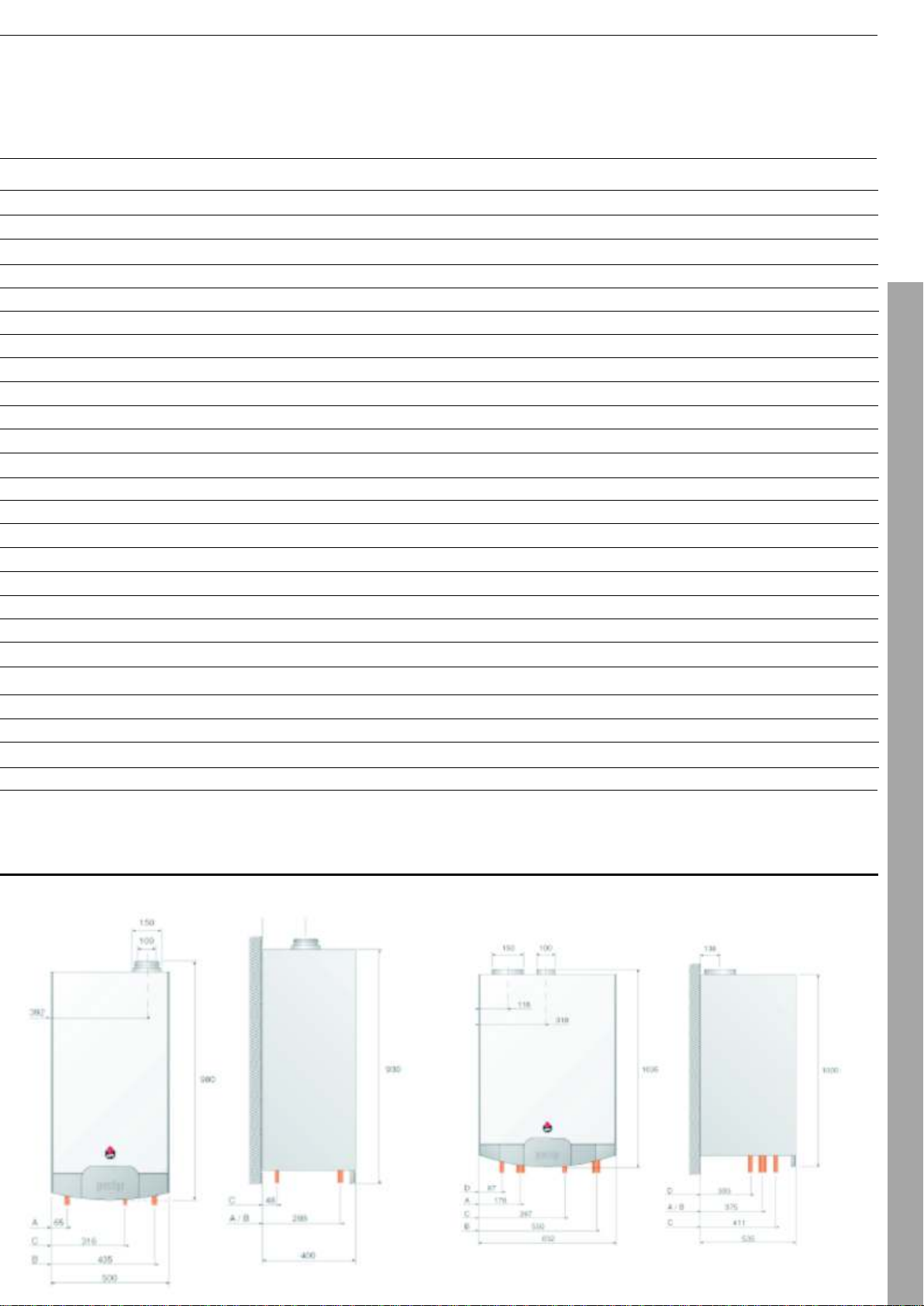

PRESTIGE SOLO 50 - 75

DIMENSIONS

PRESTIGE SOLO 120

Page 10

10

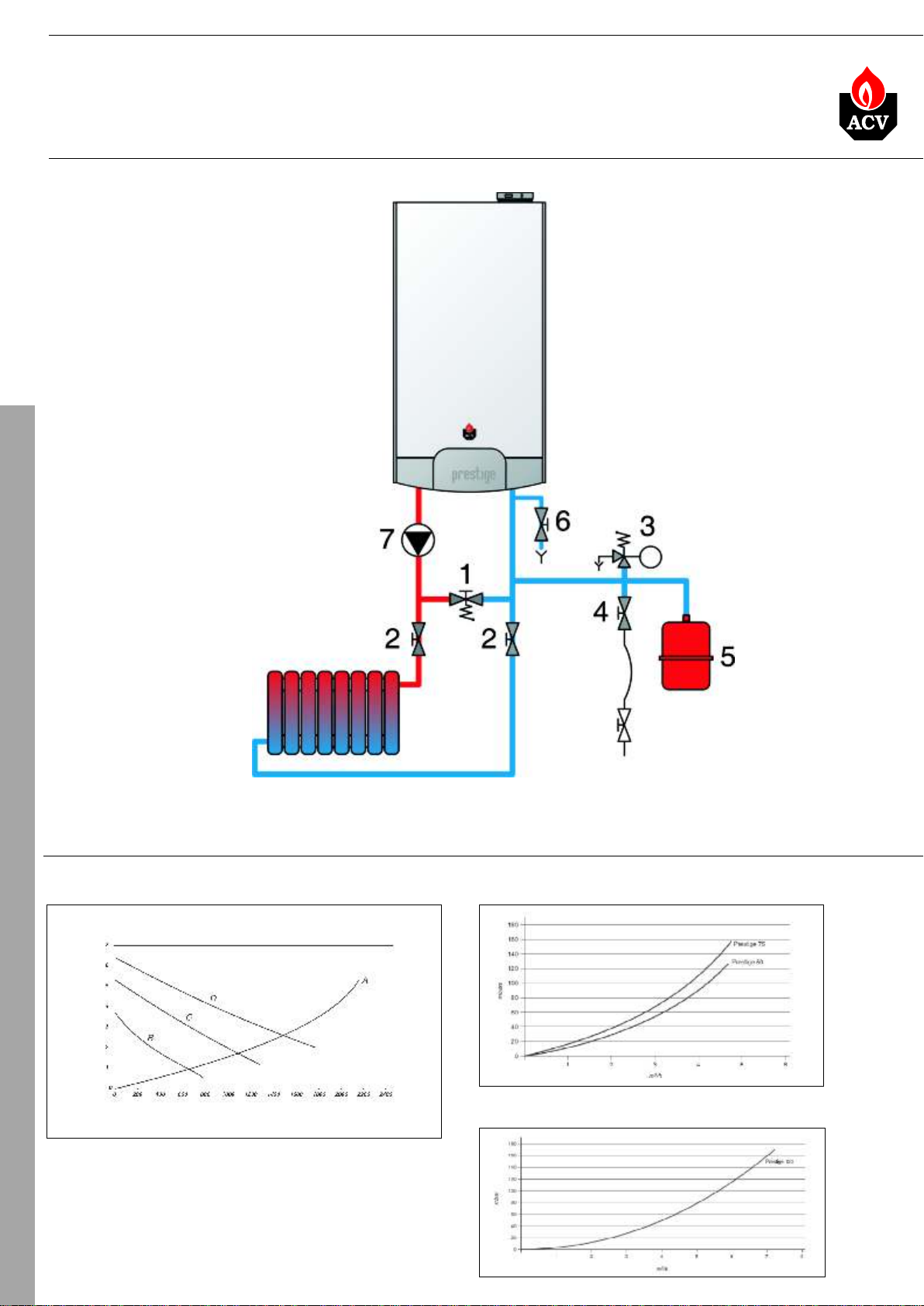

CONNECTIONS

HEATING CONNECTIONS

1. By-pass with differential pressure valve

2. Isolating valve, heating system

3. Safety valve calibrated to 3 bar, with

pressure gauge

4. System filling valve

5. Expansion vessel

6. Drain cock

7. Loading pump, heating system

excellenceinhot waterexcellencein hotwater

PRESTIGETECHNICAL

DIAGRAMS OF PRESSURE DROP - HEATING SIDE

PRESTIGE 24 - 32 SOLO PRESTIGE 50 - 75 SOLO

Pressure (mH2O)

Flow (litres/hour)

A = pressure drop of the boiler

B = pressure available circulator on 1

C = pressure available circulator on 2

D = pressure available circulator on 3

PRESTIGE 120 SOLO

Page 11

11

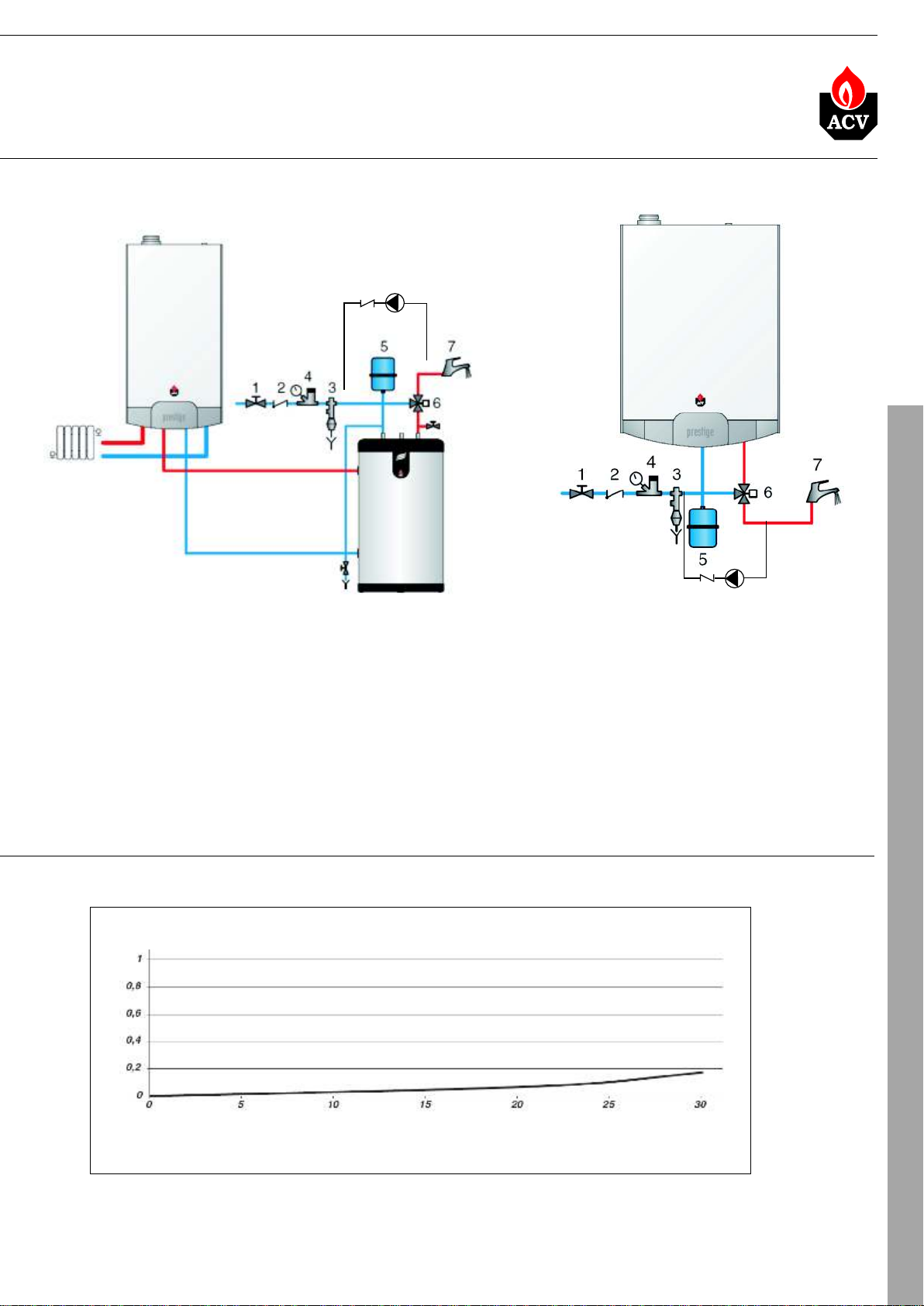

DOMESTIC HOT WATER CONNECTIONS

PRESTIGE SOLO

2

excellenceinhot waterexcellencein hotwater

PRESTIGE EXCELLENCE

8

CONNECTIONS

8

2

1. Isolating valve

2. Non-return valve

3. Safety valve

4. Pressure reducing valve (4 bar)

5. Expansion vessel

6. Thermostating mixing valve

7. Hot outlet

8. Circulating pump

DIAGRAMS OF PRESSURE DROP - DOMESTIC HOT WATER SIDE

Pressure drop (bar)

A

Volume of domestic hot water (litres/min)

A = pressure drop on the domestic hot water side - Prestige Excellence

Page 12

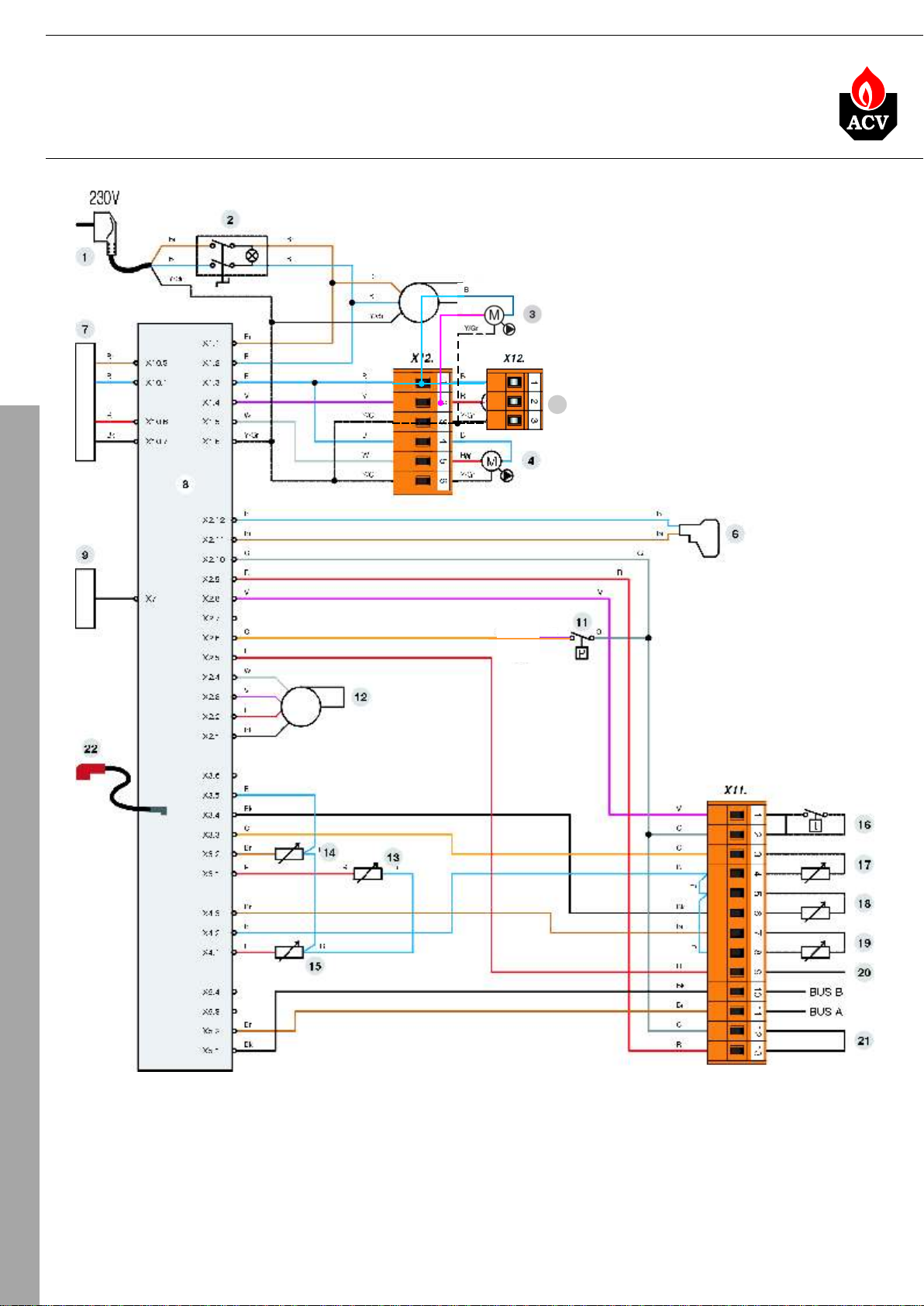

12

CONNECTIONS

WIRING DIAGRAM - PRESTIGE 24 - 32

excellenceinhot waterexcellencein hotwater

V

23

W

PRESTIGETECHNICAL

1. 230V connection cord

2. On/off switch

3. Heating pump

4. Hot water pump - Excellence

(Solo - option)

5. Burner

6. Gas valve

7. Transformer 230V-24V

8. MCBA

9. Screen

11. Water pressure switch

12. Burner connection

13. NTC1 flow sensor

14. NTC2 return sensor

15. NTC5 flue gas temperature sensor

16. Room thermostat (option)

17. NTC3 hot water sensor - Excellence

(Solo - option)

18. NTC4 outdoor temperature sensor

(option)

19. NTC6 second circuit sensor

(option)

20. Zero volt of 24V circuit

21. External safety thermostat

(RAM-option)

22. HT lead for ignition electrode

23. Heating pump connection of the

direct circuit (2 heating circuits)

Page 13

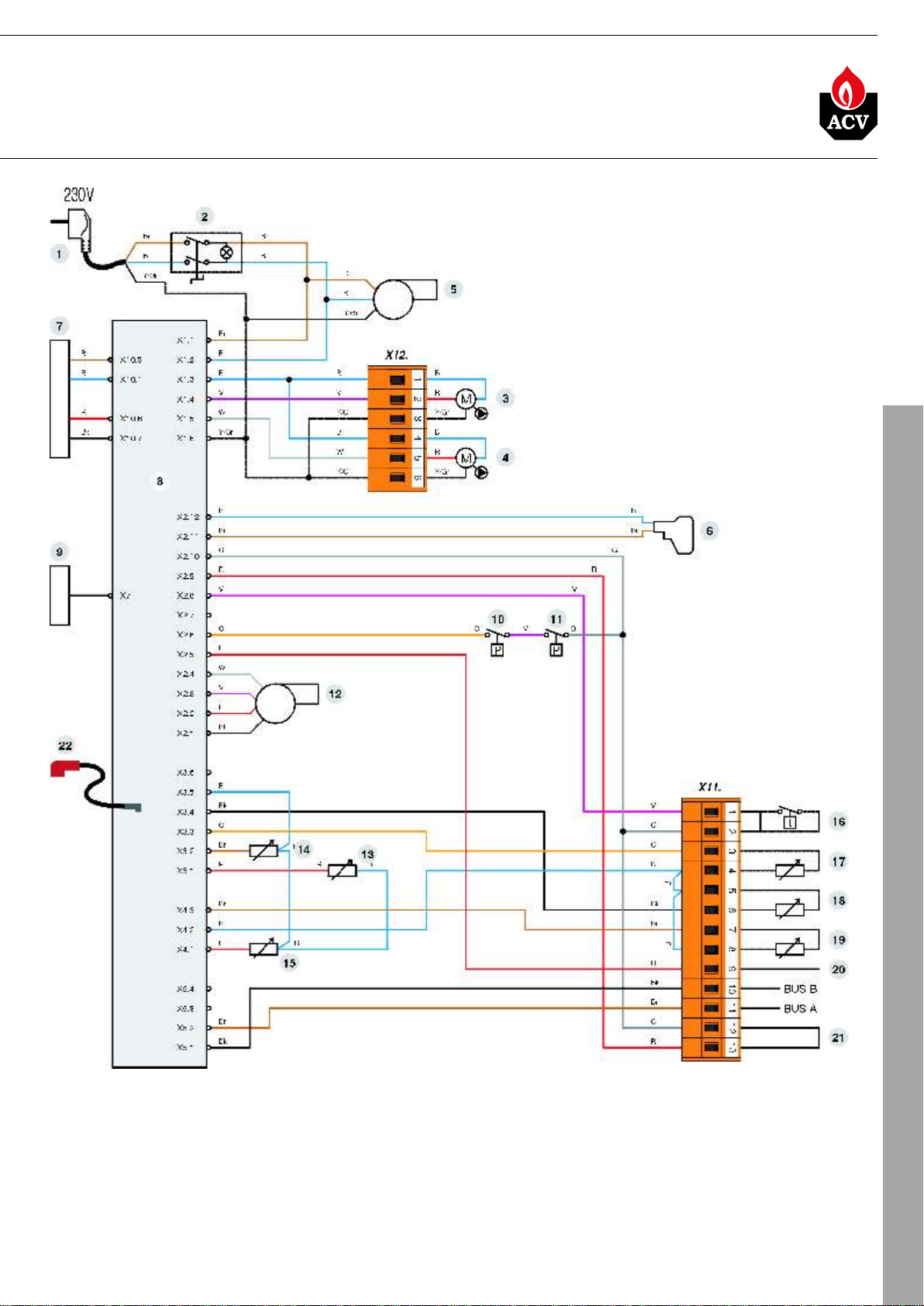

13

WIRING DIAGRAM - PRESTIGE 50 - 75

excellenceinhot waterexcellencein hotwater

PODŁĄCZENIA

CONNECTIONS

1. 230V connection cord

2. On/off switch

3. Heating pump

4. Hot water pump (option)

5. Burner

6. Gas valve

7. Transformer 230V-24V

8. MCBA

9. Screen

10. Gas pressure switch

11. Water pressure switch

12. Burner modulation

13. NTC1 flow sensor

14. NTC2 return sensor

15. NTC5 flue gas temperature sensor

16. Room thermostat (option)

17. NTC3 hot water sensor (option)

18. NTC4 outdoor temperature sensor

(option)

19. NTC6 second circuit sensor

(option)

20. Zero volt of 24V circiut

21. External safety thermostat

(RAM-option)

22. HT lead for ignition electrode

Page 14

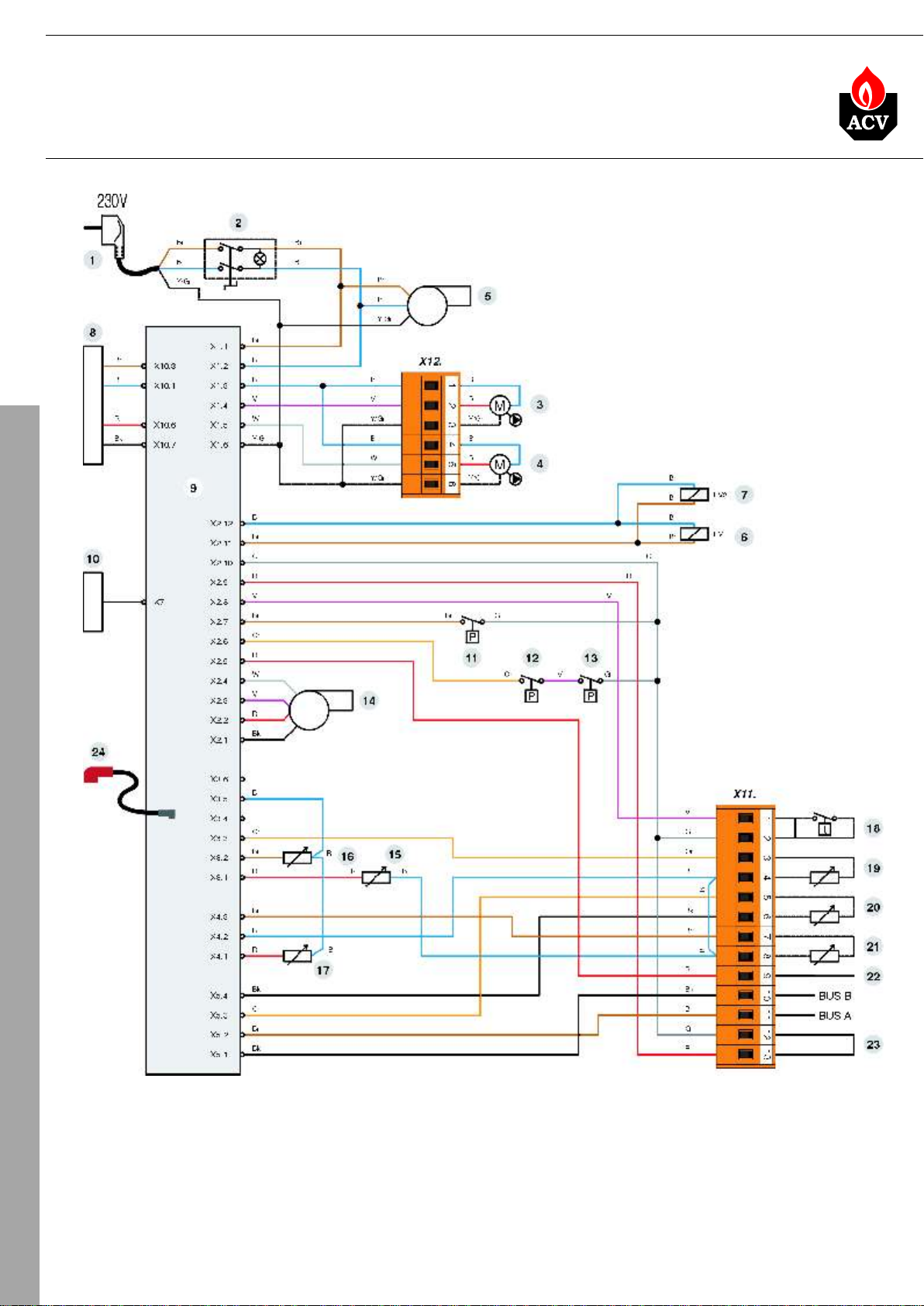

14

14

CONNECTIONS

WIRING DIAGRAM - PRESTIGE 120

excellenceinhot waterexcellencein hotwater

excellenceinhot waterexcellencein hotwater

PRESTIGETECHNICAL

1. 230V connection cord

2. On/off switch

3. Heating pump

4. Hot water pump

5. Burner

6. Gas valve 1

7. Gas valve 2

8. Transformer 230V-24V

9. MCBA

10. Screen

11. Air pressure switch

12. Gas pressure switch

13. Water pressure switch

14. Burner modulation

15. NTC1 flow sensor

16. NTC2 return sensor

17. NTC5 flue gas temperature sensor

18. Room thermostat (option)

19. NTC3 hot water sensor (option)

20. NTC4 outdoor temperature sensor

(option)

21. NTC6 second circuit sensor

(option)

22. Zero volt of 24V circuit

23. External safety thermostat

(RAM-option)

24. HT lead for ignition electrode

Page 15

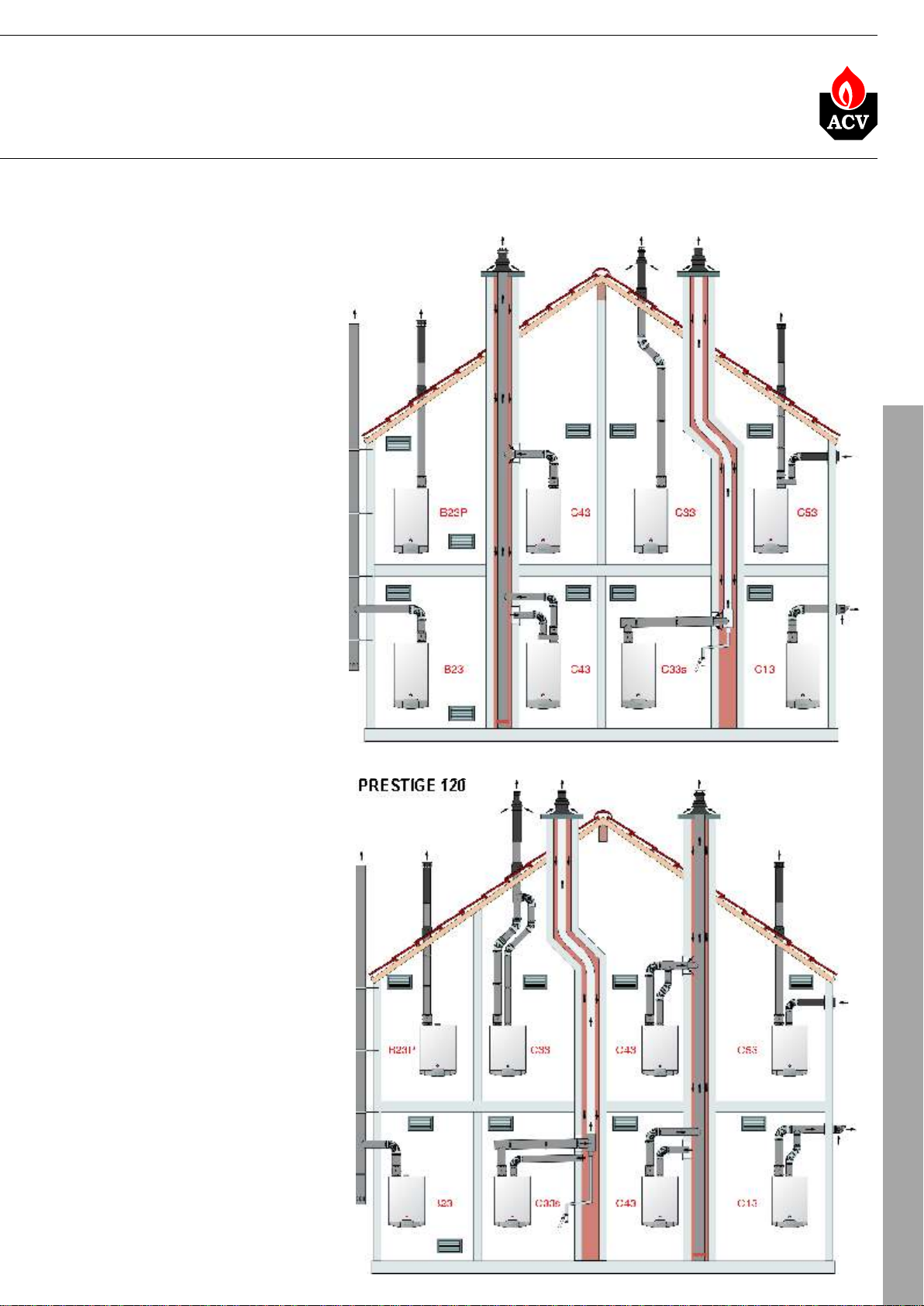

15

CHIMNEY CONNECTIONS

B - connection to an exhaust duct

23

venting the combustion products

outside of the installation area,

with the combustion air being

drawn directly from this area.

B - connection to an exhaust

23P

system of the combustion

products designed to operate with

positive pressure.

C - appliance connection with a

13

horizotal balanced flue/onlet air

ducts to outside atmosphere.

C - appliance connection with a

33

vertical balanced flue/inlet air

ducts to outside atmosphere.

C - connection with an individual

33S

system of which the exhaust duct

for the combustion products is

installed in an exhaust pipe that is

part of the building. The

appliance, the exhaust duct and

the terminal units are certified as

an assembly that cannot be

dissociated.

excellenceinhot waterexcellencein hotwater

PRESTIGE 24 - 32 - 50 - 75

CONNECTIONS

C - connection by two ducts to a

43

collective duct system serving

more than one appliance; this

system of collective ducts features

two ducts connected to a terminal

unit that simultaneously intakes

fresh combustion air and

discharges the combustion

products outside through

openings that are either

concentric or close enough

together to be subjected to similar

wind conditions. “U” duct system.

C - appliance connection to an

53

non balanced flue/inlet air ducted

system.

Note: maximum flow resistance is

shown in the technical manual for

the boiler.

PRESTIGE 120

Page 16

16

BURNER, REGULATOR, CASCADES

BURNER

THE INTELIGENT ACV

BURNER

ECONOMIC OPERATION

QUIET OPERATION OF

THE PREMIX BURNER

REGULATOR ACV MCBA

PRESTIGETECHNICAL

excellenceinhot waterexcellencein hotwater

The innovative gas premix burner in the Prestige has been designed to provide high efficiency

and clean combustion. Premix technology makes it possible to perfectly mix gas and air before

combustion, in all operating conditions and to guarantee optimal efficiency with no hazardous

emissions. In addition, the burner modulates from about 25% to 100% of nominal capacity to

adapt power continously to the current heat requirement: operating cycles are longer, resulting in

less starts and stops, less harmful emissions, less maintenance and longer lifetime of the burner.

Moreover, the burner head is covered with a metalic fibre engineered both to withstand high

thermal loads and to reach near perfect radiant combustion mode at low load.

The Prestige Solo is equipped with an inlet temperature sensor, an outlet temperature sensor

and a flue gas temperature sensor. In addition the Prestige Excellence is equipped with a hot

water temperature sensor. All the sensor information is transmitted to the MCBA that will

precisely adapt the power of the burner for the most efficient operation possible.

ACV has adopted BG 2000 M burners for Prestige boilers. This is a safe and quiet air/gas premix

burner that limits polluting emissions (NOx and CO) to incredibly low levels. Although thoroughly

modern, the ACV BG 2000 M burner uses proven technology and widely distributed standard

components.

The casing of the Prestige is made from insulated steel that completely encloses the burner,

guaranteeing extremely quiet operation. Also, the heat emitted by the heat exchanger is

absorbed into the combustion air, which improves efficiency and prevents heat radiation.

Prestige is equipped with an integrated MicroproCessor Burner Automate (MCBA) that controls

the safety-functions of the boiler and offers a wide band of built-in temperature controls, which

can be selected and adapted through a number of parameters, with different access levels (enduser, service engineer, ...)

If an outside sensor is connected to the MCBA it becomes a complete weather-dependent

control, with the possibility of having night set-back if an external clock is used.

An outside sensor connected to the MCBA will determine the basic flow temperature. If the room

thermostat contact remains closed for a longer period, the flow temperature setting will be

increased by 10 C until the desired room temperature is achieved. In this way an auto-adaptive

heating curve is achieved which combines the advantages of a fast heat-up curve with the

temperature stability of a standard weather-dependent control.

o

CASCADE OF BOILERS

EXCELLENT REASONS

TO INSTALL A

CASCADE

BALANCED HEADER

Efficiency: a cascade system allows modulation of the heating power, from the minimum output

of one boiler up to the maximum output of all the boilers. Which, in the case of a four-boiler

cascade, gives a modulation ratio of 16:1.

Back up: the ACV cascade controllers optimise the potential of the available boilers, if one of the

boilers fail, the controller simply adjust the power of the remaining boilers to compensate.

Easy commissioning: one, two, three or four boilers, the commissioning procedure is the

same, simple and easy when undertaken by a qualified engineer.

Easy maintenance: any one boiler in a cascade can be serviced and maintained easily whilst

the other boilers are operational. This enables the servicing to be carried out at any time of the

year and not just during the traditional summer shut down period.

A wide spectrum of modulation reduces number of starts in comparision to a single more

powerful boiler, as a result less fuel is used. The electrical energy used to transport heating water

by the boilers is also reduced as the main regulator decides how many boilers need to operate

and how many pumps are required.

To connect one or more boilers with one or more heating circuits, the balanced header can be

installed. It removes the most frequent causes of faults in heating systems and allows for stable

operation without need to balance the flow. Boiler or heating circuit pump start/stop has no effect

on other devices or regulation systems. This configuration makes the operation of the whole

system very flexible, because the volume of the water in heating generators is not in direct

conjunction with the water volume in heating circuits. For correct operation of the balanced

header at maximum power consumption, the flow of the water in primary (boilers) circuit has to

be at a higer level than the flow in the secondary (heating) circuits.

In addition, the balanced header also operates as a trap. Sediment from the heating circuits falls

to the lowest part of the header and cannot contaminate the boilers.

Page 17

SAMPLES OF INSTALLATIONS

17

LEGEND

excellenceinhot waterexcellencein hotwater

PICTURE CODE NAME MARK

10800018

5476G003

10510100

537D3040

10510900

ROOM THERMOSTAT ACV 22

Installed inside the building on the wall. Controls room set temperature.

Operates with MCBA. Connected to the boiler terminals 1-2 instead of the bridge.

HOT WATER SENSOR

Senses the temperature in the external hot water tank. Controls set temperature.

Connected to the boiler terminals 3-4

OUTSIDE TEMPERATURE SENSOR NTC 4 (AF 120)

Installed on the external wall of the building. Controls outside temperature and regulates

boiler operation. Connected to the MCBA terminals 5-6.

CONTACT SENSOR NTC 6

Installed on the outlet of controlled circuit. Allows weather dependent regulation.

Connected to the boiler terminals 7-8.

CONTACT SENSOR RAM 5109

Installed on the outlet of the floor heating circuit, to protect pipe work overheating.

Connected to the boiler terminals 12-13.

NTC 3

A

B

C

D

E

10800095

10800119

10800034

10800030

10800121

AM 3 - 11 MODULE

Controls the second heating circuit - communicates directly with the MCBA. Operates

with room thermostat.

ZMC -1 MODULE

Controls the second heating circuit - alarm contact - operates only in cojunction with the

Room Unit RSC. Needs RMCI installed directly in MCBA.

ROOM UNIT RSC

Room regulator, controls heating and hot water production, installed inside of the

building on the wall. Supplied with outside temperature sensor. Allows heating curve

regulation, room and hot water temperature. Displays all temperatures. Connected to

the terminals 10-11 of the boiler terminal block.

CONTROL UNIT

Regulates one or more boiler (cascade of max 8 boilers) Prestige with modulating

burners. Allows control of 3 heating circuits (2 mixed, 1without mixer) and hot water

production. Equipped with 2 outputs and 3 programmable inputs, allowing solar system

and solid fuel boiler regulation. Installed in the wall mounting socket.

WALL MOUNTING SOCKET FOR THE CONTROL UNIT

F

G

H

SAMPLES OF INSTALLATIONS

I

J

10800057

10800036

INSTALLER TERMINAL BLOCKS FOR THE CONTROL UNIT

CLIP-IN INTERFACE RMCI

Installed directly in the MCBA. Enables communication between the boiler MCBA, the

Room Unit and the Control Unit.

K

L

Page 18

18

SAMPLES OF INSTALLATIONS

LEGEND

PICTURE CODE

10800108

10800044

10800045

10800120

10800056

excellenceinhot waterexcellencein hotwater

NAME

OUTSIDE TEMPERATURE SENSOR AF 200

Installed on the oustide north wall of the building. Operates with Control Unit. Connected

to terminals 26-23 of Control Unit terminal block.

POCKET SENSOR KVT

Installed in the hot water tanks and in the balanced header. Connected to the Control Unit.

CONTACT SENSOR VF 202

Installed on the outlet of the mixed heating circuit. Operates with the ZMC-1 module and

the Control Unit.

ROOM TEMPERATURE SENSOR RFF

Operates with the Control Unit. Can be mounted on every heating circuit. Connected to

Control Unit terminals 24-25.

ZONE UNIT RS

Shows internal temperature and allows for remote control of 1 heating circuit.

Communicates with the Control Unit. For 3 heating circuits - max 3 Zone Units. Allows

correction of the heating curve, temperatures and shows information from installed

sensors. Connected to the Control Unit terminals 24-25.

MARK

M

N

O

P

R

PRESTIGETECHNICAL

002202

10800104

10800105

10800142

10800107

SOLAR SENSOR PT 1000

Installed in the solar collector. Controls temperature of the solar system. Co-operates

with the Control Unit that regulates the solar system pump group. Connected to the

Control Unit terminals 34-23.

COLLECTOR 2 CIRCUITS DN 32

Installed directly under the boiler. Allows connection of 2 heating circuits. Internal

regulation of the by-pass allows it to become a balanced header.

COLLECTOR 3 CIRCUITS DN 32

Installed directly under the boiler. Allows connection of 3 heating circuits. Internal

regulation of the by-pass allows it to become a balanced header.

CONNECTION KIT DN 32 TO THE MANIFOLD

Includes: two flexible 1 1/2” hoses and 1 1/4” reduction fittings.

HIGH TEMPERATURE KIT DN 32

Installed to the collector under the boiler. Supplies high temperature circuit or water tank

primaries. Includes: 1 circulation pump, 2 isolating valves, check valve, 2 thermometers.

S

T

U

V

W

10800106

10800019

LOW TEMPERATURE KIT DN 32

Installed to the collector under the boiler. Supplies low temperature circuit and controls

its temperature. Includes: 1 circulation pump, 2 isolating valves, check valve, 2

thermometers and the 3-way valve with the integrated by-pass.

SERVOMOTOR SQK 349

Installed on the 3-way mixing valve of the low temperature kit. Controls the temperature

of the low temperature circuit.

X

Y

Page 19

excellenceinhot waterexcellencein hotwater

PICTURE CODE NAME MARK

19

10800161

10800162

10800167

10800168

10800171

10800172

10800169

10800170

BALANCED HEADER DN 80

BALANCED HEADER DN 100

Three functions in one device: air separator, hydraulic separator and dirt tap.

the most frequent causes of faults in heating systems. Includes flange connections,

automatic air vent, sludge cock, temperature sensor tube and EPP insulation

KIT COLLECTOR DN 80 FOR 2 BOILERS

Two connections (flow and return) with isolating valves and pumps. Allows for quick

installation of 2 boilers in cascade. Possible extenstion.

KIT COLLECTOR DN 80 FOR 3 BOILERS

Two connections (flow and return) with isolating valves and pumps.

installation of 3 boilers in cascade. Possible extenstion.

CONNECTION KIT BOILER - COLLECTOR DN 80

Couplings DN 32 (L=100 and 135 mm) with unions and gaskets to connect boiler with

the collector kit.

CONNECTION KIT BOILER - COLLECTOR DN 100

Couplings DN 32 (L=170 and 320 mm) with unions and gaskets to connect boiler with

the collector kit.

FLOOR COLLECTOR SUPPORT CASCADE DN 80

FLOOR COLLECTOR SUPPORT CASCADE DN 100

Removes

.

Allows for quick

X1

X2

X3

X4

X5

X6

10800164

ADAPTOR KIT DN 80 - DN 100

Adaptor to connect the collector kit DN 80 to the balanced header DN 100.

X7

SAMPLES OF INSTALLATIONS

Page 20

20

SAMPLES OF INSTALLATIONS

SCHEME 1:

excellenceinhot waterexcellencein hotwater

PRESTIGE 50 - 75 SOLO FOR 1 HEATING CIRCUIT AND HOT WATER PRODUCTION, WEATHER DEPENDENT

REGULATION BY THE BOILER MCBA AND THE ROOM THERMOSTAT.

C

A

B

W

PRESTIGETECHNICAL

List of elements

Electrical connection schematic

Mark

A

B

C

T

W

V

Code

10800018

5476G003

10510100

10800104

10800107

10800142

T

W

Name of the element

Room thermostat

Hot water sensor NTC 3

Outside temperature sensor NTC 4

Collector 2 circuits DN 32

High temperature kit DN 32

Connection kit DN 32 to the manifold

Quantity

1

1

1

1

2

1

W

W

ABC

Connect room thermostat instead

of the bridge 1-2

Page 21

21

SCHEME 2:

excellenceinhot waterexcellencein hotwater

PRESTIGE 50 - 75 SOLO FOR 1 HEATING CIRCUIT AND HOT WATER PRODUCTION, WEATHER DEPENDENT

REGULATION BY THE BOILER MCBA AND THE ROOM UNIT

C

H

L

B

W

T

List of elements

Mark

B

C

H

L

T

W

V

Electrical connection schematic

Code

5476G003

10510100

10800034

10800036

10800104

10800107

10800142

W

Name of the element

Hot water sensor

NTC 3

Outside temperature sensor NTC 4 (AF 120)

Room Unit

Clip-in interface RMCI

Collector 2 circuits DN 32

High temperature kit DN 32

Connection kit DN 32 to the manifold

Quantity

1

1

1

1

1

2

1

SAMPLES OF INSTALLATIONS

W

W

C

B

H

Page 22

22

SAMPLES OF INSTALLATIONS

SCHEME 3:

excellenceinhot waterexcellencein hotwater

PRESTIGE 50 - 75 SOLO FOR 2 HEATING CIRCUITS AND HOT WATER PRODUCTION, REGULATED BY THE

BOILER MCBA AND THE AM 3-11 MODULE

C

A

F

D

B

W

X

W

V

U

List of elements

PRESTIGETECHNICAL

Mark

A

B

C

D

E

F

U

W

X

V

Y

Code

10800018

5476G003

10510100

537D3040

10510900

10800095

10800105

10800107

10800106

10800142

10800019

Y

Name of the element

Room thermostat

Hot water sensor NTC 3

Outside temperature sensor NTC 4 (AF 120)

Contact sensor NTC 6

Contact sensor RAM 5109 (for floor heating)

AM 3-11 module

Collector 3 circuits DN 32

High temperature kit DN 32

Low temperature kit DN 32

Connection kit DN 32 to the manifold

Servomotor SQK 349

Quantity

1

1

1

1

1

1

1

2

1

1

1

Page 23

Electrical schematic

23

excellenceinhot waterexcellencein hotwater

A

B

C

D

E

W

SAMPLES OF INSTALLATIONS

W

AM 3-11 module and low temperature kit

Y

F

X

MCBA

Page 24

24

SAMPLES OF INSTALLATIONS

SCHEME 4:

excellenceinhot waterexcellencein hotwater

PRESTIGE 50 - 75 SOLO FOR 2 HEATING CIRCUITS AND HOT WATER PRODUCTION, REGULATED BY THE

BOILER AUTOMATE MCBA AND THE ZMC-1 MODULE

C

H

E

G

O

W

B

L

List of elements

PRESTIGETECHNICAL

Mark

B

C

E

G

H

E

L

O

U

V

W

X

Y

Code

5476G003

10510100

10510900

10800119

10800034

10800036

10800045

10800105

10800142

10800107

10800106

10800019

X

Y

W

Name of the element

Hot water sensor

NTC 3

Outside temperature sensor NTC 4 (AF 120)

Contact sensor RAM 5109 (for floor heating)

ZMC - 1 module

Room Unit

Clip-in interface RMCI

Contact sensor VF 202

Collector 3 circuits DN 32

Connection kit DN 32 to the manifold

High temperature kit DN 32

Low temperature kit DN 32

Servomotor SQK 349

V

U

Quantity

1

1

1

1

1

1

1

1

1

2

1

1

Page 25

Electrical schematic

25

excellenceinhot waterexcellencein hotwater

B

C

H

E

E

Y

X

SAMPLES OF INSTALLATIONS

W

G

O

W

Page 26

26

SAMPLES OF INSTALLATIONS

SCHEME 5:

excellenceinhot waterexcellencein hotwater

PRESTIGE 50 - 75 SOLO FOR 2 HEATING CIRCUITS AND HOT WATER PRODUCTION, REGULATED BY THE

CONTROL UNIT.

EM

O O

I

N

W

X

X

N

L

V

U

List of elements

PRESTIGETECHNICAL

Mark

I

J

L

EM

N

O

P

R

U

V

Y

W

X

Y

Code

10800030

10800121

10800036

10800108

10800044

10800045

10800120

10800056

10800105

10800142

10800107

10800106

10800019

Y

Y

Name of the element

Control Unit

Wall mounting socket for the Control Unit

Clip-in interface RMCI

Outside temperature sensor AF 200

Pocket sensor KVT

Contact sensor VF 202

Room temperature sensor RFF

or

Zone Unit

Collector 3 circuits DN 32

Connection kit DN 32 to the manifold

High temperature kit DN 32

Low temperature kit DN 32

Servomotor SQK 349

Quantity

1

1

1

1

2

2

0 (max 2)

0 (max 2)

1

1

1

2

2

Page 27

Electrical schematic

27

excellenceinhot waterexcellencein hotwater

Wall mounting

socket for the

Control Unit

SAMPLES OF INSTALLATIONS

Bolier 1

PRESTIGE

Page 28

28

SAMPLES OF INSTALLATIONS

SCHEME 6:

excellenceinhot waterexcellencein hotwater

PRESTIGE 50 - 75 - 120 SOLO WITH SOLAR SYSTEM AND SLME CYLINDER FOR 2 HEATING CIRCUITS AND HOT

WATER PRODUCTION, REGULATED BY THE CONTROL UNIT

List of elements

PRESTIGETECHNICAL

Mark

I

J

L

EM

N

O

P

R

S

W

Y

X

Y

Code

10800030

10800121

10800036

10800108

10800044

10800045

10800120

10800056

002202

10800107

10800106

10800019

Name of the element

Control Unit

Wall mountig socket for the Control Unit

Clip-in interface RMCI

Outside temperature sensor AF 200

Pocket sensor KVT

Contact sensor VF 202

Room temperature sensor RFF

or

Zone Unit

Solar sensor PT 1000

High temperature kit DN 32

Low temperature kit DN 32

Servomotor SQK 349

Balanced header has to be sized separately according to the flow and power of the

installation.

Quantity

1

1

1

1

3

1

0 (max 2)

0 (max 2)

1

2

1

1

Page 29

Electrical schematic

29

excellenceinhot waterexcellencein hotwater

Wall mounting

socket for the

Control Unit

SOLAR COLLECTOR

SAMPLES OF INSTALLATIONS

Bolier 1

PRESTIGE

BALANCED HEADER

Page 30

30

SAMPLES OF INSTALLATIONS

SCHEME 7:

excellenceinhot waterexcellencein hotwater

PRESTIGE 50 - 75 - 120 SOLO WITH SOLID FUEL BOILER FOR 2 HEATING CIRCUITS AND HOT WATER PRODUCTION,

REGULATED BY THE CONTROL UNIT

MM

L

N

O

N

X

Y

W

Y

N

W

I

N

X1

List of elements

PRESTIGETECHNICAL

Mark

I

J

L

MM

N

O

P

R

W

X

Y

X1

Y

Code

10800030

10800121

10800036

10800108

10800044

10800045

10800120

10800056

10800107

10800106

10800161

10800019

Name of the element

Control Unit

Wall mounting socket for the Control Unit

Clip-in interface RMCI

Outside temperature sensor AF 200

Pocket sensor KVT

Contact sensor VF 202

Room temperature sensor RFF

or

Zone Unit

High temperature kit DN 32

Low temperature kit DN 32

Balanced header DN 80

Servomotor SQK 349

Quantity

1

1

1

1

3

1

0 (max 2)

0 (max 2)

2

1

1

1

Page 31

Electrical schematic

31

excellenceinhot waterexcellencein hotwater

Wall mounting

socket for the

Control Unit

SOLID FUEL BOILER

PLATE HEAT

-EXCHANGER

Bolier 1

PRESTIGE

SAMPLES OF INSTALLATIONS

BALANCED HEADER

Page 32

32

SAMPLES OF INSTALLATIONS

SCHEME 8:

excellenceinhot waterexcellencein hotwater

CASCADE OF 2 PRESTIGE 50 - 75 - 120 SOLO FOR 2 HEATING CIRCUITS AND HOT WATER PRODUCTION,

REGULATED BY THE CONTROL UNIT

List of elements

PRESTIGETECHNICAL

Mark

I

J

L

MM

N

O

P

R

X1

X2

X4

X6

Code

10800030

10800121

10800036

10800108

10800044

10800045

10800120

10800056

10800161

10800167

10800171

10800169

Name of the element

Control Unit

Wall mounting socket for the Control Unit

Clip-in interface RMCI

Outside temperature sensor AF 200

Pocket sensor KVT

Contact sensor VF 202

Room temperature sensor RFF

or

Zone Unit

Balanced header DN 80

Kit collector DN 80 for 2 boilers

Connection kit boiler - collector DN 80

Floor collector support cascade DN 80

High and low temperature kits have to be sized

separately according to the flow and power of

the installation.

Quantity

1

1

2

1

2

2

0 (max 2)

0 (max 2)

1

1

2

1

Page 33

Electrical schematic

33

excellenceinhot waterexcellencein hotwater

Wall mounting

socket for the

Control Unit

BALANCED HEADER

SAMPLES OF INSTALLATIONS

Bolier 1

PRESTIGE

Bolier 2

PRESTIGE

Page 34

34

SAMPLES OF INSTALLATIONS

SCHEME 9:

excellenceinhot waterexcellencein hotwater

CASCADE OF 3 PRESTIGE 50 - 75 - 120 SOLO WITH SOLAR SYSTEM FOR 2 HEATING CIRCUITS AND HOT WATER

PRODUCTION BY SLME CYLINDER, REGULATED BY THE CONTROL UNIT.

List of elements

PRESTIGETECHNICAL

Mark

I

J

L

MM

N

O

P

R

S

X1

X3

X4

X6

Code

10800030

10800121

10800036

10800108

10800044

10800045

10800120

10800056

002202

10800161

10800168

10800171

10800169

Name of the element

Control Unit

Wall mounting socket for the Control Unit

Clip-in interface RMCI

Outside temperature sensor AF 200

Pocket sensor KVT

Contact sensor VF 202

Room temperature sensor RFF

or

Zone Unit

Solar system PT 1000

Balanced header DN 80

Kit collector DN 80 for 3 boilers

Connection kit boiler - collector DN 80

Floor collector support cascade DN 80

High and low temperature kits have to be sized

separately according to the flow and power of

the installation.

Quantity

1

1

3

1

3

1

0 (max 2)

0 (max 2)

1

1

1

3

1

Page 35

Electrical schematic

35

excellenceinhot waterexcellencein hotwater

Wall mounting

socket for the

Control Unit

SOLAR COLLECTOR

Bolier 1

PRESTIGE

SAMPLES OF INSTALLATIONS

Bolier 2

PRESTIGE

BALANCED HEADER

Bolier 3

PRESTIGE

Page 36

36

SAMPLES OF INSTALLATIONS

SCHEME 10:

excellenceinhot waterexcellencein hotwater

CASCADE OF 2 PRESTIGE 50 - 75 - 120 SOLO FOR 4 HEATING CIRCUITS AND HOT WATER PRODUCTION,

REGULATED BY 2 CONTROL UNITS.

MM

List of elements

PRESTIGETECHNICAL

Mark

I

J

L

MM

N

O

P

R

X1

X2

X4

X6

Code

10800030

10800121

10800036

10800108

10800044

10800045

10800120

10800056

10800161

10800167

10800171

10800169

Name of the element

Control Unit

Wall mountig socket for the Control Unit

Clip-in interface RMCI

Outside temperature sensor AF 200

Pocket sensor KVT

Contact sensor VF 202

Room temperature sensor RFF

or

Zone Unit

Balanced header DN 80

Kit collector for 2 boilers DN 80

Connection kit boiler - collector DN 80

Floor collector support cascade DN 80

High and low temperature kits have to be sized

separately according to the flow and power of

the installation.

Quantity

2

2

2

1

2

3

0 (max 4)

0 (max 4)

1

1

2

1

Page 37

Electrical schematic

37

excellenceinhot waterexcellencein hotwater

BALANCED HEADER

Wall mounting

socket for the

Control Unit

Bolier 1

PRESTIGE

Bolier 2

PRESTIGE

SAMPLES OF INSTALLATIONS

Wall mounting

socket for the

Control Unit

Page 38

38

SAMPLES OF INSTALLATIONS

SCHEME 11:

excellenceinhot waterexcellencein hotwater

CASCADE OF 2 PRESTIGE 50 - 75 - 120 SOLO WITH HEAMASTER 201 (HOT WATER PRODUCTION) FOR 3

HEATING CIRCUITS, REGULATED BY THE CONTROL UNIT.

List of elements

PRESTIGETECHNICAL

Mark

I

J

L

MM

N

O

X1

X2

X4

X6

Code

10800030

10800121

10800036

10800108

10800044

10800045

10800161

10800167

10800171

10800169

Name of the element

Control Unit

Wall mounting socket for the Control Unit

Clip-in interface RMCI

Outside temperature sensor AF 200

Pocket sensor KVT

Contact sensor VF 202

Balanced header DN 80

Kit collector DN 80 for 2 boilers

Connection kit boiler - collector DN 80

Floor collector support cascade DN 80

High and low temperature kits have to be

sized separately according to the flow and

power of the installation.

Quantity

1

1

3

1

1

2

1

1

2

1

Page 39

Electrical schematic

39

excellenceinhot waterexcellencein hotwater

Wall mounting

socket for the

Control Unit

SAMPLES OF INSTALLATIONS

Bolier 1

PRESTIGE

BALANCED HEADER

Bolier 2

PRESTIGE

Bolier 3

HM 71-101-201

Page 40

40

SAMPLES OF INSTALLATIONS

SCHEME 12:

excellenceinhot waterexcellencein hotwater

CASCADE OF 2 PRESTIGE 50 - 75 - 120 SOLO WITH CASCADE OF 2 HEAMASTER 201 (HOT WATER

PRODUCTION) FOR 3 HEATING CIRCUITS, REGULATED BY 2 CONTROL UNIT.

List of elements

PRESTIGETECHNICAL

Mark

I

J

L

MM

N

O

X1

X2

X5

X6

X7

Code

10800030

10800121

10800036

10800108

10800044

10800045

10800162

10800167

10800172

10800170

10800164

Name of the element

Control Unit

Wall mounting socket for the Control Unit

Clip-in interface RMCI

Outside temperature sensor AF 200

Pocket sensor KVT

Contact sensor VF 202

Balanced header DN 100

Kit collector DN 80 for 2 boilers

Connection kit boiler - collector DN 100

Floor collector support cascade DN 100

Adaptor kit DN 80 - DN 100

High and low temperature kits have to be sized

separately according to the flow and power of the

installation.

Quantity

2

2

4

1

1

2

1

1

2

1

1

Page 41

Electrical schematic

41

excellenceinhot waterexcellencein hotwater

Wall mounting

socket for the

Control Unit

Bolier 1

PRESTIGE

BALANCED HEADER

Bolier 2

PRESTIGE

Wall mounting

socket for the

Control Unit

SAMPLES OF INSTALLATIONS

Bolier 3

HM 71-101-201

Bolier 4

HM 71-101-201

Page 42

42

SAMPLES OF INSTALLATIONS

SCHEME 13:

CASCADE OF 8 PRESTIGE 50 - 75 - 120 SOLO, REGULATED BY THE CONTROL UNIT.

excellenceinhot waterexcellencein hotwater

List of elements

PRESTIGETECHNICAL

Mark

I

J

L

MM

N

O

X1

X2

X3

X5

X6

X7

Code

10800030

10800121

10800036

10800108

10800044

10800162

10800167

10800168

10800172

10800170

10800164

Name of the element

Control Unit

Wall mounting socket for the Control Unit

Clip-in interface RMCI

Outside temperature sensor AF 200

Pocket sensor KVT

Balanced header DN 100

Kit collector DN 80 for 2 boilers

Kit collector DN 80 for 3 boilers

Connection kit boiler - collector DN 100

Floor collector support cascade DN 100

Adaptor kit DN 80 - DN 100

High and low temperature kits have to be sized

separately according to the flow and power of the

installation.

Quantity

1

1

8

1

1

1

1

2

8

3

1

Page 43

43

ELEMENTS OF THE CASCADES - PRESTIGE 50

CODE

10800030

10800036

10800121

10800161

10800167

10800168

10800171

10800169

NAME OF THE ELEMENT

Control Unit

Clip-in interface RMCI

Wall mounting socket for the Control Unit

Balanced header DN 80 < 480 kW

Kit collector DN 80 for 2 boilers

Kit collector DN 80 for 3 boilers

Connection kit boiler - collecot DN 80

Floor collector support cascade DN 80

ELEMENTS OF THE CASCADES - PRESTIGE 75

CODE

10800030

10800036

10800121

10800161

10800162

10800167

10800168

10800171

10800172

10800164

10800169

10800170

NAME OF THE ELEMENT

Control Unit

Clip-in interface RMCI

Wall mounting socket Control Unit

Balanced header DN 80 < 480 kW

Balanced header DN 100 > 480 kW

Kit collector DN 80 for 2 boilers

Kit collector DN 80 for 3 boilers

Connection kit boiler - collector DN 80

Connection kit boiler - collector DN 100

Adaptor kit DN 80 - DN 100

Floor collector support cascade DN 80

Floor collectr support cascade DN 100

2

PCS

1x

2x

1x

1x

1x

/

2x

1x

2

PCS

1x

2x

1x

1x

/

1x

/

2x

/

/

1x

/

excellenceinhot waterexcellencein hotwater

NR OF BOILERS IN THE CASCADE

3

PCS

1x

3x

1x

1x

/

1x

3x

1x

3

PCS

1x

3x

1x

1x

/

/

1x

3x

/

/

1x

/

4

PCS

1x

4x

1x

1x

2x

/

4x

2x

NR OF BOILERS IN THE CASCADE

4

PCS

1x

4x

1x

1x

/

2x

/

4x

/

/

2x

/

5

PCS

1x

5x

1x

1x

1x

1x

5x

2x

5

PCS

1x

5x

1x

1x

/

1x

1x

5x

/

/

2x

/

6

PCS

1x

6x

1x

1x

/

2x

6x

2x

6

PCS

1x

6x

1x

1x

/

/

2x

6x

/

/

2x

/

7

PCS

1x

7x

1x

1x

2x

1x

7x

3x

7

PCS

1x

7x

1x

/

1x

2x

1x

/

7x

1x

/

3x

8

PCS

1x

8x

1x

1x

1x

2x

8x

3x

8

PCS

1x

8x

1x

/

1x

1x

2x

/

8x

1x

/

3x

ELEMENTS OF THE CASCADES- PRESTIGE 120

CODE

10800030

10800036

10800121

10800161

10800162

10800167

10800168

10800171

10800172

10800164

10800169

10800170

NAME OF THE ELEMENT

Control Unit

Clip-in interface RMCI

Wall mounting socket for the Control Unit

Balanced header DN 80 < 480 kW

Balanced header DN 100 > 480 kW

Kit collector DN 80 for 2 boilers

Kit collector DN 80 for 3 boilers

Connection kit boiler - collector DN 80

Connection kit boiler - collector DN 100

Adaptor kit DN 80 - DN 100

Floor collector support cascade DN 80

Floor collector support cascade DN 100

2

PCS

1x

2x

1x

1x

/

1x

/

2x

/

/

1x

/

NR OF BOILERS IN THE CASCADE

3

PCS

1x

3x

1x

1x

/

/

1x

3x

/

/

1x

/

4

PCS

1x

4x

1x

1x

/

2x

/

4x

/

/

2x

/

5

PCS

1x

5x

1x

/

1x

1x

1x

/

5x

1x

/

2x

6

PCS

1x

6x

1x

/

1x

/

2x

/

6x

1x

/

2x

7

PCS

1x

7x

1x

/

1x

2x

1x

/

7x

1x

/

3x

SAMPLES OF INSTALLATIONS

8

PCS

1x

8x

1x

/

1x

1x

2x

/

8x

1x

/

3x

Page 44

44

SAMPLES OF INSTALLATIONS

BALANCED HEADER

excellenceinhot waterexcellencein hotwater

Removes the most frequent causes of faults in heating systems. Three functions in one

device: air separator, hydraulic separator, dirt trap (with option of magnetic separator).

Sludge chamber mounted at the bottom with 4 x 1” sockets for magnetic cartidges. Automatic

air vent with isolation valve, temperature sensor tube 3/4” in the top, rinsing valve 1” mounted in

the top and in the bottom. Insulation max. temperature 130 C.

Max operation pressure: 6 bar

Max temperature 110 C

Automatic air vent

Resistance plate

Air venting duct

Magnetic core (option)

o

Drain valve

Reverse chamber

Temperature sensor tube

Rectifier

Baffels

Sludger

Slugde valve

Air venting

duct

Perforated plates

o

DIMENSIONS

a

mm

b

mm

c

mm

mm

d

mm

h

DN 80

220

382

225

700-1100

1000-1400

DN 100

300

500

340

900-1300

1250-1650

CASCADE’S CONNECTION KITS

PRESTIGETECHNICAL

Adaptor to connect kit collector DN 80 to the balanced header

DN 100. Including gaskets and screws.

Collectors DN 80 to connect 2 or 3 boilers in the cascade system.

Collector equipped with flange connections, isolation valves, non-return

valves, reductions 1 1/2” x 1 1/4” and pumps Wilo Star RS 30/7, 12 UHR.

These collectors allow assembly of cascades of 4, 5, 6, 7 or 8 boilers (see

table “Elements of the casades”).

Connection kits boiler - collector

A - DN 32, 2 x 1 1/2” GW, L = 170 / 320 mm

B - DN 32, 2 z 1 1/2” GW, L = 100 / 135 mm

Page 45

NOTES

45

excellenceinhot waterexcellencein hotwater

NOTES

Page 46

46

NOTES

excellenceinhot waterexcellencein hotwater

PRESTIGETECHNICAL

Page 47

Page 48

Thanks to its state-of-art technology,

ACV offers reliable, powerful, cost effective

and environment friendly solutions for most

demanding applications in Domestic Hot

Water for both commercial and residential

users.

ACV has become a world leader distributing

engineered products in more than 40

countries over 5 continents.

ACV UK Ltd

St. Davids Business Park

Dalgety Bay, Fife KY11 9PF

TEL.: 01383 820100, FAX: 01383 820180

E-MAIL: information@acv-uk.com

www.acv-uk.com

Loading...

Loading...