Page 1

Installation, operating and

maintenance Instructions

N-Mini / N 1 / N 2 / N 3

ENGLISHFRANCAISNEDERLANDSESPAÑOL

664Y1000.C

EN • 1

Page 2

INDEX

INTRODUCTION 3

Who should read these instructions 3

Symbols 3

Applicable standards 3

Important notes 3

ENGLISHFRANCAISNEDERLANDSESPAÑOL

USER GUIDE 4

Use of the boiler 4

Setting the burner to safety mode 4

DESCRIPTION 5

General description 5

Operating principle 5

Design characteristics 5

Boiler views and key to parts 5

TECHNICAL CHARACTERISTICS 6

General 6

Operating condition limits 6

Dimensions 6

Hot water output data 6

General characteristics 6

BURNER CHARACTERISTICS 13

Description of the burner 13

Factory settings parameters 14

Burner dimension 14

COMMISSIONING 15

Filling the hot water and heating circuits 15

Using the boiler for the first time 15

MAINTENANCE 15

Recommendation 15

Boiler maintenance 15

Safety equipment maintenance 15

Draining the boiler 15

SPARE PARTS See at the end of this manual

INSTALLATION 7

Boiler room 7

Chimney connections 7

Fuel oil supply 7

Heating connection 8

Hot water connection 8

Electrical connections 9

Control kit 10

N + Smart installation with ACV control 11

664Y1000.C

EN • 2

Page 3

INTRODUCTION

WHO SHOULD READ THESE INSTRUCTIONS

These instructions should be read by:

- the specifying engineer

- the installer

- the user

- the service engineer

SYMBOLS

The following symbols are used in these instructions:

Important instructions for correct operation of the

installation.

APPLICABLE STANDARDS

The products described in this document have been certified at

European level (European Directive 92/42/EEC «Efficiency»). They

have also been awarded the Belgian “OPTIMAZ” LABEL (fuel oil

boiler).

ENGLISHFRANCAISNEDERLANDSESPAÑOL

Essential instructions to ensure the safety of

persons and the environment.

Danger of electrocution.

DANGER

HOT

IMPORTANT NOTES

These instructions are an integral part of the equipment to which

they relate and must be handed to the user.

The product must be installed and serviced by qualified engineers

in accordance with the regulations in force.

ACV declines all liability for any damage caused as a result of

incorrect installation or in the event of the use of appliances or

accessories that are not specified by ACV.

Failure to follow the instructions describing the

test operations and procedures may cause injury to

persons or risks of environmental pollution.

N.B.:

ACV reserves the right to change the technical characteristics and

specification of its products without notice.

Danger of burning.

664Y1000.C

EN • 3

Page 4

USER GUIDE

USE OF THE BOILER

To ensure that your system operates correctly, please

have it serviced annually by a qualified engineer;

servicing should be completed before the start of the

heating season.

ENGLISHFRANCAISNEDERLANDSESPAÑOL

Starting the burner:

in normal operation the burner starts automatically if

the temperature of the boiler is below the set point.

Before carrying out any work on the boiler, isolate it

from the electrical supply at the switch on the external

control box.

Also place the main switch on the control panel to

“OFF”.

You should familiarise yourself with the control panel

(fig. 1)

The user must not attempt to gain access to the

components inside the control panel.

1. Control thermostat

When the boiler is used for heating only, the boiler temperature may

be set at 60 to 90°C. If the boiler is used to generate domestic hot

water and heating, the boiler’s control thermostat should be set at

80°C to ensure optimum operating conditions.

2. Main switch

Use this switch to turn the boiler on and off.

45

30

60

15

31

75

0

0

9

°C

fig. 2 : N-Mini Control panel

Pump operation:

The pump is controlled by a reset high limit thermostat, which is

located at the rear of the boiler. This is pre-set at 45°C. When the

boiler starts up, it delays the activation of the boiler pump, thereby

preventing any risk of corrosion in the combustion chamber.

Gauge pressure of the heating system

Your system must be fitted with a heating safety valve calibrated to

3 bars.

Ensure that the system is always under water pressure. When the

system is cold and the air inside it has been vented, the gauge

must indicate a pressure between 0.5 and 1.5 bar depending on

the height of the building.

To add water: (refer to Fig. 10 on Page 8)

• Open the filling valve (5).

• Close the valve properly after filling.

• Vent the system in order to obtain an accurate reading of the

pressure inside the heating circuit.

Safety valves (heating circuit)

If water is found to be escaping from one of the safety valves, stop

the boiler and contact your installer for advice.

A monthly test is recommended:

Lift the lever on the drain cock for a few seconds to ensure that the

safety valve is working correctly.

3. Summer/Winter switch

Use this switch to start and stop the heating pump.

4. Thermostat-pressure gauge

This gauge shows the temperature of the boiler and the pressure in

the primary heating circuit. The temperature must not exceed 90°C.

If it rises above this point, turn off the boiler and check the settings

on the thermostat. If the problem persists, call a technician.

The pressure must not fall below 1 bar. If it does fall below this point,

look up the section entitled “Gauge pressure of the heating installation”

in this section below.

5. Manual reset high-limit thermostat

If the boiler temperature exceeds 103°C, this safety device will be

enabled. The boiler temperature must drop below 60°C to re-start.

Unscrew the cover and press the re-start key with a pen or an object

with a similar sharp point. Replace the cover. If the fault persists,

turn off the boiler and call a technician.

60

90

If there is a problem after this short test, please

contact your installer for advice.

The water escaping from the safety valve can

DANGER

be extremely hot and cause serious burns.

HOT

BURNER SHUTDOWN

If the burner is not working:

1. The burner indicator lamp lights up.

2. Press the burner reset button (Fig. 3) on the burner. Turn the

boiler off for several seconds at the main switch, then restart the

boiler.

3. If the burner still does not work, rearm the manual reset highlimit

thermostat on the control panel (Fig. 4).

4. If the anomaly persists, please contact your installer.

664Y1000.C

25143

fig. 1 : Control panel

fig. 3 fig. 4

EN • 4

Page 5

DESCRIPTION

GENERAL DESCRIPTION

• Model N is a single boiler (heating).

• Equipment required: a water connection kit for the heating circuit

supply

(optional).

• The N-Mini control panel includes a control thermostat and a

thermostat pressure gauge.

• The control panel on N 1 - 2 - 3 boilers includes a main switch,

a Summer/Winter switch, a thermostat pressure gauge, a control

thermostat and a manual reset high-limit thermostat.

• The N boiler can be connected directly to the chimney using a

B23 chimney connector.

• N-Mini Model: output of 16.6 kW.

• N1 Model: Outputs in the range 20 to 25 kW.

• N2 Model: Outputs in the range 28 to 36 kW.

• N3 Model: Outputs in the range 36.5 to 51 kW.

OPERATING PRINCIPLE

Simple to control, safety assured

The temperature of the water in both the heating circuit and the hot

water circuit is regulated by a single control. This is achieved by

means of the control thermostat and the bulb is located beside the

boiler outlet. switch.

Casing

The boiler is covered with a steel casing that has been stove enamelled

at 220°C after scouring and phosphating.

BOILER VIEWS AND KEY TO PARTS

1. Top cover

2. Heating outlet

3. Heating return

4. Chimney connection

5. Heating circuit

6. Combustion chamber

7. Boiler drain cock

8. Fuel oil burner

9. Left-right removable burner chamber plate

10. Exchanger (flue ways)

11. Front panel

12. Control panel

12

12

11

10

3

4

ENGLISHFRANCAISNEDERLANDSESPAÑOL

• A manual reset high-limit thermostat locks the burner if the

primary water temperature reaches 103°C.

• A minimum thermostat, fitted at the rear of the boiler, and preset

at 45°C, delays the activation of the boiler pump. This prevents

any risk of corrosion in the combustion chamber.

Generation of domestic hot water

Boiler N can be combined with the Smart tank (100L) superimposed

with the boiler or with any other ACV tank.

DESIGN CHARACTERISTICS

Outer body

The outer body which holds the primary water is made from STW 22

heavy gauge steel.

Flue ways

The boiler’s flue ways can be accessed from the front and include

a set of removable turbulators, in either stainless steel or chrome,

which have been specially designed to provide the optimum

combustion efficiency.

Combustion chamber

The boiler features a large, water-cooled combustion chamber to

guarantee a good flame.

Removable burner chamber plate

The chamber plate is fitted on a hinge (left or right) and made from

STW 22 steel. It is protected from the flame by a ceramic fibre

padding and a vermiculite brick.

9

8

756

fig. 5

Insulation

The burner body is insulated with rock wool padding (50mm thick).

664Y1000.C

EN • 5

Page 6

TECHNICAL CHARACTERISTICS

GENERAL

The appliances are supplied fully assembled, tested and packed

standing on a timber base with impact protection strips and wrapped

in heat-shrunk plastic film. When the appliance arrives, remove the

packaging and check that no parts have been damaged in transit.

Refer to the dimensions and weights listed below for handling

ENGLISHFRANCAISNEDERLANDSESPAÑOL

purposes:

DIMENSIONS

G

E

Ø

D

OPERATING CONDITION LIMITS

Maximum service pressure (tank filled with water)

- Heating circuit: 3 bar

- Domestic hot water circuit : 10 bar (*)

Test pressure (tank filled with water)

- Heating circuit: 4,5 bar

- Domestic hot water circuit : 13 bar (*)

Operating temperature

- Maximum temperature: 90°C

(*) if the boiler is connected to a domestic hot water production tank.

C

B

F

A

A mm B mm C mm D Ø mm E mm F mm G mm Kg (*)

N-Mini

N 1

N 2

N 3

The weights shown are the drained weights.

(*)

370 565 495 80 425 357 187 62

470 700 566 130 550 445 260 108

470 765 566 130 615 510 260 122

530 805 656 150 645 550 260 157

DOMESTIC HOT WATER PERFORMANCE “N + SMART (100 L)” N 1 N 2

Operating conditions at 85°C

Peak flow at 45°C (ΔT = 35°C)

Peak flow at 60°C (ΔT = 50°C)

L/10’

L/10’

202 202

117 117

GENERAL CHARACTERISTICS N-Mini N 1 N 2 N 3

Input

Output

Pressure loss of the flue gas circuit

Heating circuit capacity

Heating connection (female)

664Y1000.C

kW

kW

mbar

EN • 6

18.4 22.0 / 28.0 30.4 / 40.0 40.0 / 57.0

16.6 20.0 / 25.0 27.0 / 35.7 36.5 / 51.0

0.11 0.15 0.17 0.15

17 31 37 53

L

3/4” 1” 1” 1” 1/4

Ø

Page 7

INSTALLATION

BOILER ROOM

Important

• Never obstruct the ventilation.

• Do not store inflammable products in the boiler room.

• Avoid storing corrosive products such as paint, solvents, chlorine,

salt, soap or other cleaning products near the boiler.

Accessibility

The boiler room should be big enough to allow easy access to the

boiler. Minimum clearances around the boiler (mm):

- to the front 500

- to the rear 150

- to the sides 100

- above 700

Ventilation

The boiler room must have both low- and high-level ventilation

(see fig. 6).

For your information, the table below gives the minimum

ventilation requirements according to Belgian regulations.

The user must ensure that his boiler room ventilation complies

with local regulations.

A. High-level ventilation

B. Low-level ventilation

C. Draught stabiliser

D. Flame inspection window

E. Height of lined chimney

F. Chimney diameter

A

B

fig. 6 : Boiler ventilation and B23 chimney connector

F

C

Important note:

The above table is shown by way of indication only as

regulations vary from country to country.

The high output of our boilers means that the flue

gases are at a low temperature.

The attendant risk of condensation may cause damage

to some chimneys. To avoid this risk we strongly advise

that you line the chimney.

Please contact your installer for any further information.

E

ENGLISHFRANCAISNEDERLANDSESPAÑOL

D

Ventilation N-Mini N 1 N 2 N 3

Fresh air supply min.

High-level ventilation (A)

Low-level ventilation (B)

m

dm

dm

3

33 50 72 102

/h

2

150 150 150 150

2

150 150 150 170

Base

The base on which the boiler will be mounted must be made from

noncombustible materials.

CHIMNEY CONNECTIONS

IMPORTANT

The boiler must be installed by a qualified engineer

in accordance with the local standards and codes of

practice.

The diameter of the chimney must not be less than the

diameter of the boiler’s chimney reducer.

Chimney connector type: B23 (fig.6)

The chimney must be connected to the boiler by means of a metal

pipe rising at an angle from the boiler to the chimney.

FUEL OIL SUPPLY

Single-pipe installation (fig. 7)

Height H Ø 8 mm Ø 10 mm

0,5 m L = 10 m L = 20 m

1.0 m L = 20 m L = 40 m

1.5 m L = 40 m L = 80 m

2.0 m L = 60 m L = 100 m

Two-pipe installation (fig. 8)

Height H Ø 8 mm Ø 10 mm

0 m L = 35 m L = 100 m

0.5 m L = 30 m L = 100 m

1.0 m L = 25 m L = 100 m

1.5 m L = 20 m L = 90 m

2.0 m L = 15 m L = 70 m

3.0 m L = 8 m L = 30 m

3.5 m L = 6 m L = 20 m

fig. 7 fig. 8

H

L1

A chimney connector is required.

Chimney N-Mini N 1 N 2 N 3

E = 5 m Ø min. F mm 97 130 143 170

E = 10 m Ø min. F mm 82 130 130 143

E = 15 m Ø min. F mm 80 130 130 130

664Y1000.C

EN • 7

max 4m

max 4m

H

L1

H

L1

Page 8

INSTALLATION

CONNECTING THE HEATING SYSTEM

ACV water kit

ACV can supply an optional

pre-assembled water kit.

This kit comprises:

• A pump;

ENGLISHFRANCAISNEDERLANDSESPAÑOL

• A 3-way manual valve. This

valve can be power-operated if

required;

• Connection pipes that can be

used to connect a second

heating circuit;

• Two isolating valves;

• Connectors for the right- or

efthand mounting of the

expansion vessel, the safety

valve with pressure gauge and

the fill valve.

The expansion vessel is not

included.

Typical single-circuit connection

1. 3-way power-operated mixer valve

2. Safety valve calibrated to 3 bar, with pressure gauge

3. Pump

4. Non-return valve

5. System filling valve

6. Expansion vessel

7. ACV 13.00 controller (see Controller Kit on page 9)

8. Heating system isolating valve

9. Drain cock

fig. 9 : ACV water kit

HOT WATER CONNECTION

Pressure reducing valve

If the mains water pressure exceeds 6 bar, a pressure reducing

valve calibrated to 4.5 bar must be installed.

Safety group

The safety group of the water tank must be approved by ACV and

calibrated to 7 bar; the group’s valve discharge must be connected

to the drain.

Hot water expansion vessel

Installing a hot water expansion vessel will prevent any risk of

excess pressure due to water hammer or pressure fluctuations.

Hot water circulation

If the water tank is a long way from the point of use,

installing a closed recirculation circuit can ensure a faster hot water

drawoff at any time.

Typical N + SMART domestic hot water connection

(100 L) with thermostat valve

1. Safety group

2. Pressure reducing valve

3. Thermostatic mixer

4. Hot water pump

5. Non-return valve

6. Hot water expansion vessel

7. Cold water supply tap

8. Drawoff tap

9. Drain cock

10. Air vent

11. Isolating valve

4

5

8

8 8

4

7

1

9

3

2

5

6

11

DANGER

HOT

3

10

6

fig. 11 : Hot water system connection

IMPORTANT

As a safety measure, we strongly advise the

installation of a thermostatic mixer to prevent

any risk of burning to persons.

2

1

9

7

5

fig. 10 : Heating system connection

Drain

The drain cock and safety valve must be connected to the building

drain.

664Y1000.C

EN • 8

Page 9

INSTALLATION

Optional accessories

Safety group Ø 3/4”

Pressure reducing valve Ø 3/4“

Thermostatic mixer Ø 3/4”

Expansion vessel 5 litres

ELECTRICAL CONNECTIONS

Power supply principle

The boiler operates on a single-phase supply of 230 V/50 Hz.

You should install a control box with main switch and 6A fuses

externally to the boiler to allow the boiler to be isolated from the supply

for servicing and repairs.

Statutory compliance

The installation must comply with your local standards and codes of

practice.

Safety

The stainless steel if present water tank must be provided with a

separate earth.

N-Mini

B

Bk

M

6

Br

B

3

ENGLISHFRANCAISNEDERLANDSESPAÑOL

B

t

Bk Br

5

t

G

G

4

t

B

ROrOr

S3 NT1T2 L1

T1

N

L1

S3

T2

7

230V-50 Hz

6A

The boiler must be isolated from the electrical supply

before any work is carried out on it.

Electrical wiring of N boilers

1. Main switch

2. Summer/Winter switch

3. Control thermostat (60/90°C)

4. Manual reset high-limit thermostat (103°C max.)

5. Minimum thermostat 45°C (T.O.D)

6. Pump (optional)

7. Room thermostat

Wiring diagram key

B. Blue

Bk. Black

Br. Brown

G. Grey

Or. Orange

R. Red

W. White

Y/Gr. Yellow/Green

N 1

N 2

N 3

L1

Br

3

4

1

N

B

Y/Gr

12

C

Or

12

C

Bk

R

B

W

2

Y/Gr

G

5

Or

664Y1000.C

EN • 9

Br

L1

L1

B

Y/Gr

N

N

B

Br

Y/Gr

230V-50 Hz

6A

R

T1

T1

G

W

Or

Bk

T2

S3

B4

T2

S3 B4

B

R

7

6

Page 10

INSTALLATION

CONTROL KITS (OPTIONAL)

ACV 13 electrical controller

ENGLISHFRANCAISNEDERLANDSESPAÑOL

QAD 22 heating outlet sensor

QAC 32 Outdoor sensor

• Direct control of the burner

(ON/OFF) or modulating

control of a power-operated

valve.

• Domestic hot water priority.

• For configuration with an air

temperature controller.

• For configuration with an air

temperature controller.

Electrical wiring diagram of the wall-mounted case

B2. Temperature sensor

B9. Outdoor sensor

B5. Analogue/digital room sensor

P1. Pump

Y1/Y2/N. Servomotor (SSY 319 or SQK 349)

bl. Blue N

n/z. Black Y2

br. Brown Y1

SSY 319 / SQK 349

P1 B5 B9 B3 B2

QAAD50

(QAAD70)

QAC32 QAD22

bk br

bl

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

P1Y1Y2NB5B9B3B2

Please contact your installer if you require any further

information.

SSY 319 servomotor

SQK 349 servomotor

Boiler Control BC 01

• This control box is used

to connect a single- or

dualfuel boiler to a

heating system boiler,

without hotwater priority.

• SSY 319 electromechanical

servomotor for 3-way valves.

Boiler Control BC 03

• SQK 349 electromechanical

servomotor for 3-way valves.

Wall-mounted case

664Y1000.C

• ACV 13 connecting

wiring case.

• The Boiler Control BC 03 controls a heating system boiler

without domestic hot water priority with a boiler: it controls

the burner operation, the heating pump and the boiler either through the SCE pump or the 3-way SCE valve.

• The Boiler Control BC 03 incorporates a pump anti-lock

device that regularly starts up the pump for a few seconds

after a long period of non-use.

EN • 10

Page 11

N + SMART INSTALLATION WITH ACV CONTROL

1. Room thermostat

2. Heating pump

3. Loading pump indirect tank

4. Boiler burner

5. Smart 100 L boiler

6. Electrical supply

INSTALLATION

ENGLISHFRANCAISNEDERLANDSESPAÑOL

BC 01 or BC 03

1

4

1. Room thermostat

2. Loading pump indirect tank

3. 3-way power-operated valves

4. Boiler burner

5. Smart 100 L boiler

6. Electrical supply

2

3

fig. 12 : Installation with two pumps.

BC 01 or BC 03

5

1

664Y1000.C

5

2

4

3

fig. 13 : Installation with 1 pump and one 3-way power-operated valve.

EN • 11

Page 12

INSTALLATION

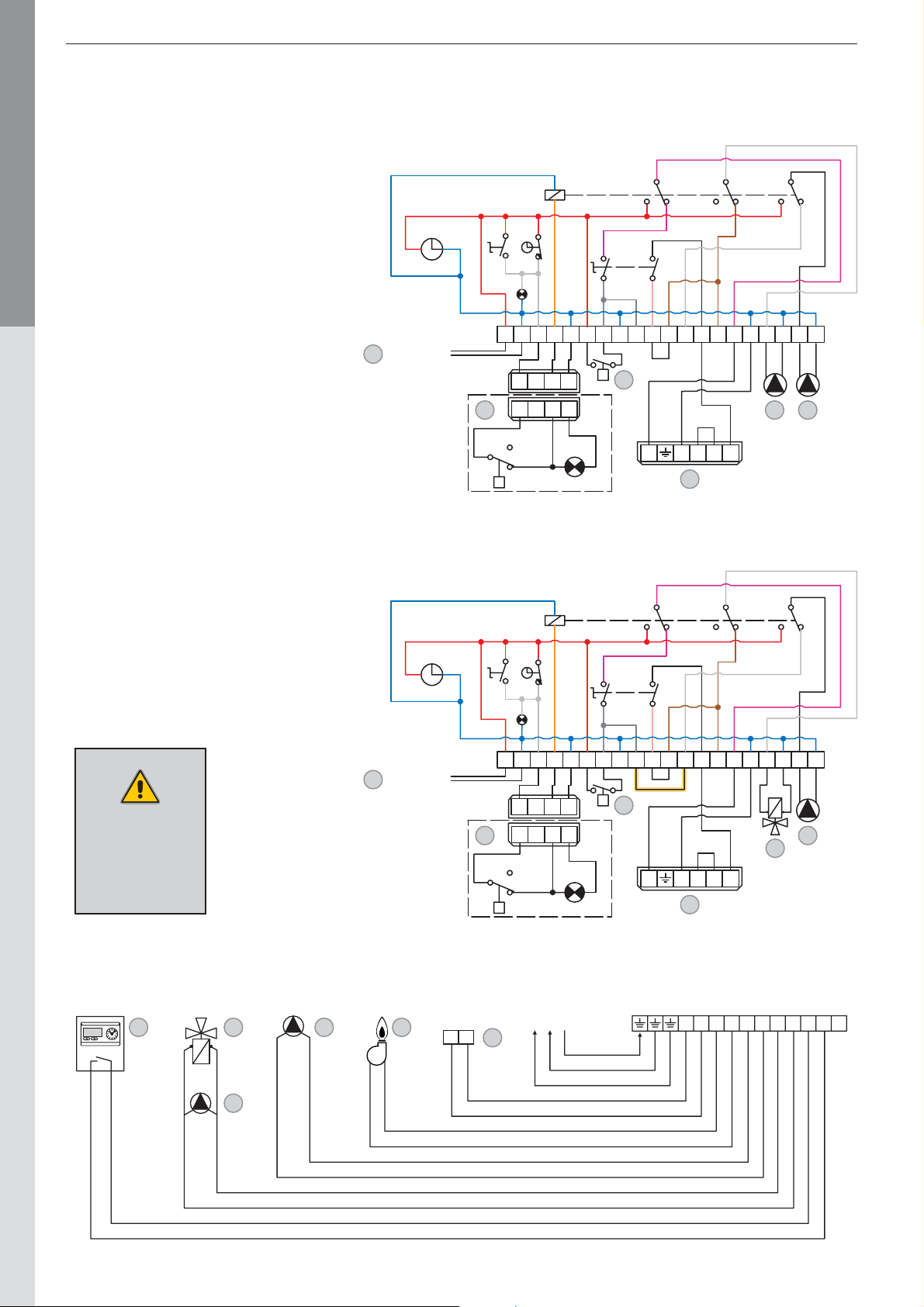

Electrical connection of BC 01 with 2 pump

1. Room thermostat

2. Heating pump

3. Loading pump indirect tank

4. Boiler burner

ENGLISHFRANCAISNEDERLANDSESPAÑOL

5. Smart 100 L boiler

6. Electrical supply

6

230 V 50Hz

1

3

11

9

4

6

7

8

5

1 2 3 4 5 6 7 8 9 1011121314151617181920

t

T8 T6T7 B5

1

5

C

t

T8 T6T7 B5

L1 T1NT2S3

4

2

Electrical connection of BC 01 with one 3-way motorised mixer valve + 1 pump

1. Room thermostat

2. Loading pump indirect tank

3. 3-way power-operated valves

4. Boiler burner

5. Smart 100 L boiler

6. Electrical supply

Attention for this

configuration it is

necessary to add

the shunt

between 9 and 12.

230 V 50Hz

6

1 2 3 4 5 6 7 8 9 1011121314151617181920

t

5

C

t

T8 T6T7 B5

T8 T6T7 B5

1

3

4

1

L1 T1NT2S3

4

11

9

6

7

8

3

3

5

2

Connecting the system’s electrical components to the BC 03

664Y1000.C

1

3

23 4

230 V ~ 50 Hz

N

L

EN • 12

PE PE

PE

6

34567891011

12

Page 13

BURNER CHARACTERISTICS

DESCRIPTION OF THE BURNER

This new generation of fuel oil burners comply with current

requirements in terms of performance and the cleanliness of

combustion gases.

The burner is fitted with the finest quality components reflecting the

latest developments in technology and the fuel-oil is pre-heated.

Components:

• “Landis & Gyr” relay

• “A.E.G.” motor

• “Suntec” pump

• “May & Christe” transformer

• “Danfoss” fuel-oil preheater

Throat

Burner socket

Nozzle line adjuster screw

Advantages

• Simple to install, it is fitted with a safety switch and a new burner

suspension system.

• A special key is provided with the burner for any maintenance

work needed.

• The burner air pressure adapts to the pressure in the combustion

chamber.

• An automatic stop check valve stops the airflow when the boiler is

turned off, preventing it from cooling.

• Silent and very reliable operation.

• Adapts to the depth of the boiler with the adjustable nozzle

clamp.

• Three air-regulation points to ensure the optimum air/fuel oil

mixture.

- The air is pre-regulated upstream;

- primary regulation;

- combustion head regulation.

ENGLISHFRANCAISNEDERLANDSESPAÑOL

Louver

Pump - nozzle connection pipe

Control relay

Burner reset

High voltage transformer

Motor

Electrical valve

Fuel oil pump

Motor capacitor

664Y1000.C

EN • 13

Page 14

BURNER CHARACTERISTICS

REGULATION PARAMENTER BM R 31 BM R 51

N1 N2 N3

Power

Electrical power

Nozzle

ENGLISHFRANCAISNEDERLANDSESPAÑOL

Nozzle angle 60° 60° 60°

Fuel oil rate of flow

Pump pressure

Flue gas index 0.6 0.6 0.6

Louver regulation 3 4.5 4

Combustion head regulation 2 1 2

Weight

kW

W

gal/h

Kg/h

bar

Kg

23.0 30.0 49.0

150 150 150

0.50 0.75 1.25

1.94 2.53 4.13

13.5 10.5 10

12 12 12

fig. 14 :

Electrode distance

BURNER DIMENSION

BM R 31

BM R 51

fig. 15 :

Combustion head

adjuster screw

A mm B mm C mm D mm E mm F mm G Ø mm L Ø mm LK Ø mm

240 270 215 280 60-130 M 8 80 85 140-165

240 270 215 280 60-130 M 8 80 85 140-165

fig. 16 :

Air flow adjuster screw

(fine tuning)

664Y1000.C

fig. 17 fig. 19fig. 18

EN • 14

Page 15

MAINTENANCECOMMISSIONING

FILLING THE HEATING CIRCUIT

IMPORTANT

If your “N” boiler is connected to an ACV tank, it is

1. Open valves 5 and 8 to fill the heating circuit and make sure the

essential to fill the domestic water circuit before the

heating circuit.

pressure does not exceed 2 bars.

8

4

7

1

3

8

2

RECOMMENDATION

It is compulsory to have the boiler serviced once a year. Boiler

servicing and checking must be carried out by a qualified engineer.

MAINTAINING THE BOILER

1. Isolate the boiler from the electrical supply at the switch on the

external control box and close the fuel oil supply valve.

2. Place the main switch on the control panel to “OFF” (except for the

N-Mini).

3. Remove the boiler front panel (1) (except for the N-Mini).

4. Loosen the two nuts or locking clamps for the N-Mini to open the

burner chamber plate (2).

5. Remove the insulating brick (for the N-Mini only).

6. Remove the stainless-steel turbulators (3).

7. Brush the flue ways, clean the chamber and vacuum up any soot

deposits.

8. Check the insulation of the burner chamber plate (4).

9. Before reassembling, clean the burner combustion head (5).

10. Check that the thermostats and safety valves are working

correctly.

4

2

1

ENGLISHFRANCAISNEDERLANDSESPAÑOL

5

6

9

fig. 20

2. Vent the system.

3. Once you have vented the system, return the pressure to the

static pressure plus 0.5 bar.

Height of the heating system:

• 10 m ➠ heating circuit pressure = 1.5 bar

• 15 m ➠ heating circuit pressure = 2 bar

USING THE BOILER FOR THE FIRST TIME

1. Check the fuel oil supply connection and ensure that it is free

from leaks.

2. Check the electrical connection to the boiler and the boiler room

ventilation, and ensure that the flue gas discharge pipes and the

burner chamber plate are properly gas tight.

3. Set the boiler thermostat to between 60° and 90°C.

4. Place the Summer/Winter switch to the required position.

5. Place the main switch to “ON”.

6. Carry out the necessary venting operations, measurements and

settings.

3

5

fig. 21

MAINTENANCE OF SAFETY EQUIPMENT

- Check that all thermostats and safety devicesoperate correctly: the

boiler thermostat and the manual reset high-limit thermostat (103°C).

- Check the heating circuit safety valves.

DRAINING THE BOILER

DANGER

HOT

Draining the heating circuit (fig. 20)

1. Place the main switch on the control panel to “OFF”, isolate the

boiler from the electrical power supply at the switch in the external

control box.

2. Close the isolating valves (8) in the heating circuit.

3. Connect a flexible tube to the drain cock (9).

4. Open the drain cock (9) to drain the heating circuit.

The water draining from the drain cock is

very hot and can cause serious burns.

Keep all persons away from running

hot water.

664Y1000.C

EN • 15

Page 16

ENGLISHFRANCAISNEDERLANDSESPAÑOL

664Y1000.C

EN • 16

Page 17

A05

A04

A01

A06

A08

A09

A02

A07

N° N-MINI N 1 N 2 N 3

A01 21471387 21471380 21471381 21471382

A02 21472387 21472380 21472381 21472382

A03 - 21473380 21473381 21473382

A04 21474387 21474380 21474381 21474382

A05 21475387 21475380 21475380 21475382

A06 21477387 21477380 21477380 21477382

A03

A07 21473387 21479380 21479380 21479382

A08 30465160 30465153 30465154 30465155

A09 2147P371 2147P380 2147P381 2147P382

Page 18

N-MINI N 1 N 2 N 3

24614108 24614108 24614109

54428116 54428116 54428116

54428107 54428107 54428107

54442045 54442045 54442045 54442045

54764009 54764009 54764009

54442015

54442027 54442027 54442027 54442027

Page 19

N-MINI N 1 N 2 N 3

54763009

54441008 54441008 54441008

55426001 55426001 55426001

47405252 47405252 47405252

47438008 47438008 47438008 47438008

49410280 49410280 49410280

50423008 50423008 50423008 50423008

Page 20

N-MINI N 1 N 2 N 3

63438001 63438001 63438001 63438001

47405137

47405004 47405004 47405004 47405004

47405005 47405005 47405005 47405005

50423098 50423097 50423097 50423098

51701000

51701001 51701002 51701003

Loading...

Loading...