Page 1

16

MCBA FOR SPECIALISTS:

INSTALLER, SERVICE ENGINEER

SAFETY STOP (ERROR MODE)

If a fault occurs while the appliance is running, the system locks and

the screen starts to flash. The first character is an E and the next two

characters give the code for this fault, as illustratedin the table below.

Table of error codes and how to resolve them

To unlock the system:

• Press RESET on the screen.

• Contact your installer if the fault happens again.

Codes Description of the fault Resolution of the fault

Abnormal flame signal

- Check the wiring (short-circuit in the 24V wiring)

- Check the electrode/ replace the MCBA (water damage).

No flame signal after five attempts at firing the boiler

- Check the ignition cable, the electrode and the

position of the electrode.

- Check that there is gas at the burner.

Persistent lock - Press RESET

EPROM error

-If the problem persists after two RESET attempts,

replace the MCBA.

Max input, thermostat open or 24V fuse gone.

- Check the wiring and check the

24V fuse on the MCBA.

Internal error

- If the problem persists after two RESET attempts,

replace the MCBA.

T1 > 110°C

- Check the NTC wiring and replace if necessary.

T2 > 110°C - Check the NTC wiring and replace if necessary.

T1 gradient too high

- Check that the pump is turning. If there is

no problem with the pump, drain the system.

No fan signal present

- If the fan is working:

• Check the fan control connection and the fan wiring

• if the problem persists after 2 RESET attempts, replace the

fan

• if the problem persists, replace the MCBA.

- If the fan is not working:

• Check that the fan 230V connection. If the problem persists,

replace the fan.

NTC 1 short-circuit

- Check the connection and the NTC1 wiring

If the problem persists, replace the NTC1.

NTC 2 short-circuit

- Check the connection and the NTC2 wiring

If the problem persists, replace the NTC2.

NTC 3 short-circuit

- Check the connection and the NTC3 wiring

If the problem persists, replace the NTC3.

NTC 1 connection open

- Check the connection and the NTC1 wiring

If the problem persists, replace the NTC1.

NTC 2 connection open

- Check the connection and the NTC2 wiring

If the problem persists, replace the NTC2.

NTC 3 connection open

- Check the connection and the NTC3 wiring

If the problem persists, replace the NTC3.

Internal error

- If the problem persists after two RESET attempts,

replace the MCBA.

Error while reading the parameters Press RESET. If the error persists, replace the MCBA.

Problem with the power supply to the fan

Check the MCBA power supply voltage. If it is OK, replace

the fan.

To

Page 2

17

MCBA FOR SPECIALISTS:

INSTALLER, SERVICE ENGINEER

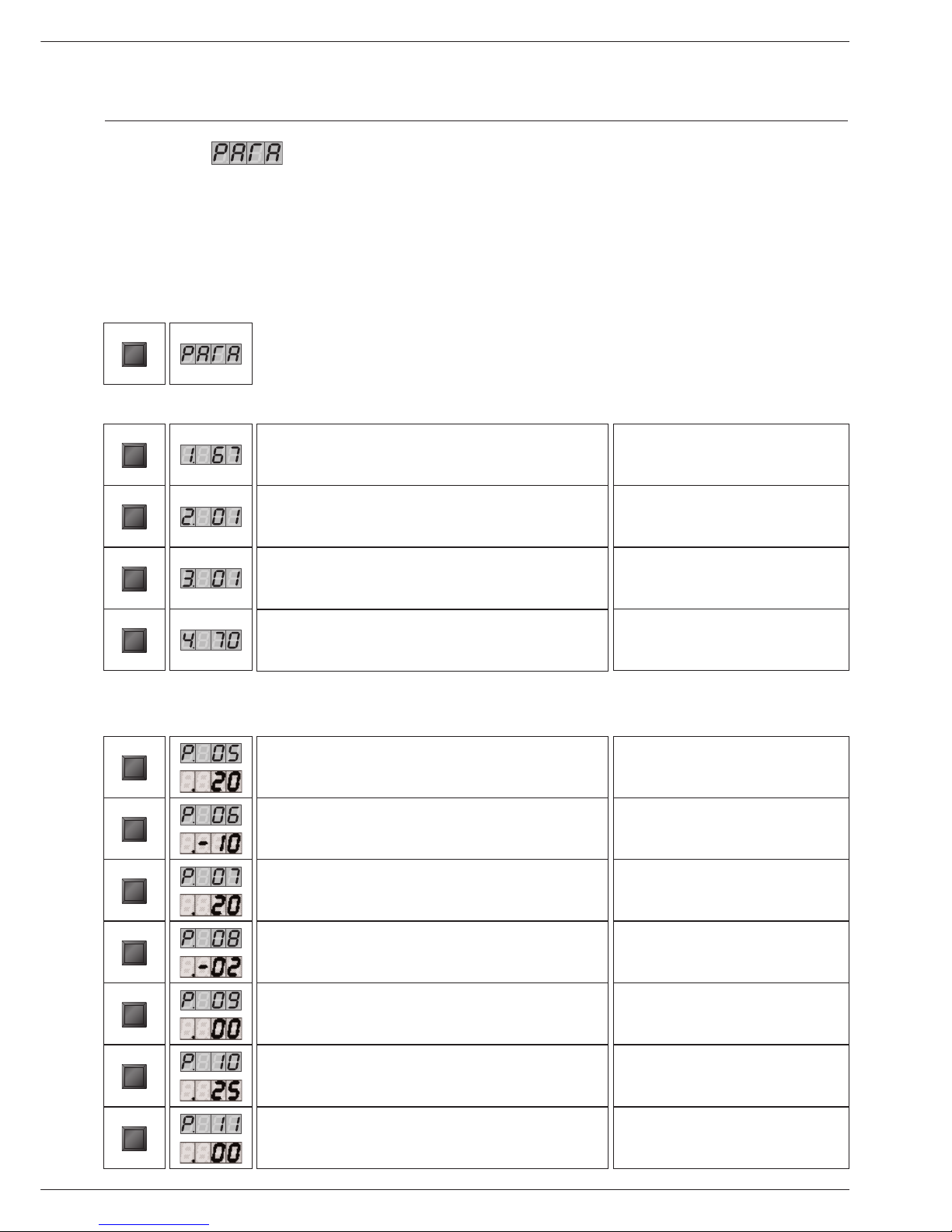

SETTING THE PARAMETERS

Parameter mode

To access Parameter mode when the system is in Pilot mode, press MODE once.

To scroll through the list of parameters, simply press “step”.To modify a parameter value, use the + or - keys.

Then press “Store” to save the value you just changed.The screen flashes once to confirm the data has been saved.

To activate the parameters you changed, press “Mode” once more (which brings you into Info mode). However, if you do not press a key, the

system returns to Pilot mode after 20 minutes and automatically enables the changes.

MODE

Adjusting the hot water temperature

STEP

STEP

STEP

STEP

Minimum central heating temperature when using an outdoor sensor

STEP

Minimum outdoor temperature

(adjust the heating curve)

STEP

Maximum outdoor temperature

(adjust the heating curve)

STEP

Frost protection temperature

STEP

Correction based on the outdoor temperature

STEP

Blockage T 0 = Disabled

90

01

01

90

60

0

20

- 15

00

00

STEP

Key Display Description of parameters Factory setting

Key Screen Description of parameters Factory setting

Key Display

Parameters for the specialist: only accessible by using the Code

Booster 00 = Stop (minute)

STEP

00

Production

of hot water

00 = Stop

01 = Start

02 = Stop + pump continuously on

03 = Start + pump continuously on

Turn on/Turn off

the heating

00 = Stop

01 = Start

02 = Stop + pump continuously on

03 = Start + pump continuously on

Maximum temperature in Central Heating mode

Page 3

18

MCBA FOR SPECIALISTS:

INSTALLER, SERVICE ENGINEER

Night-time heating temperature reduction (°C)

STEP

Fan speed in heating mode (rpm x 100)

STEP

10

52

Key Display Description of the parameters Factory setting

Max. fan speed in heating mode (rpm x 100)

STEP

00

Max fan speed in hot water mode (rpm x 100)

STEP

57

Max. fan speed in hot water mode (rpm x 100)

STEP

00

Min. fan speed (rpm x 100)

STEP

15

Min. fan speed (rpm x 100)

STEP

00

Fan speed at ignition (rpm x 100)

STEP

37

Heating pump time delay 0 = 10 sec (minute) 00

STEP

Hot water pump time delay 10.2 = 10 sec (minute) 16

00

01

01

03

STEP

Burner interlock hysteresis (heating)

STEP

Burner trigger hysteresis (heating)

STEP

Burner interlock hysteresis (hot water)

STEP

Burner trigger hysteresis (hot water)

STEP

04Hot water mode interlock hysteresis

STEP

Hot water mode trigger hysteresis

STEP

01

Page 4

19

MCBA FOR SPECIALISTS:

INSTALLER, SERVICE ENGINEER

Heating lock time (sec x 10.2)

STEP

Hot water lock time (sec x 10.2)

STEP

Lock time to switch from hot water mode to heating mode

(sec x 10.2)

STEP

Difference T1 - T2 for modulation

STEP

BUS address (-1 = disabled)

STEP

Increase the primary temperature value to generate hot

water (relative to the hot water temperature)

STEP

1st digit: heating circuit (AM3-11 – 4-way valve)

0 = disabled 5 = enabled

2nd digit: the demand for heat comes from:

0 = room thermostat

STEP

00

00

00

05

- 01

05

00

Key Display Description of the parameters Factory setting

1st digit: Hot water circulator pump (= 1)

2nd digit: tank with NTC3 sensor (= 2)

STEP

Manual fan speed (- 01 = modulation)

12

- 01

11

00

60

30

01

00

STEP

1st digit: PWM pump operating speed

2nd digit: PWM pump speed during time-delay

STEP

Holding temperature

STEP

Maximum temperature for the heating circuit outlet

(AM3-11 – 4-way valve)

STEP

Minimum temperature for the heating circuit outlet

(AM3-11 – 4-way valve)

STEP

Hysteresis of the heating circuit outlet temperature

(AM3-11 – 4-way valve)

STEP

1st digit: Special pump (0 = disabled)

2nd digit: Minimum disable cycle (0 = disabled)

STEP

Page 5

20

MCBA FOR SPECIALISTS:

INSTALLER, SERVICE ENGINEER

INFORMATION ON THE INSTALLATION

Info mode

To switch from Pilot mode to Info mode, press “Mode” twice.

ENTERING THE CODE

Code mode

You can access the following parameters by entering the service

code:

• Parameters 5 - 42

• Communication mode

• Fan Speed mode

• ERROR mode

MODE

MODE

Start temperature T1 in °C

STEP

Return temperature T2 in °C

STEP

Hot water temperature T3 in °C

STEP

Outdoor temperature T4 in °C

STEP

Not used

STEP

Start temperature calculated in °C

STEP

Rate of increase in the start

temperature in °C/s

STEP

Rate of increase in the return

temperature in °C/s

STEP

Rate of increase in the hot water

temperature in °C/s

STEP

Heating circuit outlet temperature

(AM3-11 – 4-way valve)

STEP

Press “STEP” until the system displays the information you need.

The point located behind the first position flashes to indicate that

the boiler is in “INFO” mode.

Key Display Description of parameters

Key Display

STEP

STORE

MODE STEP

+

or

-

Press “STEP” once and the system displays “C”

in position 1, followed by arbitrary

characters in positions 3 and 4.

Press “STORE”, the screen flashes

briefly to indicate that the code has been accepted.

Press “MODE” until

the system displays the correct mode.

Press “+” or “-” to change the code.

Only ACX authorised installers know the access code.

For further information, please contact our after-sales

department.

To access Code mode, press

MODE and STEP simultaneously

(only from Pilot mode!).

Page 6

21

MCBA FOR SPECIALISTS:

INSTALLER, SERVICE ENGINEER

COMMUNICATION MODE (WITH CODE)

When in this mode, the system displays the communication between

the boiler and the control module, the optional interface kit or the

optional programmable room thermostat.

FAN MODE (WITH CODE)

ERROR MODE (WITH CODE)

“ERROR” mode indicates the most recent error, as well as the

status of the boiler and its readings at the time this error occurred.

Fan speed

MODE

The current fan speed is 5,500 rpm.

STEP

Key Display Description of parameters

MODE

Code mode

(See the table on page 16 for a full list)

STEP

Status of the boiler at the time of the

error (See the table on page 16)

STEP

Start temperature T1 at the time of

the error

MODE

Return temperature T2 at the time of

the error

STEP

Hot water temperature T3 at the time

of the error

STEP

Outdoor temperature T4 at the time of

the error

STEP

Key Display

Key Display Description of parameters

MODE

No communication

Communication between the boiler

module and the optional control

modules only (RMCI)

STEP

Communication between all the

devices connected

Key Display

Key Display Description of parameters

Temp. °C R Ω Temp. °C R Ω

-20 98200 40 6650

-15 75900 45 5520

-10 58800 50 4610

-5 45900 55 3860

0 36100 60 3250

5 28600 65 2750

10 22800 70 2340

15 18300 75 1940

20 14700 80 1710

25 12000 85 1470

30 9800 90 1260

35 8050 95 1100

100 950

Temperature sensor resistance tables

Page 7

22

SPARE PARTS

No. Jackets Codes HeatMaster®201

A01 Right side 21471415

A02 Left side 21471415

A03 Right side rear corner 21478415

A04 Left side rear corner 21473415

A05 Rear panel 21474415

A06 Right side front corner 21472415

A07 Left front side 21479415

A08 Upper front panel 2147A415

A09 Lower front panel 2147B415

A10 Burner cover 21476415

A11 Rear top cover 21475415

A12 Front top cover 21475416

A13 Rear half-base 2147S415

A14 Unequipped control panel 21477416

A15 Body + accessories (package No. 1) 27300047

No. Accessories

B01 Low-water-level pressure switch 557D3011

B02 Wilo circulator pump 557A4007

B03 3 bar / Ø 3/4” - 1” safety valve 557A1048

B04 Burner chamber insulating cover 51700041

B05 8-l expansion vessel 55301200

B06 Steam trap, Ø 1/2” 557A3001

B07 Drain cock, Ø 3/4” 557A1000

B08 Fill set, Ø 1/2” 55426018

B09 Type A, high-level turbulators 507F2009

B10 Type B, low-level turbulators 507F2010

No. Setting and electrical accessories

C01 MCBA 537D8016

C02 Transformer 547D3021

C03 NTC Duplo (NTC1 - NTC2) 5476G002

C04 NTC Single (NTC3) 5476G003

C05 Module AM3-11 10800080

C06 Module AM3-2 10800060

C07 Full control panel 24614133

C08 Display 537D3020

C09 Display case 537D3023

C10 Pressure gauge-thermometer 54441008

C11 ON/OFF switch 54766016

C12 Summer/Winter switch 54766017

C13 Control panel self-adhesive 617G0105

No. Burner

D01 Full burner 237D0118

D02 Fan 537D3034

D03 Venturi 537D4042

D04 110 x 3.5mm O-ring 557A0045

D05 Plate fan seal 557A0040

D06 Burner chamber plate seal 557A0020

D07 Ø 98mm burner tube + NIT 537DZ019

D08 Chamber plate sealing cord 51700025

D09 Ignition electrode 537DZ020

D10 Ignition cable 25760046

D11 Burner chamber plate insulating stone 51700040

D12 Burner chamber plate 2147P416

D13 Gas valve 537D4041

D14 Valve flange 537D8021

Page 8

23

SERVICE RECORD

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Model:

Serial number:

Heating system pressure setting:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

INSTALLATION DETAILS

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Comments:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

SERVICE NOTES

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Comments:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Comments:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Comments:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Comments:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

Page 9

24

SERVICE RECORD

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Comments:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Comments:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Comments:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Comments:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Comments:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

Service date:

% CO2 (min. load):

% CO2 (max. load):

Gas

Propane

Comments:

❏

❏

Name and signature:

Flue gas T°:

Efficiency:

Gas pressure:

Page 10

Page 11

INTERNATIONAL

ACV international n.v

KERKPLEIN, 39

B-1601 RUISBROEK - BELGIUM

TEL.: +32 2 334 82 20

FAX: +32 2 378 16 49

E-MAIL: international.info@acv-world.com

BELGIUM

ACV BELGIUM nv/sa

KERKPLEIN, 39

B-1601 RUISBROEK-BELGIUM

TEL.: +32 2 334 82 40

FAX: +32 2 334 82 59

E-MAIL: belgium.info@acv-world.com

CHILE

ALBIN TROTTER Y ACV LTDA

SAN PABLO 3800

QUINTA NORMAL - SANTIAGO - CHILE

TEL.:+56 2 772 01 69

FAX:+56 2 772 92 62/63

E-MAIL: chile.info@acv-world.com

CZECH REPUBLIC

ACV CR SPOL. s.r.o

NA KRECKU 365

CR-109 04 PRAHA 10 - CZECH REPUBLIC

TEL.:+420 2 720 83 341

FAX:+420 2 720 83 343

E-MAIL: ceskarepublika.info@acv-world.com

DEUTSCHLAND

ACV WÄRMETECHNIK GMBH & CO KG

GEWERBEGEBIET GARTENSTRASSE

D-08132 MÜLSEN OT ST. JACOB - DEUTSCHLAND

TEL.:+49 37601 311 30

FAX:+49 37601 311 31

E-MAIL: deutschland.info@acv-world.com

ESPAÑA

ACV ESPAÑA

C/DE LA TEIXIDORA, 76

POL. IND. LES HORTES

E-08302 MATARÓ - ESPANA

TEL.:+34 93 759 54 51

FAX:+34 93 759 34 98

E-MAIL: spain.info@acv-world.com

FRANCE

ACV FRANCE sa

31, RUE AMPERE - Z.I MI - PLAINE

F-69680 CHASSIEU - FRANCE

TEL.:+33 4 72 47 07 76

FAX:+33 4 72 47 08 72

E-MAIL: france.info@acv-world.com

ITALIA

ACV ITALIA

VIA PANA 92

I-48018 FAENZA (RA) - ITALIA

TEL.:+39 0546 64 61 44

FAX:+39 0546 64 61 50

E-MAIL: italia.info@acv-world.com

NEDERLAND

ACV NEDERLAND bv

POSTBUS 350

NL-2980 AJ RIDDERKERK - NEDERLAND

TEL.:+31 180 42 10 55

FAX:+31 180 41 58 02

E-MAIL: nederland.info@acv-world.com

POLAND

ACV POLSKA sp. z.o.o.

UL.WITOSA 3

87 - 800 WWOCWAWEK - POLAND

TEL.:+48 54 412 56 00

FAX:+48 54 412 56 01

E-MAIL: polska.info@acv-world.com

PORTUGAL

BOILERNOX LDA

RUA OUTEIRO DO POMAR

CASAL DO CEGO, FRACÇÃO C,

PAVILHÃO 3 - MARRAZES

2400-402 LEIRIA - PORTUGAL

TEL.:+351 244 837 239/40

FAX:+351 244 823 758

E-MAIL: boilernox@mail.telepac.pt

RUSSIA

ACV RUSSIA

1/9, MALYI KISELNYI

103031 MOSCOW - RUSSIA

TEL.:+7 095 928 48 02 / +7 095 921 89 79

FAX:+7 095 928 08 77

E-MAIL: russia.info@acv-world.com

SLOVAK REPUBLIC

ACV SLOVAKIA s.r.o.

PLUHOVÁ 49

831 04 BRATISLAVA - SLOVAK REPUBLIC

TEL.:+421 2 444 62 276

FAX:+421 2 444 62 275

E-MAIL: slovakia.info@acv-world.com

SLOVENIA

ACV D.O.O. SLOVENIA

OPEKARNA 22b

1420 TRBOVLJE - SLOVENIA

TEL.:+386 356 32 830

FAX:+ 386 356 32 831

E-MAIL: slovenia.info@acv-world.com

UK

ACV UK Ltd

ST.DAVID’S BUSINESS PARK

DALGETY BAY - FIFE - KY11 9PF

TEL.:+44 1383 82 01 00

FAX:+44 1383 82 01 80

E-MAIL: uk.info@acv-world.com

USA

TRIANGLE TUBE PHASE III

FREEWAY CENTER - 1 TRIANGLE LANE

BLACKWOOD NJ 08012 - USA

TEL.:+1 856 228 8881

FAX:+1 856 228 3584

E-MAIL: sales@triangletube.com

excellence in hot water

www.acv-world.com

ARGENTINA

TECNOPRACTICA

ALFEREZ BOUCHARD 4857

1605 CARAPACHAY - BUENOS AIRES

TEL.: +54 11 47 65 33 35

FAX: +54 11 47 65 43 07

E-MAIL: jchas@tecnopractica.com

AUSTRALIA

HUNT HEATING PTY LTD

10 GARDEN BOULEVARD

3172 VICTORIA - AUSTRALIA

TEL.: +61 3 9558 7077

FAX: +61 3 9558 7027

E-MAIL: enquiries@huntheat.com.au

BRAZIL

SIMETAL INDUSTRIA E COMERCIO

DE FERRAMENTAS LTDA

RUA GERSON ANDREIS 535

95112 - 130 CAXIAS DO SUL - BRAZIL

TEL.: +55 54 227 12 44

FAX: +55 54 227 12 26

E-MAIL: export@simetall.com.br

BULGARIA

PROXIMUS ENGINEERING LTD

7 BIAL KREM STR.

9010 VARNA - BULGARIA

TEL.:+359 52 500 070

FAX:+359 52 301 131

E-MAIL: info@proximus-bg.com

CHINA

BEIJING HUADIAN HT POWER TECHNOLOGY

DEVELOPMENT CO. LTD

ROOM B-912, TOWER B, COFCO PLAZA

N°. 8, JIANGUOMENNEI AVENUE

BEIJING 100005 - PEOPLE’S REPUBLIC OF CHINA

TEL.:+86 10 652 30 363/393 EXT 101

FAX:+86 10 652 27 071

E-MAIL: li.zheng@acv-world.com

SHANGHAI COOLTECH LTD

14/F E. CHINA MERCHANTS PLAZA

N°. 333 CHENGDU ROAD (N)

200041 SHANGHAI - CHINA

TEL.:+86 21 52 98 11 22 - 820

FAX:+86 21 52 98 13 58

E-MAIL: cooltech@cooltech.sh.cn

DENMARK

VARMEHUSET

FRICHSVEJ 40 A

8600 SILKEBORG - DENMARK

TEL.:+45 86 82 63 55

FAX:+45 86 82 65 03

E-MAIL: vh@varmehuset.dk

ESTONIA

TERMOX AS

TAHE 112A

51013 TARTU - ESTONIA

TEL.:+372 736 73 39

FAX:+372 736 73 44

E-MAIL: termox@termox.ee

GREECE

ESTIAS

MARASLI STREET 7

54248 THESSALONIKI - GREECE

TEL.:+30 23 10 31 98 77 / +30 23 10 32 03 58

FAX:+30 23 10 31 97 22

E-MAIL: info@genikithermanseon.gr

ÎLE MAURICE

SOTRATECH

29, RUE MELDRUM

BEAU BASSIN - ÎLE MAURICE

TEL.:+230 46 76 970

FAX:+230 46 76 971

E-MAIL: stech@intnet.mu

LITHUANIA

UAB “GILIUS IR KO”

SAVARNORIU PR. 192

3000 KAUNAS - LITHUANIA

TEL.:+370 37 308 930

FAX:+370 37 308 932

MAROC

CASATHERM

PLACE EL YASSIR

20300 CASABLANCA - MAROC

TEL.:+212 22 40 15 23

FAX:+212 22 24 04 86

MOLDAVIA

STIMEX - PRIM S.R.L.

STR BUCURESTI, 60A

2012 CHISINAU - MOLDAVIA

TEL.:+37 32 22 46 75

FAX:+37 32 27 24 56

E-MAIL: stimex@slavik.mldnet.com

NEW ZEALAND

ENERGY PRODUCTS INTERNATIONAL

8/10 BELFAST PLACE

PO BOX 15058 HAMILTON - NEW ZEALAND

TEL.:+64 7 847 27 05

FAX:+64 7 847 42 22

E-MAIL: pmckenzie@tycoint.com

ÖSTERREICH

PROTHERM HEIZUNGSTECHNIK Gmbh

TRAUNUFERSTRASSE 113

4052 ANSFELDEN - ÖSTERREICH

TEL.:+43 7229 804 82

FAX:+43 7229 804 92

E-MAIL: protherm@nextra.at

ROMANIA

SC TRUST EURO THERM SA

D.N PIATRA NEAMT - ROMAN

km 2 C.P 5 O.P 3 jud. Neamt

5600 PIATRA NEAMT - ROMANIA

TEL.:+40 233 20 62 06

FAX:+40 233 20 62 00

E-MAIL: office@eurotherm.ro

TUNISIE

SO.CO.ME CHAUMAX

BOÎTE POSTALE N°44

1002 TUNIS - TUNISIE

TEL.:+216 71 78 15 91

FAX:+216 71 78 87 31

UKRAINE

UKRTEPLOSERVICE LTD

PR. LAGUTENKO 14

83086 DONETSK - UKRAINE

TEL.:+38 062 382 60 47/48

FAX:+38 062 335 16 89

Loading...

Loading...