ACV LCA HP 750 mh, LCA HP 1500 hh, LCA HP 1500 mh, LCA HP 1000 mh, LCA HP 1000 hh Technical Manual

...Page 1

TECHNICAL MANUAL

INSTRUCTIONS FOR INSTALLATION AND USE

OF ELECTRIC WATER HEATERS AND

ENAMELLED HEATER TANKS

FROM 300 to 3000L

EN 1 Document ref.: 428016 03

Page 2

EN 2 Document ref.: 428016 03

Page 3

DATASHEET

Name of

supplier

Standing

losses

[W/H] 93,23 112,09 145,57 168,2 205,92 246,25 277,52 302,05

Storage

capacity

1550

1726

2550

2746

[l]

333

516

747

917

DDEEE

ErP class

Model

ACV

LCA P 300

LCA P 500

LCA P 750

LCA P 1000

LCA P 1500

LCA P 2000

LCA P 2500

LCA P 3000

-CC

D

Name of

supplier

Standing

losses

[W/H] 95,13 114,38 148,54 171,63 210,12 251,28 283,18 308,21

Storage

capacity

ErP Class

Model

ACV

LCA 300 hh

LCA 500 hh

LCA 750 hh

LCA 1000 hh

LCA 1500 hh

LCA 2000 hh

LCA 2500 hh

LCA 3000 hh

-CCDDDEEE

1551

1727

2551

2747

[l]

333

515

744

914

Name of

supplier

Standing

losses

[W/H] 163,54 186,63 225,12 266,28 298,18 323,21

Storage

capacity

1555

1731

2552

2748

[l]

748

918EEEE

E

ErP Class-D

ACV

Model

LCA 750 mh

LCA 1000

mh

LCA 1500

mh

LCA 2000

mh

LCA 2500

mh

LCA 3000

mh

Name of

supplier

Standing

losses

[W/H] 97,03 116,67 151,51 175,06 214,32 256,31 288,84 314,37

[l]

317

489

709

Model

LCA 1CO

300 hh

LCA 1CO

500 hh

LCA 1CO

750 hh

ErP Class-CCD

Storage

capacity

865

1508

1684

D

ACV

LCA 1CO

2500 hh

LCA 1CO

3000 hh

EEEE2485

2681

LCA 1CO

1000 hh

LCA 1CO

1500 hh

LCA 1CO

2000 hh

Name of

supplier

Standing

losses

[W/H] 166,81 190,36 229,62 271,61 304,14 329,67

869

1512

1688

E

ACV

LCA 1CO

2500 mh

LCA 1CO

3000 mh

EEEE2486

2682

LCA 1CO

1000 mh

LCA 1CO

1500 mh

LCA 1CO

2000 mh

[l]

713

Model

LCA 1CO

750 mh

ErP Class-D

Storage

capacity

EN 3 Document ref.: 428016 03

Page 4

DATASHEET

Name of

supplier

Standing

losses

[W/H] 98,94 118,96 154,48 178,5 218,52 261,33 294,51 320,54

Storage

capacity

ErP Class

Model

ACV

LCA 300

2CO hh

LCA 500

2CO hh

LCA 750

2CO hh

LCA 1000

2CO hh

LCA 1500

2CO hh

LCA 2000

2CO hh

LCA 2500

2CO hh

LCA 3000

2CO hh

-DDDDEEEE

1501

1657

2476

2672

[l]

317

489

711

870

Name of

supplier

Standing

losses

[W/H] 170,08 194,1 234,12 276,93 310,11 336,14

Storage

capacity

ErP Class

Model

ACV

LCA 750

2CO mh

LCA 1000

2CO mh

LCA 1500

2CO mh

LCA 2000

2CO mh

LCA 2500

2CO mh

LCA 3000

2CO mh

-EEEEEE

1505

1674

2486

2682

[l]

715

883

supplier

Standing

losses

[W/H] 121,24 157,45 181,93 222,73 266,36

[l]

480

676

Model

LCA HP 500

hh

LCA HP 750

hh

ErP Class-D

D

Storage

capacity

838

1467

1631

D

ACV

E

E

LCA HP

1000 hh

LCA HP

1500 hh

LCA HP

2000 hh

Name of

supplier

Standing

losses

[W/H] 173,35 197,83 238,63 282,26

842

1471

1635

E

ACV

E

E

LCA HP

1000 mh

LCA HP

1500 mh

LCA HP

2000 mh

[l]

680

Model

LCA HP 750

mh

ErP Class-D

Storage

capacity

EN 4 Document ref.: 428016 03

Page 5

CONTENTS

1. RECOMMENDATIONS 7

2. INSTALLATION 10

3. HYDRAULIC CONNECTION 11

4. HYDRAULIC TESTS 13

5. ELECTRICAL CONNECTION 14

6. INSTALLATION OF HEATING COMPONENTS 15

7. ELECTRICAL SPECIFICATIONS AND CABLING DIAGRAMS 17

8. PUFFER RANGE 24

9. DOMESTIC HOT WATER STORAGE RANGE 25

10. SINGLE COIL RANGE 26

11. HEAT PUMP COIL RANGE 27

12. DOUBLE COIL RANGE 28

13. INSTALLATION OF HYDRAULIC ACCESSORIES 29

14. INSTALLATION OF THE INSULATION 30

15. COMMISSIONING 31

16. SHUTDOWN OF THE SYSTEM 31

17. USER RECOMMENDATIONS 32

18. MAINTENANCE AND CLEANING 33

19. TROUBLESHOOTING 34

20. WARRANTY 35

EN 5 Document ref.: 428016 03

Page 6

EN 6 Document ref.: 428016 03

Page 7

1. RECOMMENDATIONS

1-1 General recommendations

1. This very important manual is an indispensable part of

the appliance.

The manual must be kept in a safe place and must be

passed onto any subsequent owners or users of the

appliance and/or in the event that the boiler is

transferred to another site.

2. Read the instructions and advice provided carefully, as

this will help you to ensure your appliance is safely

installed, used and maintained.

3. The purchaser is responsible for installation, which

must be carried out by an industry professional in

accordance with the instructions in the manual.

4. Any use of the appliance other than that stipulated

herein is prohibited.

The manufacturer shall in no way be held liable for any

damages arising from the improper, incorrect or

unreasonable use of the appliance or failure to follow

the instructions contained in this manual.

5. Installation, maintenance and all other operations

must be carried out by industry professionals according

to the applicable regulations and the indications

provided by the manufacturer.

6. The manufacturer accepts no liability for any personal

injuries, injuries to animals or damage to goods as a

result of any incorrect installation

of the appliance.

7. The packaging (clips, plastic bags, expanded

polystyrene, etc.) must be kept out of the reach of

children.

8. This appliance is not designed for use by persons

(including children) with reduced physical, sensory or

mental capacities, or who do not have sufficient

knowledge or experience, unless they have benefited

from supervision and instruction concerning the use of

the appliance by the person responsible for their safety.

9. Children must be supervised to ensure they do not

play with the appliance

10. Do not touch the appliance with your bare hands or

any wet body parts.

11. For all repairs, call an accredited technician and insist

that genuine spare parts are used. Failure to comply with

these instructions could compromise safety and shall

exempt the manufacturer from all liability. Before

carrying out any repair and/or maintenance operation

on the unit, it is important to isolate all supply sources.

In case of a malfunction in the unit, switch it off and

phone technical assistance.

12. No inflammable objects must be kept near the

appliance.

13. Correct usage also includes following the instructions

for use and installation, and adhering to any additional

documentation, as well as

the inspection and maintenance conditions.

14. Any use outside these conditions is forbidden.

1-2 User recommendation

Before installing the appliance, please read the

instructions in this manual carefully. Failure to comply

with them will invalidate the warranty.

The purchaser is responsible for installing the product.

Installation, start-up, maintenance and repairs must only

be carried

out by a qualified professional in accordance with

industry practice and applicable national standards. It is

essential to comply with all prescriptions relating to

domestic hot water tanks, as well as the instructions

supplied by the manufacturer.

To prevent burns, use suitable mixing devices to avoid

exceeding a temperature of 50°C at the catchment

points.

If the appliance is inactive for a prolonged period (e.g.

during winter holidays) in an unheated area, water may

freeze in the appliance and the pipes. Ensure that the

installation is protected from freezing.

If any accessories are installed on the unit, they must

only be original parts from the manufacturer.

To clean the exterior of the unit, it is recommended to

use a damp cloth and cleaning products intended for this

purpose.

The use of abrasive products or solvents is strongly

discouraged.

No inflammable objects must be kept near the

appliance.

GENERAL SAFETY STANDARDS

Failure to respect the warnings could result in injury and

may even lead to death.

Failure to comply with warnings could result in serious

damage to objects, plants or animals.

The general and specific safety standards relating to the

product must be observed.

Do not carry out any operation which requires the

appliance to be opened.

Burn injuries from hot components or injuries caused by

parts that protrude or by sharp edges.

Do not carry out any operation which requires the

appliance to be moved.

Contact with live components can cause electrocution.

Flooding caused by water escaping from disconnected

pipes.

Do not use the connector plug on the main supply cable

to connect or shut down the appliance.

Electrocution can be caused by a damaged cable, socket

or connector plug.

Do not damage the main supply cable.

Electrocution caused by stripped live wires.

Never place any objects on the appliance.

Injuries can be caused by the item falling due to

vibrations.

Damage to the appliance or items below it caused by

items that fall because of vibrations.

Do not climb on the appliance.

Injury can be caused by the appliance falling over.

Damage to the appliance or items below it due to the

appliance becoming detached from its supports and

falling over.

Do not climb on chairs, step stools, ladders or unstable

supports to clean the appliance.

Injury due to falling or folding of the ladder (double

ladder).

Do not carry out any cleaning operations on the

appliance without having switched it off, disconnected

the connector plug or deactivated the relevant switch.

Contact with live components can cause electrocution.

Install the appliance on a solid wall that will not be

subject to vibrations.

Noise during operation.

When drilling the wall, take care not to damage the

electrical cables or pipes.

EN 7 Document ref.: 428016 03

Page 8

Contact with live conductors can cause electrical arcing.

Explosions, fires or poisoning in the event of gas leaking

from a damaged duct.

Damage to existing installations. Flooding in the event of

water leaking from damaged ducts.

Protect connection cables to prevent them from being

damaged.

Contact with live conductors can cause electrocution

Flooding caused by water escaping from damaged pipes

Check that the part and the installations to which the

appliance will be connected comply with the current

applicable regulations.

Contact with incorrectly installed live conductors can

cause electrocution.

Damage to the appliance due to unsuitable operating

conditions.

Use accessories and manual equipment suitable for the

usage (ensure that the tool is not damaged and the

handle is securely attached and in good condition), use

this equipment correctly, protect it against being

accidentally dropped and store it after use.

Injury may be caused by flying debris or fragments, dust

inhalation, impacts, cuts, pricks and abrasions.

Damage to the appliance or to nearby objects caused by

flying debris or fragments, impacts or incisions

Use suitable electrical equipment (in particular, check

that the supply cable and connector plug are in good

condition and that rotating or alternating parts are

properly secured).

Use the equipment correctly, do not allow a trailing

supply cable to obstruct access, secure it to prevent

falling, and disconnect and store it after use

Injury can be caused by electrocution, projected shards

or fragments, inhaling dust, being hit, or cuts, pricks,

abrasions, noise or vibrations.

Damage to the appliance or to objects nearby caused by

projected debris or fragments, cuts, incisions.

Ensure that portable ladders are stable and sturdy and

will not slip, and that the rungs are in good condition.

Ensure that someone is present to ensure that ladders

cannot move when someone else is using them.

Injury due to falling or folding of the ladder (double

ladder).

Ensure that materials, components or equipment used

during installation cannot fall from height.

Injury or death due to collapsing and/or falling parts.

Ensure that mobile ladders are correctly supported and

sufficiently sturdy, that the rungs are in good condition

and not slippery, and that the rungs and platforms are

fitted with rails.

Injury due to falling.

When working at height (generally during use with

height differences of more than 2 m), ensure that there

is a safety rail surrounding the working area or that

personal equipment is used to prevent falling, that the

route of any potential fall is not obstructed by

dangerous objects and that any possible impact would

be cushioned by semi-rigid or deformable supports.

Injury due to falling.

Ensure that the health and safety conditions are

adequate in terms of lighting, ventilation, structural

soundness and emergency exits.

Injury caused by being hit, tripping, etc.

During work, wear personal protective equipment and

clothing.

Injury can be caused by electrocution, projected shards

or fragments,

inhaling dust, being hit, or cuts, pricks, abrasions, noise

or vibrations.

The utmost care must be taken during operations

inside the appliance, and contact with sharp edges

avoided.

Injury caused by cuts, pricks and abrasions.

Do not use insecticides, solvents or harsh cleaning

products for maintenance of the appliance.

Painted or plastic parts can be damaged.

Do not use the appliance for any use other than

standard household use.

The appliance may be damaged by operation overload.

Damage to incorrectly treated objects.

Do not allow children or inexperienced persons to use

the appliance.

Damage to the appliance may be caused by improper

use.

Electrical connections must be made using conductors

with a suitable cross section.

Fire due to overheating caused by current passing

through cables which are too small.

Protect appliances and nearby areas using suitable

equipment.

Damage to the appliance or to objects nearby caused by

projected debris or fragments, cuts, incisions.

Move the appliance using the necessary protective

equipment and with the utmost care.

Damage to appliances or nearby objects caused by

impacts, incisions or crushing.

Ensure that all equipment is stored in a way that makes

it simple and safe to handle; avoid creating piles which

are in danger of collapsing.

Damage to appliances or nearby objects caused by

impacts, incisions or crushing.

Reset any safety and control functions affected by an

operation on the appliance, and make sure that they

are operating correctly before it is put back in service.

Damage to or stoppage of the appliance due to

uncontrolled operating conditions.

Before working on roofs, structures, surfaces, etc.,

ensure that they are stable and suitable for the work to

be carried out.

Injury or death due to collapsing and/or falling from

height.

SAFETY STANDARDS SPECIFIC TO THE PRODUCT

Drain any components which contain hot water by

activating the drain before using them.

Injury caused by burns

Descale components in accordance with the

instructions in the safety sheet for the product in

question. Carry out the operation in a well-ventilated

area and wear protective clothing.

Avoid mixing different products and protect the

appliance and nearby objects.

Personal injury through skin and eyes coming into

contact with acidic substances, inhalation of ingestion of

harmful chemical agents.

Damage to the appliance or objects nearby due to

corrosion caused by acidic substances.

Do not carry out work on the product in strong

sunlight.

Injury caused by burns

EN 8 Document ref.: 428016 03

Page 9

TRANSPORT, STORAGE AND RECYCLING

INSTRUCTIONS

The appliance must be transported in accordance with

the pictograms hereunder on the packaging.

The appliance must be transported and stored in dry

conditions and freezing conditions must be avoided.

EU directive 2002/96/EC requires selective collection

and recycling of used electrical and electronic devices.

The "crossed-out wheeled bin" symbol on the appliance

indicates that the product must be disposed of

separately from standard household waste at the end of

its useful life, and must be brought to a waste sorting

centre for electrical and electronic devices or returned

to the seller when a replacement appliance is purchased.

DECLARATION OF CONFORMITY

Conformity of design and production

This product conforms to EU directive 97/23EC, article 3,

paragraph 3 concerning pressure equipment and

93/69/CEE relating to standard EN12897-2006 specific to

indirectly heated, unvented water heaters.

If the addition of a resistance is recommended by the

manufacturer (kit specified in the manual), this product

complies with the following European directives and

standards: LVD Directive (electrical safety) 2006/95/EC

EMC Directive 2004/108/EC.

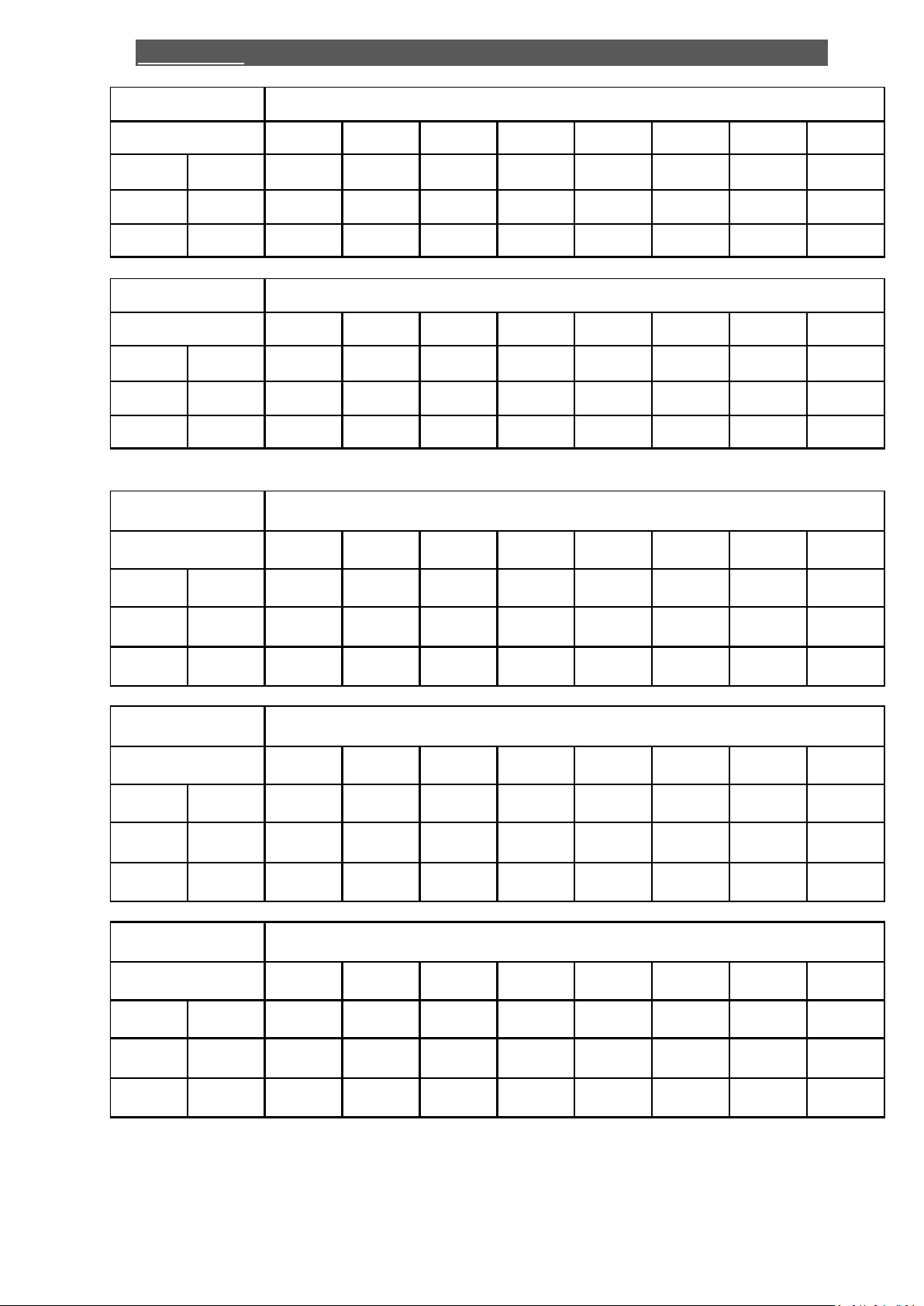

DESCRIPTION OF APPLIANCES

Enameled tanks are designed for both the production

and storage of domestic hot water.

These tanks can be combined with both solar energy

systems and more common energy systems such as gasor oil-fired boilers.

The tanks are protected by an enamel covering applied

at 850°C, in accordance with the requirements of DIN

4753/3.

EN 9 Document ref.: 428016 03

Page 10

B

A

D

C

2. INSTALLATION

The appliance must be installed in accordance with professional good practice and in

compliance with the national regulations in force for hydraulic and electrical

connections, under the entire responsibility of the installer.

This appliance must be installed in covered premises, sheltered from frost and

having sufficient upper and lower ventilation.

Installation of the water heater with its raising feet (label A)

Installation of heating components (label B)

Installation of hydraulic accessories (Option)

Installation of safety unit + drain (Option)

Installation of M1 or M0 insulation (label D)

Hydraulic connection (label C)

Principle with 1 water heater

Principle with two water heaters in series

Hydraulic tests

Electrical connection

Assembly test

IMPORTANT:

INSTALLATION OF THE APPLIANCE

EN 10 Document ref.: 428016 03

Page 11

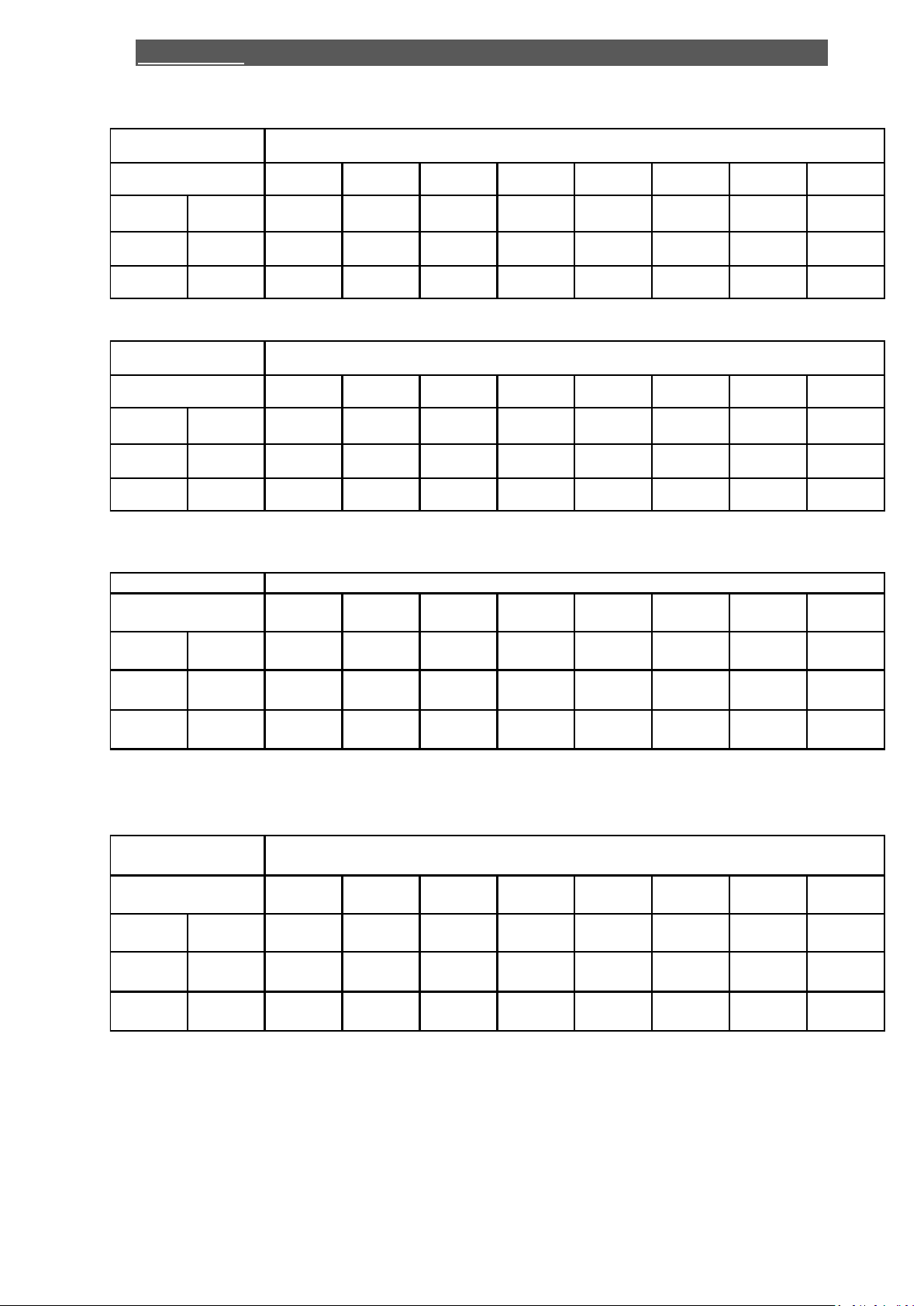

RECOMMENDATIONS

Capot électrique

Sleeves de raccordement

1.20m

0.30 m

0.30 m

0,15m

Figure 1

Figure 2

Key:

1 - Cold water inlet

2 - Stop valve

3 - Water filter

4 - Check valve

5 - Safety valve

6 - Degassing bottle with bleeder

7 - Supply points (with

thermostatic mixers).

8 - Homogenisation pump

(mandatory against

Legionnaire’s Disease)

9 - Connection sleeves

For special fitting

10 - Funnel to the drain

11 - Example special fitting

(plate exchanger)

12 - Loop pump

13 - Loop reheater

12

11

10

2

10

5

2

4

2

13

6

2

4

3

1

7

4

8

9

Electrical cover

Connecting sleeves

The appliance must be as close as possible to the supply stations.

For operations of maintenance or replacement of heating components, easy

access must be provided. (Fig 1)

Installation of raising feet (using the bolts provided) (Fig 2)

Either use of the lifting rings of the appliance (at the top of the appliance),

Or possibility of tilting the appliance (without lying it down), taking care not to

Position the water heater in its final position.

Check the stability of the water heater.

3. HYDRAULIC CONNECTION

To enable optimal use of the water heater, we recommend that you carry out the

hydraulic connection as follows:

Not all appliances labelled on these installation diagrams are supplied by us.

However, the correct installation of the appliance in accordance with the national

regulations in force is under the entire responsibility of the installer.

SCHEMA DE PRINCIPE AVEC UN CHAUFFE-EAU

EN 11 Document ref.: 428016 03

put stress on the cylinder of the tank and of course without impact.

For information any external marking may entail internal damage to the

appliance and will therefore invalidate the warranty.

IMPORTANT NOTE

DE PRINCIPE AVEC UN CHAUFFE-EAU

DIAGRAM OF PRINCIPLE WITH ONE WATER HEATER

Page 12

13

10

7

4

2

12

2

8

2

4

8

2

4

10

10

2

4

5

2

2

10

2

2

3

5

4

2

6

2

6

2

1

9 9

DIAGRAM OF PRINCIPLE WITH TWO WATER HEATERS CONNECTED IN SERIES/PARALLEL

IMPORTANT:

In the event of installation of battery appliances, it is imperative to install a safety valve specific to

each appliance.

Safety units for the whole of the range (as option) to be installed on each appliance.

These valves must be calibrated at 7 bar maximum and comply with NF.

NB:

Generally, with regard to combating the proliferation of Legionnaire’s Disease, it is

necessary to comply with the recommendations of the Conseil Supérieur d’Hygiène

Publique de France, and more particularly the conformity of materials and equipment

implemented in respect of the compatibilities defined on pages 59 & 61 of the risk

management guide linked to Legionella of November 2001

The quality of the water distribution pipes is very important.

Beware of connections between different metals; we advise you to comply with the

instructions of DTU 60-1.

Provide a dielectric insulating connection near to the appliance on each pipe connecting to

the water network.

Verify that the pressure of the distribution network does not exceed 5 bars.

Otherwise, install a pressure reducer upstream of the appliance and its safety

systems.

EN 12 Document ref.: 428016 03

Page 13

To enable the expansion of the water in the water heater, the safety valve must be

fitted with a pipe which will allow this expansion to overflow into a funnel connected

to the drain. Under no circumstances must you reduce its diameter or close this pipe

with a plug or a stop valve. Plugging will invalidate the warranty of the appliance.

Fitting of a filter on the cold water inlet is strongly recommended in order to

eliminate foreign matter such as sand, gravel, sludge, etc.

It is imperative to install a T-square on the low pipe of the appliance enabling a direct

transition valve to be fitted in order to carr out shunts ad eliiate sludge

stagnating at the bottom of the tank.

Provide a degasser with air drain on the hot water outlet (evacuation of dissolved

gas).

Equip the water heater with a domestic circulating system for proper

homogenisation of the water volume

For the purposes of combating Legionella, it is imperative that any thermostatic

mixer is installed as close as possible to the supply points, in order to minimise the

water circuit to 40°, temperature for maximum proliferation of Legionella

There must be no cutout or regulation system between the tank and the safety valve

4. HYDRAULIC TESTS

Upon first filling with water, it is down to the installer to verify the seal of the upper flange

and the manhole, and to tighten the bolts if necessary.

After hydraulic connection of all pipes, and before carrying out the electrical cabling,

completely fill the appliance and pressurise it.

Check and rectify the watertightness of each connection.

After each intervention on the hydraulic installation, it is imperative to carry out a

hydraulic seal test

EN 13 Document ref.: 428016 03

Page 14

5. ELECTRICAL CONNECTION

Before connecting the appliance, check that the power is off, that the appliance is full of

water and that it is watertight.

Recommendations for installation:

The electrical installation must comply with national regulations in force in the

country of installation. For France, see standards NF C 732OO and NFC 15100.

Install a general circuit breaker and calibrated protection upstream on the electrical

supply.

Use correctly sized ires refer to the aufacturers’ alues ad esure all

connections are fully tightened.

The components mentioned on the electrical diagrams are provided with the

electrical kits.

Each component and the tank must be connected to earth (via the sleeves situated

on the flange of the tank).

The resistances must be supplied using an electromagnetic switch (not provided).

Connect its electrical circuit and the loop pump using terminals C1 and C3 of the

terminal block.

Never block it manually.

Do not install manual override switches.

It must be sufficiently sized.

EN 14 Document ref.: 428016 03

Page 15

6. INSTALLATION OF HEATING COMPONENTS

Recommended order of assembly

0 - Assembly of the flange

with tightening to 3dN

1 - Installation of M10Pins

2 - Installation of the seal

3 - Installation of the

resistance (NB loop

downwards for 15 & 30

Kw model)

4 - 1 backflange (model 15 &

30 Kw)

5 - 6 M10 bolts

4 3 2

Duct for

thermostat

centre

Duct for

thermostat

sensor

1

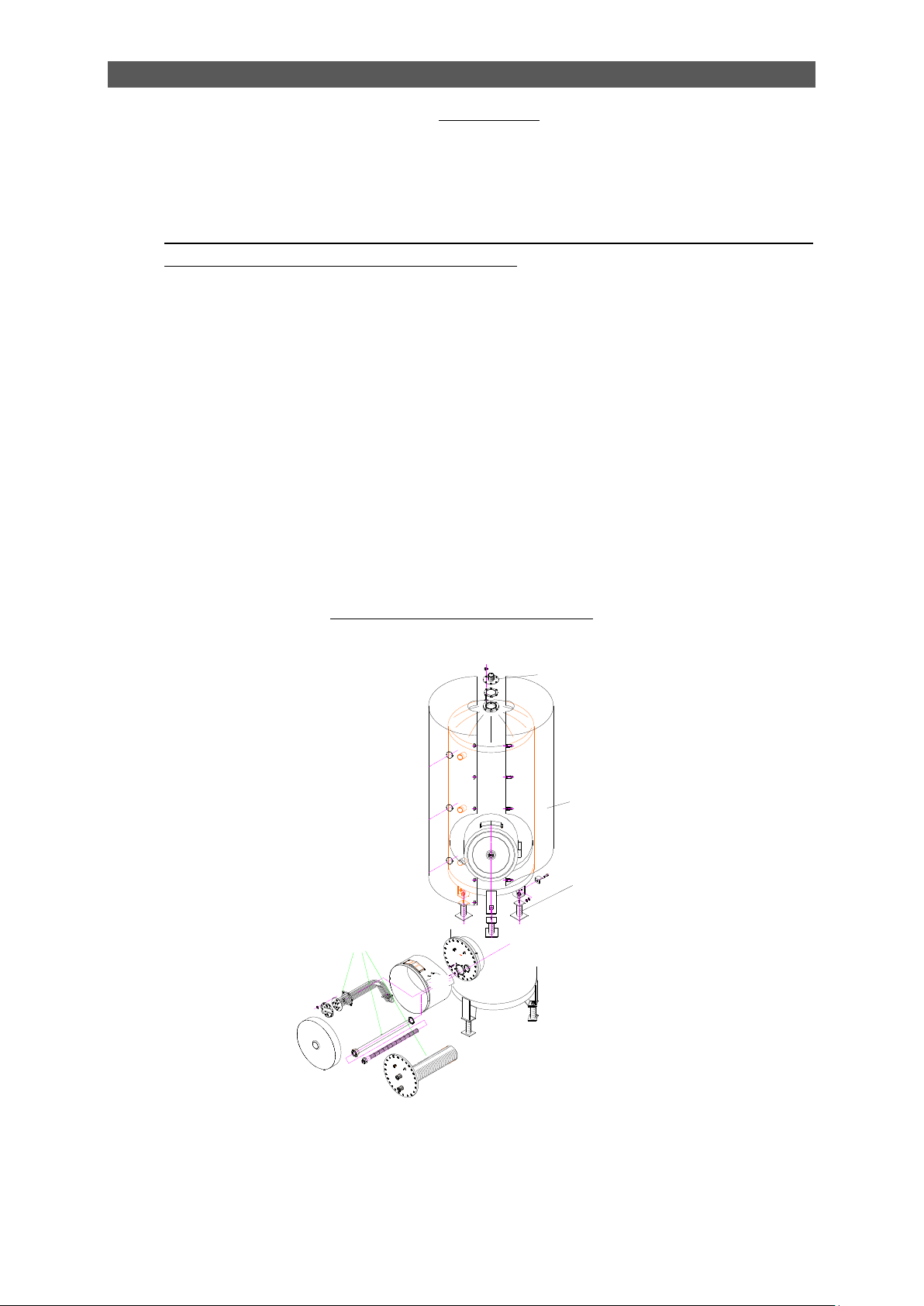

Recommended order of assembly

0 - Assembly of the flange

with tightening to 3dN

1 - Installation of Pins M10

2 - Installation of seal

3 - Installation of resistance

(NB loop downwards for

15 & 30 Kw model)

4 - 1 backflange (Model 15

& 30 Kw)

5 - 6 M10 bolts

0

0

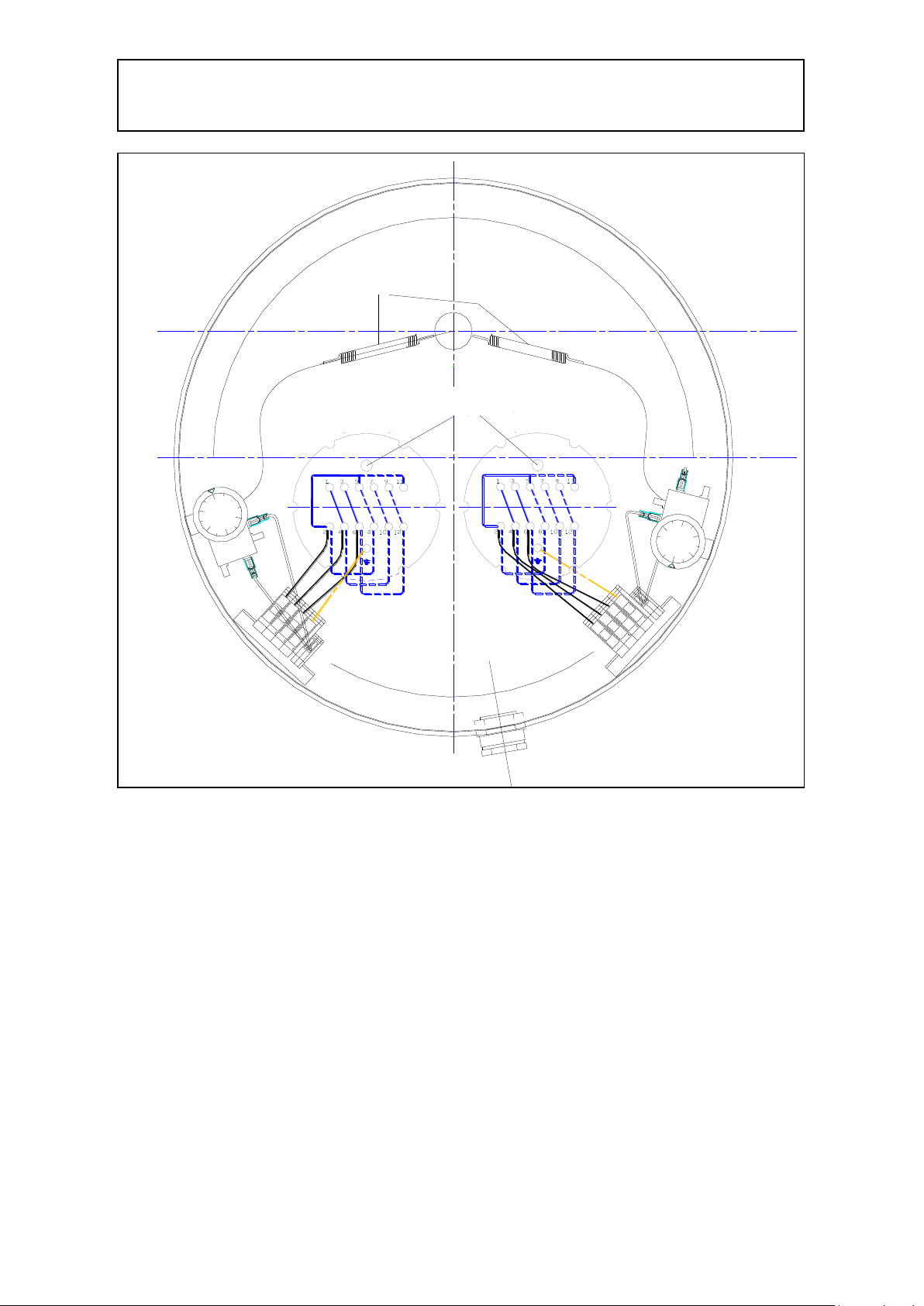

A) Single resistance platinum shielded (9Kw - 15Kw - 30Kw)

ASSEMBLY DIAGRAM

___________________________________________________________________________

B) Multi-resistance platinum shielded (45Kw - 60Kw)

5 4 3 2 5 4 3 2

EN 15 Document ref.: 428016 03

ASSEMBLY DIAGRAM

Page 16

Duct for

thermostat

sensor

3

Recommended order of assembly

0 Assembly of the flange with

tightening to 3dN

1 Installation of seals, abutting

the head of the sheaths

2 The sheaths must be

assembled by hand, using a

tube giving counterweight to

facilitate the engagement of

the thread of the sheath into

the sleeve

3 Tightening of the sheaths

using a key.

4 Installation of steatite

resistances.

Duct for

thermostat

sensor

0

3

Recommended order of assembly

0 Assembly of the flange with

tightening to 3dN

1 Installation of joints, abutting

the head of the resistances

2 The resistances must be

assembled by hand, to

facilitate engagement of the

threads in the sleeve

3 Tightening of the resistances

using a key.

2

2

C – Multi-resistance steatite

ASSEMBLY DIAGRAM

___________________________________________________________________________

D - Multi resistance screwed shielded

ASSEMBLY DIAGRAM

EN 16 Document ref.: 428016 03

Page 17

E - Coil with flange 1m² or 3m²

Capacity in

litres

Power in

kW

Heating

time Delta

T 60K

Weight with jacket

Electrical diagram

Fig N°

In h,mn

M1

M0

Star

Triangle

In Kg

In Kg

300

9

2h20mm

109

117 1 2

500

9

3h55mm

135

143 1 2

750

9

5h40mn

235

243 1 2

15

3h30mn

235

243 3

30

1h44mn

235

243 4

45

1h19mm

238

246 5

60

0h50mm

238

246 5

1000

9

7h27mm

265

273 1 2

15

4h39mn

265

273 3

30

2h20mn

265

273 4

1000

45

1h43mm

268

276 5

60

1h09mm

268

276 5

1500

9

11h12mm

245

254 1 2

Duct for

thermostat

sensor

0

2

Recommended order of assembly

0 Installation of joint on the

flange.

1 Assembly of the flange fitted

with its coil on the tank and

tighten the bolts at 3dN.

2 Installation of cap.

ASSEMBLY DIAGRAM

7. ELECTRICAL SPECIFICATIONS AND CABLING DIAGRAMS

A – Shielded platinum resistance (9 Kw - 15 Kw - 30 Kw)

Enamelled tank of 300 to 3000 litres with lateral flange DN110.

Enamelled tank of 750 to 3000 litres with lateral flange DN400.

Flange equipped with immersion resistance, straight (9 kW), bent (15 to

30 kW), directed towards the bottom of the tank, thus avoiding cold zones

and the proliferation of bacteria.

Resistance supply voltage 230 TRI, 400 V TRI without neutral.

Dual thermostat, regulation from 30 to 80°C and overheating safety device

at 95°C with manual reset.

Soft jacket cover, M1 fire classification, or steel cover, M0 fire

classification.

These appliances are delivered on a wooden pallet; the tank, insulation (if

M0 jacket, separate parcel) and the electrical kit are fixed to this.

EN 17 Document ref.: 428016 03

Page 18

15

6h59mn

345

354 3

30

3h29mn

345

354 4

45

2h41mm

348

357 5

60

1h45mm

348

357 5

2000

9

14h56mm

374

383 1 2

15

9h20mm

374

383 3

30

4h39mn

374

383 4

45

3h27mm

377

386 5

60

2h21mm

377

386 5

2500

9

18h42mm

503

513 1 2

15

11h40mm

503

513 3

30

5h49mn

503

513 4

45

4h25mm

506

516 5

60

2h57mm

506

516 5

3000

9

22h25mm

541

552 1 2

15

14h00mm

541

552 3

30

7h00mn

541

552 4

45

5h15mm

544

555 5

60

3h28mm

544

555 5

Supplied with the kit

Supplied by installer

ELECTRIC DIAGRAM

EN 18 Document ref.: 428016 03

Page 19

CABLING DIAGRAMS

Fig N° 1

Star Cabling 9 kW (3x400 V)

ID

TYPE

SECTION

COLOUR

QTY

1

Control

1.5mm²

Red 2 2

Power

10 mm²

Black 3 3

Earth

10 mm²

Green/Yellow

2 4 Power connection

6 mm²

Black

4 Bloc cond.protec. cap

16 mm²

Green/Yellow

1 L Unit block 1 jonc

16 mm²

Grey 3 C

Unit block 1 jonc

5-6 mm²

Grey

3

Fig N° 2

Triangle Cabling 9 kW (3x230 V)

ID

TYPE

SECTION

COLOUR

QTY

1

Control

1.5mm²

Red 2 2

Power

10 mm²

Black 3 3

Earth

10 mm²

Green/Yellow

2 4 Power connection

6 mm²

Black

5 Bloc cond.protec. cap

16 mm²

Green/Yellow

1 L Unit block 1 jonc

16 mm²

Grey 3 C

Unit block 1 jonc

5-6 mm²

Grey

3

Fig N° 3

Triangle Cabling 15 kW (3x400 V)

mise à la terre

mise à la terre

de la cuve

de la bride

4

2

3

A

B

1

2

C1 C2

L1 L2 L3

5

1

ID

TYPE

SECTION

COLOUR

QTY

1

Control

1.5 mm²

Red 2 2

Power

10 mm²

Black 3 3

Earth

10 mm²

Green/Yellow

2 4 Power connection

6 mm²

Black

1

5

Power bar

6 mm²

Brass

2

Bloc cond.protec. cap

16 mm²

Green/Yellow

1 L Unit block 1 jonc

16 mm²

Grey

3

C

Unit block 1 jonc

5-6 mm²

Grey

3

Fig N° 4

Triangle Cabling 30 kW (3x400 V)

ID

TYPE

SECTION

COLOUR

QTY

1

Control

1.5 mm²

Red 2 2

Power

10 mm²

Black 3 3

Earth

10 mm²

Green/Yellow

2 4 Power connection

6 mm²

Black

4

5

Power bar

6 mm²

Brass

5

Bloc cond.protec. cap

16 mm²

Green/Yellow

1

L

Unit block 1 jonc

16 mm²

Grey

3

C

Unit block 1 jonc

5-6 mm²

Grey

3

mise à la terre

mise à la terre

de la cuve

de la bride

4

54

2

3

1

A

B

1

2

C1 C2

L1 L2 L3

EN 19 Document ref.: 428016 03

Page 20

Bulbe de sécurité

Bulbe de régulation

Fig N° 5

Triangle Cabling 45 kW / 60 kW (3x400 V)

Safety bulb

Regulation bulb

EN 20 Document ref.: 428016 03

Page 21

B - Multi steatite resistances

Capacity

in litres

Power in kW

Heating time

Delta T 60K

Weight with jacket

Electrical diagrams

Fig N°

In h,mn

M1

M0

Star

Triangle

In Kg

In Kg

750

(3x3)

9

5h40mn

240

248 6 7

(4x3)

12

4h25mm

250

258 8 9

(5x3)

15

3h30mn

260

268

10

11

1000

(3x3) 9 7h27mm

270

278 6 7

(4X3)

12

5h49mn

280

288 8 9

(5x3)

15

4h39mn

290

298

10

11

1500

(3x3) 9 11h12mm

350

359 6 7

(4x3)

12

8h51mm

360

369 8 9

(5x3)

15

7h00mm

370

379

10

11

(5x6)

30

3h29mn

370

379

10

11

2000

(3x3) 9 14h56mm

377

686 6 7

(4x3)

12

11h50mm

387

396 8 9

(5x3)

15

9h20mm

397

406

10

11

(5x6)

30

4h39mn

397

406

10

11

2500

(3x3) 9 18h42mm

506

516 6 7

(4x3)

12

14h45mm

516

526 8 9

(5x3)

15

11h40mm

526

536

10

11

(5x6)

30

5h49mn

526

536

10

11

3000

(3x3) 9 22h25mm

544

555 6 7

(4x3)

12

17h42mm

554

565 8 9

(5x3)

15

14h00mm

564

575

10

11

(5x6)

30

7h00mn

564

575

10

11

Enamelled tank of 750 to 3000 litres

Flange equipped with immersion steatite resistances (from 2 to 5 steatites

depending on heating power) directed towards the bottom of the tank,

thus avoiding cold zones and the proliferation of bacteria.

Low charge (5 to 6.5W/cm²) so appliance is at low risk of scaling

Resistance power voltage 230 TRI, 400 V TRI without neutral

Dual thermostat, regulation from 30 to 80°C and overheat safety device at

95°C with manual reset

Soft jacket cover, M1 fire classification, or steel cover, M0 fire

classification.

These appliances are delivered on a wooden pallet; the tank, insulation (if

M0 jacket, separate parcel) and the electrical kit are fixed to this.

EN 21 Document ref.: 428016 03

Page 22

Fig N° 6

Star Cabling 9 – 18 kW (3x400 V)

ID

TYPE

SECTION

COLOUR

QTY

1

Control

1.5 mm²

Red 2 2

Power

10 mm²

Black 3 3

Earth

10 mm²

Green/yellow

2 4 Power connection

6 mm²

Black 6 5

Earth connection

6 mm²

Green/yellow

2 Bloc cond.protec. cap

16 mm²

Green/yellow

1 L Unit block 1 jonc

16 mm²

Grey 3 C

Unit block 1 jonc

5-6 mm²

Grey

3

Fig N° 7

Triangle Cabling 9 – 18 kW (3x230 V)

ID

TYPE

SECTION

COLOUR

QTY

1

Control

1.5 mm²

Red 2 2

Power

10 mm²

Black 3 3

Earth

10 mm²

Green/yellow

2 4 Power connection

6 mm²

Black 6 5

Earth connection

6 mm²

Green/yellow

2 Bloc cond.protec. cap

16 mm²

Green/yellow

1 L Unit block 1 jonc

16 mm²

Grey 3 C

Unit block 1 jonc

5-6 mm²

Grey

3

Fig N° 8

Star Cabling 12 kW (3x400 V)

ID

TYPE

SECTION

COLOUR

QTY

1

Control

1.5 mm²

Red 2 2

Power

10 mm²

Black 3 3

Earth

10 mm²

Green/yellow

2 4 Power connection

6 mm²

Black

9

5

Earth connection

6 mm²

Green/yellow

3

Bloc cond.protec. cap

16 mm²

Green/yellow

1

L

Unit block 1 jonc

16 mm²

Grey

3

C

Unit block 1 jonc

5-6 mm²

Grey

3

Fig N° 9

Triangle Cabling 12 kW (3x400 V)

ID

TYPE

SECTION

COLOUR

QTY

1

Control

1.5 mm²

Red 2 2

Power

10 mm²

Black 3 3

Earth

10 mm²

Green/yellow

2 4 Power connection

6 mm²

Black

9

5

Earth connection

6 mm²

Green/yellow

3

Bloc cond.protec. cap

16 mm²

Green/yellow

1

L

Unit block 1 jonc

16 mm²

Grey

3

C

Unit block 1 jonc

5-6 mm²

Grey

3

CABLING DIAGRAMS

EN 22 Document ref.: 428016 03

Page 23

Fig N° 11

Triangle Cabling 15 – 30 kW (3x230 V)

ID

TYPE

SECTION

COLOUR

QTY

1

Control

1.5 mm²

Red 2 2

Power

10 mm²

Black 3 3

Earth

10 mm²

Green/yellow

2 4 Power connection

6 mm²

Black 6 5

Earth connection

6 mm²

Green/yellow

2 Bloc cond.protec. cap

16 mm²

Green/yellow

1 L Unit block 1 jonc

16 mm²

Grey 3 C

Unit block 1 jonc

5-6 mm²

Grey

2

Fig N° 10

Star Cabling 15 – 30 kW (3x400 V)

ID

TYPE

SECTION

COLOUR

QTY

1

Control

1.5 mm²

Red 2 2

Power

10 mm²

Black 3 3

Earth

10 mm²

Green/yellow

2 4 Power connection

6 mm²

Black

12 5 Earth connection

6 mm²

Green/yellow

4 Bloc cond.protec. cap

16 mm²

Green/yellow

1 L Unit block 1 jonc

16 mm²

Grey 3 C

Unit block 1 jonc

5-6 mm²

Grey

3

EN 23 Document ref.: 428016 03

Page 24

8. PUFFER RANGE

LITRES

Ø A

(mm)

ELEVATION (mm)

WEIGHT WITH

INSULATION

(kg)

B C D E F G H

300

630

1409

1145

920

688

472

150

204

85

500

630

2005

1752

1322

893

472

150

204

112

750

790

1906

1601

1246

861

501

150

196

157

1000

790

2259

1956

1471

936

501

150

196

192

1500

1100

2085

1700

1334

967

600

200

221

314

2000

1100

2274

1888

1458

1029

600

200

221

330

2500

1400

2148

1679

1349

1010

670

200

215

516

3000

1400

2275

1808

1432

1056

670

200

215

536

HOT WATER OUTLET /

DRAIN

COLD WATER INLET /

FULL DRAIN

TEMP. SENSORS

HOT WATER INLET &

OUTLET / DRAIN

HOT WATER INLET &

OUTLET / DRAIN

This is a carbon steel tank designed for the storage of water for primary network (Operating

pressure max : 5bar).

EN 24 Document ref.: 428016 03

Page 25

9. DOMESTIC HOT WATER STORAGE RANGE

LITRES

Ø A

(mm)

ELEVATION (mm)

WEIGHT

WITH

INSULATION

(kg)

B C D E F G H I J K L M N

300

630

1386

1155

807

807

472

150

204

525 - 110

-

330

36

85

500

630

1983

1752

1494

1108

472

150

204

525 - 110

-

330

36

124

750

790

1891

1601

1246

1051

501

150

196

551

704

110 or 400

465

425

34

195/231

1000

790

2244

1956

1471

1246

501

150

196

551

704

110 or 400

465

425

34

247/283

1500

1100

2073

1700

1380

1140

600

200

221

650

803

110 or 400

620

580

32

365/406

2000

1100

2261

1888

1500

1244

600

200

221

650

803

110 or 400

620

580

32

394/430

2500

1400

2136

1680

1350

1180

680

200

216

730

883

110 or 400

730

730

31

517/559

3000

1400

2263

1808

1430

1250

680

200

216

730

883

110 or 400

730

730

31

544/586

ØK

DCW INLET / FULL DRAIN

DHW OUTLET

TEMP. SENSORS

2 or 3 anodes according to models

ØK

This is an enamelled tank designed for the storage of Domestic Hot Water (Operating

pressure max : 7bar).

Important : For the tank of 2500 and 3000L there are 3 side connections extenders in

stainless steel. These pieces are into the box of feet enhancers.

EN 25 Document ref.: 428016 03

Page 26

10. SINGLE COIL RANGE

(L)

Ø A

(mm)

ELEVATION (mm)

EXCHANGE

SURFACE

(m²)

WEIGHT

WITH

INSULATION

(kg)

B C D E F G H I J K L M N O P

300

630

1386

1055

807

807

472

150

204

525 - 110

982

472 - 330

36

1,6

127

500

630

1983

1752

1332

1108

463

150

204

525 - 110

1615

472 - 330

36 3 177

750

790

1891

1601

1246

1051

501

150

196

551

704

110 or

400

1623

502

465

425

34 4 256/295

1000

790

2244

1956

1471

1246

501

150

196

551

704

110 or

400

1929

502

465

425

34

5.2

326/362

1500

1100

2073

1700

1380

1150

600

200

221

650

803

110 or

400

1722

605

620

580

32

5,6

458/500

2000

1100

2261

1885

1500

1244

600

200

221

650

803

110 or

400

1722

605

620

580

32

5,6

489/531

2500

1400

2136

1680

1350

1180

680

200

216

730

883

110 or

400

1587

680

730

730

31 7 636/678

3000

1400

2269

1808

1432

1245

680

200

216

730

883

110 or

400

1587

680

730

730

31 7 658/700

DHW OUTLET

DCW INLET / DRAIN

TEMP. SENSORS

3 FEET ENHANCER

ØK

COIL OUTLET

COIL INTLET

2 or 3 anodes

according to

models

This is an enamelled tank with single exchanger designed for the production of Domestic

Hot Water from a heating application such as boiler or solar panels (Operating pressure max

: 7bar).

Important : For the tank of 2500 and 3000L there are 3 side connections extenders in

stainless steel. These pieces are into the box of feet enhancers.

This range is fitted with both vertical anodes on the upper flange and horizontal anodes.

EN 26 Document ref.: 428016 03

Page 27

MISECE DE

(L)

Ø A

(mm)

ELEVATION (mm)

EXCHANGE

SURFACE

(m²)

WEIGHT WITH

INSULATION

(kg)

B C D E F G H I J K L

500

630

1983

1752

1108

472

150

204

36

1390

472 - 330

5,5

253

750

790

1891

1601

1051

501

150

196

34

1611

501

465

425 7 334/370

1000

790

2244

1956

1246

501

150

196

34

1713

501

465

425 8 366/402

1500

1100

2073

1700

1150

600

200

221

32

1569

600

620

580 9 470/512

2000

1100

2261

1888

1244

600

200

221

32

1671

600

620

580

10

510/554

DCW INLET / DRAIN

3 FEET ENHANCER

DHW OUTLET

COIL OUTLET

1 or 2 vertical anodes

according to models

ANODES

COIL INLET

11. HEAT PUMP COIL RANGE

This is an enamelled tank with single exchanger designed for the production of Domestic

Hot Water from a heating application such as boiler, Heat Pump or solar panels (Operating

pressure max : 7bar).

This range is fitted with both vertical anodes on the upper flange and horizontal anodes.

EN 27 Document ref.: 428016 03

Page 28

12. DOUBLE COIL RANGE

(L)

Ø A

(mm)

ELEVATION (mm)

EXCHANGE SURFACE (m²)

Weight

(kg)

B C D E F G H I J K L M N O P Q R

Upp.

Coil.

Low.

Coil.TP

Ø 110

Low.

Coil TH

Ø 400

300

630

1386

1155

806

807

472

150

204

525 - 110

1033

880

778

472 - 330

36

0.6

1.2 - 139

500

630

1983

1752

1494

1108

472

150

204

525 - 110

1390

1033

931

472 - 330

36

1.4

1.6 - 176

750

790

1891

1601

1246

1051

501

150

196

551

704

110 or

400

1623

1266

1164

501

465

425

34

1,7 2 2

295

1000

790

2244

1956

1471

1246

501

150

196

551

704

110 or

400

1674

1317

1215

501

465

425

34

1,7

3,2

2,4

317/345

1500

1100

2073

1700

1380

1150

600

200

221

650

803

110 or

400

1695

1722

1467

600

620

580

32

1,8

3,6

3,6

460/502

2000

1100

2261

1888

1500

1244

600

200

221

650

803

110 or

400

1824

1467

1365

600

620

580

32

2,5 5 3,6

491/533

2500

1400

2136

1680

1350

1180

680

200

216

730

883

110 or

400

1689

1434

1332

680

730

730

31

2,4

5,7

4,8

638/680

3000

1400

2263

1808

1430

1250

680

200

216

730

883

110 or

400

1689

1434

1332

680

730

730

31

2,4

5,7

4.8

660/702

DCW INLET / DRAIN

3 FEET ENHANCER

SORTIE E.C.S.

R

UPPER COIL

OUTLET

LOWER COIL

INTLET

UPPER COIL

OUTLET

UPPER COIL

INTLET

ØK

2 OR 3 ANODES

ACCORDING TO

MODELS

TEMP. SENSORS

This is an enamelled tank with double exchanger designed for the production of Domestic Hot Water from

twin applications such as boiler, PAC and solar panels (Operating pressure max : 7bar).

Important : For the tank of 2500 and 3000L there are 3 side connections extenders in

stainless steel. These pieces are into the box of feet enhancers.

This range is fitted with both vertical anodes on the upper flange and horizontal anodes.

EN 28 Document ref.: 428016 03

Page 29

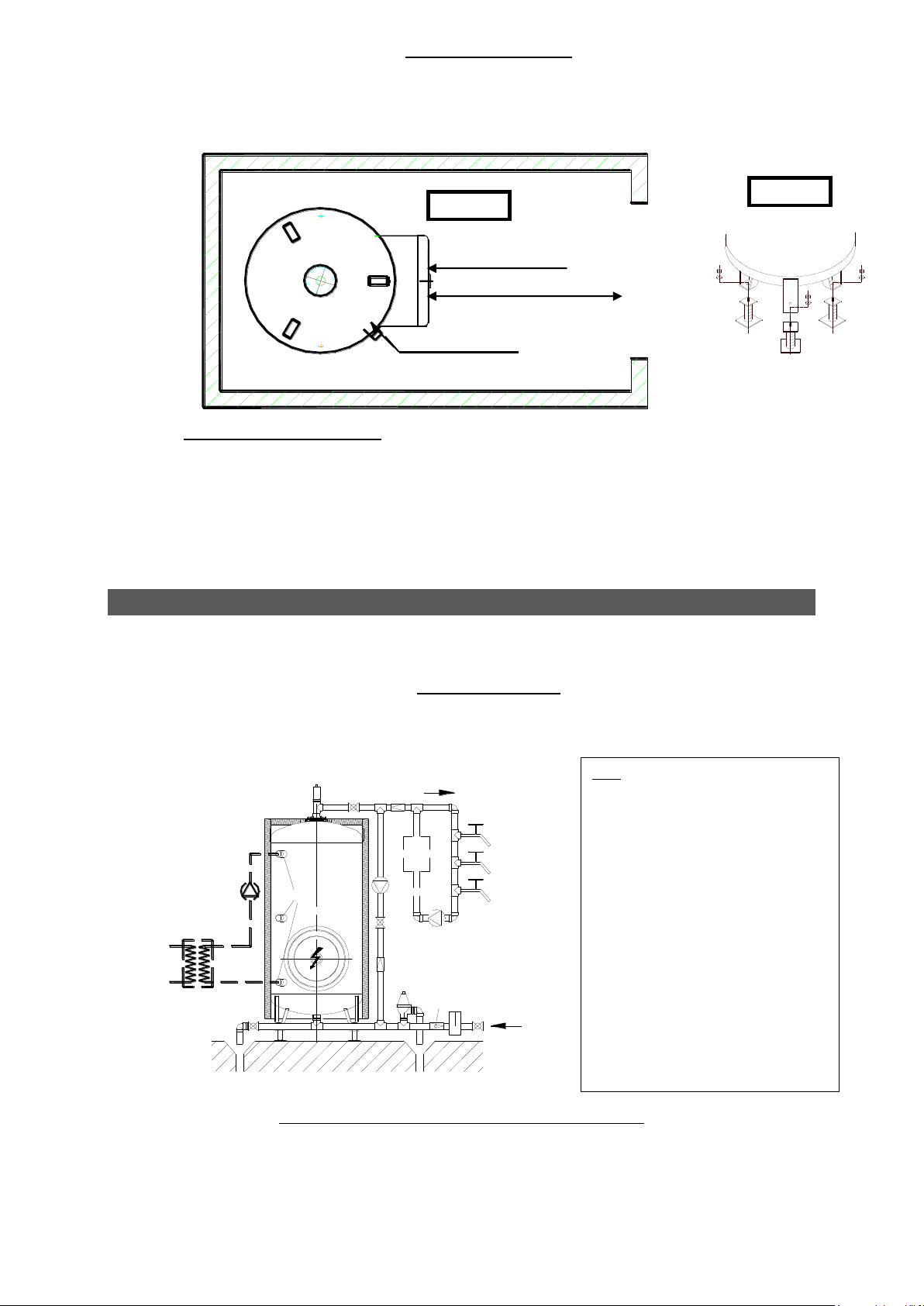

13. INSTALLATION OF HYDRAULIC ACCESSORIES

Capacity in

litres

500

750

1000

1500

2000

2500

3000

Ø of

connections

1"1/2

1"1/2

1"1/2

2"

2"

2"

2"

Discharge

Safety valve

Drain

Cold water inlet

Installation of upper flange using 6 M10 bolts and seal.

The Flange, Seal and Screws assembly is provided in a box inside the electrical kits or

fixed to the pallet.

The drain in the lower part is connected to the cold water

(If sleeves: Need to fit a coil)

(Do not connect anything to these coils before installing the insulation)

(see diagram of hydraulic installation and dimensions).

Connection coils to the left on the lateral part.

ASSEMBLY DIAGRAM OF THE HYDRAULIC KIT

(provided as Option)

IMPORTANT

Every installation MUST comprise a correctly sized hydraulic safety device against:

Overpressure in the distribution network.

Overpressure due to temperature rises (expansion during heating).

Overpressure due to failure of a thermostat or a contact switch.

The sizing of a hydraulic safety device varies according to:

the capacity of the appliance,

the power of the appliance installed.

A hot water expansion vessel and a anti hammer can also be connected to protect the entire

installation. The implementation of these devices will take into account regulatory

recommendations and those of their manufacturers

In the event of installation of battery appliances, it is imperative to install a safety valve specific to

each appliance.

Safety units for the whole range (as option) to be installed on each appliance.

These valves must be calibrated at 7 bar maximum and comply with NF.

EN 29 Document ref.: 428016 03

Page 30

14. INSTALLATION OF THE INSULATION

A – INSTALLATION OF SOFT INSULATION M1 – EUROCLASS B

B - INSTALLATION OF SOFT INSULATION M0 – EUROCLASS A2

Unpack the shells, place them near the water heater.

Install pannels A&B (or +) closed to the tank, rests on the upper bottom.

Close latches C.

EN 30 Document ref.: 428016 03

Page 31

15. COMMISSIONING

15-1 CHECK THAT THE TANK IS FULL OF WATER

To do this:

Fill the water heater (by opening the water inlet valve and a hot water

supply tap to evacuate the air from the tank).

The water heater is full when the water flows normally at this tap.

NB The appliance must never be connected to the mains when it is empty;

the electrical components (if existing) may become damaged.

VERY IMPORTANT

15-2 CHECK:

That the connections are suitable for the specifications of the current

distributed and the heating components.

That all connection terminals are securely tightened.

That the element or the thermostat is not short circuited.

The free flow of the safety valve(s) and their correct sizing.

The good watertightness of the seals, the flange and any electrical

components.

15-3 CONNECTING TO THE MAINS

Connect to the mains and monitor the first rise in temperature in order to

check the thermostat cuts in properly.

15-4 WATERTIGHTNESS

After a few days of operation, check that all seals are watertight.

16. SHUTDOWN OF THE SYSTEM

NORMAL

(less than 3 months, no risk of frost)

Shut off the power to the water heater.

Close the cold water inlet.

PROLONGED

(over 3 months)

Shut off the power to the water heater.

Drain the appliance: Close the cold water shutdown tap

Open a tap on the hot water circuit

Open the drain valve.

EN 31 Document ref.: 428016 03

Page 32

17. USER RECOMMENDATIONS

Thermostat Label

10 9 8 7 6 5 4

Temperature

75

68

60

50

45

40

35

With regard to the water temperature:

The distribution temperature of 65 °C is the ideal temperature for most

needs. However, in the event of hard water the water temperature must be

below 60 °C to limit the scaling of the heating elements.

In the event of boiling in a water heater and emission of steam jets at the

supply taps, immediately switch off the power, open a hot water tap and

notify your installer.

To define an average water temperature via the thermostat, refer to the table

below. (The temperatures on the table are only guidelines and need to be

checked by the user. They cannot be considered as formal and remain

dependent on the thermostat).

With regard to the expansion of the water volume in the tank

Normal dripping of water occurs upon each heating by the safety unit. This

normal phenomenon is inevitable following expansion of the heated water.

:

REMINDER: It is essential to connect the system or the valve to a visible

permanent discharge.

Quality of the water

I order to esure a aiu life epectac of our ater heater and benefit

from the warranty, certain rules must be respected:

:

Hard water: provide an effective anti-scale device

Soft water: Have: - a TH between 12 and 30° F,

NB: Our warranty will not apply if, in the event of incident, these

instructions have been neglected or if the water quality does not allow

correct treatment within the framework of the legislation.

- a pH between 6.8 and 7.3

- resistance between 2200 and 4500 ohm/cm.

EN 32 Document ref.: 428016 03

Page 33

18. MAINTENANCE AND CLEANING

SWITCH OFF THE ELECTRICAL SUPPLY BEFORE ANY WORK ON THE APPLIANCE

The frequency of interventions depends on the quality of the water stored and

the output. However, it is recommended to check the condition of the heating

elements and the inside of the tank twice a year. These water heaters have an

enamelled internal coating. This protection is completed with two or three

magnesium anodes accessible from the front. Check the anodes three months after

filling.

These anodes will wear according to the quality and consumption of water and

its temperature. The anodes must be checked regularly and replaced when their

diameter is below 10 mm.

The internal corrosion protection warranty shall only apply if the anodes have been

checked and changed at the appropriate times.

Nevertheless, for soft water and for regions where the water is very aggressive

or acidic, it is essential to have the water neutralised with an appropriate treatment.

Failure to observe this rule will invalidate the warranty (see Water Quality chapter).

Monthly operation

Check the correct operation of the safety valve (or safety unit) by manoeuvring

the lever that lifts the heating reset flap valve, to check that the water is

expanding normally. A slight drip may manifest during operation of the

appliance.

Carry out shunts via the quick drain valve to eliminate any sludge stagnating at the

bottom of the tank.

Half-yearly operation

Dismantle the heating elements (resistances and sheath) and clean them carefully

of any deposit.

Descaling

In regions where the water is rich in calcium, it is recommended to frequently

check the inside of the tank and remove the scale with a water jet.

If the tank is too scaled, carry out chemical descaling.

As this operation is tricky, you are strongly advised to use a specialised company.

Important note:

Before reassembling each element comprising a seal, change the seals.

EN 33 Document ref.: 428016 03

Page 34

Annual operation (mandatory)

Dissemble the flange and the heating elements (resistances and sheath)

Check the inside of the tank; descale if necessary

Change the seal

Dismantle the heating elements (resistances and sheath) and clean them

carefully of any deposit.

As this operation is tricky, you are strongly advised to use a specialised company.

Our warranty will not apply if, in the event of incident, this operation has been

neglected.

19. TROUBLESHOOTING

This appliance has been designed to give you full satisfaction. However, here are a

few examples of possible malfunctions and the related solutions.

SWITCH OFF THE POWER BEFORE ANY INTERVENTION ON THE

No hot water at all

a) The appliance has not yet worked:

First check that the safety thermostat is not activated. Press the black button

on the outside of the unit to reset it. Incident often caused by transport.

Check, using a voltmeter, that the current is reaching:

1 - the thermostat, otherwise check the circuit breaker, the fuses, the EDF

eter or a other reote cotrol prograed to “TOP.

2 - the switch, otherwise check the thermostat and its adjustment, which

may be too low.

3 - the resistances, otherwise check that the switch is not abnormally stuck

in the open position.

4 - check:

the connection of each resistance

that it corresponds to the type of current

the cabling diagram of the instructions.

5 - Lastly, replace the resistances

b) The appliance has worked before:

If the safety device is not at issue, check the power supply with a voltmeter, in the

order of points 1 to 5 above.

APPLIANCE

EN 34 Document ref.: 428016 03

Page 35

Insufficient hot water

Check successively:

the adjustment of the thermostat, and modify it if it is not in the stop position,

the correct tightening of the connections,

the power of the resistances on the three phases and the type of current used,

use an ohmmeter to check for faulty elements whose values are too far from the

averages read,

change the resistances in question.

Evaporation or water much too hot

Check

:

the condition of the thermostat and its adjustment temperature,

that the switch is not blocked and that its cutout power is adapted to the power

consumed,

that no remote control is shunting the thermostat.

descaling of the thermowell of the thermostat

Losses of earth perceived on the taps and pipes

:

Check

that the appliance and its components are properly connected to earth and that

this is effective,

the tightening of the connections,

the condition of the components (resistances, thermostat) to detect any

accidental earthing.

Water leaks

A dripping flow in the discharge of the safety valve is normal; it is caused by the

expansion of the water in the heating periods.

On an ongoing basis

Check the pressure of the cold water; if this is greater than 4 bars, install a

pressure reducer upstream of the safety valve.

Check the hot water and cold water connections and the flange seals. Tighten

them or change them.

Lastly, implicate the tank and contact the supplier.

,

20. WARRANTY

Tank guarantee: 5 years (Please refer to our General Conditions of Sale).

Parts guarantee: 2 years (Please refer to our General Conditions of Sale).

In case of trouble or damage, please note the Serial Number of the boiler in all your

enquiries. You can find it at the lowest part of the tank (see the picture below).

Then contact your authorized dealer.

EN 35 Document ref.: 428016 03

Page 36

ACV International

Oude Vijverweg 6

1653 DWORP

BELGIUM

EN 36 Document ref.: 428016 03

Loading...

Loading...