Page 1

Installation, Operating and

Servicing Instructions

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y2800.E

EN • 1

Page 2

INDEX

WARNINGS 3

Who should read these instructions

Symbols 3

Recommendations 3

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Applicable standards 3

Warnings 3

INTRODUCTION 4

Totally condensing 4

Operating mode 4

Description of the specifications 6

Production of hot water 6

Frost protection 6

USERS GUIDE 7

Direction for use 7

Settings parameters 7

TECHNICAL CHARACTERISTICS 9

Gas categories 9

Maximum operating conditions 10

Domestic hot water features 10

3

ELECTRICAL CONNECTION 11

Wiring diagram 11

INSTALLATION INSTRUCTIONS 12

Dimensions 12

Hydraulic connections 12

Boiler room 12

INSTALLATION 13

Connection to the chimney 13

Connection to the gas 15

Domestic hot water connection 15

Heating connections 16

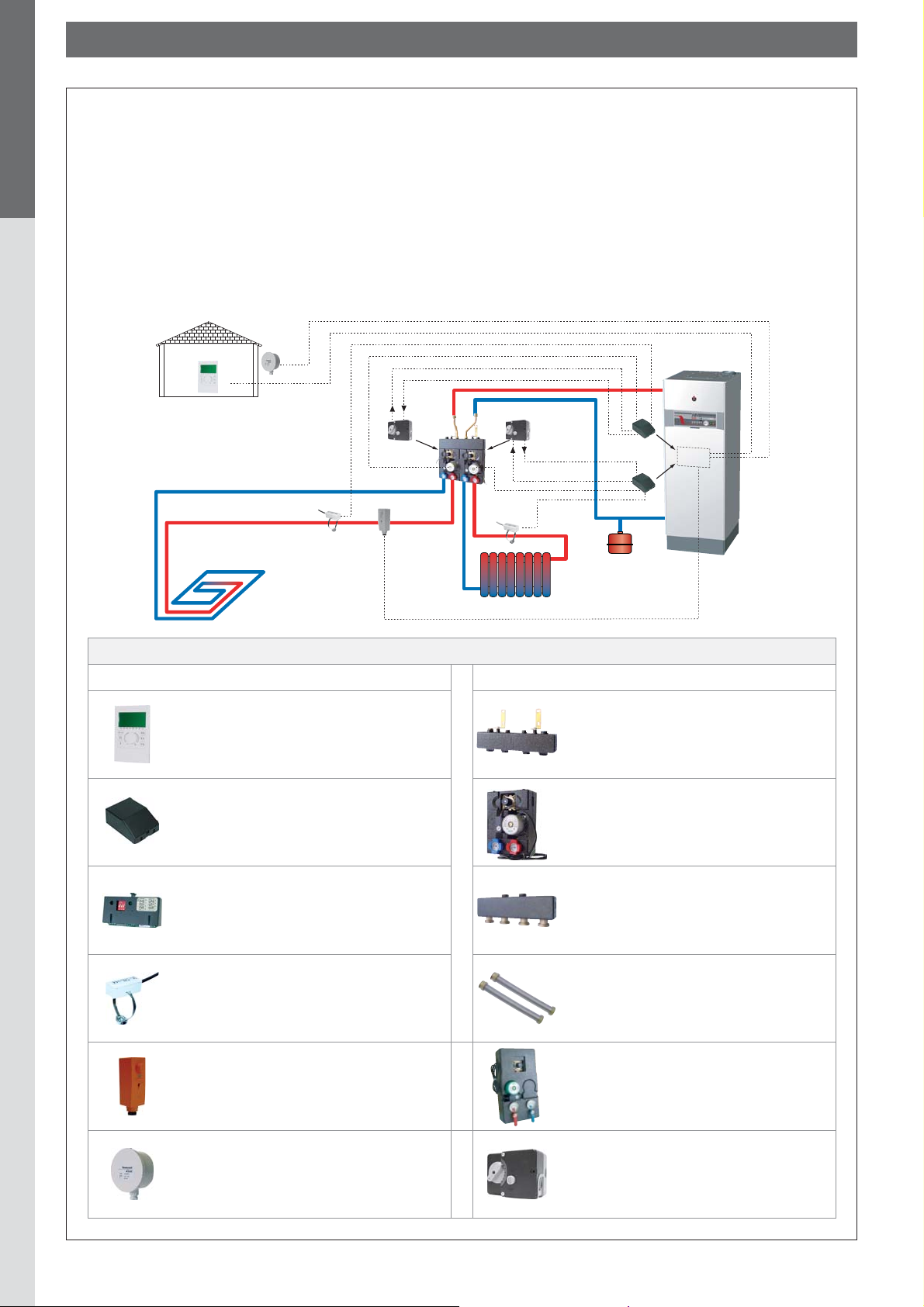

Installation of a single high temperature circuit with room thermostat ACV 15 control 17

Installation of a weather depending heating circuit high or low temperature 18

Installation of two heating circuit controlled by control unit and ZMC-1 module 20

COMMISSIONING AND MAINTENANCE 22

Commissioning the system 22

Inspection and maitenance 22

Temperature sensor resistance tables 22

Disassembling the burner 23

Disassembling and checking the electrode 23

Cleaning the heat exchanger 23

MCBA PARAMETERS FOR THE SPECIALIST 24

Standby mode 24

Setting the MCBA parameters 25

Request for information on the installation 26

Entering the code 26

MCBA parameters with code restricted access 27

Communication mode 30

Error mode 30

Safety stop [error mode] 31

SPARE PARTS See at the end of this manual

664Y2800.E

EN • 2

Page 3

WARNINGS

WHO SHOULD READ THESE INSTRUCTIONS

These instructions should be read by:

- the specifying engineer

- the installer

- the user

- the service engineer

SYMBOLS

The following symbols are used in this manual:

Essential instruction for

the correct operation of

the installation.

Essential instruction for

the safety of persons

and the environment.

Danger of electrocution.

• Specific regulation applicable in Belgium:

The CO

• It is important to switch the boiler off before carrying out

• There are no user accessible parts inside the boiler casing.

2 level, the air and gas flows and the gas / air ratio

are factory set . Any field adjustments of those settings is

not allowed in Belgium.

any work.

APPLICABLE STANDARDS

The appliances carry the CE mark in accordance with the

standards in force in the various countries (European Directives

92/42/EC “Efficiency”, 90/396/EC “Gas appliances”).

They also carry the “HR-TOP” label (Gas condensation boilers).

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Risk of scalding.

RECOMMENDATIONS

• Please, carefully read this manual before installing and

commissioning the boiler.

• It is prohibited to carry out any modifications to the inside of

the appliance without the manufacturer’s prior and written

agreement.

• The product must be installed and serviced by trained

engineers, in compliance with current standards.

• Any failure to follow instructions relating to tests and

test procedures may result in personal injury or risks of

pollution.

• To guarantee safe and correct operation of the appliance, it

is important to have it serviced and maintained every year

by an approved installer or maintenance company.

• In case of anomaly, please call your service engineer.

• Despite the strict quality standards imposed by ACV during

the manufacture, inspection and transport of its appliances,

you might notice some errors. Please report immediately

any fault to your approved installer. Remember to note the

fault code displayed on the screen.

WARNINGS

IF YOU SMELL GAS:

- Immediately isolate the gas supply.

- Open windows and doors to ventilate the area.

- Do not use any electrical appliances and do not operate any

switches.

- Immediately notify your gas supplier and/or your installer.

This documentation is part of the information delivered with the

appliance and must be given to the user and stored in a safe

place!

An approved installer must carry out the assembly, commissioning,

maintenance and repair of the system, in accordance with

current standards in force.

ACV shall not accept any responsibility for damage caused by

non-compliant location of the system or by use of the parts or

connections not approved by ACV for this application.

The manufacturer reserves the right to change the

technical characteristics and specification of its

products without notice.

The manufacturer reserves the right to change the

technical characteristics and specification of its

products without notice.

• The parts may only be replaced by genuine factory parts.

You will find a list of the spare parts and their ACV reference

number at the end of this document.

• The burners are preset in our factory for use with natural

gas [equivalent to G20].

664Y2800.E

EN • 3

Page 4

INTRODUCTION

TOTALLY CONDENSING :

The HeatMaster® TC combines the

unique ACV Tank-in-Tank concept with

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

a dual primary circuit resulting in

exceptional performance from a totally

condensing combination boiler.

Tank-in-Tank technology

ACV’s advanced implementation of thermal storage technology is

tried and tested and is remarkably simple, efficient and reliable.

At the heart of the HeatMaster® TC is a stainless steel tank

through which the flue tubes pass.

This is surrounded by a mild steel shell containing the primary

water, which extends down to the combustion chamber and even

around the flue tubes. The burner fires onto the primary water

which indirectly heats the stainless steel tank containing the hot

water. As with all Tank-in-Tanks, this is corrugated over its full

height and is suspended in the HeatMaster® TC by its hot and

cold water connections.

The area of the heat transfer surface is therefore much greater

than that of standard direct fired water heaters. A much larger

heat transfer surface means that Tank-in-Tank units recover much

faster than any other kind of hot water storage device - and keeps

boiler cycling to a minimum. The high storage temperature within

the inner tank also results in exceptional hot water outputs.

Dual primary circuit technology

The HeatMaster® TC primary circuit is split into two sections a high temperature upper circuit and a low temperature lower

circuit, divided by a separation plate. The hot water storage

tank is located in the upper circuit which always operates

at a temperature of between 60°C and 90°C. This is ideal

for hot water production as it maintains the stored water at

constantly high temperatures, eliminating bacterial formation

such as Legionellae, as well as resulting in high volume hot water

production.

The down-firing flue tubes pass through the upper circuit, through

the separation plate and into the lower circuit. The primary water

here operates at a temperature typically between 30°C and

60°C for heating (dependent on the heating return temperature),

perfect for condensing when working in heating mode.

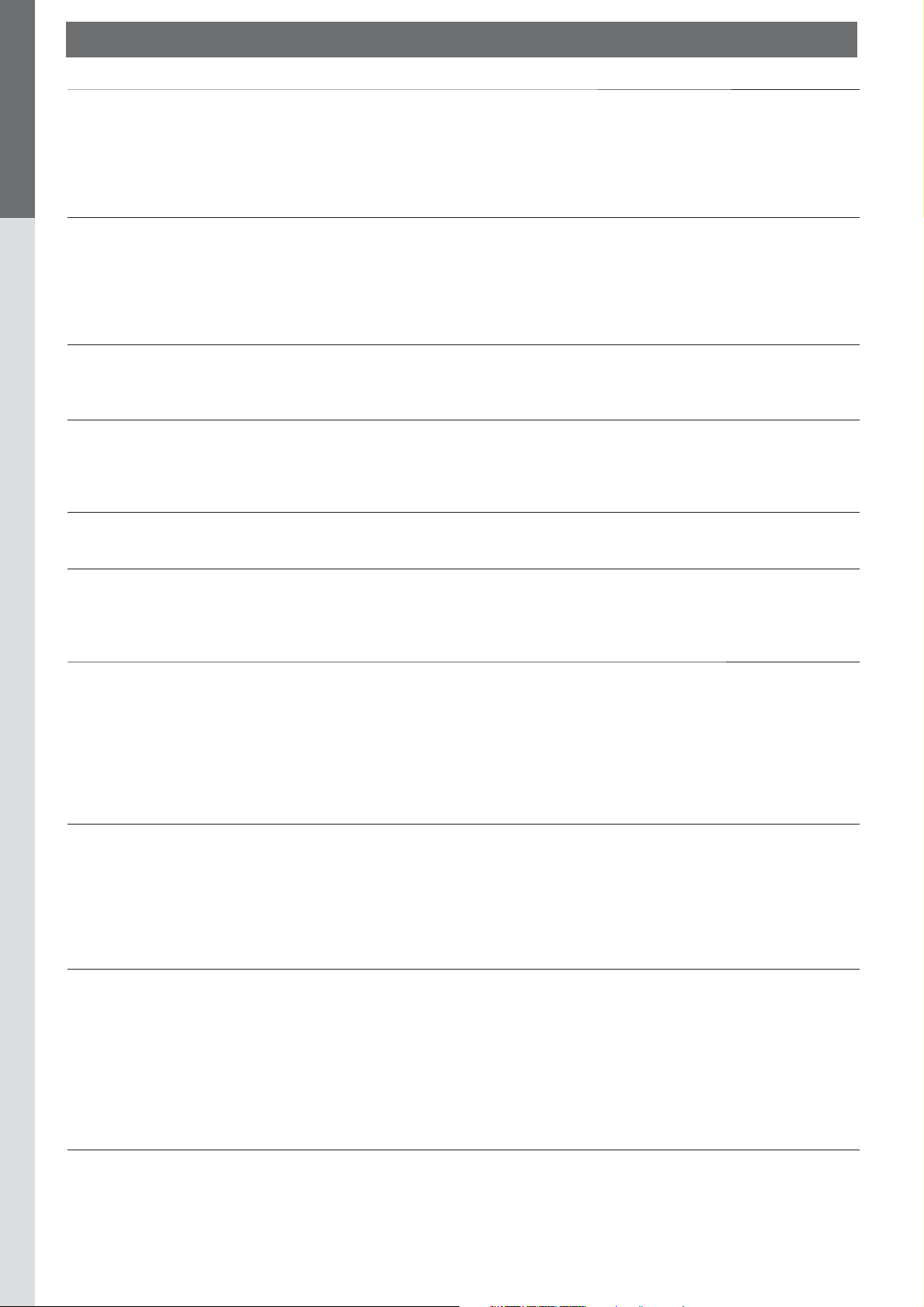

Operating modes

In both heating and hot water modes, the premix

gas burner fully modulates the power to match

the system demand.

Heating

1

The heating return

enters the lower circuit

of the boiler, which allows

the boiler to operate in

condensing mode.

The upper circuit of the

HeatMaster® TC is kept

at a consistently high

temperature due to the

internal shunt pump which

ensures that the primary

water circulates around

the heat exchanger flue

tubes.

Hot water

2

With the upper circuit

maintained at high

temperature, the

HeatMaster® TC is always

ready to supply hot water

on demand.

The cold water enters

through the indirect water

preheater at the base of

the heat exchanger and is

preheated before entering

the hot water tank.

The low temperature of the

bottom circuit results in

continuous condensation of

the flue gases in hot water

mode.

Dual domestic hot water tank technology

During hot water mode, the bottom circuit operates at a much

lower temperature, typically 5°C to 20°C depending on the cold

water inlet temperature. The incoming cold water enters the

lower primary circuit via an indirect water preheater.

As this preheater is wrapped around the lower flue tubes of the

combustion chamber, it is able to absorb the remaining heat

from the flue gases. The result is that during hot water mode the

HeatMaster® TC totally condenses whether on full or part-load.

664Y2800.E

EN • 4

Heating and

3

hot water

Once up to temperature,

the HeatMaster® TC is

capable of producing

heating and hot water

simultaneously.

Page 5

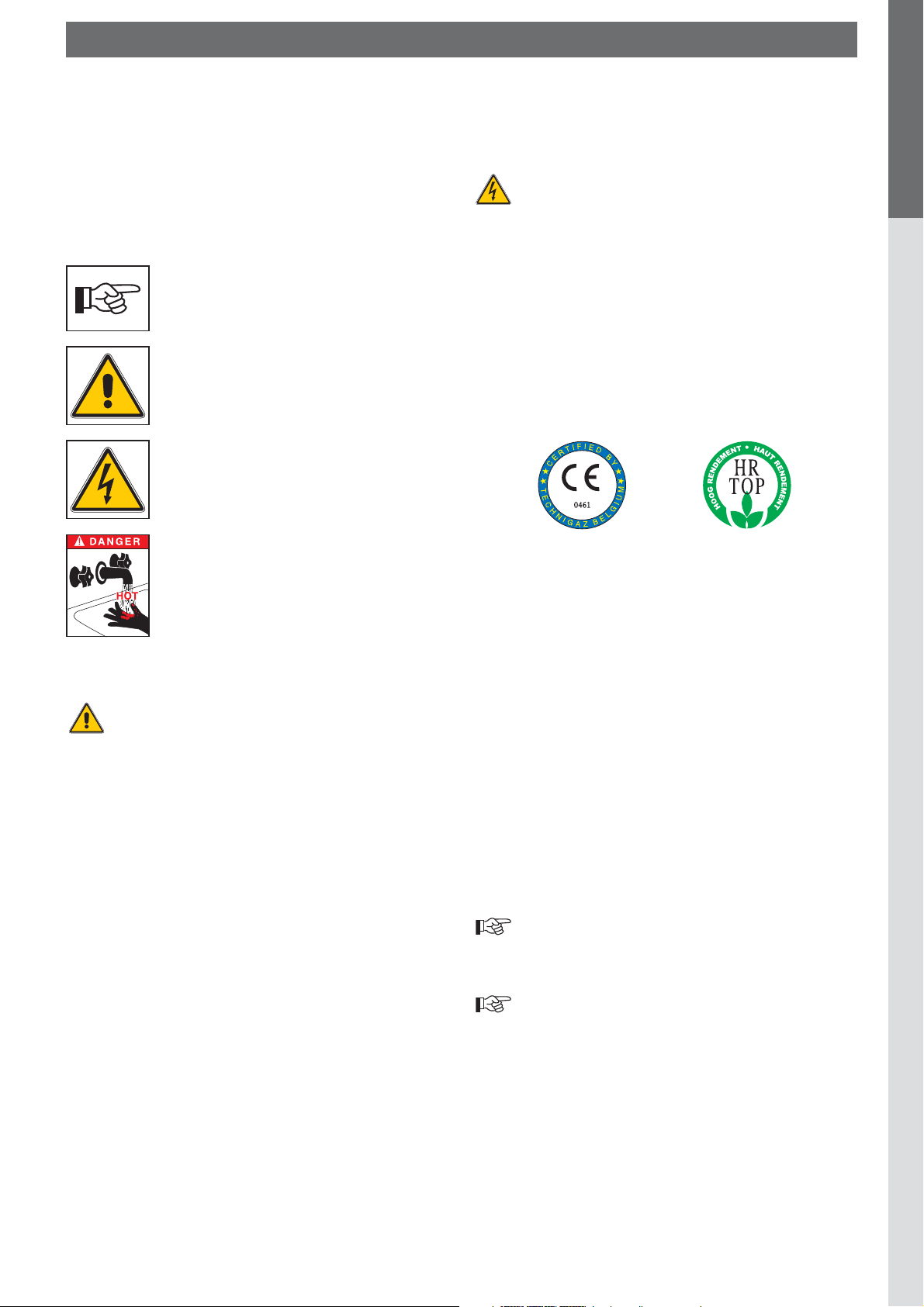

INTRODUCTION

1

10

11

2

12

3

4

5

6

7

13

14

15

16

17

8

HeatMaster® 35 TC

1. Flue connection concentric Ø 80/125 mm convertible to

parallel connection Ø 80/80 mm.

2. Domestic hot water out let

3. He at ing f lo w

4. Stainless steel heat exchanger

5. Stainless steel Tank-in-Tank hot wat er stor e

6. Indirect water preheater

7. H e a t i n g r e t u r n

8. Cold water inlet

9. Co ndenst rap

10. Modulating premix gas burner

11. Gas connec tion

12. Combustion chamber

13. Control panel

14. Primary heating cir cuit

15. Polyurethane foam insulation

16. Boiler shunt pump

17. Separation plate

18. Primary safety valve (3 bar)

19. Drain cock

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

18

9

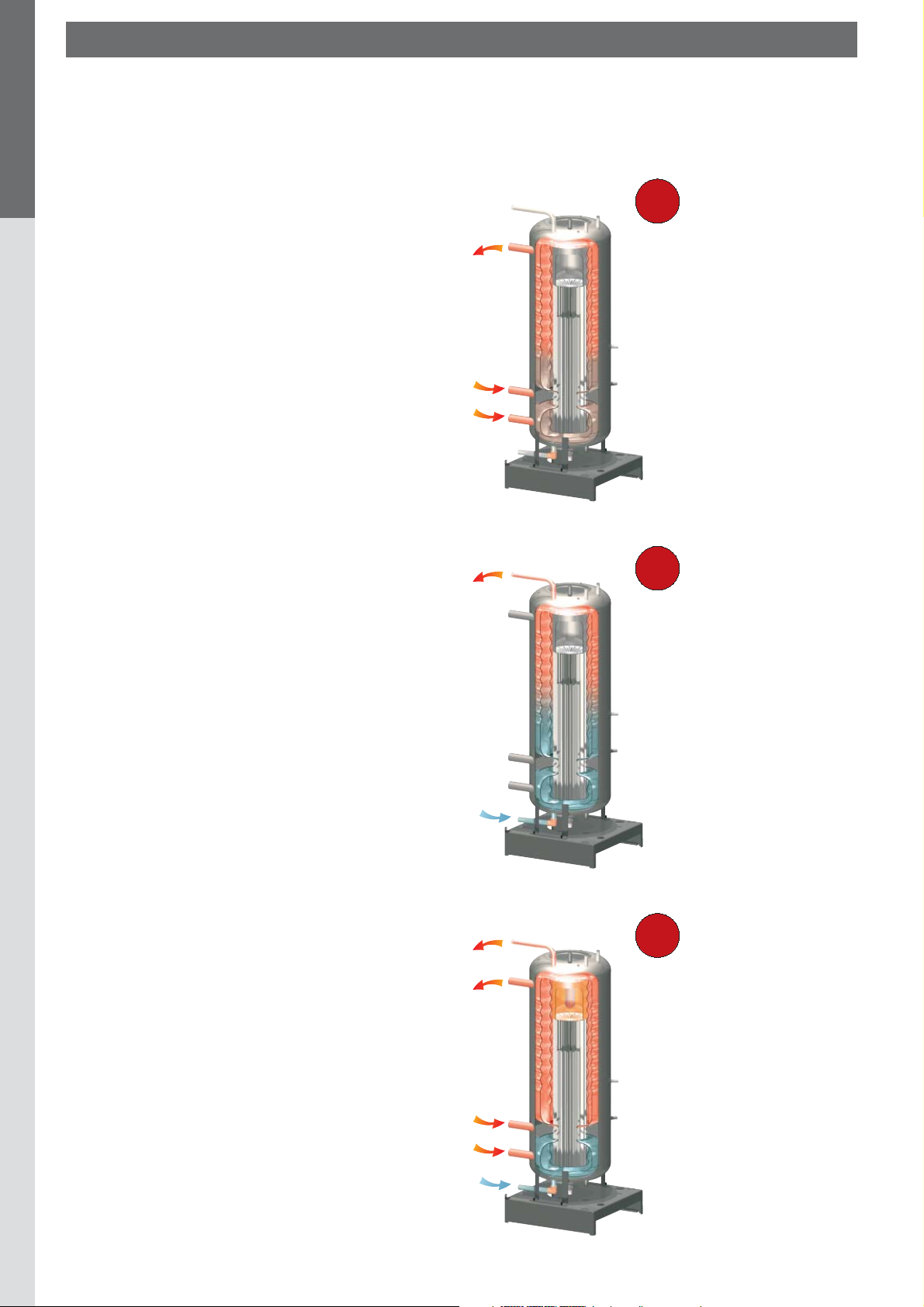

1

2

3

4

5

6

7

8

19

12

13

14

15

16

17

HeatMaster® 85 TC

1. Flue connection concentric Ø 100/150 mm conver tible to

pa r a l lel c o n nec ti o n Ø 10 0/100 m m

2. Domestic hot water outlet

3. He at ing f lo w

4. Combustion chamber

5. St ainless steel heat exchanger

6. St ainless steel Tank-in-Tank hot water s tore

7. Auxiliary tank primary return

8. Indirect water preheater

9. Heat ing re tur n

10. Cold water inle t

11. Separation plate

12. Gas connect ion

13. Modulating premix gas burner

14. Control panel

15. Primary heating circuit

16. Primary expansion vessel (2x)

17. Polyurethane foam insulation

18. Boiler shunt pump

19. Primary safety valve (3 bar)

9

10

11

664Y2800.E

18

19

EN • 5

Page 6

INTRODUCTION

DESCRIPTION OF THE SPECIFICATIONS

The HeatMaster® TC is an hot water producer combined in

a condensing boiler in accordance to the Belgium "HR-Top"

standard. The boiler is certified compliant with "CE" standards as

a connected appliance C13(x) - C33(x) - C43(x) - C53 - C83(x),

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

but it can also be connected as an open appliance in category

B23 or as an appliance of category B23P, which can operate

with a positive pressure.

Lining

The boiler is protected by a steel lining that first of all undergoes a

degreasing and phosphation process before being lacquered and

heated at 220°C. The inside of this lining is coated with a layer of

thermal and acoustic insulation, reducing losses to a minimum.

Heat exchanger

The core of the HeatMaster® TC features a new stainless steel

heat exchanger. This piece of technology represents the fruit of

exhaustive research and intensive laboratory testing. It reflects

ACV’s eighty years of experience in using stainless steel for

heating and hot water functions. The particular geometry of the

exchanger pipes is calculated to obtain a very large Reynolds

number throughout its cycles.

The HeatMaster® TC achieves an exceptional output that

remains stable throughout the boiler’s life, given that it causes

no oxidation on the exchanger, which is manufactured entirely

from quality steel.

Burner

ACV uses its BG 2000-M burner for the HeatMaster® TC: this

is an air/gas premix burner providing safe and silent operation

while limiting emissions (NOx and CO) to an incredibly low level.

Although the ACV BG 2000-M boiler is very modern, it uses

proven technology and is manufactured from standard spare

parts that are easily available on the market.

PRODUCTION OF HOT WATER

In addition to its exceptional hot water performances, the ACV

Tank-in-Tank concept provides the follwoing advantages :

- A solution for scale deposits: thanks to the specially designed

corrugations, the hot water tank expands and contracts during

the heating cycle, preventing the formation of scale.

- A guarantee against the risk of Legionnellae Disease and

bacteria: the hot water tank is fully immersed in the primary

circuit and the hot water is constantly kept at a temperature

above 60°C.

- Exceptional resistance against corrosion and aggression:

provided by the stainless steel.

FROST PROTECTION

The boiler is equipped with an integrated frost protection: as soon

as the boiler temperature drops below 7°C, the system activates

the central heating pump. As soon as the NTC1 flow temperature

drops below 3°C, the system automatically ignites the burner until

the temperature rises above 10°C. The pump continues to run

for about 10 minutes.

If an outdoor temperature sensor is connected to the system,

the pump is activated as soon as the outside temperature drops

below the specified threshold.

To provide efficient protection for the whole system against frost,

all the valves on the radiators and the convectors should be

completely open.

Temperature regulation

The basic version of the HeatMaster® TC is fitted with a

microprocessor controlled regulator (MCBA) which takes over

both the safet y functions (ignition, monitoring the flame, limiting

the temperature, etc.) and control of the boiler temperature.

This MCBA also includes a weather-dependent regulator. All you

need to do is connect the outdoor temperature sensor available

as an option to the device. However, this regulator can also

operate with a standard ON/OFF room thermostat In addition,

with the combination of a weather-dependent regulator and a

room thermostat, you can control the temperatures based on

the weather with compensation for the indoor temperature.

There are four user adjustable parameters. By entering a

special maintenance code, qualified installers can access

several other parameters to adapt the boiler to special

requirements. In principle, these parameters are factory set

for all normal applications.

664Y2800.E

EN • 6

Page 7

USERS GUIDE

DIRECTIONS FOR USE

Your system must be checked once a year by an approved

installer or maintenance company.

Starting the burner

During operation, the burner star ts automatically as soon as

the boiler temperature drops under the required set point and

it stops as soon as the boiler reaches that temperature.

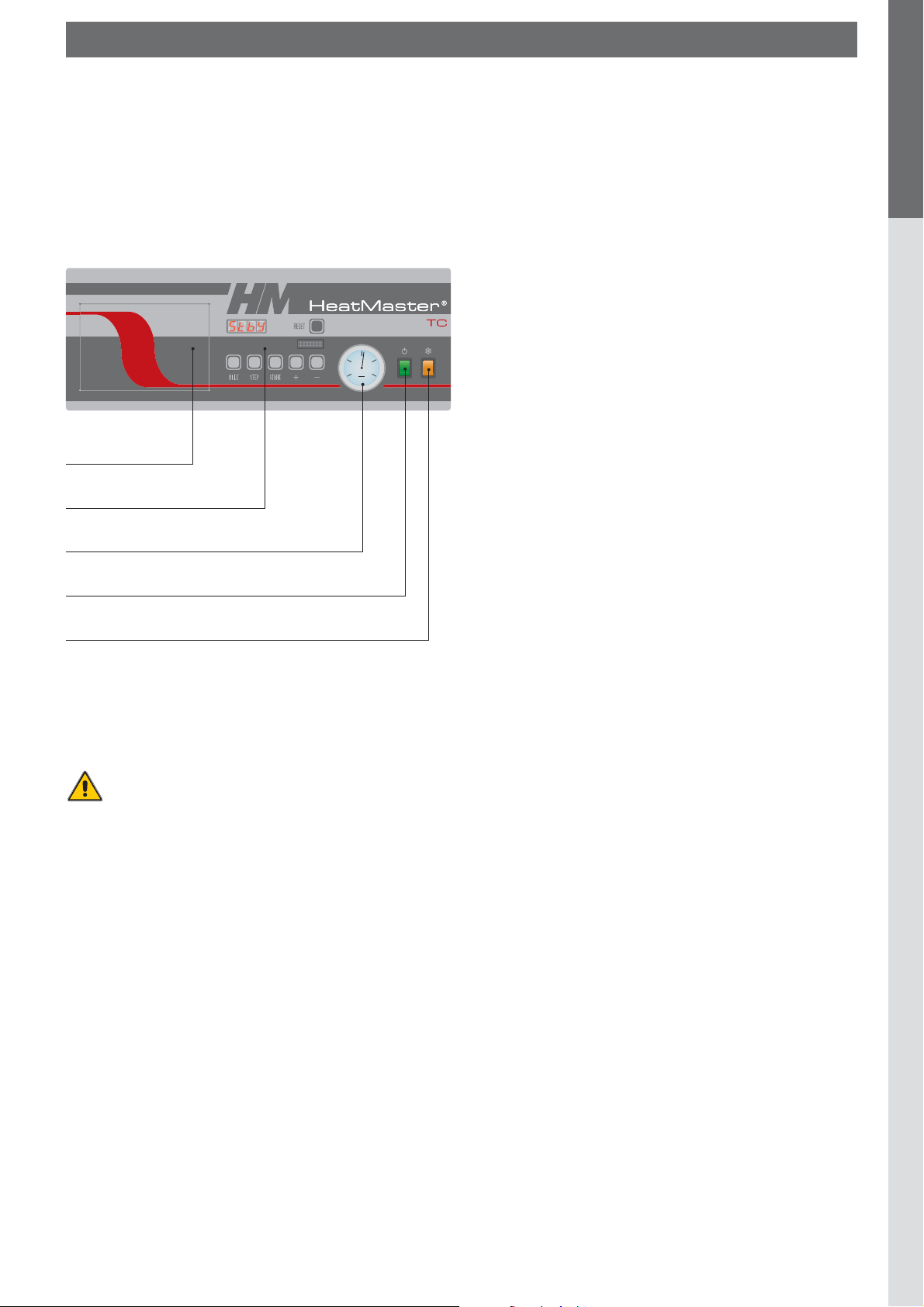

Control panel

2

1O3

bar

4

Pre-cut for an optional

Control Unit controller

MCBA display

Pressure gauge

ON/OFF switch

Summer/Winter switch

SETTINGS PARAMETERS

Setting the domestic hot water temperature:

(Hot water temperature)

- Press Mode: The screen displays PARA.

- Press Step: the first character is 1 and the last two characters

give the current hot water temperature set ting.

- To change this temperature, press + or - until the last t wo

digit s show the desired temperature value.

- Press Store to save the new temperature setting.

- Press Mode twice to return to Pilot mode (normal operating

mode).

Enabling or disabling the hot water heating mode:

(hot water)

- Press Mode: The screen displays PARA.

- Press Step twice: the first character is 2 and the last two

characters give the current setting:

00 = disabled; 01 = enabled.

- To change this parameter, press + or - until the screen displays

the desired value:

00 = disabled; 01 = enabled.

- Press Store to save.

- Press Mode twice to return to Pilot mode (normal operating

mode).

Enabling or disabling Central Heating mode:

(heating)

- Press Mode: The screen displays PARA.

- Press Step three times: the first character is 3 and the last

two characters give the current setting:

00 = disabled; 01 = enabled.

- To change this parameter, press + or - until the screen displays

the desired value:

00 = disabled; 01 = enabled.

- Press Store to save.

- Press Mode twice to return to Pilot mode (normal operating

mode).

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Heating system

The central heating circuit must be pressurized (see in the

chapter “Installation” how to define the system pressure).

The pressure indicator is located on the right-hand side of the

display.

If your system needs to be refilled more than twice

a year, please contact your installer.

The CH pressure must be a minimum of 1 bar and must be

checked by the end user on a regular basis. If the pressure

drops under 0.5 bar, the integrated water pressure switch

blocks the appliance until the pressure in the system returns to

a level above 0.8 bar. The connection for a fill valve is provided

underneath the appliance. The installer can also fit the system

with a separate valve. Make sure that the appliance is powered

off when filling the system. To do this, toggle the Start/Stop

switch located on the lef t of the screen to Of f. (see the Control

panel).

For more information, please ask your installer when the system

is delivered.

A safety valve is provided at the underneath of the appliance.

If the system pressure exceeds 3 bars, this valve opens and

drains the water from the system. In this case, please contact

your installer.

Setting the central heating temperature:

(maximum temperature for the heating circuit)

- Press Mode: The screen displays PARA.

- Press Step four times: the first character is 4 and the last

two characters give the current central heating temperature

setting.

- To change this temperature, press + or - until the last two

digit s show the desired temperature value.

- Press Store to save the new temperature setting.

- Press Mode twice to return to Pilot mode (normal operating

mode).

Fault:

The temperature setting for the appliance and the safety

functions for its various parts are continuously monitored by

a regulator controlled by a microprocessor (the MCBA). In the

event of a fault, this MCBA disables the appliance and displays

an error code: the screen flashes displaying E as the first

character, followed by the error code.

To reset the appliance:

- Press "Reset" on the screen.

- Contact your installer of the fault happens again.

664Y2800.E

EN • 7

Page 8

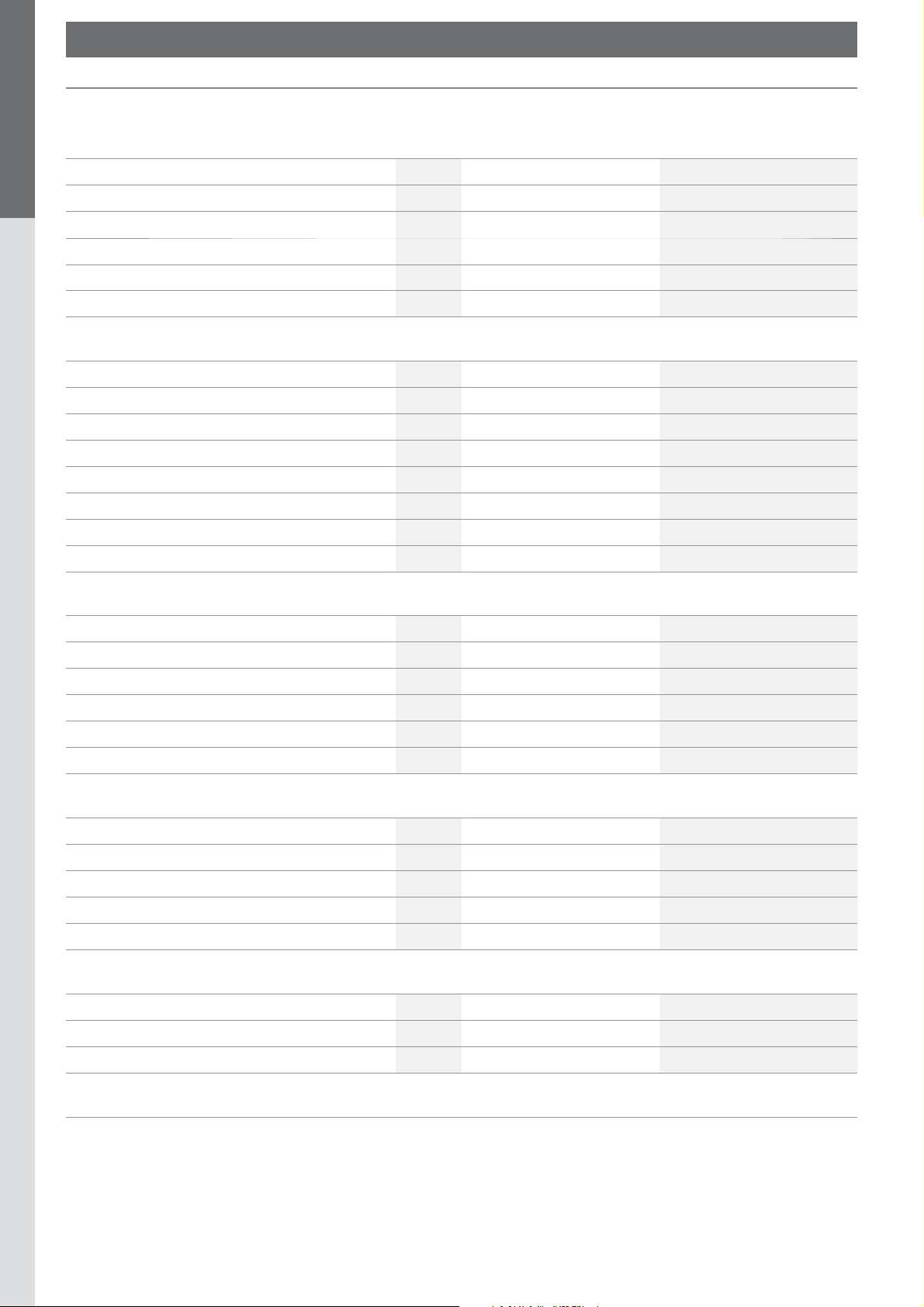

TECHNICAL CHARACTERISTICS

HeatMaster® 35 TC HeatMaster® 85 TC

Central heating Natural gas Propane Natural gas Propane

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Max. Input 80/60°C

Min. Input 80/60°C

Max. output 80/60°C

Min. output 80/60°C

Effi ciency 30% load [EN677]

Effi ciency domestic hot water mode [Δt = 30°C]

Flue gases

CO emissions max. / min. Input

NOx emissions max. / min. Input

NOx classifi cation [EN483] 5 5 5 5

Flue gas temperature — max. Input 80/60°C

Flue gas temperature — max. Input 50/30°C

Mass fl ow rate of combustion products

Flue gas pipe - Max. pressure drop

Concentric fl ue gas channel maximum length

kW

kW

kW

kW

%

%

mg/kWh

mg/kWh

°C

°C

kg/h

Pa

m

34,9 30,6 85,0 [92,0] 85,0 [92,0]

10,0 10,0 17,2 17,2

34,1 29,9 82,5 82,5

9,8 9,8 16,7 16,7

108,5 108,5 107,8 107,8

105,9 105,9 104,0 104,0

70 / 6 105 / 17 58,9 / 4,3 90,0 / 45,0

59 / 29 72 / 31 72,4 / 19 85 / 27

60 60 61,6 61,6

32 32 35,1 35,1

55 46,5 137 [148] 134 [145]

130 130 150 150

20 20 20 20

Gas

Gas pressure

G20 gas fl ow rate

G25 gas fl ow rate

G31 gas fl ow rate

max. Input

CO

2

CO

min. Input

2

Hydraulic parameters

Max. operating temperature

Total capacity

Heating circuit capacity

Maximum operating pressure central heating

Heat exchanger pressure drop [ΔT = 20°C]

Electrical connection

Class

Supply voltage

Maximum absorbed electrical power

mbar

m

m

m

% CO

% CO

mbar

V/Hz

3

3

3

°C

bar

20 / 25 30 / 37 / 50 20 / 25 30 / 37 / 50

/h

/h

/h

2

2

L

L

IP

A

3,7 — 8,99 [9,73] —

4,3 — 10,46 [11,32] —

— 1,25 — 1,25

9,4 10,5 9,3 10,9

9,0 10,1 8,6 9,0

90 90 90 90

189 189 315 315

108,5 108,5 125 125

3333

30 30 200 200

30 30 30 30

230/50 230/50 230/50 230/50

0,8 0,8 1,0 1,0

Weight empty kg 174 174 284 284

[…] = Domestic hot water mode

664Y2800.E

EN • 8

Page 9

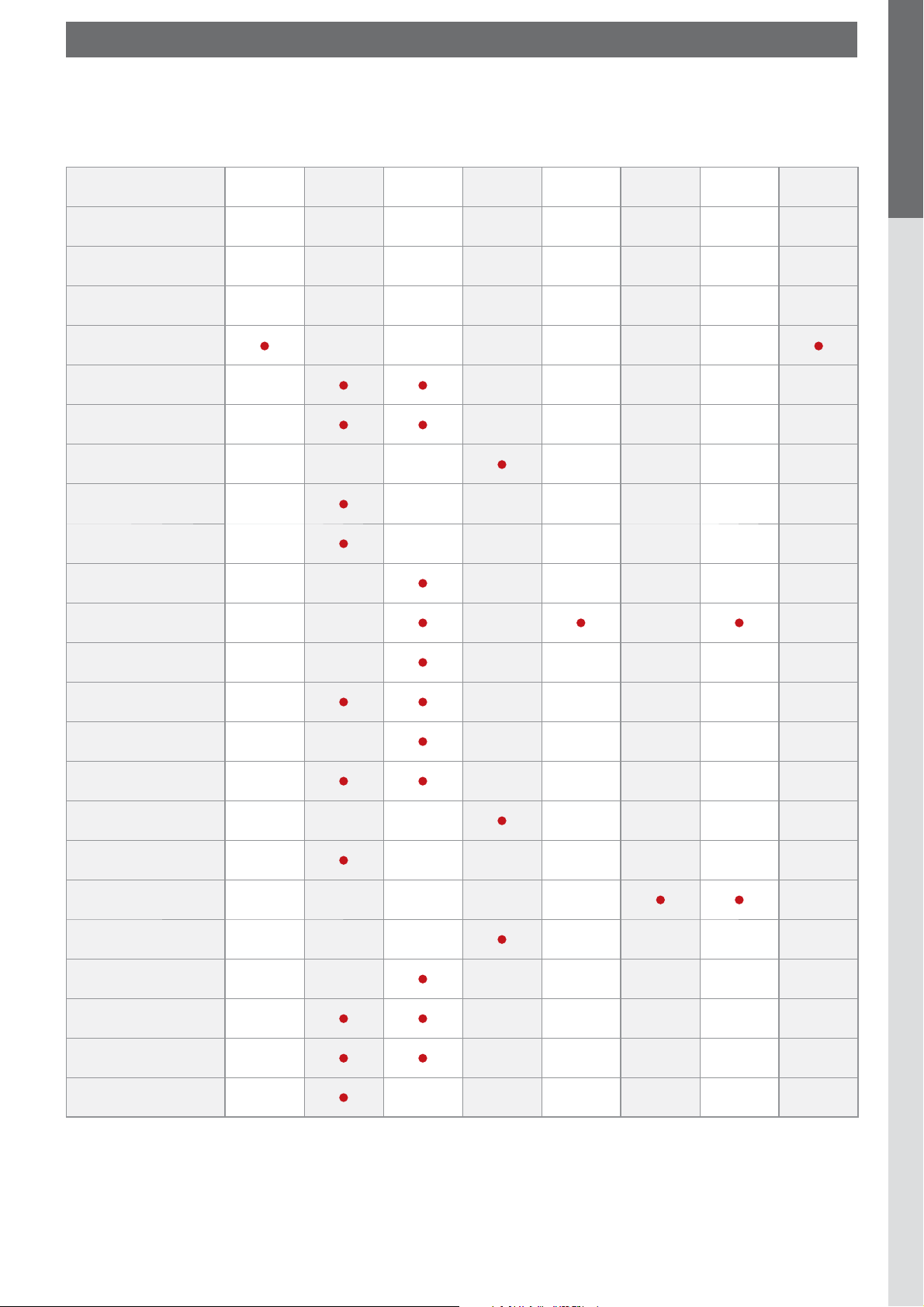

TECHNICAL CHARACTERISTICS

Gas categories HeatMaster® 35 / 85 TC

BE

CH

CZ

DE

DK

EE

ES

G20

G25

G30

G31

Belgium

Switzerland

Czech republic

Germany

Denmark

Estonia

Spain

I2E(S)B *

I2E(R)B **

20 mbar 20 mbar 20 mbar 20 mbar 20 mbar

25 mbar 25 mbar 25 mbar 25 mbar

II2H3B/P II2H3P II2E3B/P II2Er3P II2L3B/P II2L3P I3P

30 - 50 mbar 30 - 50 mbar 30 - 50 mbar

30 - 50 mbar 37 - 50 mbar 30 - 50 mbar 37 - 50 mbar 30 - 50 mbar 37 - 50 mbar 37 mbar

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

FR

GB

GR

IE

IT

LU

LT

NL

PL

PT

SI

SK

France

Great Britain

Greece

Ireland

Italy

Luxembourg

Lithuania

Netherlands

Poland

Portugal

Slovenia

Slovakia

Sweden

SE

(*) HeatMaster ® 35 TC (**) HeatMaster ® 85 TC

664Y2800.E

EN • 9

Page 10

TECHNICAL CHARACTERISTICS

MAXIMUM OPERATING CONDITIONS

Maximum service pressure (tank full of water)

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

- Primary circuit : 3 bar

- Secondary circuit : 10 bar

Maximum operting temperature : 90°C

Water quality:

- Chlorures : < 150 mg/L

- 6 ≤ PH ≤ 8

DOMESTIC HOT WATER FEATURES

Operating conditions at 90°C

Peak fl ow at 40°C [ΔT = 30°C]

Peak fl ow at 40°C [ΔT = 30°C]

Constant fl ow at 40°C [ΔT = 30°C]

Peak fl ow at 45°C [ΔT = 35°C]

Peak fl ow at 45°C [ΔT = 35°C]

Constant fl ow at 45°C [ΔT = 35°C]

Peak fl ow at 60°C [ΔT = 50°C]

Peak fl ow at 60°C [ΔT = 50°C]

Constant fl ow at 60°C [ΔT = 50°C]

Pre-heat time

L/10’

L/60’

L/h

L/10’

L/60’

L/h

L/10’

L/60’

L/h

minutes

HeatMaster

®

35 TC

472 868

1322 3076

1070 2713

389 718

1116 2513

917 2325

243 413

731 1594

642 1617

37 35

HeatMaster

85 TC

®

664Y2800.E

EN • 10

Page 11

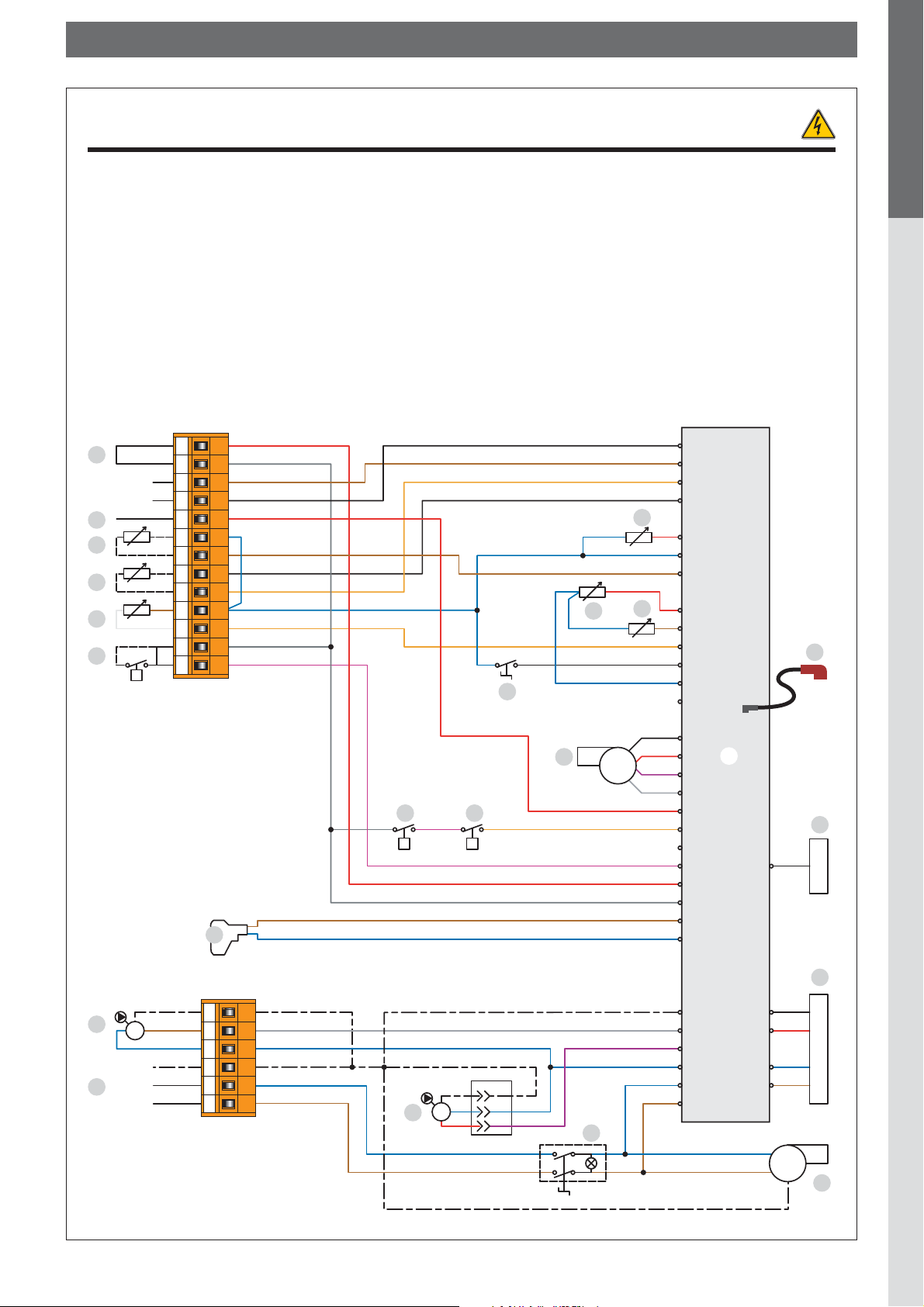

ELECTRICAL CONNECTION

WIRING DIAGRAM : HeatMaster ® TC

1. Power supply 230 V

2. ON/OFF switch

3. Boiler shunt pump

4. Heating pump (optional)

5. Gas valve rectifier

6. 230Volt - 24Volt transformer

7. MCBA

8. Display

9. Water pressure switch

10. Fan PWM control

11. Summer/Winter switch

12. NTC1 flow sensor

X11.

R

20

BUS A

BUS B

19

18

17

Br

16

15

W

t

1 2 3 4 5 6 7 8 9 10 11 12 13

G

Br

Bk

R

B

Br

Bk

B

B

Or

G

V

13. NTC2 return sensor

14. NTC5 flue gas temperature

15. Room thermostat (optional)

16. NTC3 domestic hot

17. NTC4 outdoor temperature (optional)

18. NTC6 second heating circuit flow sensor (optional)

19. Zero volt of 24V circuit.

20. Safety contact thermostat RAM (optional)

21. Ionisation and ignition cable

22. Burner power supply 230 V (only HeatMaster

23. Gas pressure switch HeatMaster® 85 TC

R B

12

11

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

®

85 TC]

Bk

X5.1

Br

X5.2

Or

X5.3

Bk

X5.4

14

R B

X4.1

B

X4.2

Br

X4.3

R

13

B

X3.1

Br

X3.2

Or

X3.3

Bk Bk B

X3.4

B

X3.5

X3.6

21

B. Blue

Bk. Black

Br. Brown

G. Grey

Or. Orange

R. Red

V. Violet

W. White

Y/Gr. Yellow/Green

Y/Gr

4

1

230V

Br

M

B

PE

N

L

5

1 2 3 4 5 6

X12.

V

R

G

Br

B

Y/Gr

W

B

Y/Gr Y/Gr

B

Br

9

V Or G

P P

M

3

Bk

X2.1

R

X2.2

X2.3

X2.4

X2.5

X2.6

X2.7

X2.8

X2.9

X2.10

X2.11

X2.12

7

8

X7

1010

23

V

W

R

Or

V

R

G

Br

B

6

Bk

R

B

Br

PE

L1

Y/Gr

X1.6

W

X1.5

V

X1.4

B

X1.3

B

X1.2

Br

N

X1.1

X10.7

X10.6

X10.1

X10.3

2

B

Br

B

Br

22

Y/Gr

664Y2800.E

EN • 11

Page 12

INSTALLATION INSTRUCTIONS

DIMENSIONS

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

HM 35 TC 1720 600 500 80 125 140 1700 670 110 100 200 960 — 170 230

HM 85 TC 2145 690 580 100 150 160 2095 725 125 105

HYDRAULIC CONNECTIONS HeatMaster ® 35 TC HeatMaster ® 85 TC

Heating connection [F] Ø 1" 1"1/2

Domestic hot water connection [M] Ø 1" 1"1/2

Gas connection [M] Ø 3/4" 3/4"

A

mmBmmCmmDmmEmmFmmGmmHmmImmJmmKmmLmmMmmNmmOmm

270 1210 200 235 240

B

H

E

C

D

2

1O3

bar

4

F

A

G

BOILER ROOM

- Make sure that all air vents are unobstructed any times.

- Do not store any flammable products in the boiler room.

- Do not store any corrosive products, paint, solvents, salts,

chlorine products and other detergent products near the

appliance.

- If you smell gas, do not switch on any lights, turn off the

gas tap at the meter, ventilate the rooms and contact your

installer.

ACCESSIBILITY

The appliance must be positioned in such a way to be

accessible any time. In addition, the following distances

are required around the appliance.

Kit “Easy Fit” only for

HeatMaster ® 35 TC

I

3 x 65

180

J

K

L

1736

M

N

O

Min. 25 mm Min. 25 mm

Min. 300 mm

690

730

2

1 O 3

bar

4

664Y2800.E

EN • 12

Page 13

INSTALLATION

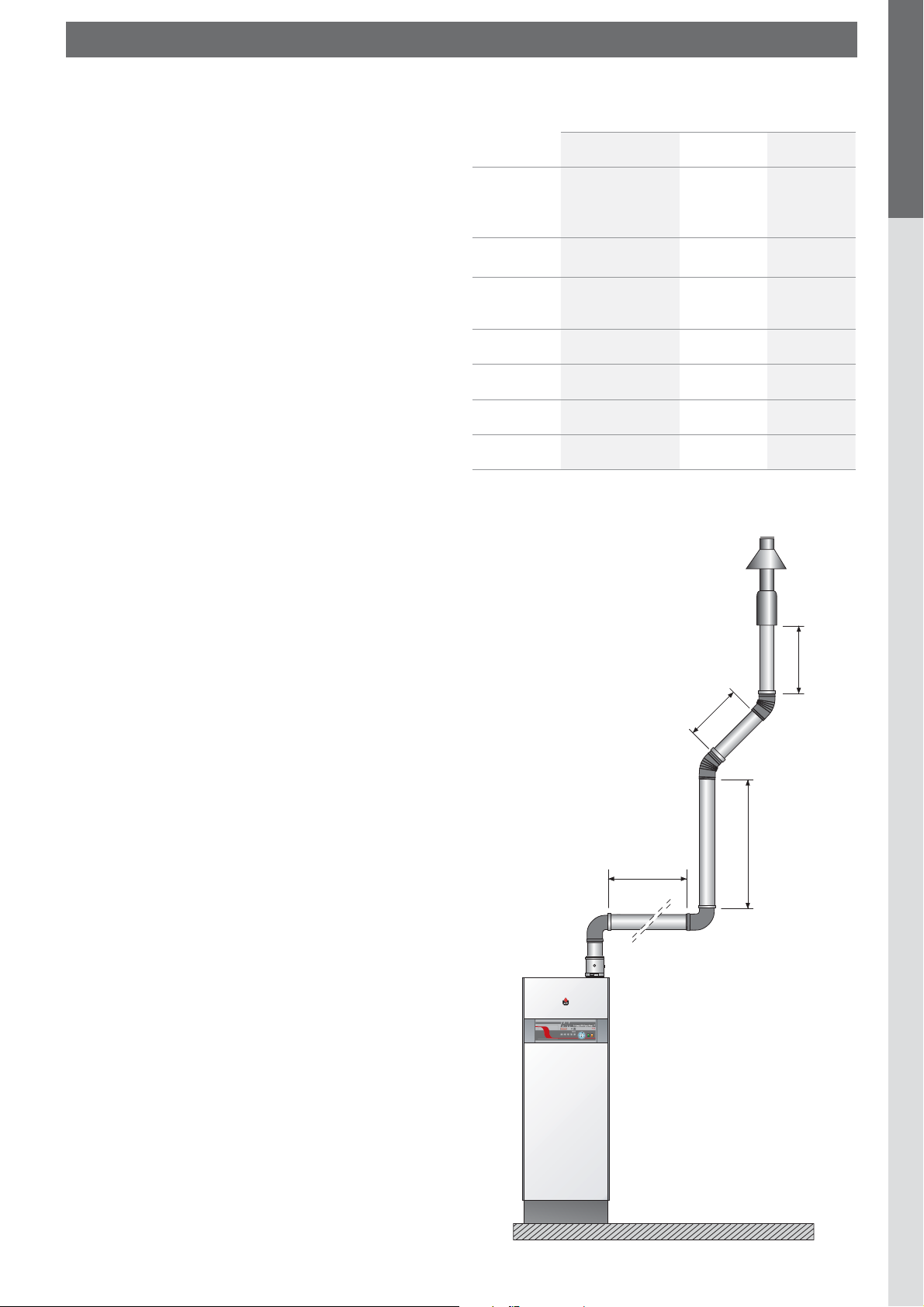

CONNECTION TO THE CHIMNEY

- The chimney connections must comply with the applicable

standards (in Belgium: NBN D51-003), the local energy

supplier’s instructions, the fire regulation and neighbourhood

good practices.

- The HeatMaster

which makes it largely independent of the pressure drop in

the air intake and flue gas extraction system. However, the

maximum pressure drop for this system may not be exceeded,

or the pressure will diminish. Nevertheless, the gas/air ratio

regulator continuously guarantees optimum combustion with

very low emission levels.

- The horizontal flue gas pipes must always be installed with a

min. slope of 5 mm per meter, upwards from the boiler side.

- There must be no obstruction or openings for any other

appliances within a radius of 0.5 metres around the flue

terminal of the HeatMaster

- The maximum flue resistance is 130 Pascal for the

HeatMaster® 35 TC and 150 Pascal for the HeatMaster® 85

TC. You can use the following table as the basis for calculating

this value (please also refer to the specimen calculation presented

under the table).

Sample calculation:

The diagram below consists of the following parts: pipe with

monitoring section + 2 * 90° pipe bends + 2 metres of horizontal

pipe + 2 * 45° pipe bends + (2 + 1 + 1) metres of vertical pipe

and fall back + discharge.

Therefore, the resistance of this system is as follows:

2.5 + (2 x 6.0) + (2 x 5.0) + (2 x 4.0) + (4 x 5.0) + 20

= 72.5 Pa.

®

TC has an inbuilt gas/air ratio regulator,

®

TC.

Table of flue resistance in Pascal

(1 Pascal = 0,01 mbar)

Pipe

concentric

HM

35 TC

Ø 80/125

mm

1 m

straight pipe

Pipe with a

monitoring

section

90° pipe bend

45° pipe bend

Vertical pipe

Horizontal pipe

This table is based on the equipment offered by ACV and cannot be applied

generally.

5.0 13,5 1.5 4,1 2.0 5,5

2.5 6,8 — — 1.0 2,7

6.0 16,4 1.9 5,2 3.4 9,3

4.0 10,9 1.3 3,5 2.3 6,3

20.0 54,5 — — — —

15.0 40,9 — — — —

HM

85 TC

Ø 100/150

mm

Air inlet

separate

HM

35 TC

Ø 80

mm

HM

85 TC

Ø 100

MM

Air extraction

separate

HM

35 TC

Ø 80

mm

1000 mm

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

HM

85 TC

Ø 100

mm

This value is less than the maximum authorised resistance,

therefore the installation is compliant.

1000 mm

2000 mm

2000 mm

2

1 O 3

bar

4

664Y2800.E

EN • 13

Page 14

INSTALLATION

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Options for connection to the chimney

2

1O3

bar

4

B23P C33

2

1O3

bar

4

B23

2

1O3

bar

4

C43

2

1O3

bar

4

C43

B23 : Connection to an exhaust duct venting the combustion

products outside of the installation area, with the

combustion air being drawn directly from this area.

B23P : Connection to an exhaust system of the combustion

products designed to operate with positive pressure.

C13 : Connection by pipes with horizontal terminal units

that simultaneously intake the combustion air and

discharge the combustion products outside through

openings that are either concentric or close enough

together to be subjected to similar wind conditions.

C33 : Connection by pipes with vertical terminal units that

simultaneously intake fresh air and discharge the

combustion products outside through openings that

are either concentric or close enough together to be

subjected to similar wind conditions.

2

1O3

bar

4

2

1O3

bar

4

C53

2

1O3

bar

4

2

1O3

bar

4

C13C33s

C33s : Connection with an individual system of which the

C43 : Connection by two ducts to a collective duct sys tem

C53 : Connection to separate ducts for the supply of

exhaust duct for the combustion products is installed

in an exhaust pipe that is part of the building. The

appliance, the exhaus t duct and the terminal units are

certified as an assembly that cannot be dissociated.

serving more than one appliance; this system of

collective duc ts features two duct s connected to

a terminal unit that simultaneously intakes fresh

combustion air and discharges the combustion

products outside through openings that are either

concentric or close enough together to be subjected

to similar wind conditions.

combustion air and for venting the combustion

products; these ducts may end in zones with different

pressure levels.

664Y2800.E

EN • 14

Page 15

CONNECTION TO THE GAS

- The HeatMaster® TC is fitted with a Ø 3/4” male fitting

connector, on which you can connect the gas tap.

- The gas connection must comply with the applicable

regulations (e.g. NBN D51-003 in Belgium) in the country

of installation.

- Where there is a risk of dirt stemming from the net work,

place a gas filter upstream from the connection.

INSTALLATION

- Drain the gas pipe and check in minute detail that all the

boiler pipes, both inside and outside, are sealed.

- Check the gas pressure in the system. Consult the technical

characteristics.

- Check the gas pressure and consumption when

commissioning the appliance.

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

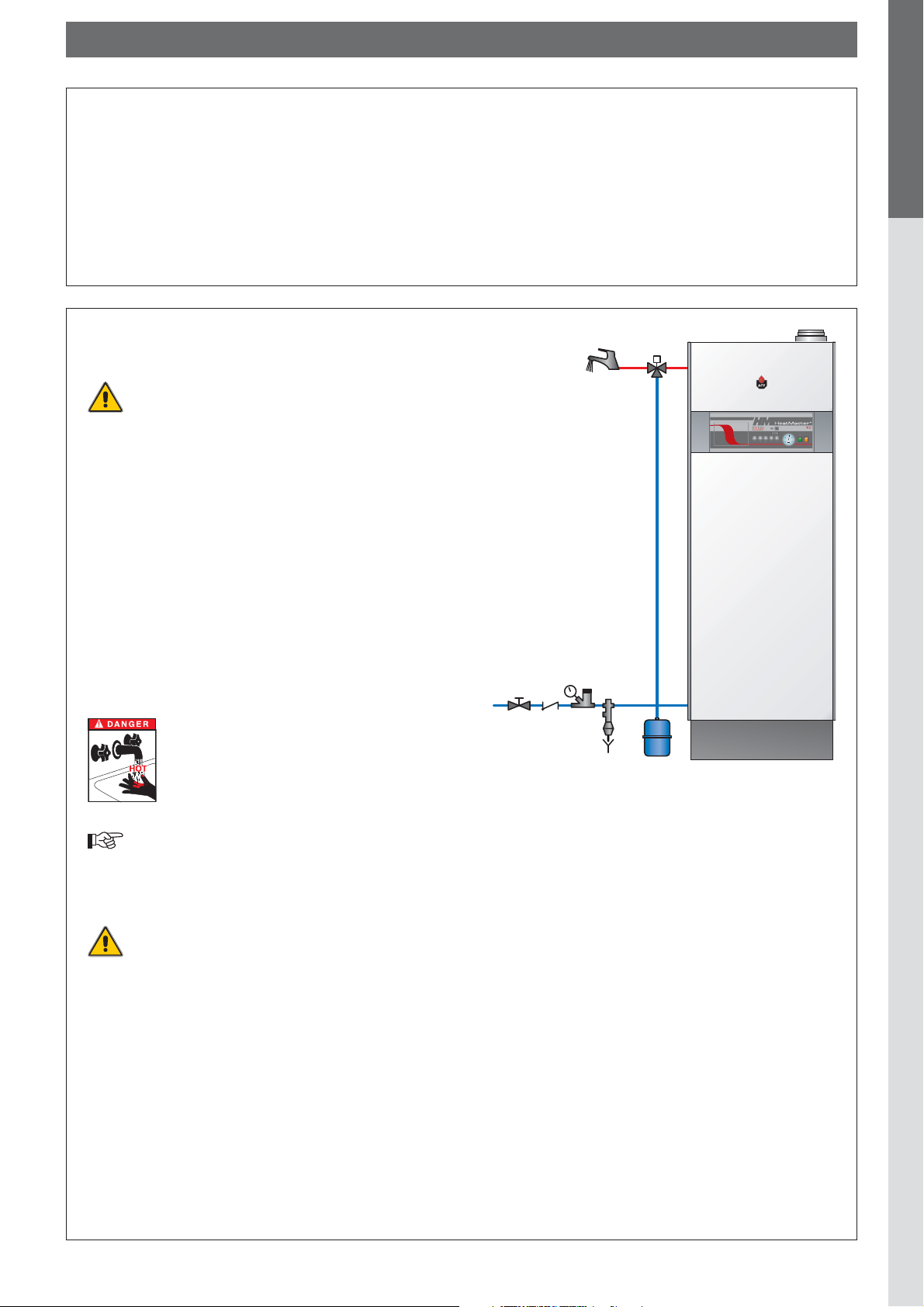

DOMESTIC HOT WATER CONNECTION

Before pressurising the central heating circuit

(primary) you should first pressurise the domestic

hot water tank (secondary).

The HeatMaster® TC boiler can be connected directly on the

domestic hot water circuit.

Flush out the system before connecting the domestic hot

water par t.

The installation must be fitted with an approved safety unit

with a 7-bar safet y valve, a non-return valve and a shut-off

valve.

During the heating process, the domestic hot water dilates

and the pressure increases. As soon as the pressure exceeds

the safet y valve setting, the valve opens and discharges a

small quantity of water. Using a hot water expansion vessel

(2 litres at least) will prevent this phenomenon and reduce

water hammer ef fect.

The hot water output temperature may

reach temperatures in excess of 60°C, which

can cause burns. We therefore recommend

that that you install a thermostatic mixer

immediately after installing the appliance.

If stop valves are used in the domestic hot water

system, they can cause pressure waves when

closed. Use devices designed to reduce water

hammer to avoid this phenomenon.

7

3

1 2

1. Cold water supply tap

2. Non-return valve

3. Pressure reducing valve

4. Safety group

5. Hot water expansion vessel

6. Thermostatic mixer

7. Drawoff tap

4

5

6

2

1 O 3

bar

4

664Y2800.E

If the HeatMaster® 35 TC is used as a DHW- boiler

without connection to heating circuit, an external

primary expansion vessel of minimum 16 litres

should be installed in the system (no internal

expansion vessel on HeatMaster

®

35 TC).

EN • 15

Page 16

INSTALLATION

HEATING CONNECTIONS

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Recommendations

Before pressurising the central heating circuit

(primary) you should first pressurise the domestic

hot water tank (secondary).

- The central heating system must be completely flushed

out with tap water before connecting the boiler.

- The central heating safety valve is incorporated under the

appliance and must be routed to the drain with an open

connection (to allow inspection).

- Two primary expansion vessels of 10 litres are integrated in

the HeatMaster® 85 TC (none in the HeatMaster® 35 TC).

In function of the installation, an external expansion vessel

has to be installed.

- A temperature homogeneisation pump fits the boiler. That

pump runs aswell during hot water mode aswell in heating

mode. The speed selection of the pump must be set to 3.

- Fill the system with fresh water. Contact your ACV

representative about the use of inhibitors.

- It is possible that the pumps are locked due to the

presence of residual water from tests completed on the

appliance. Therefore, we recommend that you unblock

the pumps before filling the appliance.

- You will find the connection for the filling valve and/or

drainage valve on the bot tom of the appliance. Fill the

appliance to a minimum pressure of one bar. Drain the

whole system and re-fill the appliance to a pressure of 1,5

bar.

HEATING CONNECTIONS : GENERAL

1. Isolating valve, heating system

2. Internal primary safety valve calibrated to 3 bar

3. System filling valve

4. Expansion vessel

5. Drain cock

6. Condenstrap

7. Heating pump

7

1

1

4

3

2

5

2

1 O 3

bar

4

6

- Fit the condens trap, fill it with tap water and connect the

hose to the drain using a connection with an inspection

section. Make sure you prevent the freezing of the

condensates.

The condense water-trap must be connection to

the drainage system in accordance with current

standards in force.

If there is a risk of low pressure in the hot water

circuit (installation of HeatMaster® on the roof

of a building), it is essential to install a vacuum

breaker device onto the cold water supply.

ASSEMBLING THE BALL CONDENSATE TRAP

664Y2800.E

EN • 16

Page 17

INSTALLATION

INSTALLATION OF A SINGLE HIGH

TEMPERATURE CIRCUIT WITH ROOM

THERMOSTAT ACV 15 CONTROL

General diagram

The On/Off room thermostat controls the central heating

system (radiators only).

The pump is powered as soon as the room thermostat

generates an heat demand.

Advantages for the user:

- Simplicity of the system

- Direct connecton to exis ting inst allations

Remove this

shunt before

connectiong

a room

thermostat

1 2 3 4 5 6 7 8 9 10 11 12 13

ACV 15

Optional accessories

Code Description

10800018 Room themostat ACV 15

10800097

[HM 35 TC]

10800107

[HM 85 TC]

High temperature kit DN 20

Including: one circulation pump,

two isolating valves, check valve,

two thermometers

High temperature kit DN 32

Including: one circulation pump,

two isolating valves, check valve,

two thermometers

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Factory

setting

MCBA

1 2 3 4 5 6

Typical

setting Description

00 : Heating mode “OFF”

01 : Heating mode “ON”

Setting temperature for the heating water (adjustable between 30 and 85°C).

00 : Using a outside temperature sensor and a room thermostat

664Y2800.E

EN • 17

Page 18

INSTALLATION

INSTALLATION OF A WEATHER DEPENDING

HEATING CIRCUIT HIGH OR LOW TEMPERATURE

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

General diagram

This is a simple way to control two heating circuits (radiators

or floor heating) with weather depending control.

Advantages for the user:

- Comfort

- Efficiency

ACV 15

AF120

SQK 349

MCBA

AM3 - 11

RAM NTC12K

Optional accessories

Code Description Code Description

10800018 Room themostat ACV 15 10510100

10800095

537D3040

10510900

AM3-11 module

Controls the second heating circuit

- communicates directly with the

MCBA

Contact sensor 12kΩ

To be mounted on the outlet of

controlled circuit

Contact thermostat RAM 5109

Required to protect all fl oor

heating circuits

10800152

[HM 35 TC]

10800106

[HM 85 TC]

10800019

Outside temperature sensor

12kΩ — AF120

Low temperature kit DN 20

Including: one circulation pump,

two isolating valves, check valve,

two thermometers, the 3-way valve

with integrated bypass.

Low temperature kit DN 32

Including: one circulation pump,

two isolating valves, check valve,

two thermometers, the 3-way valve

with integrated bypass

Servomotor SQK 349

Electromechanical servomotor SQK

349 for the three-way valve included

in low temperature kit

150 seconds)

(opening times :

664Y2800.E

EN • 18

Page 19

To be wired in accordance with the applicable regulations.

INSTALLATION

1 2

Ph PE

N N

X1

X2

X3

90

80

70

60

50

P39

40

30

20

P40

T° departure boiler (°C)

10

0

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

-20-25 -10-15 0-5 1052015 25

P6 P7

Outside T° (°C)

Y1

Y2

N

L1

L

1 2 3 4 5 6 7 8 9 10 11 12 13

Factory

setting

Typical

setting Description

Maximum setpoint in domestic hot water mode

00 : Domestic hot water mode “OFF”

01 : Domestic hot water mode “ON”

00 : Heating mode “OFF”

01 : Heating mode “ON”

Maximum temperature of the heating circuit (must be higher than hot water setpoint)

Minimum outside temperature [T4] (adjustable between -20 and 10°C).

Maximum outside temperature [T4] (adjustable between 15 and 25°C).

10 : Heating pump controlled by room thermostat - hot water priority active

21 : Heating pump runs continuously - hot water priority active

50 : Heating pump controlled by room thermostat - hot water priority not active

61 : Heating pump runs continuously - hot water priority not active

Maximum temperature of the heating circuit

Minimum temperature of the heating circuit

664Y2800.E

EN • 19

Page 20

INSTALLATION

INSTALLATION OF TWO HEATING CIRCUIT CONTROLLED

BY ROOM UNIT AND ZMC-1 MODULE

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

General diagram

This configuration controls t wo heating circuit s (radiators or floor heating). In addition, the Room unit features a remote

monitoring of the two circuits

You can adjust those two circuits depending on the outside temperature.

This is the ideal configuration for floor heating with additional heating provided by radiators.

You can select various heating functions, and program up to three weekly schedules, as well for the central heating as for

the hot water production.

Room Unit

AF120

VF202

RAM

SQK 349

SQK 349

VF202

ZMC1

ZMC1

MCBA

Optional accessories

Code Description Code Description

10800034

Room Unit RSC

Supplied with outside temperature

sensor

10800077

[HM 35 TC]

Collector 2 circuits DN 20

With bypass, connecting tubes

and integrated wall brackets

10800119

X2

10800036

10800045

X2

10510900

10510100

ZMC-1 module (kit)

Controls the second heating circuit

- alarm contact - operates only in

conjonction with the Room Unit

RSC.

Clip-in interface RMCIEBV3

Enables communications between

the MCBA and the Room Unit RSC.

Contact sensor 2kΩ — VF202

To be mounted on the outlet of

controlled circuit

Contact thermostat RAM 5109

Required to protect all fl oor heating

circuits

Outside temperature sensor

12kΩ — AF120

10800152

[HM 35 TC]

X2

10800104

[HM 85 TC

10800142

[HM 85 TC]

10800106

[HM 85 TC

X2]

10800019

X2

Low temperature kit DN 20

Including: one circulation pump,

two isolating valves, check valve,

two thermometers, the 3-way valve

with integrated bypass.

Collector 2 circuits DN 32

With integrated wall brackets

Connection kit DN 32 to the

manifold

Including: Two fl exible 1"1/2 hoses

and 1"1/4 reduction fi ttings

Low temperature kit DN 32

Including: one circulation pump,

two isolating valves, check valve,

two thermometers, the 3-way valve

with integrated bypass

Servomotor SQK 349

Electromechanical servomotor SQK

349 for the three-way valve included

in low temperature kit

150 seconds)

(opening times :

664Y2800.E

EN • 20

Page 21

INSTALLATION

To be wired in accordance with the applicable regulations.

Y1

Y2

Ph

N

PE

N

N

N

AV MPK ZU AUF

ZMC1

0

24V

A B VF VE

Y1

Y2

N

AV MPK ZU AUF

ZMC1

0

24V

A B VF VE

1 2 3 4 5 6 7 8 9 10 11 12 13

A

B

B A

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

1 2 A B

Factory

setting

10800036: Interface address “0”

1 2 3 4 5 6 7 8 9 10 11 12 13

Typical

setting Description

= 0

= 1

= 2

= 3

= 4

= 5

= 6

= 7

664Y2800.E

Maximum setpoint in domestic hot water mode

00 : Domestic hot water mode “OFF”

01 : Domestic hot water mode “ON”

00 : Heating mode “OFF”

01 : Heating mode “ON”

Maximum temperature of the heating circuit (must be higher than hot water setpoint)

EN • 21

Page 22

COMMISSIONING AND MAINTENANCE

COMMISSIONING THE SYSTEM

Before pressurising the central heating circuit

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Both the domestic hot water tank and the central

- Slowly fill the tank and drain it by opening a hot water tap. Drain

- Fill the whole system up to a minimum pressure of 1 bar

- Vent the shunt pump and unblock it if necessary.

- Open the gas tap, drain the pipe and check that there are no

- Place the condensing trap on the bottom face of the boiler and

- Connect the plug to the wall socket and power on the

- Set the central heating and hot water temperatures following

- Drain the central heating system again and, if necessary, re-fill it.

- Make sure the central heating system is correctly balanced

Moreover this pipe can never be blocked.

(primary) you should first pressurise the domestic hot

water tank (secondary).

heating circuit must be filled before using the boiler.

all the taps and check that there are no leaks in the domestic

hot water system.

(preferably 1.5 bar), using the boiler’s fill valve. Fill the system

slowly. Also check that the automatic air vent on the tank is

working. Check that there are no leaks in the central heating

system.

leaks in the system.

check it is fill with water.

appliance. If needed, place the room thermostat to its highest

position. The boiler should start. Check the gas pressure and

allow the boiler to heat up for a few minutes. Set the boiler

to High Power mode and check the CO2 level (see the table of

Technical Characteristics)

. Then, set the boiler to Low Power

mode and check the CO2 level again (see the table of Technical

Characteristics)

.

the values given in the Directions for Use.

and, if necessary, adjust the valves to prevent a greater or

lesser flow than planned to some circuits or radiators.

The condensate flow pipe diameter can not be decreased.

- Check the dynamic gas pressure at the gas valve

below, ref. 1)

. This must be at least 18 mbars. Wait a few minutes

(see diagram

for the appliance to heat up to a minimum temperature of 60°C.

Check the CO

2 setting using a measurement instrument.

Please see in the Technical Characteristics for optimum

value.

To increase the CO

2 value, turn the venturi screw counterclockwise;

turn it clockwise to reduce the value (see diagram below ref. 2).

Then put the appliance to High Power mode by simultaneously

pressing the mode and Plus keys. Wait a few minutes to

stabilise.

Check the CO2 value. It should be either equal to the full power

value or a maximum of 0.5% less than this value. If you record

a significant deviation,please contact the ACV maintenance

department.

INSPECTION AND MAINTENANCE

ACV recommends that you have your boilers inspected

and cleaned if need be at least once a year.

Plug out the appliance before undertaking any work, even if only

recording measurements and adjusting the settings.

- Check that the condenstrap is not fouled, fill it, if need be, and

check that there are no leaks.

- Check that the safety valves are operating correctly.

- Drain the whole system and if necessary re-fill the appliance to

pressure of 1.5 bar.

If you have to refill your circuit more than twice a year,

please contact your installer.

- Check the boiler charge in High Power mode. If there is a

big difference between this value and the original setting, the

deviation could mean a blockage in the air intake pipes or flue

gas extraction pipes, or that the exchanger has become fouled

with an accumulation of dirt.

CHECKING THE SETTING

- Check that the parameters are set in accordance with the

user’s needs: see page 3, Directions for Use.

- Check the boiler settings: this task can only be carried out by an

ACV-trained installer or by the ACV maintenance department.

- Set the appliance to High Power mode by simultaneously pressing

the mode and Plus keys.

Réf. 3:

2

The gas valve

offset setting is

3

a sealed factory

setting.

In principle,

it may not be

modified.

1

TEMPERATURE SENSOR RESISTANCE TABLES

T° [°C]

- 20 98200 25 12000 70 2340

- 15 75900 30 9800 75 1940

- 10 58800 35 8050 80 1710

- 5 45900 40 6650 85 1470

0 36100 45 5520 90 1260

5 28600 50 4610 95 1100

10 22800 55 3860 100 950

15 18300 60 3250

20 14700 65 2750

R Ω

T° [°C]

R Ω

T° [°C]

R Ω

664Y2800.E

EN • 22

Page 23

COMMISSIONING AND MAINTENANCE

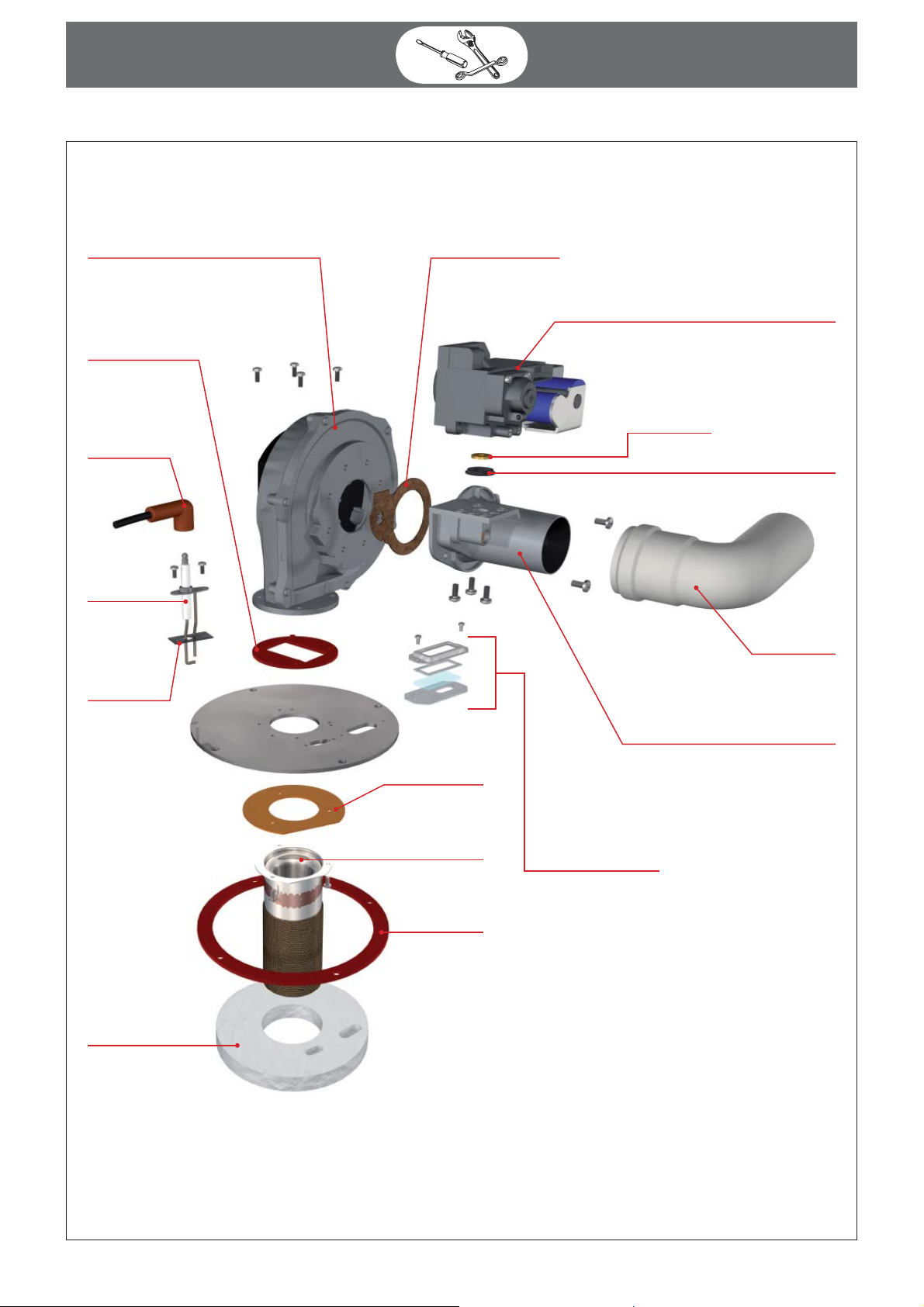

DISASSEMBLING THE BURNER

- Close the inlet gas valve.

- Remove the top front panel of the boiler.

- Unplug the fan plugs (24 Volt), the ignition cable, the gas valve

control and the ignition electrode earth.

- Loosen the 4 burner nuts using a ratchet wrench.

- Unscrew the three-way coupling on the gas pipe.

- In one unit, lift up the burner with the fan and the gas valve to

remove them from the exchanger. Be careful not to damage

the burner insulation in the exchanger.

- Check the condition of the insulation and the seals and replace

them if necessary before re-assembling the burner following

the same procedure but in the reverse order.

CLEANING THE HEAT EXCHANGER

- Remove the burner assembly as described above.

- Remove the burner gasket.

- Clean the combustion chamber using a vacuum cleaner.

- It could be necessary to clean the flue tubes by putting water

in the combustion room. Af ter that operation, it is necessary

to clean the condensing trap.

- Check the burner insulation and the burner gasket; replace

the parts if necessary.

- Check the igniter, replace if necessary

- Reassemble the burner and check for leakages.

- Power up the appliance, set the boiler in full power mode and

recheck for leaks.

- Check the gas pressure and the CO

previous paragraf.

2 level as explained in

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

X 4

DISASSEMBLING AND CHECKING THE ELECTRODE

- Remove the ignition cable.

- Remove the two fixing screws.

- Remove the electrode earth but make sure the serrated

washer is fixed between the earth cable and the electrode

when re-assembling.

- Check the condition of the seals and replace them if necessary

before re-assembling the electrode following the same procedure

but in the reverse order.

HeatMaster® 35 TC HeatMaster® 85 TC

3

3 - 4

5

664Y2800.E

3

EN • 23

Page 24

MCBA PARAMETERS FOR THE SPECIALIST

STANDBY MODE

Standby Mode

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

After you power down the appliance the screen displays Pilot

mode, as shown in the figure above.

This is the standard MCBA mode. The MCBA automatically

returns to this mode after 20 minutes if no keys have been

pressed on the screen. Any parameters that were modified are

then enabled.

The first character shows the current status of the boiler

depending on the condition of both the boiler and the burner. The

last 2 characters indicate the start temperature.

Status Boiler function

Standby, no demand for heat

Fan first, fan after

Ignition

Once the cause of the blockage has been resolved, the burner

starts automatically within 150 seconds at most.

Status Boiler function

Internal check — three-way valve

Boiler burner in hot water ready function

Test function: Central heating high power

Test function: Central heating low power

Test function: Boiler with fixed number of

revolutions

Operation of the boiler burner for the heating

Operation of the boiler burner for the

domestic hot water

Air pressure limit or obtaining

the number of start revolutions

The burner goes out when the specified value

is reached.

A demand for heat is present nonetheless.

Pump over-run time after the demand for

central heating

Pump over-run time after the demand for

domestic hot water

Burner blocked:

• : T1 > 95°C

•

•

•

•

•

•

•

•

•

•

•

•

•

: T2 > 95°C

: T2 - T1 > 10°C after 90 seconds

: dT1/dt > maximum gradient T1

: water pressure switch not off

: no fan signal

: erroneous fan signal

: T1 - T2 > Δ max.

: NTC3 short-circuit

: NTC5 short-circuit

: NTC3 interrupt

: NTC5 interrupt

: T5 > T5 max

: wait for the fan to start

If the burner is blocked for one of the reasons mentioned above,

the screen display alternates between a 9 followed by the

temperature (two last digits) and b with the error code.

664Y2800.E

EN • 24

Page 25

MCBA PARAMETERS FOR THE SPECIALIST

SETTING THE MCBA PARAMETERS

Parameter Mode

To access Parameter mode when the system is in Pilot mode, press MODE once.

To scroll through the list of parameters, simply press “step”. To modify a parameter value, use the + or - keys.

Then press “Store” to save the value you just changed. The screen flashes once to confirm the data has been saved.

To activate the parameters you changed, press MODE once more (which brings you into Info mode). However, if you do not press a

key, the system returns to Pilot mode after 20 minutes and automatically enables the changes.

Key Screen

MODE

Factory setting

Key Screen Description of parameters

HeatMaster

35 TC

®

HeatMaster

85 TC

®

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

STEP

STEP

STEP

STEP

Adjusting the hot water temperature

Production

of hot water

Turn On/

Turn Off

the heating

Maximum temperature in

Central Heating mode

00 = Stop

01 = Start

00 = Stop

01 = Start

664Y2800.E

EN • 25

Page 26

MCBA PARAMETERS FOR THE SPECIALIST

REQUEST FOR INFORMATION

ON THE INSTALLATION

Info Mode

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

To switch from Standby to Info mode, press Mode twice.

Key Screen

MODE

MODE

Key Screen

STEP

Press STEP until the system

displays the information you

need. The point located behind

the first position flashes to

indicate that the boiler is in

INFO mode.

Description of

parameters

Boiler temperature T1

[Top of the primary]

ENTERING THE CODE

Code Mode

You can access the following parameters by entering the service

code:

• Parameters 5 - 42

• Communication mode

• Fan Speed mode

• ERROR mode

To access Code mode, press

MODE and STEP simultaneously

[only from Standby mode!].

MODE STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

Boiler temperature T2

[Top of the primary]

Hot water temperature T3 in °C

[Bottom of the hot water tank]

Outdoor temperature T4 in °C

Flue gas temperature

Calculated boiler

temperature in °C

Rate of increase of T1

temperature in °C/s

Rate of increase of T2

temperature in °C/s

Press STEP once and the system displays C

in position 1, followed by arbitrary

characters in positions 3 and 4.

STEP

Press + or - to change the code.

+ -

or

Press STORE, the screen flashes briefly

to indicate that the code has been accepted.

STORE

Press MODE until the system

displays the correct mode.

STEP

STEP

664Y2800.E

Rate of increase in the hot water

temperature in °C/s

Flow temparature of the heating

circuit (with module AM3-11 only)

Only ACV authorised installers know the access code.

For further information, please contact our after-sales

department.

EN • 26

Page 27

MCBA PARAMETERS FOR THE SPECIALIST

MCBA PARAMETERS WITH CODE RESTRICTED ACCESS

Factory setting

Key Screen Description of parameters HM 35 TC HM 85 TC

Minimum temperature of the top part of the boiler in heating mode

when using an outdoor sensor

STEP

STEP

STEP

STEP

STEP

In order to avoid cycling between heating and hot water mode, it is

preferable to set that parameter higher than DHW set point [Para 1]

Minimum outdoor temperature [adjust the heating curve]

Maximum outdoor temperature [adjust the heating curve]

Frost protection temperature

Correction of outdoor temperature

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

STEP

STEP

STEP

STEP

STEP

STEP

Blockage T

0 = Disabled

Acceleration time lag

00 = Stop [minute]

Night reduction heating (°C)

Natural gas

Maximum number of fan revolutions in CH mode

[rpm x 100]

Propane

Natural gas

Maximum number of fan revolutions in CH mode

[rpm /min.]

Propane

Natural gas

Max. number of revs in domestic hot water mode

[rpm x 100]

Propane

STEP

STEP

664Y2800.E

Maximum number of fan revolutions in domestic

Natural gas

hot water mode [rpm]

Propane

Natural gas

Minimum number of fan revolutions [rpm x 100]

Propane

EN • 27

Page 28

MCBA PARAMETERS FOR THE SPECIALIST

Factory setting

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Key Screen Description of parameters HM 35 TC HM 85 TC

STEP

STEP

STEP

STEP

STEP

STEP

Gaz naturel

Minimum number of fan revolutions [rpm]

Propane

Gaz naturel

Number of fan revolutions at ignition [rpm x 100]

Propane

CH pump over-run

0 = 10 sec. [step = 1 minute]

Domestic hot water pump over-run time

[step = 10.2 sec]

Central Heating modulation hysteresis enabled

Central Heating modulation hysteresis disabled

STEP

STEP

STEP

STEP

STEP

STEP

STEP

Domestic hot water modulation hysteresis enabled

Domestic hot water modulation hysteresis disabled

Detection of domestic hot water hysteresis enabled

Detection of domestic hot water hysteresis disabled

Central Heating blockage time

[sec. x 10,2]

Domestic hot water blockage time

[sec. x 10,2]

Domestic hot water ➙ Central Heating

blockage time [sec. x 10,2]

664Y2800.E

EN • 28

Page 29

MCBA PARAMETERS FOR THE SPECIALIST

Factory setting

Key Screen Description of parameters HM 35 TC HM 85 TC

Re-modulate the difference T1 - T2

STEP

Bus address

STEP

STEP

STEP

[-1 = disabled]

Temperature increase set point

for the production of hot water

00 : High temperature circuit - heating pump controlled by room

thermostat - hot water priority active

10 : Controlled circuit (outside sensor + AM3-11 module) - heating

pump controlled by room thermostat - hot water priority active

21 : Controlled circuit (outside sensor + AM3-11 module) - heating

pump runs continuously - night reduction possible - hot water

priority active

50 : Controlled circuit (outside sensor + AM3-11 module) - heating

pump controlled by room thermostat - hot water priority not

active

61 : Controlled circuit (outside sensor + AM3-11 module) - heating

pump runs continuously - night reduction possible - hot water

priority not active

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

STEP

STEP

STEP

STEP

STEP

STEP

STEP

Selection of the type of hot water production - That parameter is

fixed in a HeatMaster® TC and must not be changed

Manual fan speed

First position: PWM pump level during burning in, not used

Second position: PWM pump level during over-run time, not used

T set hold boiler warm

Maximum temperature for the 2nd heating circuit

Minimum temperature for the 2nd heating circuit

2nd circuit temperature hysteresis

STEP

664Y2800.E

First position: Special pump [0 = disabled]

Second position: Minimum disable cycle [0 = disabled]

EN • 29

Page 30

MCBA PARAMETERS FOR THE SPECIALIST

COMMUNICATION MODE [with code]

When in this mode, the system displays the communication

between the boiler and the control module, the optional interface

kit or the optional programmable room thermostat.

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Key Screen

MODE

Key Screen

STEP

Description of

parameters

No communication

Communication between the

boiler module and the optional

control modules only

Communication between all the

devices connected

ERROR MODE [with code]

ERROR mode indicates the most recent error, as well as the status

of the boiler and its readings at the time this error occurred.

Key Screen

MODE

Key Screen

STEP

STEP

Description of

parameters

Code error of the last lock-out

Status of the boiler at the time

of the error

FAN MODE [with code]

Key Screen

MODE

STEP

Description of

parameters

Fan speed

The current fan speed is

5.500 rpm.

Temperature T1 at the time

of the error

STEP

Temperature T2 at the time

of the error

STEP

Hot water temperature T3 at

the time of the error

STEP

Outdoor temperature T4 at the

time of the error

STEP

664Y2800.E

EN • 30

Page 31

MCBA PARAMETERS FOR THE SPECIALIST

SAFETY STOP [ERROR mode]

To unlock the system:

If a fault occurs while the appliance is running, the system locks

and the screen starts to flash. The first character is an E and

the next two characters give the code for this fault, as illustrated

in the table below.

Codes Description of the fault Resolution of the fault

Abnormal flame signal

No flame signal after five attempts at firing the boiler

Rectifier or gas valve error Replace the rectifier or gas valve

Persistent lock Press “RESET”

Internal error

EPROM error

• Press RESET on the screen.

• Contact your installer if the fault happens again.

- Check the wiring (short-circuit in the 24V wiring)

- Check the electrode

- Replace the MCBA (water damage)

- Check the ignition cable

- Check the electrode and the position of the electrode

- Check that there is gas at the burner.

If the problem persists after two RESET attempts,

replace the MCBA.

If the problem persists after two RESET attempts,

replace the MCBA.

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Max input, thermostat open or 24V fuse gone.

Internal error

T1 > 110°C

T2 > 110°C - Check the NTC wiring and replace if necessary.

T1 gradient too high

No fan signal present

The tacho signal of the blower does’nt go to zero.

- Check the wiring

- Check the 24V fuse on the MCBA.

- Shunt12-13 missing

If the problem persists after two RESET attempts,

replace the MCBA.

- Check the NTC wiring and replace if necessary.

If NTC1 is OK, please verify that the water flows trough the

boiler.

- Check that the pump is turning.

- If there is no problem with the pump, drain the system.

- Check the fan control connection

- Check the fan wiring

If the problem persists after two RESET attempts,

replace the MCBA.

- Check that the convection flow through the chimney is not

high enough to rotate the blower.

If not, exchange the blower.

664Y2800.E

NTC1 short-circuit

NTC2 short-circuit

- Check the connection of the NTC1 sensor

- Check the wiring of the NTC1 sensor

If the problem persists, replace the NTC1 sensor

- Check the connection of the NTC2 sensor

- Check the wiring of the NTC2 sensor

If the problem persists, replace the NTC2 sensor

EN • 31

Page 32

MCBA PARAMETERS FOR THE SPECIALIST

Codes Description of the fault Resolution of the fault

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

NTC3 short-circuit

NTC1 connection open

NTC2 connection open

NTC3 connection open

- Check the connection of the NTC3 sensor

- Check the wiring of the NTC3 sensor

If the problem persists, replace the NTC3 sensor

- Check the connection of the NTC1 sensor

- Check the wiring of the NTC1 sensor

If the problem persists, replace the NTC1 sensor

- Check the connection of the NTC2 sensor

- Check the wiring of the NTC2 sensor

If the problem persists, replace the NTC2 sensor

- Check the connection of the NTC3 sensor

- Check the wiring of the NTC3 sensor

If the problem persists, replace the NTC3 sensor

Internal error

Flue gas temperature too high (NTC5)

Error while reading the parameters

Problem with the power supply to the fan

If the problem persists after two RESET attempts,

replace the MCBA.

- Check the connection of the NTC5 sensor

- Check the wiring of the NTC5 sensor

If the problem persists, replace the NTC5 sensor

Press RESET

If the error persists, replace the MCBA.

- Check the MCBA power supply voltage.

If it is OK, replace the fan.

664Y2800.E

EN • 32

Page 33

664Y2800.E

Page 34

HeatMaster® 35 TC

537D3041

557A0054

257F1071

537DZ023

557A0095

557A0026

537D4033

537D4020

557D6039

537D6090

51700061

557A0048

537DZ025

557A0058

537D4034

507F4164

664Y2800.E

Page 35

HeatMaster® 85 TC

557A0026

537D3033

557A0054

257F1069

537DZ020

537D4033

537D4037

557D6039

537D4028

557A0095

51700062

557A0065

537DZ019

557A0066

507F4164

664Y2800.E

Page 36

HeatMaster® 35 TC

5476G008

557A3001

5476G008

547D3018

507F4111

507F3046

537D6237

39438027

557A5005

55426017

557A1056

557A4009

5476G008

664Y2800.E

55426001

557A8002

Page 37

557A7006

HeatMaster® 85 TC

507F4137 507F0040

5476G008

557A3001

537DC000

5476G008

537D6258

5476G003

557A7006

39438046

557A1056

557A5005

5476G008

557A4007

55426017

664Y2800.E

55426001

557A8002

Page 38

HeatMaster® 35 - 85 TC

HM 35 TC : 21475425

HM 85 TC : 21475426

HM 35 TC : 21474425

HM 85 TC : 21474426

HM 35 TC : 2147C425

HM 85 TC : 2147C426

HM 35 TC : 21471425

HM 85 TC : 21471426

HM 35 TC : 21478425

HM 85 TC : 21478426

HM 35 TC : 21471425

HM 85 TC : 21471426

664Y2800.E

HM 35 TC : 21473425

HM 85 TC : 21473426

HM 35 TC : 21477425

HM 85 TC : 21477426

HM 35 TC : 21476425

HM 85 TC : 21476426

Page 39

HeatMaster® 35 - 85 TC

54763017 54766016

54766017

537D3039

537D3020

1080080

547D3021

1080060

664Y2800.E

HM 35 TC : 5476G042

HM 85 TC : 5476G043

Page 40

HeatMaster® 35 TC - (Ø 80/125 mm)

HeatMaster 35 TC

A

537D6184

B

537D6185

C

537D6186 L. 250 mm

D

537D6187 L. 500 mm

E

537D6188 L. 1000 mm

F

537D6189 L. 325 / 400 mm

G

537D6190 43° - 45°

H

537D6191 87° - 90°

I

537D6193

J

537D6192

K

537D6232

L

537D6182

M

537D6194 Ø 390 mm

N

537D6183 Ø 125 mm

C13 C33

A

B

M L

Ø 80/125 mm - 2 x Ø 80 mm

G

D

H

E

N

F

C

I

2

1O3

bar

4

J

664Y2800.E

K

Page 41

HeatMaster® 85 TC - (Ø 100/150 mm)

HeatMaster 85 TC

A

537D6197

B

537D6198

C

537D6199 L. 250 mm

D

537D6200 L. 500 mm

E

537D6201 L. 1000 mm

F

537D6202 L. 325 / 400 mm

G

537D6203 43° - 45°

H

537D6204 87° - 90°

I

537D6206

J

537D6205

K

537D6207

L

537D6209

M

537D6208 Ø 430 mm

N

537D6210 Ø 150 mm

C13 C33

A

B

M L

Ø 100/150 mm - 2 x Ø 100 mm

G

D

H

E

N

F

C

I

2

1O3

bar

4

J

664Y2800.E

K

Page 42

664Y2800.E

Loading...

Loading...