ACV HeatMaster71, HeatMaster101, HeatMaster201 INSTALLATION OPERATING AND SERVICING INSTRUCTIONS

Page 1

®

HeatMaster

Installation, operating and

servicing instructions

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

HeatMaster

HeatMaster

HeatMaster

®

71

®

101

®

201

664Y2500.B

EN • 1

Page 2

INDEX

IMPORTANT NOTES 3

Who should read these instructions 3

Symbols 3

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Recommendations 3

Certification 3

Important notes 3

DESCRIPTION 4

Working principle 4

Temperature control 4

Building characteristics 4

Frost protection 4

Packaging 4

USER GUIDE 6

Use of the boiler 6

Setting the parameters 7

TECHNICAL CHARACTERISTICS 8

General characteristics 8

Water quality 8

Gas category 9

Domestic hot water performance 9

ELECTRICAL CONNECTION 10

Electrical supply 10

Alarm module 10

HeatMaster® 71-101wiring diagram 12

HeatMaster® 201 wiring diagram 13

INSTALLATION 14

Dimensions 14

Boiler Room 15

Chimney connection 16

Domestic hot water connection 18

Heating connection 19

Gas connection 19

BURNER CHARACTERISTICS 20

ACV BG 2000-M air/gas pre-mix burners 20

INSTALLATION AND COMMISSIONING 22

Filling of domestic hot water and heating circuits 22

MAINTENANCE 23

Annual maintenance 23

Boiler maintenance 23

Maintenance of safety devices 23

Burner maintenance 23

Draining of the boiler 23

MCBA PARAMETERS FOR THE SPECIALIST 24

Standby Mode 24

Setting the parameters 25

System information 26

Entry of the maintenance code 26

Setting the parameters: only accessible using the code 27

Communication mode 30

Error Mode 30

List of error codes + solutions 31

PARTS LIST at the end of the instructions

664Y2500.B

EN • 2

Page 3

IMPORTANT NOTES

WHO SHOULD READ THESE INSTRUCTIONS

These instructions should be read by:

- the design engineer/consultant

- the user

- the installer

- the service engineer

SYMBOLS

The following symbols are used in this manual:

Essential instruction for the correct

operation of the installation.

Essential instruction for the safety

of persons and the environment.

Electrocution hazard: use a qualified

technician.

• Defective parts can only be replaced with original factory

parts. You will find a list of spare parts and their ACV

reference number at the end of this manual.

• The burners are pre-adjusted in the factory for natural gas

[equivalent to G20].

• Specific regulation in Belgium:

The CO2, gas flow, air flow and air/gas supply parameters

are adjusted in the factory and cannot be changed in Belgium,

except for type 1 2E(R)B boilers.

• Before carrying out any work on the boiler, it is important to

isolate the electrical supply to the unit.

• The user must not attempt to gain access to the components

inside the boiler or the control panel.

CERTIFICATION

The appliances bear the “CE” mark, in accordance with the

standards in force in the various countries [European Directives

92/42/EEC “Efficiency”, 90/396/CEE “Gas Appliances”].

These appliances also bear the Belgian gas boiler quality label

“HR+”[gas boiler].

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Burn hazard.

RECOMMENDATIONS

• Before installing and bringing the boiler into service, first

carefully read this manual.

• It is prohibited to modify the interior of the appliance in any

way, without the manufacturer’s prior written agreement.

• The boiler must be installed by a qualified engineer, in

accordance with applicable local standards and local codes

in force.

• Failure to follow the instructions describing test operations

and procedures could result in personal injury or a risk of

environmental pollution.

• In order to ensure the appliance operates safely and

correctly, it is important to have it serviced by an approved

contractor.

• If there is a problem please contact your contractor for

advice.

• In spite of the strict quality standards that ACV applies to

its appliances during production, inspection and transport,

faults may occur. Please immediately notify your approved

contractor of any faults. Remember to indicate the fault

code as it appears on the screen.

IMPORTANT NOTES

IF YOU SMELL GAS:

- Isolate the gas supply immediately.

- Ventilate the room (Open the windows).

- Do not use electrical appliances and do not operate switches.

- Notify your gas supplier and/or your installer immediately.

This manual forms part of the items delivered with the appliance

and must be given to the user to keep in a safe place!

The system must be installed, commissioned, serviced and

repaired by an approved installer, in accordance with current

standards in force.

The manufacturer declines all liability for any damage caused

as a result of incorrect installation or in the event of the use

of appliances or accessories that are not specified by the

manufacturer.

The manufacturer reserves the right to change the

technical characteristics and features of its products

without prior notice.

The availability of certain models as well as their

accessories may vary according to markets.

664Y2500.B

EN • 3

Page 4

DESCRIPTION

WORKING PRINCIPLE

The HeatMaster® is a high performance hot water producer

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

using indirect heat transfer due to it’s Tank-in-Tank technology.

At the centre of the HeatMaster® there is a stainless steel

cylinder through which the flue tubes pass. It is surrounded by

a mild steel shell containing the primary water (neutral fluid).

The outer shell extends down to the combustion chamber and

also surrounds the flue gas tubes. The heat exchange surface

is therefore larger than that of traditional direct fired hot water

boilers.

A circulating pump installed on the primary circuit moves the

water around the tank, heating rapidly and maintaining it at a

constant temperature across the primary circuit.

The burner heats the primary fluid which indirectly heats

the stainless steel cylinder containing the hot water. As with

all Tank-in-Tank systems, the cylinder is corrugated over its full

height and suspended in the HeatMaster® by its hot and cold

water connections.

The fact that the cylinder expands and contracts during use

and that the cold water is not in contact with the intense heat

from the burner flame means that the build-up of lime scale is

prevented.

This resistance to lime scale, along with the corrosion resistance

of the stainless steel, eliminates the need for sacrificial anodes.

The HeatMaster® has a major advantage over other hot water

boilers: it heats hot water with a primary circuit, which allows the

primary fluid to also be used for heating.

The connection of two, three, four or more HeatMaster® in a

cascade meets the most demanding requirements in hot water

and in heating.

Indeed, if it is used in combination with Smart, HR and Jumbo

cylinders, the HeatMaster® can respond to the most demanding

hot water requirements.

TEMPERATURE CONTROL

The HeatMaster® 201 are equipped with an electronic

controller MCBA [MicroproCessor Burner Automate], which

handles both the safety functions (ignition, flame monitoring

temperature limitation, etc,…) and the temperature control of

the boiler. This MCBA can also operate as a regulator governed

by outdoor temperature when the outside temperature sensor

is fitted.

However, this regulator can also operate with a standard room

thermostat (on/off). Combining this regulator with a room

thermostat provides temperature control governed by outdoor

weather conditions, with indoor compensation.

The user may access four parameters to adjust all the necessary

settings. By entering a specific maintenance code into the unit,

qualified installers may access certain parameters, in order to

adapt the boiler to special requirements. In principle, these are

factory preset for all normal applications.

CONSTRUCTION FEATURES

Outer body

The outer body containing the primary fluid is constructed from

carbon steel (STW 22).

TANK-IN-TANK accumulator/heat exchanger

The internal large surface ring-shaped inner tank for the production

of hot water is constructed from Chrome/Nickel 18/10 stainless

steel. It is corrugated over its height by an exclusive manufacturing

process and is entirely argon arc welded using the TIG (Tungsten

Inert Gas) method.

Combustion gas circuit

The gas combustion circuit is protected by paint and includes:

• Flue tubes

The HeatMaster® include 8 tubes (HeatMaster® 71-101)

and 15 tubes (HeatMaster® 201) in steel with an internal

diameter of 64 mm. Each tube is equipped with a stainless

steel turbulator designed to improve thermal exchange and

reduce flue gas temperature.

• Combustion chamber

The combustion chamber of the HeatMaster® models is

entirely water cooled.

Insulation

The boiler body is fully insulated by rigid polyurethane foam

with a high coefficient thermal insulation, sprayed on without the

use CFC’s.

Casing

The boiler is covered with a steel jacket which has been de-greased

and phosphated before being stove enamelled at 220 °C.

Burner

The HeatMaster® 71 - 101 - 201 models are always supplied with

a low NOx air/gas pre-mix burner ACV BG 2000-M.

FROST PROTECTION

The boiler is equipped with an integrated frost protection: as

soon as the boiler temperature [NTC1 probe] drops below 7°C,

the central heating pump is activated. As soon as the NTC1

temperature is lower than 3°C, the burner ignites until the

temperature exceeds 10°C. The pump continues to turn for

approximately 10 minutes. If an outside temperature sensor

is connected, the pump is activated as soon as the external

temperature goes under the pre-defined threshold.

In order to enable the HeatMaster® boiler to protect the system

against freezing, all the valves of the radiators and the convectors

should be completely open.

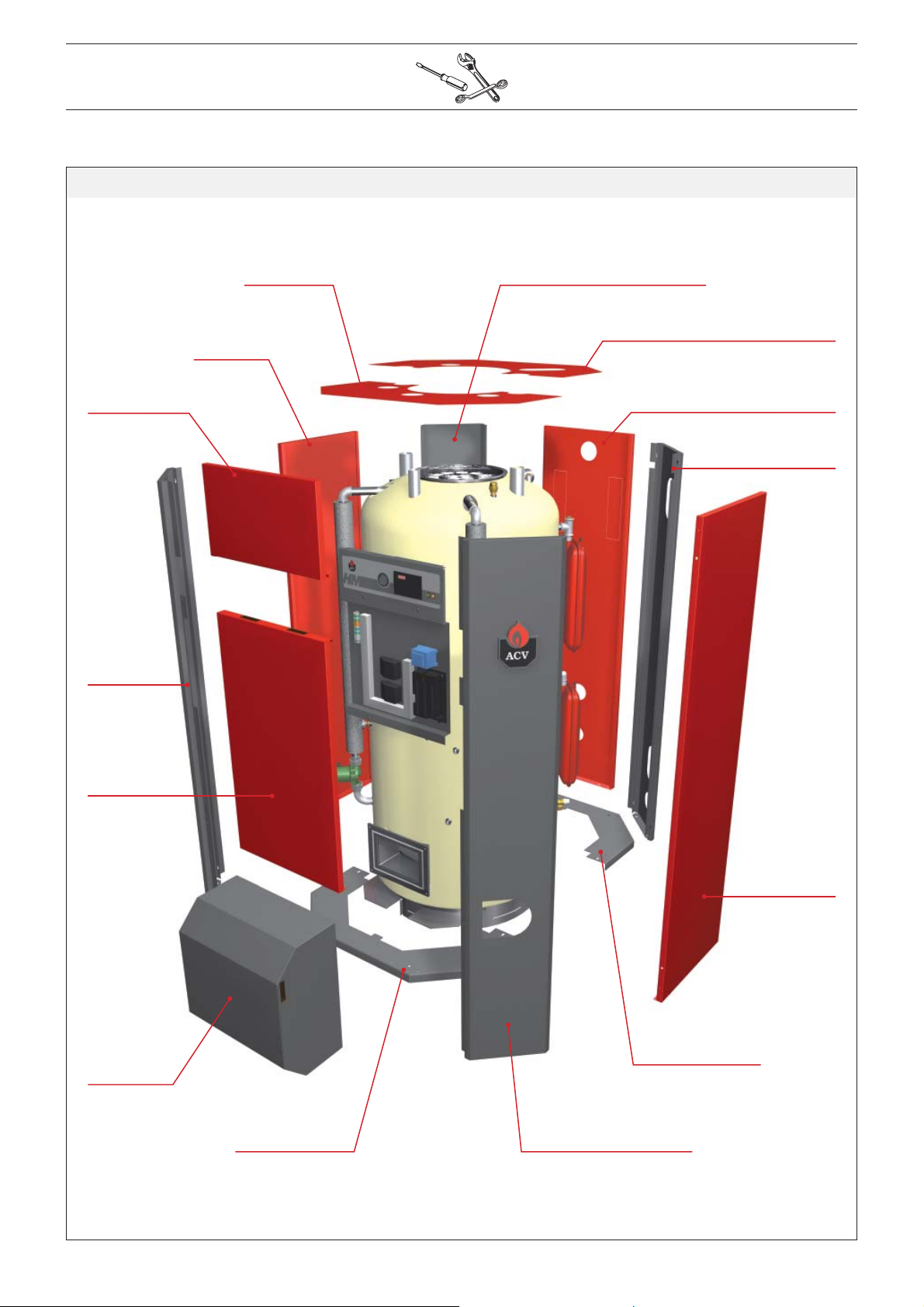

PACKAGING

HeatMasters® 71 and 101 are supplied completely assembled

and ready for use.

The HeatMaster® 201 is supplied in four separate packages.

664Y2500.B

• Package N° 1: Foam insulated body + hydraulic accessories +

control board.

• Package N° 2: Flue reducer.

• Package N° 3: The jacket.

• Package N° 4: The burner and its cover, door insulation and

sealing cord.

EN • 4

Page 5

DESCRIPTION

HeatMaster® 71 / 101

1. Cold water inlet and filling loop connection

2. Au t o-air vent

3. Primary NTC 1 and 2 sensors

4. Primary expansion tank (2x)

5. Filling loop connection to primary circuit

6. Low- wate r p res sur e s w itch

7. Thermometer bulb and pressure gauge connection

8. Primary safety valve

9. Char ging pum p

10. Rigid polyurethane foam insulation

11. Chimney reduction with vertical outlet

12. Turbulators

13. Heating flow

14. Domestic hot water outlet

15. Internal stainless steel tank

16. Stainless steel dry-well with ECS NTC 3 sensor

17. Primary tank

18. Flue tubes

19. Heating return

20. Drain cock

21. Combustion chamber

1

11

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

2

3

4

5

6

7

8

9

12

13

14

15

16

17

18

19

20

HeatMaster® 201

1. Chimney reduction with horizontal outlet

(vertical outlet optional)

2. Cold water inlet

3. Primary NTC 1 and 2 sensors

4. T&P valve connection (optional)

5. Au t o -air vent

6. Rigid polyurethane foam insulation

7. Internal stainless steel tank

8. Low - wat er pre ssure swi t ch

9. Pressure gauge connection

10. Thermostat control bulb

11. C h ar gi n g p u mp (2 x)

12. Stainless steel dry-well with ECS NTC 3 sensor

13. Domestic hot water outlet

14. Heating flow

15. Filling loop connection

16. Filling of primary circuit

17. Primary expansion vessel (4x)

18. Flue gas tubes and turbulators

19. Heating return

20. Drain cock

21. Primary safety valve

22. Primary circuit tank

23. Combustion chamber

10

10

11

21

1

12

2

3

4

5

6

13

14

15

16

17

7

18

8

19

9

20

21

22

23

664Y2500.B

EN • 5

Page 6

USER GUIDE

USE OF THE BOILER

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

ACV recommends that the boiler is inspected and serviced, if required, at least once a year by a competent and qualified

engineer. More frequent servicing may be required depending on boiler use, if this is the case consult your installer for

advice.

Starting the burner:

In normal operation, the burner starts automatically as soon as the boiler drops below the temperature setpoint.

The user must not attempt to gain access to the components inside the control panel.

HeatMaster

1. Temp e r at u r e - p r e s sure g a u g e

2. Display - MCBA cont roller

3. General switch

4. Summer/winter switch

®

control panel

Heating circuit pressure

It may be necessary to add water to obtain the correct

pressure required in the heating system. This pressure

is displayed on the temperature-pressure gauge on the

boiler control panel.

The minimum cold fill pressure should be 1 bar. The

precise operational pressure will depend on the height

of the building (See Bringing Into Service section - Filling up of

DHW and heating circuits)

.

1 2 43

If the pressure falls to below 1 bar, the boiler low water

pressure switch will stop the boiler until the pressure is

re-established.

Safety valves

If water is discharged from one of the safet y valves, stop

the boiler and call an engineer.

664Y2500.B

EN • 6

Page 7

USER GUIDE

SETTING THE PARAMETERS

• Domestic hot water temperature instruction:

(Hot water temperature)

- Press the “mode” key once: the screen indicates “PARA”.

- Press the “step”key: the first digit is 1 and the last two digits

indicate the current hot water temperature setting.

- To change this temperature, press “+” or “-” keys until the

temperature indicated by the last t wo digits is the desired

temperature.

- Press “store” to save the setting.

- Press the “mode” key twice to return to normal operating

mode [Stand-by).

• Enabling and disabling hot water mode:

(Hot water)

- Press “mode” once: the screen displays “PARA”.

- Press the “step” button twice: the first digit is 2 and the las t

two digits indicate the current setting.

00 = disabled; 01 = enabled.

- To change this parameter, press the “+” or “-” keys until you

reach the desired value:

00 = disabled; 01 = enabled.

- Press “store” key to save the setting.

- Press the “mode” key twice to return to normal operating

mode [Stand-by).

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

• Enabling and disabling central heating mode:

(Central heating)

- Press “mode” key once: the screen displays “PARA”.

- Press the “step” key three times: the first digit is 3 and the

last t wo digits indicate the current setting.

00 = disabled; 01 = enabled.

- To change this parameter, press the “+” or “-” keys until you

reach the desired value:

00 = disabled; 01 = enabled.

- Press “store” key to save the setting.

- Press the “mode” key twice to return to normal operating

mode [Stand-by).

• Setting the temperature of the central heating:

(the maximum temperature for the heating circuit)

- Press “mode” once: the screen displays “PARA”.

- Press the “step” key four times: the first digit is 4 and the last

two digits indicate the current temperature setting for the central heating.

- To change this t emperature, press the “+” or “-” keys until the

temperature indicated by the last t wo digits is the desired

temperature.

- Press “store” to save the setting.

- Press the “mode” key twice to return to normal operating

mode [Stand-by).

MCBA Display

Fault:

The temperature setting of the appliance and the safety functions of its various parts are constantly monitored by the MCBA

controller. If a fault occurs, the MCBA turns the unit off and indicates an error code: the display flashes and the first character

is an “E” followed by the fault code (see list of faults).

To reset the unit:

- Press the “reset” key on the display panel.

- If the fault code appears again, contact your contractor.

664Y2500.B

EN • 7

Page 8

TECHNICAL CHARACTERISTICS

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Central heating

Input power (Input)

Useful nominal power (output)

Maintenance loss of the nominal value at 60°C

Flue gas

Flue gas circuit loss

Net fl ue gas temperature

Mass fl ow rate of combustion products

CO

natural gas

2

Gas

Gas fl ow rate G20 - 20 mbar

Gas fl ow rate G25 - (25 mbar)

Gas fl ow rate G31 (30 / 37 / 50 mbar)

Gas connection [F]

Hydraulic parameters

Max operating temperature

Total capacity

Heating circuit capacity

DHW cylinder heat exchange surface

Max operating pressure of the heating circuit

Max operating pressure of the secondary circuit

Primary circuit pressure drop

Mbar

g/sec.

% CO

M

M

M

Bar

Bar

Mbar

kW

kW

3

3

3

m

HeatMaster® 71 HeatMaster® 101 HeatMaster® 201

20.0 - 69.9 25.0 - 107.0 60.0 - 220.0

18.4 - 63.0 23.0 - 96.8 56.4 - 200.2

%

°C

2

/h

/h

/h

Ø

°C

L

L

2

0.60 0.65 0.30

0.6 1.4 2.4

172 165 190

9.2 - 32.1 11.5 - 49.2 27,6 - 101,2

9.0 9,0 9.0

2.17 - 7.40 2.64 - 11.32 6.35 - 25.40

2.46 - 8.60 3.08 - 13.17 7.38 - 29.54

0.82 - 2.86 0.94 - 4.50 2.45 - 9.81

3/4” 1” 1”1/4

95 95 95

239 330 641

108 130 241

3.14 3.95 5.30

333

10 10 10

46 83 240

Electrical connection

V/Hz

IP

W

30 30 30

230 / 50 230 / 50 230 / 50

180 200 800

Class

Supply voltage

Maximum electrical consumption.

Drained weight Kg 282 320 550

WATER QUALITY

• Chlorides: < 150 mg/l (304)

< 2000 mg/l (Duplex)

• 6 ≤ ph ≤ 8

664Y2500.B

EN • 8

Page 9

GAS CATEGORY

TECHNICAL CHARACTERISTICS

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Natural gas categories

I 2E(S)B *

I 2E(R)B **

I 2Er

I 2L

I 2E

I 2ELL

I 2H

I 2HS

(*) HeatMaster® 71 - (**) HeatMaster ® 101 - 201

[G20] 20 mbar - [G25] 25 mbar

[G20] 20 mbar - [G25] 25 mbar

[G20] 20 mbar - [G25] 25 mbar

[G25] 25 mbar

[G20] 20 mbar

[G20] 20 mbar - [G25] 20 mbar

[G20] 20 mbar

[G20] 25 mbar

Propane gas categories

I 3P

I 3P

I 3P

I 3+ ***

I 3B/P ***

I 3B/P ***

(***) HeatMaster ® 201

[G31] 30 mbar

[G31] 37 mbar

[G31] 50 mbar

[G30 + G31] 28 / 30 / 37 mbar

[G30] 28 / 30 mbar

[G30] 50 mbar

BE FR NL LU DE

DK - NL

NO - IT

BE - CH - ES

FR - UK - IE

PT - FI - SE

IT - GR

AT - CH

CZ - ES

NL - DE

LU - HU

AT - CH - CZ - DK - ES - IT -

FI - UK - IE - PT - SE - GR

BE - CH

ES - FR

UK - IE

IT - PT

CZ - DK - ES

FI - FR - UK

IE - IT - NL

NO - PT - SE

HU

AT - CH

CZ - DE

FR

DOMESTIC HOT WATER PERFORMANCE

System operating at 80°C

Peak fl ow rate at 40°C [ΔT = 30°C]

Peak fl ow rate at 45°C [ΔT = 35°C]

Peak fl ow rate at 60°C [ΔT = 50°C]

Peak fl ow rate at 70°C [ΔT = 60°C]

Peak fl ow rate at 80°C [ΔT = 70°C]

Peak fl ow rate at 40°C [ΔT = 30°C]

Peak fl ow rate at 45°C [ΔT = 35°C]

Peak fl ow rate at 60°C [ΔT = 50°C]

Peak fl ow rate at 70°C [ΔT = 60°C]

Peak fl ow rate at 80°C [ΔT = 70°C]

Continuous fl ow rate at 40°C [ΔT = 30°C]

Continuous fl ow rate at 45°C [ΔT = 35°C]

Continuous fl ow rate at 60°C [ΔT = 50°C]

Continuous fl ow rate at 70°C [ΔT = 60°C]

Continuous fl ow rate at 80°C [ΔT = 70°C]

L/10’

L/10’

L/10’

L/10’

L/10’

L/60’

L/60’

L/60’

L/60’

L/60’

L/h

L/h

L/h

L/h

L/h

HeatMaster® 71 HeatMaster® 101 HeatMaster® 201

646 905 1745

543 777 1489

346 514 971

268 385 763

203 290 586

2133 3172 6690

1794 2680 5667

1219 1813 3534

971 1378 2554

710 1003 1723

1835 2776 6117

1573 2379 5039

1101 1665 2914

918 1241 2128

675 903 1468

Reheat time at 60°C

664Y2500.B

Minutes

23 22 23

EN • 9

Page 10

ELECTRICAL CONNECTION

Electrical supply

The boiler uses a single phase supply at 230V - 50 Hz. A double

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

pole isolator with a 6 Amp fuse or a 6 Amp MCB must be

fitted outside the boiler to allow the power to be shut off during

servicing and before any repairs are carried out.

Compliance

The installation must comply with current technical standards and

legislation in force.

Safety

The stainless steel cylinder must be connected separately to

earth.

The power to the boiler must be isolated before any

work is carried out on it.

Internal MCBA connections

X1: MCBA 230 V connection

X2: 24 V connector

X3: NTC connector

X4: NTC 6

X5: Communication

X7: Display connection

X8: Flat cable connection for alarm module AM3-2 and / or AM3-11

heating circuit control module

Alarm module

• Connect the alarm module ribbon cable “X7” to the MCBA

connector “X8”.

The volt free relays on the alarm module are activated as

described below.

1 - Alarm:

This contact closes if the MCBA is in safety shutdown position.

2 - External / burner gas valve - indication of function:

This contact closes if there is a heating request and the burner

is operating.

• Technical data:

- Ambient temperature: 0…60 °C

- Contact values: I

230 V (+10% / 15%) 50 Hz

If the inductor loads are connected it is necessary to

protect them against peak voltages (e.g. RC network).

RMS

1A

1 2

Alarm module (AM3-2)

The AM3-2 and AM3-11 alarm modules are only an option

for the HeatMaster® 71 / 101models.

Connection

for transformer

X1 X2 X5X4X3

X8

664Y2500.B

X7

MCBA

EN • 10

Page 11

ELECTRICAL CONNECTION

Second circuit module

(AM3-11)

Alarm module kit (optional)

1 2 3

1 - Heating pump switch:

This switch closes when there is a heating request.

2 - Four way valve closing switch (Three ways):

This switch closes if the MCBA regulator has to close the four

(3) way valve in accordance with the heating circuit start set

point.

3 - Four way (3 way) valve opening switch:

This switch closes if the MCBA regulator has to open the four (3)

way valve in accordance with the heating circuit start set point.

From delivery the heating circuit controlled by Module

AM3-11 is de-activated; to bring into service

parameter 34 needs to be modified (50 in place of

00) see pages 20 to 22.

ATTENTION: This parameter can only be changed by

approved ACV contractors.

Codes

AM3-2 : 10800094

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

HeatMaster® 71 / 101 Panel

AM3-11 : 10800095

1. Alarm module flat cable connection

(option)

2. AM3-2 module (option)

3. AM3-11module (option)

664Y2500.B

1

2 3

EN • 11

Page 12

5

ELECTRICAL CONNECTION

WIRING DIAGRAM: Heatmaster® 71 / 101

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

1. 230 Volt supply

2. 230 Volt outlet for AM3-11module (optional)

3. Charging pump

4. Heating pump

5. General switch

6. 230 Volt - 24 Volt transformer

7. MCBA controller

8. MCBA Display

9. Ignition and ionisation cable

10. SUMMER/winter switch

1 2 3 4

11. 7 pin burner plug

12. 4 pin burner plug

13. Room thermostat (optional)

14. Low water pressure safety switch

15. Primary NTC1 temperature sensor

16. Primary NTC2 temperature sensor

17. NTC3 hot water temperature sensor

18. NTC4 external temperature sensor (optional)

19. NTC6 2nd heating circuit temperature sensor (optional)

20. Zero volt of 24V circuit

B. Blue

Bk. Black

Br. Brown

G. Grey

Gr. Green

Or. Orange

Pk. Pink

R. Red

V. Violet

W. White

Y. Yellow

Y/Gr. Yellow/Green

Br

1 3 2

1 3 2

6

8

9

Y/Gr

M M

BBrY/GrBBr

Y/GrBBr

Y/GrBBr

4 6 5

7 9 8

4 6 5

7 9 8

B

B

Br

Br

B

Bk

X10.3

X10.1

X10.6

X10.7

Y/Gr

Br

5

X1.1

X1.2

X1.3

X1.4

X1.5

X1.6

Y/Gr

10 12 11

X12.

10 12 11

Y/Gr

B

Br

B

B

G

Y/Gr

Br Br

BBBr

BB

G

BrR

Y/Gr

Gr

Bk

Y

G

B

Y/Gr

Br

Y/Gr

G

Bk

B

Br

Y/Gr

7

X2.12

X2.11

X2.10

Bk

X2.9

X7

X2.8

X2.7

X2.6

X2.5

X2.4

X2.3

X2.2

X2.1

X3.6

X3.5

X3.4

X3.3

X3.2

X3.1

X4.3

X4.2

X4.1

X5.4

X5.3

X5.2

X5.1

B

Br

Bk

G

V

G

R

Gr

Bk

Y

G

B

Bk Br

Or

Br

R

Bk

Br

B

Bk

Or

V

G

Y/Gr

V

Bk

Bk

G

Y/Gr

R

Br

Or

B

10

Bk Y

BBBk

Or

Bk

Br

B

G

V

R

X11.

1 2 3 4 5 6 7 8 9 10 11 12

13

14

15

16

17

18 19

11

12

T8 T6 T7 B5 B4 T2 S3 T1 N L1

1 2 3 4 5 6 7 8 9 10 11 12 19

Br

Br

Br

B

Y/Gr

G

Gr

G

Br

Br

13

14

15

16

17

BUS B

18

BUS A

13

t

14

P

1

16

17

18

19

20

664Y2500.B

EN • 12

Page 13

ELECTRICAL CONNECTION

WIRING DIAGRAM: Heatmaster® 201

1. General switch

2. Module AM3-11:

3. Module AM3-2:

4. MCBA controller

5. 24 Volt Transformer

6. MCBA Display

7. Room thermostat (optional)

8. Low water pressure safety switch

9. NTC1 primary temperature sensor

10. NTC2 primary temperature sensor

11. NTC3 hot water temperature sensor

12. NTC4 outside temperature sensor (optional)

13. Summer/winter switch

14. NTC6 heating circuit start sensor (optional)

15. Heating circulator (not supplied)

16. Heating circulator (not supplied) if four way

valve motor driven on AM3-11

17. Charging pump

18. Charging pump

19. Booster circulating pump

20. Motor driven four way valve

21. Alarm switch

2

AM3 - 11

X1.1

X1.2

X2.1

X2.2

X3.1

X3.2

2

14 x 0,25mm

X7 X7

3

AM3 - 2

X1.1

X1.2

X2.1

X2.2

X3.1

X3.2

X3

7

t

01

02

03

04

G

V

X2.8

X2.10

X7

X1.3

X1.4

X1.1

X1.2

22. External gas valve switch/burner function

23. DHW mode function switch

24. Fan (BG 2000-M / 201)

25. Gas valve (BG 2000-M / 201)

26. Gas pressure switch (BG 2000-M / 201) (optional)

27. Charging pump control relay

9

12

8

10

P

11

06

05

07

08

09

10

11

13

Bk

B

Or

Br

R

X2.9

X3.1

X3.2

X3.3

X3.5

4

X10

MCBA

X1.5

X1.6

X2.4

14

BUS B

BUS A

O Volt

12

13

15

16

17

18

X2.11

19

G

Bk

V

X4.2

X5.1

X5.2

X2.5

X7

X2.6

X2.12

14

B

Br B W

Bk

Or

X5.4

X5.3

X4.3

X3.4

X2.1

X2.3

X2.2

2

14 x 0,25mm

6

2 x 2 fils

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

5

B. Blue

Bk. Black

Br. Brown

G. Grey

Or. Orange

R. Red

V. Violet

W. White

Y/Gr. Yellow/Green

Bk

Br

B

R

V

Or

W G

B

B

Bk

Bk

V

W

R

Or

V

G

Bk

W

R

W

V

Bk

B B

1

Bk

X1

Br

B

01

02

03

L

N

X2

B

02

01

R

Bk

B

1

3

27

2

4

Or Or

B

V

B

G

B

10

07

05

04

03

06

R

B

R

M

M1 M M2 M M3 M M4

Y/Gr

15

16

11

08

09

B

R

B

Y/Gr

17

B

W

B

Bk

5

13

A1 A2

6

14

W

B

W

B

13

14

12

R

B

Y/Gr

Y/Gr

18

B

W

B

15

17

18

16

R

B

M

M5

Y/Gr

19

W

Bk

W

R

R

W W

B R R W Bk G V

21

20

22

19

Y/Gr

23

24

N

M

M6

20

Ph

N

Ph

21

Or

Or

V

G

Bk

B W V R Bk

Or

L1 N T1

X4

28

27

26

25

N

Ph

3 x 0,75

T2

S3

B4

4 x 0,75

23

N

22

2 1 3 2 1 5 4

3 2 1

BG 2000-M/201

24

5 4 3 2 1

X5

Br

Br

2 x 0,75

B5

B

G

Or

T6

T7

T8

B

P

25

26

664Y2500.B

EN • 13

Page 14

DIMENSIONS

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

The boiler is delivered completely assembled, tested and packaged on a wood suppor t with anti-shock edges and protected

by a heat-shrunk plastic film.

On receipt and after having removed the packaging, check that the boiler is not damaged.

For transport, please refer to sizes and weights mentioned below.

AMm1743 2093 2085

BMm1630 2030 300

CMm680 680 1020

DMm937 937 1320

EMm680 680 1020

FMm390 390 600

GMm— — 1383

HMm1355 1750 590

JMm285 285 2117

KMm1720 2120 —

Weight when empty (kg] Kg 282 335 550

Heating connection [F] Ø 1”1/2 1”1/2 2 ”

DHW connection [M] Ø 1” 1” 2”

Gas connection [F] Ø 3/4” 1” 5/4”

INSTALLATION

HeatMaster® 71 HeatMaster® 101 HeatMaster® 201

HeatMaster® 71 - 101 HeatMaster® 201

C/2

A

C

D

G

F

K

HB

A J

B

F

D

G

H

510

C

664Y2500.B

E

J

E

302

338

250

250

190

EN • 14

Page 15

INSTALLATION

INSTALLATION AREA

- Make sure that all air vents are unobstructed.

- The boiler must be placed on a non-combustible surface.

- Do not store any flammable materials in this room.

- Do not store any corrosive materials, paint, solvents, salts, chlorine products or any other detergent products in the vicinity

of this appliance.

- If you smell gas, do not operate electrical switches, close the gas valve on the meter, ventilate the rooms and contact your

installer.

ACCESSIBILITY

The appliance must be placed in such a way that it is always easily accessible. Furthermore, the unit must have the following

minimum clearance around it.

HeatMaster® 71 - 101 HeatMaster® 201

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Min. 100mm Min. 100 mm

Min. 700 mm

Min. 100mm Min. 100 mm

Min. 700 mm

664Y2500.B

EN • 15

Page 16

INSTALLATION

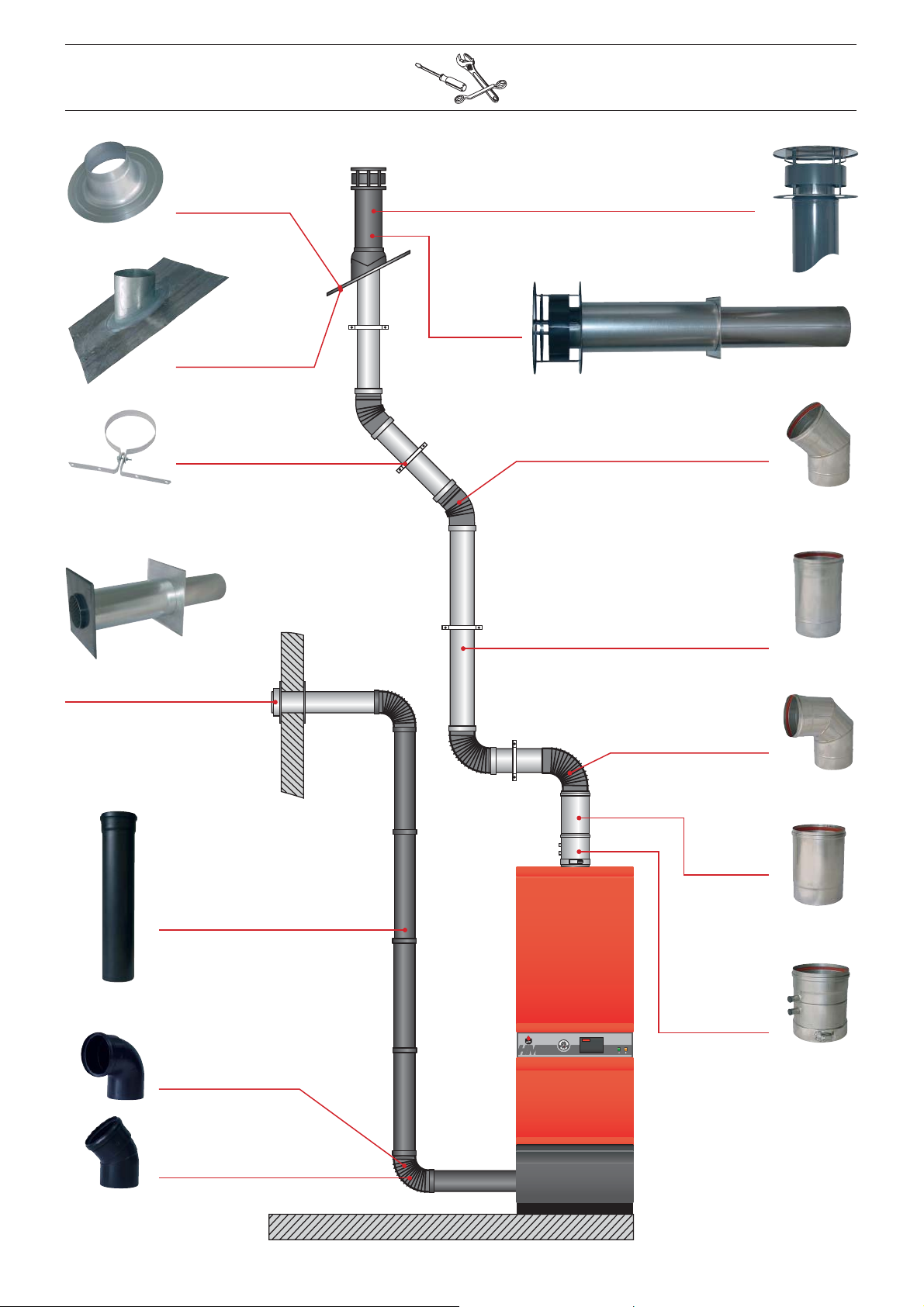

FLUE CONNECTION

- The flue connection must be carried out in compliance with the

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

standards in force, (example: Belgium NBN B61-001), taking

account of local energy supplier and fire regulations as well as

regulations relating to “noise pollution”.

- The flue pipe size must not be smaller than the size of the

boiler outlet connection.

Type of B23 chimney connection

The flue connection shall be achieved by means of a metal pipe

rising at an angle from the boiler towards the chimney. A flue

disconnection piece is necessary.

It must be easily removable to allow access to the flue gas tubes

for boiler maintenance.

The high performance of our boilers involves an exit of flue gas

at a low temperature. Accordingly, there is a risk that the flue

gasses may condense. In order to avoid this risk, it is strongly

recommended that your chimney is insulated.

Ventilations HM 71 HM 101 HM 201

Minimum supply of fresh air m3/h 126 194 436

2

High ventilation dm

Low ventilation dm

Ø minimum from the chimney duct

E = 5 m Ø F min. mm 189 234 350

F = 10 m Ø F min. mm 159 178 300

E = 15 m Ø F min. mm 150 150 270

2,4 3,20 2,45

2

2,0 2,0 7,30

Type C boiler connection type:

• C13: horizontal balanced flue connection

• C33: vertical balanced flue connection

• C53: connection in different pressure zones

• In concentric connection, the total length of the

connection is limited to 6 metres.

• In parallel connection, the total length of the

connection is limited to 12 metres.

A condensate recovery device must be provided for in

the boiler flue outlet, so as to avoid flue condensate

entering the boiler.

To avoid condensation water flowing from the terminal,

all horizontal pipe lengths must fall back towards the

boiler.

The total load loss (air inlet + flue gas outlet) cannot

exceed the value (Pa) indicated in the table below showing the

pressure drops for the various components.

Comment:

Given that regulations vary from one country to

another, the table above is given by way of indication

only.

PRESSURE DROP TABLE

HeatMaster

Air

80 mm

Straight pipe 1 m

90° bend

45° bend

Condensates recovery device

Terminal

Maximum pressure drop. (Pa)

This table is based on ACV equipment and cannot be applied elsewhere.

636433

15515101410

61626—

—2—4—5

20 10 10 10 22 20

®

71 HeatMaster® 101 HeatMaster® 201

Flue gases

150 mm

100 100 130

Air

100 mm

Flue gases

150 mm

Air

150 mm

Flue gases

250 mm

664Y2500.B

EN • 16

Page 17

A. High ventilation

B. Low ventilation

C. Draught regulator

D. Inspection cover

E. Height of the lined chimney

F. Diameter of the chimney

INSTALLATION

®

HeatMaster

120

71 - 101

150 min.

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

F

A

A. High ventilation

B. Low ventilation

C. Draught regulator

D. Inspection cover

E. Height of the lined chimney

F. Diameter of the chimney

C13

C33

C33

HeatMaster

E

®

201

C53

B23C53

A

A

C

D

B

F

664Y2500.B

C53

A

E

A

C53

C

D

B23

B

A

EN • 17

Page 18

INSTALLATION

DOMESTIC HOT WATER CONNECTION

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

The DHW tank (secondary) must filled and pressurised

before filling and pressurising the heating circuit

(primary).

The HeatMaster® can be connected directly to the DHW

circuit.

Flush the system before connecting the DHW circuit.

The system must be equipped with an approved safety unit

including a 7 bar safety valve, a non-return valve and a stop

valve.

During the heating process, the domestic water expands and

the pressure increases. As soon as the pressure exceeds the

safety valve set ting, the valve opens and ejects a small quantity

of water. The use of a DHW expansion tank, which must be

calculated according to storage volume, will avoid this and

reduce water hammer.

The hot water will reach temperatures greater

than 60°C, which can cause burns.

Therefore, the installation of a temperature

control valve on the hot flow immediately after

the appliance is advised.

Example of parallel connection

Recommended for applications with high continuous flow rate.

So as to balance out the passage of water in the

th r ee b oil ers, equ ali sing val ves are c ompulso r y in this

type of system.

Example of series connection

Preferable for high temperature applications with up to three

units.

If stop valves are used in the inst allation, they can cause

pressure waves when they are closed.

To avoid this, use devices to reduce water hammer.

6

2

12

1. Stop valve

2. Non-return valve

3. Pressure reducer

4. Safety valve

5. Domestic hot water expansion tank

6. Secondary circulation pump (if fitted)

7. Temperature control valve

8. Hot water outlet

9. Drain down valve

10. Stop valve for cleaning

11. Primary circuit filling valve

12. Temperature and pressure safety valve (UK only)

3

4

5

9

7

10

11

8

Example of connection

of HeatMaster® + storage cylinder

Recommended for applications requiring a high peak flow rate.

If there is a risk of low pressure in the hot water

circuit (installation of HeatMaster® on the roof of a

building), it is essential to install a vacuum breaker

device onto the cold water supply.

664Y2500.B

EN • 18

Page 19

INSTALLATION

HEATING CONNECTION

The DHW tank (secondary) must filled and pressurised

before filling and pressurising the heating circuit

(primary).

The HeatMaster® has two couplings at the rear which can serve

as a central heating circuit connection.

Coupling to a heating distribution network may reduce the hot

water performance.

Expansion

The HeatMaster® 201models are equipped with 4 8L tanks.

The expansion tanks are sized only for the “hot water” function.

In the case of primary circuit connection, it is necessary to

calculate the expansion capacity necessary for the total heating

system volume (Refer to the expansion tank manufacturer’s technical

instructions for a broader explanation).

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

ATTENTION

The primary safety valve is supplied with a plastic

discharge tube - this is a temporary fitting and should

be replaced.

The safety valve must be connected to the drain by a

rigid tube, in copper for example.

If a low heating temperature is required, the use of the

kit (code: 10800099) is required.

Connection for filling

A. Cold inlet connection and filling point.

The pressure of the HeatMaster® expansion tanks

must be adjusted to the same pressure as the

heating circuit expansion tanks.

1. Four way mixer valve

2. Circulator

3. Non-return valve

4. Heating isolating valves

5. Safety valve calibrated to 3 bar, with pressure gauge

6. Expansion tank

7. Drain valve

8. Primary circuit filling valve

9. MCBA Regulator, AM3-11 module

9. Pipe sensor (optional)

8

B. Primary circuit filling point (heating).

HeatMaster® 71 - 101

A

B

HeatMaster® 201

A

5

1

4

9

7

423

GAS CONNECTION

- The HeatMaster® 71/101/201 boiler s ar e equipped with

a BG 2000-M 71/101/201burner with a gas Ø 3/4” - 1”

and 1”1/4 connection [F] to connect a gas supply valve.

- The gas connections must comply with all applicable

standards (in Belgium: NBN D51-003).

- If there is a risk of dirt stemming from the gas network,

place a gas filter upstream of the connection.

664Y2500.B

B

6

- Purge the gas pipe and carefully check that there are no

leaks on the boiler’s internal and external pipes.

- Check the syst em’s gas pressure. Please refer to the

technical data table.

- Check the gas pressure and consumption when

commissioning the appliance.

EN • 19

Page 20

BURNER CHARACTERISTICS

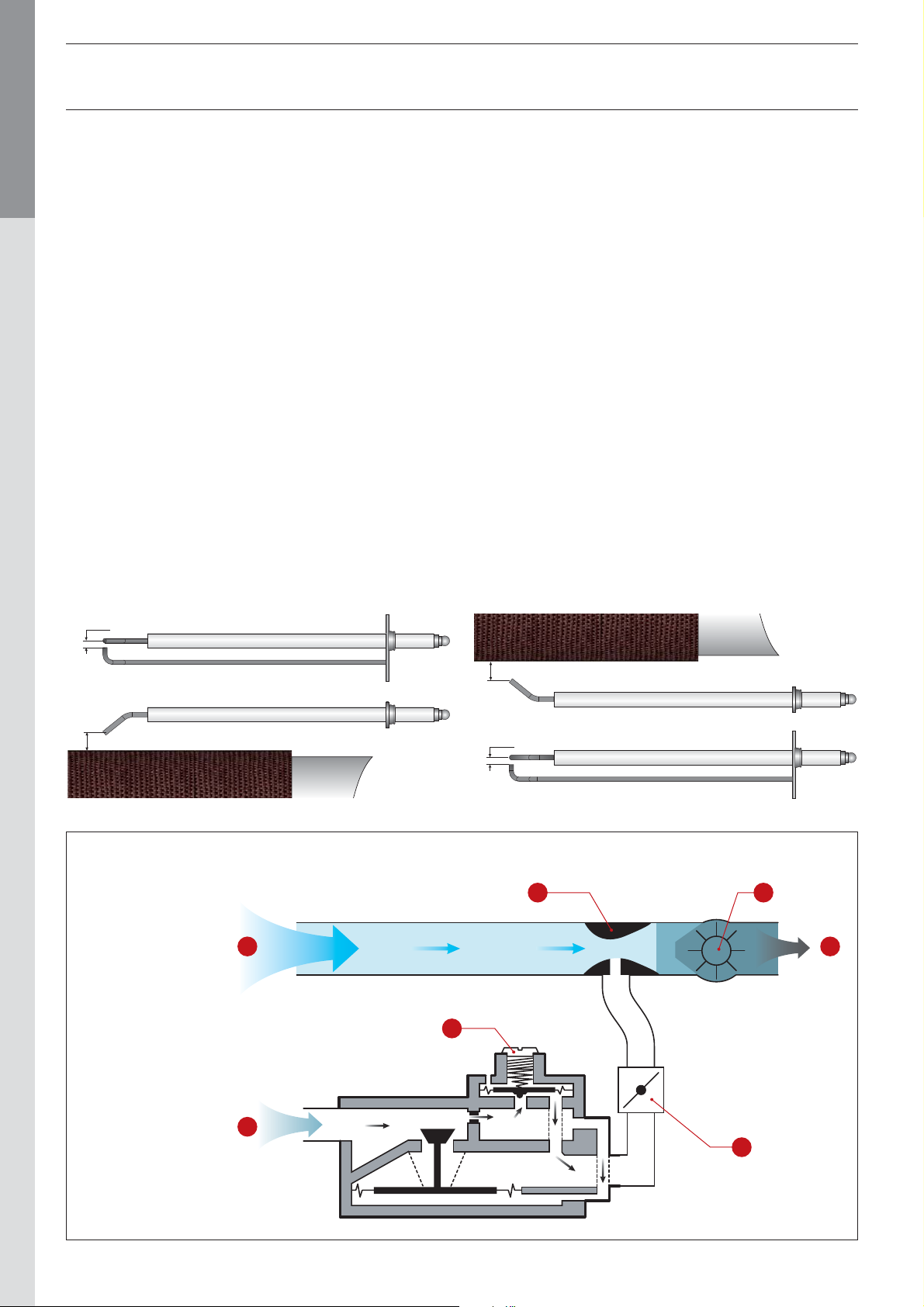

AIR/GAS PRE-MIX BURNERS

ACV BG 2000-M

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Description

The power continually adjusts itself according to demand; this

greatly improves the operating ef ficiency for heating and hot

water.

The burner tube is covered with a metal fibre (NIT), which,

besides its remarkable heat exchange capacity, guarantees

longer burner life.

The burner’s main components are:

- a variable speed fan

- an automatic ignition and flame detection system

- a gas valve and venturi tube set specially developed for low NOx

pre-mix air/gas burners

Gas pressure in the gas valve outlet is kept equal to the absolute

air pressure in the venturi tube inlet, corrected by the offset

adjustment on the regulator.

The fan pulls the combustion air through the venturi tube whose

neck is connected t o the gas valve outlet. The pressure differential

created at the neck of the venturi tube by the airflow rate induces

gas intake proportional to its level (the larger the air flow rate,

the greater the differential and there is a larger quantity of gas

intake). The air/gas combination is then introduced into the burner

via the fan.

HeatMaster® 71 - 101

This principle guarantees safe and quiet operation:

• In the event of low air flow, the differential across the

venturi tube falls, the gas flow rate diminishes, the flame

extinguishes and the gas valve closes: the burner is then in

safety mode.

• In the event of flue blockage or restriction, the air flow

rate falls, and there are then the same reactions as those

described before causing burner stop in safety mode.

®

• The BG 2000 -M burner installed on HeatMaster

controlled by a MCBA Honeywell controller which manages

both the burner safety function and its modulation according

to temperature.

HeatMaster® 201

models is

15

3 - 5

5

3 - 5

Air/gas mix control principle

C

A

D

E

F

A. Air

B. Gas

C. Venturi tube

D. Fan

E. Air - Gas mix

F. O ff se t a d j us t me n t s c r ew

G. Gas flow rate adjustment screw

664Y2500.B

B

G

EN • 20

Page 21

1. Bu r n e r t ub e

2. Ignition and ionisation electrode

3. Gas valve

4. Gas connection

5. Flame sight glass

6. Fan

7. V en t u r i t u be

BURNER CHARACTERISTICS

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

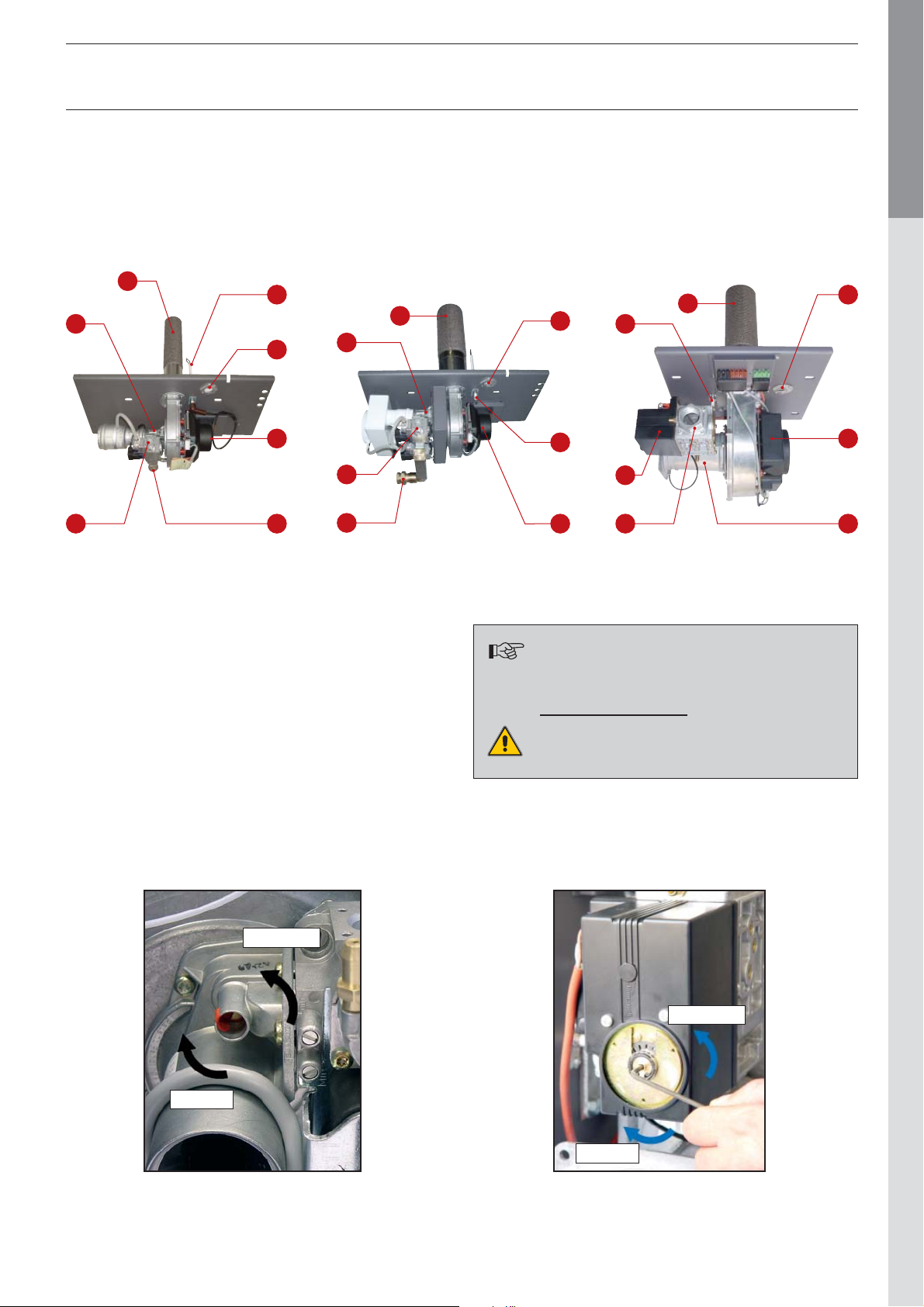

BG 2000-M/71

BG 2000-M/101

1

2

7

5

7

1

6

3

3 4

4

Burner adjustment

When the burner operates at full power, the CO2 must be 8.8%

to 9.2% (natural gas) or 10.5% to 10.6% (propane).

If necessary adjust the CO2 by turning the screw in the

clock wise direction to reduce and the anti-clock wise to increase.

(see photo)

BG 2000-M/201

1

5

2

2

3

6

The BG 2000-M burners are pre-adjusted for

natural gas in the factory.

Conversion to propane:

4 7

5

6

BG 2000-M/71 - 101

Increase

Reduce

Prohibited in Belgium.

BG 2000-M/201

Increase

Reduce

664Y2500.B

EN • 21

Page 22

BRINGING INTO SERVICE

FILLING OF DHW AND HEATING CIRCUITS

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

IMPORTANT

It is essential that the DHW cylinder is filled and

pressurised before filling the heating circuit.

1. Open the stop valve (1) and the outlet (8).

When the water flows from the outlet, the DHW cylinder is

filled and the outlet can be closed (8).

2. Fill the primary circuit (heating) and pressurise to 1 Bar.

3. Open the automatic air vent situated in the upper part of the

boiler.

IMPORTANT: the screw cap must be left loose to allow

future automatic venting to take place.

4. After venting the air from the system, bring the pressure up

to the static head plus 0.5 bar:

1.5 bar = 10m and 2 bar = 15 m.

5. Check that the electrical connection and the boiler room

ventilation are in accordance with the relevant standards.

2

3

12

6. Put the general switch to the ON position.

7. Adjust temperature set points via the MCBA display.

8. Check the gas supply pressure.

9. When the boiler is in operation, check that the flue

connections are gas tight.

10. After operating for five minutes, switch the boiler off and vent

the heating circuit again, maintaining a pressure of 1 bar.

11. Turn the appliance back on and check the combustion.

6

8

7

10

4

11

5

9

664Y2500.B

EN • 22

Page 23

MAINTENANCE

ANNUAL MAINTENANCE

ACV recommends that the boiler is inspected and serviced,

including the burner, at least once a year by a competent and

qu a l i f ied e n g i nee r...

More frequent servicing may be required depending on boiler

use, if this is the case consult your installer for advice.

BOILER MAINTENANCE

1. Turn the general switch on the control panel to OFF and

isolate the external electrical supply.

2. Close the gas supply valve.

Vertical flue gas outlet reduction:

3. Disengage and remove the flue connection to the boiler

4. Remove the flue reducer by un-tightening the nuts.

5. Extract the turbulators from the flue gas tubes for

cleaning.

6. Dismantle the fire door and withdraw the burner.

7. Brush the flue gas tubes.

8. Clean the combustion chamber and the burner.

9. Replace the turbulators, chimney reduction and flue

connection, and check that the seal on the flue reducer is in

good condition. Replace the seal if necessar y.

Horizontal flue gas outlet reduction:

Drainage of the heating circuit

1. Turn the general switch on the control panel to OFF position,

isolate the external electrical supply and close the gas

supply valve.

2. Close the isolation valves (4) or manually position the four

way valve (1) onto “0”.

3. Connect a flexible pipe to the drain valve (7).

4. Open the drain valve t o empty the primary circuit.

8

5

1

7

4

9

423

6

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

3. Remove the cover from the flue reducer by un-tightening the

nuts.

4. Extract the turbulators from the flue gas tubes for

cleaning.

5. Dismantle the fire door and withdraw the burner.

6. Brush the flue gas tubes.

7. Clean the combustion chamber and the burner.

8. Replace the turbulators, chimney reduction and flue

connection, and check that the seal on the flue reducer is in

good condition. Replace the seal if necessar y.

MAINTENANCE OF SAFETY DEVICES

- Check that all thermostats and safety devices are working

well.

- Check the safety valves of the heating and DHW circuits.

BURNER MAINTENANCE

- Check that the insulation and seal of the fire door are in

good condition - replace them if necessary.

- Check and clean the boiler and the electrodes.

Replace the electrodes if necessary (once a year for normal

use).

- Check that the safety valves are in good work ing order.

- Check the combustion (CO

, CO and burner pressure).

2

Drainage of the DHW circuit

1. Turn the general switch on the control panel to OFF position,

isolate the external electrical supply and close the gas

supply valve.

2. Lower the heating circuit pressure until the pressure gauge

indicates zero bar.

3. Close the valves (1) and (8).

4. Open the valves (9) and (10) (first of all 9 then 10).

5. Allow the hot water to flow to the drain.

6

12

2

3

4

5

8

7

10

11

DRAINING OF THE BOILER

The water flowing from the drain valve is

very hot and can cause very serious burns.

Make sure that nobody is near the hot

water discharge.

664Y2500.B

9

The drain valve (9) must be at ground level to allow the

cylinder to drain.

EN • 23

Page 24

MCBA PARAMETERS FOR THE SPECIALIST

STANDBY MODE

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Standby Mode

When the boiler is switched on, it starts up in Stand-by mode, as

shown in the figure above.

This is the standard mode of the MCBA. The MCBA automatically

returns to this mode after 20 minutes if no key is pressed on

the display. When one or more parameters were stored, the new

parameters will become active.

The first digit indicates the boiler’s current status, depending

on the situation of the boiler and the burner. The last two digits

indicate the boiler temperature.

Status Boiler function

Standby, no heat demand

Fan pre-purge / post-purge

Ignition

Operation of the burner for heating

Once the cause of the blocking has been resolved, the burner

starts up automatically after a maximum of 150 seconds.

Status Boiler function

Internal adjustment — Three-way valve

Burner on for holding boiler warm

Test function: max RPM in CH mode

Test function: min RPM in CH mode

Test function: burner on with fixed fan speed

Operation of the burner for domestic hot water

Waiting for signal from the air pressure switch

or to obtain number of start revolutions

The burner is off because the set value has been

reached. There is still a demand for heat

Pump over run after the heating demand

Pump over run after the hot water demand

Blocked burner:

• : T1 > 95°C

•

•

•

•

•

•

•

•

•

•

: T2 > 95°C

: T2 - T1 > 10°C after 90 seconds

: dT1/dt > maximum gradient T1

: low water pressure switch not closed

: no tachometer signal

: erroneous tachometer signal

: T1 - T2 > Δ max.

: Short circuit NTC 3

: interruption NTC 3

: waiting for fan to start

If the burner is blocked for one of the above reasons, the screen

display alternates between 9 and the temperature (last two

digits) and b with the error code (last two digits).

664Y2500.B

EN • 24

Page 25

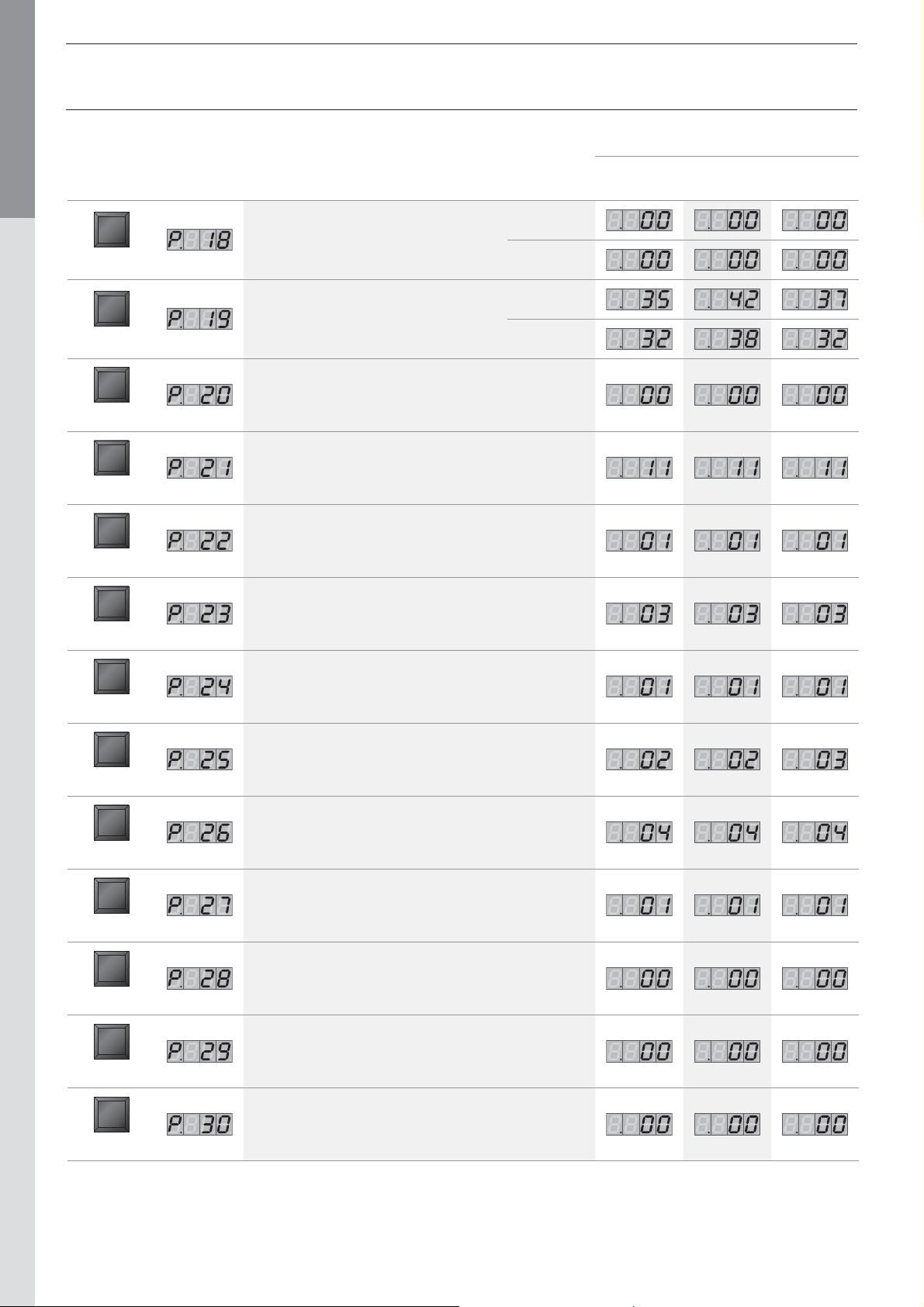

MCBA PARAMETERS FOR THE SPECIALIST

SETTING THE PARAMETERS

Parameter mode

To access Parameter mode when the system is in Standby mode, press the “MODE” key once.

To scroll through the list of parameters press “STEP”. To modify the value of the parameter, use the“+” or “-” keys.

Next, press the “STORE” to record the modified value. The screen will flash once to confirm the data has been saved.

To activate the modified parameters, press “MODE” key again (this will switch you to Info mode). However, if you do not press any key,

the system returns to Standby mode after 20 minutes and activates the changes.

Key Display

MODE

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Factory setting

Key Display Description of the parameters HM 71 HM 101 HM 201

Setting the hot water temperature

STEP

00 = Off

01 = On

00 = Off

01 = On

STEP

STEP

Hot water

generation

Switching

heating

On / Off

STEP

664Y2500.B

Maximum temperature in central heating mode

EN • 25

Page 26

MCBA PARAMETERS FOR THE SPECIALIST

INFORMATION ON THE INSTALLATION

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Info mode

To switch from Standby mode to Info mode,

press twice on “MODE”

Key Display

MODE

MODE

Key Display

T1 boiler temperature in °C

STEP

ENTERING THE CODE

Code mode

You can access the following parameters

by entering the service code:

• Parameters 5 through 42

• Communication mode

• Fan speed mode

• ERROR mode

Press the “STEP” key until you

see the desired information.

The dot located behind the

first position flashes to indicate

that the boiler is in Info mode.

To access Code mode, simultaneously press the MODE

and STEP keys. (Only from Stand-by mode!)

Description

of the parameters

MODE STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

T2 boiler temperature in °C

Domestic hot water temperature

T3 in °C

Outside temperature T4 in °C

Not used

Calculated boiler

temperature in °C

Speed of increase of T1

temperature in °C/s

Speed of increase of T2

temperature in °C/s

Press STEP once and the screen indicates “C”

in the first position, then random characters

in the third and fourth positions.

STEP

Press on the “+” or “-” key to select the code.

+ -

Or

Press the STORE key and the screen flashes briefly

to indicate that the code has been accepted.

STORE

Press the MODE key until the desired mode appears.

STEP

STEP

664Y2500.B

Rate of increase of hot water

temperature in °C/s

Central heating

circuit temperature

[with AM3-11 module only]

Only ACV approved installers know the access code.

For more information, please contact our after-sales

service.

EN • 26

Page 27

MCBA PARAMETERS FOR THE SPECIALIST

SETTING THE PARAMETERS:

Factory setting

only accessible with the code

Key Display Description of the parameters HM 71 HM 101 HM 201

Minimum boiler temperature using outdoor sensor

To avoid problems with the hot water function it is not

STEP

STEP

STEP

STEP

STEP

advised to adjust this parameter below 60°C

Minimum external temperature

[adjustment of the heating curve]

Maximum external temperature

[adjustment of the heating curve]

Frost protection temperature

Correction based on external temperature

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

STEP

STEP

STEP

STEP

STEP

STEP

Tblocking 0 = Disabled

Booster 00 = Stop - [minute]

Night time central heating reduction (°C)

Natural gas

Max. fan speed in heating mode

[rpm x 100]

Propane

Natural gas

Max. fan speed in central heating mode

[rpm]

Propane

Natural gas

Max fan speed in domestic hot water mode

(rpm x 100)

Propane

STEP

STEP

664Y2500.B

Max fan speed in domestic hot water mode

Natural gas

(rpm)

Propane

Natural gas

Min. fan speed [rpm x 100]

Propane

EN • 27

Page 28

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Key Display Description of the parameters HM 71 HM 101 HM 201

STEP

STEP

STEP

STEP

MCBA PARAMETERS FOR THE SPECIALIST

Factory setting

Natural gas

Min. fan speed [rpm]

Propane

Natural gas

Max fan speed during ignition [rpm x 100]

Propane

Central heating pump over run

0 = 10 sec. [min.]

Domestic hot water pump over run

[sec. x 10.2]

STEP

STEP

STEP

STEP

STEP

STEP

STEP

CH hysteresis on

CH hysteresis off

DHW hysteresis on

DHW hysteresis on

DHW detection hysteresis on

DHW detection hysteresis off

Central heating block time [sec. x 10.2]

STEP

STEP

664Y2500.B

Domestic hot water block time [sec. x 10.2]

DHW ➙ CH blocking time [sec. x 10.2]

EN • 28

Page 29

MCBA PARAMETERS FOR THE SPECIALIST

Factory setting

Key Display Description of the parameters HM 71 HM 101 HM 201

Difference T1 - T2 for modulation

STEP

BUS -1address = de-activated

STEP

Increase of the primary temperature set point to generate

STEP

STEP

hot water

00 = high temperature circuit - circulator controlled by room

thermostat - DHW priority active.

50 = controlled circuit [external sensor and AM3-11 module]

- circulator controlled by the room thermostat - DHW priority

is not active.

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

STEP

STEP

STEP

STEP

STEP

STEP

STEP

DHW production type:

This parameter cannot be modified

in any way on a HeatMaster

Manual fan speed (- 01 = modulation enabled)

Maintenance temperature

Maximum temperature of the heating circuit

(AM3-11 - four way valve)

Minimum temperature of the heating circuit

(AM3-11 - four way valve)

Heating circuit hysteresis temperature

(AM3-11 - four way valve)

®

Not used

STEP

664Y2500.B

1st position:

special pump [0 = disabled]

2nd position:

minimum disabling cycle [0 = disabled]

EN • 29

Page 30

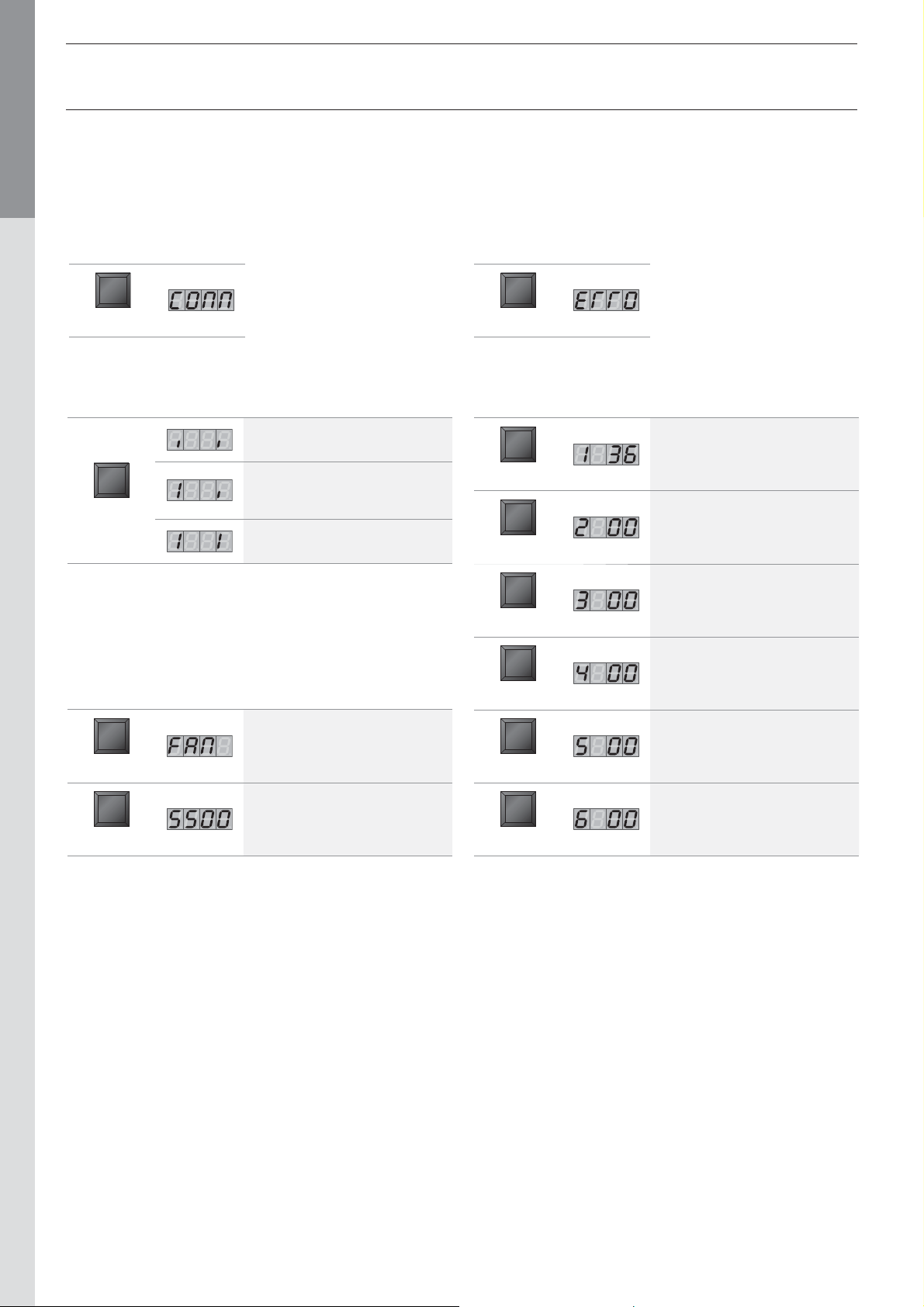

MCBA PARAMETERS FOR THE SPECIALIST

COMMUNICATION MODE [with code]

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

This mode displays communication between the boiler

and the control module, the optional interface kit

or the optional programmable room thermostat.

Key Display

MODE

Key Display

STEP

of the parameters

No communication

Communication between

the boiler module and the

optional control module

Communication between all

the connected devices

Description

ERROR MODE [with code]

The ERROR mode indicates the most recent error, as well

as the status of the boiler and the temperature values at

the time of this error.

Key Display

MODE

Key Display

Error code at last lockout.

STEP

Status of the boiler at the time

of the error

STEP

Description

of the parameters

Fan mode [with code]

Key Display

MODE

STEP

Description

of the parameters

Fan speed

The fan’s current speed

is 5500 rpm.

T1 temperature at the time

of the error

STEP

T2 temperature at the time

of the error

STEP

Hot water temperature T3

at the time of the error

STEP

Outdoor temperature T4

at the time of the error

STEP

664Y2500.B

EN • 30

Page 31

MCBA PARAMETERS FOR THE SPECIALIST

LIST OF ERROR CODES + SOLUTIONS

[in ERROR mode]

If a fault occurs during operation, the system locks out

and the screen starts to flash.

The first character is an “E” and the following two indicate

the fault code, as indicated in the table below.

Codes Description of the fault Resolution of the fault

Abnormal flame signal detected

No flame presence after five start-up attempts

Rectifier or gas valve error Replace the rectifier or gas valve

Persistent lockout Press “RESET”

Internal error

EPROM error

To unlock the system:

• Press “RESET” on the screen.

• If the fault is repeated continually, contact your

installer.

- Check the wiring (short circuit in the 24V wiring)

- Check the electrode

- Replace the MCBA (water damage)

- Check the ignition wiring

- Check the electrode and its position

- Check the gas supply to the burner

If the problem persists after two “RESET” attempts,

replace the MCBA

If the problem persists after two “RESET” attempts,

replace the MCBA

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

- If the primary water pressure is lower than 0.5 bar,

Low water safety or 24 V fuse damaged

Internal error

T1 > 110°C

T2 > 110°C - Check the NTC wiring and replace it if necessary

T1 gradient too high

No tachometer signal from the fan

The fan’s tachometer signal does not drop back to “0”

re-establish the pressure to a minimum of 0.8 bar

by adding water to the system

- Check the wiring

- Check the 24 Volt fuse of the MCBA

If the problem persists after two “RESET” attempts,

replace the MCBA

- Check the NTC wiring and replace it if necessary

- If the NTC 1 sensor is OK, check if there is water flow

in the boiler

- Check if the pump is running

- If there is no problem with the pump, vent the system

- Check the PWM connection

- Check the fan’s wiring

If the problem persists after two “RESET” attempts,

replace the fan, otherwise, change the MCBA

- Check the draft in the chimney.

If the draught is correct replace the ventilator

664Y2500.B

Short circuit NTC 1

Short circuit NTC 2

- Check the connection of the NTC 1 sensor

- Check the wiring of the NTC 1 sensor

If the problem persists replace the NTC 1 sensor

- Check the connection of the NTC 2 sensor

- Check the wiring of the NTC 2 sensor

If the problem persists, replace the NTC 2 sensor

EN • 31

Page 32

Codes Description of the fault Resolution of the fault

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

MCBA PARAMETERS FOR THE SPECIALIST

- Check the connection of the NTC 3 sensor

Short circuit NTC 3

NTC 1 connection open

NTC 2 connection open

NTC 3 connection open

- Check the wiring of the NTC 3 sensor

If the problem persists replace the NTC 3 sensor

- Check the connection of the NTC 1 sensor

- Check the wiring of the NTC 1 sensor

If the problem persists replace the NTC 1 sensor

- Check the connection of the NTC 2 sensor

- Check the wiring of the NTC 2 sensor

If the problem persists replace the NTC 2 sensor

- Check the connection of the NTC 3 sensor

- Check the wiring of the NTC 3 sensor

If the problem persists replace the NTC 3 sensor

Internal error

Error during reading of the parameters

Fan power supply problems

If the problem persists after two “RESET” attempts,

replace the MCBA

Press RESET

If the error persists, replace the MCBA

- Check the supply voltage of the MCBA

If you detect no problems with it, replace the fan

664Y2500.B

EN • 32

Page 33

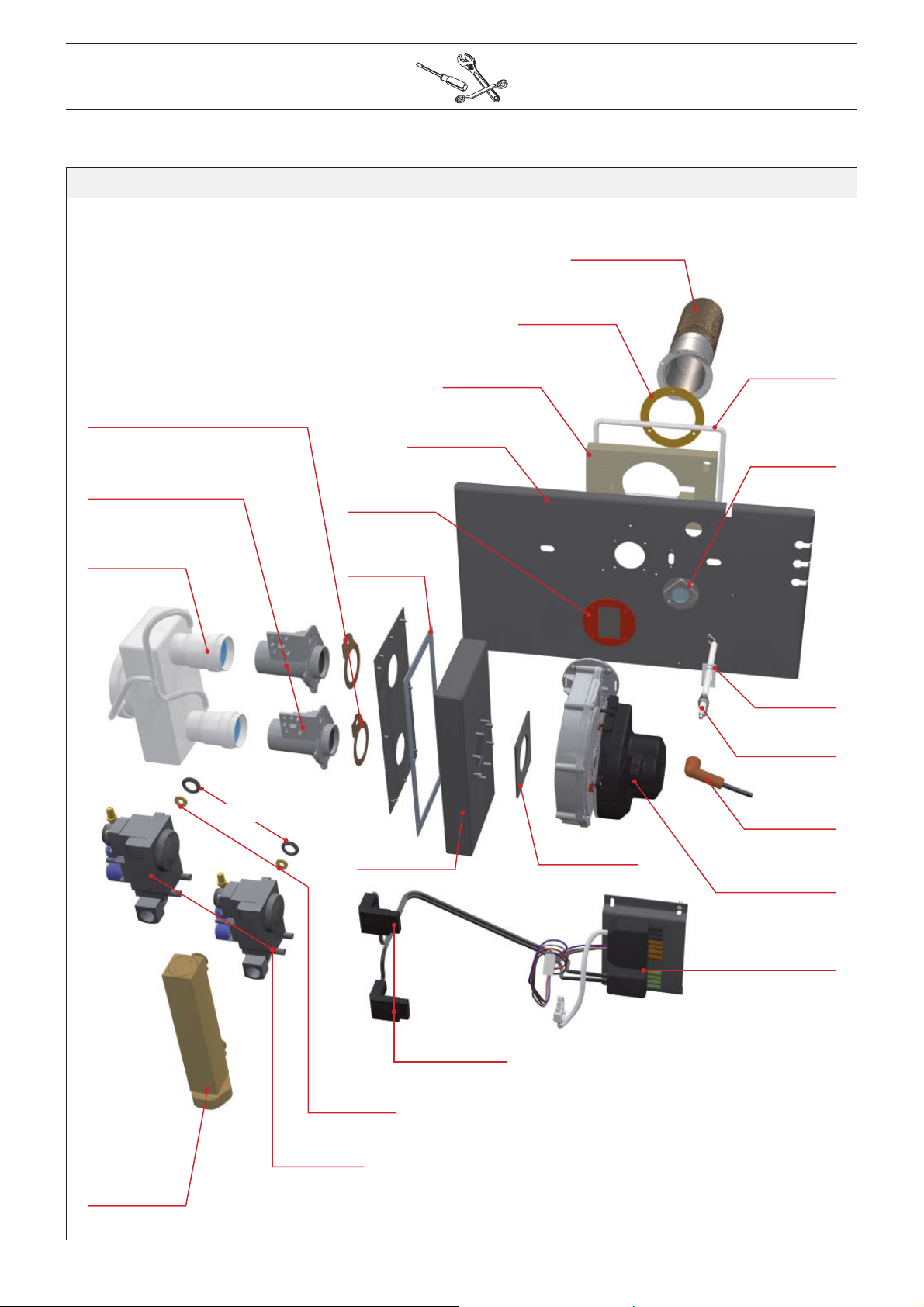

51700034

BG 2000 - M / 71

537DZ029

51700025

21479369

55412000

557A0026

55700026

50423365

557A0012

257F1108

537DZ020

257F1073

537D3027

537D4028

537D6135

537D4037

537D4033

557D6039

537D3017

664Y2500.B

Page 34

BG 2000 - M / 101

557A0020

537DZ019

557A0026

537D4028

507F4008

557D6039

55700026

557A0025

557A0021

21479370

51700025

50423365

557A0012

537DX020

257F1073

507F4007

664Y2500.B

537D4037

537D4033

2147B369

557A0019

537D3033

257F1107

537D3016

Page 35

BG 2000 - M / 201

537DZ019

537DX021

557A0012

557A0020

2147P416

50423365

557A0040

257F1105

537D3034

43726007

42714000

257F1069

557A0045

537D8022

664Y2500.B

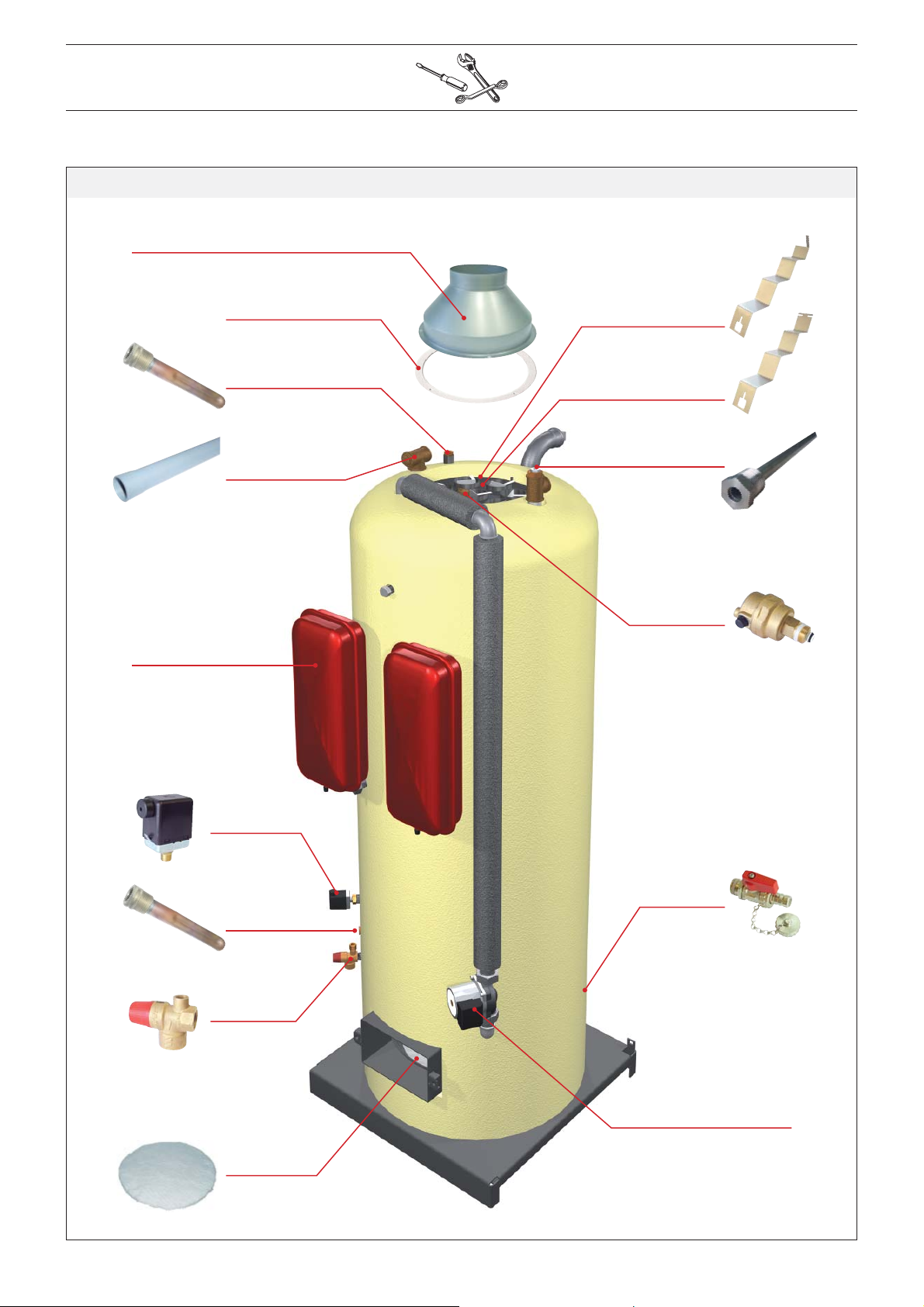

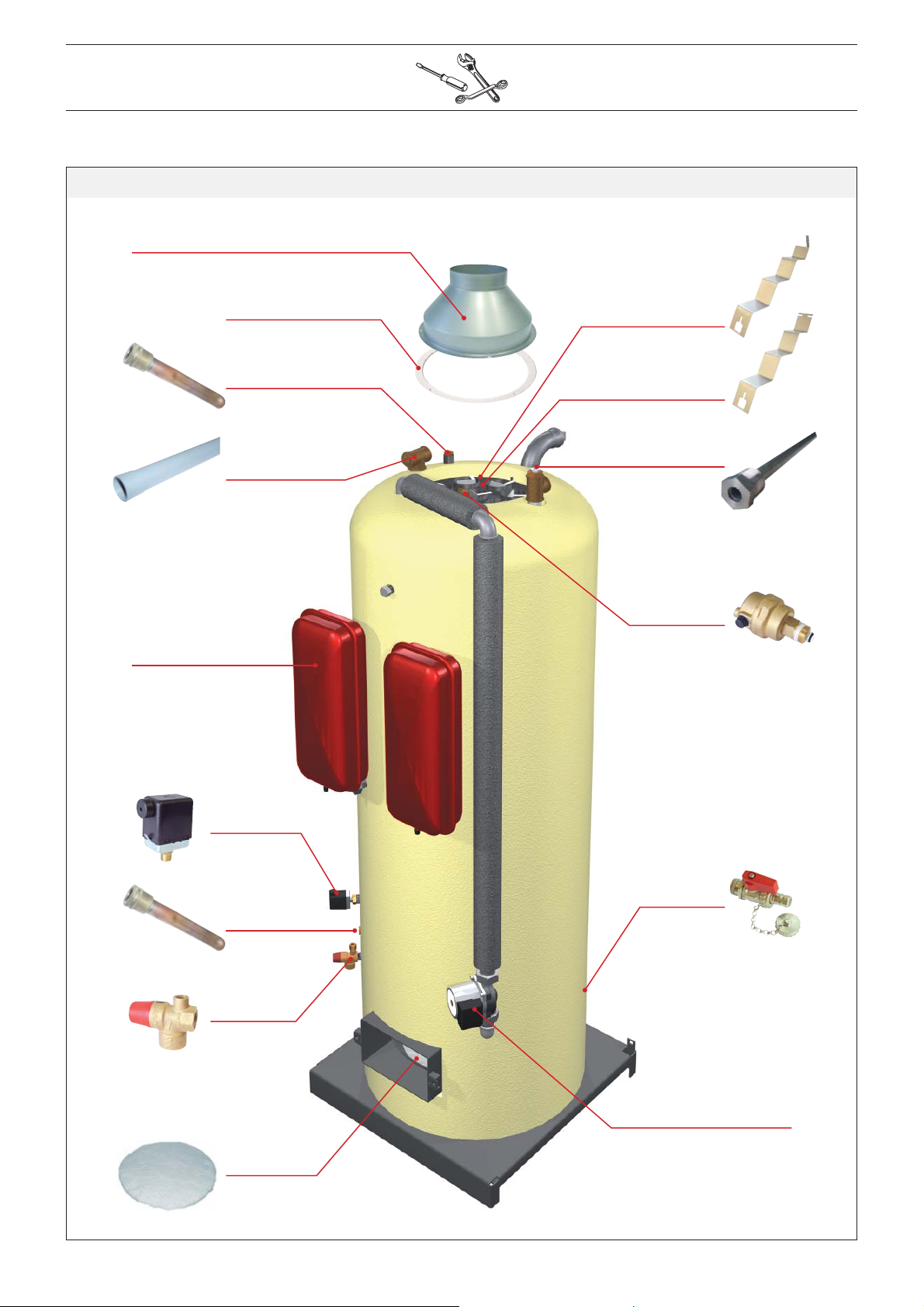

Page 36

21472369

21473369

HeatMaster® 71

21475369

21474369

21477370

21478369

21476369

21471369

664Y2500.B

Page 37

507F3033

HeatMaster® 71

557A7006

557A0016

63438001

497B0001

8 x 507F2009

16 x 507F2010

39438046

55445007

557A1056

63438001

55426017

51305000

55426001

557A4009

664Y2500.B

Page 38

21472370

21473370

HeatMaster® 71

HeatMaster® 101

21475369

21474370

21477370

21478369

21476369

21471370

664Y2500.B

Page 39

507F3033

HeatMaster® 101

557A7006

557A0016

63438001

49410071

8 x 507F2009

24 x 507F2010

39438047

55445007

557A1056

63438001

55426017

51305000

55426001

557A4009

664Y2500.B

Page 40

HeatMaster® 201

2147A415

21479415

21471415

21475416

21473415

21475415

21474415

21478415

2147B415

21476416

2147S415

21471415

2147S415

21472415

664Y2500.B

Page 41

507F3044

HeatMaster® 201

557A0059

557A0055

8 x 507F2009

39438030

24 x 507F2010

497B0502

63438001

557A3001

557A4007

557A1056

63438001

51700041

55301200

55301200

557A1048

557A1000

51700040

664Y2500.B

557A4007

Page 42

537D6224

Ø 150 mm

537D6225

Ø 150 mm

537D6211

Ø 150 mm

537D6212

Ø 150 mm

537D6213

Ø 100 mm

537D6210

Ø 150 mm

537D6219

Ø 150 mm - 45°Mm

537D6214

Ø 150 mm - L 250 mm

537D6215

Ø 150 mm - L 500 mm

537D6216

Ø 150 mm - L 1000 mm

537D6219

Ø 150 mm - 90°

537D6218

Ø 150 mm

664Y2500.B

537D6217

Ø 100 mm - L 500 mm

537D6223

Ø 150 mm

537D6222

Ø 100 mm - 90°

537D6222

Ø 100 mm - 45°

Page 43

HeatMaster® 71 / 101

54441008

537D3020 54766016 54766017

537D3023

547D3021

664Y2500.B

AM3-2

10800060

HM 71 : 537D8037

HM 101 : 537D8038

AM3-11

10800080

Page 44

54441008

HeatMaster® 201

537D3020 54766016 54766017

537D3023

54452082

AM3-11

10800080

547D3021

537D8039

664Y2500.B

AM3-2

10800060

Loading...

Loading...