Page 1

®

HeatMaster

Assembling and installation instructions

HeatMaster® 201 Booster

HeatMaster® 200N (Gas) Booster

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y2900.C

EN • 1

Page 2

INDEX

WARNINGS 3

Who should read these instructions 3

Symbols 2

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Applicable standards 2

Recommendations 2

Warnings 2

DESCRIPTION 3

Packing 3

Technical characteristics 3

Hydraulic connections 3

Dimensions 3

WHO SHOULD READ THESE INSTRUCTIONS

These instructions should be read by:

- the specifying engineer

- the installer

- the user

- the service engineer

SYMBOLS

The following symbols are used in this manual:

Essential instruction for the correct operation of

the installation.

Essential instruction for the safety of persons

and the environment.

ELECTRICAL CONNECTION 4

HeatMaster 201: serial number > at 1000 4

HeatMaster 201: serial number < at 1000 4

HeatMaster 200N 6

BOOSTER KIT ASSEMBLY 7

WARNINGS

• The product must be installed and serviced by trained

engineers, in compliance with current standards.

• Any failure to follow instructions relating to tests and test

procedures may result in personal injury or risks of pollution.

• To guarantee safe and correct operation of the appliance, it

is important to have it serviced and maintained every year by

an approved installer or maintenance company.

• In case of anomaly, please call your service engineer.

• Despite the strict quality standards imposed by ACV during

the manufacture, inspection and transport of its appliances,

you might notice some errors. Please report immediately any

fault to your approved installer.

• The parts may only be replaced by genuine factory parts. You

will find a list of the spare parts and their ACV reference

number at the end of this document.

Danger of electrocution.

APPLICABLE STANDARDS

The appliances carry the CE mark in accordance with the

standards in force in the various countries (European Directives

92/42/EC “Efficiency”, 90/396/EC “Gas appliances”).

They also carry the “HR Top” label (Gas boilers).

RECOMMENDATIONS

• Please, carefully read this manual before installing and

commissioning the boiler.

• It is prohibited to carry out any modifications to the inside of

the appliance without the manufacturer’s prior and written

agreement.

WARNINGS

This documentation is part of the information delivered with the

appliance and must be given to the user and stored in a safe

place!

An approved installer must carry out the assembly, commissioning,

maintenance and repair of the system, in accordance with current

standards in force.

ACV shall not accept any responsibility for damage caused by

non-compliant location of the system or by use of the parts or

connections not approved by ACV for this application.

The manufacturer reserves the right to change the

technical characteristics and specification of its

products without notice.

The availability of some versions and their accessories

is market dependant..

664Y2900.C

EN • 2

Page 3

DESCRIPTION

PACKING

The HeatMaster® 200N / 201 Booster

are delivered in several packing:

Pack 1 : HeatMaster insulated body with control panel.

Pack 2 : Complete jacket

Pack 3 : Chimney reduction with horizontal exhaust and gasket.

Pack 4 : Low temperature hydraulic kit including 4-ways valve,

tubes and hydraulic components.

Pack 5 : Motor and temperature sensor kit (to control the

4-ways valve).

Pack 6 : Booster kit including the Booster, bracket and holder,

tubes and hydraulic components for the heating and

shunt loops.

Pack 7 : Gas burner with insulation and gasket

(only HeatMaster 201).

TECHNICAL CHARACTERISTICS

Heating Mode

HeatMaster® 201 Booster

- Input: 220,0 kW

- Output: 210,1 kW

- 100% load efficiency - 80/60 mode: 95,5%

- 100% load efficiency - 50/30 mode: 106,1%

- 30% load efficiency - return at 30°C: 107,9%

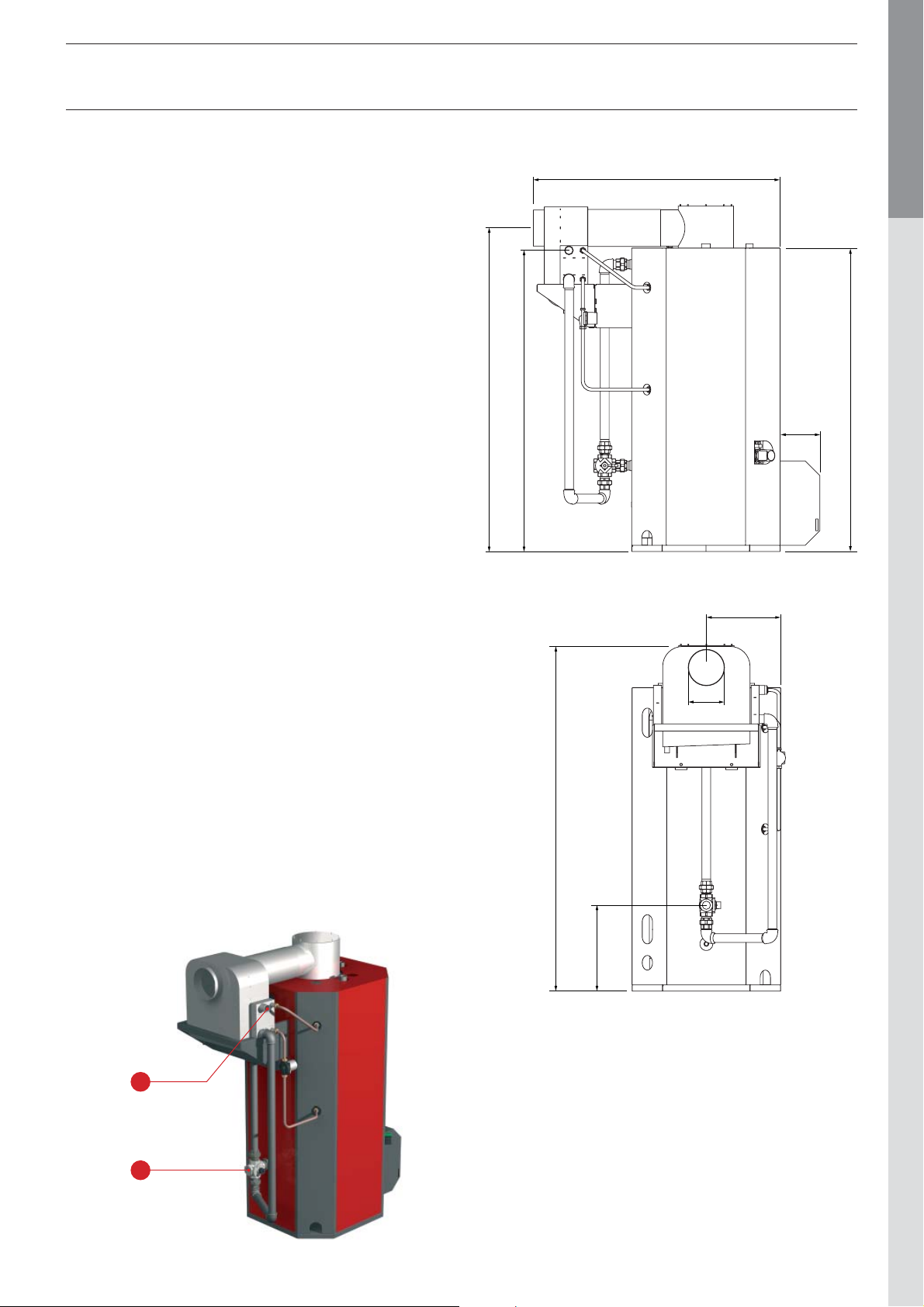

DIMENSIONS

2224

2070

1696

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

2085

274

Hot water mode - set point 90°C

HeatMaster® 201 Booster

- Input: 240,0 kW

- Output: 225,0 kW

- Continuous flow rate at 40°C cold water at 10°C: 6425 l/h

Pressure drops (Booster alone)

- Hydraulic (ΔT = 20): 20 mbar

- Flue gas circuit: 0,3 mbar

HYDRAULIC CONNECTIONS

A. Heating return Ø 2” M

B. Heating f low Ø 2”

510

250

2370

590

664Y2900.C

A

B

EN • 3

Page 4

ELECTRICAL CONNECTION

t

BUS

S

O

t

P

1211

10

8

7

M

3

M

15

1

18

2

Bl

Y/Gr

Bl

Y/Gr

Bl

Y/Gr

HeatMaster® 201:

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

serial number > at 1000

Flow sensor (14)

- Mount the NTC6 sensor on the flow tube.

- Connect the sensor to the 15 and 16 terminals.

Heating pump (16)

Connect the heating pump on the terminal block:

line voltage to 07, neutral to 08 and ground to 09.

Motor of the 4-ways valve (20)

- Connect the ground to 19.

- Connect the brown wire to 20 (closing contact)

- Connect the blue wire to 21 (neutral)

- Connect the black wire to 22 (Opening contact)

Booster shunt pump (19)

- Connect the line connection of the Booster shunt pump to

16, the neutral to 17 and the ground to 18.

16

19

7

20

Y/Gr

Y/Gr

M6

M2

M

M5

X2

01

02

03

04

05

R

M

Bl

4

R

M

Bl

Y/Gr

N

M

3

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

X3

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

BU

14

B

A

Vol

9

664Y2900.C

EN • 4

Page 5

ELECTRICAL CONNECTION

t

BUS

S

O

t

P

1211

10

8

7

M

3

M

15

1

18

2

Bl

Y/Gr

Bl

Y/Gr

Bl

Y/Gr

HeatMaster® 201:

serial number < at 1000

Flow sensor (14)

- Mount the NTC6 sensor on the flow tube.

- Connect the sensor to the 15 and 16 terminals.

Heating pump (16)

Connect the heating pump on the terminal block:

line voltage to 07, neutral to 08 and ground to 09.

Motor of the 4-ways valve (20)

- Connect the ground to 16.

- Connect the brown wire to 17 (closing contact)

- Connect the blue wire to 18 (neutral)

- Connect the black wire to 19 (Opening contact)

Booster shunt pump (19)

- Connect the line connection of the Booster shunt pump to

13, the neutral to 14 and the ground to 15.

16

19

7

20

Y/Gr

Y/Gr

M6

M2

M

M5

X2

01

02

03

04

05

R

M

Bl

4

R

M

Bl

Y/Gr

N

M

3

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

X3

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

BU

14

B

A

Vol

9

664Y2900.C

EN • 5

Page 6

ELECTRICAL CONNECTION

9

L1N

T1T2S3B

S3

N

L1N

O

C

C

C

HeatMaster® 200N

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

The terminals numbering refer to the control panel of the

HeatMaster® 200N

- Connect terminals 9 and 10 to the solenoid of the reversing

relay (18). (optional)

- Connect terminal 12 to the common of the relay (18).

- Connect the neutral of the Booster shunt pump (19) to

terminal 10.

- Connect the hot line of the Booster shunt pump (19) to the

“normally closed” terminal of the relay (18).

19

18

1 2 3 4 5 6 7 8 9 1011121314151617181920212223

Base for relay and reversing relay

ACV code:

54428195 : base relay

54428220 : reversing relay

4

11

7

03

5

16

- 90

7

L1

664Y2900.C

EN • 6

Page 7

BOOSTER KIT ASSEMBLY

1. Replace the two plugs located on the T - of both expansion

vessels to the right of the boiler by two 3/4” - 1” reducers.

5. Mount the two M-M union

6. Mount a 90° elbow on the upper

connexion and the 4-ways valve on the

lower one.

Mount the M-F union connexion on

the 4-ways-valve; place the 2” tube

between the 90° elbow and the 4-ways

valve. This 2” tube must be perfectly

vertical : if necessary, adjust the

position of the 90° elbow and/or the

4-ways valve.

connections on the flow

and the return of the

boiler-body.

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

2. Fix the two Booster mounting legs on the brackets located on the

back side of the HeatMaster with four M10 screws.

3. Punch the pre-cut parts

from the rear panel

4. Put the rear panel in place.

7. Fix the Booster holder on the mounting legs with four M10 bolts.

664Y2900.C

8. Place the Booster on its

holder

EN • 7

Page 8

BOOSTER KIT ASSEMBLY

9. - Place the back right side panel.

- Connect the the upper tube of the Booster shunt loop.

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

10. Mount a 90° elbow on the

lower nipple of the Booster.

13. Mount the second 2” tube

with the left hand thread

on the coupling. Leave

some threads for later

adjustment.

14. Mount the 90° elbow on the

2”tube.

11. On this elbow, mount the

2" tube with the two righthand threads.

Pay attention to the

threads : one tube has a

left-hand thread.

12. On this 2" tube, mount the

left hand and right hand

threaded coupling; screw

it half-way to leave the

adjustment.

15. Mount the third 2” tube

with the 90° elbow and the

union connexion.

16. Ensure that the union

connection is aligned with

the 4-ways valve.

664Y2900.C

EN • 8

Page 9

BOOSTER KIT ASSEMBLY

17. Adjust the RH / LH

coupling to mate the faces

of union connection.

18. Tighten the union

connexion.

20. Mount the 6 studs on the

flange and put the gasket

in place.

21. Locate the flue collector

hood and fit it together with

the flue tube of the Booster.

Fix the flue collector with

the nuts.

22. Fit the condense trap on

the Booster condense

outlet.

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

19. Connect the shunt

pump with its upper and

lower tube between the

HeatMaster and the

Booster.

23. Overall picture.

664Y2900.C

EN • 9

Page 10

24. Hydraulic connexion of the heating system.

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

BOOSTER KIT ASSEMBLY

M5

25. Electric connexion of the shunt pump (M5) : see pages 4, 5

and 6.

26. Commissioning of the system and control of the complete

installation : see HeatMaster 200N / 201 technical manual.

664Y2900.C

EN • 10

Loading...

Loading...