Page 1

MODULE 5

SYSTEM ARCHITECTURE

Overview 5-4

Objective 5-4

Purpose 5-4

Instructions 5-4

System Architecture 5-5

System Chassis 5-5

Basic System Architecture 5-6

Coherent Imageformer 5-7

Coherent Imageformer 5-7

Multiple Beamformation 5-7

Coherent Imageformer PCBs 5-7

Theory of Operation 5-8

Transmission 5-8

Reception 5-9

Transmitter Board 5-11

TX3 5-11

Function 5-11

Troubleshooting Hints 5-11

Multiplexer Board 5-12

MX2/3 5-12

Function 5-12

Troubleshooting Hints 5-12

Receiver Board 5-13

RX 5-13

Function 5-13

Troubleshooting Hints 5-13

RI Board 5-14

Beamformer Board 5-15

BF3 5-15

Function 5-15

Troubleshooting Hints 5-15

Controller Board 5-16

CN2/3 5-16

Function 5-16

Troubleshooting Hints 5-16

DIMAQ Integrated Ultrasound Workstation 5-17

The DIMAQ Workstation PCBs 5-17

Page 2

Module 5 - System Architecture Acuson Confidential

Theory of Operation 5-18

Acquisition and Preprocessing 5-18

Reconstruction 5-18

Video Conversions 5-18

DIMAQ Workstation Subsystem Control 5-18

System Supervisory Processor 5-18

Scan Formats 5-19

User Interface 5-19

Color and Spectral Doppler Board 5-22

CSD1/2 5-22

Function 5-22

Spectral and Audio Processing 5-22

Color Doppler Processing 5-22

Troubleshooting Hints 5-22

BDM Board 5-23

BDM1/2 5-23

Function 5-23

SMM Processor 5-23

Reconstruction and Display Processor Board 5-24

RDP2/5 5-24

Function 5-24

SSP 5-24

Troubleshooting Hints 5-24

Input/Output Video Board 5-25

IOV1/2 5-25

Function 5-25

Troubleshooting Hints 5-25

Input/ Output Expansion Board 5-26

IOE3 5-26

Function 5-26

Troubleshooting Hints 5-26

Peripheral Interface Controller Board 5-27

PIC1/2 5-27

Function 5-27

Troubleshooting Hints 5-27

Physio Interface Module 5-28

FIZ 5-28

Function 5-28

Troubleshooting Hints 5-28

Front Panel Processor Board 5-29

FPP 5-29

Function 5-29

Troubleshooting Hints 5-29

2-D/ M-Mode Signal Flow 5-30

Transmission 5-30

Module 5-2 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 3

Acuson Confidential

Reception 5-30

Reconstruction and Display 5-30

Solo™ Spectral Doppler Signal Flow 5-33

Doppler Theory 5-33

Pulse Wave Doppler 5-33

Nyquist Limit 5-33

High PRF 5-33

Continuous Wave Doppler 5-33

Solo™ Spectral Doppler 5-34

Display 5-34

Audio 5-34

Color Doppler Signal Flow 5-35

Color Doppler 5-35

SST™ Color Doppler 5-35

ECG/Physio Signal Flow 5-37

DIMAQ System Store and Review 5-38

Acquisition 5-38

Review 5-38

VCR Playback 5-40

Acquisition 5-40

Playback 5-40

Worksheet: System Architecture 5-41

REVISION HISTORY

QRC P/N-REVISION INITIATOR APPROVAL DATE CHANGE

S. Williams July 1999 Incorporate reviewer comments

A3210 59155 Rev. 1 J. Madarasz S. Williams Dec. 2000 Initial Release

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 3

Page 4

Module 5 - System Architecture Acuson Confidential

OVERVIEW

OBJECTIVE To explain the signal paths for different the Sequoia system

ultrasound modalities and board functions, in order for Customer

Engineers, International Distributors and BioMed Engineers to

troubleshoot a Sequoia sy stem problem.

PURPOSE Troubleshooting a Sequoia system at a customer site can be a

demanding task. Most of the time, isolating the cause of a failure is

an easy task using the state-of-the-art service diagnostic software.

However, occasionally the failure symptom must be related to th e

function of a specific board. Following the signal path for the

modality can also be a useful tool in such a situa tion.

INSTRUCTIONS 1 Listen to the presentation.

2 Read the module.

3 Answer the questions in the worksheet provided at the end of the

module.

Module 5-4 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 5

Acuson Confidential System Architecture

SYSTEM ARCHITECTURE

SYSTEM CHASSIS The Sequoia system consists of a card cage with a capacity for up to

15 printed circuit boards (PCB), plus the backplane. Access to the

PCBs is available by removing the right side cover and removing

the shielding cover from the card cage.

CAUTION! The Sequoia system contains numerous devices sensitive to

electrostatic discharge (ESD). Failure to observe strict ESD prevention

procedures may damage components. Access to internal assemblies is

restricted to Acuson trained service personnel only.

T ransducers are plugged directly into the system via the MX board.

Depending on the system configuration, up to three 128-element

transducers or one 256-element transducer and two 128-element

transducers may be connected at one time. The right transducer

connector only supports a 256-element transducer on the Sequoia

512 system.

The DC power is supplied to the chassis from a single power supply

located at the rear of the chassis, behind the service access cover.

Power connections to the printed circuit boards are made via the

backplane of the card cage. See the Following Power Distribution

module for more detail.

WARNING!

Voltages present within the Sequoia system are capable of causing

injury or death. Access to internal assemblies is restricted to Acuson

trained service personnel.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 5

Page 6

Module 5 - System Architecture Acuson Confidential

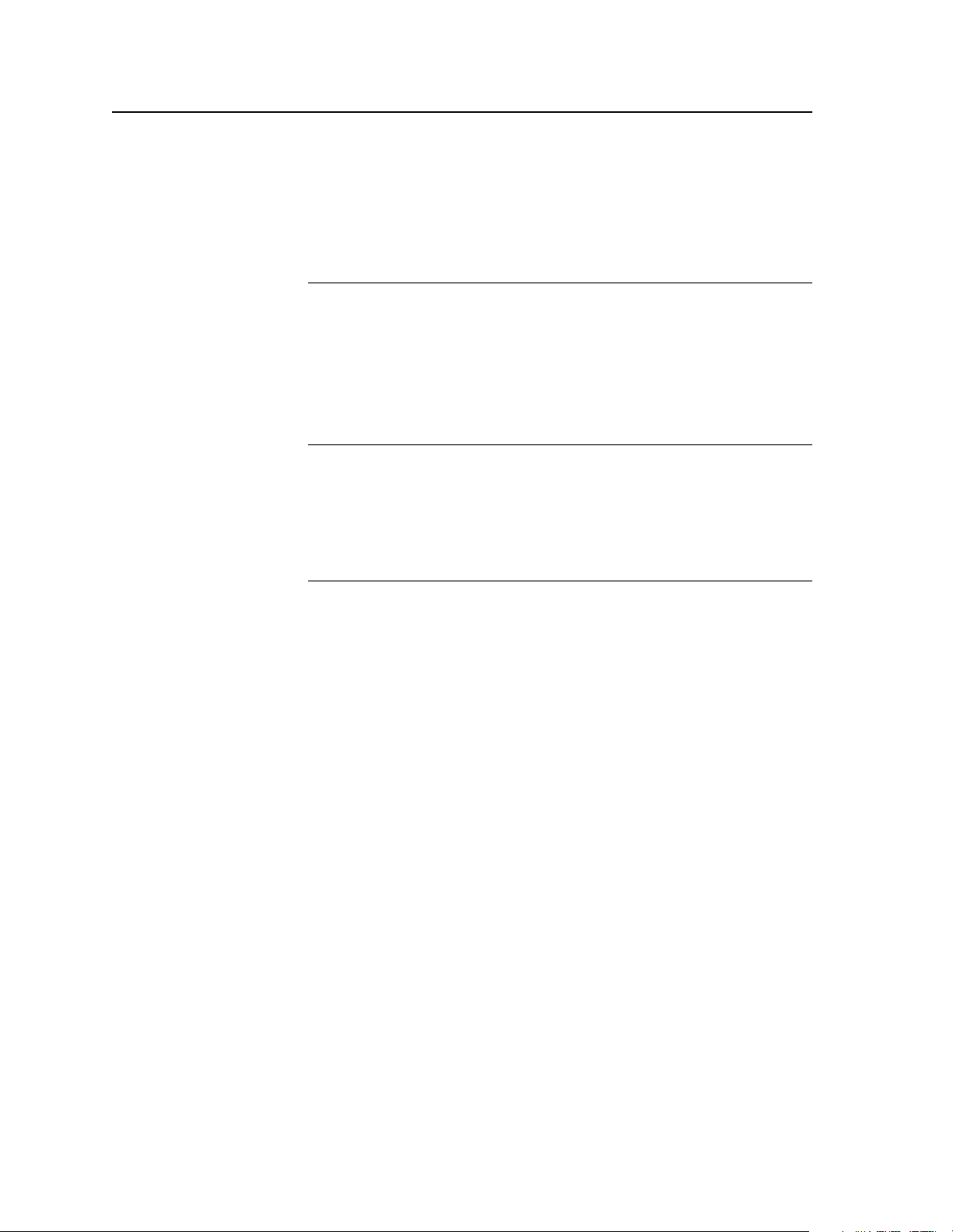

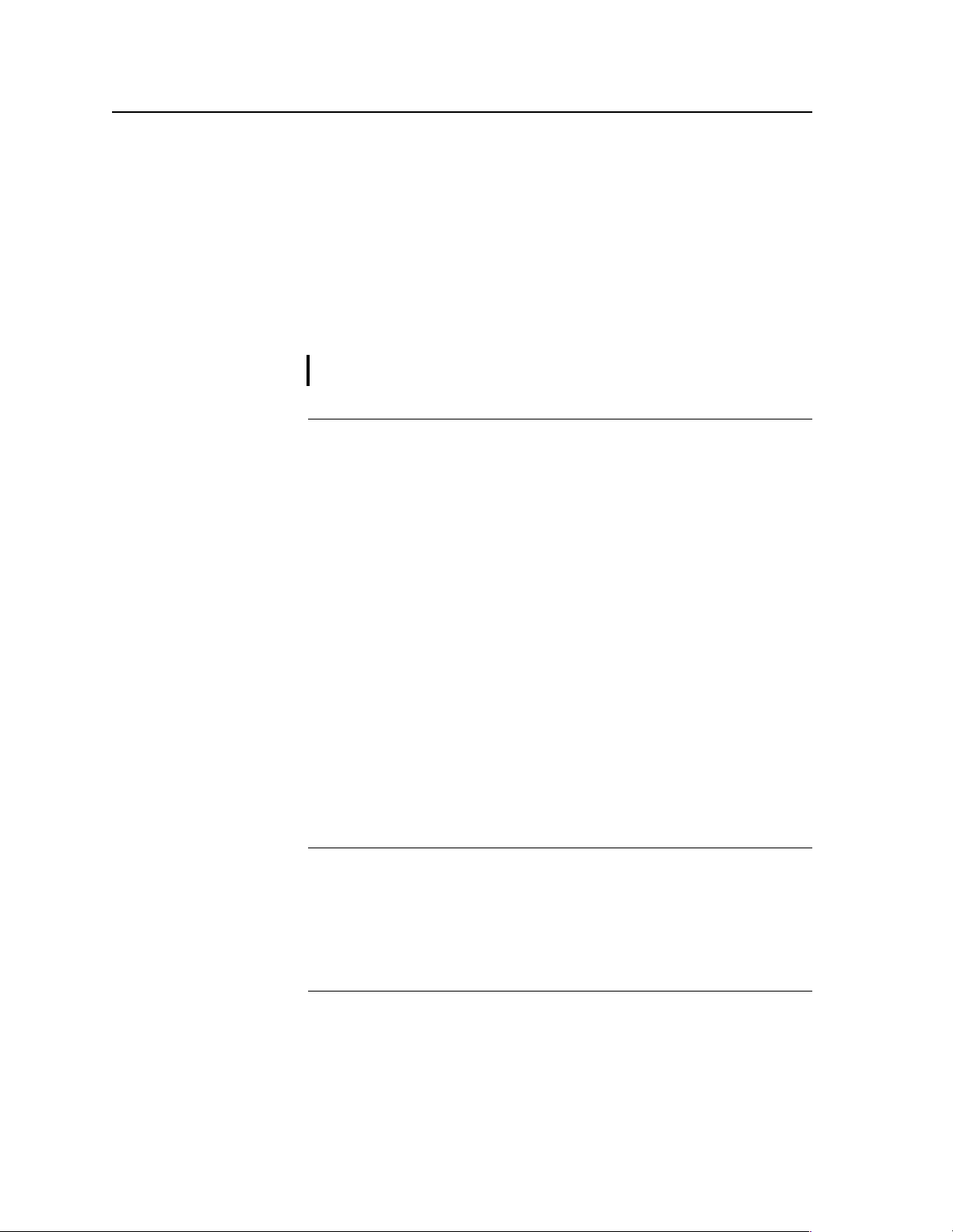

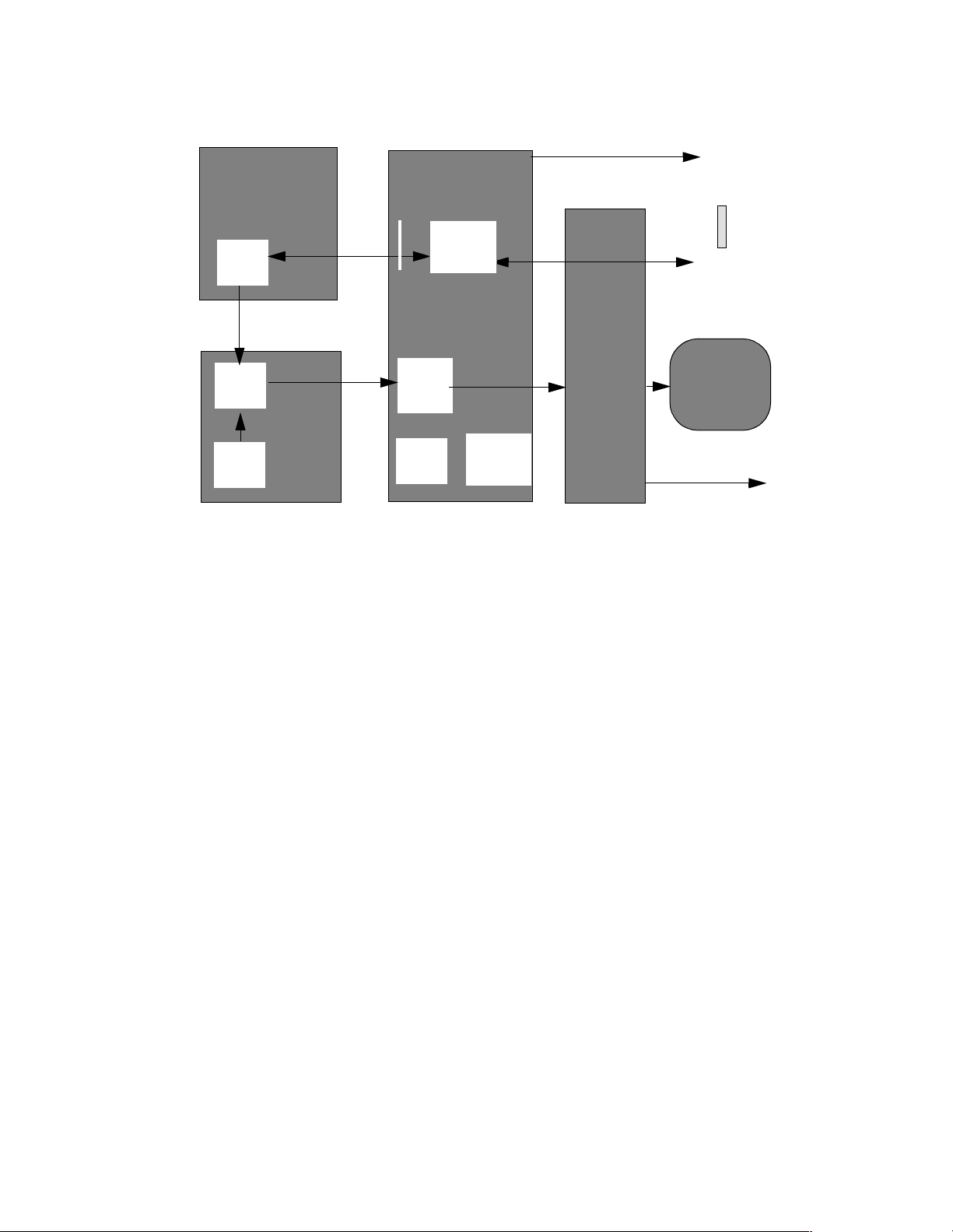

BASIC SYSTEM

A

RCHITECTURE

Sequoia system technology represents the most fundamental and

far-reaching advance in ultrasound technology since the advent of

Computed Sonography in 1983. It incorporates four foundation

technologies that produce dramatic image quality, performance,

and functionality improvements in all mode s of operation. The

system architecture can be divided into three major subsystems:

• Coherent Imageformer

•DIMAQ workstation

• Power Subsystem

Figure 5-1 illustrates the basic Sequoia system architecture.

Xdcr

Audio FRQ

Spectral Beamformer

Digital Receive

Xmt/Rcv

Switching

Imageformer Subsystem

Beamformer

Transmit

Beamformer

Control

User

PW

CW

Color

2-D

M-mode

Monitor

Interface

System

Supervision

Memory

&

Scan

Conversion

AEGIS system &

Ethernet

DIMAQ Integrated Workstation

OEMs

Peripheral

Interface

Video

Conversion

PPS

Power Subsystem

Main Power Supply

Figure 5-1 Basic System Architecture of Sequoia System

Module 5-6 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 7

Acuson Confidential Coherent Imageformer

COHERENT IMAGEFORMER

COHERENT

IMAGEFORMER

MULTIPLE

EAMFORMATION

B

The Coherent Imageformer subsystem performs three primary

functions. These are:

• Transmission of focused ultrasound energy

• Receive and process of back scattered ultrasound energy

• Control of transmit and receive parameters to sweep the

ultrasound beams through the field of view

The Coherent Imageformer performs these functions by setting the

phase and amplitude parameters for each transmit/r eceive element

in the transducer. Sophisticated computer control of these

parameters provides extensive flexibility in controlling the

transmitted ultrasound beam and processing the back-scattered

energy picked up by each transducer element.

The Multiple Beamformer is a new beamformer architecture that

utilizes up to 512 digital processing channels. This unique

architecture:

• Processes phase and amplitude

• Acquires multiple beams simultaneously to capture

information

• Acquires multiple beams in the same amount of time that a

single beamformer acquires a single beam

COHERENT IMAGEFORMER PCBS

The high-speed data acquisition generated by multiple

beamformers translates directly into significantly higher frame

rates, higher spatial resolution and increased sensitivity in 2-D and

Color Doppler imaging modes.

Phase information is utilized by the Coherent Imageformer to

acquire additional information that cannot be done without the use

of phase.

Five major board types make up the Coherent Imageformer. Each of

these boards performs specific functions in the formation of an

ultrasound image cell.

BOARD NAME ACRONYM

Transmitter Board TX

Multiplexer Board MX

Receiver Board RX

Beamformer Board BF

Controller Board CN

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 7

Page 8

Module 5 - System Architecture Acuson Confidential

THEORY OF OPERATION

TRANSMISSION All Coherent Imageformer functions are controlled by the

Controller board (CN). Data regarding the type of ultrasound

information to acquire, (e.g., 2-D mode, Color, Pulse Doppler, Depth

of Scan, Power to use, etc.) are passed to the CN board on the

system control bus.

The CN then passes parameter data to the transmitter boards on the

Imageformer bus. In addition, configuration data is also passed to

the Multiplexer (MX) and Receiver (RX) boards.

The Tr ansmitter (TX) boards use this data to determine the pulse

characteristics and time delay requir ed. The digital pulse waveform

is passed to a D/A converter, which creates the analog wave used to

drive a high voltage amplifier. This amplifier output drives the

transducer piezoelectric-crystal element. Two TX boards may be

used to process a total of 512 digital processing channels. The high

voltage pulses from the TX board are passed to the Multiplexer

board (MX).

The MX board switches the transmit pulses to the appropriate

transducer element, based upon the transducer(s) connected and

the scan format used.

Each transducer consists of a number of piezoelectric-crystal

elements. A piezoelectric-crystal element changes spatially when a

voltage is applied across it. On receiving a high-frequency electric

wave, the piezoelectric-crystal element vibrates and creates a highfrequency ultrasound wave.

The ultrasound wave propagates into the tissue of the patient being

scanned. Wherever there is a change in the acoustic impedance,

such as the interface between dissimilar tissues, a portion of the

ultrasound wave is reflected. The magnitude of the reflected wave

is a function of the difference in acoustic impedance between the

tissues.

Module 5-8 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 9

Acuson Confidential Theory of Operation

RECEPTION Immediately after transmitting the ultrasound wave, the system

begins acquiring echo data. A piezoelectric-crystal element not only

changes geometry when a voltage is applied, it also creates an

electric charge when the geometry of the element is mechanically

changed. The ultrasound echo data returning from the patient

excites the piezoelectric-crystal elements. The crystals output a

small electric signal that is proportional to the amplitude of the

received ultrasoun d waves.

The MX board r outes these i n dividual s ignal s to th e Recei ver bo ard

(RX). The RX board provides initial amplification of the echo data.

The signals are processed for gain and then passed to the

Beamformer board (BF), where apodization occurs. The RX board

also creates the clock signals used to synchronize system

operations.

During spectral Doppler operation, the Doppler data is passed to

the Spectral Doppler Preprocessor located on the RX board. The PW

Doppler data is sampled only at the range gate. CW Doppler data is

acquired from the entire sample line. The Doppler data is then

processed and the quadrature data I&Q derived. The I&Q data are

then digitized and placed on the RX I/Q data path for processing

and display by the DIMAQ workstation.

The Beamformer board (BF) rece ives the back-scatter ed echoes from

each receive channel. By processing echoes from numerous

transducer arrays, the BF defines a series of coherently-focused

image cells.

Two BF boards may be used to process four different ultrasound

beams utilizing a total of 512 digital processing channels.

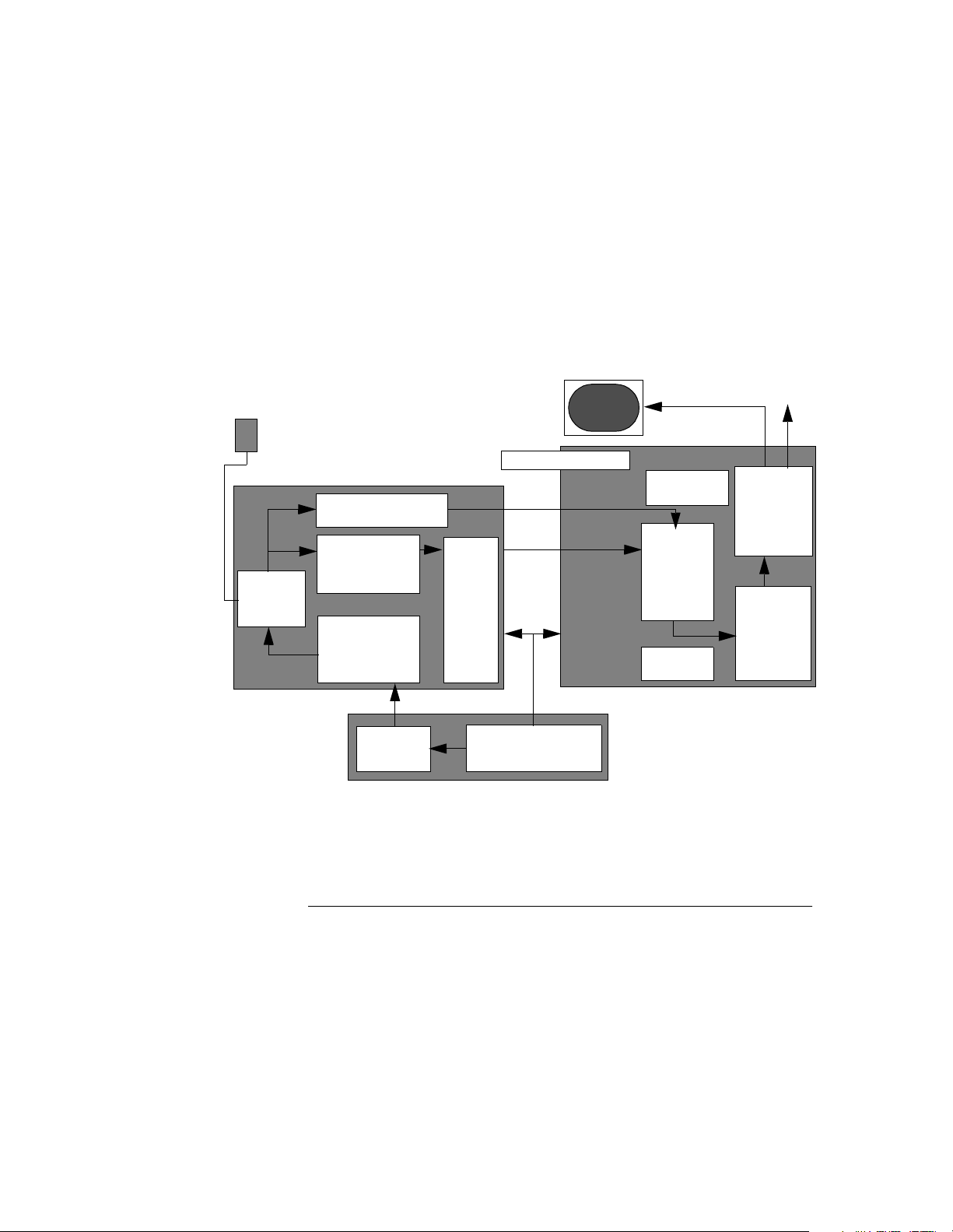

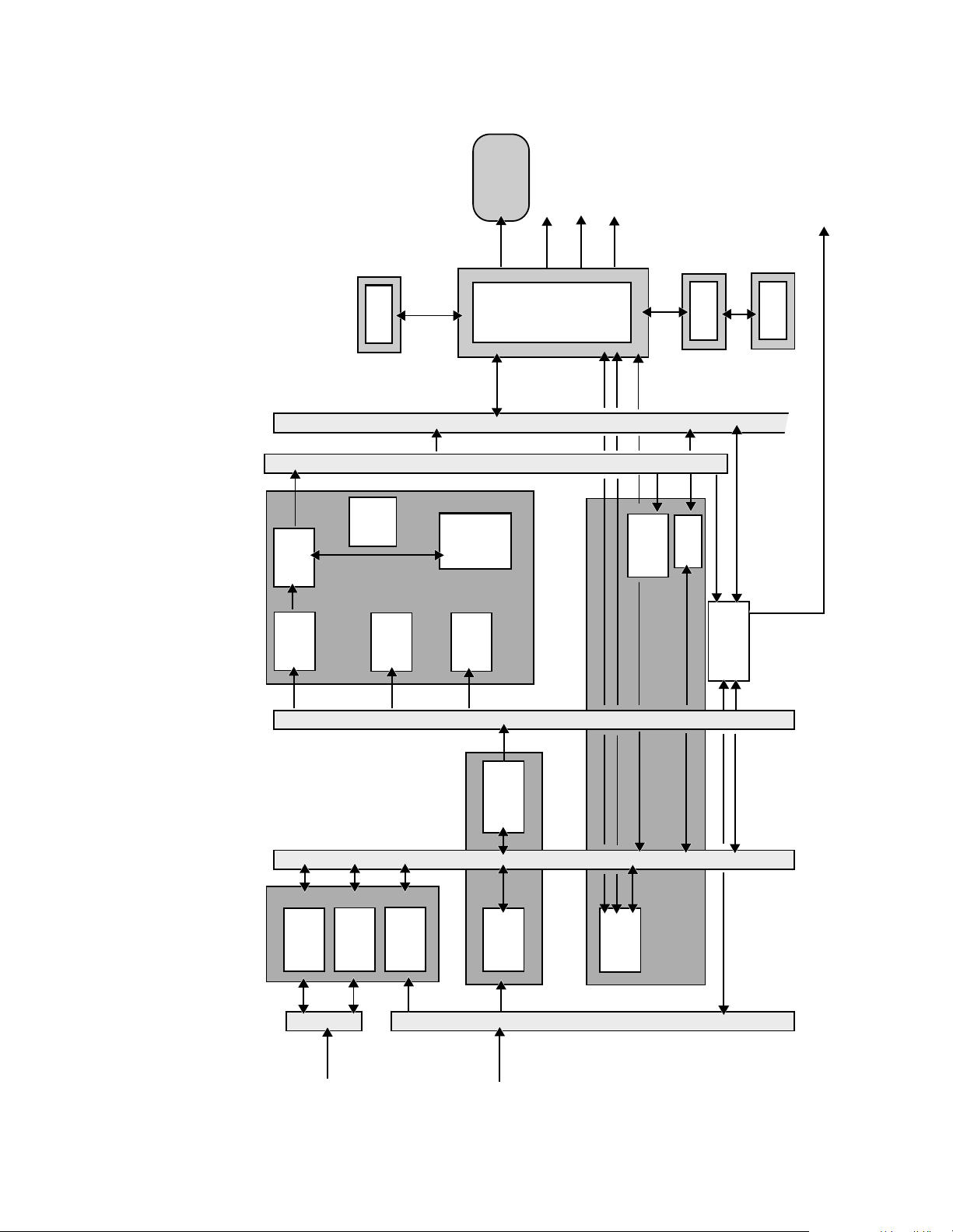

Figure 5-2 diagrams the Imageformer functions.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 9

Page 10

Module 5 - System Architecture Acuson Confidential

Freq

Gain

Block

LVA

Gen

SDP

DIMAQ

Workstation

To

AUX

Amplifier

Connectors

MP

MX

RX

RI

RMX

Control &

Calibration

TMX

MAC

PWG

DAC

ADC

CFB

ADC

BFP

CFB

BF-A BF-B

PPS

ACP

PWG

DAC

BBF

BFP

CN

To

DIMAQ

Workstation

FCP

HV

HV

Output

Amplifier

TX-A

Output

Amplifier

TX-B

Figure 5-2 Imageformer Block Diagram

Module 5-10 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 11

Acuson Confidential Transmitter Board

TRANSMITTER BOARD

TX3

Part Number TX2 35282

Part Number TX3 39142

Quantity Cardiology: 1, Radiology: 2

Power Supplies +5 VDC, +5.5 VDC, -5.7 VDC,

Signals In TX Apodization, TX Delay

Signals Out TX Signal (1-64)

FUNCTION The Transmitter board (TX) provides the electrical signal used to

drive the piezoelectric elements in the transducer. The TX is

controlled by the Controller board (CN) via the IAB bus.

Apodization and delay parameters are passed to the TX by separate

signal lines.

The programmable wave generator (PWG) ASIC generates a digital

transmit waveform for up to four beams.

±12 VDC; Vxmt

TROUBLESHOOTING

H

INTS

The pulse parameters are specified for each transducer element

based on the ultrasound line being fired. The parameters are

converted to an analog signal, which is used to drive a high voltage

amplifier. The high voltage amplifier uses the output from the

Programmable Power Supply (PPS). The PPS is set by software to a

given voltage based on the ultraso und line being fired. The highvoltage transmit pulses for each transducer element are then passed

to the MX board.

Failures of the TX board are most likely to interrupt a single

transmitter channel only. This is unlikely to be visually perceptible.

If problems are suspected, replace the board to check for image

improvement.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 11

Page 12

Module 5 - System Architecture Acuson Confidential

MULTIPLEXER BOARD

MX2/3

Part Number MX2 Cardiology: 39052, Radi ology: 36262

Part Number MX3 Cardiology: 50642; Radi ology: 39132

Quantity One

Power Supplies +5.5 VDC;

Signals In TX Signal (64 or 128 channels), TX Off, Control

data

Signals Out MX Signal (64 or 128 channels)

FUNCTION The Multiplexer board (MX) provides the electrical connection

between the Imageformer and the transducers supported by the

Sequoia system.

The MX board has three functions:

±12 VDC; ±100 V

TROUBLESHOOTING HINTS

• To switch the electrical transmit pulse from a selected

transmitter channel to the appropriate transducer element.

• To switch the appropriate transducer element to the proper

receive channel.

• Provide a signal path for calibration signals generated by a

selected transmitter channel to be monitored by a selected

receive channel.

The MX board is controlled by the Controller board (CN) via the

MX/RX Bus. The CN configures the MX based upon the

transducer(s) connected and selected.

Calibration signals may be passed from the Transmitter board (TX)

to the Receiver board (RX) via the MX board. If a transmit or receive

channel fails diagnostics and replacement of the board does not

correct the problem, it is possible that the MX is not providing the

necessary signal path.

Module 5-12 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 13

Acuson Confidential Receiver Boa rd

RECEIVER BOARD

RX

Part Number RX2 Cardiology: 39052, Radiology: 32012

Part Number RX4 Cardiology: 51642; Radiology: 51562

Quantity One

Power Supplies +5.5 VDC; -5.7 VDC;

Signals In MX Signal (64, or 128)

Signals Out RX Signal, RX I/Q, Master System Clocks

FUNCTION The Receiver board (RX) operates in two ways, depending upon the

type of ultrasound data being processed. When a 2-D, F-mode or Mmode ultrasound line is being processed, the receive signal from

MX for each channel is acquired and passes through circuitry that

amplifies and preprocesses it. The signal is then passed to the

Beamformer board (BF) for construction of an image cell.

±12 VDC

TROUBLESHOOTING

INTS

H

When PW Doppler or CW Doppler data is being acquired, the data

path is quite different. The Doppler data is amplified and

preprocessed based on range gate position (PW), or acquired over

the entire sample line (CW). The Doppler signals are then shifted

temporally to create a coherent ultrasound image cell.

The temporally shifted Doppler data is summed and passed to the

Color Spectral Doppler board (CSD) for conversion from time

domain to the frequency domain.

The RX board also generates the master clock signals used by the

system to synchronize operations.

The RX board is the point in the system where 2-D, F-mode, and

M-mode signal processing diverge from PW Doppler and CW

Doppler signal processing. For this reason, it is valuable to check

each mode to see if symptoms that appear are present in each.

For instance, if a 2-D image has noise artifacts in one area of the

image, then placing the PW Doppler cursor in that area provides an

important troubleshooting clue. If the noise is present in both

modes, then it is being introduced at RX board, or earlier in the

processing path (e.g., RX, MX, TX, Power Supplies). If the noise is

only in PW Doppler then it is being introduced in the RX boa rd or

later in the PW signal path (e.g., RX, CSD).

Failures of the RX board are most likely to interrupt a single signal

path to/from the transducer. This is not visually perceptible. If

problems are suspected, replace the board to check for image

improvement.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 13

Page 14

Module 5 - System Architecture Acuson Confidential

Failure of the clocks causes the system to stop executing the boot

sequence. The system display and boot appear “dead.”

RI BOARD The Receiver Interconnect board or RI is located on top of the MX

and RX boards in the cardcage. The main functions of this board

are:

• Connects the signal from MX board to the RX board

• Passes clock signal to the MX board

Two versions of the RI boards are available. P/N 31992 is used on

Sequoia 512 ultr asound syst ems, and P /N 35662 is used for Seq uoia

256 echocardiography systems.

Module 5-14 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 15

Acuson Confidential Beamform er Board

BEAMFORMER BOARD

BF3

Part Number 39152

Quantity Cardiology: 1, Radiology: 2

Power Supplies +5 VDC, +5.5 VDC, -5.7 VDC

Signals In RX(0-63)

Signals Out BF I/Q

FUNCTION The Imageformer subsystem contains one Beamformer board (BF)

in 256-channel syste ms and two BF boards in 512-channel systems.

The BF performs digitizing of data from each receiver channel. This

data is then processed by Acuson-developed proprietary BFP ASIC

circuits. These ASICs perform the delay, apodization, phase adjust,

and summation of the individual channels. The summed data is

then mixed to convert it into a baseband signal (I&Q), which is then

passed to the Controller board (CN). Systems with two BF boards

have their outputs summed on the CN board.

Primary control and setup of the board for each ultrasound line is

done by the Controller board (CN), over the IAB Control bus.

TROUBLESHOOTING

INTS

H

Failures of the beam formation process are generally perceived as

one or more ultrasound lines being affected throughout the depth of

the scan. The failure may be loss of data, noisy data, or other

artifacts affecting a subset of the ultrasound lines throughout the

depth of the scan.

On 512-channel systems, the location of the two BF boards can be

switched, to see if the affected ultrasound lines move to a different

part of the image area. If the artifact moves, the BF board is the

defective assembly.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 15

Page 16

Module 5 - System Architecture Acuson Confidential

CONTROLLER BOARD

CN2/3

Part Number CN2 35822

Part Number CN3 39522

Quantity One

Power Supplies +5 VDC

Signals In BF I/Q, PPS status

Signals Out 2-D, M Mode, F Mode data, PPS control

NOTE: CN3 is required for Sequoia Signature Option.

FUNCTION The Controller board (CN) provides the overall control and timing

for the Imageformer subsystem. It has a n A c quisition Control

Processor (ACP) that controls the Imageformer and interfaces with

the DIMAQ workstation subsys tem to ascertain the scan format

(e.g., depth, focal zone, mode, gain vectors, etc.).

TROUBLESHOOTING HINTS

Based on the scan format, the CN determines the parameters

required to configure each board in the Imageformer, as well as the

CSD and BDM boards, to achieve the correct scan format. These

parameters are passed to each board over the Acquisition Control

bus.

The Focus Control Processor (FCP) generates transmit and receive

apodization profiles. The CN also processes the ultras ound data

from the BF board(s). When two BF boards are present in a system,

the echo data is summed and gain-corrected by the CN.

F-mode data is then passed to the Color Spectral Doppler board

(CSD), where the Color Doppler velocity data is derived from the

ultrasound data. 2-D and M-mode data are passed to the 2-D

mode/M-mode Processin g and System Data Memory board (BDM)

for preprocessing, temporal processing and storage.

Because the CN board contro ls the other boar ds in the Imagefo rmer,

failure of the CN could create a wide variety of imaging problems.

In general, if an imaging problem cannot be resolved by replacing a

suspected Imageformer board or boards, then replacing the CN

would be recommended.

Module 5-16 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 17

Acuson Confidential DIMAQ Integrated Ultrasound Workstation

DIMAQ INTEGRATED ULTRASOUND WORKSTATION

The integration of a special purpose ultrasound workstation into

the system architecture is at the heart of the Sequoia system’s digital

image management capabilities.

The DIMAQ workstation has numerous system capabilities which

allow it to:

• Expand the science of quantification

• Expand Network and AEGIS system capability

• Perform JPEG compression, direct DICOM connectivity and

display of multiple static and dynamic im ages

• Spec i al applicat io ns , su c h as stress echo.

The primary function of the DIMAQ workst ation is the display of

data received from the Coherent Imageformer. Ultrasound data can

be acquired in one of four formats, linear, sector, curved, or Vector

Wide-View Array. None of these formats are similar to the video

raster format, therefore a conversion process must take place in

order to display the ultrasound data on a video monitor.

THE DIMAQ WORKSTATION PCBS

In addition to this, the DIMAQ workstation incorpora tes a number

of other functions. These are to process ultrasound 2-D mode and

Doppler data, to perform calculations, and to interface the system to

various input and output devices including the user controls.

Overall control of the system is the job of the System Supervisory

Processor , which is located on the Reconstruction Display Processor

board (RDP).

The DIMAQ workstation is made up of six printed circuit boards.

Each of these boards performs specific functions in the formation

and display of an ultrasound image cell. They are:

BOARD NAMES ACRONYMS

Color Spectral Doppler Board CSD

2-D mode/M-mode Acquisition & Preprocessing and

System Data Memory Board

Reconstruction Display processor Boa rd RDP

Input/Output Video Board IOV

Input/Output Expansion Board IOE

BDM

Peripheral Interface Controller Board PIC

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 17

Page 18

Module 5 - System Architecture Acuson Confidential

THEORY OF

O

PERATION

ACQUISITION AND

REPROCESSING

P

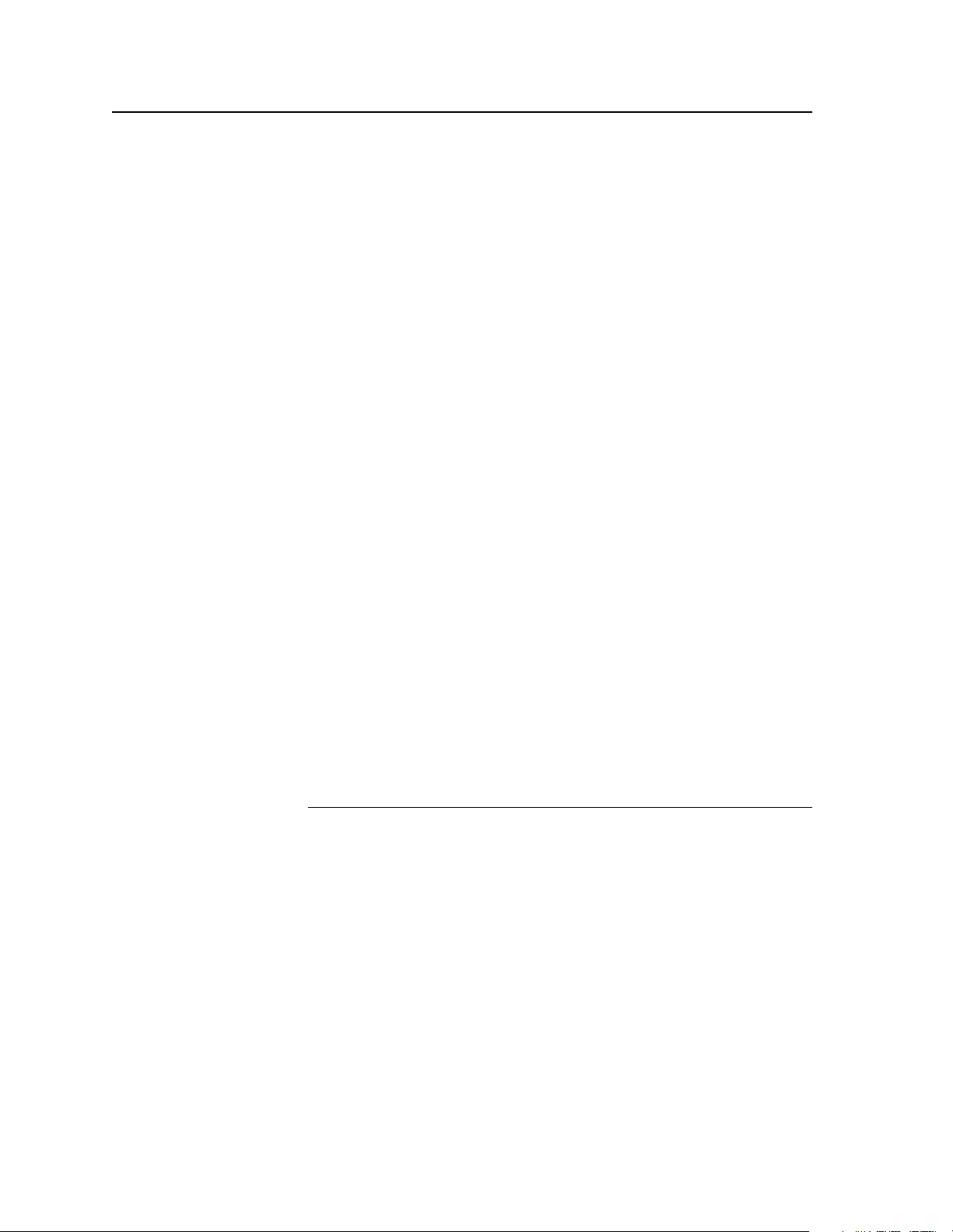

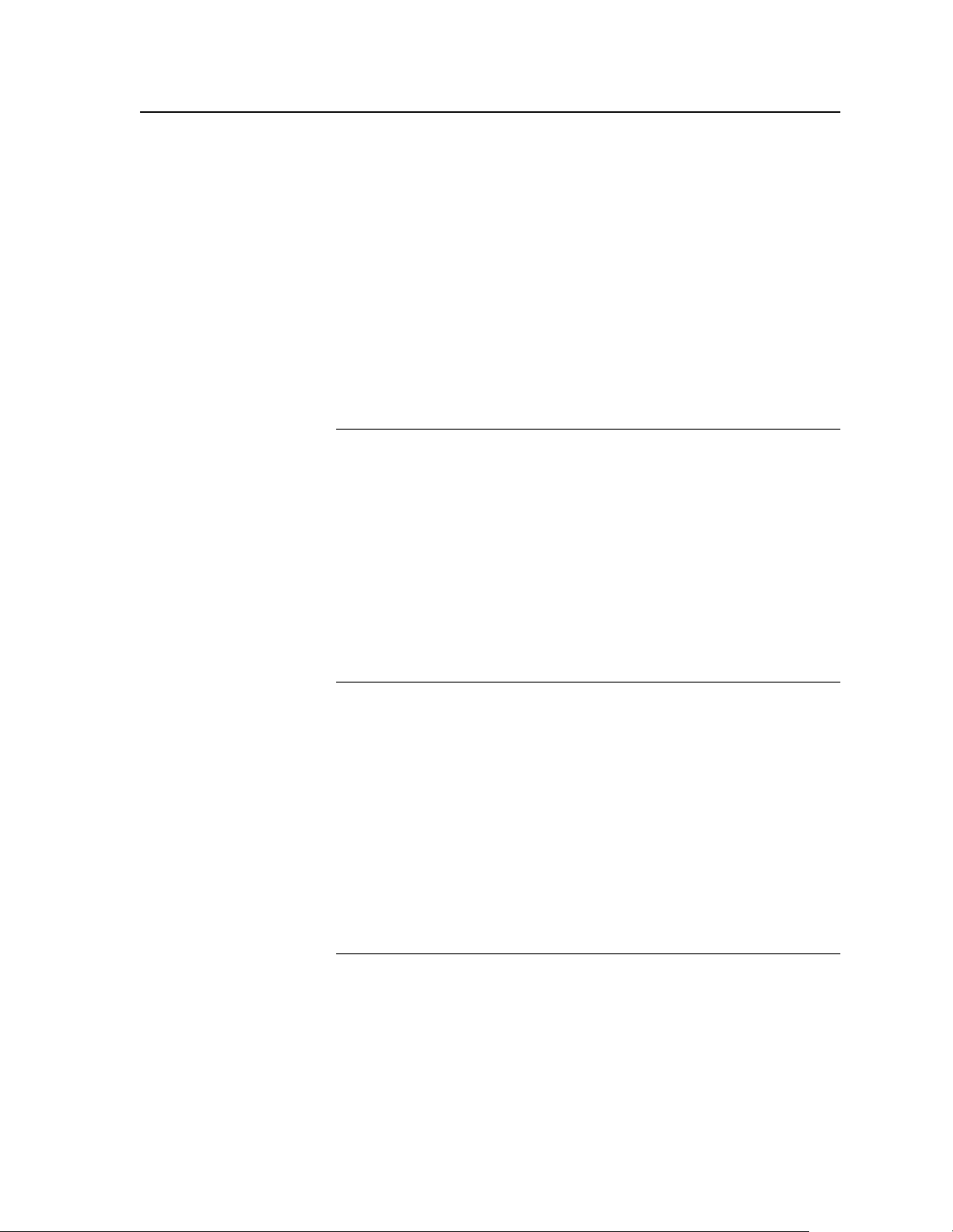

The DIMAQ workstation, as shown in the functional block diagram

in Figure 5-3, performs the following major functions for normal 2D mode imaging:

• Overall control of the Sequoia system

• Storage of ultrasound data for CINE functions

• Conversion of ultrasound scan format to video scan format

• Image enhancement and postprocessing

• Conversion to various video formats

• Alphanumeric and graphic display

• Interface to operator (front panel controls)

• Interface to peripheral recording devices (AEGIS system, VCR,

Printers, etc.)

Digital ultrasound video information is sent to the DIMAQ

workstation from the Coherent Imageformer. In the DIMAQ

workstation, the information is stored in the proper locations in the

system data memory.

RECONSTRUCTION From the system data memory, data is passed to the Reconstruction

Display Processor (RDP). Here, 2-D and Color Doppler data are

combined, M-mode or pulse Doppler data are stored to strip

displays, and graphics and data block information are overlaid.

VIDEO CONVERSIONS The data is then passed to the Input/Output Video board (IOV).

Here the data is converted to a variety of video standards.

Progressive RGB video is provided to the internal monitor. Also,

interlaced composite and component video are derived from the

progressive RGB. NTSC and PAL video standards are supported.

DIMAQ WORKSTATION SUBSYSTEM CONTROL

SYSTEM SUPERVISORY PROCESSOR

The DIMAQ workstation provides overall control of the system,

including user interface and high level control of other processors

which, in turn, control subsystems. The main processor is the

System Supervisory Processor (SSP) and is located on the

Reconstruction Display Processor board (RDP).

This processor communicates with the BDM and CN via the system

control bus. The SSP can also communicate with the PIC board via

the Aux bus. This is used to configure the inputs and outputs from

the PIC board, as well as to communicate with the SCSI devices on

the system.

Module 5-18 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 19

Acuson Confidential DIMAQ Integrated Ultrasound Workstation

Whenever a key is pressed or a knob is adjusted, the SSP interprets

this data and configures the system accordingly.

SCAN FORMATS High-level information about the scanning mode is passed to the

CN board. The CN, in turn, configures the Coherent Imageformer to

scan in a mode that reflects the user’s parameters.

The SSP also sends high-level configuration information to the

BDM. The BDM is configured to capture data from the Coherent

Imageformer, as appropriate for the scanning mode.

When a change is made to the scanning parameters, the

corresponding graphic element on the monitor is changed to blue

while the transition to the new format is performed. When the

system is displaying data as selected by the new parameters, the

graphic element reverts to white. This allows the user to know

precisely when the system has completed reconfiguration of the

scan format.

USER INTERFACE The User Interface provides the interface between the user and the

Sequoia system. One of the components of the User Interface is the

Front Panel Processor (FPP) board. The FPP monitors the status of

the user controls and, when changes occur, sends an interrupt to the

System Supervisory Processor (SSP) located on the RDP board. The

SSP then initiates the sequence of events needed to configure the

Sequoia system as required.

The User Interface is designed in a modular fashion. The FPP board

mates to the switch assembly via stand offs and hard connectors.

The trackball, QWERTY (Alphanumeric keyboard), and DGC

potentiometers assembly are connected with ribbon cables.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 19

Page 20

Module 5 - System Architecture Acuson Confidential

Monitor

Serial Ports

SCSI

Video/Audio

User

Controls

Digital

Video Bus

Aux Bus

FIZ

Physio

Module

PIC

Peripheral

Interface

Conntroller

Audio I/O

Physio I/O

FPP

Front Panel

Processor

Ethernet

RDP

CSD

Video

Display

Image

Reconst.

Doppler

Buffer

Block

Audio

Processor

Text &

Spectral

Doppler

Processor

Static

Graphics

CDI

Post-Proc.

Color

Doppler

Processor

System

Supervisory

Processor

Waveform

Graphics

BDM

Processor

System

Data

B/M Mode

Acq. and

Memory

Preproc.

IOV

I/O

Processor

Video

Standards

SDM Data

Port

Conversion

I/O Expansion

(JPEG Compr.)

IOE

SDM

Reconstruction Bus

SDM

Acq. Bus

Acq

RX

I/Q

Doppler

Serial

Data

Acq

I/Q

Figure 5-3 DIMAQ Workstation Block Diagram (IOE3)

Module 5-20 Sequoia Service Training Manual P/N 59155 Rev. 1

Control Bus

Page 21

Acuson Confidential DIMAQ Integrated Ultrasound Workstation

Monitor

Serial Ports

SCSI

Video/Audio

Ethernet

User

Controls

Digital

Video Bus

Aux Bus

FIZ

Physio

Module

PIC2

Peripheral

Interface

Conntroller

Audio I/O

Physio I/O

FPP

Front Panel

Processor

RDP

CSD

Video

Display

Image

Reconst.

Doppler

Buffer

Block

Audio

Processor

Text &

Spectral

Doppler

Processor

Static

Graphics

CDI

Post-Proc.

Color

Doppler

Processor

System

Supervisory

Processor

Waveform

Graphics

Processor

BDM

System

Data

Memory

B/M Mode

Acq. and

Preproc.

IOV2

I/O

Processor

Video

Standards

SDM Data

Port

Conversion

I/O Expansion

(JPEG Compr.)

SDM

Reconstruction Bus

SDM

Acq. Bus

Acq

RX

I/Q

Doppler

Serial

Data

Acq

I/Q

Figure 5-4 DIMAQ Workstation Block Diagram (IOV2/PIC2)

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 21

Control Bus

Page 22

Module 5 - System Architecture Acuson Confidential

COLOR AND SPECTRAL DOPPLER BOARD

CSD1/2

Part Number CSD1 32082

Part Number CSD2 41462

Quantity 1

Power Supplies +5VDC, -5.7VDC

Signals In RX I/Q, Mode I/Q

Signals Out Spectral frequency da ta , spectral audio data,

Color Doppler data

FUNCTION The CSD board processes the ultrasound echo data to extract

spectral and color flow data. The CSD may be thought of as

comprising three distinct functional subsections. These are spectral

Doppler processing, audio Doppler processing, and Color Doppler

processing.

SPECTRAL AND

UDIO PROCESSING

A

COLOR DOPPLER PROCESSING

TROUBLESHOOTING HINTS

The spectral and audio sections of the CSD board receive RX I&Q

data from the RX board directly. Echo clutter is removed from the

signal. Then the data is converted from time domain to frequency

domain. Both are then passed to the system data memory on the

BDM for further processing and display.

The Color Doppler data is received from the CN board as F-mode

I&Q. The color flow parameters are extracted from the raw echo

data and processed to derive a velocity estimate. The data is then

passed to the system data memory on the BDM for further

processing and display.

The CSD board is divided into three functional subsections, all

processing data independently of each other. This provides

important clues about possible failures.

When attempting to isolate a problem, first note the modality in

which the problem occurs. If a manifestation of the problem occurs

in all modalities then it is highly unlikely that CSD is responsible.

Problems likely to be related to the CSD board are those which

appear in only one of the three modalities discussed earlier.

Module 5-22 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 23

Acuson Confidential BDM Board

BDM BOARD

BDM1/2

Part Number BDM1 32062

Part Number BDM2 41472

Quantity 1

Power Supplies 5VDC

Signals In Acq. I/Q

Signals Out SDM bus

FUNCTION The 2-D mode, M-mode, Spectral and System Data Memory board

consists of two distinct functional components: the 2-D mode /Mmode Acquisition and Preprocessing (BAP) and System Data

Memory (SDM). The BAP performs all detection an d pr e p r o cessing

operations for B/M mode. The SDM is a high-bandwidth, highcapacity memory subsection for use in temporal processing, cine

data storage, and buffering between acquisition and recons truction

functions.

SMM PROCESSOR The System Memory Manager Processor (SMM) is responsible for

management an d a lloc ation o f th e SDM mem ory, managem ent, an d

synchronization of data to be displayed. Any access to SDM

memory must have prior setup performed by the SMM.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 23

Page 24

Module 5 - System Architecture Acuson Confidential

RECONSTRUCTION AND DISPLAY PROCESSOR BOARD

RDP2/5

Part Number RDP2 38282

A

Part Number RDP5

Quantity 1

Power Supplies +5VDC

Signals In 2-D, M Mode Spectral, VCR playback, and AEGIS

Signals Out Setup parameters for the system, digital

A. RDP5 is compatible with Sequoia 4.0 and higher.

FUNCTION The RDP performs two primary functions. First, it has the System

Supervisory processor located on it. Second, it takes the data for

each mode from the BDM board and reconstructs an image.

53552

system review data

progressive RGB video

The RDP board constantly receives data from the BDM board,

overlays or mixes color data on the 2-D image, incorporates

graphics, and displays M-mode and spectral strip data, etc. as

required. When a frame of data has bee n completed, the data is read

out to the IOV board.

SSP The System S upervisory processor is, as the name suggests,

responsible for managing the system at large. This includes

processing user requests initiated at the user interface, setup of the

Imageformer subsystem for the scanning mode selected,

configuration of each of the PCBs to process the data required, etc.

The SSP also handles communica tion with most of the Sequoia

system and maintains system control bus accuracy.

TROUBLESHOOTING HINTS

The SSP performs many validations of its own functionality and its

ability to communicate with o ther boards during the power on

cycle. If the SSP fails to complete these self-tests, then the system

will fail to boot.

The other function of RDP board is to read out the image, spectral,

flow, VCR, or AEGIS system data from the BDM board, construct

one image frame and pass the image format data to the IOV. Failure

of this process may result in an image reconstruction problem or no

update on the frame displayed.

Module 5-24 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 25

Acuson Confidential Input/Output Video Board

INPUT/OUTPUT VIDEO BOARD

IOV1/2

Part Number IOV 33342

A

Part Number IOV2

Quantity 1

Power Supplies +5VDC, +12VDC, -5.7VDC, ±12VDC

Signals In Video data from RDP, Audio data from BDM,

Signals Out Progressive RGB, S-VHS, VHS, voidable or NTSC

A. IOV2 requires a PIC2 and eliminates the IOE3.

FUNCTION The primary function of the IOV board is to provide conversion to

and from various video format standards; e.g., NTSC, PAL; S-VHS

and VHS. The video format used by the system monitor is a

progressive, i.e., noninterlaced RGB video.This format is not

compatible with most of the peripherals.

41482

VCR playback data, AEGIS system review data

video formats, system audio.

TROUBLESHOOTING HINTS

The IOV board supports other processes as well. These include

processing audio data from BDM, and interfacing with the Physio/

ECG board (FIZ).

The IOV2 also provides JPEG compression circuitry that was

previously on the IOE3.

The IOV board is responsible for the video format conversion. If

video is corrupted on one peripheral device but not on the other

(e.g., video is OK on the display monitor but VCR recording is not

correct and interface cable has been replaced), then it is likely that

IOV is malfunctioning.

If the video is corrupted at all outputs than the RDP may be giving

corrupted data to the IOV board, or the IOV itself is corrupting the

video data.

Communication problems with FIZ board may be caused by the

IOV board. If replacing the FIZ board doesn’t correct the problem,

try replacing the IOV board.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 25

Page 26

Module 5 - System Architecture Acuson Confidential

INPUT/ OUTPUT EXPANSION BOARD

IOE3

Part Number 42532

Quantity 1

Power Supplies +5 VDC

Signals In AEGIS system data, Ethernet communication

Signals Out AEGIS system data, Ethernet communication

FUNCTION The IOE board provides the hardware needed to interface to

Ethernet networks. The Sequoia system uses 10BaseT Ethernet

connection.

In addition, the IOE board has provisions for installing other circuit

boards as daughter boards, to allow for future additions to the

system’s functionality.

Newer systems have the IOV2 and PIC2 boards, which eliminate

the need for the IOE3.

TROUBLESHOOTING

INTS

H

The IOE board has sole responsibility for Ethernet communication

of the Sequoia system to an Ethernet network. If the network setups

and the interface to the network are OK then the IOE board may be

replaced to correct the problem.

Module 5-26 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 27

Acuson Confidential Peripheral Interface Controller Board

PERIPHERAL INTERFACE CONTROLLER BOARD

PIC1/2

Part Number PIC 30132

A

Part Number PIC2

Quantity 1

Power Supplies +5 VDC, +12 VDC, -5.7 VDC, and ±12 VDC

Signals In All Video formats from IOV board, All playback

Signals Out All Video formats to Peripheral devices, All

A. PIC2 requires the IOV2.

43242

video from the Peripheral devices, Audio from

BDM, Audio from Peripherals.

playback video to the IOV board, Audio to

Peripherals, speakers, headphones.

FUNCTION The PIC board provides interconnections between the Sequoia

system card cage and other assemblies or peripheral devices. These

connections are made through the rear panel located at the rear of

the Sequoia system.

Assemblies that are connected to the PIC board include the FPP

board, FIZ board, Audio speakers, Monitor assembly, and the SCSI

devices. Peripheral devices connected to the PIC bo ar d may in clude

a VCR, Printers, Multi-Image camera, or the QV150.

The PIC board stores the system serial number in the BBRAM, and

contains circuitry for reset, start-up and shutdown, etc.

The PIC board also has the capability to monitor many aspects of

the system. These include power supply voltages, fuses, AC line

voltage, and system temperature.

The PIC2 board provides the hardware needed to interface to

Ethernet networks. The Sequoia system uses 10BaseT Ethernet

connection.

TROUBLESHOOTING HINTS

The PIC board provides interconnections between various

assemblies and peripherals. It is also an integral part of the power

up/down sequences.

Generally, if a problem persists a fter replacing the assembly or the

interface cabling, then try replacing the PIC board.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 27

Page 28

Module 5 - System Architecture Acuson Confidential

PHYSIO INTERFACE MODULE

FIZ

Part Number 35992

Quantity 1

Power Supplies +5 VDC and ±12 VDC

Signals In Three lead ECG, Pulse, Phono, and Respiratory

transducers, AUX Inputs.

Signals Out ECG, Pulse, Phono, and Respirato r y trace data,

AUX outputs.

FUNCTION The Physio Interface module is located above the card cage with the

input/output jacks available at the left side of the system. The FIZ

module provides a three-lead ECG input, pulse, phono, and

respiratory input. Additionally, there are input ports available for

auxiliary functions. Refer to the user manu al for the supported

auxiliary devices.

TROUBLESHOOTING

H

INTS

After configuration by the system supervisory processor on the

RDP, based on the user controls, the FIZ module acquires data and

passes it to the IOV over the same bus used for configuration.

The FIZ module contains multiple dat a ch annels, all of which are

passed to the Sequoia system on a single bus. It is useful to know if

the problem exists in one channel or all.

The user controls for the FIZ module are located on the User

Interface. Check for a stuck or broken switch on the User Interface.

Also verify operation of the gain control encoder for gain- or

position-related problems.

Module 5-28 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 29

Acuson Confidential Front Panel Processor Board

FRONT PANEL PROCESSOR BOARD

FPP

Part Number 31642

Quantity 1

Power Supplies +5 VDC, +12 VDC

Signals In User Interface switch selections

Signals Out User Interface changes to SSP on RD P board, LED

annunciators, Two line LCD display.

FUNCTION The PIC board provides the interface between the Sequoia system

card cage and the user. The FPP has a processor on board that

continually monitors the status of the user controls. When changes

occur, the FPP sends an interrupt to the System Supervisory

processor located on the RDP board. The SSP interrog at es the user

controls to find out which ones have been changed and initiates the

sequence of events needed to configure the Sequoia system as

required.

TROUBLESHOOTING HINTS

The User Interface is designed in a modular fashion. The FPP board

mates to the switch assembly via standoffs and hard connectors.

The trackball, alphanumeric keyboard, and the DGC

potentiometers assembly are connected with ribbon cables. Two

additional modules, which contain more controls, are connected to

the FPP by ribbon cables.

All controls except the DGC pots are switches or digital encoders.

The switches are decoded through the use of a switch grid, that is,

each switch occupies the intersection of a pair of wires. The

switches share each wire with other switches, but only one switch

occupies each intersection.

The PIC board provides interconnections between various

assemblies and peripherals. It is also an integral part of the Power

on/off sequences.

Generally , if the pr oblem persists after replacing the assembly or the

interface cabling, try replacing the PIC board.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 29

Page 30

Module 5 - System Architecture Acuson Confidential

2-D/ M-MODE SIGNAL FLOW

TRANSMISSION All Coherent Imageformer functions are controlled by the

Controller board (CN). The CN passes parameter data to the TX

boards on the Imageformer bus. In addition, configuration data is

also passed to the MX and RX boards.

The high-voltage pulses from the TX board are passed to the

Multiplexer board (MX). The MX board directs the transmit pulses

to the appropriate transducer element, based upon the

transducer(s) connected and the scan format used.

Each transducer consists of a piezoelectric-crystal element. A

piezoelectric-crystal element changes spatially when a voltage is

applied across it. On receiving a high-frequency electric wave, the

piezoelectric-crystal element vibrates and creates a high-frequency

ultrasound wave.

The ultrasound wave propagates into the tissue of the patient being

scanned. Wherever there is a change in the acoustic impedance,

such as at the interface between dissimilar tissues, a portion of the

ultrasound wave is reflected. The magnitude of the reflected wave

is a function of the difference in acoustic impedance between tissues

at their interfaces.

RECEPTION Ultrasound signal reception begins when the Coherent

Imageformer fires an ultrasound wave. The digital ultrasound data,

representing the instantaneous phase and amplitude values of the

analog ultrasound signal, are loaded into the BDM board. Her e, the

data is preprocesse d and loaded i nto the sys tem data memory. Each

frame of data is stored for CINE review and persistence functions.

The number of frames that may be stored varies, depending upon

the scan format used.

Persistence is implemented by the BDM board. It is achieved by

modifying the current and previous data with a complex algorithm

to remove temporally transient artifacts.

RECONSTRUCTION

AND DISPLAY

The 2-D mode data stored in the BDM board is transferred to the

RDP board, and mapped into the proper raster display format. The

2-D mode data is also combined with the graticules, static graphics,

alphanumer ic and waveform graphics that will ultimately appear

on the monitor.

The digital RGB progressive video is passed to the Input/Output

Video board (IOV). The IOV converts the digital RGB progressive

video into an analog video.

Module 5-30 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 31

Acuson Confidential 2-D/ M-Mode Signal Flow

The analog video is then converted into various video standards,

e.g. NTSC and PAL video standards, interlaced composite or

component (Y/C) video as well as interlaced RGB. These formats

allow interfacing of peripheral recording devices on non-AEGIS

systems.

Analog progressive RGB video is then passed to the Peripheral

Interface Controller board (PIC). The PIC board provides buffering

and connections for each of the supported peripheral devices as

well as the system monitor. The progressive RGB is then passed to

the system video monitor for d isplay.

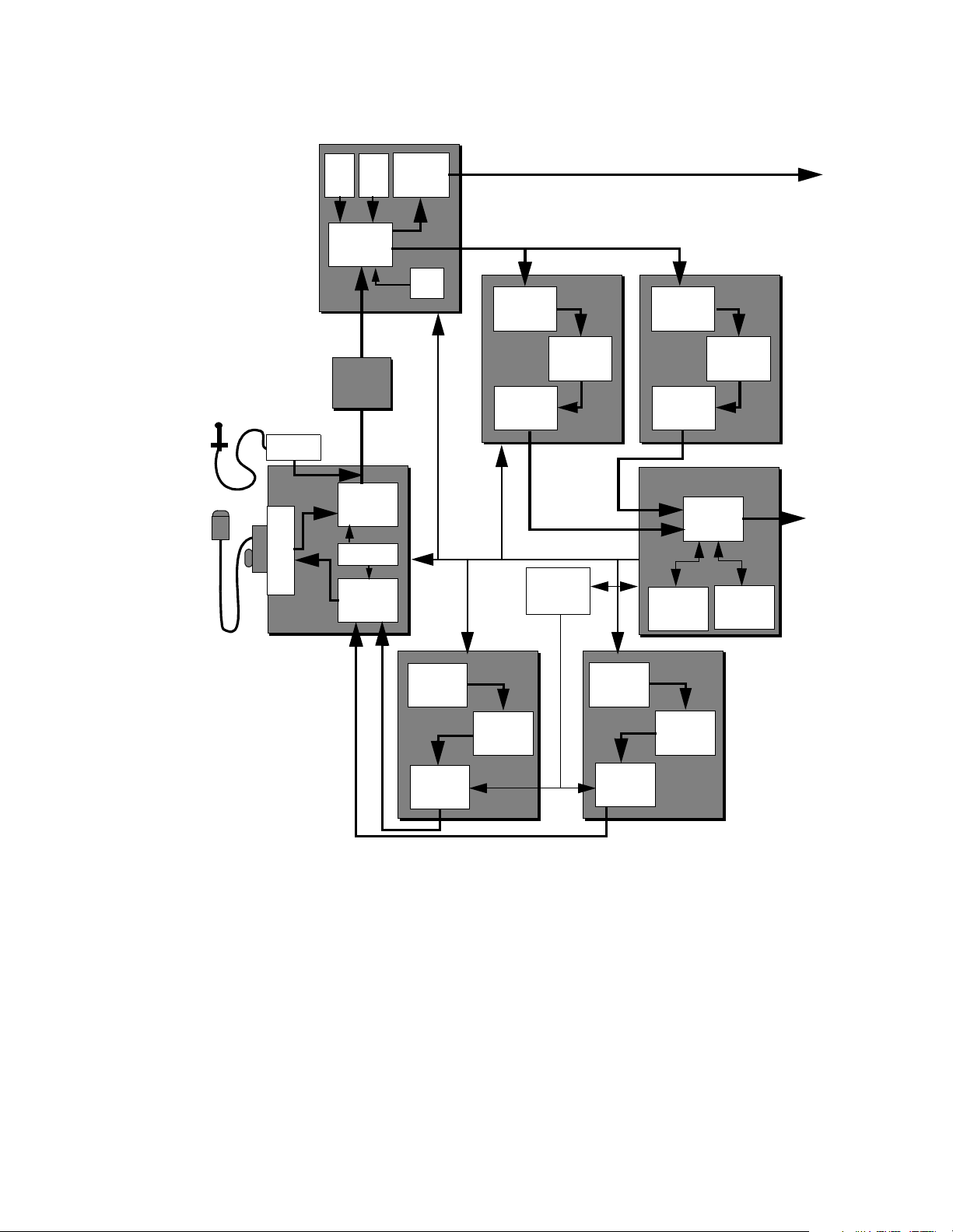

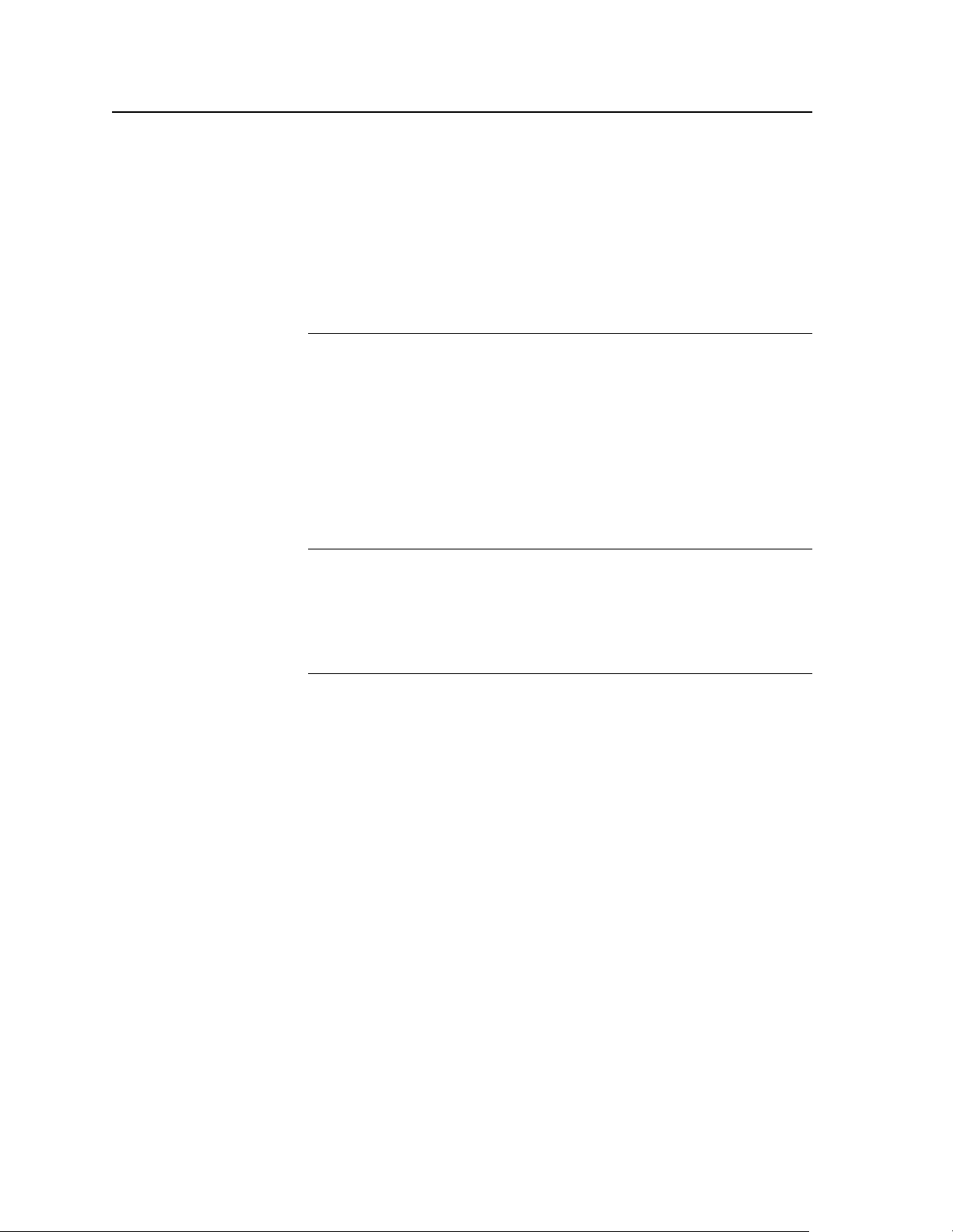

Figure 5-5 illustrates the 2-D mode/M-Mode signal flow.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 31

Page 32

Module 5 - System Architecture Acuson Confidential

MO Dri ve

C31

Physio

System Audio

Monit or

Patient :

FPP

C31

Switch Panel

Hard Drive

Ethernet

UART

FIZ

Intf

IOV PIC

Audio

BDM

CSD

System

Audio

IOP

C31

RDP

Audio/VCR Playback/Physio

C31

C31

(DSP)

Audio

Doppler

(DAP)

Video

Buffers

System

Data

Memory

C31

Color

(CSP)

(VSC)

Video

Conversion

(VDB)

C31

B,D,F,M-Date

(SDM)

Prog

Video

Pal/NTSC

via SW

(IRB)

C31

Image

Reconstr.

(BAP)

Gain

Acq.

Processing

B, M- Data

C31

Cntlr

SCSI

IOE3

(SSP)

Supervisory

Processor

486

(SMM)

Memory

Manager

C31

(ALC)

Aegis

Control

486

CDI Data

CN

BF3_B

Doppler Data

+

BF3_A

Doppler

RX

(BBF)

Baseband

Filter

(BFP)

Dig.

Bfmr

A/D

64

64

MAC

cntl

Beamformer

(SDP)

Low Noise

128

Clks

Amplifier

(LVA)

MX2

RMX

(FCP)

Focus

Control

Apod/Delay

Gain/Interploation

MX/RX Bus

IAB Bus

Apodization/Delay

cntl

MXC

MP

TMX

DMA

C31

TX_B

TX_A

(PWG)

Pgm Waveform

Generator

486

(ACP)

Acquistion

Co ntro l

D/A

64

(HVA)

High Volt age

Amp

64

Figure 5-5 2-D Mode/M-Mode Sign al Path

Module 5-32 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 33

Acuson Confidential Solo™ Spectral Doppler Signal Flow

SOLO™ SPECTRAL DOPPLER SIGNAL FLOW

DOPPLER THEORY Spectral Doppler is a way of processing echo data whereby the

frequency shift of the echo data is mapped to a strip display,

showing velocity distribution on one axis and time on the other.

The amount of shift is dependent upon the velocity of the reflector,

while the direction of shift (e.g., higher or lower pitch) is dependent

upon whether the reflector is moving towards or away from the

transducer . The frequency received by the transducer will be shifted

upwards if the target is moving towards the transducer and

downwards if the target is moving away. Echo data shifted in

frequency is called the Doppler signal. There is a major echo

component that is not shifted in frequency, which comes from

stationary tissue. This is known as clutter.

PULSE WAVE DOPPLER

Pulse W ave Spectral Doppler (PW Doppler) mode emits a pulse into

the body and then monitors the echo data over a time interval that

is set by the positioning of a range gate on the system monitor. By

sampling the data at a specific area, clutter can be reduced

dramatically.

NYQUIST LIMIT If the sampling rate is not adequate for high-frequency Doppler

shifts, artifactual lower frequency shifts are displayed. The

requirement that the sampling rate must be at least twice the

maximum frequency present in the Doppler signal is referred to as

Nyquist criterion. One half of the pulse repetition frequency (PRF)

is the Nyquist limit.

HIGH PRF There is a high PRF mode that may be invoked, wh ich results in a

phantom range gate at a depth other than the area of interest. If

there is no blood flow in the phantom area, this is an acceptable way

of increasing the PRF.

CONTINUOUS WAVE DOPPLER

Continuous Wave Doppler (CW Doppler) mode emits a continuous

ultrasound wave from a subset of the transducer elements. Other

elements of the transducer continuously monitor the echo data. This

allows many more samples than PW Doppler mode, but does not

allow for ranging of the data. For this reason, the signal received has

large amounts of clutter from the entire sample line. The Doppler

signal is very small relative to this clutter. The D oppler signal m ust

be separated from the clutter to be useful.

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 33

Page 34

Module 5 - System Architecture Acuson Confidential

SOLO™ SPECTRAL

D

OPPLER

The Sequoia 512 system has a unique spectral Doppler architecture.

It consists of a dedicated audio beamformer for spectral Doppler

only. The Doppler beam formation is performed at audio

frequencies because Doppler signal is an audio signal.

During spectral Doppler operation, the Doppler data is passed to

the Spectral Doppler Preprocessor (SDP) subsystem, located on the

RX board. The PW Doppler data is sampled only at the range gate.

CW Doppler data is acquired from the entire sample line.

The Doppler data is then processed and the quadrature data (I&Q)

derived. The I&Q data is then digitized and placed on the RX I/Q

data path for processing and display by the DIMAQ workstation.

T o achieve maximum performance, the spectral Doppler signal path

in the Sequoia system is significan tly different from the 2-D and

Color Doppler signal paths. Refer to Figure 5-6 for a diagram of the

signal path.

Spectral Doppler I&Q data is received at the Color Spectral Doppler

board (CSD), directly fro m the Receiver boar d (RX ) in the

Imageformer. The BF board and CN board do not process the

spectral echo data. The CSD provides the time domain to frequency

domain conversion. Furthermore, the CSD generates the audio

corresponding to the Doppler data received.

The spectral Doppler and audio data are then passed to the BDM

board where they are stored to allow CINE and other temporal

processing functions to be performed.

DISPLAY The spectral Doppler data is passed to the RDP where it is merged

with the spectral strip graphics as well as any other data to be

displayed on the monitor . This data i s then passed to the IOV board

and then to the PIC board in a fashion similar to the 2-D mode data.

AUDIO Audio data is passed directly from the BDM to the IOV board. It is

not processed by the RDP. The audio data is then passed to the PIC

board, which drives the speakers in the system, or is output to

headphones or a video recorder.

Module 5-34 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 35

Acuson Confidential Color Doppler Signal Flow

COLOR DOPPLER SIGNAL FLOW

COLOR DOPPLER Color Doppler imaging is a modality whereby the frequency shift of

echo data is sampled at a large number of points within a defined

area of the image. This area is defined using a CD Res box. The

frequency shift samples are converted to a velocity est imation and

mapped onto the monitor as a color, e.g., blue if the signal is

frequency-shifted downward and red if the signal is frequencyshifted upward. This results in a graphic representation of blood

flow or other motion.

SST™ COLOR DOPPLER

The Sequoia 512 system incorpora tes SST Color Doppler. This is

enhanced by multiple Color Doppler beamformers and proprietary

Color Doppler processing, to improve S

emporal resolution. The Color Spectral Doppler (CSD) board

and T

receives color I&Q signals from the Controller (CN) board. The CSD

performs the majority of Color Doppler processing and uses

memory located on the BDM to store intermediate results of this

processing.

The color I&Q values represent the instantaneous data from a single

temporal and spatial point. Processing velocity information for

many points uses algorithm s that require multiple samples of the

same data point. For this reason, the results of color processing are a

“time averaged” velocity.

The results of CSD processing are passed to the BDM board for

storage. This is where the data is held for CINE review, as well as

temporal persistence processing. The data is then passed to the RDP

to be overlaid/mixed with the 2-D information. The color data is

then passed to the IOV board and then to the PIC board in a fashion

similar to the 2-D data.

Figure 5-6 illustrates the SST Color Doppler signal path.

ensitivity, Spatial resolution

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 35

Page 36

Module 5 - System Architecture Acuson Confidential

MO Dri ve

C31

Physio

System Audio

Monit or

Patient :

FPP

C31

Switch Panel

Hard Drive

Ethernet

UART

FIZ

Intf

IOV PIC

Audio

BDM

CSD

System

Audio

IOP

C31

RDP

Audio/VCR Playback/Physio

C31

C31

(DSP)

Audio

Doppler

(DAP)

Video

Buffers

System

Data

Memory

C31

Color

(CSP)

(VSC)

Video

Conversion

(VDB)

C31

B,D,F,M-Date

(SDM)

Prog

Video

Pal/NTSC

via SW

(IRB)

C31

Image

Reconstr.

(BAP)

Gain

Acq.

Processing

B, M- Data

C31

Cntlr

SCSI

IOE3

(SSP)

Supervisory

Processor

486

(SMM)

Memory

Manager

C31

(ALC)

Aegis

Control

486

CDI Data

CN

BF3_B

Doppler Data

+

BF3_A

Doppler

RX

(BBF)

Baseband

Filter

(BFP)

Dig.

Bfmr

A/D

64

64

MAC

cntl

Beamformer

(SDP)

Low Noise

128

Clks

Amplifier

(LVA)

MX2

RMX

(FCP)

Focus

Control

MP

cntl

IAB Bus

Apodization/Delay

TMX

Apod/Delay

Gain/Interploation

MX/RX Bus

MXC

DMA

C31

TX_B

TX_A

(PWG)

Pgm Waveform

Generator

486

(ACP)

Acquistion

Co ntro l

D/A

64

(HVA)

High Volt age

Amp

64

Figure 5-6 Color Doppler Signal Flow

Module 5-36 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 37

Acuson Confidential ECG/Physio Signal Flow

ECG/PHYSIO SIGNAL FLOW

The Physio Interface allows an ECG, physio logic transducers and

auxiliary signals to be displayed on the Sequoia system monitor.

These signals may be used to trigger the 2-D mode image update

when using Pulsed Doppler or M mode, or they may be used as a

timebase when reviewing the CINE memory.

WARNING!

ECG

Pulse

Phono

Respiratory

Monitor

Peripherals

The Physio Interface is not designed for use in conjunction with

electrosurgery or diathermy equipment.

The Physio Interface board (FIZ) provides a three lead ECG input, a

heart sounds input, a pulse input, and a respiration input. There are

four additional inputs available for auxiliary functions. It is also

possible to configure two of the auxiliary inputs with output signals

under software control. Refer to the <Sequoia 512 User Manual for

supported modes.

The Physio Interface board is located above the card cage with the

input/output jacks available at the left side of the sy stem.

Under software control, the RDP sends configuration data to the

IOV board on the system control bus. The data is transferred from

the IOV board to the FIZ board on a dedicated bus.

After configuration, the FIZ board acquires data and passes this

data to the IOV over the same bus used for configuration. The IOV

routes this data to the BDM where it is stored for CINE review. The

physio data is then passed to the RDP, where the graphic display is

overlaid on the video image.

FIZ

Module

PIC

Physio

Bus

Interlaced RGB

Progressive RGB

Component Video

Composite Video

Physio

Data

IOV

BDM

RDP

Figure 5-7 ECG/ Physio Signal Path

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 37

Page 38

Module 5 - System Architecture Acuson Confidential

DIMAQ SYSTEM STORE AND REVIEW

ACQUISITION The Sequoia systems supports the acquisition of both static and

dynamic clips. For acquisition, the DIMAQ wo rkstation receives

video data from the IOV board in interlaced RGB format, performs

color space conversion to Y, R-Y, and B-Y (YUV), prior to JPEG

compression. The compressed images are stored in the SDM on the

BDM board, from which they can be decompressed for review, or

transferred out for storage on an MO drive or hard drive.

REVIEW For review, the IOE board in the DIMA Q workstation provides the

ability to decompress the video acquired in JPEG format, a nd store

the Run Length Encoded (RLE) YUV raster format data in SDM on

BDM board. This allows reconstruction by RDP board, and

subsequent conversion to video by IOV board, for display on the

monitor via the PIC board.

BDM

IOE

PIC

JPEG

SDM

Video

Display

Buffer

Reconstructio

n Block

Figure 5-8 DIMAQ System Signal Flow (Systems with IOE3 board)

RDP

Compress

Video

Standard

Conver-

SDM

Data

Port

-ion

I/O

Processor

IOV

<

MOD

;

Monitor

HD

Module 5-38 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 39

Acuson Confidential DIMAQ System Store and Review

SDM

Video

Display

Buffer

Reconstructio

n Block

BDM

IOV2

<

JPEG

compress-

ion

RDP

Figure 5-9 DIMA Q S ystem Signal FLow (systems with IOV2/PIC2)

Video

Standard

Conver-

SDM

Data

Port

I/O

Processor

PIC2

;

Monitor

Ethernet

MOD

HD

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 39

Page 40

Module 5 - System Architecture Acuson Confidential

VCR PLAYBACK

ACQUISITION The Video Standard Converter (VSC) on IOV board receives the

external video input from VCR via the PIC board and converts it to

digital format for storage into SDM on BDM board.

VCR autocalibration data is digitized as part of video input process

and captured by this block.

PLAYBACK The video data stored in the BDM board is transferred to the RDP

board, and mapped into the proper raster display format.The

digital RGB progressive video is passed to the Input/Output Video

board (IOV). The IOV converts the digital RGB progressive video

into an analog video.

The analog video is then converted into various video standards.

Analog progressive RGB video is then passed to the Peripheral

Interface Controller board (PIC). The PIC board provides buffering

and the progressive RGB is then passed to the system video monitor

for display.

RDP

Video

Display

Buffer

Image

Reconstr

SDM

BDM

Video

Standar

d

SDM

Data

IOV

I/O

Process

Figure 5-10 Video Playback Signal Path

PIC

VCR

Monitor

Module 5-40 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 41

Acuson Confidential Worksheet: System Architecture

WORKSHEET: SYSTEM ARCHITECTURE

1 Describe three hardware differences between the Sequoia 512 and

Sequoia C256 systems?

2 How many TX boards are there on a Sequoia C256 system?

3 Where is the ACP processor located?

4 Where is preprocessing done for spectral Doppler?

5 Where is the Master Clock located?

6 What is the SSP? Where is it located?

7 Do Sequoia systems support interlaced video or progressive?

8 Where are graphics overlaid onto the image?

9 Which board generates the Sequ oia system tree splash screen?

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 41

Page 42

Module 5 - System Architecture Acuson Confidential

10 Write down the names of the SCSI devices in a Sequoia system.

11 Where does the OS (Operating System Software) resi de: RDP or

HD?

12 Where is compression/decompression done for AEGIS system

images?

13 Which board supports the Ethernet interface?

14 What is RI? Describe its function.

15 Where does the TX board get high voltage for transmission?

16 Does CSD support spectral Doppler?

17 Where is Persistence performed for 2-D mode?

Module 5-42 Sequoia Service Training Manual P/N 59155 Rev. 1

Page 43

Acuson Confidential Worksheet: System Architecture

18 Which board stores CINE?

19 Which board supports hardware monitoring?

P/N 59155 Rev. 1 Sequoia Service Training Manual Module 5- 43

Page 44

Module 5 - System Architecture Acuson Confidential

Module 5-44 Sequoia Service Training Manual P/N 59155 Rev. 1

Loading...

Loading...