Page 1

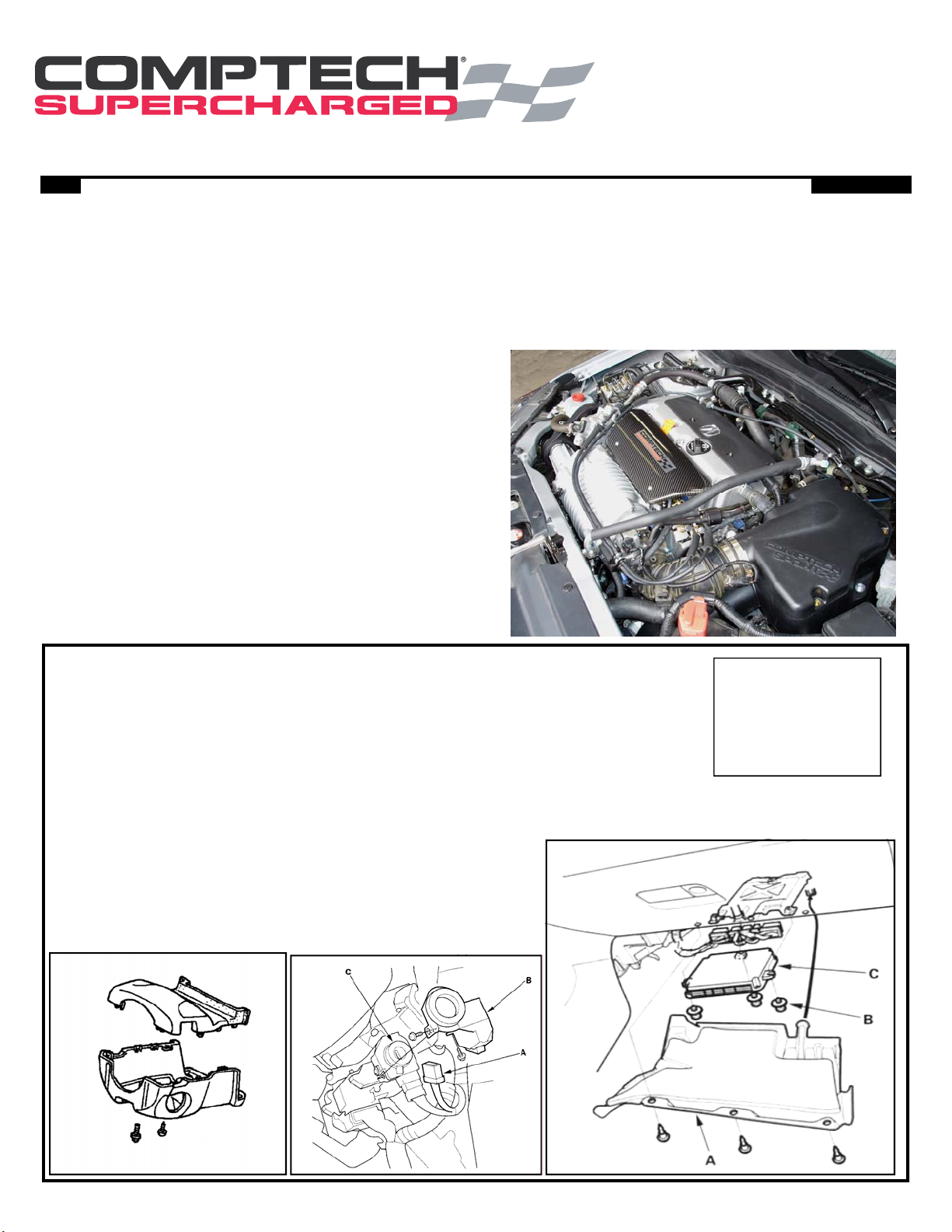

Acura RSX S

Supercharger Kit

Installation Instruction

(2005-2006 models) Kit #350-029

4717 GOLDEN FOOTHILL BLVD • EL DORADO HILLS, CA 95762 • 916.933.1080 • FAX 916.939.9196 • www.comptechusa.com • M-F 8:00 AM—5:00 PM PST

INS-156

Thank you for purchasing the Comptech Supercharger kit for the 2005-2006 Acura RSX Type S. All components

have been designed and manufactured utilizing the latest in technology and materials. Please take a moment to read this

instruction manual and warranty information page thoroughly before starting any work. Always work in a clean environment

and use the appropriate safety equipment and tools to avoid any potential damage or injuries. Comptech recommends the

use of a Genuine Honda Service Manual to supplement these instructions. All Comptech products are intended to be installed by a professional installer. Many stock parts are reused during installation. Do not damage or discard any pieces

during disassembly or installation. We recommend marking any hose or wire before disconnecting to avoid confusion during

reassembly.

10.3.2006 VERSION:

Torque Specifications:

M5 = 3 ft-lbs

M6 = 6 ft-lbs

M8 = 16 ft-lbs

M10 = 31 ft-lbs

M12 = 54 ft-lbs

M14 = 87 ft-lbs

STEP #1 Remove ECU/Immobilizer & Ship to Comptech:

• Disconnect the negative side of the battery.

• Remove the lower dash board cover (A).

• Disconnect the wire plugs at the ECU.

• Remove the three ECU mounting bolts (B) and remove the ECU (C).

• Place the included sticker on the ECU and fill out all of the info.

Immobilizer Removal:

• Remove the steering column covers (2 self tapping screw & 1 washer screw)

• Remove the 2 screws holding the immobilizer control unit-receiver to the ignition key cylinder.

• Disconnect the 7 pin connector (A) and remove the unit (B).

• Send the ECU, immobilizer unit, and your key to HONDATA

using the supplied box (see Address to right).

Ship ECU to:

HONDATA

386 BEECH AVE.

UNIT B2

TORRANCE, CA 90501

1

Page 2

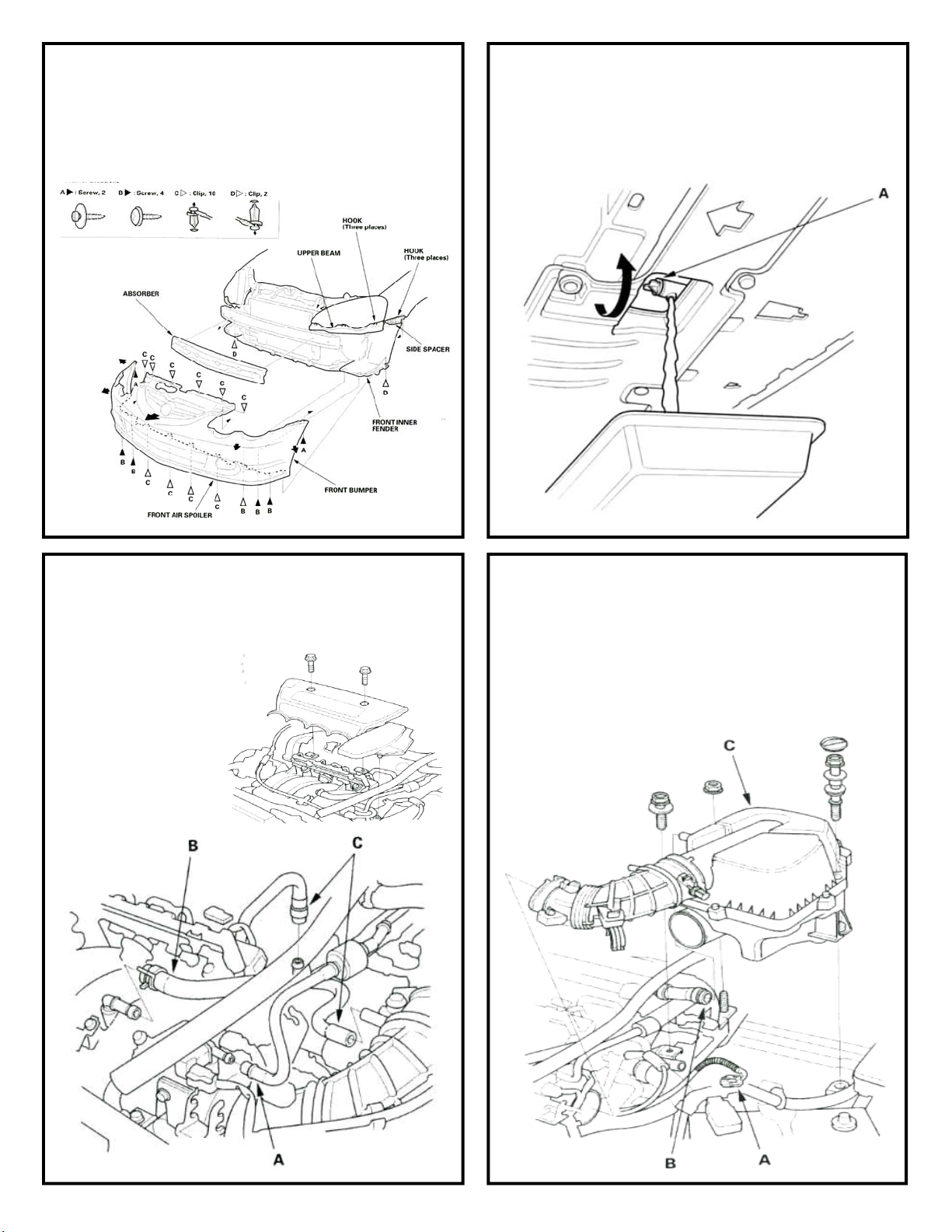

STEP #2 Remove Front Bumper:

• Jack up and support the front of the car using jack

stands.

• Remove the front bumper being careful not to damage

any of hardware because it will be reused.

STEP #3 Prep to remove Manifold:

• Make sure the engine is cool and remove the radiator

cap.

• Drain the cooling system by loosening the drain plug

(A) at the bottom of the radiator.

• Once all of the coolant is drained close the drain plug.

STEP #4 Remove Cover & Disconnect Hoses:

• Remove the intake manifold cover. The cover and

hardware will not be reused.

• Remove the Evaporative Emissions (EVAP) canister

hose (A), brake

booster vacuum

hose (B) and vacuum hoses (C).

Keep all of the

hoses as some will

be reused.

STEP #5 Remove Air Box:

• Disconnect the Intake Air Temperature (IAT) sensor

connector (A), and remove the breather hose (B), then

remove the air cleaner housing (C), and inlet tube.

Keep all of the parts because they will be reinstalled.

2

Page 3

STEP #6 Remove Throttle Body:

• Disconnect the water bypass hoses, then plug the water bypass hoses.

• Disconnect the MAP Sensor, IAC valve connector, TP

sensor, and EVAP canister purge valve connector.

• Remove the (2) M8 nuts and (2) M8 bolts holding the

throttle body to the manifold.

• Leaving the cables attached, carefully move the throttle body out of the way. Making sure not to bend or

kink the cables.

• Use two M8 Flange nuts and remove the Throttle body

studs from the manifold they will be reinstalled into

the new SC manifold.

EVAP Valve

STEP #7 Remove harness:

• Remove the PVC hose (A) but save the clamps because they will be reused.

• Remove the harness holder mounting bolt (B) and harness clamp mounting bolt (C). Remove the harness

holder from the harness it and the hardware will not

be reused.

MAP Sensor

TPS Sensor

STEP #8 Relieve fuel Pressure:

• Loosen the fuel fill cap to relieve any pressure in the

tank.

• Place a wrench on the fuel pulsation damper (A) at

the fuel rail.

• Place a rag (B) over the fuel pulsation damper.

• Slowly loosen it one complete turn

• Once all the fuel is drained retighten the damper.

STEP #9 Remove Fuel Rail:

• Disconnect the fuel line from the rail by squeezing the

lock tabs, push and pull the line until it is loose.

• Remove the harness ground from the manifold and

keep the M6x15 bolt; it will be reused.

• Disconnect the injector harness from each injector and

the harness cover from the rail (B). Trim harness cover

as shown.

• Remove the two M8 nuts holding the rail to the manifold and

remove the rail with injectors

(A). Keep the two rail spacers

and the rail they will be reused.

3

Trim Off Tab

Page 4

STEP #10 Remove Manifold supports:

• From the bottom of the car remove the two

M8 Bolts holding the supports to the manifold.

• Remove the two M8 bolts holding the supports

to the block and remove the supports. They

will not be reused.

STEP #11 Remove Stock Manifold:

• Remove the (2) M8 nuts and (4) M8 flange bolts.

• Use two M8 Nuts and remove the two studs from the cylinder

head (A).

• Remove the intake manifold (B) and gasket. Neither of these

will be reused.

STEP #12 Remove Belt:

• Remove the power steering reservoir from its mounting bracket.

• Move the auto-tensioner (A) to relieve tension from

the belt (B), and remove the belt, it will not be reused.

STEP #13 Remove Power Steering Pump:

• Remove the (2) M8x45 bolts holding the power steering pump to the engine.

• Move the pump out of the way but do not disconnect

the lines

• Save the M8x45 bolts, they will be reused in a

later step.

4

Page 5

STEP #14 Remove the Stock Tensioner:

• Remove the (3) M8 bolts holding the auto tensioner to the

engine and remove the tensioner.

• Remove the tensioner pulley

from the tensioner, the pulley

will be reused.

• The tensioner and the hardware will not be reused.

STEP #15 Remove Alternator:

• Disconnect the power wire (B) (M6 nut), harness connector (A) and the harness bracket (M4 nut) from the

back of the alternator.

• Remove the

M8x105 and

the (2)

M8x45 bolts

from the alternator.

Save the Alternator, it

will be reused, but the

hardware will

not.

Step #16 Remove Radiator overflow bottle:

• Remove the (2) M6x16 washer bolts holding the upper

radiator brackets.

• Remove the (2) M6x25 bolts holding the A/C condenser to the chassis. Pull the radiator and condenser

out and away from the chassis being careful not to

damaged the A/C lines.

• Remove the (2) M6x25 bolts holding the overflow bottle to the fan shroud. Pull the overflow bottle up

through the gap in the radiator and chassis.

• Save all of the parts as they will be reinstalled.

STEP #17 Install Alternator Relocation Brackets:

• For the top bracket remove the M10x105 bolt and reinstall it with the new bracket using the M8x40 allen

bolt supplied in the kit.

• For the bottom bracket use the new (2) M8x20 allen

bolts to mount the new lower bracket.

5

Page 6

Step #18 Reinstall the Alternator:

• Bend the A/C line towards the front of the car by

pushing the line using your hand or a pry bar. Be

very careful not to damage the A/C line.

• Using the new M8x80 and the two new M8x40 flange

bolts supplied in the kit, reinstall the alternator.

• Check to make sure

you have bent the

A/C line enough

(see picture).

STEP #19 Remove the Water outlet:

• Remove the (2) M6x20 water outlet mounting bolts.

• Remove the small rear water line and the larger pas-

senger-side bypass water line. You can leave the

other two waterlines connected. Move the water outlet out of the way.

STEP #20 Move starter cable:

• Remove the harness support bracket as it will not be

reused.

• Move the main

harness to the

passenger side of

the starter.

• Clock the main

starter power

wire down as far

as it will go.

STEP #21 Preinstall Manifold support bracket:

• Loosely mount the lower block to the engine using the

supplied M8x55 flange

bolt.

• Using the supplied

M8x25 flange bolt

loosely mount the drop

link to the lower support.

• Loosely attach the top

mounting block using

the supplied M8x25

flange bolt to the passenger side of the drop

link.

• Leave all the hardware

loose; they will be tightened after the manifold

is installed.

6

Page 7

STEP #22 Main Manifold Installation:

• The blower gets shipped already attached to the main

manifold. Remove the (6) M8x20 bolts holding the

blower plate to the manifold and separate the two.

• Install the main manifold to the cylinder head using

the supplied (5) M8x25 bolts, (2) M8x60 flange bolts,

and heat insulation gasket. Use the supplied Loctite

on the threads of all the bolts. Torque the manifold

bolts to 20 ft-lbs.

• Install the manifold brace to the manifold using the

supplied M8x30 flange bolt. Use Loctite on the threads

going into the manifold.

• Now tighten all of the bolts left loose in Step #22.

STEP #23 Reinstall Water Outlet:

• Reinstall the water outlet removed in step #20.

• Make sure to reconnect the hose, do not forget the

small one on the back.

• Make sure that all of the hose clamps are clocked like

the picture to allow clearance for the throttle cables.

STEP #24 Install P/S Pump Relocation Bracket:

• Using the supplied (3) M8x30 flange bolts, mount the

bracket to the original tensioner mounting points.

STEP #25 P/S pump install:

• Using an air gun and 19mm socket, remove the nut

holding the factory P/S pump pulley. Change the pulley to the new smaller one supplied. Using the air gun

reinstall the nut.

• Mount the pump in place using the M8x45 flange bolt

removed in step #14 on the bottom hole.

• On the top hole use the supplied M8x55 flange bolt

and spacer nut to secure the top of the pump.

• Check to make

sure there is

clearance between the

spacer nut and

the motor

mount stud. If

there is not,

loosen both the

pump bolts,

push the pump

down and retighten.

7

Page 8

STEP #26 Blower Area Preparation:

• Install the new PVC hose (5/16 x 30”) using the stock

clamps removed in step #8. Run the hose out through

the gap between the radiator and chassis for now, it

will be connected in a later step.

STEP #27 Blower Installation:

• Make sure the (6) M8x20 flange bolts are in place before lowering the blower to the main manifold.

• Install the blower on to the main manifold making

sure to line up the roll pins already installed in the

main manifold.

• Start the M8x20

flange bolt under the by-pass

valve first.

• Tighten all 6 of

the blower

mounting plate

flange bolts.

• Install the

blower by-pass

valve vacuum

line.

STEP #28 Install Inlet Manifold:

• Route the fuel injector harness under the end of the

blower on top of the blower mounting plate.

• Using the supplied M8x20 bolts, install the inlet manifold starting with the rear lower bolt first. Also make

sure the injector harness is not pinched between the

inlet manifold and plate.

STEP #29 Install the Blower belt:

• Route the new belt supplied in the kit.

8

Page 9

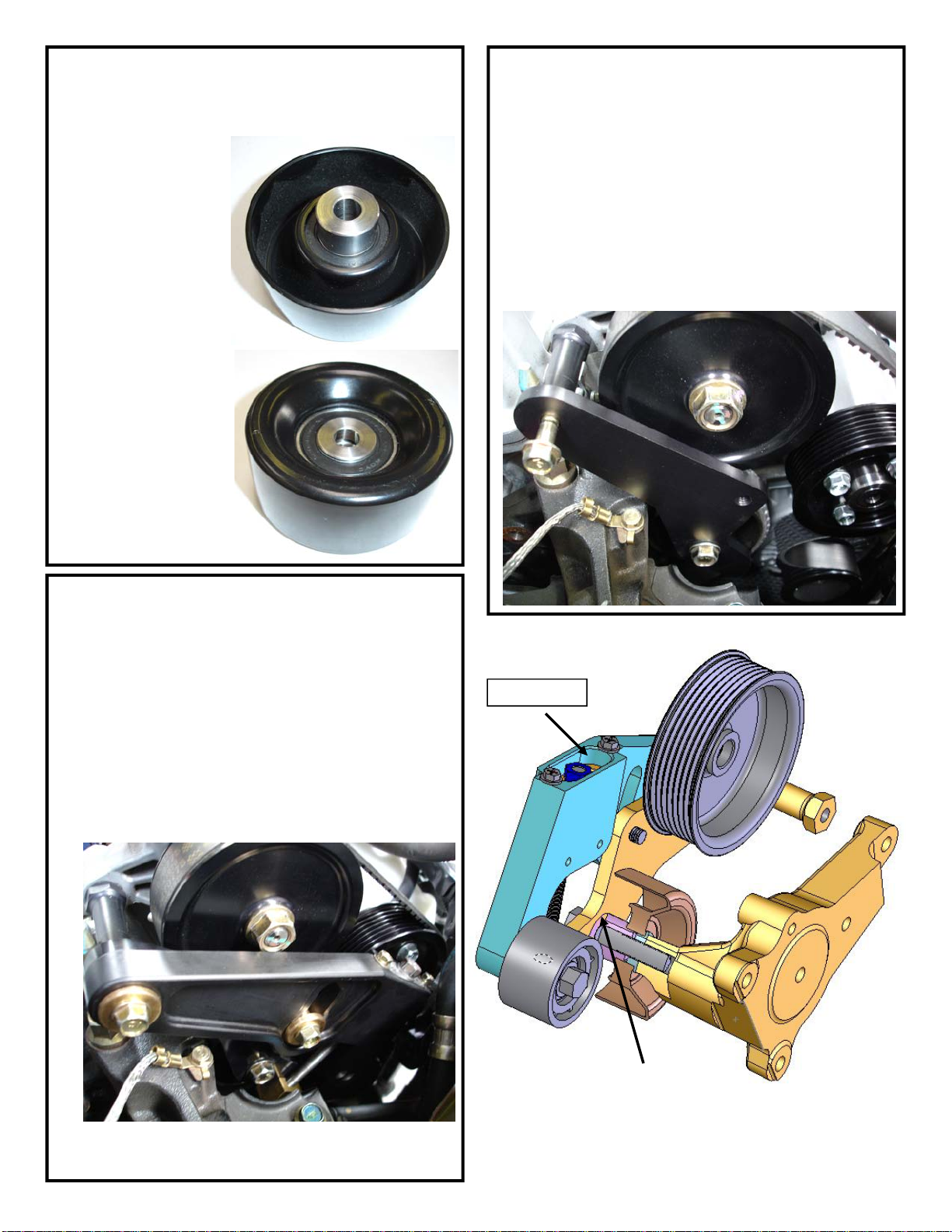

STEP #30 Pulley Prep:

• Using the stock steel pulley removed in step # 15.

• Press the shorter supplied spacer on the closed side

of the stock pulley.

• Press the longer

supplied spacer into

the open side of the

stock pulley.

STEP #31 Install Fixed Idler Pulley:

• Using the fixed idle plate and the supplied M10x55

bolt, install the pulley with the longer spacer facing

away from the engine. There is also a small spacer

that needs to go in between the tall spacer and the

idle plate.

• Temporally install the upper M8 flange bolt and torque

the M10 bolt to 31 ft-lbs. Once the M10 bolt is tight

remove the upper M8 flange bolt.

• Make sure the belt runs around the front side of the

pulley.

STEP #32 Install Tensioner:

• Using both the supplied M8x25 bolt with the short

spacer and the M8x45 (removed in step #14) bolt

with the long spacer, mount the tensioner plate making sure that the belt is routed on the back side of the

pulley.

• Make sure that the slot in the brass adjuster foot is

hooked on the edge of the fixed idler pulley plate installed in step #32.

• Once everything is in place, tighten the two M8 bolts

to 16 ft-lbs. Make sure to not over tighten the

bolts.

1/2” Step

9

Insert small spacer here.

Page 10

STEP #33 Setting Belt Tension:

• Tighten the adjusting bolt down until you

have a 1/2” step from the top of the tensioner down to the spring perch. See pic-

ture on page 9.

After about 10 minutes of engine

•

running you will need to reset

the belt tension again.

•

After another 50 miles of driving

you will need to reset the belt

tension again.

• After your 3rd adjustment you should not

have adjust it again.

• But make sure to check it at every oil change.

STEP #34 Relocate P/S Reservoir:

• Remove the P/S bracket from the chassis and using a

letter D drill bit, drill a new hole about .65” over from

the original hole in the bracket.

• Flatten out the location tab so the bracket is flat

across the base.

• Reinstall the bracket to the chassis using the new

hole. Install the P/S reservoir into the bracket. Check

to make sure the reservoir and hoses do not touch

any part of the tensioner or belt.

.65”

STEP #35 Install Spark Plugs:

• Remove the Ignition Coil cover.

• Remove the Coils.

• Remove the stock spark plugs.

• Install the supplied Denso IK24 plugs.

• Reinstall the coils and ignition coil cover.

10

Page 11

STEP #36 Reinstall the Air Bypass Hose:

• Reinstall the original Intake Air Bypass Control Thermal Valve hose using only the clamp on the valve

side.

STEP #37 Fuel Rail Installation Prep:

• Make sure the injector adaptor bushings are pushed all

the way into the manifold. These adaptors make the

Comptech manifold work with the Honda factory fuel

injectors.

• Install the supplied bushings onto each stud along with

the original fuel rail spacers.

STEP #38 Install Fuel Rail:

If this is a Stage 2 upgraded kit install the sup-

•

plied Comptech high flow injectors

• Use a small amount of oil on the fuel injector seal and

reinstall the fuel rail with all of the injectors still in the

rail. Use the supplied spacer nuts to secure the rail to

the manifold.

• Reconnect the fuel supply hose. A small amount of oil

on the end will help.

STEP #39 Install Wiring Harness:

• Reinstall the factory wiring harness cover onto the rail

and reconnect each fuel injector.

• Reinstall the harness ground using the original M6x15

flange bolt.

11

Page 12

STEP #40 Install Throttle Body:

• Install the studs removed in step #6 in to the new

inlet manifold.

• Move the throttle

body back in to

position making

sure that the

throttle cables are

not twisted.

• Reconnect the

Idle Air control

Valve.

• Using the supplied new throttle

body gasket and

original hardware,

mount the throttle body to the

blower inlet manifold.

STEP #41 MAP Sensor Relocation:

• Remove the M5x20 screw holding the MAP sensor in

place. The screw will not be reused.

• Using the MAP sensor spacer block, M5x35 bolt, and

new o-ring supplied in the kit, remount the MAP sensor on to the throttle body.

• Using the supplied

13” vacuum line,

connect the spacer

port to the intake

manifold.

STEP #42 Throttle Body Connections:

• Reinstall the two water lines to the bottom of the

throttle body that were removed in step #7.

• Reconnect the wiring harness connectors back onto

the MAP sensor,

Throttle Position

Sensor and the

EVAP purge

valve connector.

EVAP Valve

MAP Sensor

STEP #43 Reinstall Air Intake Box (C):

• Additional power is available by using a Comptech

IceBox Intake Kit with the supercharger.

• Be sure to reconnect the Inlet Air Temp sensor (A)

and the air tube (B) for the Intake Air Bypass Control

Thermal Valve as seen in step #35.

TPS Sensor

12

Page 13

STEP #44 Reinstall the overflow bottle:

• Insert the bottle between the chassis and the radiator

and remount it

reusing the

stock hardware.

• Reinstall the upper radiator

mounting brackets.

• Remount the A/

C condenser

using the stock

hardware.

• Route the PVC

line above the

overflow bottle

and through the

chassis to the

lower inlet fitting

on the inlet

manifold.

STEP #45 Install Vacuum Lines:

• Reinstall the

factory EVAP

hose. You

may need to

bend the

steel lines

upward to

clear the

throttle cables.

• Install the

supplied

5/16x12”

line for the

brake

booster.

STEP #46 Raise Fuel line pressure:

• Remove the rear lower seat cushion.

• Remove the access panel (A) from the floor. Disconnect the two electrical

connections (B,C) and using a rag to catch the excess fuel disconnect the

fuel line from the fuel tank unit.

• Use the factory Honda tool to remove the top of the pump/sender assembly (we have also found you can also use a larger flat bladed screw driver

as a punch to remove it also).

• Using rags to catch the fuel, slowly pull the pump assembly out of the

tank be very careful not to damage the sending unit float.

• Remove the terminal (A) and the clip (B), remove the regulator.

• Once the regulator is removed disconnect the hose

from the end. Using the supplied tools compress

the regulator in a vice until the tool is bottomed out

(see picture).

• Reinstall the regulator into the pump unit ( a little

oil on the seals will help) in the reverse order as

removal and reinstall everything into the tank.

Make sure to get the top of the unit, clocked correctly in the tank (see picture). Reconnect the electrical connector and fuel line. Reinstall the top

panel and seat.

13

Page 14

STEP #47 Reinstall ECU/Immobilizer & Install ACM:

• Reinstall the immobilizer unit & reinstall the steering column panels. (see step #1)

• Remount the ECU in the reverse order of removal. Plug in connectors (C,D & E only).

• Install the ACM in between the factory wiring harness and the ECU (connectors A &B), using the supplied jumper har-

ness. Tuck the ACM box up on top of the ECU.

• Once everything is installed reconnect negative side of the battery.

STEP #48 Refill Cooling System/Install Bumper:

• Refill the cooling system using a mixture of 50% antifreeze and 50% water.

• Fill the radiator to the base of the filler neck.

• Loosely install the radiator cap and proceed to

step#49.

• Reinstall the front bumper see step #2.

STEP #49 Starting the Car:

• Turn the ignition key on and off a few times to run the

fuel pump and build fuel pressure.

• Check for any fuel or coolant leaks.

• If everything checks out OK, start the car.

• Once the car is running let it idle until the cooling fans

come on at least twice. Make sure all of the air is bled

out of the cooling system.

• Shut the engine off. Check the coolant level in the

radiator. Top it up if necessary and install the radiator

cap tightly.

• Install the supplied Emissions Information sticker to

the bottom side of the hood next to the stock emissions

sticker.

14

Page 15

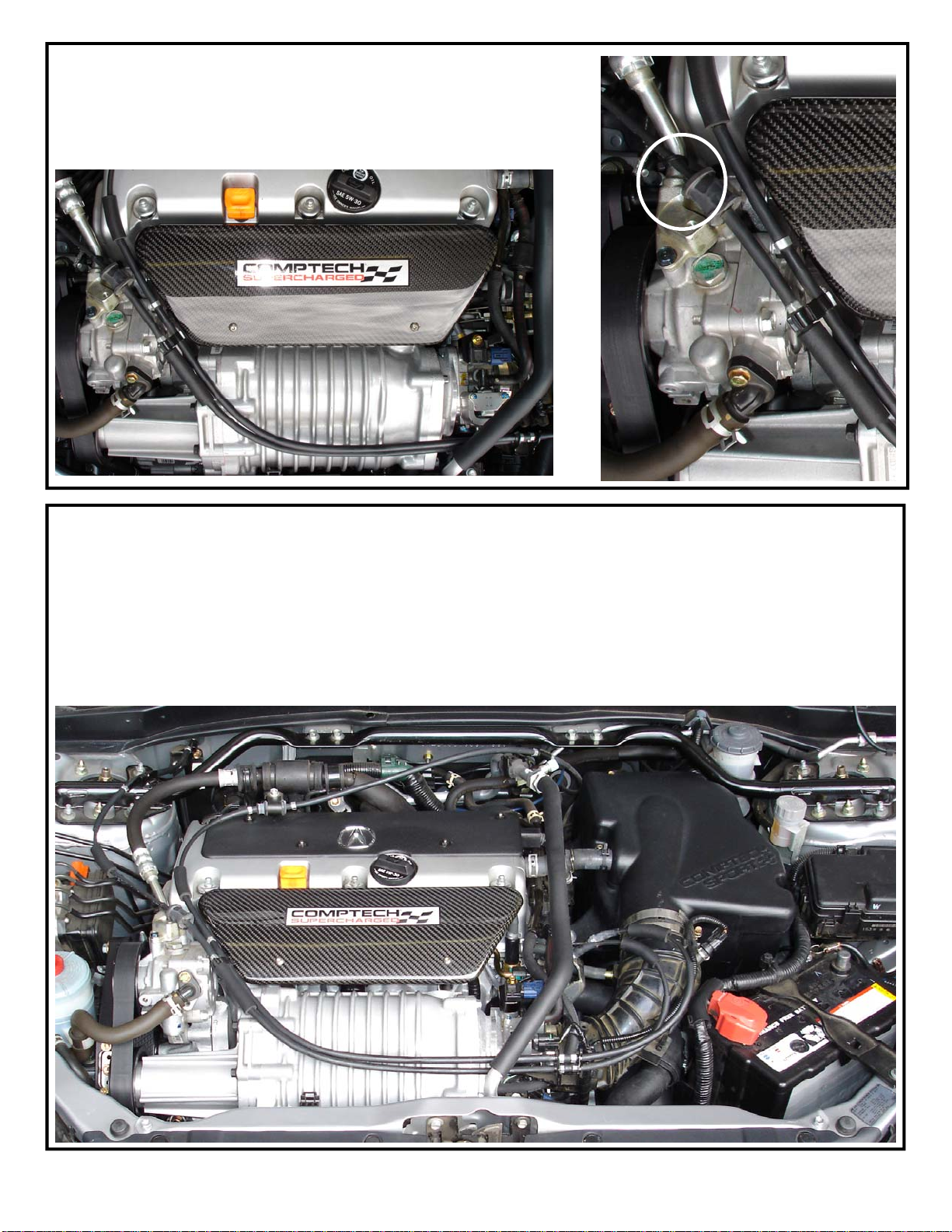

STEP #50 Install Fuel Rail Cover:

• Using the supplied M6x10 Button head allen bolts install the Comptech

Carbon Fiber fuel rail cover.

• Remove the throttle cable routing bracket off of the P/S pump. Use the

supplied 4” ty-rap to hold the cables to the P/S line.

STEP #51 Drive the car :

• Always use the Highest Octane fuel available.

• Check your engine oil level on a regular basis.

• Check your belt tension.

• If you have any questions please call (888)-626-6783 between the hours of 8:00 AM and 5:00 PM Pacific Standard

time.

• Please put a copy of these installation instructions in the car for your customer.

• To further improve the performance of your Comptech Supercharger kit we recommend the use of a Comptech Ice-

box, Header and Cat-Back exhaust system.

• Enjoy.

Comptech® 4717 GOLDEN FOOTHILL BLVD • EL DORADO HILLS, CA 95762 • 916.933.1080 • FAX 916.939 .9196 • www.comptechusa.com •

15

Page 16

Comptech® Product Warranty

Comptech - All products manufactured by Comptech are warranted against defects in materials and workmanship for

a period of three years from date of original purchase. This warranty is applicable only to parts which were

purchased on or following January 1, 2006. All parts purchased on or preceding December 31, 2005 are

subject to the conditions of our previous warranty period of two years. This warranty applies only to the

original retail purchaser and is not transferable. This warranty is intended to cover Comptech products when they are

used in the manner for which they were originally designed. This limited warranty shall be void on all products found to

have been used in racing or off-road applications, of any nature whatsoever, and on all products that show evidence of

abuse, lack of maintenance, improper installation, misapplication, alteration in any way whatsoever from their original

design or negligence in the use of Comptech products by the original retail purchaser or by any agent of the original

purchaser. The warranty specifically excludes, but is not limited to; brake pad material, brake rotors, clutch friction surfaces, belts, normal maintenance items, and those items designated as a racing part. This warranty applies only to

products made by Comptech, and does not include claims for labor or inconvenience. This warranty does not cover

consequential damages claimed as a result of the failure or use of a Comptech product. Other products distributed by

Comptech are covered by the terms of that manufacturer's warranty. Comptech reserves the right to change product

design and/or specification without prior notice.

Warranty Service Procedure - In the event a problem develops with a Comptech product, please contact Comptech at

916.933.1080 during our normal business hours (8 AM to 5 PM M-F PST).

1. It may be determined that the product will have to be returned to Comptech for warranty inspection. A Return

Goods Authorization will be assigned to you and is required for return, unless specified otherwise by a Comptech employee.

2. The retailer or the customer should return the product in question, freight prepaid. It must be accompanied by the

original sales receipt and a clear description of the problem.

3. If the product is determined to be defective and within the warranty period, Comptech will repair, replace or issue a

credit to the customer at Comptech's discretion. Any repaired or replaced product will be returned to sender, freight

prepaid via UPS or truck.

4. No replacement warranty parts will be shipped until original parts are returned to Comptech for inspection.

Returns - In the event that a purchase must be returned, please contact a Comptech salesperson for a Return Goods

Authorization number.

1. All returns must have the RGA number clearly written on shipping label or box, or shipment may be refused.

2. No returns after 14 days.

3. A 20% restocking fee will be assessed on all merchandise returned in 100% resalable condition (clean packaging, all

pieces intact, etc.). If returned goods are not 100% resalable, an additional charge will be assessed. If mer chandise is

damaged, or shows signs of installation, the return will be disallow ed.

4. All returns must be freight prepaid.

5. Special Orders parts are not returnable.

6. All approved returns are for credit only.

Comptech®

4717 Golden Foothill Parkway

El Dorado Hills, CA 95762

Phone : 916.933.1080

Fax: 916.939.9196

16

Loading...

Loading...