Page 1

P.T. Rail

The “Patient Transfer” Rail

TM

INSTALLATION

INSTRUCTIONS

Models:

PT-WR32L, PT-WR32R,

PT-WR28L, PT-WR28R

PT-FIX32L, PT-FIX32R,

PT-FIX28L, PT-FIX28R

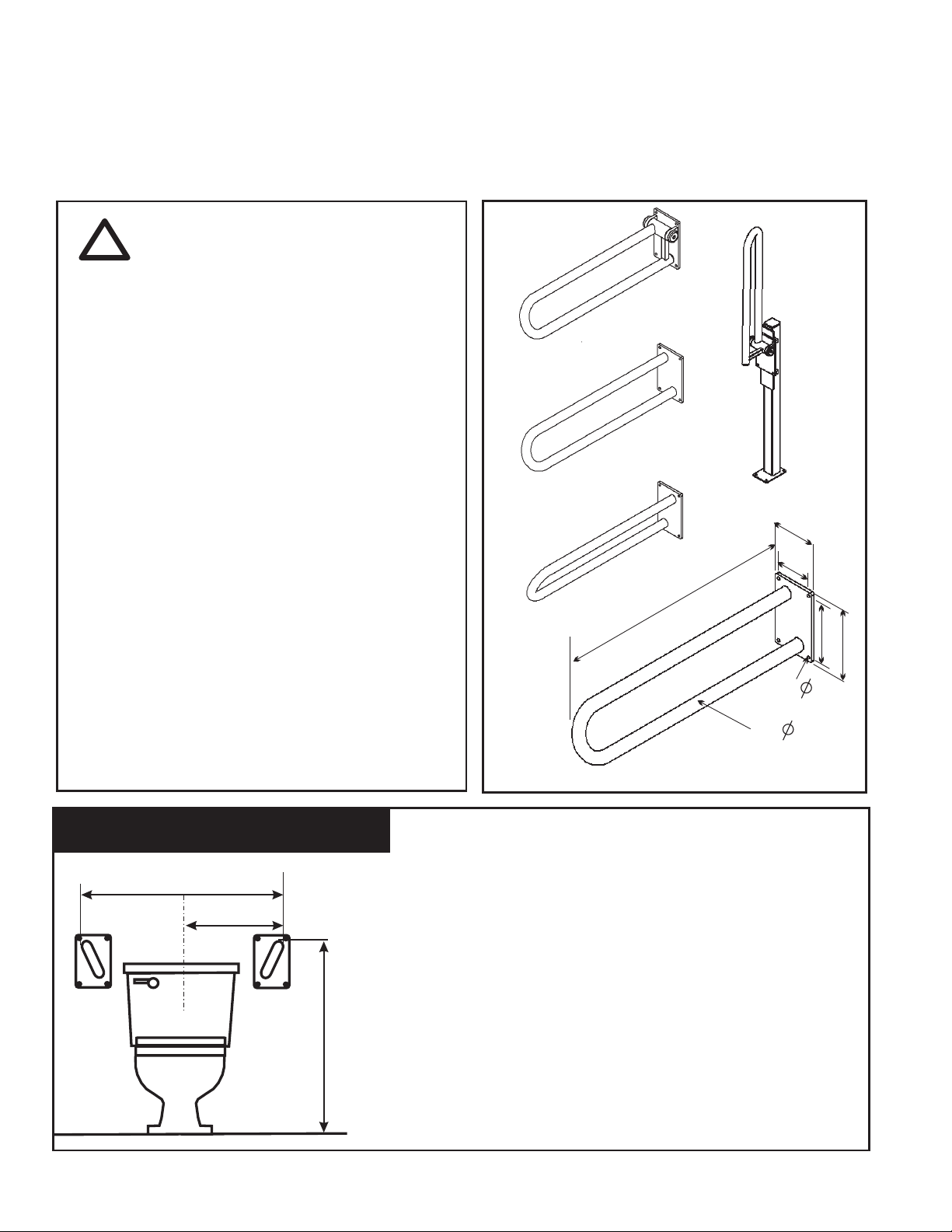

CAUTION

!

RISK OF INJURY!

Thank you for investing in your independence with

HealthCraft Products. Be certain to read &

understand these instructions prior to using your new

P.T. Rail

Rail is properly assembled, installed, operated, and

TM

. It is your responsibility to see that your P.T.

TM

cared for. Failure to follow these instructions could

result in injury.

The P.T. Rail should only be installed in areas where

TM

the mounting surface is structurally sound. If you are

not equipped to undertake the outlined work we

recommend that you have your P.T. Rail installed by

TM

a qualified contractor. The P.T. Rail, ( or P.T. Rail

Mast) must be secured to wall (or floor) with fasteners

appropriate to the structural material. Fasteners must

be rated for certain retention force each for maximum

weight capacity (see within for recommendations).

Mounting fasteners should be inspected monthly and

tightened if necessary. is capable of

P.T. Rail

TM

supporting a maximum suggested user weight of

350lbs/160kg. NOTE - Due to variances in needs,

materials and local construction methods, the

information contained within concerning mounting

location, fasteners and wall fabrication is provided as

suggestion only. Consult the appropriate local

professionals for best advice.

Hinged Model,

Right Side

(PT-WRxxR)

Fixed Model,

Right Side

PT-FIXxxR

Fixed Model,

Left Side

PT-FIXxxL

28”, 32”/

710, 810 mm

Hinged Model,

shown on

optional

Floor Mast

5.5”/

140mm

4.5”/

115mm

3/8”/

9.5mm

1-1/2”/

38mm

8”/203mm

9”/229mm

Installation NotesInstallation Notes

We strongly recommend that you give some thought as to the

optimal location of your PT-Rails before installation. The

W= 28-32” (71-81 cm)

W/2

following suggestions are offered for your consideration,

however, it is recommended to consider advice from the

appropriate healthcare professional for locating of any

support rail. The PT Rails may be installed on only one side

or, more typically, both sides of a toilet. The PT Rail(s)

typically provide(s) most optimal support with a height to top

rail (H) of between 32-34” (81-86 cm), or more in some

Right Side

Model

Left Side

Model

H= 32 - 34”

( 81-86 cm)

cases.

In the case of two PT Rails being installed, one on each side

of the toilet, a suggested width between top rails (W) would

be in the range of 28 - 32” (71-81 cm). Always ensure that

the proposed location of your PT Rail will not obstruct access

to other parts of the bathroom. For folding models, ensure

that the space above the rail is clear to permit folding.

HealthCraft Products Inc. 2790 Fenton Rd., Ottawa, Ontario, Canada, K1T 3T7

Copyright 2003, Specifications subject to change without notice.

TM

Page 2

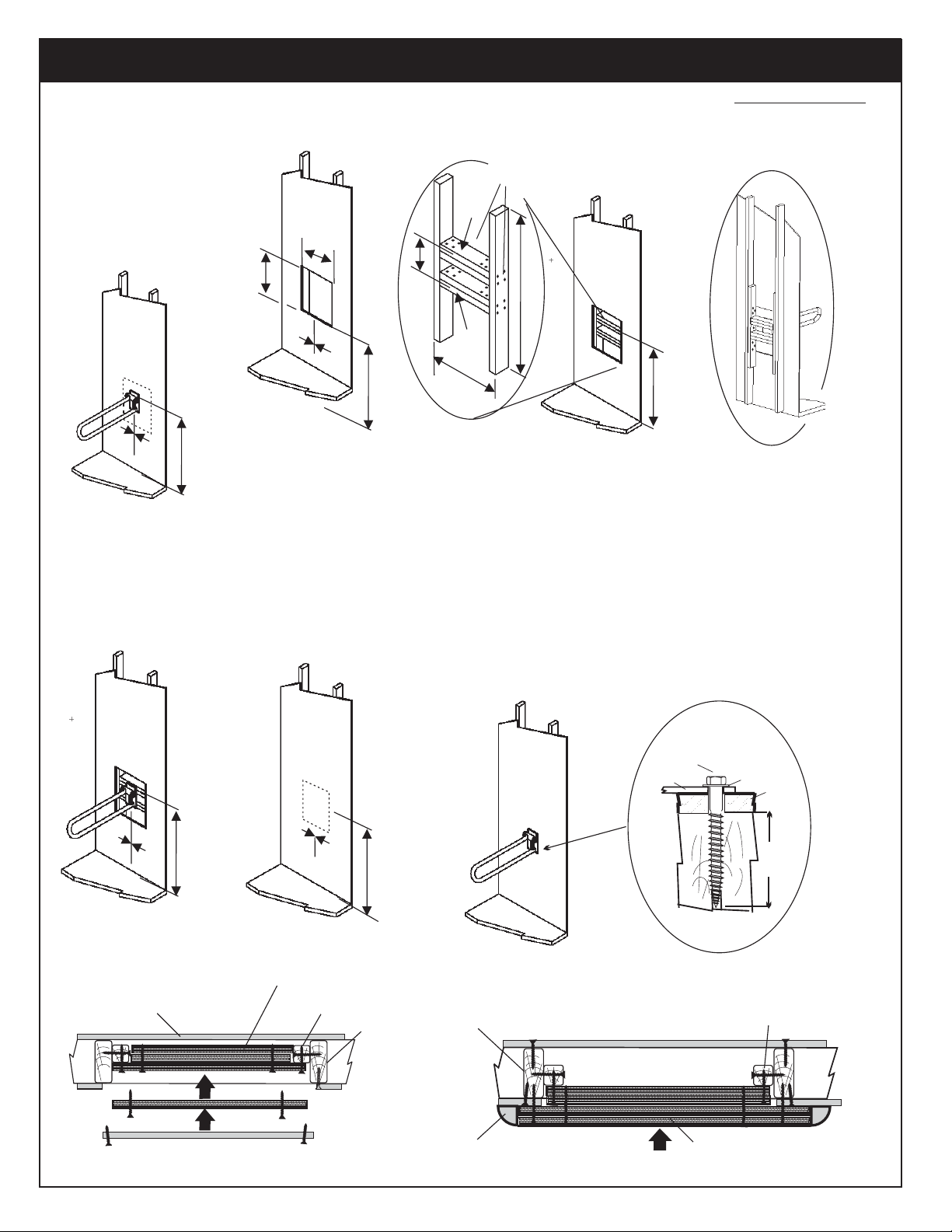

Installation Suggestions - Frame & Wallboard WallInstallation Suggestions - Frame & Wallboard Wall

NOTE: Due to variances in local construction methods, and materials used, details given below are

suggestions only.

Consult the appropriate local contractor for specific advice. For concrete walls, you may be able to install fasteners

(such as a wedge anchor) directly into the concrete wall without modification.

1. Choose optimal mounting

location of rail including height (H)

and side to side location (L). Mark

the height and location on the wall

for future reference.

B

C

Wood Screws

F

Back view,

inside wall

A

E

G

L

H

4. Insert support

frame structure

through hole in

wall and secure

uprights to wall

studs using a

generous amount

of wood screws.

L

H

5. Hold the PT Rail against

the support frame to confirm

your support frame cross

members are in the correct

location.

H

2. Find wall support studs & cut

hole in wall board to expose wall

studs. Suggested hole size is

height (A) of 18-24+”(48-61cm)

and width (B) corresponding to

wall stud spacing. Expose half

width of each stud to facilitate reinstallation of wall board patch.

(* Take care not for any utilities

located in wall!)

6. Ensure your “H” and “L”

locations are marked on the

wall. Then, patch the wall

cutout to match the

surrounding wall.

D

3. Fabricate a support frame structure from suitable wood

pieces as shown above. Support frame width (D) should fit

snugly within wall studs. Support frame height (E) should

be from 24-32” (61-81cm) high or more, depending on

material and stiffness of wall studs. Locate top cross

member (F) to position in line with top fastener holes when

rail is located at the height (H). Lower cross member

should be spaced at C= 8”(20cm) from top cross member.

Use a generous quantity of wood screws and glue to hold

the support frame structure together as shown.

7. Install the PT Rail in the noted location using the previously recorded height

and location marks. Use fasteners of sufficient strength:

200 lbs/90kg user - 330lbs/150 kg rated fastener (1/4” dia wood lag*)

350 lbs/160kg user - 580lbs/263 kg rated fastener (5/16” dia wood lag*)

(* suggestion only based on min 2.5”/6.3 cm thread engagement in quality wood in pre-drilled pilot hole b)ased on full weight of user near end of one rail only

H

L

L

H

Alternative 1 - Multi-layer Plywood inside wall with

wallboard patch (Top view)

Back of wall

(can insert structure

from this side too)

Generous amounts of wood screws & glue

Multi layers of 3/4” plywood

(approx 24”+ high)

2” x 2” nom. Stud

(approx 36” high)

Wall Stud

3/4” plywood

Wallboard patch

Suggested

Wood Lag Screw

Detail

1/4” or 5/16” hex cap head

wood lag screw (Stainless)

P.T. Rail Wall Plate

Quality

Wood

Frame

Structure

washer (stainless)

** drill pilot hole!

2.5"/6.3 cm

minimum

thread

engagement

Alternative 2 - Multi-layer Plywood inside wall with

multilayer plywood covering hole in wall (Top View)

Wall Stud

Trim moulding

Generous amounts of wood screws & glue

Back of wall

Multi layers of 3/4” plywood

(approx 24”+ high)

Multi-layer 3/4” wall patch

Wall board,

or stiff

wood spacer

2” x 2” nom. Stud

(approx 36” high)

Page 3

Installation Suggestions - Frame & Wallboard WallInstallation Suggestions - Frame & Wallboard Wall

NOTE: Due to variances in local construction methods, and materials used, details given below are

suggestions only.

Consult the appropriate local contractor for specific advice. For concrete walls, you may be able to install fasteners

(such as a wedge anchor) directly into the concrete wall without modification.

1. Choose optimal mounting

location of rail including height (H)

and side to side location (L). Mark

the height and location on the wall

for future reference.

B

C

Wood Screws

F

Back view,

inside wall

A

E

G

L

H

4. Insert support

frame structure

through hole in

wall and secure

uprights to wall

studs using a

generous amount

of wood screws.

L

H

5. Hold the PT Rail against

the support frame to confirm

your support frame cross

members are in the correct

location.

H

2. Find wall support studs & cut

hole in wall board to expose wall

studs. Suggested hole size is

height (A) of 18-24+”(48-61cm)

and width (B) corresponding to

wall stud spacing. Expose half

width of each stud to facilitate reinstallation of wall board patch.

(* Take care not for any utilities

located in wall!)

6. Ensure your “H” and “L”

locations are marked on the

wall. Then, patch the wall

cutout to match the

surrounding wall.

D

3. Fabricate a support frame structure from suitable wood

pieces as shown above. Support frame width (D) should fit

snugly within wall studs. Support frame height (E) should

be from 24-32” (61-81cm) high or more, depending on

material and stiffness of wall studs. Locate top cross

member (F) to position in line with top fastener holes when

rail is located at the height (H). Lower cross member

should be spaced at C= 8”(20cm) from top cross member.

Use a generous quantity of wood screws and glue to hold

the support frame structure together as shown.

7. Install the PT Rail in the noted location using the previously recorded height

and location marks. Use fasteners of sufficient strength:

200 lbs/90kg user - 330lbs/150 kg rated fastener (1/4” dia wood lag*)

350 lbs/160kg user - 580lbs/263 kg rated fastener (5/16” dia wood lag*)

(* suggestion only based on min 2.5”/6.3 cm thread engagement in quality wood in pre-drilled pilot hole b)ased on full weight of user near end of one rail only

H

L

L

H

Alternative 1 - Multi-layer Plywood inside wall with

wallboard patch (Top view)

Back of wall

(can insert structure

from this side too)

Generous amounts of wood screws & glue

Multi layers of 3/4” plywood

(approx 24”+ high)

2” x 2” nom. Stud

(approx 36” high)

Wall Stud

3/4” plywood

Wallboard patch

Suggested

Wood Lag Screw

Detail

1/4” or 5/16” hex cap head

wood lag screw (Stainless)

P.T. Rail Wall Plate

Quality

Wood

Frame

Structure

washer (stainless)

** drill pilot hole!

2.5"/6.3 cm

minimum

thread

engagement

Alternative 2 - Multi-layer Plywood inside wall with

multilayer plywood covering hole in wall (Top View)

Wall Stud

Trim moulding

Generous amounts of wood screws & glue

Back of wall

Multi layers of 3/4” plywood

(approx 24”+ high)

Multi-layer 3/4” wall patch

Wall board,

or stiff

wood spacer

2” x 2” nom. Stud

(approx 36” high)

Loading...

Loading...