Page 1

Efficacy of High-Level Disinfection

®

with CIDEX

OPA Solution

OPA Solution

Page 2

ospital-acquired infections (HAIs) pose a

eat to patient safety, affecting

H

the Unit

serious thr

more than 2 million patients every year in

ed States and many more worldwide.

result, they have received increasing attention from

healthcare professionals, as well as state and federal

regulatory agencies, hospital administrators, payors,

the media, and patients. A number of campaigns are

underway to reduce the incidence of HAIs, focusing on

prevention practices and changes in reimbursement.

The Joint Commission has added preventable infections

as one of its National Patient Safety Goals,2and the

Association for Professionals in Infection Control

and Epidemiology (APIC) has launched a campaign

emphasizing prevention of HAIs and other adverse

3

events.

In addition, the Centers for Medicare

and Medicaid Services will no longer provide

reimbursement for the added cost of care of patients

4

with several types of HAIs.

The implications of these

initiatives are far-reaching for hospitals and infection

prevention professionals.

With more than 10 million

gastrointestinal endoscopic

“CIDEX®OPA

and 500,000 flexible

bronchoscopic procedures

Solution...is proven

effective against a

broad range of

viruses, fungi,

and mycobacteria.”

performed every year in the

5,6

United States,

reusable

flexible endoscopes have

the potential to play a role

in HAIs. During clinical

use, endoscopes are

contaminated by multiple

microorganisms, and

failure to appropriately

clean, disinfect, or sterilize endoscopes has resulted

in nosocomial outbreaks and serious infections.

esult, pr

a r

delic

saf

ety and maint

oper cl

ate endoscopes are crucial to ensure patient

eaning and disinf

ain optimal function.

ection of expensive,

7,9

The clinic

established efficacy of detergents and disinfectants

clearly plays a key part in instrument processing,

and their selection is an important clinical and risk

management decision.

High-Level Disinfection

Endoscopes and other devices that contact muc

membranes but normally do not cross the blood

barrier are, by definition, semi-critical devices and

must undergo high-level disinfection. According to

APIC, this means elimination of many or all pathogenic

organisms, except bacterial spores.

disinfectants cleared for use with semi-critical

medical devices must demonstrate 100% kill of 10

to 106mycobacteria in the presence of 2% horse

serum in quantitative tests and pass the sporicidal

10

High-level

1

As a

7,8

ous

all

5

As

test of AOAC International, the Association of

ytical Communities.

Anal

11

Liquid chemical germicides that are high-level

disinfectants ideally should offer effectiveness, speed,

and ease of use and be compatible with a variety of

erials used in medical devices. These chemicals

mat

also should not be noxious or toxic to personnel.

The high-level disinfectant CIDEX®OPA Solution

(0.55% ortho-phthalaldehyde) (Advanced Sterilization

Products [ASP], Division of Ethicon, Inc.) meets these

criteria and, in nearly 10 years of clinical use and

efficacy testing, is proven effective against a broad

range of viruses, fungi, and mycobacteria.

CIDEX®OPA Solution

CIDEX®OPA Solution was introduced by ASP in

1999 to meet the need for effective, fast, easy-to-use

high-level disinfection and to address staff concerns

about the saf

Solution is bactericidal, sporicidal, virucidal, fungicidal,

and tuberculocidal. It achieves high-level disinfection

in 12 minutes at room temperature and also has been

cleared for marketing in the United States for use

in automatic endoscope reprocessors (high-level

disinfection in 5 minutes at 25ºC). Extensive

testing has shown that the high-level disinfectant is

non-corrosive and is compatible with a wide variety of

materials commonly found in endoscopes and other

medical devices. (See Table 1) It also is gentler on

flexible endoscopes than peracetic acid.

Table 1: Materials Shown To Be Compatible with

CIDEX®OPA Solution*

Metals

• Aluminum • Anodized aluminum

• Brass • Carbon steel

• Chrome-plated brass/steel • Copper

• Nickel-plated brass • Nickel-silver alloy

y

• Stainless-steel/titanium • Tungsten carbide/

Plastics & Elastomers

Acetal • Acrylonitrile-butadiene-styrene (ABS)

•

• Nylon • Polyamide

• Polycarbonate • Polyethylene

• Polypropylene • Polystyrene

• Polysulfone • Polyvinyl chloride (PVC)

• PTFE • Kraton G

• Natural rubber latex • Polychloraprene (Neoprene)

• Polyurethane • Silicone rubber

ethyl

y

ol

P

•

es

y

(pol

Adhesives

• Cyanoacrylate • EPO-TEK 301 epoxy

• EPO-TEK 353 epoxy

Dental Materials

• Addition silicone • Polyether

• Polysulphide

ta on fil

*Da

ety of glutaraldehyde. CIDEX OPA

12

vanadium steel

ene terephthalate • Polymethylmethacrylate

(acrylic)

er)

t

e at ASP.

•

7

2

Page 3

CIDEX®OPA Solution has no offensive odor. In contrast

o glutaraldehyde, the Occupational Safety & Health

t

Administration has not set permissible exposure limits

or CIDEX OPA Solution and does not require special

f

venting or air monitoring in areas where the solution

is used or monitoring of staff who work with it. Local

regulations may vary, but generally the solution can be

discarded with running water into an ordinary drain.

®

CIDEX

OPA Solution is ready to use from the bottle

and requires no mixing or activation. Test strips are

used to verify that the germicide has maintained

the minimum effective concentration (MEC) of 0.3%

CIDEX OPA Solution. Tests have shown that even

reused, stressed solution diluted to the MEC remains

bactericidal, sporicidal, virucidal, fungicidal, and

13–17

tuberculocidal at room temperature.

Solution has a 14-day r

euse life and an open-bottle

CIDEX OPA

shelf life of 75 days. Unopened bottles have a shelf

life of two years when stored at 15–30°C. Although

provided at a near-neutral pH of 7.5, the solution is

stable for use over a wide range of pH (3-9).

Efficacy

The efficacy of CIDEX®OPA Solution as a high-level

disinfectant has been established through extensive

evaluation by ASP over the past 10 years. A summary

of key efficacy testing follows.

Methodology

Two types of quantitative tests have been used

predominantly to evaluate the efficacy of CIDEX

Solution. The first type utilized suspensions of

microorganisms diluted 1:10 into the solution at a

specified concentration and temperature. After a

specified period (usually minutes), a neutralizer was

added or the microorganisms were removed from the

suspension by vacuum filtration and then rinsed. The

number of viabl

ganisms r

e or

emaining aft

to the solution then was determined by quantitative

assay and compared quantitatively with organisms

that had no exposure to the solution. The reduction

in viable microorganisms is expressed as a log of the

number of organisms.

A second, more stringent test type evaluated the

efficacy of CIDEX®OPA Solution in inactivating

microorganisms, including methicillin-resistant

Staphylococcus aureus (MRSA), vancomycin-resistant

Enterococcus faecalis (VRE), and viruses that had dried

onto a flat solid surface. After exposure to CIDEX OPA

Solution, the microbes were recovered, rinsed, and

quantitatively assayed.

CIDEX®OPA Solution has been cleared for mark

in the United States as a high-level disinfectant for

reusable medical and dental equipment processed at

er e

®

OPA

xposur

eting

e

20°C (12 minutes) and at 25°C (5 minutes).* Because

the solution is used ar

ound the world and claims vary

by country, evaluations also have been done based on

other times and t

emperatures. Testing shows that

CIDEX OPA Solution is bactericidal when instruments

are processed at 20°C for five minutes.

Mycobacteria

Effective control of mycobacteria is crucial in preventing

the transmission of disease by contaminated medical

devices. Mycobacteria demonstrating resistance to

aldehyde-based disinfectants (i.e., glutaraldehyde and

formaldehyde) have caused nosocomial infections in

the United States and elsewhere, and glutaraldehyderesistant mycobacteria have been isolated from flexible

endoscope reprocessing machines.

problem, the efficacy of reused CIDEX®OPA Solution

was tested against glutaraldehyde-resistant

Mycobacterium chelonae. The test was based on a

protocol determined by the Environmental Protection

Agency (EPA) to simulate clinically reused disinfectants.

Suspensions of

M. chelonae were exposed to reused

0.5% OPA at 20°C. The result: 5-log reduction after

5 minutes and complete kill (of 10

units/mL) after 15 minutes. By comparison, a solution

of reused 2.0% glutaraldehyde showed a 4-log

reduction in 20 minutes at 20°C.

Similar assays with Mycobacterium bovis (BCG) were

done with 0.2% OPA. Results showed a complete kill

.5 log10) of viable mycobacteria after 5 minutes at

(

20°C. In contrast, although this mycobacterium was

not resistant to glutaraldehyde, 2.0% glutaraldehyde

gave a 2-log reduction after 10 minutes at the same

temperature.

13

Subsequent studies have provided more information

about the effic

acy of CIDEX

®

OP

a 2001 comparison of the mycobactericidal activity of

tho

or

-phthalaldehyde (OP

dialdehydes by quantit

A), glut

e suspension testing found

ativ

Table 2: Bactericidal Efficacy Test with CIDEX®OPA

Solution, 5 Minutes at 20°C

Organism Tested Result

ylococcus aureus(ATCC 6538) No growth

Staph

Salmonella choleraesuis (ATCC 10708) No growth

seudomonas aeruginosa(AT

P

Methicillin-resistant

(MRSA) (ATCC 33592) No growth

Vancomycin-resistant

CC 51299)

T

(VRE) (A

Staph

ylococcus aureus

Enterococcus hirae (CIP 58.55) .5 log reduction

Pseudomonas aeruginosa (ATCC 103467) .5 log reduction

*When used or reused in a legally marketed AER that can be set to a

minimum of 25C.

3

CC 15442) No growth

Staphylococcus aureus

Enterococcus faecalis

(CIP 4.83) .5 l

18,19

To address this

6

colony-forming

13

A Solution. For example,

aldehyde, and other

ar

owth

No gr

og reduction

Page 4

0

1

2

3

4

5

6

0.3% OPA vs.

C. difficile

vegetative cells

at 20°C

0.3% OPA vs.

C. difficile

spores

at 20°C

0.3% OPA vs.

C. difficile

spores

at 25°C

0.5% OPA vs.

C. difficile

spores

at 25°C

Log of Survivors

0 min. 2 min. 5 min.

10 min. 12 min. 15 min.

Tes t Conditions

that a 0.5% OP

both “clean” and “dirty” conditions.

A was rapidly mycobactericidal under

19

In particular,

the solution was active against glutaraldehyde-resistant

19

strains of mycobacteria.

quantit

ative suspension protocol found that OPA is

Another study using a

effective as a tuberculocidal disinfectant: at MEC levels,

A achieved a 6-log

OP

bovis

in nearly one-sixth the time required with

glutaraldehyde (5.5 minutes versus 32 minutes).

eduction of Mycobacterium

r

10

20

In a study of the mechanisms of the mycobacterial

action of ortho-phthalaldehyde, glutaraldehyde, and

chlorhexidine diacetate, Fraud and colleagues concluded

that, “The rapid micobactericidal effect of OPA probably

arises from its more efficient penetration across

biological membranes.”

21

Antibiotic-Resistant Bacteria

Drug-resistant bacterial infection is a widespread health

concern, and some controversy exists as to whether

resistance to antibiotics is somehow related to resistance

to disinfectants. Two common drug-resistant organisms,

®

MRSA (ATCC

#33592) and VRE (ATCC® #51299), have

been tested with CIDEX® OPA Solution.

As in the efficacy tests with mycobacteria, these assays

evaluated reused CIDEX®OPA Solution in conformance

with EPA specifications. Stainless steel carriers coated

with bacteria were submerged in reused solution diluted

to 0.3% at 20°C. After a 10-minute exposure, carriers

were placed into individual containers of culture

medium containing an agent that neutralizes

ortho-phthalaldehyde. Each strain was

used in triplicate tests involving 10 carriers

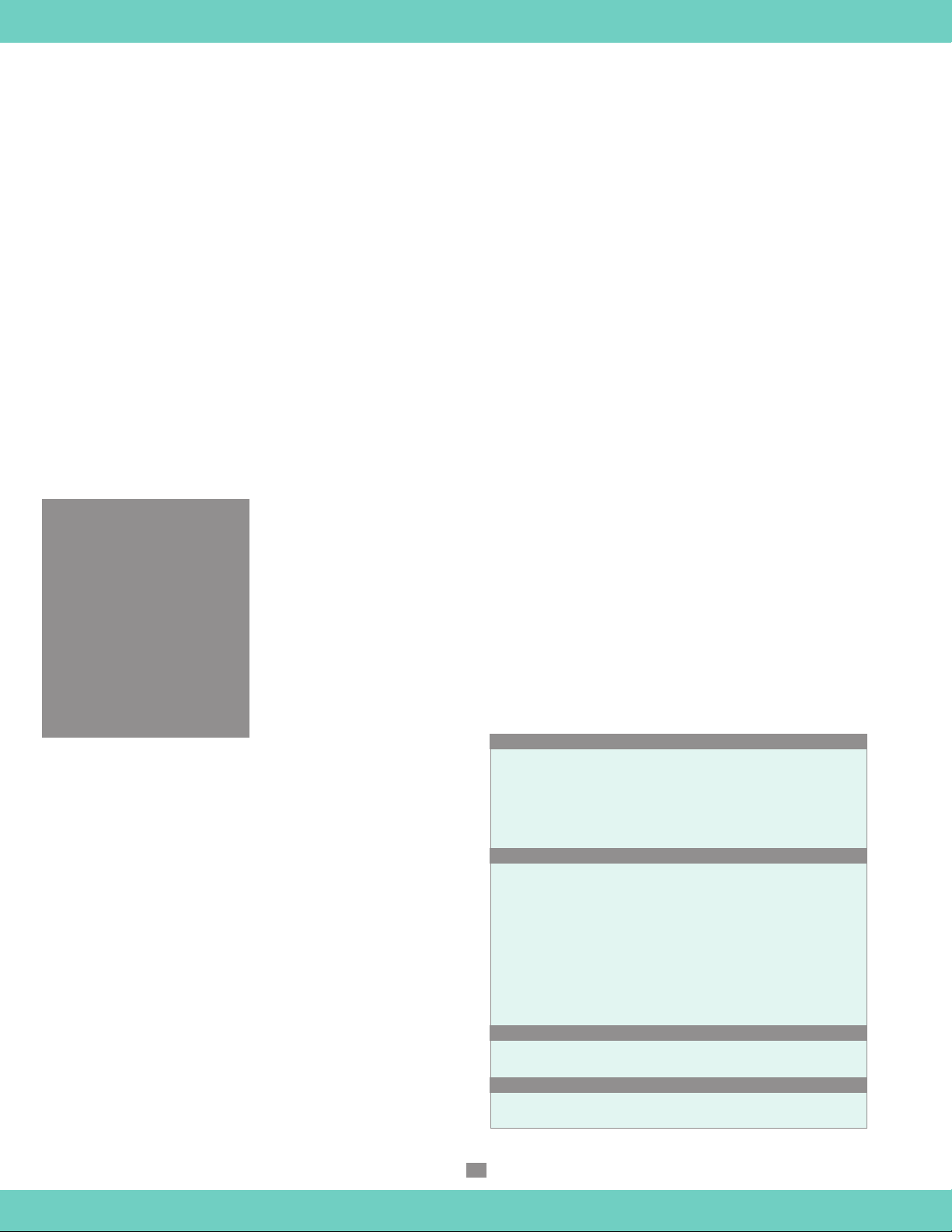

Figure 1. OPA Solution Versus Clostridium Difficile at Various

Study Conditions.

each. No organisms survived exposure to

the dilute solution, illustrating that the

antibiotic-resistant strains of

S. aureus

and E. faecalis demonstrate no increased

resistance to dilute CIDEX OPA Solution.

17

Clostridium Difficile

Clostridium difficile, a spore-forming,

gram-positive anaerobic bacillus, is the

leading cause of antibiotic-associated

diarrhea in hospitalized patients. The serious

health effects of

colitis, blood poisoning, and even death.

This, combined with an increasing prevalence

and incidence, make C. difficile a significant

healthcare issue.

A recent study, results of which were

presented at the APIC 2008 Annual

Conference, evaluated the biocidal activity

of an ortho-phthalaldehyde solution

(prepared from CIDEX

against C. difficile. Results showed that

OPA is efficacious against the vegetative

C. difficile include diarrhea,

22

®

OPA Solution)

orm and achieves a significant reduction of the spore

f

form of

C. difficile. (See Figure 1) In particular, there

were no surviving C. difficile vegetative cells observed

after a 2-minute exposure in 0.3% OPA at 20° C. With

the spor

e form of

C. dif

ficile,

a 2.4 l

og

r

10

eduction was

demonstrated with 0.3% OPA and at least 4.9 log

eduction with 0.5% OPA after a five-minute exposure.

r

Viruses

Hepatitis B and C viruses (HBV and HCV)—the most

prevalent blood-borne viruses

transmitted infectious agents that are a major cause

of acute hepatitis and chronic liver disease, including

cirrhosis and cancer. Disinfection of HBV is assayed

with an

in vitro test using duck hepatitis B virus as a

surrogate for HBV.

o test the efficacy of CIDEX® OP

T

the HBV surrogate, a suspension of duck hepatitis

B virus was dried on a Petri dish, then exposed to

0.3% or

tho

-phthalaldehyde f

The bottom of the dish was scraped, and the resulting

suspension was passed though a filtration column to

remove the CIDEX OPA Solution. In the immunofluorescence assay, the number of viable virus

particles was reduced by more than 4 logs after

exposure to 0.3% CIDEX OPA Solution.

Similar tests were done with bovine viral diarrhea virus,

a surrogate for HCV. For these tests, virus suspensions

also contained 5% horse serum as organic soil. This

4

24

—are parenterally

A Solution against

or 5 minutes at 20°C.

15

10

23

Page 5

e was dried on Petri dishes and recovered as

0

1

2

3

4

5

6

7

8

9

0246810121416

Exposu

re Time (minutes)

SA vs OPA + 5% serum

PA vs OPA + 5% serum

SA vs OPA + 20% serum

PA vs OPA + 20% serum

SA vs OPA + 40% serum

PA

vs OPA + 40% serum

mixtur

described above. Exposure to 0.5% CIDEX

®

OPA Solution

for 5 minutes at 20°C caused a .4-log reduction in the

15

number of viable virus particles.

(See Table 3)

Table 3: Virucidal Test with CIDEX®OPA Solution,

5 Minutes at 20°C (Pass Test=

Virus Tested Result

Adenovirus Type 5 Pass test

Herpes Simplex Type 1 (HSV1) Pass test

HSV 2 Pass test

Influenza A (Hong Kong) Pass test

Coxsackievirus Type B3 Pass test

Polio Type 1 (Brunhilde strain) Pass test

Rhinovirus Type 37 Pass test

Vaccinia Pass test

ype 1 Pass test

HIV T

Cytomegalovirus Pass test

Human Coronavirus Pass test

Rotavirus (Strain WA) Pass test

Duck Hepatitis B Virus (surrogate for Hepatitis B) Pass test

Bovine viral diarrhea virus (surrogate for Hepatitis C) Pass test

Rotavirus (Strain WA) Pass test

Feline calicivrus as (surrogate for Norovirus) Pass test

Avian influenza A (H5N1) virus Pass test

Canine Parvovirus Pass test

Hepatitis A virus Pass test

.3-log Reduction)

Temperature

The effect of temperature on biocidal activity was further

assessed in quantitative tests of

Bacillus subtilis spores

(ATCC #19659). Suspensions of spores were diluted

into various concentrations of CIDEX®OPA Solution

and tested at 35°C, 40°C, 45°C, and 50°C. Results

showed that the solution is sporicidal and that, within

defined parameters, study temperature has a bigger

influence on the degree of sporicidal activity than the

concentration of the solution. For example, a

reduction in the number of viable spores occurred with

2-hour exposure to 0.05% disinfectant at 50°C, and a

oncentrated

eduction was observ

og r

3-l

solution of 0.3% OP

A at 35

ed in the mor

16

°C.

e c

Organic Soil

Cleaning of instruments before disinfection is the

first step in removing bioburden from instruments.

However, manual cleaning is known to have variable

results,

disinfection. To assess the impact of an organic load

on bactericidal activity of 0.3% CIDEX®OPA Solution,

suspensions of S. aureus and Pseudomonas aeruginosa

were exposed to 0.3% CIDEX OPA Solution at room

temperature (20°C) in the presence of 0%, 5%, 20%,

and 40% horse serum. For exposure times of up t

5 minutes, bactericidal activity decreased with increasing

concentration of horse serum. However, when exposure

to 0.3% CIDEX OPA Solution was 10 minutes or longer,

these concentrations of horse serum did not prevent

.7-log reduction of viable bacteria.

25

potentially reducing the effectiveness of

17

>6-log

o

e 2. Biocidal Activity of 0.3% CIDEX

Figur

Biocidal activity of 0.3% CIDEX®OPA Solution was evaluated in

the presence of variable amounts of horse serum. Suspensions of

Staphyloccoccus aureus (SA) or Pseudomonas aeruginosa (PA) were

diluted 1:10 into 0.3% OPA+horse serum. After exposure to disinfectant,

viable organisms were assayed quantitatively.

®

A Solution.

OP

17

Summary

For more than 10 years, CIDEX®OPA Solution has

been successfully utilized by healthcare facilities

worldwide to high-level disinfect reusable medical and

dental devices. As part of its commitment to infection

prevention, ASP has conducted extensive tests to

evaluate the efficacy of CIDEX OPA Solution. Results

show that CIDEX OPA Solution is bactericidal—including

for MRSA and VRE—mycobactericidal, sporicidal, and

virucidal—including for surrogates for HBV and HCV.

®

CIDEX

wide variety of devices, including delicate and costly

flexible gastroenterology endoscopes. This range of

applications is possible because of the solution’s broad

mat

materials compatibility is simple standardization of

pr

developed for disinfection of many items.

The f

Solution also contribute to rapid turnaround time,

allowing smaller inventories of instruments and

pot

ealized by eliminating the monitoring of air and

r

personnel exposure required with glutaraldehyde.

Combined, these factors demonstrate why CIDEX

Solution makes both clinical and economic sense for

facilities seeking an effective, more cost-efficient

option for instrument reprocessing. Furthermore,

the efficacy testing and quality assurance measures

applied by ASP should be an important consideration

or healthc

f

ontrol and prevention of HAIs.

c

5

OPA Solution is currently used to disinfect a

erials c

es

oc

ompatibility. An important benefit of broad

ocols—a single protocol can be

sing pr

ot

ast processing time and ease of use of CIDEX

ential c

t savings. Cos

os

sonnel as they work toward the

e per

ar

t savings also might be

n

®

®

OP

OPA

A

Page 6

References

www.ActiveForever.com

1. Centers for Disease Control and Prevention. Public health focus: Surveillance, prevention and control of nosocomial infections. Morbidity and Mortality

Weekly Report. 1992;41(42):783–787.

2. Joint Commission 2009 National Patient Safety Goals—Hospital 2008.

3. APIC Vision 2012. Washington, D.C.: Association for Professionals in Infection Control and Epidemiology.

4. Mitka M. Public, priv

5. Mehta A, Prakash U, Garland R, et al. Prevention of flexible bronchoscopy-associated infection. Chest. 2005;128:1742–1755.

6. Nelson D, Jarvis W, Rut

2003;24:532–537.

7. Rutala W, Weber D. Disinfection of Endoscopes: Review of new chemical sterilants used for high-level disinfection. Infect Control Hosp Epidemiol.

1999;20:69–76.

8. Spach D, Silverstein F, Stamm W. Transmission of infection by gastrointestinal endoscopy and bronchoscopy. Ann Intern Med. 1993;118:117–128.

er M. ICRE-1108: Instrument processing overview: cleaning, disinfection, sterilization. http://www.iceinstitute.com/. Accessed Nov. 11, 2008.

9. Mill

10. Association for Professionals in Infection Control and Epidemiology (APIC). Disinfection and sterilization principles; 2002.

11. Committ

12. Abraham J, Abdelshehid C, Lee H, et al. Effects of Steris 1™ sterilization and Cidex®ortho-phthalaldehyde high-level disinfection on durability of

new-generation flexible ureteroscopes. J Endourol. 2007;21:985–992.

13. Roberts C, Chan-Myers H. Efficacy of dilute ortho-phthalaldehyde solutions with glutaraldehyde-resistant mycobacteria. American Society for

Microbiol

14. Roberts C, Chan-Myers H, Ascenzi J. Activity of dilute ortho-phthalaldehyde solutions against drug-resistant bacteria. American Society for

Microbiology; 2001; Olando.

15. Roberts C, Chan-My

2008;36:223–226.

16. Chan-Myers H, Roberts C. The role of temperature and concentration on the sporicidal activity of ortho-phthalaldehyde. Society for Healthcare

Epidemiologists of America; 2001; Baltimore.

17. Chan-Myers H, Roberts C. Effect of temperature and organic soil concentration on biocidal activity of ortho-phthalaldehyde solution. Association for

Professionals in Infection Control and Epidemiology (APIC); 2000.

18. van Klingeren B, Pullen W. Glutaraldehyde resistant mycobacteria from endoscope washers. Hosp Infect. 1993;25:147–149.

19. Fraud S, Maillard J, Russell A. Comparison of the mycobactericidal activity of ortho-phthalaldehyde, glutaraldehyde and other dialdehydes by a

quantitative suspension test. J Hosp Infect. 2001;48:214–221.

20. Gregory A, Schaalje G, Smart J, Robison R. The mycobactericidal efficacy of ortho-phthalaldehyde and the comparative resistance of Mycobacterium

bovis, Mycobacterium terrae, and Mycobacterium chelonae. Infect Control Hosp Epidemiol. 1999;20:324–330.

21. Fraud S, Hann A, Maillard J, Russell A. Effects of ortho-phthalaldehyde, glutaraldehyde and chlorhexidine diacetate on Mycobacterium chelonae and

Mycobacterium abscessus strains with modified permeability. JAC. 2003;51:575–584.

22. Agency for Healthcare Research and Quality. Potentially deadly infection doubles among hospital patients over last 5 years. Statistical Brief #50; 2008.

23. Chan-Myers H, Roberts C. Evaluation of the biocidal efficacy of ortho-phthalaldehyde solution with vegetative and spore forms of Clostridium difficile.

Association for Professionals in Infection Control and Epidemiology (APIC); June 15–19, 2008; Denver.

24. Sattar S, Tetro J, Springthorpe V, Guilivi A. Preventing the spread of hepatitis B and C viruses: where are germicides relevant? Am J Infect Control.

2001;29:187–197.

25. Alf

retrograde choliangiopancreatography duodenoscopes used in Canadian centers. Infect Control Hosp Epidemiol. 2002;23:198–206.

ee on Antimicrobial Efficacy Testing. Methods Committee Report. J AOAC Int. 2008;91:68B–72B.

ogy; 1998; Atlanta.

a M, Olson N, Degagne P, Jackson M. A survey of reprocessing methods, residual viable bioburden, and soil levels in patient-ready endoscopic

ate insurers refusing to pay hospitals for costs of avoidable errors. JAMA. 2008;299:2495–2496.

ala W, et al. Multi-society guideline for reprocessing flexible gastrointestinal endoscopes. Infect Control Hosp Epidemiol.

ers H, Favero M. Virucidal activity of ortho-phthalaldehyde solutions against hepatitis B and C viruses. Am J Infect Control.

This white paper was funded by Advanced Sterilization Products.

33 Technology Drive • Irvine CA 92618 • (888) 783-7723

AD-090186-01-US_A ©ASP 2009

Loading...

Loading...