1

SERVO DRIVE

A3 SERIES INSTRUCTION MANUAL

Preface ................................................................................................................................ 2

1. About the instruction manual .................................................................................... 2

2. Confirm the following items before unpacking. ........................................................ 2

3. Safety precautions .................................................................................................... 2

1. Product introduction and model selection ................................................................. 6

1.1 Introduction of nameplate and model name (For servo motor and drive) ............. 6

1.2 Parts name of servo motor and drive ..................................................................... 7

1.3 Model name of servo drive and motor.................................................................... 8

1.4 Model selection of peripheral braking resistor ....................................................... 8

1.5 Selection of cables and connector accessories for A3 products ........................... 9

2. Installation and size of servo motor and drive ......................................................... 10

2.1 Installation environment conditions ...................................................................... 10

2.2 Dustproof and waterproof ..................................................................................... 10

2.3 Installation method and space .............................................................................. 10

2.4 Dimensions of servo motor................................................................................... 12

2.5 Dimensions of servo drive .................................................................................... 17

3. Wiring explanation for servo motor and drive ......................................................... 19

3.1 Wiring diagram ..................................................................................................... 19

3.2 Drive connector and pins arrangement ................................................................ 22

3.3 Terminal arrangement and wiring color of motor connector ................................. 24

4. Parameter Description ................................................................................................ 27

5. Operation ...................................................................................................................... 50

5.1 Preface ................................................................................................................. 50

5.2 Position control mode (Pulse position command input) ....................................... 55

5.3 Speed control mode (Analog speed command input) .......................................... 66

5.4 Speed control mode (Internal speed command) .................................................. 71

5.5 Torque control mode (Analog torque command input) ......................................... 75

5.6 Position control mode(Internal position command) .............................................. 81

5.7 Description of User I/O connector (CN1) terminal arrangements ........................ 82

6. Troubleshooting and countermeasures .................................................................... 90

6.1 Alarm display ........................................................................................................ 90

6.2 Alarm handling and alarm reset ........................................................................... 90

6.3 Troubleshooting .................................................................................................... 93

2

Thank you for purchasing the Action Technology products.

This Instruction Manual provides instructions for advanced use of the A3 series servo motors.

●Before use, read this manual and manuals of relevant products fully to acquire proficiency in handling and operating the

product.

●Please read the safety precautions before using.

●Store this manual in a safe place so that you can take it out and read it whenever necessary.

●As for products under development, specifications are subject to change without notice.

Preface

Incorrect operation and handling, couldn’t have a full display of the various performance that designed, and may cause

hazardous conditions and shorten the service life. Please operate the product correctly before you have read through the

instruction manual correctly.

1. About the instruction manual

○,1We make an effort to perfect this instruction manual, but if you have found some mistakes or uncertain points, please

contact Action Technology at any time.

○,2Please note the following items on the instruction manual

●Danger exists as it’s the high-voltage device.

●There are some residual voltage on the terminals or the units after power OFF and it is dangerous.

●High temperature locally

●Disassembling is prohibited.

○,3The product specifications and functions may change and increase, as the product performance upgraded. They are

subject to change without notice.

○,4Plan to obtain the Certificate of safety specification for the product’s device, please consult our sales representative.

○,5To extend the service life of motor and drive, it is necessary to use it under the correct conditions. Please follow the

instruction manual for details.

○,6The latest information should be recorded in the instruction manual and manual will be updated accordingly. If you need

the latest version, please contact the Action Technology.

○,7Without the approval of company, it is forbidden to reprint some or all of the instruction manual.

2. Confirm the following items before unpacking.

●Check if the products are the ones you ordered.

●Check if there are some damage to the products during transportation.

●Any questions, please contact the Action Technology.

3. Safety precautions

Please pay attention to the flowing safety precautions anywhere and any time during acceptance inspection, installation,

3

wiring, operation and maintenance.

Indicates that incorrect handling may result in death or severe injury.

Indicates that incorrect handling may result in medium or slight personal injury or physical damage.

Indicates “Prohibitions”(Indicates what must not be done.)

Indicates “Forced”.(Indicates what must be done.)

Installing and wiring

Do not connect the motor to the commercial power.

To prevent fire or malfunction.

Do not place the combustibles around the servo motor and drive.

To prevent fire.

Be sure to protect the drives through the case, and leave specified

clearances between the case or other equipment and the drive.

To prevent electric shock, fire or

malfunction.

Install it at the place free from excessive dust and dirt, water and oil mist

To prevent electric shock, fire ,

malfunction or damage

Install the equipment to incombustibles, such as metal.

To prevent fire.

Any person who is involved in wiring and inspection should be fully

competent to do the work.

To prevent electric shock.

FG terminal of motor and drive must be grounded.

To prevent electric shock.

Perform the wiring correctly after cut off the breaker.

To prevent electric shock, injury,

malfunction or damage

Have the insulation processing when connecting cables.

To prevent electric shock, fire or

malfunction.

Operation and running

During operation, never touch the internal parts of the drive.

To prevent burns or electric shock.

The cables should not be damaged, stressed loaded, or pinched.

To prevent electric shock, malfunction

or damage.

During operation, never touch the rotating parts of the servo motor.

To prevent injury.

Do not install the equipment under the conditions with water, corrosive

and flammable gas.

To prevent fire.

Do not use it at the location with great vibration and shock.

To prevent electric shock, injury or

fire.

Do not use the servo motor with its cable soaked in oil or water.

To prevent electric shock, malfunction

or damage

Operate the switches and wiring with dry hand.

To prevent electric shock, injury or

fire.

Do not touch the keyway directly when using the motor with shaft-end

keyway

To prevent injury.

Do not touch the motor and drive heat sink, as they are very hot.

To prevent burns or parts damaged.

Do not drive the motor by external drive.

To prevent fire.

Other safety instructions

Confirm the equipment’s safety after the earthquake happens.

To prevent electric shock, injury or

fire.

Installing and setting correctly to prevent the fire and personal injury when

To prevent injury, electric shock, fire,

4

earthquake happens.

malfunction or damage.

Provide an external emergency stop circuit to ensure that operation can

be stopped and power switched off immediately.

To prevent injury, electric shock, fire,

malfunction or damage.

Before wiring or inspection, turn off the power and wait for 5 minutes or

more.

To prevent electric shock.

Installing and wiring

Please follow the specified combination of the motor and drive.

To prevent fire or malfunction.

Do not touch the terminals of connector directly.

To prevent electric shock or

malfunction.

Do not block intake and prevent the foreign matters from entering into the

motor and drive.

To prevent electric shock or fire.

Fix the motor and have the test run away from the mechanical system.

After confirming the operation, the motor can be securely mounted to

mechanical system.

To prevent injury.

The servo motor must be installed in the specified direction.

To prevent injury or malfunction.

Install the equipment correctly in accordance with its weight and rated

output.

To prevent injury or malfunction.

Operation and running

Do not climb or stand on servo equipment. Do not put heavy objects on

equipment.

To prevent electric shock, injury, fault

or damage.

The parameter settings must not be changed excessively. Operation will

be instable.

To prevent injury.

When power is restored after an instantaneous power failure, keep away

from the machine because the machine may be restarted suddenly

(design the machine so that it is secured against hazard if restarted).

To prevent injury.

Keep it away from the direct sunlight.

To prevent malfunction.

Do not put strong impact on the motor, drive and motor shaft.

To prevent malfunction.

The electromagnetic brake on the servo motor is designed to hold the

servo motor shaft and should not be used for ordinary braking.

To prevent injury or malfunction.

Do not install or operate a faulty servo motor or drive.

To prevent injury, electric shock or fire

Check the power specification.

To prevent fault.

The electromagnetic brake may not hold the servo motor shaft. To ensure

safety, install a stopper on the machine side.

To prevent injury.

A sudden restart is made if an alarm is reset with the run signal on.

To prevent injury.

Connect the relay for emergency stop and for brake in series.

To prevent injury or malfunction.

Transportation and storage

Do not subject the equipment to the place with rain, waterdrop, poisonous

gases or liquids.

To prevent malfunction.

Do not carry the servo motor by the cables, shaft or encoder during

transportation.

To prevent injury or malfunction.

5

Do not drop or dump the motor during transportation and installation.

To prevent injury or malfunction.

Store the unit in a place in accordance with the instruction manual.

To prevent malfunction.

Other safety instructions

Please dispose the battery according to your local laws and regulations.

When disposing of the product, handle it as industrial waste.

Maintenance and inspection

Do not disassemble and/or repair the equipment on customer side.

To prevent malfunction.

Do not turn on or switch off the main power frequently.

To prevent malfunction.

Do not touch the servo drive heat sink, regenerative resistor, servo motor

etc. Their temperatures may be high while power is on or for some time

after power-off.

To prevent burns or electric shock.

When the drive become faulty, switch off the control circuit and main

power.

To prevent fire.

If the servo motor is to be stored for a long time, switch off the power.

To prevent mis-operation and injury.

Warranty period

The term of warranty for the product is 12 months from the date of manufacture. It’s exceptional to brake motors as they are

warranted when acceleration / deceleration times is not beyond the specified service life.

Warranty coverage

This warranty applies only when the condition, method, environment, etc. of use are in compliance with the terms and

conditions and instructions that are stated in the instruction manual and user manual for the Product.

However, even during warranty period, the repair cost will be charged on customer in the following cases.

1) A failure caused by improper storing or handling, repair and modification.

2) A failure caused by the parts which have dropped down or damaged during transportation

3) A failure caused when the products have been used beyond the product specification

4) A failure caused by external factors such as inevitable accidents, including but not limited to fire, earthquake, lightning

stroke, windstorm disaster, flood, salt damage, abnormal fluctuation of voltage and other natural disaster.

5) A failure caused by the intrusion of water, oil, metal and other foreign matters.

The warranty coverage is only for the product itself. We assume no responsibilities for any losses of opportunity and/or profit

incurred by you due to a failure of the Product.

6

1. Product introduction and model selection

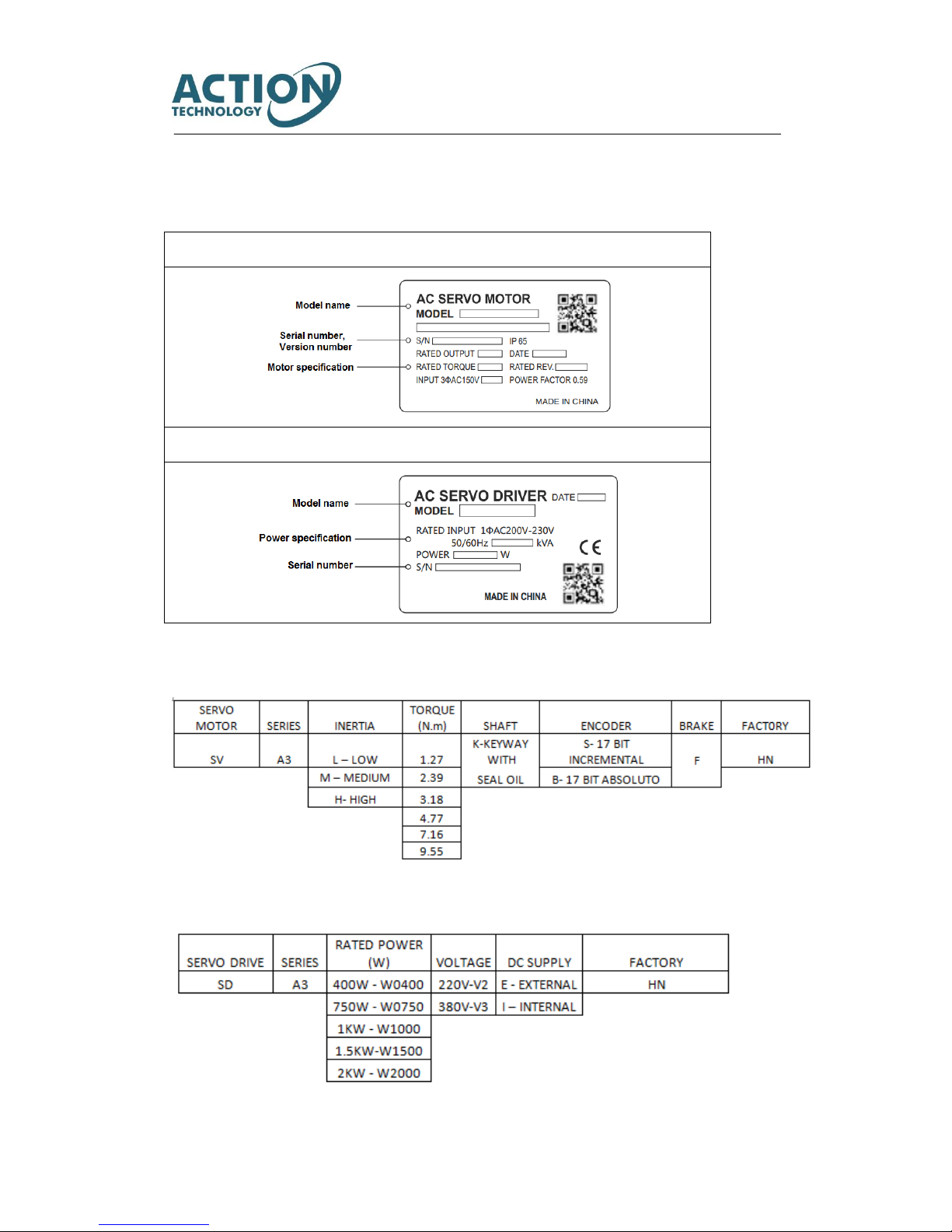

1.1 Introduction of nameplate and model name (For servo motor and drive)

Servo motor nameplate

Servo driver nameplate

Model name

1) Servo motor

2) Servo drive

7

1.2 Parts name of servo motor and drive

Figure 1.2.1 Parts name of servo motor

Figure 1.2.2 Parts name of servo drive.

8

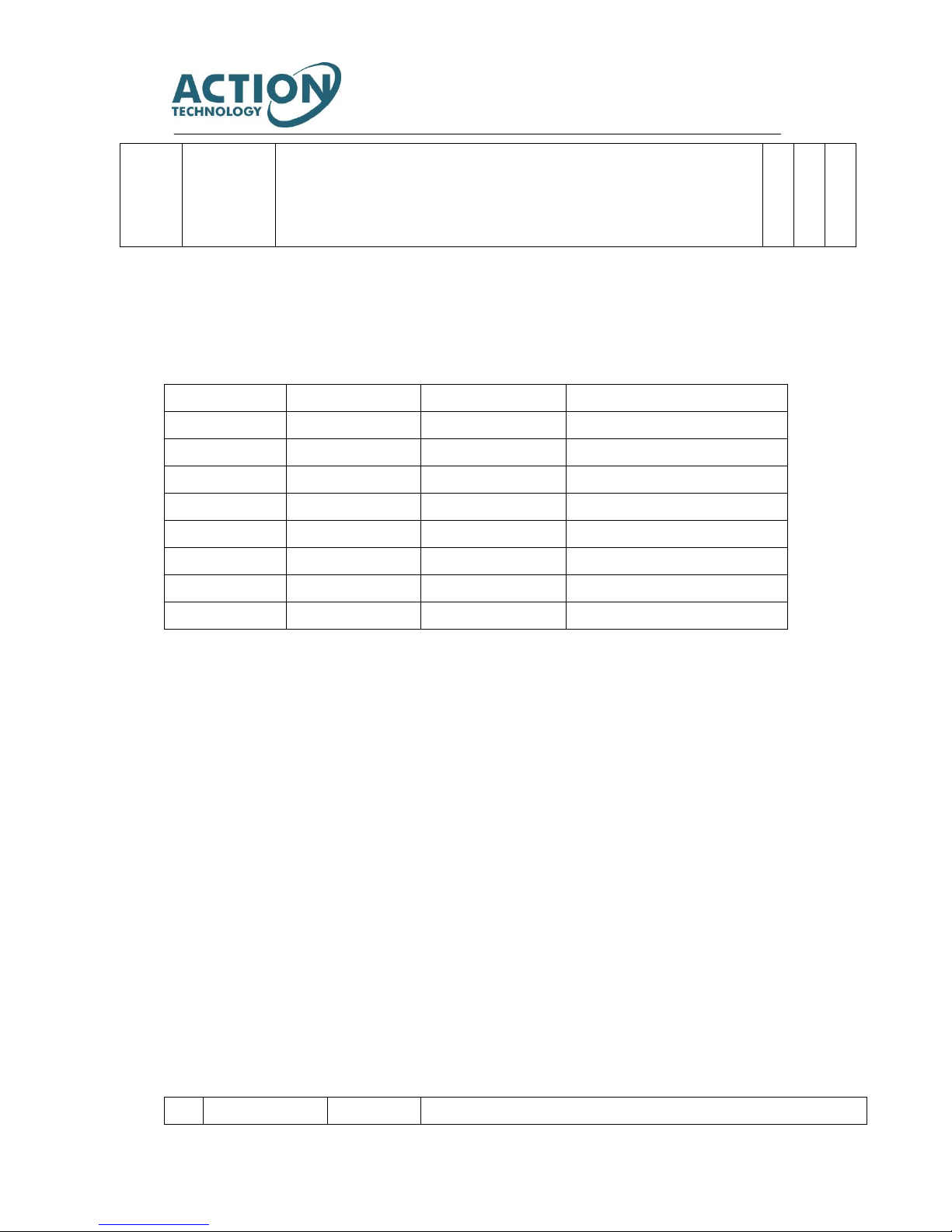

1.3 Model name of servo drive and motor

Capacity

Motor model

SV-A3□□□□□-*HN**

Motor size

(Flange

installation size)

Drive model

Drive size

400W

Low inertia

L1.27

60

SD-A3W0400V2E-HN

Frame A

High inertia

H1.27

750W

Low inertia

L2.39

80

SD-A3W0750V2E-HN

High inertia

H2.39

1kW

Middle inertia

M4.77

130

SD-A3W1000V2I-HN

Frame B

High inertia

H4.77

1.5kW

Middle inertia

M7.16

SD-A3W1500V2I-HN

High inertia

M7.16

2kW

Middle inertia

M9.55

SD-A3W2000V2I-HN

1.4 Model selection of peripheral braking resistor

Rated output

400W

750W

1kW

1.5 kW

2 kW

Resistance

40~50Ω

40~50Ω

30Ω

30Ω

20Ω

Allowable

power

20W

20W

40W

40W

60W

The Status monitoring mode on the setting panel can be used to confirm whether a regenerative resistor is needed. Select

「St_REG」on the setting panel to display 「in00_-」. When the display changes from 「in00_-」 to 「in00_A」, it means the

regenerative resistor is needed. For details, refer to [5.4 Status display mode [Regenerative resistor]].

Starting from low speed operation (20% of the max. speed) to the desired operation and observing if the display value

changes from 「in00_-」 to 「in00_A」 If 「in00_A」displays, a regenerative resistor is needed.

If the regenerative resistor is needed, refer to the installation of regenerative resistor. The use of regenerative resistor cannot

necessarily guarantee the performance. When heating temperature is too high, please increase the resistance, or the

permissible power.

9

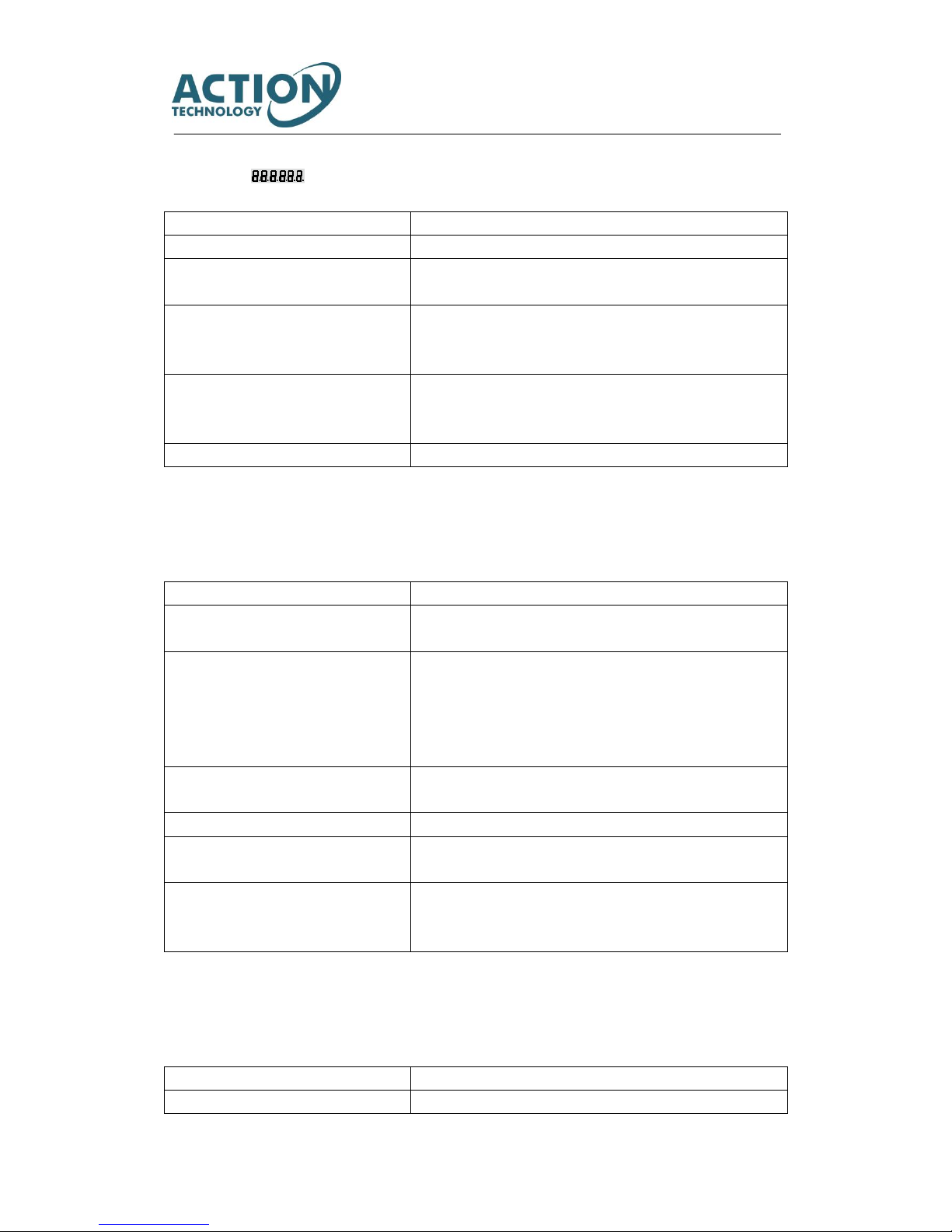

1.5 Selection of cables and connector accessories for A3 products

● For 750W or less

Items

Usage

Model name

Remark

1

Connector for drive and motor

Power connector - SY-A3CNPW750W-HN

2

Cable for drive and motor

Power cable - SY-A3CBPW750W0.5M-HN

Length: 0.5m

Power cable - SY-A3CBPW750W1.5M-HN

Length: 1.5m

Power cable - SY-A3CBPW750W3M-HN

Length: 3m

Power cable - SY-A3CBPW750W4M-HN

Length: 4m

Power cable - SY-A3CBPW750W5M-HN

Length:5m

Power cable - SY-A3CBPW750W6M-HN

Length:6m

Power cable - SY-A3CBPW750W7M-HN

Length:7m

Power cable - SY-A3CBPW750W10M-HN

Length: 10m

3

Brake connector

Not available

4 Encoder cable terminal

Encoder connector SY-A3CNEN750W-HN

5

Encoder cable

- SY-A3CBEN750W0.5M-HN

Length: 0.5m

- SY-A3CBEN750W1.5M-HN

Length: 1.5m

- SY-A3CBEN750W3M-HN

Length: 3m

- SY-A3CBEN750W5M-HN

Length:5m

- SY-A3CBEN750W10M-HN

Length: 10m

6

Encoder cable for absolute

Not available

● 1KW or more

Items

Usage

Model name

Remark

1

Connector for drive and motor

Power connector SY-A3CNPW0102K-HN

2

Cable for drive and motor

Power cable - SY-A3CBPW0102K0.5M-HN

Length: 0.5m

Power cable - SY-A3CBPW0102K1.5M-HN

Length: 1.5m

Power cable - SY-A3CBPW0102K3M-HN

Length: 3m

Power cable - SY-A3CBPW0102K5M-HN

Length:5m

Power cable - SY-A3CBPW0102K10M-HN

Length: 10m

3

Brake connector

Not available

4

Encoder cable terminal

Encoder connector SY-A3CNEN0102K-HN

5

Encoder cable

- SY-A3CBEN0102K0.5M-HN

Length: 0.5m

- SY-A3CBEN0102K1.5M-HN

Length: 1.5m

- SY-A3CBEN0102K3M-HN

Length: 3m

- SY-A3CBEN0102K5M-HN

Length:5m

- SY-A3CBEN0102K10M-HN

Length: 10m

10

6

Encoder cable for absolute

- Not available

Length: 0.5m

- Not available

Length: 1.5m

- Not available

Length: 3m

- Not available

Length:5m

- Not available

Length: 10m

7

50P pulse connector

Pulse connector

2. Installation and size of servo motor and drive

2.1 Installation environment conditions

About the environmental conditions, make sure to follow the company’s instructions. If you need to use the product outside the

scope of the environmental conditions, please consult ACTION TECHNOLOGY in advance.

○,1 Keep it away from the direct sunlight.

○,2 Drive must be installed in the cabinet.

○,3 Keep it away from the water, oil (cutting oil, oil mist) and moisture.

○,4 Do not install the equipment under the conditions with water, corrosive and flammable gas.

○,5 Free from the dust, iron powder, cutting powder and so on.

○,6 Keep it away from the area with high temperature, excessive vibration and shock.

2.2 Dustproof and waterproof

The servo drive is non-waterproof structure. Protection level of motor (excluding the connector) is IP65 according to IEC

34-5(International Electrotechnical Commission).

2.3 Installation method and space

Impact & load

①The impact that the motor can stand should be less than 200m/s2(20G). Don’t apply excessive impact load to the motor

during transporting, installing and disassembling. And do not hold encoder, cable and connector to transport the motor.

②The pull claw device must be used when removing the belt pulley and coupler from the motor

Combination with mechanical system

①The motor specification in the user manual has specified the permissible load to the motor shaft. Exceeding the permissible

load will shorten the shaft life and cause damage to the shaft. Please use coupling which could fully absorb eccentric load.

②The stress on the encoder cable should be less than 6kgf during assembling.

③The bending radius of power cable and encoder cable should be R20mm and more.

Installation direction and clearance of drives

Leave sufficient space around the drive to ensure the heat dissipation and convection in the cabinet when installing the drive.

●Install the drives in the vertical direction. Please use two M5 screws to fix the drive, master drive and slave drive

11

respectively which is less than 800W Please use three M5 screws to fix the drive and master drive respectively which is

more than 1kW.

●In order to ensure that surrounding temperature between internal boards is not more than 55℃, cooling fan or cooler need

to be installed to reduce the temperature, when the drives are installed in the sealed cabinet.

●The temperature on the surface of cooling plate would be 30℃ higher than the surrounding temperature.

●Use heat-resistant material for the wiring and isolate wiring from the machine and other cables which are easily affected by

the temperature.

●The service life of servo drive depends on the temperature around the electrolytic capacitor. When the electrolytic capacitor

is close to the service life, the static capacity will decrease and internal resistance will increase. Consequently, it will lead to

overvoltage alarm, malfunction caused by noise and components damage. The service life of electrolytic capacitor is approx. 5

to 6 years under the condition 「average annual temperature 30℃, load rate 80% and operation of less than 20 hours a day on

average」

Additional instructions

①The motor shaft is covered with anti-rust oil before leaving factory. Please have the antirust treatment again to the shaft to

prevent it from rust when installing load.

12

②Never disassemble the encoder or motor.

③The GND of 24VDC input and the grounding cable of device can be connected to each other.

※Please use the same power supply for control voltage(24V and GND) and upper control device.

④Do not remove or maintain the encoder battery until the main power supply is switched OFF.

⑤After switching off the main power supply, please note that there is residual voltage of approx. 30 seconds on the power

components.

⑥Do not replace the fuse.

⑦The servo drives of more than 750W are installed with a cooling fan on the right side. Do not touch or block the ventilation

ports of servo drive

2.4 Dimensions of servo motor

13

14

15

16

17

2.5 Dimensions of servo drive

18

19

3. Wiring explanation for servo motor and drive

3.1 Wiring diagram

3.1.1 Wiring diagram

20

[Points for correct wiring]

※ 24VDC and 200VAC input (main circuit) power supply should be wired from the same 200VAC main power supply.

※ Do not access switch between 24VDC power supply and drive. If you need switch, put it on the 200VAC cable of 24VDC

input power supply.

※ A twisted-pair shielded cable should be used when I/O cable length is over 50cm.

※ The encoder cable should be less than 20m.

① Please note that there is high voltage in the solid line of wiring diagram when wiring and using.

② The broken lines in the wiring diagram indicates the non-dangerous voltage circuit.

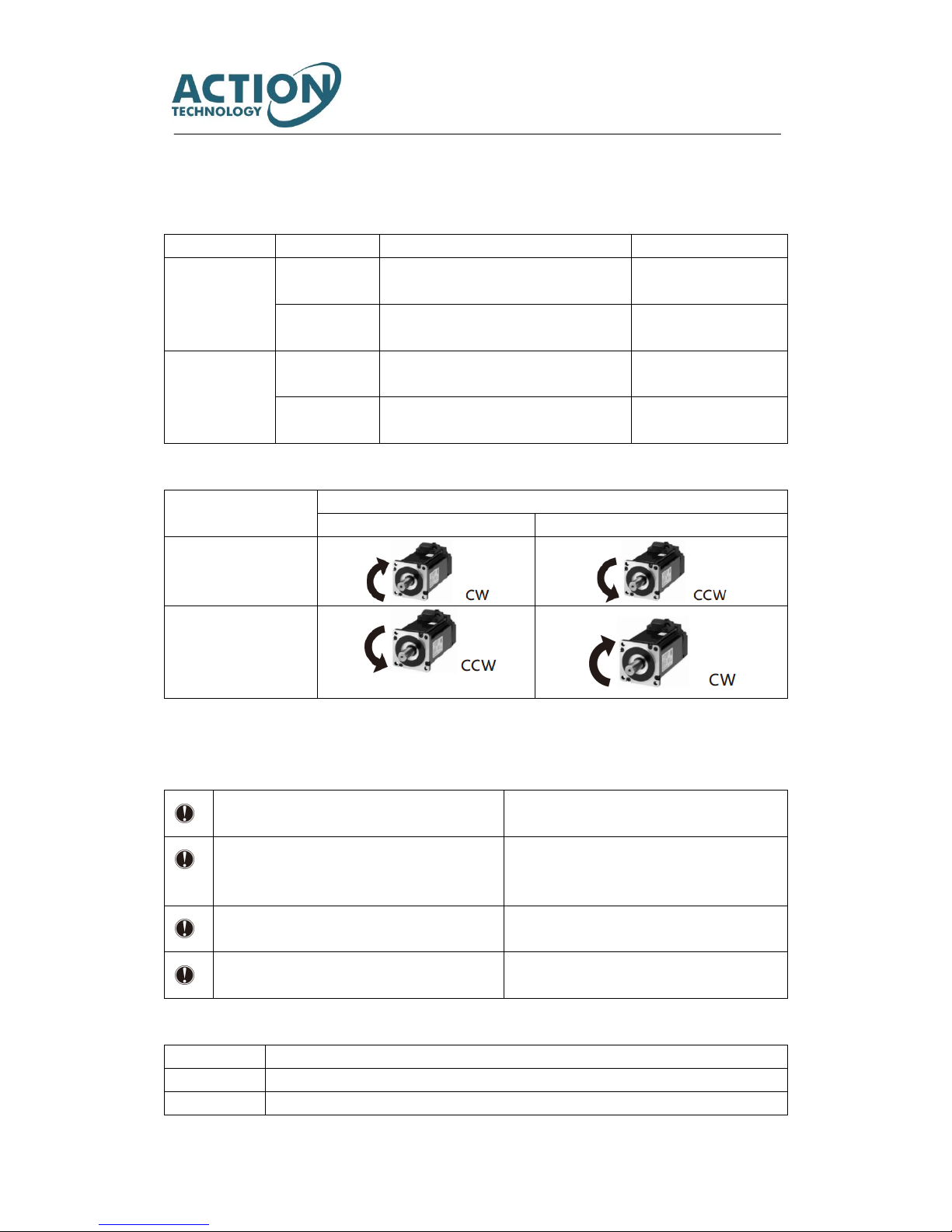

3.1.2 Connection of servo drive and motor

Items

Description

Peripheral device

Conform to European EC Directive. Select the device which meets corresponding standards

and install them in accordance with User’s Manual.

Installation environment

Install the servo drive to the environment which conform to Pollution degree 2 or 1 of

IEC60664-1.

Power supply 1: 200~

230VAC (main circuit)

This product can be used under the conditions that conform to IEC60664-1 and overvoltage

category Ⅱ.

Power supply 2: 24VDC

♦ control power supply of drive

♦ I/O power supply

♦ Power supply for brake

release

The specification of 24VDC external power supply should satisfy the following conditions.

Using SELV power supply(※) and power less than 150W. This is the CE corresponding

conditions.

※SELV: safety extra low voltage

(Reinforced insulation is needed for safety extra low voltage, non-dangerous voltage and

dangerous voltage.)

Wiring

Please use withstand voltage cables which are equivalent to AWG18/600V or AWG14/600V

for motor power cable, encoder cable, AC220 input cable, FG cable and main circuit power

distribution cable under multi-axis drive structure respectively when drives are less than

21

750W or more than 1kW .

Breaker

Switch off the power supply to protect power cord when overcurrent occurs.

Make sure to use the breaker between power supply and interference filter that conforms to

IEC specification and UL recognition in accordance with the User manual.

Please use the breaker with leakage function recommended by ACTION TECHNOLOGY in

order to meet EMC standards.

Noise filter

To prevent the outside interference from power cables.

Please use the interference filter recommended by ACTION TECHNOLOGY in order to

meet EMC standards.

Magnetic contactor

Switch main power supply (ON/OFF). And use it after installing a surge absorber.

Surge absorber

Please use the surge absorber recommended by ACTION TECHNOLOGY in order to meet

EMC standards.

Interference filter for signal

cable / ferrite filter

Please use the interference filter recommended by ACTION TECHNOLOGY in order to

meet EMC standards.

Regenerative resistor

This product is not equipped with regenerative resistor.

The external regenerative resistor is necessary when the internal capacitor cannot absorb

more regenerative power. Confirm the regenerative status on the panel. When the

regenerative voltage alarm is ON, a regenerative resistor is needed.

For the reference specification of regenerative resistor, please refer to user manual.

Use a built-in thermostat and set overheat protect circuit.

Grounding

This product belongs to Class 1 and need grounding protection.

Using protection grounding terminal. Grounding should be executed by the case and cabinet

that conforms to EMC.

The following symbol indicates the protection grounding terminal.

22

3.2 Drive connector and pins arrangement

3.2.1 Drive connector terminal

Figure 3.2.1 Drive connector terminal

Table 3.2.1 Terminal arrangement of drive connector/ 750W or less

Name

Symbol

Pin No.

Signal name

Contents

Regenerative

resistance connection

B1/B2/L1

/L2

1

B1

P interface of regenerative resistor

2

B2

N interface of regenerative resistor

Single-phase 200VAC

input

4

Primary-power 1

L 5 Primary power 2

N

Motor power output

U/V/W

1 U Motor power U phase output

2 V Motor power V phase output

3 W Motor power W phase output

Encoder

CN2

1

VCC

Encoder power supply 5V output

2

GND

Signal grounding

3

NC

-

4

NC

-

5

+D

Encoder signal: data input/output

6

-D

Encoder signal: data input/output

-

FG

Connect SHIELD to the connector housing

PC communication

CN3

1

VBUS

USB power supply

2

D-

USB data-

3

D+

USB data+

23

4

NC - 5

GND

USB signal grounding

24V power supply and

communication

CN4

1

24V

Drive control power supply 24V input

2

G24

Drive control power supply GND input

3

485

485 signal from upper control device Multi-station

communication

4

/485

/485 signal from upper control device Multi-station

communication

5

SG

Communication signal grounding

External fan

CN14

1

24V

24V for external fan

2

G24

GND for external fan

3

NC - User I/O

CN1

Refer to “Operation”

Table 3.2.2 Terminal arrangement of drive connector/ 1kW or more

Name

Symbol

Pin No.

Signal name

Contents

Regenerative

resistance connection

-/B1/B2

1

-

- 2 B1

P interface of regenerative resistor

3

B2

N interface of regenerative resistor

Three-phase 200VAC

input

L1C/L2C

L1/L2/L3

1

L1C

Control power AC input

2

L2C

Control power AC input

3

L1

Primary power 1

4

L2

Primary power 2

5

L3

Primary power 3

(Do not connect it when single-phase used)

Motor power output

U/V/W

1 U Motor power U phase output

2 V Motor power V phase output

3 W Motor power W phase output

Encoder

CN2

1

VCC

Encoder power supply 5V output

2

GND

Signal grounding

3

NC - 4

NC - 5

+D

Encoder signal: data input/output

6

-D

Encoder signal: data input/output

-

FG

Connect SHIELD to the connector housing

PC communication

CN3

1

VBUS

USB power supply

2

D-

USB data-

3

D+

USB data+

4

NC

-

5

GND

USB signal grounding

24V power supply and

CN4 1 24V

Drive control power supply 24V input

24

communication

2

G24

Drive control power supply GND input

3

485

485 signal from upper control device Multi-station

communication

4

/485

/485 signal from upper control device Multi-station

communication

5

SG

Communication signal grounding

User I/O

CN1

Refer to “Chapter 5 Operation”

3.3 Terminal arrangement and wiring color of motor connector

3.3.1 Motor connector and pins arrangement (750W or less)

Figure: 3.3.1 Motor connector and pins arrangement

Table 3.3.1 Cable list (For motor of 750W or less)

Name

Cable

Motor power input

AWG18

Brake

note 1

AWG22

Encoder (Incremental)

Power supply:AWG22

Signal:AWG24

Encoder (Absolute)

Power supply:AWG22

Signal:AWG24

Note 1 For the motor with brake

25

Table 3.3.2 For the motor of 750W or less

Name

Pin

No.

Signal

name

Contents

Wiring color

Motor power

input

1 U Motor power U phase

Red 2 V

Motor power V phase

White

3 W Motor power W phase

Black 4 FG

Motor housing grounding

Green

Brake

(※ 1)

1

BRK+

Brake power supply 24VDC

Yellow

2

BRK-

Brake power supply GND

Blue

Encoder(incr

emental)

1 - NC - 2

+D

Serial communication data + data

White (red point)

3

-D

Serial communication data - data

White (black point)

4

VCC

Encoder power supply 5V

Orange (red point)

5

GND

Signal ground

Orange (black point)

6

SHIELD

Shielded wires

Black

Encoder(Abs

olute)

1

BAT

External battery (※ 2)

Yellow (black point)

2

+D

Serial communication data + data

White (red point)

3

-D

Serial communication data - data

White (black point)

4

VCC

Encoder power supply 5V

Orange (red point)

5

GND

Signal ground

Orange (black point)

6

SHIELD

Shielded wires

Black

※1 For motor with brake.

※2 External capacitor and battery are taking GND as the reference potential.

3.3.2 Motor connector and pins arrangement (1kW or more)

Figure 3.3.2 Motor connector and pins arrangement (1kW or more)

26

Table 3.3.3 Cable list ( for motor of 1kW or more)

Name

Cable

Motor power input

AWG14

Brake

note 1

AWG18

Encoder (Incremental)

Power supply:AWG22

Signal:AWG24

Note 1 For the motor with brake

Table 3.3.4 For the motor of 1kW or more

Name

Pin

No.

Signal

name

Contents

Remark

Motor power

input

A U Motor power U phase

B V

Motor power V phase

C W

Motor power W phase

D FG

Motor housing grounding

Brake

(※ 1)

1

BRK1

Brake power supply 24VDC

2 BRK2

Brake power supply GND

Encoder(incr

emental)

1

VCC

Encoder power supply 5V output

2 GND

Signal ground

3 -

NC 4 - NC 5

+D

Serial communication data + data

6 -D

Serial communication data - data

7 -

NC 8 - NC 9 - NC 10

SHIELD

Shielded wires

Encoder(Abs

olute)

1

VCC

Encoder power supply 5V output

2 GND

Signal ground

3 CAP

External capacitor (※2)

4 BAT

External battery (※2)

5 +D

Serial communication data + data

6 -D

Serial communication data - data

7 IC

Internal connection (※ 3)

8 IC

Internal connection (※ 3)

9 GND

Signal ground

10 - NC

※1 For motor with brake.

※2 External capacitor and battery are taking GND as the reference potential.

※3 Internal connection (IC) has been connected internally. Do not connect it with any other wires.

27

4. Parameter Description

Parameter list

This section gives a detailed description of the displayed parameters on the panel.

The column of 「No.」is the parameter number. Two numbers separated by “/” are the numerator and denominator number of

parameters. Take 034.0/036.0 as the example, 034.0 is the numerator number and 036.0 is the denominator number. [Basic

setting] in Parameter list are the initial setting values determined by the device. [Adjustment] indicates gain and other

parameters that need to be adjusted to get the expected operation. [Special setting] indicates the parameters set according to

the actual needs. The parameters with 「r」displayed on the right side of parameter number, are the ones that need to restart

the drive control power supply after saving. 「Yes」will be displayed in the parameters of 「Whether to restart 24VDC power

supply」. After saving the parameters in 「Parameter saving mode」, 「Whether to restart 24VDC power supply」will be

displayed for the parameters which are valid after restarting 24VDC power supply. For the models of 750W or less, the control

power is supplied from external 24VDC. For the models of 1kW or more, the control power is supplied from internal power and

please cut off 220V power of main circuit if restart needed.

<Notice>

Each parameter has its setting range, but it also depends on the setting value of other parameter. There are some parameters

unable to set, even though they are in the setting range. The following is the interdependent parameter number.

No.102.0 Inertia ratio

No.103.0 Damping ratio

No.104.0 Conversion ratio of inertia ratio

No.115.0 Control gain 1 (Position control mode)

No.116.0 Control gain 2 (Position control mode)

No.117.0 Gain FF compensation 1(Position control mode)

No.118.0 Gain FF compensation 2(Position control mode)

No.119.0 Integral gain(Position control mode)

No.131.0 Control gain 1(Speed control mode)

No.132.0 Gain FF compensation 1(Speed control mode)

No.133.0 Integral gain(Speed control mode)

Table 4.1.1 Parameter list

No

Parameter

Contents

Whethe

r to

restart

control

power

supply

002.0r [Basic setting]

Control mode

Control mode selection.

Note) Do not change when servo is ON.

0= Position control mode

1= Speed control mode

2= Torque control mode

[Initial value] 0 (Position control mode)

Yes

28

[Setting range] 0 to 2

003.0r [Basic setting]

Command mode

selection

Command mode selection

0= Zero command (select in position control/ speed control mode)

1= Pulse command (Used in position control)

2= Analog command (Used in speed control)

3= Internal generation command (Used in speed control)

[Initial value] 1 (Pulse train command )

[Setting range] 0 to 3

Yes

004.0r [Basic setting]

Communication address

Set the communication address of servo drive.

Set to “1” when not using RS-485 multi-station communication. If using

multi-station communication, refer to 「RS-485 communication wiring」. Setting

different values for each axis.

[Initial value] 1

[Setting range] 1 to 32

Yes

008.0

[Basic setting]

Selection of host

communication mode

Select host communication mode.

0= Disable

1= RS-485 asynchronous serial communication

When connecting RS-485 signal cable and using RS-485 asynchronous serial

communication, select to “1”. If not, select to “0”.

If the USB is irrelevant to this setting, it can communicate anytime.

[Initial value] 0 (Disable)

[Setting range] 0 or 1

No

009.0

[Basic setting]

Operation mode

selection

Select the operation mode.

0=I/O

1=Communication

When select “1”, the signal assigned to the input port of parallel I/O can be

operated by HCX-SETUP. Then, the input of parallel I/O will become invalid.

When select “0”, the input of parallel I/O will become valid. At this time, the

signal assigned to the input port of parallel I/O cannot be operated by

HCX-SETUP.

[Initial value] 0(I/O)

[Setting range] 0 or 1

No

011.0

[Basic setting]

RS485 communication

minimum response time

Set the minimum response time for RS485 communication

The response time of drive can be adjusted according to the minimum

response time.

For details, refer to [Communication time] of [Communication interface].

[Initial value] 3

[Setting range] 0 to 255

Yes

032.0r [Basic setting]

Pulse train command

input mode

Select pulse signal type of pulse command input.

0= Pulse and direction: using pulse and direction input

1= Orthogonal phase difference: using orthogonal phase pulse

(A-phase/B-phase) input

Yes

29

2= CCW/CW: using positive pulse and negative pulse

[Initial value] 0 (Pulse/direction)

[Setting range] 0 to 2

032.1r [Basic setting]

Pulse train command

Rotation direction

Select rotation direction of pulse command input

0: CCW Negative direction

1: CW Positive direction

[Initial value] 1 (CW Positive direction)

[Setting range] 0 or 1

Yes

032.2r [Basic setting]

With(out) use of

automatic command

interpolation for division/

multiplication

When setting command division/ multiplication, the command will be

processed by smoothing interpolation automatically.

0= Disable

1= Enable

[Initial setting] 1 (Enable)

[Setting range] 0 or 1

Yes

032.3

[Basic setting]

Selection of Pulse train

input logic

Select the logic for pulse train input.

0= Positive logic : Up counting from Low to High

1= Negative logic: Downing counting from High to Low

[Initial setting] 0 (Positive logic)

[Setting range] 0 or 1

Yes

033.0r [Basic setting]

Pulse command input

filter selection

The function of input filter is to reduce the fault caused by noise. Select the

pulse width of passing pulse command input.

0= No filter

1= Pulse width 25ns

2= Pulse width 50ns

3= Pulse width 100ns

4= Pulse width 150ns

5= Pulse width 200ns

6= Pulse width 300ns

7= Pulse width 400ns

8= Pulse width 600ns

9= Pulse width 800ns

10= Pulse width

1000ns

11= Pulse width 1200ns

12= Pulse width 1600ns

13= Pulse width 2000ns

14= Pulse width 2300ns

15= Pulse width 3100ns

When the input frequency is high, please set the small passing pulse width. To

improve interference immunity, please set the large passing pulse width.

Yes

When pulse command is open collector

circuit, it is recommended to set the best

filter. The following table indicates the

corresponding filter optimum value between

input pulse frequency and pulse duty ratio.

Select the best value according to input pulse

frequency and pulse duty ratio.

30

[Initial setting] 4 (Passing pulse width is 150ns or less)

[Setting range] 0 to 15

034.0

r

/

036.0

r

[Basic setting]

Division/ multiplication

(Numerator /

Denominator )

Set the parameters of position command pulse division/ multiplication.

When the number of upper command pulse and motor pulse per revolution is

different, calculate in terms of [(Numerator) / (Denominator )=(Number of

pulse per servo motor revolution) / (Number of host command pulse per

revolution)

[Setting example]

The number of pulse per motor revolution is 131072[pulse/rev]. Numerator can

be set 32768 by a quarter of 131072. Denominator can be set by a quarter of

the number of upper command per revolution. The corresponding parameter

setting of the number of upper command pulse per revolution is as follows.

Number of host

command per

revolution

Command division/

multiplication

(Numerator)

Command division/

multiplication

(Denominator)

131072

1000(Initial value)

1000(Initial value)

16384

32768

4096

10000

32768

2500

4096

32768

1024

4000

32768

1000

[Initial value] (Numerator / Denominator ) =1000/1000

[Setting range] (Numerator) 1 to 65535, (Denominator) 1 to 65535.

Setting range of Division/ multiplication ratio is from 0.001 to 1000.Normal

operation is not guaranteed while division/ multiplication ratio is beyond setting

range.

Yes

048.0

/

049.0

[Adjustment]

Analog command input

Filter parameter

(Numerator /

Denominator )

Low-pass filter parameter for smoothing analog speed command input.

It is valid when input filter selection (No.062.1) is set “1”,.

Parameter decrease→Smoothing effect becomes stronger, command

traceability reduces.

Parameter increase→command traceability increases,, susceptible to

interference

(Numerator / Denominator ) the value must be less than 1.

(Numerator / Denominator ) =1, filter invalid

[Initial setting] (Numerator / Denominator )= 16000/65535

[Setting range] 0~65535/1~65535

No

050.0

/

051.0

[Adjustment]

Analog command input

Gain

(Numerator /

Denominator )

Gain of analog speed command input.

When (Numerator) / (Denominator )=1 and ±10V analog command voltage is

input, the highest rotation speed of motor can be reached.

※As for the highest rotation speed of motor, refer to 「Basic specification」

According to different choice of symbol and polarity for analog command

voltage, the rotation direction of motor is different.

Decreasing this value has the effect of decreasing proportional gain of position

No

31

loop at upper controller.

[Initial setting] (Numerator / Denominator )=1000/1000

[Setting range] 0~65535/1~65535

052.0

/

053.0

[Basic setting]

Analog speed command

CCW speed limit

threshold value

(Numerator /

Denominator )

Analog speed command CCW speed limit threshold value.

Analog command CCW speed limit = (the highest speed of motor) * (threshold

value(numerator))/ (threshold value(denominator))

[initial setting] (Numerator / Denominator )=5000/5000

[Setting range] 0~65535/1~65535

No

054.0

/

055.0

[Adjustment]

Analog speed command

CW speed limit

threshold value

(Numerator /

Denominator )

Analog speed command CW speed limit threshold value.

Analog command CW speed limits = (the highest speed of motor) * (threshold

value(numerator))/ (threshold value(denominator))

[initial setting] (Numerator / Denominator )=5000/5000

[Setting range] 0~65535/1~65535

No

060.0

[Basic setting]

Analog speed command

fixed offset value

When using manual adjustment to adjust offset value of analog speed

command, set the adjustment value. It’s valid when the offset adjustment is

selected to “1= manual adjustment”. Adjust the corresponding analog speed

command input to 0r/min at the 0V input voltage.

<setting method>.

1. Servo ON (motor will rotate if offset exists)

2. When rotating at the speed of ±10r/min or less, set the value to ±50 to

confirm the operation.

(CCW direction, set to「-50」; CW direction, set to「+50」.

3. Set the offset value while observing the motor operation. (If rotate at CCW

direction, setting values change in response to 「-direction」. If rotate at CW

direction, setting values change in response to 「+direction」.

[Initial value] 0

[Setting range] -32768/32768

No

062.0

[Basic setting]

Analog speed command

rotation direction

Select rotation direction of analog speed command.

0=Inputting negative voltage, the motor has CCW rotation; Inputting positive

voltage, the motor has CW rotation.

1= Inputting positive voltage, the motor has CCW rotation; Inputting negative

voltage, the motor has CW rotation.

[Initial value] 1 (Inputting positive voltage, the motor has CCW rotation)

[Setting range] 0 or 1

No

062.1

[Basic setting]

Select analog speed

command input filter

Select analog speed command input filter.

Input filter constant can be set in No.048.0, No.049.0.

0= Disable

1=Enable (one IIR filter)

[Initial value] 1 (Enable)

[Setting range] 0 or 1

No

32

062.2

[Basic setting]

Select offset adjustment

type of analog speed

command

Select offset adjustment of analog speed command.

0=Auto tuning

1=Manual tuning

Auto tuning works under the voltage which corresponds to 0r/min of speed

command while servo ON.

Manual tuning means input offset manually to make sure input voltage

0Vcorresponds to speed command 0r/min. . Offset value can be adjusted by

parameter No.60.0(fixed offset value).

[Initial value] 1 (manual tuning)

[Setting range] 0 or 1

No

064.0

[Basic setting]

Judgment of positioning

completion

Select the output form of positioning completion signal.

0=Position difference + speed

1=Position difference+ speed+ pulse command input(speed)

When selecting 0, after the position difference is in the positioning

completion range No.68.0 and speed is in the range of positioning completion

speed No.69.0,, positioning completion signal will be output.

When selecting 1, after the position difference, speed and pulse command

input(speed) are all in the range of positioning completion range No.68.0 ,

positioning completion speed No.69.0 and positioning pulse train command

input(speed) No.70.0 respectively, positioning completion signal will be output.

The delay time from positioning completion to output positioning completion

signal can be set in No.71.0.

[Initial setting] 0

[Setting range] 0 or 1

No

065.0

[Special setting]

With or without use of

position difference error

detection

Select whether to use position difference error detection. Usually set value to

“1”.(Enable)

Only when suing torque command limit, set to “0”. Set the position deviation

value of error detection by No.87.0 and set the delay time from position error

occurred to output stop by No.89.0.

0=Disable

1=Enable

[Initial value] 1 (Enable)

[Setting range] 0 or 1

No

065.1

[Special setting]

With(out) use of speed

deviation error detection

Select whether to use speed deviation error detection. Usually set value is

“1”.( Enable)

Only when suing torque command limit, set “0”. Set the speed deviation value

of error detection by No.90.0 and set delay time from speed error occurred to

output stop by No.91.0.

0= Disable

1=Enable

[Initial value] 1 (Enable)

[Setting range] 0 or 1

No

33

066.0

r and

066.1

r

[Adjustment]

With(out) use of position

command smoothing

filter 1 and position

command filter 2

Select position command smoothing filter1 (No.66.0) and position command

smoothing filter 2 (No.66.1)

0=Disable

1=Enable

Command will be smooth as shown below after using a smoothing filter.

[Adjustment method]

Used when command acceleration or deceleration are too fast.

Used to suppress device resonance when positioning. Measuring the resonant

frequency in torque command curve and setting a corresponding average

movement number in position command smoothing filter1 moving average

time No,80 or position command smoothing filter2 average movement

number No.81, may inhibit resonance. The relation between resonant

frequency and average movement number is stated under parameter

specification of No.80 and No,81.

[Notes] This parameter can be set after more than 1.5s when the command

pulse input is 0. And the servo must be off while setting. If there is pulse input

or residual pulse setting, position difference will occur.

[Initial setting] Command smoothing filter 1 is ‘0”. (Not used)

Command smoothing filter 2 is ‘1”.(Used)

[Setting range] 0 or 1

Yes

066.3

[Special setting]

With(out) the Feed

forward delay

compensation in position

control mode

Enable/Disable Feed forward delay compensation in position control mode.

0=Disable

1= Enable

<Note> Generally set to “1”. Do not make the changes and cannot be done on

setting panel.

[Initial setting] 1 (Enable)

[Setting range] 0 or 1

Yes

067.0r [Adjustment]

Selection of drive

restriction options

Select the drive restriction options

Note) Do not modify the parameter while the servo is ON.

0=Invalid

1=CW restriction.

2=CCW restriction.

3= CW/CCW restriction.

Yes

34

[Initial setting] 0 (Invalid)

[Setting range] 0 to 3

067.1

[Basic setting]

Selection of deceleration

method at drive

restriction input

Select deceleration method at drive restriction input.

Note) Do not modify the parameter while the servo is ON.

When using deceleration method No.67.1 and stopping method No.67.2,

please follow the following combination methods.

0=Free-run

1=Short brake

2= Prompt stop

Combination

Deceleration method

No.67.1

Stopping method

No.67.2

1

0: Free-run

0: Free-run

2

1: Short brake

0; Free-run

3

2: Prompt stop

1: zero clamp

4

2: Prompt stop

0: Free-run

[Initial setting] 1

[Setting range] 0 to 2

No

067.2

[Basic setting]

Selection of stop status

at drive restriction

Select stop status at drive restriction.

Note) Do not modify the parameter while the servo is ON.

When using deceleration method No.67.1 and stopping method No.67.2,

please follow the above combination methods.

0= Free-run

1= zero clamp

[Initial setting] 1

[Setting range] 0 or 1

No

067.3

[Basic setting]

Selection of position

difference counter status

at drive restriction

Select position difference counter status at drive restriction

Note) Do not modify the parameter while the servo is ON.

0= Keep

1=Clear

[Initial setting] 1

[Setting range] 0 or 1

No

068.0

[Basic setting]

Positioning completion

range

As the reference of outputting positioning completion signal to upper controller,

this parameter is the pulse width for judging positioning completion.

The setting value should be less than the number of positioning judge pulse of

upper controller.

[Initial value] 40[Pulse](±40[pulse])

[Setting range] 0 to 32767

No

35

069.0

[Basic setting]

Positioning completion

speed

As the reference of outputting positioning completion signal to upper controller,

this parameter is the speed limit for judging positioning completion.

The setting value should be less than the number of speed limit of upper

controller.

[Initial value]

750W or less:2 [pulse/160μs] (±2 [pulse/160μs] ・・・5.72[r/min]

1kW or more : 2 [pulse/200μs] (±2 [pulse/200μs]) ・・・

4.58[r/min]

[Setting range] 0 to 32767

No

070.0

[Basic setting]

Positioning completion

pulse command input

(speed)

As the reference of outputting positioning completion signal to upper controller,

this parameter is the pulse command input(speed) for judging positioning

completion

[Initial setting]

750W or less: 0 [pulse/160μs] (±0 [pulse/160μs])

1kW or more:0 [pulse/200μs] (±0 [pulse/200μs])

[Setting range] 0 to 32767

No

071.0

[Basic setting]

Delay time of positioning

completion detection

Select the delay time from positioning completion to output signal to upper

controller.

[Initial value]

750W or less:20 [160μs]・・・3.2ms

No

36

1kW or more:16 [200μs]・・・3.2ms

[Setting range] 0 to 65000

077.0

[Adjustment]

With(out) the use of

speed command

smoothing filter

Choose whether to use speed command smoothing filter. The average

movement time can be set in No.78.0.

0=Disable

1=Enable

[Initial value] 0

[Setting range] 0 or 1

No

078.0

[Adjustment]

Average movement time

of speed command

smoothing filter

Set the average movement time of speed command smoothing filter.

It can be used when No.77.0 is effective.

[Initial value] 100 [ms]

[Setting range] 1 to 1000

No

080.0

r and

081.0

r

[Adjustment]

Average movement

number of position

command smoothing

filter 1 and average

movement number of

position command

smoothing filter 2

Set the position command smoothing filter 1 to “1(Used)” in No.66.0 to make

No.80.0 valid.

Set the position command smoothing filter 2 to “1(Used)” in No.66.1 to make

No.81.0 valid.

When the setting value of average movement number increases, the

acceleration/ deceleration will be smooth, but the response will be slow.

Setting filter 1, the average movement number can be set between 1 and

6250; setting filter 2, the average movement number can be set between 1

and 1250.

The average movement time can be represented by the following formula.

200~ 750W : (average movement time)=(average movement number)

×0.16ms

1k~2kW: (average movement time)=(average movement number) ×0.2ms

[Adjustment method]

●Smoothing will make positioning time longer in response to above average

movement time. Please have settings within the permissible range..

●When resonant occurs at constant move after acceleration or positioning

after deceleration, measuring the resonant frequency in torque command

curve and setting a corresponding average movement number in position

command smoothing filter1 moving average time No,80 or position command

smoothing filter2 average movement number No.81, may inhibit resonance.

Yes

37

The calculation of average movement number and its corresponding

suppressed resonance frequency is shown below.

750W or less: Setting value of smoothing filter=6250/(suppressed vibration

frequency[Hz])

1kW or more: Setting value of smoothing filter=5000/(suppressed vibration

frequency[Hz])

Average movement number No.080.0,

No.081.0

64

256

1024

4096

750W or less: suppressed vibration

frequency(Hz)

100

23 6 1.5

1kW or more: suppressed vibration

frequency(Hz)

80

20 5 1.2

●The vibration caused by gain FF compensation 2 can be suppressed by

position command smoothing filter 2.

When using gain FF compensation 2 No.117.0, vibration can be reduced by

using the average movement number of position command smoothing filter 1

and filter 2.

[Notes] This parameter can be set when the command pulse input is “0” for

more than 1.5s and there is no command pulse input. If possible, it is

recommended to turn off the servo. If you set the parameter when there is

pulse input or residual pulse, position shift will occur.

[Initial value] Filter 1: 25 for 200~750W, 20 for 1k~2kW

Filter 2: 10 for 200~750W, 10 for 1k~2kW

[Setting range] 1 to 6250 for filter 1, 1 to 1250 for filter 2.

087.0

[Special setting]

Position deviation error

detection value

When set No.65.0 to “1(enable)”, it is valid to detect the position deviation

errors. Normally it’s effective.

When the position deviation exceeds the setting value, the output position

deviation errors occur.

It is more difficult to detect the position deviation if the value is greater.

[Initial value] 196608[pulse] (※Equivalent to the number of 1.5 turns pulse)

[Setting range] 0 to 2147483647.

No

089.0

[Special setting]

Delay time of position

deviation error detection

When set No.65.0 to “1(enable)”, it is valid to detect the position deviation

errors.

The time is from exceeding setting value 「Position deviation error detection

value」 to outputting position deviation error signal.

It takes longer from error occurred to error output when the value is greater.

[Initial value]

200~750W: 250 [160μs]・・・40ms

1k~2kW: 200 [200μs]・・・40ms

[Setting range] 0~32767

No

090.0

[Basic setting]

Speed deviation error

When set No.65.1 to “1(enable)”, it is valid to detect the speed deviation

errors.

No

38

detection value

Normally it’s effective. When the speed deviation exceeds setting detection

value, speed deviation error occurs.

It is more difficult to detect speed deviation error if the value is greater.

[Initial value] 200~750W:524[pulse/160μs] ・・・1499[r/min]

1k~2kW: 655[pulse/200μs] ・・・11499[r/min]

[Setting range] 0 to 32767

091.0

[Special setting]

Delay time of speed

deviation error detection

When set No.65.1 to “1(enable)”, it is valid to detect the speed deviation error.

Normally it is effective.

The time is from exceeding setting value 「Speed deviation error detection

value」 to output speed deviation error signal.

It takes longer from error occurred to error output stopped when the value is

greater.

[Initial value] 200~750W: 250 [160μs] ・・・40ms

1k~2kW: 200 [200μs]・・・40ms

[Setting range] 0 to 32767

No

102.0

[Adjustment]

Inertia ratio

Set Inertia ratio by the device load .

[Initial value] 250 [%]

[Setting range] 100 to 3000

No

103.0

[Adjustment]

Damping ratio

Set Damping ratio on the device side. When the friction and inertia ratio is very

big, the change of damping ratio value may shorten the setting time.

[Initial setting] 100 [%]

[Setting range] 10 to 5000

No

110.0

[Adjustment]

With or without the use

of estimated inertia ratio

Setting of auto tuning mode.

If the movement direction of machine connected to the motor is horizontal,

select “standard mode”. If vertical, select “Unbalanced mode”.

1=Standard mode

1=Unbalanced mode

[Initial value] 1 (Standard mode)

[Setting range] 1 to 2

No

110.1

[Adjustment]

With(out) the use of

real-time auto tuning

Select whether to use real-time auto tuning.

0 = Disable

1 = Enable and Apply Inertia ratio

2 = Enable and Apply Inertia ratio and Dumping ratio

[Initial value] 0 (Disable)

[Setting range] 0 to 2

No

113.0

[Adjustment]

Control gain level

(position control)

Set the control gain level in position control mode. If traceability to command is

slow or rigidity of drive system is low, set a lower value; If traceability to

command is rapid or rigidity of drive system is high, set a higher value.

When setting this parameter, No. 115.0~119.0 will be set automatically and

No.114.0 becomes invalid.

[Initial value] 15

[Setting range] 5 to 45

No

39

113.1

[Adjustment]

Inertia condition

Set the inertia condition of position control mode.

0= Can interchange with F/W version of 2.0.4.0 or prior

1= For the device of heavy load and low rigidity, or large load changes

2= Standard setting

3= For the device of light load and CW/CCW frequently

[Initial value] 2 (Standard)

[Setting range] 0 to 3

No

114.0

[Adjustment]

Control level (position

control)

Set control level of position control mode. If traceability to command is slow or

rigidity of drive system is low, set the lower value; If traceability to command is

rapid or rigidity of drive system is high, set the higher value.

When setting this parameter, No. 115.0, No.116.0 will be set automatically and

No.113.0 becomes invalid.

When the inertia condition No.113.1 is set to “0”(servo drive version 2.0.4.0 or

prior), the setting range is from 1 to 46.

[Initial value] 15

[Setting range] 5 to 45

No

115.0

[Adjustment]

Control gain 1 (position

control)

Set the Control gain 1 at position control mode. Higher setting value can

shorten the setting time. Set the Control gain 2 as the following values.

[Initial value] 50 [rad/s]

[Setting range] 5 to 1000

No

116.0

[Adjustment]

Control gain 2 (position

control)

Set the Control gain 2 at position control mode. Higher setting value can

improve the traceability to the command. Too high setting value can cause

overshoot and vibration.

When No.113.0 control gain level or No.114.0 control level is adjusted to set

automatically, sometimes the setting values will exceed the setting range.

[Initial value] 200[rad/s]

[Setting range] 80 to 5000

No

117.0

[Adjustment]

Gain FF compensation 1

(position control)

Set feed forward compensation ratio (speed) of the Control gain 1 in position

control mode. After confirming inertia ratio, adjusting this parameter will

shorten the setting time. Too high setting value will lead to overshoot. And too

low setting value will make setting time longer.

[Initial value] 10000[0.01%]

[Setting range] 0 to 15000

No

118.0

[Adjustment]

Gain FF compensation 2

(position control)

Set feed forward compensation ratio (torque) of the control gain 2 in position

control mode. It is suitable to adjust this parameter when it requires small

following error and precise trajectory. After Gain FF compensation 1

shortens setting time, please increase this parameter value. If vibration

occurs, adjusting No.81.0 position command smoothing filter 2 average

movement times may suppress the vibration.

[Initial setting] 0 [0.01%]

[Setting range] 0 to 15000

No

119.0

[Adjustment]

Setting integral gain in position control mode can suppress external

No

40

Integral gain (position

control)

interference. When the setting value is higher, the position deviation

convergence of positioning setting will become fast. But if setting value is too

high, vibration will occur.

When No.113.0 control gain level or No.114.0 control level is adjusted to set

automatically, sometimes the setting values will exceed the setting range.

[Initial value] 160[rad/s]

[Setting range] 45 to 5000

129.0

[Adjustment]

Control gain level (speed

control)

Select control gain level in speed control mode. If traceability to command is

slow or rigidity of drive system is low, set the lower value; If traceability to

command is rapid or rigidity of drive system is high, set the higher value.

When setting this parameter, No. 131.0~133.0 will be set automatically and

No.130.0 becomes invalid.

[Initial value] 15

[Setting range] 1 to 46

No

130.0

[Adjustment]

Control level (speed

control)

Select control level in speed control mode. If traceability to command is slow

or rigidity of drive system is low, set the lower value; If traceability to command

is rapid or rigidity of drive system is high, set the higher value.

When setting this parameter, No. 131.0 will be set automatically and No.129.0

becomes invalid.

[Initial value] 15

[Setting range] 1 to 46

No

131.0

[Adjustment]

Control gain 1 (speed

control)

Set the control gain in speed control mode.

It corresponds to proportional gain of speed control loop.

[Initial value] 399[rad/s]

[Setting range] 100 to 6000

No

132.0

[Adjustment]

Gain FF compensation 1

(speed control)

Set feed forward compensation in speed control mode. The higher the setting

value, the better the traceability to command. But Too high setting value may

lead to overshoot or vibration

[Initial value] 0 [0.01%]

[Setting range] 0 to 15000

No

133.0

[Adjustment]

Integral gain(speed

control)

Select integral gain in speed control mode.

The higher the setting value, the smaller the speed change caused by external

disturbance.

[Initial value] 300[rad/s]

[Setting range] 45 to 5000

No

144.0

[Basic setting]

With or without the use

of torque command limit

override

Select torque command limit value in No.147.0, No.148.0

Confirm the following items when using torque limit.

①「No.65.0 Selection of Position deviation error detection」, please set it to

“0=Disable”

②「No.65.1 Selection of Speed deviation error detection」, please set it to “0=

No

41

Disable”

When the command deviation value is small, even though the torque limit is

set to be valid, it will be OK to set ① or ② to “1(enable)”.

0= Disable

1= Enable

[Initial setting] 0 (Disable)

[Setting range] 0 or 1

144.1

[Basic setting]

Torque limit state

output mode

Select the output condition for torque limit.

0= All conditions

(Torque is limited by torque command limit value 1 (No.147.0), max. torque

limit value of motor and torque limit value of home position return (No. 656.0),

not limited by speed in torque control mode)

1= Torque command limit Override 1 (No.147.0) or 2 (No.148.0)

2= Torque command limit Override 2 (No.148.0)

[Initial setting] 0 (All conditions)

[Setting range] 0 to 2

No

147.0

148.0

[Basic setting]

Torque command limit

override 1, 2

It is valid when No.144.0 torque command limit override is set to “1(enable)”.

Set torque command limit override relative to rated torque ratio.

Tow torque limits could be set.

[Initial value] 3000[0.1%] for torque limit 1; 2000[0.1%] for torque limit 2

[Setting range] 0 to 65535

No

151.0

[Basic setting]

Torque command limit

override at prompt stop

Set the torque command limit override relative to rated torque, if the stop type

in No.224.0 is set to “2=prompt stop” when servo is OFF.

[Initial value] 5000[0.1%] (When set 3000 or more, the limit value of max.

torque command is 300%. If the setting value is bigger than 1000 , overload

error will occur according to overload characteristics specified time.

[Setting range] 0 to 65535

No

152.0

[Basic setting]

Analog torque command

speed limit value

Set Speed limit value of analog torque control mode.

[Initial value] Max. speed of the motor

[Setting range] 0 to 10000

No

160.0

[Adjustment]

Selection of torque

command low-pass filter

Select torque command low-pass filter.

0=No filter

1= Preliminary IIR filter

[Initial value] 1 (Preliminary IIR filter)

[Setting range] 0 or 1

No

160.1

[Adjustment]

Torque command

Selection of whether to

use notch filter

Whether the notch filter is used to set the torque command.

0=Disable

1=Enable

[Initial value] 0 (Disable)

[Setting range] 0 or 1

No

160.2

[Adjustment]

Select whether to use the auto setting for torque command low-pass filter in

No

42

Auto setting ON/OFF for

Torque command

Low-pass filter

control gain level (No. 113 and No. 129).

0 = Auto setting OFF

1 = Auto setting ON

[Initial value] 1 (Auto setting ON)

[Setting range] 0 or 1

162.0

[Adjustment]

Torque command

preliminary filter time

constant for Low-pass

filter

Set the torque command preliminary filter time constant for Low-pass filter

[Initial value] 20 [0.01ms]

[Setting range] 0 to 65535

No

168.0

[Adjustment]

Torque command notch

filter frequency

Set Notch filter notch frequency of Torque command

[Initial value] 5000[Hz]

[Setting range] 0 to 5000

No

169.0

[Adjustment]

Torque command Notch

filter width

Set notch filter width of torque command.

Set the ratio relative to a frequency band with 0 notch depth and -3[dB]

attenuation rate. The larger the value, the greater the width of the notch

[Initial value] 8

[Setting range] 0 to 16

No

170.0

[Adjustment]

Torque command Notch

filter depth

Set the notch depth at the notch frequency of torque command notch filter,

Set the I/O ratio of notch frequency. When the setting value is 0, the notch

frequency input is completely cut off. When the setting value is 256, the notch

frequency input is completely through. The notch depth becomes shallow

when the value is bigger.

[Initial value] 0

[Setting range] 0 to 256

No

224.0

[Basic setting]

Type selection

deceleration stop at

servo OFF

Select the deceleration stop type when the alarm occurs or servo ON signal is

off in motor revolution.

0=No brake

1=Short brake mode

2= Prompt stop

[Initial value] 1 (Short brake mode)

[Setting range] 0 to 2

No

224.1

[Basic setting]

Deceleration stop at

Servo off: cancelation

reasons

Select cancellation reasons for deceleration stop at servo OFF

0 = Operating time

1 = Rotations of cancelation or operating time

[Initial value] 1 (Rotations of cancelation or operating time)

[Setting range] 0 or 1

No

224.2

[Basic setting]

Use of a deceleration

stop in case of control

power supply voltage

drop

Enable/Disable Deceleration Stop when the voltage from a control power

supply drops by No. 228.0.

0 = Disable

1 = Enable

[Initial value] 1 (Enable)

No

43

[Setting range] 0 or 1

226.0

[Basic setting]

Deceleration stop :

operating time at servo

off

Set the operating time for deceleration stop at servo OFF.

(If “0(No brake)” is set to No.224, this parameter is invalid.)

[Initial value] 200W~750W: 313 [160μs] ・・・50ms,

1kW~2kW: 250 [200μs] ・・・50ms

[Setting range] 0 to 16383

No

227.0

[Basic setting]

Cancellation speed of

deceleration stop and

brake cancellation OFF

at servo OFF.

Set the cancellation speed of deceleration stop at servo OFF. It sets the speed

of brake OFF cancellation.

(If “0(No brake)” is set to No.224.0 and “0(Operation time)” set to No.224.1,

this parameter is invalid.)

[Initial value] 200W~750W: 17[pulse/160μs] ・・・50r/min,

1kW~2kW: 22[pulse/200μs] ・・・50r/min

[Setting range] 0 to 32767

No

228.0

[Basic setting]

Operating time of

deceleration stop at

control power supply

voltage drop

Set the operating time of deceleration stop at control power supply voltage

drop in motor rotation.

[Initial value] 62 [160μs] ・・・10ms

[Setting range] 0 to 16383 [ms]

No

237.0

[Basic setting]

Delay time at servo OFF

Set the delay time between getting the input signal of Servo OFF and motor

excitation OFF.

(The disconnection of COM2 and SVON terminal indicates the servo ON

input signal is OFF.)

[Initial value] 200W~750W: 0[160μs] ・・・0ms,

1kW~2kW: 0[200μs] ・・・0ms

[Setting range] 0 to 3125

No

238.0

[Basic setting]

Delay time of brake

release

Set the delay time from motor excitation start to brake release output signal

(MBRK)ON. (The connection of COM2 and SVON terminal indicates the

brake release output signal is ON.)

[Initial value] 200W~750W: 25[pulse/160μs],

1kW~2kW: 20[pulse/200μs]

[Setting range] 0 to 3125

No

257.0

[Basic setting]

Selection of an encoder

system

Select an option for Absolute system or Incremental system.

0 = Incremental system

1 = Absolute system (multi-rotation counter overflow detection disabled)

2 = Absolute system (multi-rotation counter overflow detection enabled)

[Initial value] 0 (Incremental system)

[Setting range] 0 to 2

Yes

272.1r [Basic setting]

Encoder output rotation

direction

Set the rotation direction of encoder output.

0 = Down counting in the case of CCW rotation

1 = Up counting in the case of CCW rotation

[Initial value] 1 (Up counting in the case of CCW rotation)

[Setting range] 0 or 1

Yes

44

276.0

r /

278.0

r

[Basic setting]

Division and

multiplication of encoder

pulse

output(Numerator /

Denominator )

Set the division and multiplication of encoder pulse output.

When the 1-roration pulse number of encoder and the motor is different, set it

to ‘Numerator / Denominator =1-roration pulse number of encoder/ 1-roration

pulse number of motor.

If the output Z-phase pulse width is narrow and the upper control device

cannot identify it correctly, we can reduce the division and multiplication ratio

or speed to increase the pulse width by encoder pulse output division and

multiplication No. 276. 0 and 278. 0.

[Pulse width]= 1/ rotation speed (division/ multiplication ratio × 217)